Machining technology for ultrasonic welding copper strip

A technology of ultrasonic welding and processing technology, applied in metal processing equipment, manufacturing tools, metal rolling, etc., can solve the problems of poor uniformity of copper strip surface roughness, easy peeling, scratches on copper strip surface, etc., and achieve processing technology design Reasonable, uniform surface roughness, the effect of increasing surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

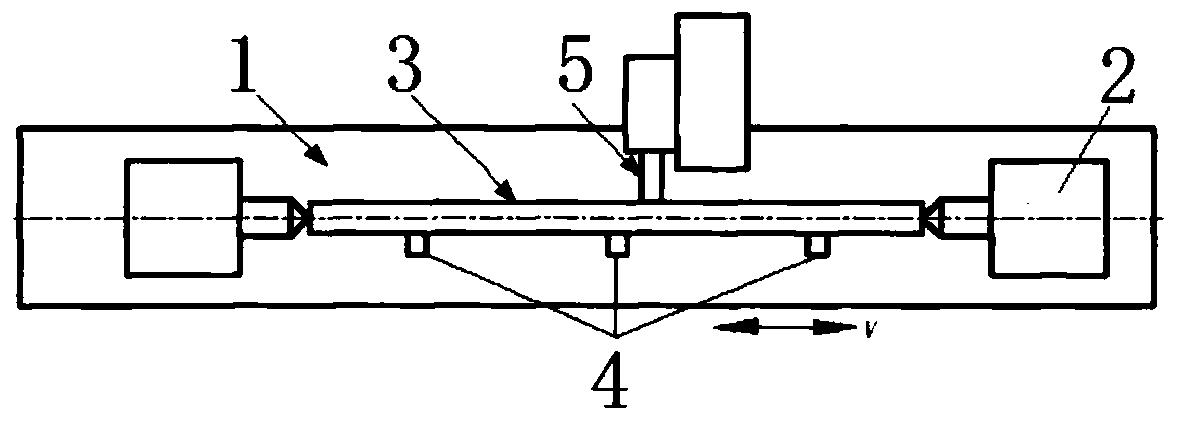

Image

Examples

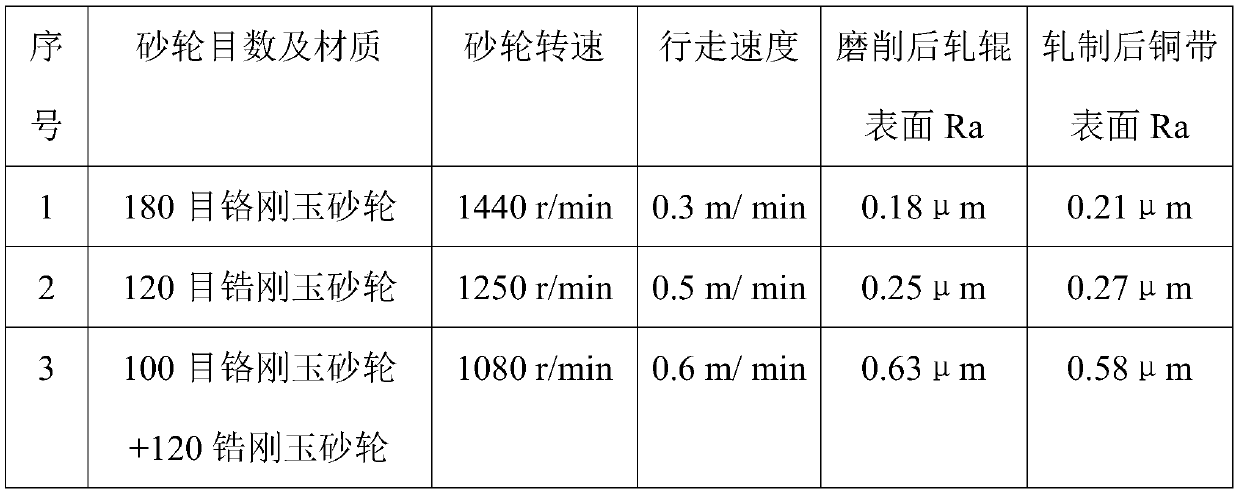

specific example

[0034] The processing technology includes the following steps:

[0035] 1) Grinding the surface roughness of the roll by the grinding wheel:

[0036] 1a: Install 100 mesh chrome corundum grinding wheel - adjust the position of the grinding wheel - adjust the position of the roll bracket - grind the surface of the roll - clean the surface of the roll - measure the surface roughness of the roll after cleaning the surface of the roll;

[0037] 1b: Replace with a 120-mesh zirconium corundum grinding wheel - grind the roll surface again - clean the roll surface - obtain a roll with a surface roughness of Ra0.6-0.7μm;

[0038] Among them, in the roller grinding process, the grinding wheel speed is controlled at 1080r / min, and the working walking speed is controlled at 0.6m / min; the surface roughness of the copper strip is rolled by the roller after the grinding process, and the surface roughness is Ra0.5-0.65 μm copper strip, the surface roughness of the copper strip is uniform, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com