Honed embossed adhesive tape basilemma and production method thereof

A production method and embossing technology, applied in the field of unstretched matte embossed tape base film, can solve the problems of large difference in longitudinal and transverse tearing properties, poor coating performance on the surface of the film, poor appearance effect and hand feeling, etc. The effect of good longitudinal and transverse tear resistance, uniform surface roughness, and excellent gluing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

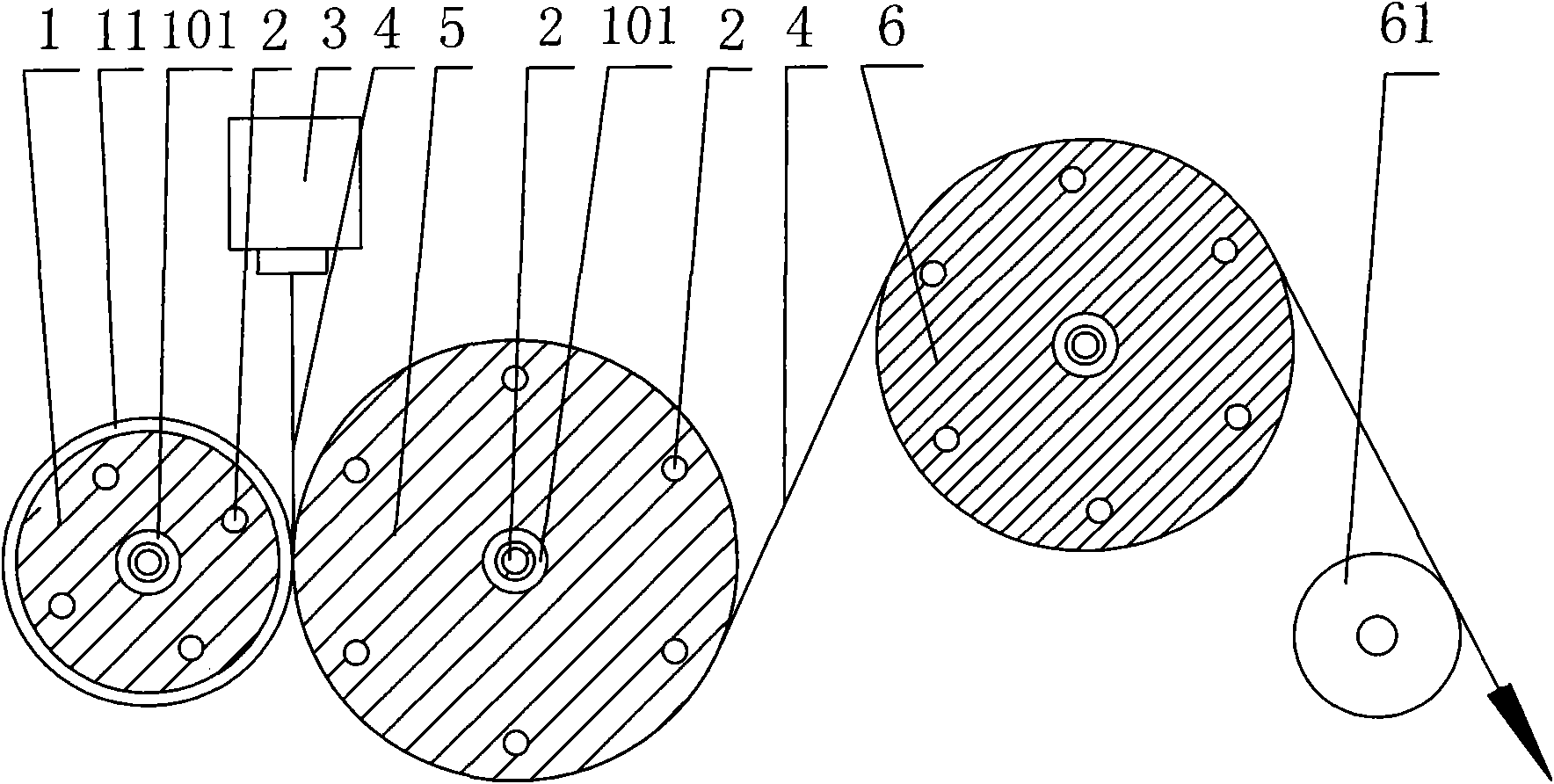

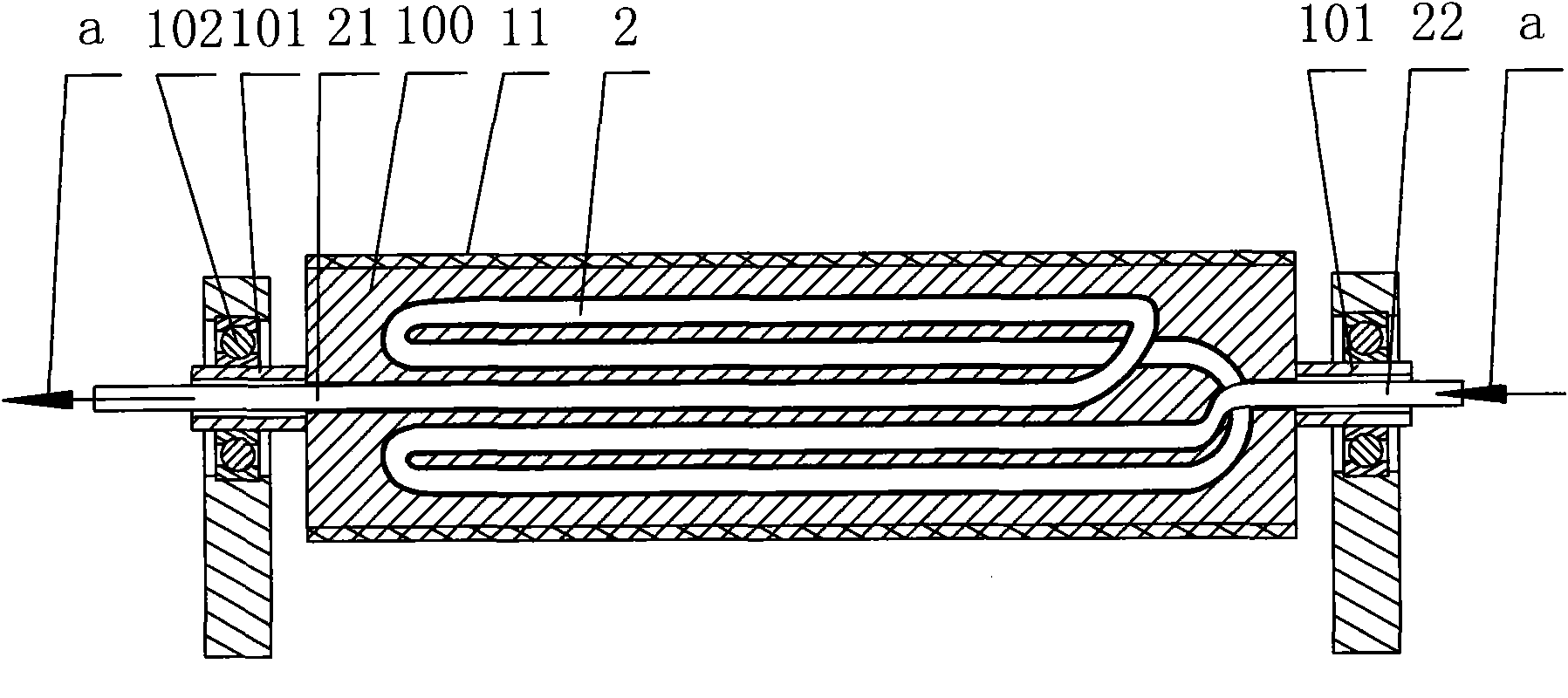

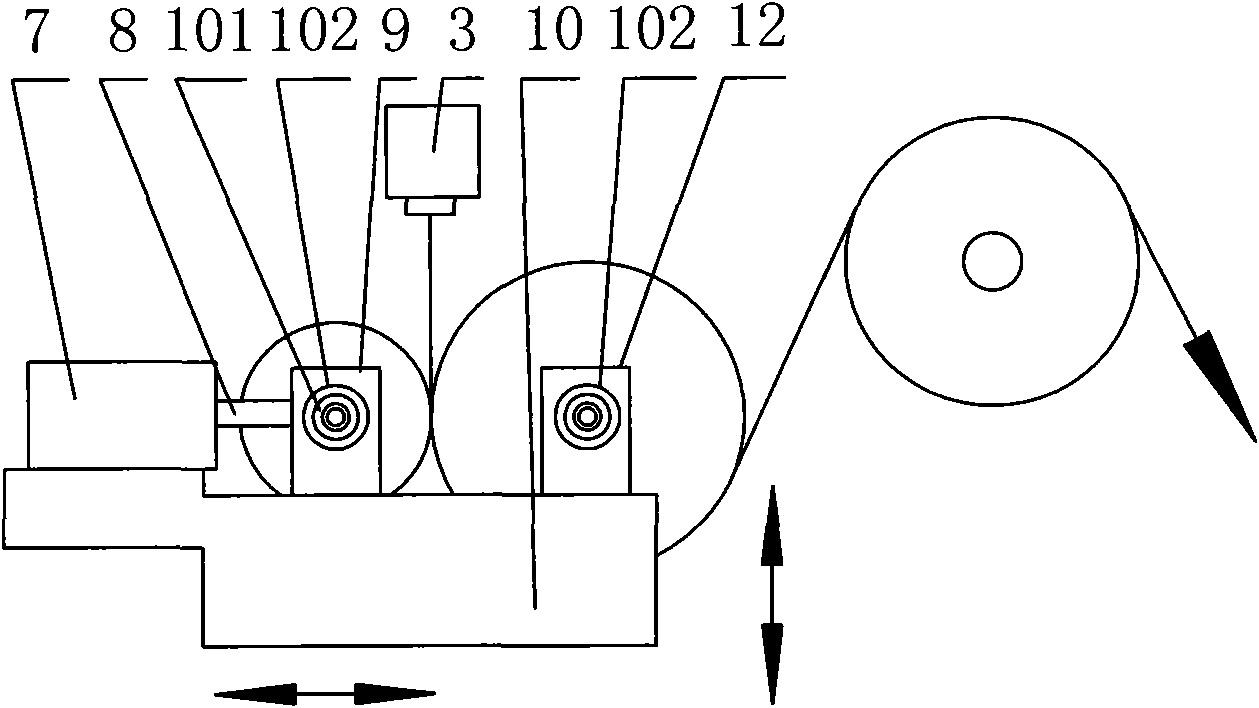

Method used

Image

Examples

Embodiment 2

[0031]Embodiment 2: production line speed is 60m / min, and polypropylene resin is put into the hopper of screw extruder, after extruder is fully melted and plasticized, the melt that forms molten state is from the T-type die head (die head) of extruder Temperature 210 ~ 240 ℃) extrusion; the extruded polyolefin resin melt immediately enters the gap between the rollers formed by the rubber roller and the pressure roller. The surface roughness Ra of the rubber roller is 40μinch, and the roller surface The temperature is controlled at 60°C, the surface roughness Ra value of the pressure roller is 200μinch, the surface temperature of the roller is controlled at 40°C, the pressure between the rollers is 2bar, the roller is initially cooled to the melt, and the roller is melted at the same time. Hot pressing to obtain an embossed film with different embossments on the front and back sides, and the embossed film is then passed through a cooling roller with a surface temperature of 20°C...

Embodiment 3

[0032] Embodiment 3: production line speed is 60m / min, and polypropylene resin is put into the hopper of screw extruder, after extruder is fully melted and plasticized, the molten melt that forms molten state is from the T-type die head (die head) of extruder Temperature 210~240 ℃) extrusion; the extruded polyolefin resin melt immediately enters the gap between the rollers formed by the rubber roller and the pressure roller. The surface roughness Ra value of the rubber roller is 60μinch, and the surface The temperature is controlled at 55°C, the surface roughness Ra value of the pressure roller is 150μinch, the surface temperature of the roller is controlled at 30°C, the pressure between the rollers is 1bar, the roller is initially cooled to the melt, and the roller is melted at the same time. Hot pressing to obtain an embossed film with different embossments on the front and back sides, and the embossed film is then passed through a cooling roller with a surface temperature of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com