Method for surface treatment of high-purity copper rotary target material

A surface treatment and rotating target technology, applied in the field of surface treatment, can solve the problems of low adhesion strength between copper and organic dielectric materials, large thin-film targets, low resistivity, etc., and improve coating quality, target yield, and surface roughness The uniformity of the degree and the effect of improving the adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

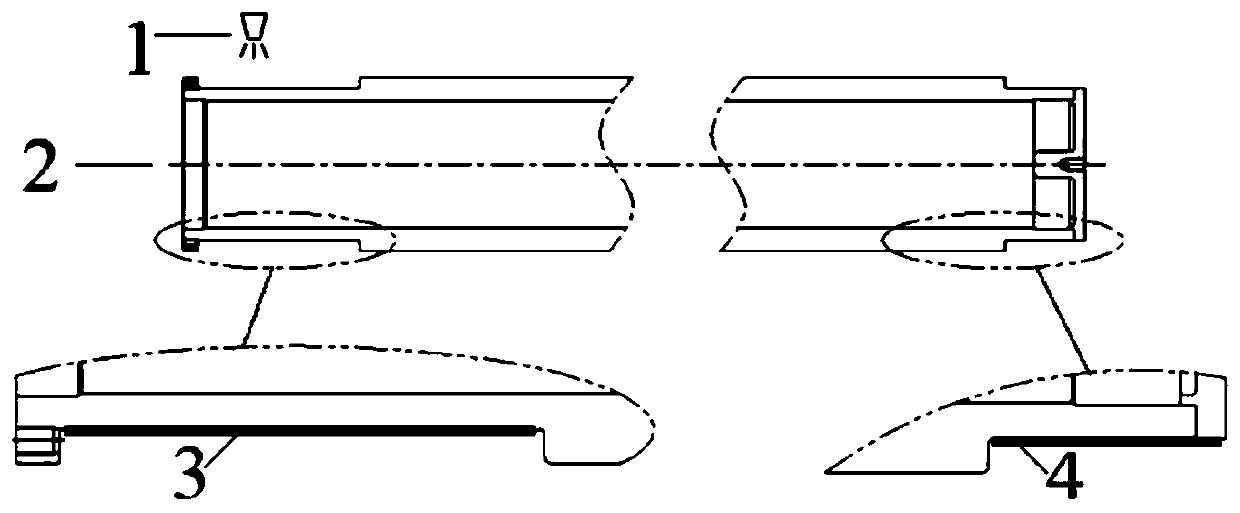

[0032] This embodiment provides a method for surface treatment of a high-purity copper rotating target. The sandblasting position in the method is as follows: figure 1As shown, the method includes: performing a shielding treatment on the high-purity copper rotating target, and performing sandblasting after the shielding treatment is completed;

[0033] Wherein, the masking process is to use adhesive tape to shield the sputtering surfaces and sides of the target at both ends; the adhesive tape in the masking process includes insulating and heat-resistant tape; the operating pressure in the sandblasting is 3MPa; The sand grains used in the sandblasting are white corundum; the grain size of the sand grains used in the sandblasting is 0.35mm; the distance between the sandblasting gun head and the surface of the target material in the sandblasting is 15mm; the sandblasting is performed twice.

[0034] After the sandblasting is completed, the roughness test of the sandblasting surfa...

Embodiment 2

[0036] This embodiment provides a method for surface treatment of a high-purity copper rotating target, the method comprising: performing shielding treatment on the high-purity copper rotating target, and performing sandblasting after the shielding treatment is completed;

[0037] Wherein, the masking process is to use adhesive tape to shield the sputtering surfaces and sides of the target at both ends; the adhesive tape in the masking process includes insulating and heat-resistant tape; the operating pressure in the sandblasting is 4MPa; The sand grains used in the sandblasting are white corundum; the grain size of the sand grains used in the sandblasting is 0.4mm; the distance between the sandblasting gun head and the target surface in the sandblasting is 20mm; the sandblasting is carried out 3 times.

[0038] After sandblasting, the roughness test of the sandblasting surface was carried out, and the measured roughness Rz was 45-55 μm. The adsorption capacity of back-sputtere...

Embodiment 3

[0040] This embodiment provides a method for surface treatment of a high-purity copper rotating target, the method comprising: performing shielding treatment on the high-purity copper rotating target, and performing sandblasting after the shielding treatment is completed;

[0041] Wherein, the masking process is to use adhesive tape to shield the sputtering surfaces and sides of the two ends of the target; the adhesive tape in the masking process includes insulating and heat-resistant tape; the working pressure in the sandblasting is 5MPa; The sand grains used in the sandblasting are white corundum; the grain size of the sand grains used in the sandblasting is 0.45mm; the distance between the sandblasting gun head and the target surface in the sandblasting is 25mm; the sandblasting is performed twice.

[0042] After sandblasting, the roughness of the sandblasting surface was tested, and the measured roughness was 45-55μm. The adsorption capacity of back-sputtered objects was si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com