Ultrasonic cavitation and magnetic field assisted low-pressure abrasive flow polishing method and device

A magnetic field-assisted and abrasive flow technology, applied in the field of ultra-precision machining, can solve problems such as low surface quality, low processing efficiency, and uneven surface roughness of workpieces, and achieve consistent surface roughness, improve processing efficiency, and improve polishing force distribution uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

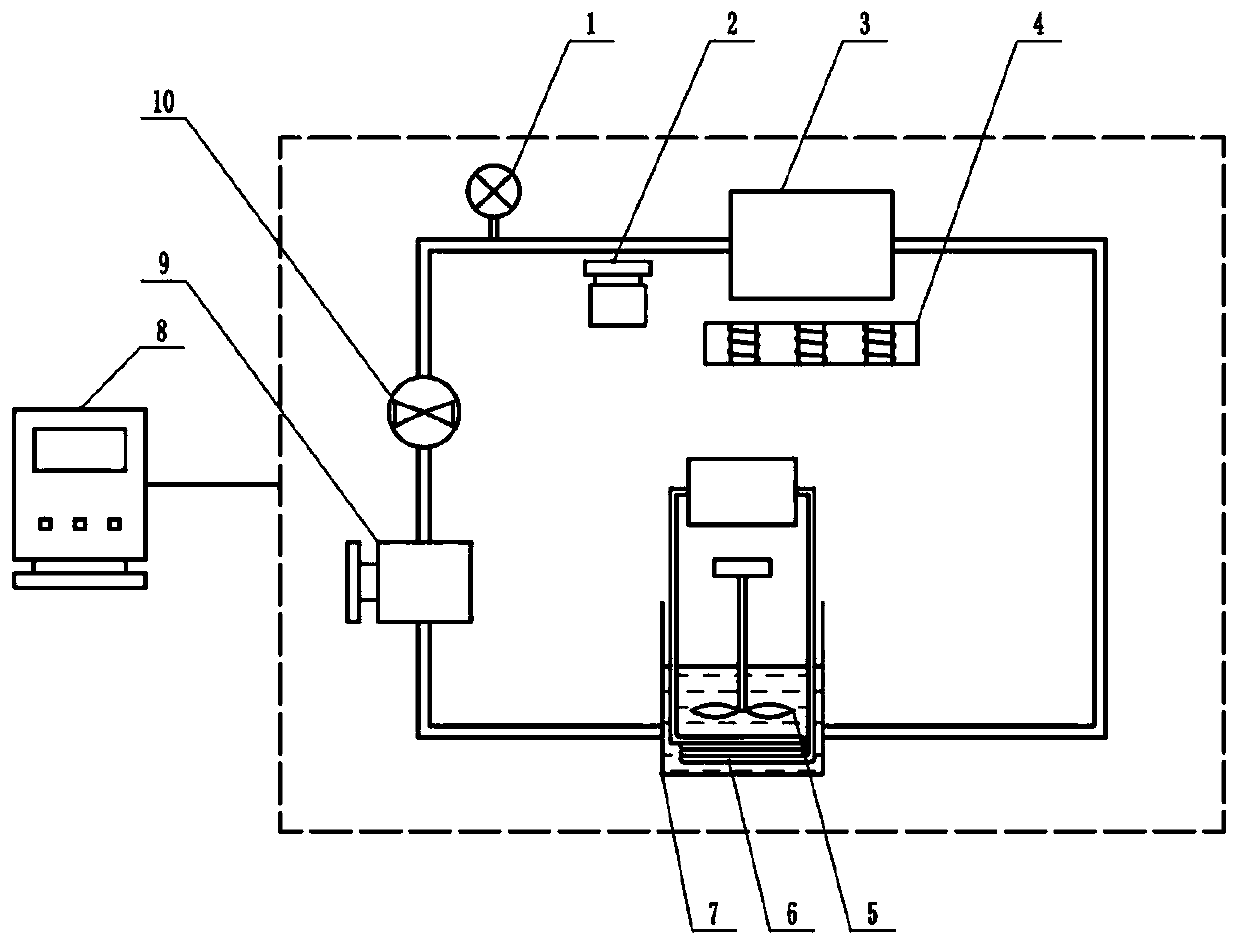

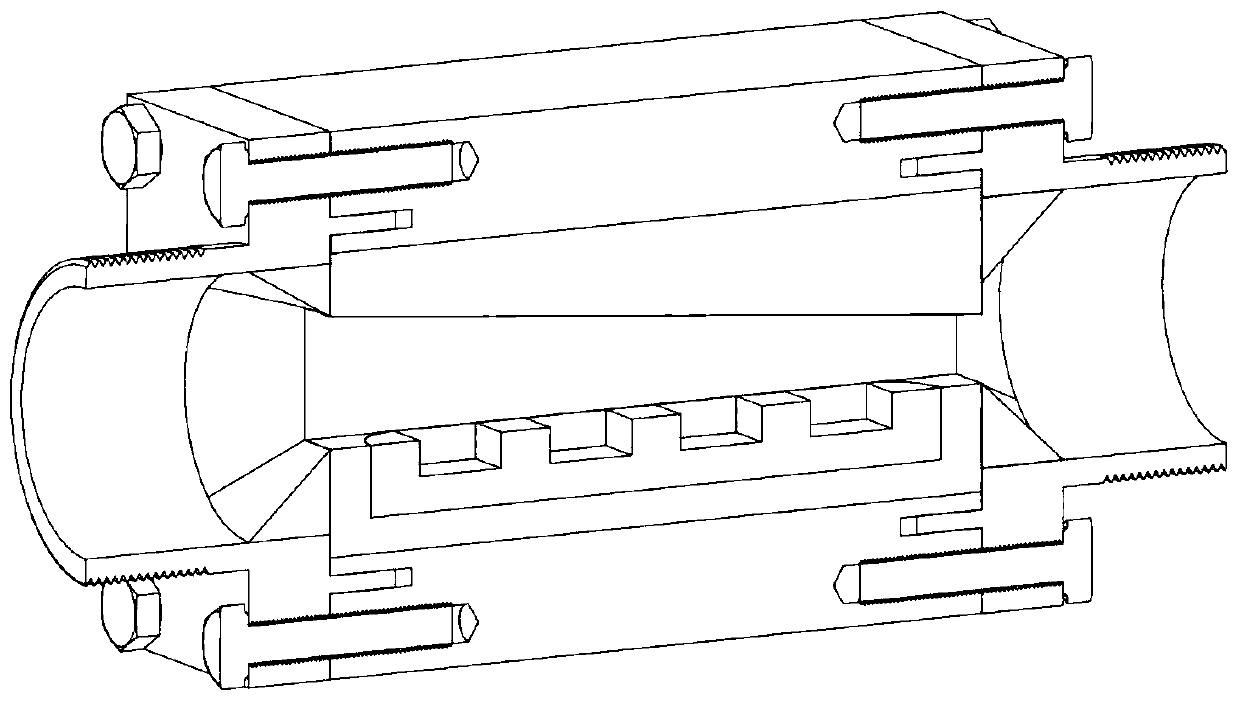

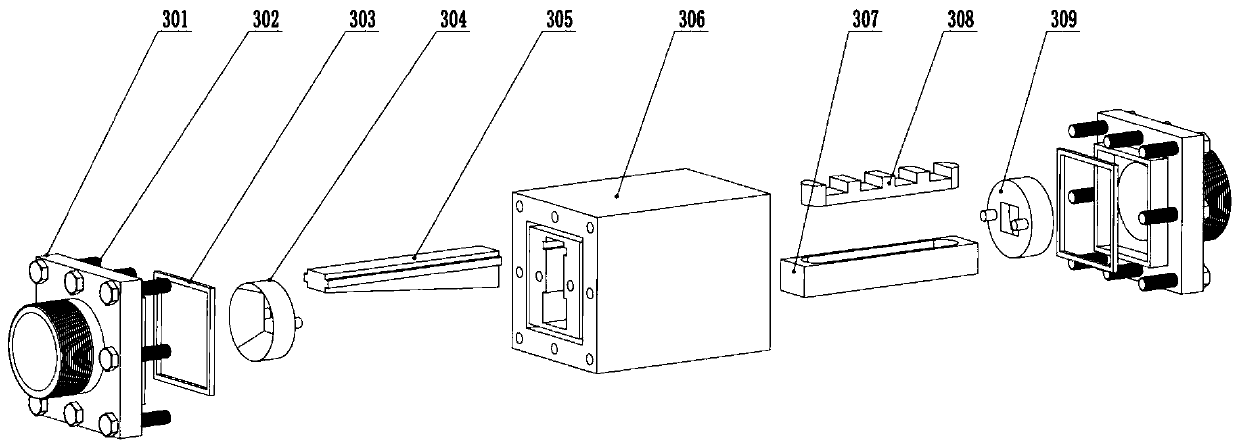

[0026] refer to Figure 1 to Figure 7 , an ultrasonic cavitation and magnetic field-assisted low-pressure abrasive flow polishing method, wherein the abrasive flow polishing is carried out in a low-pressure fluid; the abrasive flow polishing is carried out in a wedge-shaped flow channel; the inclination angle of the upper top surface of the wedge-shaped flow channel can be Adjustment is achieved by replacing the angle block parts placed in the processing device; the cavitation is ultrasonic cavitation, and cavitation bubbles are generated in the abrasive flow by an ultrasonic generator installed in front of the flow channel inlet of the processing device; the magnetic field An adjustable and uniform magnetic field perpendicular to the surface of the workpiece generated by an electromagnet placed directly below the processing device. Under the action of the magnetic fie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com