Patents

Literature

33results about How to "Roughness is easy to control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

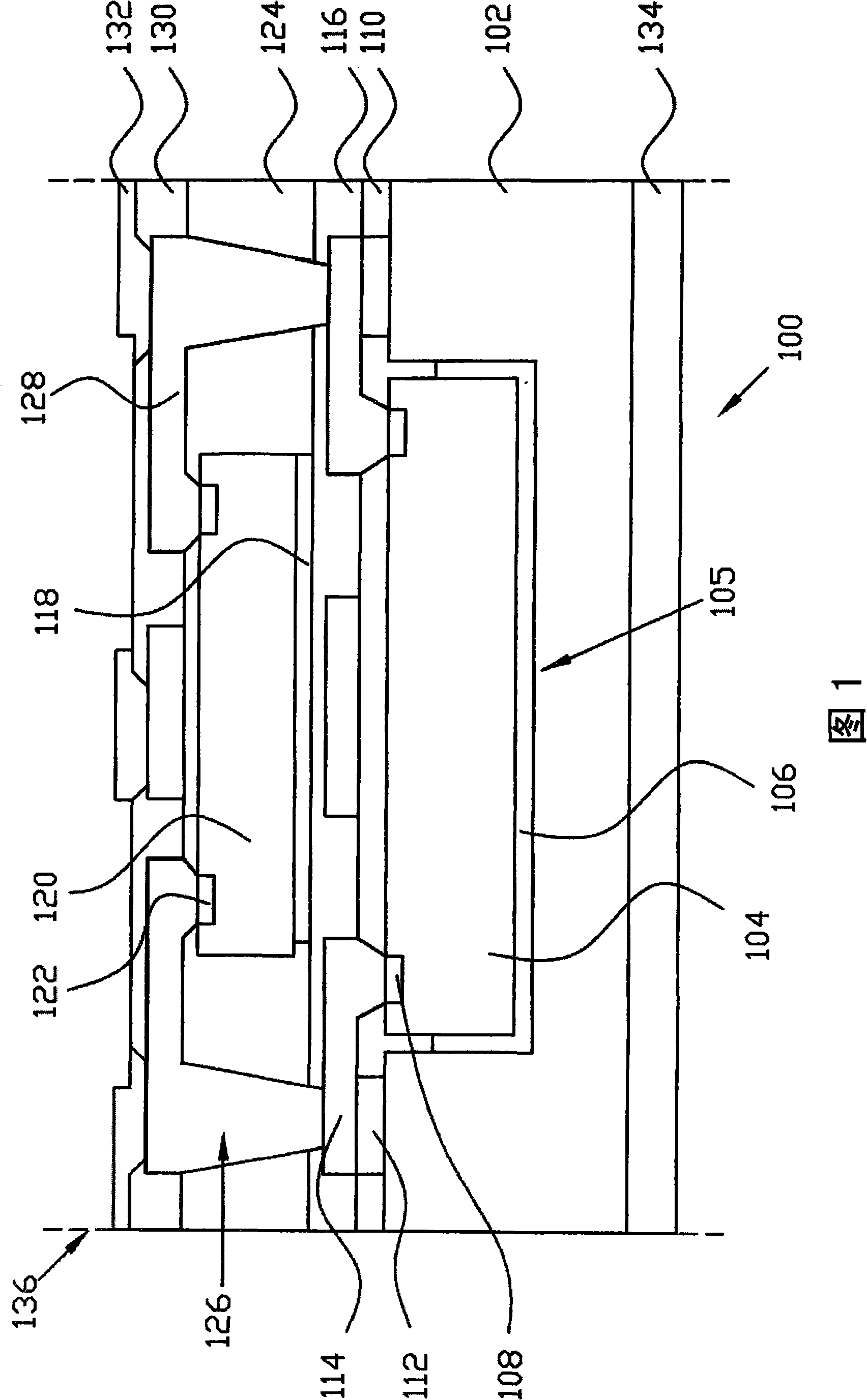

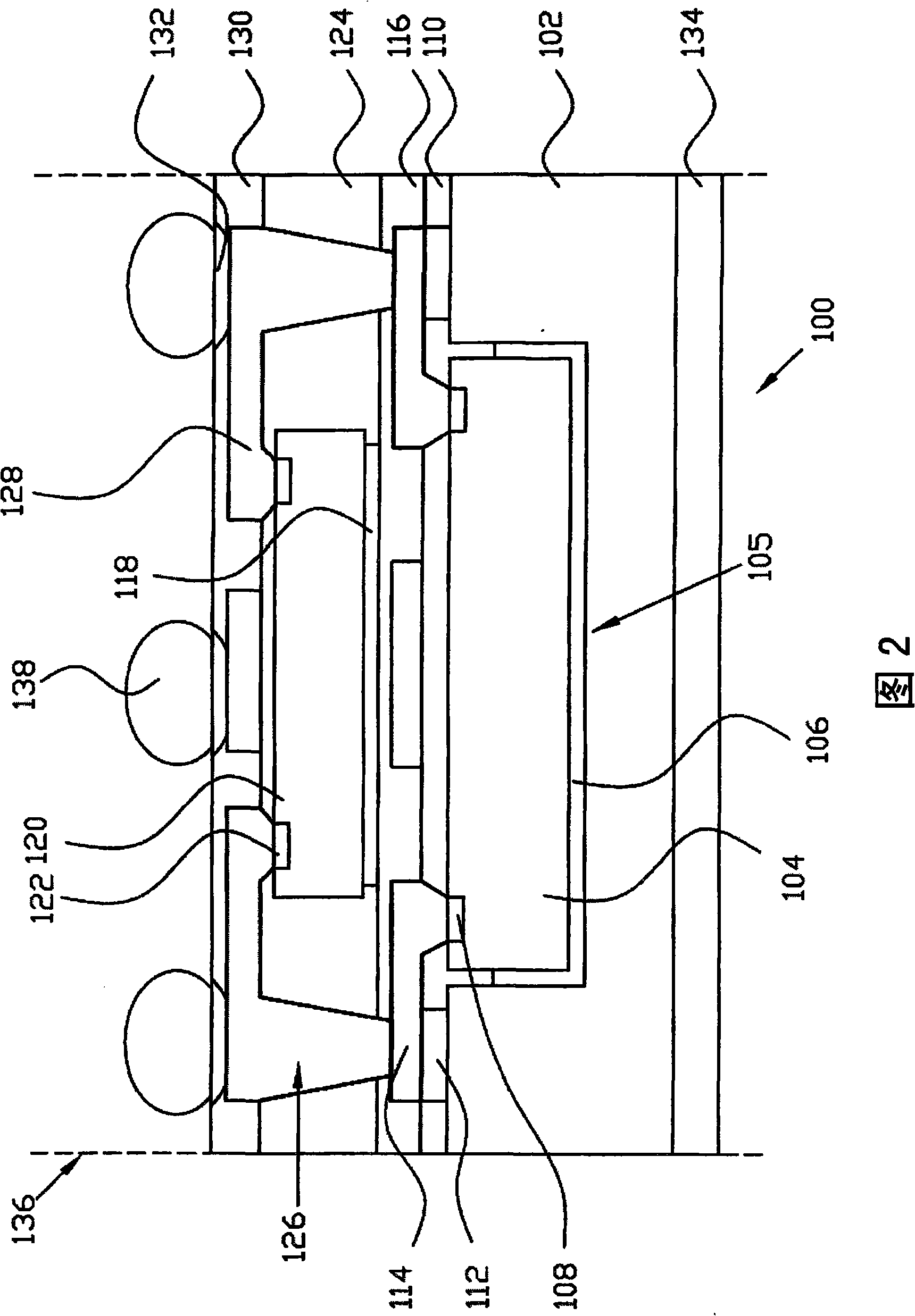

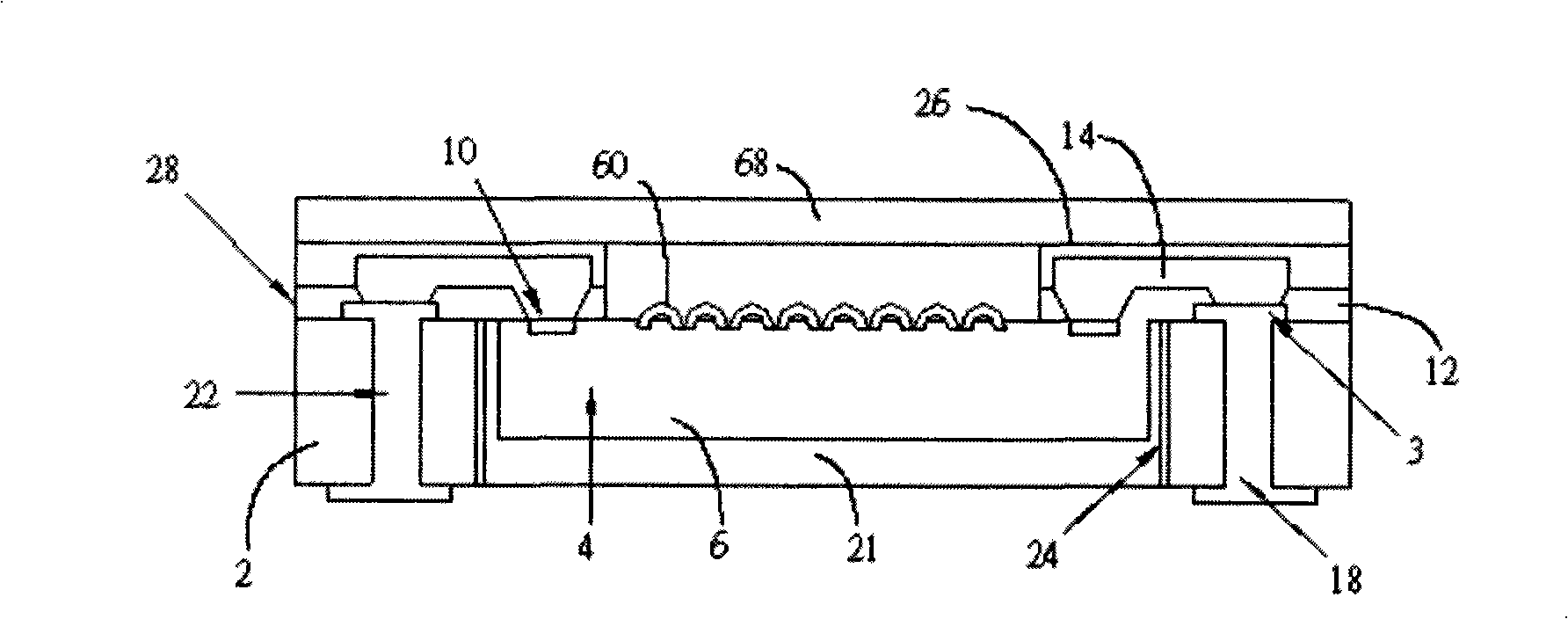

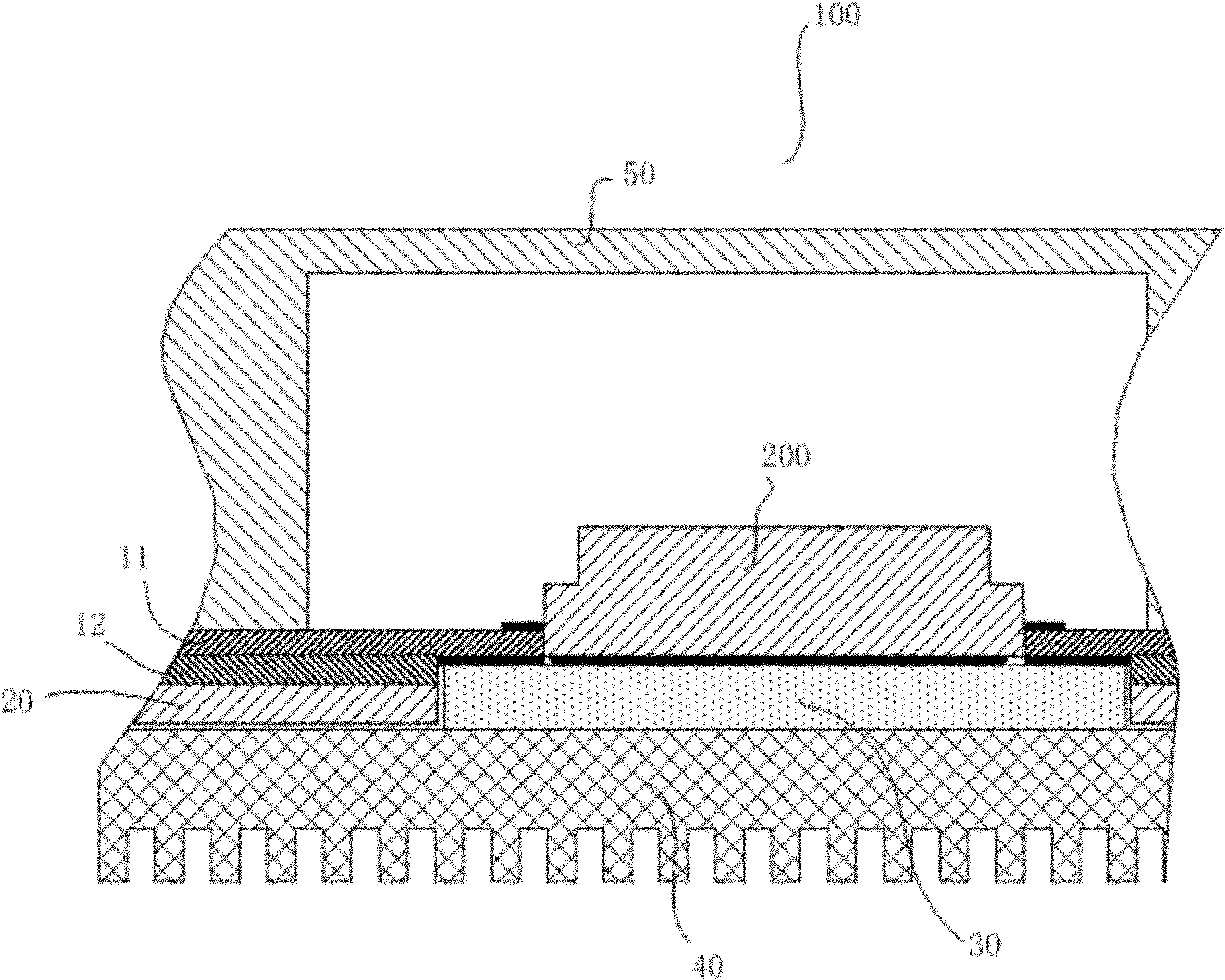

Structure of semiconductor device package and the method of the same

InactiveCN101261984ARoughness is easy to controlThickness is easy to controlSemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageEngineering

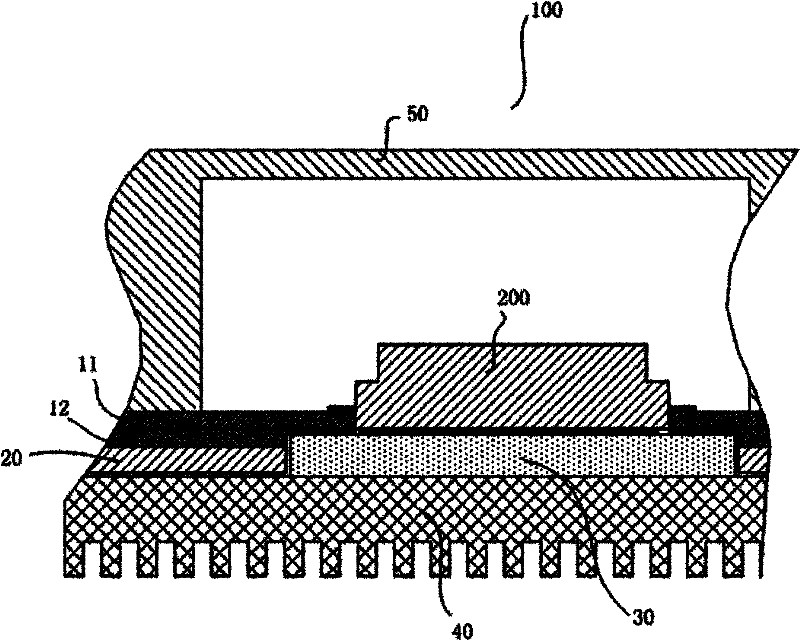

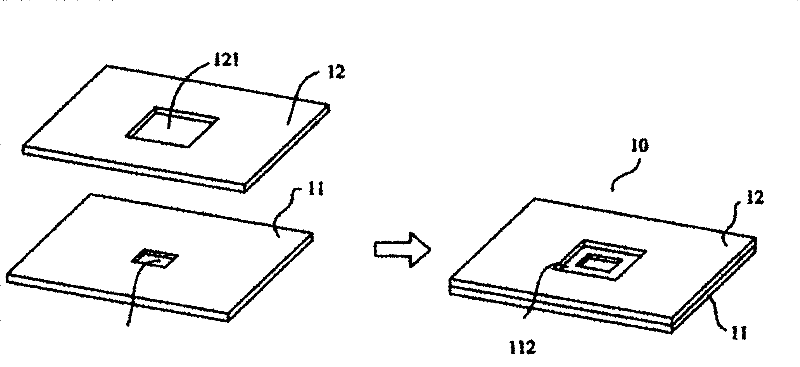

The present invention provides a semiconductor device package comprising a substrate with at lease a pre-formed die receiving cavity formed and terminal contact metal pads formed within an upper surface of the substrate. At lease a first die is disposed within the die receiving cavity. A first dielectric layer is formed on the first die and the substrate and refilled into a gap between the first die and the substrate to absorb thermal mechanical stress there between. A first re-distribution layer (RDL) is formed on the first dielectric layer and coupled to the first die. A second dielectric layer is formed on the first RDL, and then a second die is disposed on the second dielectric layer and surrounded by core pastes having through holes thereon. A second re-distribution layer (RDL) is formed on the core pastes to fill the through holes, and then a third dielectric layer formed on the second RDL.

Owner:ADVANCED CHIP ENG TECH INC

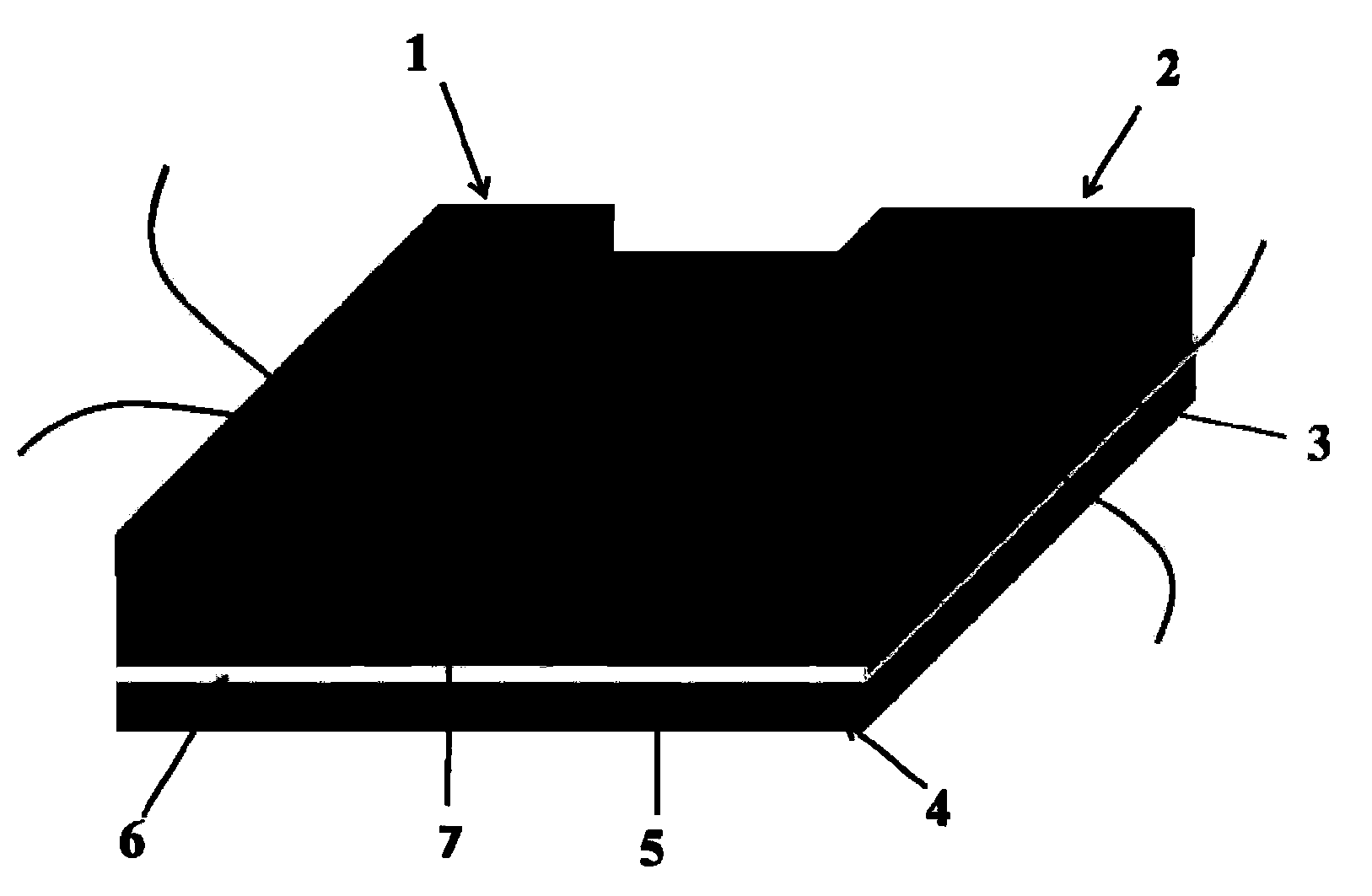

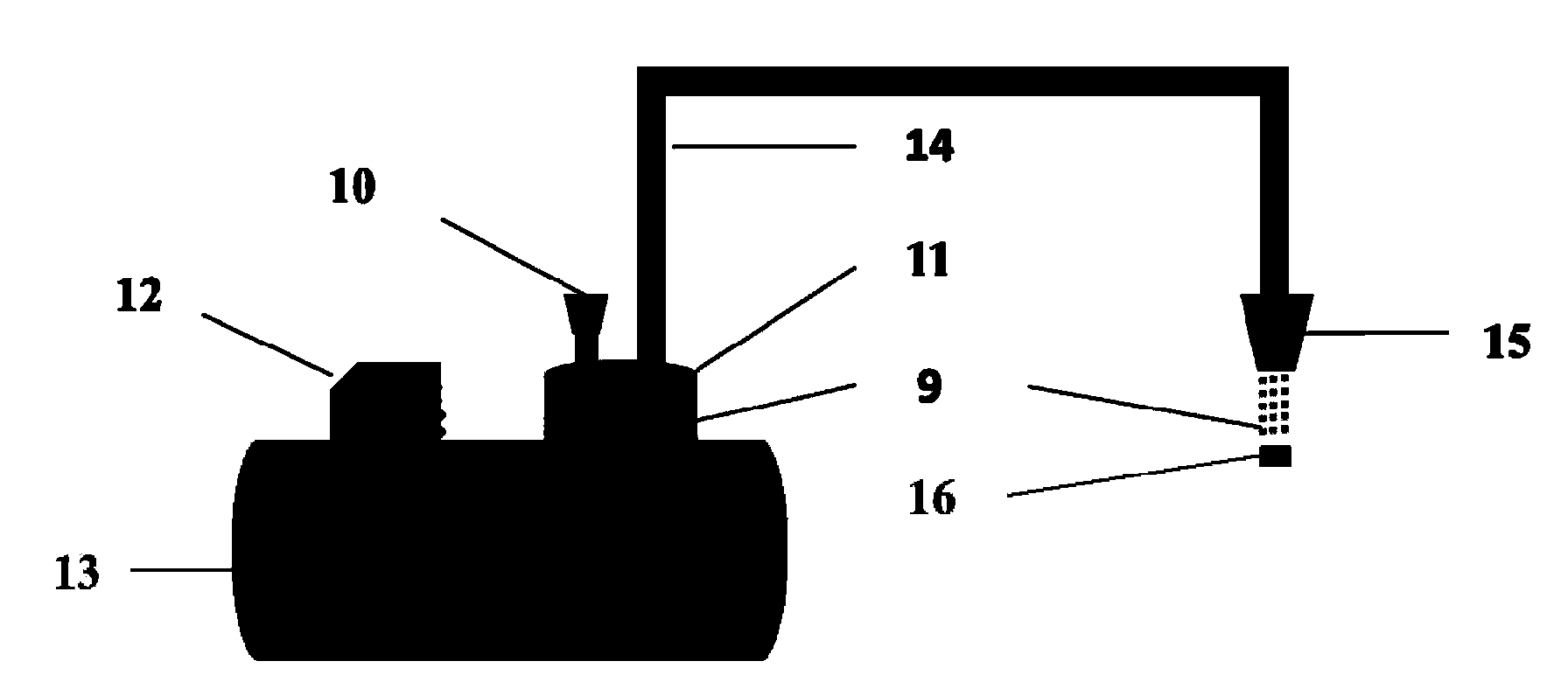

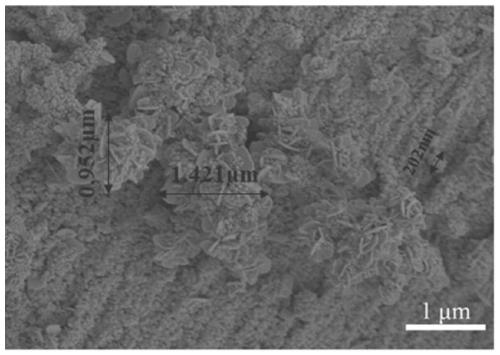

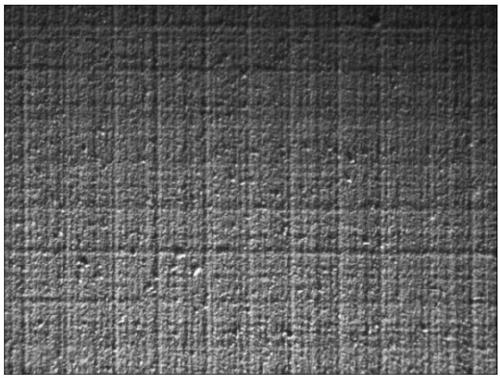

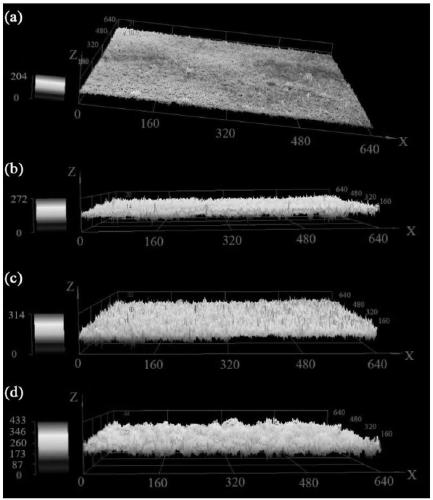

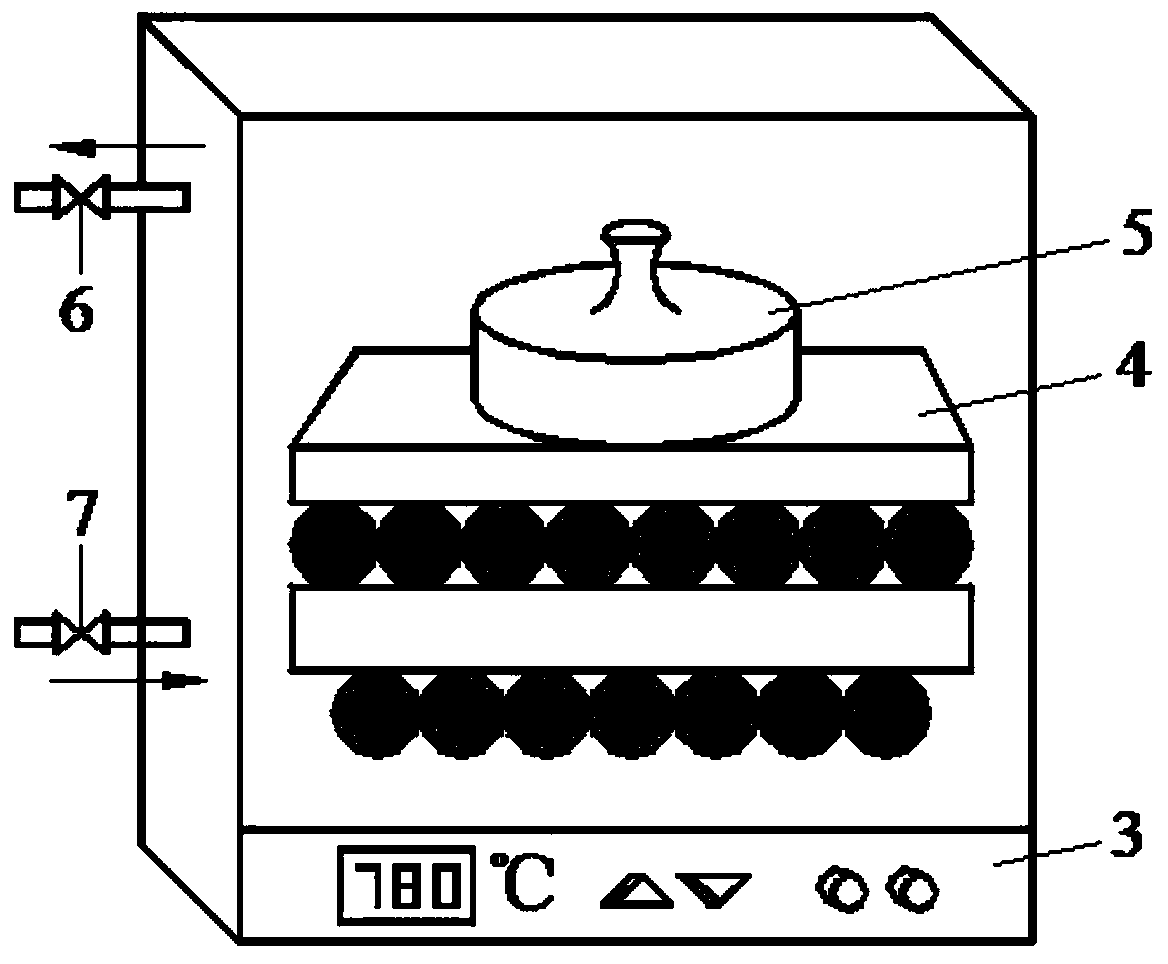

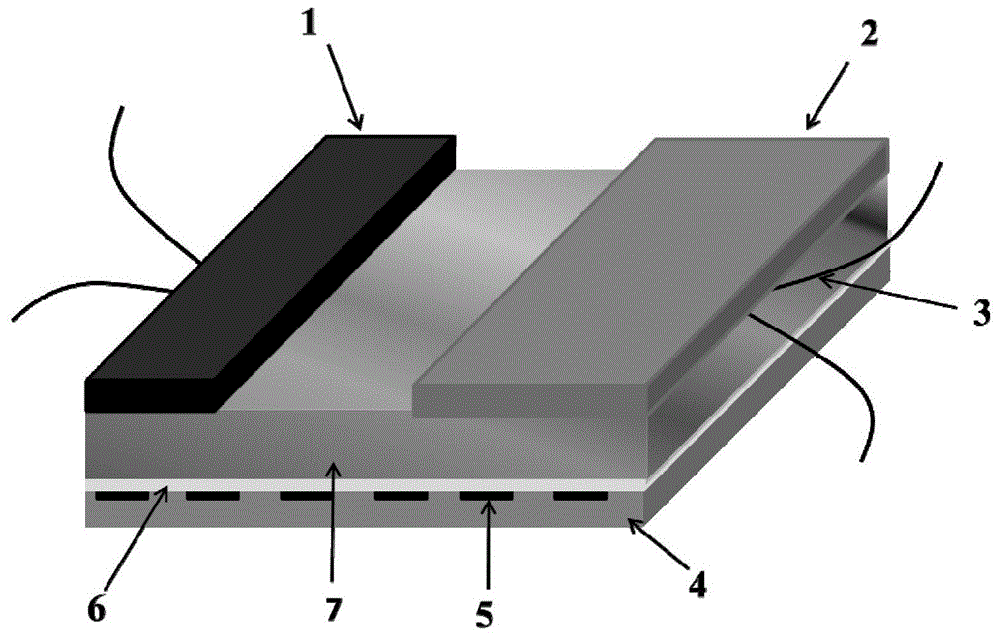

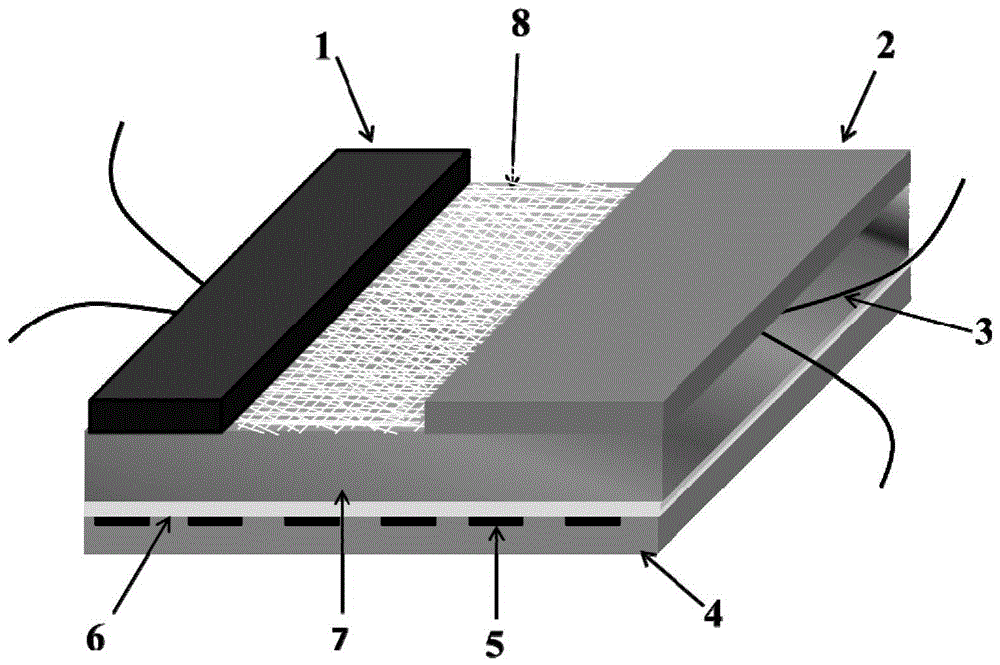

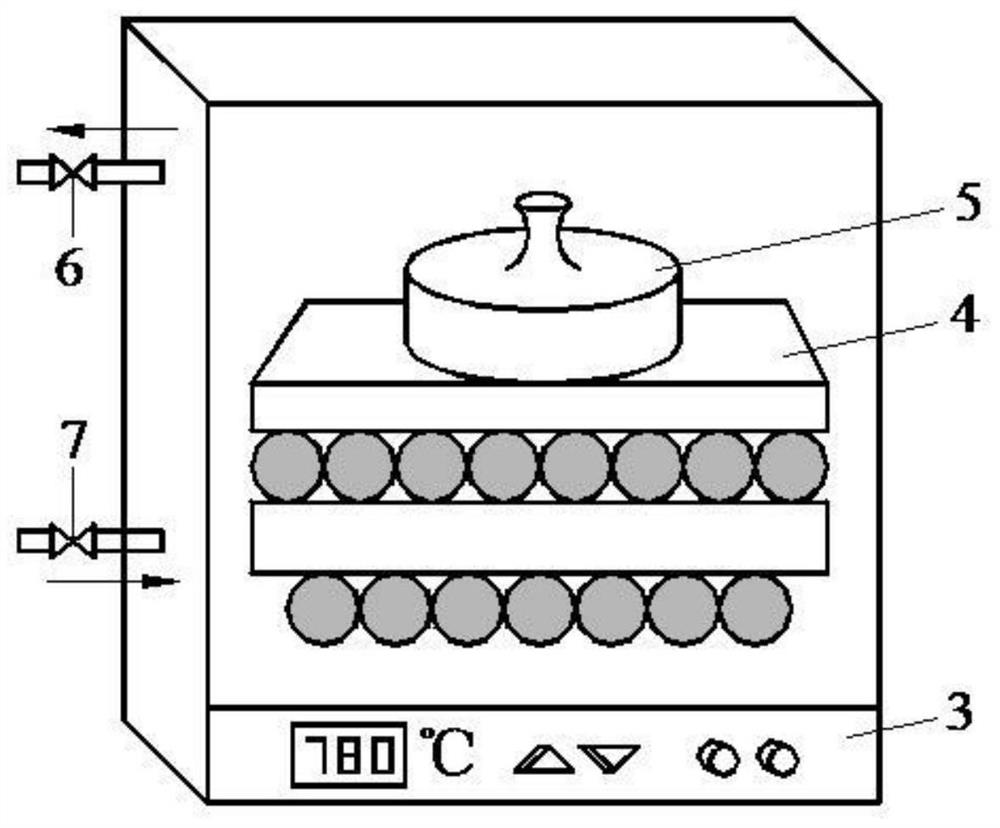

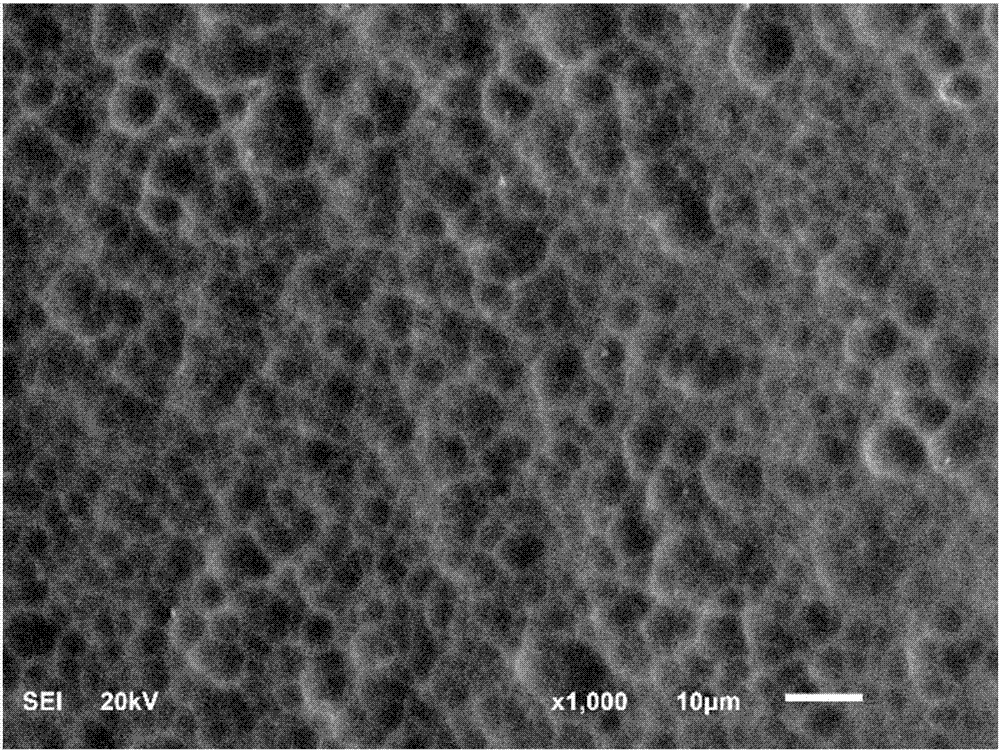

Mixing potential NO2 sensor based on sand-blast machining porous YSZ (Yttria Stabilized Zirconia) base plate and preparation method of sensor

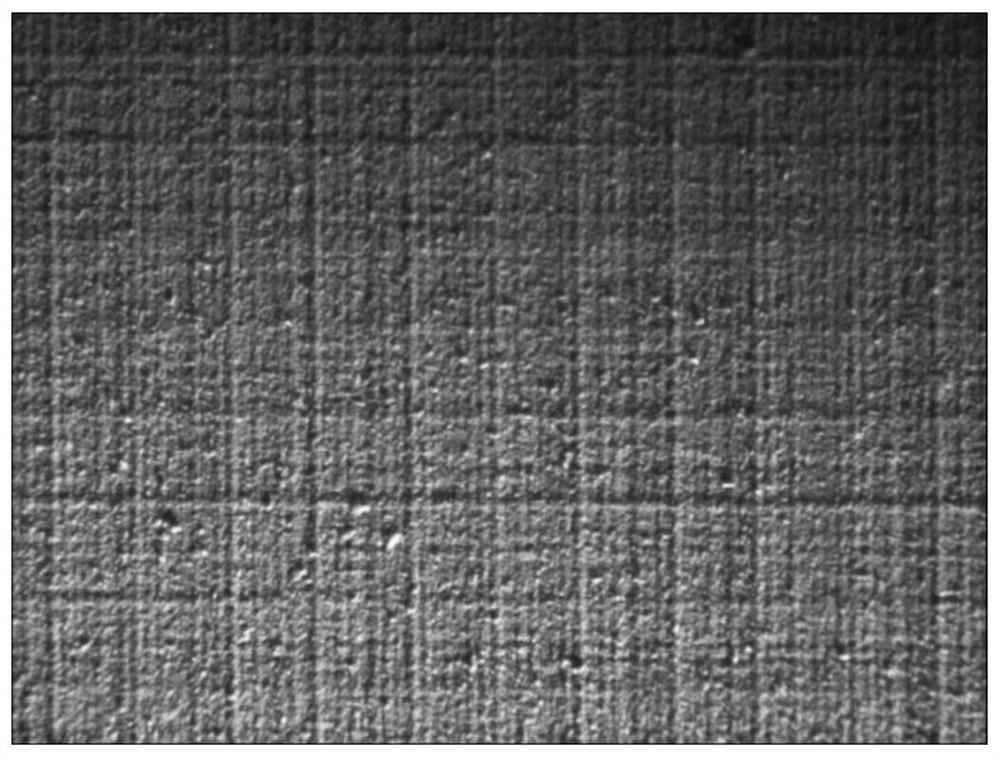

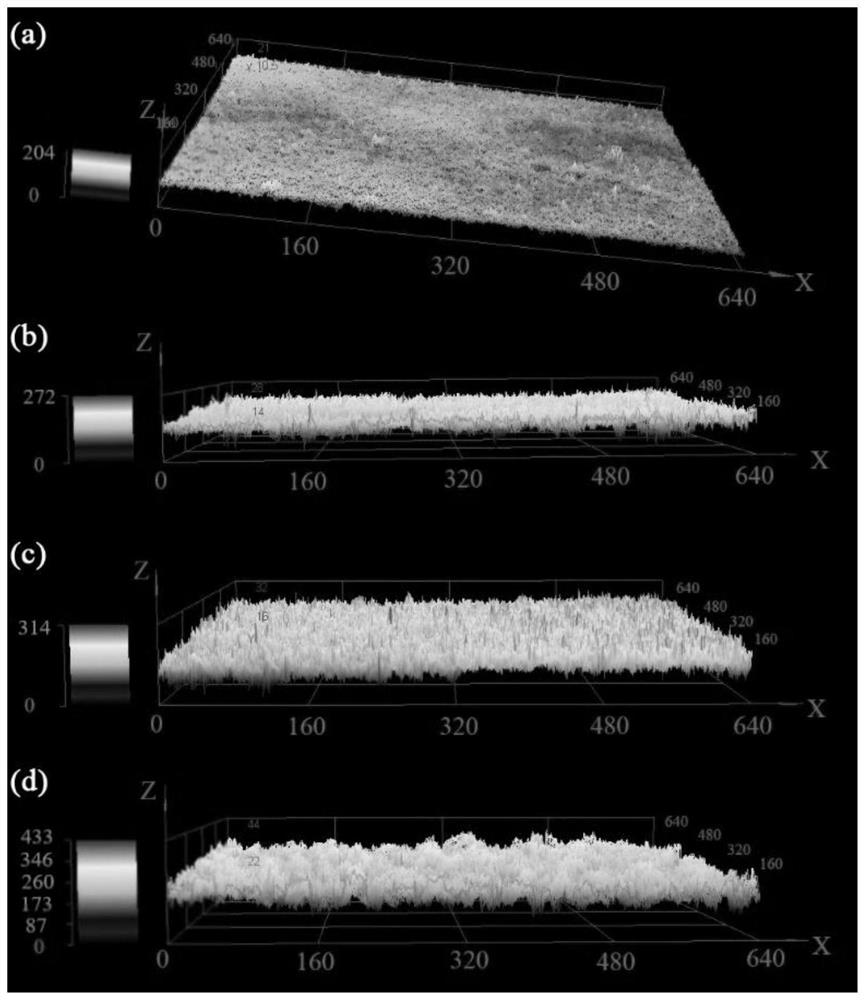

ActiveCN103954665AImprove thermal stabilityGood chemical stabilityMaterial electrochemical variablesAbrasive blastingRough surface

The invention relates to a mixing potential NO2 sensor based on sand-blast machining type porous YSZ (Yttria Stabilized Zirconia) base plate and a preparation method of the sensor, and belongs to the technical field of gas sensors. The mixing potential NO2 sensor is mainly used for detecting automobile tail gas exhaust and sequentially comprises an Al2O3 ceramic plate, a YSZ base plate, a reference electrode and a sensitive electrode, wherein the Al2O3 ceramic plate is provided with a Pt heating electrode; the YSZ base plate has a rough porous surface; the reference electrode is made of strip-shaped Pt; the sensitive electrode is made of strip-shaped NiO; the two electrodes are mutually discretely and symmetrically prepared on the rough surface of the YSZ base plate; the lower surface of the YSZ base plate is adhered to the Al2O3 ceramic plate together. According to the mixing potential NO2 sensor, the sand-blast machining type YSZ base plate is utilized as electrolyte, and a rough porous structure of the surface of the sand-blast machining type YSZ base plate increases the contact of gas to be tested and the electrolyte so as to increase reaction activity sites, so that the purpose of enhancing the sensitivity of the sensor is achieved.

Owner:JILIN UNIV

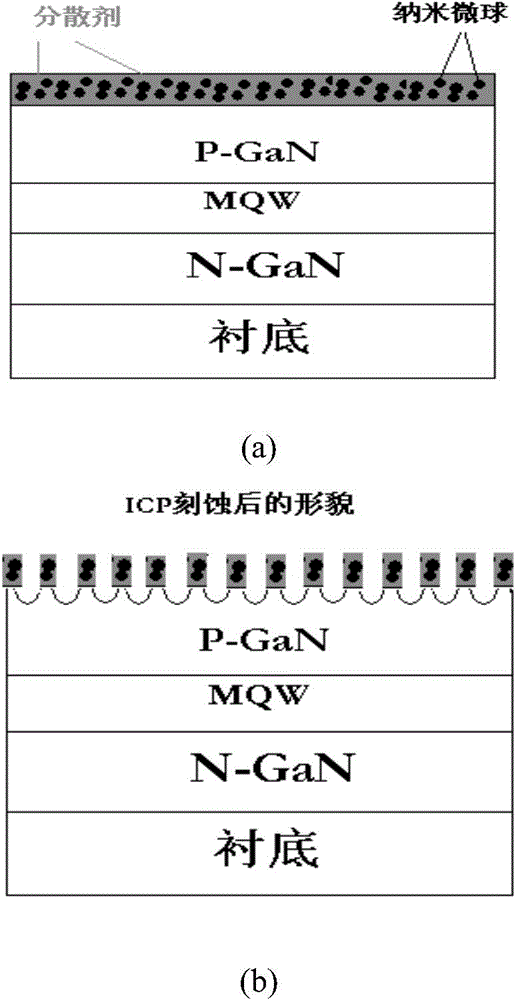

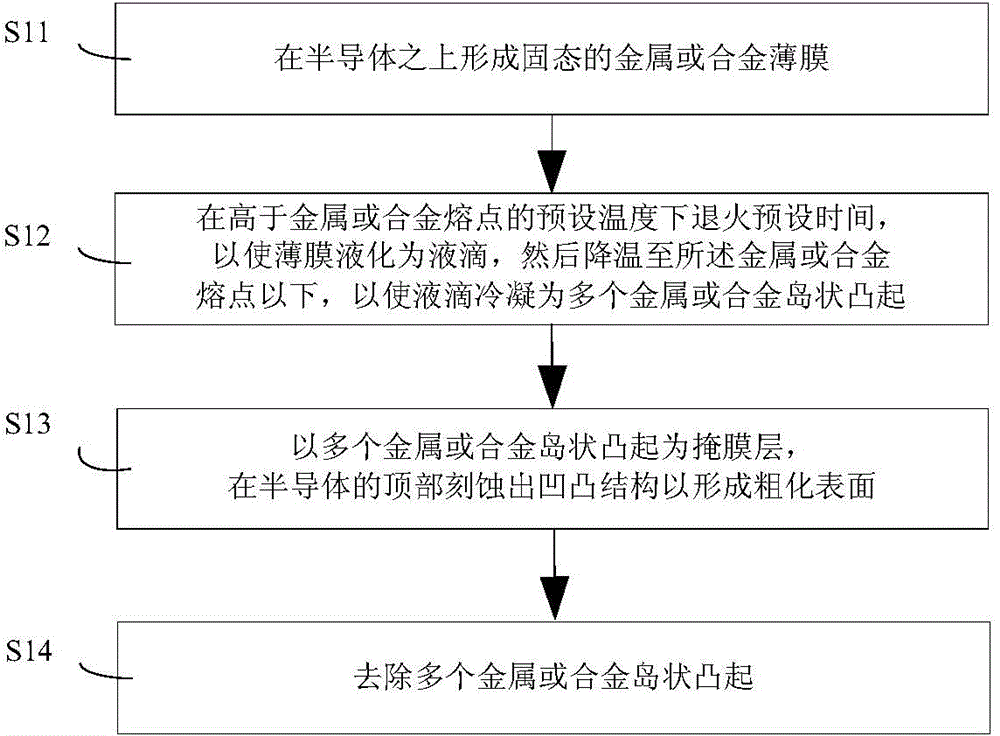

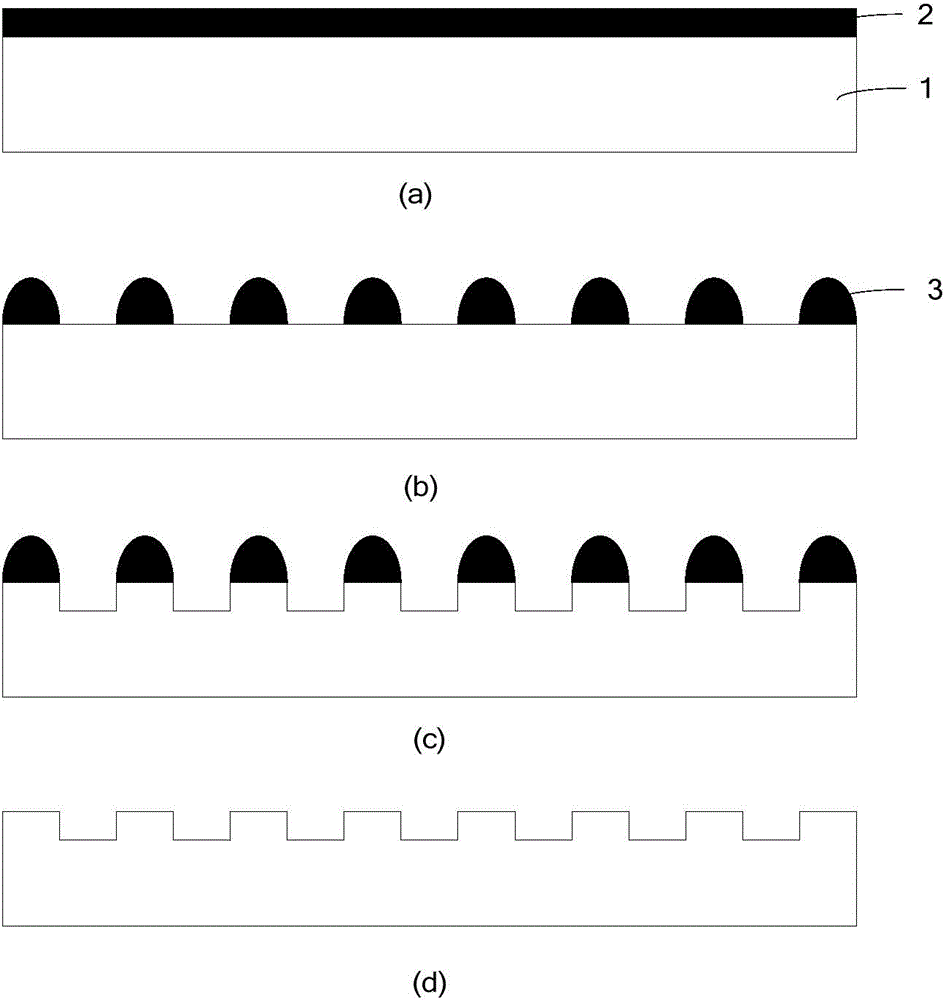

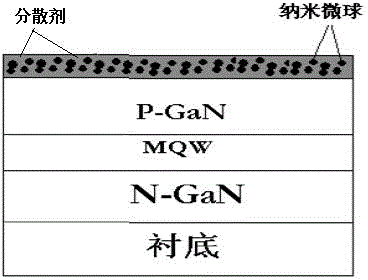

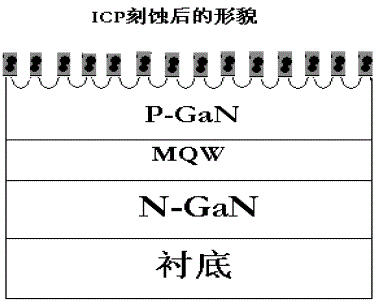

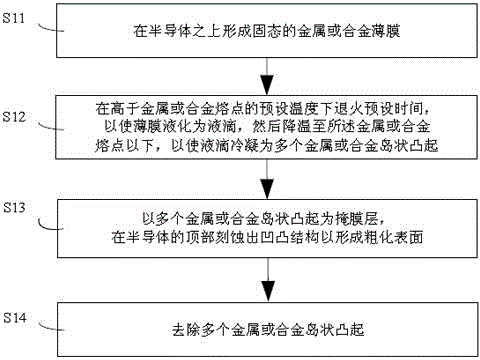

Method for roughening surface of semiconductor layer, and method for forming LED structure with roughened surface

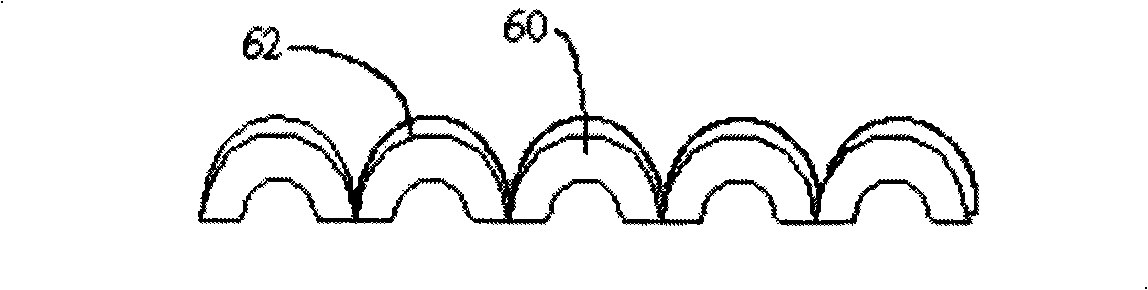

InactiveCN105097441AImprove uniformityEvenly distributedSemiconductor/solid-state device manufacturingSemiconductor devicesConvex structureSemiconductor package

The present invention puts forward a method for roughening a surface of a semiconductor layer, comprising: forming a solid metal or alloy film on a semiconductor layer; performing annealing for preset time at a preset temperature above the melting point of the metal or alloy to enable the metal or alloy film to be liquefied into a plurality of metal or alloy liquid drops, then cooling to the temperature below the melting point of the metal or alloy to enable the plurality of metal or alloy liquid drops to be condensed into a plurality of metal or alloy island-shaped projections; etching a concave-convex structure on the top surface of the semiconductor layer by taking the plurality of metal or alloy island-shaped projections as mask layers, so as to form a roughened surface; and removing the plurality of metal or alloy island-shaped projections. The method for roughening the surface of the semiconductor layer has the advantages of good uniformity, stability and reliability. The present invention also puts forward a method for forming an LED structure with a roughened surface.

Owner:BYD CO LTD

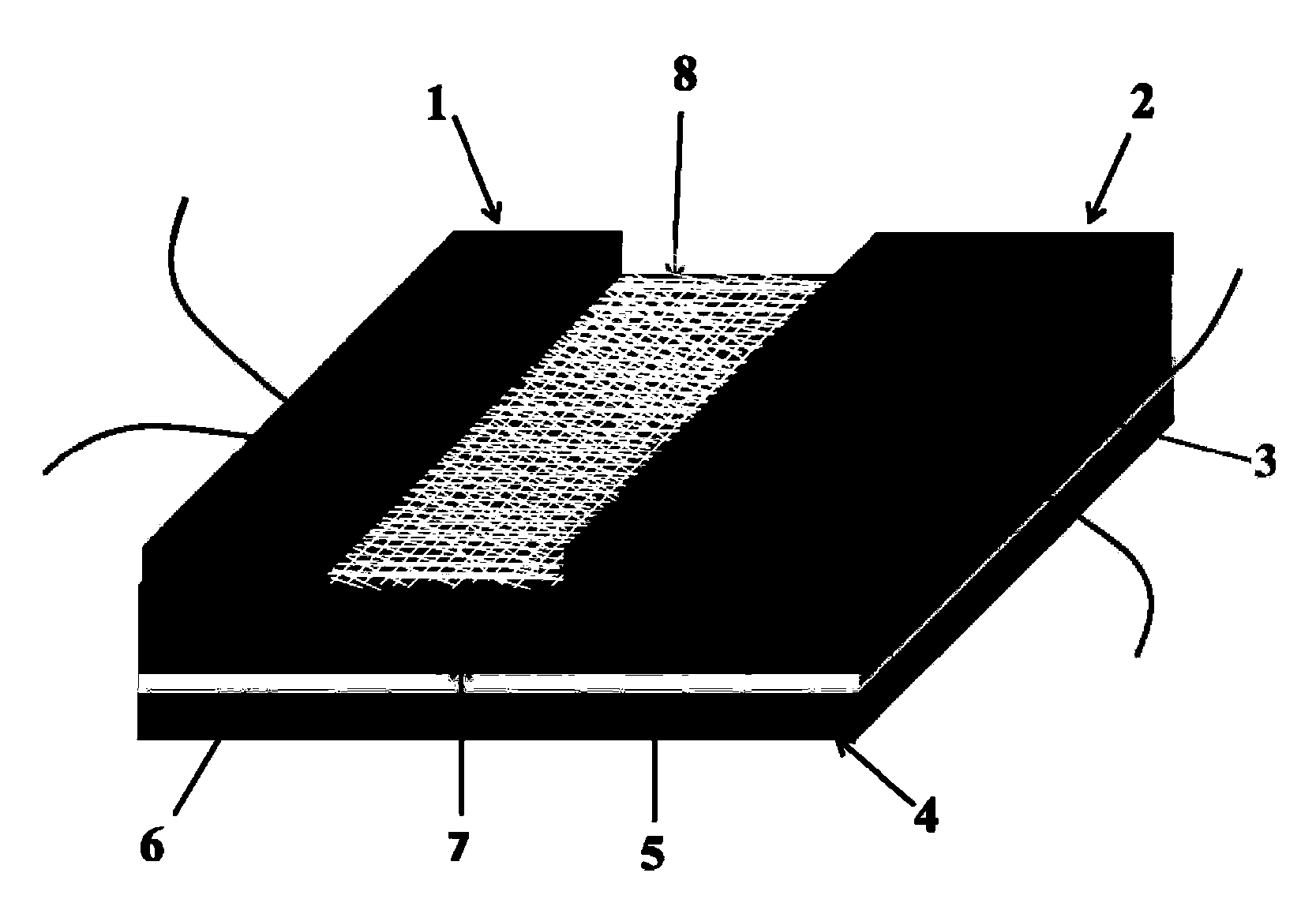

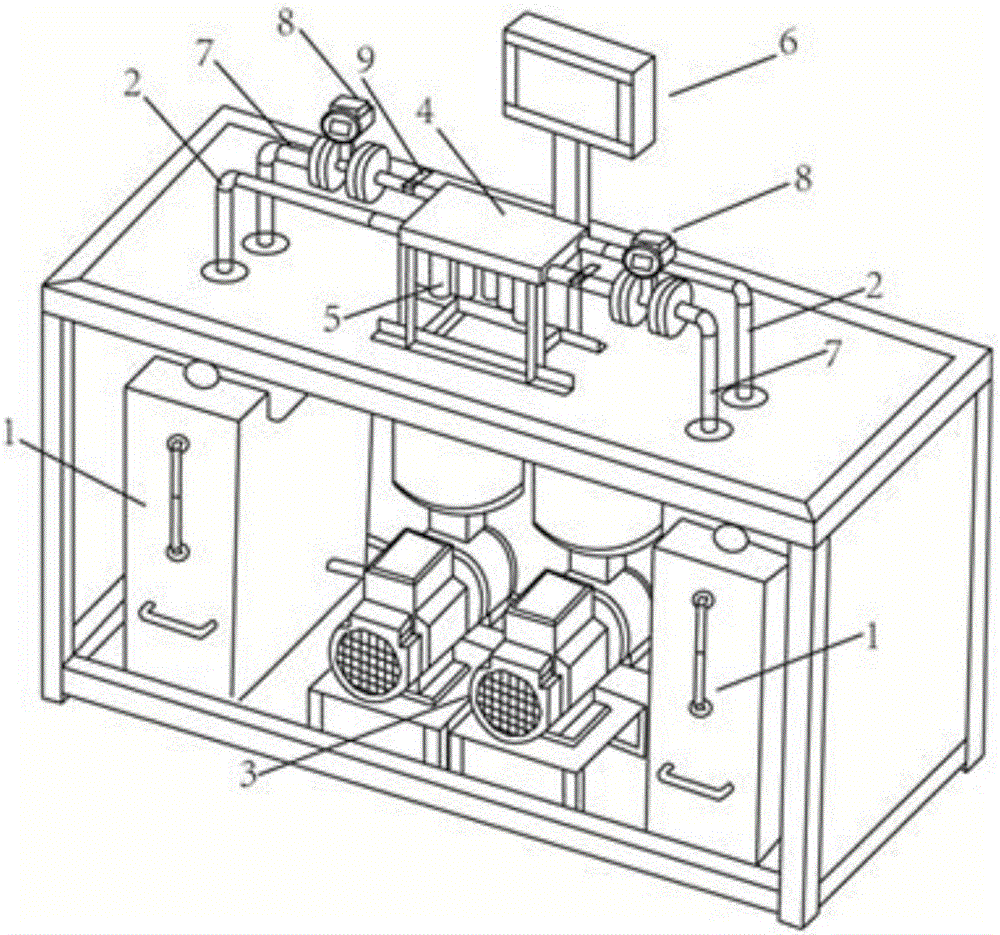

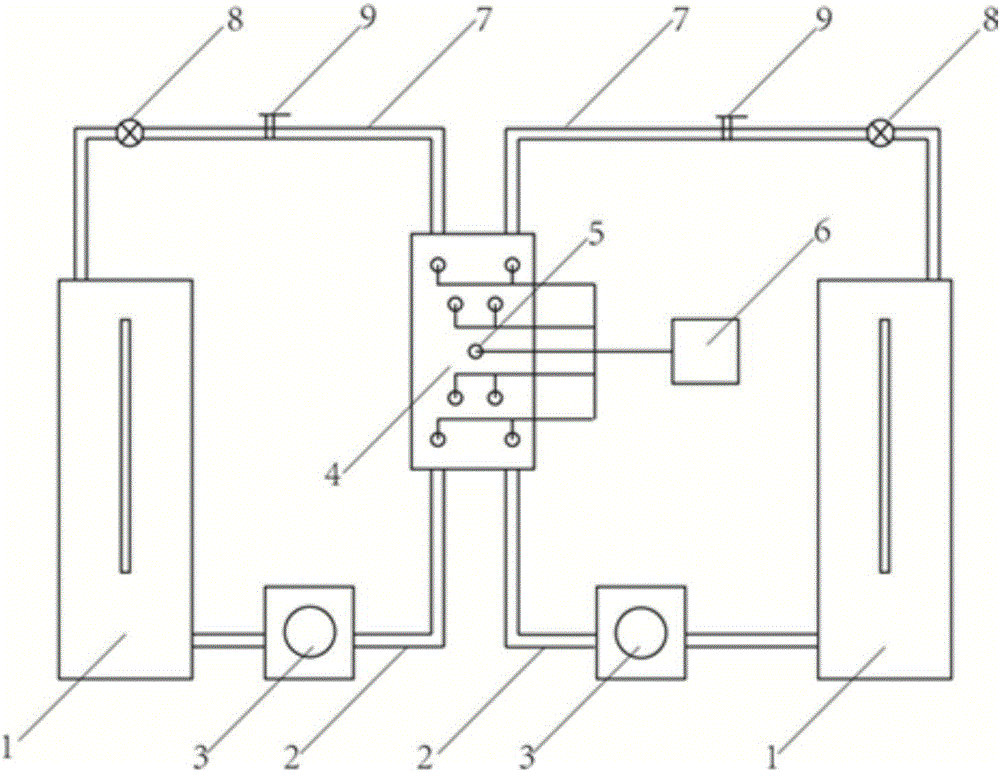

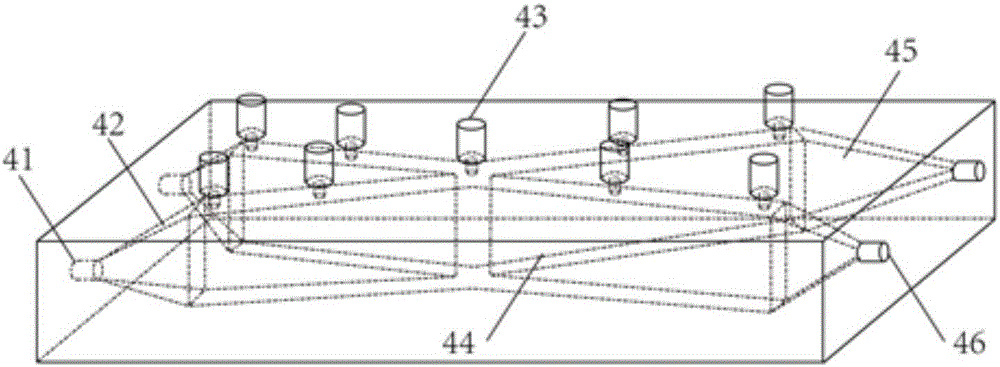

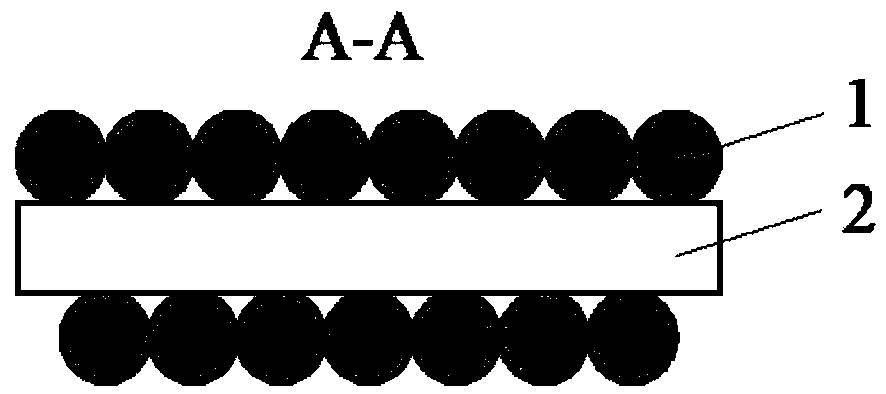

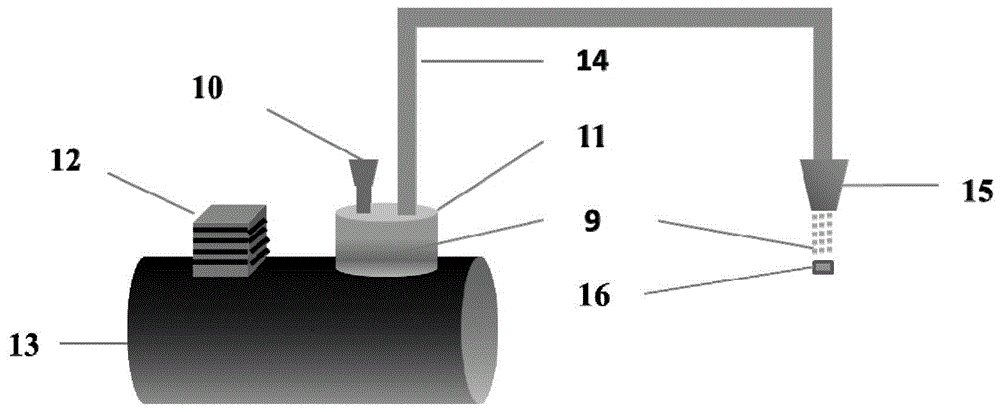

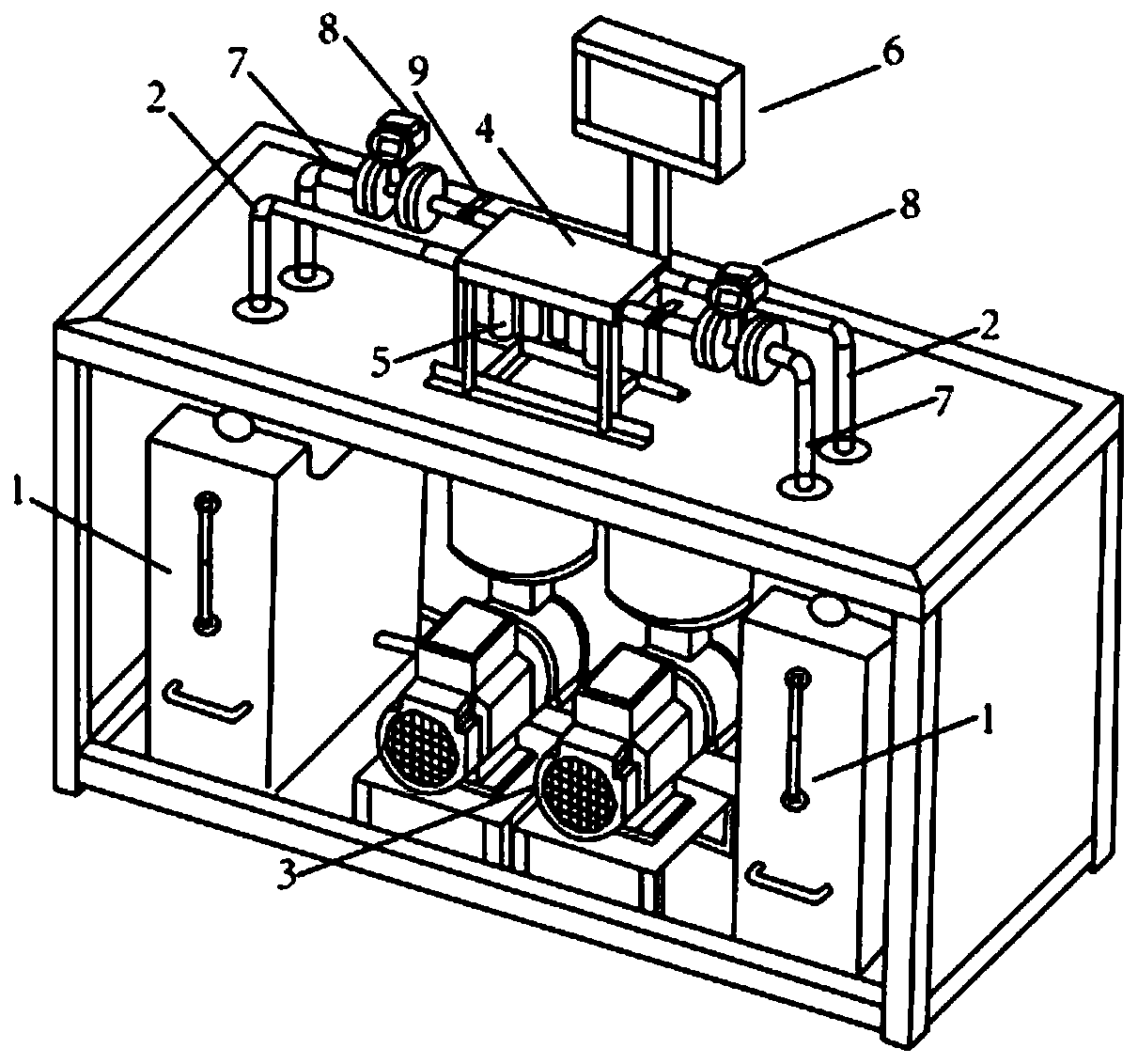

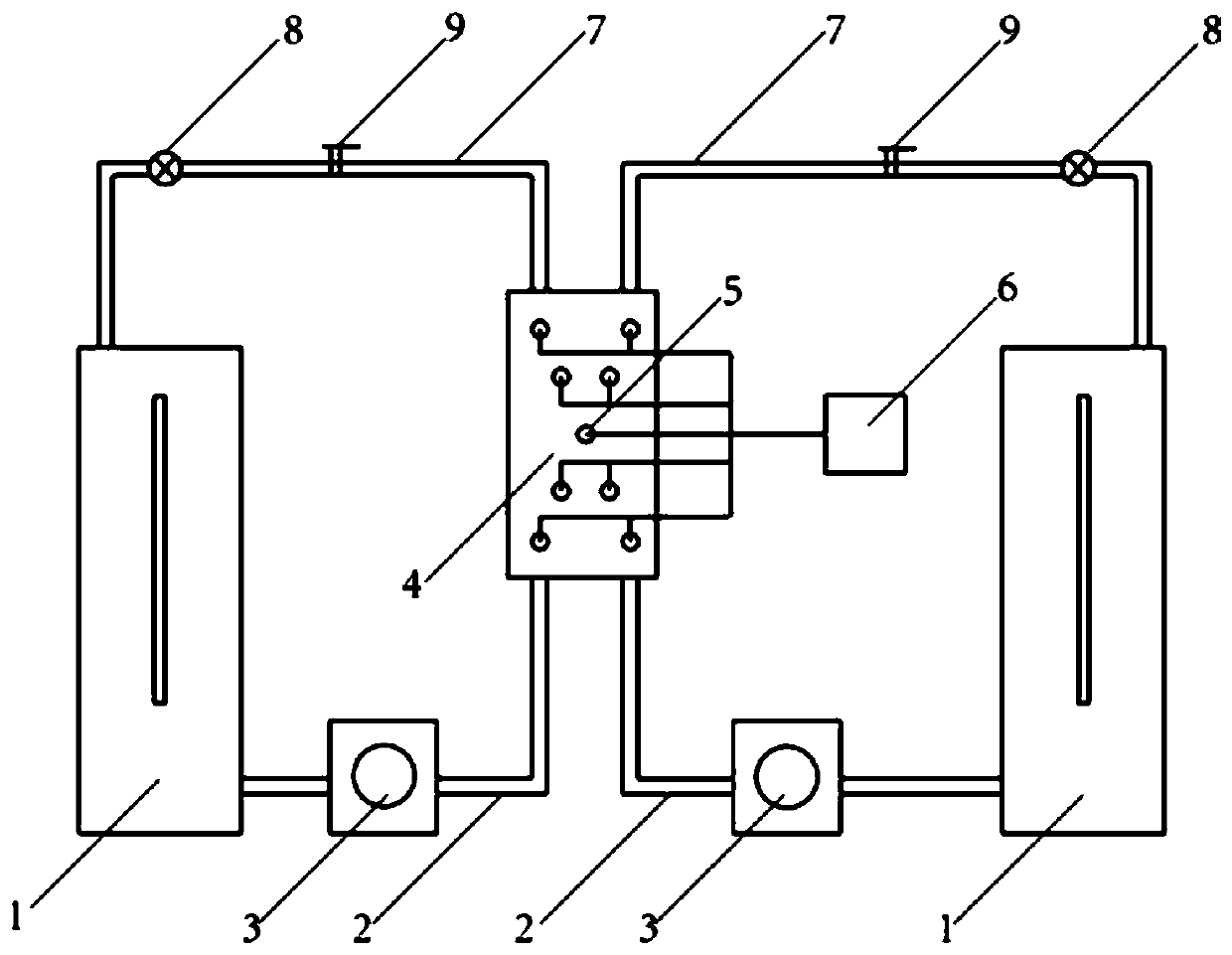

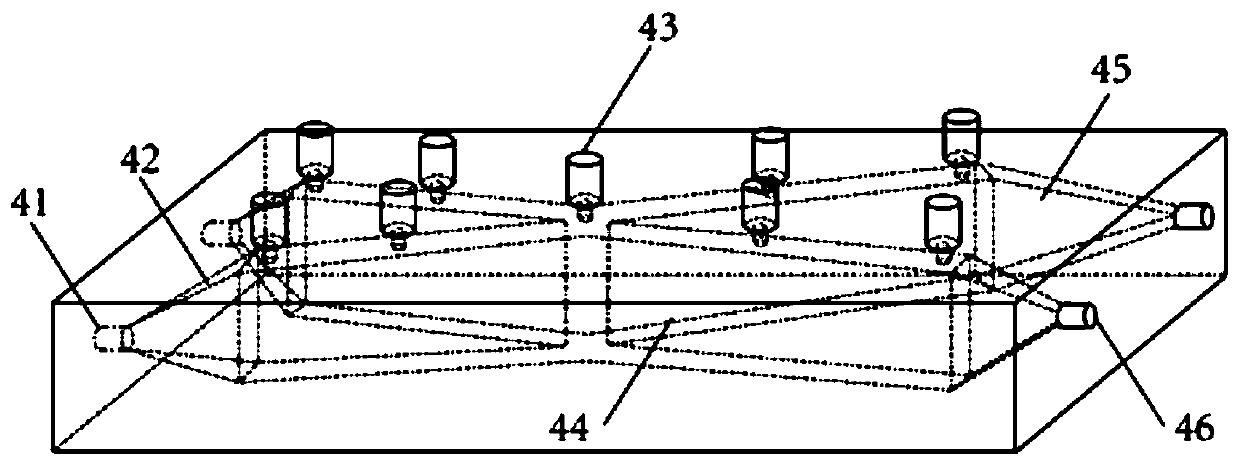

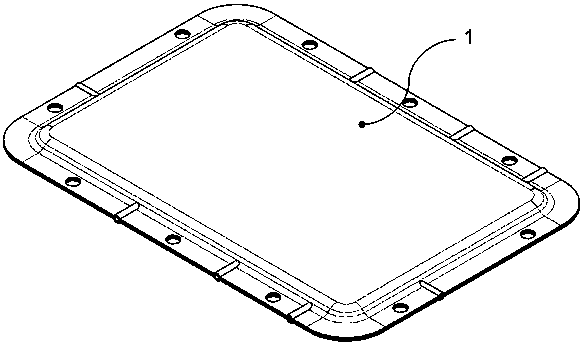

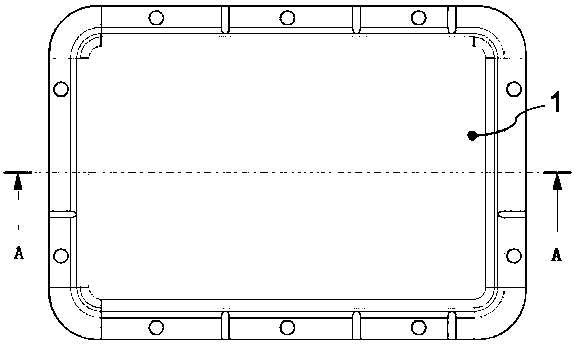

Rough cross crack seepage testing device and method

ActiveCN106290107ARoughness is easy to controlAdjustable crack crossing anglePermeability/surface area analysisStructure of the EarthEngineering

The invention discloses a rough cross crack seepage testing device and method. The rough cross crack seepage testing device comprises a cross crack model, the interior of the cross crack model is of a crossed crack structure, dewatering areas and water gathering areas are arranged on the two sides of the crack structure, the dewatering areas are communicated with water inlets respectively, the water gathering areas are communicated with water outlets respectively, and the water inlets and the water outlets located on the same side of the cross crack model are connected with the same water tank and form a circulation loop; by means of the two circulation loops, crack seepage of one-way entering and multi-way exiting, multi-way entering and one-way exiting and multi-way entering and multi-way exiting is achieved; besides, pressure measuring holes communicated with the crack structure are further formed in the crack structure, and water pressure sensors for measuring fluid pressure are arranged in the pressure measuring holes.

Owner:SHANDONG UNIV

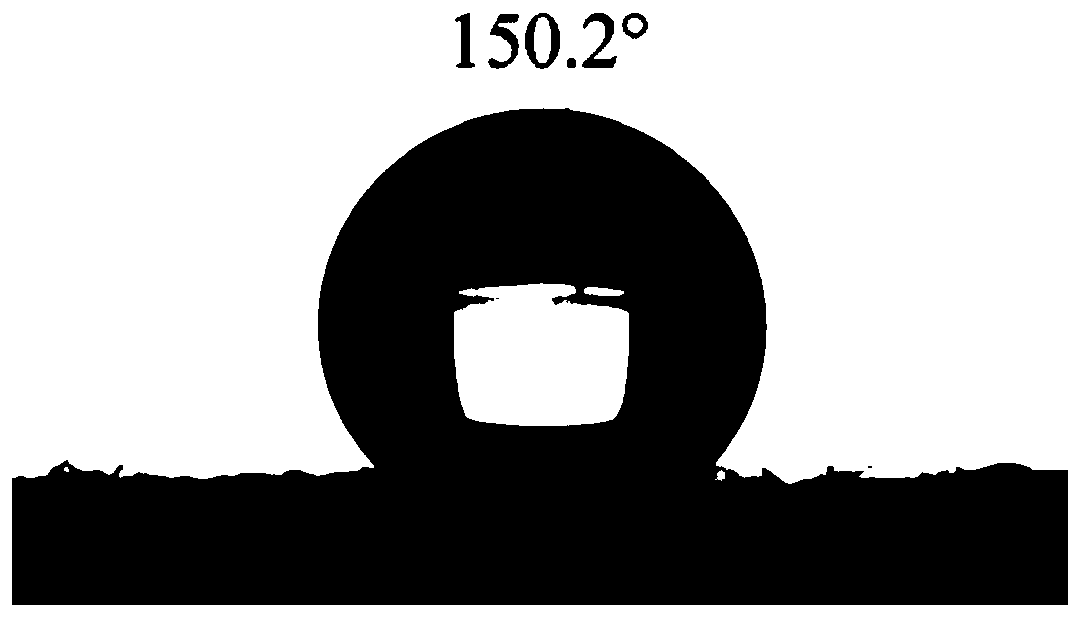

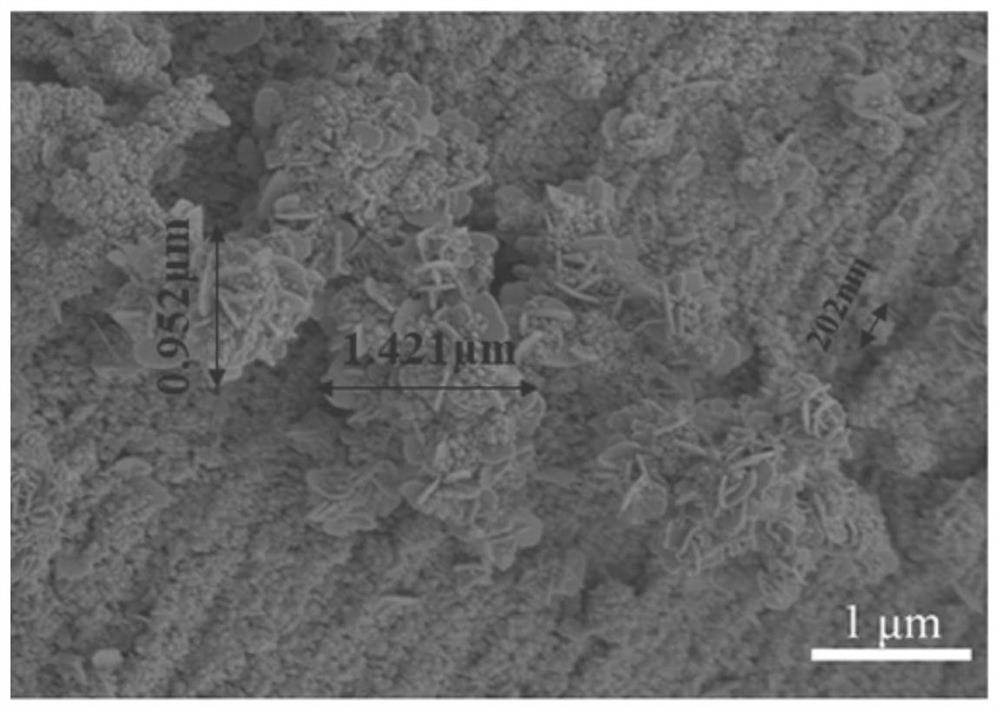

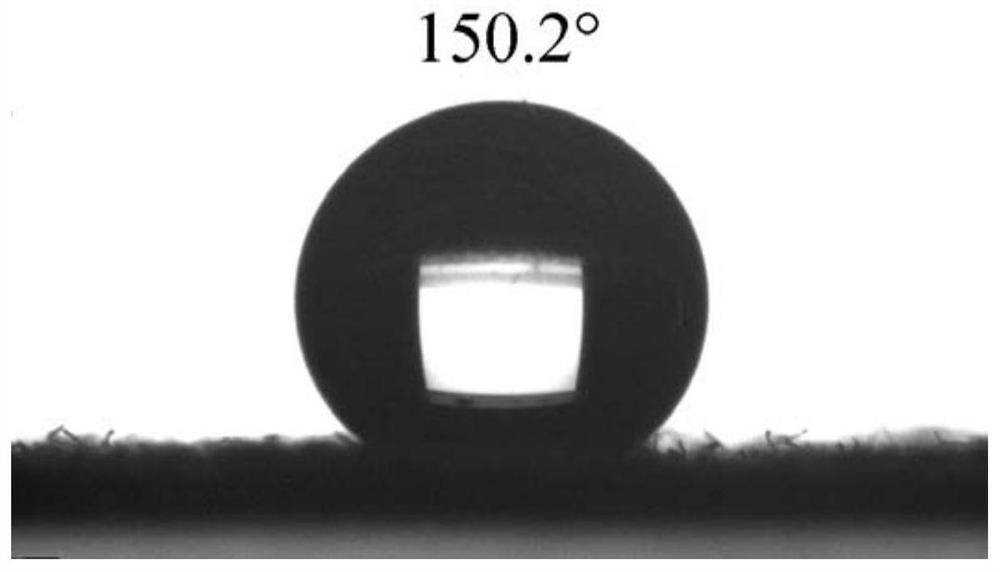

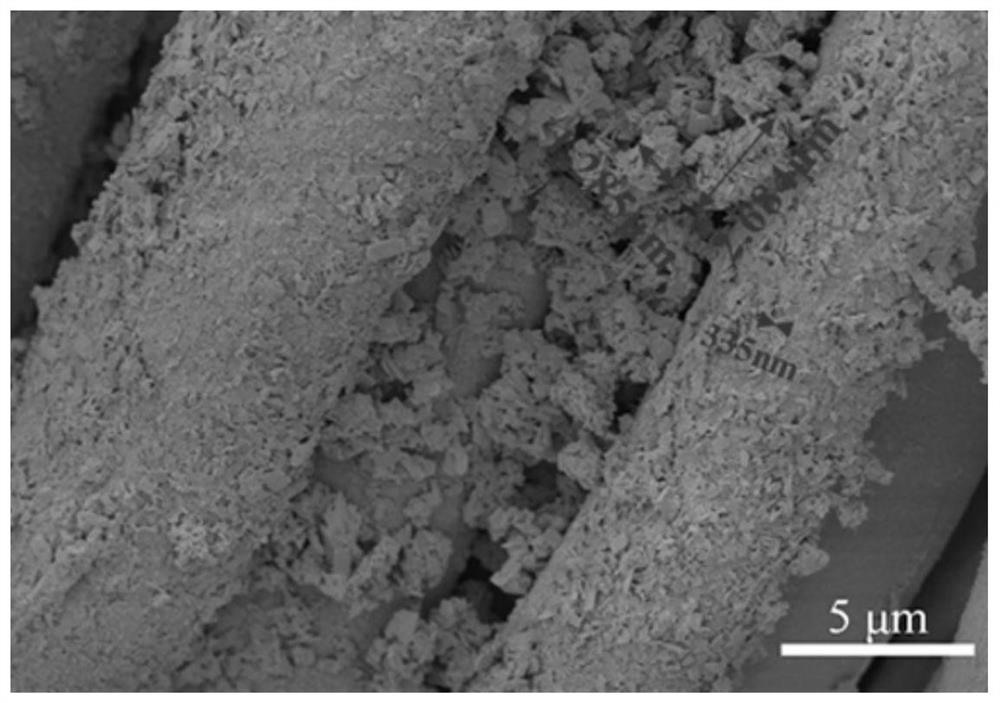

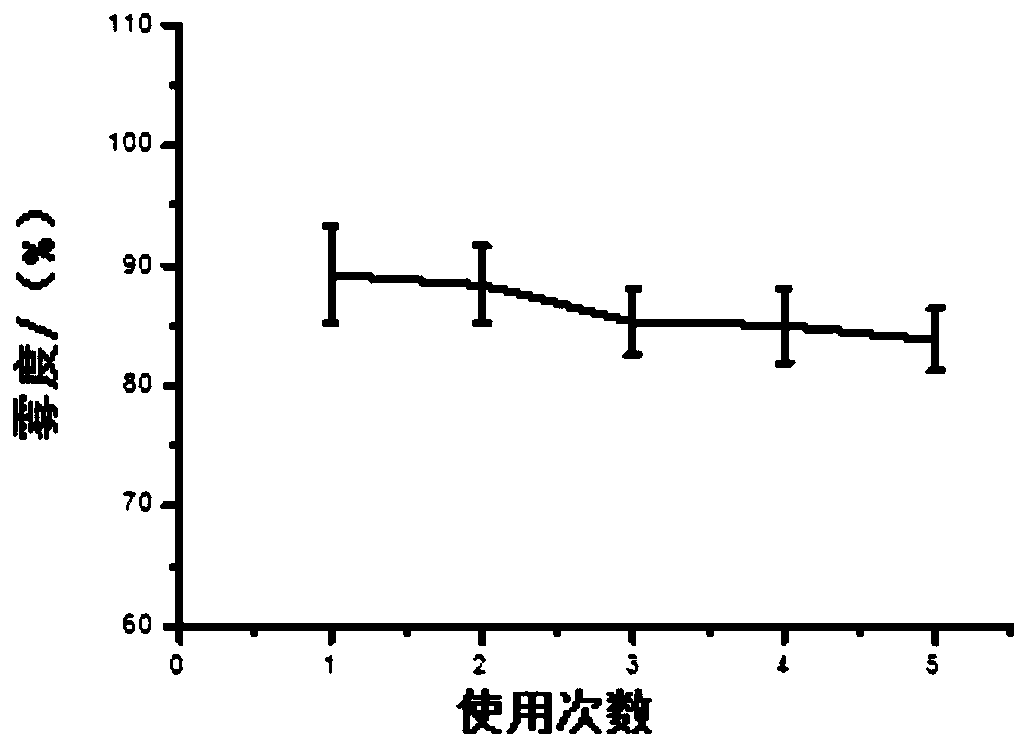

Waterproof cloth surface flexible composite material and preparation method thereof

ActiveCN111593570AExcellent durabilityGuaranteed strongSynthetic resin layered productsLiquid repellent fibresFiberPolymer science

The invention discloses a waterproof cloth surface flexible composite material and a preparation method thereof. The waterproof cloth surface flexible composite material is characterized in that one surface of a super-hydrophobic fabric is bonded with a plastic film by using an adhesive to obtain the washable waterproof cloth surface flexible composite material. The preparation method comprises the following steps of diazotizing a fluorine-containing alkyl aniline monomer in a dilute acid solution of sodium nitrite to form fluorine-containing alkyl benzene diazonium salt; carrying out reduction reaction on the fluorine-containing alkylbenzene diazonium salt under the action of a reducing agent to obtain a fluorine-containing alkylbenzene free radical monomer; and carrying out in-situ single-electron free radical covalent graft polymerization reaction on the fluorine-containing alkylbenzene free radical monomer in the fabric fiber to obtain the super-hydrophobic fabric. As the super-hydrophobic fabric obtained through chemical grafting, the fiber surface coating is combined with the fiber through covalent bonds, so that the super-hydrophobic fabric has excellent fastness, the flexibility and the hand feeling of the fabric are not influenced, and the problems of poor fastness and poor hand feeling of the super-hydrophobic fabric obtained through methods such as the coating are solved.

Owner:SUZHOU UNIV

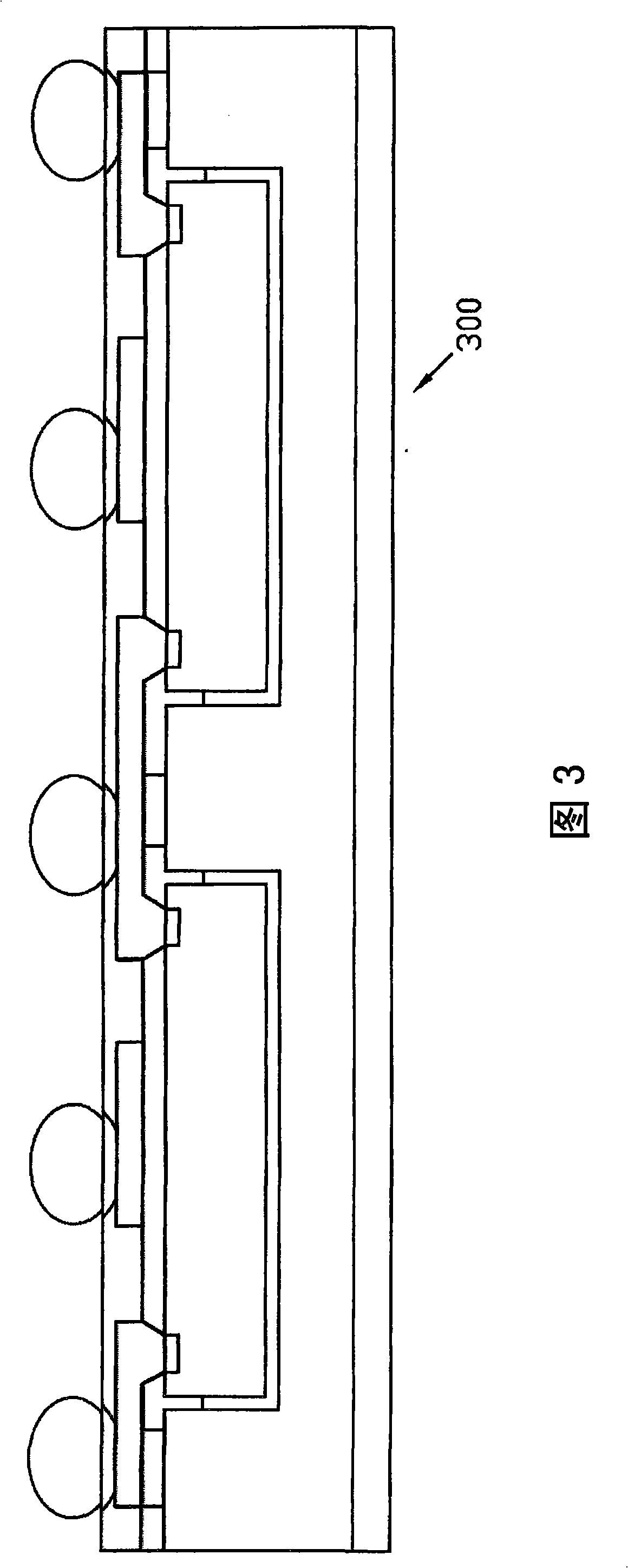

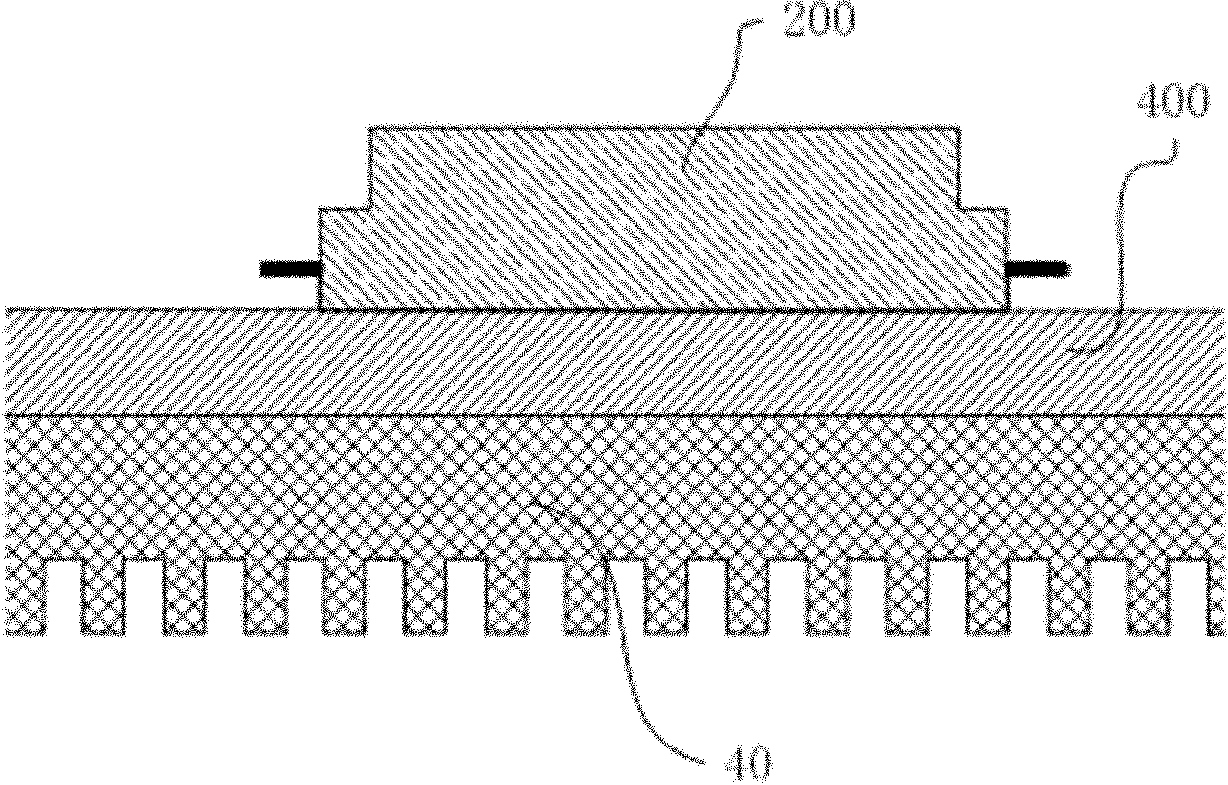

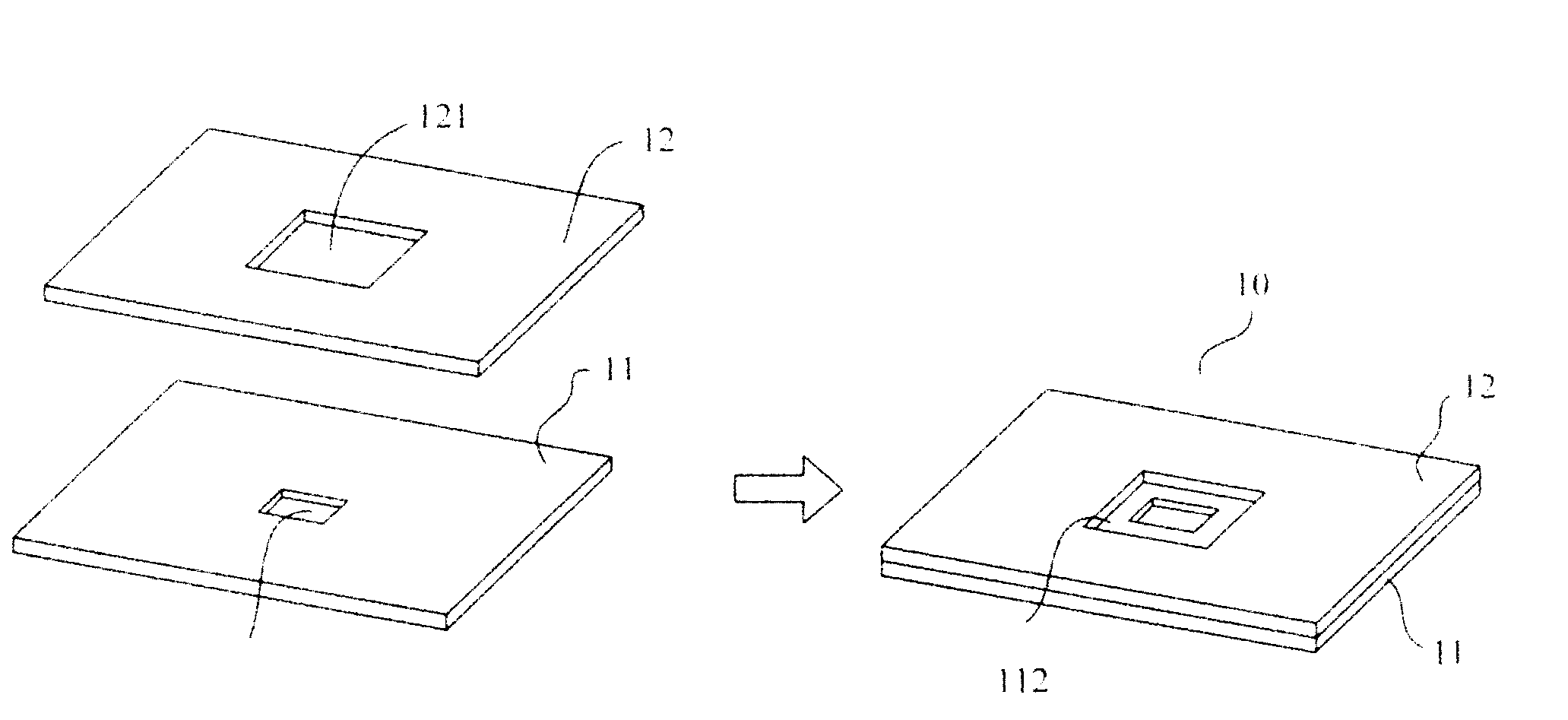

Image sensor chip scale package having inter-adhesion with gap and method of the same

InactiveCN101312203AThe production process is simpleAvoid pollutionSemiconductor/solid-state device detailsSolid-state devicesContact padChip size

Owner:ADVANCED CHIP ENG TECH INC

Preparation method of high-thermal-conductivity copper for chemical plating on silicon nitride ceramic surface

The invention discloses a preparation method of high-thermal-conductivity copper for chemical plating on the silicon nitride ceramic surface. The preparation method includes preforming of a silicon nitride ceramic green body, laser scanning on the surface of the green body, surface protective treatment , sintering densification treatment, electroless copper plating treatment, and heat treatment inprotective atmosphere. By the preparation method, a flat and smooth metal copper layer with high adhesive force is formed on the surface of the green body, the preparation method is easy to operate,has high processing efficiency, can avoid accumulation of laser heat effect, achieves energy saving, and realizes controllability of roughness of the ceramic surface.

Owner:YANGZHOU FINE ELECTRON TECH

Method for reducing nucleation density of graphene wafers

ActiveCN109609924AImprove production efficiencyAchieve polishAnodisationChemical vapor deposition coatingVolumetric Mass DensityCopper foil

The invention discloses a method for reducing the nucleation density of graphene wafers. The method includes the following steps that firstly, polishing and oxidizing pretreatment is performed on a copper foil surface, and then the graphene wafers are prepared on the treated copper foil surface. The new method for reducing the nucleation density of the graphene wafers is put forward, and the method is simple, convenient, easy to implement and good in effect. Meanwhile, the influences of the roughness and the oxidizing degree of a copper base on the nucleation density of the graphene wafers canbe explored, so that the size of the graphene wafers can be increased further, and the quality of thin graphene films can be improved.

Owner:北京石墨烯技术研究院有限公司

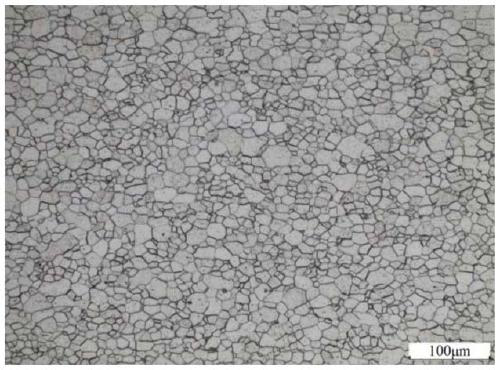

Cold rolled thin steel strip for battery shell and production method thereof

The invention discloses a cold rolled thin steel strip for a battery shell and a production method thereof. The cold rolled thin steel strip is prepared from the following chemical components in percent by mass: 0.006-0.009% of C, 0.20-0.45% of Mn, less than or equal to 0.03% of Si, less than or equal to 0.015% of P, less than or equal to 0.004% of S, less than or equal to 0.004% of N, 0.030-0.045% of Als, 0.030-0.045% of Ti and the balance Fe and inevitable impurities. The cold rolled thin steel strip disclosed by the invention has the advantage that the steel strip is reasonable in proportion of alloy components, relatively low in cost, good in forming performance and excellent in surface quality.

Owner:ZHANGJIAGANG YANGTZE RIVER COLD ROLLED PLATE CO LTD +2

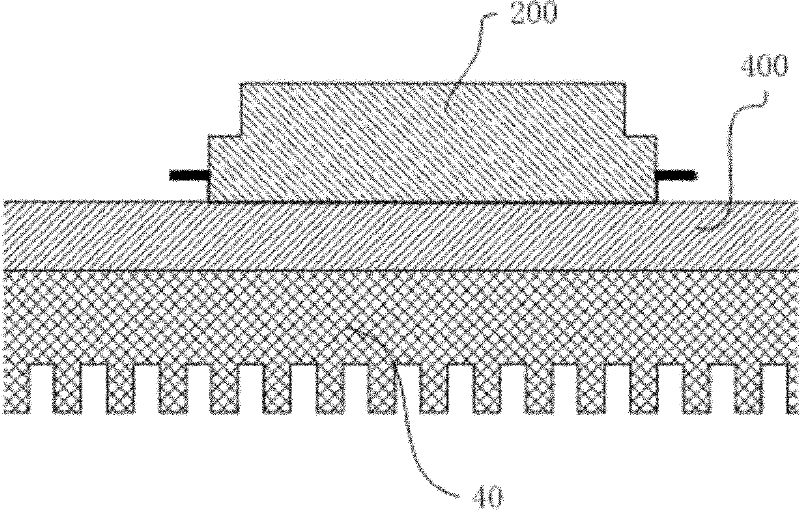

Radiating structure and manufacturing method thereof as well as electronic device with radiating structure

InactiveCN102014600AReduce areaEasy to processPrinted circuit assemblingPrinted circuit detailsHeat sinkElectronic component

The invention discloses a radiating structure, which comprises a double-layer circuit board, a bottom shell and a radiating fin, wherein the double-layer circuit board comprises a first circuit board and a second circuit board which are mutually fit; the first circuit board is provided with a first opening; the second circuit board is correspondingly provided with a second opening bigger than the first opening; a fixed connection zone is formed between the first opening and the second opening by the first circuit board; the bottom shell is fit below the second circuit board and is correspondingly provided with a third opening with the size equal to that of the second opening; the radiating fin is fixedly arranged below the bottom shell; a metal substrate with an adaptive shape is embedded in the space formed by the second opening and the third opening; the upper surface of the metal substrate is fixedly connected with the fixed connection zone and the lower surface thereof is contacted with the radiating fin; and an electronic component is embedded in the first opening and the radiating part of the electronic component is fixedly connected with the upper surface of the metal substrate. The invention correspondingly provides an electronic device with the radiating structure and a manufacturing method of the radiating structure. The invention has better radiating effect, lower cost and higher product reliability.

Owner:MOBILE ANTENNA TECH SHENZHEN

Semiconductor layer surface roughening method and formation method for LED structure with roughened surface

The invention provides a semiconductor layer surface roughening method. The semiconductor layer surface roughening method comprises steps: a semiconductor layer is provided, and the semiconductor layer is a nitride semiconductor layer; a solid metal or alloy film is formed on the semiconductor layer; annealing is carried out for preset time at a preset temperature higher than the melting point of the metal or the alloy thus the metal or alloy film is liquefied into a plurality of metal or alloy liquid drops, then the temperature is lowered to a temperature lower than the melting point of the metal or the alloy, thus the plurality of metal or alloy liquid drops are condensed into a plurality of metal or alloy island-shaped projections; the plurality of metal or alloy island-shaped projections are employed as a mask layer, and a concave-convex structure is etched on the layer top surface of the semiconductor and a roughed surface is formed; the plurality of metal or alloy island-shaped projections are removed. The semiconductor layer surface roughening method is advantageous in that the uniformity is good, and the method is stable and reliable. The invention also provides a formation method for an LED structure with a roughened surface.

Owner:HUIZHOU BYD IND

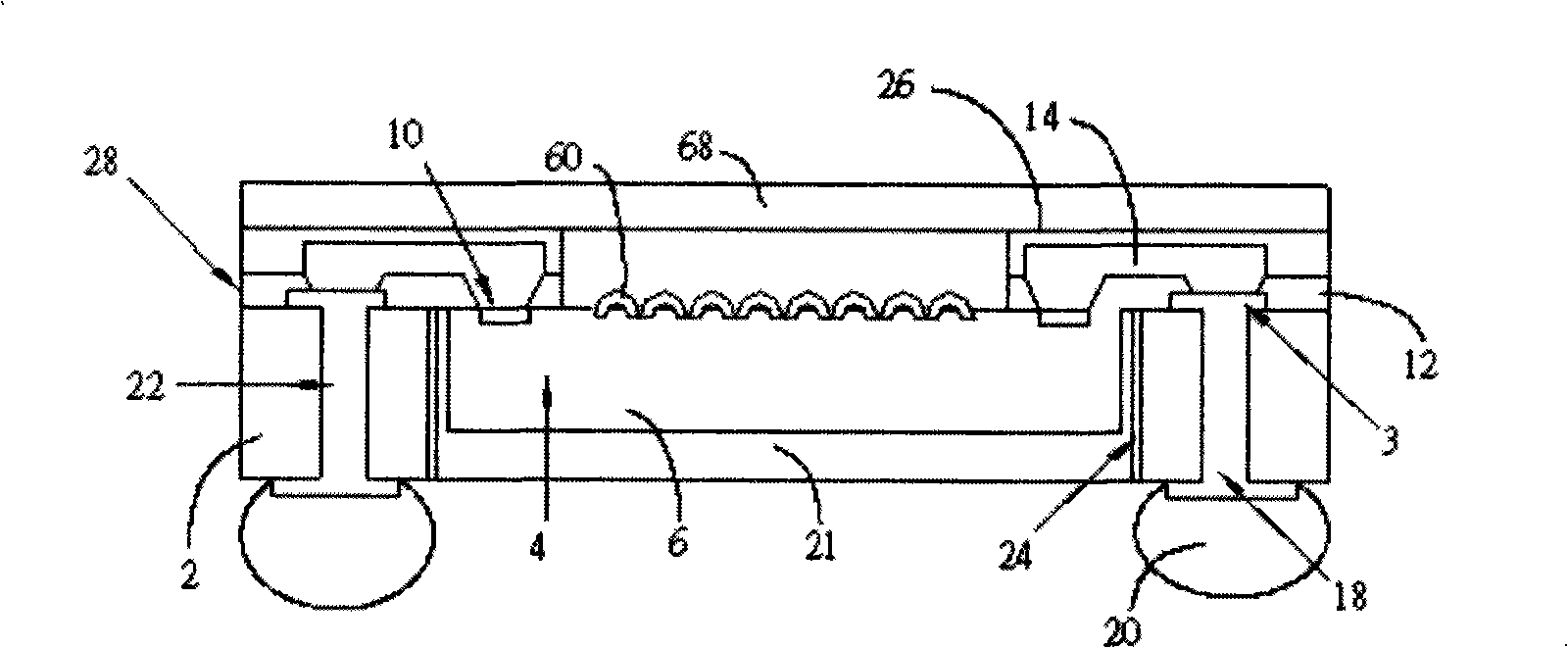

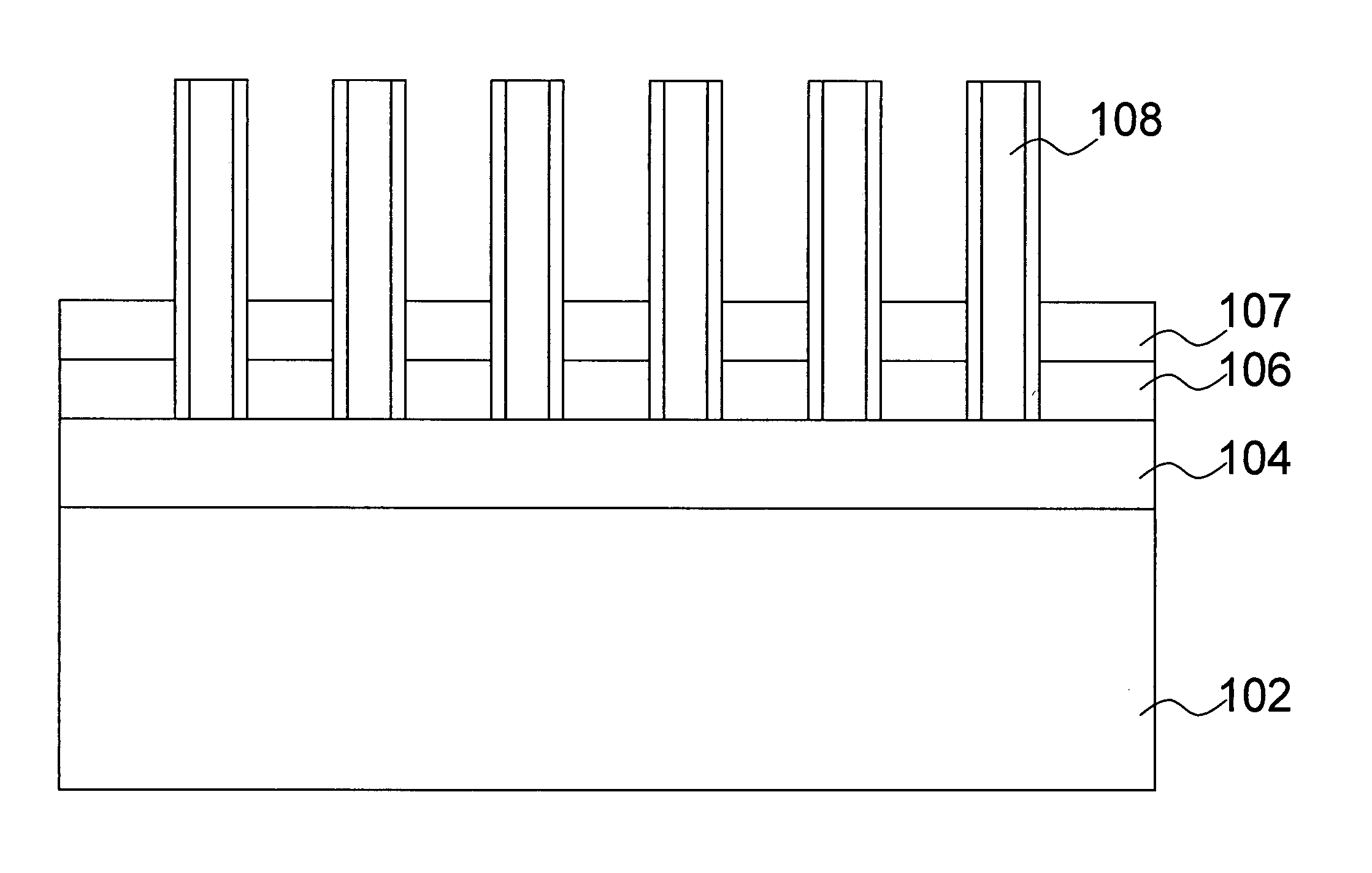

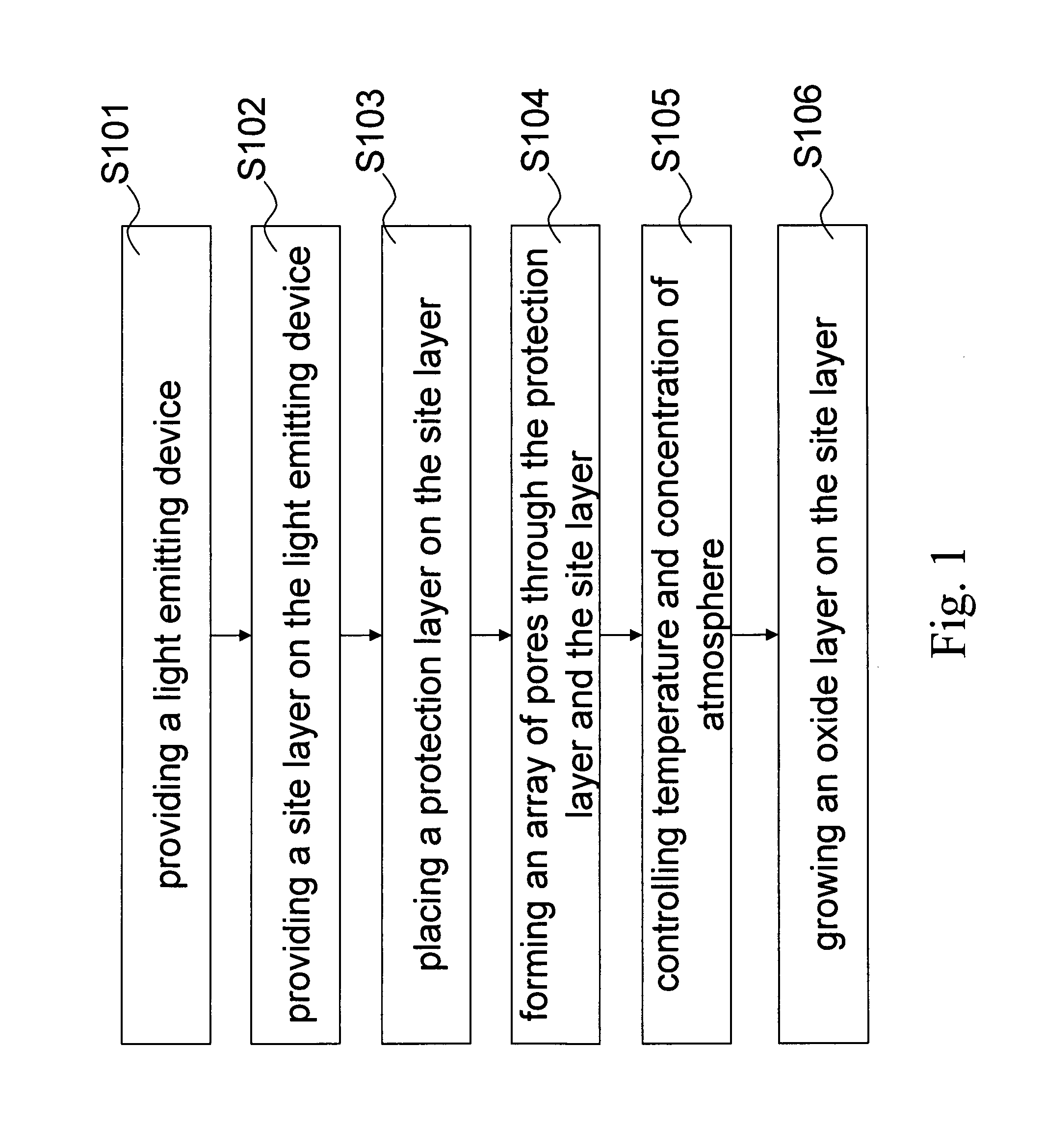

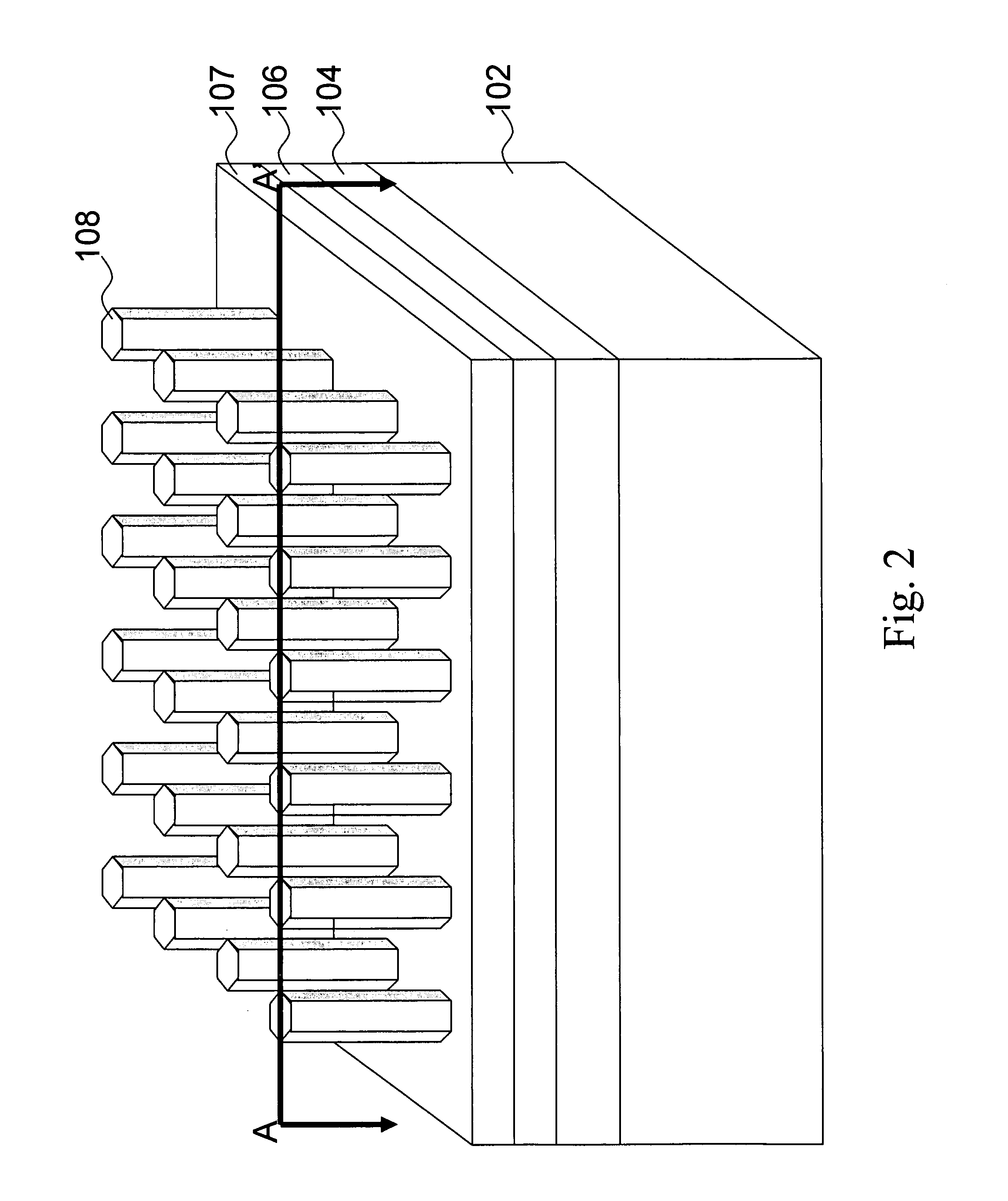

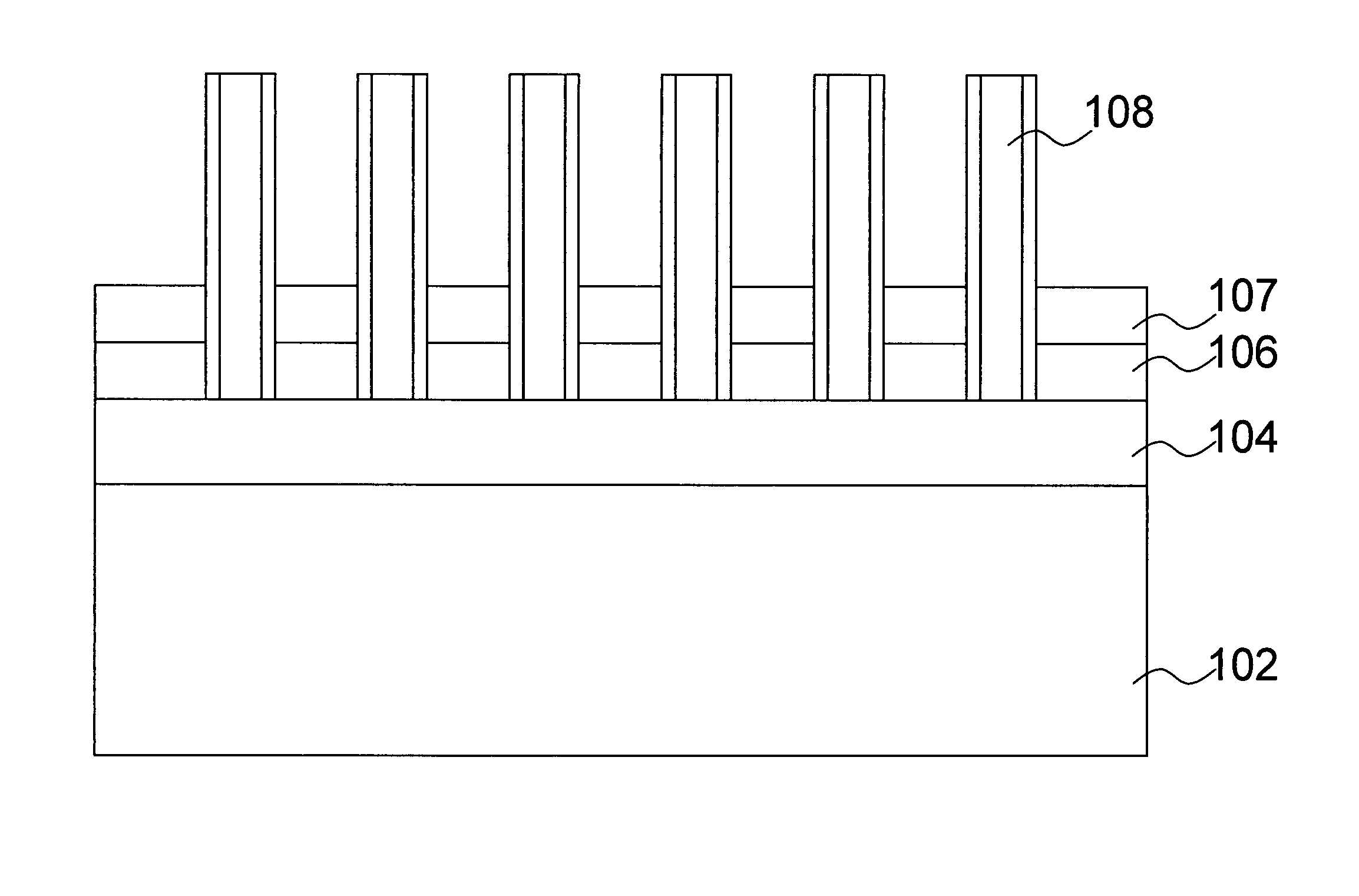

Light emitting device and method for enhancing light extraction thereof

InactiveUS20110095314A1Improve light extractionRoughness is easy to controlSolid-state devicesSemiconductor/solid-state device manufacturingOxideProtection layer

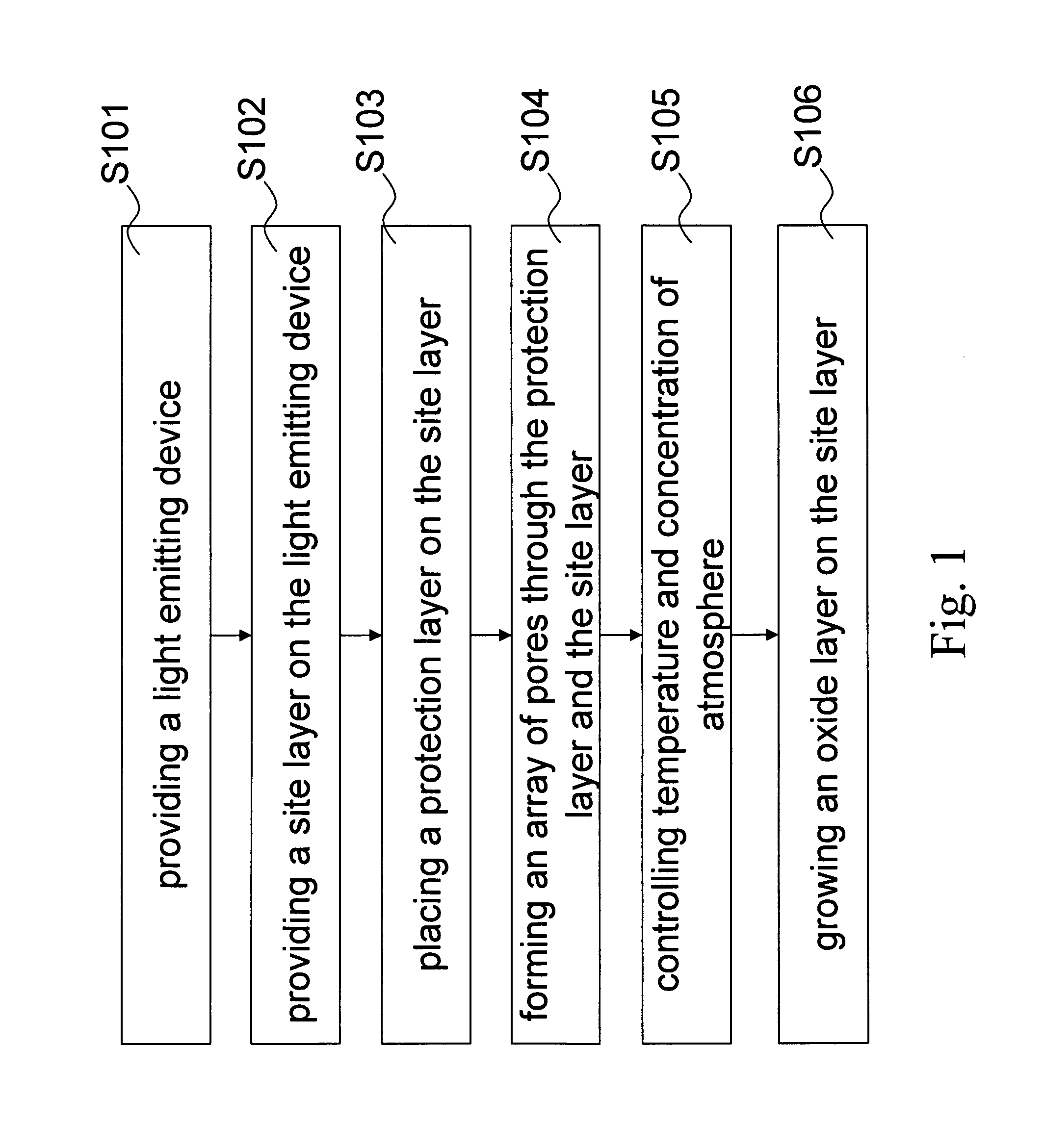

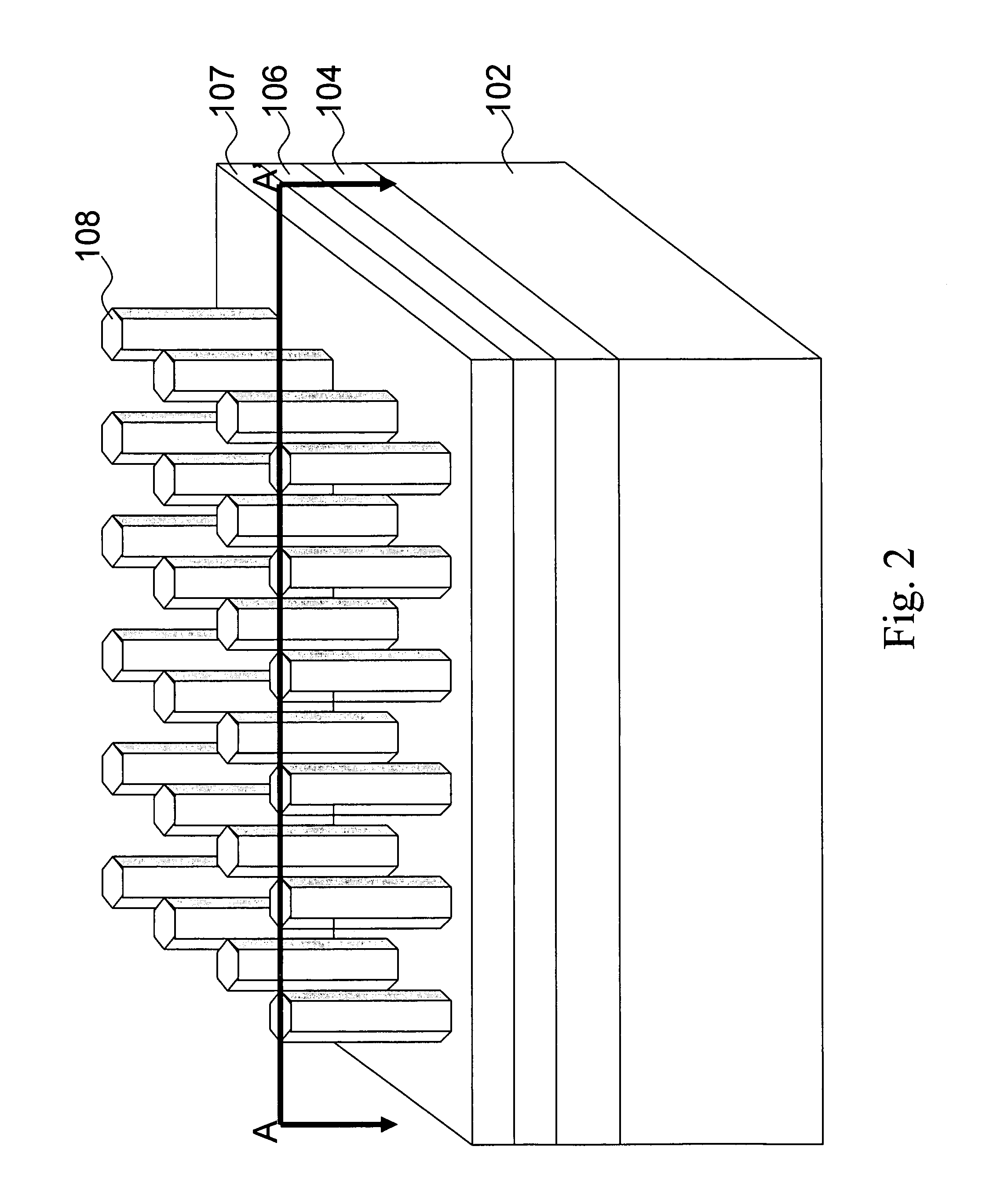

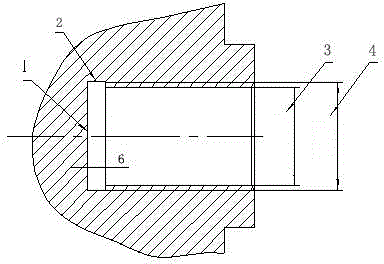

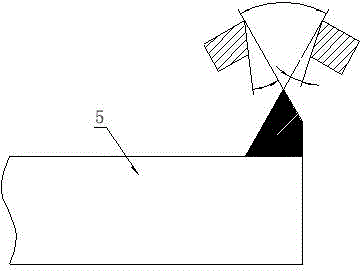

A method for enhancing light extraction of a light emitting device is disclosed. The method includes the steps of: providing a site layer on the light emitting device; placing a protection layer on the site layer; forming an array of pores through the protection layer and the site layer; and growing on the site layer an oxide layer, having a plurality of rods, each of which is formed in one of the pores. The shapes of the rods can be well controlled by adjusting reactive temperature, time and N2 / H2 concentration ratio of atmosphere such that the shape and light escape angle of the rods can be changed.

Owner:WALSIN LIHWA

Light emitting device and method for enhancing light extraction thereof

InactiveUS8129728B2Improve light extractionRoughness is easy to controlSolid-state devicesSemiconductor/solid-state device manufacturingConcentration ratioProtection layer

A method for enhancing light extraction of a light emitting device is disclosed. The method includes the steps of: providing a site layer on the light emitting device; placing a protection layer on the site layer; forming an array of pores through the protection layer and the site layer; and growing on the site layer an oxide layer, having a plurality of rods, each of which is formed in one of the pores. The shapes of the rods can be well controlled by adjusting reactive temperature, time and N2 / H2 concentration ratio of atmosphere such that the shape and light escape angle of the rods can be changed.

Owner:WALSIN LIHWA

Method for processing internal threads of blind hole

InactiveCN104096922ARoughness is easy to controlFast turning speedThread cutting machinesSurface roughnessEngineering

A method for processing internal threads of a blind hole comprises the following steps: firstly turning an inner hole, then turning an inner groove and finally processing the internal threads of the blind hole, wherein the processing of the internal threads of the blind hole is realized in a manner that a threading tool is fed from the inner groove in a reverse-turning way. According to the method, the internal threads of the blind hole are processed in a manner that the threading tool is fed from the inner groove in a reverse-turning way, so that the threading tool is not collided with and damage the bottom surface of the blind hole, the threading tool is positioned in a fixed-tool manner, and can reach the inner groove to turn the internal threads of the blind hole, thus roughness of the bottom surface of the blind hole can be controlled, the turning speed is high, the efficiency is improved, and the rejection rate is reduced.

Owner:GUIZHOU AEROSPACE PRECISION PRODS

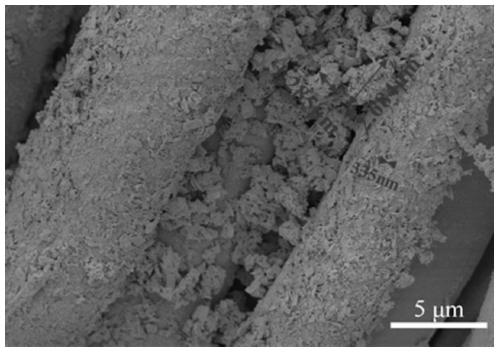

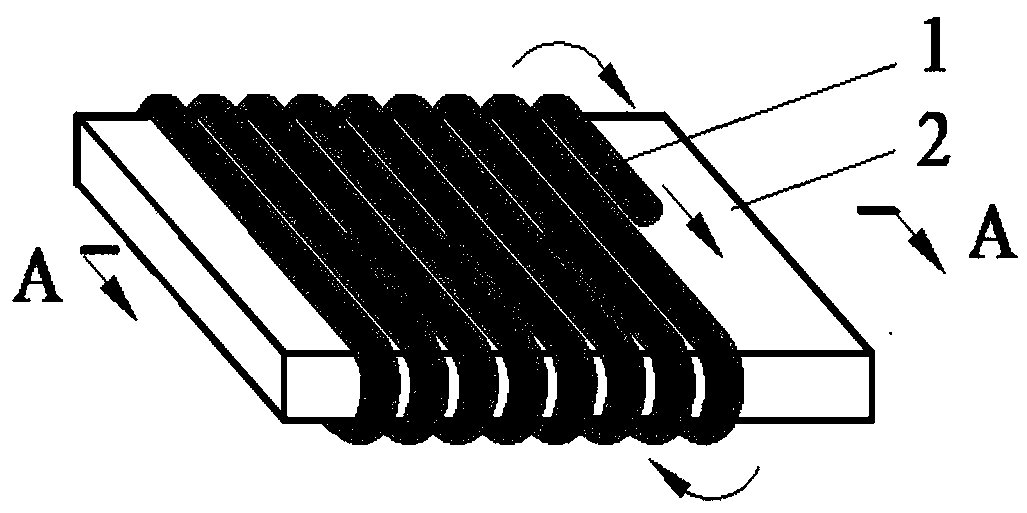

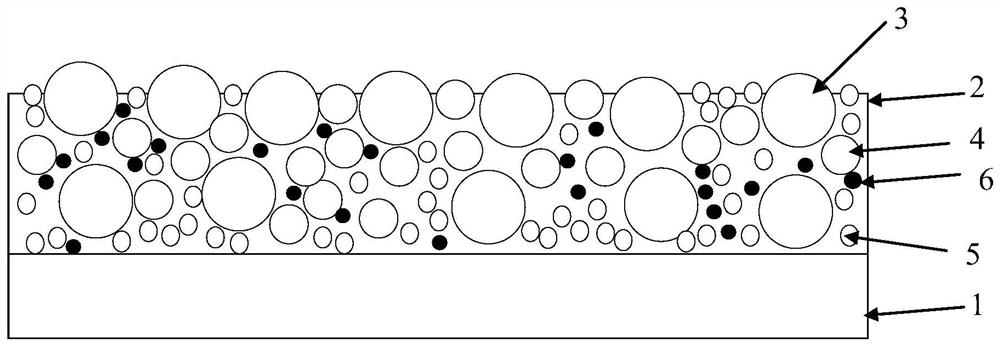

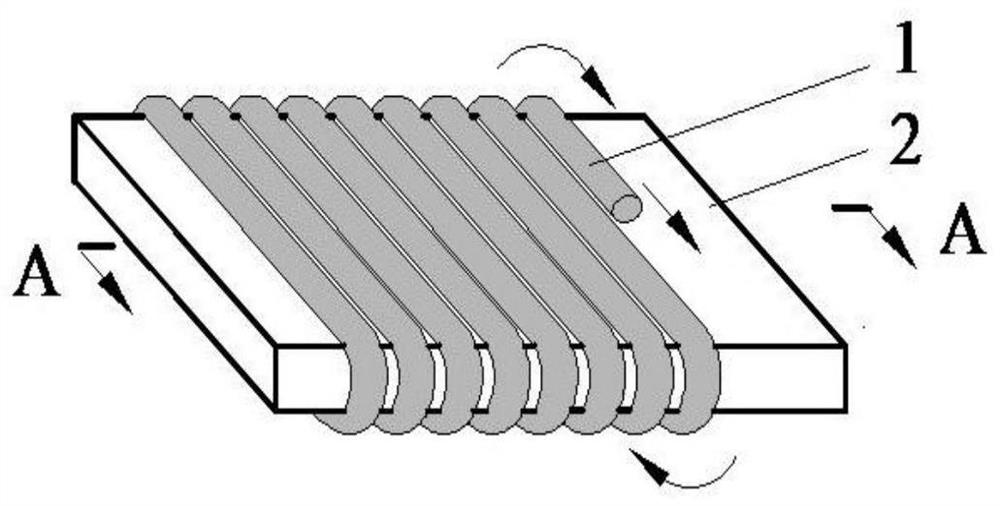

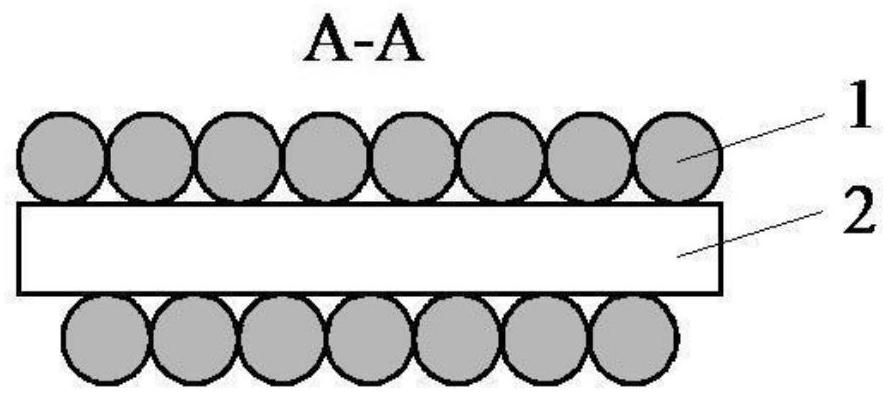

Method for constructing metal-based surface with alternate hydrophilic and hydrophobic strips

ActiveCN108889575AControllable microscopic morphologyThickness is easy to controlPretreated surfacesCoatingsNanoparticleMetal

The invention discloses a method for constructing a metal-based surface with alternate hydrophilic and hydrophobic strips in the technical field of non-silicon micromachining and micronano functionalmaterial preparation. The method comprises the steps that a metal wire is tightly wound on a substrate, the wire and the substrate are integrally sintered under the pressure of weight, after the obtained sintered body is immersed in a hydrophobic nanoparticle turbid liquid, hydrophobic nanoparticles are deposited on the area, not covered by the metal wire, of the substrate, and the superhydrophobic strips are formed after high-temperature film hardening; the metal wire is peeled off from the substrate, and the exposed area forms the hydrophilic strips. The spacing and width of the strips of the constructed metal-based surface with the alternate hydrophilic and hydrophobic strips can be adjusted by adjusting the diameter of the metal wire and the pressure of the weight respectively; the method is simple and easy in operation, and has broad application prospects.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Chalk writable anti-dazzle film

ActiveCN112485853AControllable roughnessHigh hardnessDiffusing elementsWriting boardsCrystallographySolid content

The invention discloses a chalk writable anti-dazzle film. The chalk writable anti-dazzle film comprises a base material and an anti-dazzle coating arranged on the base material; the surface roughnessof the anti-dazzle coating is 0.9-2.5 [mu]m, the anti-dazzle coating is formed by coating the base material with an anti-dazzle coating liquid with the solid content of 40-65%, the anti-dazzle coating liquid contains first anti-dazzle particles, second anti-dazzle particles and third anti-dazzle particles, the particle size of the first anti-dazzle particles is 5-15 [mu]m, and the first anti-dazzle particles account for 50-80% of the total content of the anti-dazzle particles; the particle size of the third anti-dazzle particles is 0.5-3[mu]m, and the third anti-dazzle particles account for 10-25% of the total content of the anti-dazzle particles; and the particle size of the second anti-dazzle particles is 3-5 [mu]m. The chalk writable anti-dazzle film disclosed by the invention is goodin chalk writing effect, good in hardness and wear resistance and relatively good in flash point.

Owner:NUOVO FILM SUZHOU CHINA INC

Etching solution of low doped silicon electrode

InactiveCN109575923AUniform surfaceStable etch rateSurface treatment compositionsUltrapure waterRadical ion

The invention discloses etching solution of a low doped silicon electrode. The etching solution comprises the following main components according to a total weight of the etching :45-65% of sulfuric acid, 1-10% of nitric acid, 1-10% of ammonium fluoride, 1-10% of ammonia chloride, and 5-52% of ultrapure water. The etching solution is capable of, through using the nitric acid with low content, reducing a whole etching rate; through using the ammonium fluoride to replace hydrofluoric acid, guaranteeing the stable etching rate; and adding the ammonia chloride as a replenisher of an ammonium radical ion, generating intensive small bubbles in an etching process, and conveniently controlling roughness on the surface of a silicon electrode. The etching solution is capable of completely removingdamage caused by grinding, stable in etching rate, uniform in etching surface, and controllable in surface roughness.

Owner:湖北兴福电子材料股份有限公司

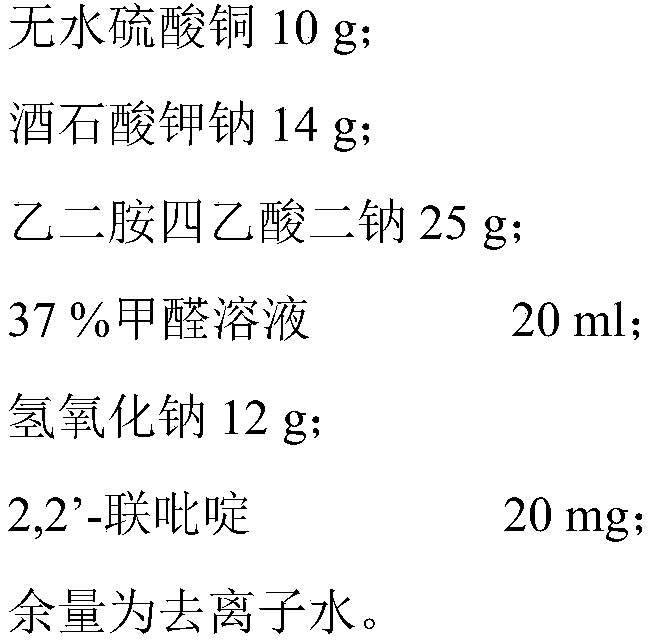

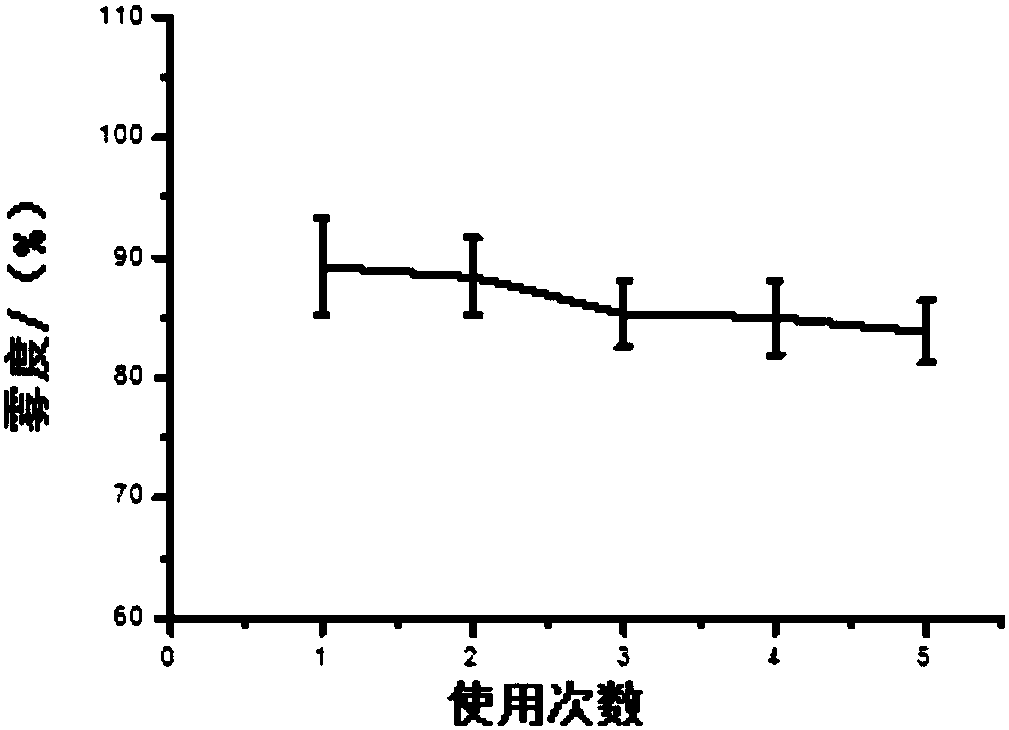

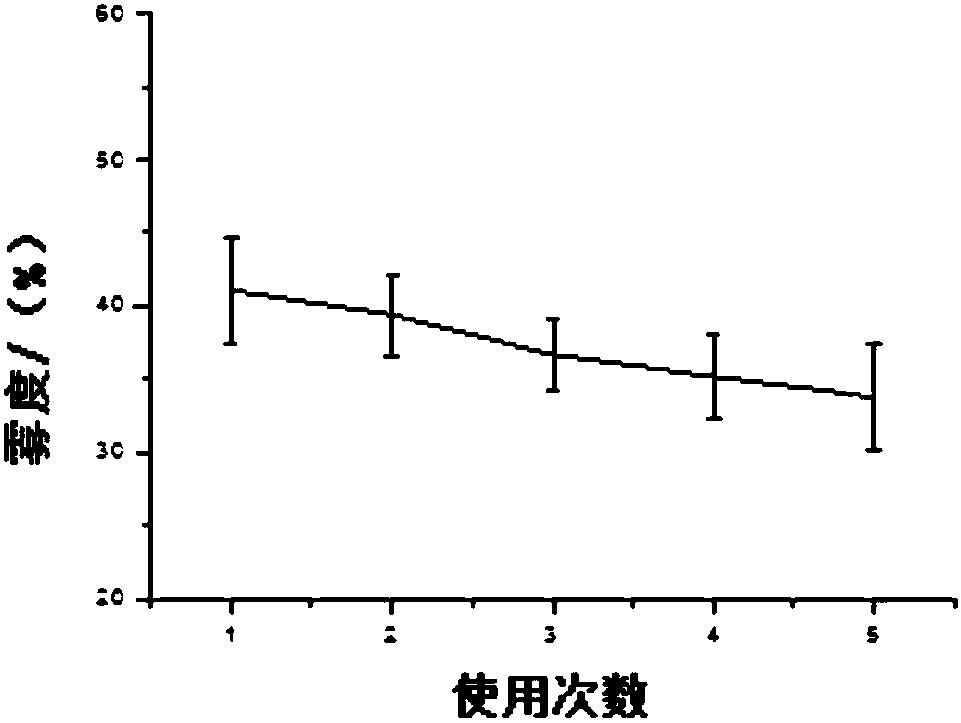

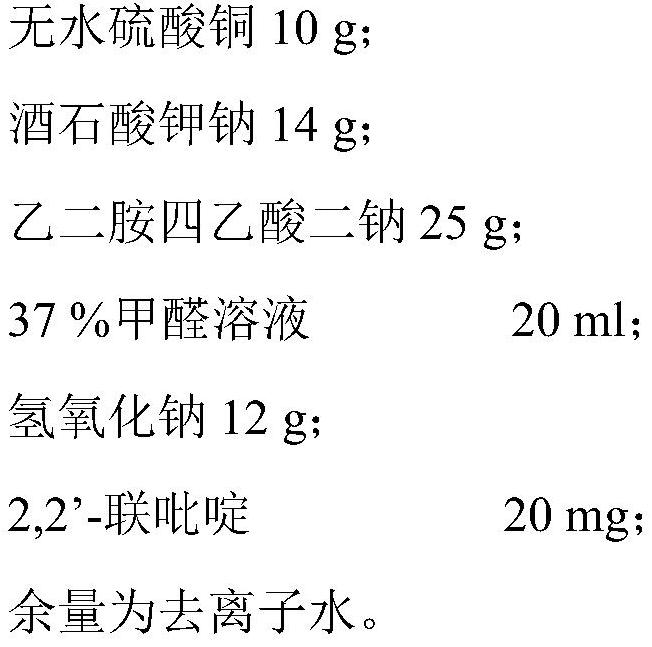

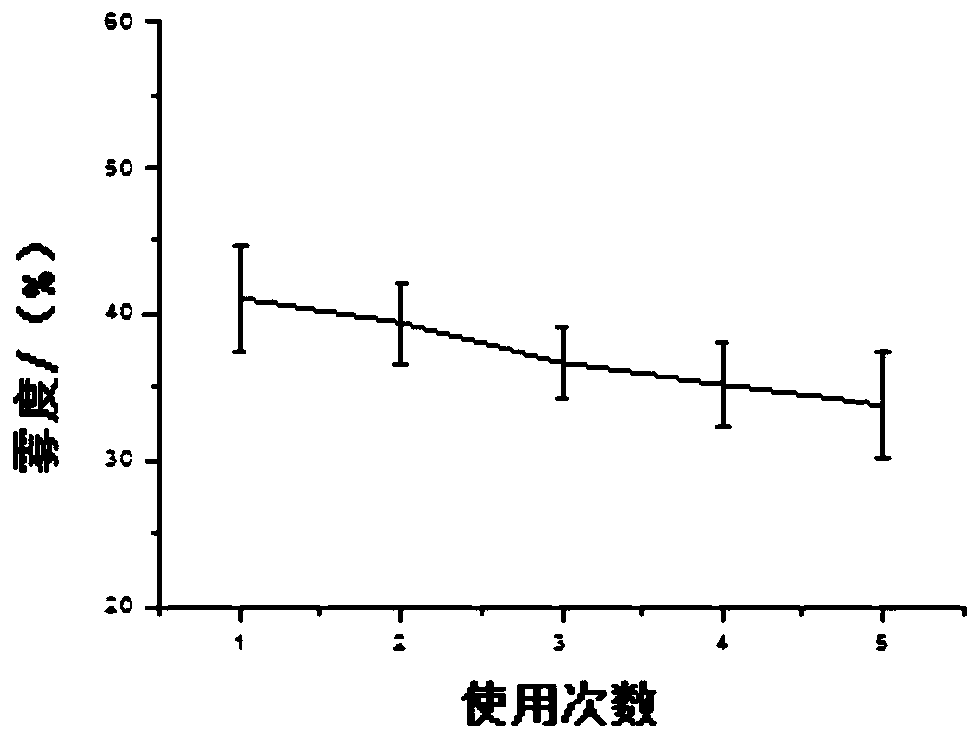

Electroplating technology for satin nickel of back coating mold and application of back coating mold electroplated with stain nickel

The invention belongs to the technical field of electroplating and particularly relates to an electroplating technology for satin nickel of a back coating mold and the application of the back coatingmold electroplated with the stain nickel. Polishing treatment, oil removal treatment and acid pickling treatment are conducted on the surface of a copper mold; then electroplating of the stain nickelis conducted, wherein the copper mold is used as the cathode, a titanium basket containing nickel cakes is used as the anode, the copper mold and the titanium baske are placed in a satin nickel plating solution for electroplating, and a layer of satin nickel having certain roughness is obtained from the surface of the copper mold. Through addition of a non-ionic surface active agent and a stabilizer to a watt type plating solution, the satin nickel electroplating technology achieving the aims that the plating solution can be recycled, the change of the roughness of the plating layers is smallafter the plating solution is recycled, the surface roughness is uniform, and the roughness is controllable is obtained.

Owner:CHANGZHOU HUAWEI ADVANCED MATERIAL

Mixed potential type no based on sandblasting processed porous ysz substrate 2 Sensor and preparation method

ActiveCN103954665BImprove thermal stabilityGood chemical stabilityMaterial electrochemical variablesRough surfaceActive site

Owner:JILIN UNIV

A method for constructing metal-based hydrophilic and hydrophobic stripes and phases

ActiveCN108889575BControllable microscopic morphologyThickness is easy to controlPretreated surfacesSpecial surfacesMetal filamentSilicon micromachining

The invention discloses a method for constructing a metal-based hydrophilic-hydrophobic stripe-interface surface, which belongs to the technical field of non-silicon micromachining and preparation of micro-nano functional materials. In this method, the metal wire is tightly wound on the substrate, and sintered under the pressure of a heavy object to form a whole. After the obtained sintered body is immersed in a suspension of hydrophobic nanoparticles, the hydrophobic nanoparticles are deposited on the area of the substrate that is not covered by the metal wire. Superhydrophobic stripes are formed after the film is hardened; the metal wire is peeled off from the substrate, and the exposed area forms hydrophilic stripes; the distance and width of the surface stripes between the metal-based hydrophilic and hydrophobic stripes can be adjusted by the diameter of the metal wire and the pressure of the weight, respectively. , the method is simple, easy to operate, and has broad application prospects.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Apparatus and method for seepage test in rough intersecting fractures

ActiveCN106290107BRoughness is easy to controlAdjustable crack crossing anglePermeability/surface area analysisEngineeringWater pressure

The invention discloses a rough cross crack seepage testing device and method. The rough cross crack seepage testing device comprises a cross crack model, the interior of the cross crack model is of a crossed crack structure, dewatering areas and water gathering areas are arranged on the two sides of the crack structure, the dewatering areas are communicated with water inlets respectively, the water gathering areas are communicated with water outlets respectively, and the water inlets and the water outlets located on the same side of the cross crack model are connected with the same water tank and form a circulation loop; by means of the two circulation loops, crack seepage of one-way entering and multi-way exiting, multi-way entering and one-way exiting and multi-way entering and multi-way exiting is achieved; besides, pressure measuring holes communicated with the crack structure are further formed in the crack structure, and water pressure sensors for measuring fluid pressure are arranged in the pressure measuring holes.

Owner:SHANDONG UNIV

Etching method of three-dimensional microstructures and application of three-dimensional microstructure

InactiveCN107204288AEasy to prepareEasy to operateMaterial nanotechnologySemiconductor/solid-state device manufacturingMicro nanoThree dimensional microstructure

The invention discloses an etching method of three-dimensional microstructures. The method comprises the steps as follows: a micro-nano particle suspension for inhibiting etching is applied to the surface of a substrate, drying treatment is performed to allow micro-nano particles to be deposed on the surface of the substrate, then the substrate is etched with an etching solution, and the substrate with the three-dimensional concave microstructures is obtained. Multiple concave microstructures are arranged on the surface of the substrate produced with the method, the substrate can be used for sorting and enriching large-flux, mark-free and large-size circulating tumor cells after being produced into a micro-fluidic chip, the capturing capacity for the circulating tumor cells can be improved, and the technical problems that substrates produced with traditional methods are poor in cell adhesion and low in cell capturing efficiency due to smooth surfaces are solved.

Owner:WUHAN TEXTILE UNIV

A preparation method for electroless copper plating on the surface of silicon nitride ceramics with high thermal conductivity

The invention discloses a preparation method of electroless copper plating on the surface of silicon nitride ceramics with high thermal conductivity. Copper treatment and heat treatment in a protective atmosphere. This method forms a metal copper layer with strong adhesion and smoothness on the surface of the green body. It is easy to operate and high in processing efficiency. It can avoid the accumulation of laser thermal effects, save resources, and the surface roughness of ceramics is controllable.

Owner:YANGZHOU FINE ELECTRON TECH

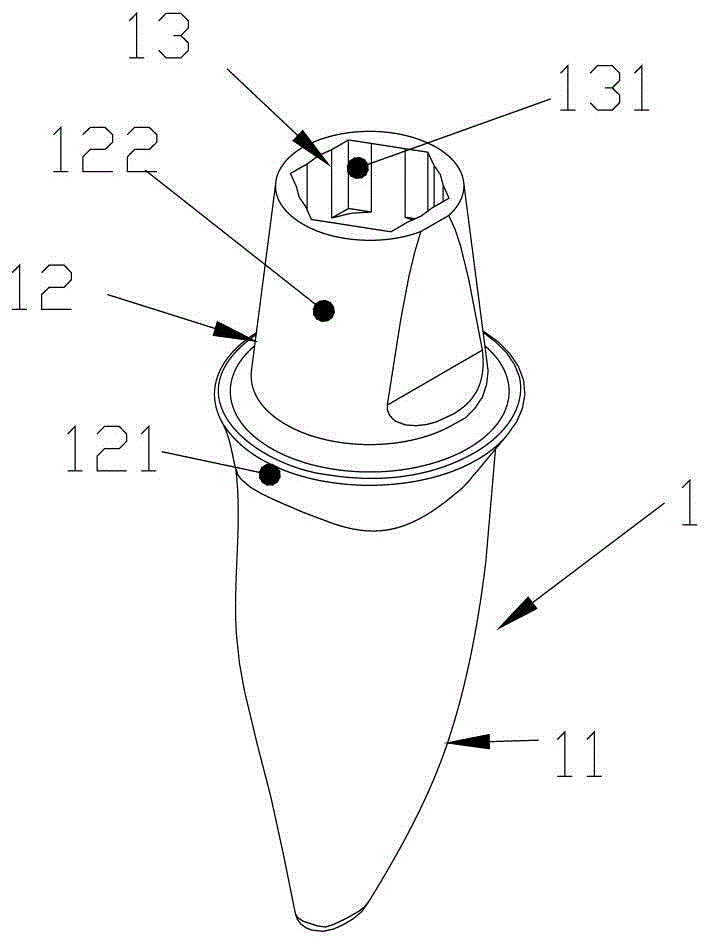

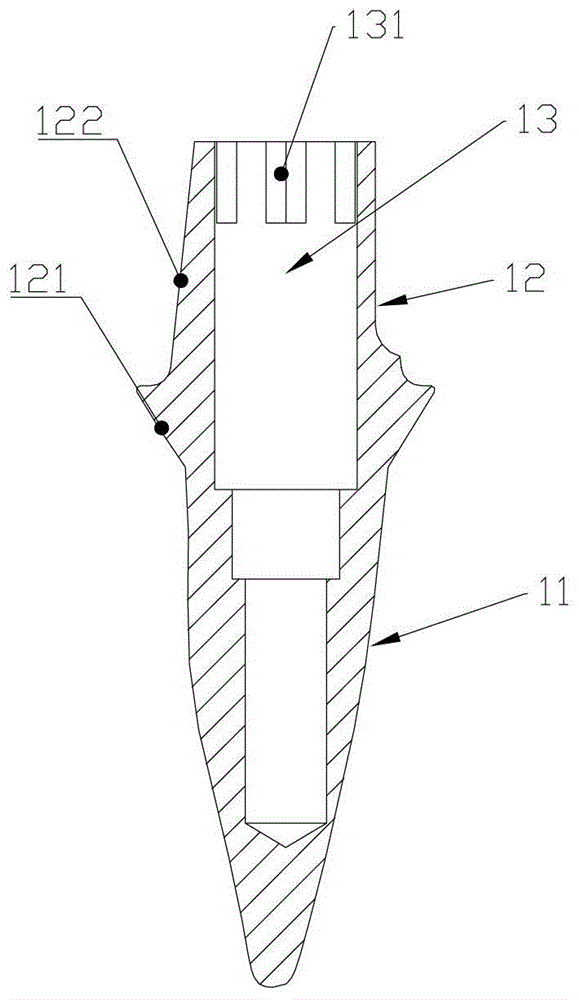

A kind of dental implant and its 3D printing manufacturing method

ActiveCN104055592BReduce processing efficiencyReduce processing costsDental implantsDental prostheticsProcessing costDental implant

Owner:广东健齿生物科技有限公司

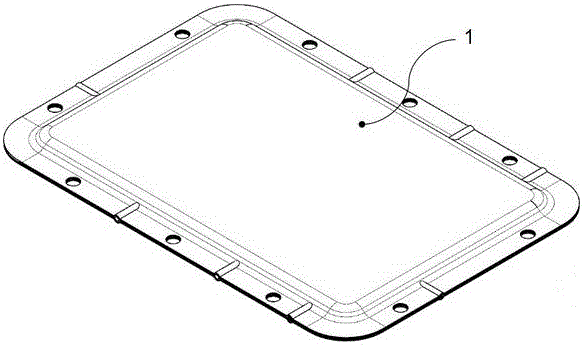

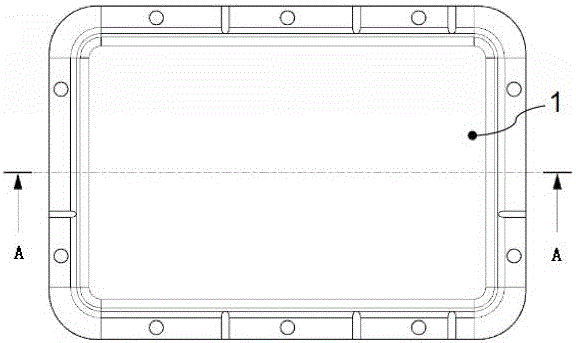

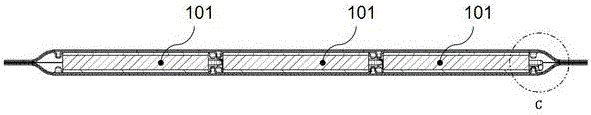

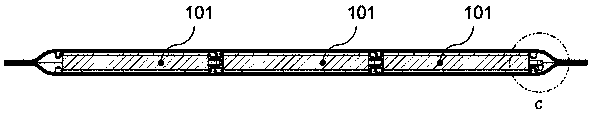

Thermoelectric cell group

ActiveCN105957953AEffective anti-vibrationEffective impact resistanceThermoelectric device detailsWhole bodyEngineering

The invention relates to a thermoelectric cell group which comprises upper and lower shells, upper and lower shell heat transfer groups and thermoelectric cell units. The external surfaces of the upper and lower shells are provided with upper and lower shell heat transfer layers. The upper and lower shells are internally provided with a plurality of groove-shaped positioning structures capable of installing the thermoelectric cell units, and the thermoelectric cell units in a 3 by 3 arrangement, a parallel connection, a series connection or a series and parallel mixed connection can be embedded by the upper and lower shells. Each of the thermoelectric cell units is provided with positive and negative electrodes and a temperature sensor. Upper and lower buffer heat conduction shock-absorbing pads are arranged between the thermoelectric cell units and the upper and lower shells, and the upper and lower shell are connected through threaded connection or dot welding connection to form a cell group whole body. Through the above structural design, the reasonable and firm sealing and shock absorption are achieved, through sanding and polishing a working and adjusting the parallelism, the parallelism and accuracy of the working surface of the upper and lower shells are ensured, the thermal resistance is low, the production assembly is convenient, the thermoelectric cell group is convenient to use, the service life is long, and the thermoelectric cell group can be actively promoted and used.

Owner:上海松芝酷能汽车技术有限公司

A kind of superhydrophobic fabric and preparation method thereof

ActiveCN111472171BExcellent durabilityHigh fastnessLiquid repellent fibresVegetal fibresFiberSodium nitrite

The invention discloses a superhydrophobic fabric and a preparation method thereof. Using fluoroalkyl aromatic amine as the reaction monomer and sodium nitrite as the diazotization reagent, the aromatic amine diazonium salt is obtained through low-temperature diazotization in dilute acid solution; the diazonium salt is reduced under the action of a chemical reducing agent A fluorine-containing aromatic radical is formed; the diazo radical monomer undergoes a single-electron free radical-initiated polymerization reaction on natural fabric fibers to prepare a superhydrophobic fabric with a roughened fiber surface. The fabric treatment of the present invention is completed by grafting and polymerization at room temperature, the production process conditions are mild, high equipment requirements and possible potential risks of electrochemical reduction are avoided, and the product preparation process is simple and safe in operation. As a super-hydrophobic fabric obtained by chemical grafting, the fiber surface coating is covalently bonded to the fiber, which has excellent fastness and does not affect the wearing performance of the fabric. It solves the problem of obtaining super-hydrophobic fabric fastness by coating and other methods. Poor puzzle.

Owner:SUZHOU UNIV

A kind of electroplating process and application of back-coated mold pearl nickel

The invention belongs to the technical field of electroplating and particularly relates to an electroplating technology for satin nickel of a back coating mold and the application of the back coatingmold electroplated with the stain nickel. Polishing treatment, oil removal treatment and acid pickling treatment are conducted on the surface of a copper mold; then electroplating of the stain nickelis conducted, wherein the copper mold is used as the cathode, a titanium basket containing nickel cakes is used as the anode, the copper mold and the titanium baske are placed in a satin nickel plating solution for electroplating, and a layer of satin nickel having certain roughness is obtained from the surface of the copper mold. Through addition of a non-ionic surface active agent and a stabilizer to a watt type plating solution, the satin nickel electroplating technology achieving the aims that the plating solution can be recycled, the change of the roughness of the plating layers is smallafter the plating solution is recycled, the surface roughness is uniform, and the roughness is controllable is obtained.

Owner:CHANGZHOU HUAWEI ADVANCED MATERIAL

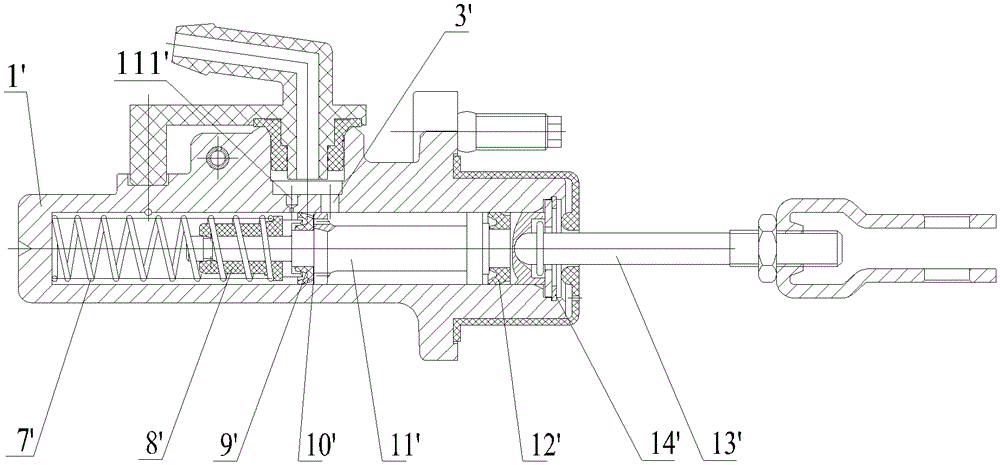

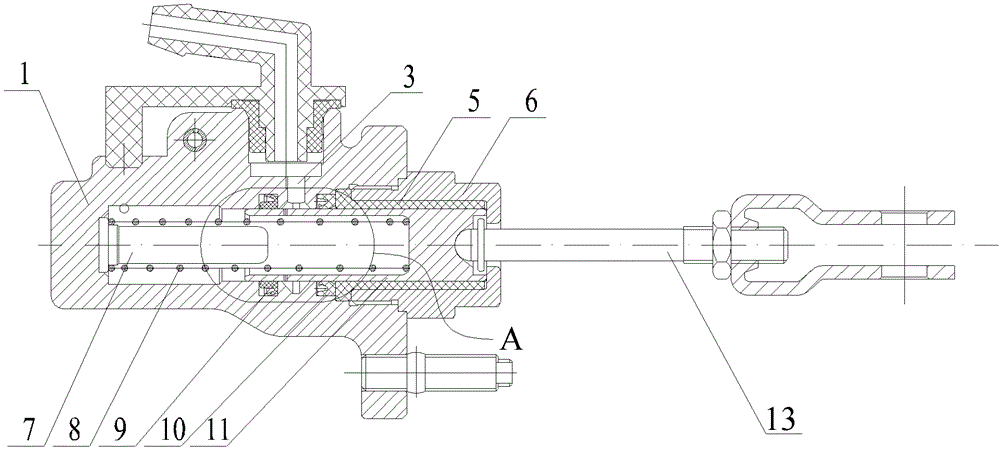

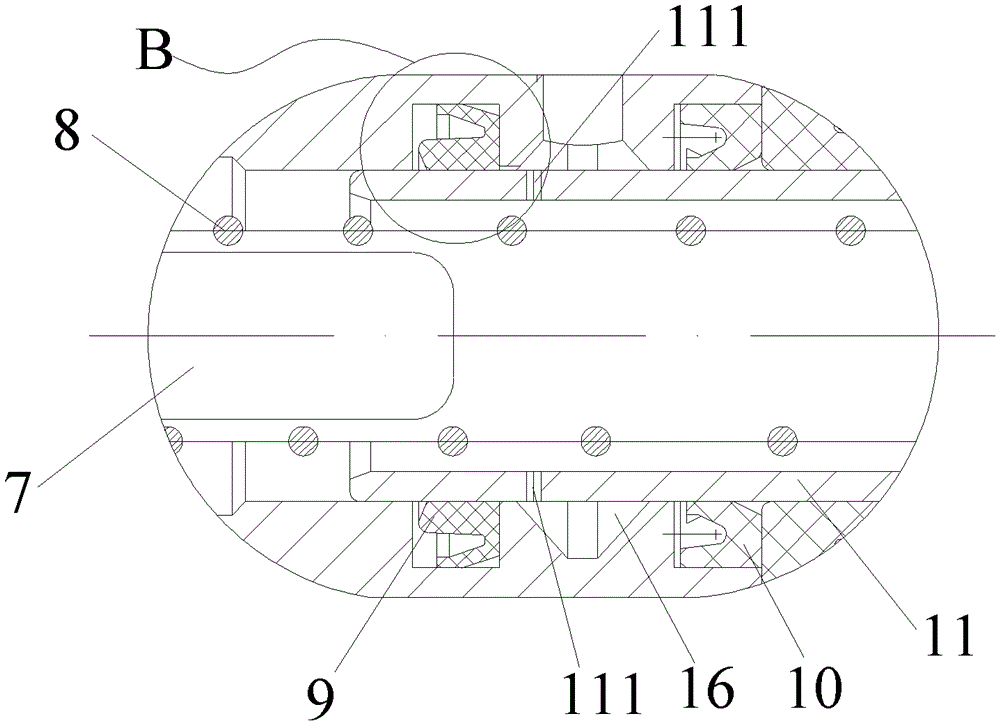

clutch master cylinder

InactiveCN103133559BIncreased durabilityRoughness is easy to controlFluid actuated clutchesMaster cylinderCylinder block

Owner:BEIJING JINLIAN GUOYU BRAKE PUMP

A thermoelectric battery pack

ActiveCN105957953BEffective anti-vibrationEffective impact resistanceThermoelectric device detailsThermodynamicsSpot welding

Owner:上海松芝酷能汽车技术有限公司

Radiating structure and manufacturing method thereof as well as electronic device with radiating structure

InactiveCN102014600BReduce areaEasy to processPrinted circuit assemblingPrinted circuit detailsHeat sinkElectronic component

The invention discloses a radiating structure, which comprises a double-layer circuit board, a bottom shell and a radiating fin, wherein the double-layer circuit board comprises a first circuit board and a second circuit board which are mutually fit; the first circuit board is provided with a first opening; the second circuit board is correspondingly provided with a second opening bigger than thefirst opening; a fixed connection zone is formed between the first opening and the second opening by the first circuit board; the bottom shell is fit below the second circuit board and is correspondingly provided with a third opening with the size equal to that of the second opening; the radiating fin is fixedly arranged below the bottom shell; a metal substrate with an adaptive shape is embeddedin the space formed by the second opening and the third opening; the upper surface of the metal substrate is fixedly connected with the fixed connection zone and the lower surface thereof is contacted with the radiating fin; and an electronic component is embedded in the first opening and the radiating part of the electronic component is fixedly connected with the upper surface of the metal substrate. The invention correspondingly provides an electronic device with the radiating structure and a manufacturing method of the radiating structure. The invention has better radiating effect, lower cost and higher product reliability.

Owner:MOBILE ANTENNA TECH SHENZHEN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com