Polyaniline composite antibacterial plastic as well as preparation method and application thereof

A composite antibacterial and composite plastic technology, applied in the direction of polyamide coatings, botanical equipment and methods, applications, etc., to reduce application costs, reduce usage, and improve performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

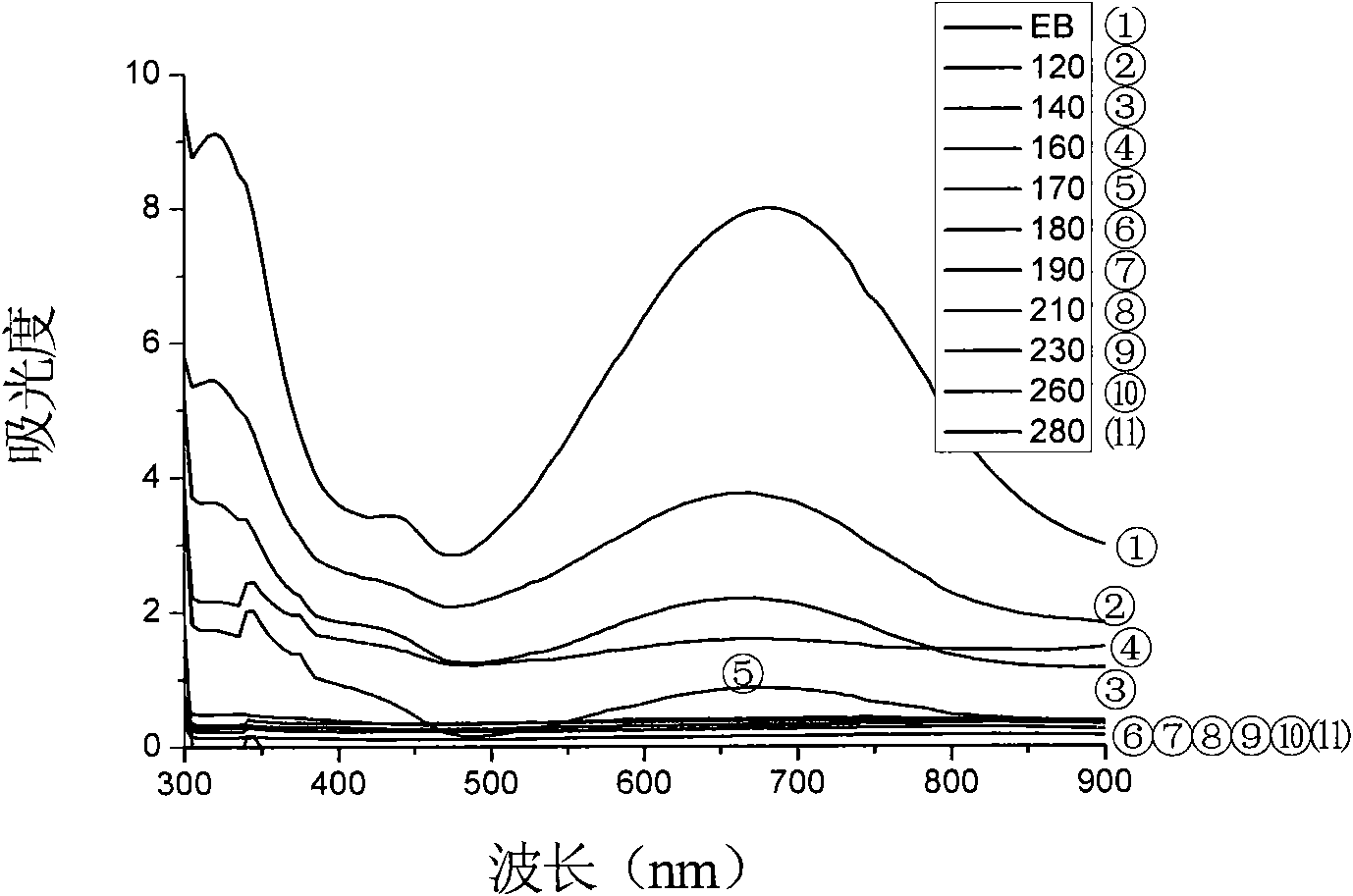

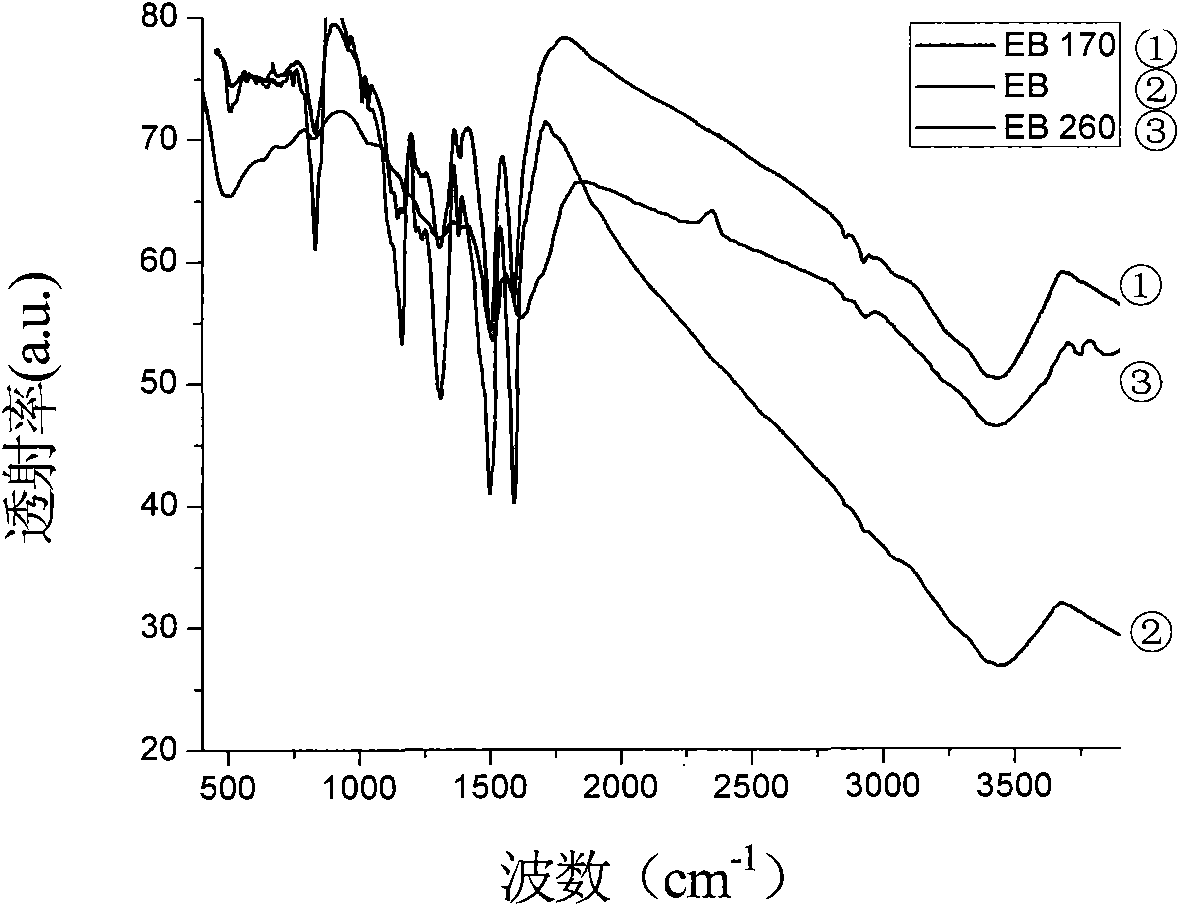

[0047] Add 18 liters of tap water in the reactor, drop into 500 grams of aniline, stir for 1 hour, obtain aniline aqueous solution; Add 1 liter of water in the reactor of 2 liters again, add the concentrated hydrochloric acid (concentration 37%wt) of 500 milliliters slowly again, prepare into hydrochloric acid aqueous solution. Then slowly pour the hydrochloric acid solution into the above aniline aqueous solution, and stir the reaction solution for 1 hour. 1225 grams of ammonium persulfate was added into 3 liters of water to form an aqueous solution, and then added dropwise to the reaction solution for about 2 hours. After 24 hours of reaction, polyaniline doped with hydrochloric acid was suspended in the reaction liquid, and the pH value of the reaction liquid was adjusted to 8-9 with an alkaline aqueous solution made of about 500-700 grams of sodium hydroxide, etc., and continued to stir for 24 hours to remove Doping, filtering, and washing with water to remove residual in...

Embodiment 2

[0051] 15 grams of embodiment 1 intrinsic state polyaniline and 485 grams of low density polyethylene masterbatch (density is 0.910~0.926 / cm 3 , particle size is 3mm), with a blender at 130-150 ° C under the melt mechanical mixing, then pulverized to make polyaniline PE (polyethylene) masterbatch, tablet molding to make antibacterial test pieces. According to the Japanese National Standard JISZ 2801: 2000 Detection and evaluation of antibacterial properties of antibacterial products to test the antibacterial effect of polyaniline plastic film. The antibacterial performance test results of the composite material show that the antibacterial rate against Escherichia coli, Staphylococcus aureus and Candida albicans reaches 99%.

[0052] The mechanical performance test results of the composite material show that it maintains the mechanical performance of the matrix polymer material.

Embodiment 3

[0054] 15 grams of embodiment 1 intrinsic state polyaniline and 485 grams of polypropylene masterbatches (particle size is 3mm), carry out melting mechanical mixing at 200-220 ℃ with the blender first, then pulverize and make polyaniline PP (polypropylene ) masterbatch, tablet molding to make antibacterial test pieces. The antibacterial performance test results of the composite material show that it has no antibacterial effect on Escherichia coli, Staphylococcus aureus and Candida albicans.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Surface resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com