Electric connector cable outlet vulcanization sealing method

An electrical connector and cable outlet technology is applied in the field of vulcanization and sealing of cables at the cable outlet of the electrical connector, which can solve the problems of low application field and limited structure of the cable outlet sealing of the electrical connector, and achieves a simple structure and improved finished products. High efficiency and practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] A method for vulcanizing and sealing cables at outlets of electrical connectors, comprising the following steps in sequence:

[0031] Step 1: Vulcanized surface pretreatment: Grind the surface of the cable pre-vulcanized sealing area with coarse sandpaper and fine sandpaper in sequence, and the surface roughness of the polished cable is uniform, and then use a cotton swab to soak acetone to clean the vulcanized surface dust or grease, and air dry naturally;

[0032] Step 2: Surface treatment agent treatment: apply the treatment agent on the pre-vulcanized surface treated in step 1 by brushing method and dry the treatment agent at room temperature, and keep the cleanliness of the pre-vulcanized surface. Apply 4 layers evenly on the pre-vulcanized surface with a brush, the thickness of the treatment agent on the pre-vulcanized surface is 17.5 μm, and the drying time is 65 minutes;

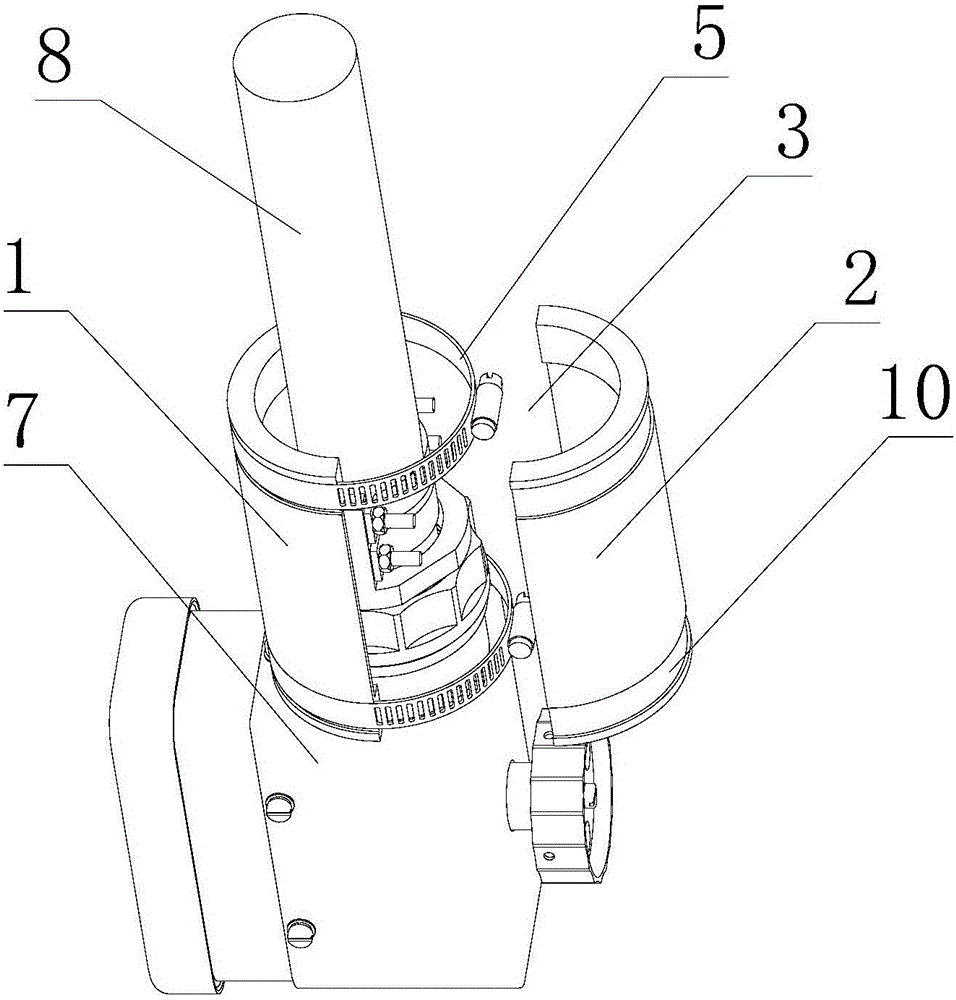

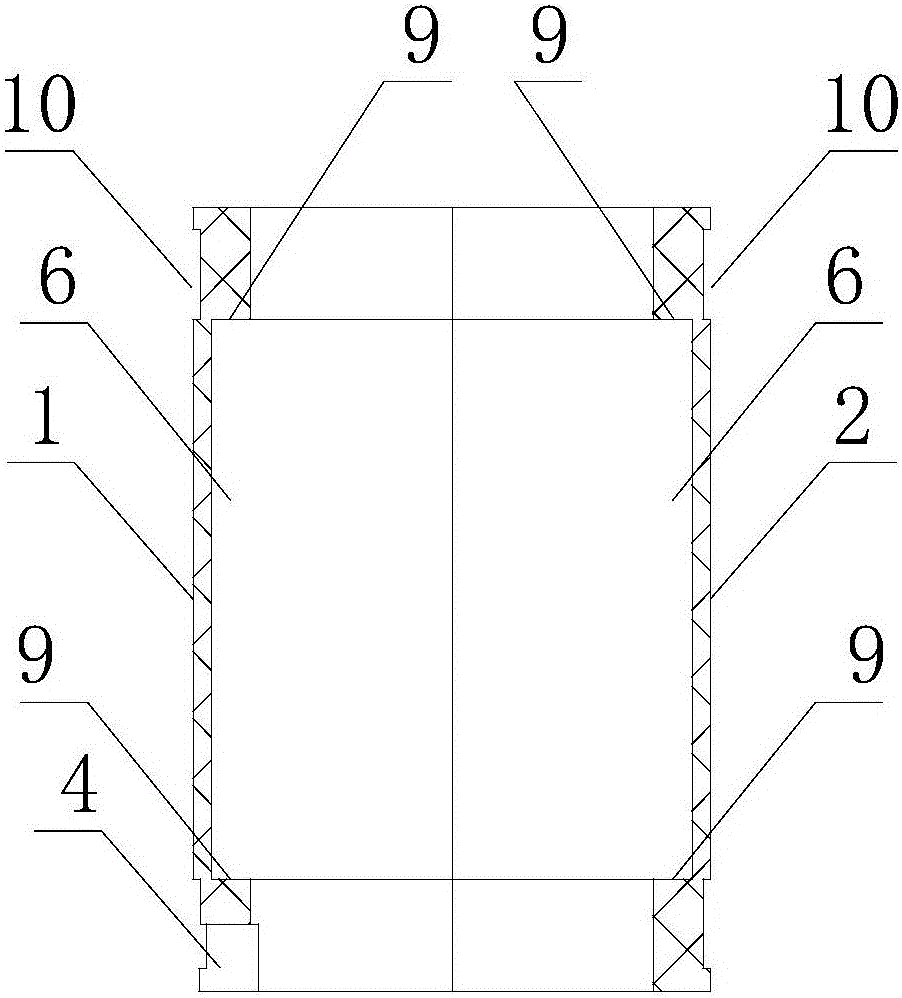

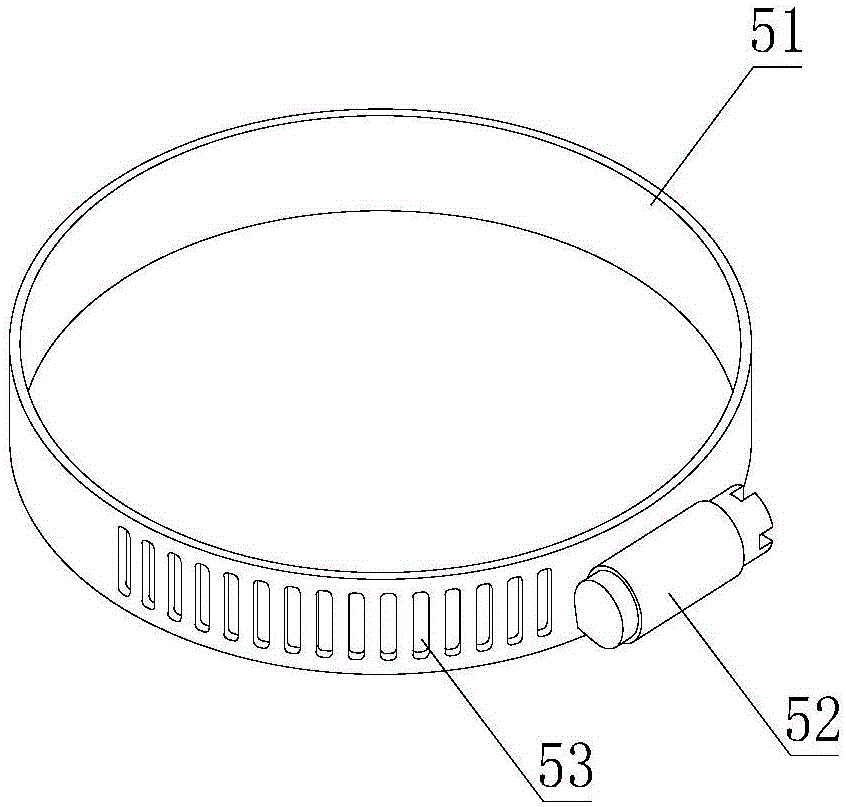

[0033] Step 3: Mold installation: install the cable treated in step 2 in the mold to ensu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com