Patents

Literature

55 results about "Membrane channel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Membrane channels are a family of biological membrane proteins which allow the passive movement of ions (ion channels), water (aquaporins) or other solutes to passively pass through the membrane down their electrochemical gradient. They are studied using a range of channelomics experimental and mathematical techniques. Insights have suggested endocannabinoids (eCBs) as molecules that can regulate the opening of these channels during diverse conditions.

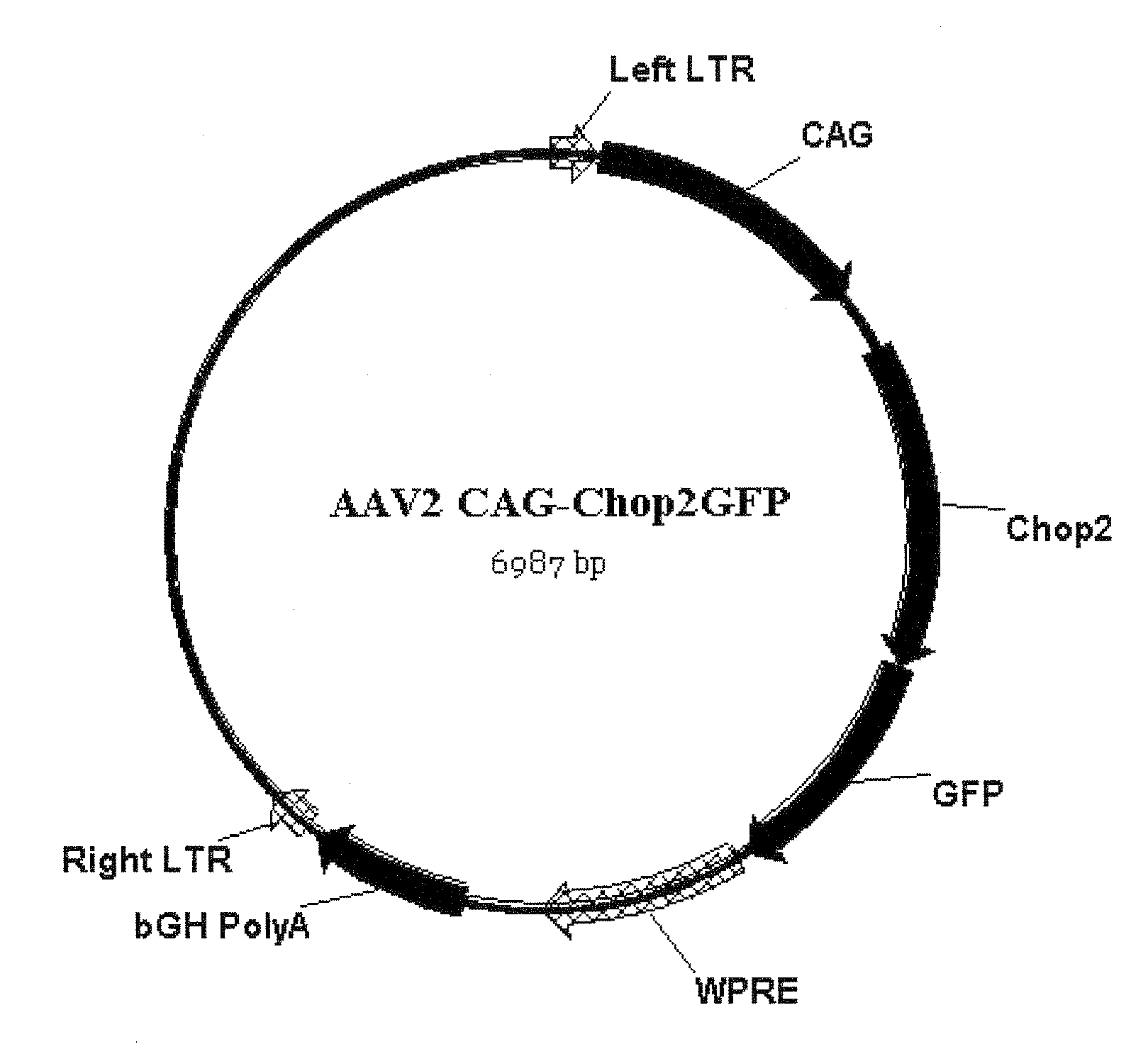

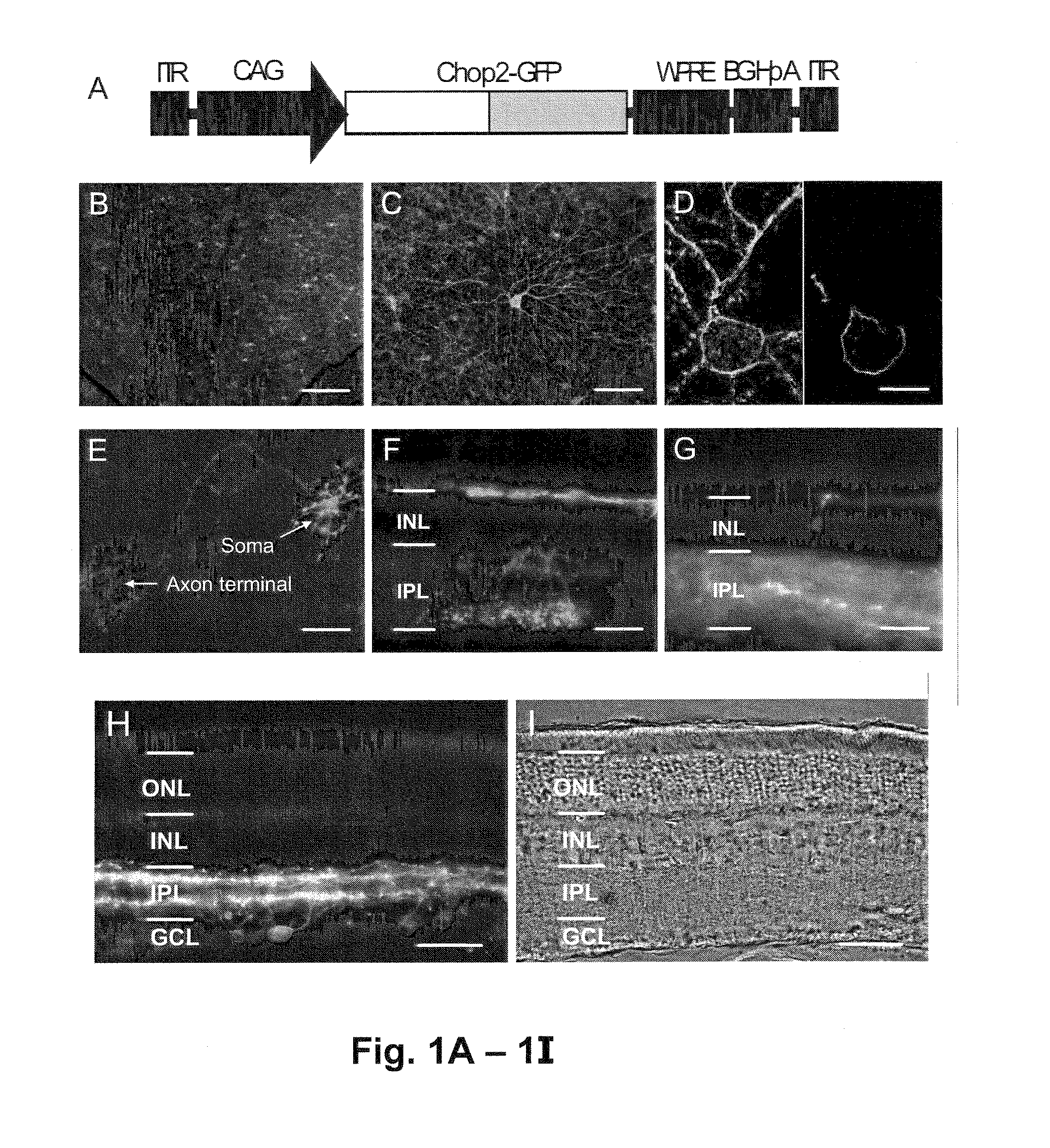

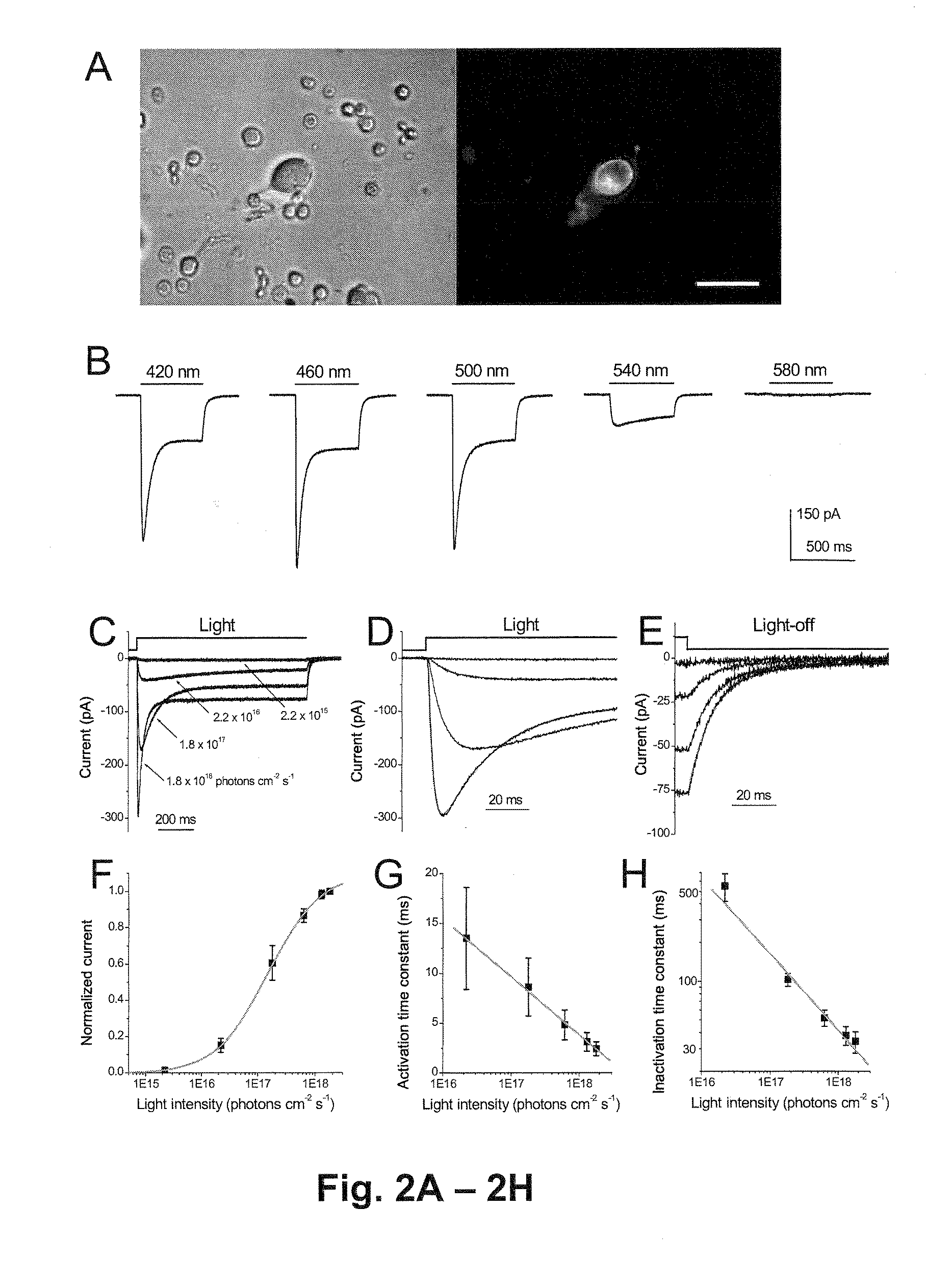

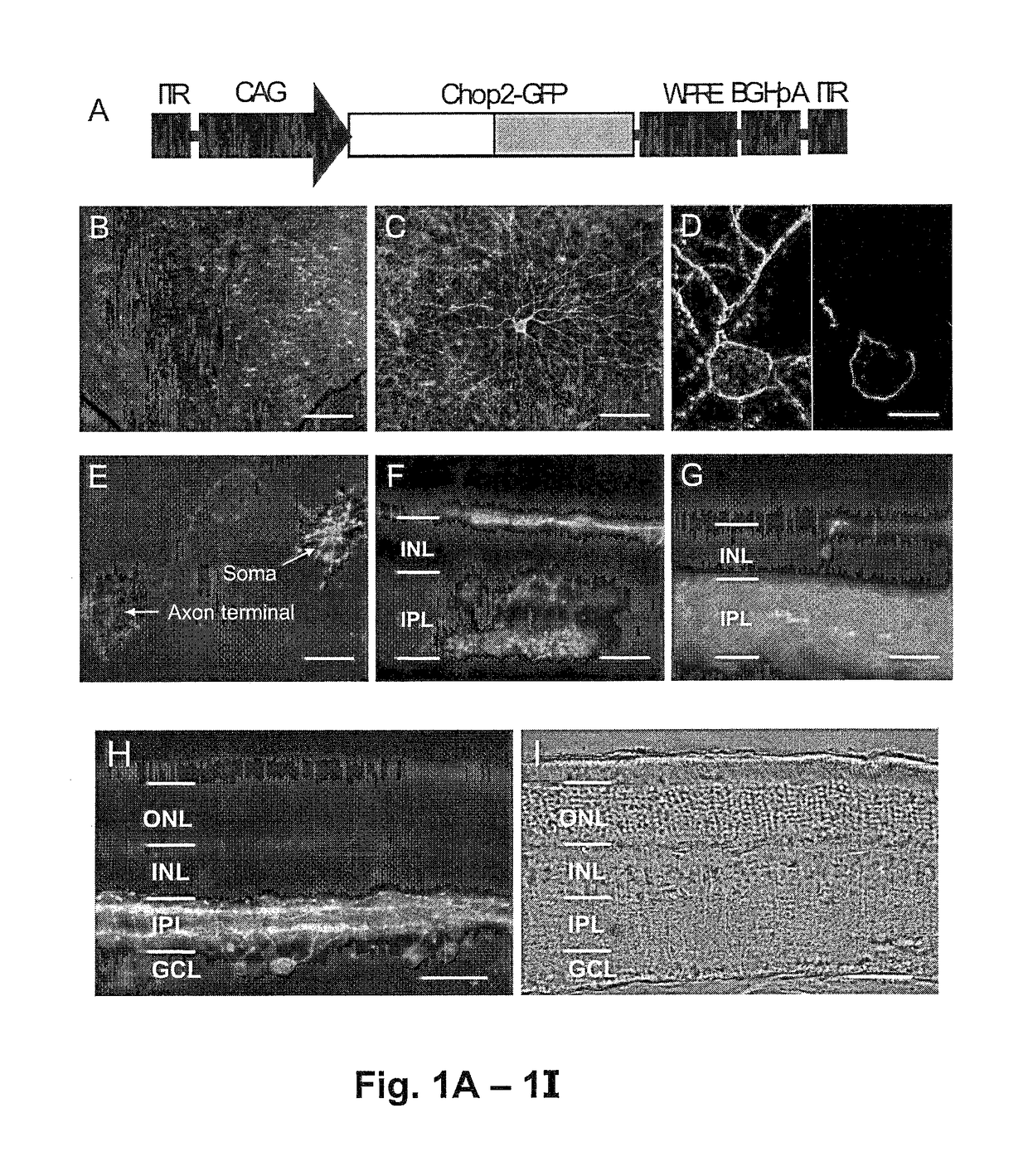

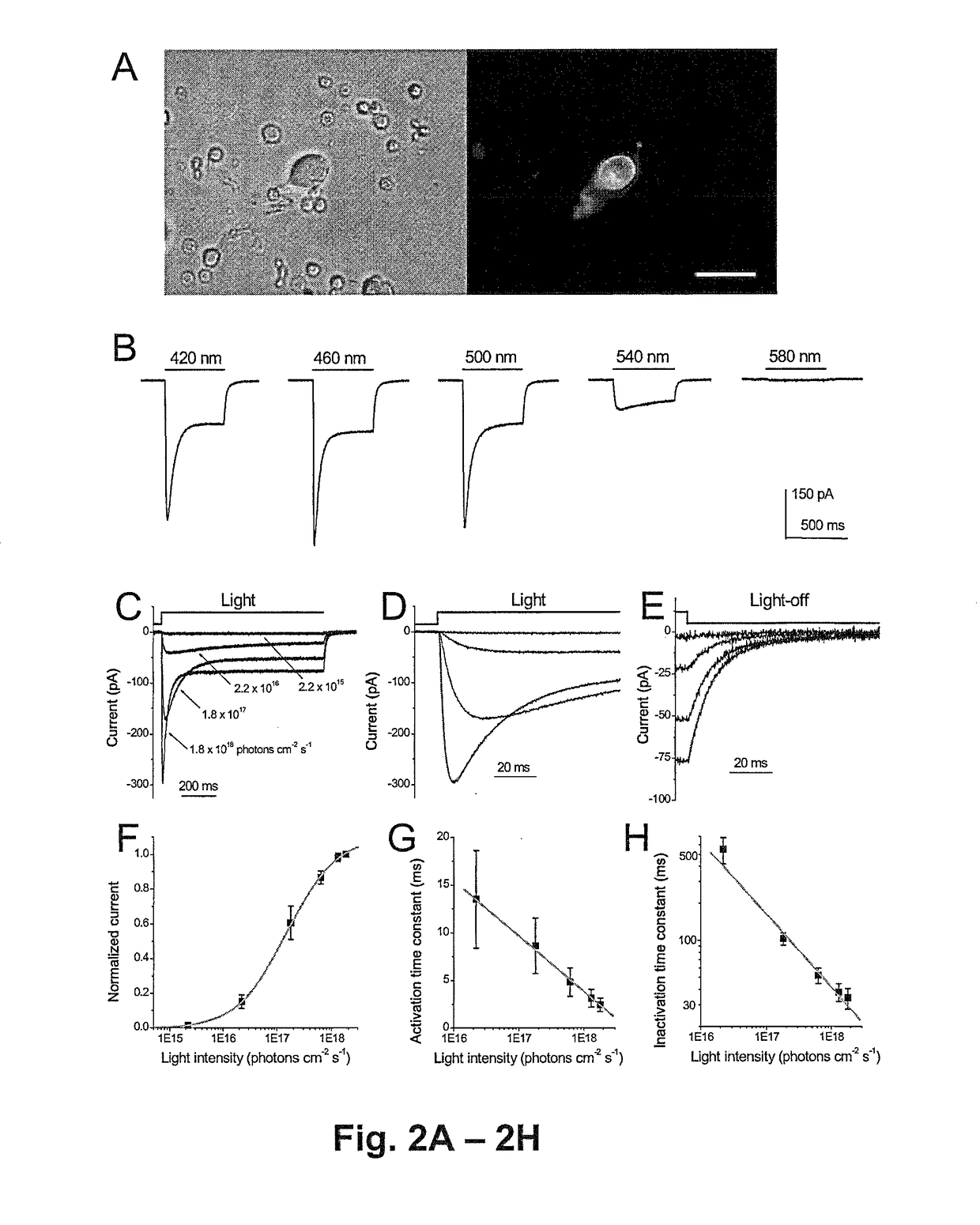

Restoration of visual responses by in vivo delivery of rhodopsin nucleic acids

ActiveUS20100015095A1Restoring light sensitivityLoss can be compensatedOrganic active ingredientsBiocideOpen reading frameIn vivo

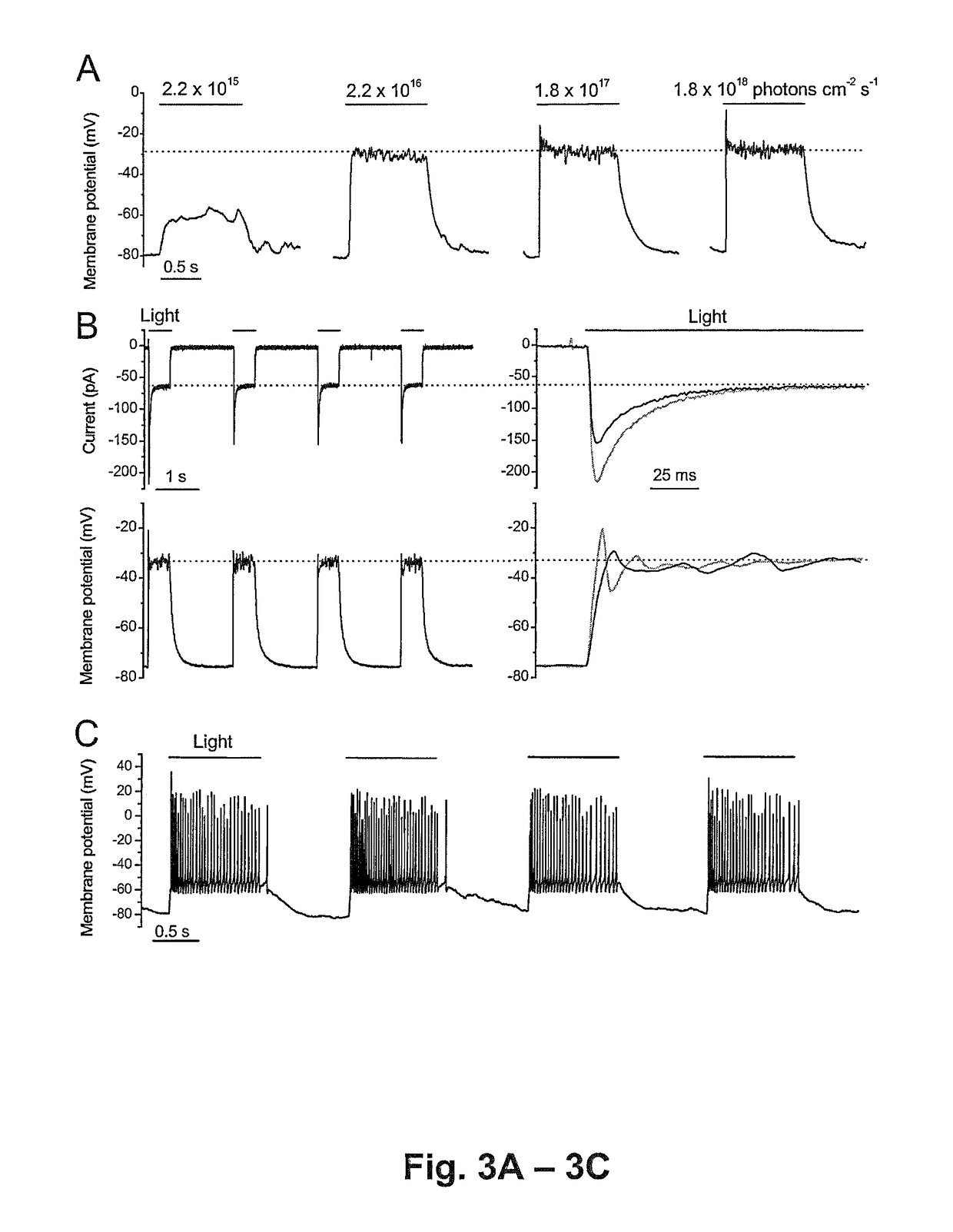

Nucleic acid vectors encoding light-gated cation-selective membrane channels, in particular channelrhodopsin-2 (Chop2), converted inner retinal neurons to photosensitive cells in photoreceptor-degenerated retina in an animal model. Such treatment restored visual perception and various aspects of vision. A method of restoring light sensitivity to a retina of a subject suffering from vision loss due to photoreceptor degeneration, as in retinitis pigmentosa or macular degeneration, is provided. The method comprises delivering to the subject by intravitreal or subretinal injection, the above nucleic acid vector which comprises an open reading frame encoding a rhodopsin, to which is operatively linked a promoter and transcriptional regulatory sequences, so that the nucleic acid is expressed in inner retinal neurons. These cells, normally light-insensitive, are converted to a light-sensitive state and transmit visual information to the brain, compensating for the loss, and leading to restoration of various visual capabilities.

Owner:WAYNE STATE UNIV +1

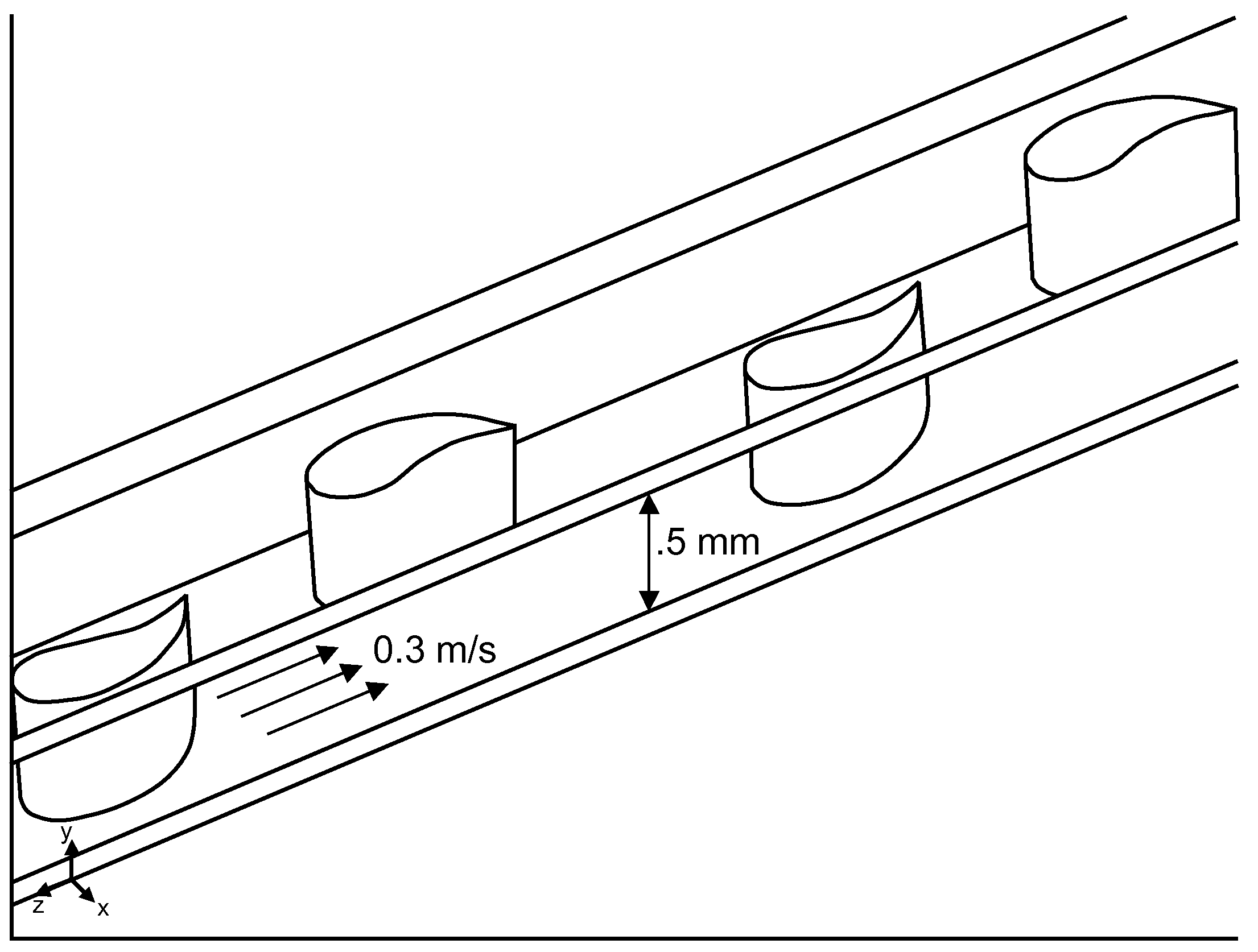

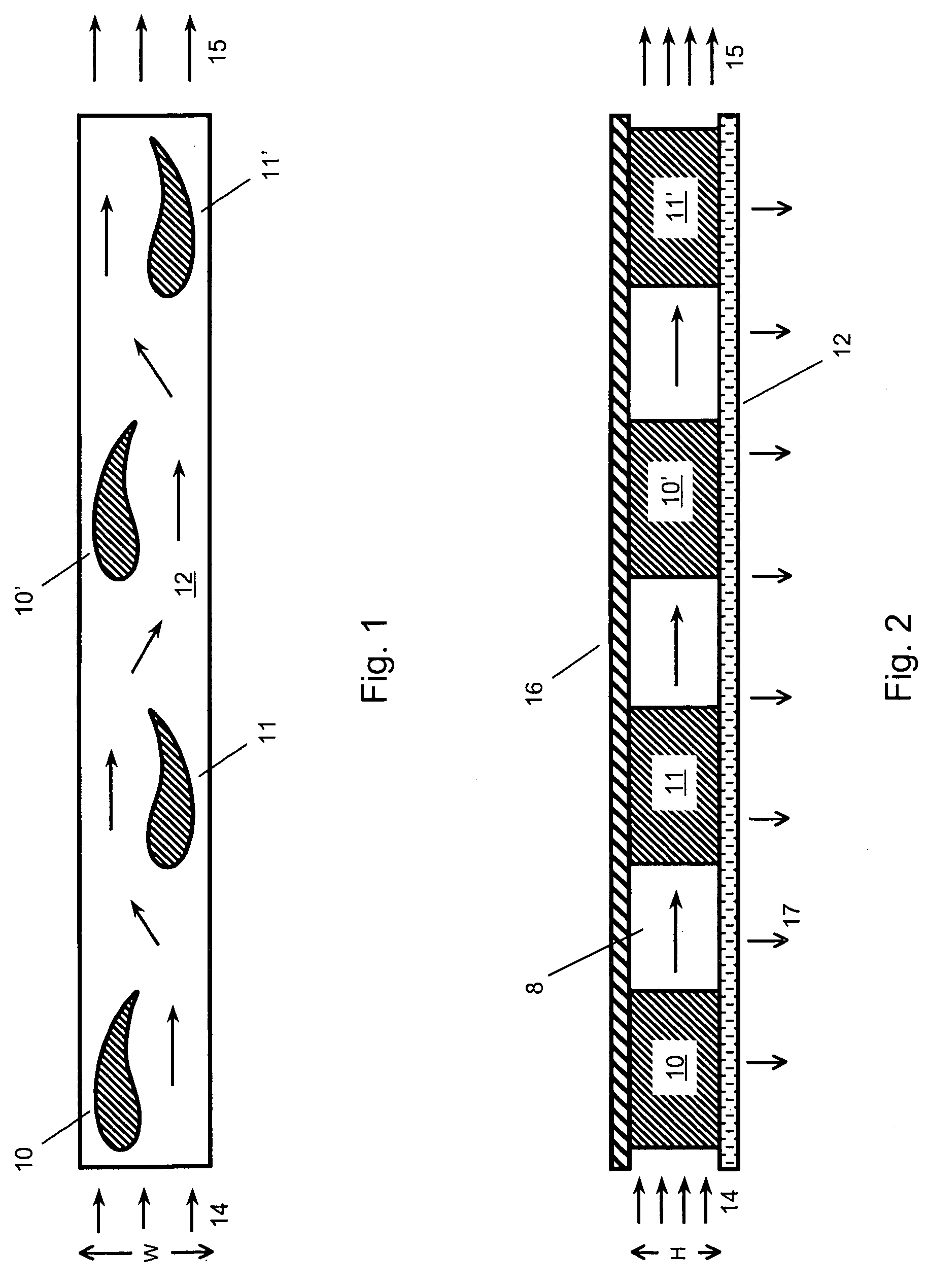

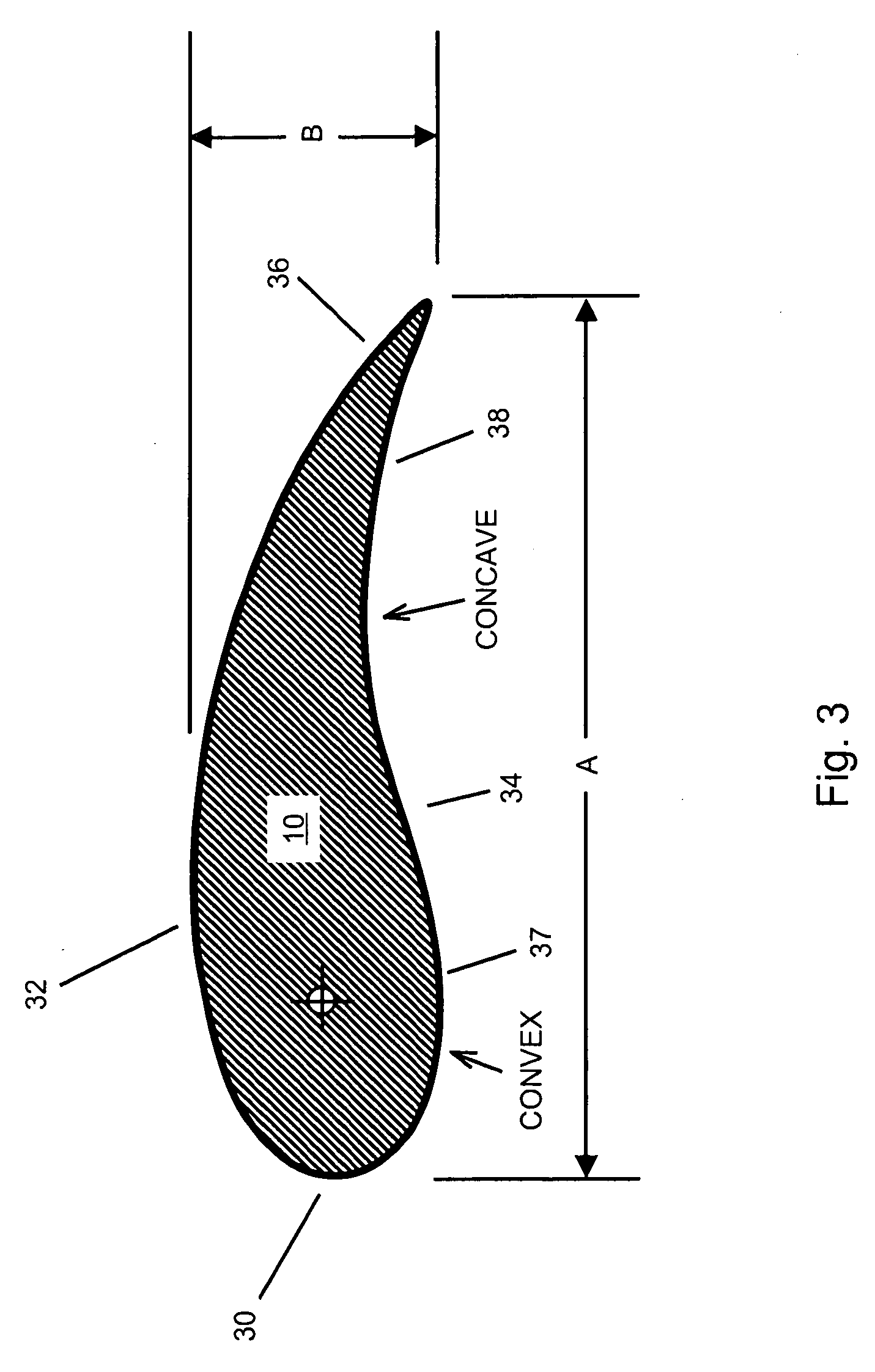

Airfoil-Shaped Micro-Mixers for Reducing Fouling on Membrane Surfaces

ActiveUS20100118642A1Enhance fluid mixingMinimized pressure dropSemi-permeable membranesMembranesFiltrationMembrane channel

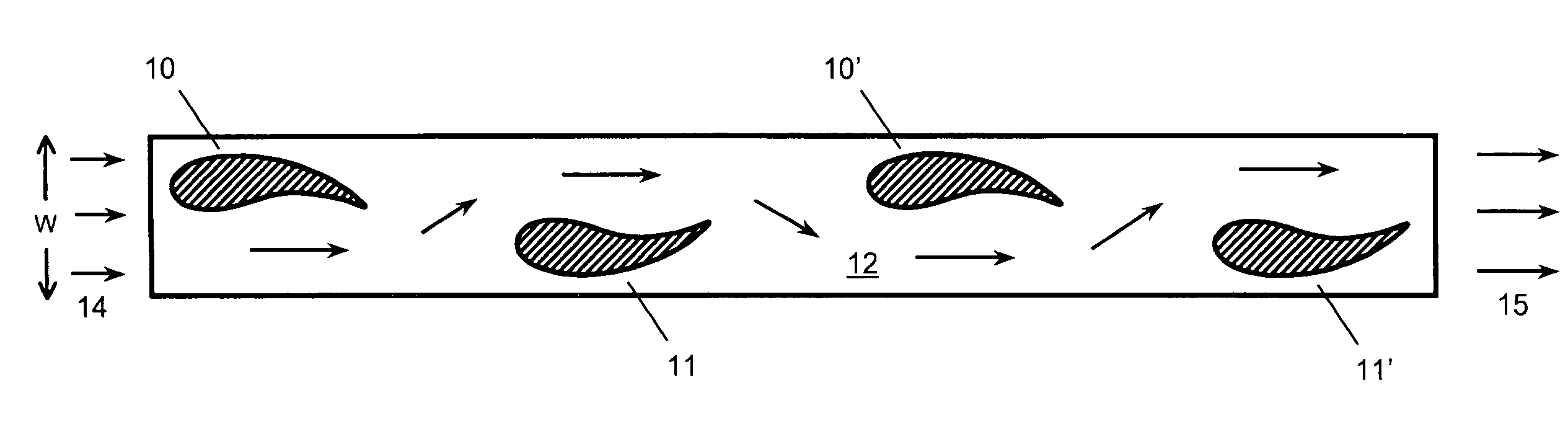

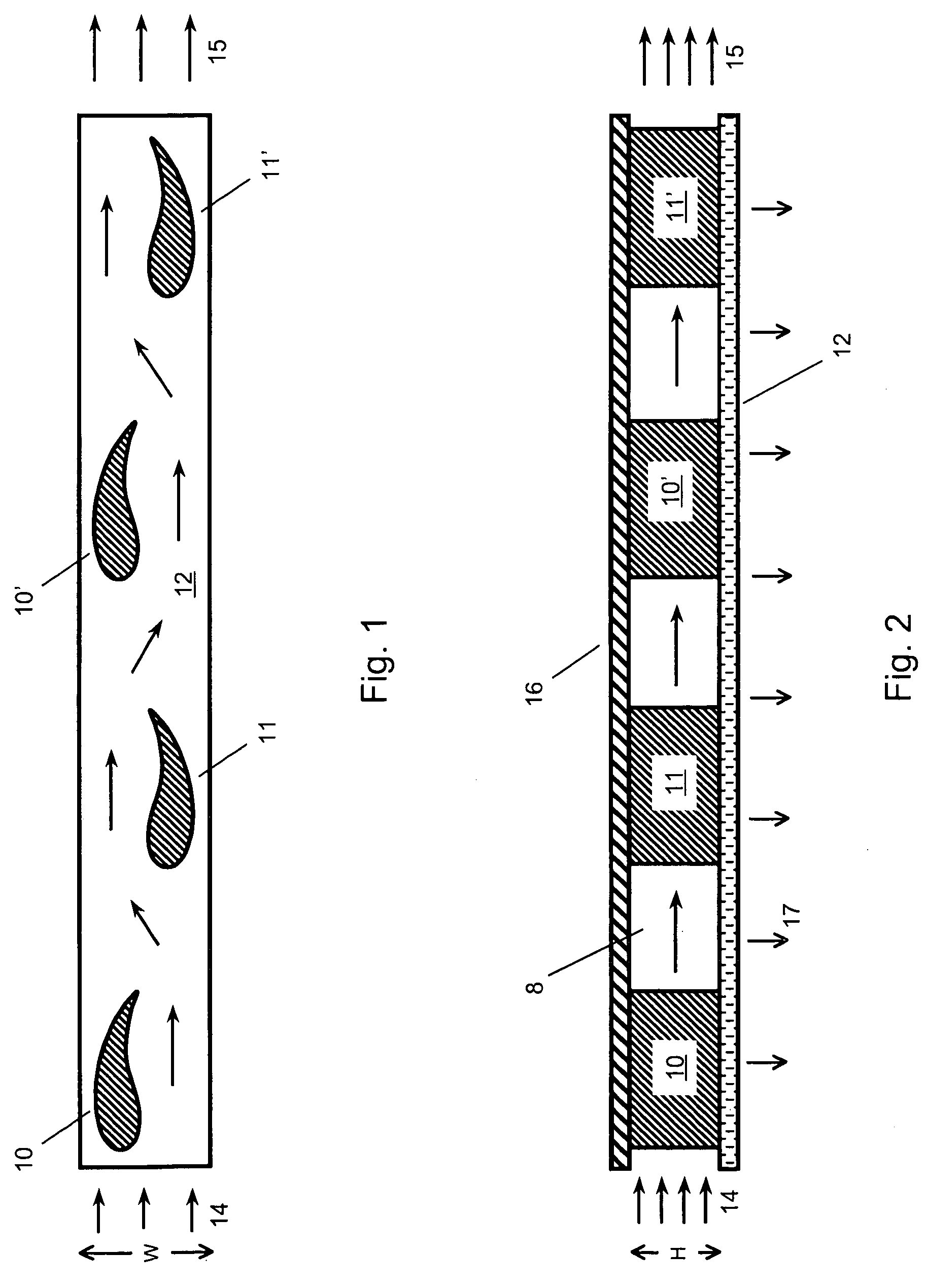

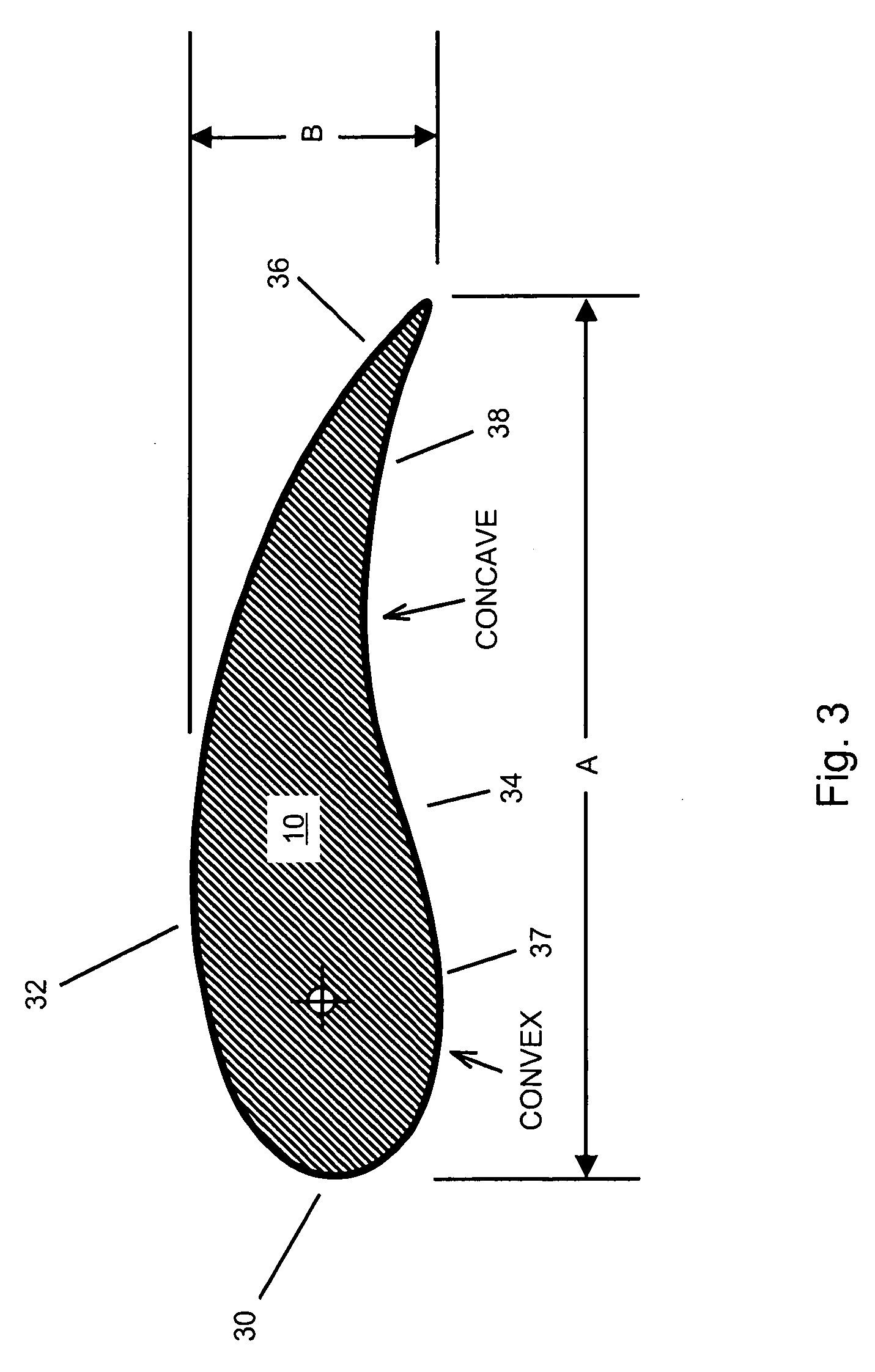

An array of airfoil-shaped micro-mixers that enhances fluid mixing within permeable membrane channels, such as used in reverse-osmosis filtration units, while minimizing additional pressure drop. The enhanced mixing reduces fouling of the membrane surfaces. The airfoil-shaped micro-mixer can also be coated with or comprised of biofouling-resistant (biocidal / germicidal) ingredients.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

Restoration of visual responses by in vivo delivery of rhodopsin nucleic acids

ActiveUS8470790B2Restore sensitivityLoss can be compensatedBiocideSenses disorderOpen reading frameIn vivo

Nucleic acid vectors encoding light-gated cation-selective membrane channels, in particular channelrhodopsin-2 (Chop2), converted inner retinal neurons to photosensitive cells in photoreceptor-degenerated retina in an animal model. Such treatment restored visual perception and various aspects of vision. A method of restoring light sensitivity to a retina of a subject suffering from vision loss due to photoreceptor degeneration, as in retinitis pigmentosa or macular degeneration, is provided. The method comprises delivering to the subject by intravitreal or subretinal injection, the above nucleic acid vector which comprises an open reading frame encoding a rhodopsin, to which is operatively linked a promoter and transcriptional regulatory sequences, so that the nucleic acid is expressed in inner retinal neurons. These cells, normally light-insensitive, are converted to a light-sensitive state and transmit visual information to the brain, compensating for the loss, and leading to restoration of various visual capabilities.

Owner:WAYNE STATE UNIV +1

Airfoil-shaped micro-mixers for reducing fouling on membrane surfaces

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

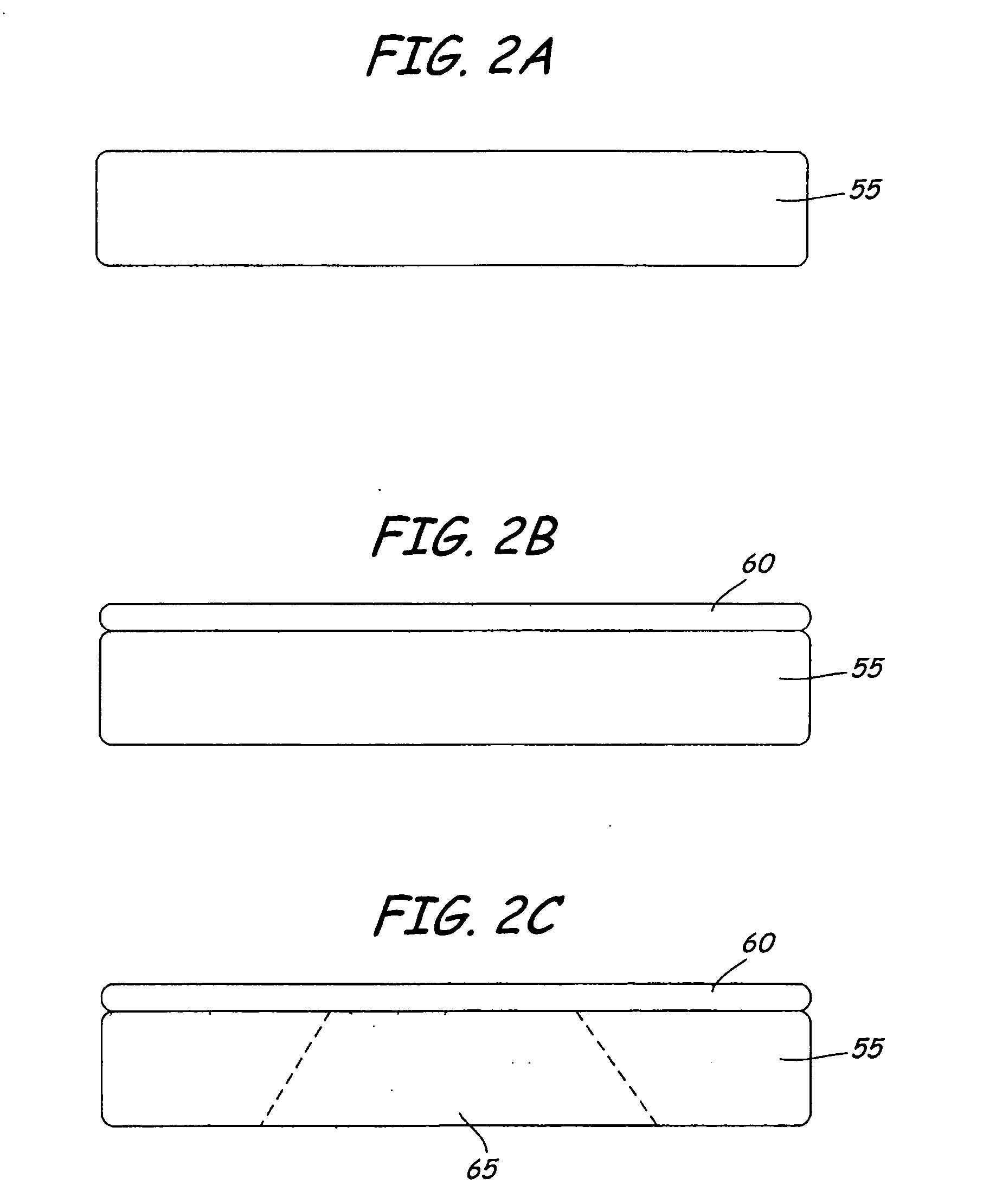

Solid state membrane channel device for the measurement and characterization of atomic and molecular sized samples

InactiveUS7235184B2Effectively protect and insulateSimple manufacturing processNanostructure manufacturePaper/cardboard articlesMaterial removalMembrane channel

A solid state device is formed through thin film deposition techniques which results in a self-supporting thin film layer that can have a precisely defined channel bored therethrough. The device is useful in the chacterization of polymer molecules by measuring changes in various electrical characteristics as molecules pass through the channel. To form the device, a thin film layer having various patterns of electrically conductive leads are formed on a silicon substrate. Using standard lithography techniques, a relatively large or micro-scale aperture is bored through the silicon substrate which in turn exposes a portion of the thin film layer. This process does not affect the thin film. Subsequently, a high precision material removal process is used (such as a focused ion beam) to bore a precise nano-scale aperture through the thin film layer that coincides with the removed section of the silicon substrate.

Owner:ADVANCED RES

Solid state membrane channel device for the measurement and characterization of atomic and molecular sized samples

InactiveUS20060292041A1Effectively protect and insulateSimple manufacturing processMaterial analysis by electric/magnetic meansMaterial analysis by optical meansMembrane channelOptoelectronics

The present invention relates to an apparatus for characterization of molecules through measurement of various electrical characteristics. The apparatus has a substrate on which is formed a thin film layer. Further, the apparatus has an insulation layer formed on the thin film layer. The thin film layer has a defined channel bored therethrough, the substrate has an aperture bored therethrough, and the insulation layer has a hole formed therethrough.

Owner:ADVANCED RES

Solid state membrane channel device for the measurement and characterization of atomic and molecular sized samples

InactiveUS20090277869A1Effectively protect and insulateSimple manufacturing processVolume/mass flow by thermal effectsFixed microstructural devicesMembrane channelMaterial removal

A solid state device is formed through thin film deposition techniques which results in a self-supporting thin film layer that can have a precisely defined channel bored therethrough. The device is useful in the chacterization of polymer molecules by measuring changes in various electrical characteristics as molecules pass through the channel. To form the device, a thin film layer having various patterns of electrically conductive leads are formed on a silicon substrate. Using standard lithography techniques, a relatively large or micro-scale aperture is bored through the silicon substrate which in turn exposes a portion of the thin film layer. This process does not affect the thin film. Subsequently, a high precision material removal process is used (such as a TEM) to bore a precise nano-scale aperture through the thin film layer that coincides with the removed section of the silicon substrate.

Owner:ADVANCED RES

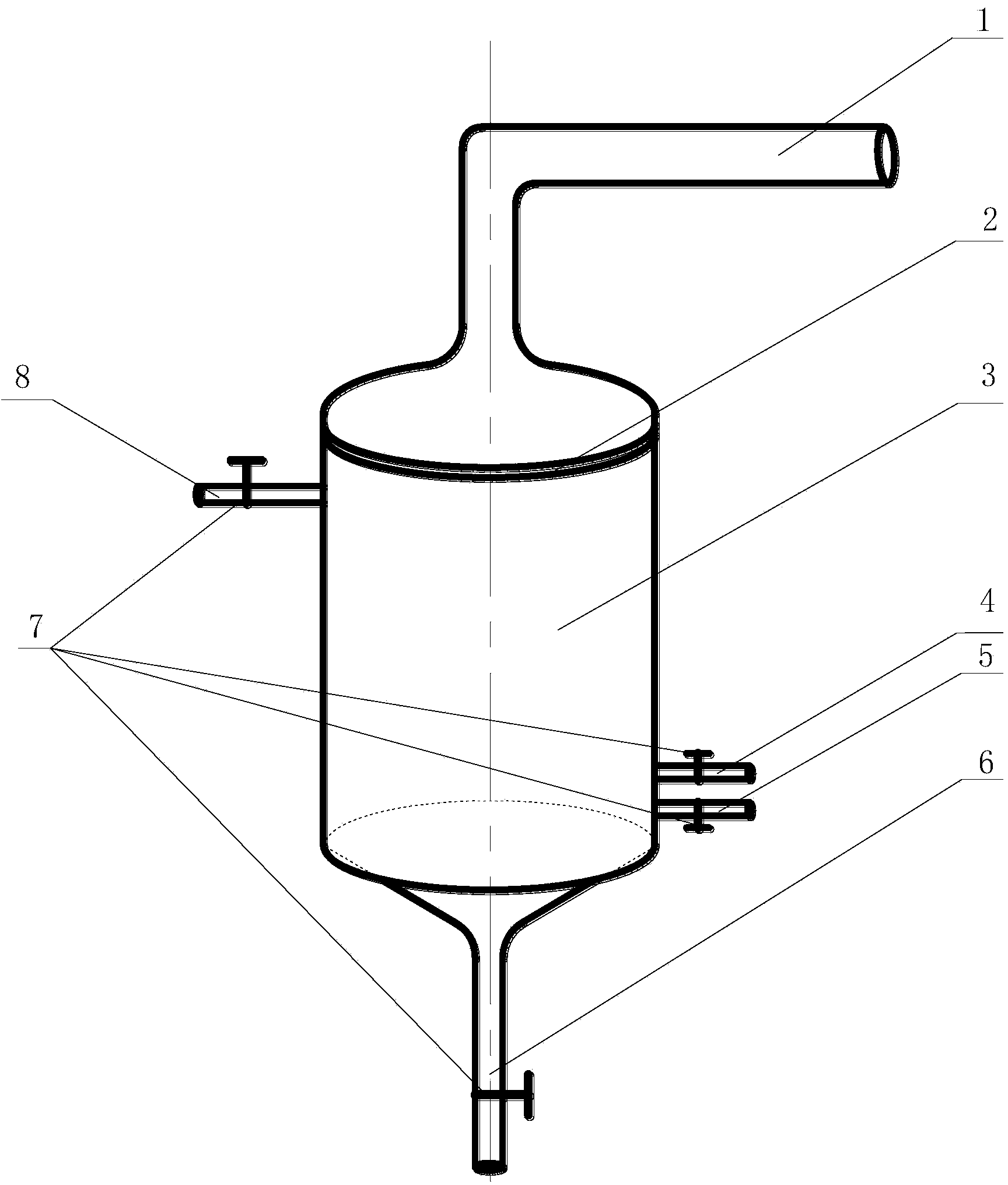

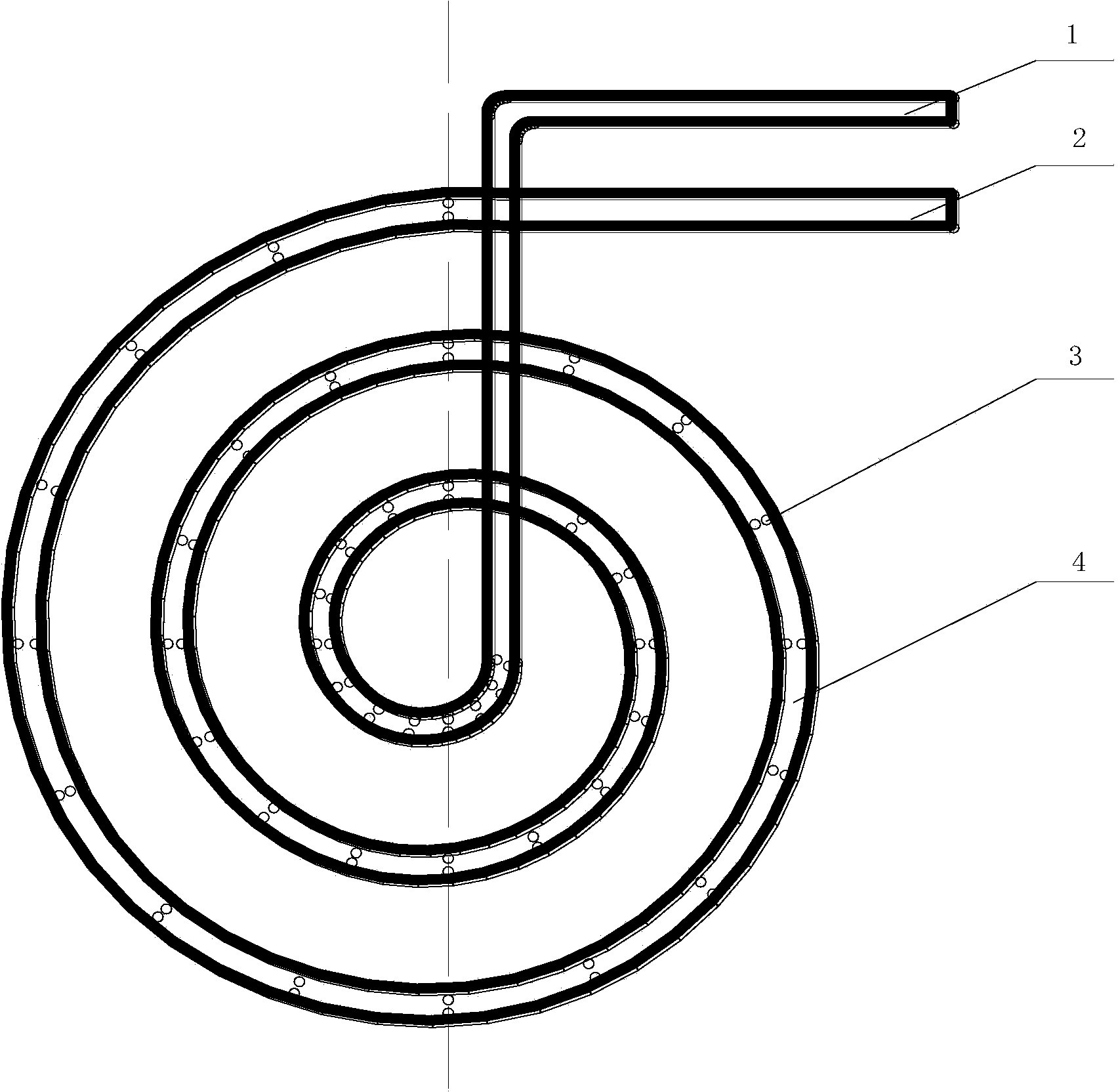

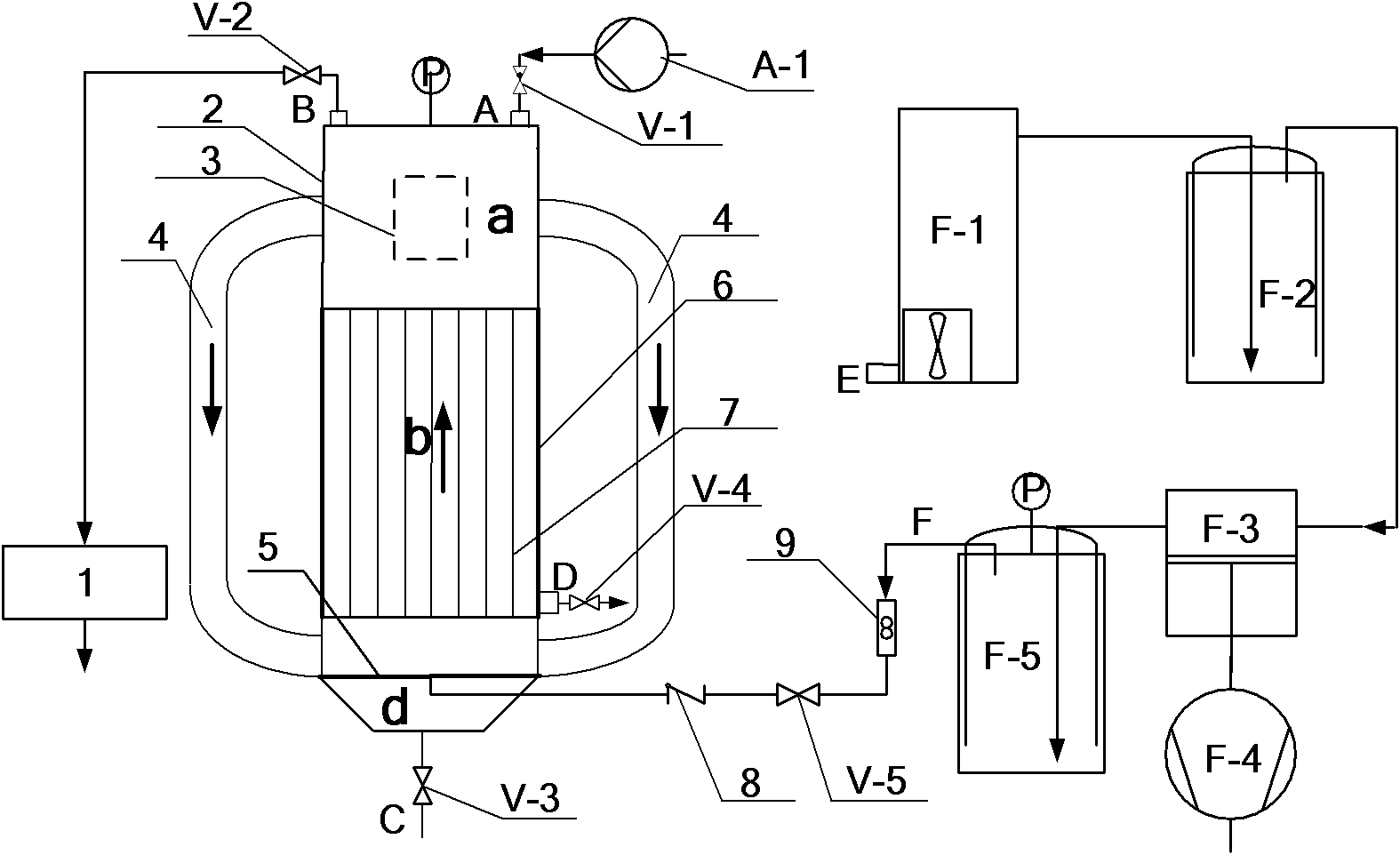

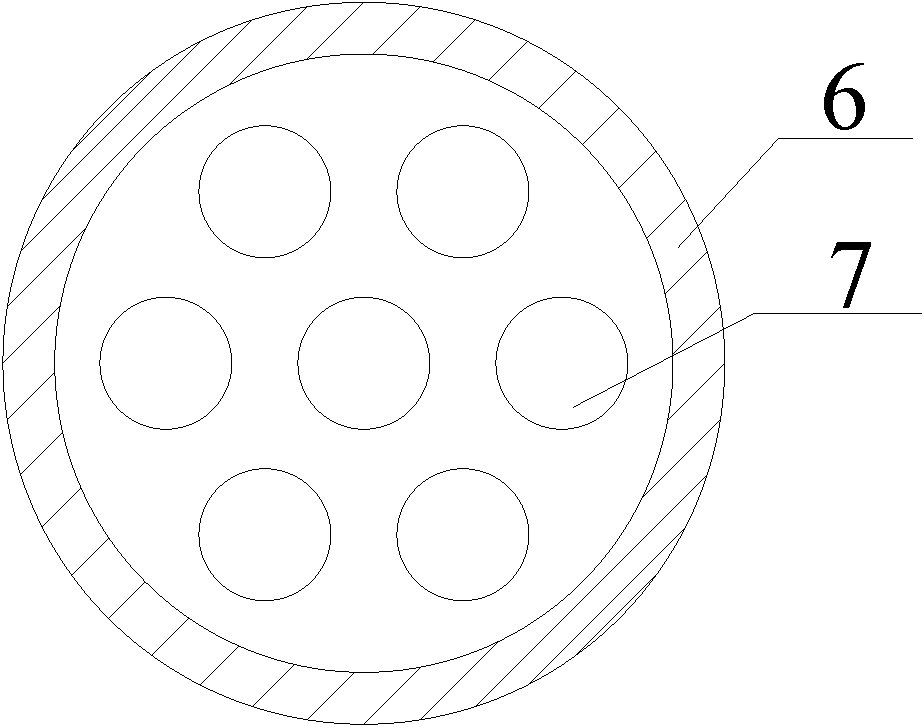

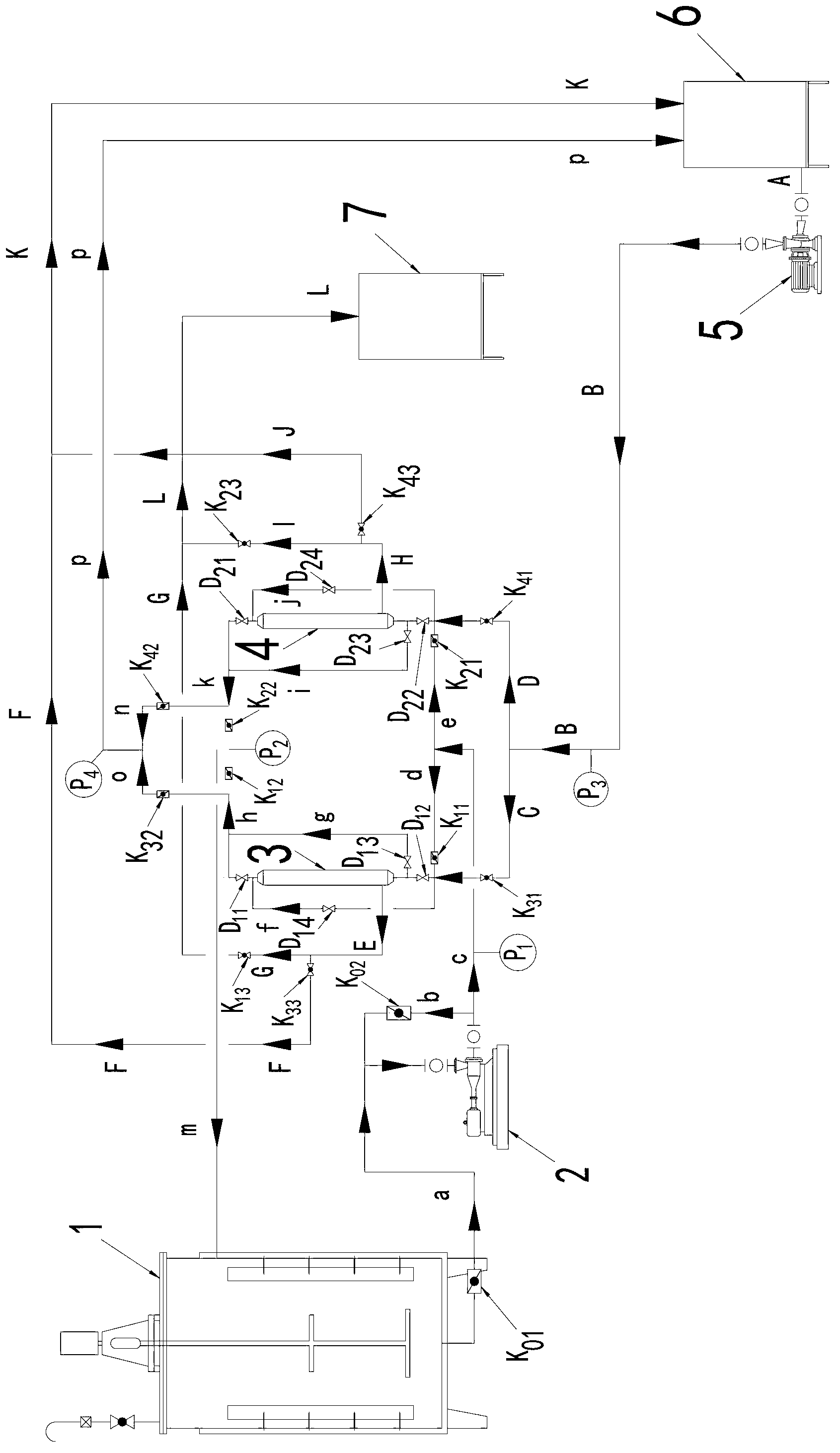

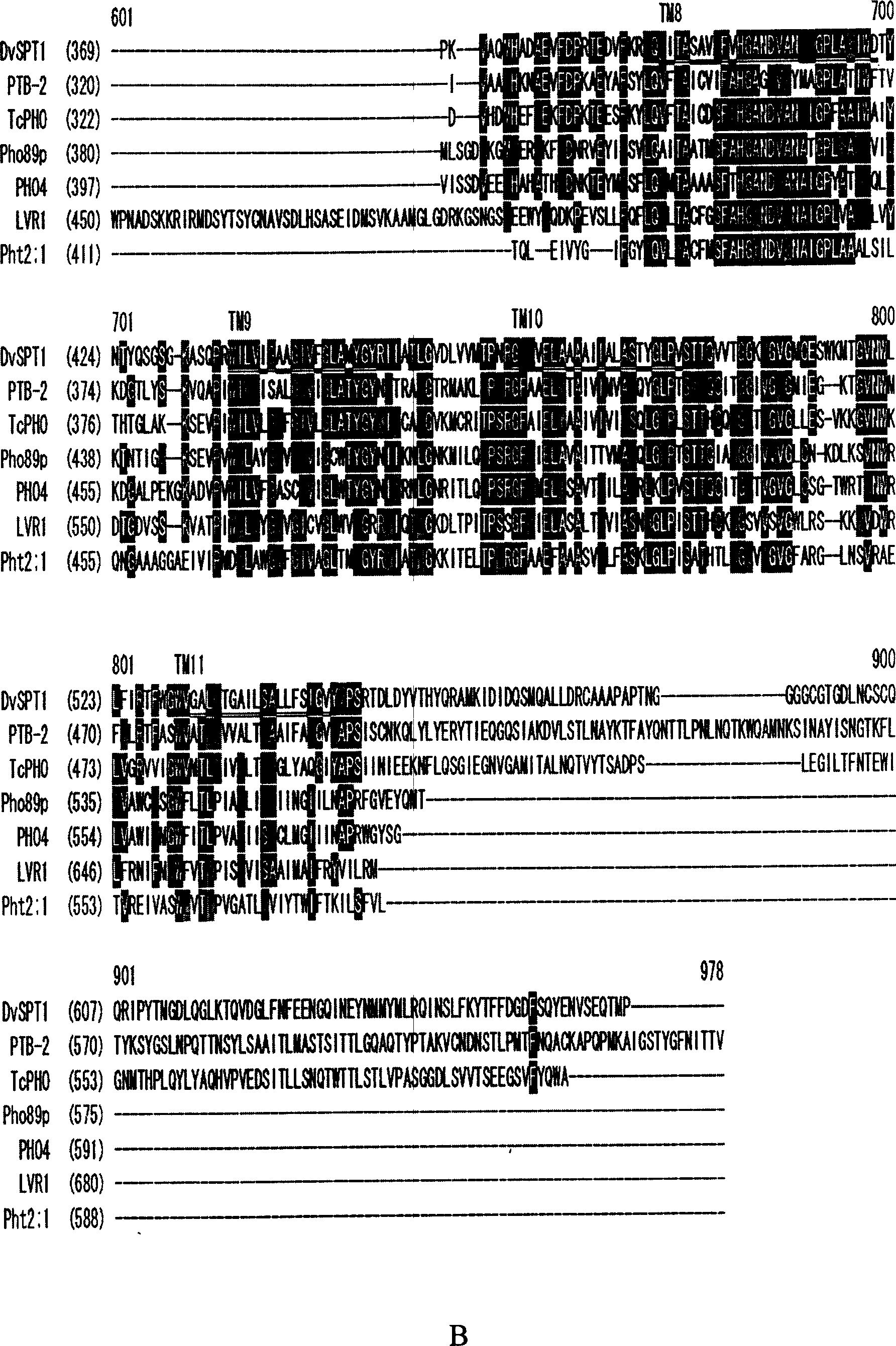

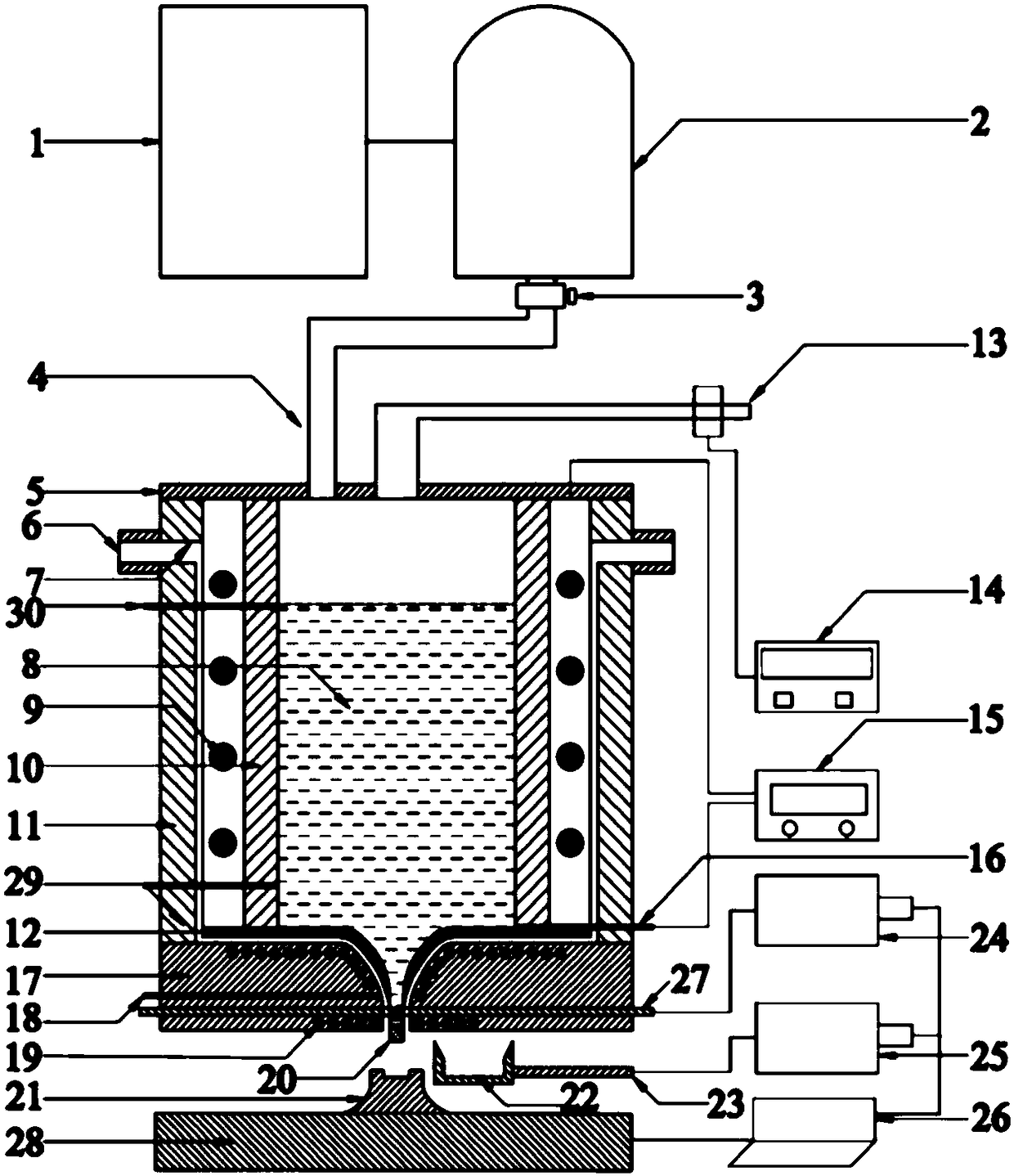

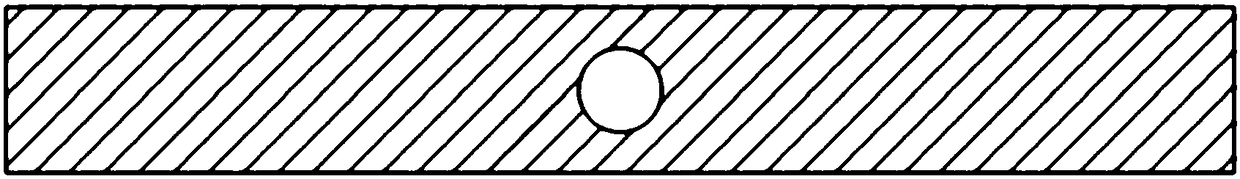

Oxidation nanofiltration membrane reactor

ActiveCN102219326AIncrease concentrationSmall footprintWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentAir compressorHigh pressure

The invention relates to an oxidation nanofiltration membrane reactor. The oxidation nanofiltration membrane reactor consists of a reaction-separation system (a raw material pump, an oxidation reaction kettle, a circulating pipe and a gas distribution plate), a pressurizing system (an ozone generator, a buffer tank, a pneumatic booster pump, an air compressor and a pressure-stabilizing tank) and a tail gas treatment system (an ozone absorption device), wherein a membrane component is encapsulated in a membrane component and placed into the reaction kettle; the circulating pipe is arranged at the position of a side arm of the kettle body; and the gas distribution plate is positioned on the top of a settling region. In the reactor, the kettle body serves as a liquid ascending region, the circulating pipe serves as a liquid descending region, gas is redistributed through a membrane channel, and gas liquid phases form slug flow in the membrane channel, so that gas liquid mass transfer is enhanced, the reaction process is enhanced and the utilization ratio of the gas is increased; and high-pressure ozonized air generated by the pressurizing system serves as a reaction source and a circulating power source of the reactor, so that the degradation of organic matters in the reactor is accelerated and a necessary impelling force is provided for separation of the nanofiltration membrane.The reactor has the advantages of simpleness and convenience in operation, high mass transfer efficiency, low energy consumption, easiness in amplification and the like.

Owner:南京工大釜鼎能源技术有限公司

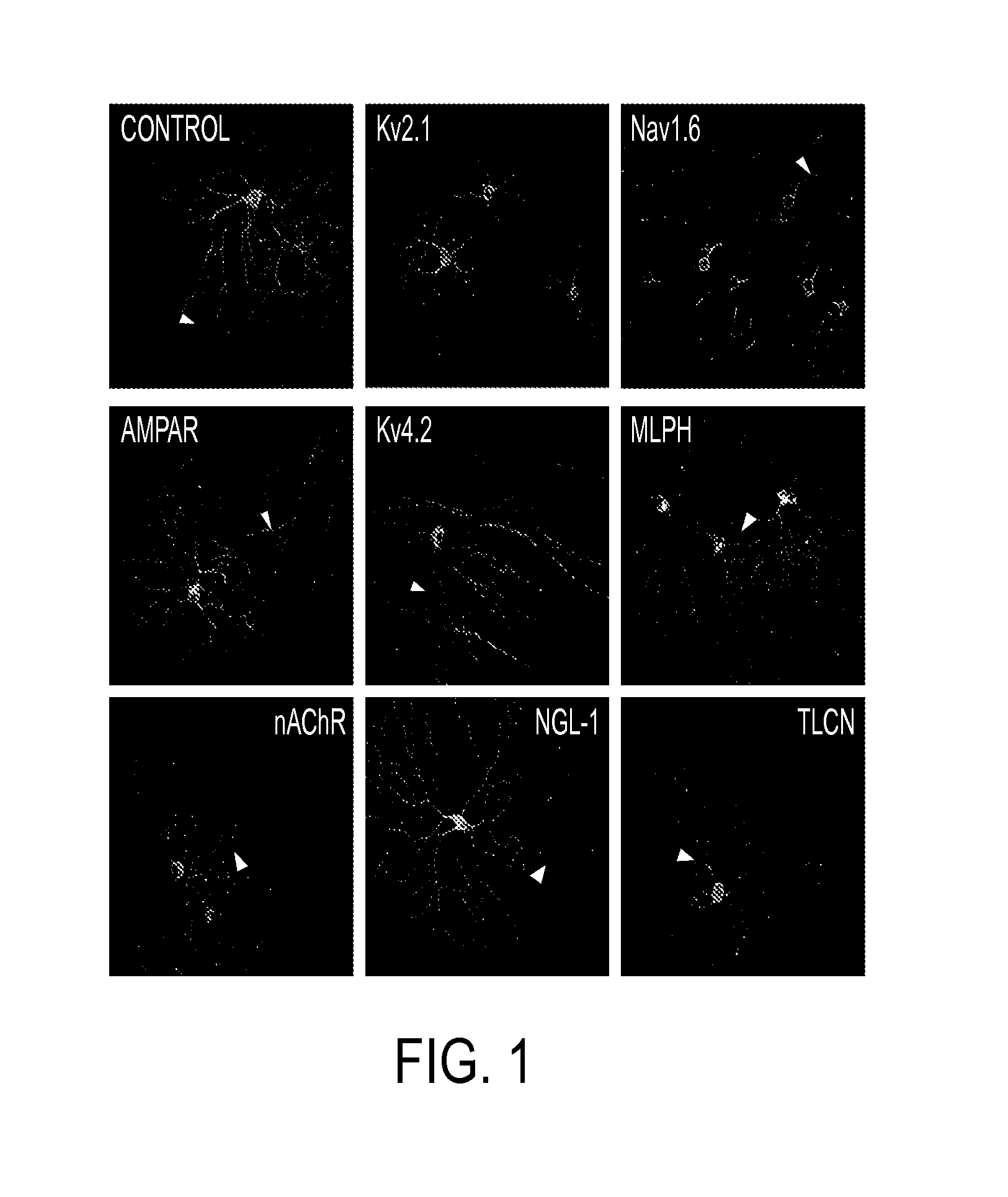

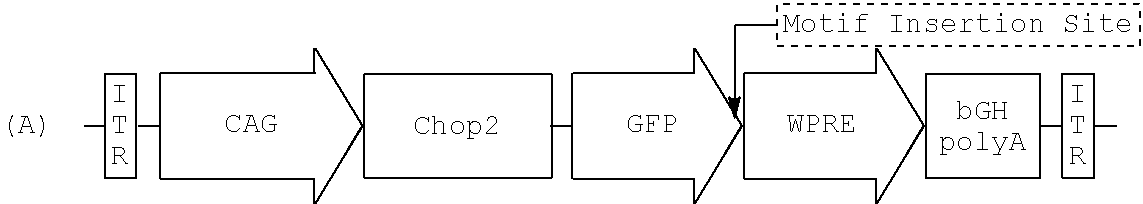

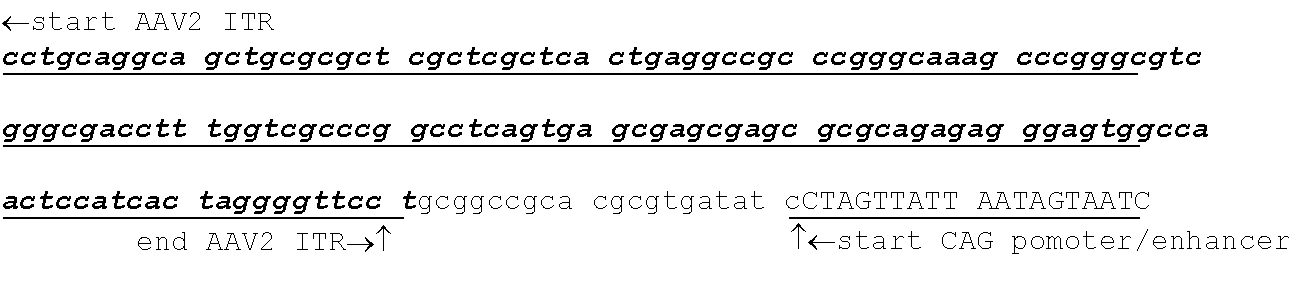

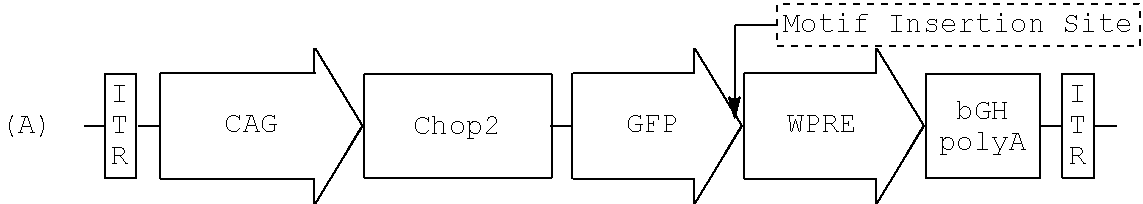

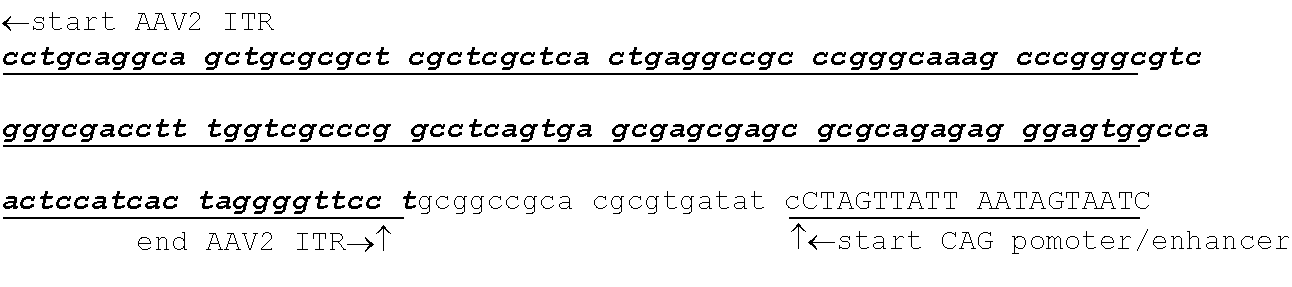

AAV-Mediated Subcellular Targeting of Heterologous Rhodopsins in Retinal Ganglion Cells

ActiveUS20130259833A1Enhanced spatial controlStrong specificityBiocideSenses disorderHeterologousDisease

Microbial type rhodopsins, such as the light-gated cation-selective membrane channel, channelrhodopsin-2 (Chop2 / ChR2) or the ion pump halorhodopsin (HaloR) are expressed in retinal ganglion cells upon transduction using recombinant AAV vectors. Selective targeting of these transgenes for expression in discrete subcellular regions or sites is achieved by including a sorting motif in the vector that can target either the central area or surround (off-center) area of these cells. Nucleic acid molecules comprising nucleotide sequences encoding such rhodopsins and sorting motifs and their use in methods of differential expression of the transgene are disclosed. These compositions and methods provide significant improvements for restoring visual perception and various aspects of vision, particular in patients with retinal disease.

Owner:WAYNE STATE UNIV

AAV-mediated subcellular targeting of heterologous rhodopsins in retinal ganglion cells

Microbial type rhodopsins, such as the light-gated cation-selective membrane channel, channel-rhodopsin-2 (Chop2 / ChR2) or the ion pump halorhodopsin (HaloR) are expressed in retinal ganglion cells upon transduction using recombinant AAV vectors. Selective targeting of these transgenes for expression in discrete subcellular regions or sites is achieved by including a sorting motif in the vector that can target either the central area or surround (off-center) area of these cells. Nucleic acid molecules comprising nucleotide sequences encoding such rhodopsins and sorting motifs and their use in methods of differential expression of the transgene are disclosed. These compositions and methods provide significant improvements for restoring visual perception and various aspects of vision, particular in patients with retinal disease.

Owner:WAYNE STATE UNIV

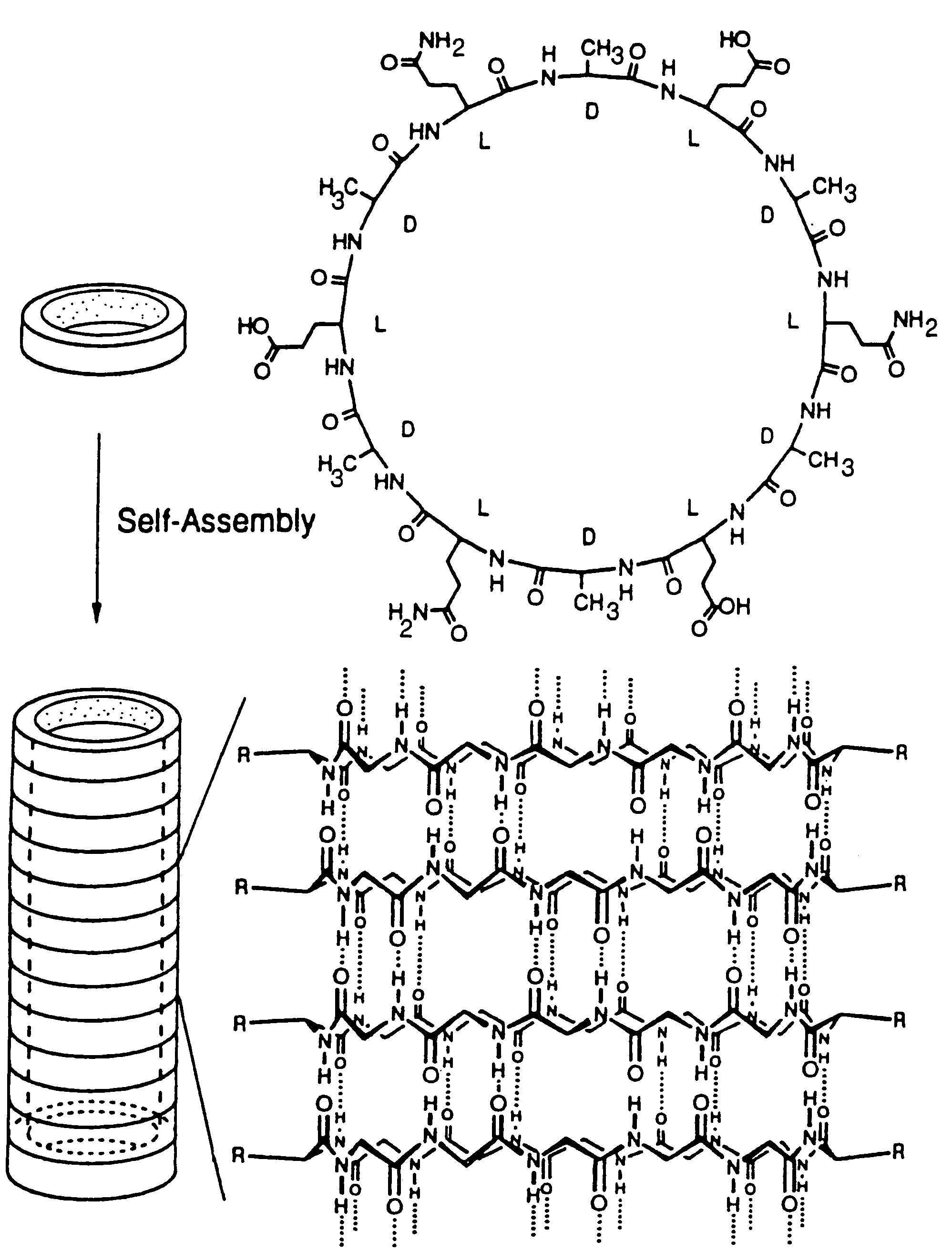

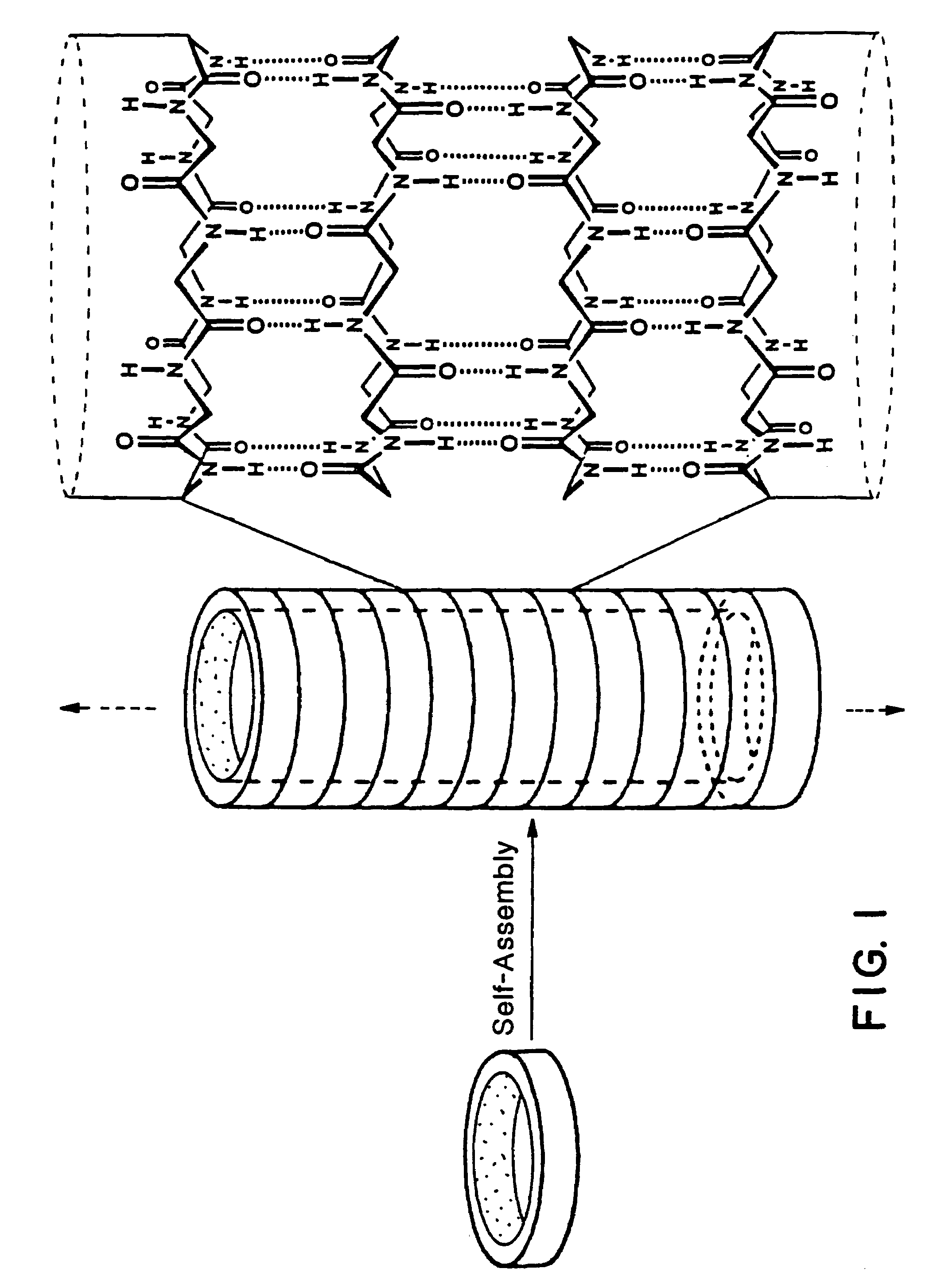

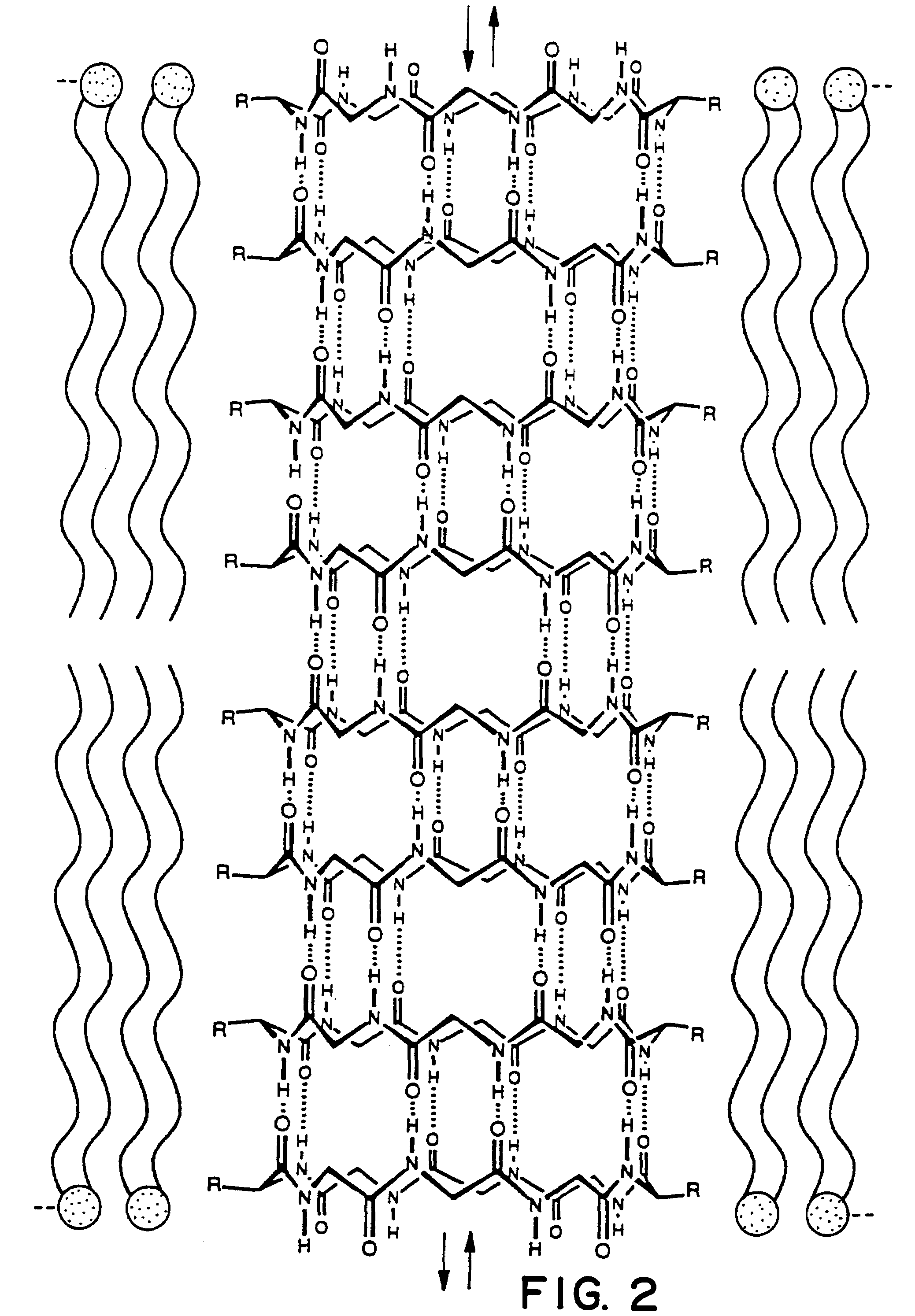

Cyclic peptide tube

InactiveUS7288623B2Easy to controlPromotes self-assemblyPeptide preparation methodsImmunoglobulinsLipid formationCyclic peptide

Cyclic homodetic peptides having a repeating D-L-chirality motif are shown to have a stable disk conformation with the amino acid side chains extending radially outward and the carbonyl and amino groups extending axially upward or downward. Such cyclic peptides can be employed as subunits in the assembly of molecular tubes. Cyclic peptides having a repeating D-L-chirality motif and lacking mutually repulsive side-chains are shown to stack atop one another in an anti-parallel fashion and are shown to be held together by the formation of β-sheet hydrogen bonding. The stacked cyclic peptides form a molecular tube having a central channel. The diameter of the channel is determined by the size cyclic peptide. If the cyclic peptide includes ionizable amino acid residues, e.g. glutamic acid or lysine, assembly and disassembly of the molecular tubes can be controlled by varying the pH. If the cyclic peptide includes hydrophobic amino acid residues, the molecular tube will insert into a lipid membrane. In such instances, the molecular tube provides a transmembrane channel. The channel can be gated or ungated. Molecular tubes can be terminated with a terminal cyclic peptide having methylated amino groups in one orientation. Molecular tubes may be employed as drug carriers, molecular sieves, reaction vessels, membrane channels, and other uses.

Owner:THE SCRIPPS RES INST

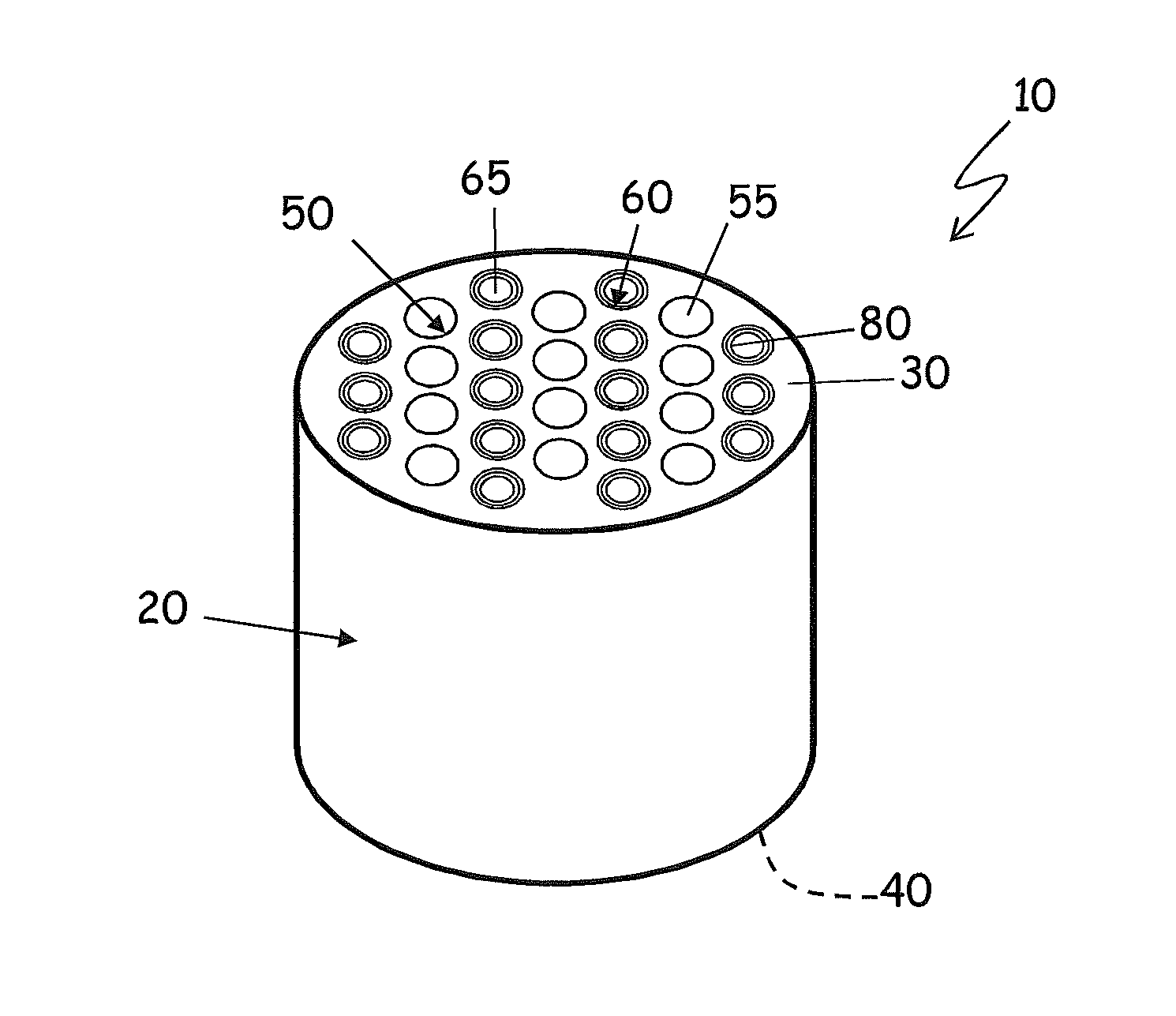

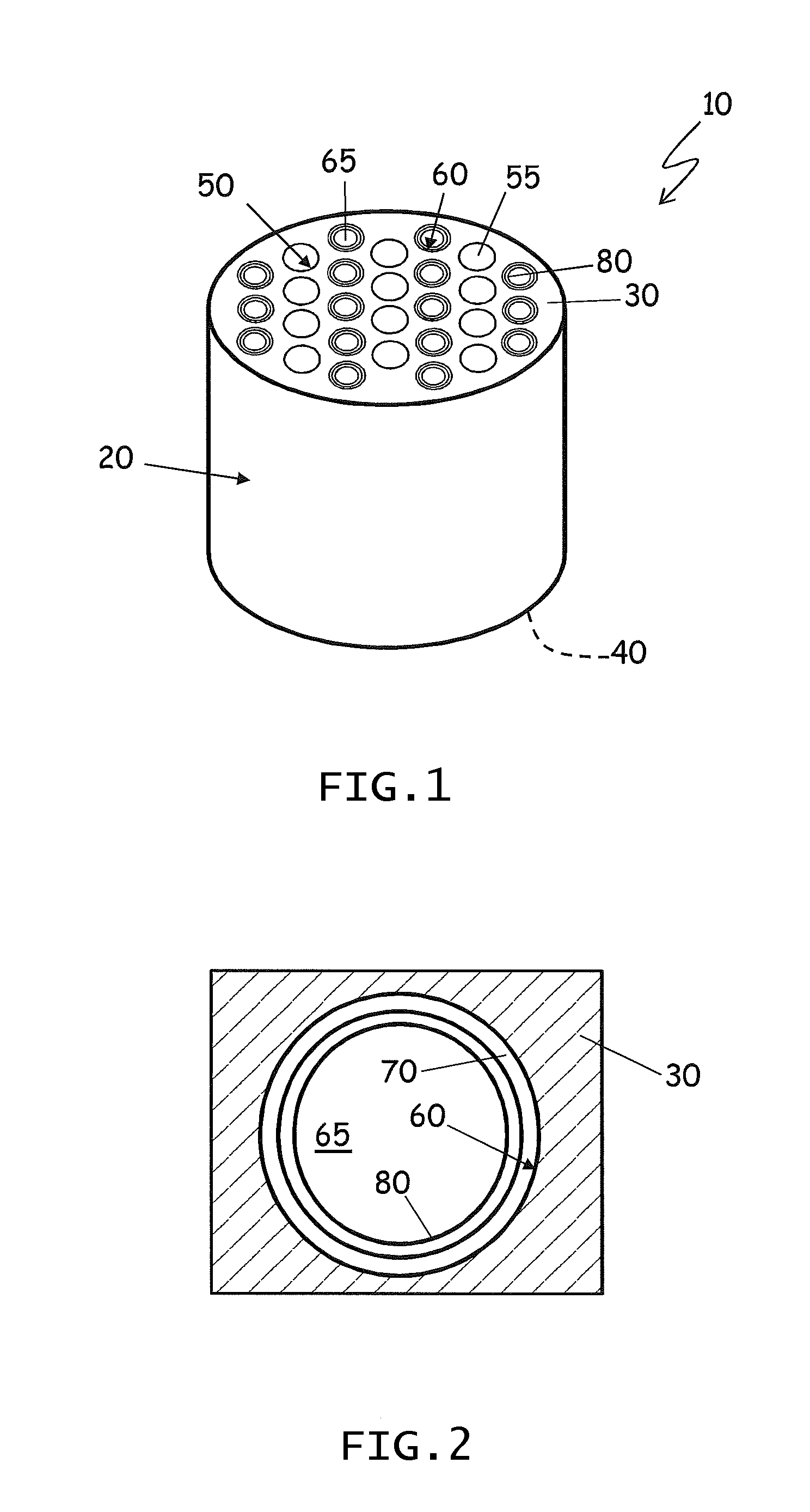

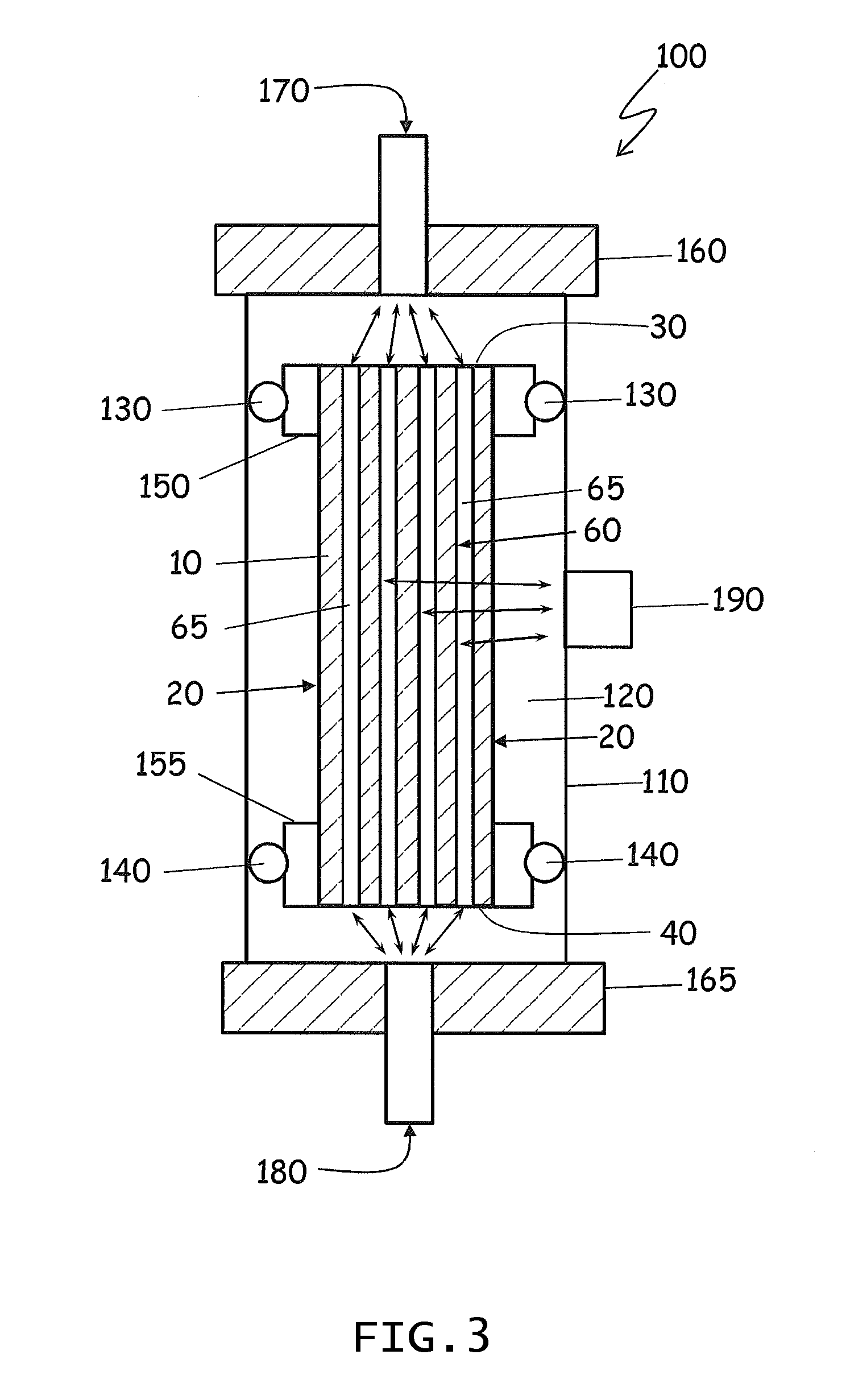

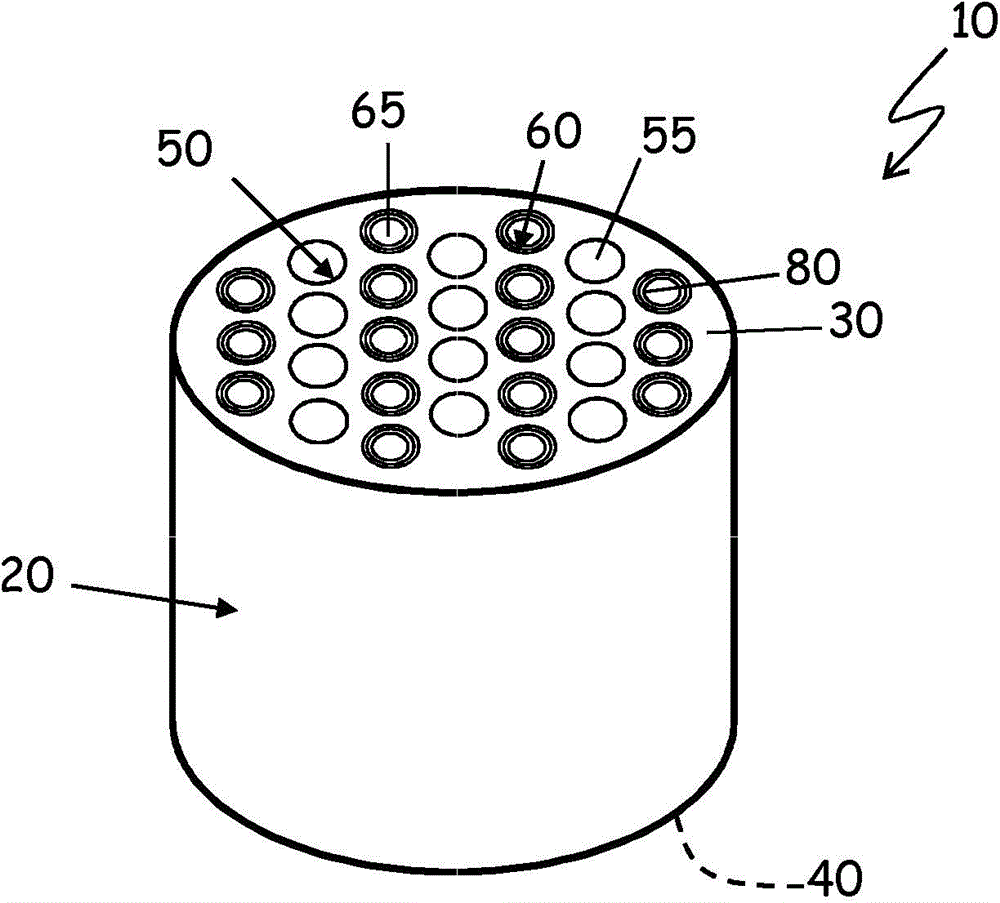

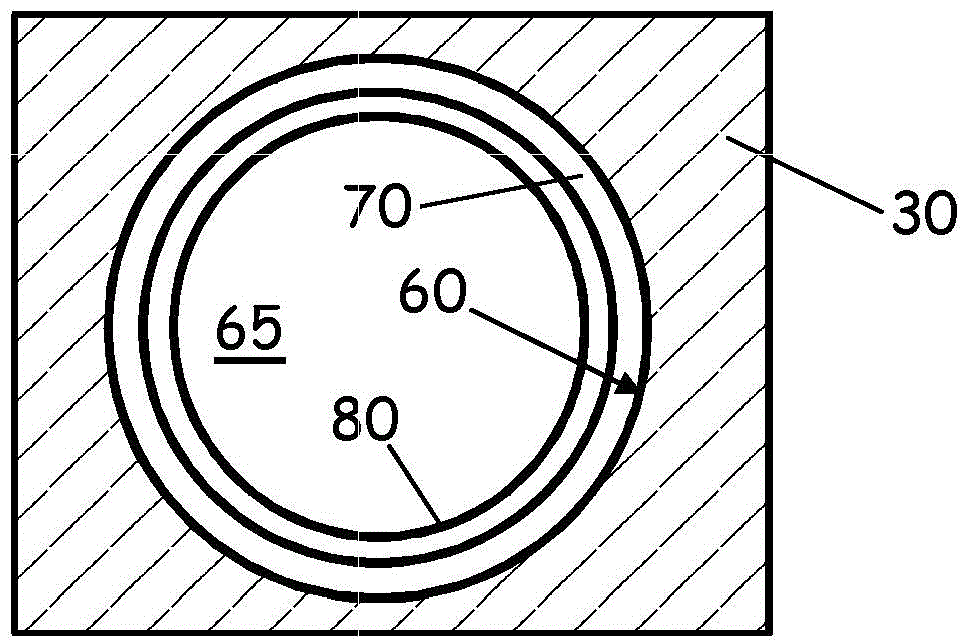

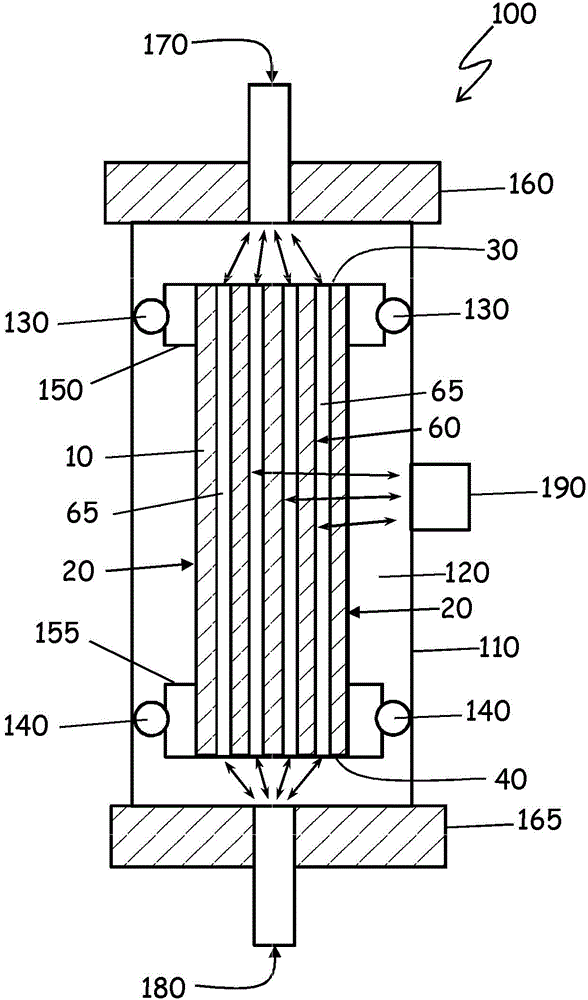

Methods for preparing polymer membranes on porous supports

Methods for preparing a polymer membrane on a porous support may include providing a porous support having an outer wall, a first end, a second end, and porous channel surfaces that define a plurality of channels through the porous support from the first end to the second end. The plurality of channels includes membrane channels. The channel surfaces that define the membrane channels are membrane-channel surfaces. The polymer membrane may be coated onto the porous support by first establishing a pressure differential between the outer wall and the plurality of channels. Then, a pre-polymer solution may be applied to the membrane-channel surfaces and, optionally, the first and second ends, by slip coating or emulsion coating while the pressure differential is maintained. This results in formation of a pre-polymer layer on at least the membrane-channel surfaces. Then, the pre-polymer layer may be cured to form the polymer membrane.

Owner:CORNING INC +1

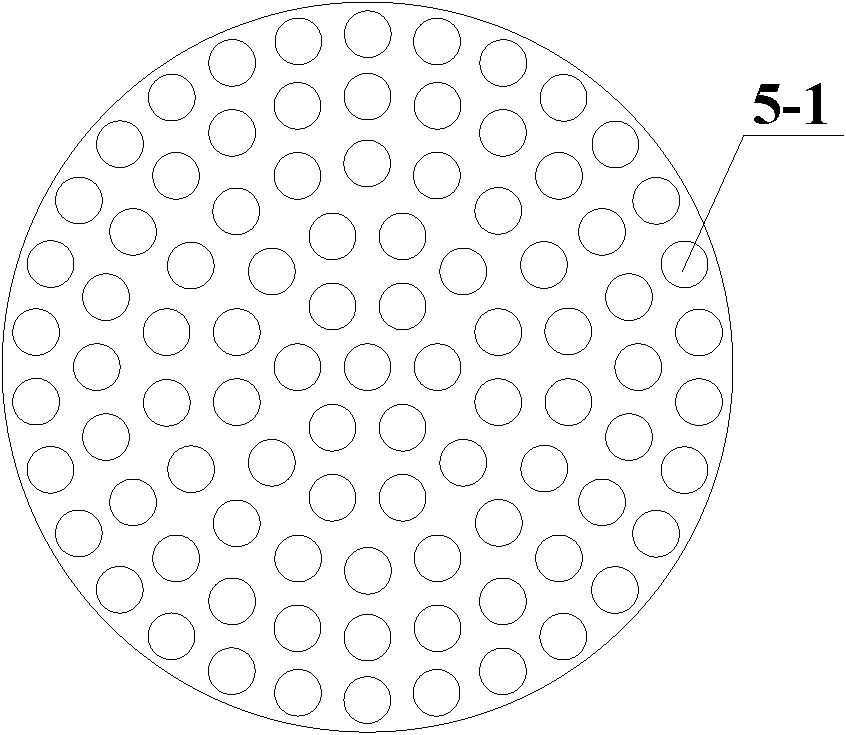

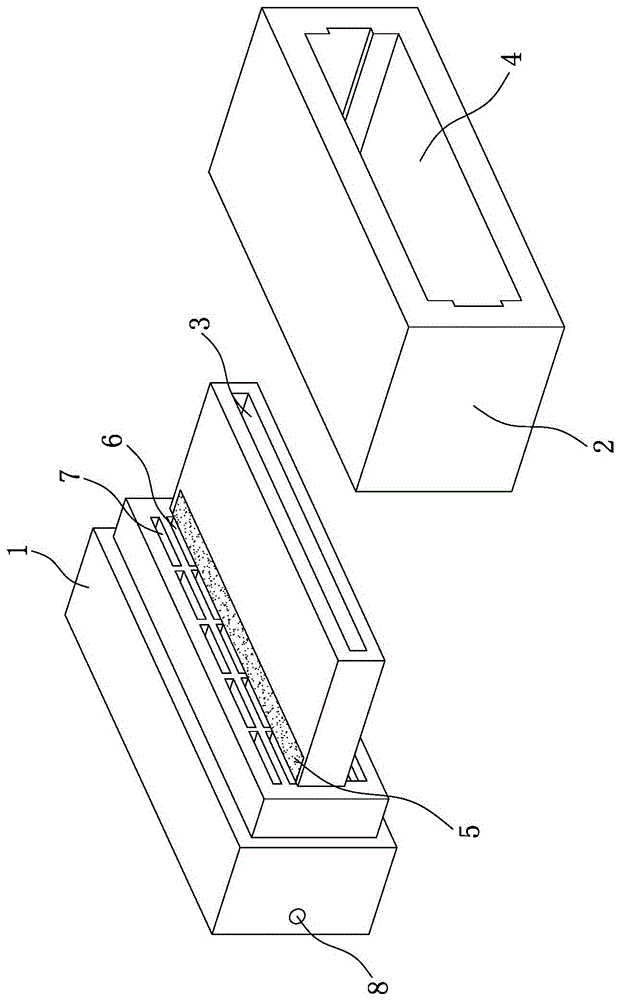

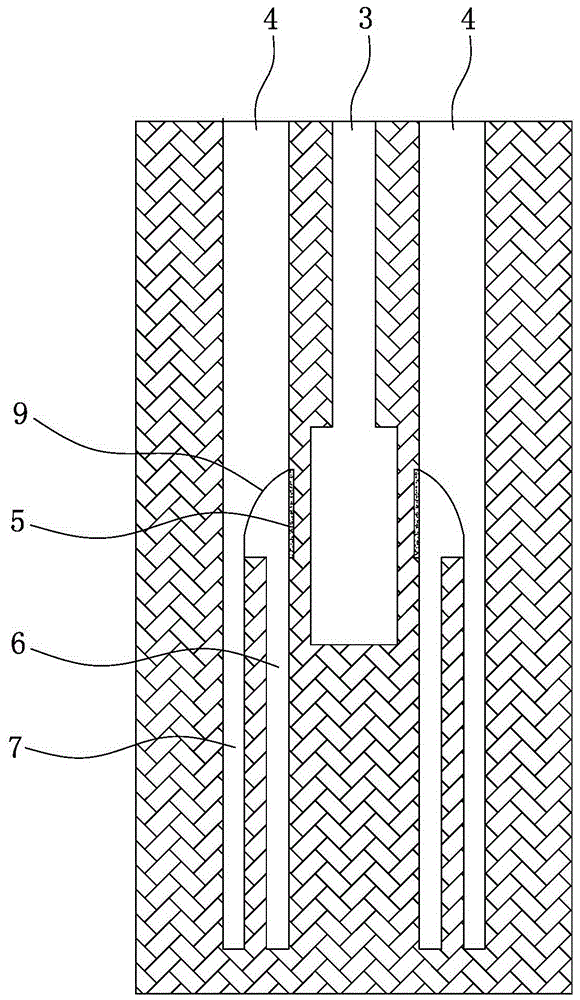

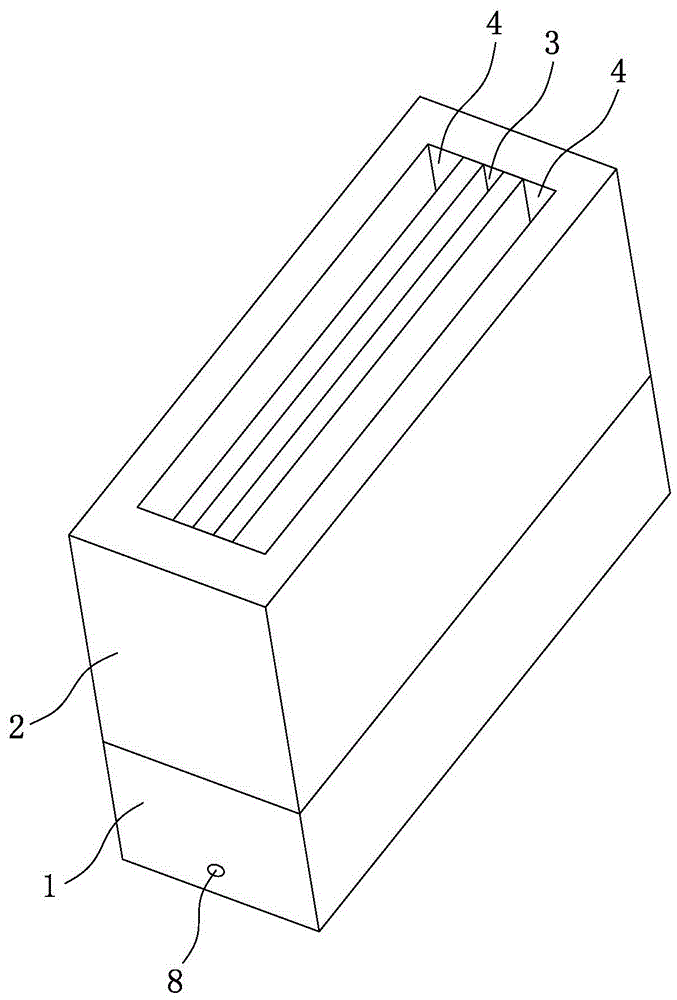

Solid-liquid separation device for organic carbon sources in excess sludge

ActiveCN102701553AEffective elutionPromote hydrolysis and acidificationSludge treatment by de-watering/drying/thickeningBiological sludge treatmentSolubilitySludge

The invention discloses a solid-liquid separation device for organic carbon sources in excess sludge. The solid-liquid separation device comprises an anaerobic hydrolysis reactor, a screw pump, a chemical cleaning tank, a chemical cleaning pump, a ceramic membrane microfiltration device I, a ceramic membrane microfiltration device II and a carbon source storage tank; the bottom of the anaerobic hydrolysis reactor is communicated with the screw pump; the outlet of the screw pump is communicated with the ceramic membrane microfiltration device I and the ceramic membrane microfiltration device II respectively; the chemical cleaning tank is communicated with the chemical cleaning pump; the outlet of the chemical cleaning pump is communicated with the ceramic membrane microfiltration device I and the ceramic membrane microfiltration device II respectively; and both the ceramic membrane microfiltration device I and the ceramic membrane microfiltration device II are communicated with the carbon source storage tank through hydrolyzed filtrate pipelines. Through the solid-liquid separation device, the dissoluble organic carbon sources can be effectively eluted, so that hydrolysis and acidification of the sludge are promoted; membrane channel blockage can be controlled and reduced in double flow directions, and continuous operation is realized; and a high solid-liquid separation effect is achieved, and the concentration of effluent microbes is less than 100 microbes per milliliter.

Owner:TSINGHUA UNIV

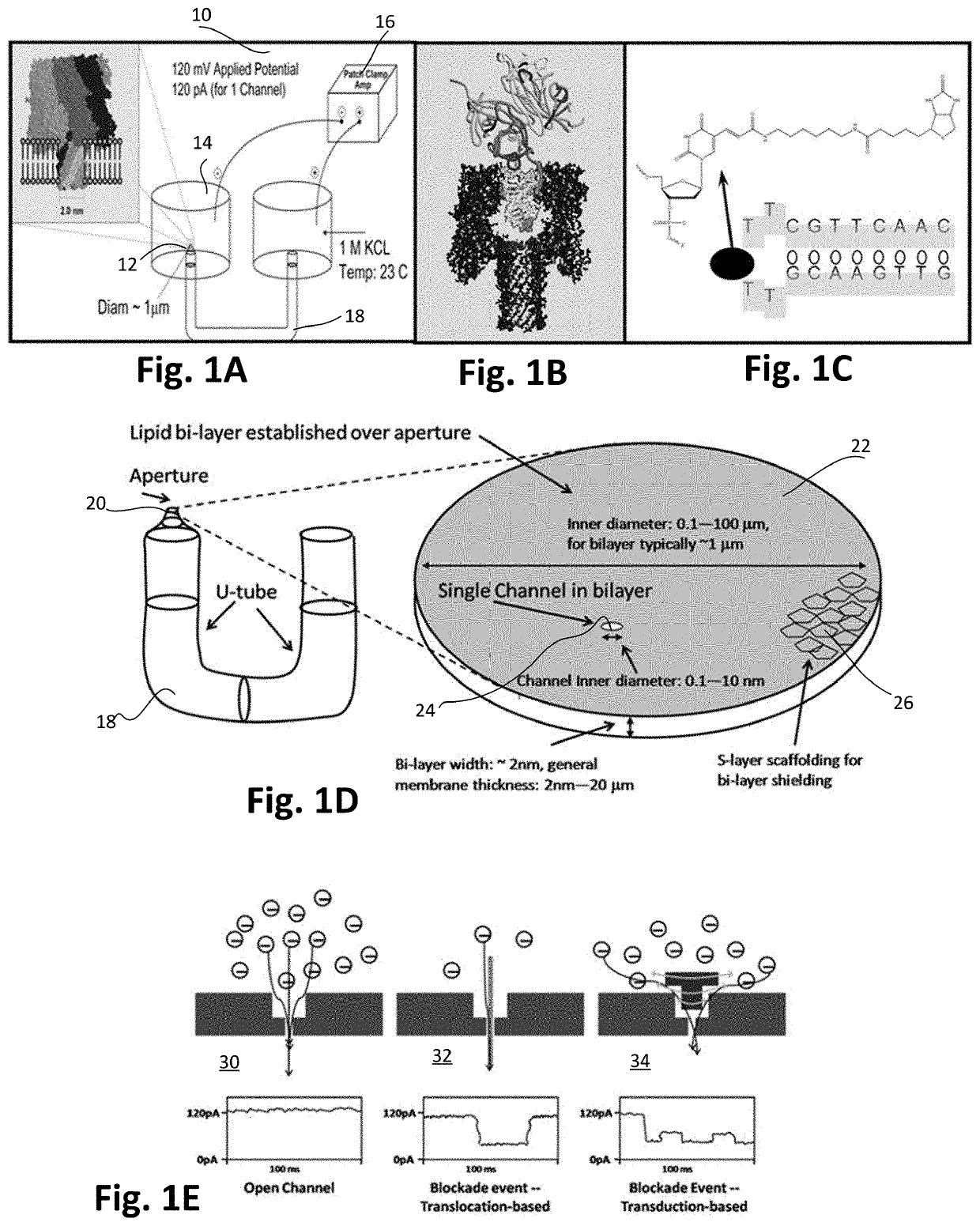

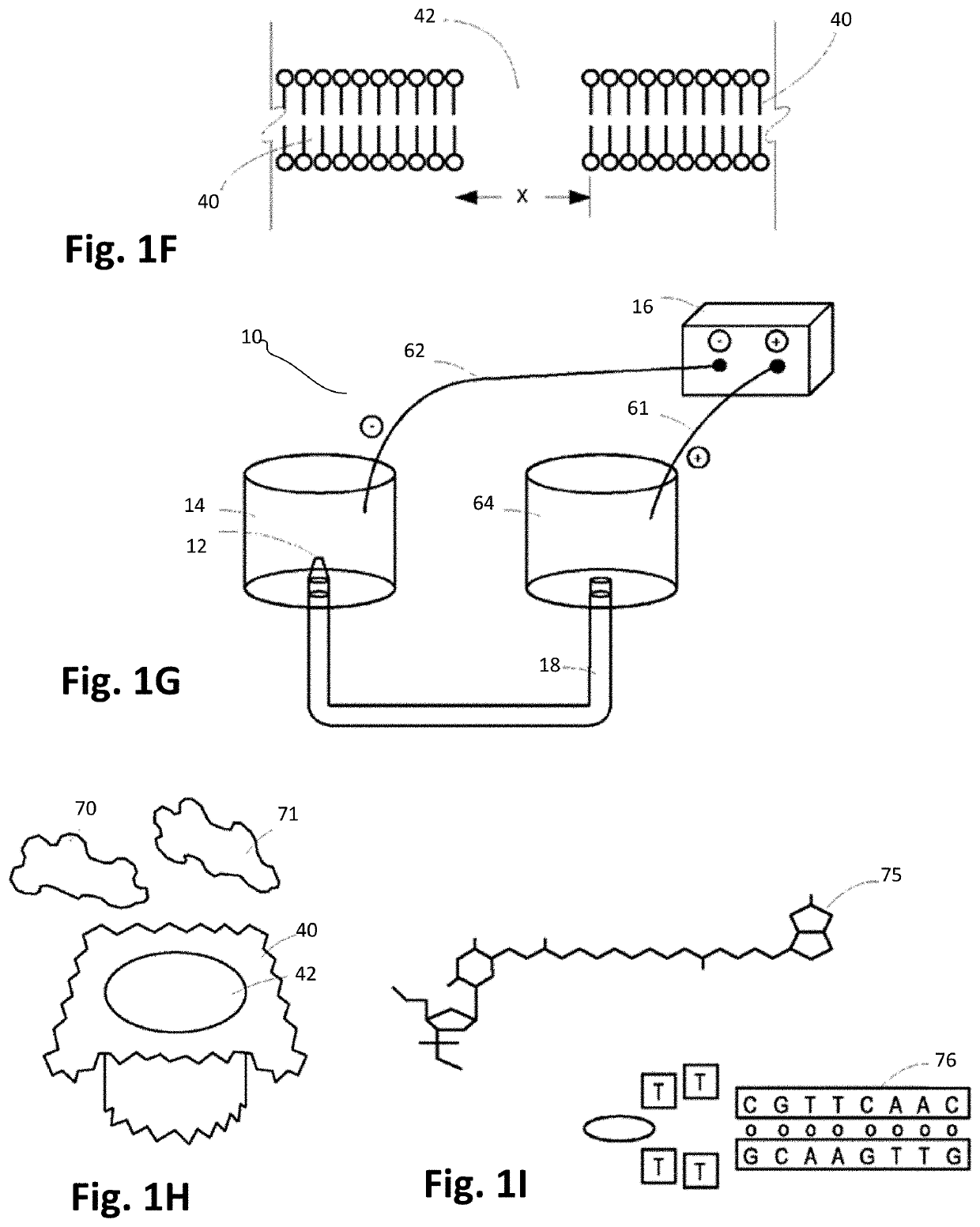

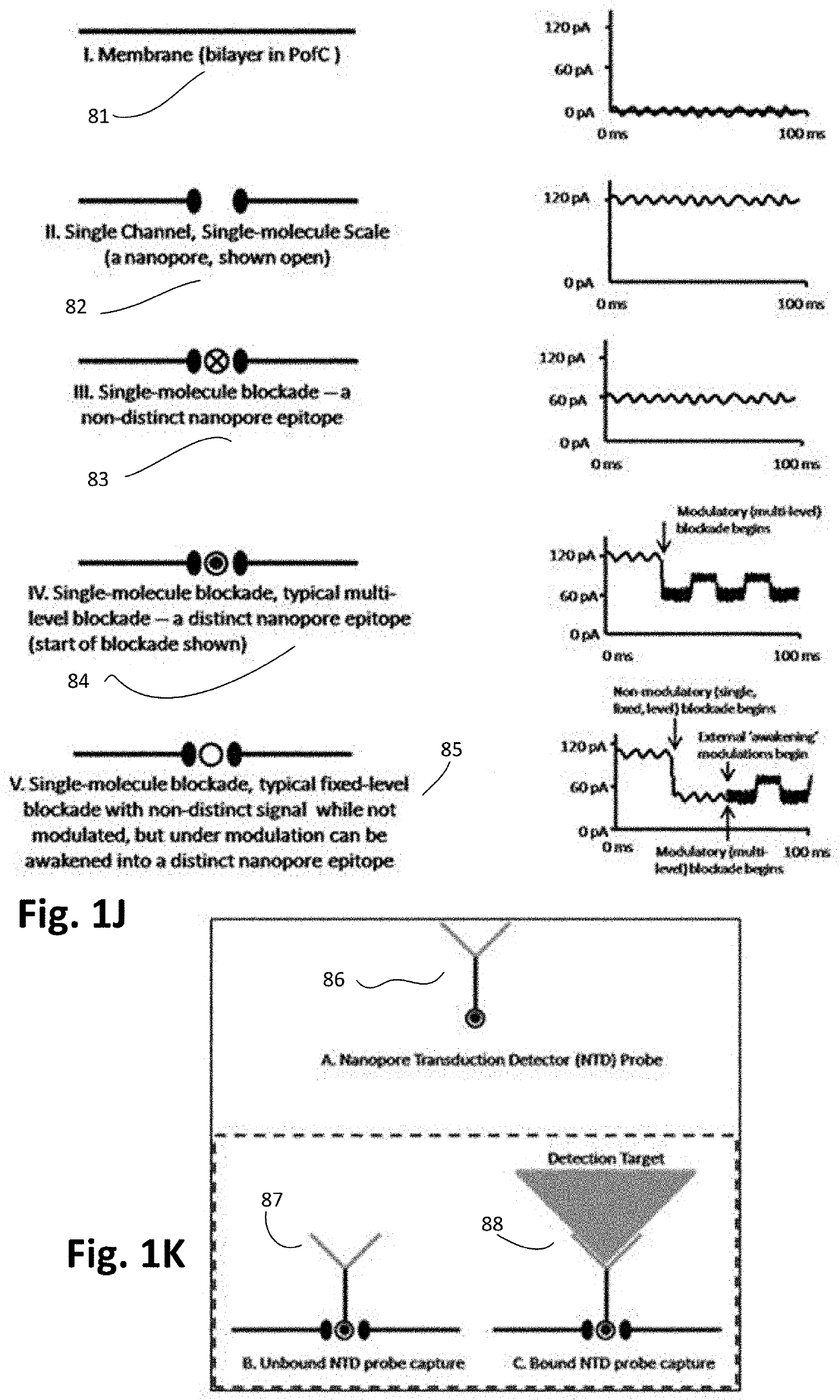

Cannabinoid Profiling Using Nanopore Transduction

ActiveUS20190376929A1Material analysis by electric/magnetic meansBiological testingElectrophoresesMembrane channel

Embodiments profile cannabinoids using a nanopore detector. Embodiments use an applied potential to electrophoretically draw a nanopore blockade reporter molecule into a nanopore channel to establish an electrophoretic molecular channel-capture for the reporter molecule. The reporter molecule includes one of an aptamer or a monoclonal antibody and has a specific binding to at least one of: a specific cannabinoid, a particular cannabinoid isoform; or a specific cannabinoid family. Embodiments receive a blockade channel current signal in response to a nanoscale membrane channel of the nanopore detector being partially blockaded by a presence of the reporter molecule non-covalently bonded to the membrane channel. Embodiments receive a blockade signal for the reporter molecule that is toggling between more than one level.

Owner:CANNAPTIC BIOSCI LLC

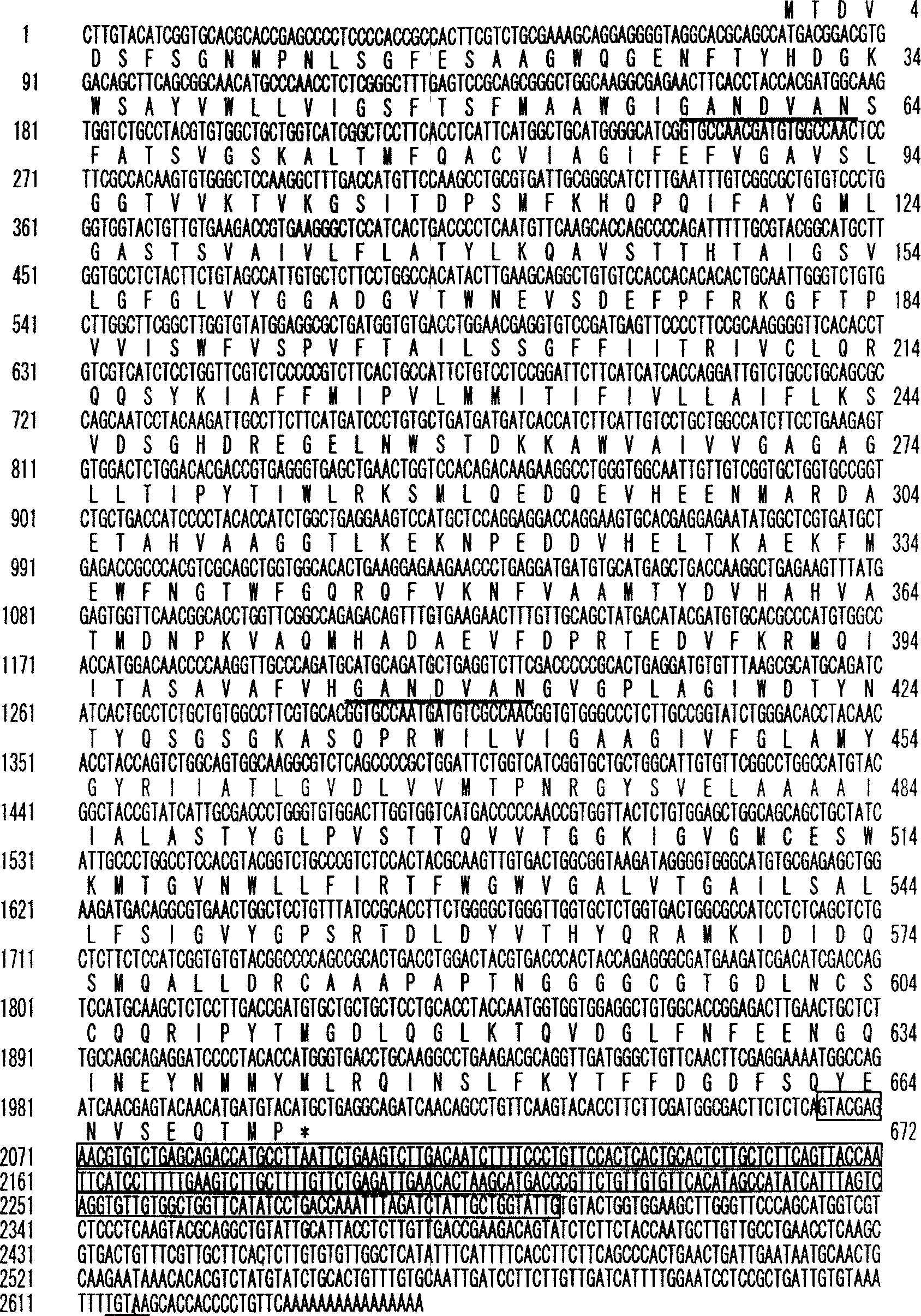

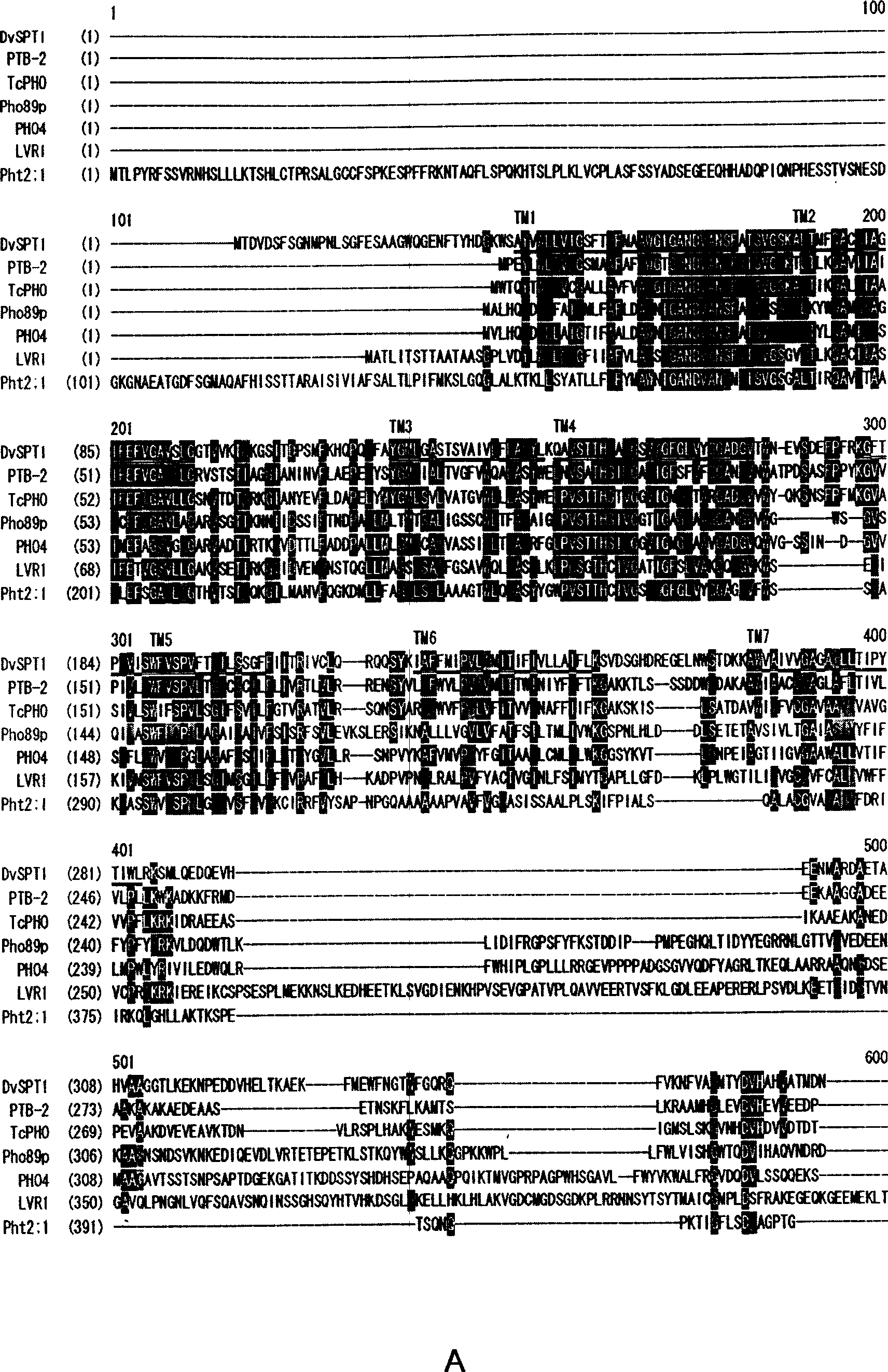

High salt induced dunaliella salina gene fragment and gene of sodium/phosphorus co-transport channel

InactiveCN1840664AEasy to separateEfficient separationAlgae/lichens peptidesFermentationCDNA libraryPlant genetic engineering

The invention provides a dunaliella salina cDNA library induced by high salt as well as screening its cDNA fragment and gene. Wherein, it constructs the library with inhibiting hybridization, and discloses the cDNA fragment and dunaliella salina Na+ / H2PO4- co-ttransfer membrane channel protein cDNA, whole gene and its amino acid sequence. This cDNA can screen the specific express of dunaliella salina induced by high salt, and settles foundation for corresponding molecular mechanism research.

Owner:SHANGHAI UNIV

3D printing device

InactiveCN108380884AAvoid cloggingImprove molding efficiencyManufacturing enclosuresTemperature controlLiquid temperature

The invention provides a 3D printing device which comprises a housing, a crucible arranged in the housing, a cover plate fixed at the top of the housing and sealing the crucible, a liquid transportingdevice and a pressure transporting device communicating with the crucible, an outer spray nozzle fixed at the bottom of the housing, a first temperature control device for controlling the liquid temperature in the crucible, and an industrial control device, and further comprises a second thermocouple and a second heater, which are arranged in the outer spray nozzle and are close to an outlet, anda second temperature controller electrically connected with the second thermocouple and the second heater. A slide block is arranged in the outer spray nozzle, is connected with a first motor, and can open or close the outlet under the driving action of the first motor. The first motor is electrically connected with the industrial control device. A concentrated liquid flow is in the high-temperature state by heating of the heater, so that the condition that liquid is cooled and solidified to block the outlet of the spray nozzle is avoided, and a gas membrane channel constrains the concentrated liquid flow, so that the concentrated liquid flow is prevented from being in contact with the spray nozzle, and the blocking of the spray nozzle is further prevented.

Owner:陈锦华

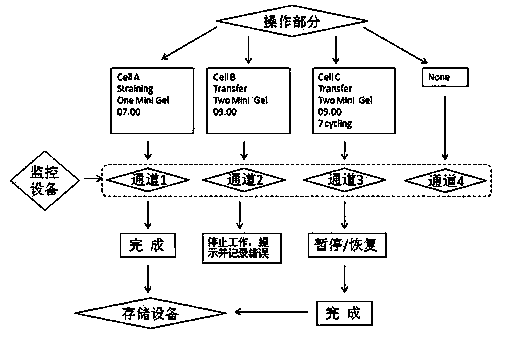

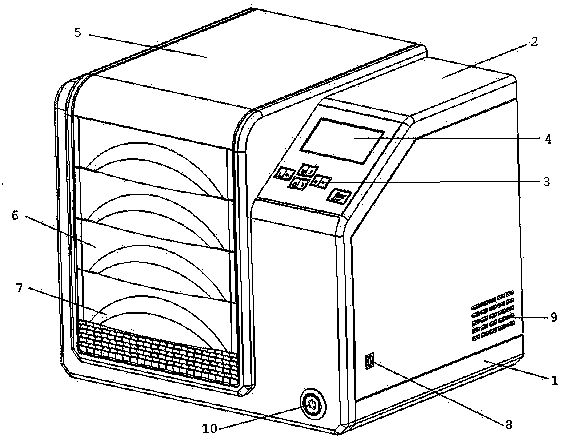

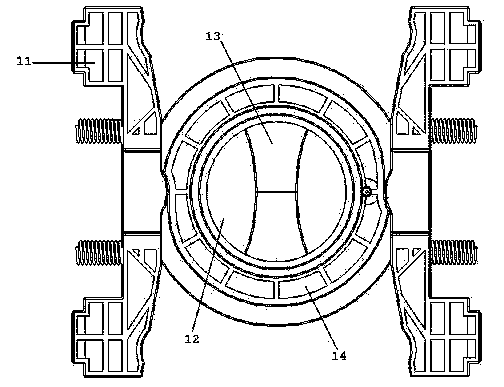

High-efficiency and high-sensitivity biomacromolecule trans-membrane and staining system and device

InactiveCN104075916AReduce stainsShorten the timePreparing sample for investigationStainingMembrane channel

The invention discloses a high-efficiency and high-sensitivity biomacromolecule trans-membrane and staining system. The high-efficiency and high-sensitivity biomacromolecule trans-membrane and staining system comprises a working unit and an operating portion which is associated with the working unit, wherein the working unit is provided with at least one channel used for detecting and analyzing a sample, the operating portion is used for creating at least one staining or trans-membrane channel parameter, and each staining or trans-membrane channel parameter comprises at least one electric field cycle. The invention further discloses a device based on the high-efficiency and high-sensitivity biomacromolecule trans-membrane and staining system. The device comprises a base and a shell, an operating panel is arranged on the outside of the shell, a working region, a system power source and a working circuit board are arranged in the base and the shell, the system power source and the working circuit board are connected with the working region, the working region is at least provided with one pull-out-type independent working chamber, and a positive and negative electrode board providing an electric field is installed in the working chamber. According to the system or the device, rapid staining and trans-membrane of biomacromolecules can be controlled by driving movement of biological charged particles through the electric field; meanwhile, the requirement for high sensitivity of biological detection can be further met.

Owner:NANJING GENSCRIPT BIOTECH CO LTD

Methods for preparing polymer membranes on porous supports

Methods for preparing a polymer membrane on a porous support may include providing a porous support having an outer wall, a first end, a second end, and porous channel surfaces that define a plurality of channels through the porous support from the first end to the second end. The plurality of channels includes membrane channels. The channel surfaces that define the membrane channels are membrane-channel surfaces. The polymer membrane may be coated onto the porous support by first establishing a pressure differential between the outer wall and the plurality of channels. Then, a pre-polymer solution may be applied to the membrane-channel surfaces and, optionally, the first and second ends, by slip coating or emulsion coating while the pressure differential is maintained. This results in formation of a pre-polymer layer on at least the membrane-channel surfaces. Then, the pre-polymer layer may be cured to form the polymer membrane.

Owner:CORNING INC +1

3D printing sea water desalination chip device based on ion concentration polarization principle

ActiveCN105731566ASmall sizeGood precisionSeawater treatmentWater/sewage treatmentWater desalinationMicro nano

The invention relates to a 3D sea water desalination chip device based on an ion concentration polarization principle. The 3D sea water desalination chip device comprises a base adopting 3D printing and a shell adopting 3D printing, a convexly formed buffer solution channel is formed in the base, and a micro-nano membrane channel, a desalted water channel, a concentrated saline water channel and a water outlet are also formed in the base; after the shell and the base are combined, a saline water channel is formed. After a 3D printing material is adopted for combination, fit is tight, no seam is formed, and leakproofness is extremely good; the base and the shell are clamped, connected and fixed by virtue of a 3D printing surrounding edge, the fixed position is accurate, glue or a nail does not need to be used, the integrity can be guaranteed, and the device can not be destroyed by the glue or nail; the manufacturing cost is low, and the device has mass production potency and is recyclable; the device is supported by 3D printing, so that the precision of the dimensions and shape of the device is not limited by familiarity degree of skills of workers, and the obtained finished product has relatively good dimensions and precision; the ion concentration polarization principle is utilized for carrying out sea water desalination, the energy consumption is low, the desalination efficiency is high, and no harm is done to the environment.

Owner:THIRD INST OF OCEANOGRAPHY STATE OCEANIC ADMINISTATION

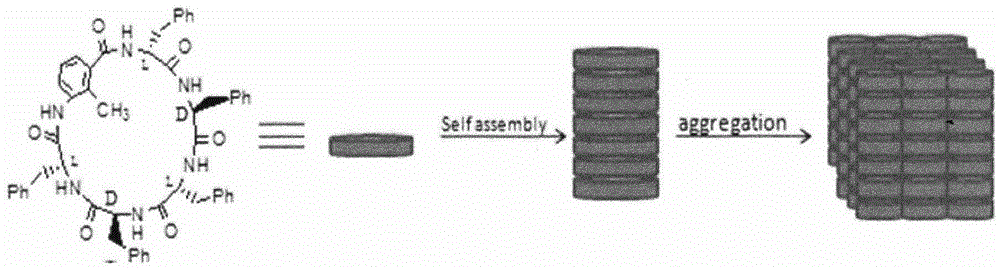

Novel cyclic peptide containing 2-methyl-3-aminobenzoic acid

The invention relates to a novel cyclic peptide containing 2-methyl-3-aminobenzoic acid (gamma-Mba). The cyclic peptide contains at least one 2-methyl-3-aminobenzoic acid (gamma-Mba) and 3-31 nonpolar amino acids, wherein the nonpolar amino acids are L- or D- alpha-amino acids and are any one or more of 8 natural nonpolar amino acids. The cyclic peptide can be assembled into nanotubes, so as to be used as medicament carriers, membrane channels, biosensors and the like.

Owner:CHINA PHARM UNIV

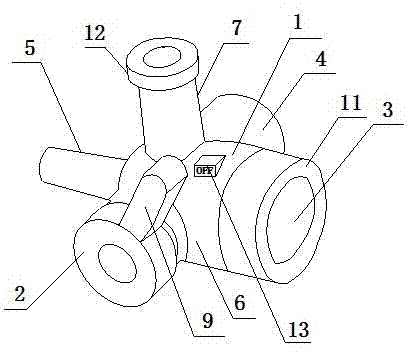

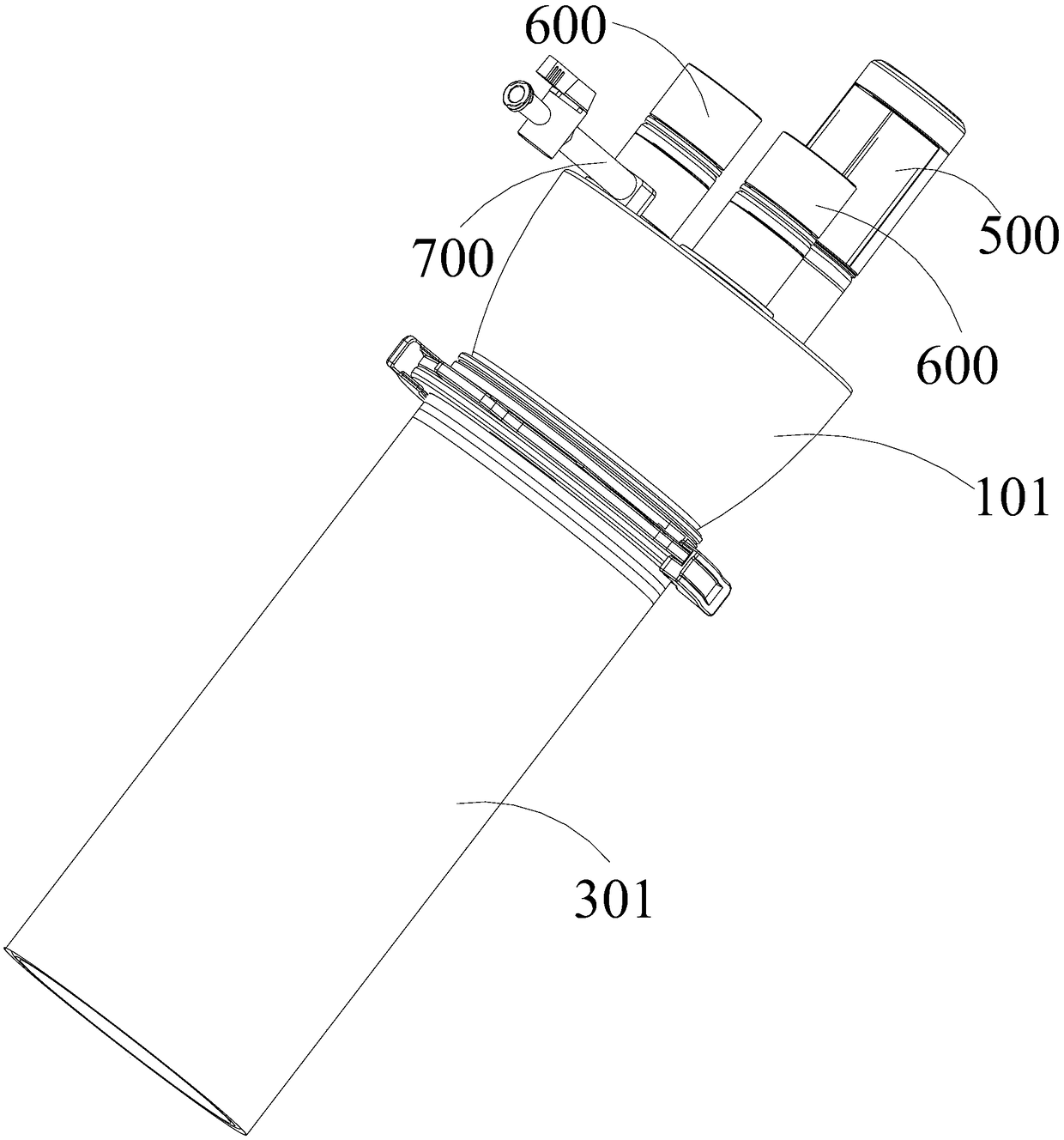

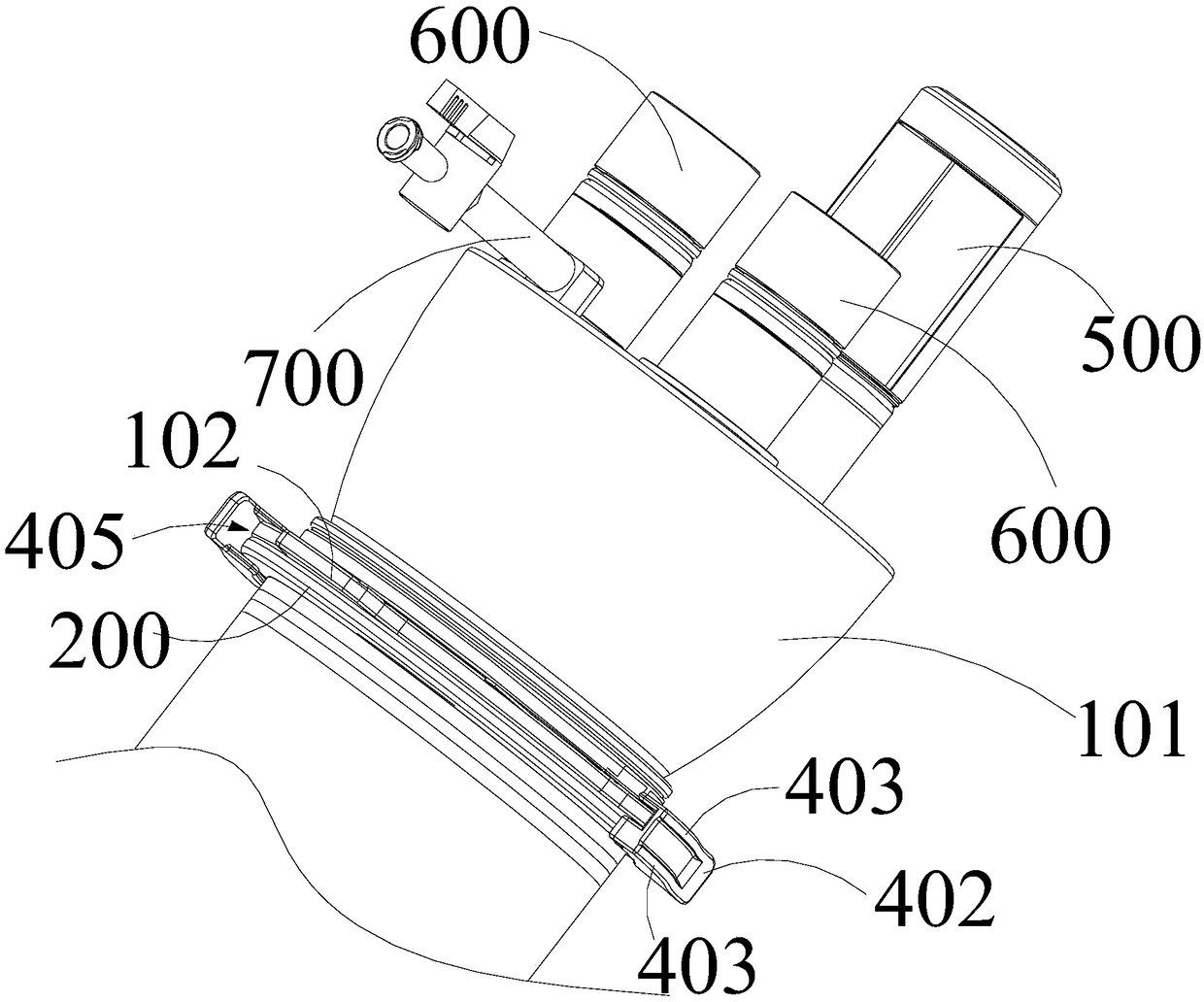

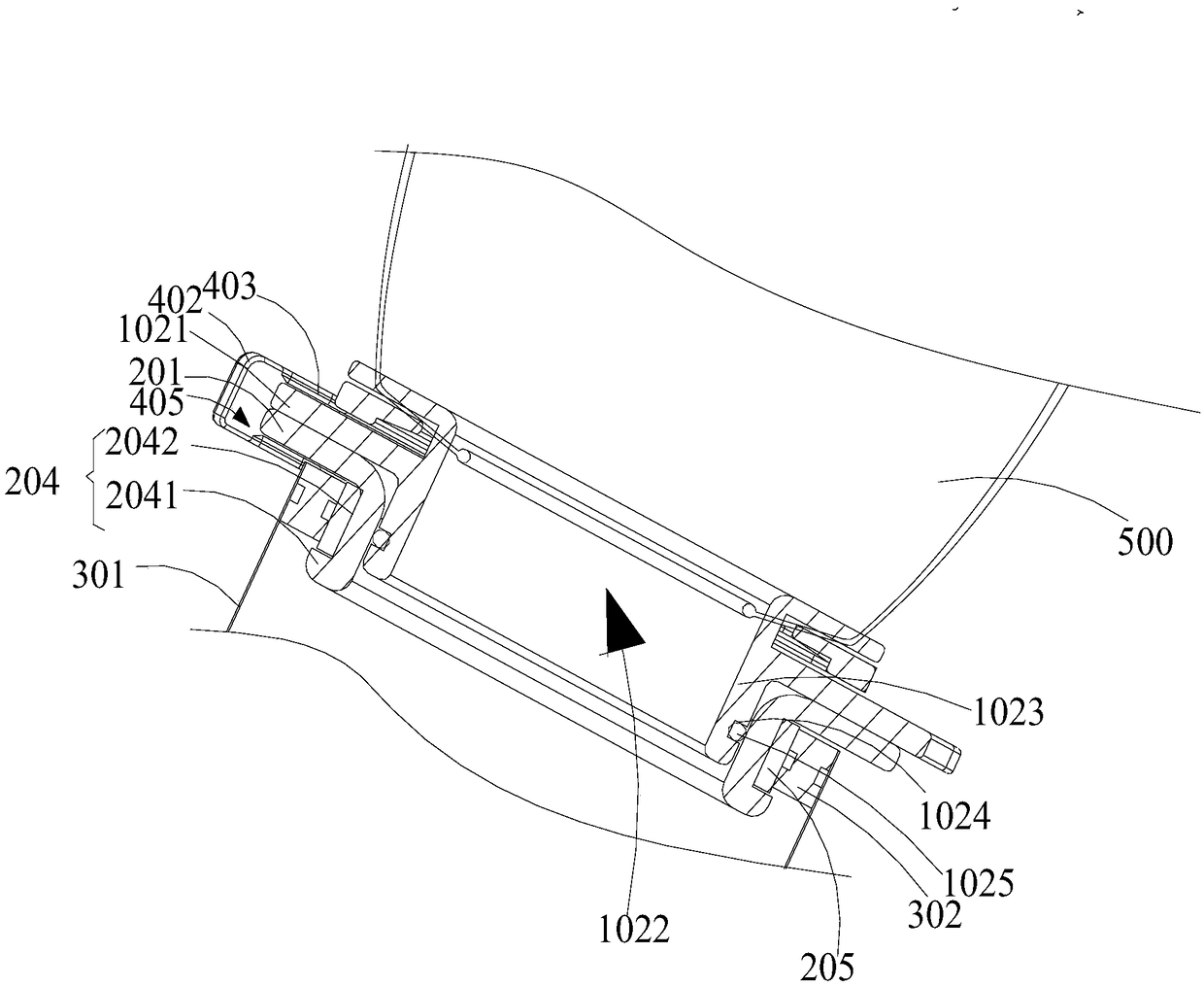

Multi-channel puncture apparatus

PendingCN109009271AEasy and fast connected operationGuaranteed air tightnessCannulasSurgical needlesAbdominal cavityMembrane channel

The invention discloses a multi-channel puncture apparatus, which comprises a porous operating platform placed outside the abdominal cavity, a celiac channel tube connected to the porous operating platform and is suitable for insertion into the abdominal cavity. The porous operating platform comprises a bowl-shaped shell with one end closed and the other end open, a platform fixing ring which is arranged at the opening end of the bowl-shaped shell and is suitable for forming a cavity with the bowl-shaped shell, and several separate instrument channels located at the closed end of the bowl-shaped shell and being suitable for communicating with the cavity. The celiac channel tube comprises a flexible membrane channel assembly and a channel fixing ring being suitable for the flexible membranechannel assembly. The channel fixed ring is suitable for coupling with the platform fixing ring which is provided with at least a set of locking components being symmetrically arranged for simultaneously locking the channel fixing ring and the platform fixing ring.

Owner:欣瑞德(江苏)医疗科技有限公司

Method for preparing high performance silicalite-1 zeolite membrane

InactiveCN105289324AEasy to separateReduce manufacturing costSemi-permeable membranesSucroseGlycerol

The invention discloses a method for preparing a high performance silicalite-1 zeolite membrane, which relates to a method for preparing a zeolite membrane, wherein a mixed solution which is prepared through porous anodic alumina or silica ceramic tube carriers by utilizing acacia gum, carboxymethyl cellulose, tannic acids, soluble starch, sucrose and glycerol is soaked and dried for many times, deionized water is weighed and is hydrothermally compounded to prepare the silicalite-1 zeolite membrane, the dried silicalite-1 zeolite membrane is activated fat a certain time in 400-600 DEG C to remove a diaphragm agent in a zeolite membrane channel. The method for preparing the high performance silicalite-1 zeolite membrane can effectively improve separation performance, is beneficial to reduce preparation cost of the silicalite-1 zeolite membrane, is simple simultaneously, can be used for chip carriers, also can be used for tubular carriers and multi-channel carriers, is suitable to prepare the silicalite-1 zeolite membrane in a large scale, and is convenient for application and promotion. The method for preparing the high performance silicalite-1 zeolite membrane is beneficial to reduce preparation cost, and supplies necessary technical support to urge large-scale preparation of the high performance silicalite-1 zeolite membrane to achieve at an early date.

Owner:SHENYANG UNIV

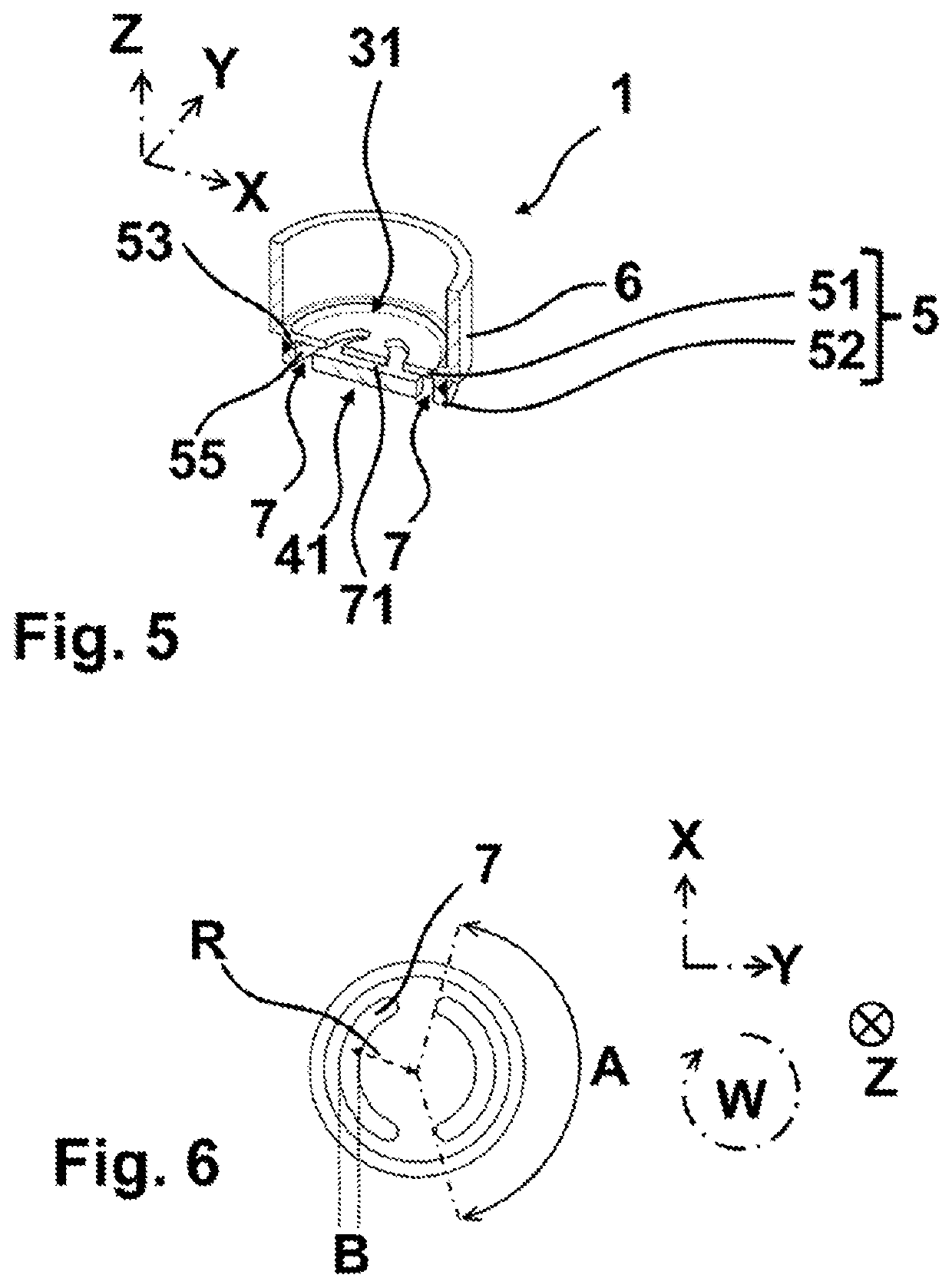

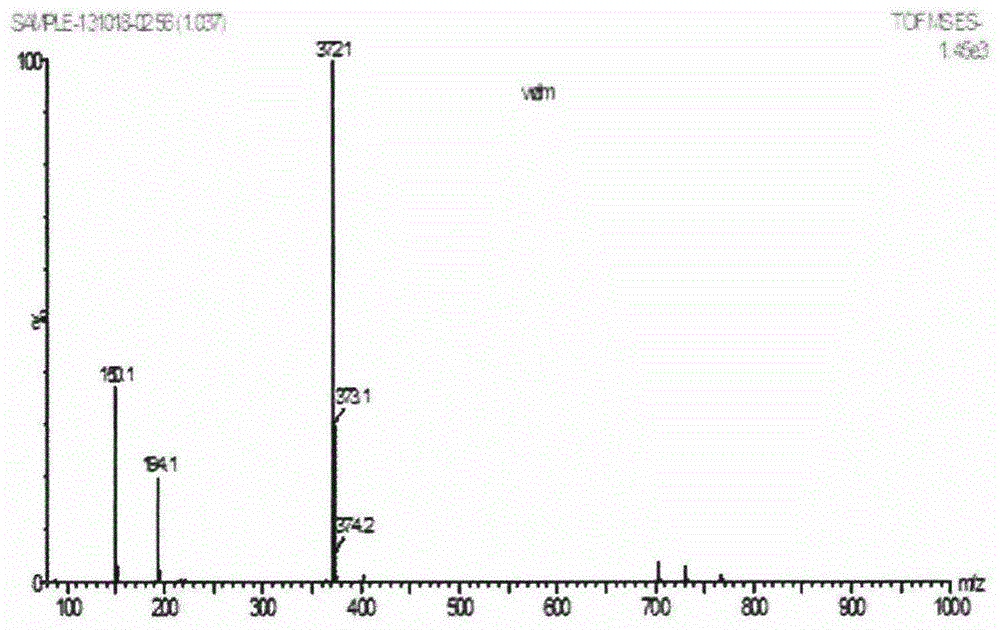

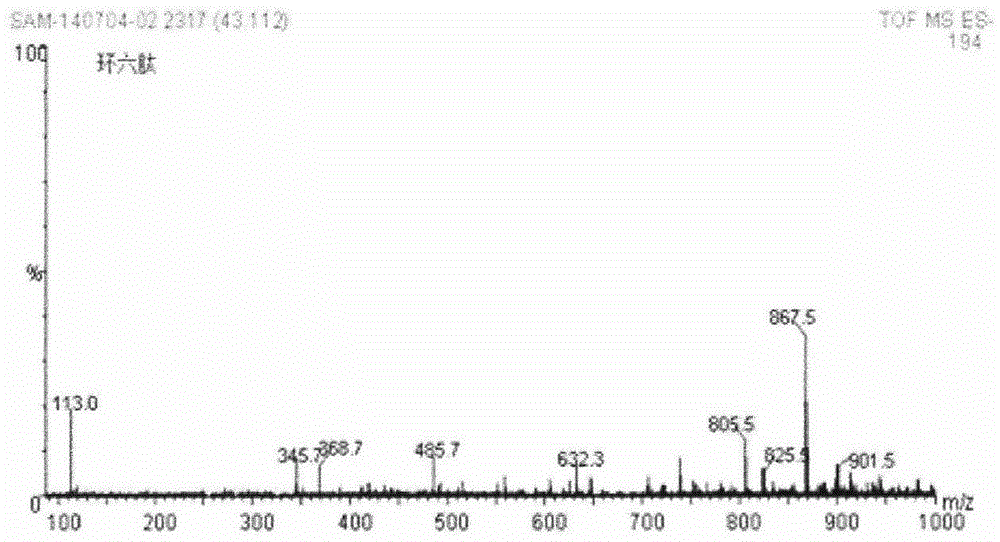

Preparation method of homocyclic peptide Cyclo-[(Asn)5-Cys]

ActiveCN107400162AImprove regularityHigh reactivityPeptide preparation methodsBulk chemical productionCyclic peptideSolubility

Owner:INST OF NUCLEAR PHYSICS & CHEM CHINA ACADEMY OF

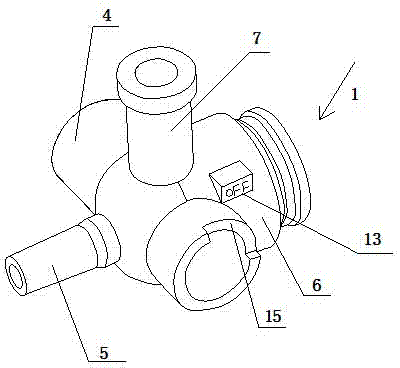

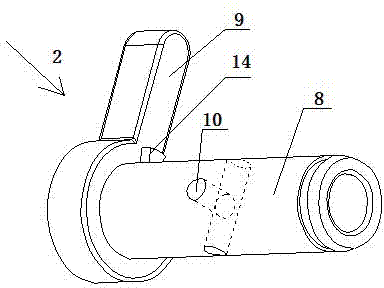

Device and method for security detection of epidural anesthesia puncture

The invention relates to the technical field of medical apparatuses and instruments, in particular to a device for security detection of an epidural anesthesia puncture. The device comprises a valve body, a valve core and a testing membrane. The valve body is a four-way valve body. The testing membrane is arranged at a port of a testing membrane channel in a sealed mode. The valve core comprises a valve core body and a valve rod. The valve core body is tightly installed inside the valve core channel in a sleeved mode. The valve rod can rotate around the valve core channel. Three valve core through holes are formed in the valve core body. When the device is at the injection position or the closed position or the puncture position, the corresponding channel can be arranged at the required closed position by rotating the valve rod. The invention further discloses a method for the security detection of the epidural anesthesia puncture. According to the method and device for the security detection of the epidural anesthesia puncture, whether an anesthesia puncture needle punctures a ligamentum flavum can be visually and effectively detected and prompted, the anesthesia puncture needle reaches an epidural space, pain, caused by puncture failure, to a patient is avoided, operation and teaching by a clinician are also facilitated, and the visual and clear evidence is provided for medical confirmation of complications in anesthesia.

Owner:潘乐屹

Method for removing trace iodine in chlor-alkali brine by using ozone

InactiveCN103866348AReaction is easy to controlSuitable for industrial applicationsElectrolysis componentsElectrolysisImpurity

Currently, alkali is made mainly by using an ion membrane electrolysis technology in industry, and mainly adopted raw materials include industrial brine, salted bittern and whole bittern. Due to the particularity of ionic membrane caustic soda production, brine is always recycled and not discharged to the outside, and some ions can not be processed by existing primary brine and secondary brine, over time, ion concentration is formed, and causes serious influence on the current efficiency and the service lives of ionic membranes. Especially, iodine ions exist in large-molecular-weight Na3H2IO6 and Ba3H4 (IO6) 2 forms in the process of electrolysis, so that the iodine ions block an ionic membrane channel so as to hinder the passing of sodium ions, thereby reducing the current efficiency, and shortening the service lives of ionic membranes. The ionic membranes are expensive, so that the frequent replacement of the ionic membranes is adverse to the benefits of factories. Therefore, removing iodine in brine is the most economic and effective measure. According to a method for removing trace iodine in chlor-alkali brine by using ozone, disclosed by the invention, ozone is taken as an oxidant and iodine blowing for gas removal is implemented, so that iodine in brine is removed in one step, no impurity is introduced, and no pollution is caused. The method is simple in operation, high in efficiency and low in energy consumption, and can remove most of iodine in brine, therefore, the method has obvious application advantages.

Owner:CHONGQING UNIV

Protective device

ActiveUS20210063264A1Raise the resonance frequencyEliminate the effects ofFluid pressure measurementMembrane channelEngineering

A protective device for a membrane of a sensor that detects a physical parameter acting upon the membrane includes a hollow main body that elongates in a direction along a longitudinal axis. The main body is open at one opposite end of the main body along the longitudinal axis, and at the end of the main body opposite the open end the protective device includes a bottom in which is defined a passage through which the medium is able reach the membrane when the protective device is attached to the sensor. The passage is defined in part by a wall that is configured so that the electromagnetic radiation propagating in the passage cannot reach the membrane without being reflected at least once on the wall.

Owner:KISTLER HLDG AG

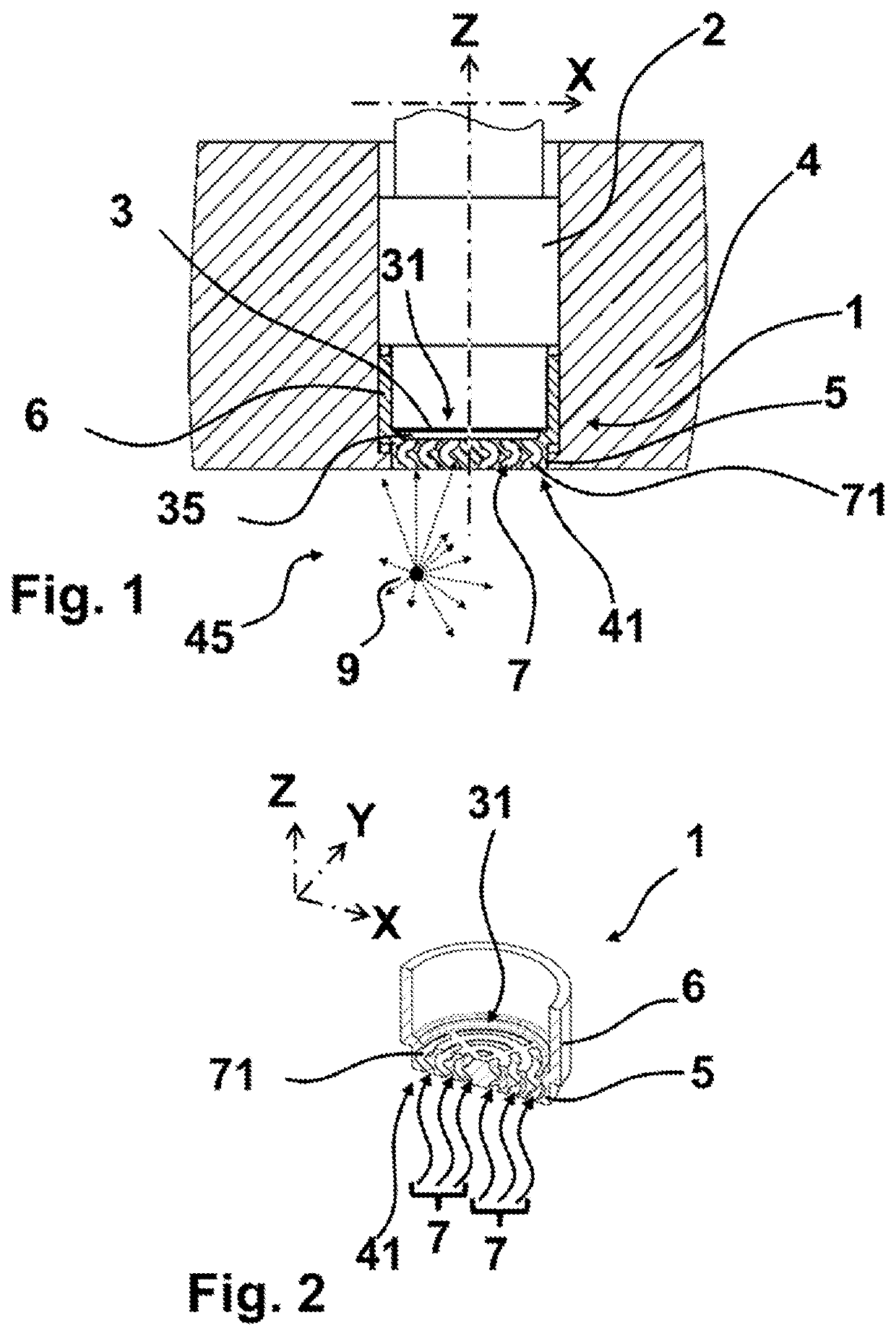

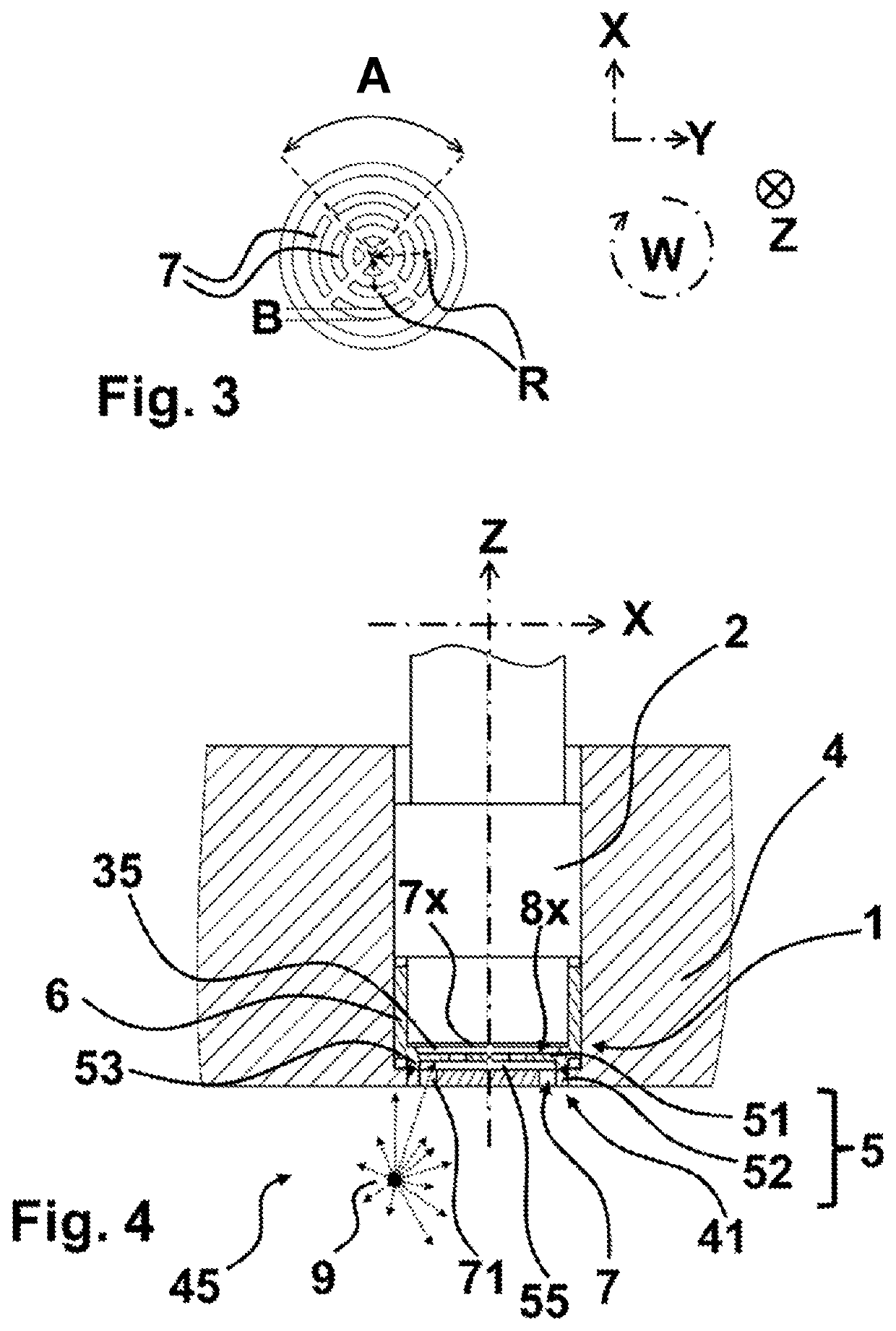

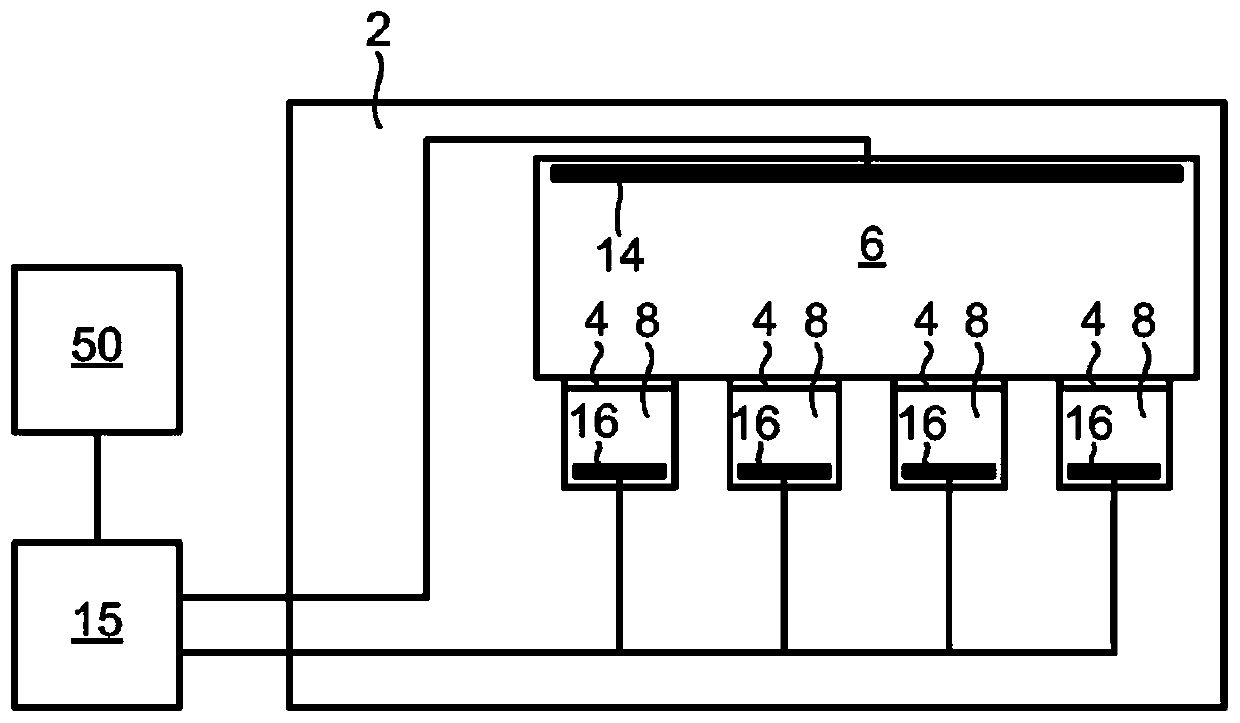

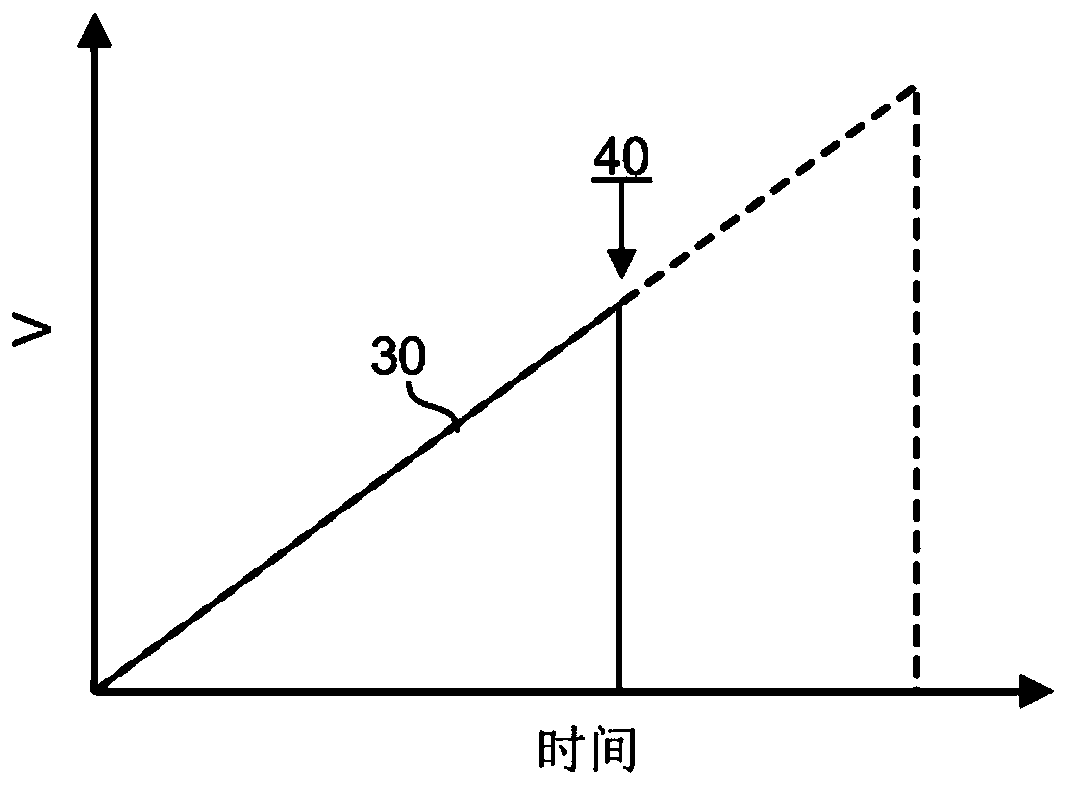

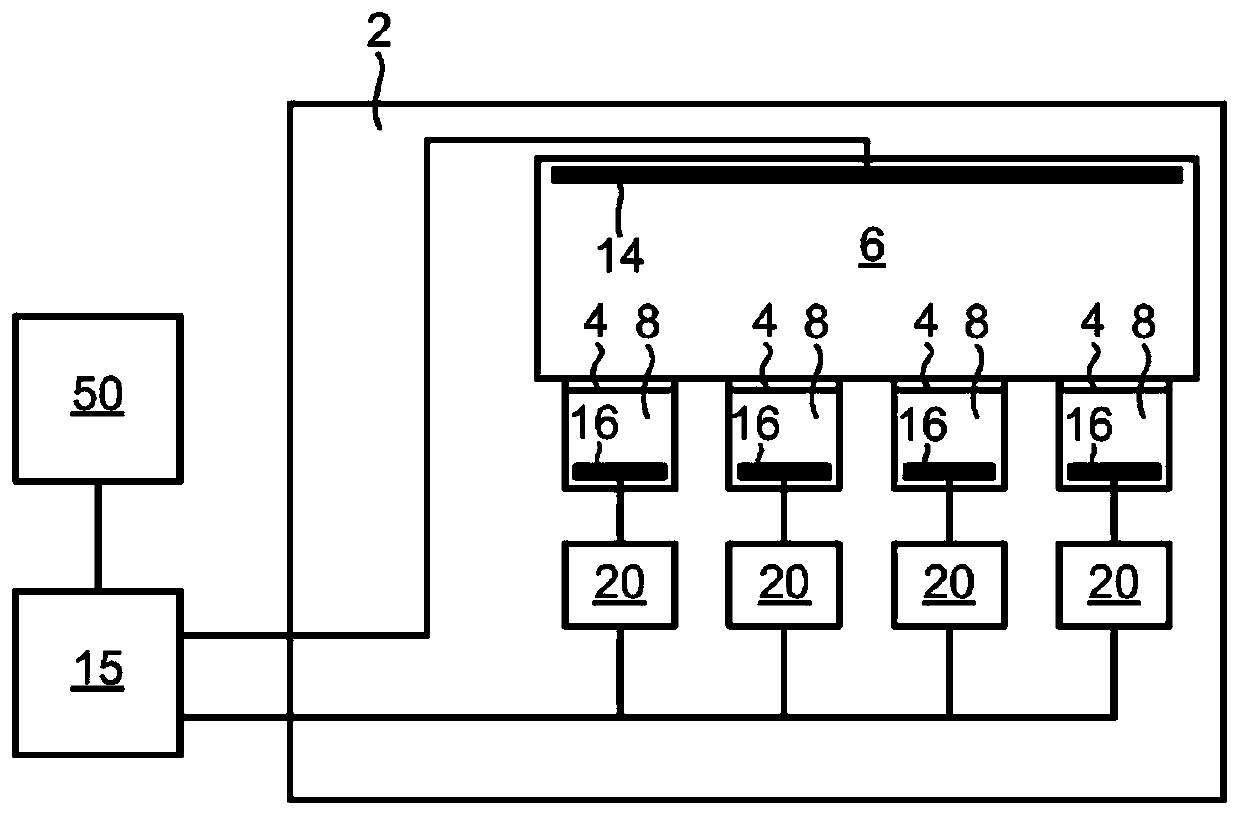

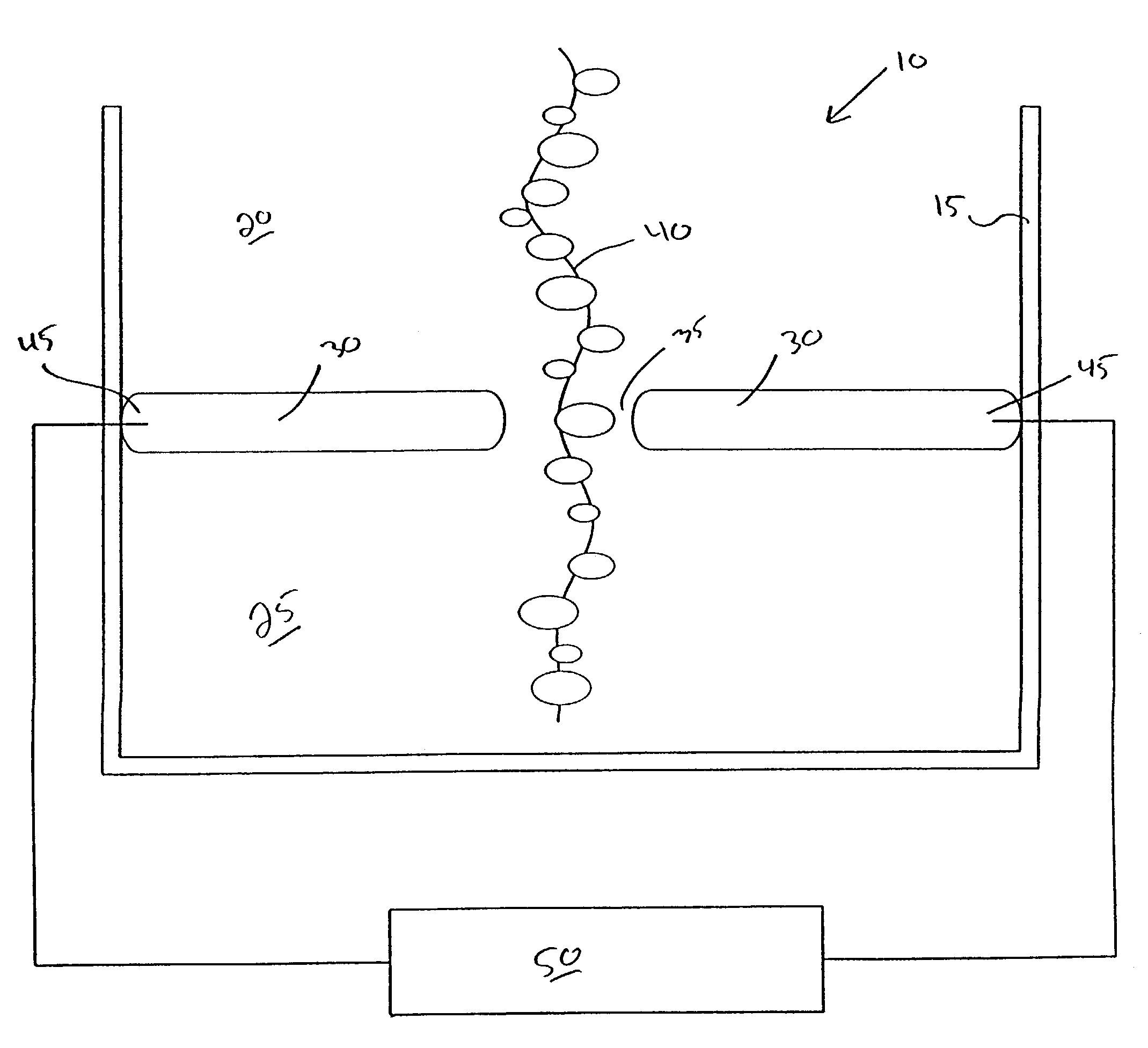

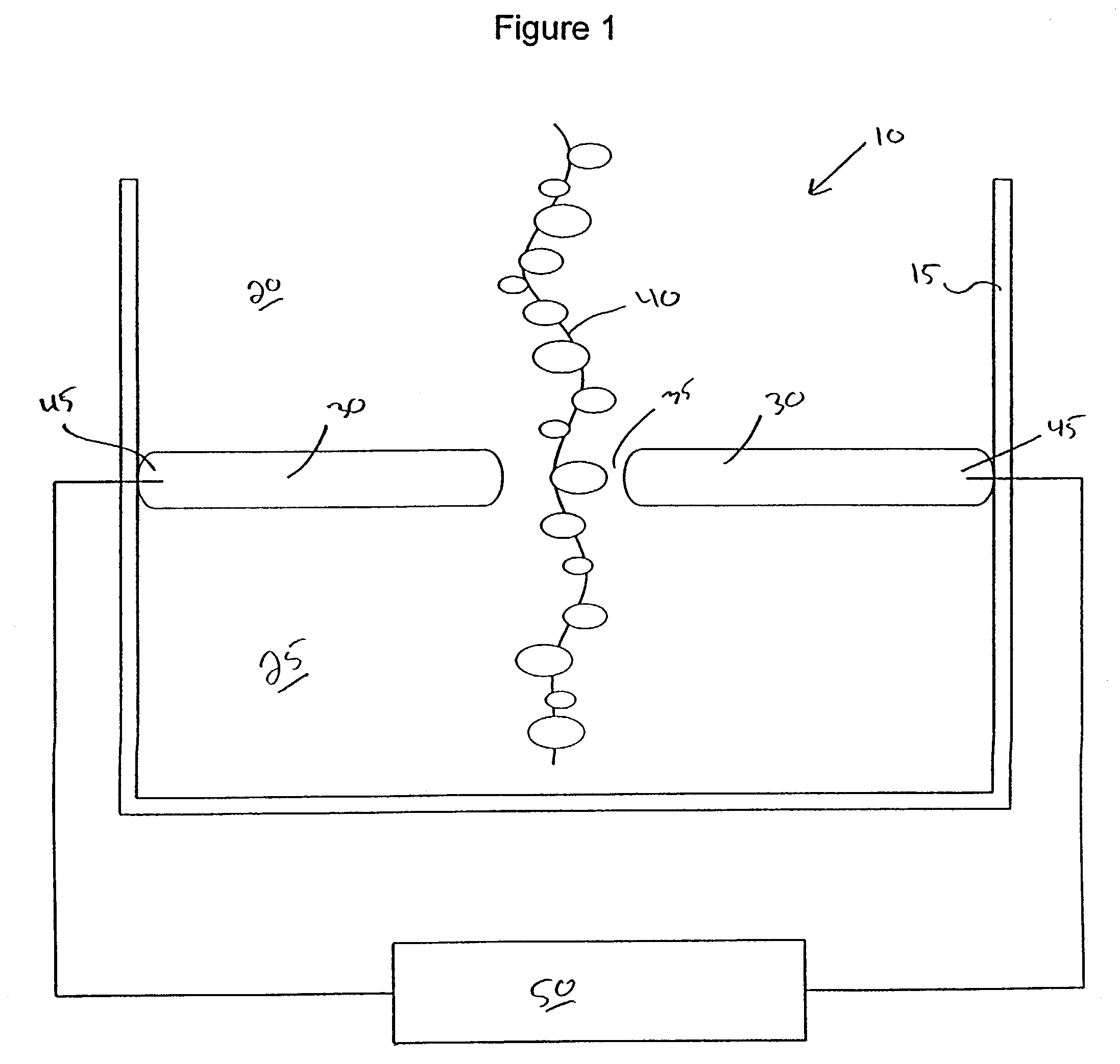

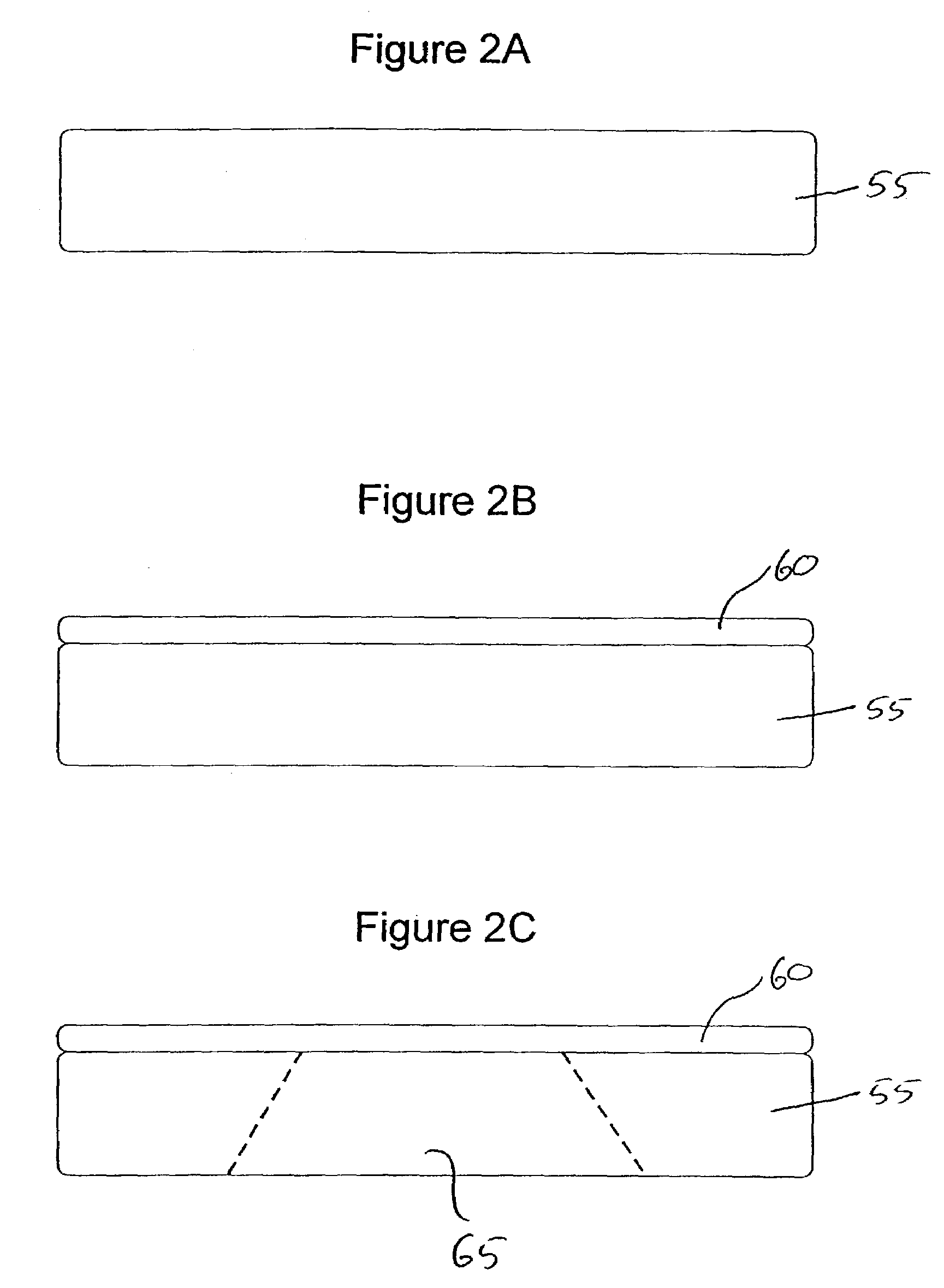

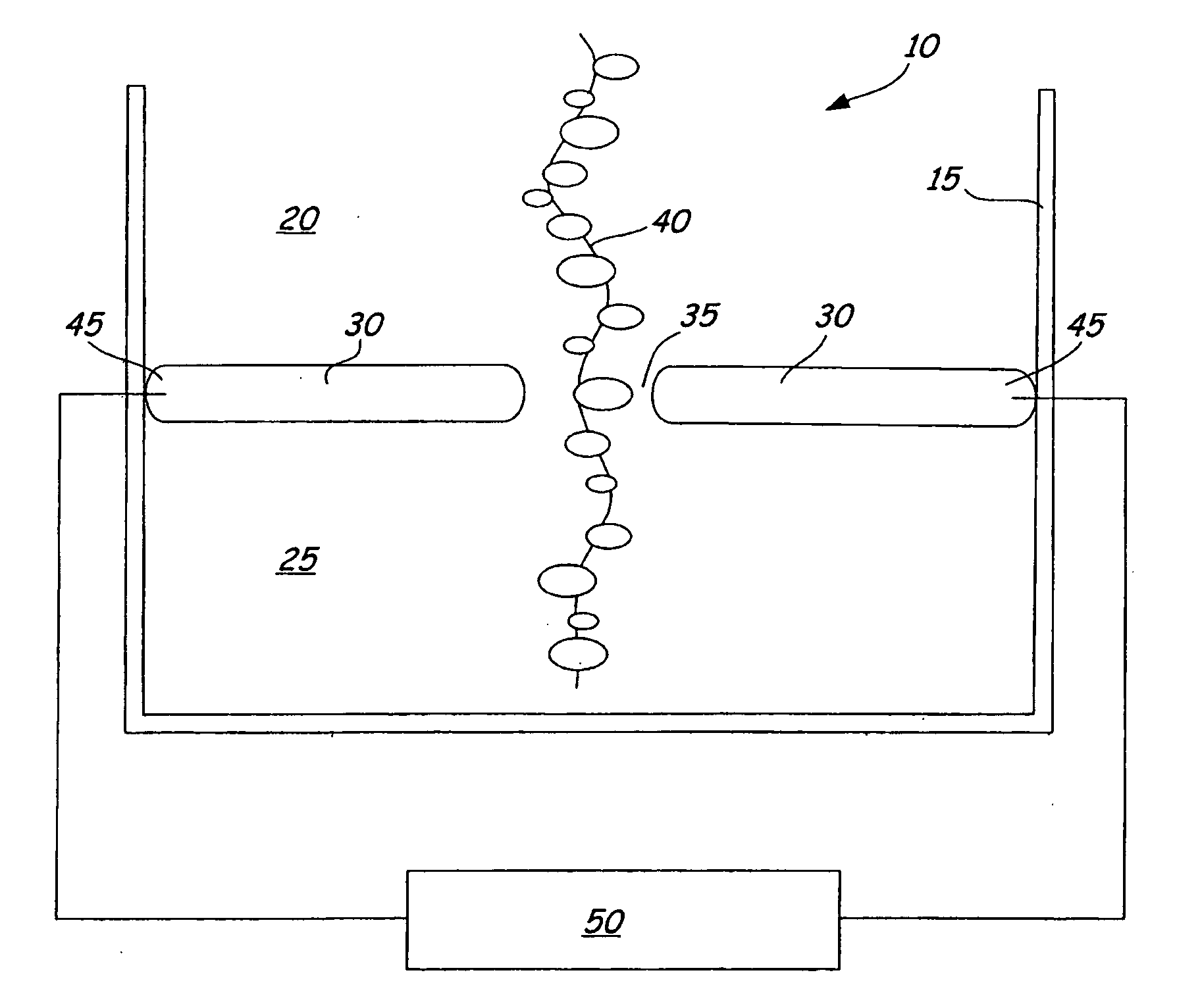

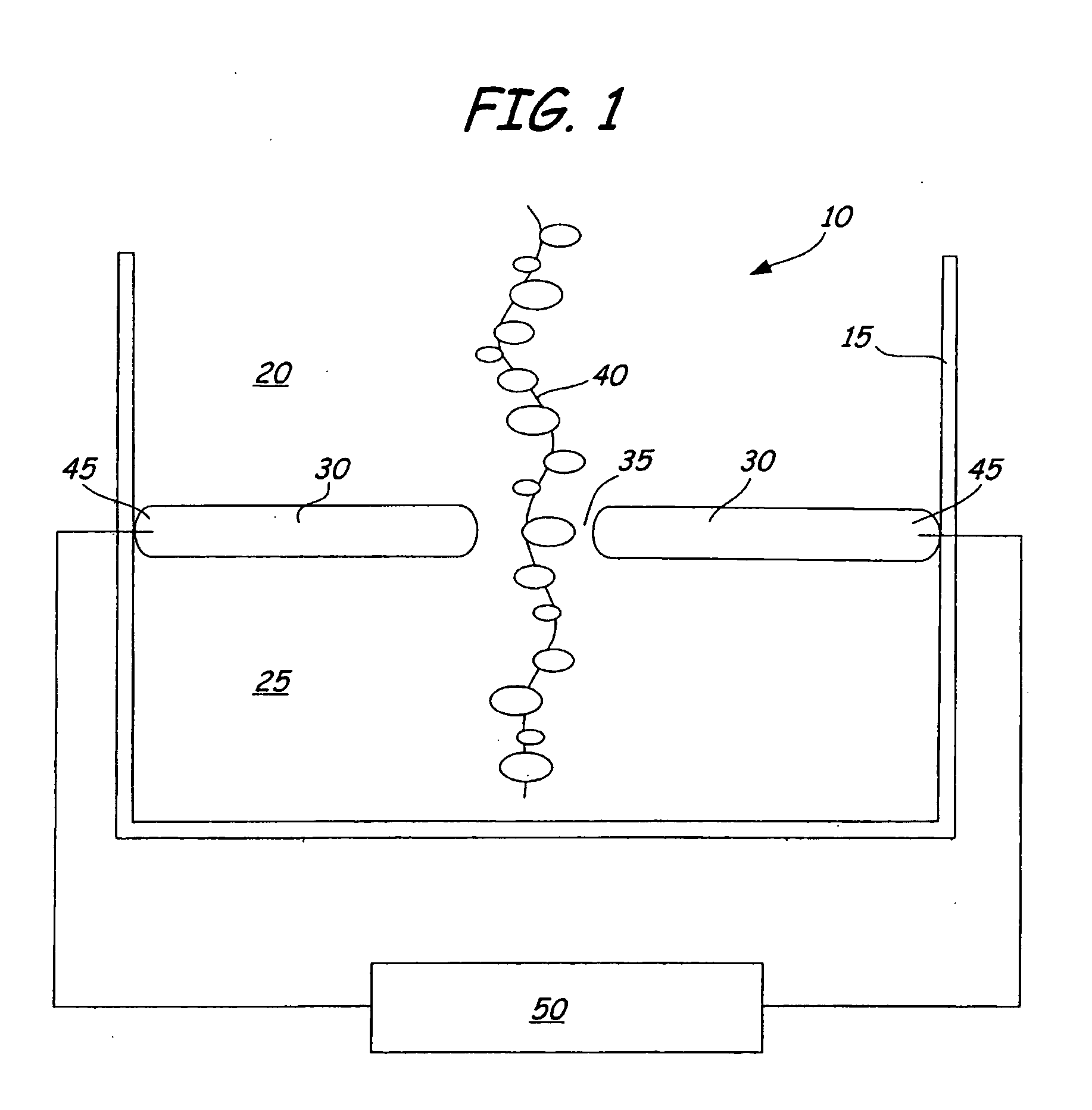

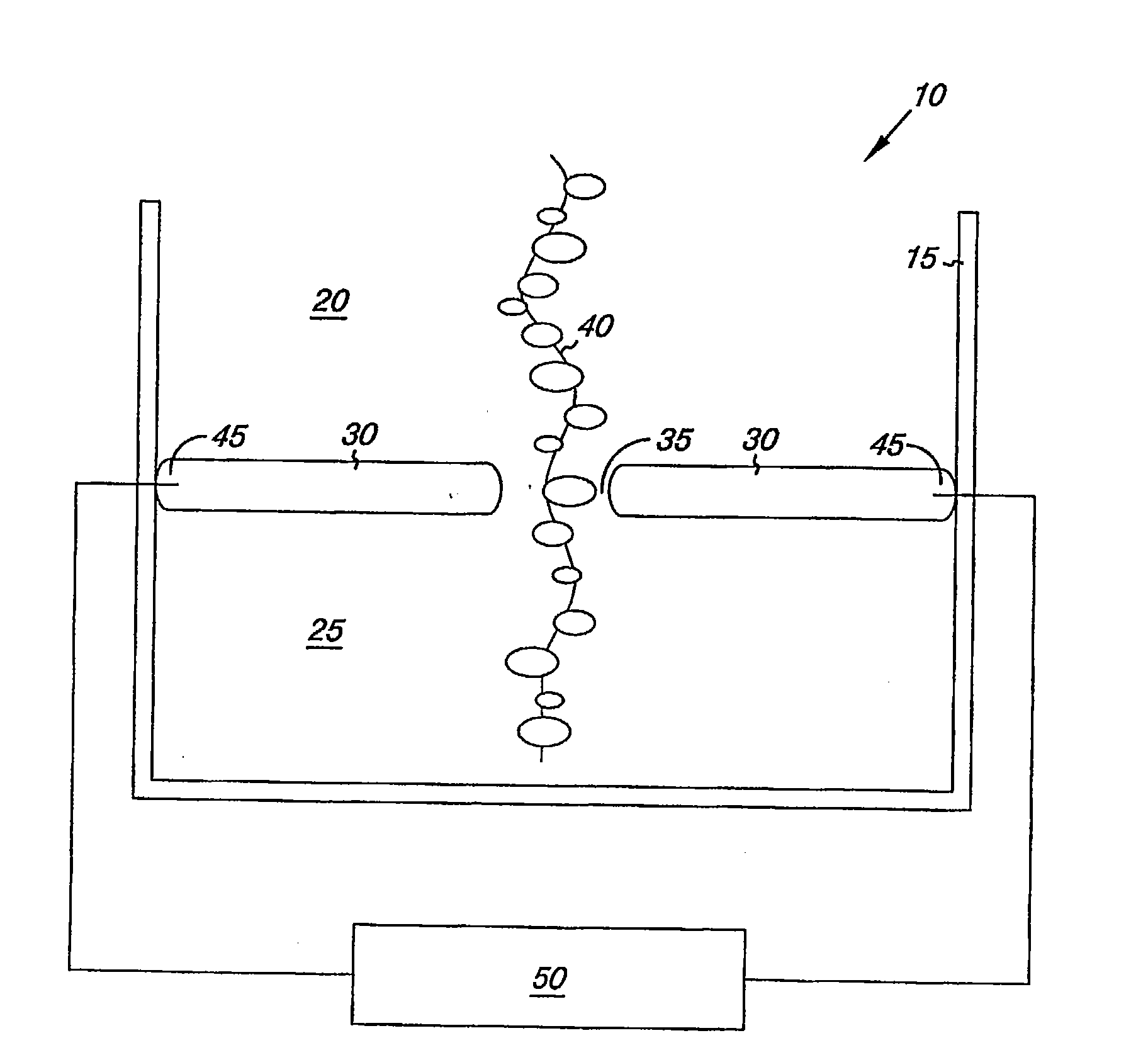

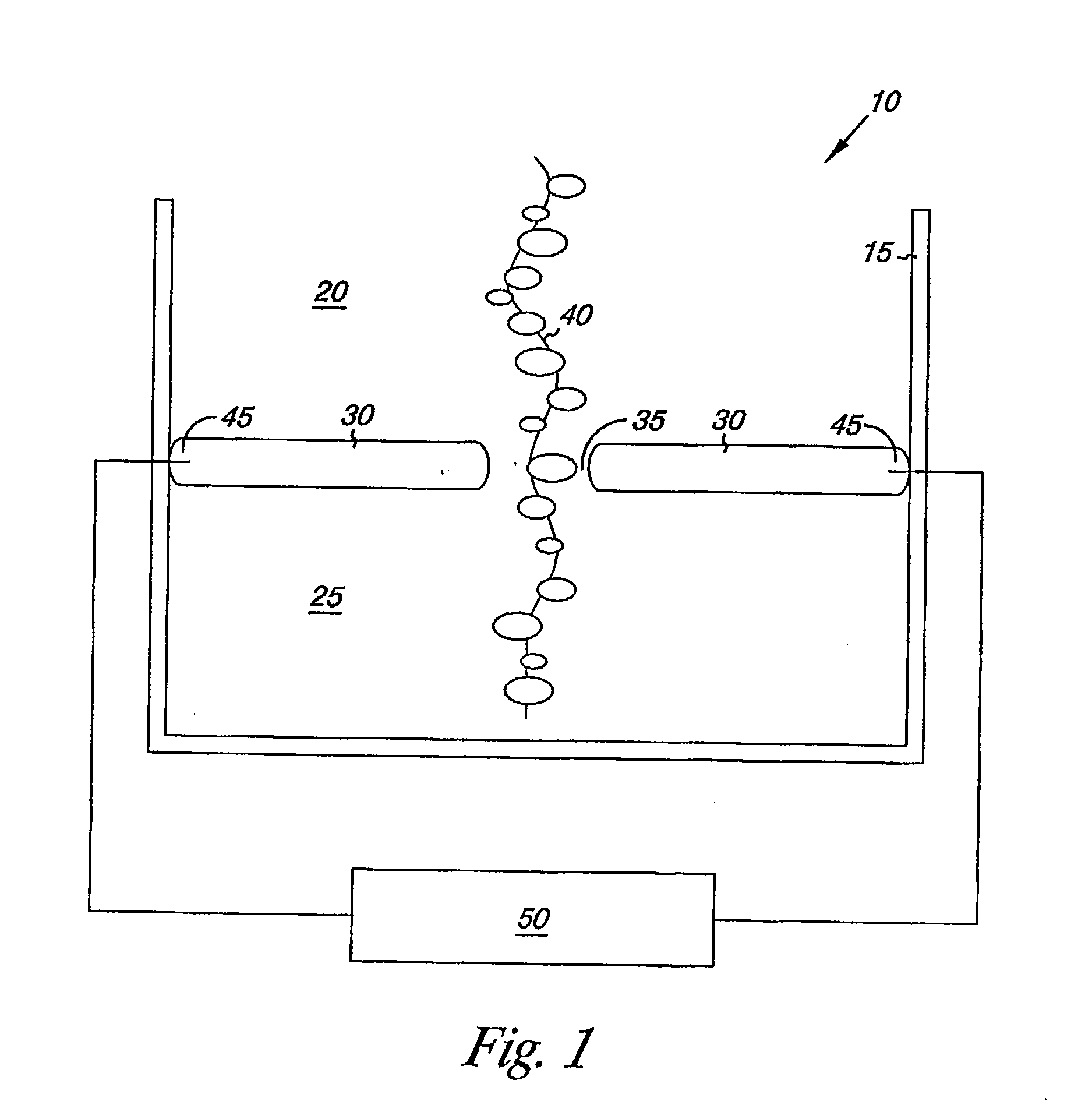

Apparatus and methods for controlling insertion of a membrane channel into a membrane

ActiveCN110023753ALaboratory glasswaresMicrostructural device manufacturePotential differenceMembrane channel

Apparatus and methods for controlling the insertion of a membrane channel into a membrane are disclosed. In one arrangement a first bath holds a first liquid in contact with a first surface of a membrane. A second bath holds a second liquid in contact with a second surface of the membrane. The membrane separates the first and second liquids. A first electrode contacts the first liquid. A second electrode contacts the second liquid. A driving unit applies a potential difference across the membrane via the first and second electrodes to promote insertion of a membrane channel into the membrane from the first liquid or the second liquid. A membrane voltage reduction unit is connected in series with the membrane. The driving unit applies a driving voltage across the membrane voltage reductionunit and the membrane, the driving voltage providing the potential difference across the membrane. The membrane voltage reduction unit is configured such that a reduction in resistance through the membrane caused by insertion of a membrane channel intrinsically increases a potential difference across the membrane voltage reduction unit thereby lowering the potential difference across the membrane.The lowering of the potential difference across the membrane is sufficient to prevent or reduce promotion of insertion of a further membrane channel.

Owner:OXFORD NANOPORE TECH LTD

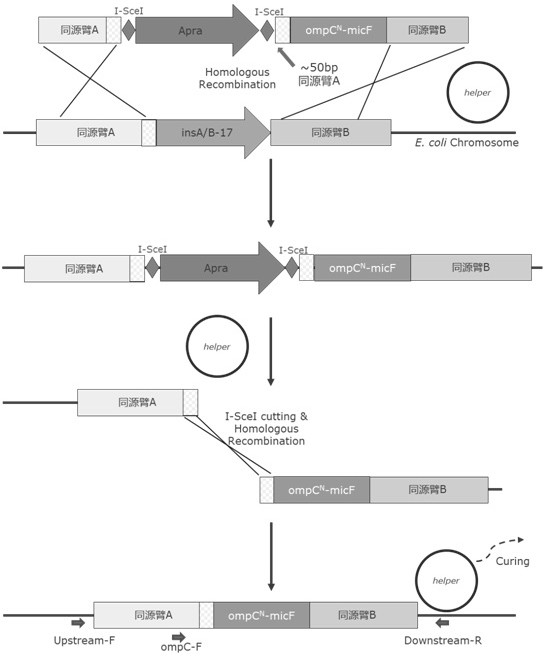

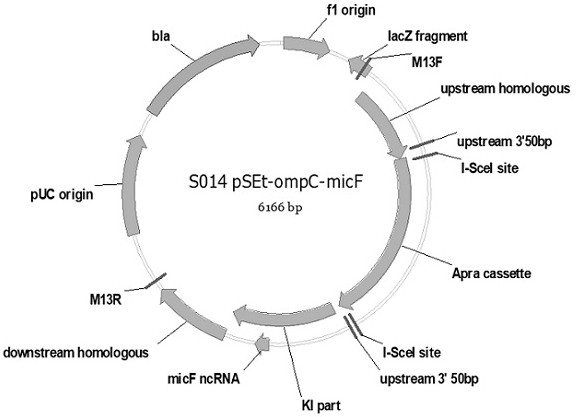

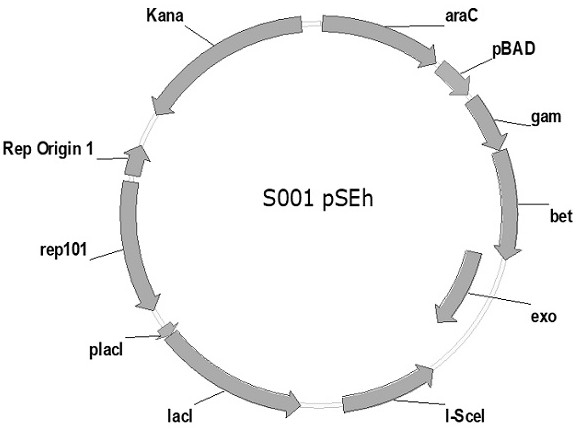

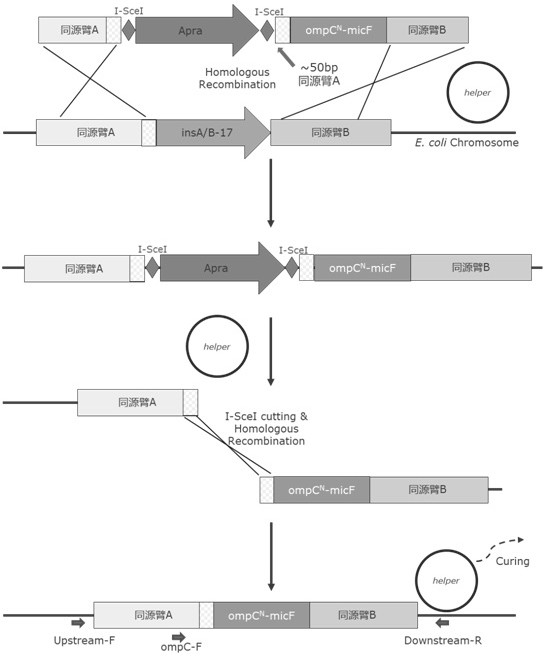

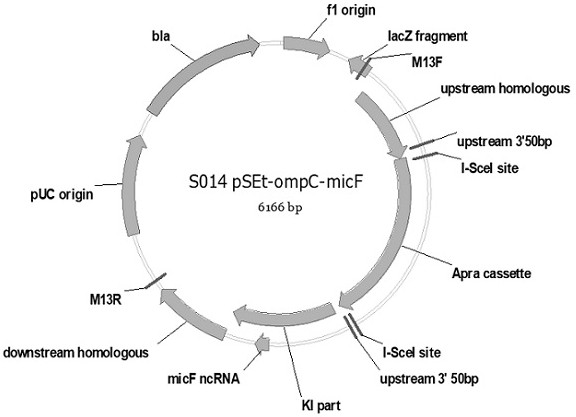

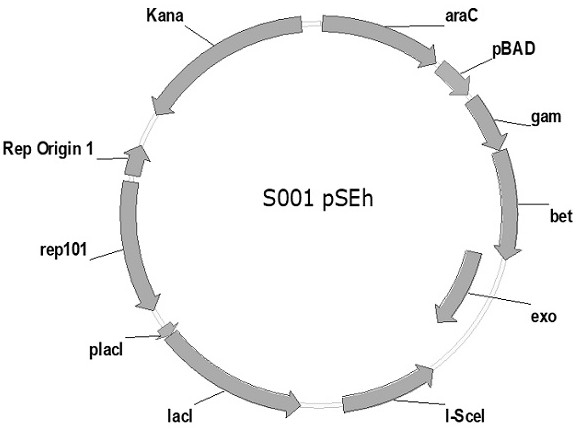

Escherichia coli recombinant strain as well as preparation method and application thereof

The invention provides an escherichia coli recombinant strain as well as a preparation method and application thereof, and particularly relates to modification of an ompC site of an escherichia coli B strain, recovery of the integrity of ompC protein and an expression regulation mechanism of two membrane channel proteins of ompC and ompF. The modified new strain can improve the expression quantity and secretion efficiency of recombinant protein.

Owner:BEIJING QL BIOPHARMACEUTICAL CO LTD

A kind of Escherichia coli recombinant strain, its preparation method and application

The invention provides a recombinant strain of Escherichia coli, a preparation method and application thereof. Specifically, the ompC site of Escherichia coli B strain is transformed, the integrity of the ompC protein is restored, and the expression regulation mechanism of the two membrane channel proteins of ompC and ompF is provided. . The modified new strain can improve the expression and secretion efficiency of the recombinant protein.

Owner:BEIJING QL BIOPHARMACEUTICAL CO LTD

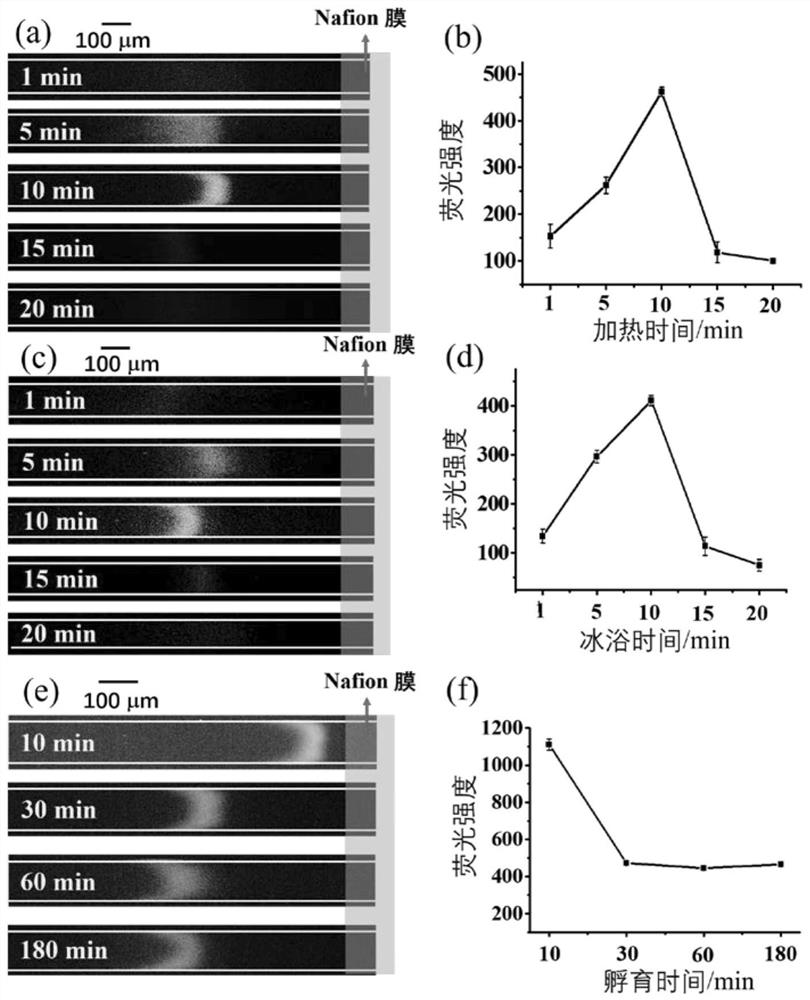

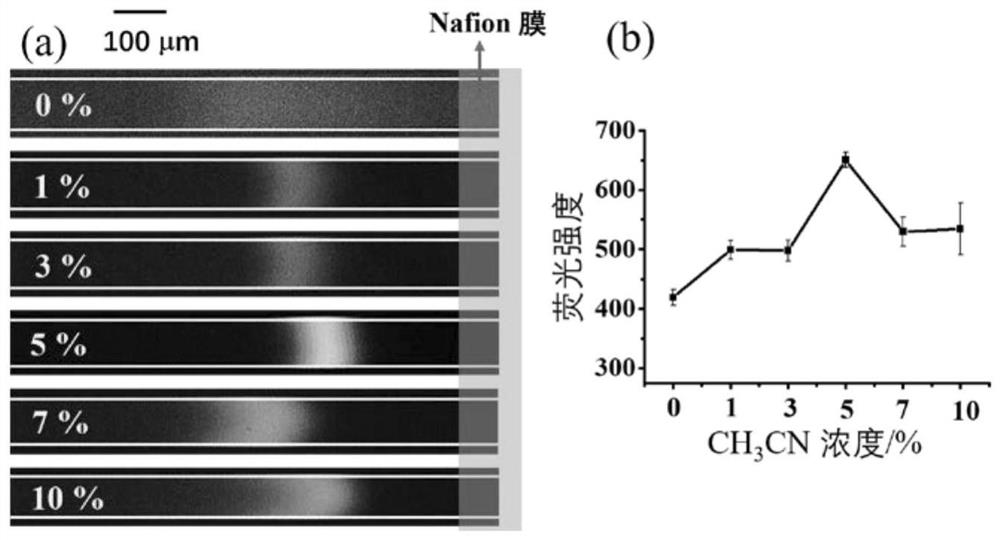

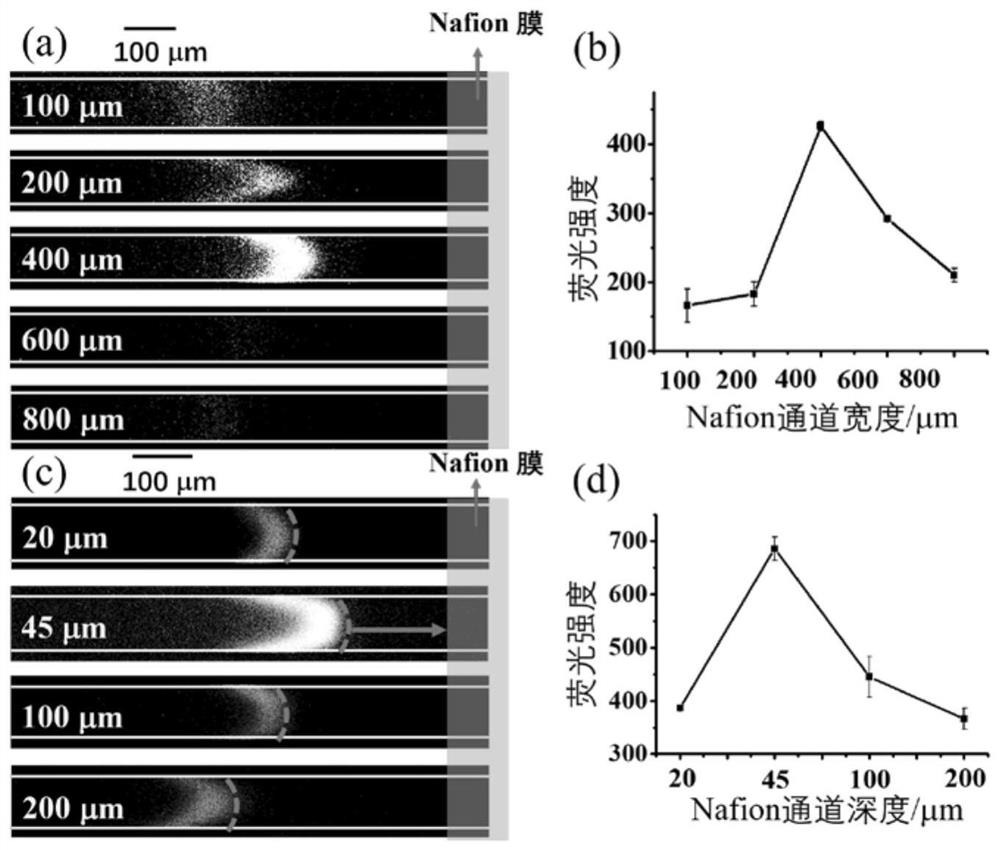

A method for detecting endotoxin

The invention discloses a method for detecting endotoxin. The method comprises: incubating a sample to be tested with a fluorescently labeled LPS aptamer; adding reduced graphene oxide and TBE buffer solution, and incubating; and incubating the incubated sample Load the sample into the inlet of the microfluidic chip, apply a voltage between the inlet and outlet of the microfluidic chip for processing, the inlet is the anode, and detect the fluorescence between the Nafion membrane channel and the anode after voltage treatment Intensity; determine the content of LPS in the sample to be tested according to the fluorescence intensity and the standard curve. The method of the invention has a minimum detection limit of 8 fM, a wide linear range, high sensitivity, good selectivity, strong anti-interference ability, and can quickly distinguish Gram-positive bacteria, Gram-negative bacteria and fungi.

Owner:SOUTHERN MEDICAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Preparation method of homocyclic peptide Cyclo-[(Asn)5-Cys] Preparation method of homocyclic peptide Cyclo-[(Asn)5-Cys]](https://images-eureka.patsnap.com/patent_img/f9ef9853-8e8c-44eb-88a6-a3753c5efdd6/HDA0001412269870000011.png)

![Preparation method of homocyclic peptide Cyclo-[(Asn)5-Cys] Preparation method of homocyclic peptide Cyclo-[(Asn)5-Cys]](https://images-eureka.patsnap.com/patent_img/f9ef9853-8e8c-44eb-88a6-a3753c5efdd6/HDA0001412269870000012.png)