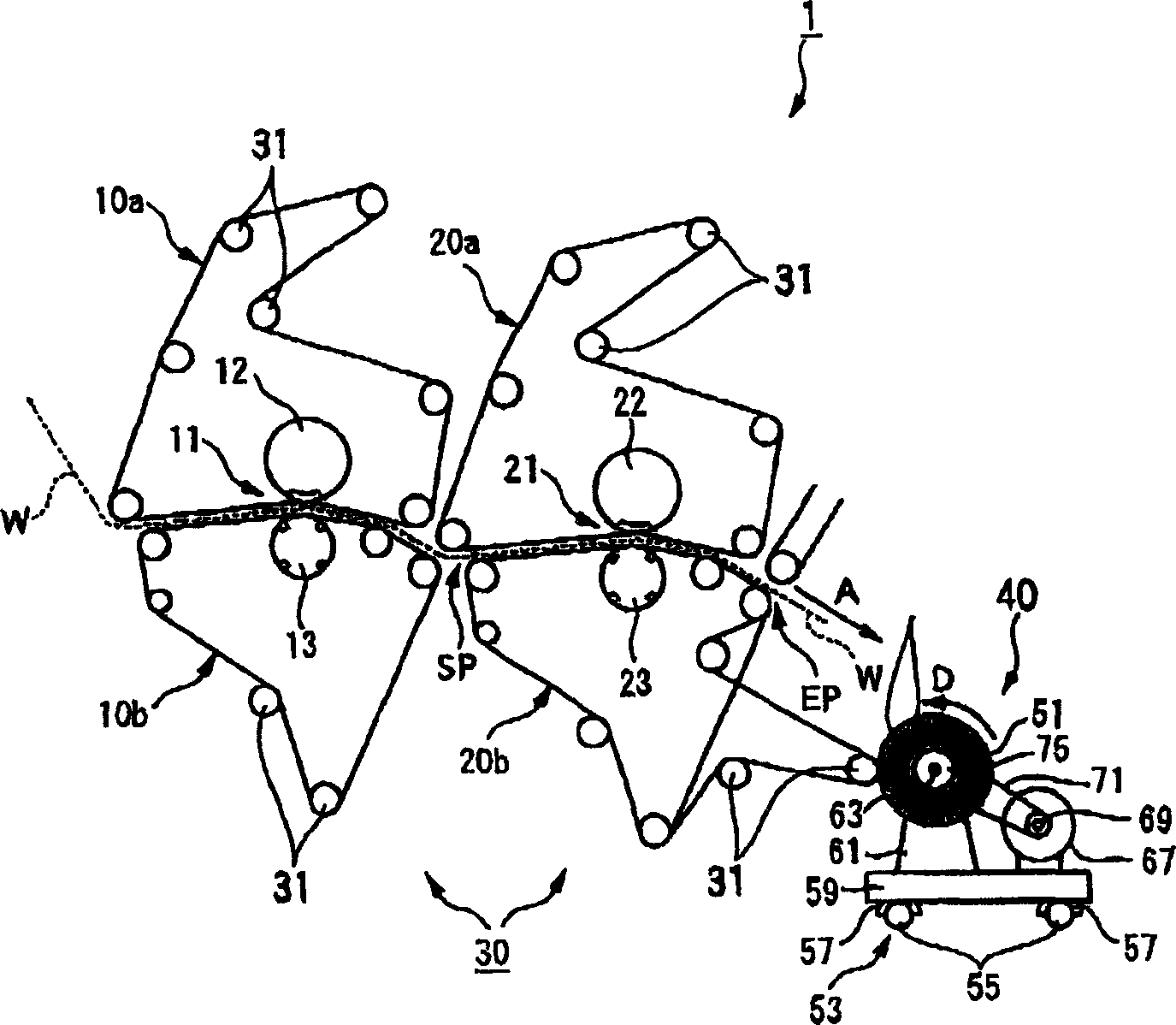

Paper machine and method for reconditioning a conveying belt of a paper machine

A technology for a conveyor belt and a paper machine, which is applied in the field of paper machines and can solve the problems of reduced normal working time, increased cost, and degraded wet paper peeling properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

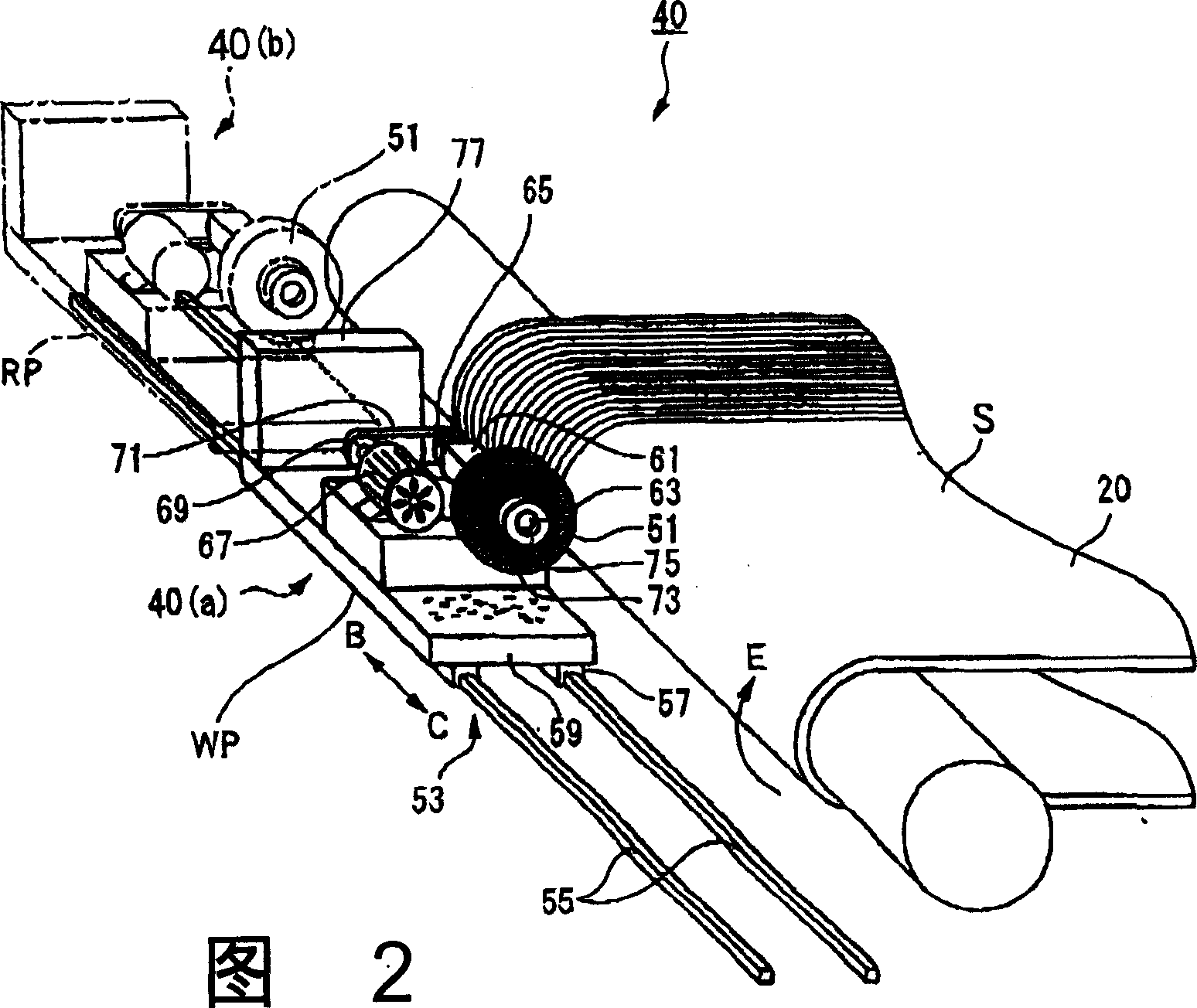

[0067] use Figure 6 The apparatus in , carried out the running test of the wet paper transfer belt, and evaluated the improvement characteristics after polishing by the wet paper peeling characteristics of the wet paper transfer belt. It should be noted that the test conditions are as follows.

[0068] 1. Operating conditions

[0069] (1) Belt running speed: 150m / min

[0070] (2) Pressure at the extrusion part: 40kg / cm 2

[0071] (3) Vacuum value of suction roller: 150mmHg

[0072] 2. Wet paper used

[0073] Formed from hand craft pulp. Basic weight: 80g / m 2 , Dryness: 38%

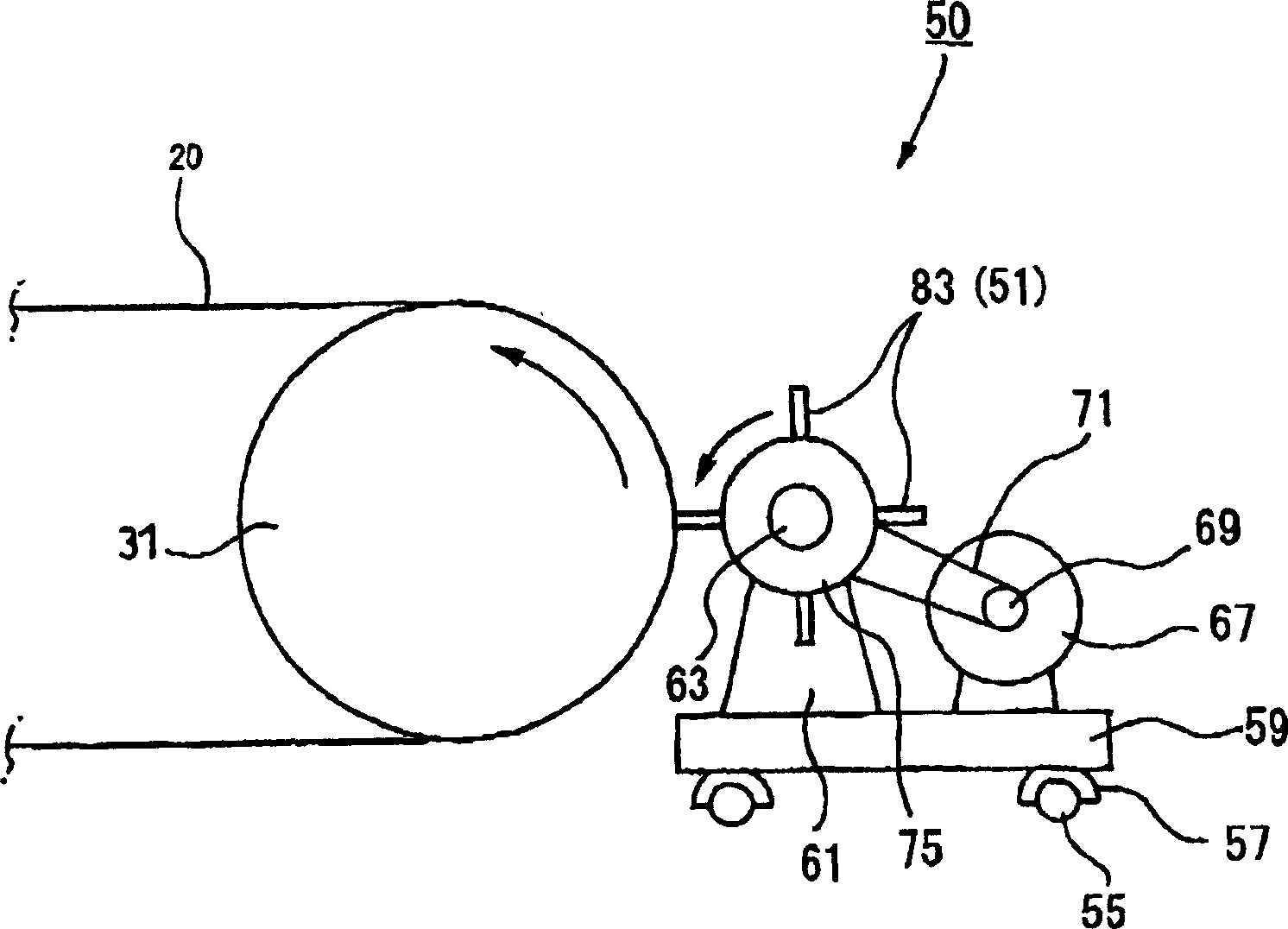

[0074] 3. Polishing device

[0075] (1) Polishing device: rotary sandpaper device

[0076] (2) Polisher: #100 aluminum oxide sandpaper

[0077] 4. Scraper device

[0078] The scraper terminal is made of #600 aluminum oxide sandpaper. The end of the scraper is attached to the surface of the belt, and at the same time, the sandpaper transfer belt 10 runs around, so that the used state of the be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com