Test system and test method for water tightness test of tunnel deformation joint waterstop

A test system, deformation joint technology, used in highway and bridge engineering, construction engineering, port engineering, and can solve problems such as damage to waterstops and leakage of bolt holes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

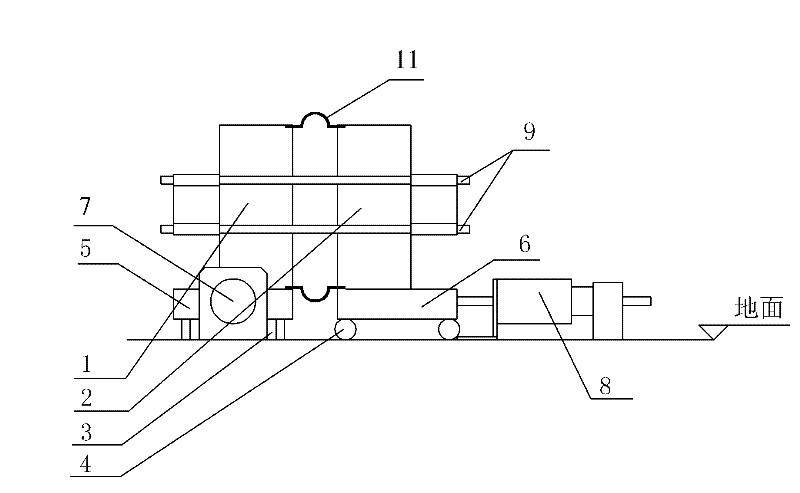

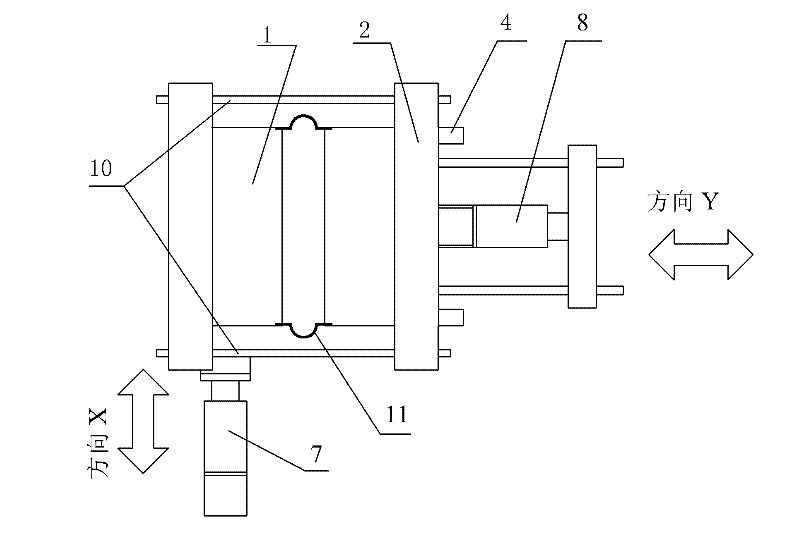

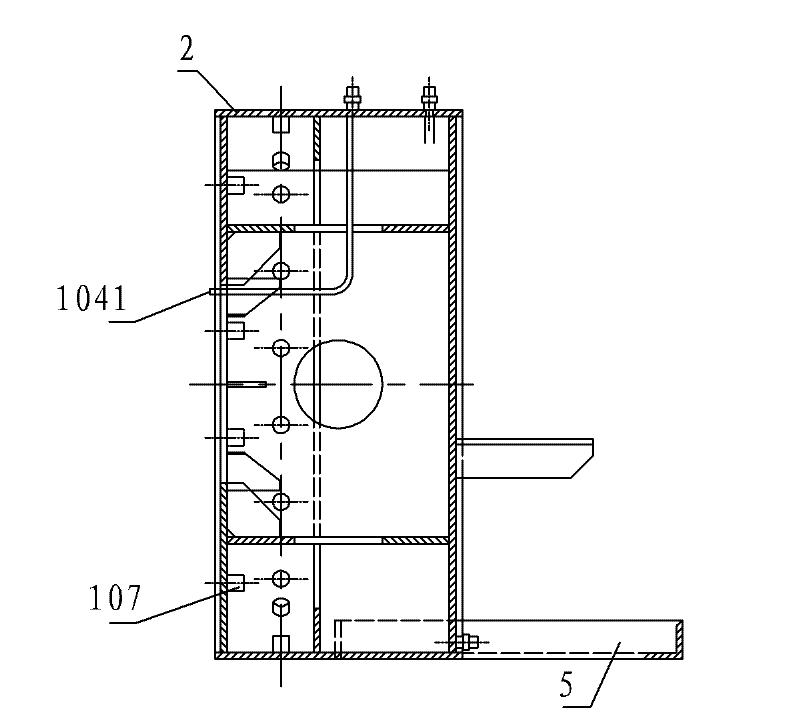

[0035] The whole system of the present invention mainly includes steel boxes 1 and 2, a steel structure test bench, a pneumatic test bench, a hydraulic test bench, an air compressor, and a set of long-distance automatic observation and reading equipment and a safety protection device. Such as figure 1 , figure 2 As shown, the steel structure test bench is the load-bearing and operating platform of the steel box. The steel boxes 1 and 2 are placed on the base 5 and 6 respectively, and the base 5 is installed on the horizontal guide rail 3, which can be moved along the horizontal guide rail in the X direction. To move, the base 6 is installed on the longitudinal guide rail 4 and can move in the Y direction along the longitudinal guide rail. The jack 7 is used to drive the steel box 1 and its base 5 to move along the X direction, and the jack 8 is used to drive the steel box 2 and its base 6 to move along the Y direction. Positioning pull bar 9,10 is used for demarcating the d...

Embodiment 2

[0048] As in the installation steps of Example 1, the expandable waterstop is fixed between the steel boxes of the test system through the fastening device. Such as Figure 6 As shown, start the test of the expandable waterstop, first install the waterstop to be tested, and then check the test bench; adjust the displacement of the steel box to make the opening amount reach the preset value; pressurize the air compressor; give the expandable waterstop Add air to the hose bladder; inject water into the steel box; check the water pressure equipment; pressurize the air compressor; add the first water pressure; stabilize the pressure, maintain the pressure and read data; add the next level of water pressure; end test, or enter the next water pressure cycle test, and then end the test of the opening amount.

Embodiment 3

[0050] This example is an application example, which is a watertight model test of the deformation joint of the Hong Kong-Zhuhai-Macao Bridge pipe joint.

[0051] This invention has been successfully applied in the "Watertightness Model Test of the Pipe Joint Deformation Joints of the Hong Kong-Zhuhai-Macao Bridge". The maximum working water pressure is 0.48MPa, the safety factor is 2.5, and the maximum water pressure applied during the test is 1.2MPa.

[0052] The test implementation steps are as follows: adjust the steel box model according to the preset deformation combination and fix it, apply the preset water pressure to the steel box-waterstop cavity by using the pressurization equipment, keep the pressure for 2 hours, observe the pressure drop, If the pressure drop is not greater than 5%, the waterstop under the combination of the amount of deformation and the applied water pressure passes the watertightness test.

[0053] The appearance qualification standard of the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com