Patents

Literature

78results about How to "Good plating performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

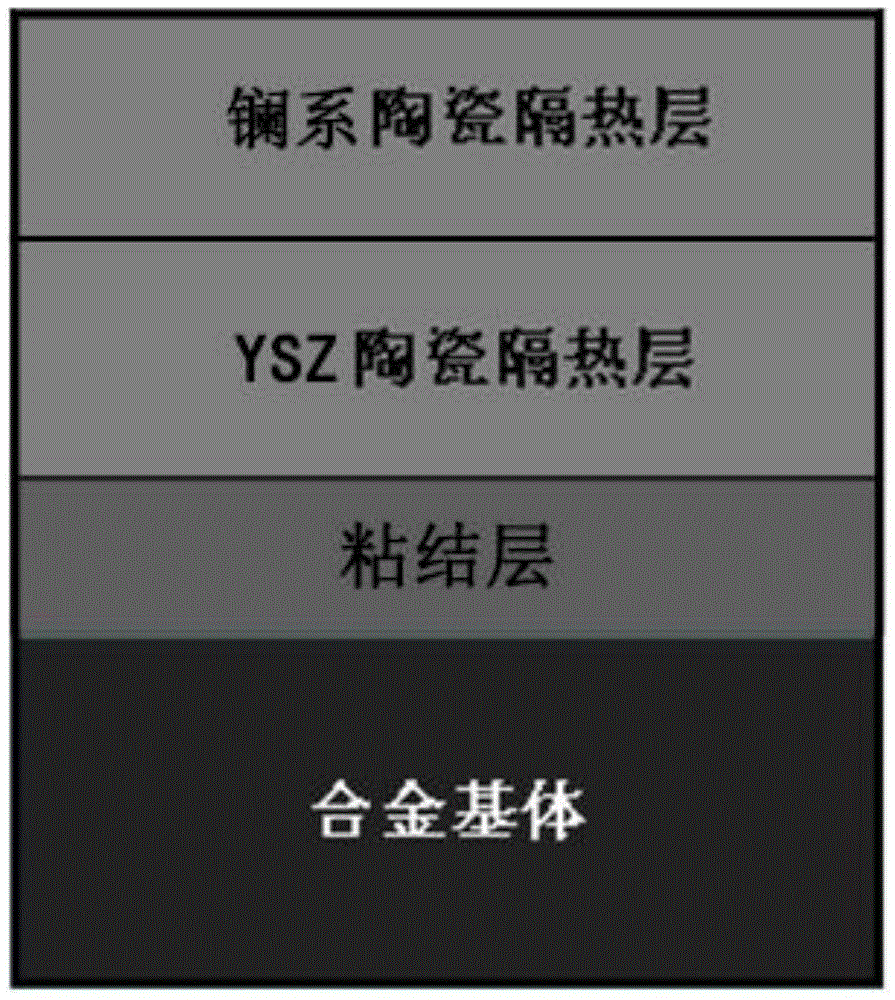

Plasma evaporation deposition lanthanide thermal barrier coating ceramic layer with long service lifer, high insulation performance and composite structure, and preparation method thereof

ActiveCN103966539AImprove deposition efficiencyPollution controlMolten spray coatingVacuum evaporation coatingLanthanideNanostructure

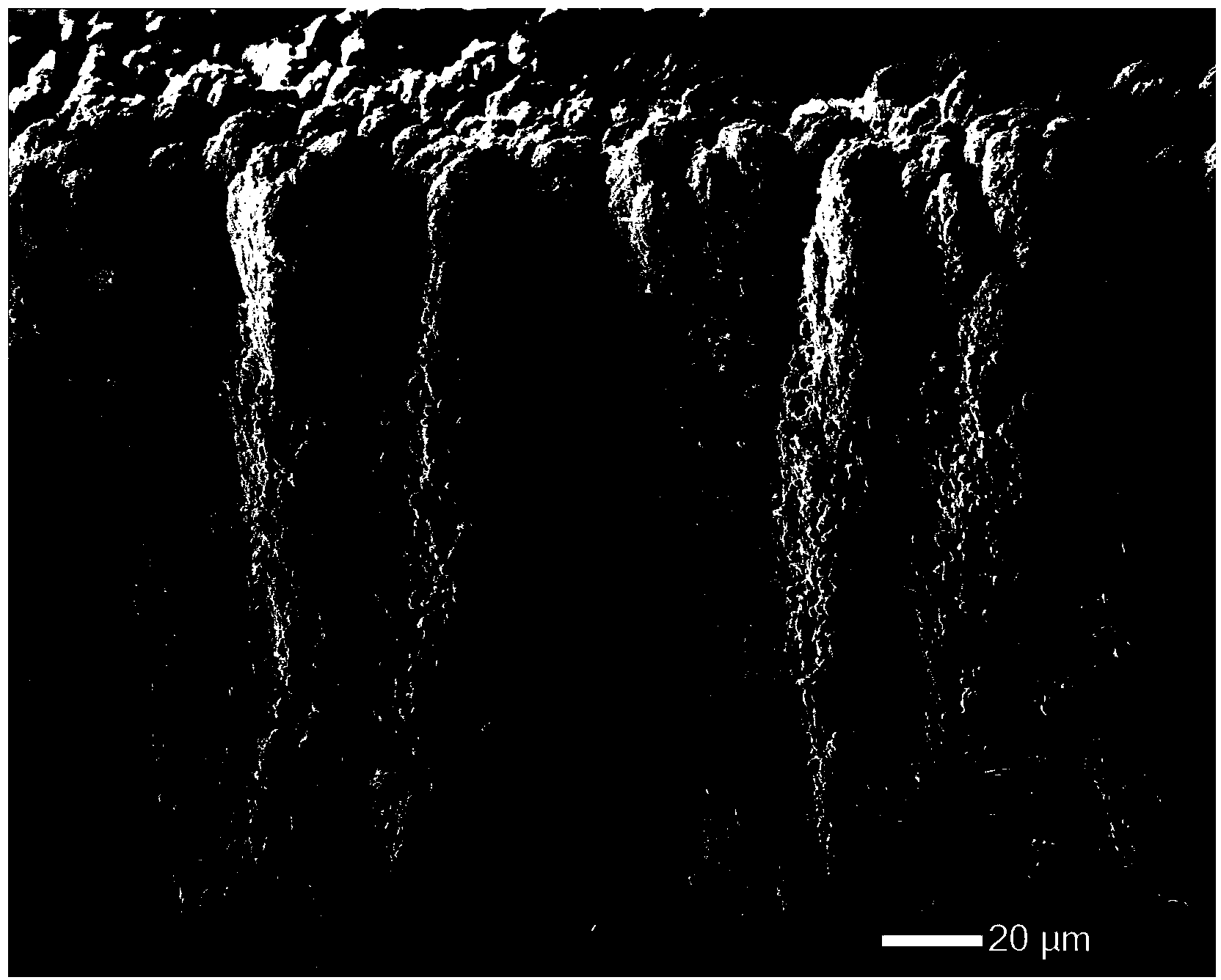

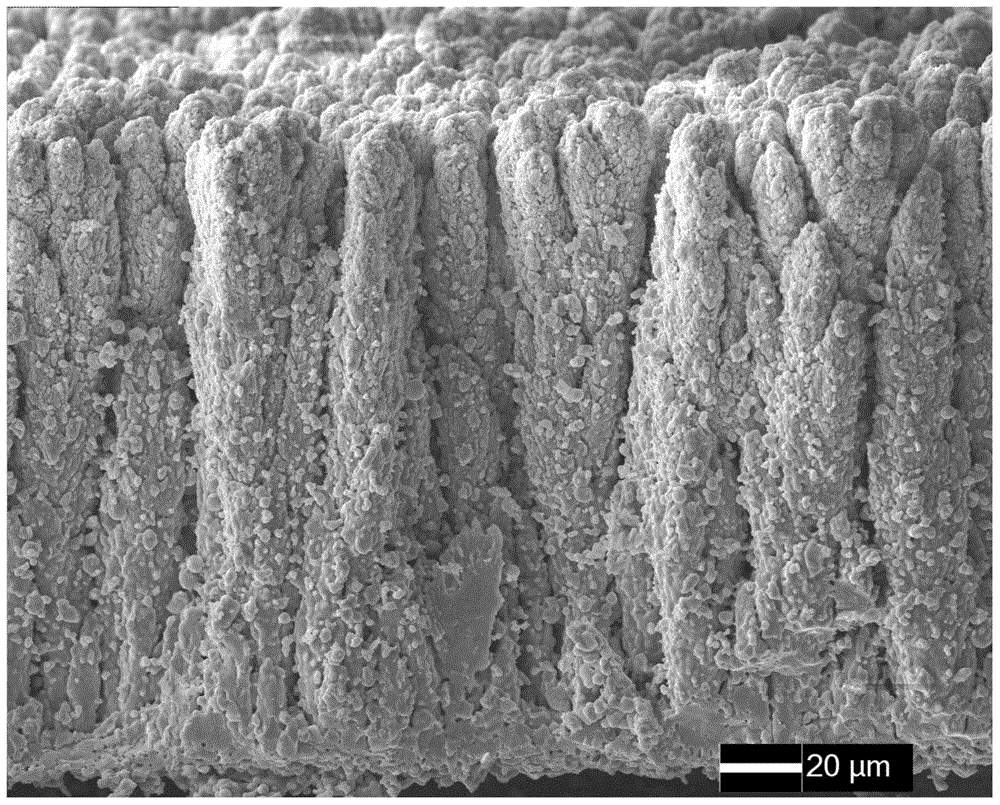

The invention discloses a plasma evaporation deposition lanthanide thermal barrier coating ceramic layer with a long service life, a high insulation performance and a composite structure, and a preparation method thereof, and belongs to the technical field of thermal barrier coating. The ceramic layer material comprises lanthanum zirconate or cerate; the thermal barrier coating comprises a bonding layer, a first ceramic layer and a second ceramic layer which are prepared on a base body, wherein the first ceramic layer adopts a YSZ coating; the second ceramic layer comprises the lanthanum zirconate or cerate; in the preparation method of the ceramic layer, the pressure of a vacuum chamber is lower than 1 mbar; through adjusting parameters of spraying electric power, current, gas flow rate, temperature of the basal body, powder feeding rate, spraying distance and the like, the YSZ coating layer and the lanthanide thermal barrier coating ceramic layer which are provided with microstructures of columnar crystal structures, layered structures, layered structures and columnar crystal structures, or nano- structured coating and the like can be obtained. The service life of the thermal barrier coating is long and the heat-insulating property is favorable.

Owner:BEIHANG UNIV

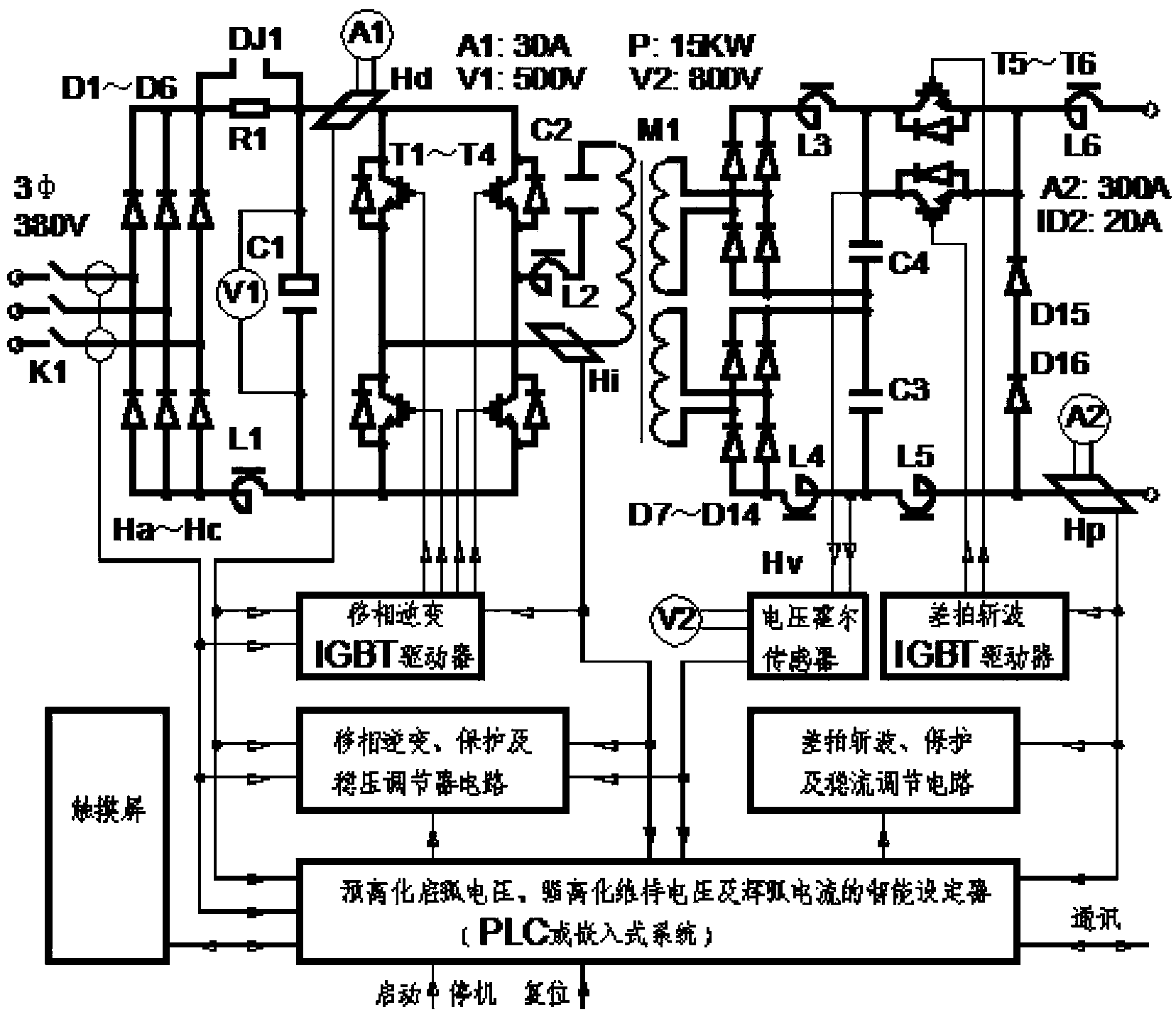

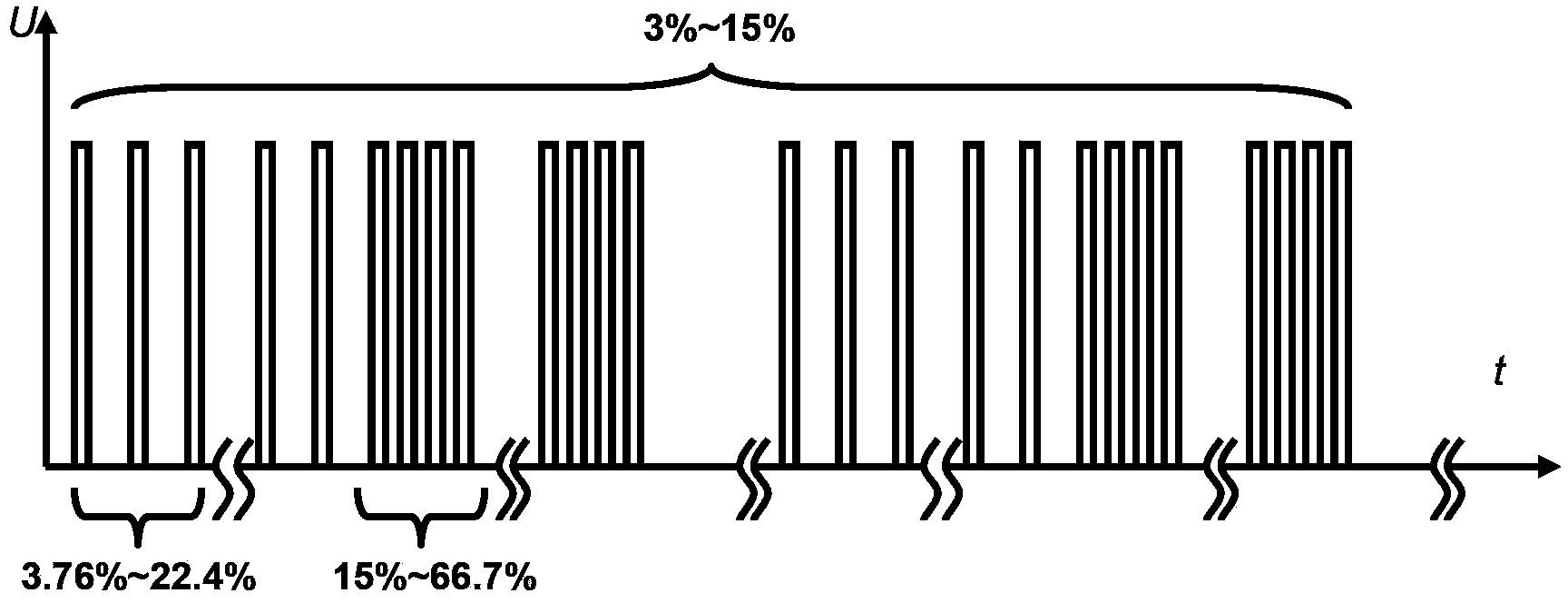

Micro-arc ion plating method

InactiveCN103397304AImprove compactnessGood plating performanceVacuum evaporation coatingSputtering coatingVacuum chamberElectric field

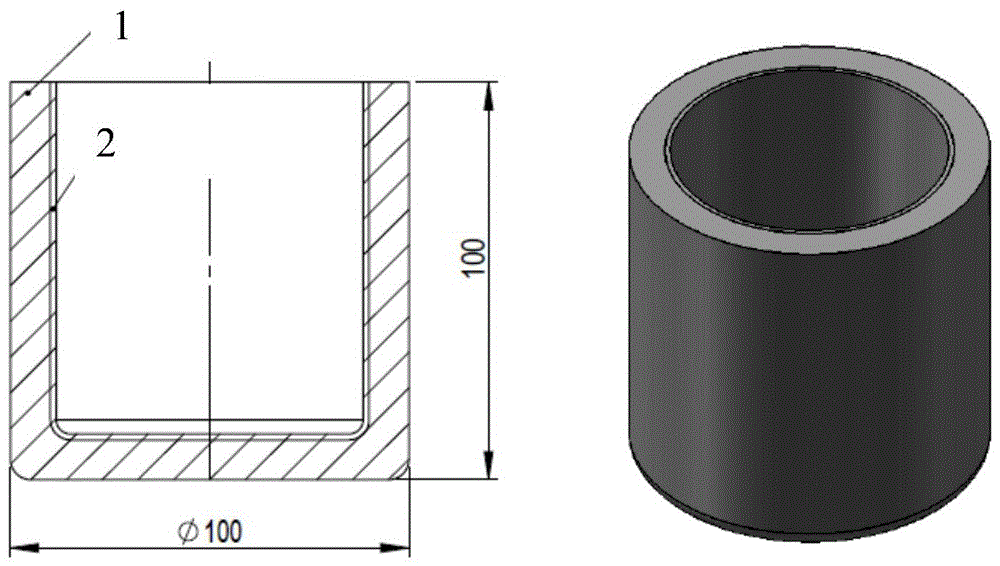

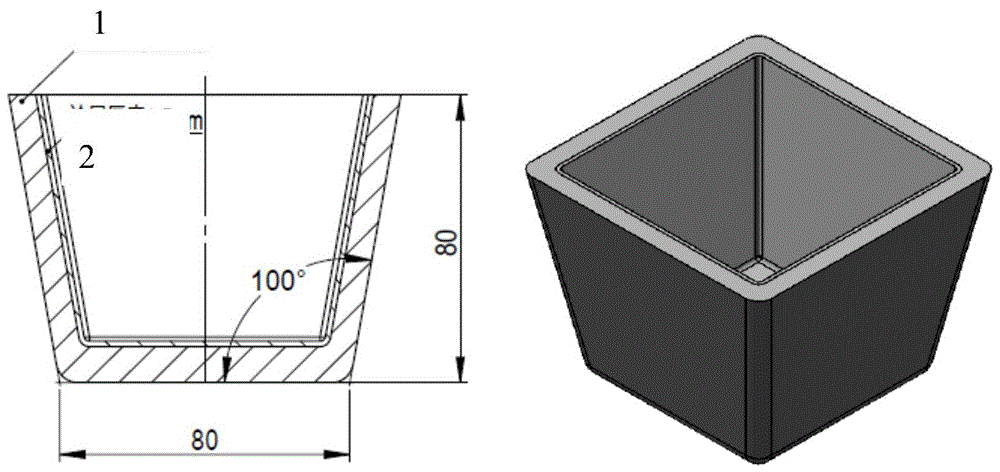

The invention discloses a vacuum plating method integrating advantages of magnetron sputtering and multiple-arc ion plating, in particular to a micro-arc ion plating method. The method comprises the steps as follows: a high-frequency impulse electric field with negative 1,200 V to negative 900 V output voltage, 0.5 KHz-60 KHz frequency and 0.5 mu s-30 mu s pulse width is firstly established, a high-frequency impulse signal output from the high-frequency impulse electric field is modulated by an adjustable inductance attenuation and a digital logic circuit and loaded to a rectangular cathode target with an area of 300 mm*100 mm and two ends of an anode vacuum chamber casing with a volume of Phi 450 mm *H 400 mm, and argon (Ar) gas charged into a vacuum chamber is subjected to an ion plating process when volt-ampere characteristics of negative 900 V to negative 600 V voltage, 100 A-300 A current, 1 ms-5 ms pulse width and 3%-15% duty ratio are generated during discharge. The method is simple and stable; and by means of the method, the yield is high, and industrial production can be realized.

Owner:NANJING HAORANG ENVIRONMENT SCI & TECH

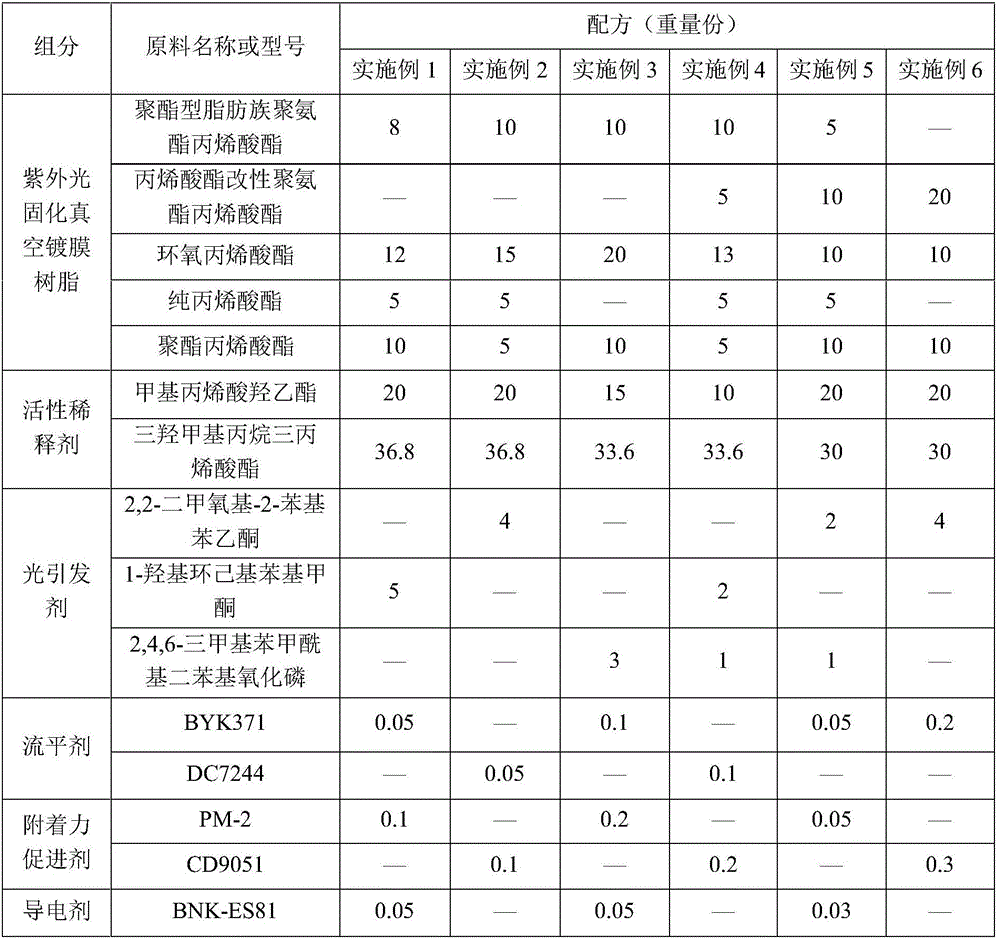

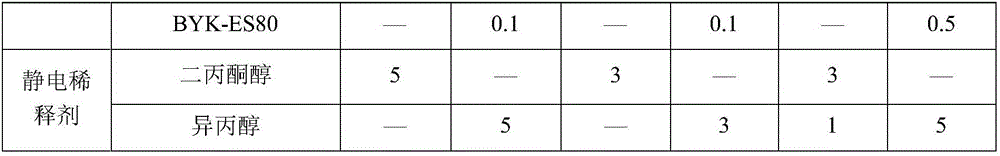

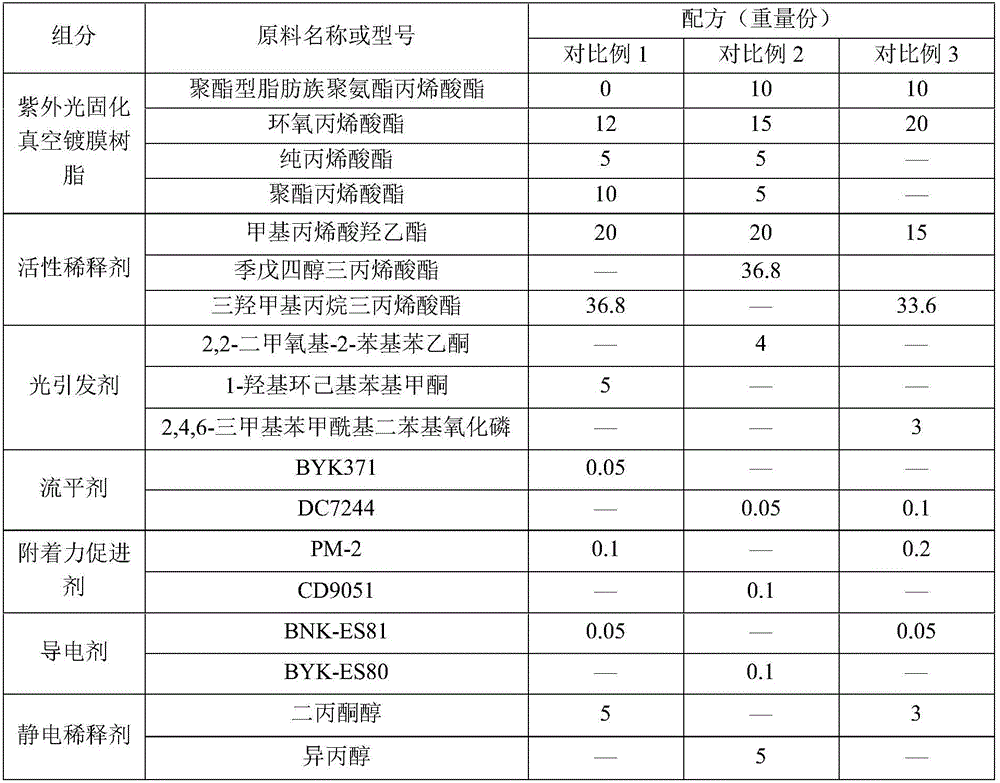

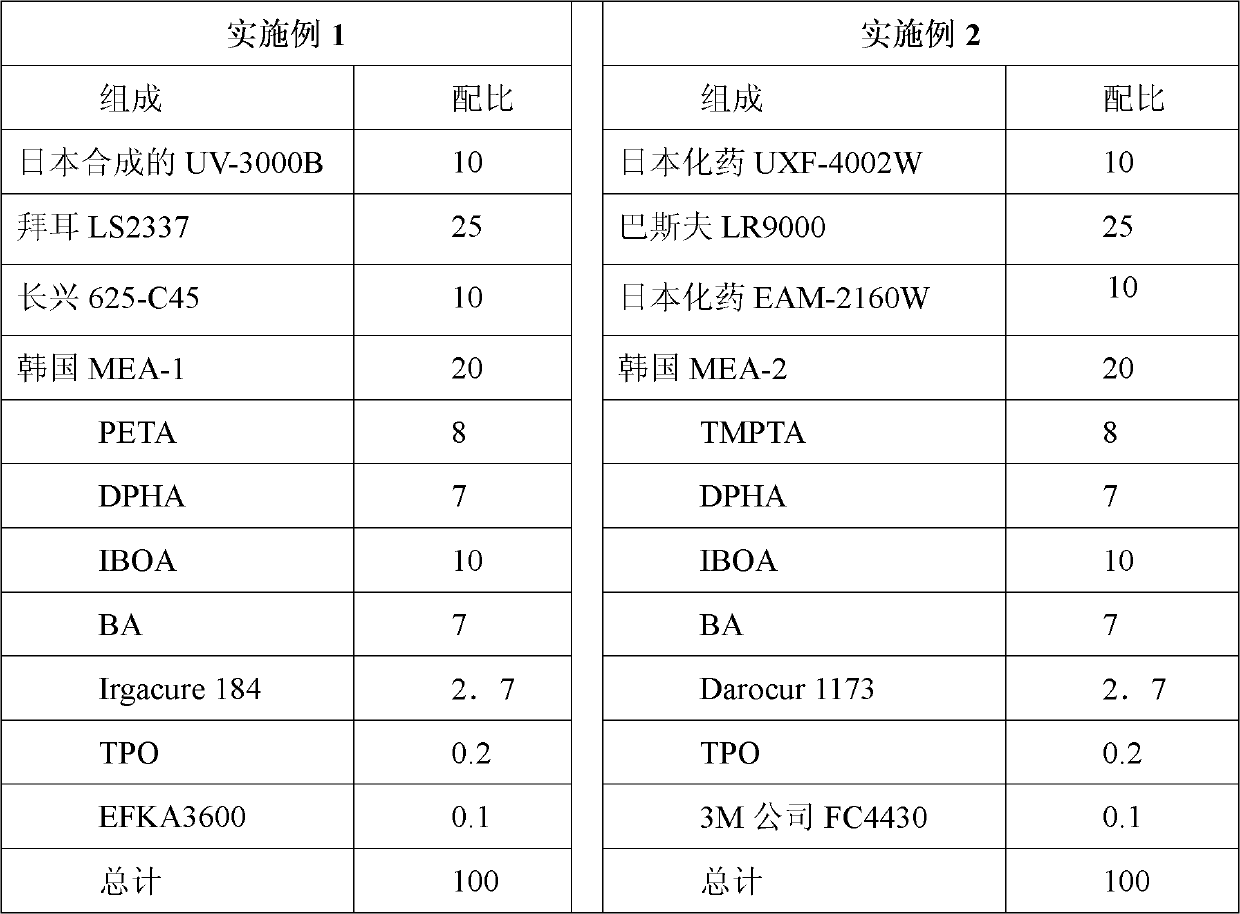

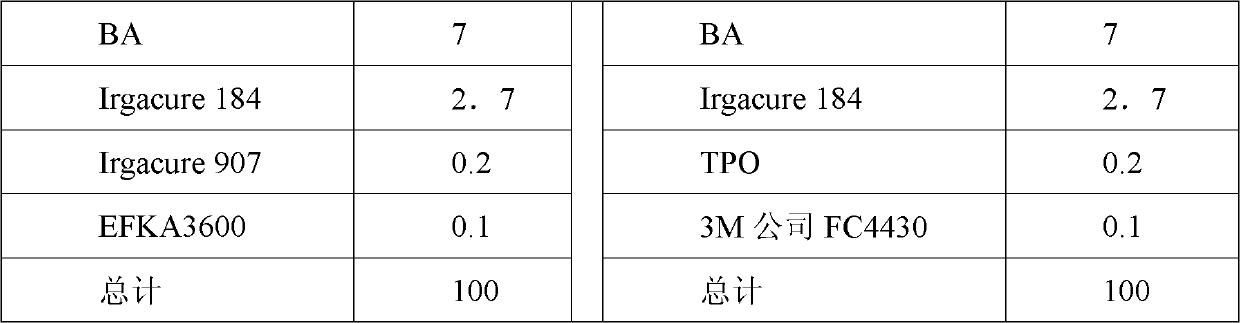

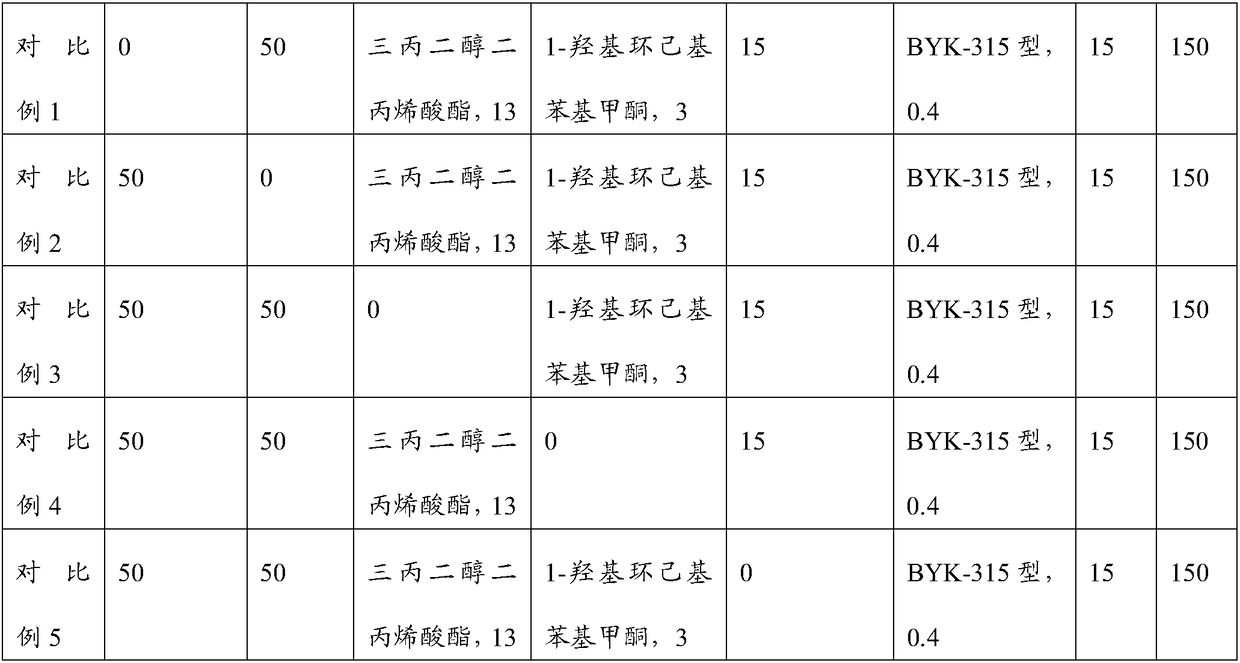

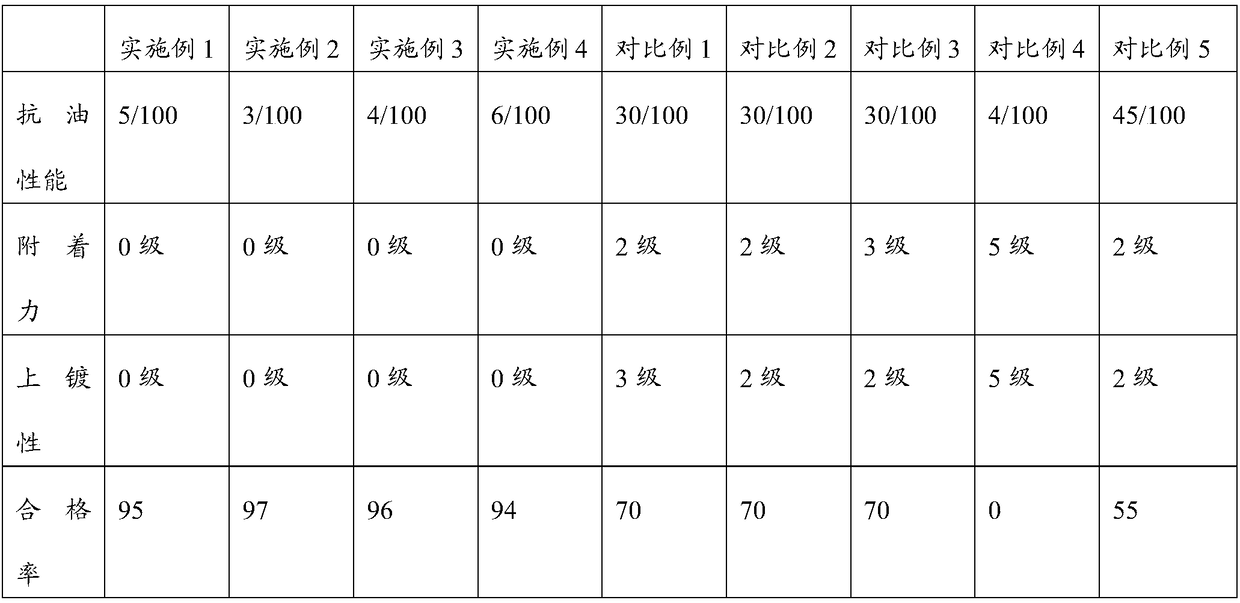

Ultraviolet curing vacuum coating metal primer capable of achieving electrostatic spraying

ActiveCN105670463ALow priceHigh viscosityPolyurea/polyurethane coatingsPowdery paintsUltravioletUrethane acrylate

The invention discloses ultraviolet curing vacuum coating metal primer capable of achieving electrostatic spraying and a preparation method thereof.The ultraviolet curing vacuum coating metal primer capable of achieving electrostatic spraying is prepared from, by weight, 5-20 parts of urethane acrylate, 10-20 parts of epoxy acrylate, 0-5 parts of pure acrylate, 5-10 parts of polyesteracrylate, 30-40 parts of trimethylolpropane triacrylate, 10-20 parts of low-functionality active diluted monomers, 2-5 parts of photoinitiator, 0.05-0.1 part of a flatting agent, 0.05-0.5 part of adhesion promoter, 0.01-0.5 part of a conductive agent and 3-5 parts of electrostatic thinner.The ultraviolet curing vacuum coating metal primer prepared through the method can be used for electrostatic spraying, has the advantages of being good in coating performance, good in adhesion, high in salt fog resistance, high in production efficiency, high in paint utilization rate and the like, and has wide market prospects.

Owner:GUANGDONG SHEN ZHAN IND CO LTD

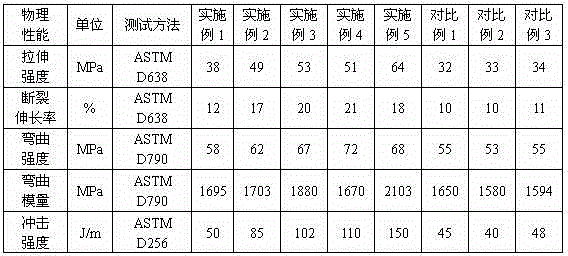

Thermoplastic composition, preparation method and application thereof

The invention discloses a thermoplastic composition, a preparation method and an application thereof. The thermoplastic composition comprises 25-87% of a thermoplastic resin, 8%-35% of a laser direct pattern additive, 0.5%-10% of a high dielectric additive, 2-10% of an inorganic filler, 1-10% of a rubber solubilizing polymer, 1-10% of a surface modification agent and 0.1-0.5% of an antioxygen. The obtained thermoplastic composition is used in a laser direct pattern method and is good in dispersibility, excellent in mechanical property and chemical plating performance, good in plating performance and processing shaping performance, capable of achieving fine lines with sizes below 100 mu m, and wide in application prospects in the aspect of weak current circuits of communication devices such as notebook computers, portable computers, mobile phones and hand-held terminals, medical treatment, a radio frequency identification (RFID) technology, automobiles, sensors, connectors and the like.

Owner:邓文 +2

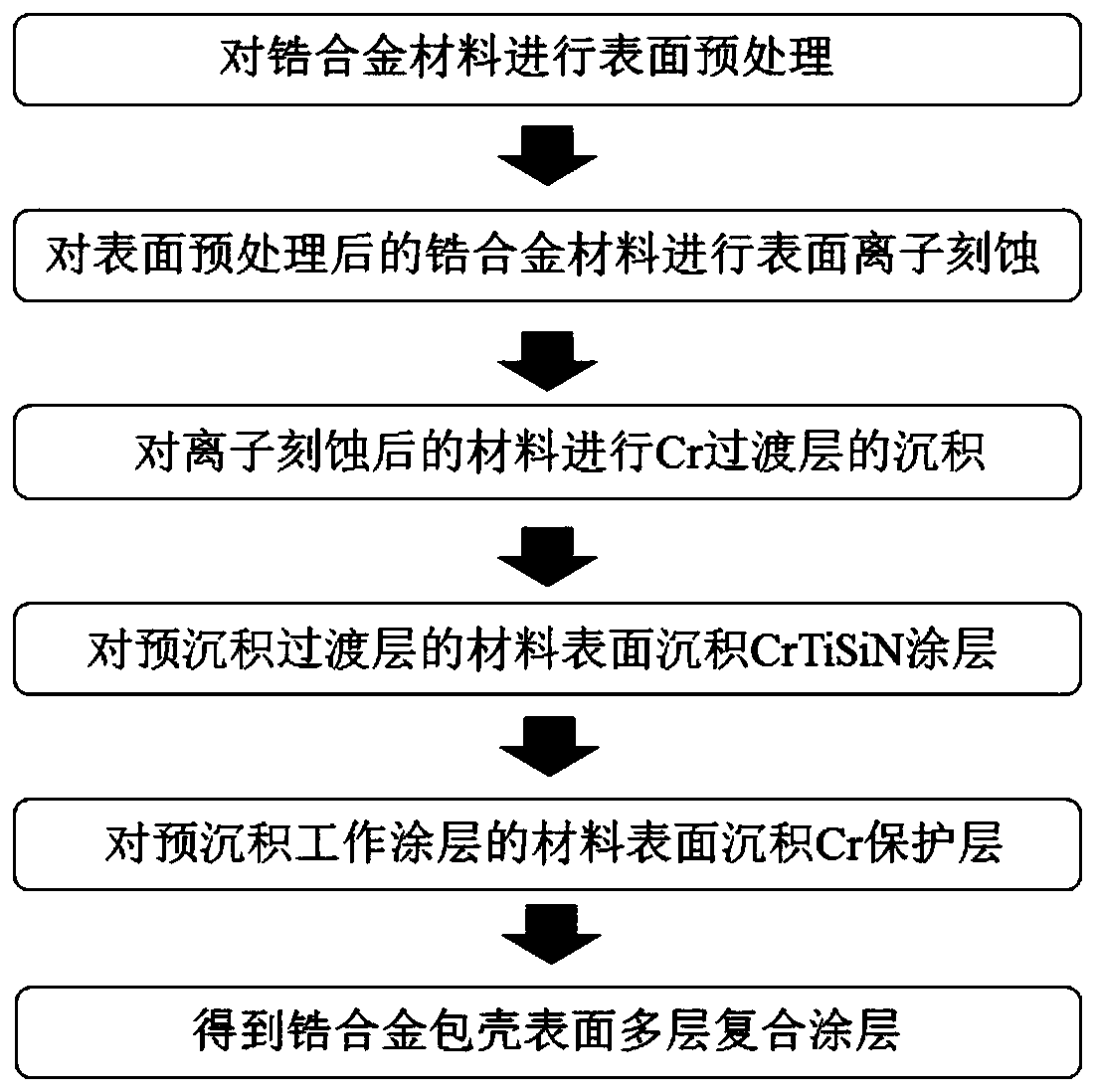

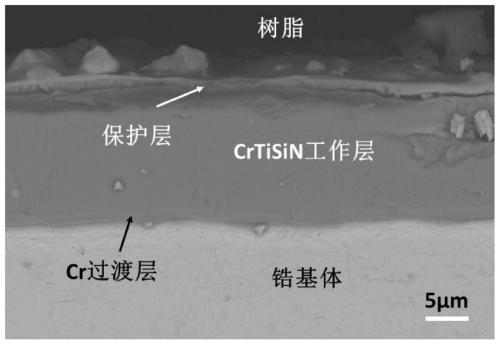

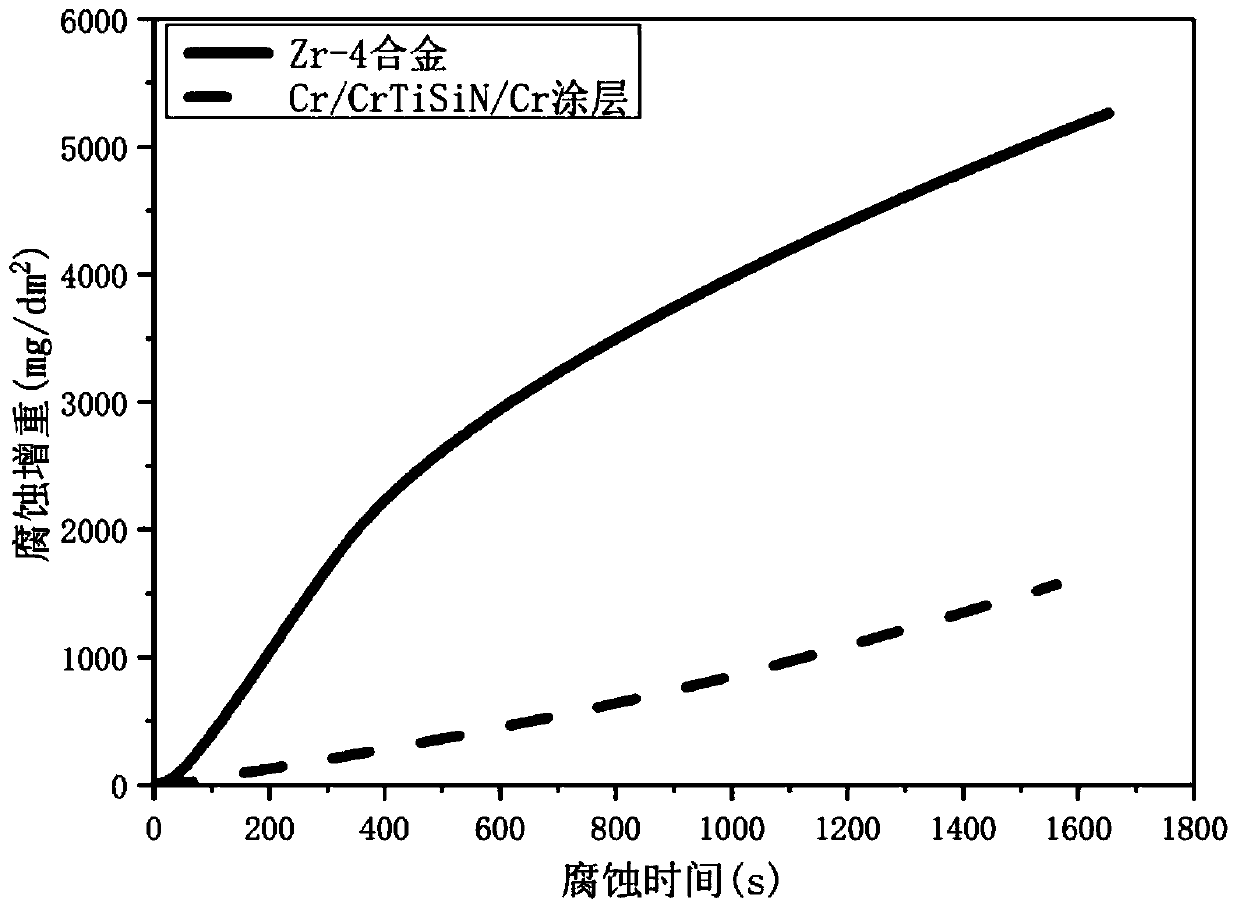

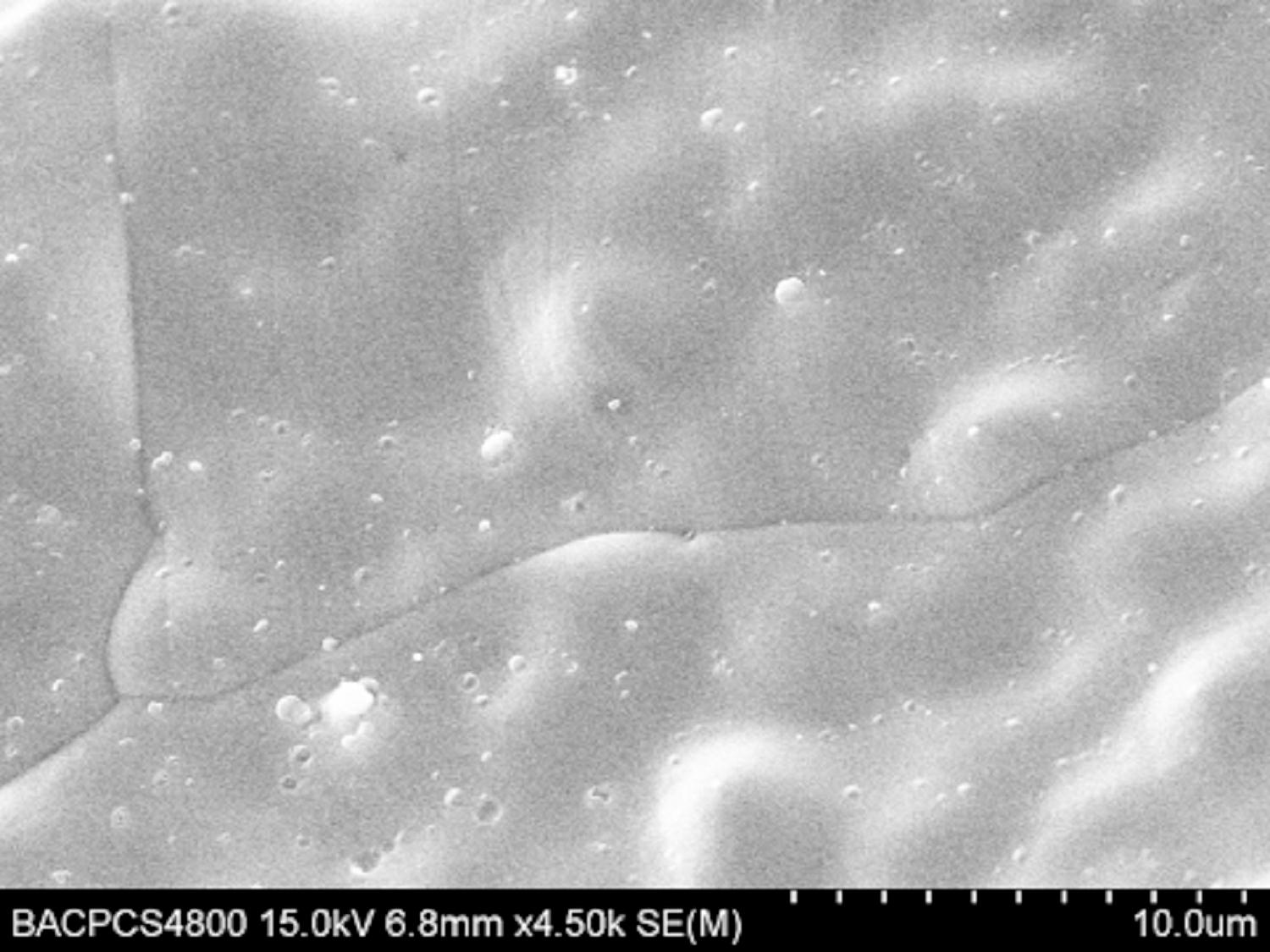

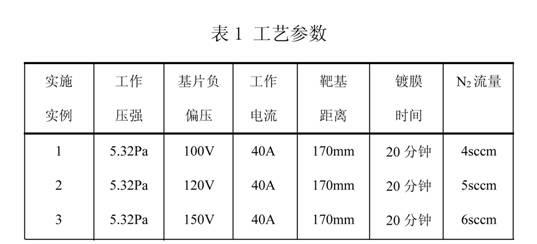

Multilayer composite coating of zirconium alloy cladding surface, and preparation method thereof

ActiveCN111172503AImprove economyUniform thicknessVacuum evaporation coatingSputtering coatingFrettingNitrogen gas

The invention discloses a multilayer composite coating of a zirconium alloy cladding surface, and a preparation method thereof. According to the method, a multi-arc ion plating technology is adopted,and zirconium alloy materials are used as a base; high purity nitrogen is used as reaction gas, and high purity argon is used as protective gas; the vacuum degree, arc current, temperature, depositiontime, gas flow and other parameters of a vacuum chamber are regulated; and a three-layer composite coating, using Cr as a transition layer, a CrTiSiN as a working coating and Cr as a protective coating, are formed on the surface of the zirconium alloy materials through deposition. The coating is uniform and compact, and the binding force between the coating and the zirconium alloy base is strong;the cladding integrity is ensured, and generation of hydrogen is inhibited; and hydrogen explosion is avoided. The coating is extremely high in hardness, and the friction resistance of zirconium alloy can be improved effectively; the a cladding pipe is prevented from being failed due to fretting wear, and the safety and accident tolerance of a reactor are improved.

Owner:XI AN JIAOTONG UNIV

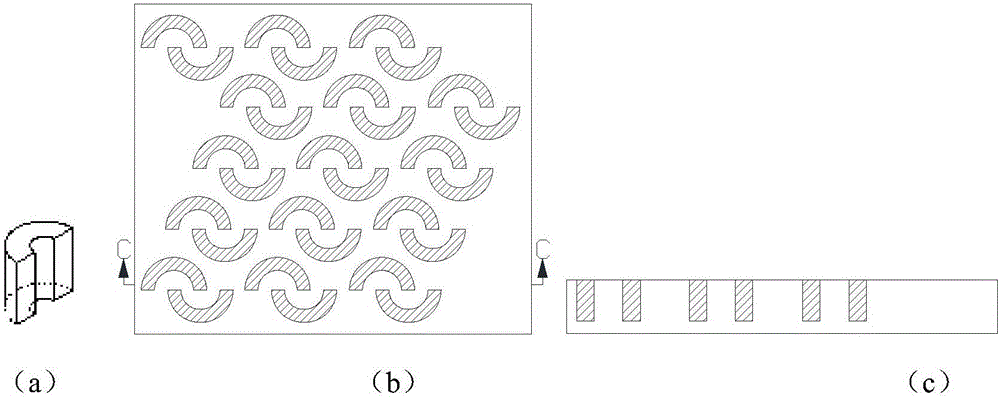

Preparation method of nitrogen-doped titanium dioxide photochemical catalyst loaded with foam metal carrier

InactiveCN102350364AFast depositionImprove photocatalytic activityPhysical/chemical process catalystsWater/sewage treatment by irradiationNitrogen dopedIon plating

The invention provides a preparation method of a nitrogen-doped titanium dioxide photochemical catalyst loaded with a foam metal carrier. In the preparation method provided by the invention, a vacuum arc ion plating process is used and a prepared nitrogen-doped titanium dioxide film of a photochemical catalyst can be uniformly distributed on the surface of a porous metal, so that the contact areafor a catalytic reaction of the photochemical catalyst is increased and the photocatalytic activity of the photochemical catalyst is higher.

Owner:BEIJING UNION UNIVERSITY

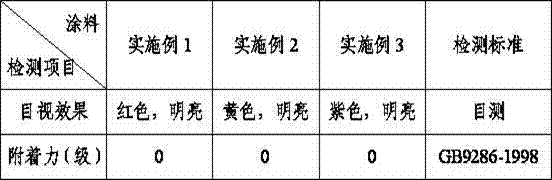

Ultraviolet curing colored coating for glass color mirror and application thereof

InactiveCN107974193AExcellent mirror leveling performanceSmooth appearancePolyurea/polyurethane coatingsEpoxy resin coatingsOligomerUV curing

The invention discloses an ultraviolet curing colored coating for a glass color mirror. The ultraviolet curing colored coating comprises an acrylic oligomer, a reactive acrylate monomer, a photoinitiator, pigments and aids. The coating is environmental-friendly, pollution-free and excellent in mirror leveling performance and can realize rapid UV curing coloring, and the cured coating has the characteristics of being flat in appearance, high in hardness, excellent in scratch resistance, high in adhesive force, excellent in plating property and the like. The invention further relates to a glasscolor mirror made by utilizing the coating and a making method of the glass color mirror.

Owner:ZHUHAI DONGCHENG UV MATERIALS

Environment-friendly dual-curing vacuum coating primer special for automobile wheel hub

InactiveCN102167951ACover up blemishesHigh glossPolyurea/polyurethane coatingsEpoxy resin coatingsUrethane acrylateReactive diluent

The invention discloses an environment-friendly dual-curing vacuum coating primer special for an automobile wheel hub, which is prepared from the following components in percentage by mass: 25-35% of NCO-containing polyurethane acrylate, 5-10% of aliphatic polyurethane diacrylate, 5-10% of phenolic epoxy acrylate, 10-20% of aliphatic epoxy acrylate, 20-35% of reactive diluent, 1-5% of photoinitiator and 0.1-1% of assistant. The primer has the advantages of energy saving, environment friendliness, strong adhesive force on the metal surface, excellent leveling property and high gloss; the primer can well cover defects on the material only after one primer coating is applied, thereby having favorable covering power; the primer has favorable adhesive force with both the wheel hub material and the vacuum coating layer; after the primer is baked at 170 DEG C for 2 hours, the surface looks no difference; and the primer also has recoating property.

Owner:YIXING HONGTAI CHEM

Platable polyformaldehyde composition and preparation method and electroplating method thereof

ActiveCN103554826AGood plating performanceHigh bonding strengthNational standardUltimate tensile strength

The invention provides a platable polyformaldehyde composition. The composition is prepared by the following raw materials in parts by weight: 100 parts of polyformaldehyde resin, 15-30 parts of acrylonitrile-butadiene-styrene, and 0-30 parts of inorganic powder. Compared with pure polyformaldehyde resin, after the composition is processed and electroplated, the bonding strength between the plating layer and the substrate is greatly improved, and the plating layer and the substrate cannot be separated. As to another unique feature of the composition, after the platable polyformaldehyde composition is electroplated, the plating layer and the substrate are likely to be separated, but after the coarsening surface is treated by a surface treating agent containing reactive perssads, the bonding strength between the plating layer and the substrate of the obtained electroplated product is further improved, and polyformaldehyde electroplated products according with related national standards are obtained.

Owner:SICHUAN UNIV

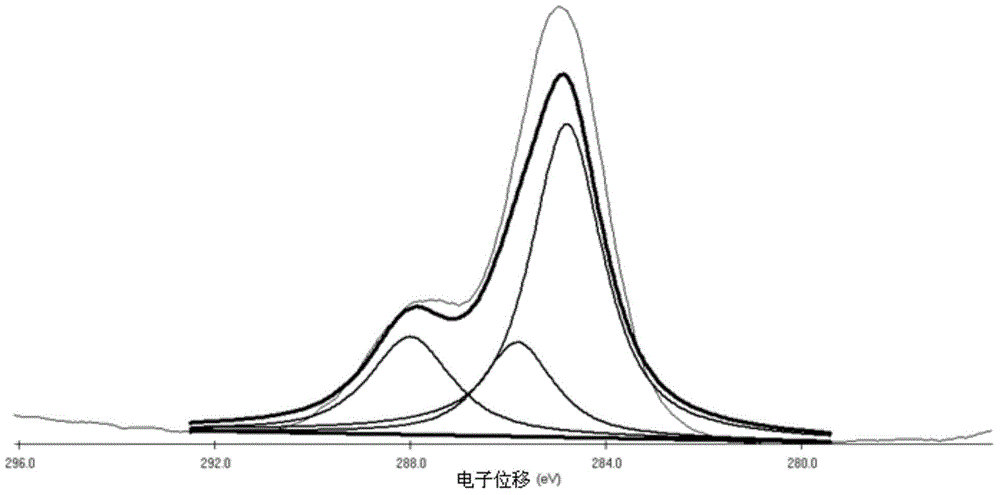

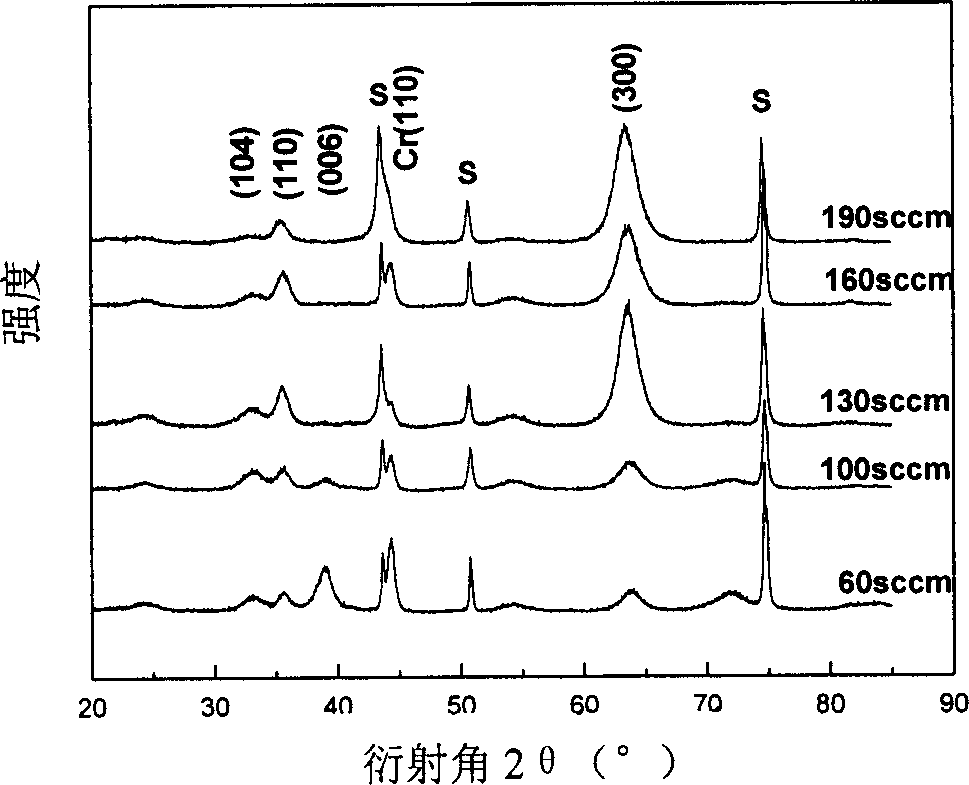

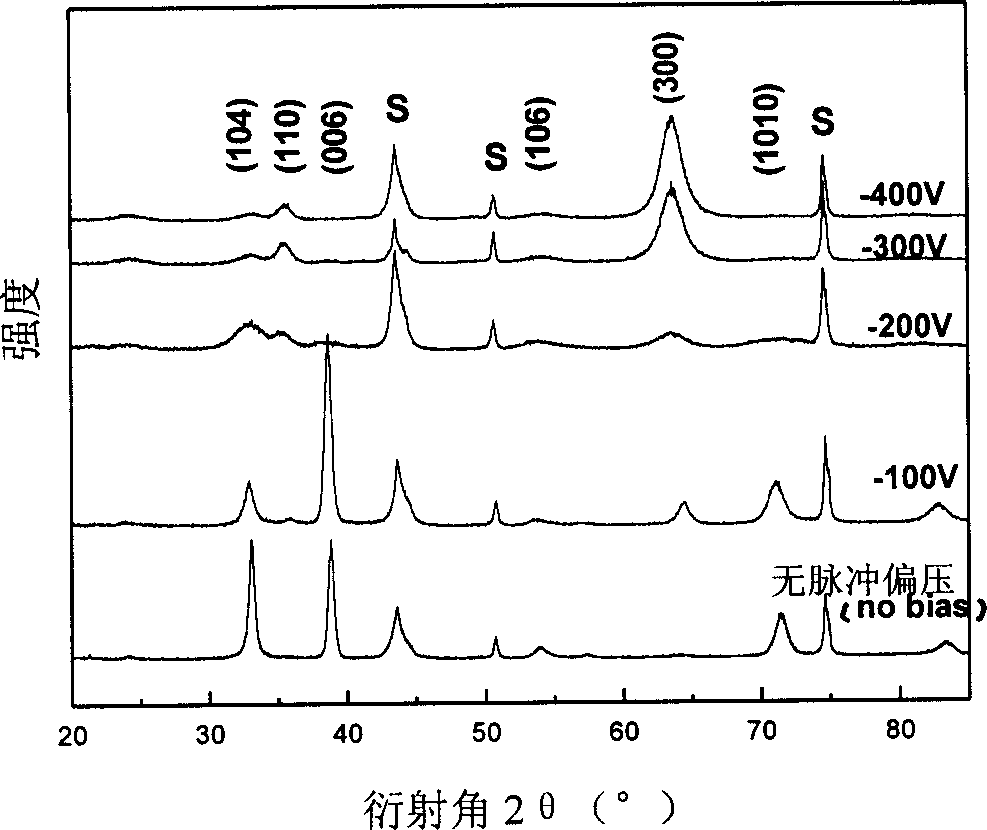

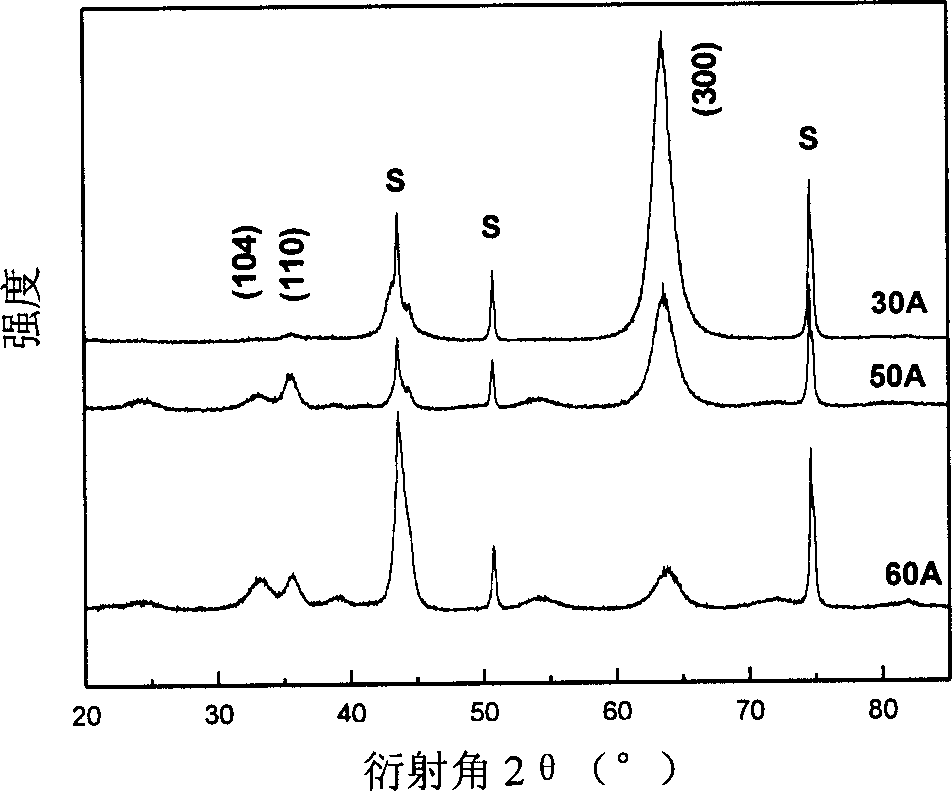

Chromium oxide coating preparing process

InactiveCN1506492AHigh energyHigh densityVacuum evaporation coatingSputtering coatingChemistryPower flow

The chromium oxide coating preparing process is one ion plating process with pure chromium cathode target, anode connected to the vacuum chamber, low voltage and great current power supply of 15-40 V voltage and 10-100 A current, O2 as reaction gas, and Ar as protective gas. Before plating, high bias voltage of -700 to -1000 V is applied for glow discharge to bombard the base body surface for 2-5 min. The arc current Ia is 30-60 A and arc voltage is 15-40 V; and after bombardment, oxygen of flow rate 60-270 sccm at pressure 0.4-0.8 Pa is introduced, while a pulse bias Vp of from 0 to -500 V and duty ratio 0-40 % is applied. The said chromium oxide coating preparing process is low in cost, environment friendly, fast in deposition speed, low deposition temperature and high compactness.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Polyphenyl ether/ABS (Acrylonitrile Butadiene Styrene) alloy and preparation method thereof

Owner:上海日之升科技有限公司

A high strength steel excellent in uniform elongation properties and method of manufacturing the same

InactiveCN1970812AHigh strengthImprove balanceTemperature control deviceHeat treatment process controlCarbideHigh intensity

The present invention is intended to provide a high strength steel sheet having a strength not lower than 780 MPa and exhibiting a high yield ratio, an excellent balance between the strength and the uniform elongation, and a good plating property in addition to a good balance between the strength and the stretch flangeability. The present invention provides a high strength steel, comprising 0.05 to 0.25 % of C, less than 0.5 % of Si, 0.5 to 3.0 % of Mn, not more than 0.06. % of P, not more than 0.01 % of S, 0.50 to 3.0 % of Sol. A1, not more than 0.02 % of N, 0.1 to 0.8 % of Mo, 0.02 to 0.40 % of Ti, and the balance of iron and unavoidable impurities, wherein the steel has a structure formed of at least three phases including a bainite phase, and a retained austenite phase in addition to a ferrite phase having a composite carbide containing Ti and Mo dispersed and precipitated therein, wherein the total volume of the ferrite phase and the bainite phase is not smaller than 80%, the volume of the bainite phase is 5% to 60%, and the volume of the retained austenite phase is 3 to 20%.

Owner:JFE STEEL CORP +1

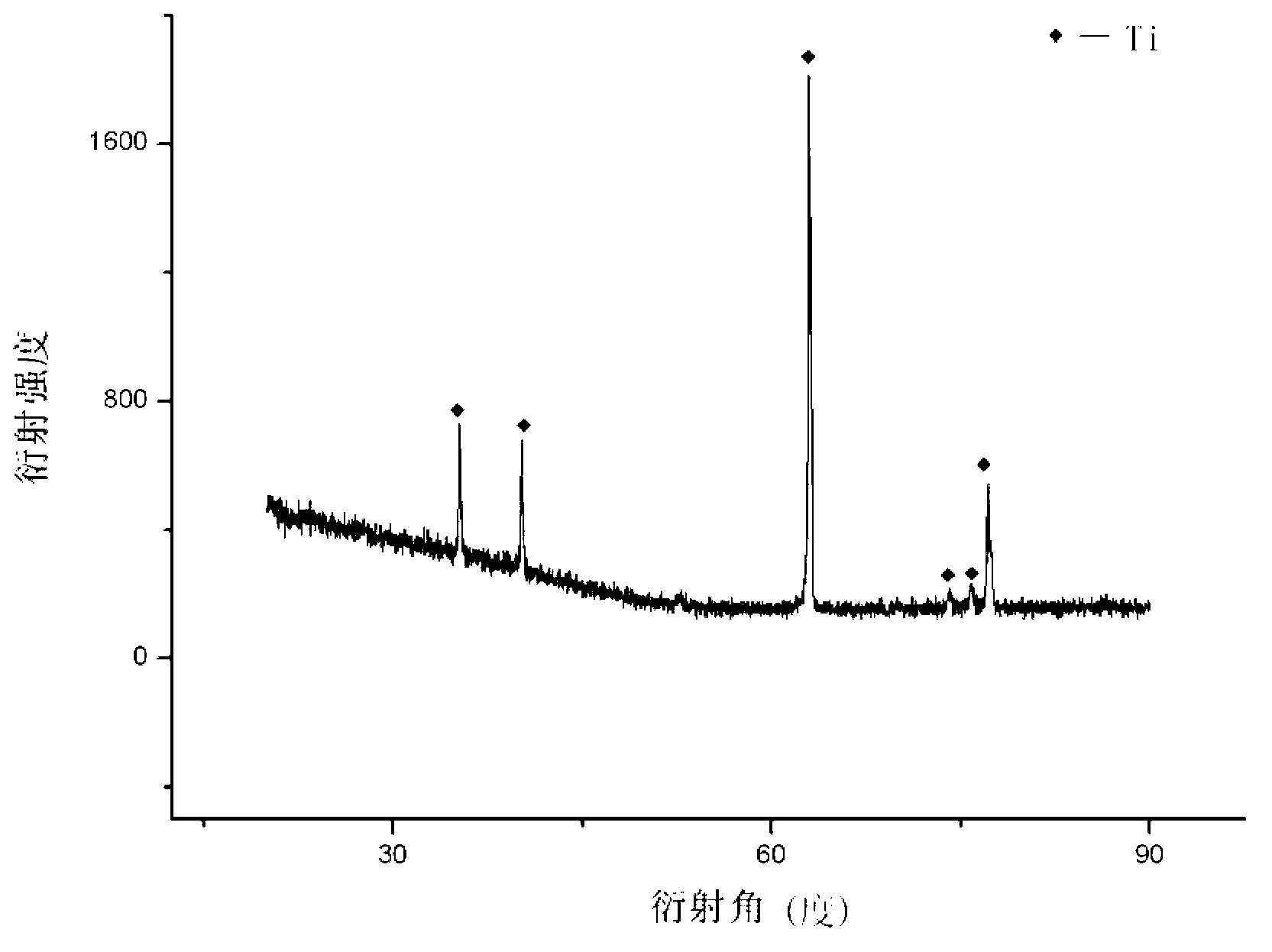

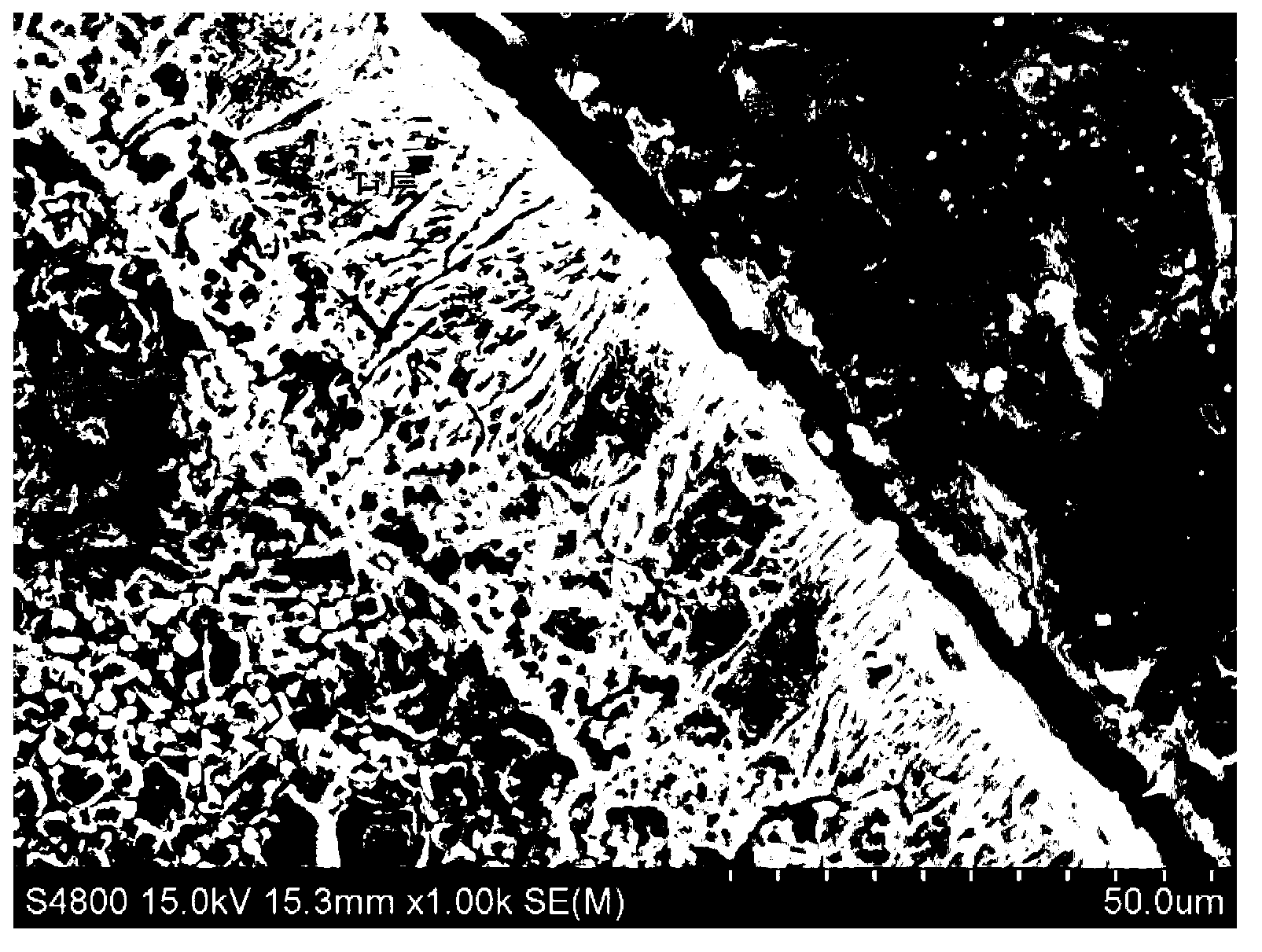

Method for preparing titanium metal coating on ceramic surface

The invention discloses a method for preparing a titanium metal coating on a ceramic surface. The method for preparing the titanium metal coating on the ceramic surface comprises the following steps of: firstly, placing ceramic the surface of which is treated into a quartz tube; then placing a mixture of titanium powder and iodine powder into a container, and placing the container into the quartz tube; then placing the quartz tube into a program control furnace, vacuumizing the program control furnace repeatedly, and introducing an inert gas, warming the program control furnace at the warming speed of 15-20 DEG C / min to 1030-1200 DEG C and carrying out heat preservation, and cooling, thereby obtaining the ceramic the surface of which is coated with the metal coating. The coating provided by the invention is high in purity, and has strong bonding force with base body ceramic, is uniform in distribution on the whole ceramic plane, can form a smooth deposition surface easily; and the device is simple, low in cost and simple to operate.

Owner:CHANGAN UNIV

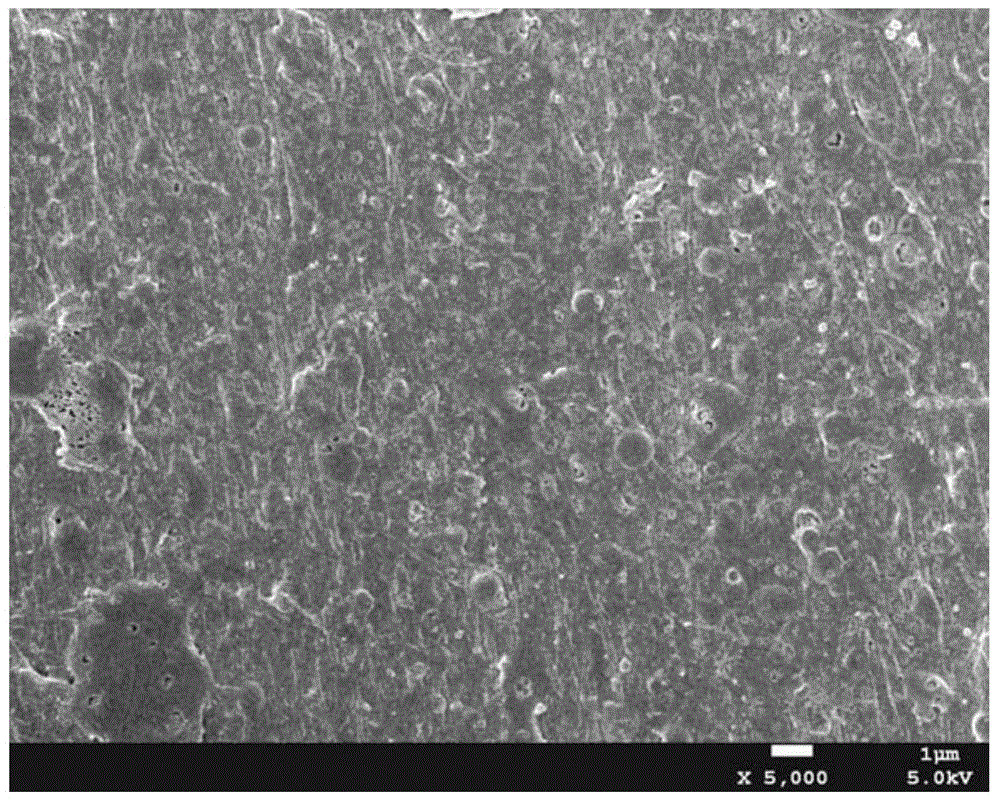

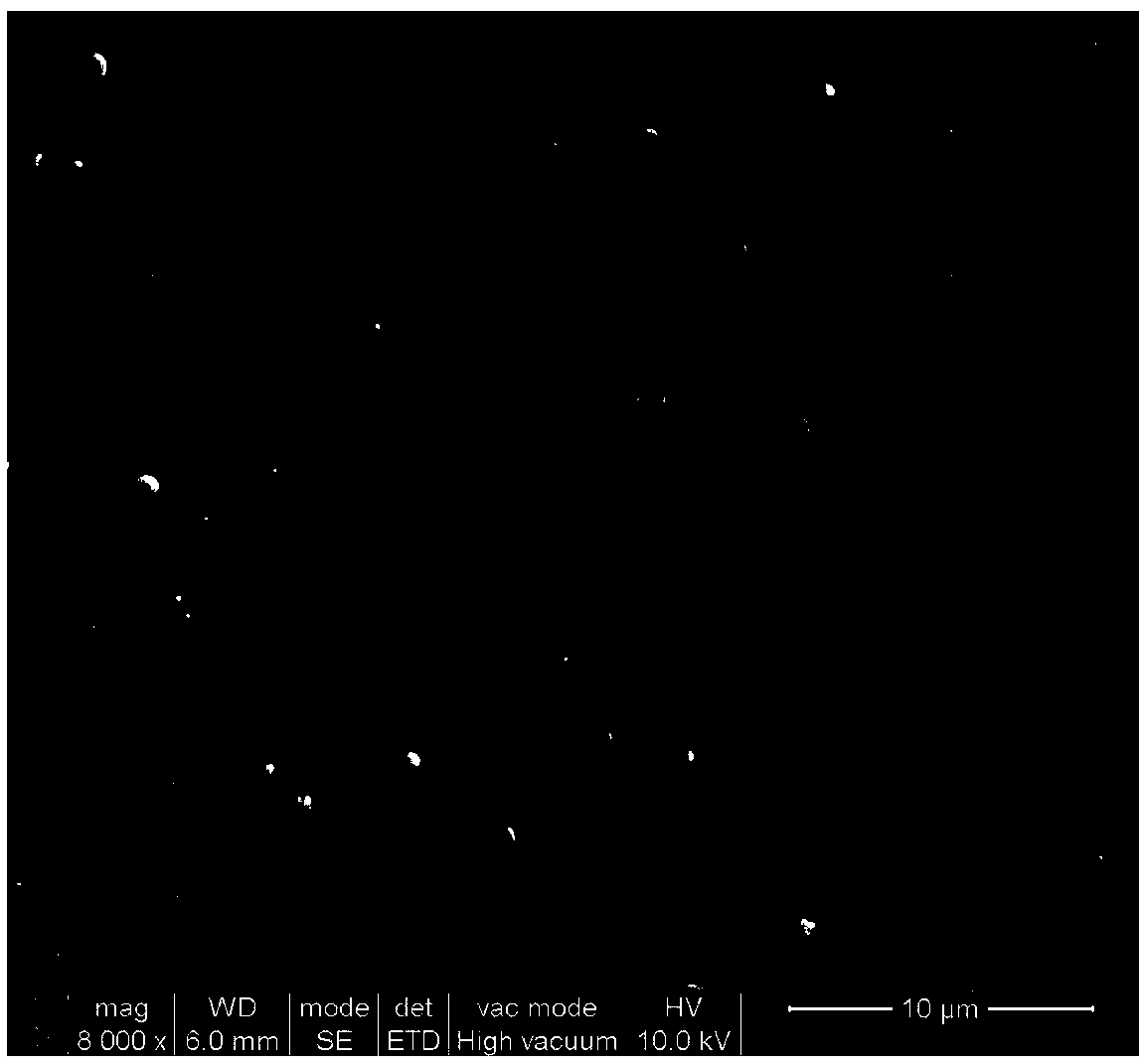

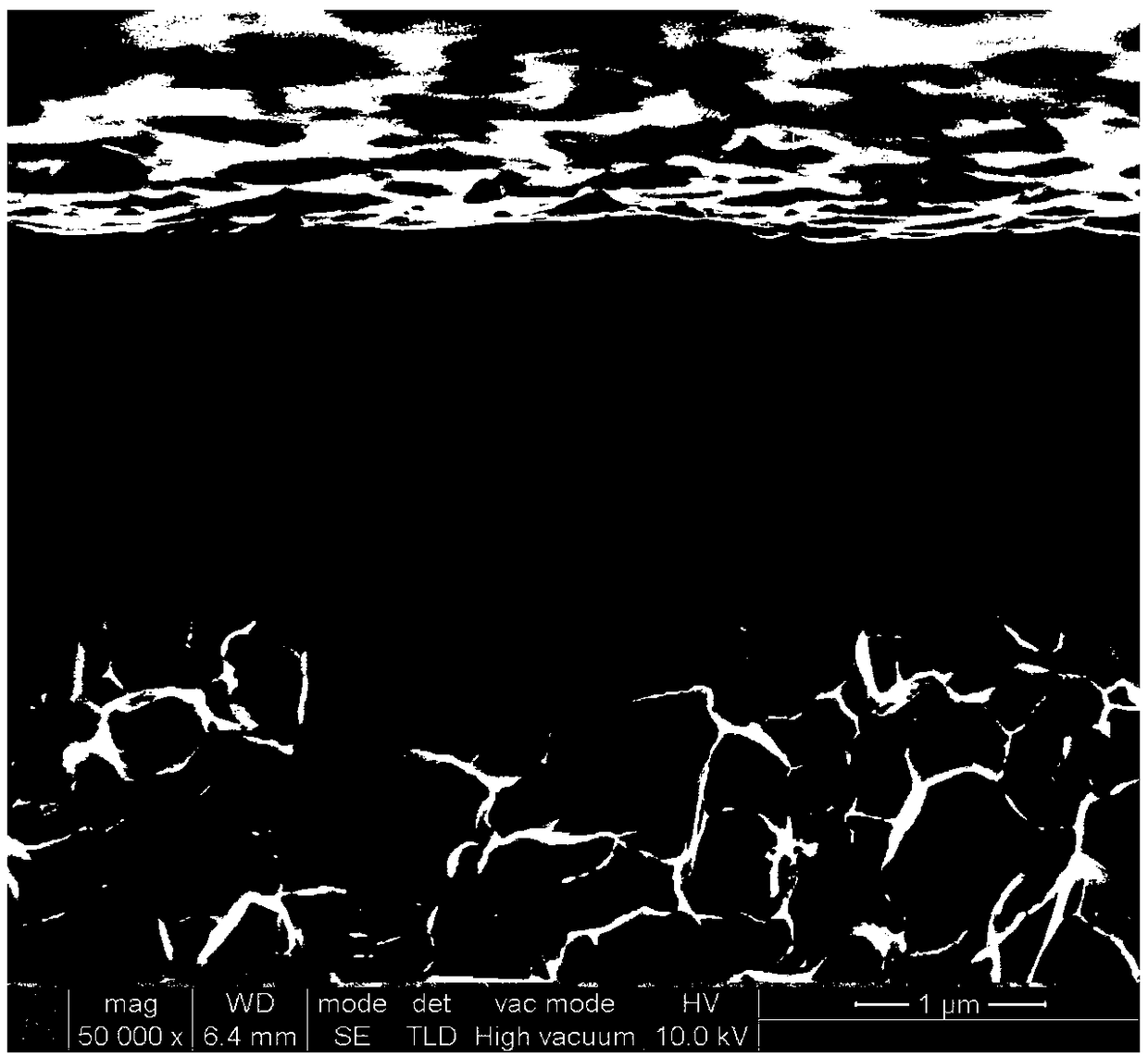

AlCrSiN nano-composite coating resistant to high temperature and abrasion and preparation method thereof

ActiveCN108796453AHigh hardnessImprove high temperature stabilityVacuum evaporation coatingSputtering coatingFilm baseUltimate tensile strength

The invention belongs to the technical field of coating preparation and particularly relates to an AlCrSiN nano-composite coating resistant to high temperature and abrasion and a preparation method thereof. According to the AlCrSiN nano-composite coating resistant to high temperature and abrasion and the preparation method thereof, a pulsed arc ion plating method is adopted; and a Cr interface implantation layer, a CrN transition layer and an AlCrSiN surface functional layer are sequentially deposited on the surface of a base body from bottom to top. Experimental results show that the AlCrSiNnano-composite coating obtained through the preparation method is excellent in high-temperature stability and abrasion resistance and has the advantages of being small in number of surface large particles, low in internal stress, high in film base bonding strength and the like; and the AlCrSiN nano-composite coating is applicable to surface protection of products such as mechanical parts, tools and molds.

Owner:GUANGDONG UNIV OF TECH

Electroplatable ABS/polyester blended alloy and preparation method thereof

The invention relates to an electroplatable ABS / polyester blended alloy and a preparation method thereof. The electroplatable ABS / polyester blended alloy comprises ABS resin and neopentyl glycol modified PETG copolyester, wherein the ABS resin is non-electroplating-grade or recovered ABS resin. By means of an ordinary conventional method, all raw materials are weighed in proportion, processes suchas uniform mixing, melt extrusion, granulation are performed, the blended alloy material with enhanced shock resistance and weather resistance can be obtained, and the blended alloy material is electroplatable, has processing conditions similar to those of ABS resin and can meet the adhesion test standard.

Owner:腾龙特种树脂(厦门)有限公司

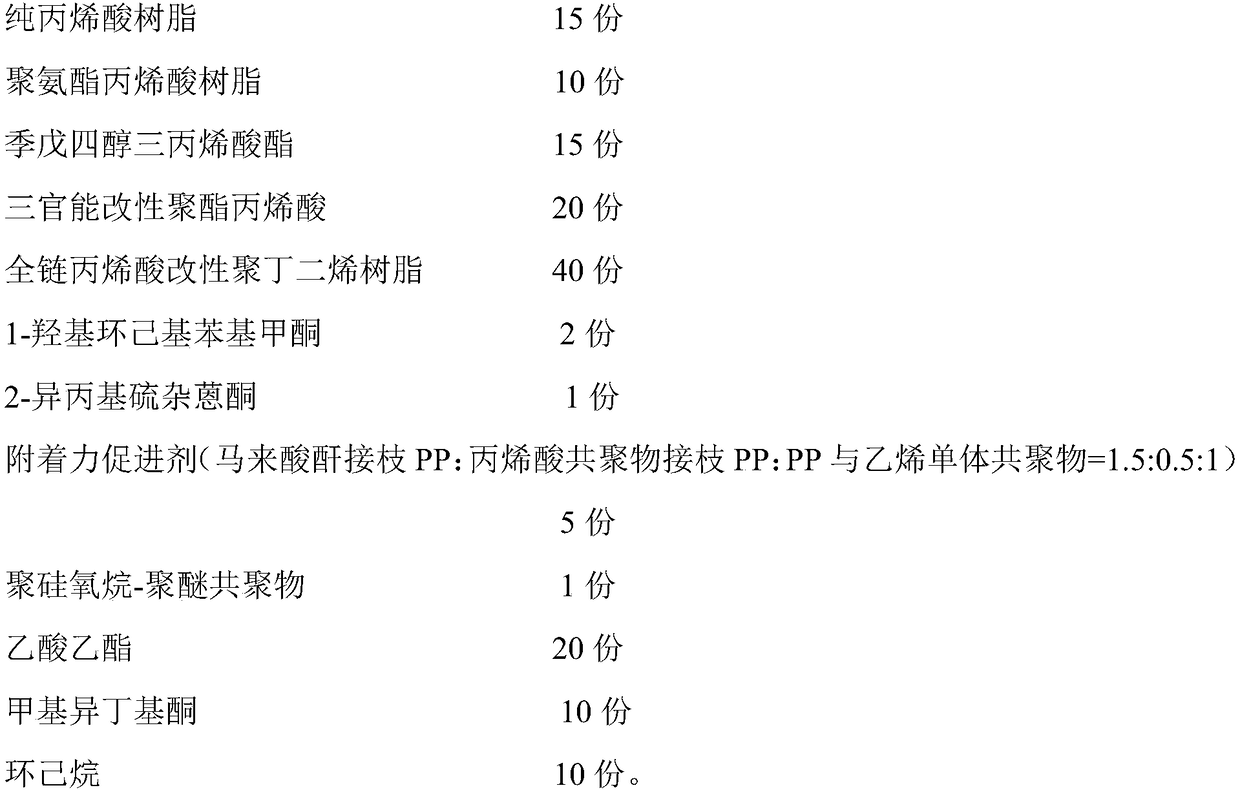

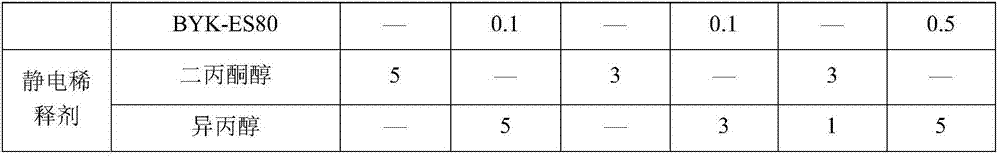

UV-curable PP treating water-free PVD priming paint and preparation method thereof

ActiveCN108690449AReduce energy consumptionReduce manufacturing costPolyurea/polyurethane coatingsEpoxy resin coatingsPolyesterAcrylic resin

The invention discloses a UV- curable PP treating water-free PVD priming paint, which is characterized by comprising the following ingredients (by weight): 20-30 parts of acrylic resin, 10-20 parts ofacrylic monomer, 15-20 parts of modified polyester acrylic acid, 30-45 parts of whole-chain acrylic modified polybutadiene resin, 1-5 parts of a photoinitiator, 5-10 parts of an adhesion promoter, 0.5-3 parts of an auxiliary agent and 30-40 parts of a solvent. The paint of the invention has good weatherability and strong adhesion. Requirements of people on surface finishing of high-grade productsare met. As spraying of PP treating water is avoided, consumption for production of unit product is reduced, labor productivity is raised, production cost of unit product is greatly reduced, and environmental pollution and the damage to human body are also avoided.

Owner:YIXING HONGTAI CHEM

Silver plating method for electric contact

ActiveCN107557733AFast deposition rateGood around platingVacuum evaporation coatingSputtering coatingEnvironmental resistanceNegative bias

The invention discloses a silver plating method for an electric contact. The silver plating method for the electric contact includes the following steps that firstly, surface oil removing and rust removing treatment is performed on the electric contact, and cleaning and drying are performed; secondly, the electric contact is placed in a plating chamber, then the plating chamber is vacuumized to 10<-5>Pa to 10<-4>Pa, then argon gas is introduced, and the vacuum degree is kept smaller than 2Pa; thirdly, a pulse Ag target power source and a pulse negative bias power source are started to performion bombardment cleaning on the electric contact; fourthly, the gas discharging current density of a cathode is adjusted to be in micro arc discharging, silver plating is performed through a micro arcion plating method with the current density larger than 0.1 A / cm<2> and smaller than 1 A / cm<2>, and the silver plating time is 1-2 h, and the silver plated electric contact is obtained; and fifthly,temperature lowering and cooling are performed, and after temperature lowering along a furnace is performed till room temperature is achieved, the silver plated electric contact is taken out. Silver plating treatment is performed on the electric contact through the micro arc ion plating method, and the beneficial effects of environment friendliness, better clad layer binding force, high efficiencyand the like are achieved.

Owner:SHAANXI SIRUI ADVANCED MATERIALS CO LTD +1

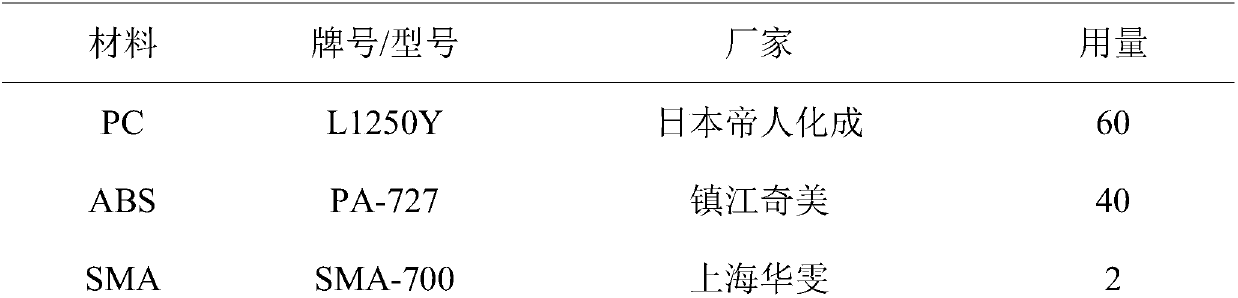

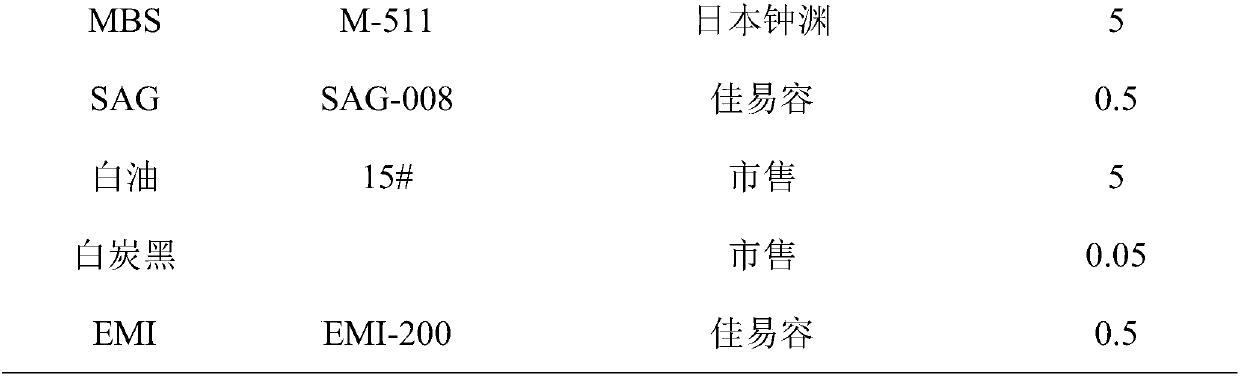

High-gloss PC/ABS (polycarbonate/acrylonitrile butadiene styrene) electroplating material for vehicles and method for preparing high-gloss PC/ABS electroplating material

The invention discloses a high-gloss PC / ABS (polycarbonate / acrylonitrile butadiene styrene) electroplating material for vehicles and a method for preparing the high-gloss PC / ABS electroplating material. The high-gloss PC / ABS electroplating material comprises 50-80 phr of PC, 50-20 phr of ABS, 0-1 phr of lubricants, 0-10 phr of compatilizers, 0-5 phr of processing auxiliaries, 0-10 phr of toughening agents and 0.1-0.5 phr of antioxidants. The high-gloss PC / ABS electroplating material and the method have the advantages that stripping force of 5-6 N can be generated by the high-gloss PC / ABS electroplating material, the thermal deformation temperature of the high-gloss PC / ABS electroplating material is higher than 130 DEG C, and the high-gloss PC / ABS electroplating material is high-temperature-resistant and is excellent in electroplating performance.

Owner:太仓市华鼎塑料有限公司

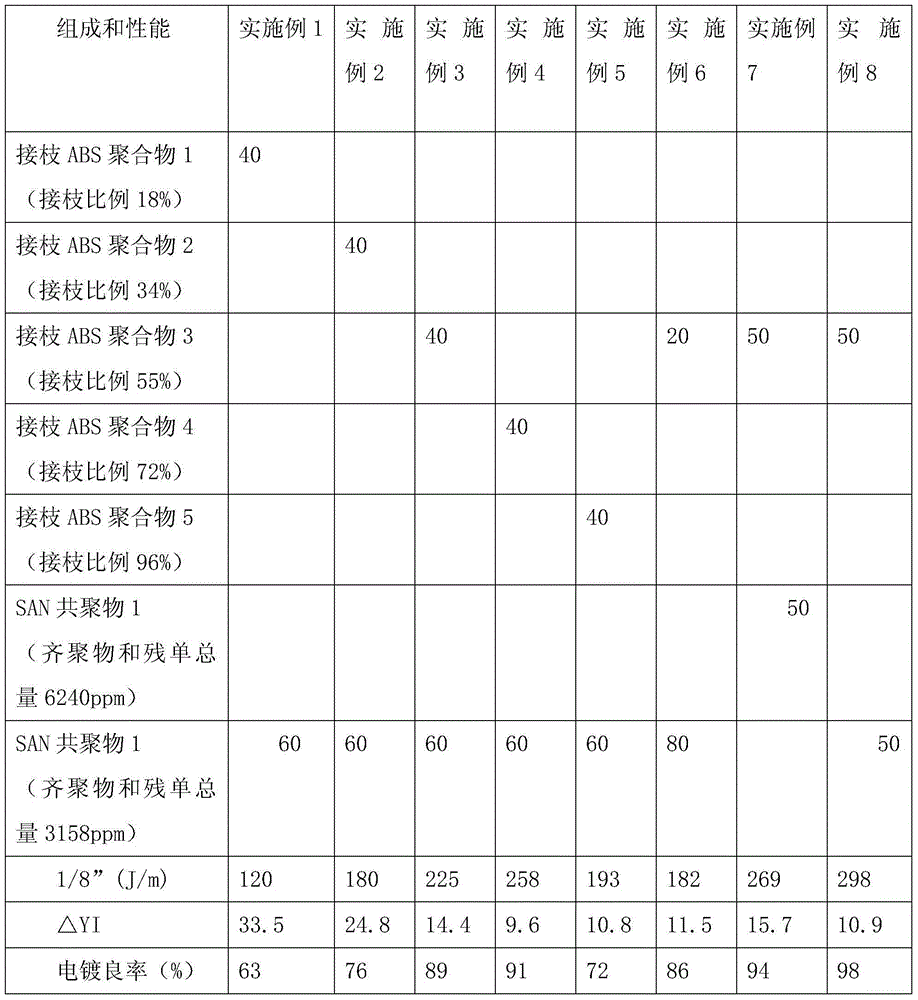

ABS resin composition for electroplating and preparation method thereof

InactiveCN104004313AExcellent thermal stability and plateabilityImprove thermal stabilityResidual monomerOligomer

The invention discloses ABS resin composition for electroplating and a preparation method thereof. The electroplating ABS resin composition with excellent heat stability and electroplating practicability is prepared by controlling the grafting ratio of grafted ABS polymer, the total amount of oligomers and residual monomers in SAN copolymer and the vacuum degree during extrusion mixing, and the molding yield of electroplated products and the electroplating yield are substantially improved.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

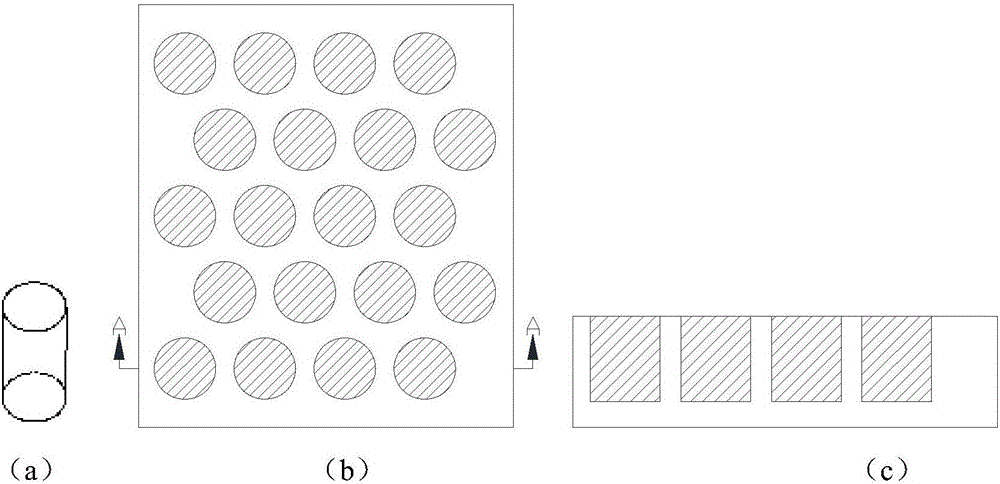

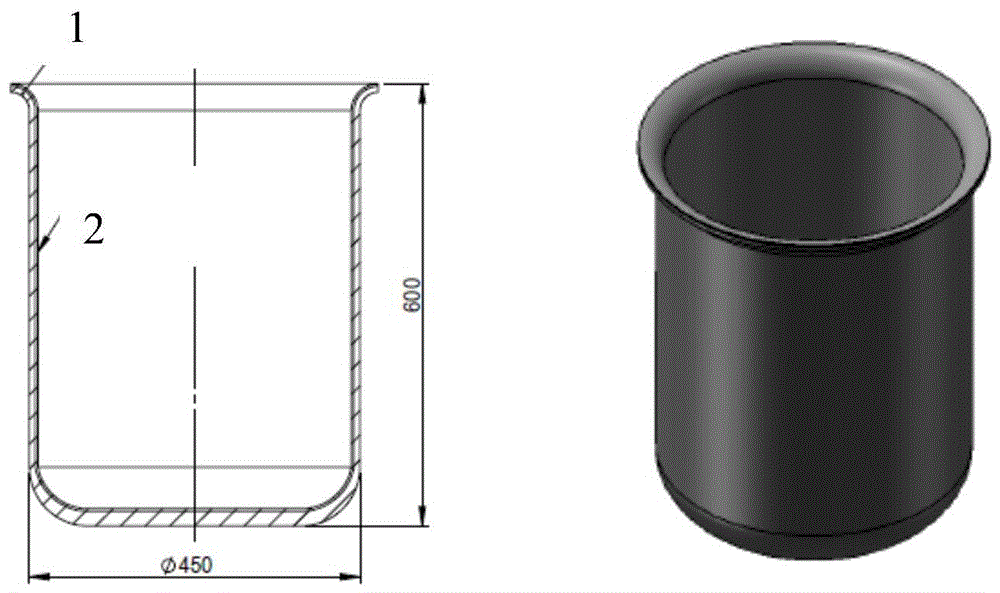

A kind of preparation method of crucible containing tungsten coating

ActiveCN104213096BExtended service lifePrevent infiltrationChemical vapor deposition coatingCrucibleAlloy

The invention discloses a preparation method of a crucible with a tungsten coating. The preparation method comprises the following steps: (1) a needed pure tungsten, pure molybdenum or molybdenum alloy crucible base material is obtained through a specific processing technology according to a needed size; (2) a certain degree of surface roughening treatment is performed for the obtained crucible base material; and then, the surface is cleaned to remove an oxide layer; and (3) tungsten hexafluoride serves as a raw material, hydrogen serves as reducing gas, and the chemical vapor deposition (CVD) is performed for the surface of the crucible base material under the condition of the base material temperature of 350-600 DEG C to form a tungsten coating layer with the thickness of 0.01-3 mm so as to obtain a crucible product coated with the tungsten coating layer. The CVD tungsten coating layer with high purity and high compactness has excellent metal or nonmetallic solution corrosion resistance, so that the protecting effect on the crucible basal body is achieved, and the service life and the performance of the crucible under such high-temperature environments as metal or nonmetal smelting and crystal growth are prolonged and improved.

Owner:XIAMEN HONGLU TUNGSTEN MOLYBDENUM IND CO LTD

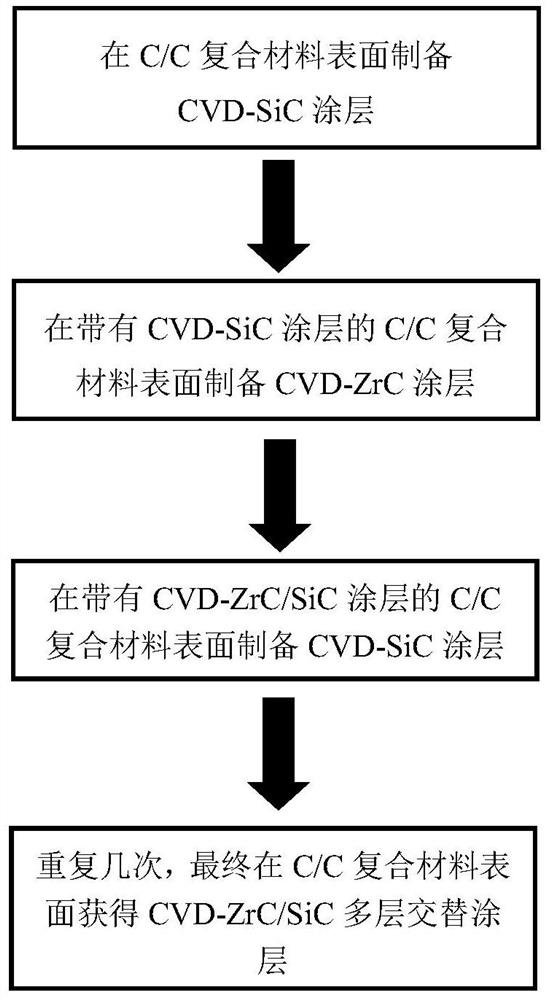

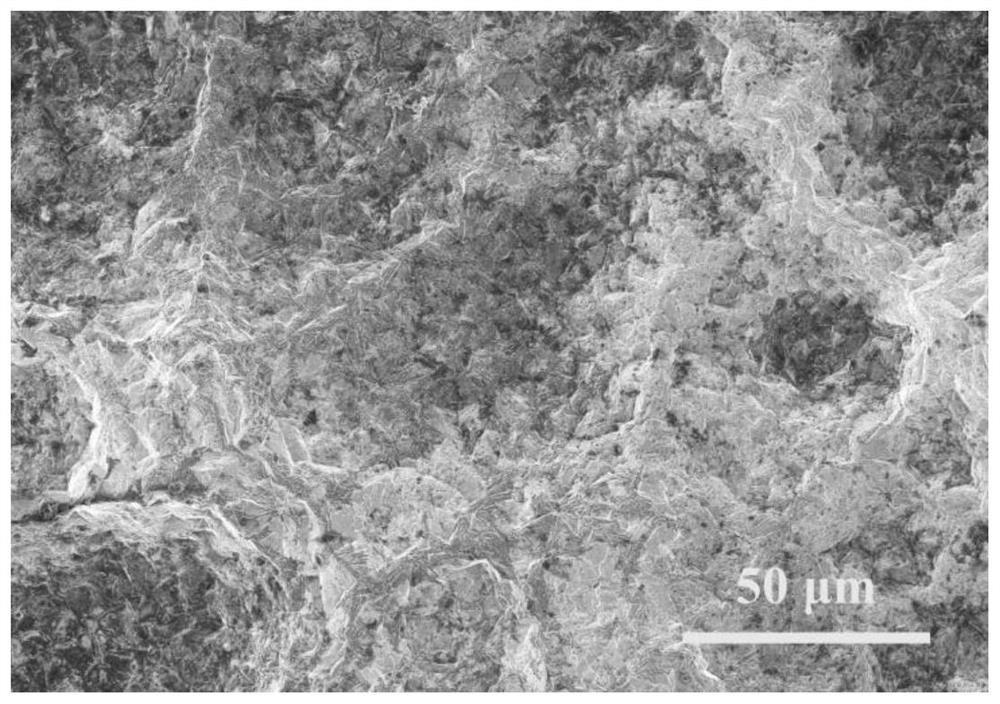

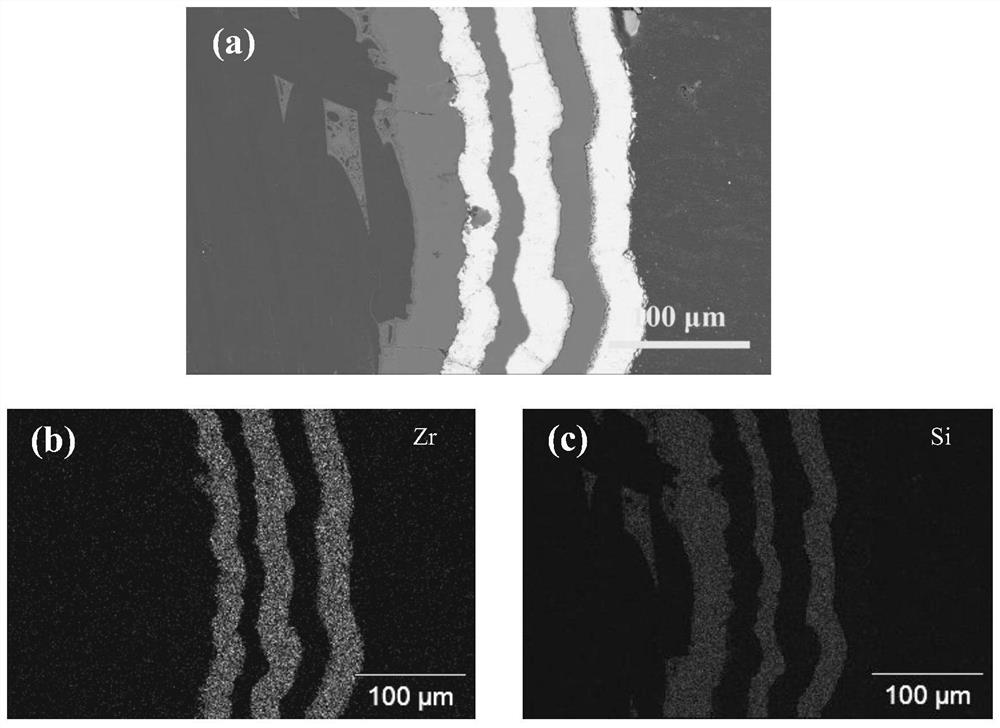

Anti-ablation ZrC/SiC multilayer alternate coating and preparation method thereof

PendingCN113106416AImprove anti-ablation performanceEffective control of thermal expansion differencesChemical vapor deposition coatingThermal dilatationCrazing

The invention relates to an anti-ablation ZrC / SiC multilayer alternate coating and a preparation method. The thermal expansion difference between coatings and a substrate and among coatings can be effectively regulated and controlled through multilayer alternation of SiC and ZrC, meanwhile, the designability of the multi-layer alternate coatings is high, and thermal stress matching of the coatings and the substrate can be better achieved by adjusting the thickness and the number of the SiC layers and the ZrC layers, on the other hand, after the multiple layers are compounded, a large number of interlayer interfaces can exist, cracks can be deflected or terminated in the expansion process, and therefore generation of penetrating cracks is reduced. In conclusion, according to the anti-ablation ZrC / SiC multilayer alternate coating and the preparation method thereof, the coatings provided by the invention can effectively improve the ablation resistance, and the substrate can be better protected.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

A kind of lanthanide thermal barrier coating ceramic layer with long life, high heat insulation and composite structure deposited by plasma evaporation and preparation method thereof

ActiveCN103966539BImprove deposition efficiencyDense tissueMolten spray coatingVacuum evaporation coatingLanthanideCrystal structure

The invention discloses a plasma evaporation deposition lanthanide thermal barrier coating ceramic layer with a long service life, a high insulation performance and a composite structure, and a preparation method thereof, and belongs to the technical field of thermal barrier coating. The ceramic layer material comprises lanthanum zirconate or cerate; the thermal barrier coating comprises a bonding layer, a first ceramic layer and a second ceramic layer which are prepared on a base body, wherein the first ceramic layer adopts a YSZ coating; the second ceramic layer comprises the lanthanum zirconate or cerate; in the preparation method of the ceramic layer, the pressure of a vacuum chamber is lower than 1 mbar; through adjusting parameters of spraying electric power, current, gas flow rate, temperature of the basal body, powder feeding rate, spraying distance and the like, the YSZ coating layer and the lanthanide thermal barrier coating ceramic layer which are provided with microstructures of columnar crystal structures, layered structures, layered structures and columnar crystal structures, or nano- structured coating and the like can be obtained. The service life of the thermal barrier coating is long and the heat-insulating property is favorable.

Owner:BEIHANG UNIV

A method for preparing thread wear-resistant, corrosion-resistant and anti-locking coatings by multi-arc ion plating

ActiveCN108179385BReduce coefficient of frictionImprove thermal stabilityVacuum evaporation coatingSputtering coatingSputter cleaningArgon atmosphere

Owner:西安赛福斯材料防护有限责任公司

Vacuum plating UV base coat and preparation method thereof

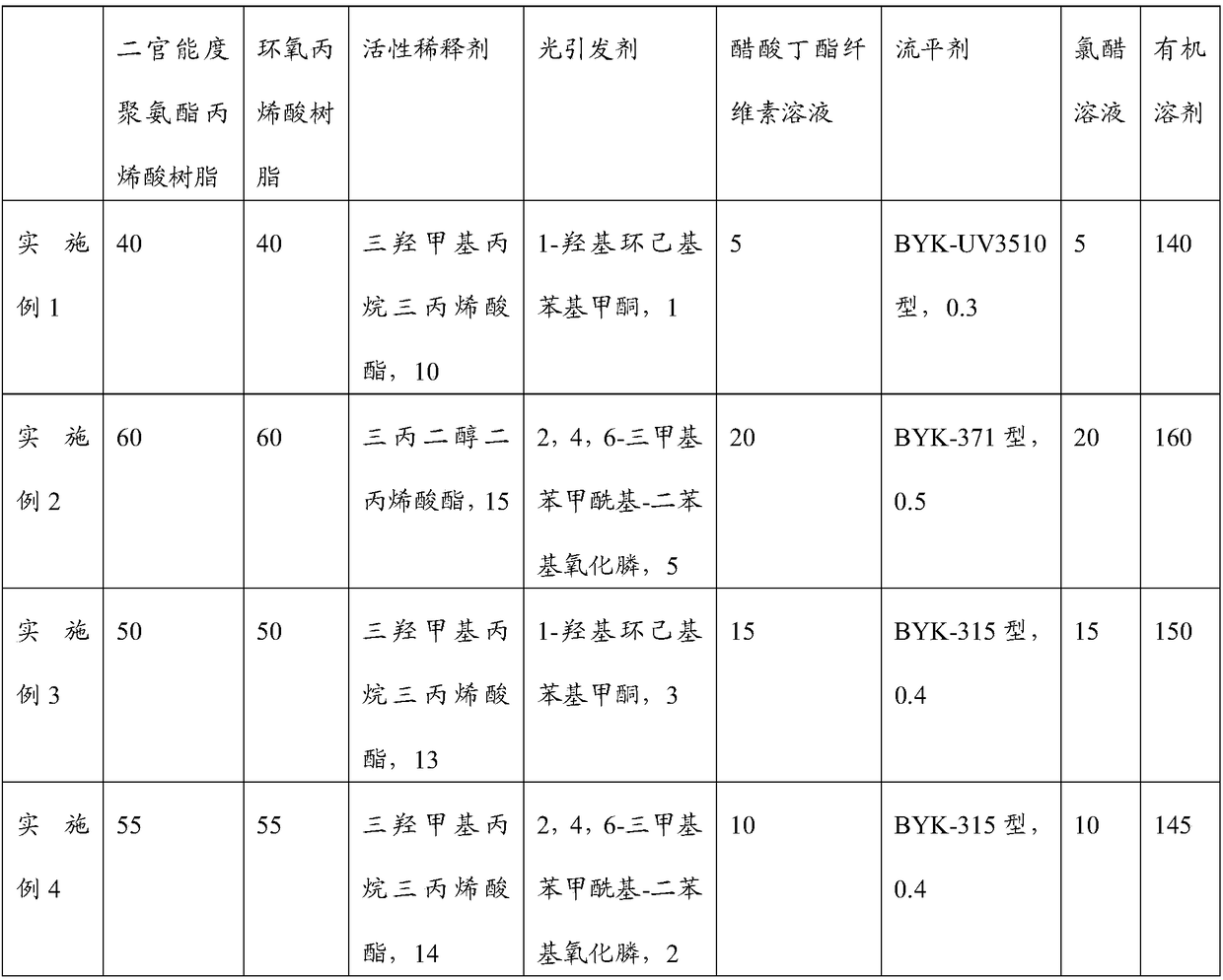

ActiveCN109135548AGuaranteed surface coating performanceImprove adhesionPolyurea/polyurethane coatingsEpoxy resin coatingsCelluloseAcrylic resin

The invention provides a vacuum plating UV base coat. The base coat comprises, by weight, 40-60 parts of bis-functional polyurethane acrylic resin, 40-60 parts of epoxy acrylic resin, 10-15 parts of reactive diluent, 1-5 parts of photoinitiator, 5-20 parts of butyl acetate cellulose solution, 140-160 parts of organic solvent and 5.3-20.5 parts of other auxiliaries. According to the base coat, themoisturizing performance on plastic substrates of the vacuum plating UV base coat can be significantly improved through the mutual action of the epoxy acrylic resin and the butyl acetate cellulose solution, the base coat particularly has a better moisturizing effect on the plastic substrates with residual demolding agent, the surface coating performance of the vacuum plating UV base coat can be ensured when demolding agent removing process on the plastic substrates is not conducted to allow the base coat has excellent adhesion force, and the problems of the influence on the base coat and plastic substrate coating quality due to residual demolding agent, lengthening production line, increasing production cost, high rejection rate of products and the like are solved.

Owner:东莞大宝化工制品有限公司 +1

An electrostatic sprayable UV-curable vacuum coating metal primer

ActiveCN105670463BLow priceHigh viscosityPolyurea/polyurethane coatingsPowdery paintsUrethane acrylateMetal Primer

Owner:GUANGDONG SHEN ZHAN IND CO LTD

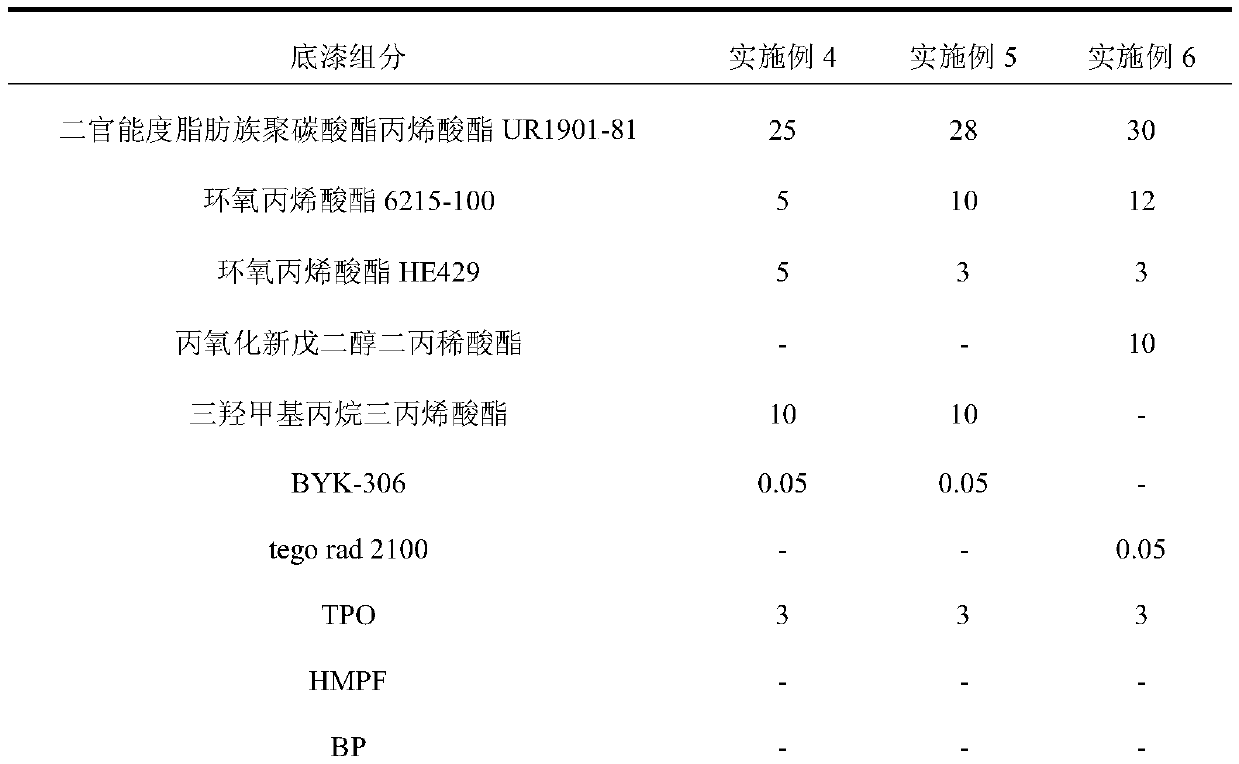

Vacuum plating UV coating for PET plastic cement

InactiveCN105238259AHigh fullnessImprove the defects of poor fullnessPolyurea/polyurethane coatingsPolyester coatingsPolyesterCyclohexanone

The invention discloses a vacuum plating UV coating for PET plastic cement. The vacuum plating UV coating for the PET plastic cement is prepared from, by weight, 10%-25% of polyurethane-modified acrylic acid oligomers, 10%-20% of polyester acrylate, 5%-15% of trimethylolpropane triacrylate, 1.5%-4% of alpha-hydroxycyclohexyl phenyl ketone, 1%-8% of 10% acrylic acid function resin, 2%-15% of methyl ethyl ketone, 35%-50% of ethyl acetate, 5%-20% of n-butyl acetate and 1%-8% of cyclohexanone. According to the vacuum plating UV coating for the PET plastic cement, the vacuum plating UV coating is a UV vacuum aluminum plating primer which has the excellent adhesion on a PET plastic cement substrate, the high fullness, the excellent levelling property and the wonderful plating effect are achieved; the defect of over crispness or pseudo adhesion of similar products is overcome, and the excellent overall adhesion effect can be supplied; the excellent physical and chemical properties and the excellent levelling property and fullness are achieved.

Owner:德阳森华涂料化工有限公司

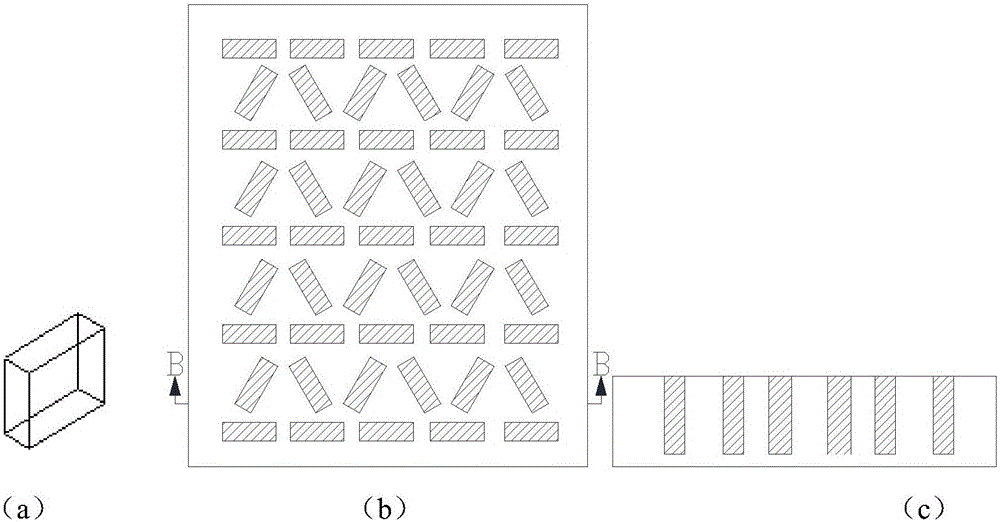

Method for preparing screw-thread wear-resistant corrosion-resistant anti-lock coating by adopting multi-arc ion plating

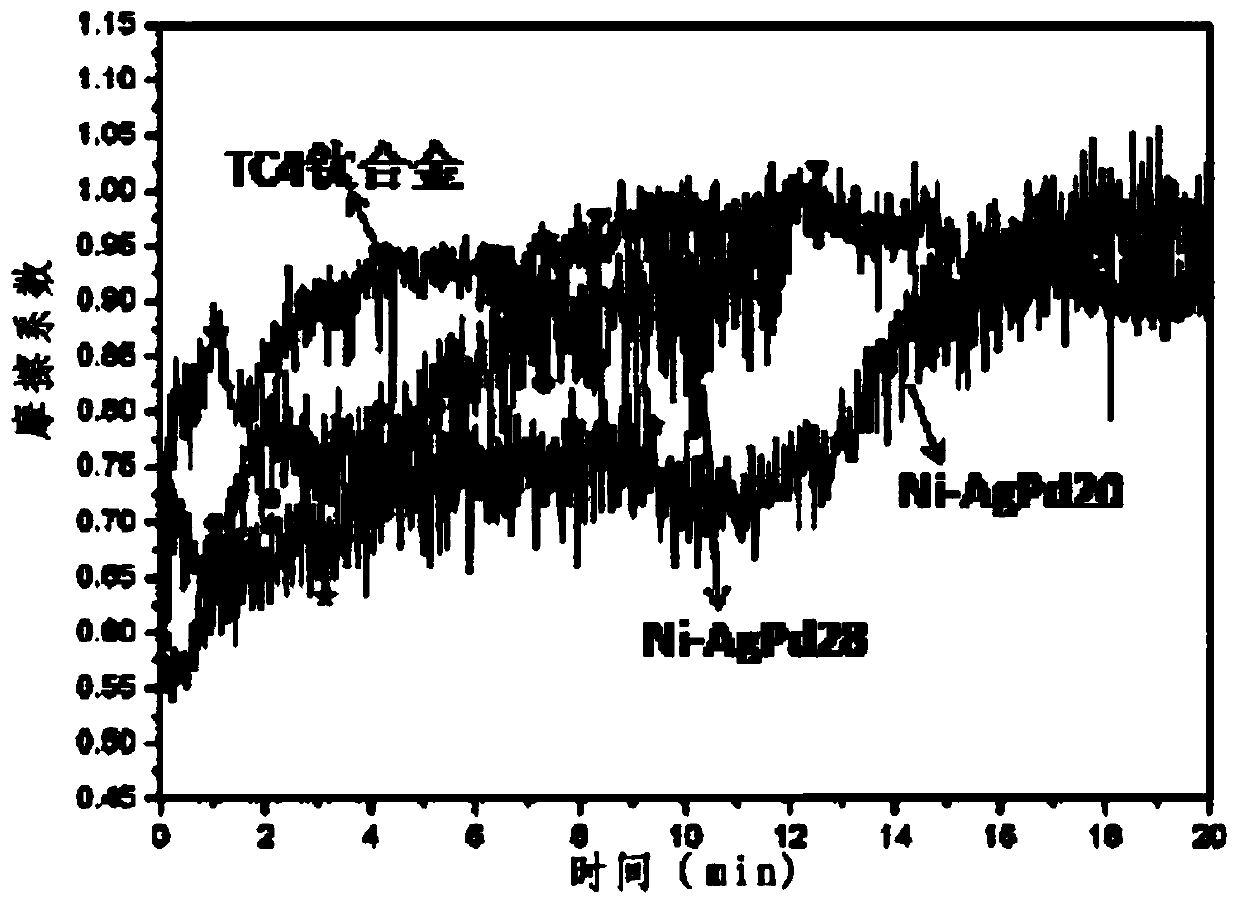

ActiveCN108179385AReduce coefficient of frictionImprove performanceVacuum evaporation coatingSputtering coatingIonCorrosion resistant

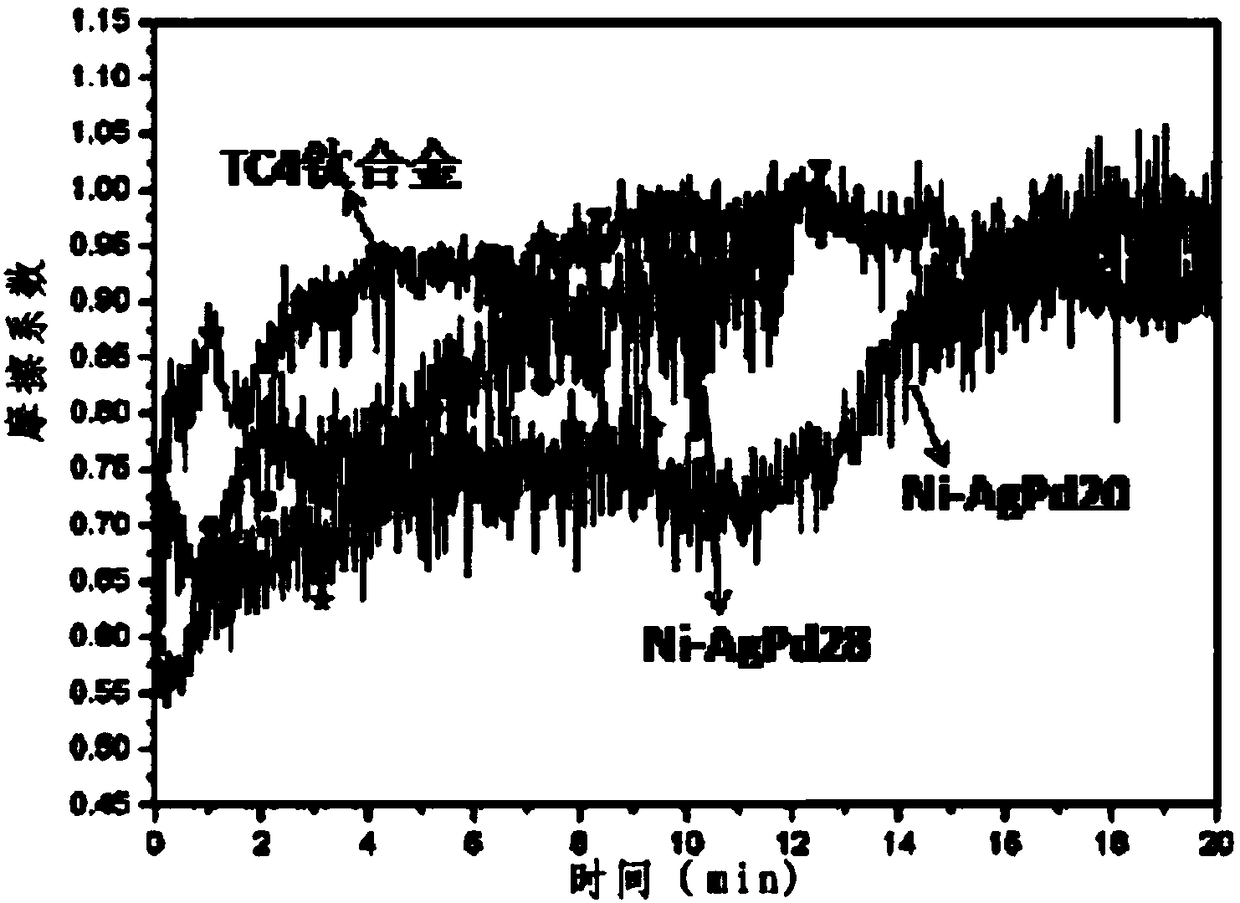

The invention discloses a method for preparing a screw-thread wear-resistant corrosion-resistant anti-lock coating by adopting multi-arc ion plating. The method comprises the steps of (1) sequentiallypolishing, ultrasonically cleaning and drying a metal thread; (2) sand-blasting roughening the dried metal thread; (3) sputter cleaning the sand-blasting roughened metal thread, and obtaining a surface activated metal thread; (4) plating the surface-activated metal thread under an argon atmosphere for the first time, and obtaining a metal thread with an Ni transition layer on a surface; and (5) plating the metal thread with the Ni transition layer on the surface under the argon atmosphere for the second time, preparing an AgPd coating, and obtaining a metal thread with an Ni-AgPd coating on asurface. According to the method for preparing the screw-thread wear-resistant corrosion-resistant anti-lock coating by adopting multi-arc ion plating provided by the invention, multi-arc ion platingis adopted for preparing the Ni-AgPd coating on the surface of the thread, a wear resistant property of the Ni-AgPd coating is ensured through added Pd, the heat stability and the corrosion resistance of the Ni-AgPd coating are improved, and a locking problem of a fastener is solved.

Owner:西安赛福斯材料防护有限责任公司

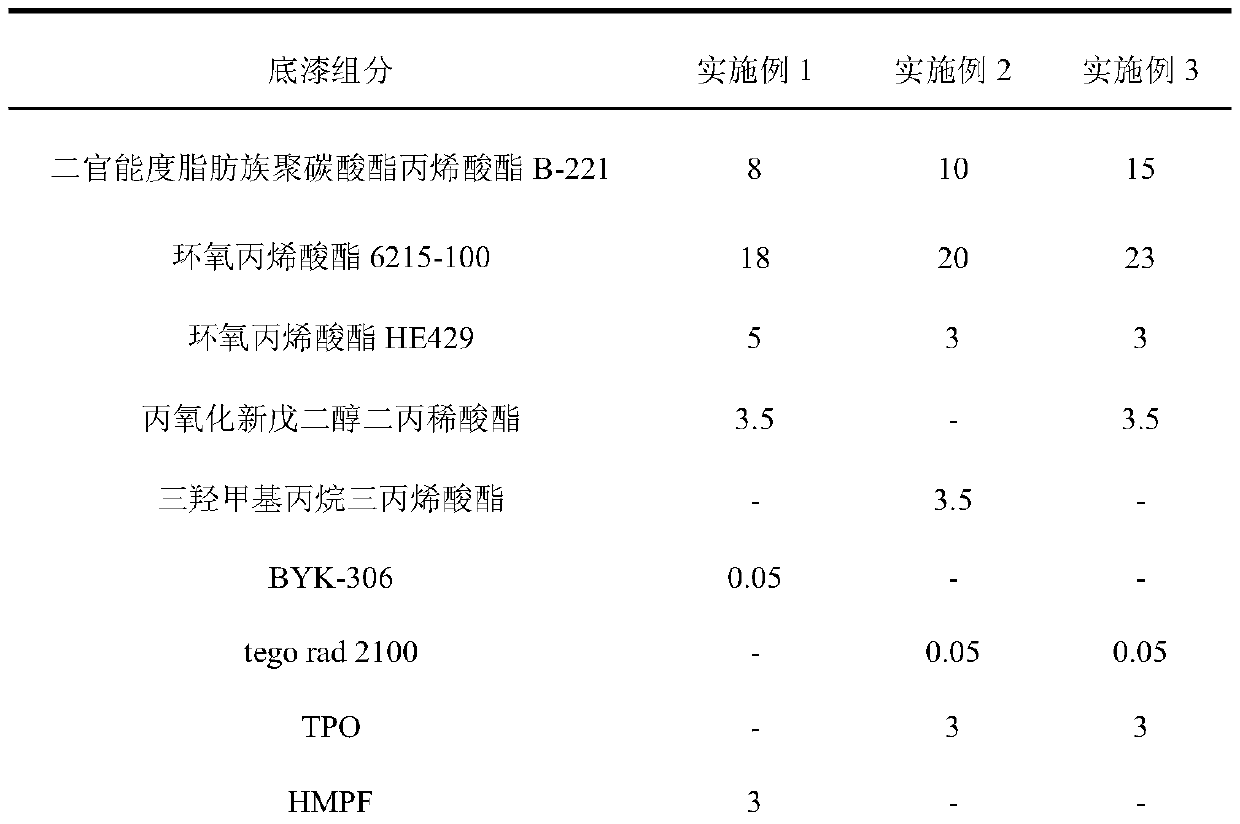

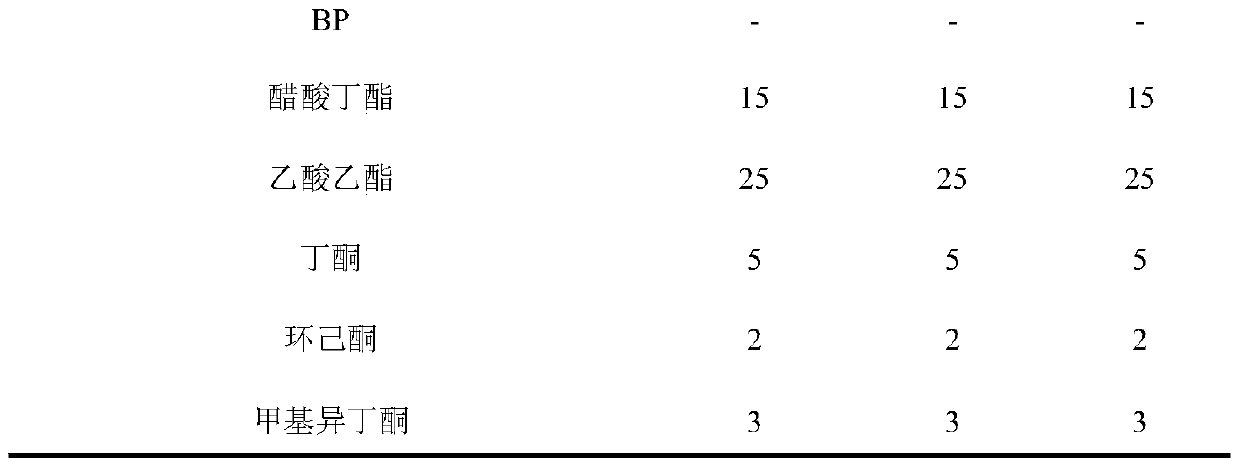

Vacuum-plated UV-cured primer, preparation method therefor and application of vacuum-plated UV-cured primer

ActiveCN110527408ALow heat resistanceHigh hiding powerEpoxy resin coatingsPriming paintsCross-linkReactive diluent

The invention discloses a vacuum-plated UV-cured primer, a preparation method therefor and an application of the vacuum-plated UV-cured primer. The vacuum-plated UV-cured primer comprises the ingredients in parts by weight: 8-30 parts of low-functionality acrylate, 3-12 parts of reactive diluent, 10-30 parts of epoxy acrylate, 0.01-0.5 part of auxiliaries, 2-3 parts of photoinitiator and 40-60 parts of organic environment-friendly solvent, wherein the low-functionality acrylate is aliphatic polycarbonate acrylate with the functionality of 1 to 4; and the epoxy acrylate is modified epoxy acrylate with the functionality of 1 to 4. According to the vacuum-plated UV-cured primer disclosed by the invention, the low-functionality acrylate, the reactive diluent and the epoxy acrylate serve as primary film forming matters, the reactive diluent can neutralize two kinds of prepolymers, and two kinds of prepolymers of different molecular structures can be rapidly crosslinked together to form cross-linked network knots and be cured to form a film, so that the vacuum-plated UV-cured primer is high in leveling and covering power and good in plating property.

Owner:HUNAN SOKAN NEW MATERIAL

High-performance vacuum electroplating UV (Ultraviolet) coating and preparation method thereof

ActiveCN108676488AGood plating performanceHigh hardnessPolyurea/polyurethane coatingsSolventPhotoinitiator

The invention discloses high-performance vacuum electroplating UV (Ultraviolet) coating. The UV coating is prepared from three coating layers including undercoat, intermediate coat and finishing coat,wherein each coating is prepared by mixing according to the weight ratio (part); the undercoat is prepared from the following components in parts by weight: 30 to 40 parts of a high polymer resin connecting material, 5 to 10 parts of an active monomer, 0.2 to 0.3 part of a flatting agent, 1.5 to 2 parts of a photoinitiator and 55 to 65 parts of a solvent; the intermediate coat is prepared from the following components in parts by weight: 30 to 40 parts of the high polymer resin connecting material, 1.0 to 1.5 parts of an adhesion promoter, 0.1 to 0.15 part of the flatting agent, 0.5 to 0.8 part of the photoinitiator and 60 to 70 parts of the solvent; the finishing coat is prepared from the following components in parts by weight: 30 to 45 parts of the high polymer resin connecting material, 2 to 5 parts of the active monomer, 0.2 to 0.3 part of the flatting agent, 0.5 to 1.5 parts of the photoinitiator, 0.3 to 1 part of the adhesion promoter and 60 to 70 parts of the solvent. The high-performance vacuum electroplating UV coating has the advantages that the construction yield is relatively high, the production efficiency is improved, the production cost is reduced and the economicbenefits are relatively good.

Owner:深圳市深赛尔股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com