Oxidation nanofiltration membrane reactor

An oxidation reaction and reactor technology, applied in chemical instruments and methods, oxidized water/sewage treatment, water/sewage multi-stage treatment, etc., to accelerate the degradation rate, increase the shear force on the membrane surface, and reduce the coalescence effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

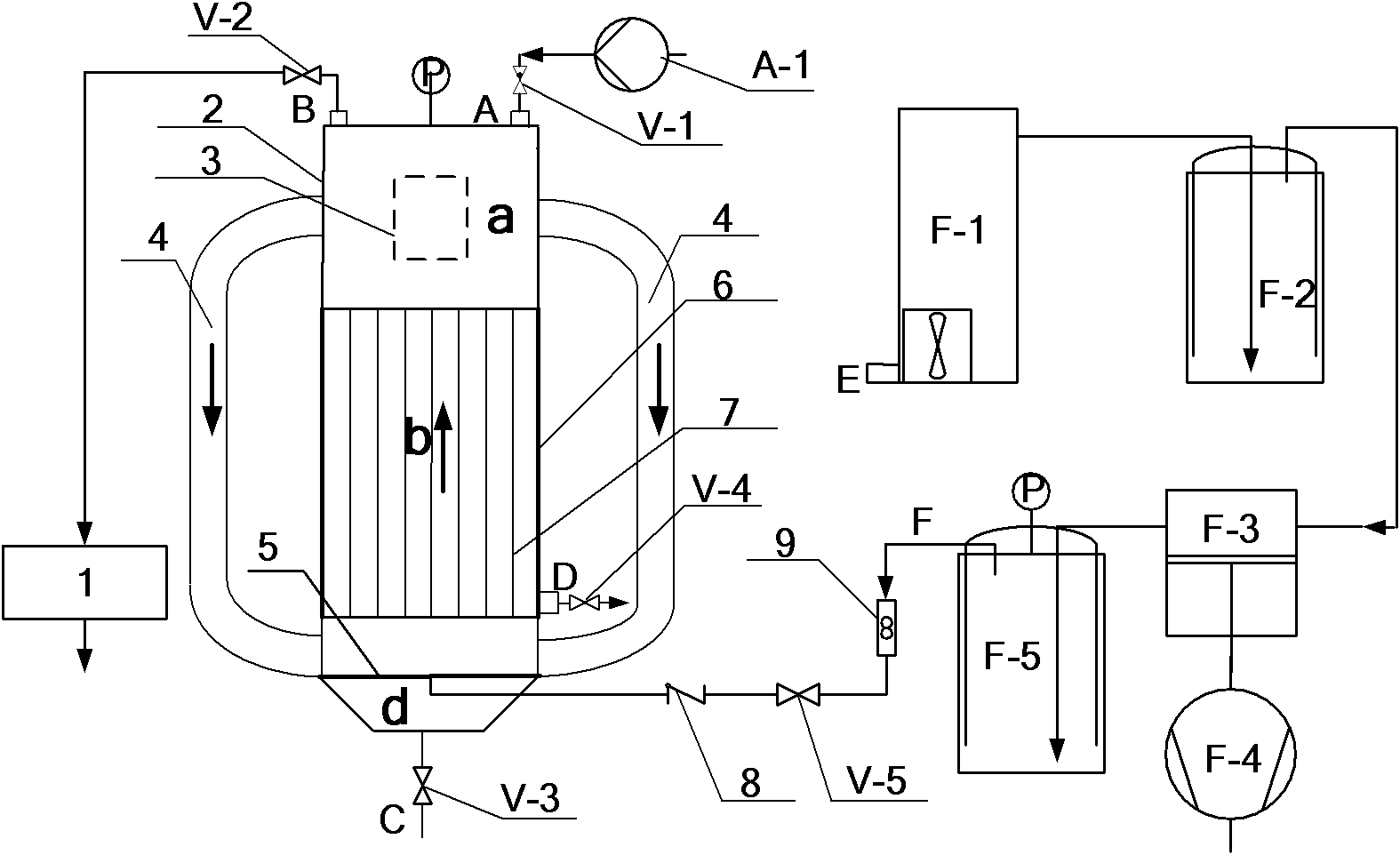

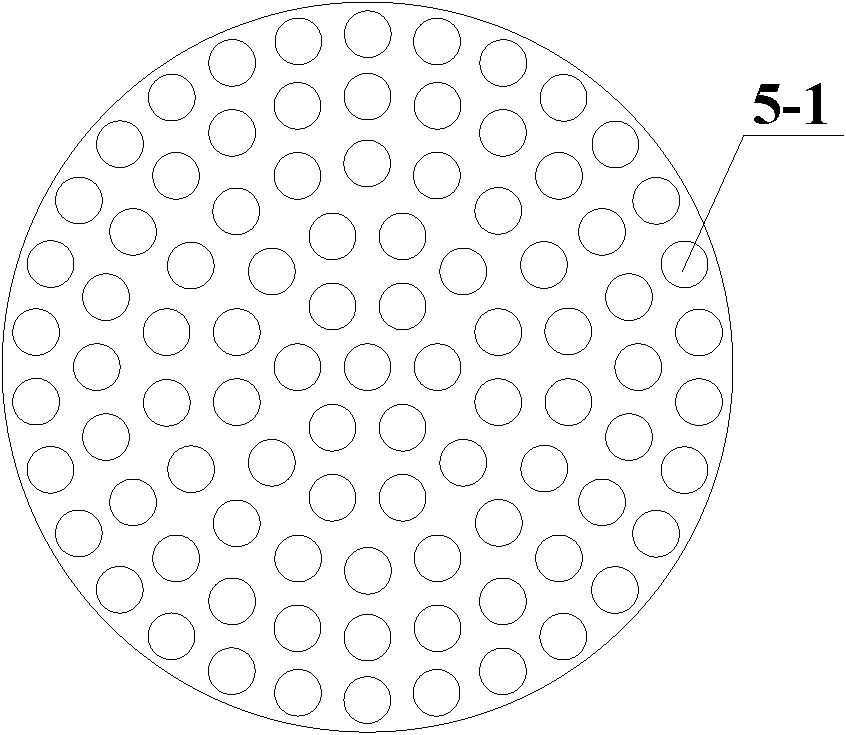

[0029]A kind of oxidation nanofiltration membrane reactor provided by the present invention, by reaction-separation system (raw material pump A-1, oxidation reactor 2, circulation pipe 4, gas distribution plate 5), pressurization system (ozone generator F- 1. It is composed of buffer tank F-2, pneumatic booster pump F-3, air compressor F-4, surge tank F-5), exhaust gas treatment system (ozone absorption device 1), and the materials of each component are conventional materials ,like figure 1 shown. Among them, the oxidation reaction kettle 2 is divided into a gas-liquid separation zone a, a reaction-separation zone b and a settling zone d. The top of the gas-liquid separation zone a has a feed liquid inlet A and an exhaust gas outlet B. The feed liquid inlet A passes through the valve V-1 and the raw material The pump A-1 is connected, and the exhaust gas outlet B is ...

Embodiment 2

[0033] The refractory humic acid solution is deeply degraded and removed by using the oxidation nanofiltration membrane reactor provided by the invention. The height of the oxidation reaction kettle of the reactor is 0.6m, its inner diameter is 0.6m, the height ratio of the reaction-separation zone to the gas-liquid separation zone is 2, the ratio of the inner diameter of the oxidation reaction kettle to the circulation pipe is 12, and there are 5 sets of symmetrical circulation pipes. The aeration aperture of the distribution plate is 4mm, and the distance between the centers of the pores is 8mm. Configure the humic acid solution to be 50mg / l and adjust the pH of the solution to 10, the TOC value is 18.95mg / l, the COD is 62mg / l, and the turbidity value is 20.4NTU; In the reactor, the concentration of ozone gas is 100mg / l, adjust the gas rotameter, control the aeration flow rate so that the gas velocity on the membrane surface is 0.5m / s, the membrane element used in this exper...

Embodiment 3

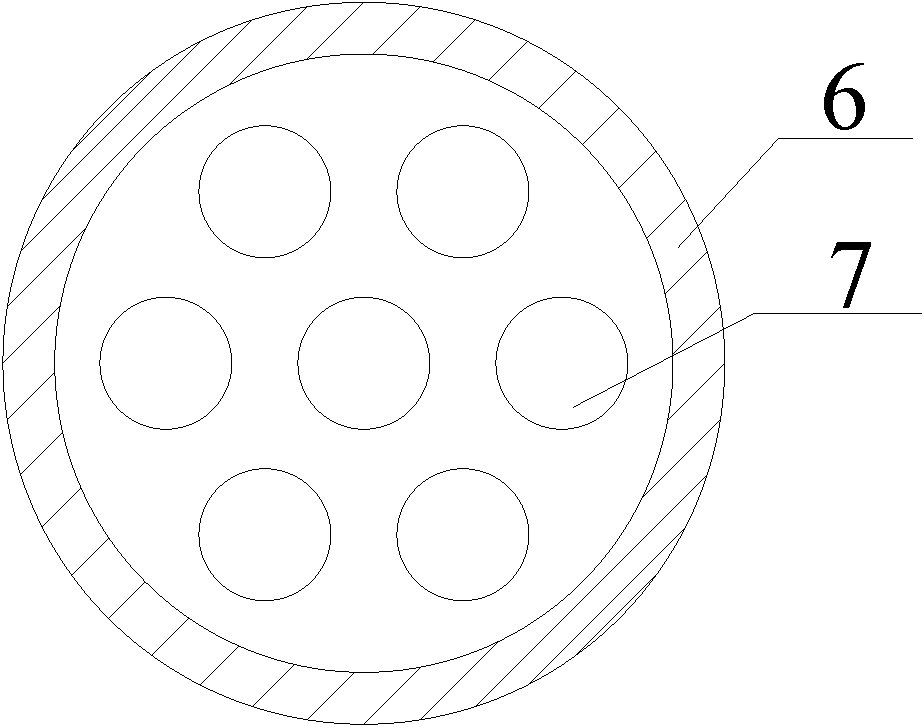

[0035] The oxidation nanofiltration membrane reactor provided by the invention is used to carry out deep degradation and removal of the refractory phenol solution. The height of the oxidation reaction kettle of the reactor is 0.8m, and its inner diameter is 0.3m. The aeration aperture of the distribution plate is 2mm, and the distance between the centers of the air holes is 4mm. Configure the phenol solution to be 100mg / l and adjust the pH of the solution to be 7, the TOC value is 90.11mg / l, the COD is 283mg / l, and the turbidity value is 9.6NTU; feed the feed liquid into the oxidation reaction kettle through the pump from the feed liquid inlet middle. The concentration of ozone gas is 200mg / l, adjust the gas rotameter, control the aeration flow rate so that the gas velocity on the membrane surface is 0.1m / s, the membrane element used in this experiment is a 19-channel TiO2 with a pore size of 0.9nm 2 Ceramic nanofiltration membrane, control the pressure of the surge tank to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com