Electroplating technology for satin nickel of back coating mold and application of back coating mold electroplated with stain nickel

An electroplating process, pearl nickel technology, which is applied in the electroplating process field of back-coated mold pearl nickel, can solve the problems of uneven surface roughness and roughness variation of the coating, and achieve roughness in a short time, with uniform surface roughness and roughness controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The electroplating solution is: nickel sulfate 400g / L; nickel chloride 40g / L; boric acid 30g / L; sodium allyl sulfonate 2g / L; polyoxyethylene oleate: 8ml / L; hydroquinone: 0.05g / L;

[0034] Electroplating solution pH=4; electroplating solution temperature T=50°C; current density during electroplating: 4A / dm 2

[0035] The surface color of the coating obtained by electroplating is soft, with excellent sandblasting and matte effect, and the surface roughness is uniform. Using UV glue, UV lamp, and PET to obtain the diaphragm for haze test, the haze is 90±4%. The surface haze is relatively uniform, basically free of defects, and can be used for the production of brightening film. Since the pearl nickel coating has good corrosion resistance, it can be stored for a long time.

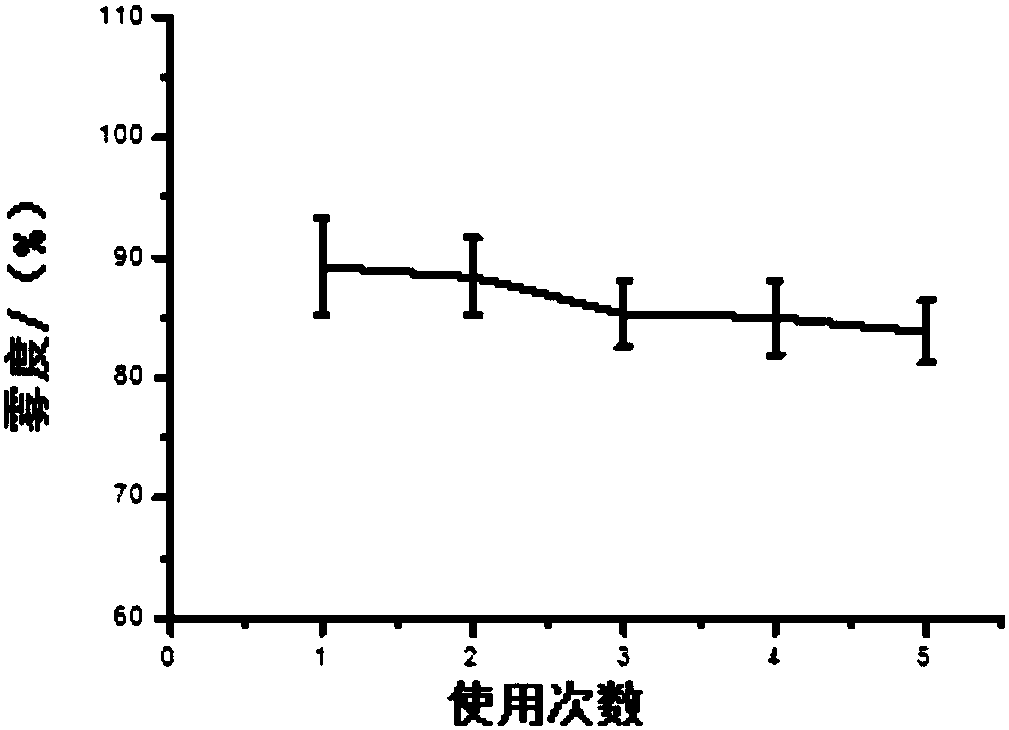

[0036] The plating solution in Example 1 is used repeatedly for electroplating to obtain different batches of pearl nickel, and the haze change of the brightness-enhancing film is tested by coating; ...

Embodiment 2

[0039] The electroplating solution is: nickel sulfate 400g / L; nickel chloride 40g / L; boric acid 30g / L; saccharin: 5g / L; polyoxyethylene laurate: 6ml / L; polyoxyethylene oleate: 4ml / L; Diphenylamine: 0.01g / L; electroplating solution pH=5; electroplating solution temperature T=55°C, current density during electroplating: 3A / dm 2 ;

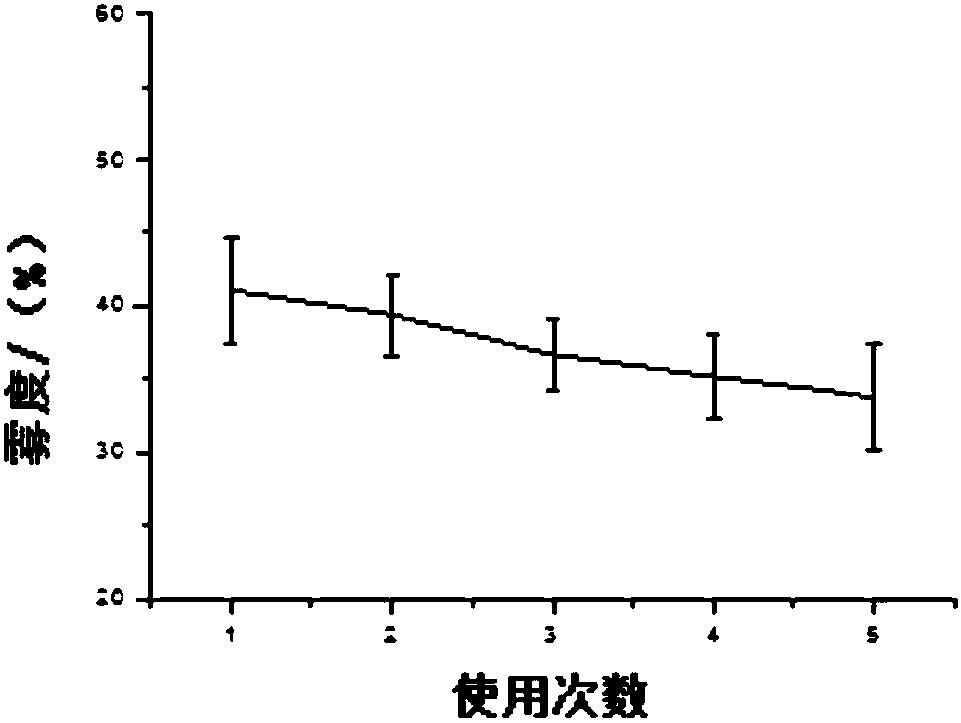

[0040] The surface color of the coating obtained by electroplating is soft, with excellent sandblasting and matte effect, and the surface roughness is uniform. Using UV glue, UV lamp, and PET to obtain the diaphragm for haze test, the haze is 40±4%. The surface haze is relatively uniform, the surface is basically free of defects, and it can be used to produce brightening films. Because the pearl nickel coating has good corrosion resistance, it can be stored for a long time; the plating solution is recycled many times for electroplating to obtain different batches of pearl nickel , the change of haze is small through coating test, and the haze stabili...

PUM

| Property | Measurement | Unit |

|---|---|---|

| haze | aaaaa | aaaaa |

| haze | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com