Cooking utensil having improved non-stick characteristics and method for manufacturing same

A technology for cooking utensils and properties, applied to cooking utensils with improved non-stick properties and used in the field of manufacturing the same, can solve the problem that the heat resistance of cooking utensils cannot be sufficiently satisfied, the non-stick properties and durability cannot be sufficiently satisfied at the same time, low Heat resistance and other problems, to achieve the effect of improving non-stick properties, preventing the decline of non-stick properties, and solving environmental problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

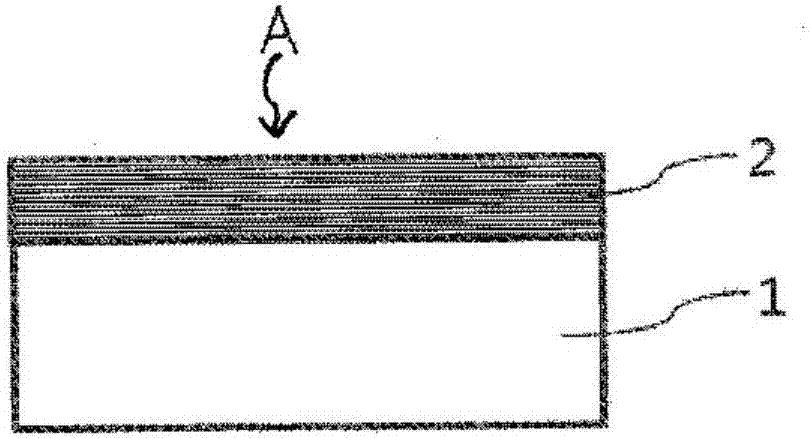

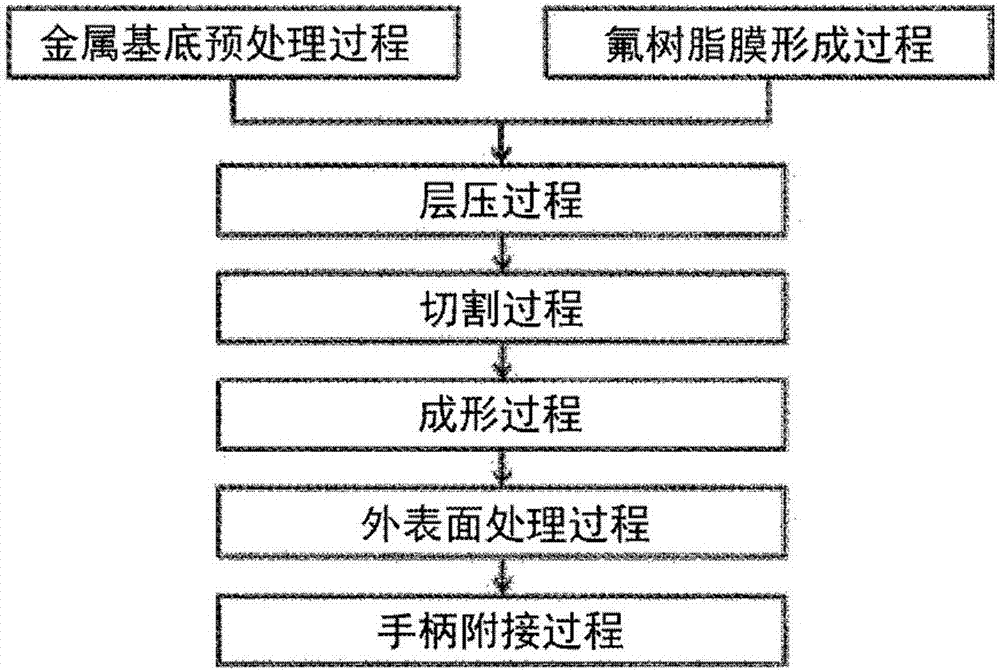

[0041]First, a multilayer polytetrafluoroethylene (PTFE) film having a thickness deviation of 1.3 μm and a surface roughness of 0.65 μm was formed by a casting method.

[0042] Meanwhile, the surface of the plate-like metal substrate 1 was pretreated, and then a polytetrafluoroethylene (PTFE) film was laminated on the pretreated surface of the metal substrate 1 to prepare a laminate.

[0043] Next, the laminated body was cut into a circular shape, and then shaped into a cookware form, and the shaped cookware was subjected to an outer surface treatment to manufacture a cookware main body A.

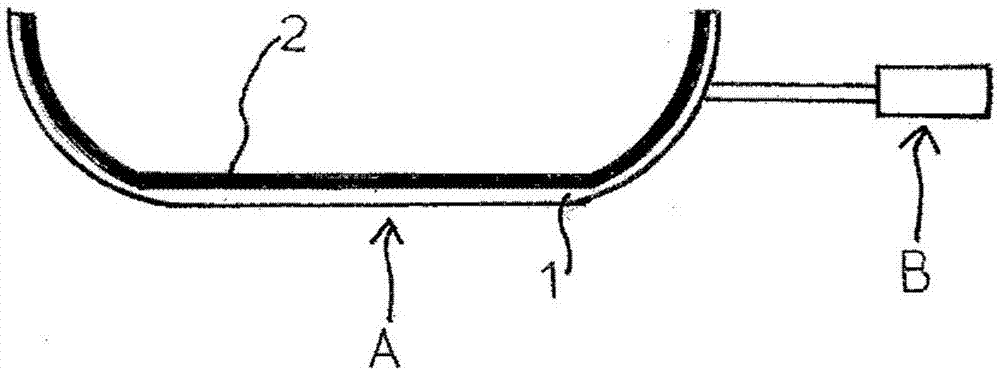

[0044] Thereafter, the cookware handle B is attached to the cookware body A manufactured as described above to manufacture the figure 1 The cooking utensil (frying pan) shown in .

[0045] The thickness variation, surface roughness, and number of times allowed to fry eggs of the fluororesin film formed on the inner bottom surface of the manufactured cooking utensil (frying pan) were measu...

Embodiment 2

[0048] First, a polytetrafluoroethylene (PTFE) film having a thickness deviation of 4 μm and a surface roughness of 1.6 μm was formed by a dicing method.

[0049] Meanwhile, the surface of the plate-like metal base 1 was pretreated, then cut into a circular shape, and then polytetrafluoroethylene (PTFE) was laminated thereto to prepare a laminate.

[0050] Next, the laminate is formed into a cooker, and the shaped cooker is subjected to an outer surface treatment to manufacture a cooker body A.

[0051] Thereafter, the cookware handle B is attached to the cookware body A manufactured as described above to manufacture the figure 1 The cooking utensil (frying pan) shown in .

[0052] The thickness variation, surface roughness, and number of times allowed to fry eggs of the fluororesin film formed on the inner bottom surface of the manufactured cooking utensil (frying pan) were measured by the following evaluation methods, and the results are listed in Table 1 below.

[0053] T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com