Etching method of three-dimensional microstructures and application of three-dimensional microstructure

A microstructure and three-dimensional technology, applied in the field of nanomaterials, can solve the problems of low cell capture efficiency and poor cell adhesion, and achieve the effect of changing poor cell adhesion, increasing roughness, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

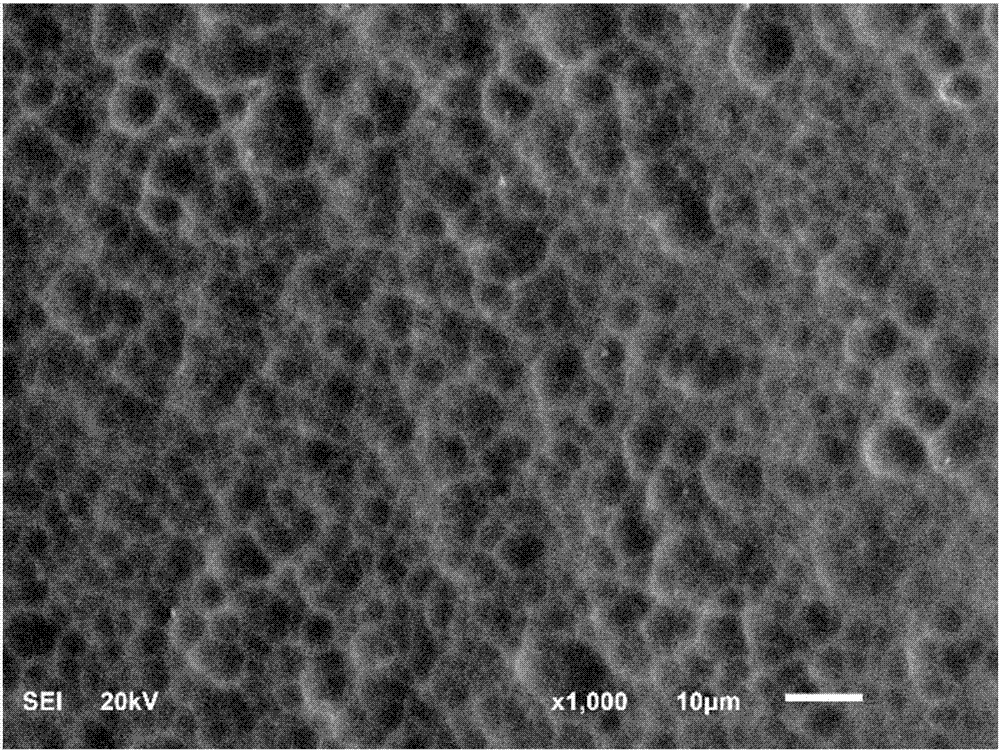

Embodiment 1

[0031] 1. Take a piece of optical glass (area: 25*75mm 2 ), and then the optical glass was ultrasonically cleaned, dried, and then the TiO 2 Suspensions of micronanoparticles (TiO 2 The diameter of micro-nano particles is 0.5-1μm, TiO 2 The mass percent concentration of the suspension is 0.5%) sprayed on one surface of the optical glass sheet, and the optical glass sheet was dried at 25°C for 10 minutes, so that the surface of the optical glass sheet was deposited with TiO 2 micron particle coating;

[0032] 2. Soak the optical glass sheet in the etching solution for etching, the etching rate is 1 μm / min, the etching time is 20 minutes, the etching solution is a mixed solution of nitric acid and hydrofluoric acid, and the mass percentage concentration of nitric acid is 10%, the mass percentage concentration of hydrofluoric acid is 11.56%, after the etching is completed, the optical glass sheet is ultrasonically cleaned for 80 minutes, the ultrasonic frequency is 45KHz, and ...

Embodiment 2

[0037] 1. Take a piece of optical glass (area: 25*75mm 2 ), and then the optical glass was ultrasonically cleaned, dried, and then the TiO 2 Suspensions of micronanoparticles (TiO 2 The diameter of micro-nano particles is 1-1.5μm, TiO 2 The mass percent concentration of the suspension is 3%) sprayed on one surface of the optical glass sheet, and the optical glass sheet was dried in the air at 25°C for 10 minutes, so that TiO was deposited on the surface of the optical glass sheet 2 micron particle coating;

[0038] 2. Soak the optical glass sheet in the etching solution for etching. The etching rate is 10 μm / min, and the etching time is 12 minutes. The etching solution is a mixed solution of nitric acid and hydrofluoric acid, and the mass percentage concentration of nitric acid is 13%, and the mass percent concentration of hydrofluoric acid is 15.04%. After the etching is completed, the optical glass sheet is ultrasonically cleaned for 80 minutes, the ultrasonic frequency i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com