Patents

Literature

634results about "Polycarbonate coatings" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

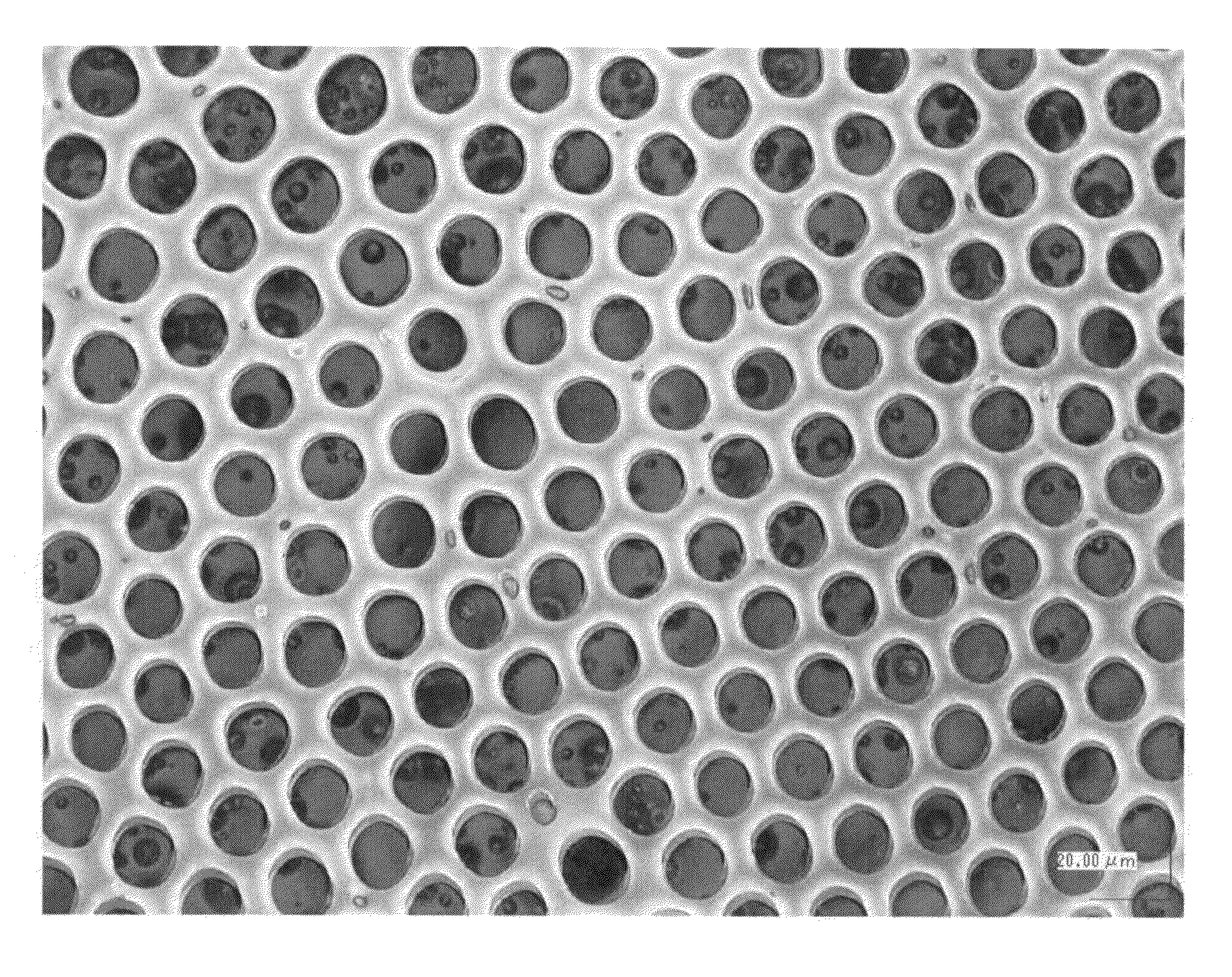

Reduced density article

InactiveUS10087556B2Additive manufacturing apparatusIncreasing energy efficiencyMicro structurePolymer science

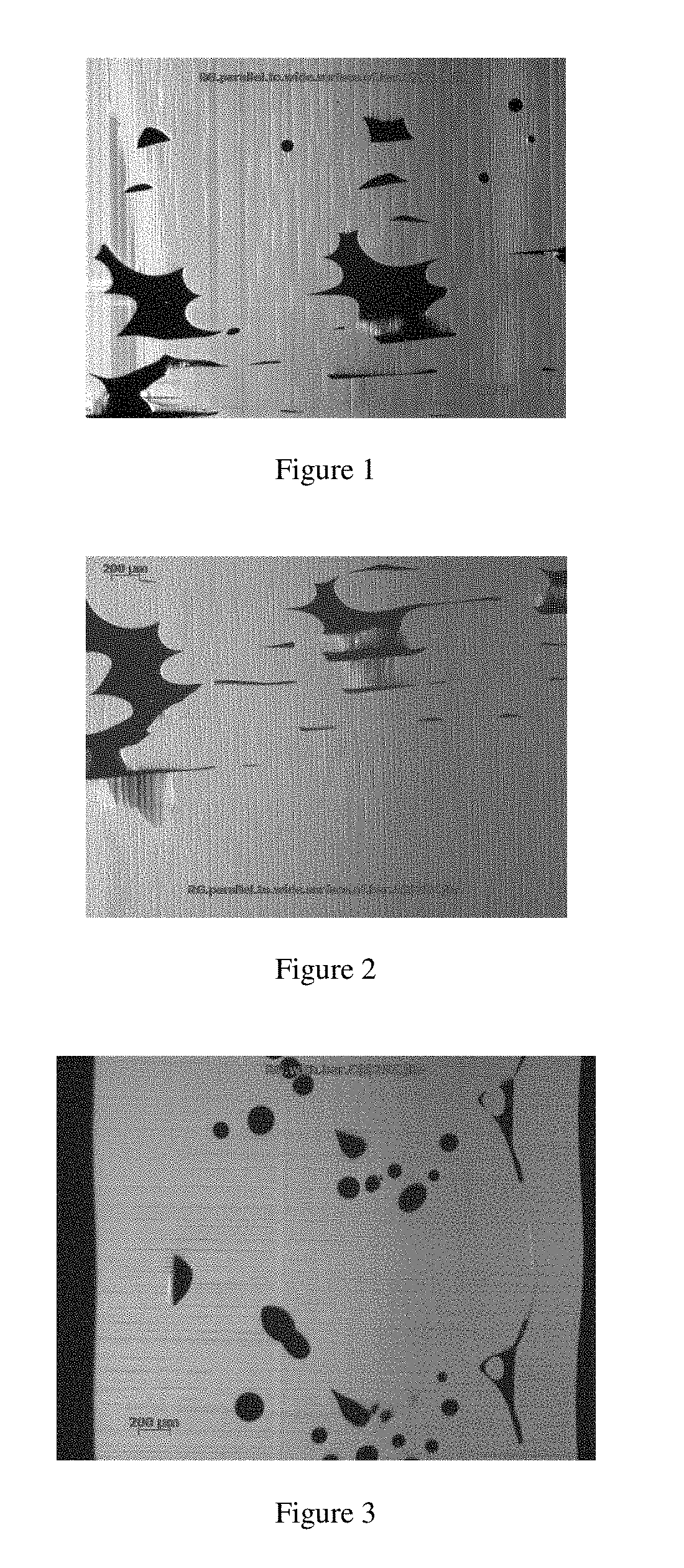

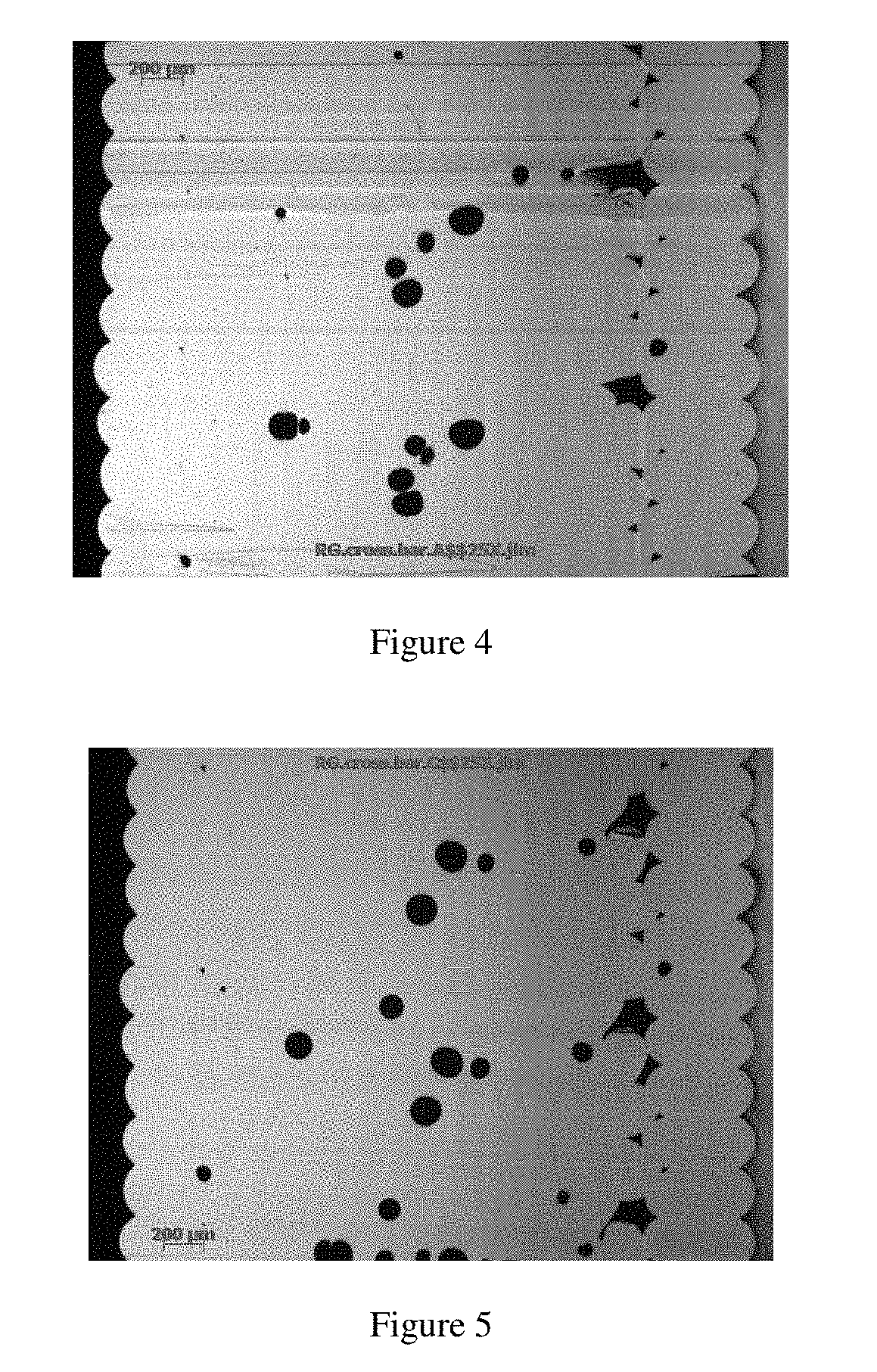

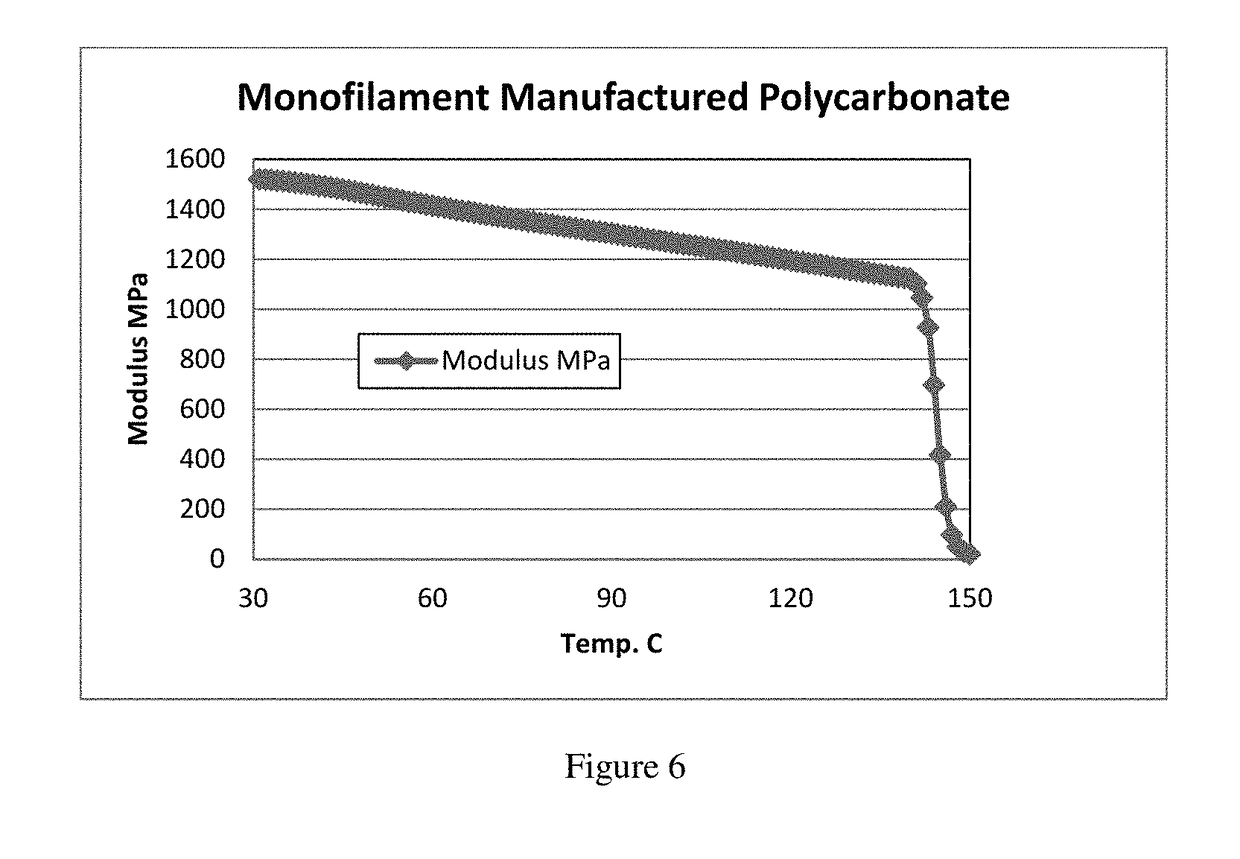

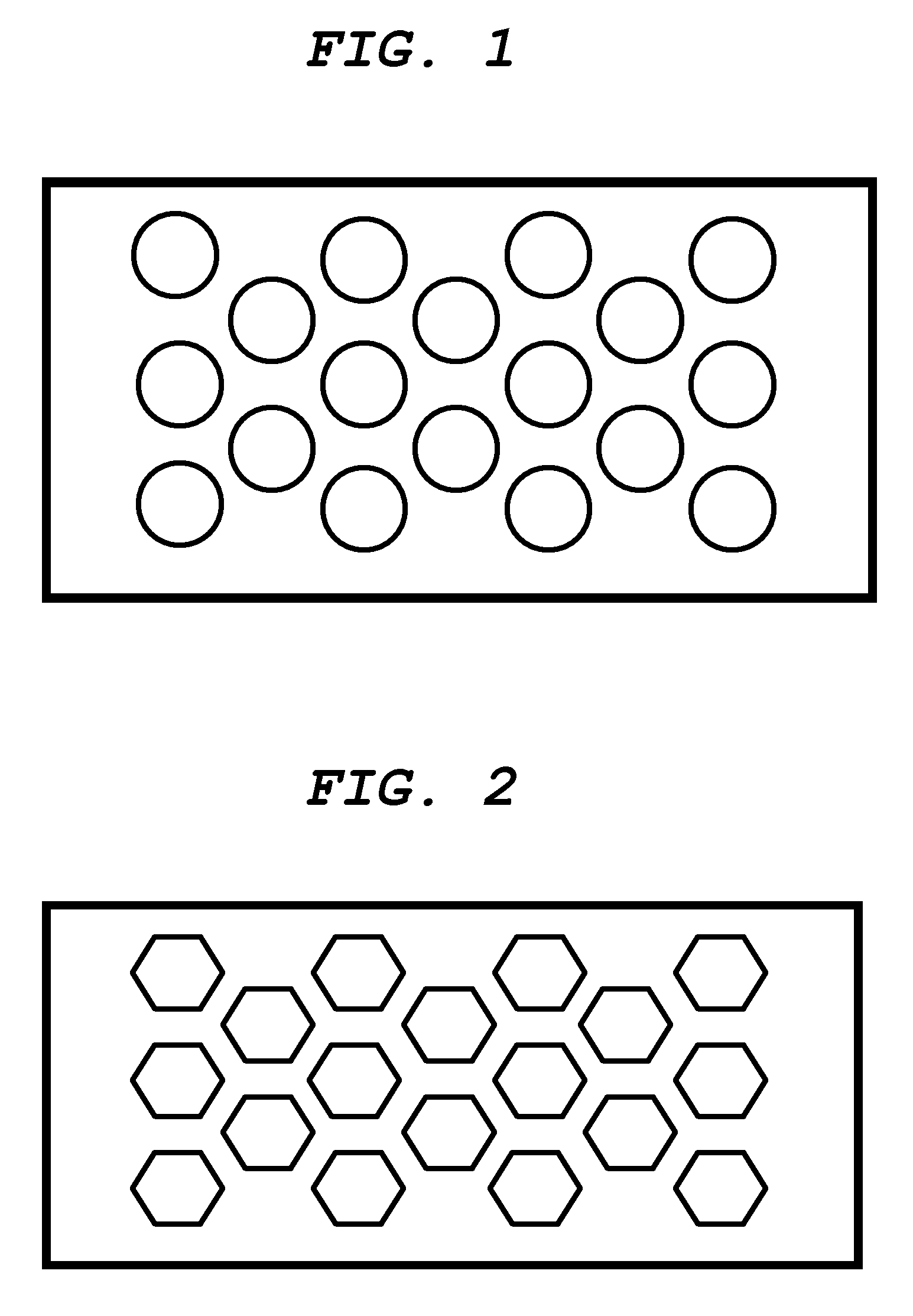

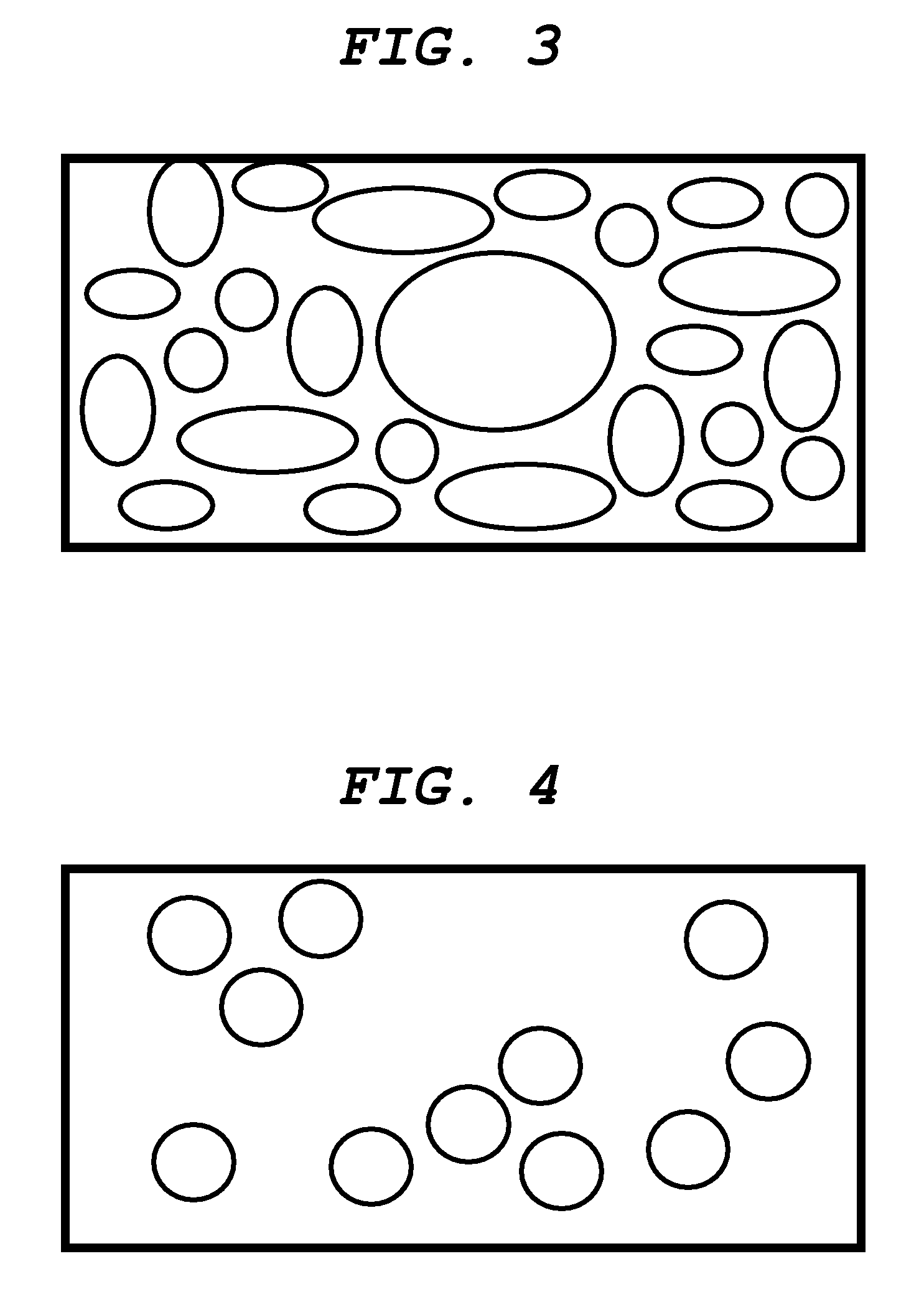

A reduced density article of manufacture, and process for making same, made from a thermoplastic polycarbonate composition. The reduced density article of manufacture has (1) a certain density and (2) a certain micro structure containing from 1% to 20% by volume of voids wherein at least 80% of the voids are high aspect voids and less than 20% of the voids are spherical voids with a diameter of 10 to 100 microns. The polycarbonate thermoplastic composition comprises at least 50 mole % of a certain bisphenol A. The reduced density article of manufacture is made by a monofilament additive manufacturing technique.

Owner:SHPP GLOBAL TECH BV

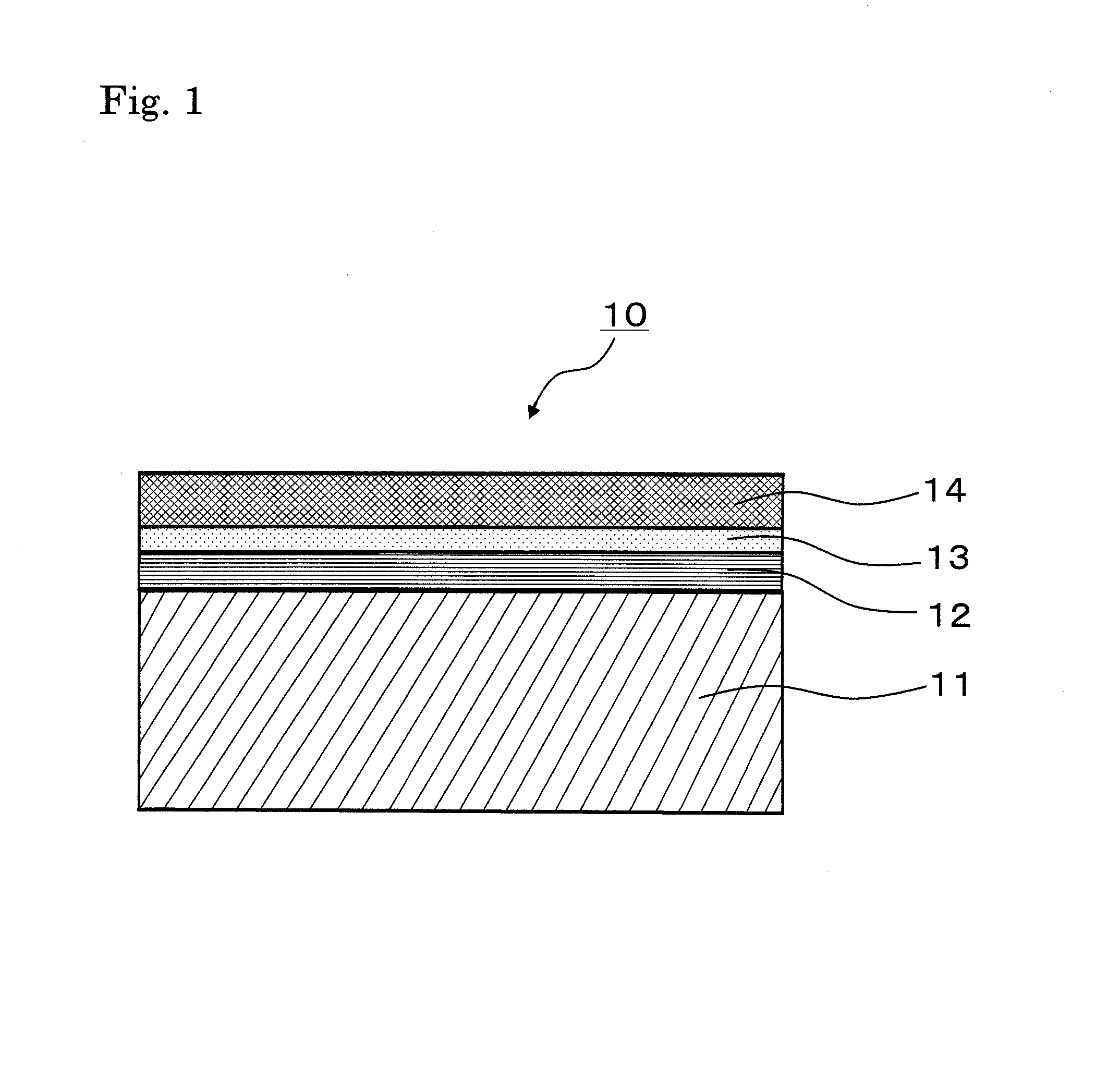

Weatherable multilayer articles and method for their preparation

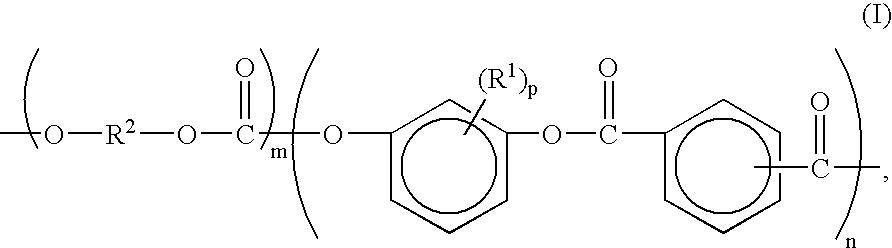

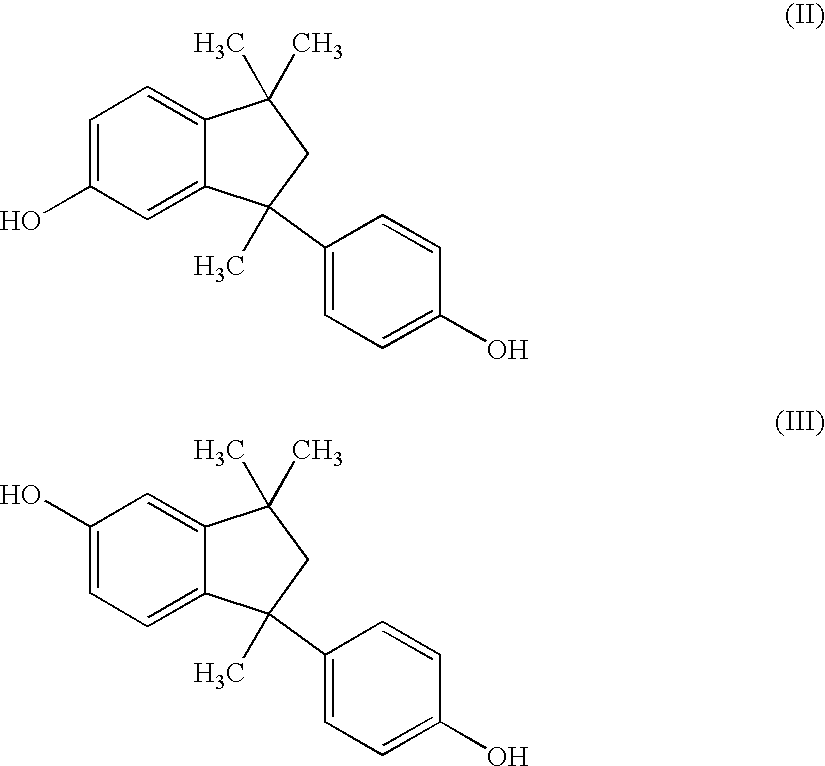

InactiveUS20040028907A1Improve adhesionAvoid insufficient thicknessAutomatic/semiautomatic turning machinesPolyureas/polyurethane adhesivesPolymer scienceDicarboxylic acid

Disclosed are weatherable multilayer articles comprising (i) a coating layer comprising a block copolyestercarbonate comprising structural units derived from at least one 1,3-dihydroxybenzene and at least one aromatic dicarboxylic acid, (ii) a second layer comprising a polymer comprising carbonate structural units, (iii) an adhesive layer comprising a polyurethane, and (iv) a substrate layer, wherein the coating layer is in contiguous superposed contact with the second layer, and the adhesive layer is in contiguous contact with the second layer and the substrate layer. Also disclosed is a method for making the multilayer article.

Owner:SABIC INNOVATIVE PLASTICS IP BV

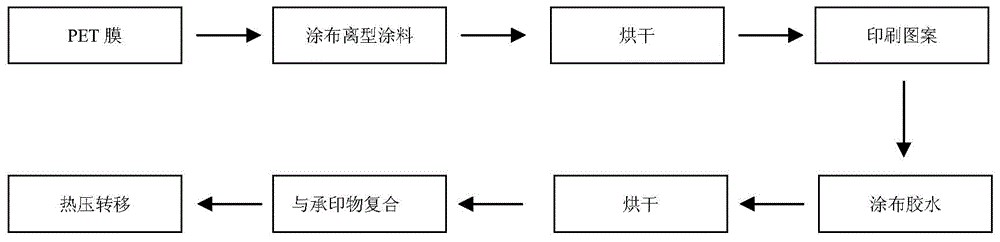

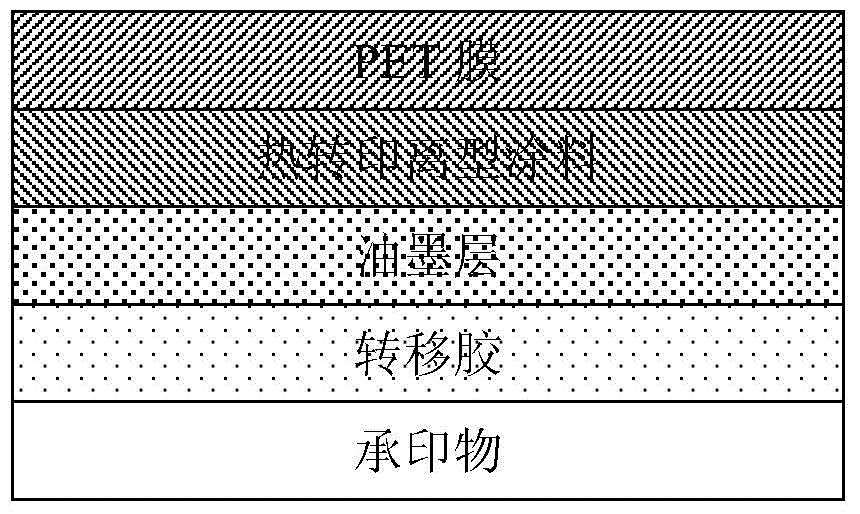

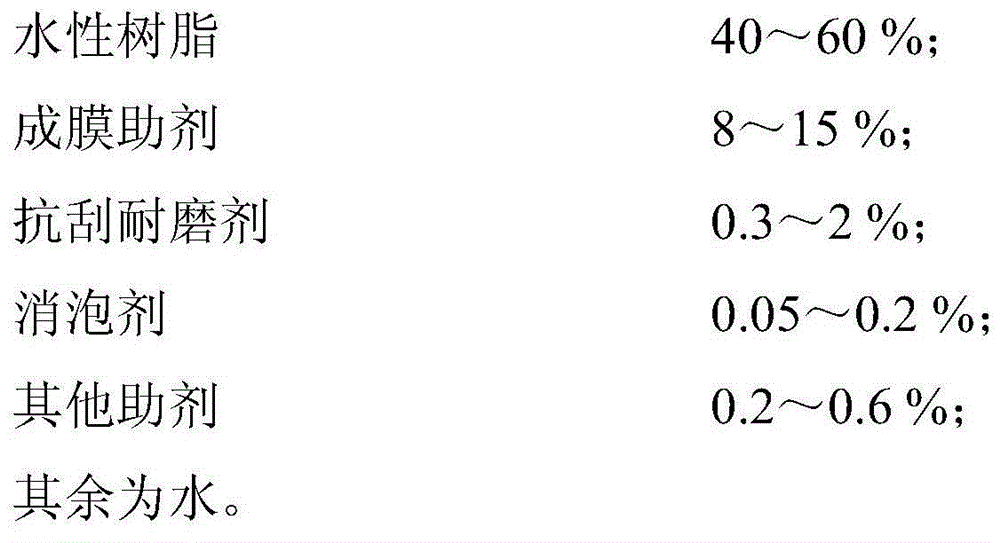

Water-based heat transfer printing release coating, and preparation method and application thereof

InactiveCN104403544ASolve the hardnessSolve the shortcomings of poor scratch resistancePolyurea/polyurethane coatingsThermographyWater basedEpoxy

The invention belongs to the technical field of preparation of release coatings and discloses a water-based heat transfer printing release coating, and a preparation method and application thereof. The water-based heat transfer printing release coating comprises the following ingredients by mass percent: 40-60 percent of water-based resin, 8-15 percent of a coalescing agent, 0.3-2 percent of a scratch-resistant anti-wear agent, 0.05-0.2 percent of a foam killer, 0.2-0.6 percent of other additives and the balance of water, wherein the water-based resin is at least one of polyurethane resin, polyacrylic acid resin, polycarbonate, polymide resin, polyethersulfone resin, epoxy resin, thermoplastic polyester resin, a styrene-maleic anhydride copolymer and phenolic resin. According to the invention, application of the water-based formula to preparation of the water-based heat transfer printing release coating is realized, the material prescription is environment-friendly, and the preparation process is safe and environment-friendly. Compared with a conventional solvent product, the water-based heat transfer printing release coating is better in heat resistance, high in glossiness and better in printing ink adhesion, effectively enhances the printing ink protecting function and can be kept colorful in a long term.

Owner:GUANGZHOU HUMAN CHEM

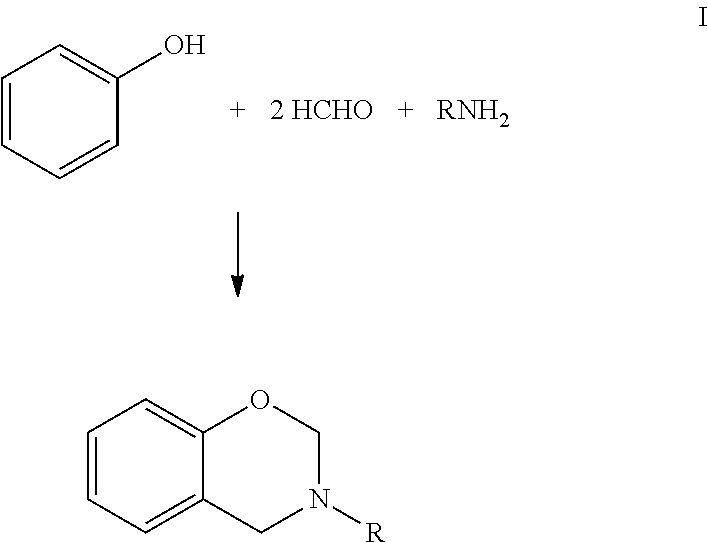

Curable benzoxazine-based phenolic resins and coating compositions thereof

A thermosetting coating composition comprising: (a) a polymer selected from a polyester, a polycarbonate, a polyamide, and an epoxy and (b) a curable benzoxazine-based phenolic resin comprising the reaction product of: (i) a phenol compound, (ii) an aldehyde, and (iii) a polyamine having at least one primary amine and at least one secondary amine.

Owner:EASTMAN CHEM CO

Electrophotographic photoconductor and method of producing aromatic polycarbonate resin for use in the photoconductor

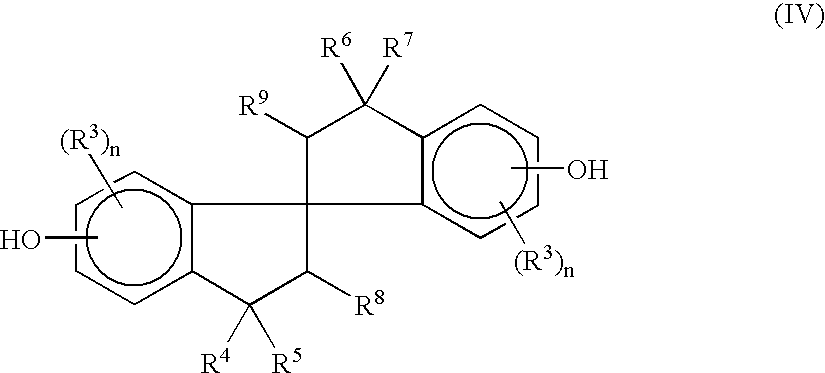

InactiveUS6486293B1High sensitivityIncreased durabilityElectrography/magnetographyPolycarbonate coatingsElectrical conductorHalogen

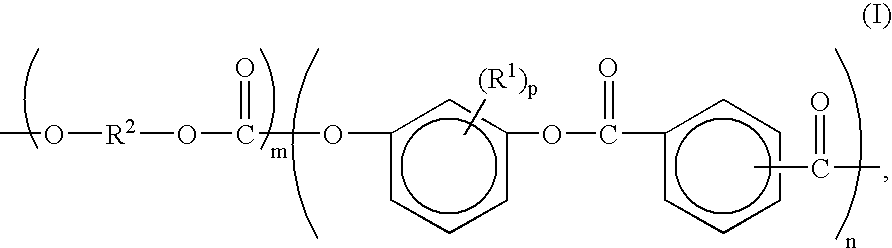

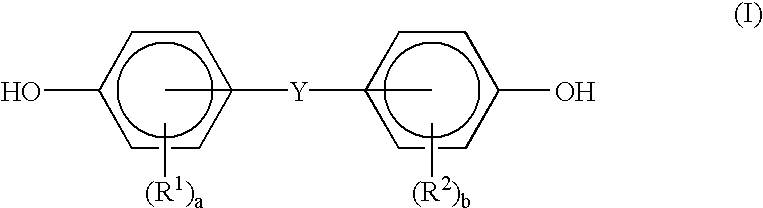

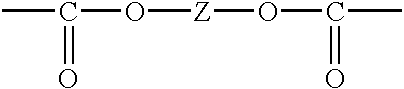

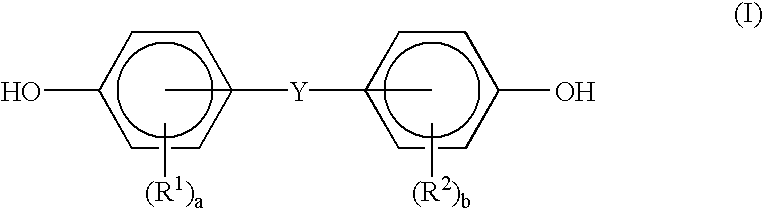

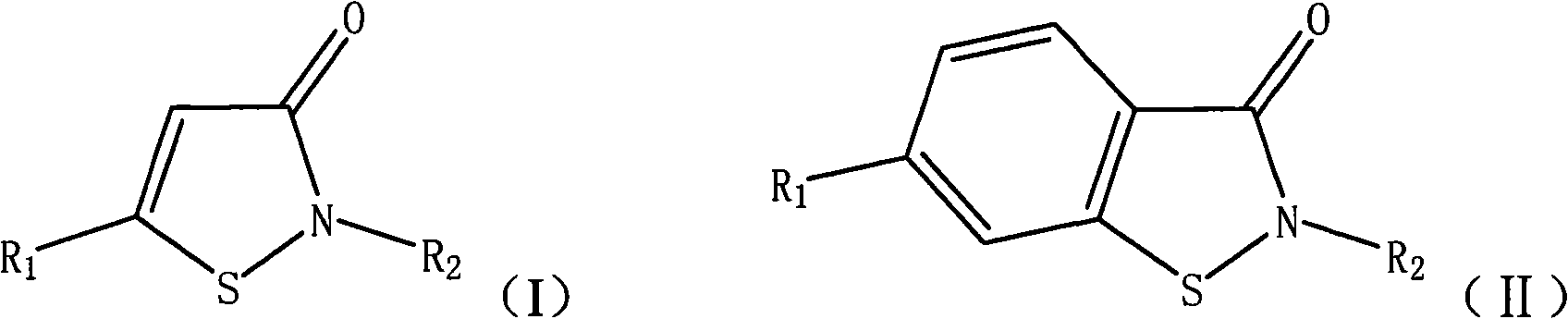

A method of producing an aromatic polycarbonate resin includes the step of carrying out solution polymerization of a diphenol compound having a triarylamine structure with a diol compound of formula (I):wherein R1 and R2 are each independently a substituted or unsubstituted alkyl croup, a substituted or unsubstituted aryl group, or a halogen atom; a and b are each independently an integer of 0 to 4: and Y is -COO- orin which Z is a substituted or unsubstituted bivalent aliphatic group or a substituted or unsubstituted arylene group. In addition, an electrophotographic photoconductor has an electroconductive support, and a photoconductive layer formed thereon containing as an effective component the above-mentioned aromatic polycarbonate resin prepared by the solution polymerization.

Owner:RICOH KK

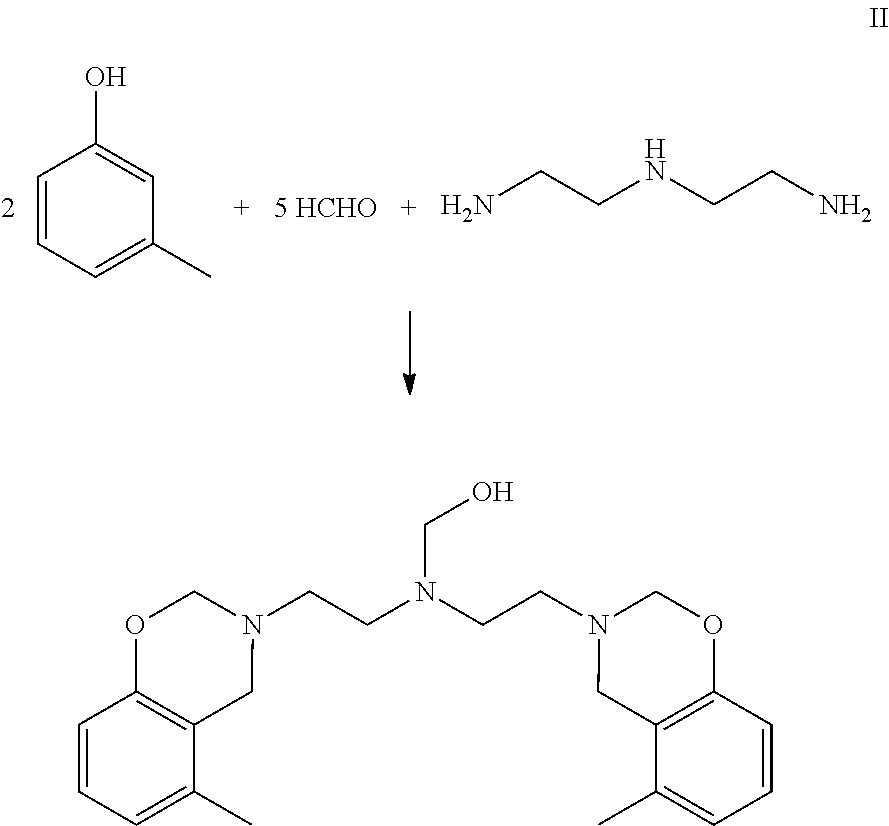

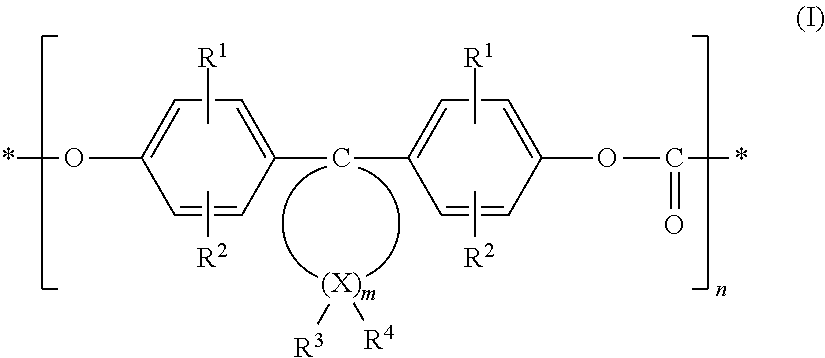

Compound antimicrobial agent, antimicrobial coating composition and antimicrobial coating materials

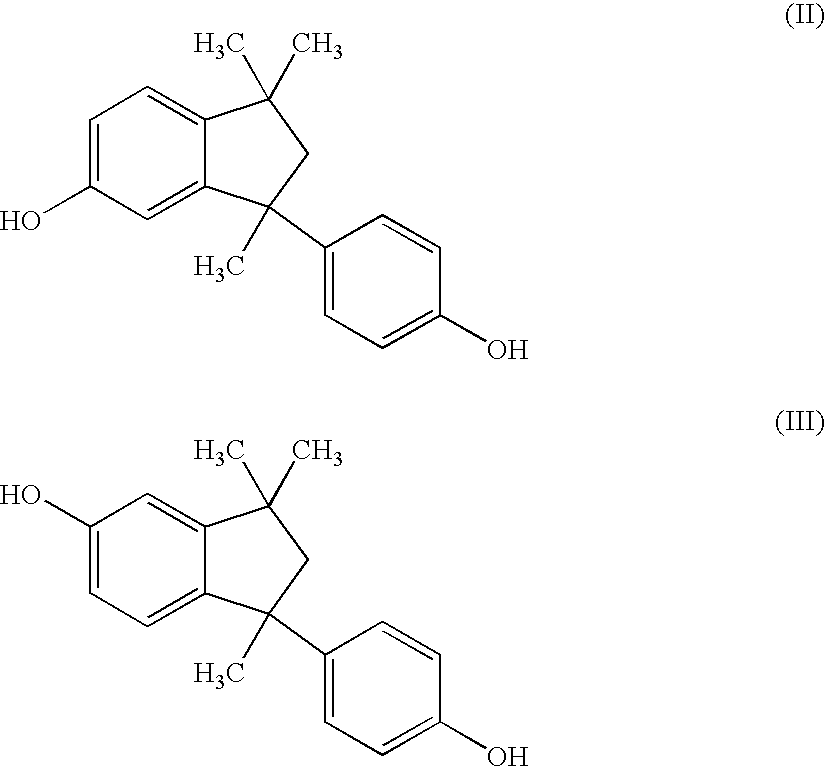

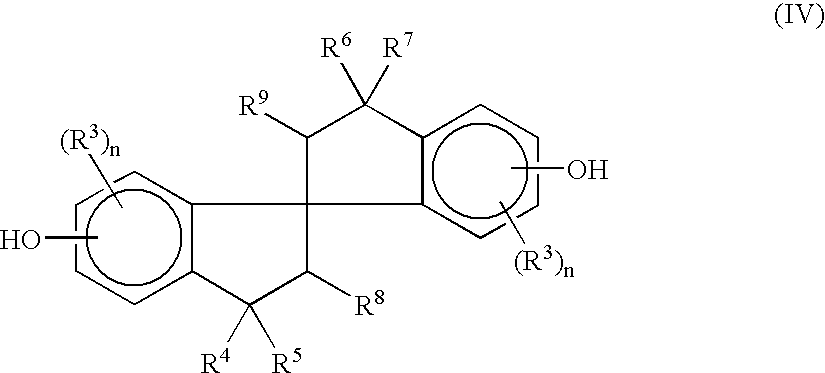

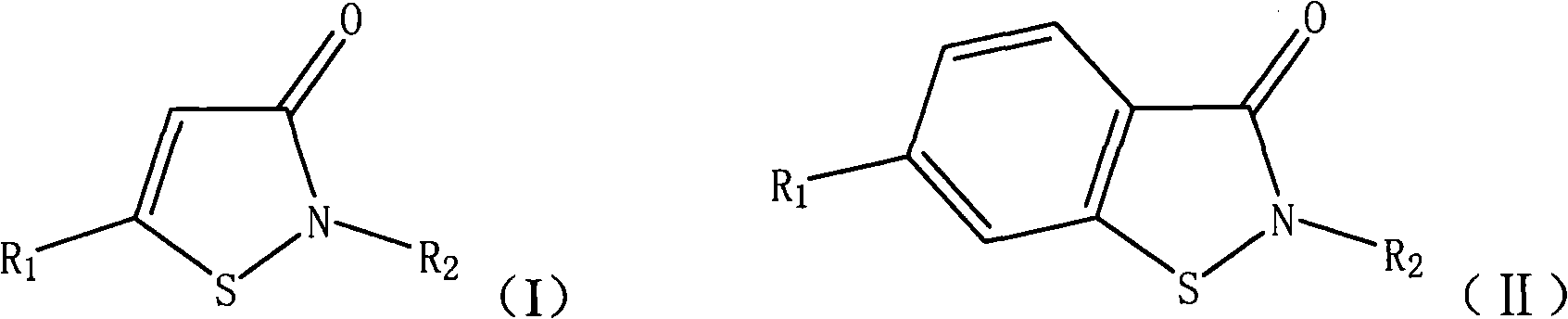

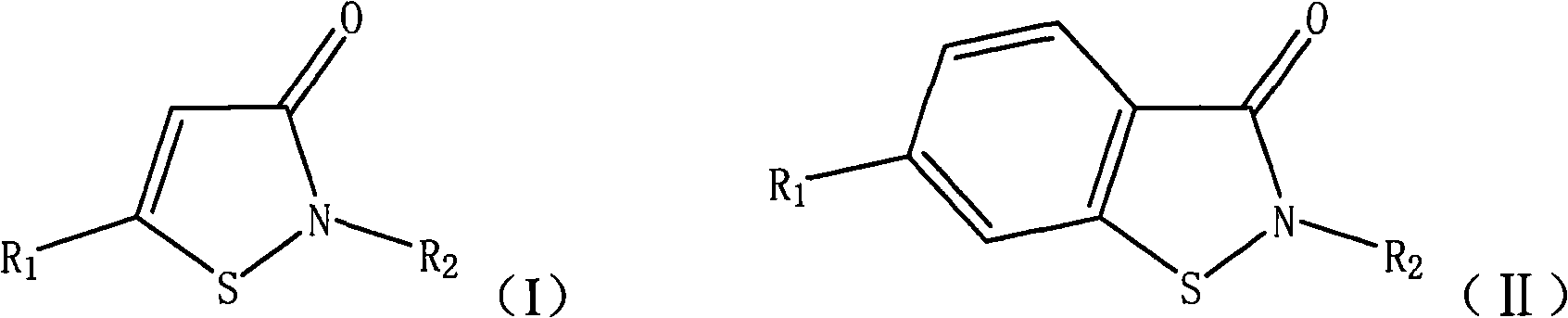

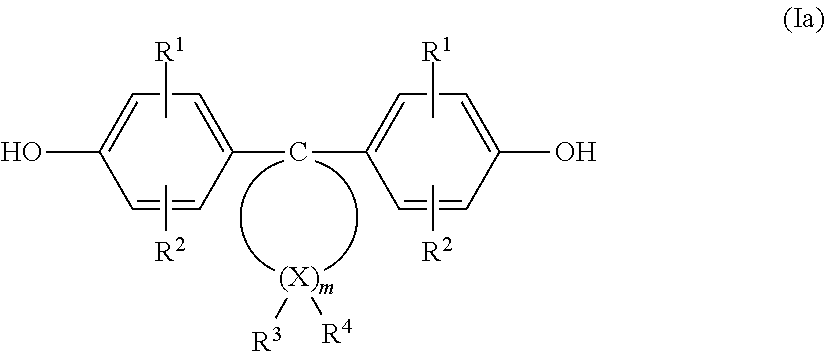

InactiveCN101595880AEasy to prepareImprove antibacterial propertiesBiocideAntifouling/underwater paintsHydrogenHydrogen atom

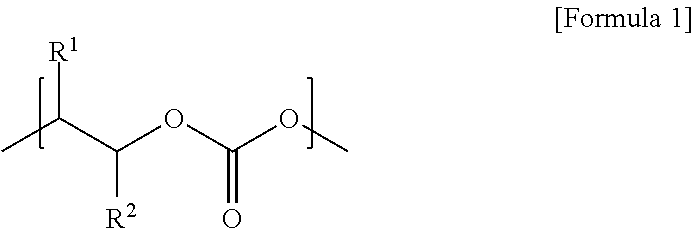

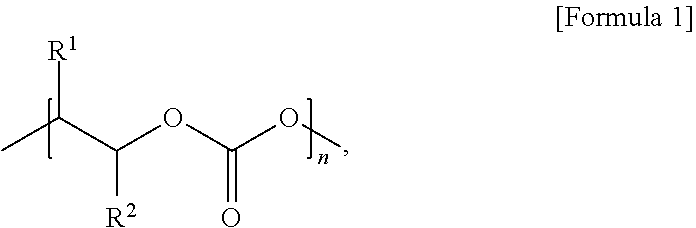

The invention provides a compound antimicrobial agent containing an inorganic antimicrobial agent and an organic antimicrobial agent, wherein the inorganic antimicrobial agent is metal salt and / or metallic oxides with antimicrobial activity; the organic antimicrobial agent is a composition the formation of which is shown in an above formula (I) and / or formula (II) and is one or several of pyridines, wherein R1 and R2 showed in the formula (I) and the formula (II) are alkyls with the number of hydrogen atoms or carbon atoms from 1 to 8. The invention also provides an antimicrobial coating composition containing the compound antimicrobial agent and antimicrobial coating materials using the antimicrobial coating composition. The compound antimicrobial agent is prepared by a very simple method and can achieve the very favorable antimicrobial effect by only simply mixing the inorganic antimicrobial agent and the organic antimicrobial agent of the compound antimicrobial agent.

Owner:BYD CO LTD

Weatherable multilayer articles and method for their preparation

InactiveUS7410700B2Improve adhesionAutomatic/semiautomatic turning machinesPolyureas/polyurethane adhesivesPolymer scienceDicarboxylic acid

Disclosed are weatherable multilayer articles comprising (i) a coating layer comprising a block copolyestercarbonate comprising structural units derived from at least one 1,3-dihydroxybenzene and at least one aromatic dicarboxylic acid, (ii) a second layer comprising a polymer comprising carbonate structural units, (iii) an adhesive layer comprising a polyurethane, and (iv) a substrate layer, wherein the coating layer is in contiguous superposed contact with the second layer, and the adhesive layer is in contiguous contact with the second layer and the substrate layer. Also disclosed is a method for making the multilayer article.

Owner:SABIC INNOVATIVE PLASTICS IP BV

Preparation method for super-hydrophobic self-luminous coating

InactiveCN104479437ASolve the problem of water instabilityHas superhydrophobic self-cleaning propertiesLuminescent paintsPolyurea/polyurethane coatingsCross-linkLuminous intensity

The invention provides a preparation method for a super-hydrophobic self-luminous coating. The method comprises the following two steps of 1, uniformly mixing a high-molecular polymer monomer, a cross-linking agent, an initiating agent, nano-particles and long-lasting phosphor materials to obtained a mixture; 2, uniformly coating the surface of a base material with the mixture, and carrying out polymerization to obtain the super-hydrophobic self-luminous coating. The preparation method for the super-hydrophobic self-luminous coating overcomes the shortcomings of the prior art, the application range of the long-lasting phosphor materials is widened, and meanwhile the problem that the super-hydrophobic self-luminous coating is decomposed or the luminous intensity is reduced when water is encountered is solved. The preparation method for the super-hydrophobic self-luminous coating is simple in process and high in universality, and the manufacturing cost is saved.

Owner:DONGHUA UNIV

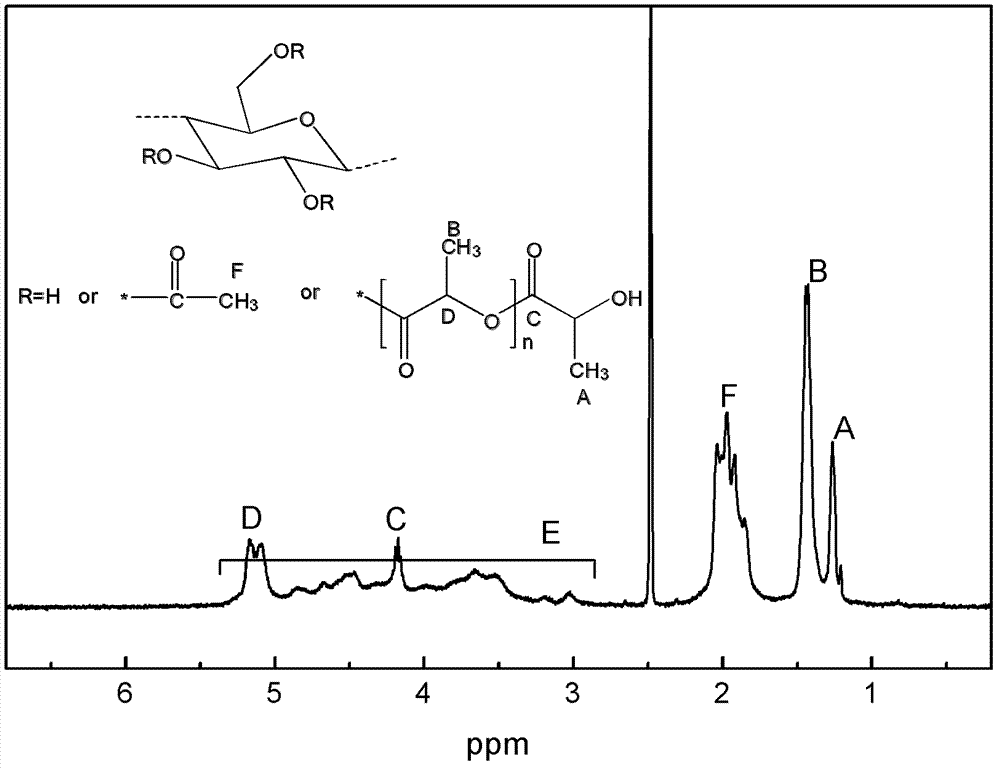

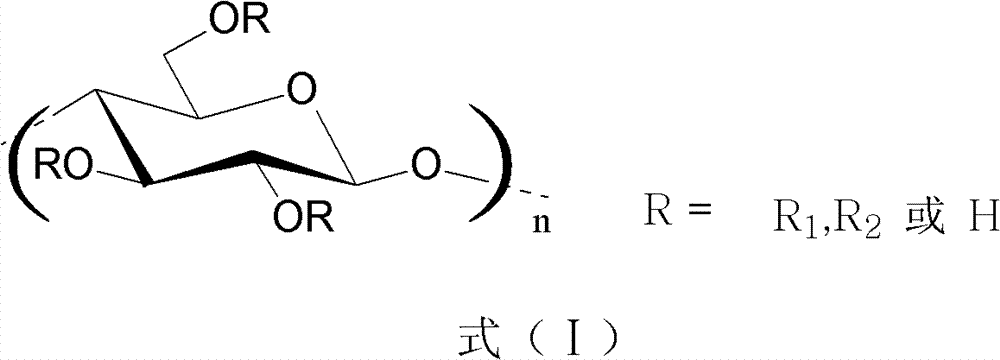

Method for preparing cellulose ester grafted aliphatic polyester copolymer

ActiveCN103193964AWide variety of sourcesSimple production processPolyester coatingsPolycarbonate coatingsCellulosePolyester

The invention discloses a method for preparing a cellulose ester grafted aliphatic polyester copolymer. The method comprises the following steps: 1) preparing a cellulose / ionic liquid solution by using cellulose as a raw material; 2) conducting a homogeneous acylation reaction of cellulose in the cellulose / ionic liquid solution to obtain partially substituted cellulose ester; and 3) further grafting aliphatic polyester to the partially substituted cellulose ester to obtain cellulose ester grafted aliphatic polyester copolymer. Compared with the existing method, the method has obvious advantages that cellulose with wide source is directly used as raw material to prepare the cellulose ester grafted aliphatic polyester copolymer by a one-pot reaction, without separation and purification of intermediate cellulose ester, and that the entire production process is greatly simplified, and has simple production process and easy operation. The cellulose ester grafted aliphatic polyester copolymer product produced by the method provided by the invention can be used for spinning, film making and molding parts, and also can be used as a compatibilizer for coating, paint, polymer and composite material.

Owner:INST OF CHEM CHINESE ACAD OF SCI

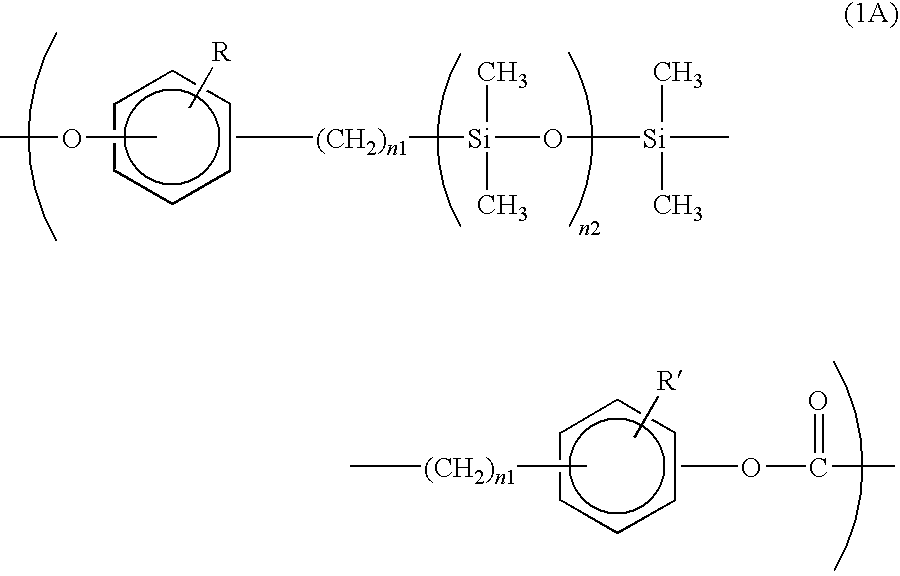

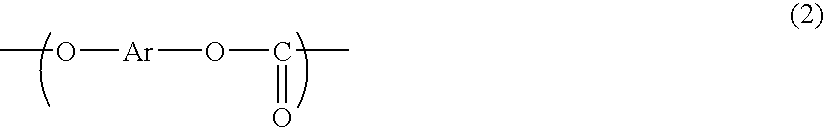

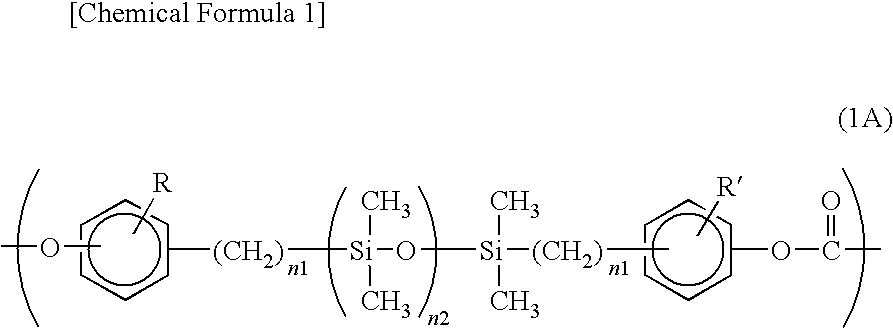

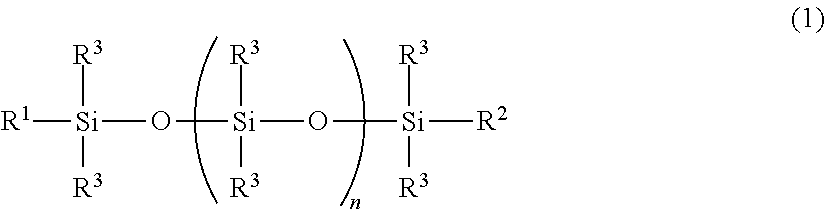

Polycarbonate polymer, coating liquid, and electrophotographic photosensitive body

ActiveUS20100233603A1Advantage is not hamperedHigh electron affinityElectrographic process apparatusCorona dischargeArylHalogen

A polycarbonate polymer includes: a monomer unit represented by a formula (1A) below; and a monomer unit represented by a formula (2). A haze of a solution that is obtained by dissolving the polycarbonate polymer in THF (tetrahydrofuran) at a concentration of 10 mass % is 5% or less (according to JIS K7105, optical path length of 10 mm).In the formula (1A), R and R′ each independently represent a hydrogen atom, a halogen atom, an alkyl group having 1 to 12 carbon atoms or a substituted or unsubstituted aryl group having 6 to 12 carbon atoms; n1 is an integer in a range of 2 to 4; and n2 is an integer in a range of 25 to 220; andin the formula (2), Ar represents a divalent aromatic group.

Owner:IDEMITSU KOSAN CO LTD

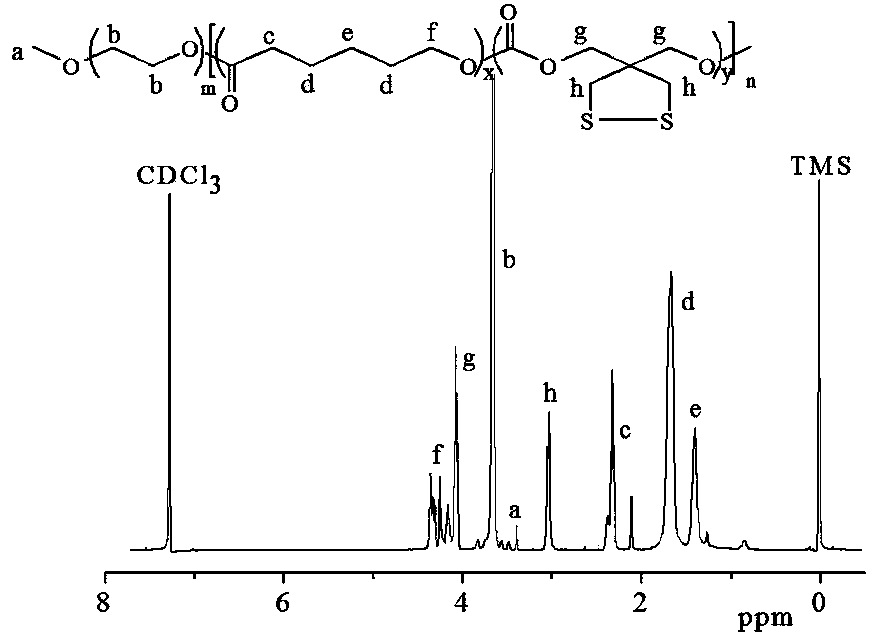

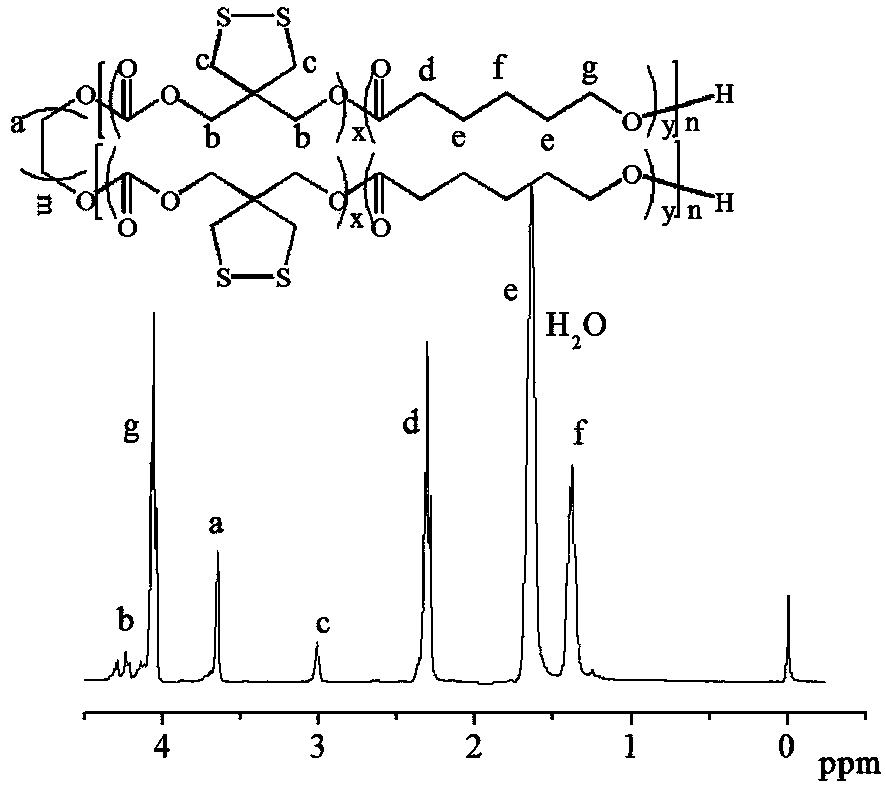

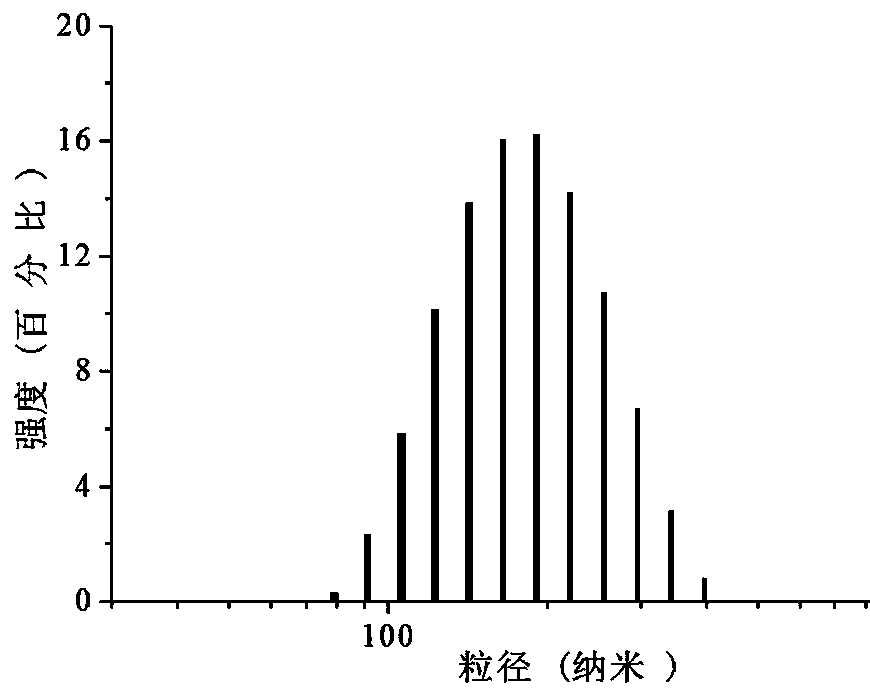

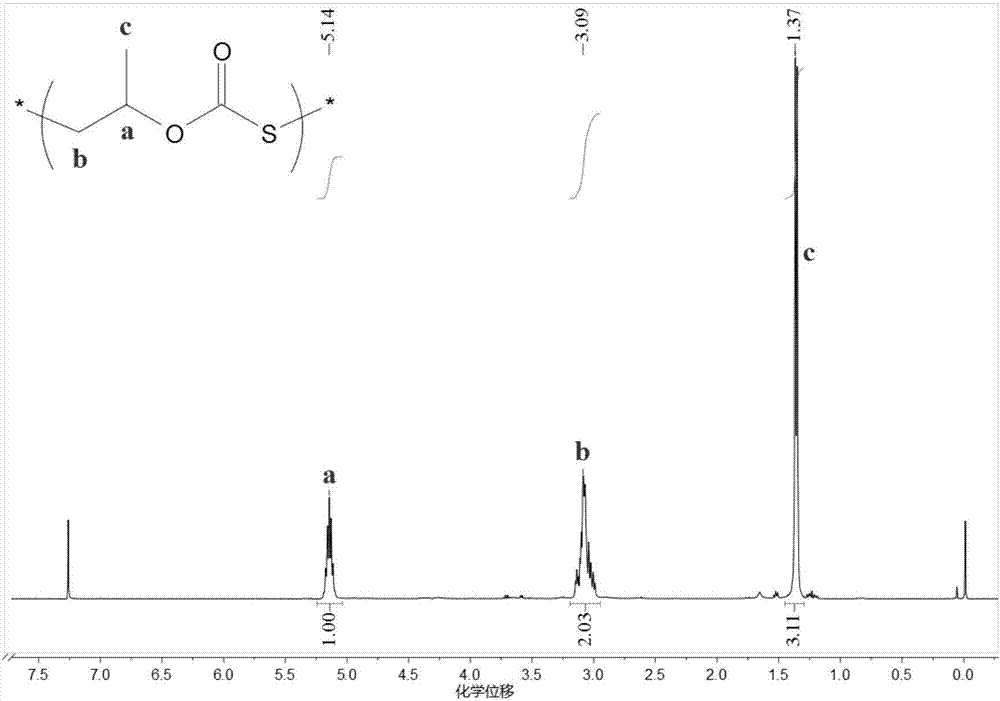

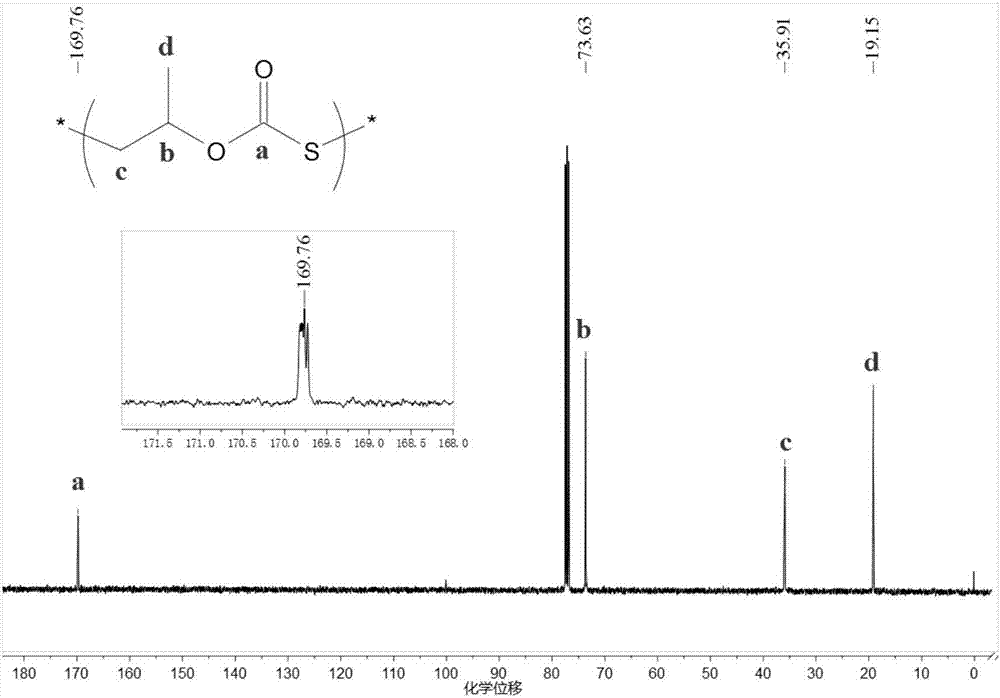

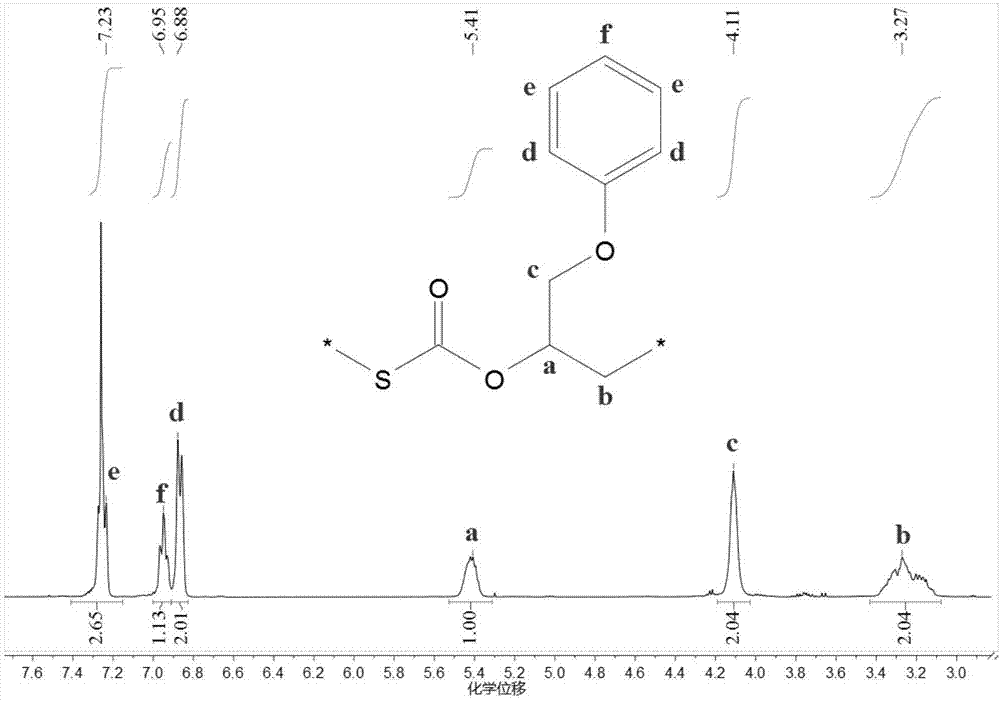

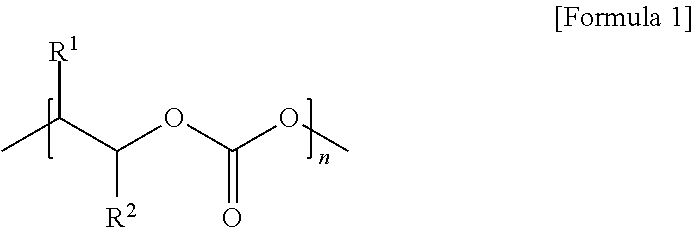

Carbonate polymer with disulfur five-membered ring functional group on side chain and application thereof

ActiveCN104031248AMolecular weight controllableNarrow molecular weight distributionOrganic active ingredientsPharmaceutical non-active ingredientsCancer cellSide chain

The invention discloses a carbonate polymer with a disulfur five-membered ring functional group on a side chain and an application thereof. The polymer is obtained by active ring opening polymerization from a cyclic carbonate monomer containing the disulfur five-membered ring functional group; the polymer is controllable in molecular weight, narrower in weight molecular distribution and free from protecting and deprotecting process. The polymer obtained by active ring opening polymerization of the cyclic carbonate monomer has biodegradability and can be used for controlling a drug release system; a reduction-sensitive reversible crosslinking nano medicine carrier targeting tumor supports long circulation in vivo but is highly enriched in tumor cells and is quickly crosslinked to release medicine in cells so as to efficiently kill the tumor cells with specificity. Meanwhile, the carbonate polymer has an application prospect in aspects such as tissue engineering scaffolds and biochip coatings and the like.

Owner:BRIGHTGENE BIO MEDICAL TECH (SUZHOU) CO LTD

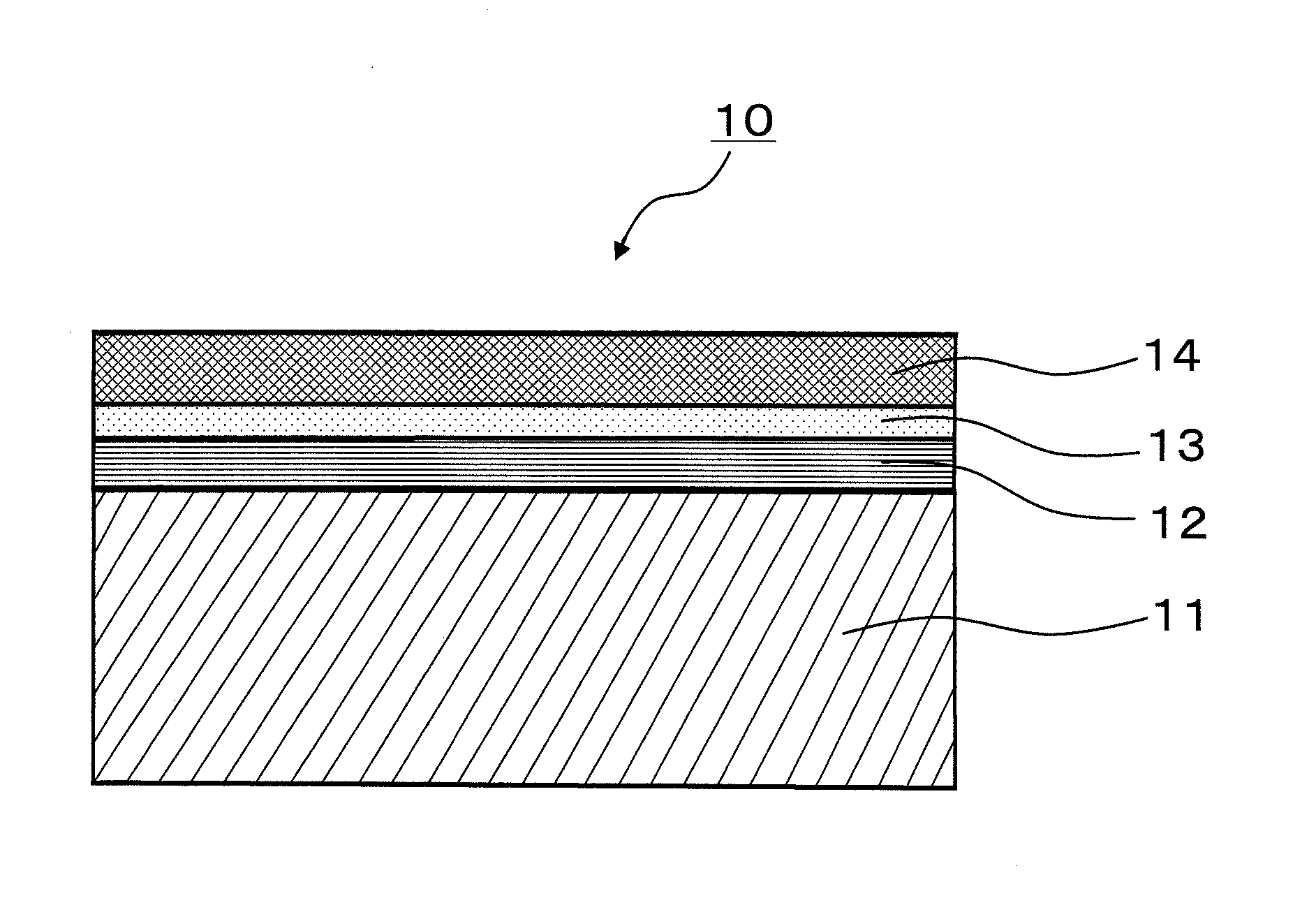

Decorative sheet, and decorative resin-molded article employing same

ActiveUS20130309460A1Good chemical resistanceEasy three-dimensional formabilityDecorative surface effectsDuplicating/marking methodsMeth-Mass ratio

The invention provides a decorative sheet including at least a surface protective layer on a substrate, in which the surface protective layer includes a cured material of an ionizing radiation curable resin composition at least containing a polycarbonate(meth)acrylate (A) and a multi-functional (meth)acrylate (B) in a mass ratio (A) / (B) of (98 / 2)-(70 / 30). The invention also provides a decorative sheet including at least a surface protective layer on a substrate, in which the surface protective layer includes a cured material of an ionizing radiation curable resin composition at least containing an acrylic silicone (meth)acrylate (C) and a multi-functional (meth)acrylate (B) in a mass ratio (C) / (B) of (50 / 50)-(95 / 5). The present invention provides a decorative sheet with a surface protective layer having scratch resistance as well as three-dimensional formability.

Owner:DAI NIPPON PRINTING CO LTD

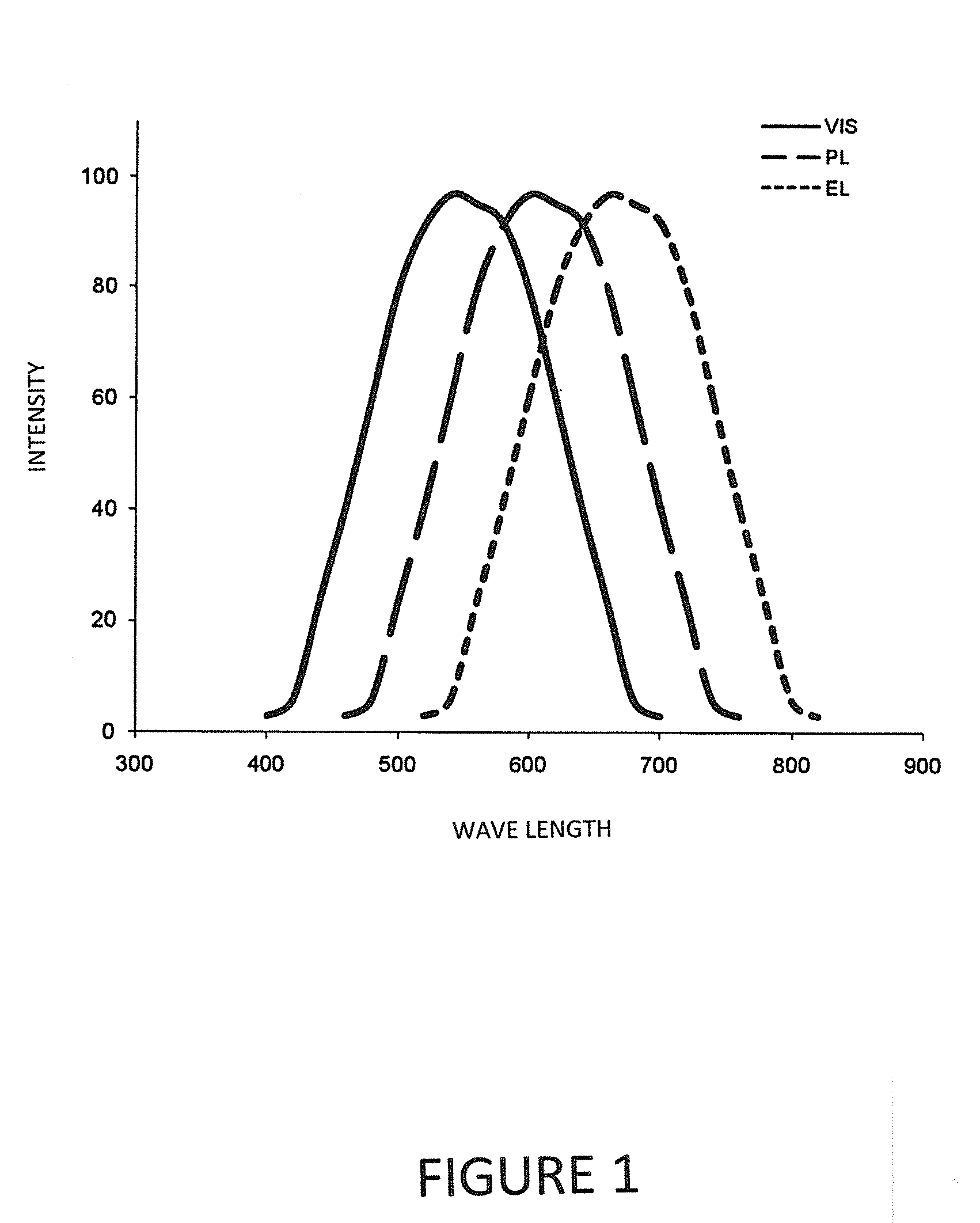

Electro-optical security element

InactiveUS20140291495A1Low costIncrease choiceSolid-state devicesSemiconductor/solid-state device manufacturingLight emissionOptical security

The invention relates to a security element for a security and / or valuable document, comprising a matrix based on an organic polymeric material, at least one electrically conductive pigment dispersed in the matrix, and at least one organic luminescent substance dispersed in the matrix, which luminescent substance is capable, in the presence of the conductive pigment, of non-contact excitation of light emission, and the particle size of which is less than 200 nm, wherein the luminescent substance is not encapsulated, and is directly surrounded by the matrix and is embedded therein, and to uses of such a security and / or valuable document and to security and / or valuable documents produced by such uses.

Owner:BUNDESDRUCKEREI GMBH

Method for preparing poly(monothiocarbonate)

ActiveCN106866952AImprove adaptabilityImprove catalytic performancePolycarbonate coatingsPhosphonium saltPhosphonium

The invention discloses a method for preparing poly(monothiocarbonate). According to the method, carbon oxysulfide and oxygen-containing monomers are used as raw materials; a catalysis system consisting of initiators and Lewis acid is used; after the bulk polymerization or solution polymerization, poly(monothiocarbonate) is obtained; the oxygen-containing monomers are selected from at least one kind of materials of epoxy compounds, oxetane and 3-substituted oxetane; the initiators are selected from quaternary ammonium salt, quaternary phosphonium salts or organic alkali. The preparation method of synthesizing the poly(monothiocarbonate) through anion ring-opening polymerization by using a catalytic system formed by at least one kind of materials from quaternary ammonium salt, quaternary phosphonium salts or organic alkali, and the Lewis acid; the poly(monothiocarbonate) with the specific chain structures can be obtained through preparation. The catalysis system can be obtained only through compounding; the metal residue and color residue problems do not exist.

Owner:ZHEJIANG UNIV

Method for preparing super hydrophobic polymeric coating using non-crystalline polymer

InactiveCN1611305AExcellent anticoagulant propertiesAchieve superhydrophobic effectSpecial surfacesPolycarbonate coatingsPhysical chemistrySolvent

Owner:INST OF CHEM CHINESE ACAD OF SCI

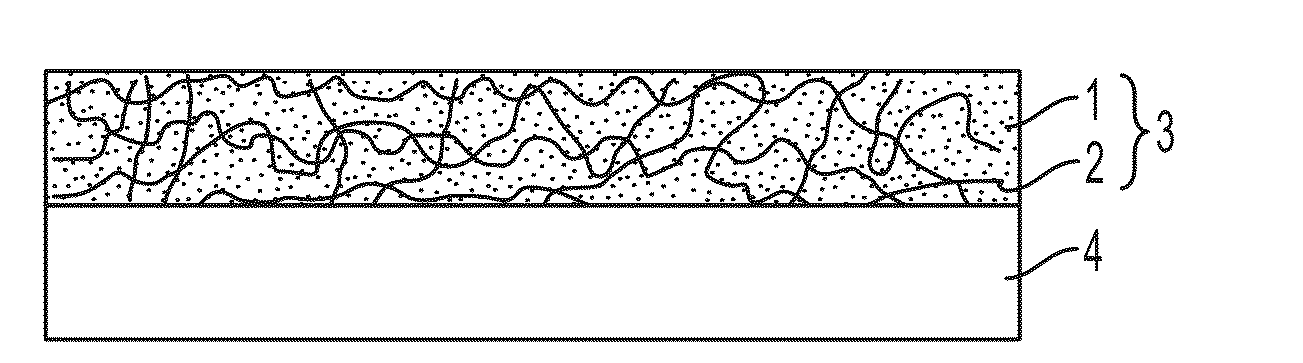

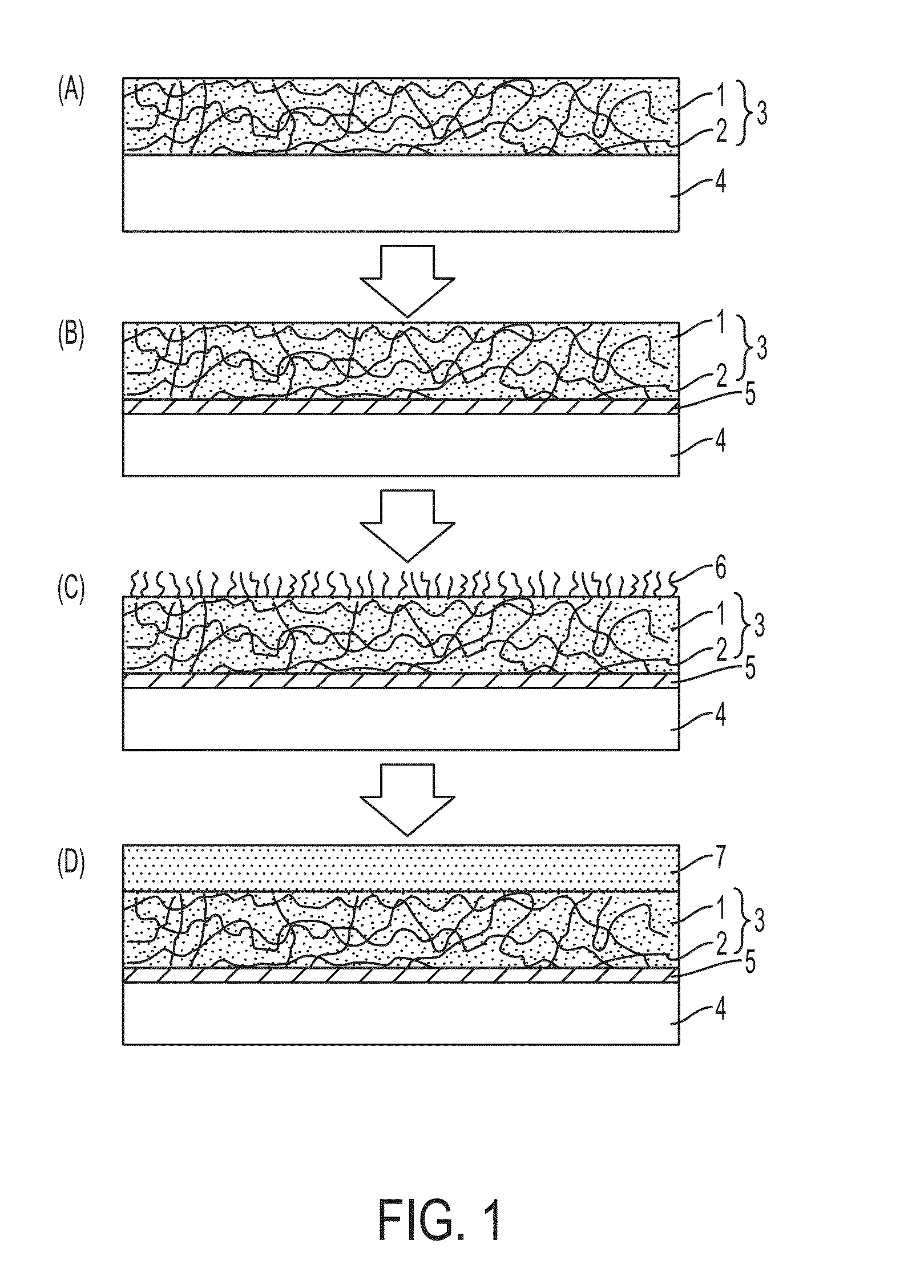

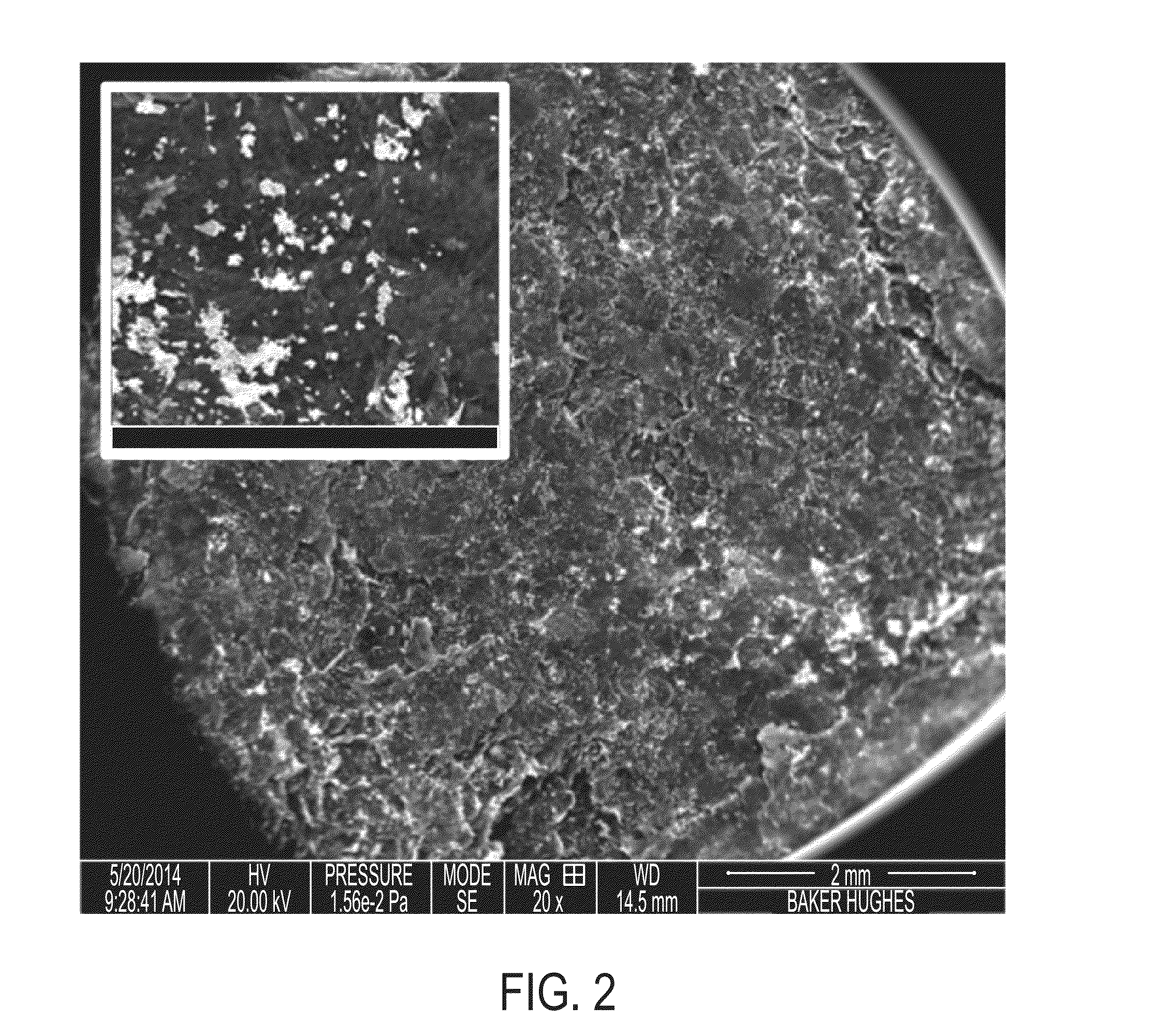

Methods of forming polymer coatings on metallic substrates

ActiveUS20160136928A1Overcome deficienciesLiquid surface applicatorsVehicle componentsCarbon compositesPolymer science

An article comprises a substrate; a polymer coating; and an intermediate layer disposed between the substrate and the polymer coating, the intermediate layer comprising a carbon composite, wherein the carbon composite comprises carbon and a binder containing one or more of the following: SiO2; Si; B; B2O3; a metal; or an alloy of the metal; and wherein the metal comprises one or more of the following: aluminum; copper; titanium; nickel; tungsten; chromium; iron; manganese; zirconium; hafnium; vanadium; niobium; molybdenum; tin; bismuth; antimony; lead; cadmium; or selenium.

Owner:BAKER HUGHES INC

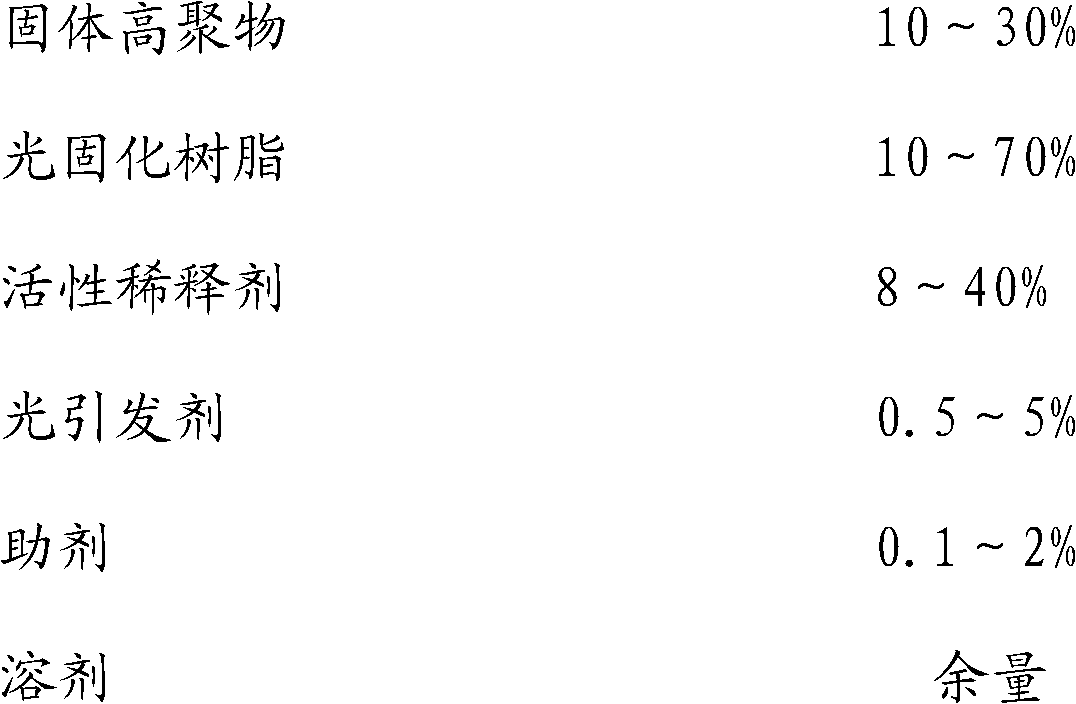

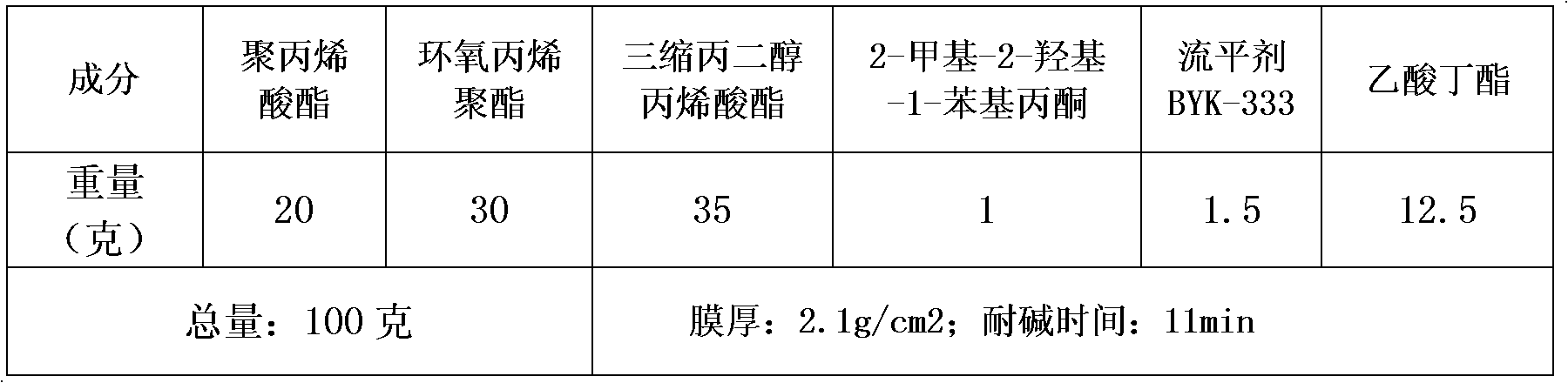

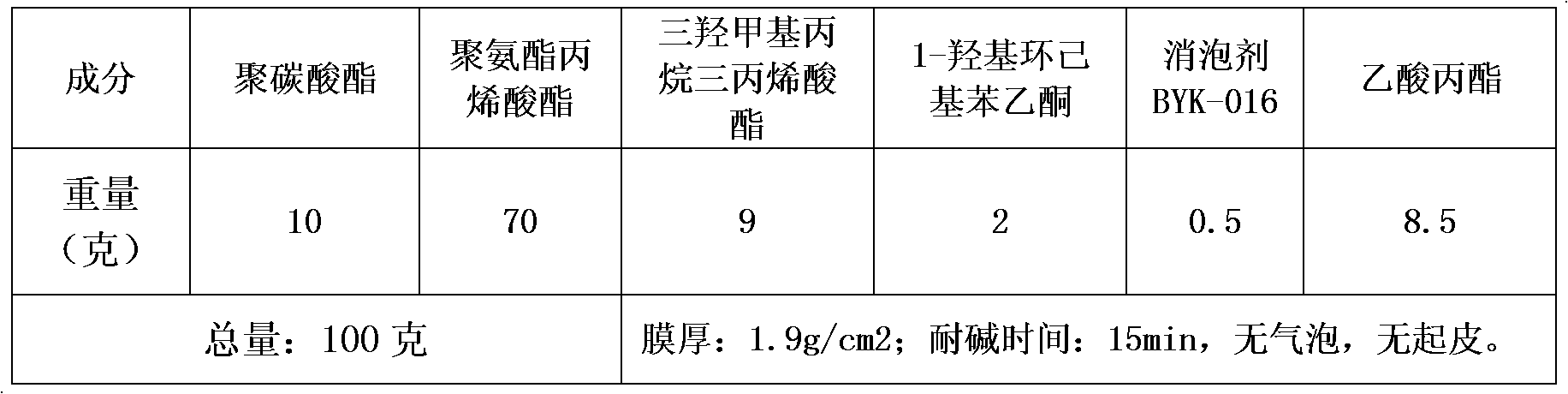

Light cured alkali resistant coating

InactiveCN102850899AImprove anti-corrosion performanceGood alkali resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsNetwork structureReactive diluent

A light cured alkali resistant coating is prepared from (by wt%) solid high polymer 10-30, light curing resin 10-70, reactive diluent 8-40, photoinitiator 0.5-5, assistant 0.1-2, and solvent in balance. The invention introduces solid high polymer into preparation raw material of current UV-light cured coating, and on the basis of original frame of UV-light cured coating, utilizes network structure constructed by solid high polymer acrylate high molecular chain, to thereby improve comprehensive anti-corrosive property of light cured coating effectively, especially improve alkali resistance of coating under thin coating condition.

Owner:SNTO TECH GRP

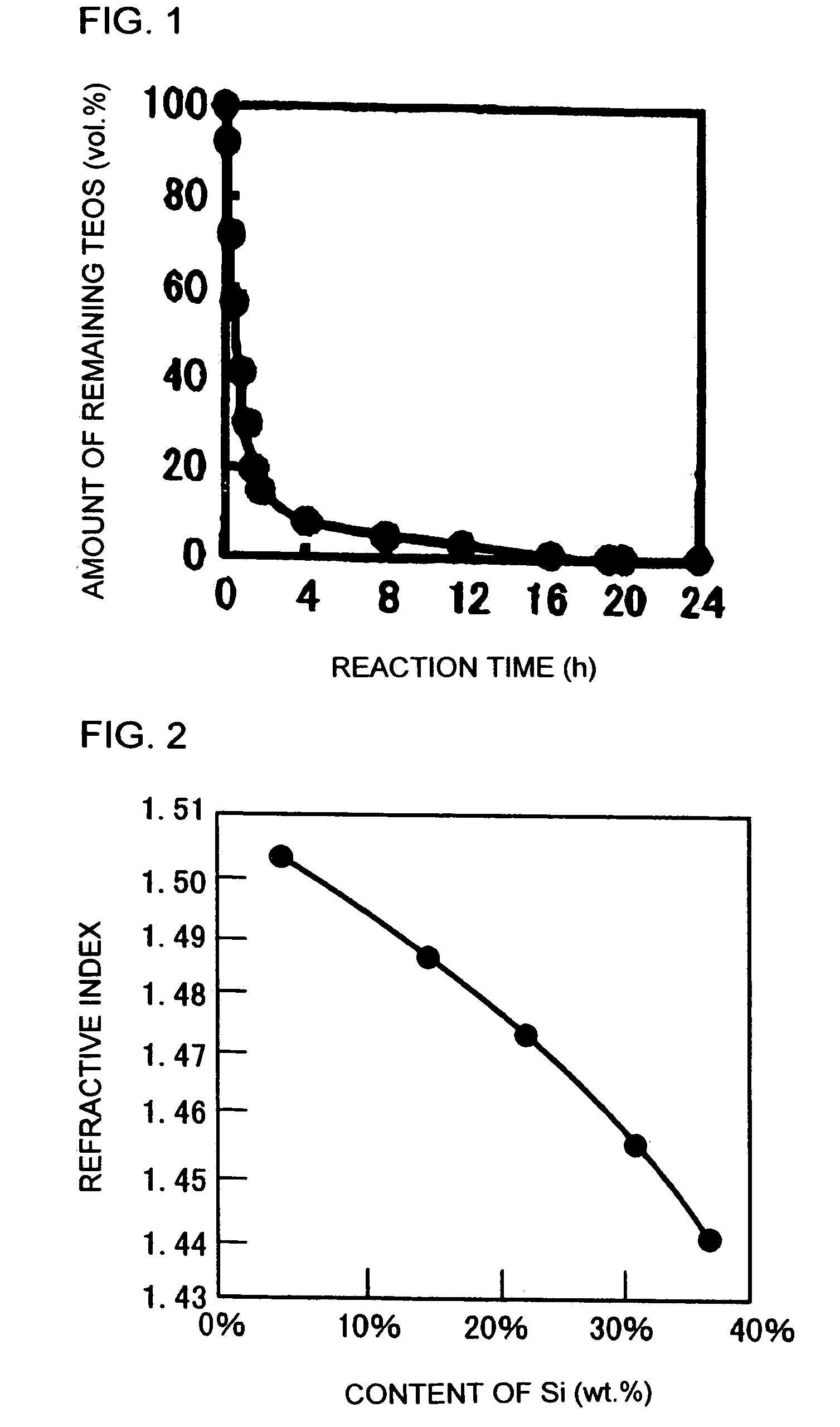

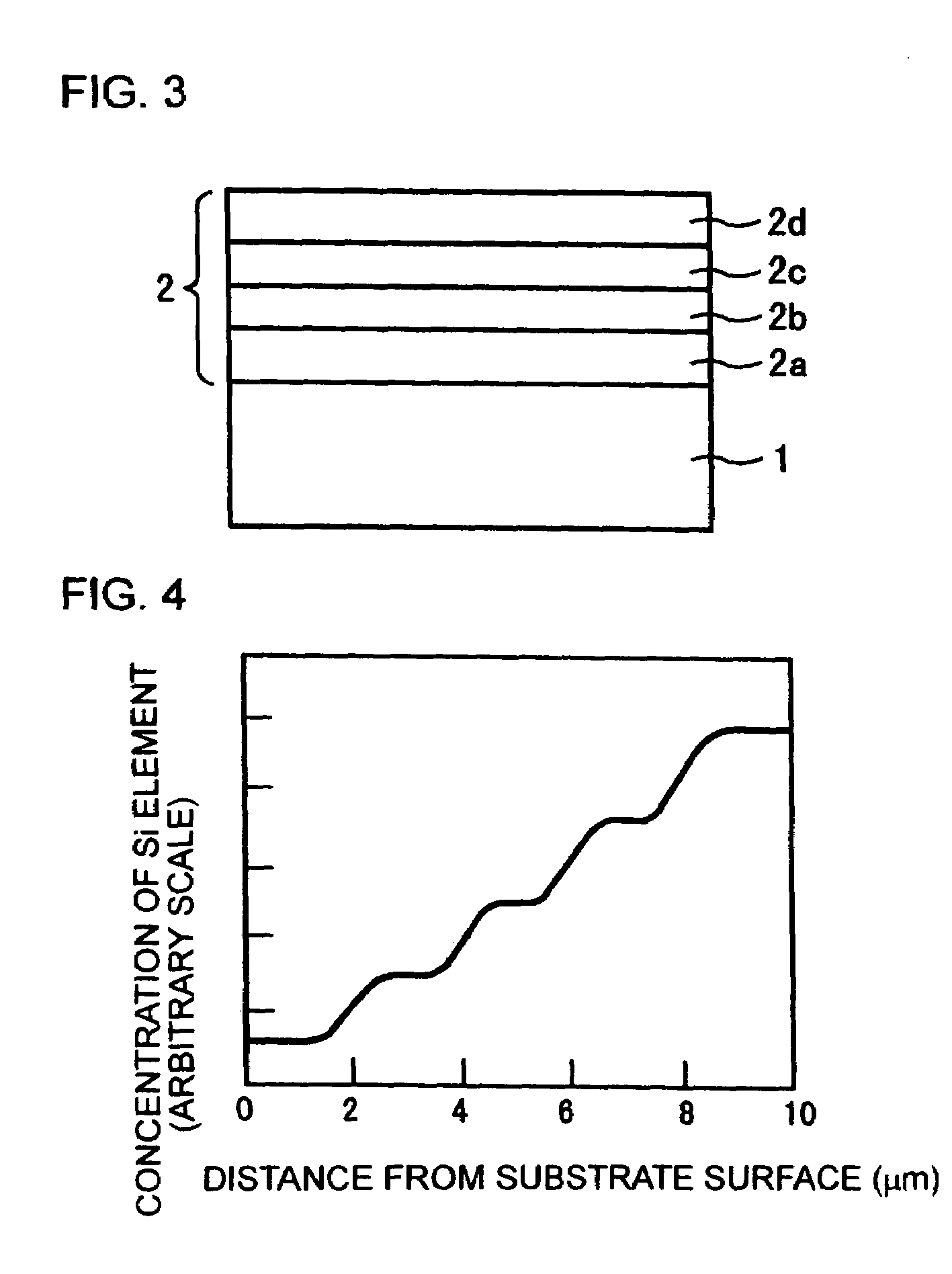

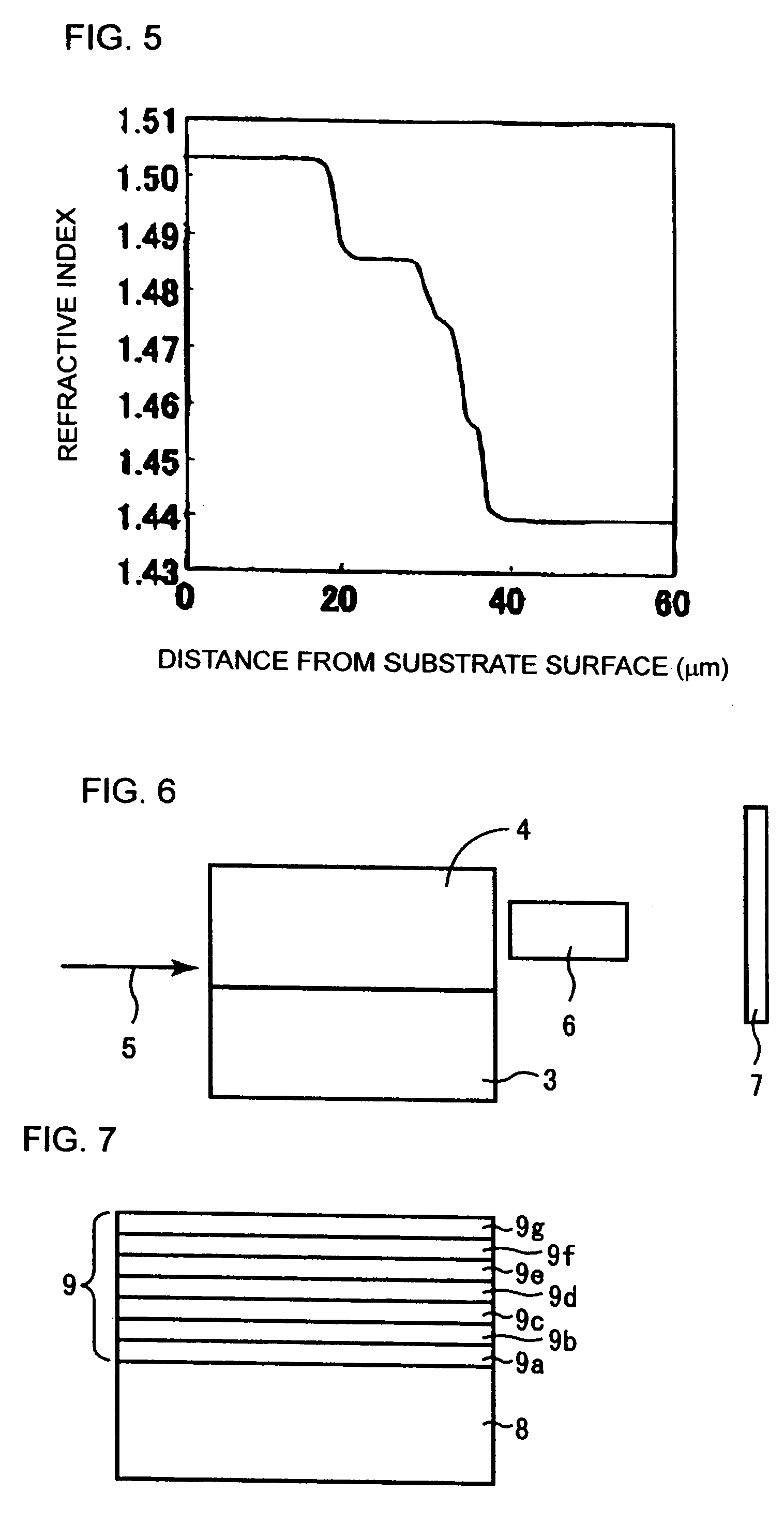

Organic-inorganic composite material and laminate, optical waveguide and light transmission structure comprising the same

InactiveUS7166661B2Good light transmissionImprove adhesionSpecial tyresNatural mineral layered productsRefractive indexTransmittance

An organic-inorganic composite material is formed by polycondensating a metal alkoxide through hydrolysis until the unreacted metal alkoxide is reduced to 3 vol. % or less, and mixing it with an organic polymer. The composite material has a light transmittance of at least 90% per 10 μm material thickness for light of 600 to 1000 nm. The metal element content of the composite material is preferably 0.1 to 46 wt. %, more preferably 5 to 37 wt. %. By laminating layers of such organic-inorganic composite materials having respective different compositions, the resulting laminate has a concentration gradient wherein the metal element content increases or decreases monotonously, or increases and decreases in succession, from one side to the other side of the laminate. The resulting refractive index varies opposite the metal element content. The material can be used for an optical waveguide or a light transmission structure.

Owner:SANYO ELECTRIC CO LTD

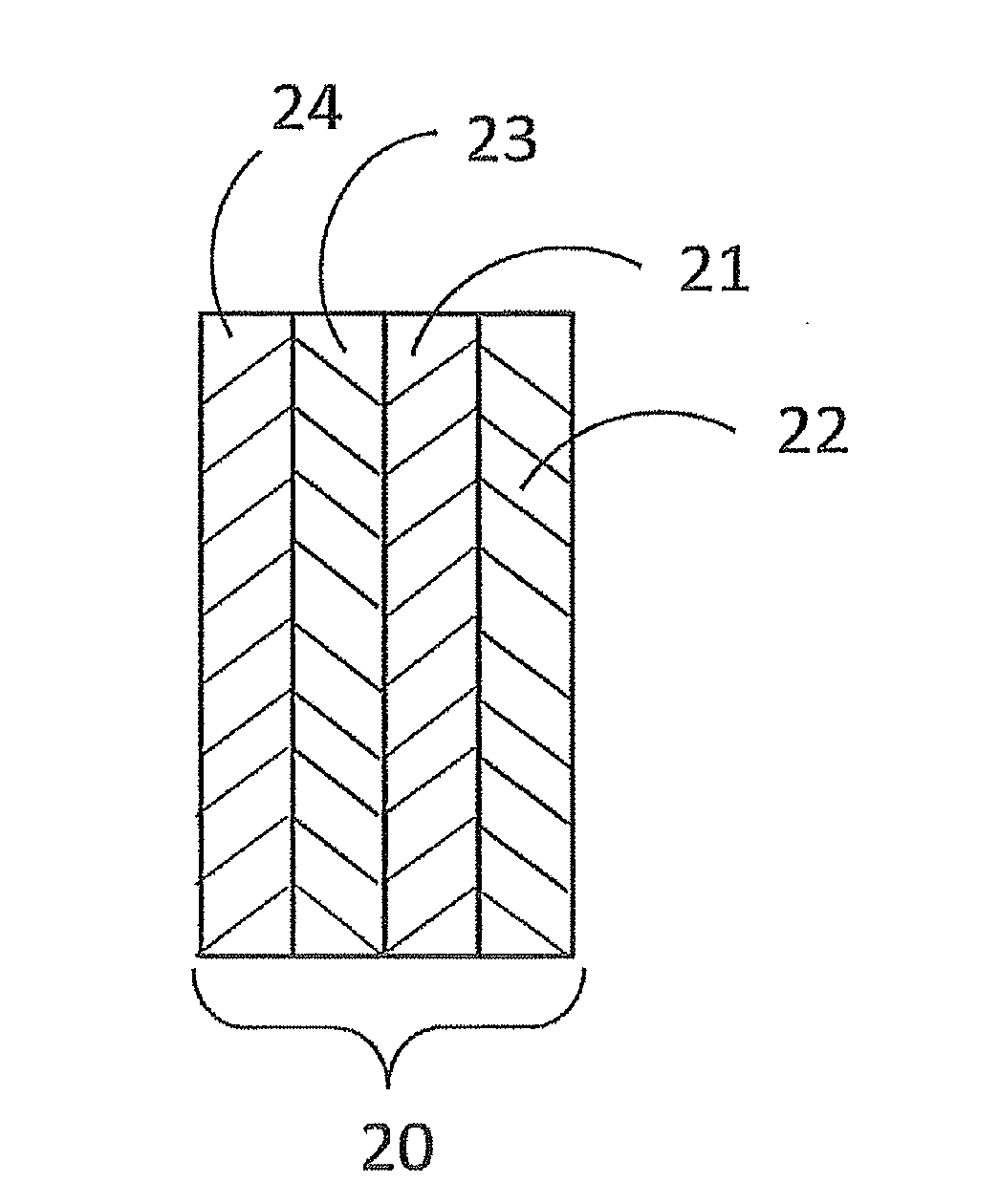

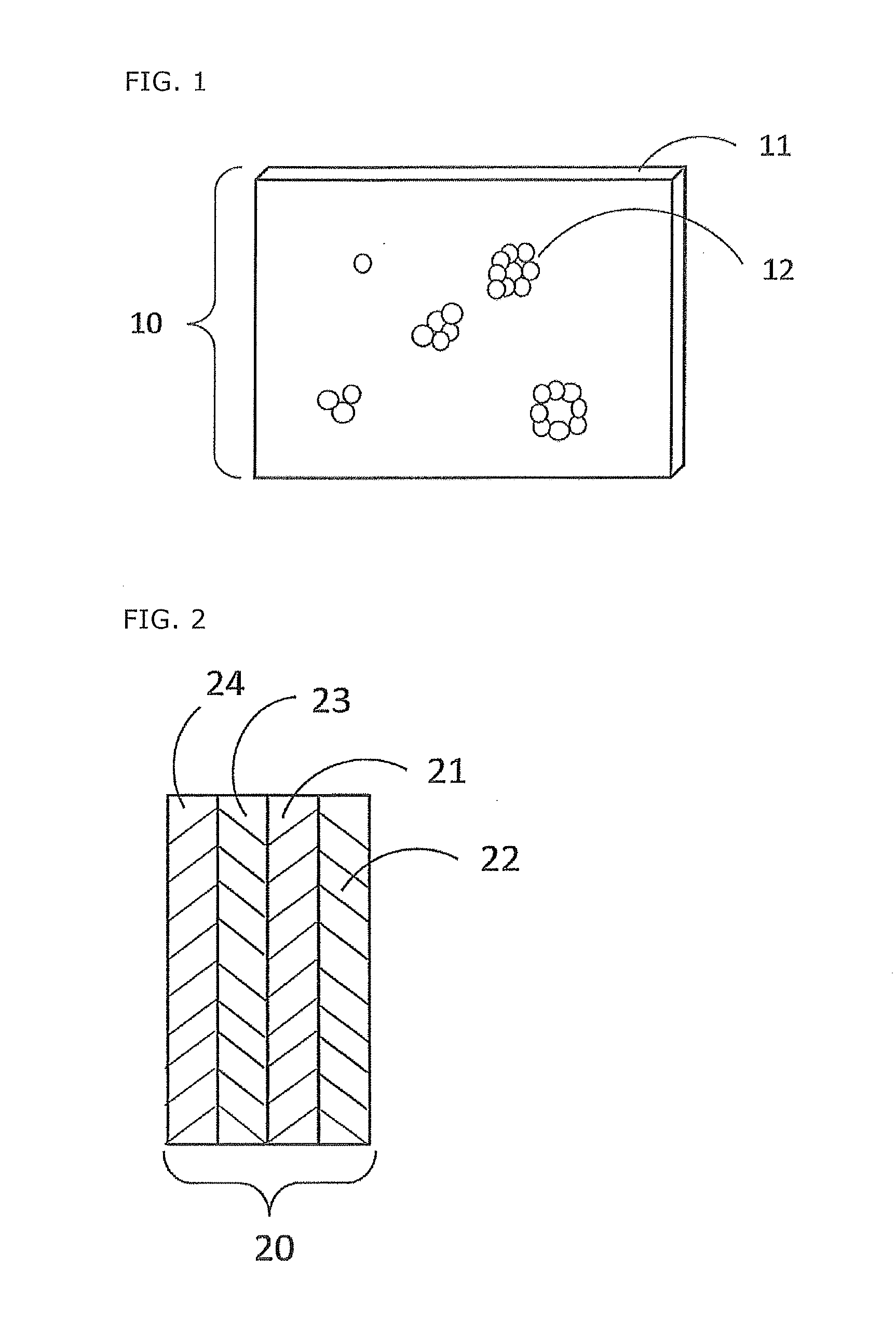

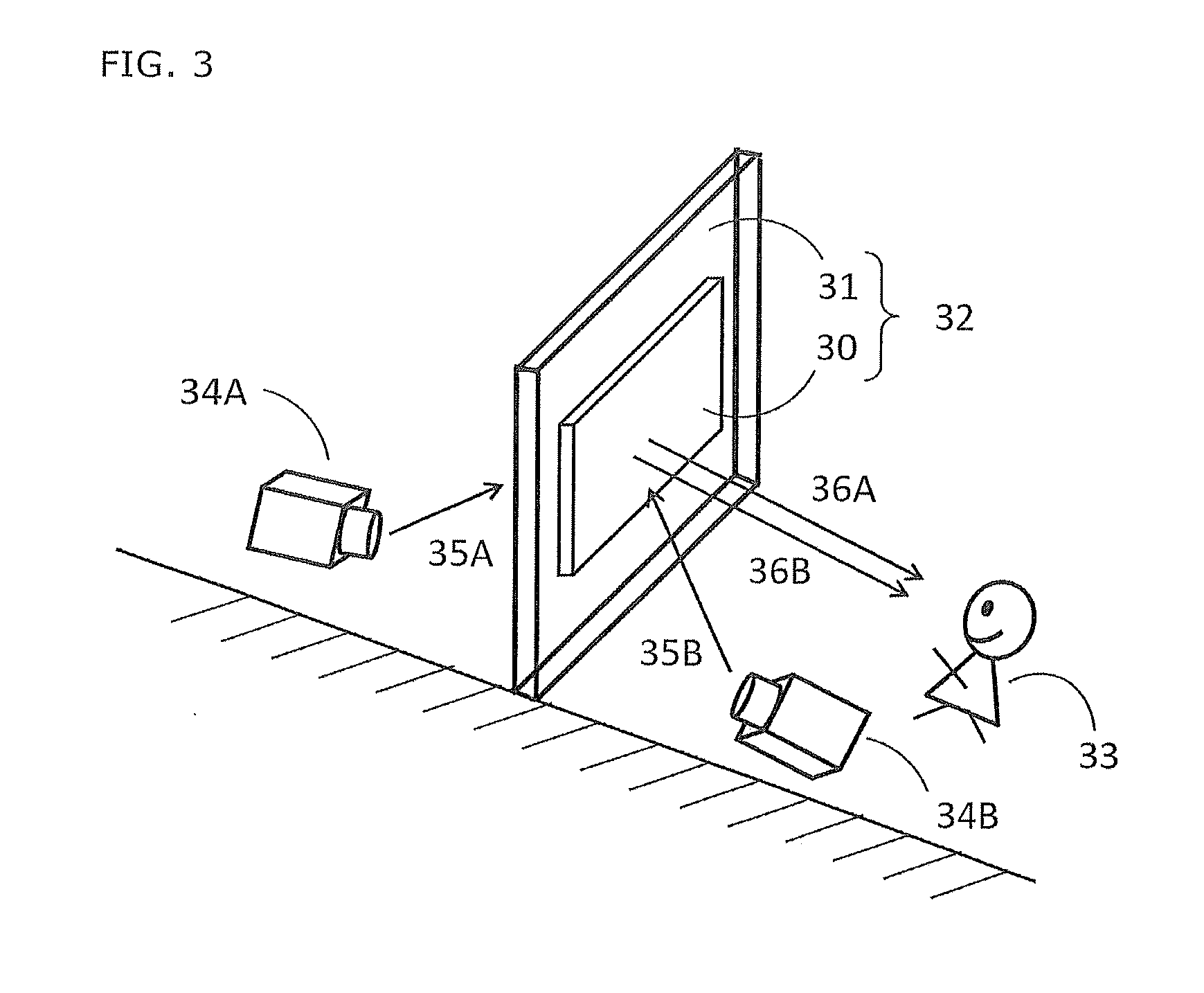

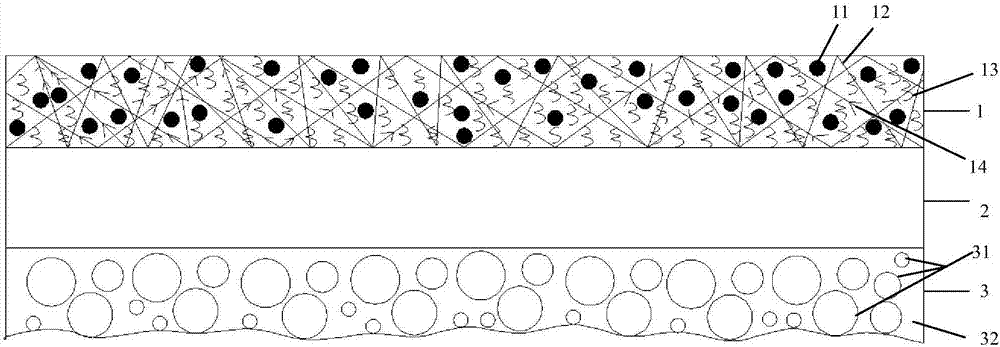

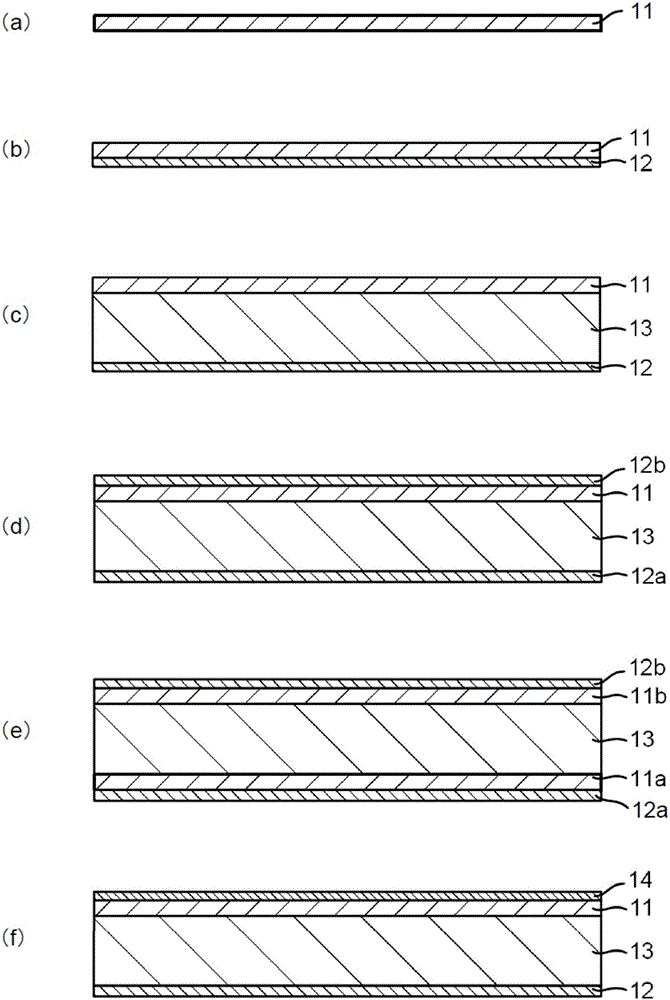

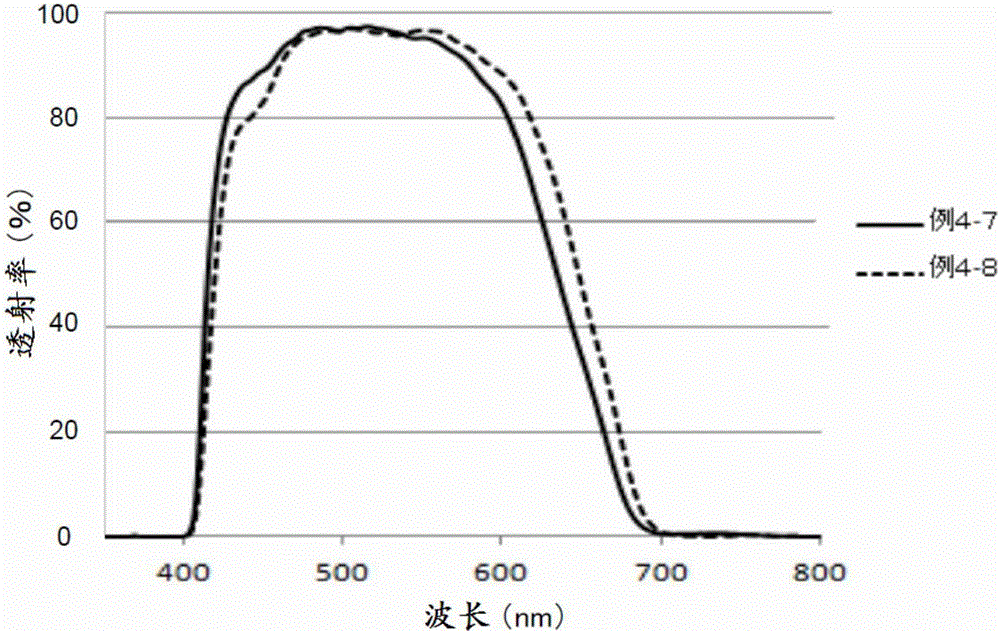

Film for transparent screen and method for manufacture thereof, and transparent screen comprising same

ActiveUS20170059982A1Improve clarityHigh transparencyTelevision system detailsDiffusing elementsVisibilityInorganic particle

Provided is a film for a transparent screen which can clearly display merchandise information, advertisement, or the like on a transparent partition or the like by projection without compromising the transmission visibility. A film for a transparent screen according to the present invention includes: a resin layer; and inorganic particles at least a portion of which is contained in an aggregated state in the resin layer, wherein primary particles of the inorganic particles have a median diameter of 0.1 to 50 nm and a maximum particle size of 10 to 500 nm, and the content of the inorganic particles is 0.015 to 1.2% by mass with respect to the resin.

Owner:TOKYO INST OF TECH +1

Perovskite quantum dot membrane, quantum dot diffusion composite membrane and preparation method of quantum dot diffusion composite membrane

InactiveCN107955199AImprove adhesionGood compatibilityLuminescent paintsPolyamide coatingsResin coatingGreen-light

The invention relates to a perovskite quantum dot membrane, a quantum dot diffusion composite membrane and a preparation method of the quantum dot diffusion composite membrane. According to the perovskite quantum dot membrane, one side of a base material is coated with a green light-emitting perovskite quantum dot layer, and the structural formula of perovskite quantum dots is CH3NH3PbClxBr3-x (0<=x<=1); the perovskite quantum dot layer is composed of the perovskite quantum dots, polymers, adhesion promoter and additives. The perovskite quantum dot membrane introduces the adhesion promoter tothe polymers to form intermediate bridge effects between the resin coating and the base material of the polymers and further to enhance adhesion; the other side of the green light-emitting perovskitequantum dot membrane is coated with a light diffusion layer to form a green light-emitting quantum dot diffusion composite membrane, and by combining the back light source design of blue LEDs (light emitting diode) and KSF red fluorescent powder, the green light-emitting quantum dot diffusion composite membrane achieves the combined effects of light conversion and light diffusion and accordingly can replace a light diffusion membrane during application to a backlight module.

Owner:HEFEI LUCKY SCI & TECH IND

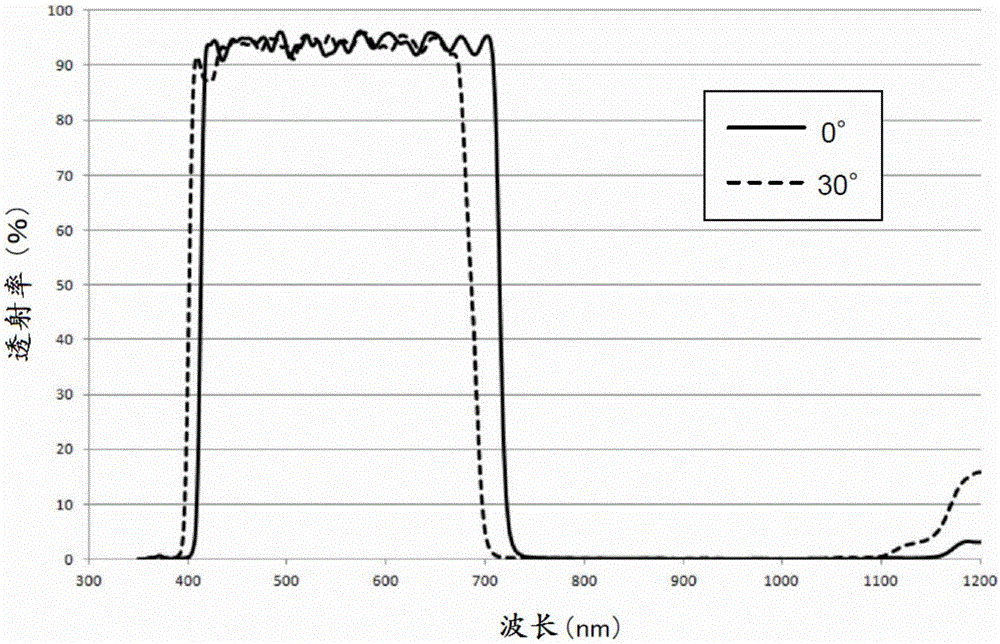

Optical filter and imaging device

ActiveCN106104319AImprove the blocking effectHigh color reproductionMethine/polymethine dyesSolid-state devicesSpectral transmittanceLength wave

An optical filter is provided with an absorbing layer containing a near-infrared ray absorbing pigment the absorption characteristics of which in dichloromethane satisfy the following conditions: - An absorption spectrum of 400 nm - 800 nm contains a maximum absorption wavelength [lambda]max between 670 nm and 730 nm. - The maximum extinction coefficient [epsilon]A for light of wavelength 430 nm - 550 nm, and the maximum extinction coefficient [epsilon]B for light of wavelength 670 nm - 730 nm have the following relationship: [epsilon]B / [epsilon]A >= 65 - In a spectral transmittance curve, the difference is 65 nm or less between the maximum absorption wavelength [lambda]max, and the wavelength [lambda]80 the transmittance of which is 80 % in the wavelengths shorter than the maximum absorption wavelength in the case where the transmittance in the maximum absorption wavelength [lambda]max is 10 %.

Owner:ASAHI GLASS CO LTD

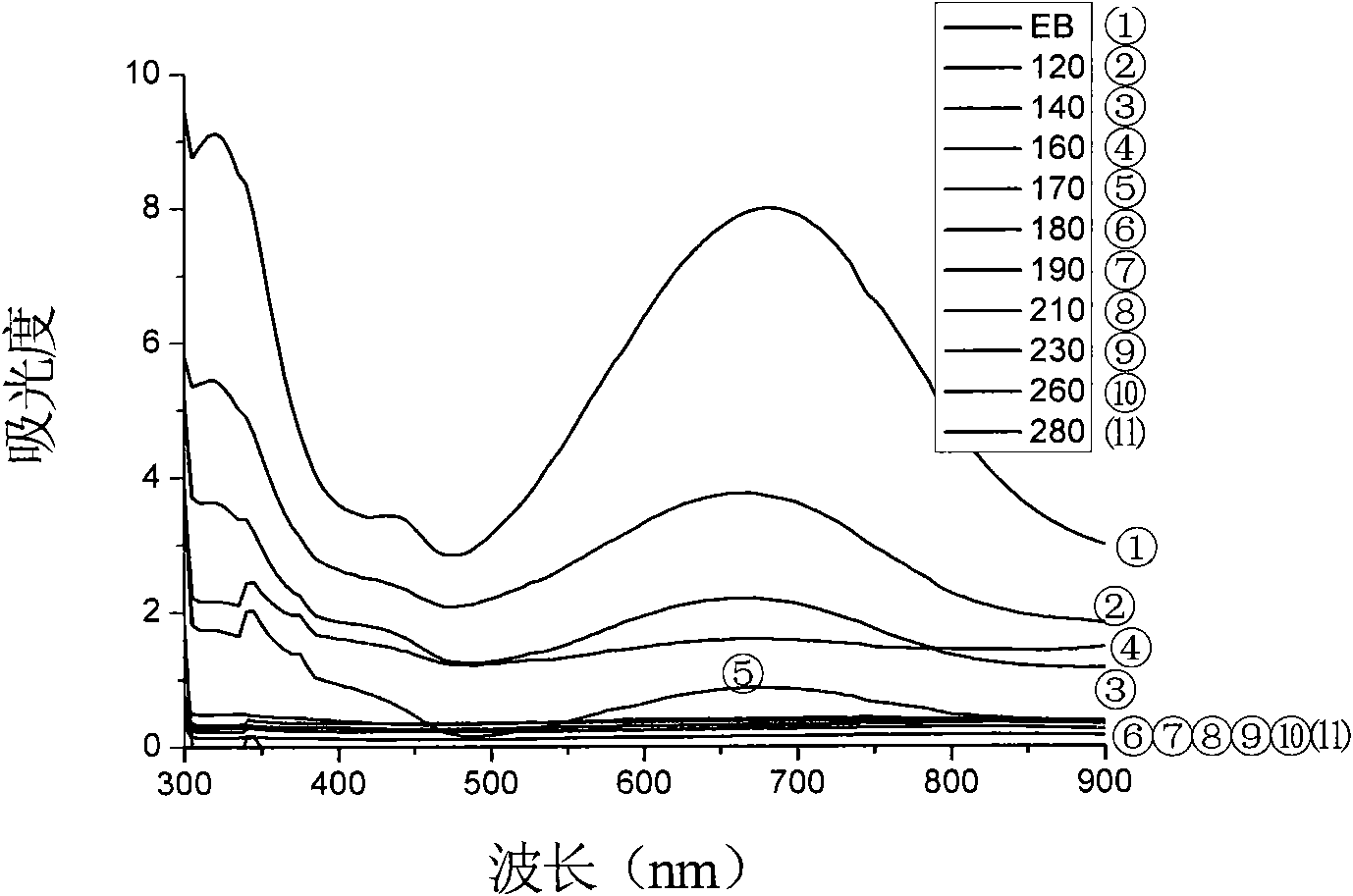

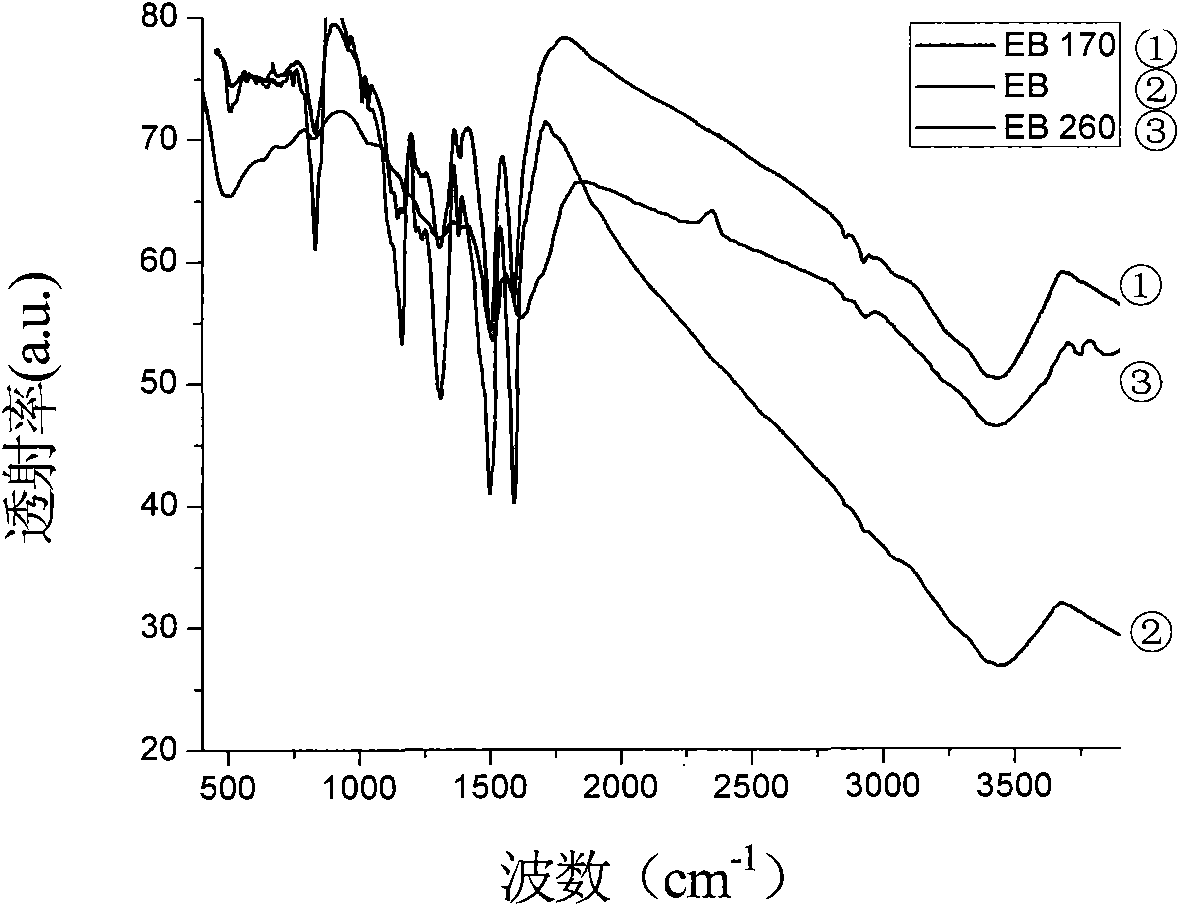

Polyaniline composite antibacterial plastic as well as preparation method and application thereof

InactiveCN102311608AReduce usageLow application costBiocideOrganic conductorsBlow moldingPolyaniline composite

The invention belongs to the field of antibacterial polymer materials and a processing method thereof, and particularly relates to a polyaniline composite antibacterial plastic as well as a preparation method and application thereof. The antibacterial plastic comprises a polyaniline main material and a polymer basis material, various forms of polyaniline or composite materials thereof, which are used as main antibacterial materials, and then are blended with other polymer basis materials, and then injection molding, blow molding, mould pressing, foaming and other plastic molding processes are carried out to obtain the polyaniline composite antibacterial environment purification material; and at a normal temperature, polyaniline can be dissolved or dispersed by solvents, and surface treatment is carried out on the plastic by being mixed with other polymers, for example, antibacterial antifouling and anticorrosive coatings and the like are manufactured through spray molding, casting, film painting, electrochemical deposition and other processes. The polyaniline composite material not only has an excellent antibacterial effect on escherichia coli, staphylococcus aureus, Candida albicans and the like, but also can be used as the environment purification material by utilizing the oxidoreduction characteristic to realize the removal of methanal, hydrothion, pollutant and other gases to keep the air fresh.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

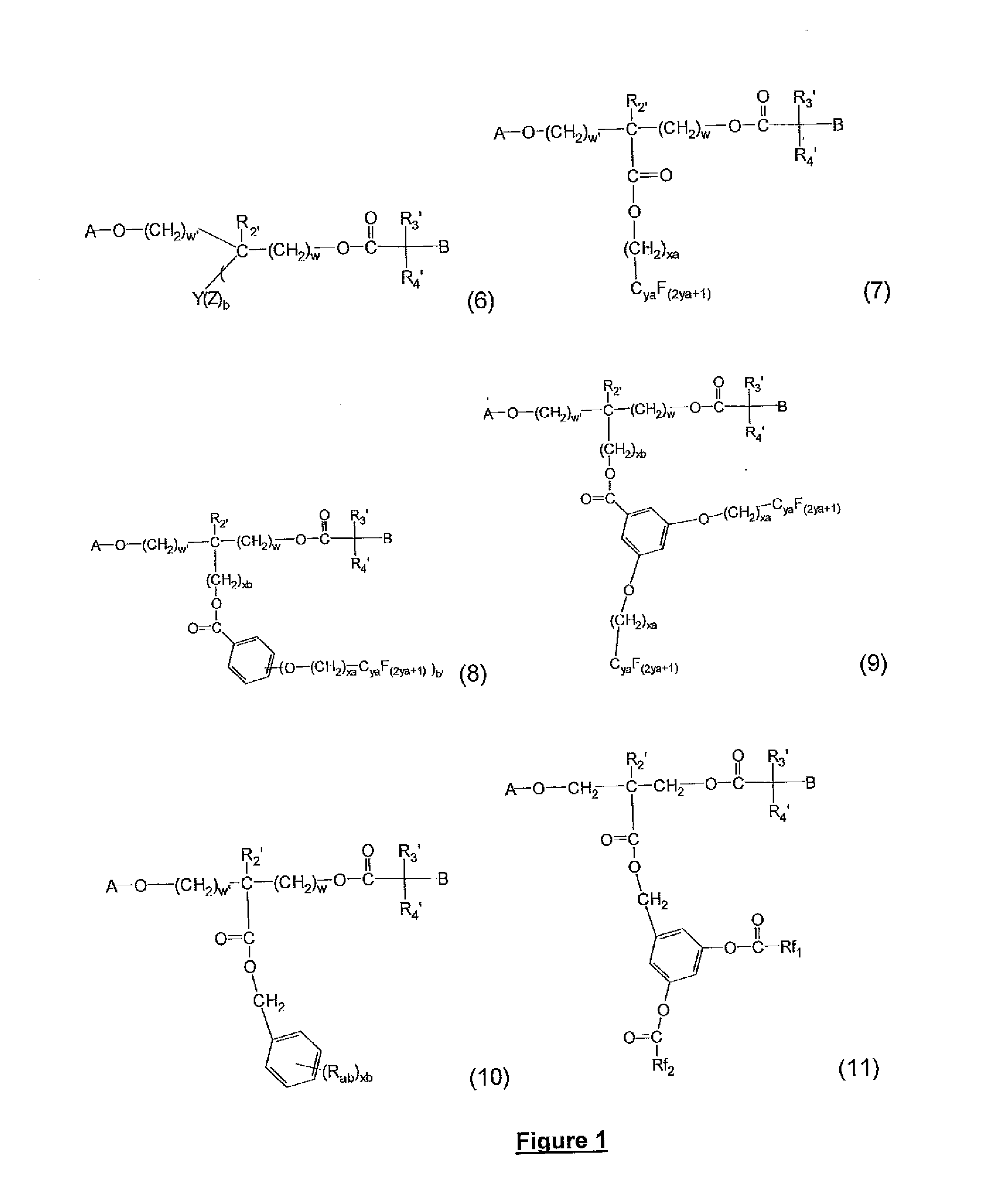

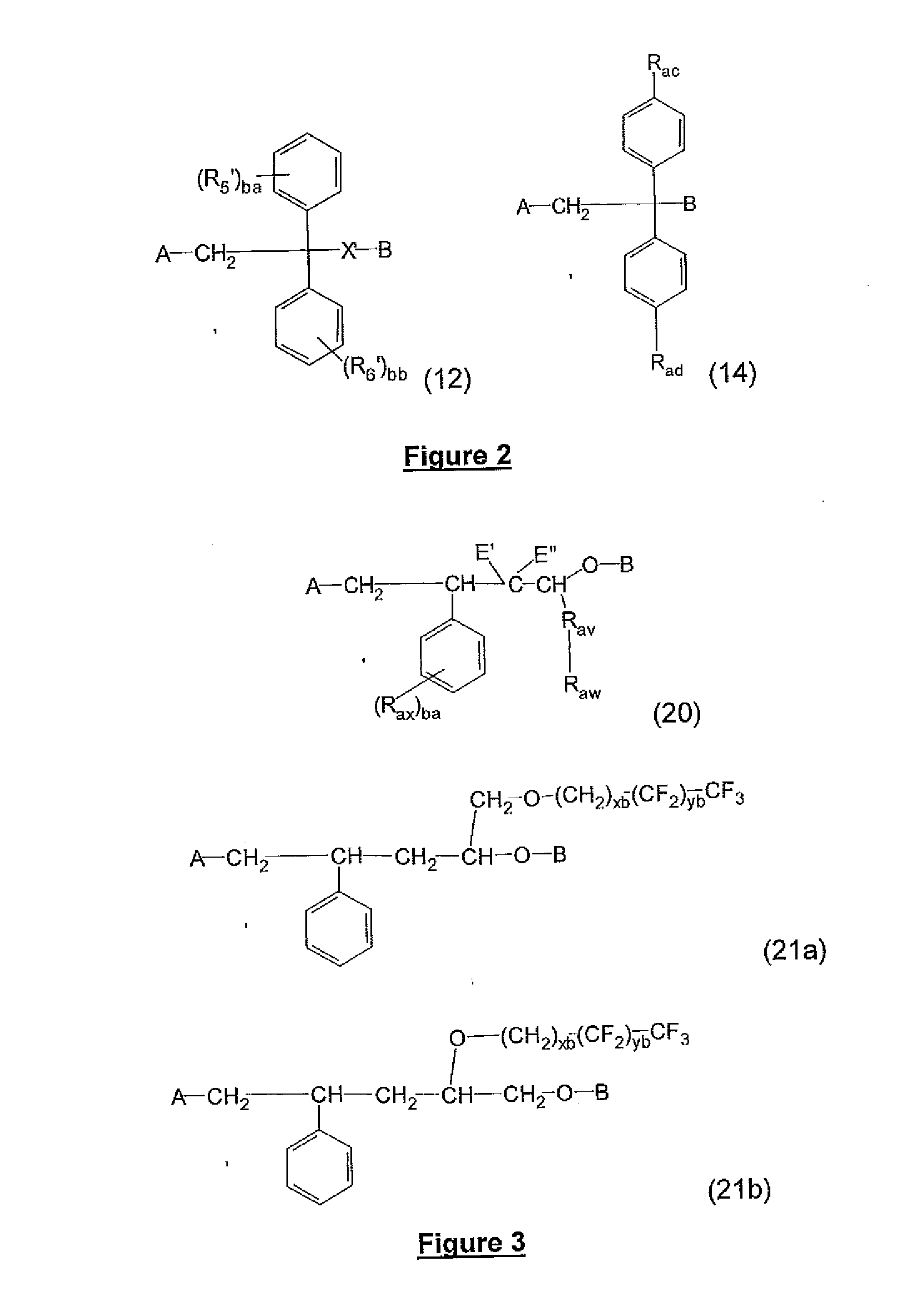

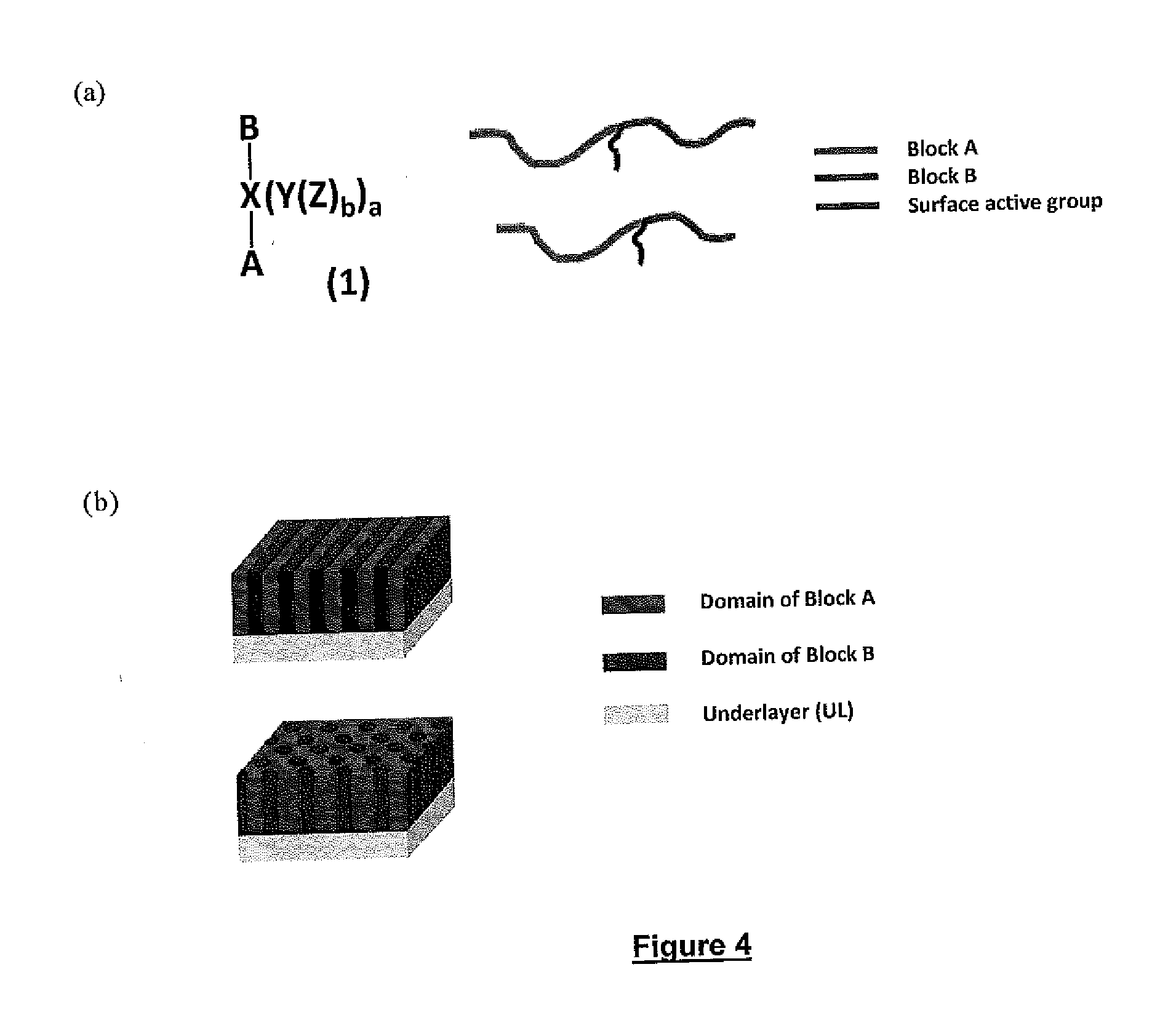

Block copolymers with surface-active junction groups, compositions and processes thereof

The present invention relates to a novel block copolymer of structure 1,wherein, A- is a block polymer chain, B is a block polymer chain,wherein, A- and B- are chemically different, covalently connected polymer chains, which are phase separable and the moiety X(Y(Z)b)a is a junction group, which comprises a surface active pendant moiety Y(Z)b wherein:a is an integer from 1 to 4 denoting the number of surface active pendant moieties Y(Z)b on X,b is an integer from 1 to 5 denoting the number of Z moieties on the linking moiety Y,X is a linking group between the A polymer block, the B polymer block and the moiety Y,Y is a linking group or a direct valence bond between X and Z; andZ is a moiety independently selected from, a fluorine containing moiety, a Si1-Si8 siloxane containing moiety or a hydrocarbon moiety with at least 18 carbons, and further wherein the junction group X(Y(Z)b)a has a surface energy less than that that of the block A and less than that of the block B. The invention also relates to a composition comprising the novel copolymer and its use in direct self-assembly processes.

Owner:IBM CORP +1

Method of producing solid body having depressed portion on surface

InactiveUS7931848B2Inexpensive and stable methodPretreated surfacesPolyester coatingsBoiling pointSolvent

Owner:CANON KK

Resin composition for disposal resin molded product, and disposal resin molded product

InactiveUS20110281048A1Improve mechanical propertiesSynthetic resin layered productsThin material handlingMechanical propertyCarbonate

Disclosed is a resin composition for disposable resin molded product, and a disposable resin molded product that enables preparation of a disposable resin molded product not only maintaining excellent mechanical properties but also having biodegradability entailing an environment-friendly feature. The resin composition for disposable resin molded product comprises a polyalkylene carbonate resin.

Owner:LG CHEM LTD

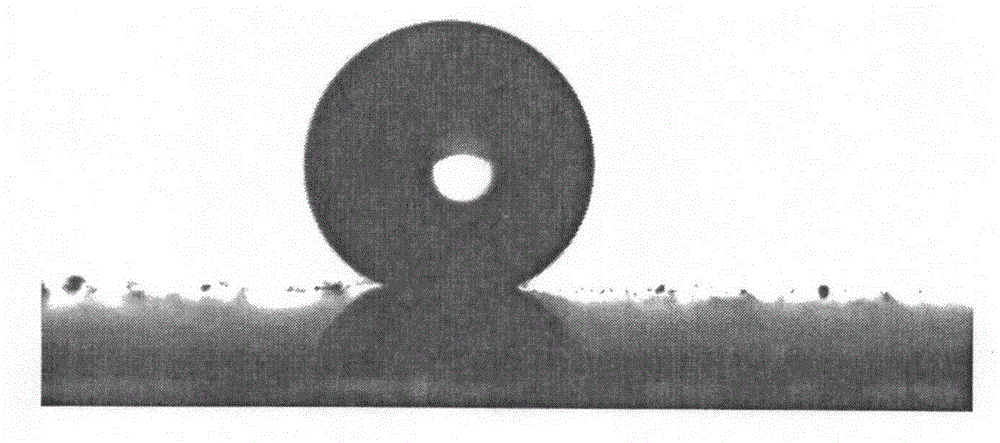

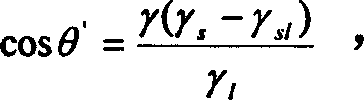

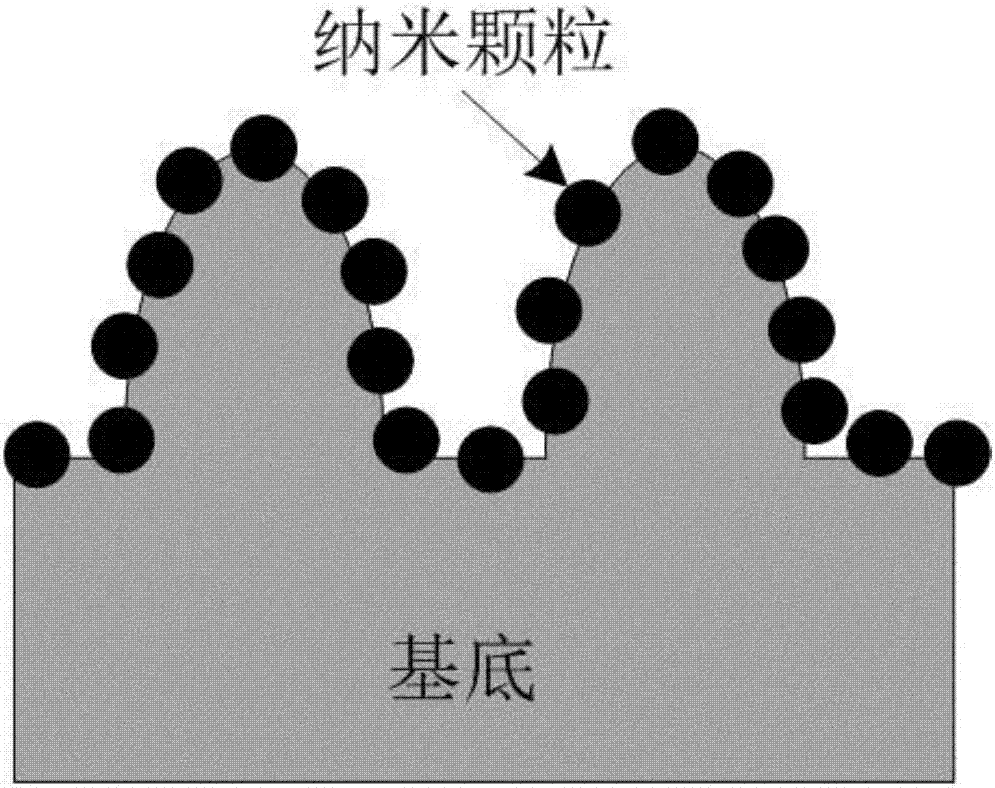

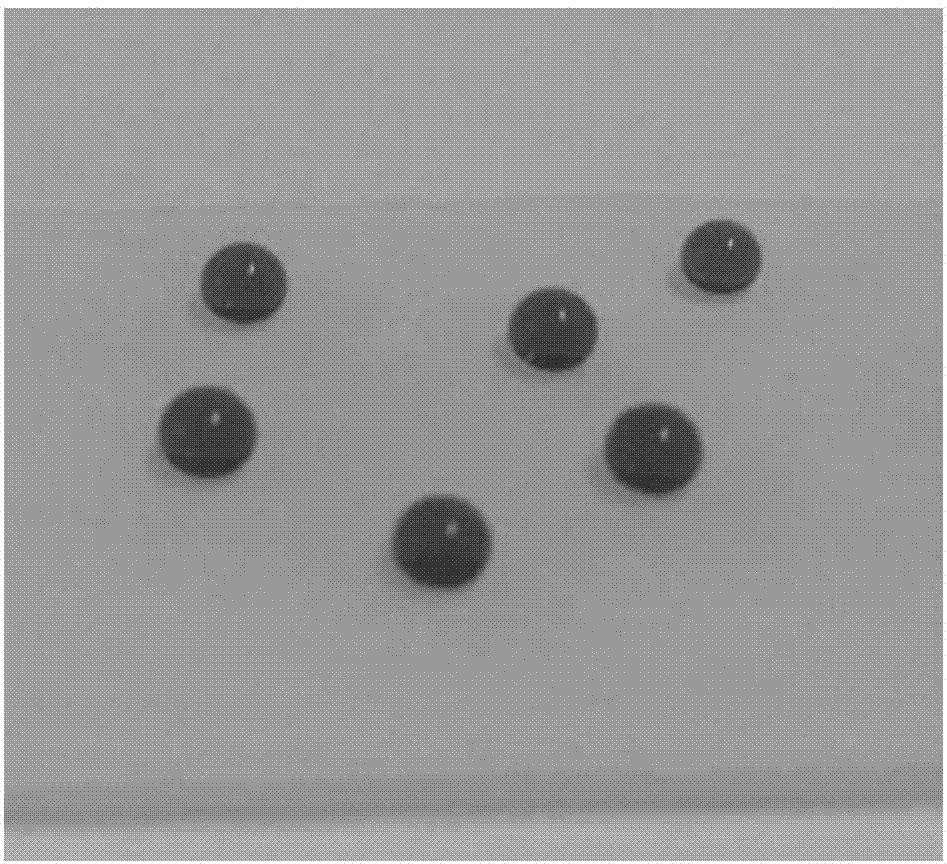

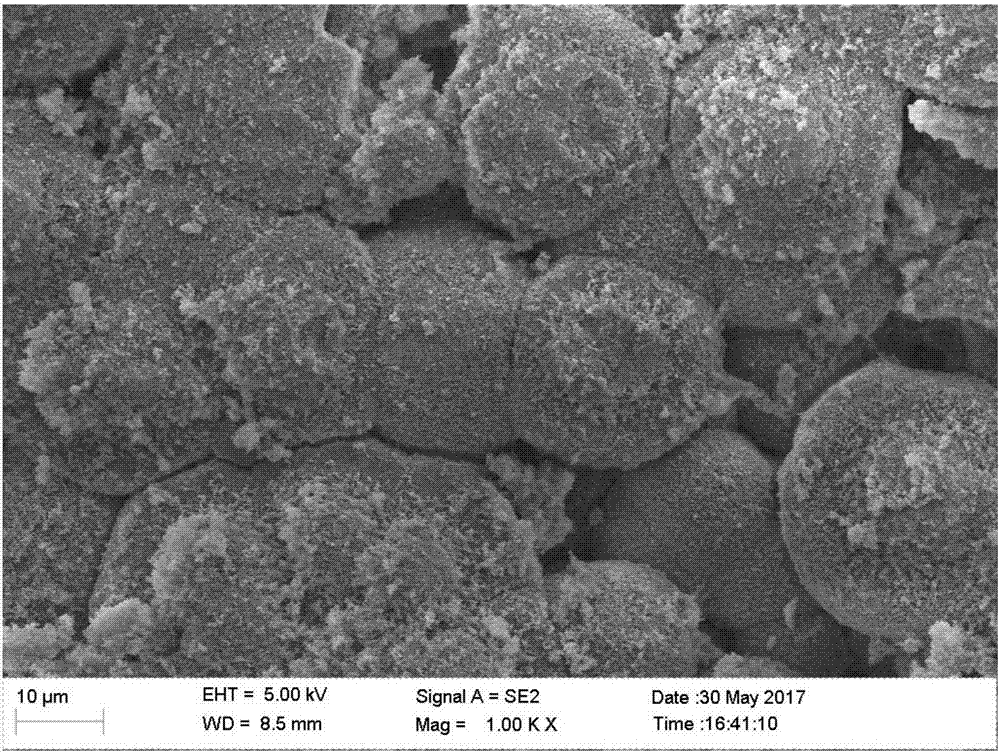

Polycarbonate-based wear-resistant superhydrophobic coating preparation method

ActiveCN107189656AImprove wear resistanceEasy to makeCoatings with pigmentsAntifouling/underwater paintsWear resistantSuperhydrophobic coating

The invention discloses a polycarbonate-based wear-resistant superhydrophobic coating preparation method. The method comprises dissolving polycarbonate and an antifoaming agent in a solvent to obtain a solution for an intermediate layer, and then dissolving hydrophobic oxide nanoparticles and a low surface energy material in an acetone solution to obtain a solution for a surface layer. In the construction process, a base is coated with commercially available polycarbonate glue, then the glue is coated with the solution for the intermediate layer, and after the solution for the intermediate layer is dried, the intermediate layer is coated with the solution for a surface layer so that the wear-resistant superhydrophobic coating is obtained after drying. Through interaction between the polycarbonate and the acetone solution, the method cleverly realizes the organic combination of the embedded nanostructure and the hierarchical structure, and the thus the prepared superhydrophobic coating has excellent wear resistance.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Actinic-ray-curable resin composition, layered film including hardcoat formed therefrom, and layered transparent resin product

ActiveUS20170198164A1Good colorIncrease resistanceSynthetic resin layered productsPolycarbonate coatingsActinic RaysTitanium

Embodiments of the invention relate to an actinic-ray-curable resin composition which includes 100 parts by mass of a polyfunctional (meth)acrylate; 0.2-4 parts by mass of a compound having an alkoxysilyl group and a (meth)acryloyl group; 0.05-3 parts by mass of an organic titanium; and 5-100 parts by mass of fine particles having an average particle diameter of 1-300 nm. Embodiments of the invention also relate to a layered transparent resin product which includes a hardcoat layer and a layer of a transparent resin sheet in this order from the outermost layer side, wherein the hardcoat has been formed from a coating material including 100 parts by mass of a polyfunctional (meth)acrylate; 0.2-4 parts by mass of a compound having an alkoxysilyl group and a (meth)acryloyl group; 0.05-3 parts by mass of an organic titanium; and 5-100 parts by mass of fine particles having an average particle diameter of 1-300 nm.

Owner:RIKEN TECHNOS CORP

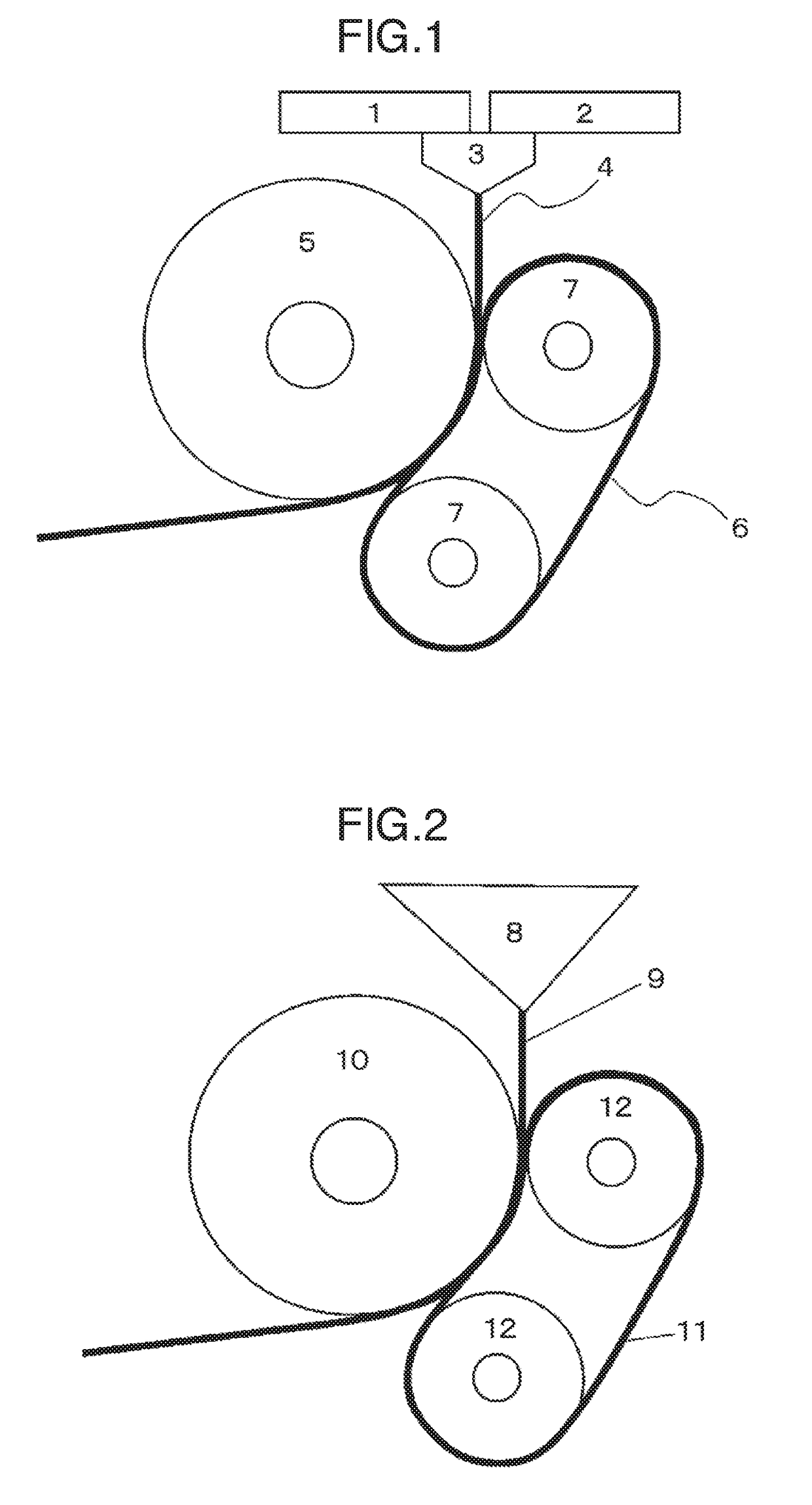

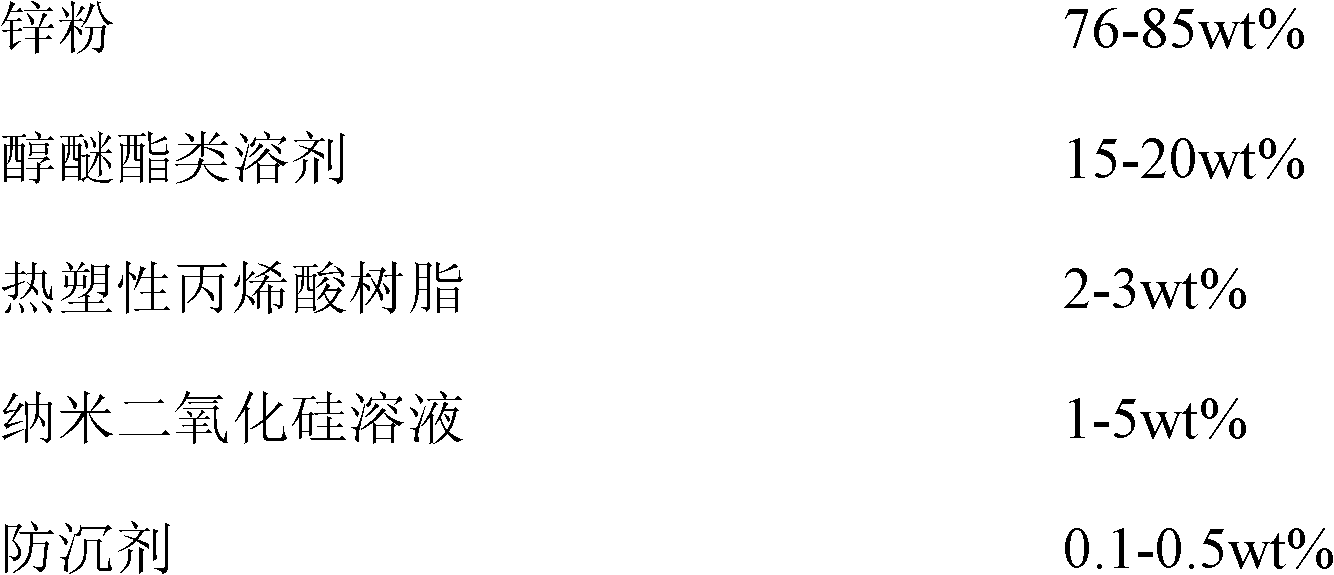

Primer-topcoat cold-spray zinc coating and preparation method for same

InactiveCN102618132ALong corrosion lifeGood compatibility with the bottom surfaceRosin coatingsAnti-corrosive paintsCoated surfaceWeather resistance

The invention relates to primer-topcoat cold-spray zinc coating, which comprises zinc powder, organic solvent, organic resin and filler, wherein the organic resin refers to thermoplastic resin, and the filler is silicon dioxide solution. The primer-topcoat cold-spray zinc coating is longer in anticorrosion service life, good in primer compatibility and compact in coating layer surface, and has good primer performances such as adhesion, anticorrosion and the like and fine weather resistance of topcoat.

Owner:TIANCHANG JULONG TRAVEL PAINT

Polymers formed from 2,3,3,3-tetrafluoropropene and articles and uses thereof

InactiveUS20130089671A1Improve and facilitate bonding of coatingGood adhesionConductive materialPretreated surfacesOrganic chemistryMonomer

The present invention generally relates to a novel polymeric material formed, at least in part, from monomeric material comprising 2,3,3,3-tetrafluoropropene (CF3CF═CH2, 1234yf), to polymeric compositions, to coating compositions, and to uses thereof.

Owner:HONEYWELL INT INC

Composition for anti-glaring film

InactiveCN102676004AEasy to control diameterRoughness is easy to controlPolycarbonate coatingsInorganic particleDisplay device

The invention relates to a composition for an anti-glaring film. The composition comprises an inorganic particle with the average surface roughness being 0.01-3 mu m, an adhesive resin and solvent. The inorganic particle can be synthesized in one step by using material monomers or prepared by self-assembling inorganic particles with small particle size, wherein the surface roughness can be easily controlled. The anti-glaring film prepared from the composition has a stable anti-glaring effect and favorable image definition, and can be applied in the fields of flat panel displays, glass curtain walls and car lights with high resolution.

Owner:上海西源新能源技术有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com