LNG ultra-low temperature top-mounting type ball valve seat capable of achieving pre-tightening force fine tuning and on-line disassembling

A technology of ultra-low temperature and pre-tightening force, which is applied in the direction of valve details, valve devices, valve housing structure, etc., can solve problems such as economic losses, potential safety hazards of LNG projects, and inability to achieve effective sealing of downstream valve seats, so as to achieve safe and reliable sealing performance, Automatic pressure relief is safe and reliable, and the effect of increasing sealing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

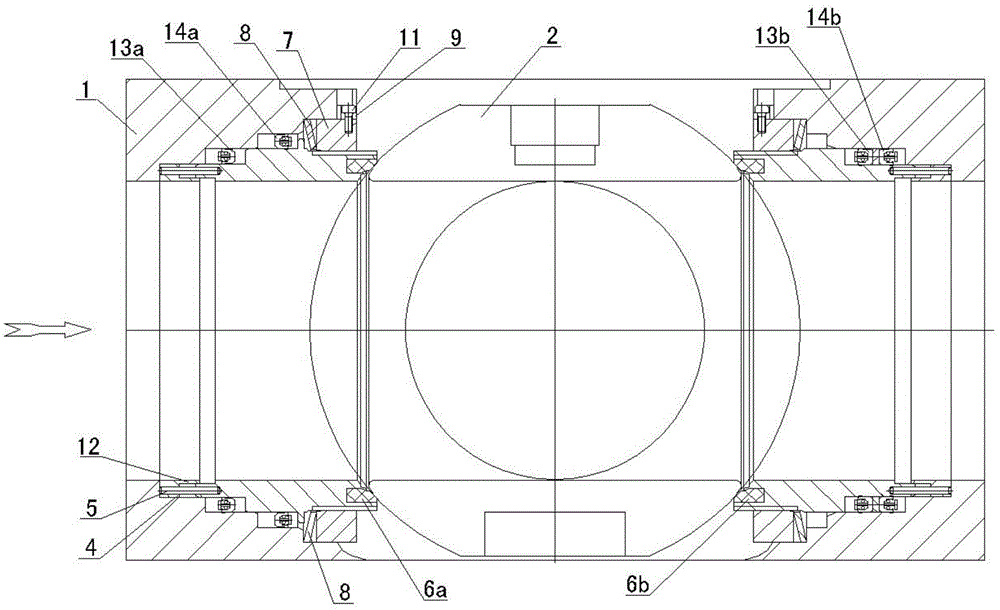

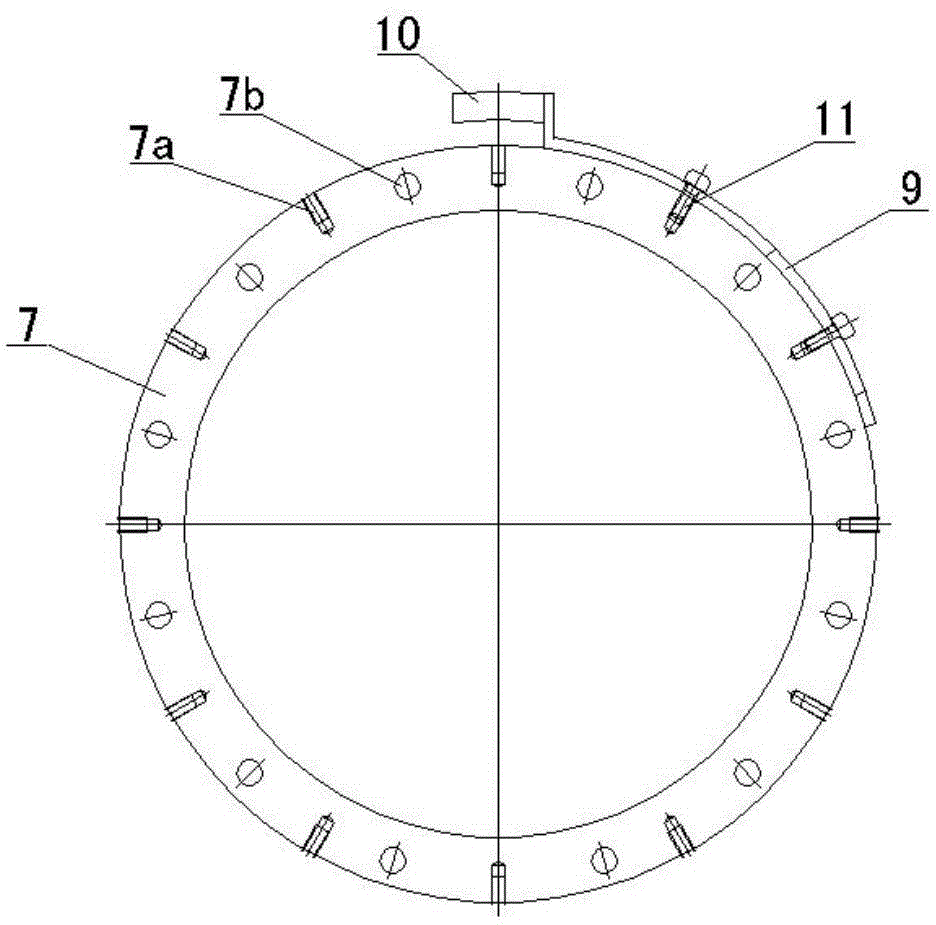

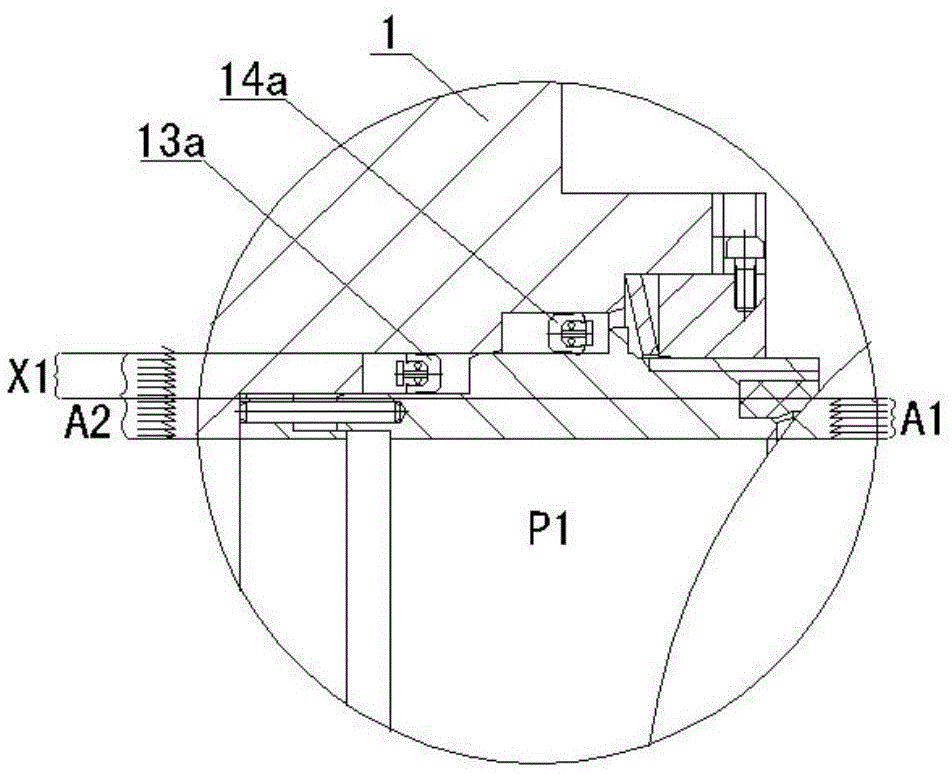

[0031] In this embodiment, the structure of the LNG ultra-low temperature top-mounted ball valve seat that can be fine-tuned and dismantled online is set as follows:

[0032] see figure 1 , In the valve body 1, the valve seat supports are arranged symmetrically on the upstream side and the downstream side of the valve core ball 2, and the symmetrically arranged valve seat supports are respectively the upstream valve seat support 3a on the upstream side and the downstream valve seat support on the downstream side Seat support 3b, positioning pin 5 is set between the tail end surface of the valve seat support and the front end surface of the valve seat fixing ring 4, and the valve seat fixing ring 4 is fixed in the valve body 1 by spot welding.

[0033] Such as figure 1 As shown, the valve seat sealing ring used to form an annular seal between the valve seat support and the surface of the valve core ball 2 includes an upstream valve seat sealing ring 6a and a downstream valve s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com