Vacuum-plated UV-cured primer, preparation method therefor and application of vacuum-plated UV-cured primer

A technology of vacuum electroplating and epoxy acrylate, used in primers, coatings, epoxy coatings, etc., can solve problems such as poor leveling effect and easy cracking, and achieve low cost, improved adhesion, and heat resistance. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

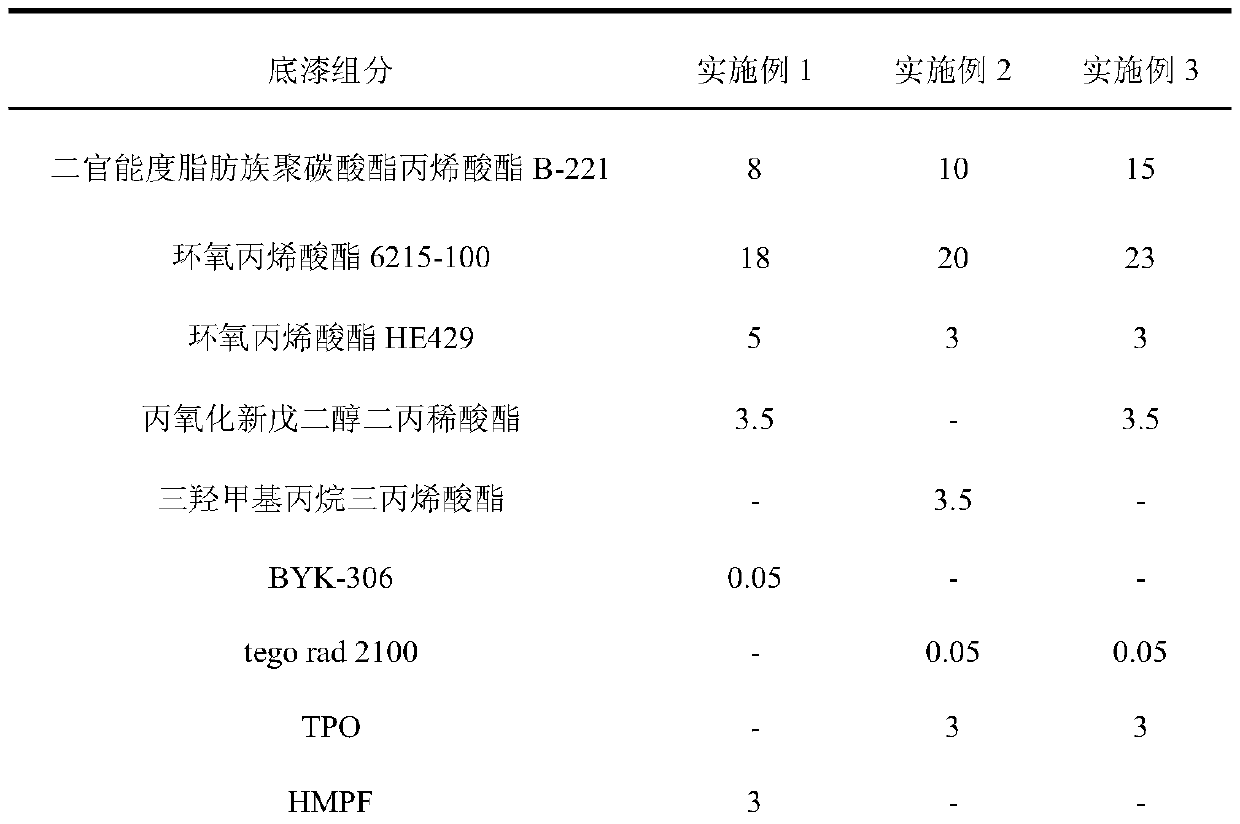

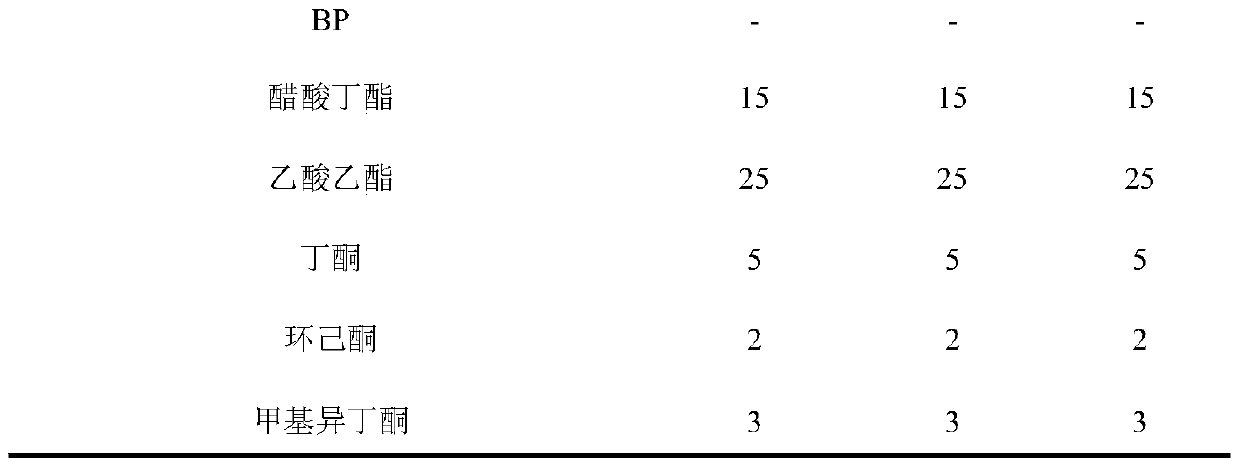

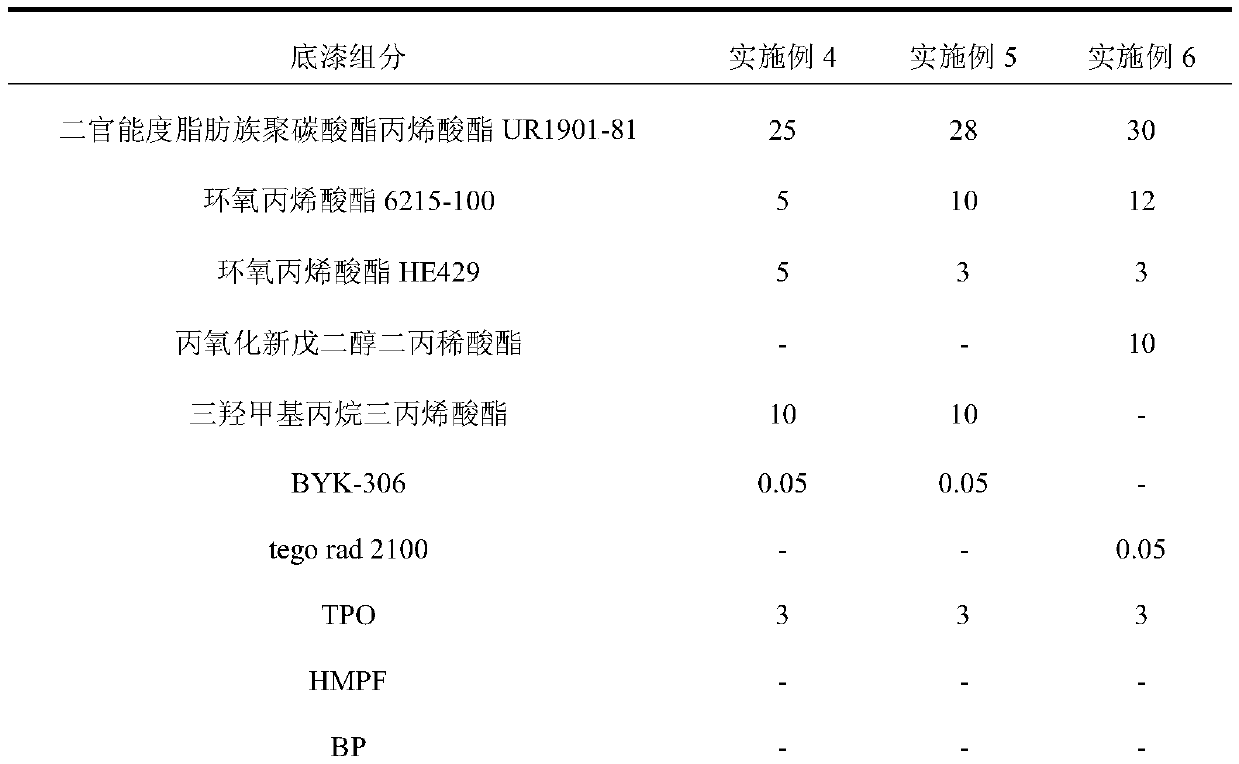

[0047] The parts by weight of each component in the vacuum electroplating UV curing primer of Example 1 are shown in Table 1 respectively.

[0048] Table 1: Parts by weight of each component in the vacuum electroplating UV curing primer of Examples 1-3

[0049]

[0050]

[0051] The preparation method of above-mentioned vacuum electroplating UV curing primer

[0052] S1. Preheat low-functionality acrylate B-221, epoxy acrylate 6215-100, and epoxy acrylate HE429. The preheating temperature is 50°C and the preheating time is 60 minutes. Mix and dissolve them with butyl acetate to form the first mixed solution;

[0053] S2. Add propoxylated neopentyl glycol diacrylate and HMPF to the first mixed solution in step S1 and stir, the stirring temperature is 450°C, the stirring time is 30min, and the stirring speed is 500 rpm, forming the second mixture;

[0054] S3, add BYK-306 and ethyl acetate, butanone, cyclohexanone and methyl isobutyl ketone to the second mixed solution ...

Embodiment 2

[0060] The parts by weight of each component in the vacuum electroplating UV curing primer of this embodiment 2 are respectively shown in Table 1. The preparation method and application of the vacuum electroplating UV curing primer and the vacuum electroplating UV curing paint are the same as in Example 1.

Embodiment 3

[0062] The parts by weight of each component in the vacuum electroplating UV curing primer of this embodiment 3 are shown in Table 1 respectively. The preparation method and application of the vacuum electroplating UV curing primer and the vacuum electroplating UV curing paint are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com