Plasma evaporation deposition lanthanide thermal barrier coating ceramic layer with long service lifer, high insulation performance and composite structure, and preparation method thereof

An evaporative deposition and thermal barrier coating technology, which is applied in the field of preparation of a new composite multiphase structure thermal barrier coating ceramic layer, can solve the problems of high production cost and low deposition efficiency, and achieves improved service life, high deposition efficiency, Good wrapping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Example 1: Depositing a columnar crystal structure La on the surface of a superalloy substrate 2 Ce 2 o 7 / YSZ double ceramic layer thermal barrier coating, the specific steps are as follows:

[0040] The first step, prepare the substrate:

[0041] (1) Prepare the original superalloy sheet with a size of Φ30×4mm, polish the surface of the sample with 200#, 600#, and 800# sandpaper respectively, put it in acetone for ultrasonic cleaning for 10 minutes, sandblast pretreatment, and set aside;

[0042] (2) The NiPtAl bonding layer is prepared by electroplating and embedding infiltration. The main process parameters are: prepare the electroplating solution for Pt, and the formula is Pt(NH 3 ) 2 (NO 2 ) 2 17g / L, NH 4 NO 3 100g / L, NaNO 2 10g / L NH 4 OH50g / L, electroplating current is 0.5-2mA / mm 2 , the electroplating time is 1h, the temperature is 90°C, and then aluminized by embedding infiltration method, and the temperature is kept at 1000°C for 90min. (3) Vacuum ...

Embodiment 2

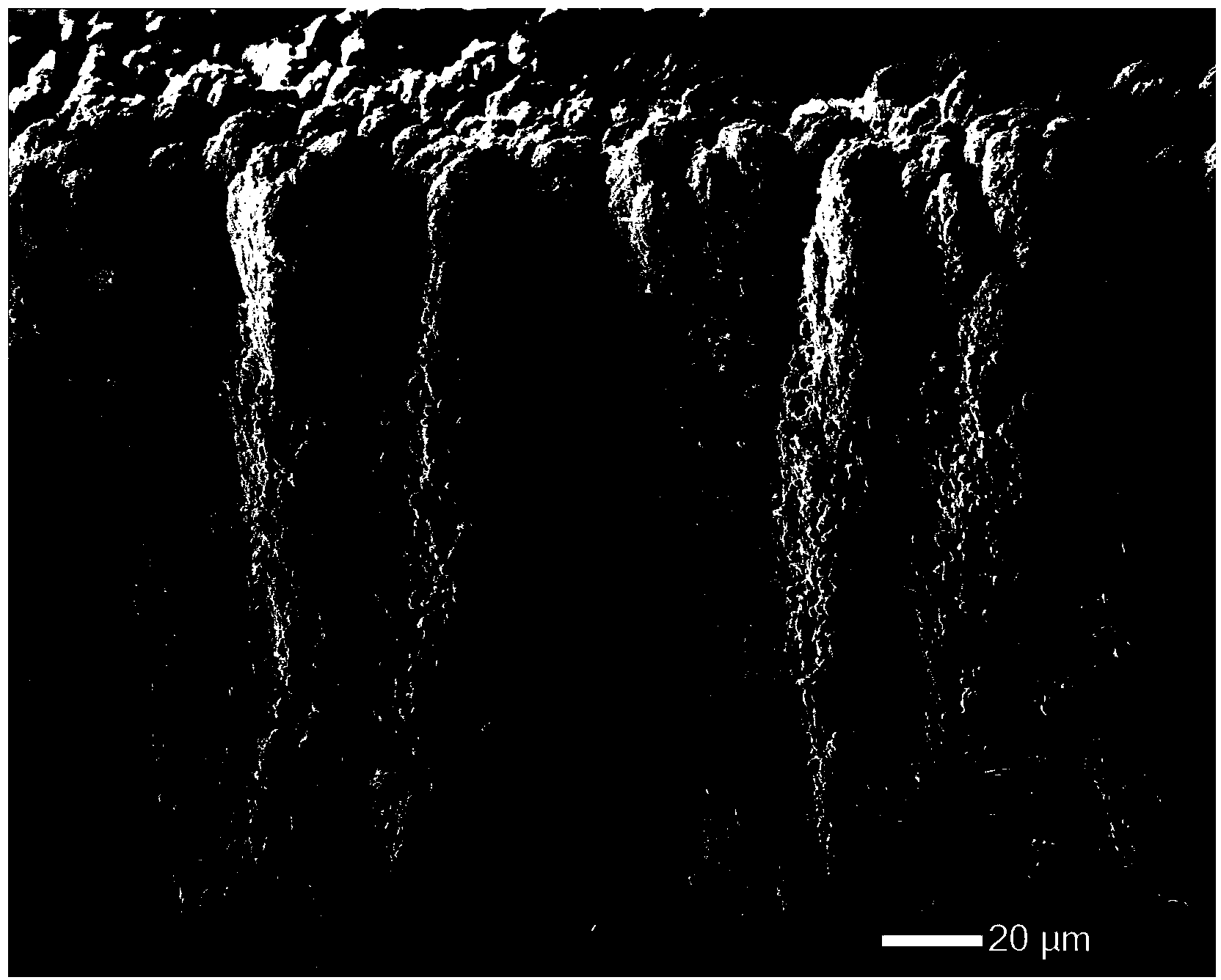

[0056] The microscopic morphology, coating thickness, heat insulation performance and thermal shock resistance performance of the prepared samples were measured. A thermal barrier coating with double ceramic layers was prepared, the schematic diagram of which is shown in figure 1 shown. The thickness of the YSZ coating was found to be about 100 μm by scanning electron microscopy, La 2 Ce 2 o 7 The thickness is 100μm; both are columnar crystal structure coatings, figure 2 The prepared columnar crystal structure La 2 Ce 2 o 7 Cross-sectional SEM photograph of the coating. This shows that after the spray powder is fed into the plasma spray gun, due to the high enough energy of the plasma flame, the spray powder is evaporated to form gas-phase atoms, and then sprayed onto the surface of the substrate with the plasma flow, and a columnar crystal structure coating is deposited. The thermal shock test was carried out on the sample. Under the thermal cycle conditions of surfa...

Embodiment 3

[0075] Example 3: Depositing columnar grains and interphase Gd with a layered structure on the surface of a superalloy substrate 2 Zr 2 o 7 / YSZ double ceramic layer thermal barrier coating,

[0076] In the first step, the base alloy is prepared, and a bonding layer is prepared on the surface of the base alloy.

[0077] (1) Prepare the original superalloy sheet with a size of Φ30×4mm, polish the surface of the sample with 200#, 600#, and 800# sandpaper respectively, put it in acetone for ultrasonic cleaning for 10 minutes, sandblast pretreatment, and set aside;

[0078] (2) Prepare NiCoCrAlY bonding layer spray powder and YSZ, Gd 2 Zr 2 o 7 ceramic layer powder,

[0079] (3) The NiCoCrAlY bonding layer was prepared by atmospheric plasma spraying equipment. The main process parameters are: current 600A, voltage 70V, powder feeding rate 10g / min, spraying distance 100mm, main gas flow Ar gas 2000L / h, H 2 The gas flow rate is 6.5L / min, the deposition time is 20min, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com