Polycarbonate-based wear-resistant superhydrophobic coating preparation method

A super-hydrophobic coating, polycarbonate technology, applied in the direction of polycarbonate coatings, coatings, pigmented coatings, etc., can solve the problems of poor wear resistance of super-hydrophobic surfaces, can not be applied under high pressure, etc., to achieve excellent durability Abrasiveness, low cost, and strong wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A method for preparing a wear-resistant superhydrophobic coating based on polycarbonate, carried out according to the following steps:

[0027] (1) 20wt% polycarbonate and 0.2wt% defoamer (BYK 320) were dissolved in tetrahydrofuran to prepare a solution for the middle layer.

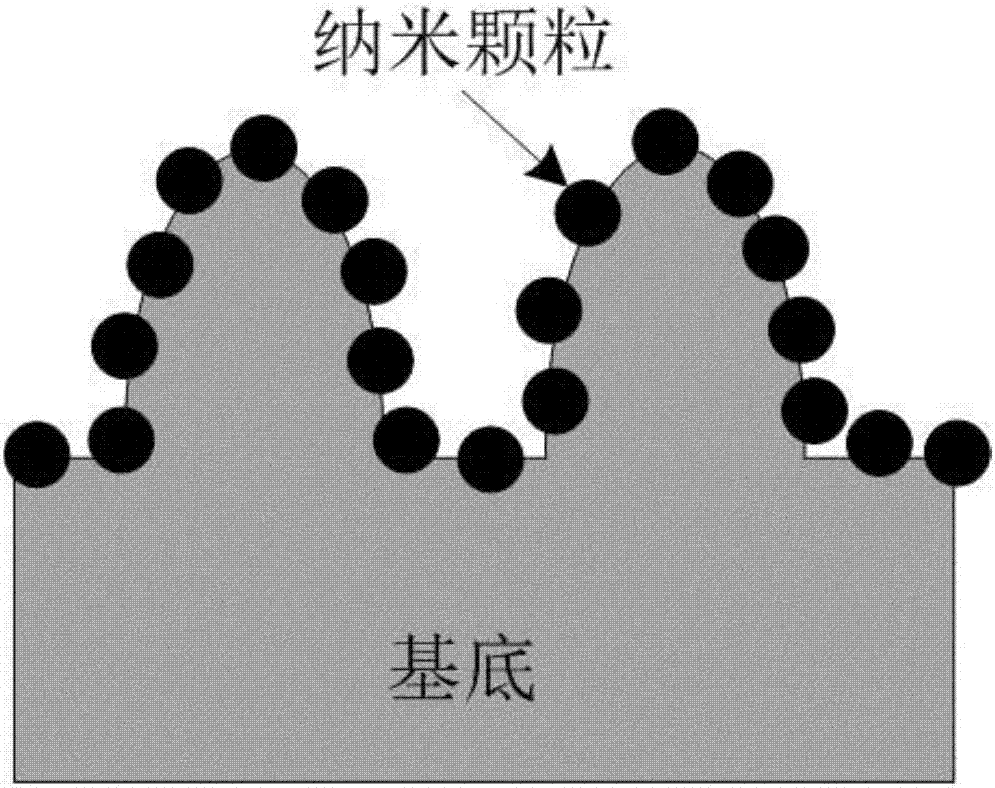

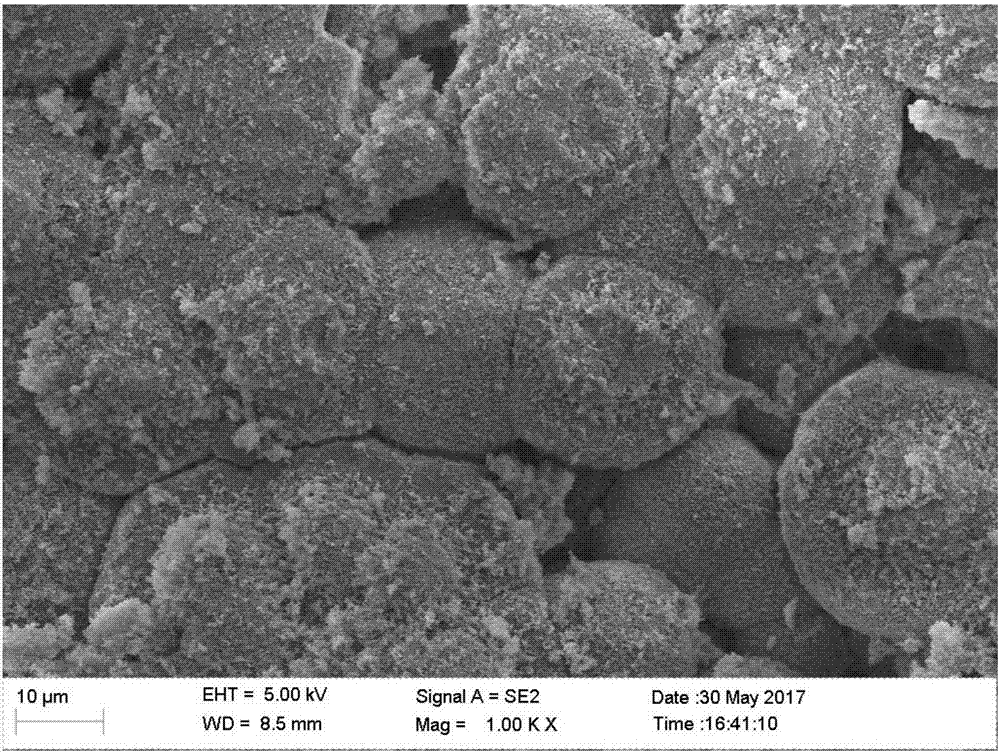

[0028] (2) Put 1wt% fatty acid and 1wt% trimethylchlorosilane into acetone, stir magnetically for 12 hours, and set the reaction temperature at 50° to fully dissolve it; then add 4wt% silicon dioxide nanoparticles into the acetone solution Fully mix to make a solution for the surface layer for subsequent use;

[0029] (3) Coating commercially available polycarbonate glue on the substrate, and waiting for 3 minutes to obtain an adhesive layer.

[0030] (4) Coat the solution for the middle layer on the adhesive layer and wait for 2 hours to allow the solvent to fully evaporate to obtain the middle layer bonded by polycarbonate glue.

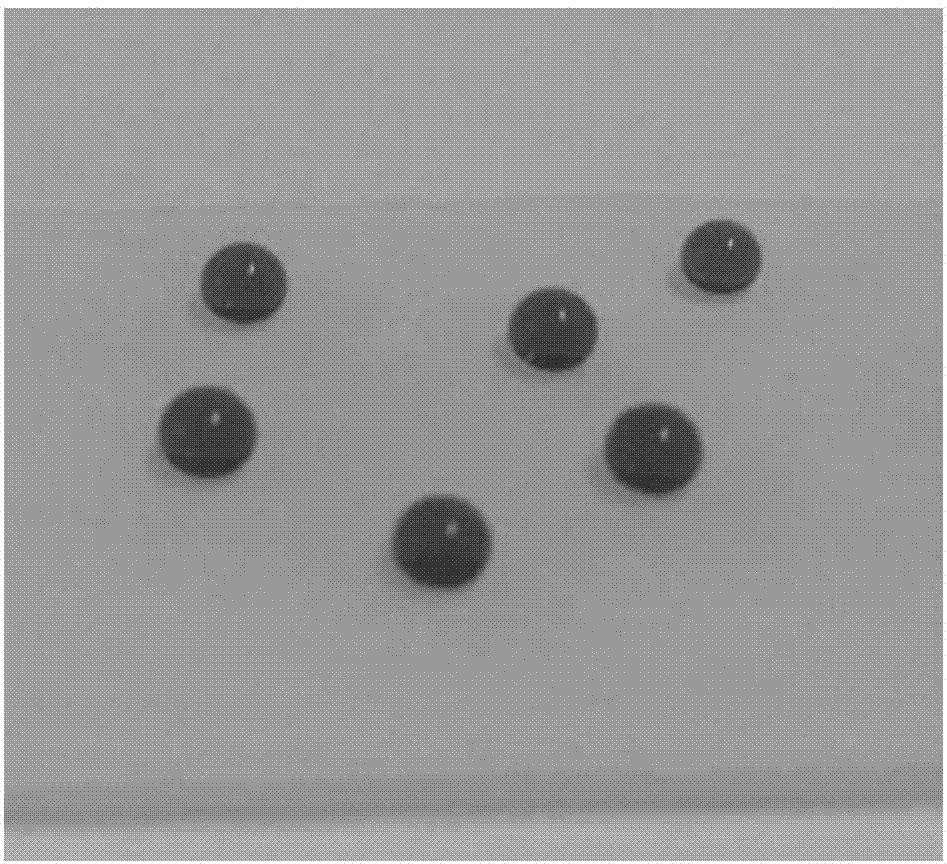

[0031] (5) Coat the solution for the surface layer on the middl...

Embodiment 2

[0034] A method for preparing a wear-resistant superhydrophobic coating based on polycarbonate, carried out according to the following steps:

[0035] (1) Dissolving 30wt% polycarbonate and 0.3wt% defoamer (BYK 320) in toluene to prepare a solution for the middle layer;

[0036] (2) Put 2wt% hexadecyltrimethoxysilane into acetone, stir magnetically for 12 hours, set the reaction temperature to make it fully dissolve; then add 5wt% titanium dioxide nanoparticles into the acetone solution and mix well to make a surface Layer with solution for standby;

[0037] (3) Coating commercially available polycarbonate glue on the substrate, and waiting for 3 minutes to obtain an adhesive layer.

[0038] (4) Apply the solution for the intermediate layer on the adhesive layer, and wait for 1 hour to allow the solvent to fully evaporate to obtain an intermediate layer bonded by polycarbonate glue.

[0039] (5) Apply the solution for the surface layer on the middle layer, wait for 3 hours, ...

Embodiment 3

[0041] A method for preparing a wear-resistant superhydrophobic coating based on polycarbonate, carried out according to the following steps:

[0042] (1) Dissolving 25wt% polycarbonate and 0.15wt% defoamer (BYK 320) in benzene to prepare a solution for the middle layer;

[0043] (2) Put 3wt% hexamethyldisilane into acetone, stir magnetically for 12 hours, set the reaction temperature to make it fully dissolved; then add 6wt% zinc oxide nanoparticles into the acetone solution and mix well to make the surface layer The solution is ready for use;

[0044] (3) Coating commercially available polycarbonate glue on the substrate, and waiting for 3 minutes to obtain an adhesive layer.

[0045] (4) Coat the solution for the middle layer on the adhesive layer and wait for 2 hours to allow the solvent to fully evaporate to obtain the middle layer bonded by polycarbonate glue.

[0046](5) Coat the surface layer solution on the middle layer, wait for 3 hours, and after the acetone in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com