Methods for preparing polymer membranes on porous supports

A technology of porous scaffolds and polymer membranes, applied in chemical instruments and methods, membranes, membrane technology, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Preparation of prepolymer emulsion solution

[0054] For use in emulsion deposition, a prepolymer coating solution is prepared. A polymer precursor solution was prepared comprising 25% by weight DENO / D400 oligomer dissolved in toluene. Then, 8 g of the polymer precursor solution and 10 g of an aqueous 10 wt % sodium dodecyl sulfate (SDS) solution were combined. The mixture was shaken and vortexed to form a white viscous slurry, which was then diluted with 182 grams of deionized water to yield 200 mL of a prepolymer coating solution comprising 0.5 wt% SDS and 4 wt% organic phase. A magnetic stir bar was added and the emulsion was stirred vigorously for 3-16 hours before being used to coat the porous scaffold.

Embodiment 2

[0056] Effect of Surfactant Content on Emulsion Coated Polymer Films

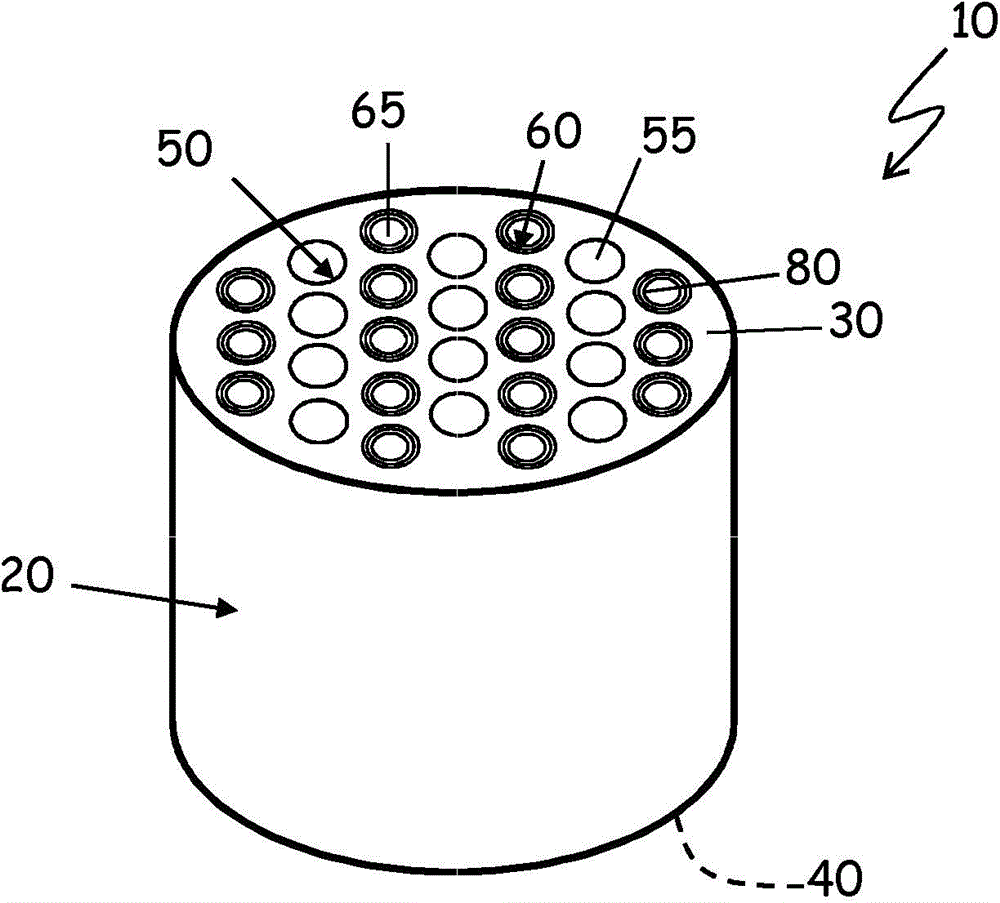

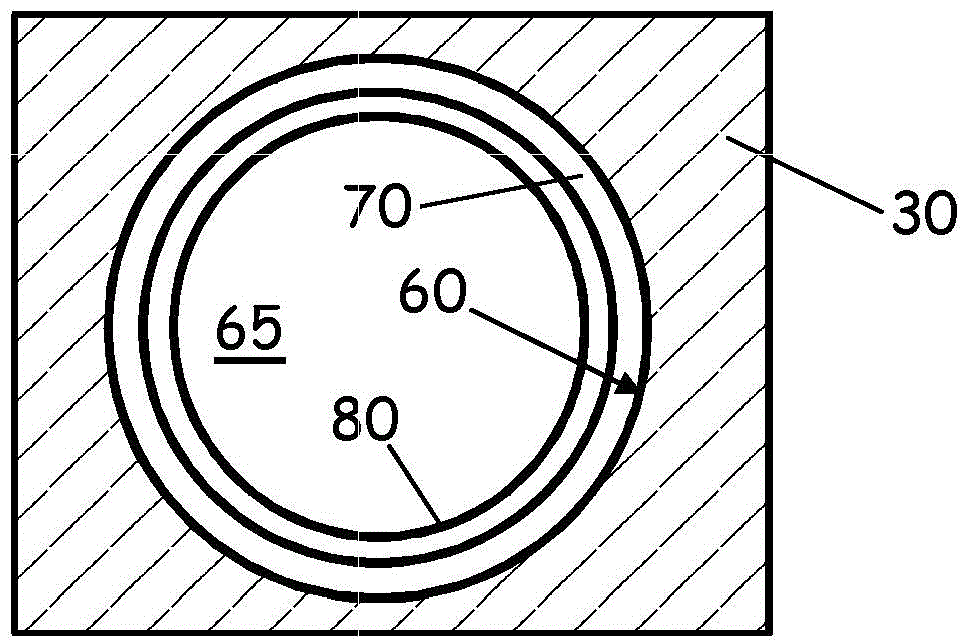

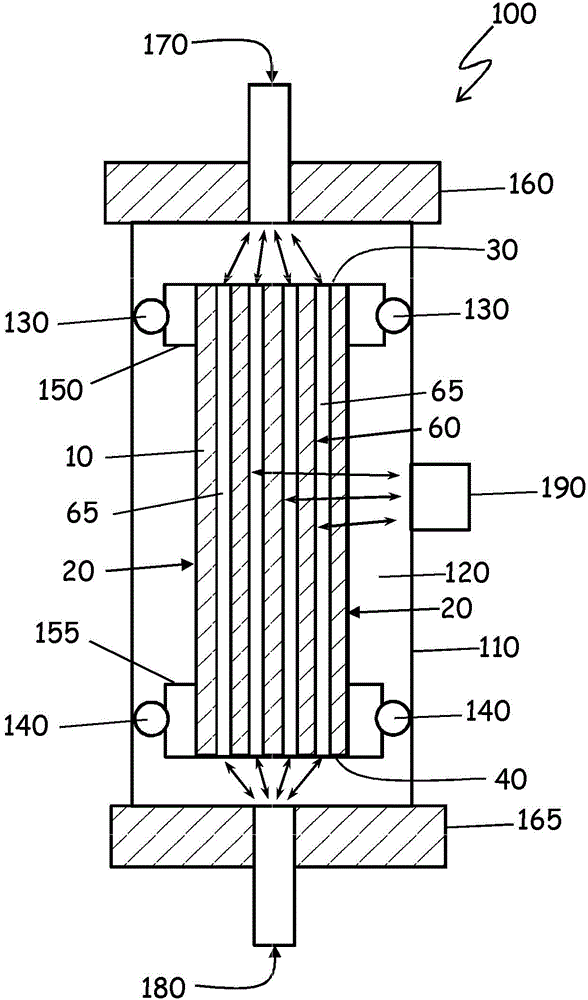

[0057] exist image 3 A polymer film of DENO / D400 was prepared on a porous support using the emulsion prepared as described in Example 1 in a coating vessel. Specifically, emulsions containing 0.1 wt. % SDS, 0.5 wt. % SDS, and 5.0 wt. % SDS were tested to evaluate the effect of surfactant content in the emulsion on the quality of the polymer film. The emulsion coating was applied to two pre-coated porous scaffolds with average pore sizes of 0.2 μm and 0.01 μm. Average pore sizes of 0.01 μm and 0.2 μm were obtained by coating precoat slips of different particle sizes onto bulk porous scaffolds used as-is.

[0058] The membrane channels of the porous scaffold are filled with emulsion from top to bottom, and the emulsion is allowed to filter through the porous scaffold. The coatings were evaluated by drying the porous scaffolds by leaving them at room temperature (25° C.) for 16 hours, followed by vacuum te...

Embodiment 3

[0064] Slurry Coated Polymer Film

[0065] Additional DENO / D400 polymer membranes were applied to porous scaffolds with average pore sizes of 0.2 μm and 0.01 μm by slip coating. The slip (12.5% by weight DENO / D400 in toluene) was coated with a prepolymer coating solution, filling the channels of the porous scaffold from bottom to top. A back pressure of about 60 kPa is applied from the outer wall into the channel. Allow the coating slip to remain in the channel for 2 minutes, then drain. A brief vacuum (10 seconds) was applied to drive excess coating solution from the channel. The porous scaffolds were removed from the coating containers, allowed to dry overnight (16 hours), and cured at 150°C (4-18 hours under nitrogen). Examine the porous scaffold to determine the mass gain and vacuum-tightness of the polymer membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com