A method for detecting endotoxin

An endotoxin and sample technology, applied in the direction of measuring devices, biological testing, material inspection products, etc., can solve the selectivity and sensitivity limitations of graphene sensors, the inability to control reaction conditions well, and the low biocompatibility of graphene, etc. problems, to achieve the effect of strong anti-interference ability, short time, and less consumption of reagents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1 A kind of method for detecting endotoxin

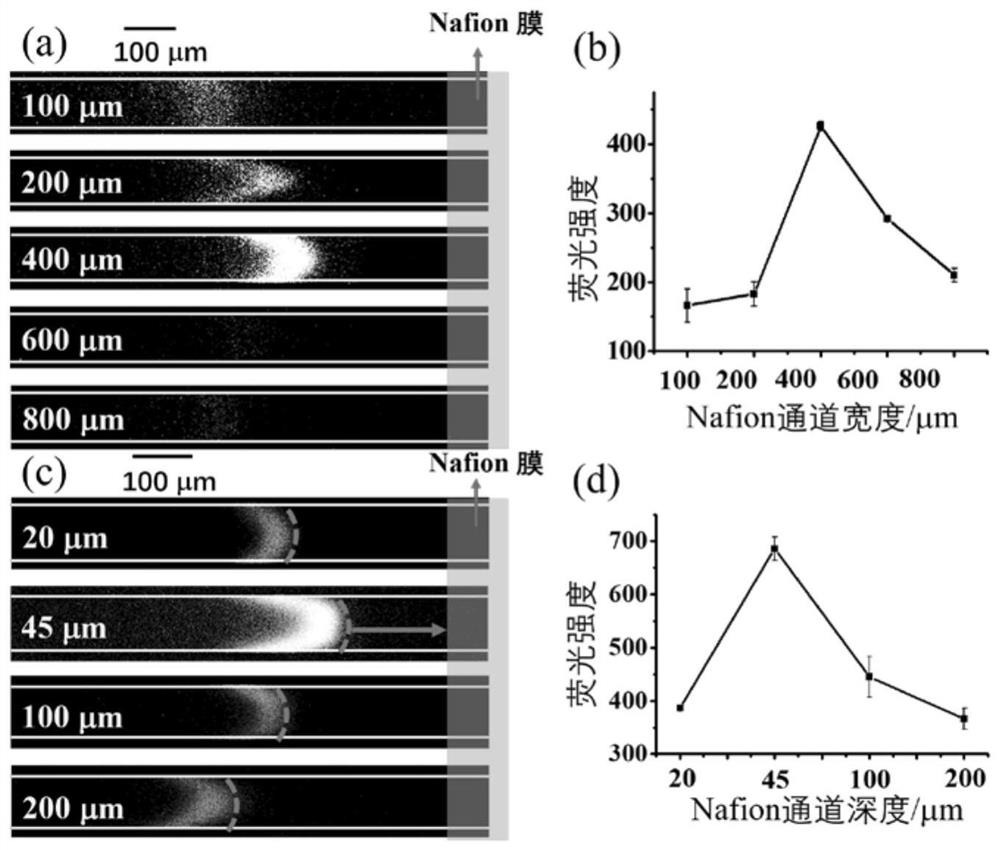

[0037] 1) Fabrication of a microfluidic chip: In this embodiment, a PDMS (polydimethylsiloxane) microfluidic chip is used, which contains a Nafion membrane, and the Nafion membrane is perpendicular to the channel in the microfluidic chip. The specific fabrication process of the microfluidic chip is as follows:

[0038]Treat the silicon wafer with trimethylchlorosilane in a vacuum desiccator to avoid adhesion of PDMS to the silicon wafer mold. PDMS and curing agent are fully mixed at a weight ratio of 10:1, placed in a vacuum desiccator for vacuum degassing until the bubbles completely disappear, and then slowly poured on the silicon wafer to avoid bubbles. Then cure on a heating plate at 95°C for 2-3h, and then peel off the PDMS from the silicon wafer, so that the microstructure on the silicon wafer is transferred to the elastic PDMS, and holes are punched at the inlet and outlet . Then make Nafion membrane on t...

Embodiment 2

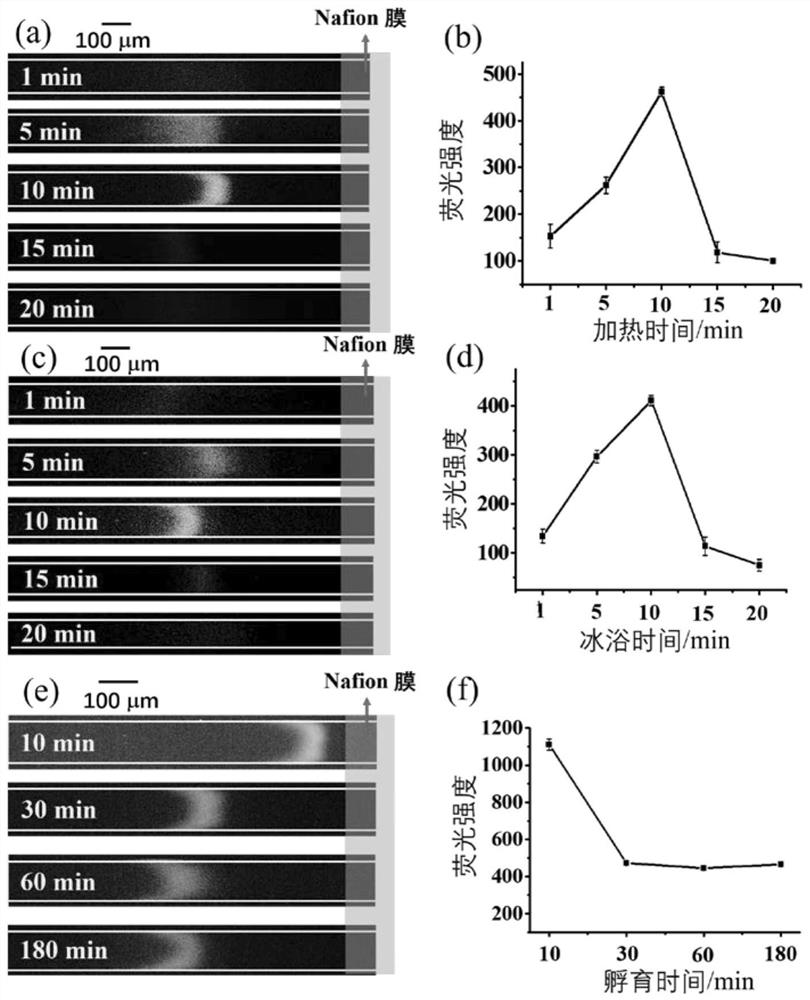

[0044] Example 2 A method for detecting endotoxin (optimization of heating time, ice bath time and incubation time with rGO of LPS aptamer)

[0045] 1) Fabrication of the microfluidic chip: same as in Example 1

[0046] 2) Sample processing:

[0047] Preparation of LPS standard solution: Prepare a standard stock solution (1 mg / mL) of LPS with ultrapure water. LPS solutions with different concentrations were prepared by diluting stock solutions appropriately. In this embodiment, 10 pM LPS solution is used as the subsequent sample to be tested.

[0048] Take the 6-FAM (6-carboxyfluorescein)-labeled LPS aptamer (designed and synthesized by the biological company) and heat it in a 95°C water bath for 1, 5, 10, 12, and 20 minutes, and then immediately put it into 15°C water and ice-bath it separately. 1, 5, 10, 12, 20 minutes. Then it was mixed with the sample to be tested (10 pM LPS solution, the final concentration of LPS was 1 pM) and the first incubation was continued at 15...

Embodiment 3

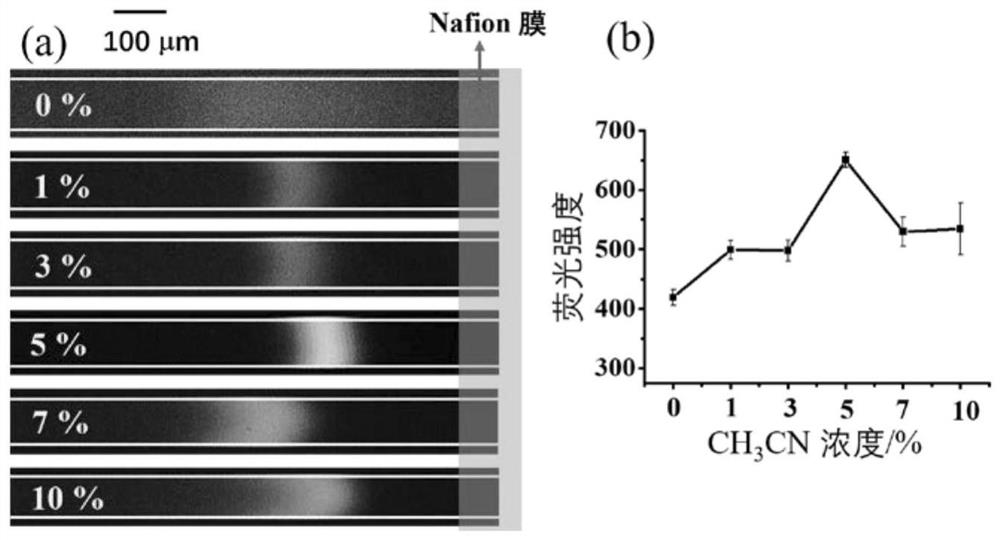

[0053] Embodiment 3 A kind of method for detecting endotoxin (CH 3 CN effect test)

[0054] 1) Fabrication of the microfluidic chip: same as in Example 1

[0055] 2) Sample processing:

[0056] Preparation of LPS spiked serum: Collect serum from healthy people, add LPS standard stock solution of known concentration in Example 2, heat the mixture in boiling water at 95°C for 5 minutes to obtain LPS spiked serum, add the spiked serum to SDS 10mg / mL, β-mercaptoethanol 5% v / v, and heated in boiling water at 95°C for 5min, as the subsequent sample to be tested.

[0057] Take the 6-FAM (6-carboxyfluorescein)-labeled LPS aptamer (designed and synthesized by Biological Company) and heat it in a water bath at 95°C for 10 minutes, and then put it into water at 15°C for 10 minutes on ice respectively. Then mix it with the above-mentioned sample to be tested and continue to incubate for the first time at 15° C. for 10 min. Then, the reduced graphene oxide rGO and 1×TBE buffer were add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com