Patents

Literature

76results about How to "Uniform surface roughness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

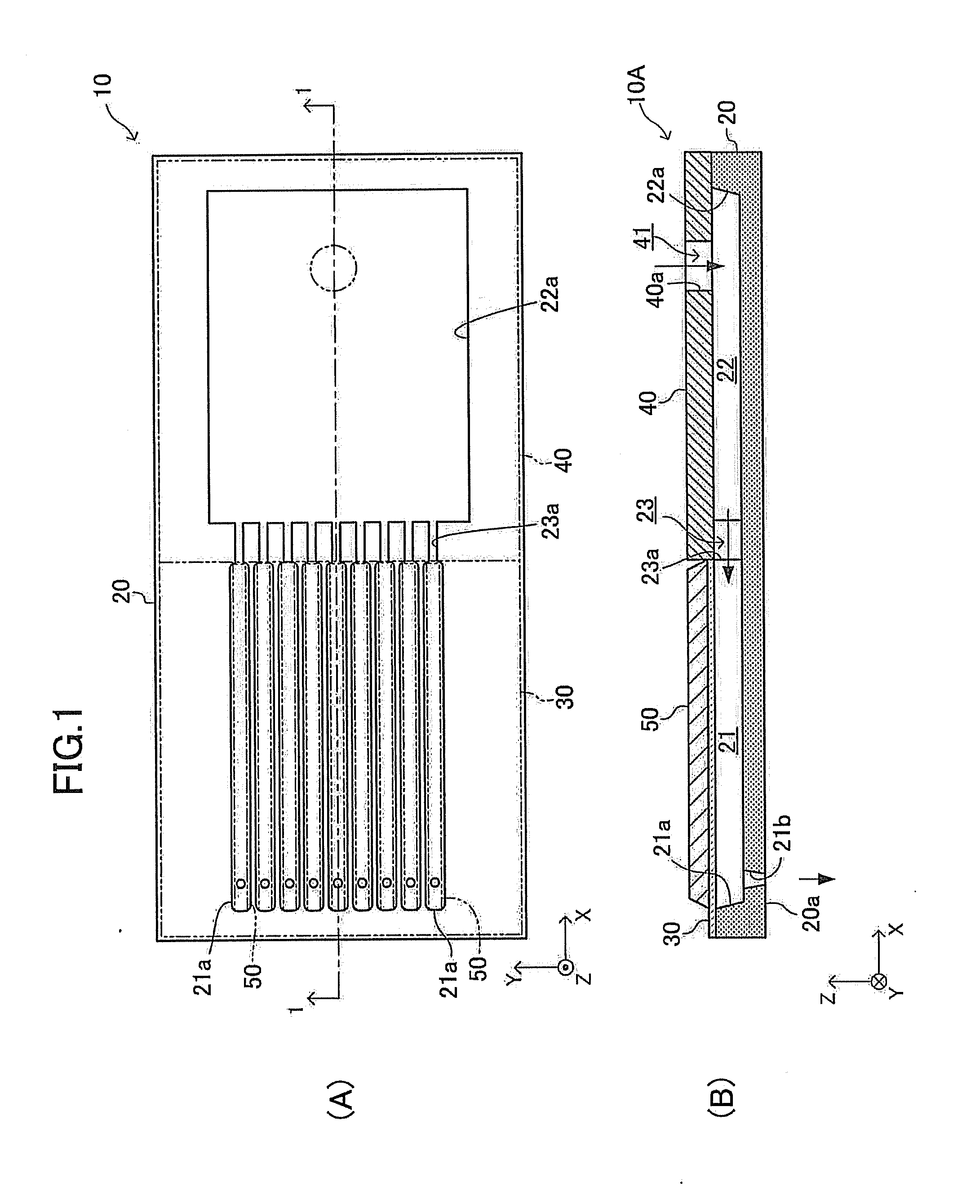

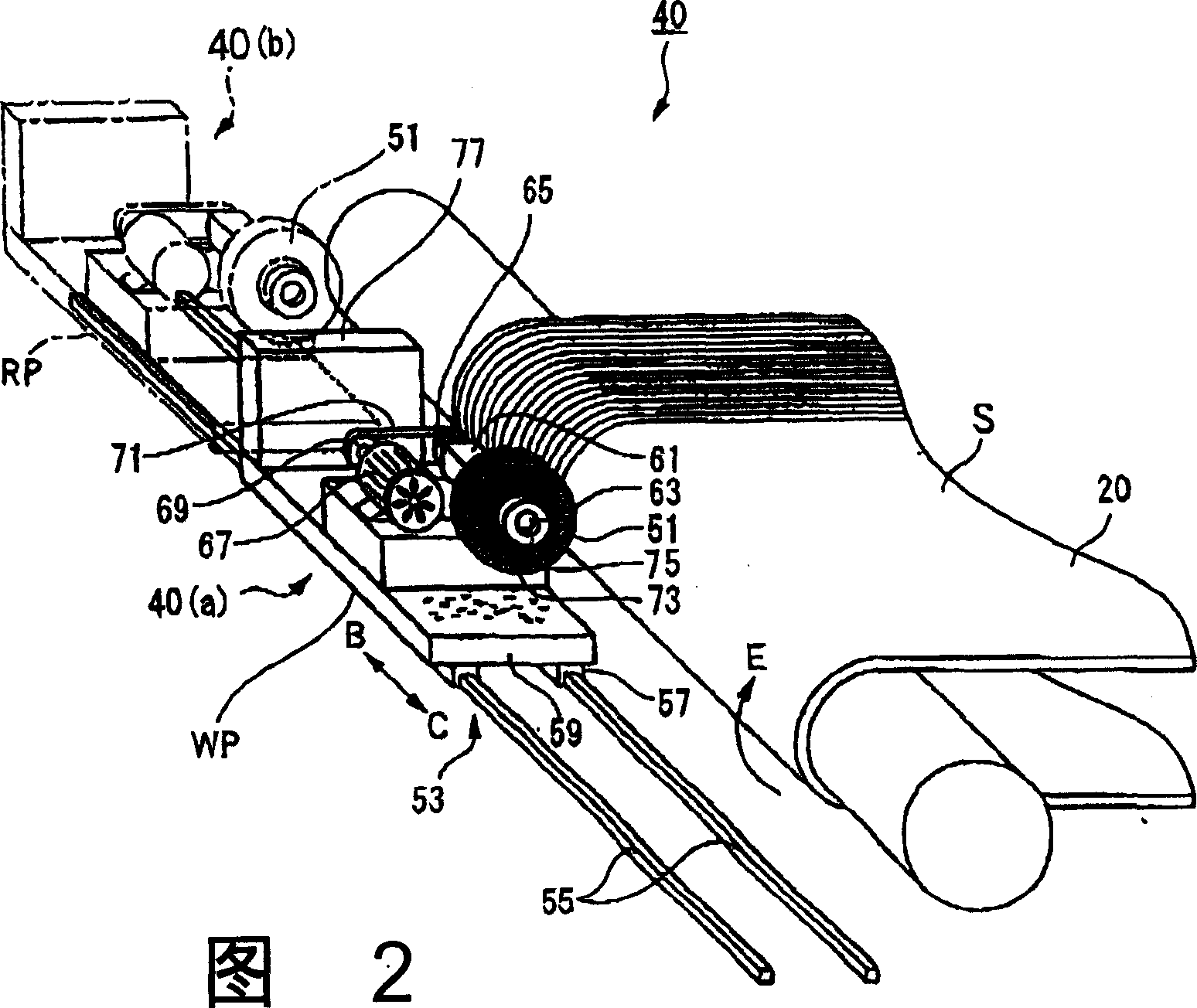

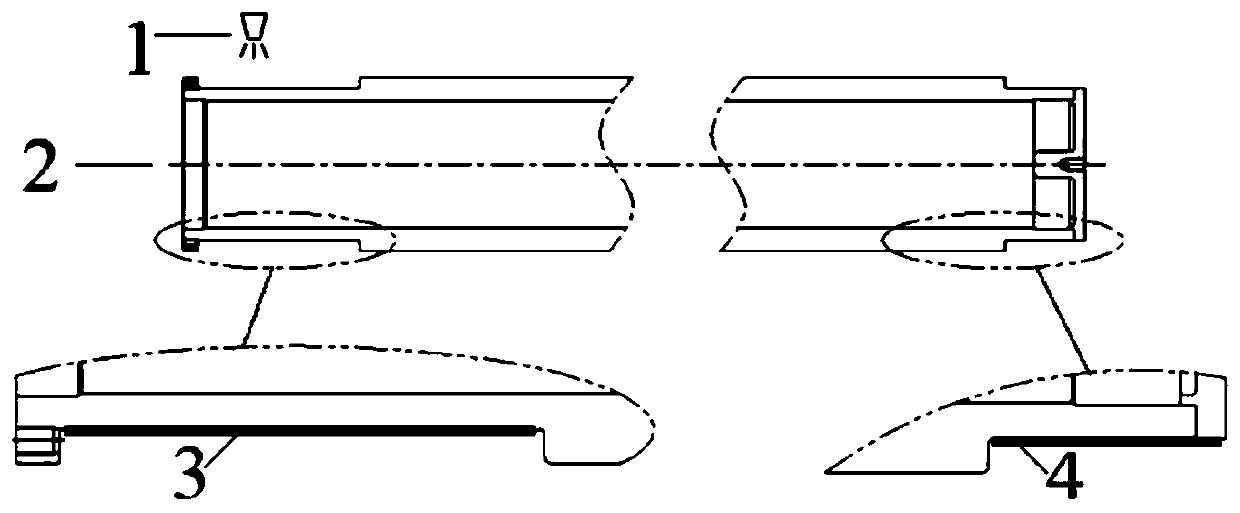

Conditioner for polishing pad and method for manufacturing the same

InactiveCN1391506AEffective regulationUniform surface roughnessSemiconductor/solid-state device manufacturingLapping machinesCarbideMechanical engineering

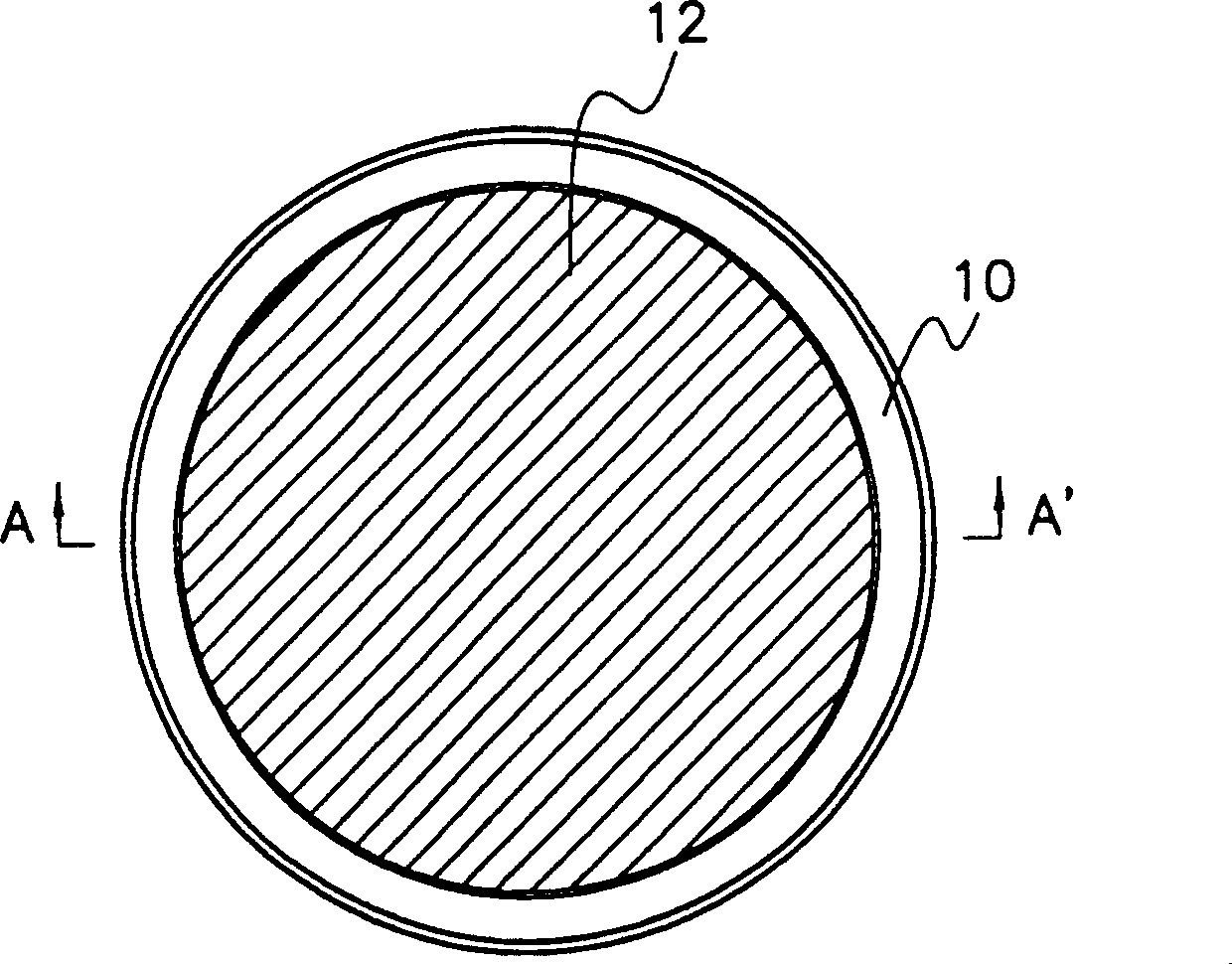

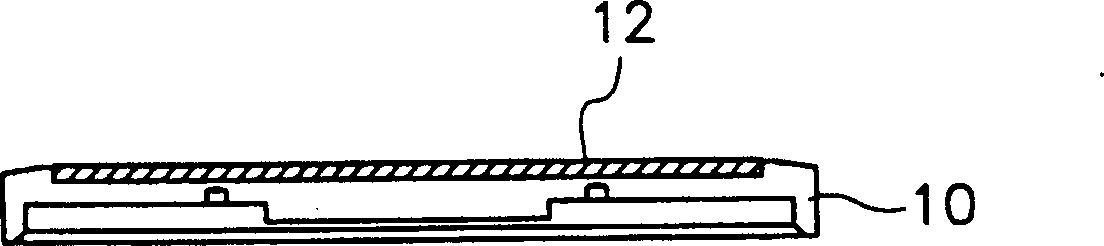

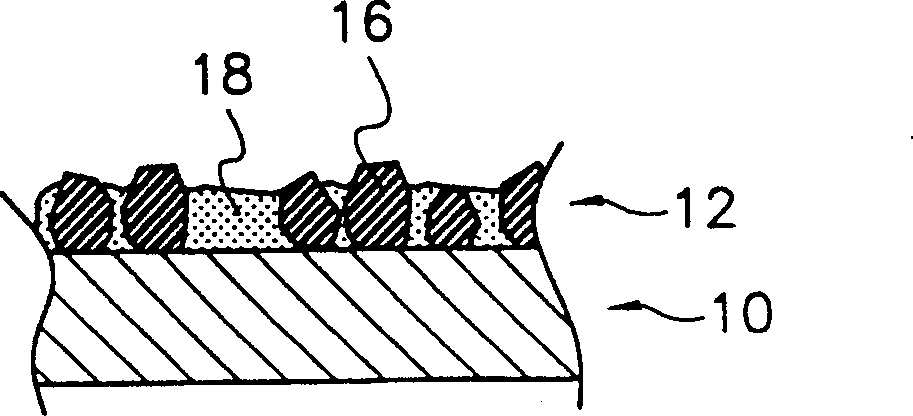

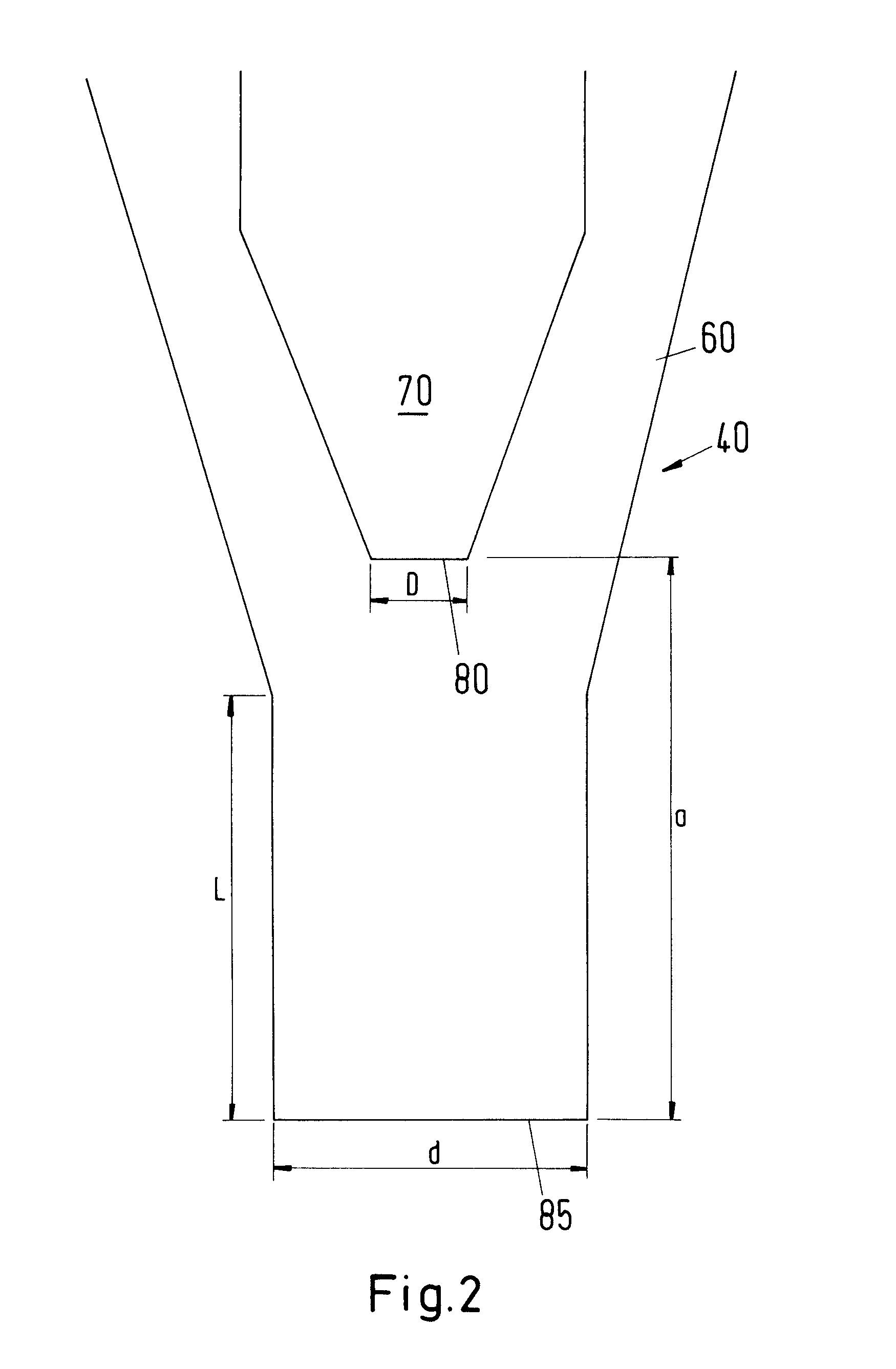

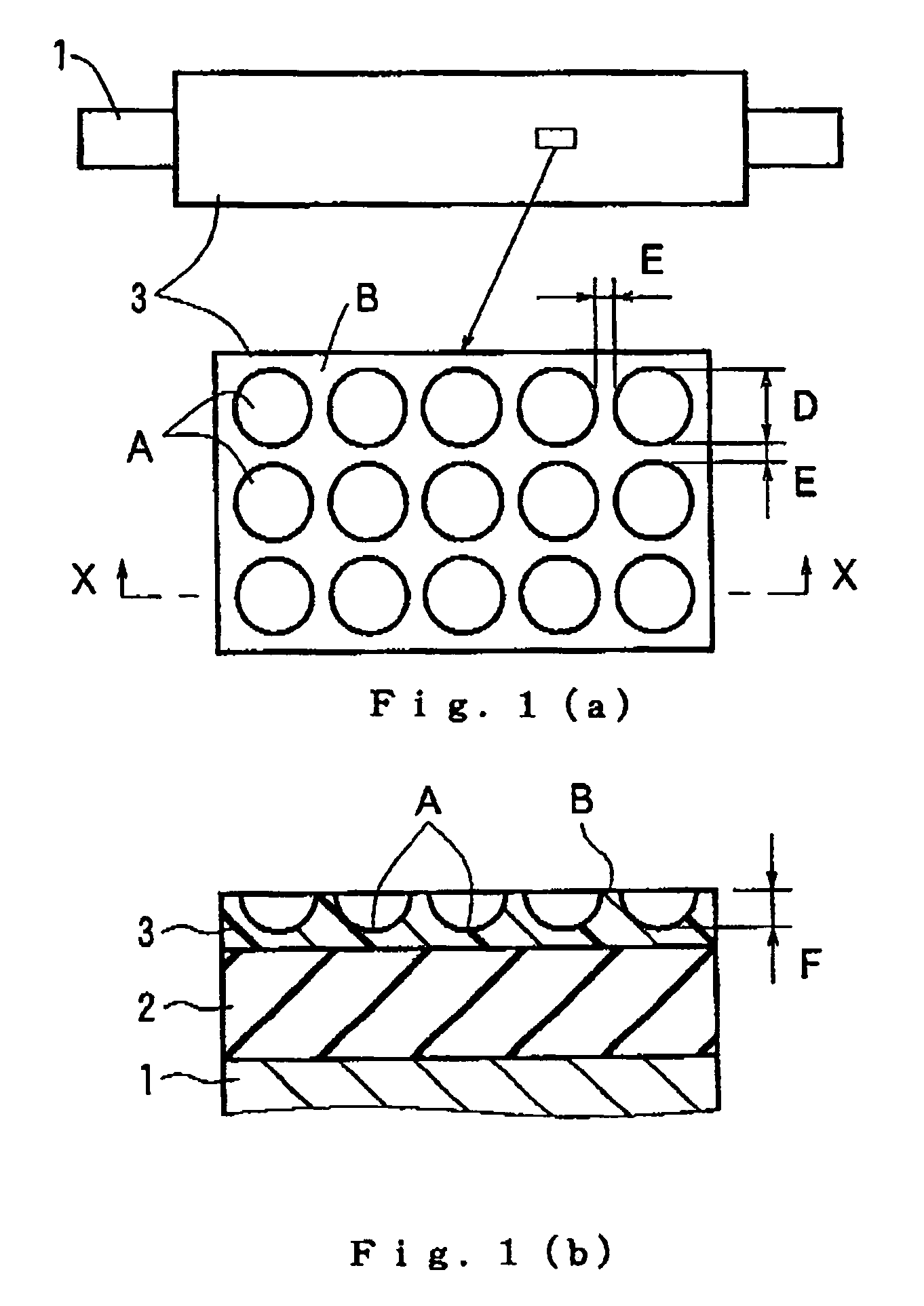

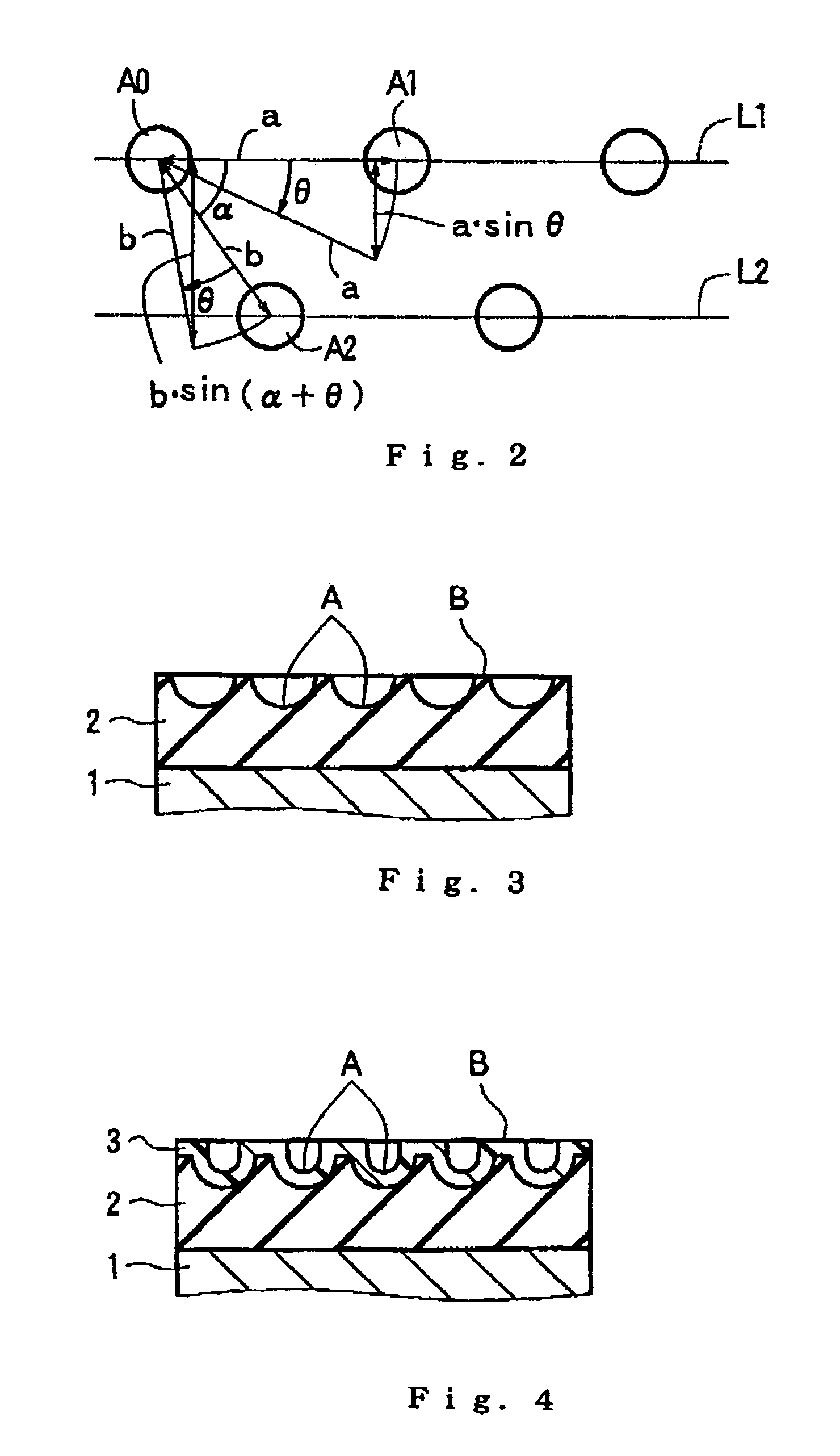

A ceramic disc-shaped substrate is formed with geometrical protrusions of a uniform height on at least one side. A cutting portion (22) is formed, with a diamond layer of a uniform thickness formed on all the surface of the side of the substrate with protrusions. The protrusions have a flat upper surface, or the upper surface may comprise several smaller protrusions formed by recessed grooves. The cutting portion makes line and surface contacts with the polishing pad surface. An independent claim is included for a method of manufacturing a conditioner for a polishing pad

Owner:二和DIAMOND工业株式会社

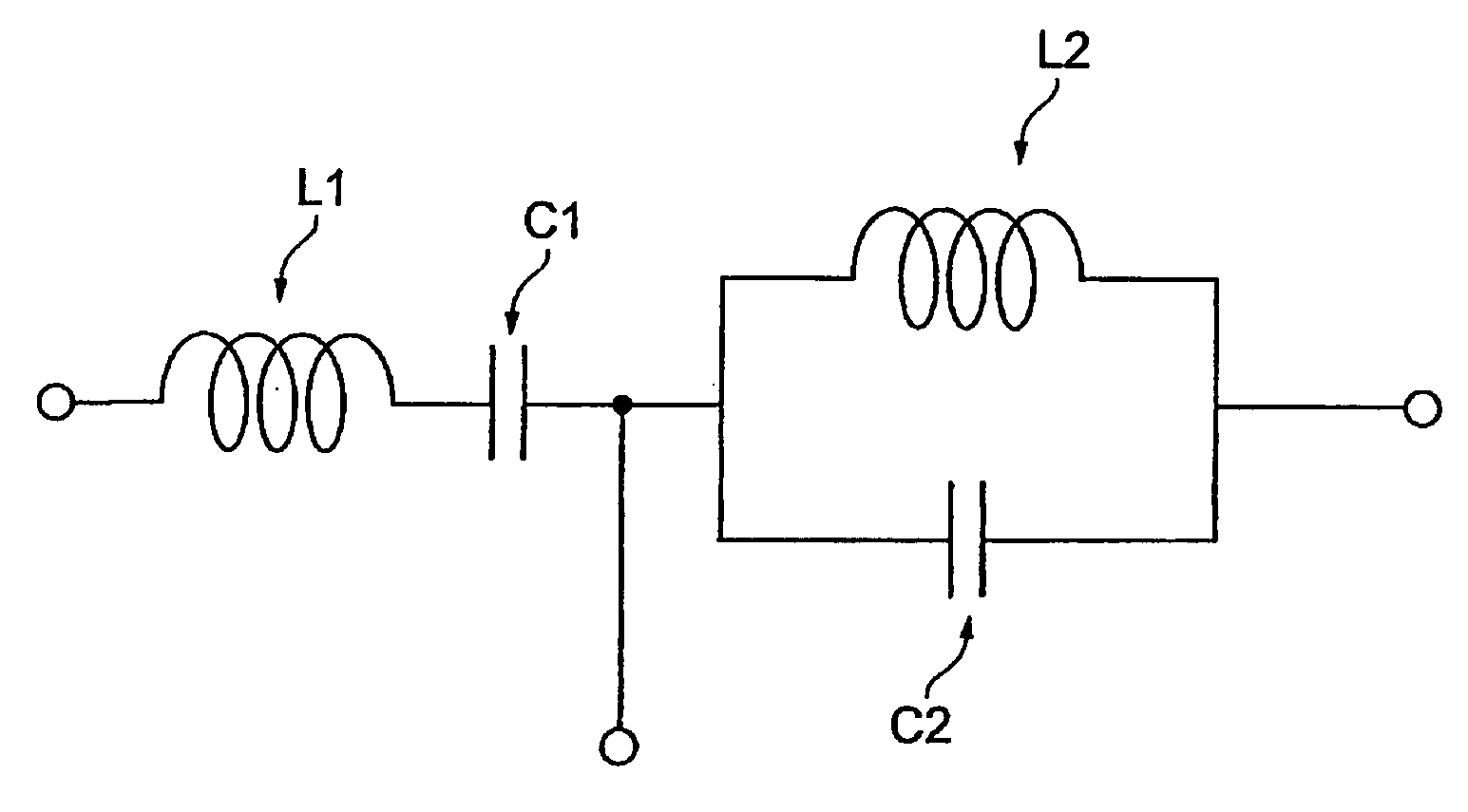

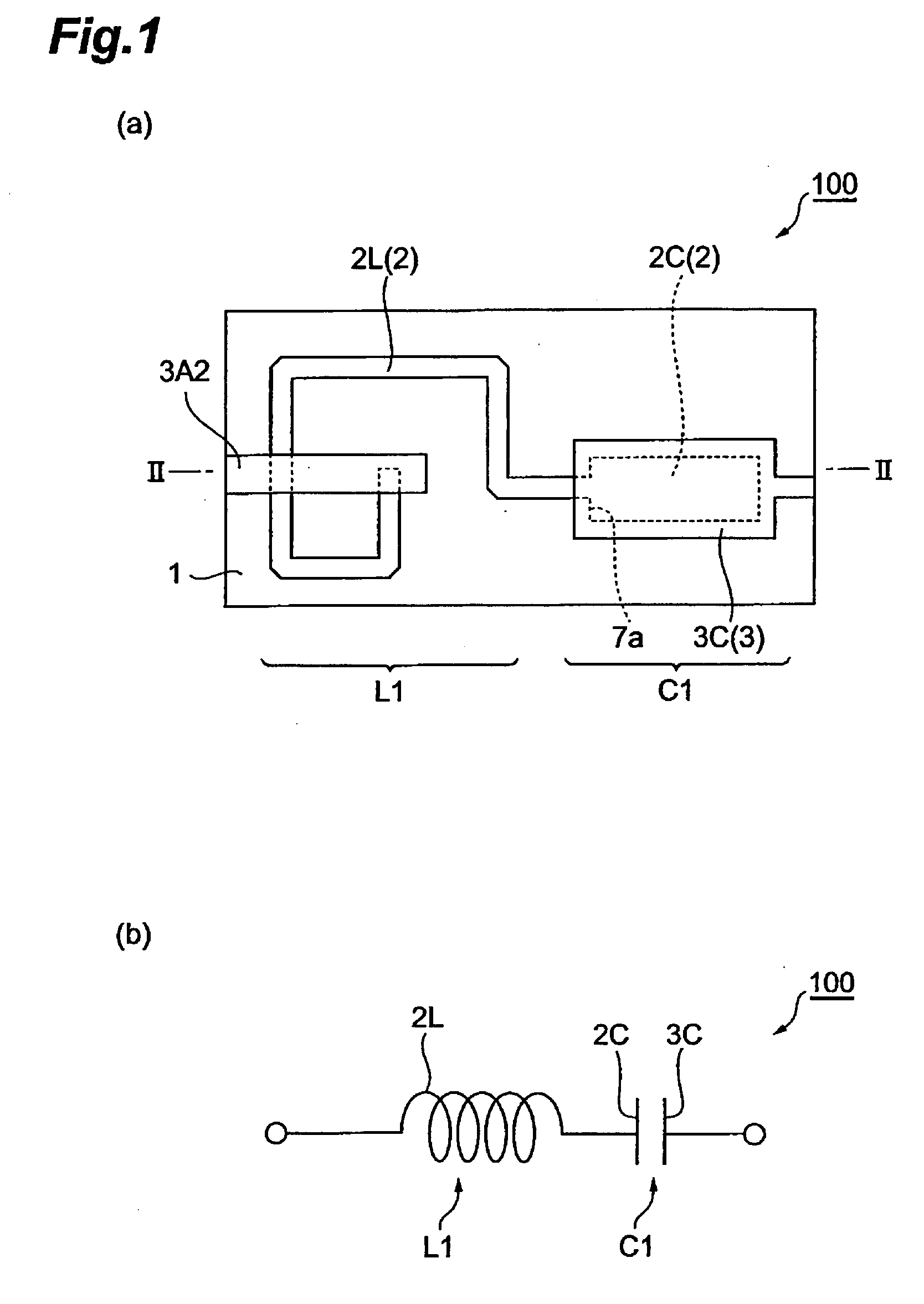

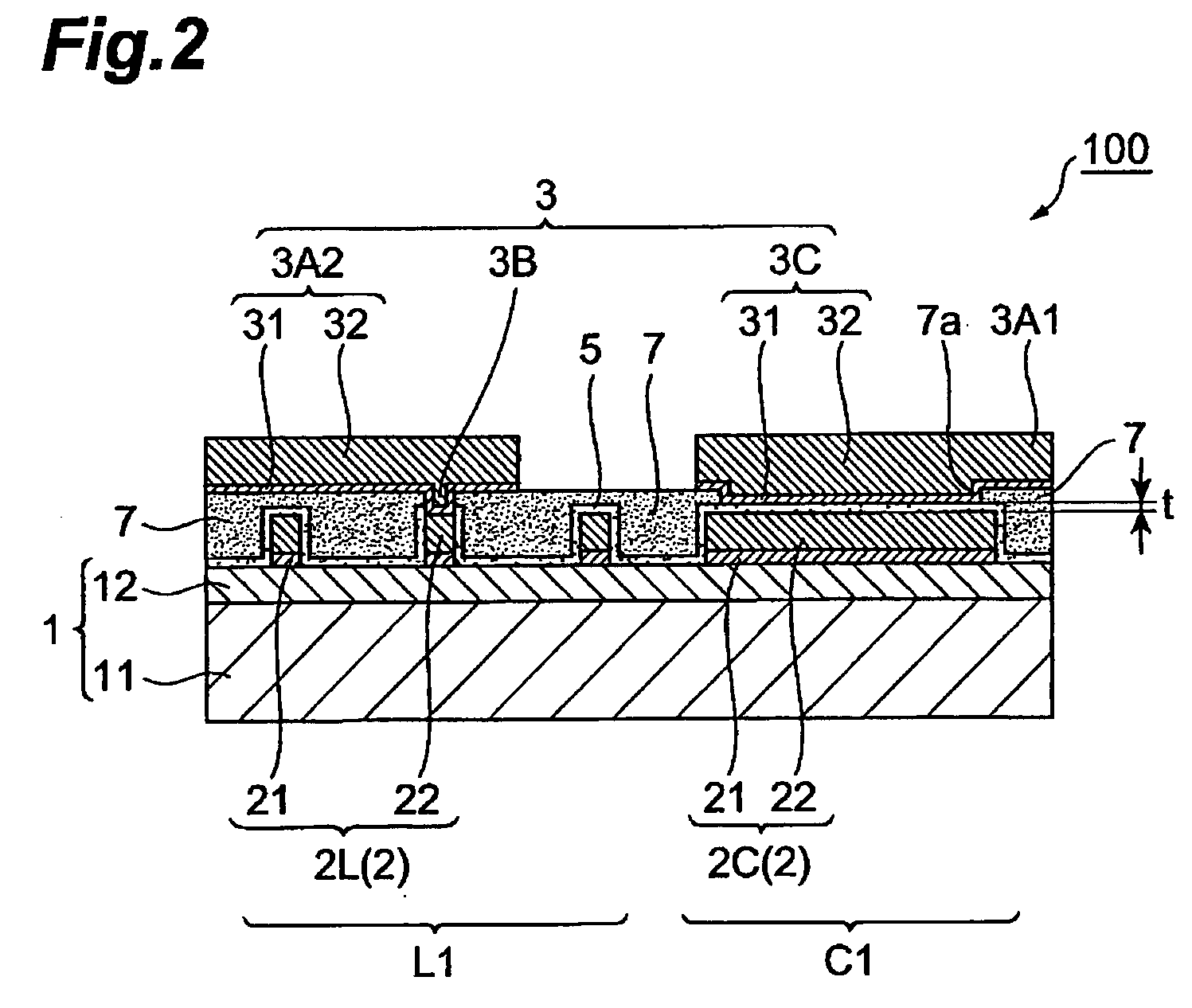

Electronic component and method for manufacturing same

ActiveUS20080023219A1Improve efficiencyLow costMultiple-port networksSolid-state devicesDielectricElectrical conductor

An electronic component having: a substrate, a lower conductor layer provided on the substrate; an inorganic dielectric film that covers the lower conductor layer; and an upper conductor layer having an upper electrode portion provided on the inorganic dielectric film. The lower conductor layer has a lower electrode portion that together with the upper electrode portion and the inorganic dielectric film constitutes a capacitor, and a coil portion that constitutes an inductor. The entire inorganic dielectric film is formed integrally, and the lower conductor layer is in contact only with the substrate, inorganic dielectric film, and upper conductor layer.

Owner:TDK CORPARATION

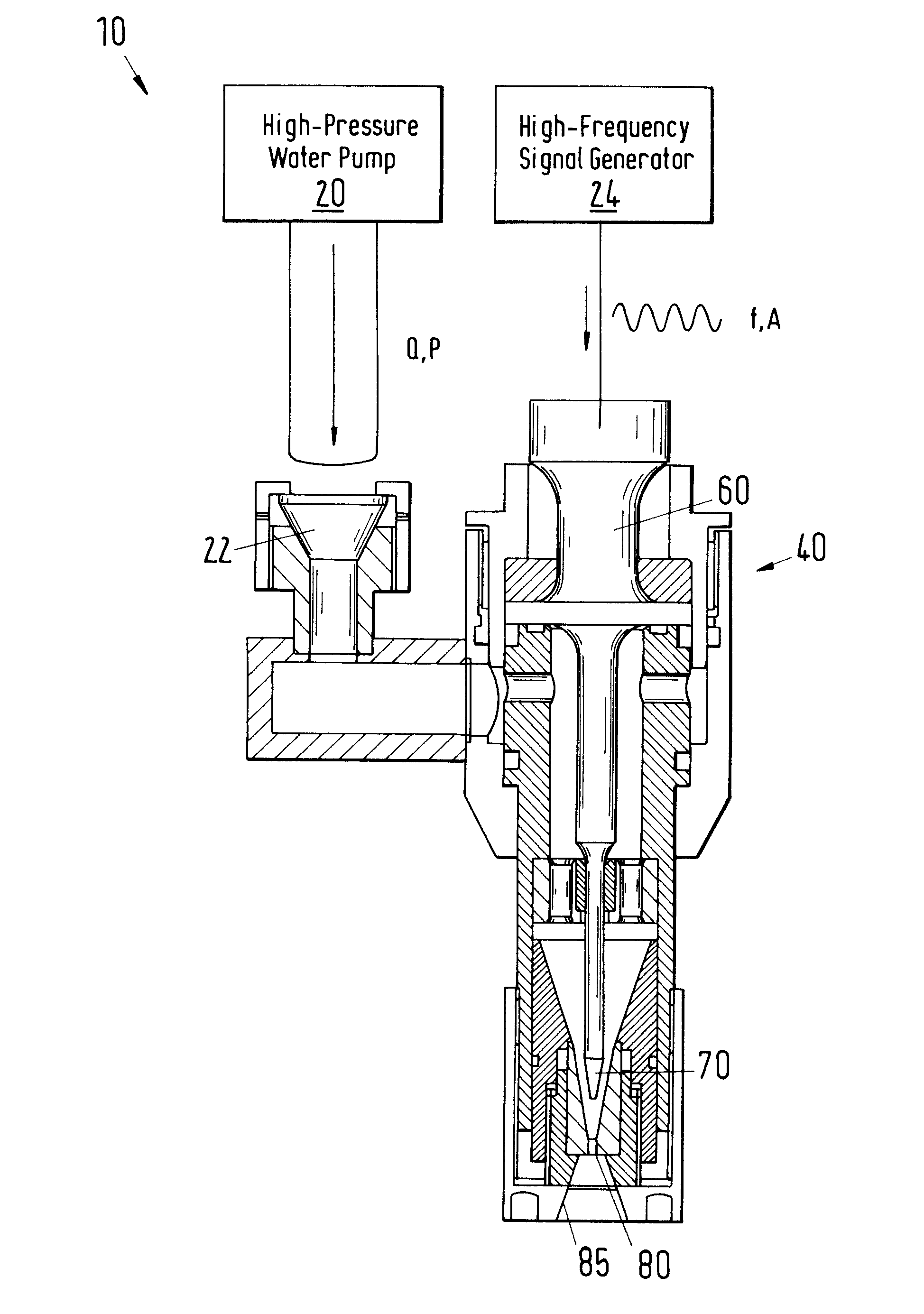

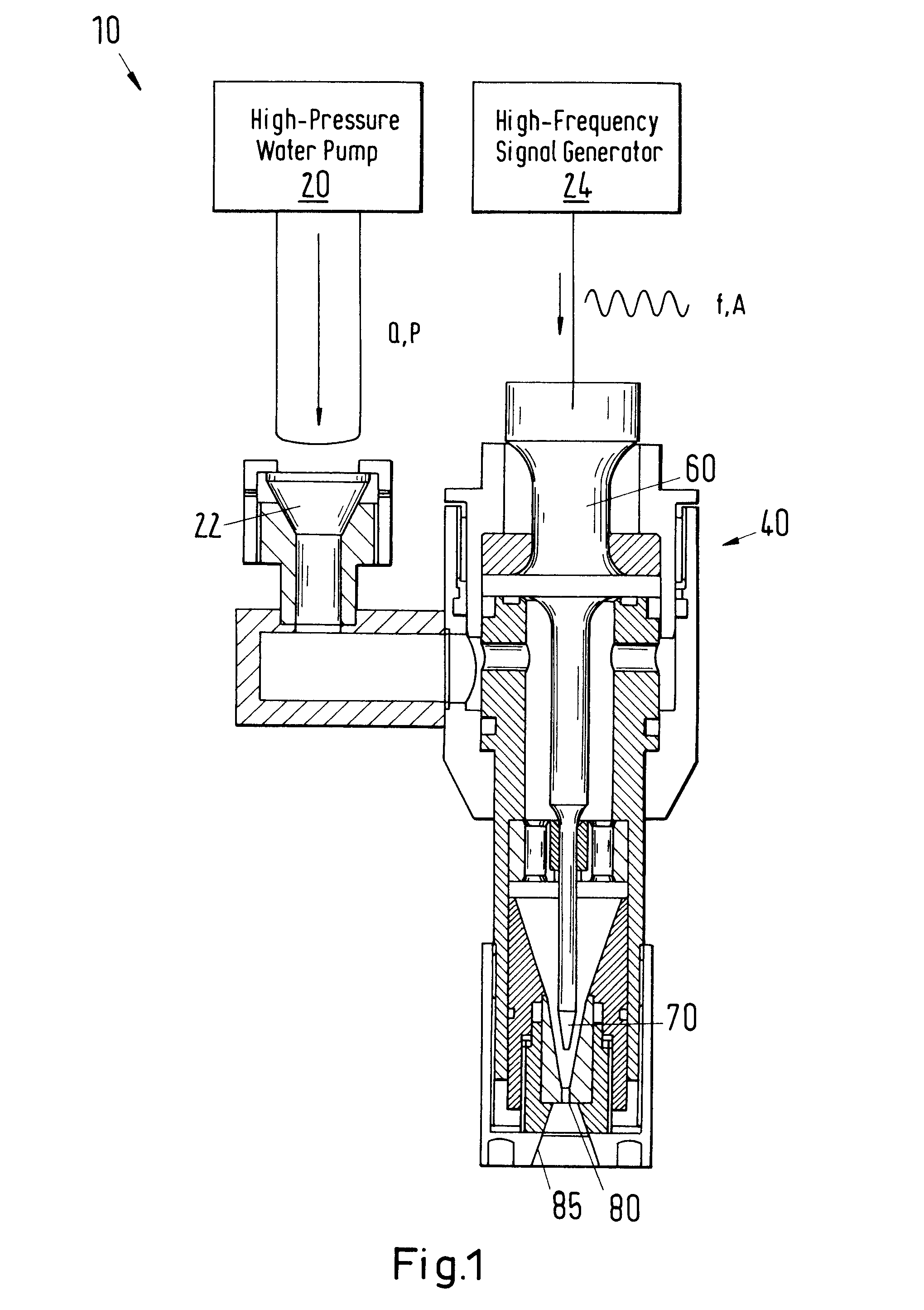

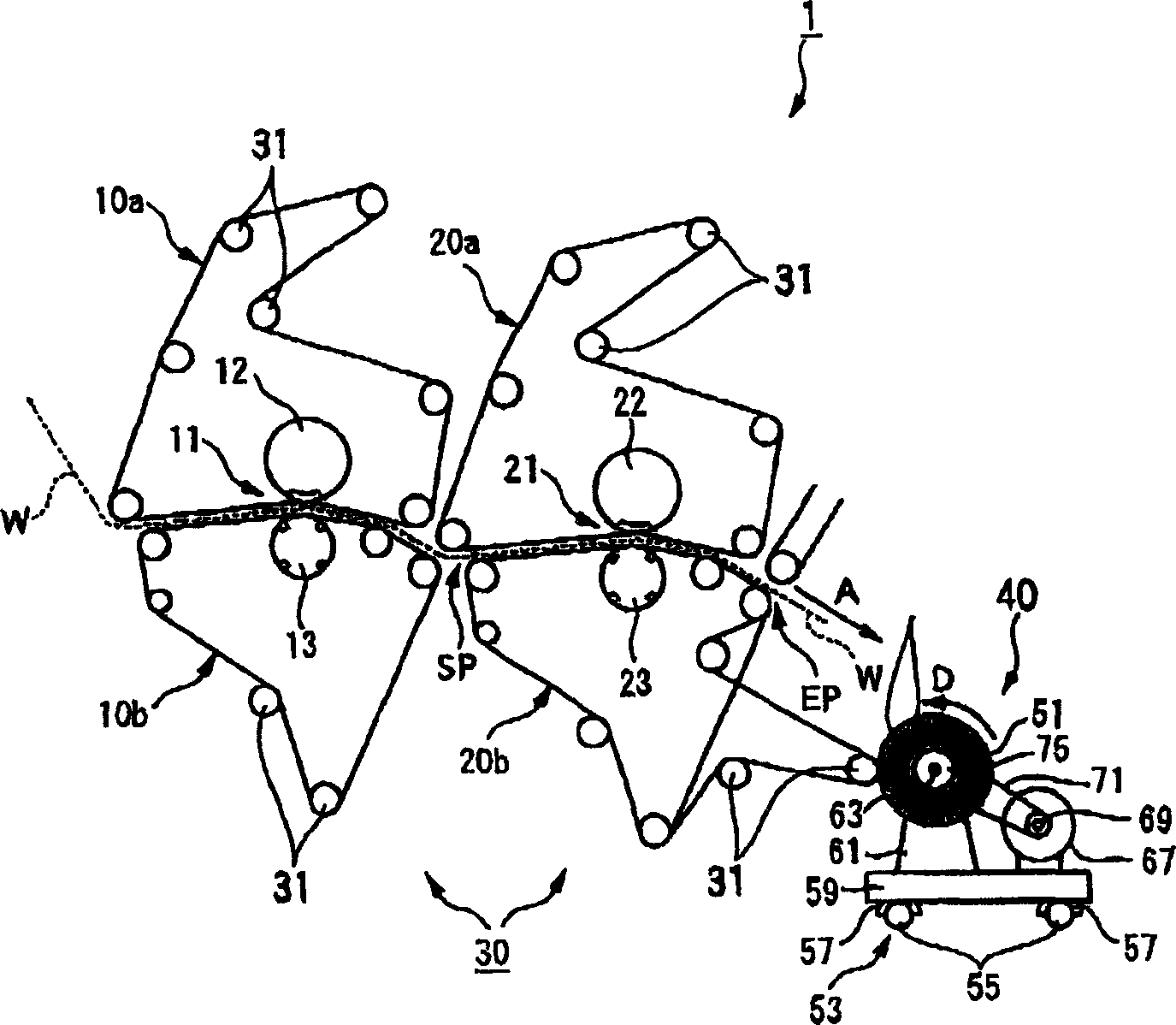

Method and apparatus for preparation of cylinder bore surfaces with a pulsed waterjet

InactiveUS20120322347A1Exact and highly uniform surface roughness characteristicHighly predictableBlast gunsMolten spray coatingSpray nozzleWater flow

An apparatus for and a method of prepping a surface of a cylinder bore using a pulsed waterjet entails generating a signal having a frequency f using a signal generator, applying the signal to generate a pulsed waterjet through an exit orifice of a nozzle having an exit orifice diameter d and a length L. The pulsed waterjet prepares the surface to within a predetermined range of surface roughness. The surface roughness is determined by selecting operating parameters comprising a standoff distance (SD), a traverse velocity VTR of the nozzle, a water pressure P, a water flow rate Q, a length-to-diameter (L / d) ratio, the frequency f, and an amplitude A of the signal.

Owner:SULZER METCO (US) INC

Honed embossed adhesive tape basilemma and production method thereof

A honed embossed adhesive tape basilemma is made of pure polyolefin resin, the roughness of the front face Ra value is 20-60 mu inch, the roughness of the back face Ra value is 60-200 mu inch, the production method thereof comprises steps of melting and extruding, embossing and finishing. The honed embossed adhesive tape basilemma prepared by the invention has special honed effect, even surface roughness, even thickness stability, good longitudinal and transverse tear resistance, good anti-blocking effect and excellent gluing effect. The method of the invention does not change the inner structure of the basilemma material, thus not influencing the physical performance of the basilemma material, and being applicable to production of honed embossed adhesive tape basilemma and production of honed basilemma for other special uses.

Owner:湖北慧狮塑业股份有限公司

Chemical granulation processing method for quartz surface

A method for chemically and roughly treating a quartz surface overcomes the defects of the prior art in which the treatment to the quartz surface easily leads to damage and influences the size accuracy of the quartz product. The method is as below: at a normal temperature and a normal pressure, immersing a quartz product into a container filled with a treating fluid so as to undergo reaction after the surface of the quartz product is polished, taking out the quartz product after two-hour reaction, and immersing the quartz product into the treating fluid again so as to repeat the preceding reaction till the roughness Ra of the surface of the quartz product is equal to 1.5 micrometers to 4.5 micrometers after attachments on the surface of the quartz product is eliminated with deionized water. The treatment process has reasonable design, involves simple devices and is easy to be operated, and the obtained quartz product has uniform surface roughness which is free from the influence of the shape. During the participation in the CVD reaction, the crazing and the shedding of a deposited film on the quartz surface is effectively reduced so as to reduce the possibility of pollution to the reaction cavity, to remarkably improve the finished product rate and the production efficiency, and then further to prolong the service life of the quartz product, save time, reduce consumption and reduce production cost.

Owner:SHENYANG HANKE SEMICON MATERIALS

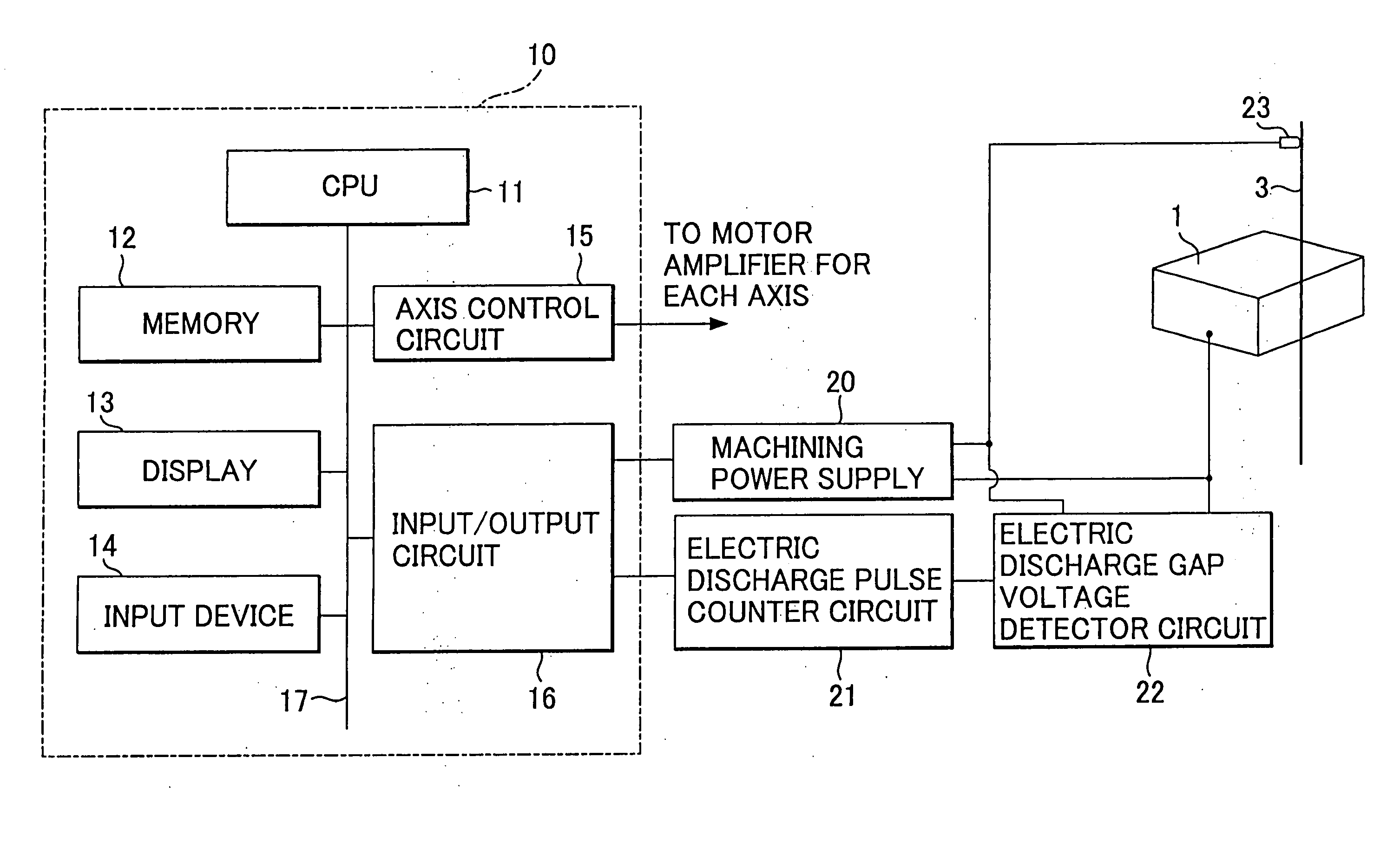

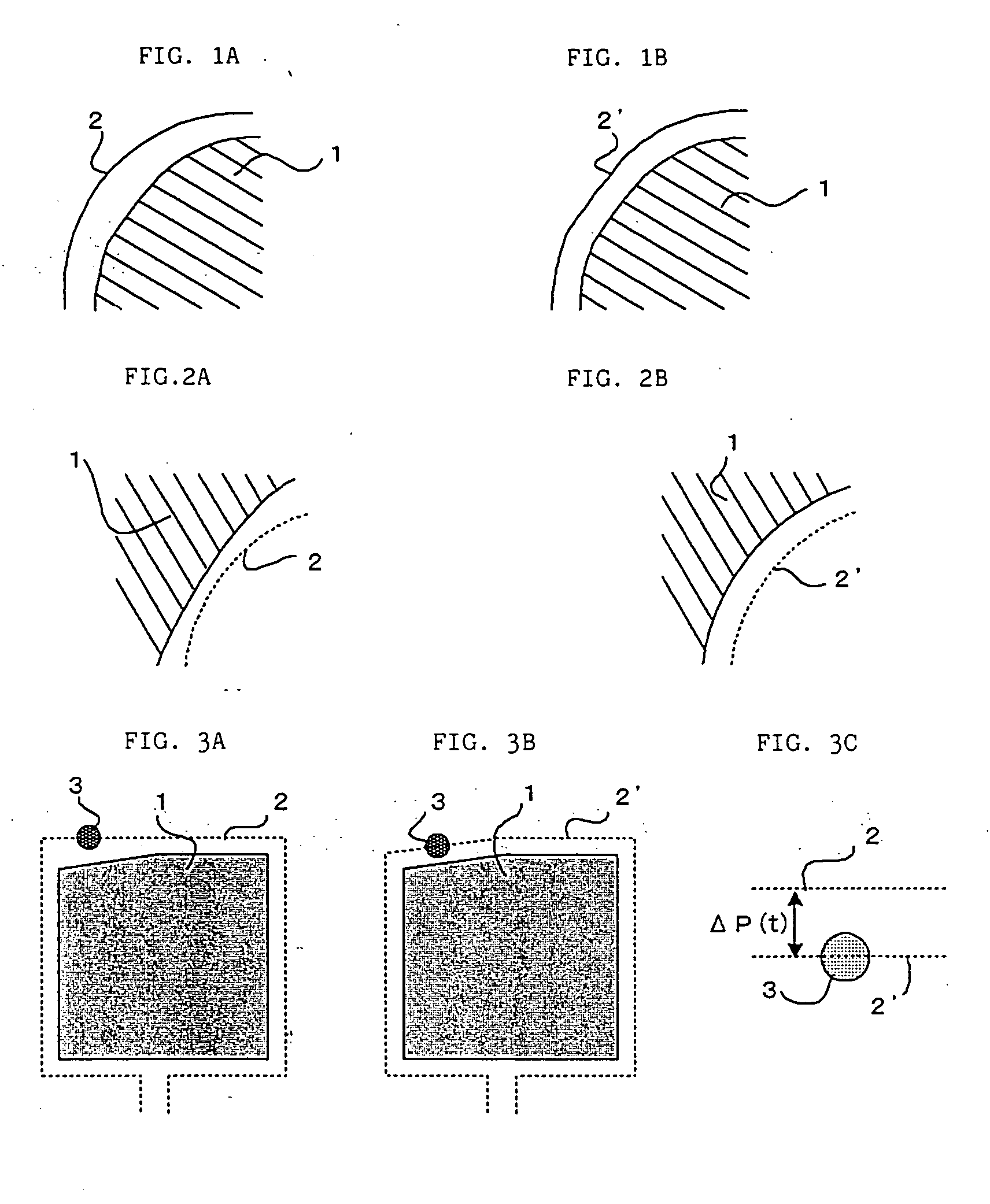

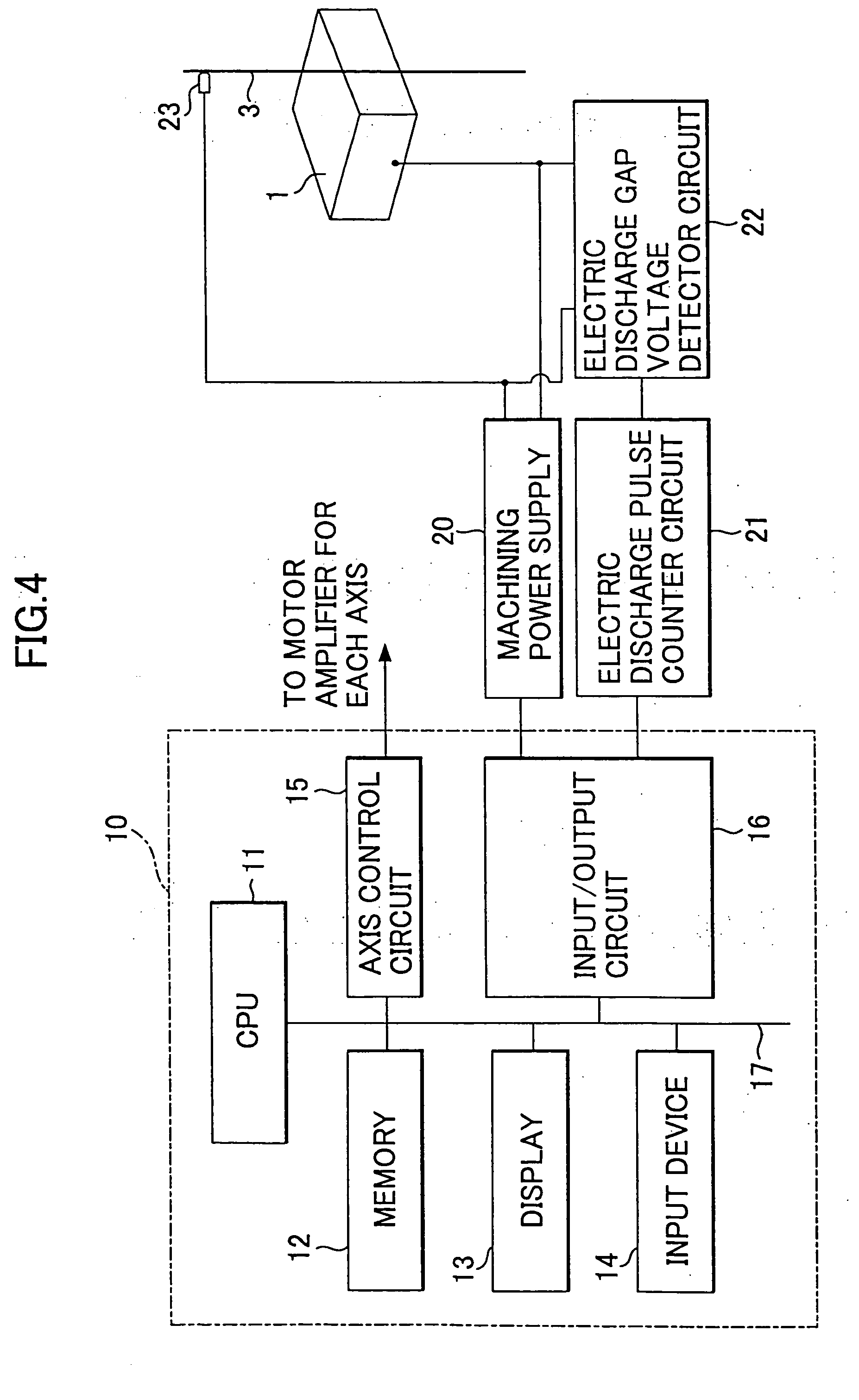

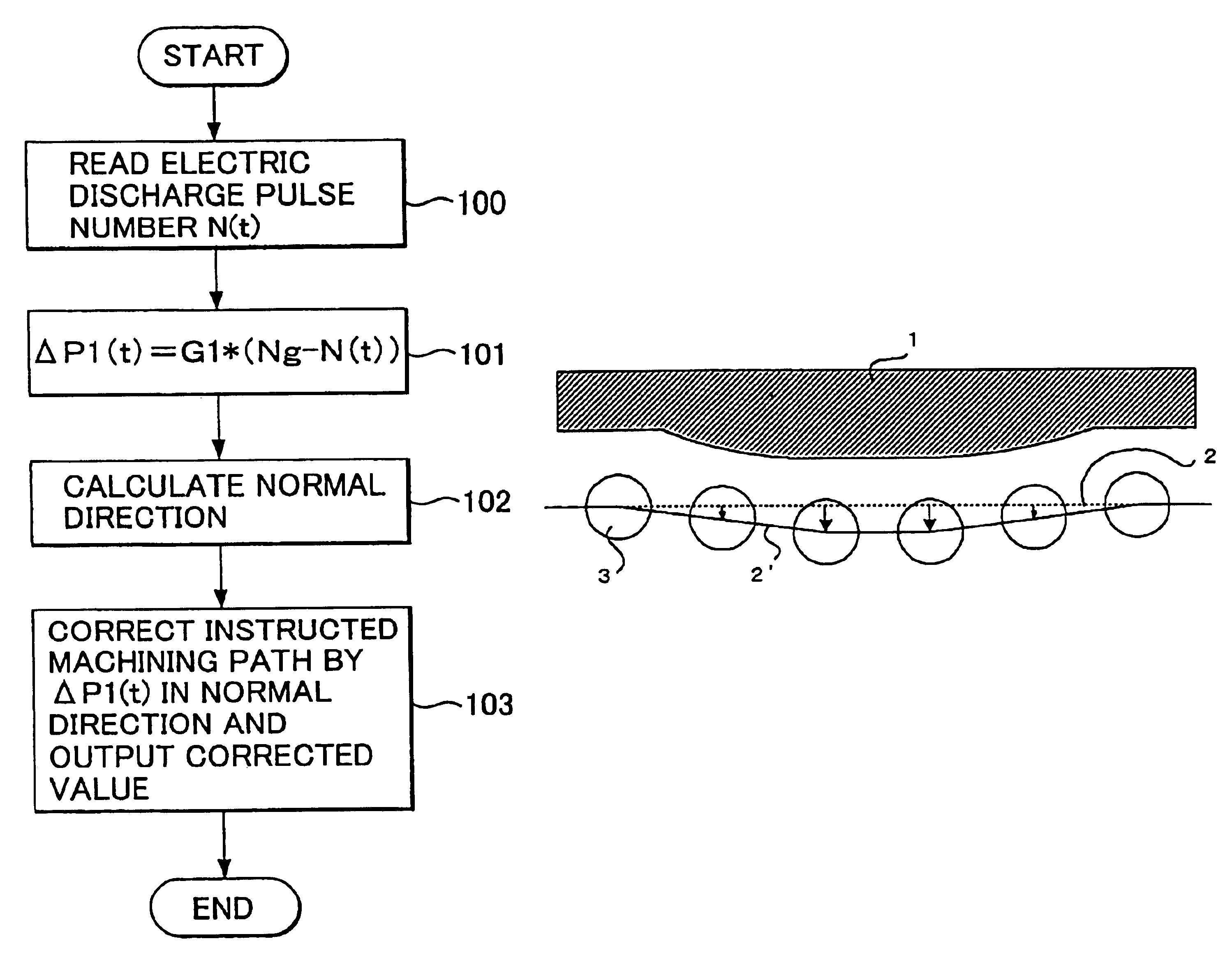

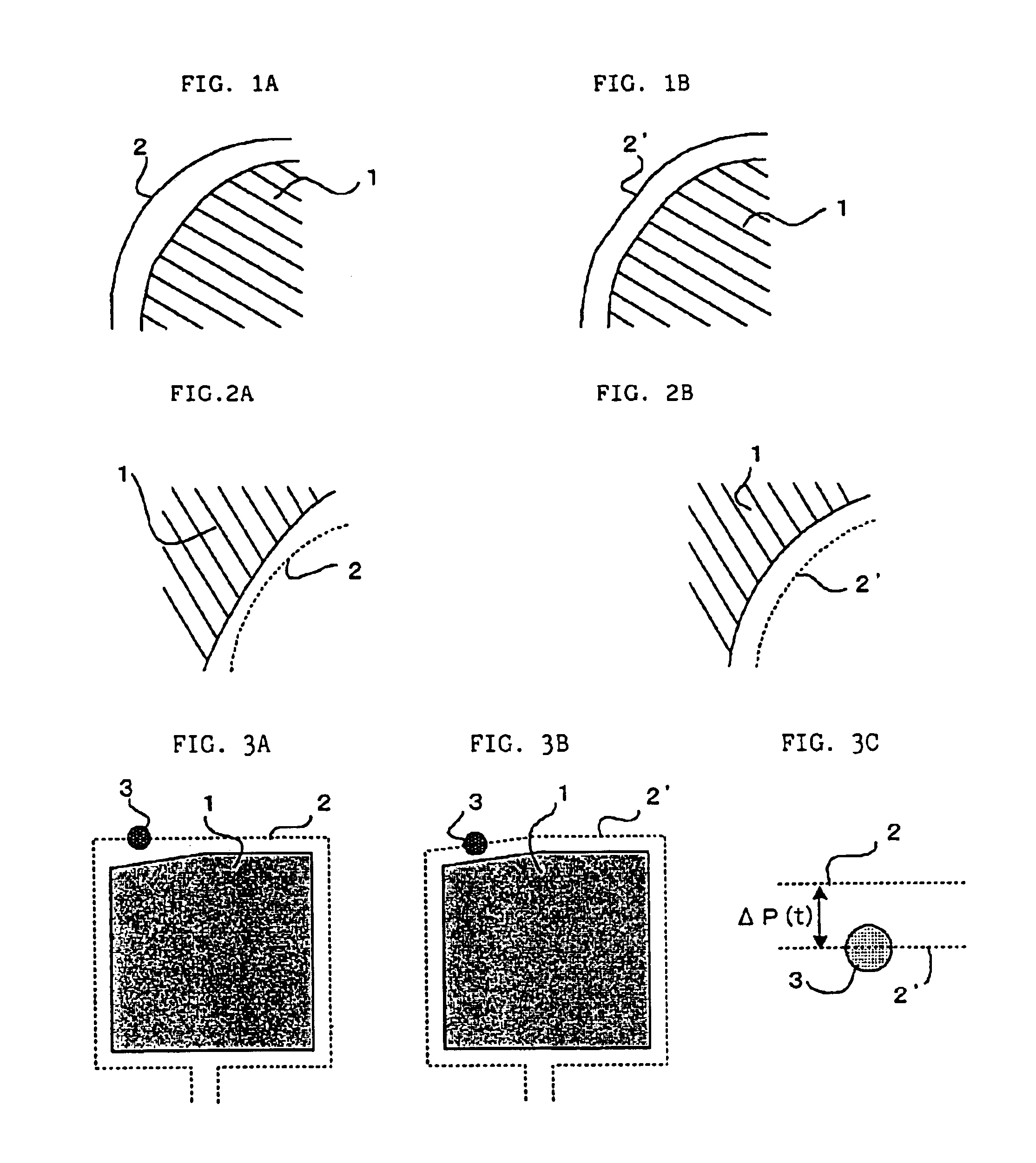

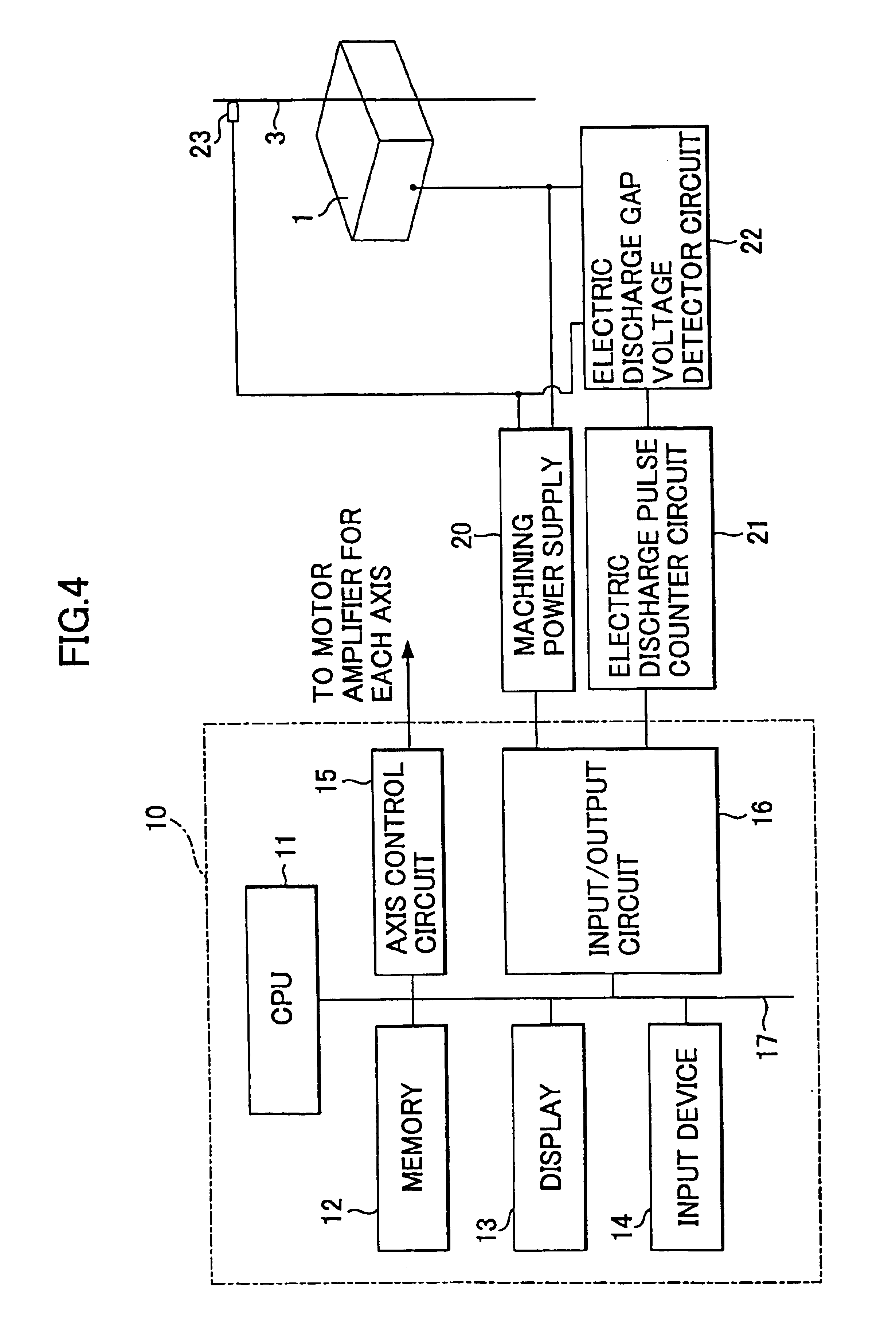

Machining control method for wire-cut electric discharge machine

InactiveUS20050040142A1Uniform surface roughnessUniform roughnessElectric circuitsMachine controlElectrical and Electronics engineering

Owner:FANUC LTD

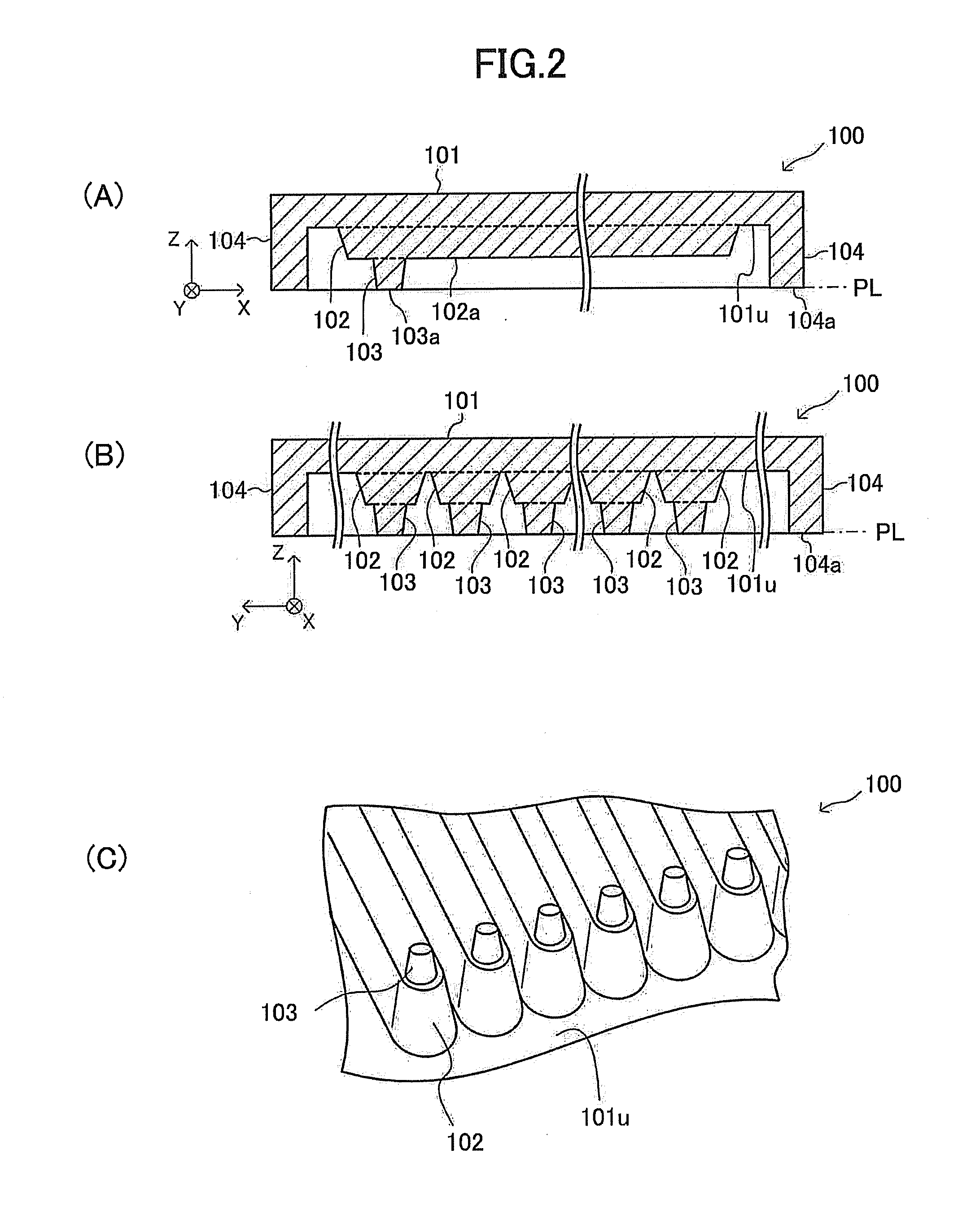

Method for manufacturing a droplet discharge head

In the method for manufacturing a droplet discharge head, a mold 100, including a convexity portion having convexities which have the substantially same shape as a liquid chamber including pressure chambers 21 and nozzle sections 21b, is prepared. A slurry SL is filled into the mold 100, and the mold 100 is placed on a porous plate 120. A solvent included in the slurry permeates into fine pores of the porous plate. Accordingly, the slurry is dried, so that a compact-after-dried 110 is formed. Thereafter, a vibration plate, and the like are joined to the compact, and the compact is fired. Further, piezoelectric elements, and the like are formed on the pressure chambers.

Owner:NGK INSULATORS LTD

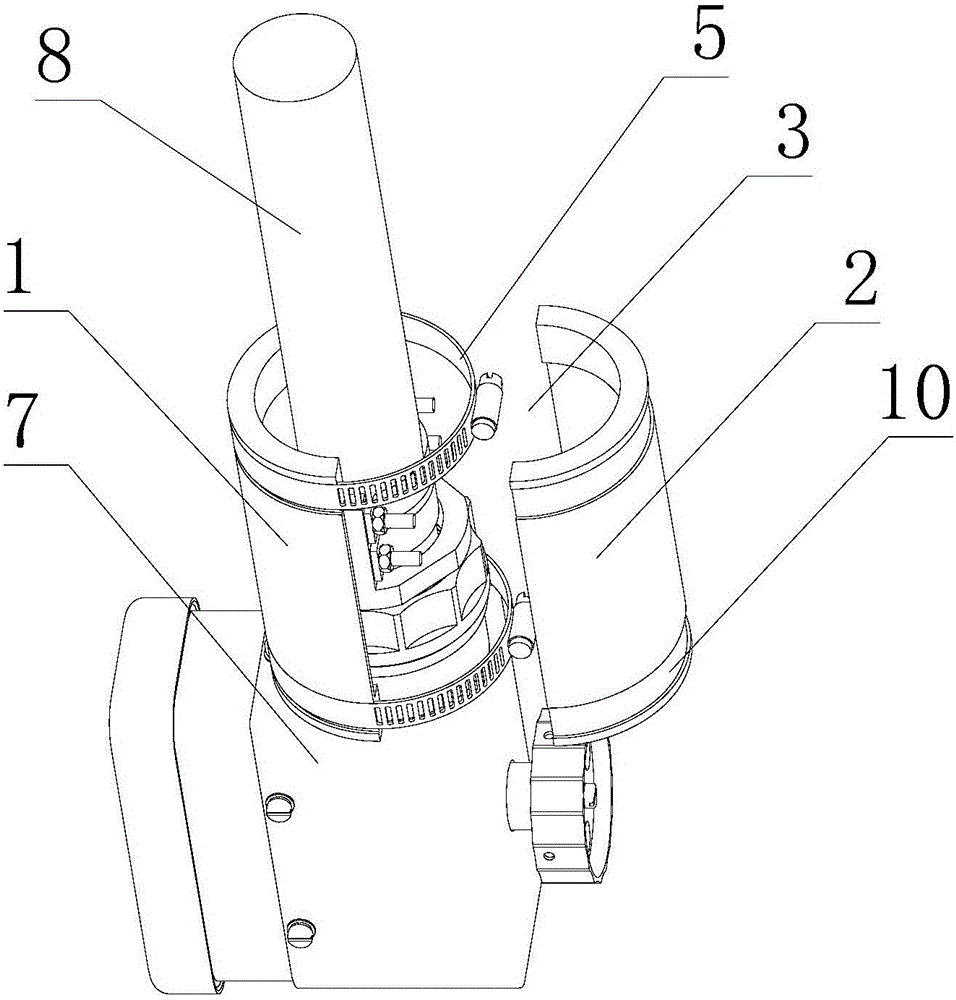

Electric connector cable outlet vulcanization sealing method

ActiveCN106058599AAchieve sealingImprove sealingDustproof/splashproof/drip-proof/waterproof/flameproof connectionVulcanizationEngineering

The invention relates to an electric connector cable outlet vulcanization sealing method which successively includes the following steps: vulcanization surface pre-treating, surface conditioning agent processing, die installation, glue pouring and vulcanization, and solidification and demoulding. According to the invention, the method is advantaged in that the method includes a step 1 of vulcanization surface pre-treating, a step 2 of surface conditioning agent processing, a step 3 of die installation, a step 4 of glue pouring and vulcanization, and a step 5 of solidification and demoulding so as to realize vulcanization sealing processing on an electric connector cable outlet; the method is safe and reliable, has simple structure and high practicality, and increases sealing property of the entire electric connector; products that undergo vulcanization moulding can meet all kinds of environments; each step of the method can be operated at normal temperature and under normal pressure, and the method avoids operation difficulty of traditional heat vulcanization moulding.

Owner:杭州航天电子技术有限公司

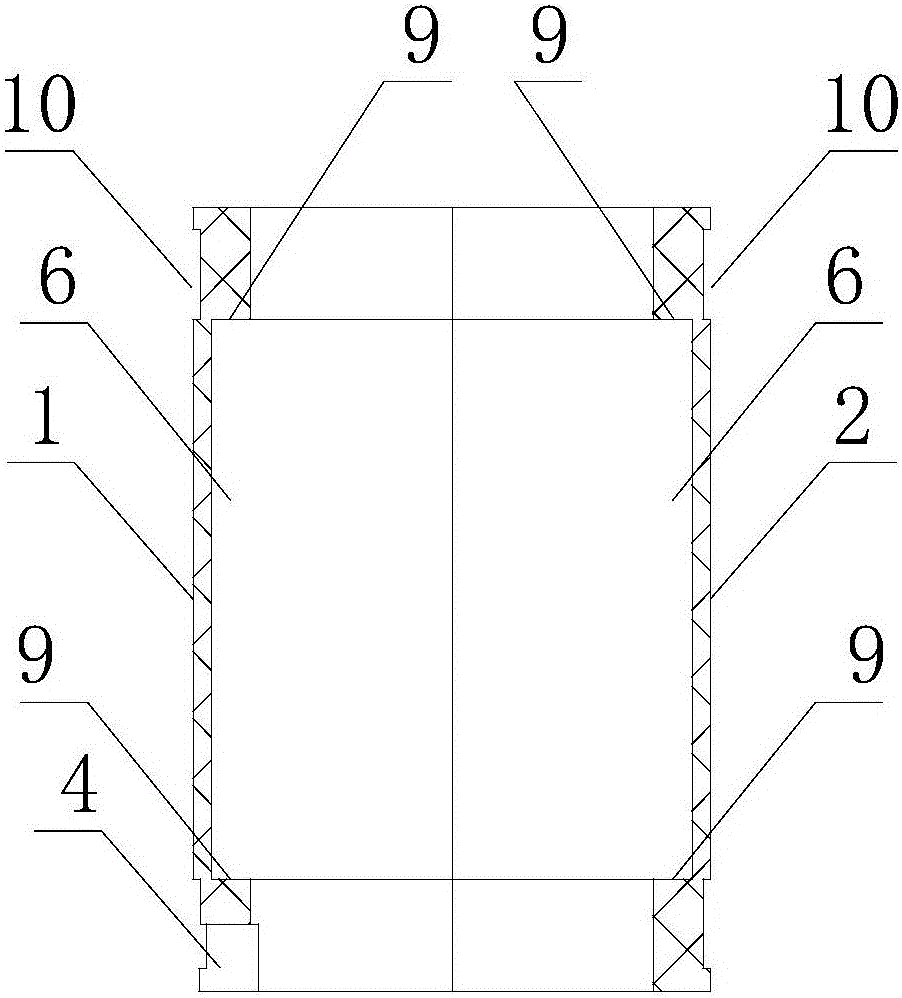

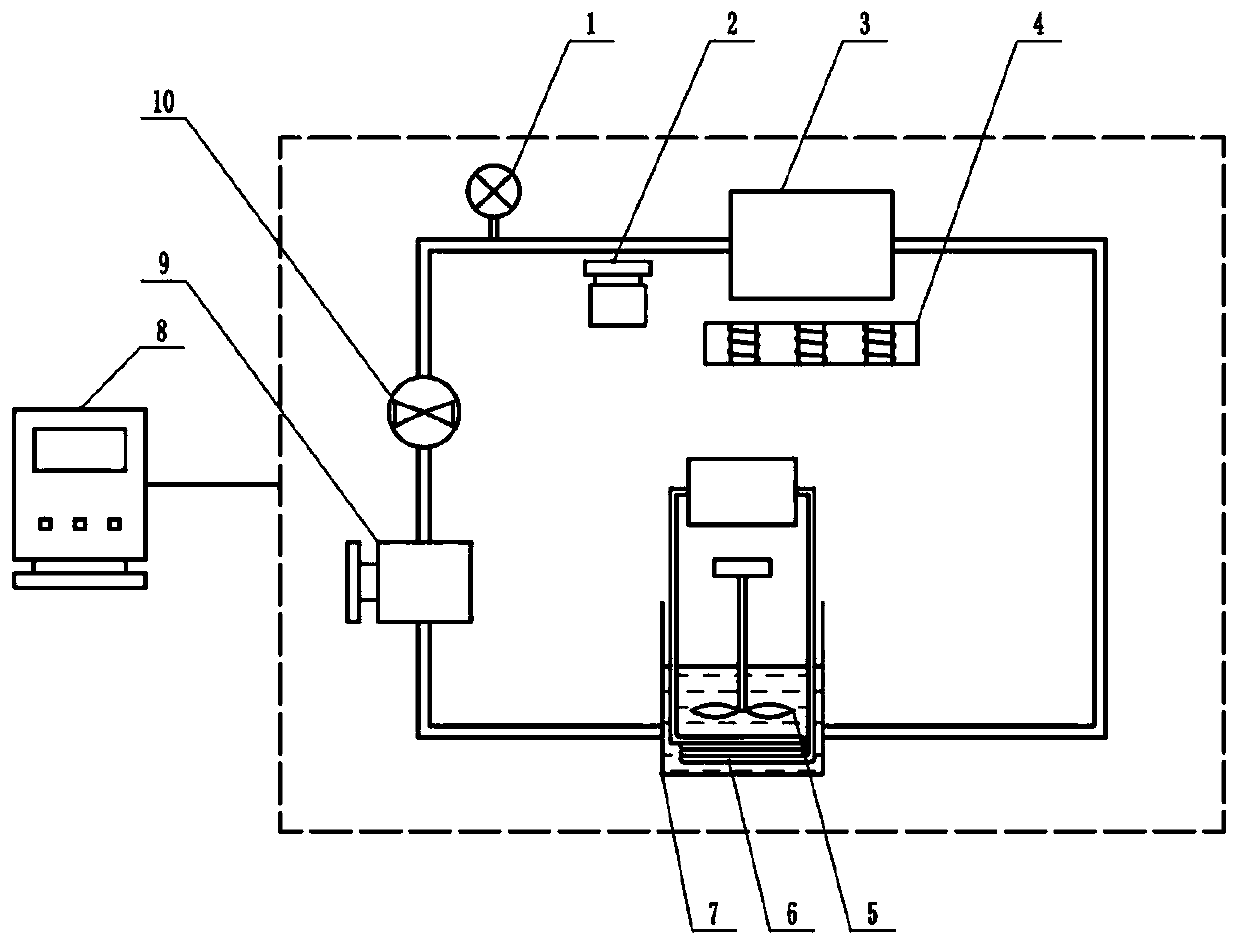

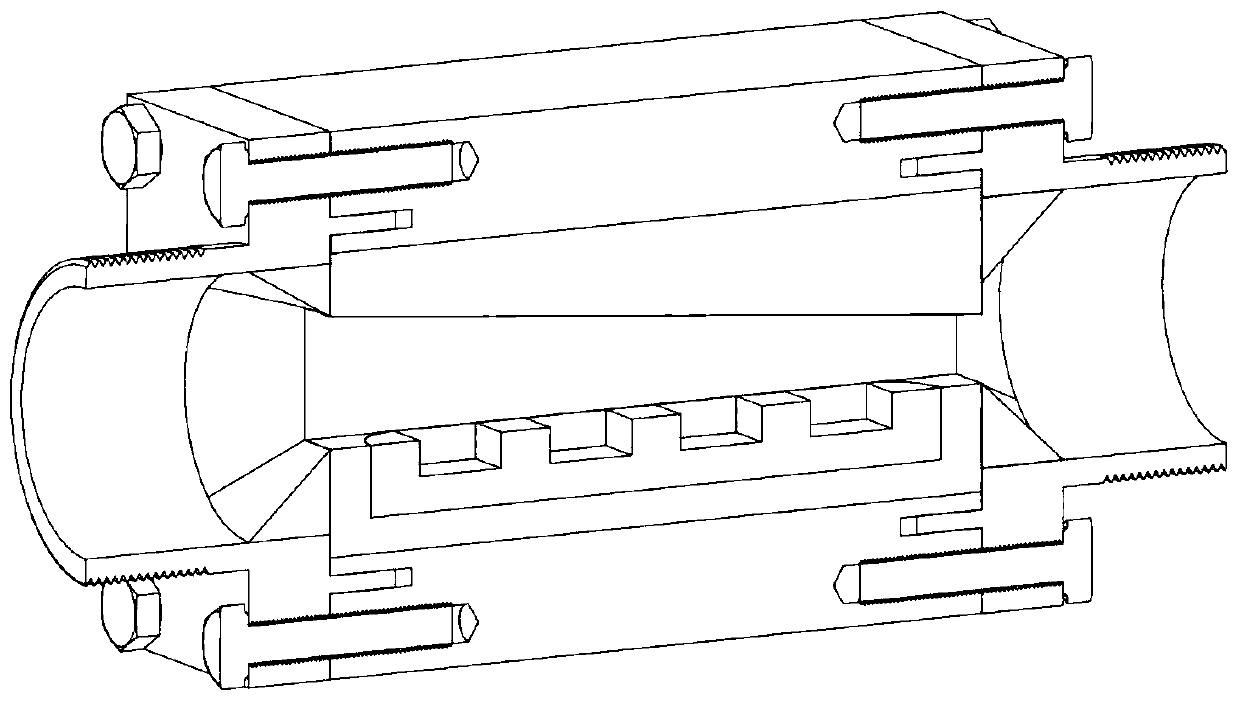

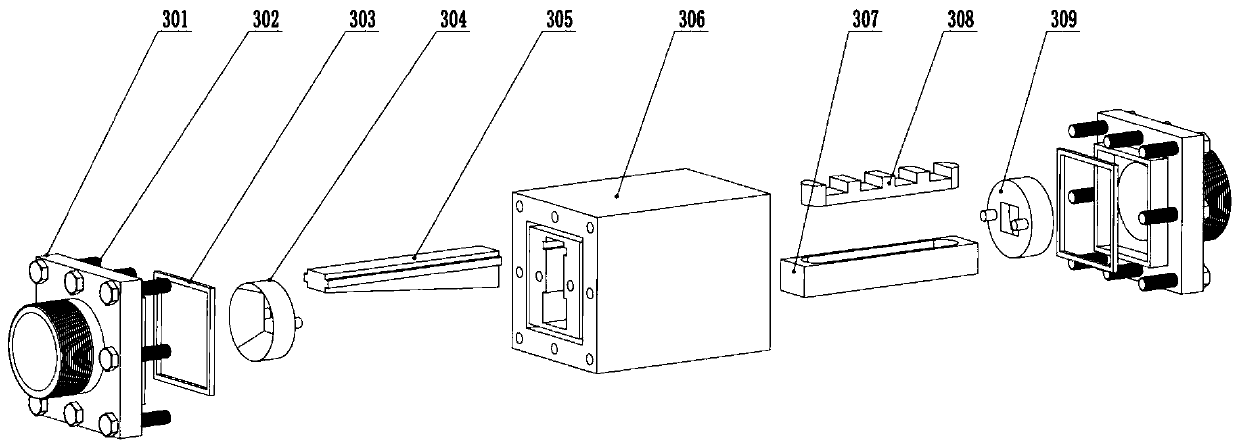

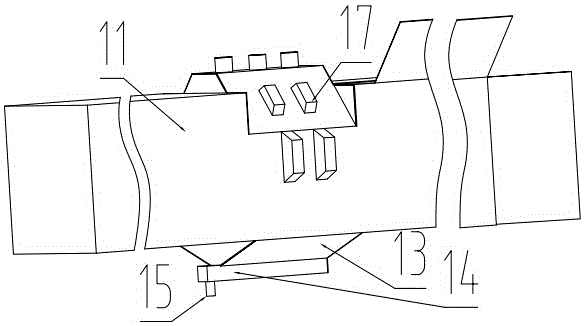

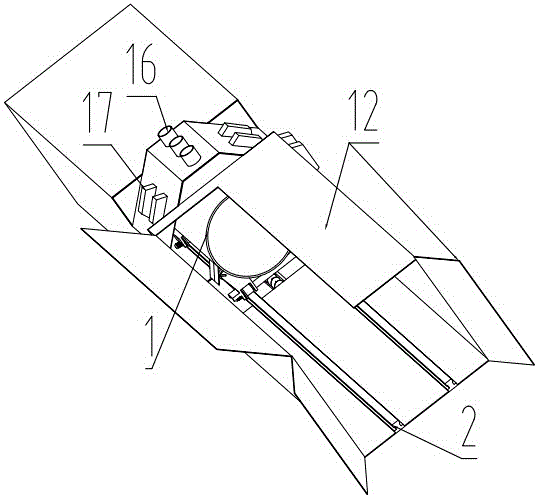

Ultrasonic cavitation and magnetic field assisted low-pressure abrasive flow polishing method and device

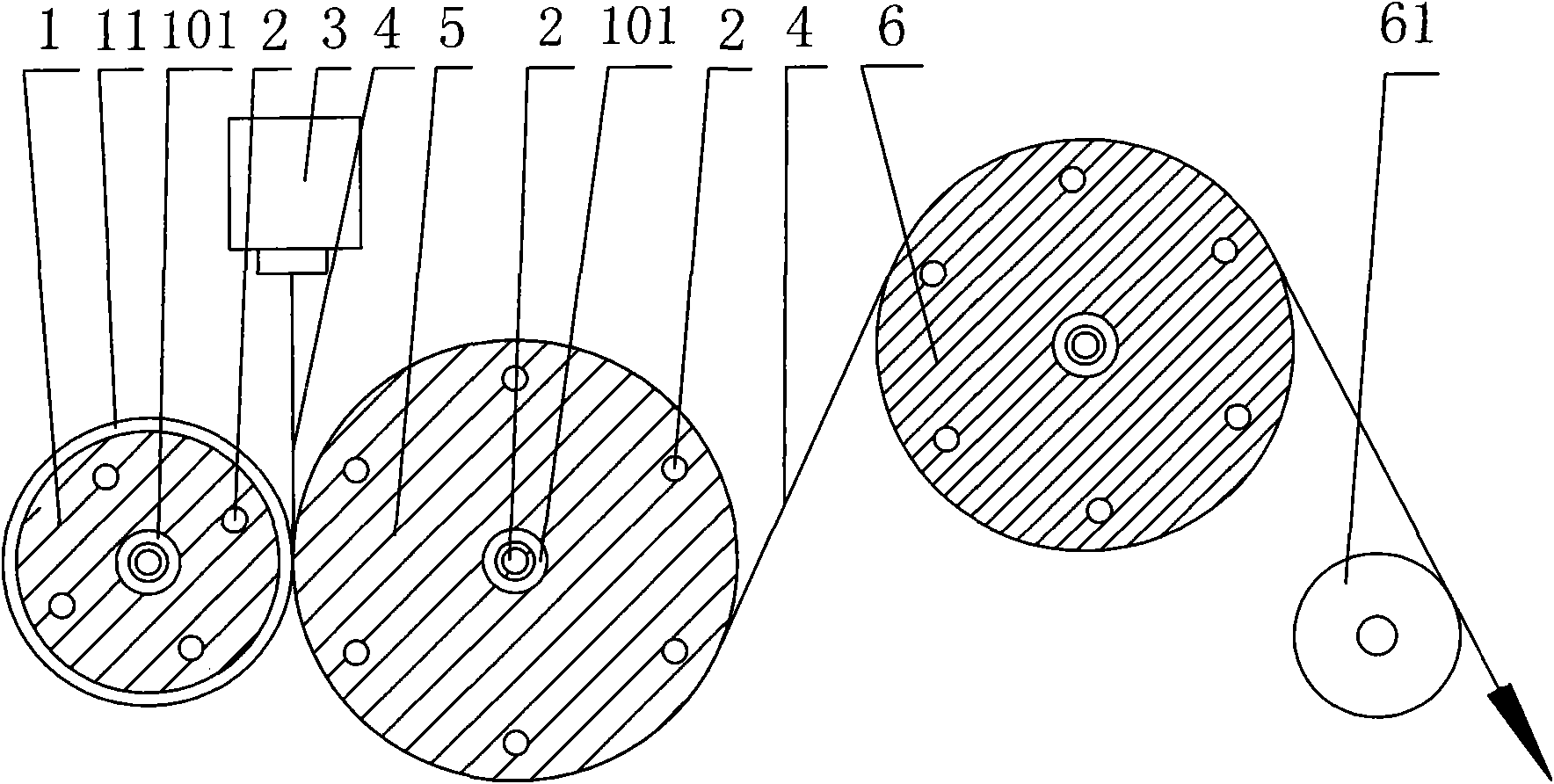

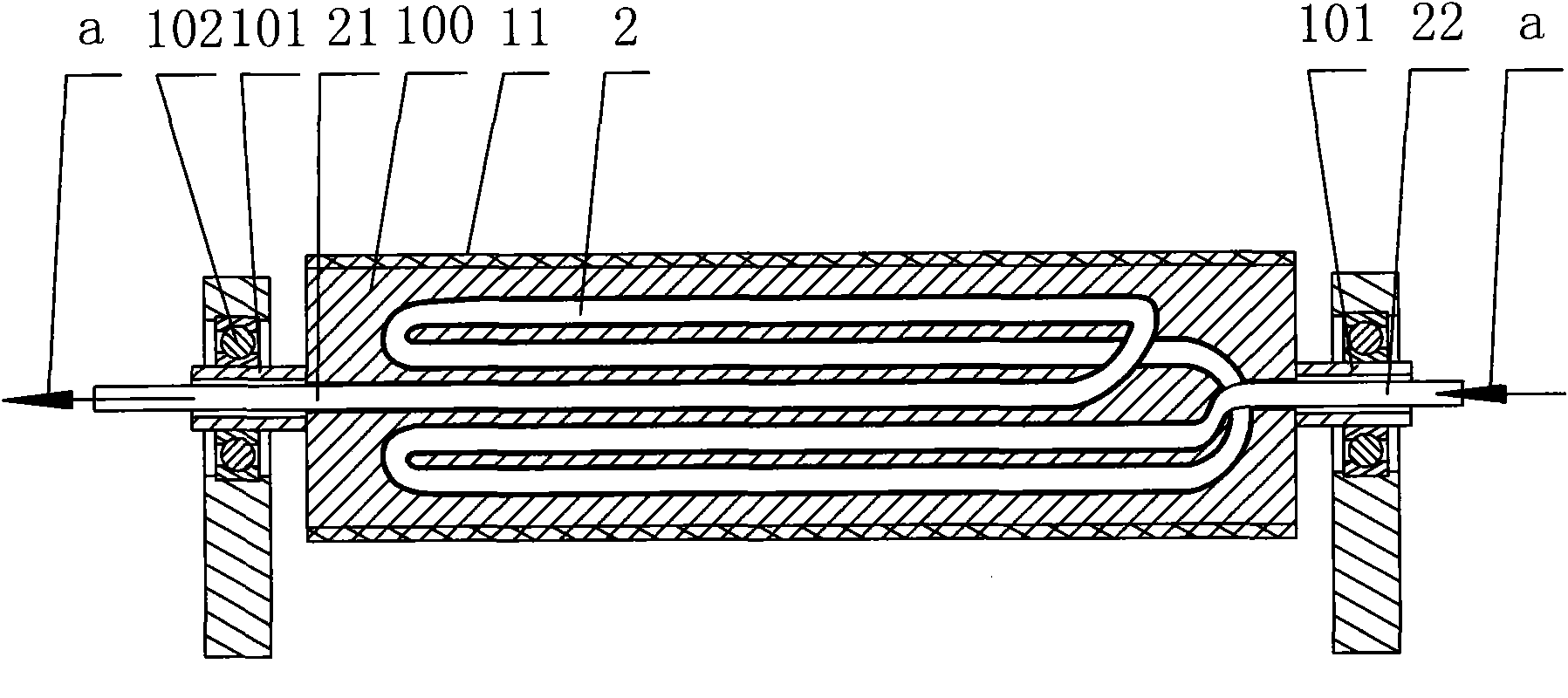

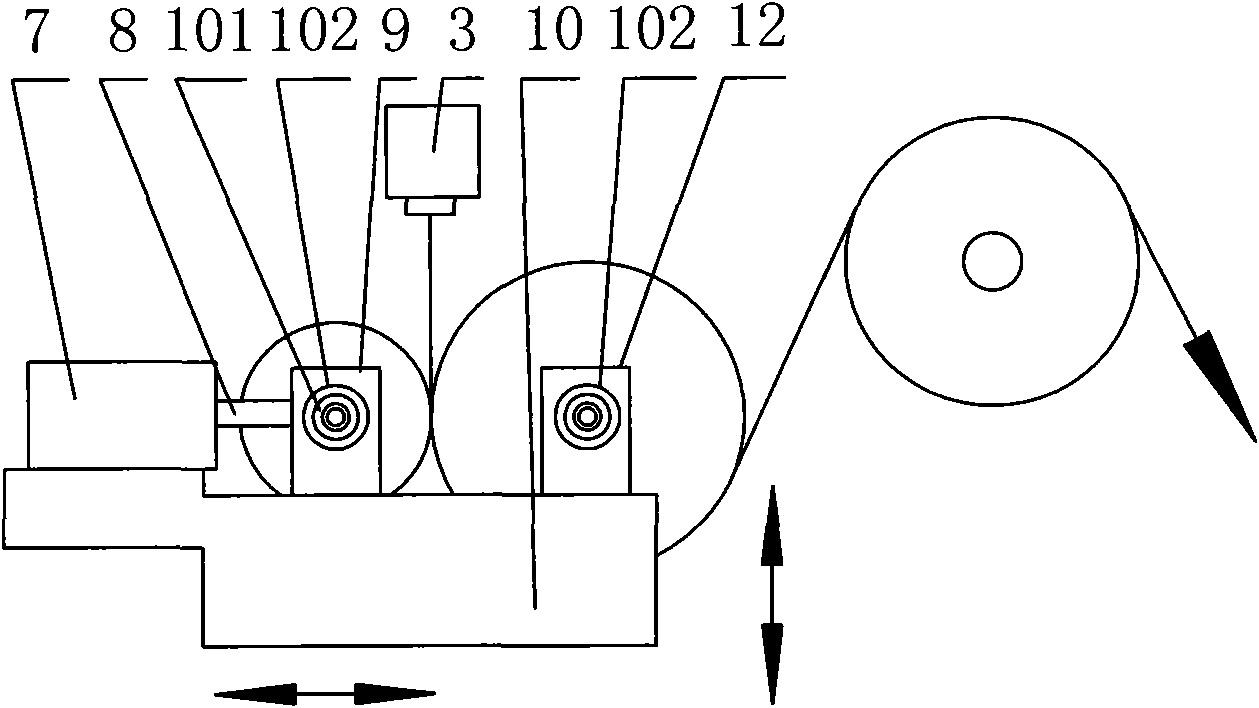

The invention discloses an ultrasonic cavitation and magnetic field assisted low-pressure abrasive flow polishing method. The abrasive flow polishing is conducted in low-pressure fluid; the abrasive flow polishing is conducted in a wedge-shaped flow channel; the inclined angle of the upper top surface of the wedge-shaped flow channel is adjustable, and the adjustment of the angle is realized by replacing an angular gauge block part arranged in a machining device; the cavitation is ultrasonic cavitation, and cavitation bubbles are generated in the abrasive flow through an ultrasonic generator installed in front of a flow channel inlet of the machining device; a magnetic field is an intensity-adjustable uniform magnetic field which is generated by an electromagnet arranged under the machining device and is perpendicular to the surface of a workpiece, under the action of the magnetic field, magnetic abrasives in a flow field are magnetized and move towards the surface of the workpiece under the action of the magnetic field force. The invention further provides an ultrasonic cavitation and magnetic field assisted low-pressure abrasive flow polishing device. The ultrasonic cavitation and magnetic field assisted low-pressure abrasive flow polishing method and device have the advantages that the surface roughness is uniform, the surface quality is improved and the machining efficiencyis improved after the workpiece is polished.

Owner:ZHEJIANG UNIV OF TECH

Machining control method for wire-cut electric discharge machine

InactiveUS6924453B2Uniform surface roughnessUniform roughnessElectric circuitsMachine controlElectric discharge

The number of electric discharge pulses is detected every given period. A deviation between the detected number and a target number of electric discharge pulses is obtained. Based on the obtained deviation, a correction value for the correction of a machining path in a direction normal to the machining path is calculated, whereby a corrected path is obtained. A wire electrode is moved relatively to a workpiece along the corrected path.

Owner:FANUC LTD

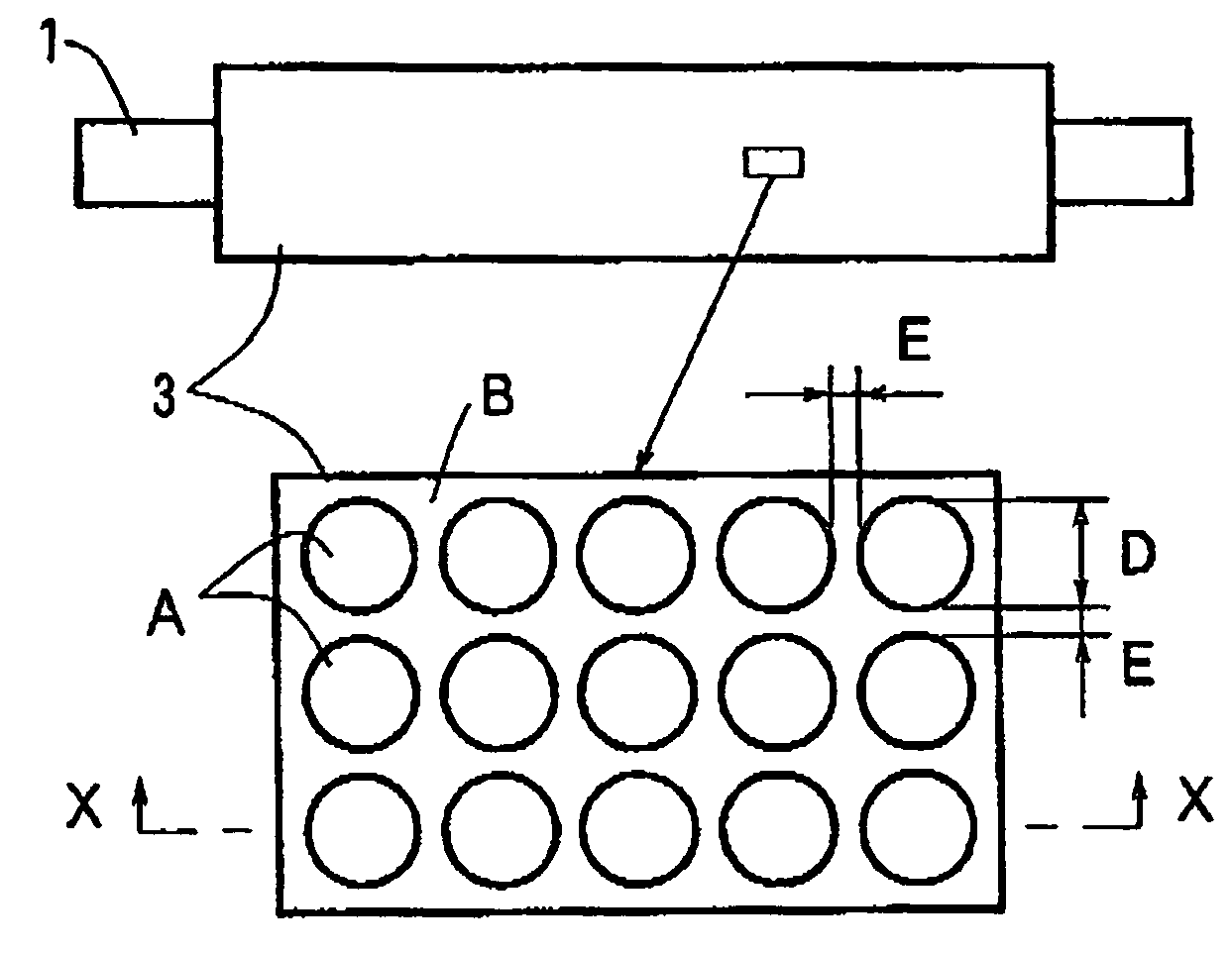

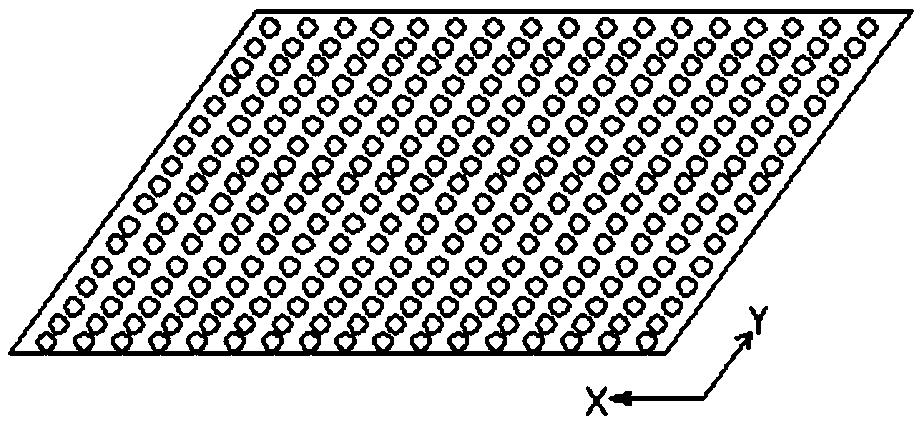

Developing roll

ActiveUS7356294B2Reduce surface hardnessReduce stressElectrographic process apparatusRough surfaceEngineering

A developing roll which may reduce stress imparted on toner and have uniform transportability of toner. The developing roll comprises a shaft, an elastic layer provided on an outer peripheral surface of the shaft, and a cylindrical outermost layer provided directly or indirectly via a layer on an outer peripheral surface of the elastic layer, wherein an outer peripheral surface of the outermost layer is formed into a rough surface by distribution of multiple dimples in such a manner that open ends thereof do not overlap one another on the surface and a portion other than the dimples on the rough surface forms a remaining portion of a cylindrical shape.

Owner:SUMITOMO RIKO CO LTD

Preparation method of magnesium alloy matt thin strip for mobile phone shell

InactiveCN102337439AUniform surface roughnessReduce lossMetal rolling arrangementsSurface roughnessMechanical property

The invention discloses a preparation method of a magnesium alloy matt thin strip for a mobile phone shell. The preparation method is characterized in that a laser roughening roller is used for rolling in the final pass of a cold rolling process, thus the surface roughness of a board is uniform and a good matt effect is achieved. Compared with a magnesium alloy board subjected to chemical matt treatment, the loss of the magnesium alloy raw material is reduced by 15-30%, and the no silking and pine grains are generated on the surface of the board. In the preparation method, alloying elements of the magnesium alloy are adjusted, thus the alloy has excellent surface quality and is suitable for preparing the matt surface. The prepared thin strip finished product has excellent mechanical properties, wherein the tensile strength is 280-320MPa, the elongation percentage is 8-10%, the earing rate is reduced to 1-3%, and the average strain ratio is 1.2-1.6; the adhesive force of painting on the surface of the magnesium alloy thin strip is improved; and the coating performance of the thin strip is improved.

Owner:JIANGSU HAODA

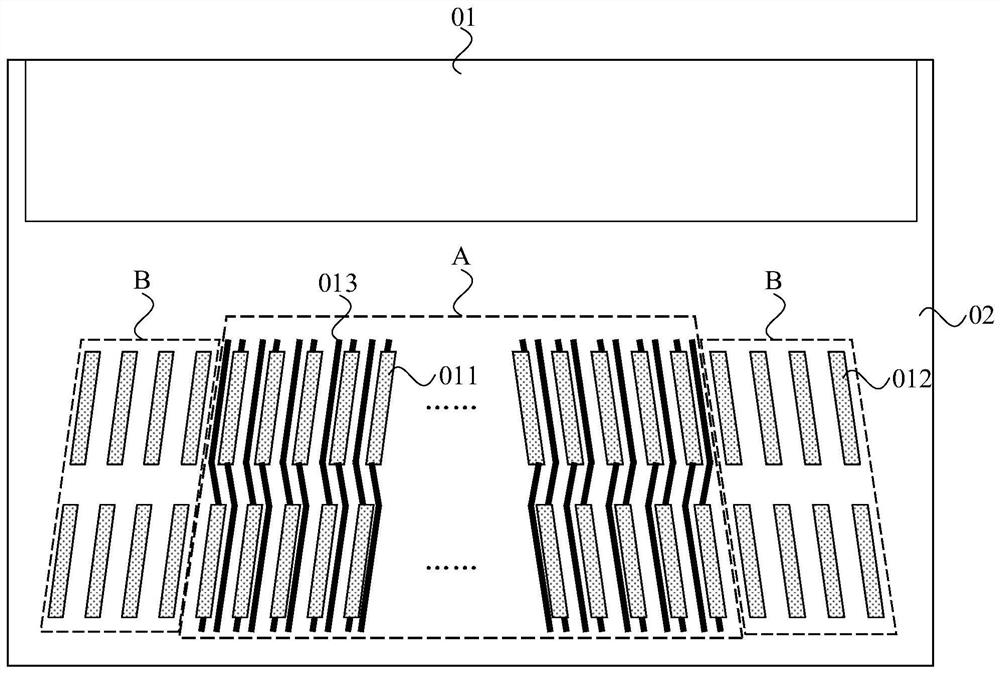

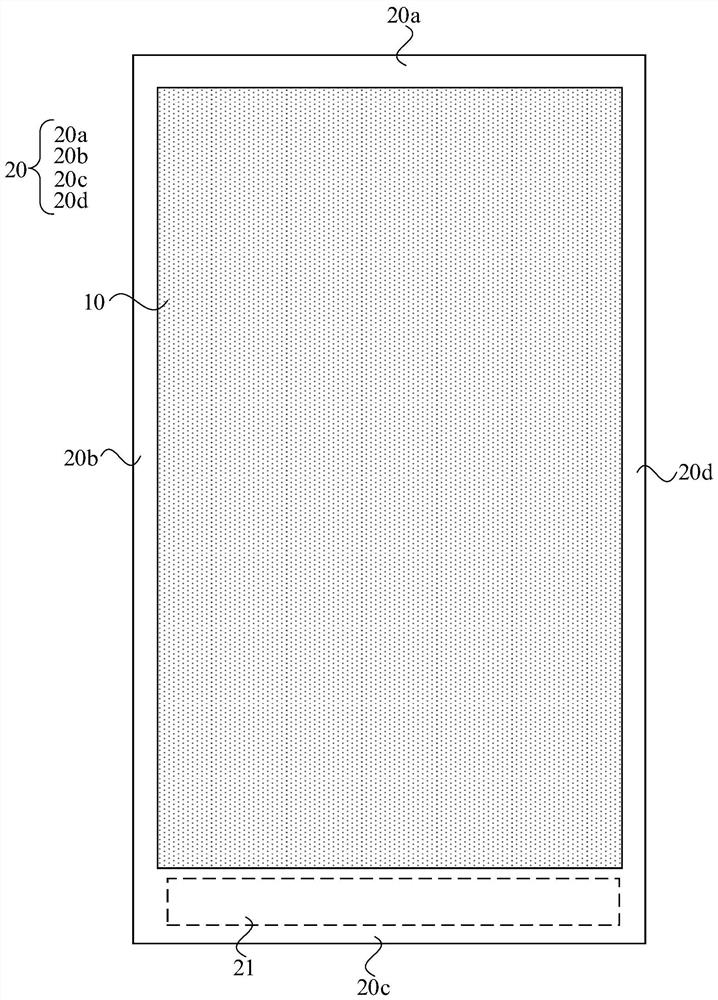

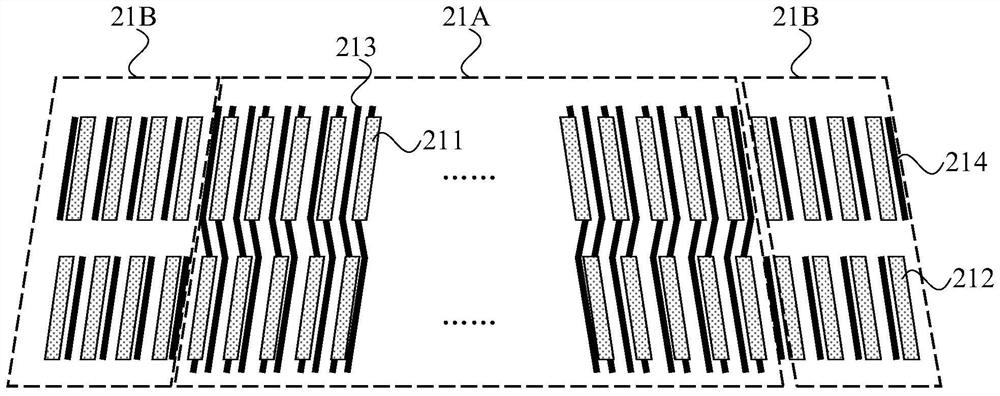

Display substrate, display panel and display device

ActiveCN112748613AUniform surface roughnessImprove process stabilityNon-linear opticsElectrical connectionDisplay device

The invention discloses a display substrate, a display panel and a display device. The display substrate comprises a display area and a frame area. The frame area comprises a binding area, the binding area comprises a first area and a second area, the first area comprises a plurality of first bonding pads, the second area comprises a plurality of second bonding pads, the first bonding pads are arranged into a first bonding pad array, and the second bonding pads are arranged into a second bonding pad array; a plurality of first signal lines are electrically connected with the first bonding pads, and at least parts of the first signal lines extend to the position between every two adjacent first bonding pads; the second bonding pads are dummy bonding pads, or a part of the second bonding pads is electrically connected with a second signal line; and the binding area further comprises a plurality of dummy wires, and at least partial areas of the dummy wires are located between every two adjacent first bonding pads, and / or between every two adjacent second bonding pads, and / or between the adjacent first bonding pads and second bonding pads. According to the technical scheme, the process stability in the binding process can be improved, and a preparation yield of the display panel is improved.

Owner:HUBEI YANGTZE IND INNOVAION CENT OF ADVANCED DISPLAY CO LTD

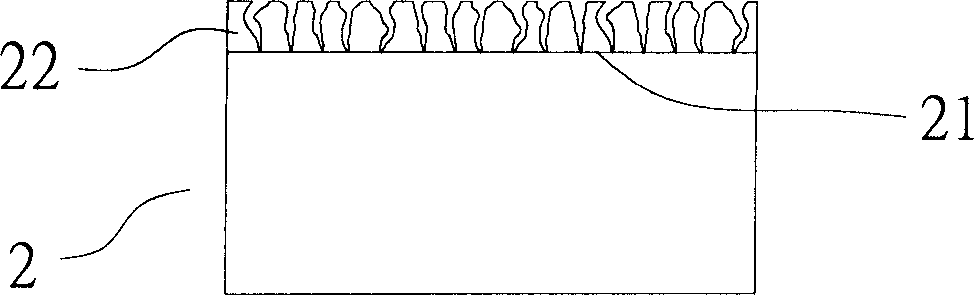

Conditioner for polishing pad and method for manufacturing the same

InactiveCN1193863CEffective regulationUniform surface roughnessSemiconductor/solid-state device manufacturingFlexible-parts wheelsCarbideMechanical engineering

A ceramic disc-shaped substrate is formed with geometrical protrusions of a uniform height on at least one side. A cutting portion (22) is formed, with a diamond layer of a uniform thickness formed on all the surface of the side of the substrate with protrusions. The protrusions have a flat upper surface, or the upper surface may comprise several smaller protrusions formed by recessed grooves. The cutting portion makes line and surface contacts with the polishing pad surface. An independent claim is included for a method of manufacturing a conditioner for a polishing pad

Owner:二和DIAMOND工业株式会社

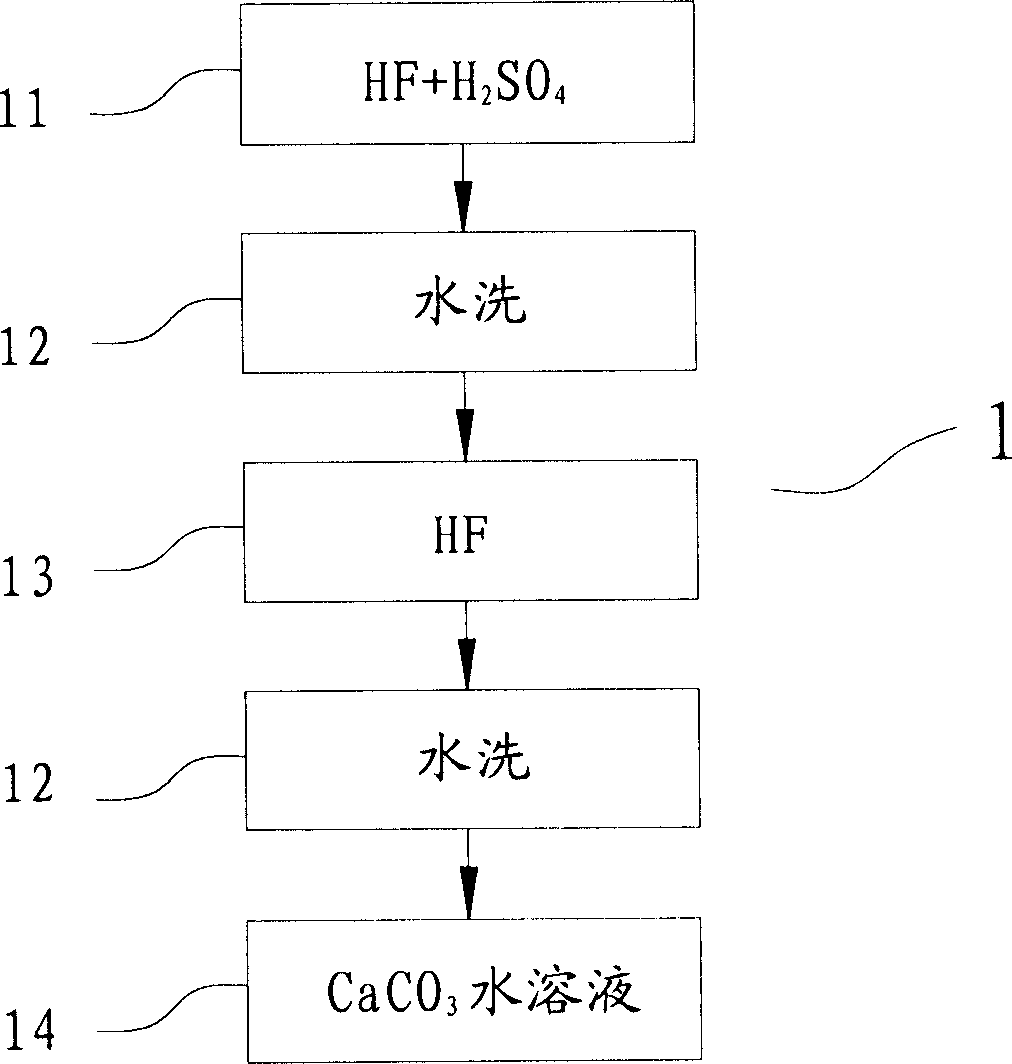

Surface treatment method of Mg alloy

This invention relates to magnesium alloy surface processing method, the procedures are that a. it is processed by the mixed solution of hydrofluoric acid and sulfuric acid. b. then it is cleaned by pure water to wash surface residual agent. c. it is processed by hydrofluoric acid. d. then it is washed by pure water to wash surface residual agent. e. it is processed by calcium carbonate water solution, so the magnesium alloy surface processing is finished. In this invention, simple etching solution is used to etch the alloy surface at room temperature to make material surface single face, and put an end of corrosion.

Owner:汪俊延 +2

Method for preparing aluminum alloy matt plate

InactiveCN101444789ASimple manufacturing methodEasy to operateRoll force/gap control deviceFurnace typesAluminium alloyRaw material

A method for preparing an aluminum alloy matt plate relates to an aluminum alloy plate preparing method and solves problems, such as a great number of procedures, great raw material loss, low finished product rate, disappointing mechanical property of the product and easy generation of silking and pine lines on the surface, which exist in present aluminum alloy matt plate production. The method for preparing the aluminum alloy matt plate is as follows: first, casting an ingot and homogenizing annealing; second, hot rolling and curling; third, cold rolling and annealing; and then obtaining the aluminum alloy matt plate. The method has the advantages of simple and easily-implemented procedures, low raw material loss, high finished product rate, good mechanical property of the product, and no generation of silking and pine lines on the surface.

Owner:NORTHEAST LIGHT ALLOY CO LTD

Quartz surface chemical roughening treatment method

InactiveCN110510886AShort processing cycleImprove cleanlinessAmmonium fluorosilicateTreatment period

The invention relates to the technical field of semiconductor quartz part surface treatment, in particular to a quartz surface chemical roughening treatment method, which can effectively reduce consumed time and shorten the surface treatment period of a quartz part for a semiconductor. The method includes the steps of: (1) pretreatment: carrying out surface polishing and annealing treatment on a quartz part needing treatment, and then performing cleaning with deionized water for 5min; (2) preparation of a treatment solution: mixing analytically pure hydrofluoric acid with a solution concentration of 40% and solid analytically pure ammonium fluoride with a solution concentration of 99%, and then adding analytically pure acetic acid with a solution concentration of 99.5% to prepare the treatment solution for standby use; (3) temperature regulation of the treatment solution; (4) reaction treatment: completely immersing the pretreated quartz part in the prepared treatment solution subjected to temperature regulation, and letting a uniform ammonium fluorosilicate attachment gradually form on the surface of the quartz part; (5) flushing; (6) repeating and thickening; and (7) detection ofthe surface roughness.

Owner:SHENYANG HANKE SEMICON MATERIALS

Metal surface pretreatment method

InactiveCN109321859AGood removal effectImprove processing efficiencyMolten spray coatingForeign matterPretreatment method

A metal surface pretreatment method comprises the following steps that after a metal surface of a metal workpiece is subjected to degreasing treatment, supersonic flame spraying equipment is used forconducting sandblasting roughening treatment, thus, the metal surface is uniformly roughed, and then the metal surface is sprayed with a coating, wherein a sandblasting roughening treatment method comprises the steps that ignition is conducted according to procedures of the supersonic flame spraying equipment, the flame temperature is adjusted to be lower than the melting point of sand, a powder feeder with sand is started, thus, a spraying gun is kept away from the metal surface of the metal workpiece by a certain distance, then the metal workpiece is driven to rotate, and the spray gun is moved relative to the metal surface at a certain speed for spraying. By ingeniously using the supersonic flame spraying equipment for conducting the sandblasting roughening treatment, oxide skins and other foreign matter on the metal surface are quickly removed, hot sand achieves a good preheating effect during sandblasting, time is further saved, and cost is further reduced. Moreover, the roughnessof the treated metal surface is quite uniform, and damage to the metal surface is slight.

Owner:GUANGDONG INST OF NEW MATERIALS

Paper machine and method for reconditioning a conveying belt of a paper machine

InactiveCN1834344AControllable surface smoothnessMeets requirements for outstanding paper qualityMachine wet endSurface roughnessPaper sheet

There is provided a paper machine, characterized by a press device including a press mechanism which pressurizes wet paper to squeeze water therefrom, and a pair of endless paper conveying belts for pinching and conveying the wet paper as well as absorbing water squeezed from said wet paper, and a polishing device having a polisher to polish the wet paper contacting face of a belt in order to control the surface smoothness of the wet paper contacting face of the belt on the return side of at least one of the paper conveying belts at such a position that the wet paper contacting face of the belt, which is running, can be polished. The paper machine maintains a smooth wet paper contacting face of a paper conveying belt and a good paper peeling performance.

Owner:ICHIKAWA ELECTRIC CO LTD

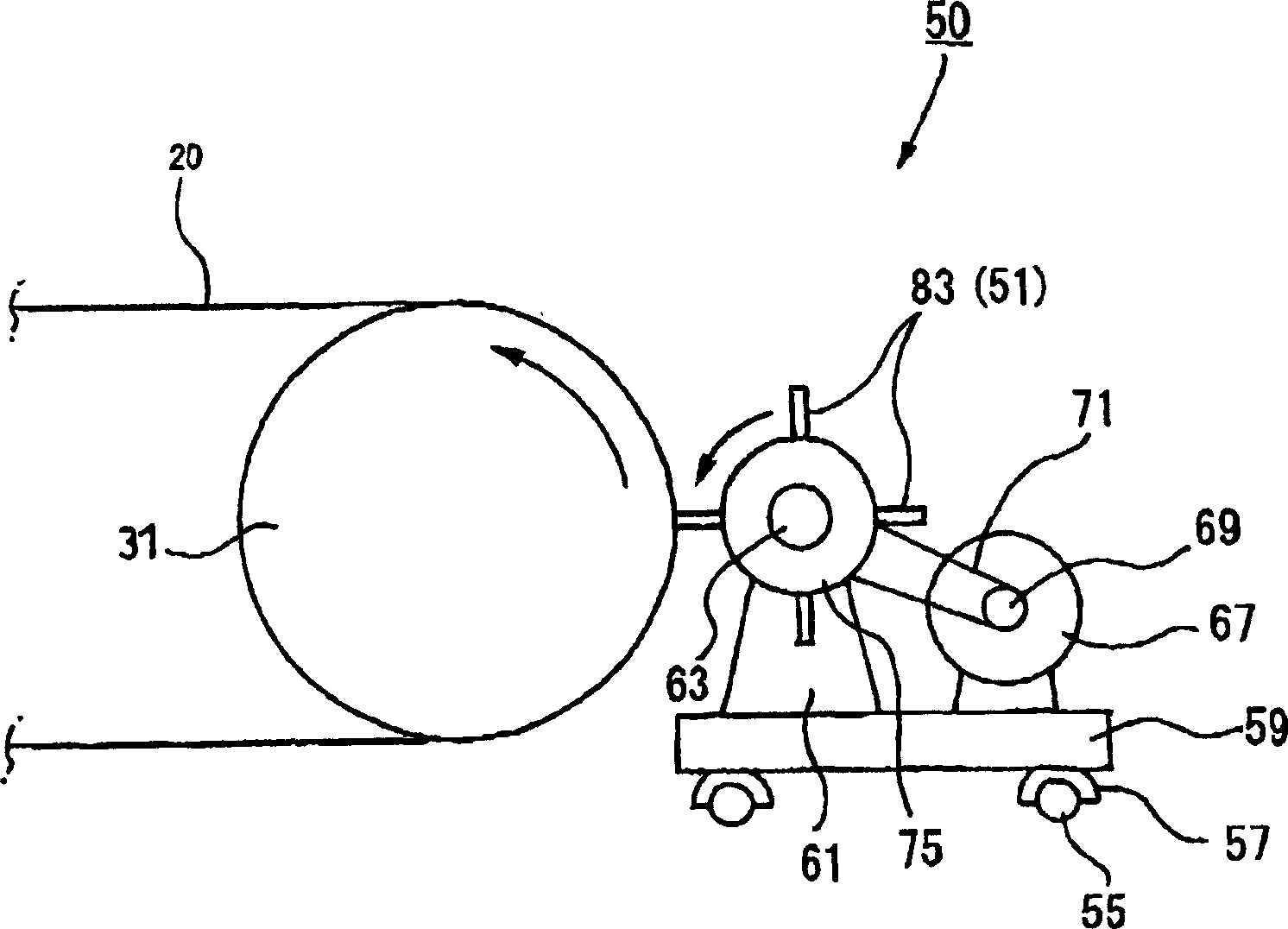

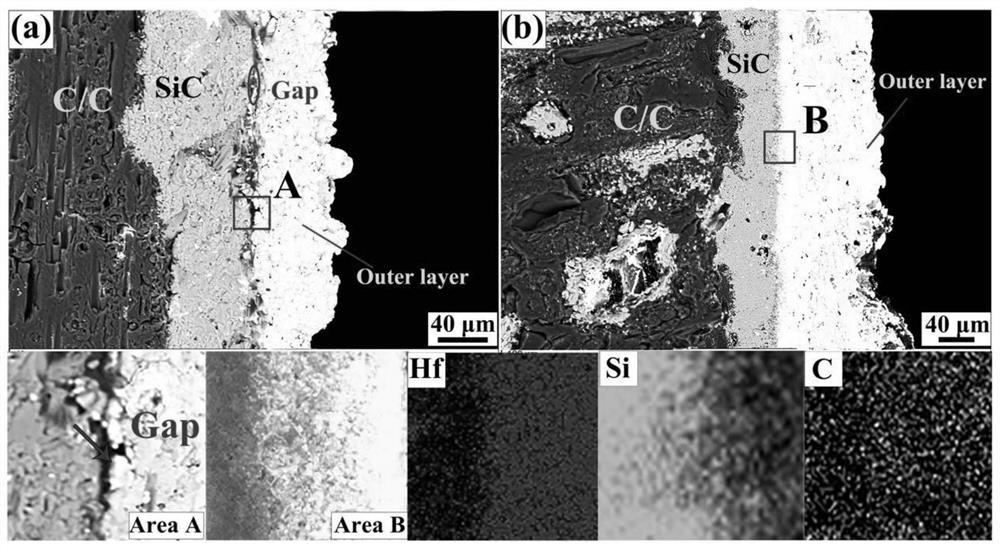

Preparation method of SiC nanowire toughened HfC-SiC complex phase coating by chemical vapor co-deposition

The invention relates to a preparation method of a SiC nanowire toughened HfC-SiC complex phase coating by chemical vapor co-deposition. The preparation method adopts a three-step method and comprises the following steps: firstly, preparing a SiC inner coating by using an embedding method, then, introducing free silicon on the surface of the SiC inner coating by using a vapor siliconizing technology, carrying out chemical vapor deposition on HfC on the surface of a C / C sample with the SiC-SiC inner coating, and enhancing the interface bonding strength between the inner coating and the outer coating through in-situ reaction and diffusion of free silicon in the vapor deposition process. The SiC / HfC-SiC coating which is uniform in thickness, compact in structure, controllable in component and high in binding force can be prepared. On the basis of a mechanical bonding interface of a traditional method, an interface diffusion layer is introduced for diffusion to form diffusion bonding. And the coating process is simple, the reaction period is short, the cost is low, and the development prospect is wide.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

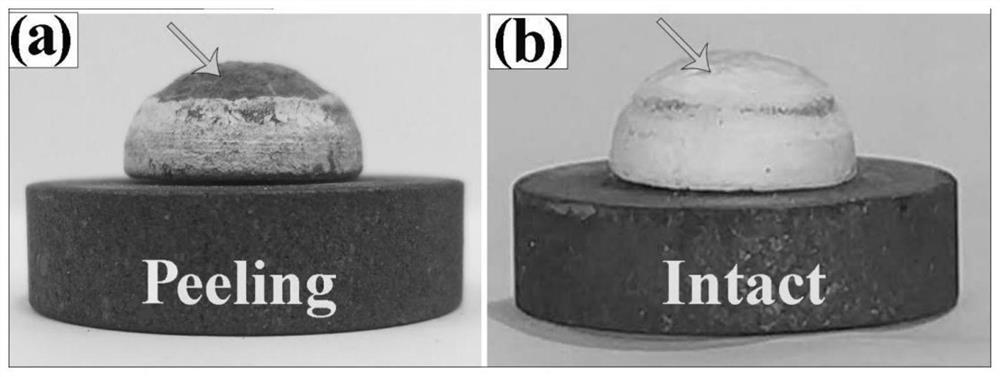

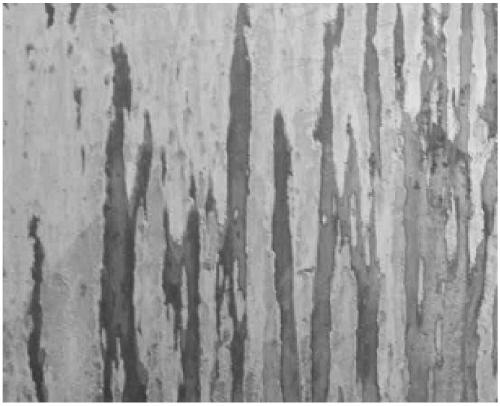

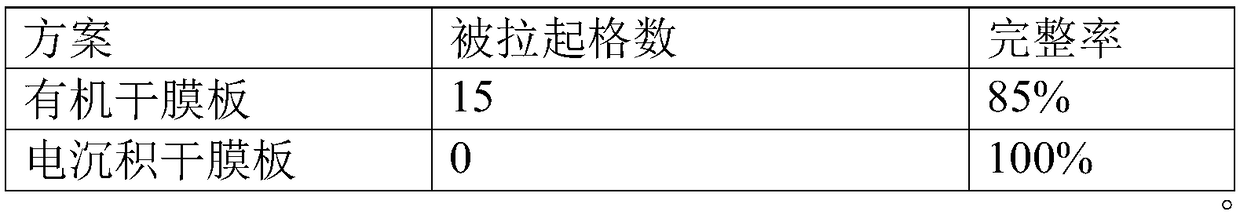

Metal-based copper surface anti-oxidizing enhancer used for pretreatment of PCB/FPC dry film and treatment method thereof

A metal-based copper surface anti-oxidizing enhancer used for pretreatment of a PCB / FPC dry film and a treatment method thereof. The invention relates to a metal-based copper surface anti-oxidizing enhancer composition for pretreatment of the PCB / FPC dry film. For solving the problems that it is difficult to give consideration to both anti-oxidization effect and combination force in the prior art,the enhancer includes 10-150 g / L of a metal main agent, 30-300 g / L of a complexing agent, 20-150 g / L of a pH regulator, 30-150 g / L of a reducing agent, and 0.001-1 g / L of an electric potential regulator. The enhancer can adapt high-temperature production environment and can improve the combination force between the copper surface and the dry film, or printing ink or like, can omit chemical (micro-etching) or mechanical roughening step, that is, the enhancer has both functions. During production, the enhancer can completely replace chemical organic film anti-oxidizing and copper surface roughening processes at the same time, thus improving product quality, shortening process steps and saving labor intensity and time.

Owner:SHENZHEN RUN SUN CHEM TECH

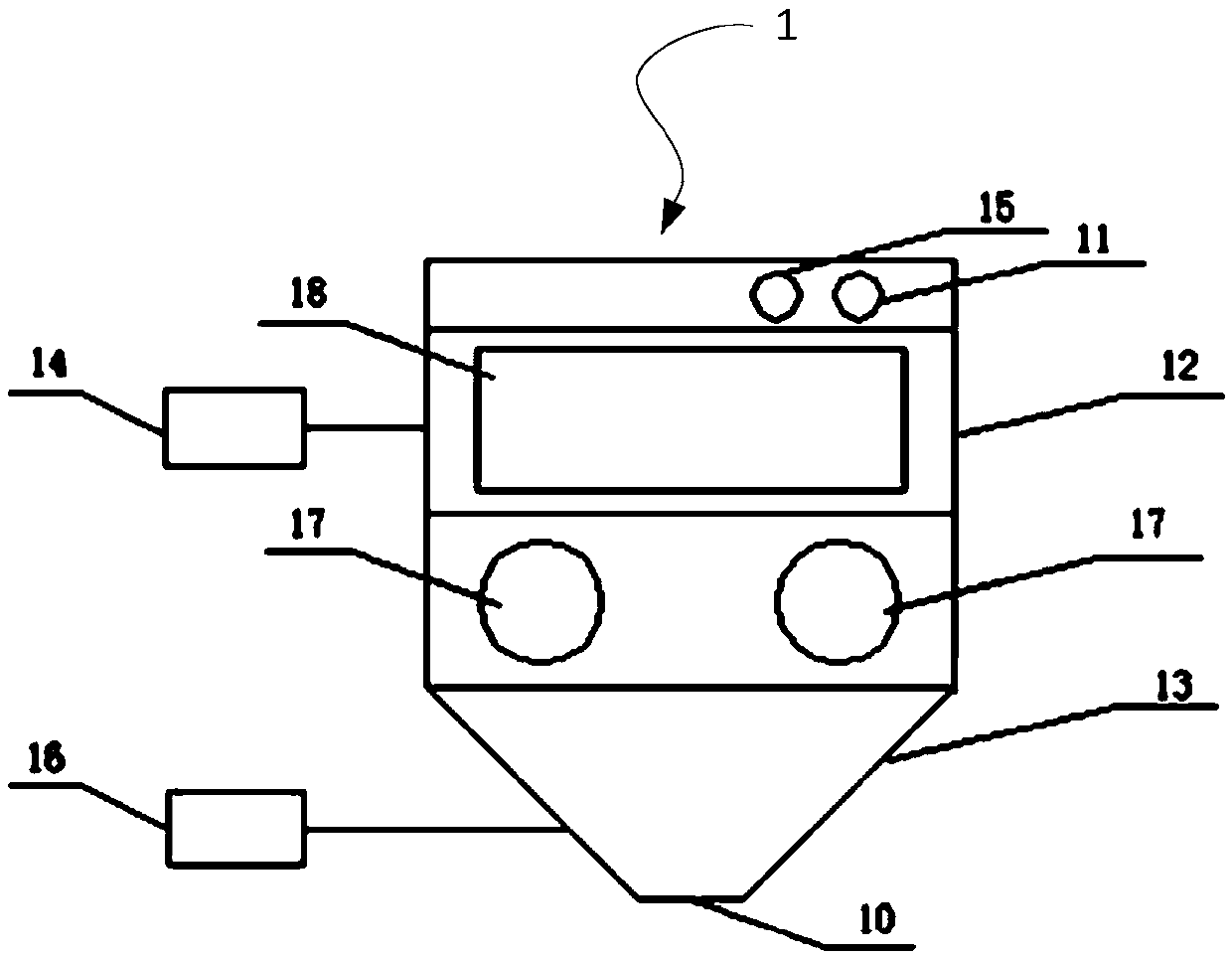

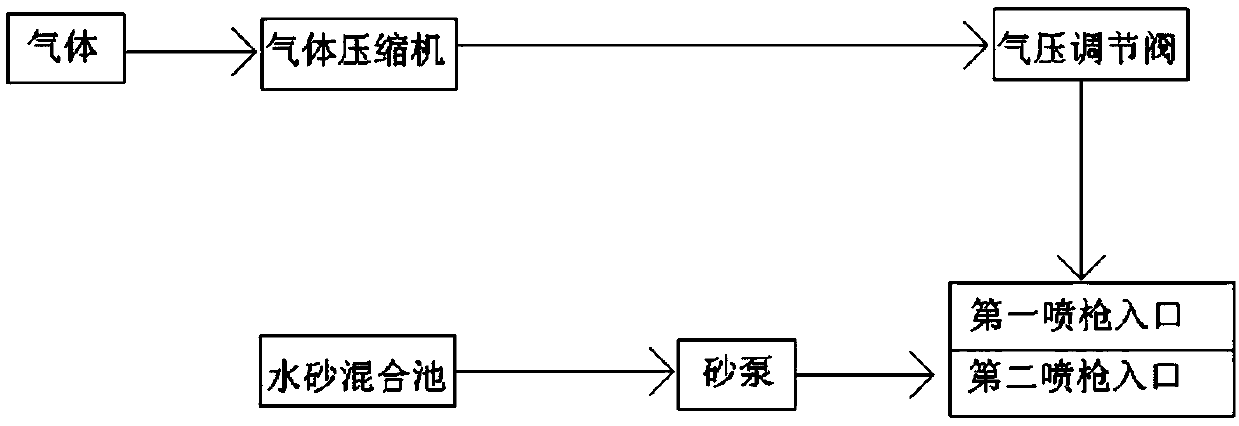

3D printed object aftertreatment device, system and method

PendingCN109093522AImprove postprocessing reliabilityImprove efficiencyBlast gunsAbrasive feeders3d printGas compressor

The invention provides a 3D printed object aftertreatment device, system and method. A 3D printed object needing aftertreatment is placed in a sand blasting chamber, a gas compressor inputs compressedgas into a sand blasting gun; meanwhile, a sand pump inputs a water and sand mixture in a water and sand mixing tank into the sand blasting gun; the sand blasting gun pressurizes and sprays the waterand sand mixture through the compressed gas to the surface of the 3D printed objected from an outlet of the sand blasting gun, sand in the water and sand mixture polishes the surface of the 3D printed object under the pressure action, a support structure on the surface of the 3D printed object is completely removed, positions where the surface of the 3D printed object and the support structure interpenetrate as well as other positions can be polished, the efficiency and reliability in removing the support structure are improved, the 3D object with uniform surface roughness is obtained, besides, water in the water and sand mixture is cooled continuously during polishing, the condition that the thermal effect caused by friction affects the structure of the 3D printed object is prevented, and the aftertreatment reliability of the 3D printed object is improved.

Owner:ZHUHAI SAILNER 3D TECH CO LTD

PCB (printed circuit board) buffing wheel production method

The invention discloses a PCB buffing wheel production method. The method includes the steps of steel roll core production, an adhesive layer coating, clean cloth piece pressing and drying. An adhesive of the adhesive layer is made by mixing epoxy resin, a curing agent and reinforcing filler in the weight ratio of 10: 10-15: 2.0-4.0. A PCB buffing wheel produced through the method is good in buffing effect and long in service life. And a PCB produced with the PCB buffing wheel is uniform in surface roughness, high in light sensitive film and green oil film adhesion and capable of significantly reducing defects of short circuit and open circuit.

Owner:DONGGUAN GOLDEN SUN ABRASIVES

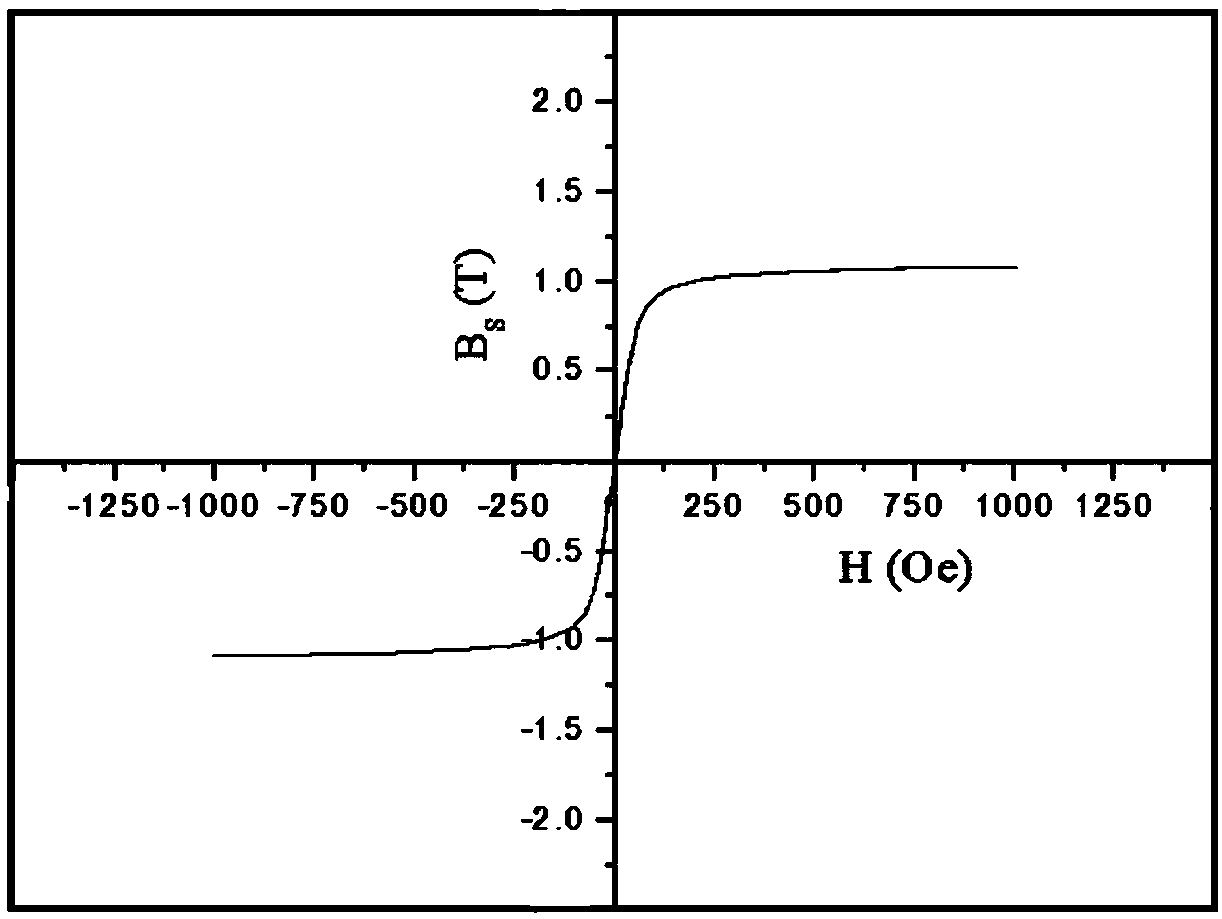

Technology for preparing coarsened nickel foil with electrodeposition method

The invention discloses a technology for preparing a coarsened nickel foil with an electrodeposition method and belongs to the technical field of nickel alloy. The technology comprises the following steps of pretreatment: cutting a purchased large metal plate, performing welding and surface decontamination; and electrodeposition: putting a treated nickel anode material in an electrolytic cell forprimary electrodeposition to prepare the coarsened nickel foil. The coarsened nickel foil prepared with primary electrodeposition is good in thickness uniformity, uniform in surface roughness, has theuniformity being 2-3 times the uniformity of the nickel foil coarsened with mechanical grinding and is suitable for thin and wide high-performance soft magnetic foil strip material insistently demanded by the electric and electronic industry.

Owner:安徽迈德福新材料有限责任公司

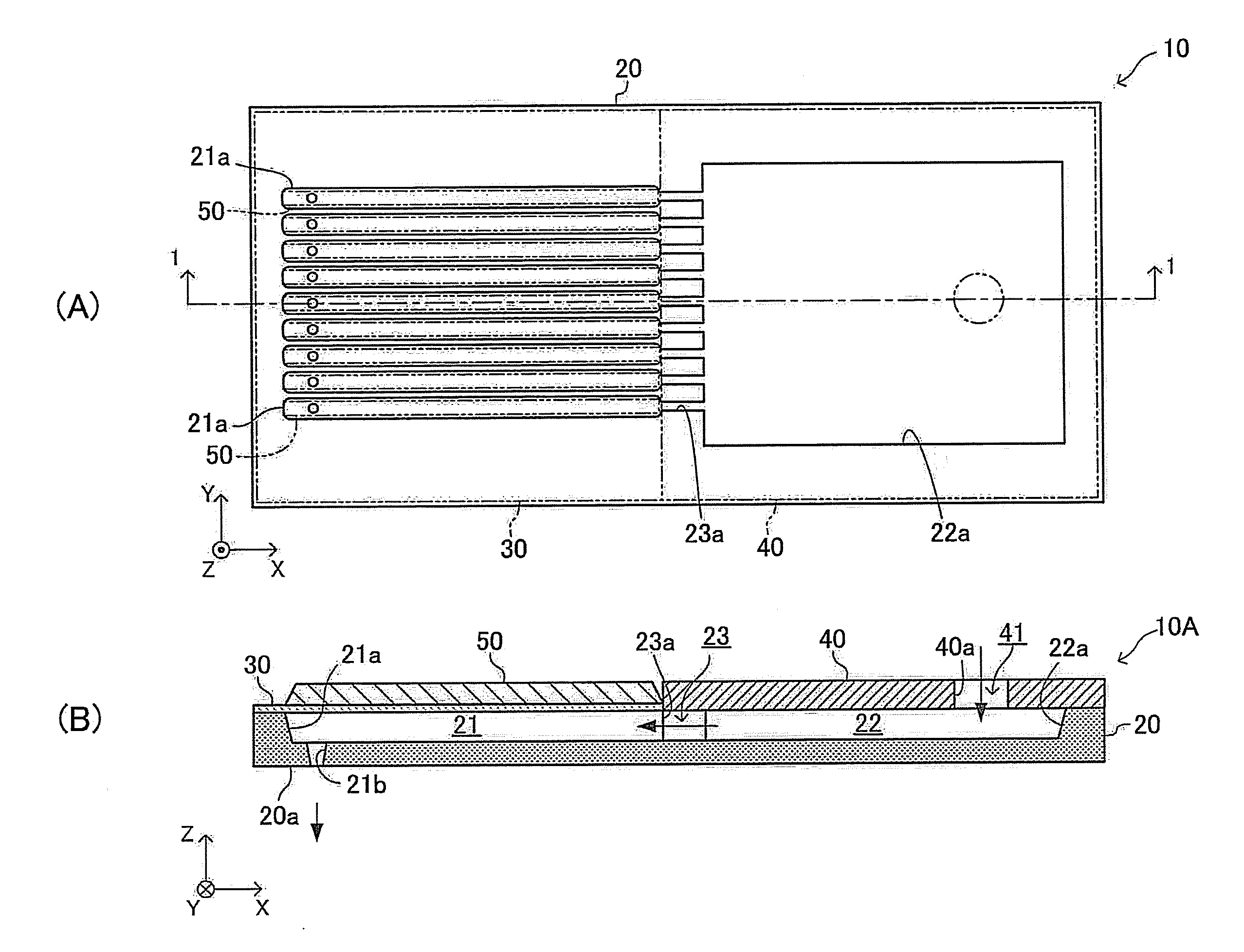

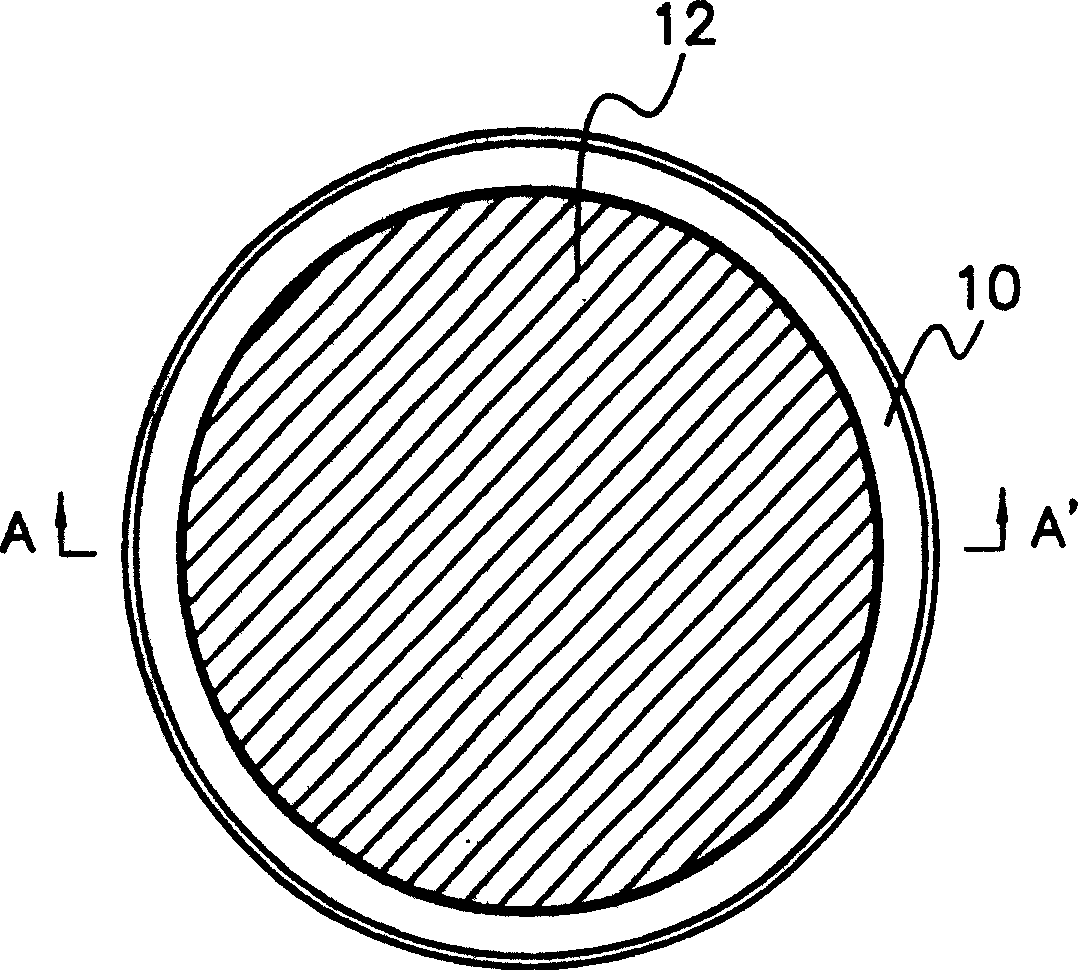

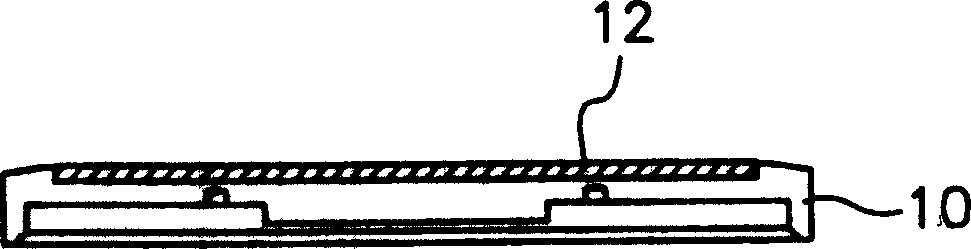

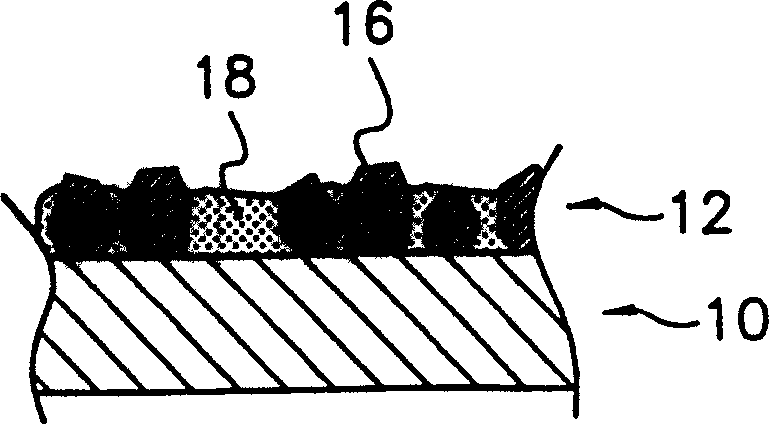

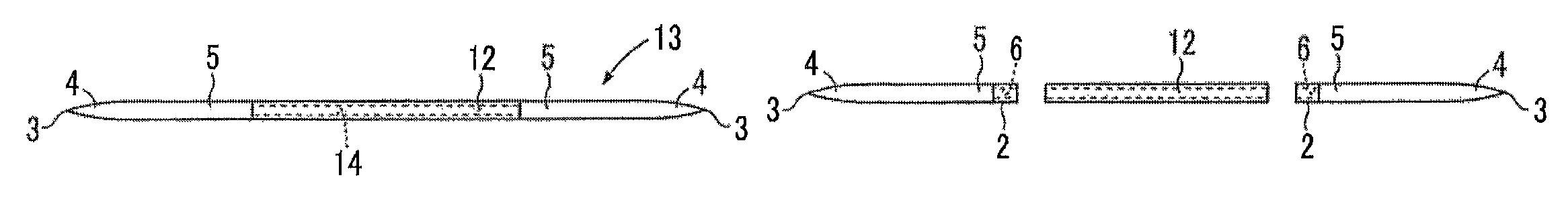

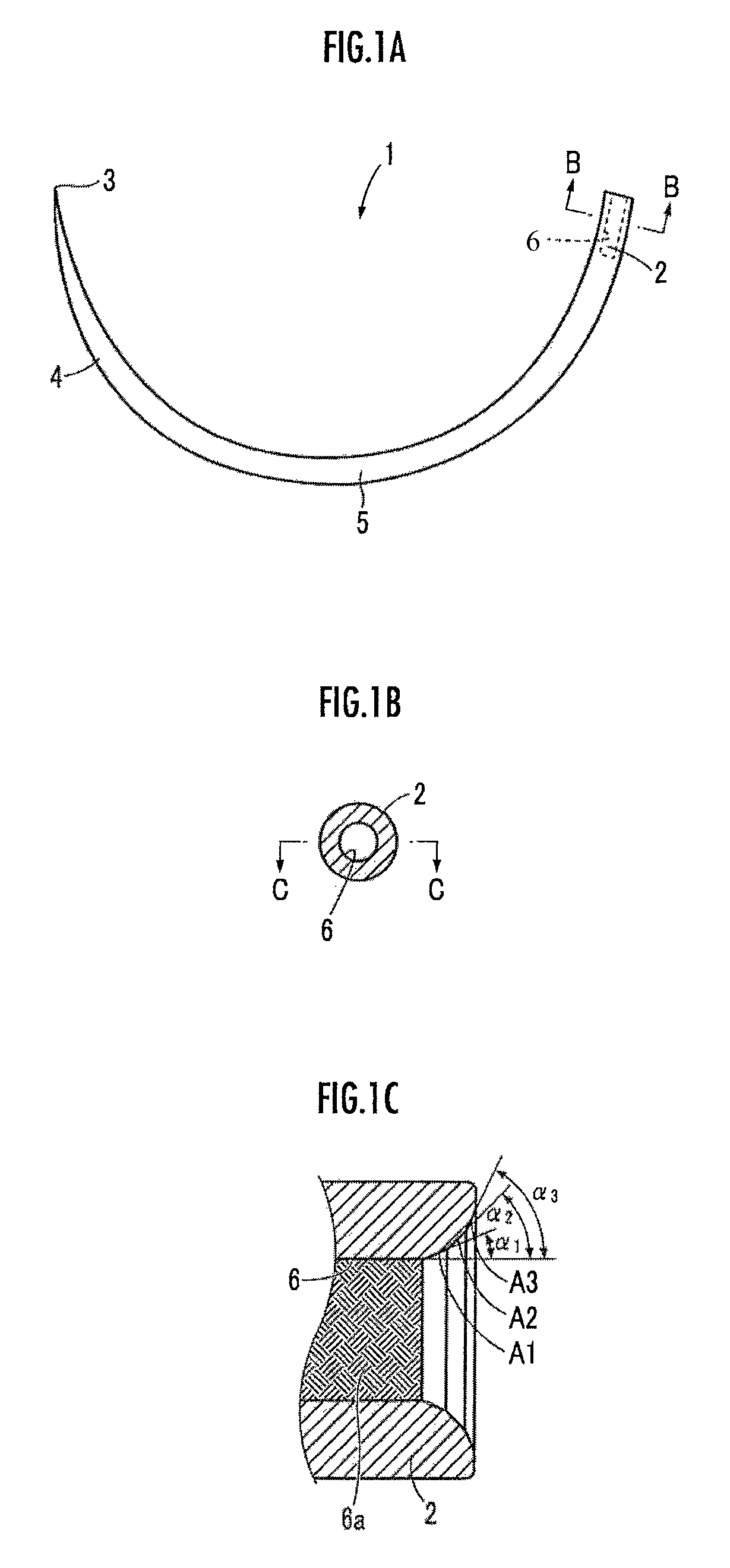

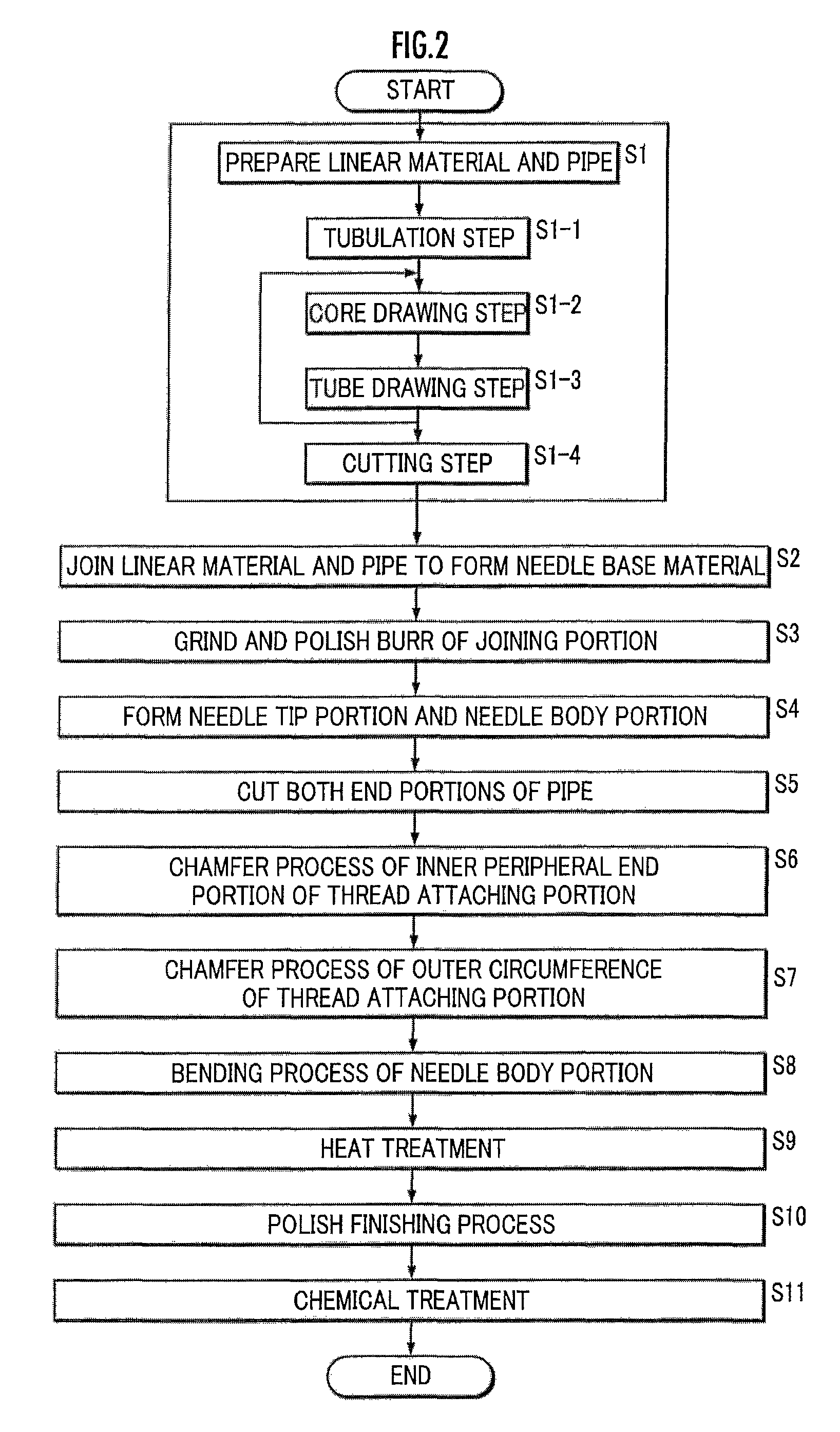

Manufacturing method of an eyeless suture needle

ActiveUS9408601B2Easy to provideReduce shapingEdge grinding machinesSurgical needlesSuturing needleTube drawing

A pipe element tube 23 is manufactured by a manufacturing method including step S1-1 for obtaining the pipe element tube 23 by rolling a stainless steel plate material 21 and welding an abutting portion, a core drawing step S1-2 for reducing a diameter and adjusting a thickness of the pipe element tube 23 by using a cored bar 24, and a tube drawing step S1-3 for reducing the diameter and adjusting an outer form of the pipe element tube 23 without using a cored bar. By adjusting repetition times of the core drawing step S1-2 and the tube drawing step S1-3, a uniform concavity and convexity are provided on an inner circumferential surface of the pipe element tube 23. Then a pipe 12 having an annular shaped cross section obtained by cutting the pipe element tube 23 and a linear material 11 having a circular cross section are joined (S2).

Owner:IKEN KOUGYO +1

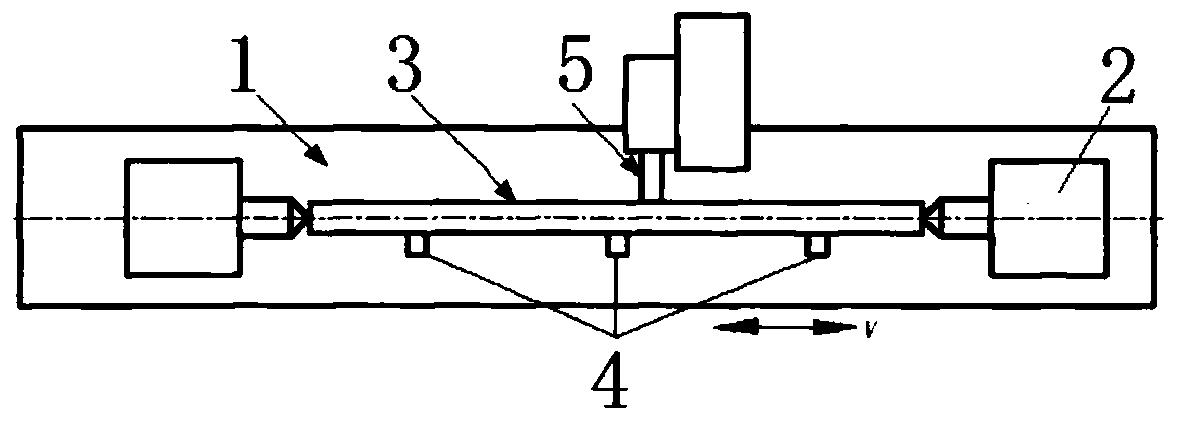

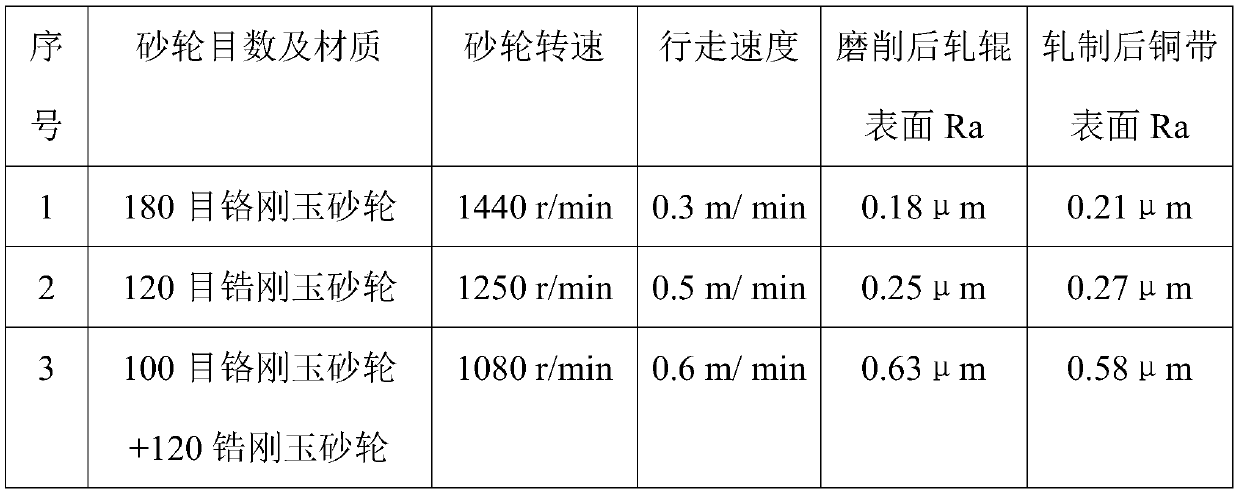

Machining technology for ultrasonic welding copper strip

InactiveCN110052897AImprove surface roughnessUniform surface roughnessRolling equipment maintainenceMetal rolling arrangementsUltrasonic weldingSurface roughness

The invention discloses a machining technology for an ultrasonic welding copper strip. The machining technology comprises the following steps that a grinding wheel is used for conducting roughness grinding machining on the surface of a roller, wherein 1a, a grinding wheel of 95-105 meshes is installed, the position of the grinding wheel is adjusted, the position of a roller bracket is adjusted, roller surface grinding treatment is conducted, and the roller surface is cleaned; and 1b, a grinding wheel of 115-125 meshes is adopted for replacement, roller surface grinding treatment is conducted again, the roller surface is cleaned, and a roller with the surface roughness being Ra0.6-0.7 micron is obtained; and secondly, the roller obtained after grinding machining is used for conducting rolling treatment on the surface of the copper strip, and the copper strip with the surface roughness being Ra0.5-0.65 micron is obtained. The copper strip surface roughness can be effectively improved, the copper strip surface roughness is uniform, the copper strip is not prone to skidding during ultrasonic welding, the contact area is large, and the welding quality is good; and the copper strip surface clearness and oxidation resisting capability are improved, and the quality of the copper strip is improved.

Owner:ANHUI ZHONGYUAN NEW MATERIALS CO LTD

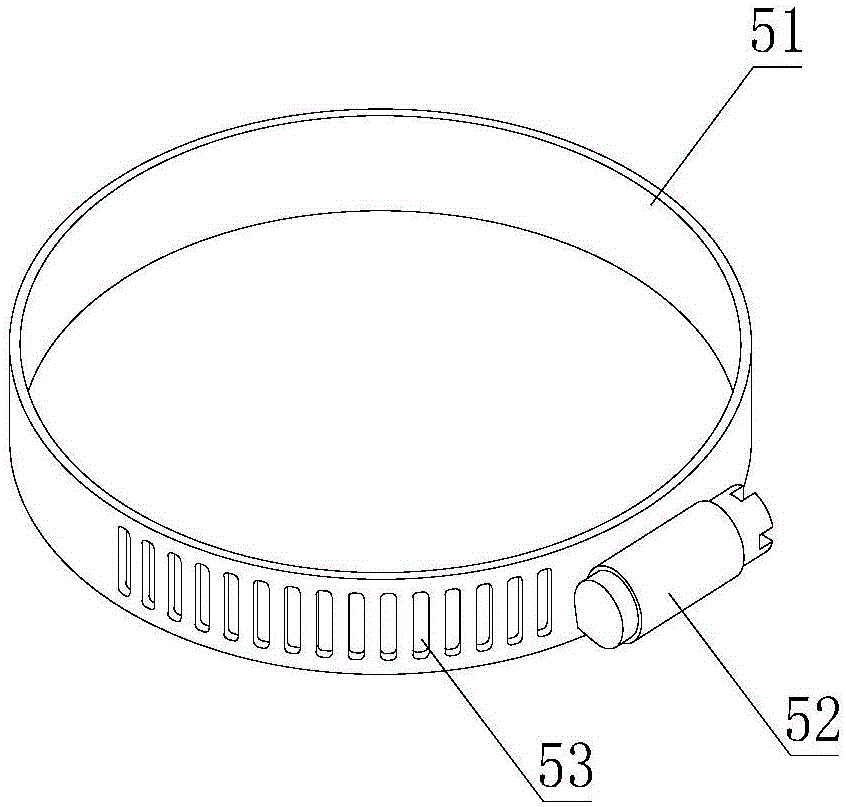

Shot-blast cleaning device for outer wall of wind power tower drum

InactiveCN104999377AReduce pollutionAvoid pollutionAbrasive machine appurtenancesAbrasive blasting machinesStress concentrationLow speed

The invention discloses a shot-blast cleaning device for the outer wall of a wind power tower drum, and belongs to the technical field of shot-blast treatment. The shot-blast cleaning device is mainly used for shot-blast treatment of the outer wall of the wind power tower drum and solves the problems of relatively low efficiency in cleaning rust, welding slag and other attachments on the outer wall of the wind power tower drum and stress concentration caused in the reeling process of the tower drum. The shot-blast cleaning device comprises a shot-blasting device, a shot-blasting room, a shot-collecting pool, a spiral conveying device, a load bearing vehicle and connecting openings. A motor provides power, the tower drum slowly moves and rotates at a low speed around the axis per se, shots blasted by the shot-blasting device continually impact the moving tower drum to finish shot-blast treatment, and scattered shots and generated dust are conveyed to other equipment connected with the connecting openings to be effectively processed. The shot-blast cleaning device for the outer wall of the wind power tower drum is high in cleaning efficiency and automation degree, low in dust pollution and improved in surface quality, reduces stress concentration, relieves the labor intensity of workers and improves the work environment of the workers.

Owner:UNIV OF JINAN

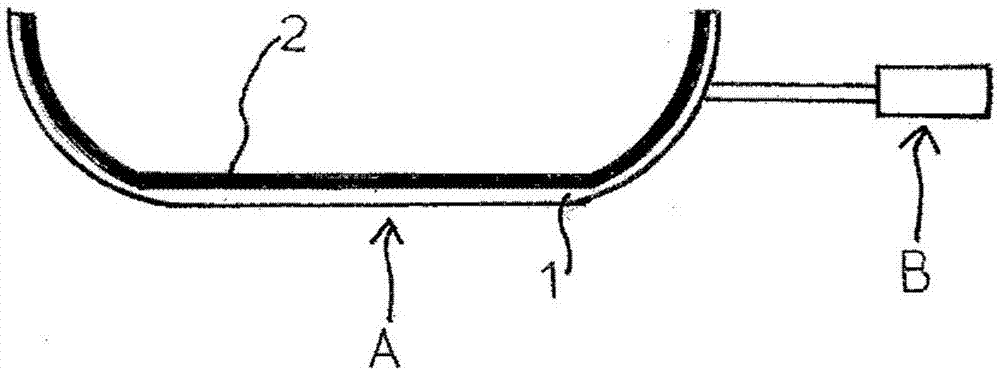

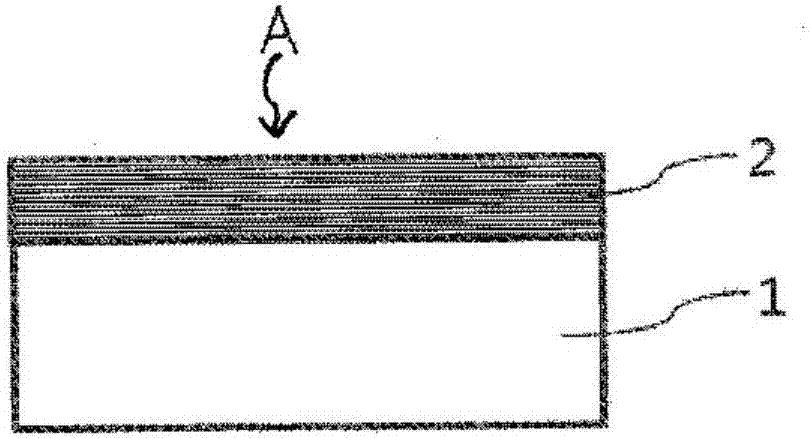

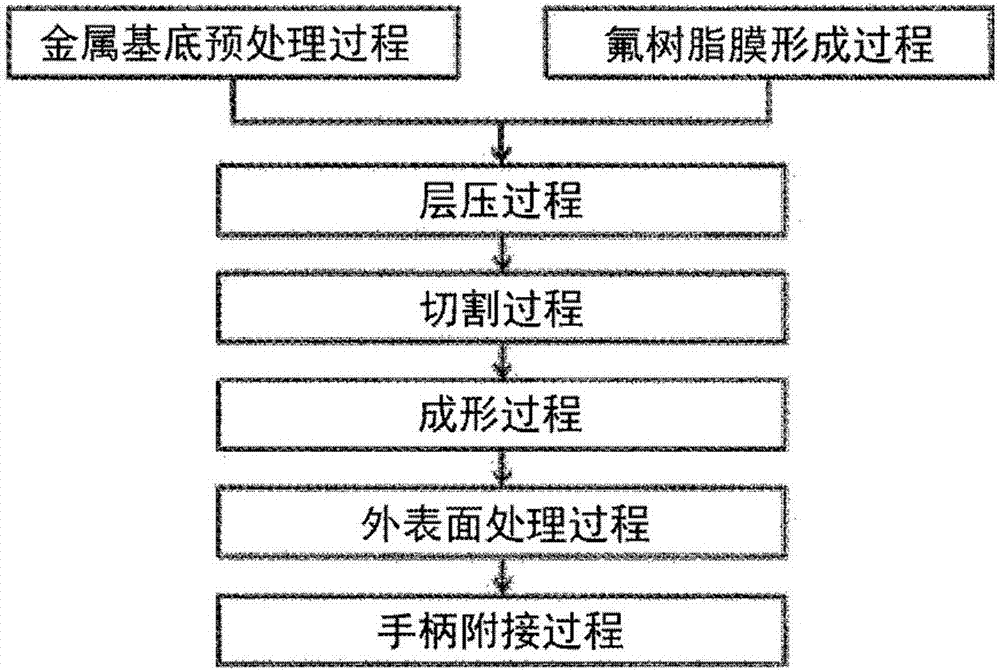

Cooking utensil having improved non-stick characteristics and method for manufacturing same

InactiveCN107205581AUniform thicknessUniform surface roughnessCooking-vessel materialsCoatingsLiquid stateSurface roughness

A cooking utensil according to the present invention comprises a cooking utensil body (A), which is configured as a laminate comprising a metal substrate (1) and a fluorine resin film (2) laminated on the metal substrate (1), the fluorine resin film (2) constituting the inner surface of the cooking utensil body (A), wherein the fluorine resin film (2) has a thickness deviation of 0.1-10[mu]m and a surface roughness of 0.1-10[mu]m. The fluorine resin film (2) is manufactured by a casting method, a cutting method, a calendar method, or an extrusion molding method, and therefore has uniform thickness and surface roughness. According to the present invention, the fluorine resin film (2) has uniform thickness and surface roughness, thereby improving non-stick characteristics. In addition, according to the present invention, the thickness of the fluorine resin film (2) can be easily formed even at a level of 20-300[mu]m. Compared with conventional methods of spraying a fluorine resin coating liquid in a liquid state, the present invention can resolve environmental problems resulting from scattering of the fluorine resin coating liquid, and can prevent degradation of non-stick characteristics due to poor coating of pinholes, for example.

Owner:KOREA TACONIC

Method for surface treatment of high-purity copper rotary target material

PendingCN111331518AConsistent colorUniform surface roughnessAbrasive machine appurtenancesCopperSurface preparation

The invention relates to a method for surface treatment of a high-purity copper rotary target material. The method comprises the steps that the high-purity copper rotary target material is subjected to shielding treatment, and sand blasting is conducted after shielding treatment is completed, wherein the roughness of the surface of the target material obtained after sand blasting is completed is Rz 35-65 microns, and according to shielding treatment, adhesive tape is adopted for shielding the sputtering faces and the side edges of the two ends of the high-purity copper rotary target material.After the surfaces of the two ends of the rotary target material treated through the method are subjected to sand blasting, the color and luster are consistent, the surface roughness is uniform and improved, impurities such as stains are avoided, the adsorption capacity to anti-sputtering objects in the target material sputtering process is improved, the target material coating quality is improved, and the yield is increased.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

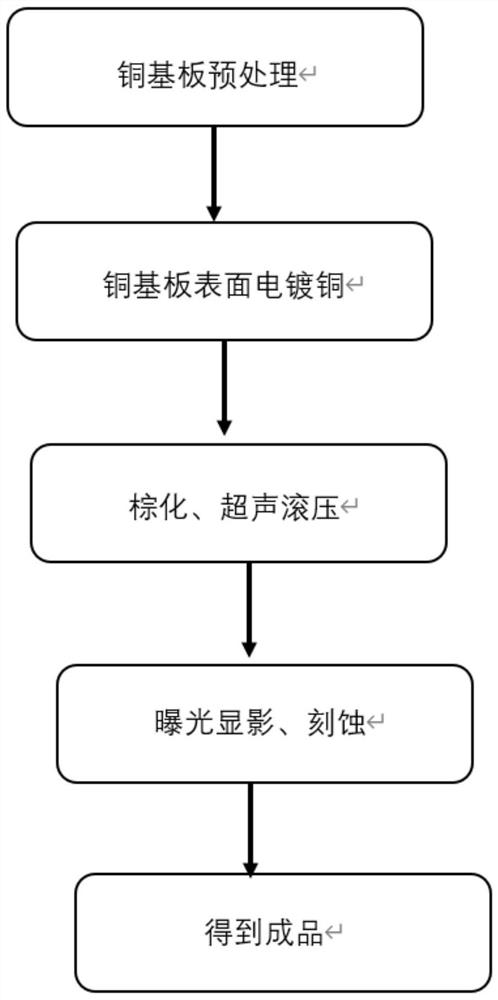

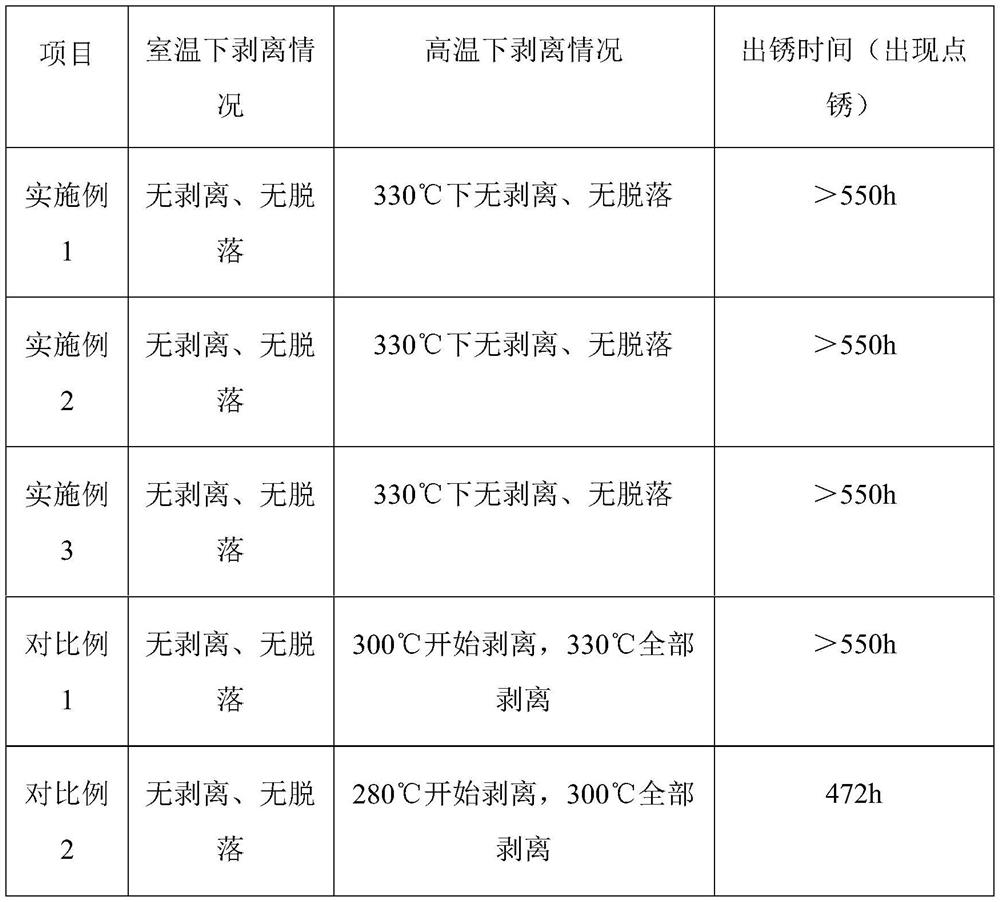

Semiconductor high-density lead frame and manufacturing process thereof

ActiveCN113113321AHigh densityHigh precisionSemiconductor/solid-state device detailsSolid-state devicesMetallurgyCopper substrate

The invention discloses a semiconductor high-density lead frame and a manufacturing process thereof. The manufacturing process includes the steps of pretreatment, electroplating, browning, rolling, photoetching and the like to prepare the high-density and high-precision semiconductor lead frame, and comprises the steps of during preparation, treating the surface of a copper substrate firstly, placing the copper substrate in an electrolyte for cathode electrolysis oil removal, and then removing the oil stains on the surface of the copper substrate to ensure that the surface of the copper substrate is clean; then placing the copper substrate in an acid solution for thoroughly removing an oxidation film on the surface of the copper substrate; and then activating the surface of the copper substrate, keeping the surface activity of the copper substrate, well combining the copper substrate and a subsequent plating layer, so that the pre-treated copper substrate is obtained. According to the present invention, the photoetching pattern is formed on the surface of the copper substrate after photoetching, the subsequent metal layer electroplating, chip bonding and other processes can be carried out in the actual operation, the surface of the prepared lead frame is free of scratches, dents and stains, and the semiconductor high-density lead frame and the manufacturing process thereof can be widely applied to the fields of chip packaging and the like.

Owner:昆山弗莱吉电子科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com