Patents

Literature

42results about How to "Change dwell time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Honed embossed adhesive tape basilemma and production method thereof

A honed embossed adhesive tape basilemma is made of pure polyolefin resin, the roughness of the front face Ra value is 20-60 mu inch, the roughness of the back face Ra value is 60-200 mu inch, the production method thereof comprises steps of melting and extruding, embossing and finishing. The honed embossed adhesive tape basilemma prepared by the invention has special honed effect, even surface roughness, even thickness stability, good longitudinal and transverse tear resistance, good anti-blocking effect and excellent gluing effect. The method of the invention does not change the inner structure of the basilemma material, thus not influencing the physical performance of the basilemma material, and being applicable to production of honed embossed adhesive tape basilemma and production of honed basilemma for other special uses.

Owner:湖北慧狮塑业股份有限公司

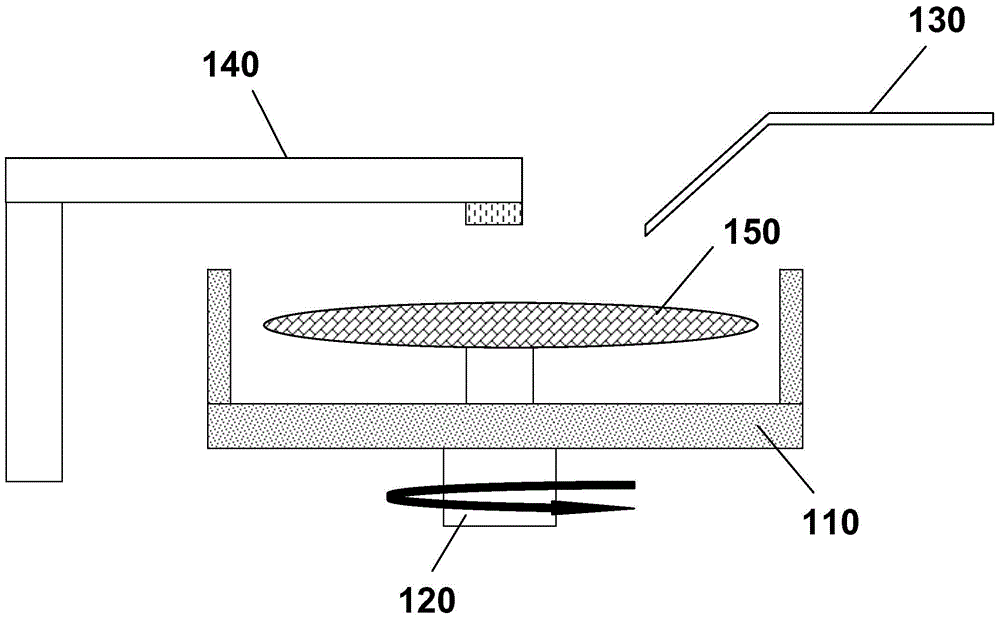

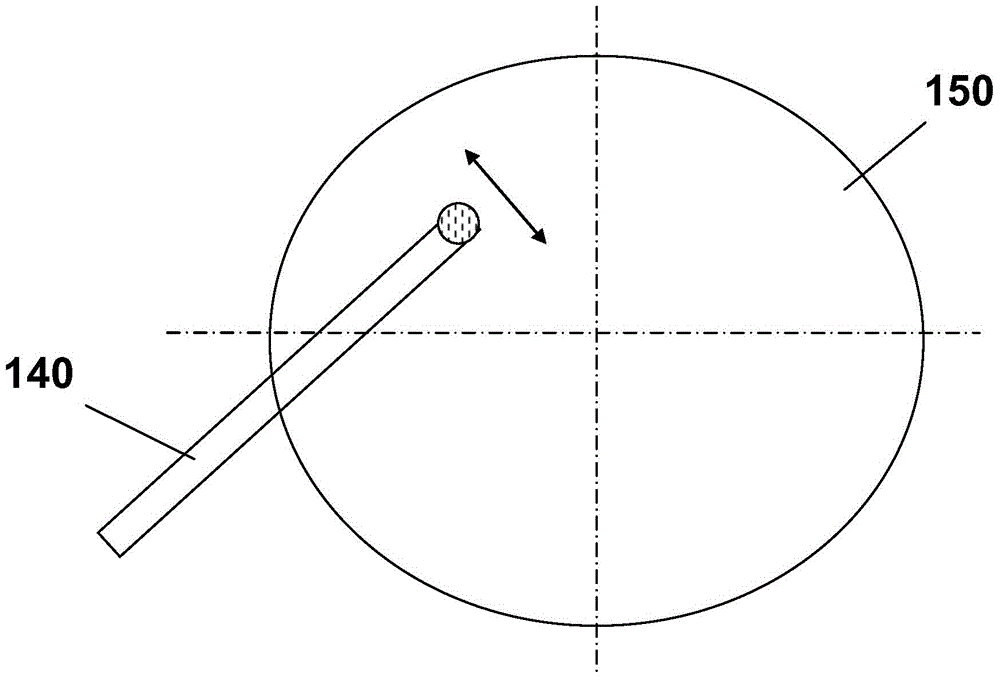

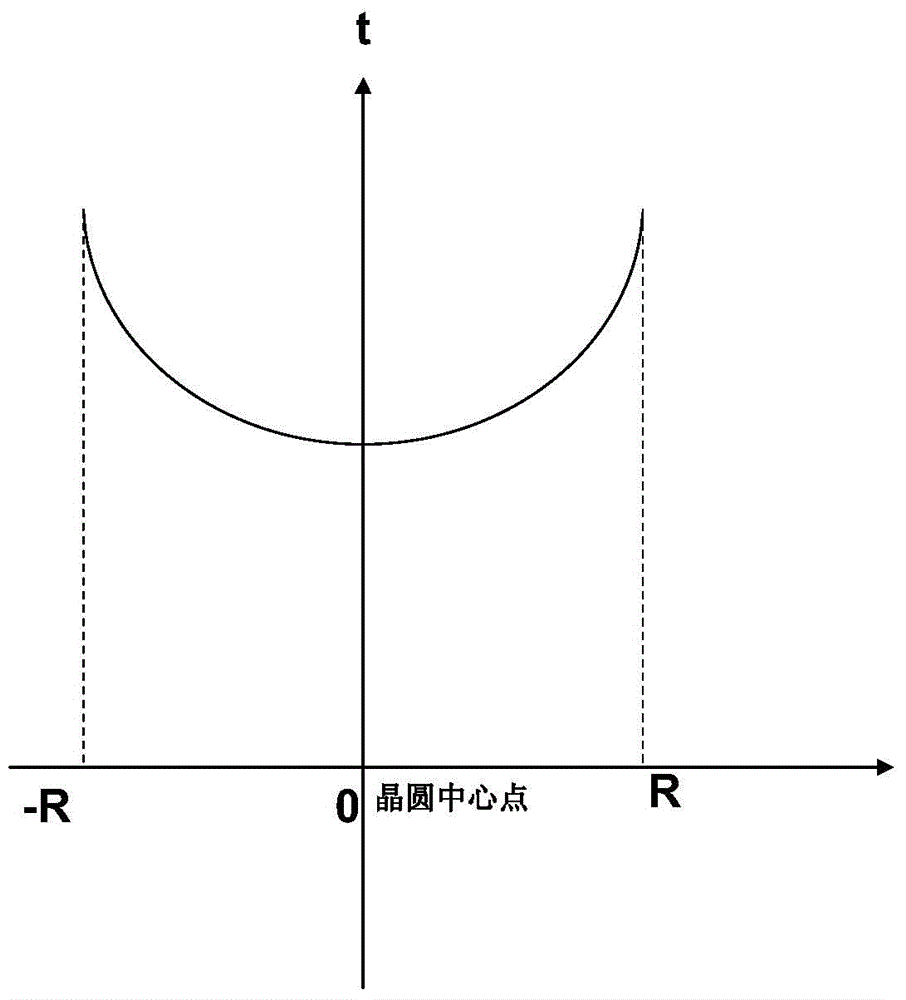

Wafer cleaning method

InactiveCN104900480AAvoid damageAvoid pittingSemiconductor/solid-state device manufacturingCleaning using liquidsEngineeringEnergy density

The invention discloses a wafer cleaning method. A mega-sonic generator is utilized to clean the surface of a wafer. The method comprises the steps that the wafer is rotated and the mega-sonic generator is enabled to move between the edge of the wafer and the center of the wafer in a reciprocating way, and energy density distribution of the mega-sonic generator on the surface of the wafer is changed in the movement process of the mega-sonic generator. The energy density distribution of the mega-sonic generator on the surface of the wafer is changed so that mega-sonic energy affected by the center point of the wafer is enabled to be consistent with mega-sonic energy affected by other positions of the wafer, and thus damage to the structural layer of the center point of the wafer in the cleaning process or generation of pits at the center of the wafer can be avoided.

Owner:ACM RES SHANGHAI

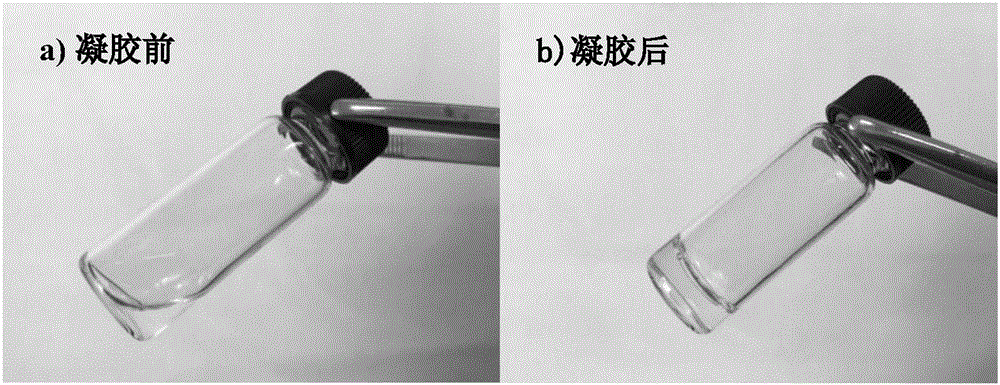

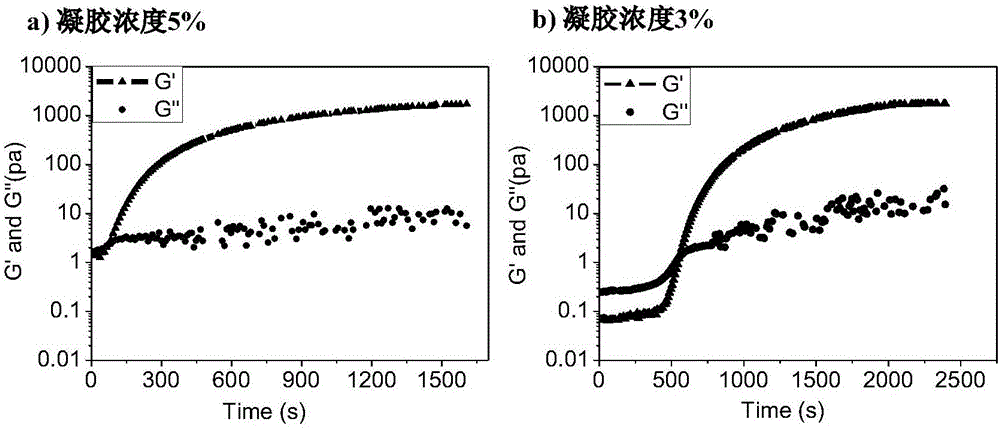

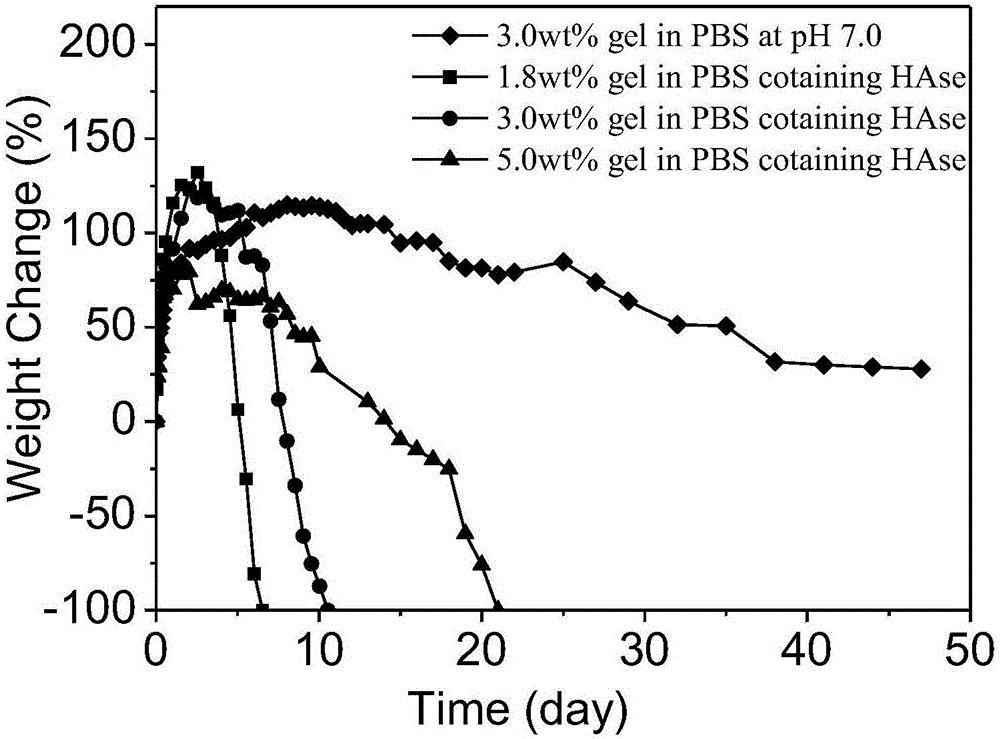

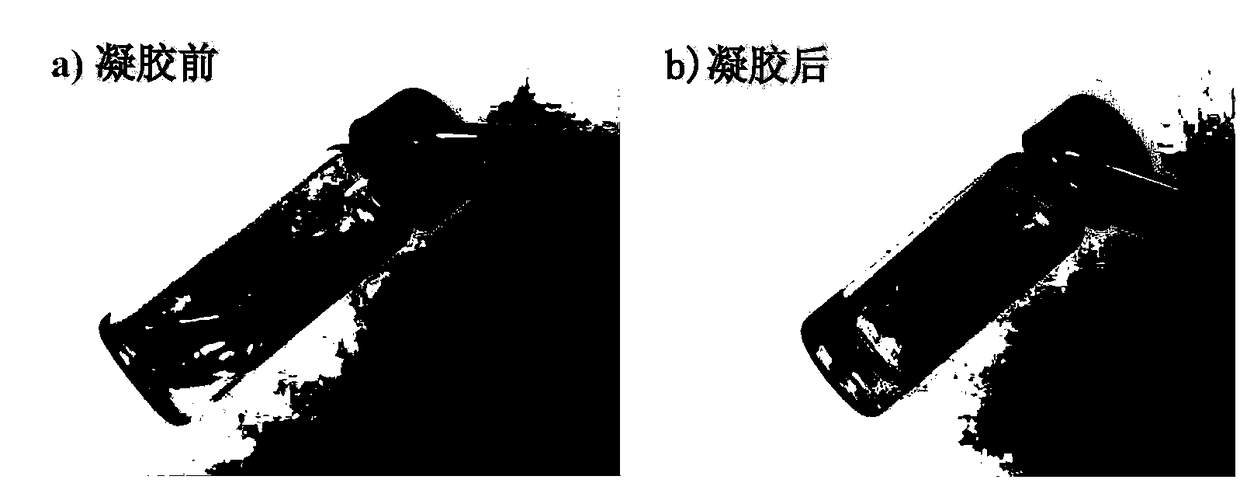

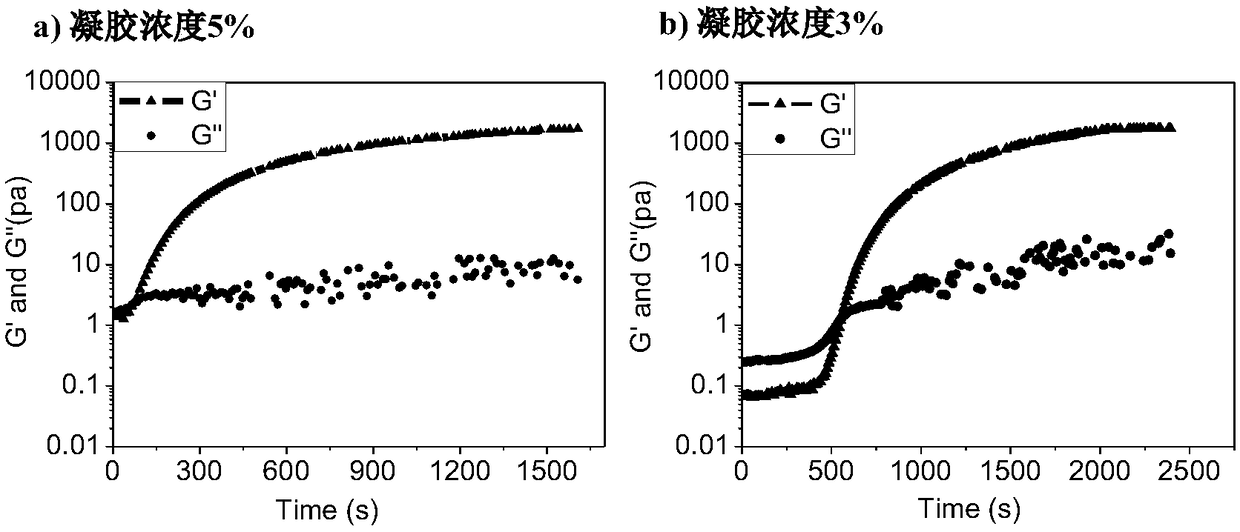

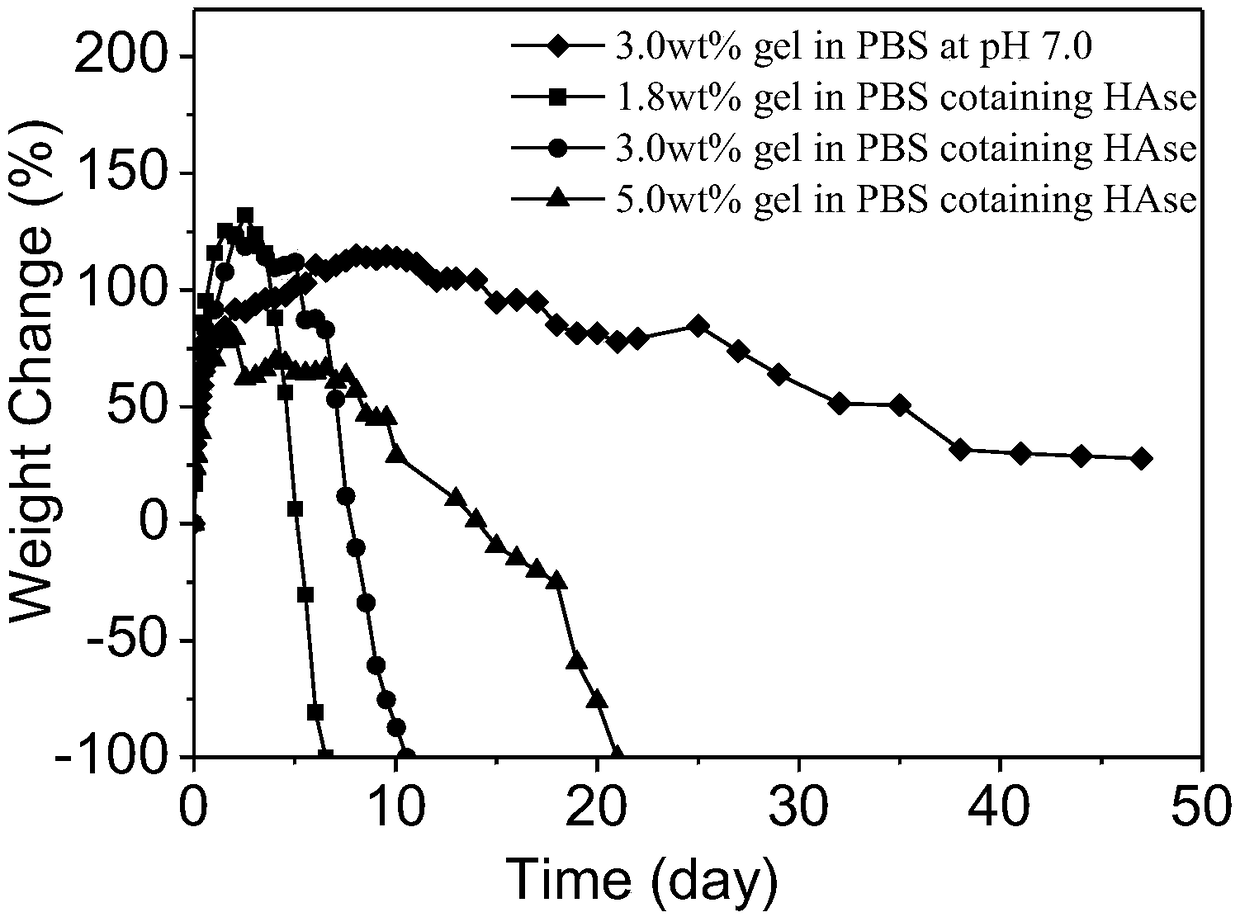

Injectable hyaluronic acid/polyethylene glycol hydrogel as well as preparation method and application thereof

ActiveCN106519072AEasy to prepareHigh yieldPharmaceutical delivery mechanismProsthesisCross-linkChemical reaction

The invention discloses injectable hyaluronic acid / polyethylene glycol hydrogel as well as a preparation method and application thereof, and belongs to the fields of plastic and cosmetic biological materials. The method is characterized in that a cyclooctyne-modified hyaluronic acid (HA) solution is mixed with a nitrine-modified polyethylene glycol (PEG) solution, a hydrogel precursor solution with favorable flowability is formed, and the hydrogel precursor solution can be quickly cross-linked through a ring tension promoted click chemical reaction to form the hydrogel after being injected into a body, so as to play roles in water retention, plastic and the like. The preparation process of the material is simple; the additional addition of a cross-linking agent is not needed; the heating is not needed; the ultraviolet treatment or the radiation and the like are not needed; one-step cross-linking is adopted; the injectable hyaluronic acid / polyethylene glycol hydrogel is non-toxic and has no stimulation; therefore, the made hydrogel is good in biocompatibility, and is insignificant in inflammatory reaction. Meanwhile, the gel is slower in degradation speed, and is excellent in mechanical performance; therefore, the material is good in durability and molding performance, is quite applicably used as a face-lifting filling material in the fields of wrinkle resisting, breast enlargement, nose augmentation, filling-padding and the like.

Owner:深圳浦瑞健康科技有限公司

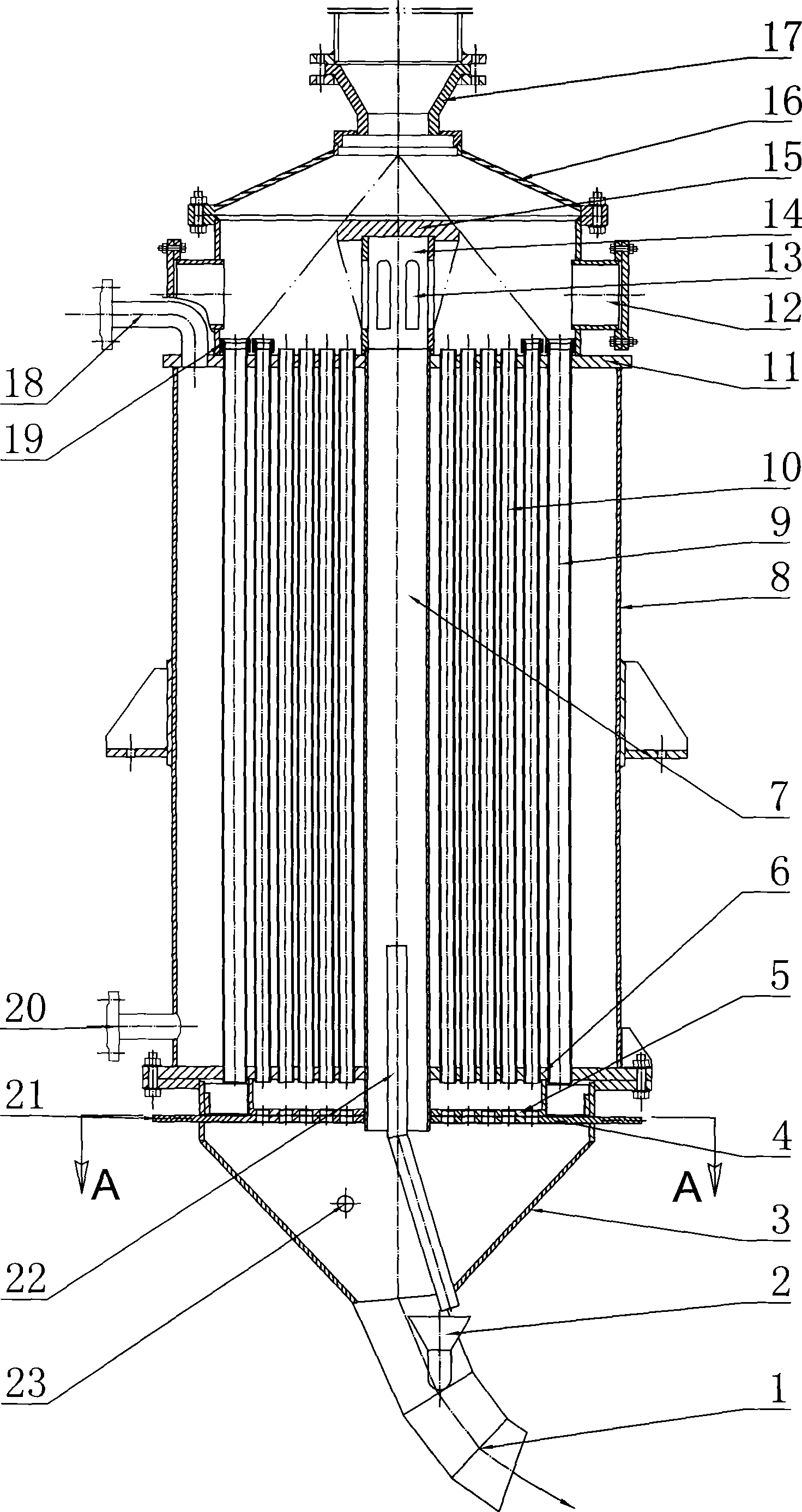

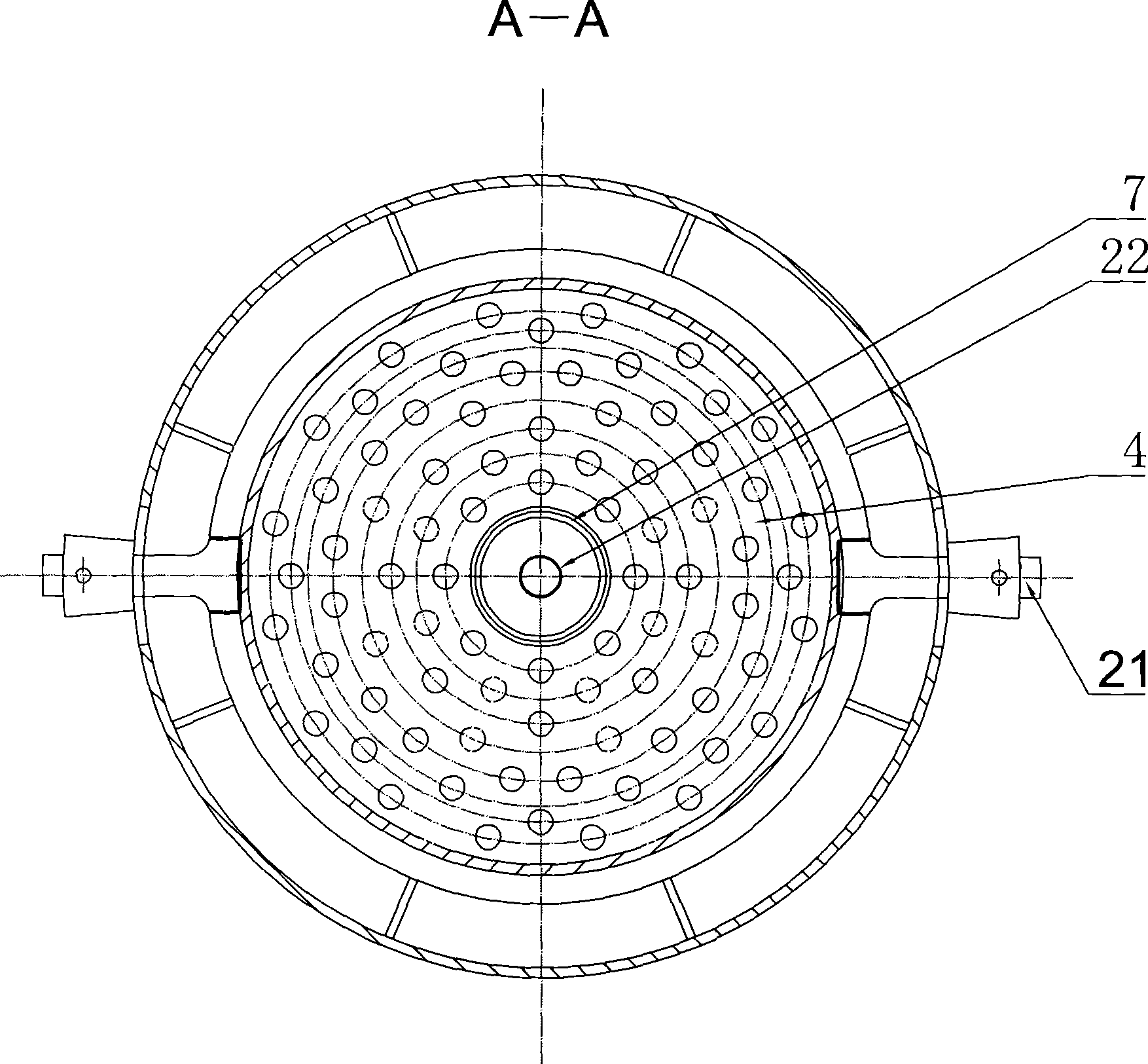

High-temperature slag economizer

InactiveCN101419031AEasy to adjust stacking heightChange dwell timeStationary tubular conduit assembliesSlagThermal water

The invention discloses a high-temperature slag economizer in the field of acid making equipment. The high-temperature slag economizer comprises a shell consisting of an upper shell, a lower shell and a heat exchange section cylinder body; the top part of the upper shell is provided with a slag inlet; the bottom of the lower shell is provided with a slag outlet; an upper tubeplate is arranged between the upper shell and the heat exchange section cylinder body; a lower tubeplate is arranged between the lower shell and the heat exchange section cylinder body; a plurality of heat exchange tubes are arranged between the upper tubeplate and the lower tubeplate; a water inlet and a water outlet are also arranged on the heat exchange section cylinder body; the centers of the upper tubeplate and the lower tubeplate are provided with central tubes; the upper end of the central tube is provided with a cylindrical central supporting seat; the side of the central supporting seat is provided with a pluralities of axial grooves; the upper end of the central supporting seat is horizontally provided with a disc-shaped feed divider; the periphery of the heat exchange tube is provided with a ring of bypassing tubes; the inside diameter of the heat exchange tube is less than that of the bypassing tube; the inside of the central tube is provided with a signal tube; and the lower part of the signal tube extends to the outside of the lower shell. The high-temperature slag economizer solves the problem that slag agglomerates and blocks the heat exchange tube, and permits the agglomerated slag to pass through the bypassing tube; and the device utilizes residual heat in the manufacturing industry of sulfuric acid to produce low-pressure steam and hot water, thereby saving fuel.

Owner:杨正清

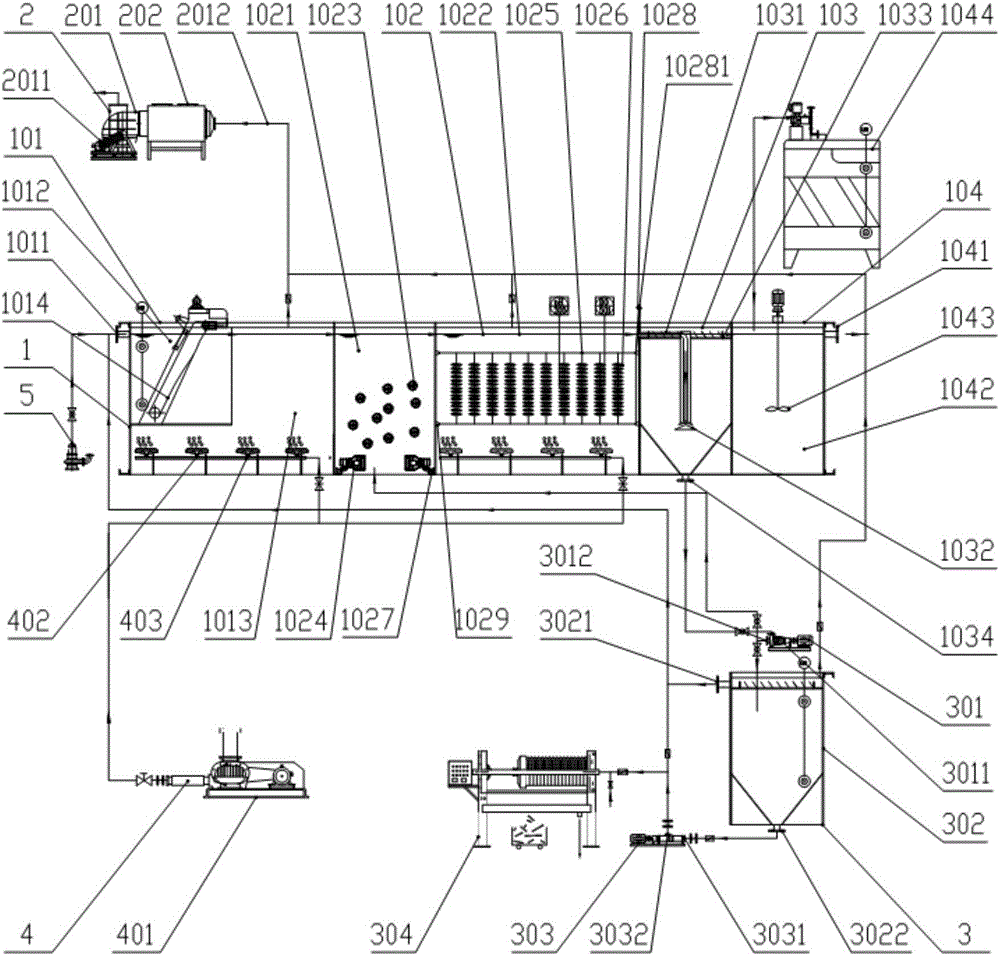

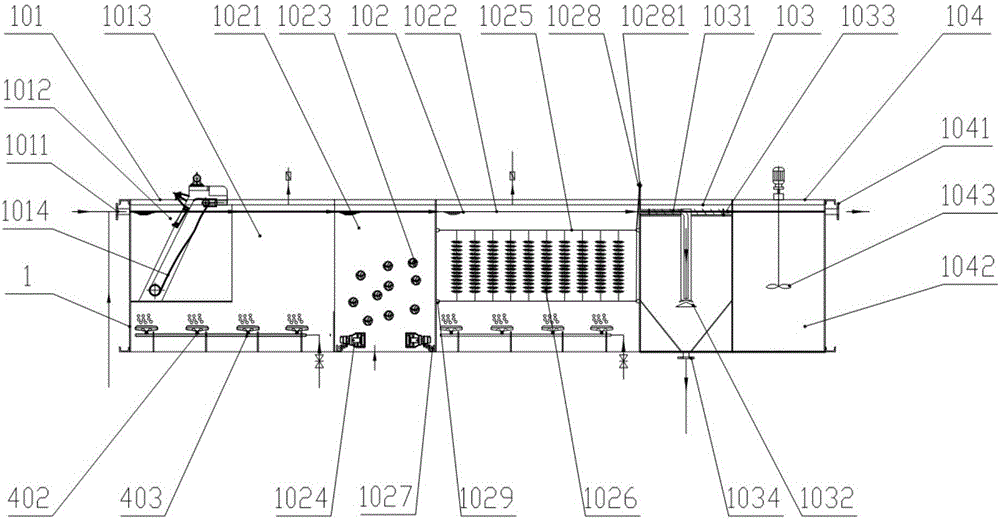

Hospital sewage integrated treatment equipment

PendingCN106830566AEasy to process and assembleReduce pollutionSludge treatment by de-watering/drying/thickeningTreatment involving filtrationIntegrated systemsSewage

The invention discloses hospital sewage integrated treatment equipment, which comprises a wastewater treatment module, a waste gas treatment module and a sludge treatment module. The wastewater treatment module comprises a pretreatment unit, a biological treatment unit, a precipitation unit and a disinfection treatment unit which are sequentially communicated; the pretreatment unit is provided with a water inlet; the water inlet is communicated with a submerged pump; inflow water is provided by the submerged pump; the disinfection treatment unit is provided with a drainage hole; the drainage hole is communicated with a drainage network; the waste gas treatment module comprises a waste gas collecting unit and a waste gas treatment unit which are communicated; the waste gas collecting unit is communicated with the pretreatment unit and the biological treatment unit; the sludge treatment module is communicated with the precipitation unit. The equipment has the beneficial effects that hospital sewage is subjected to waste water, waste gas and sludge solid integrated system treatment, and harmful water, gas and solid are prevented from entering the environment.

Owner:苏州宏安环境科技有限公司

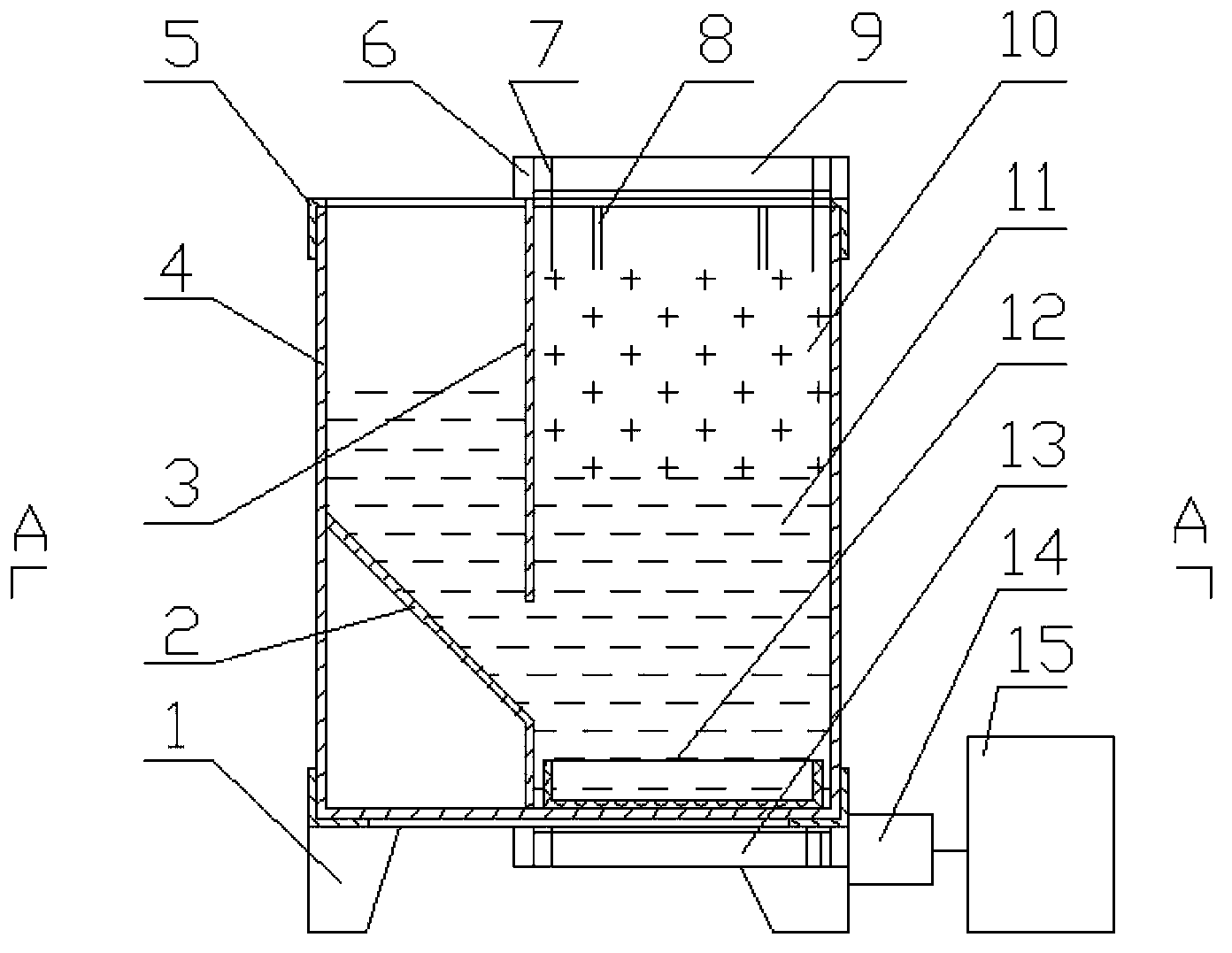

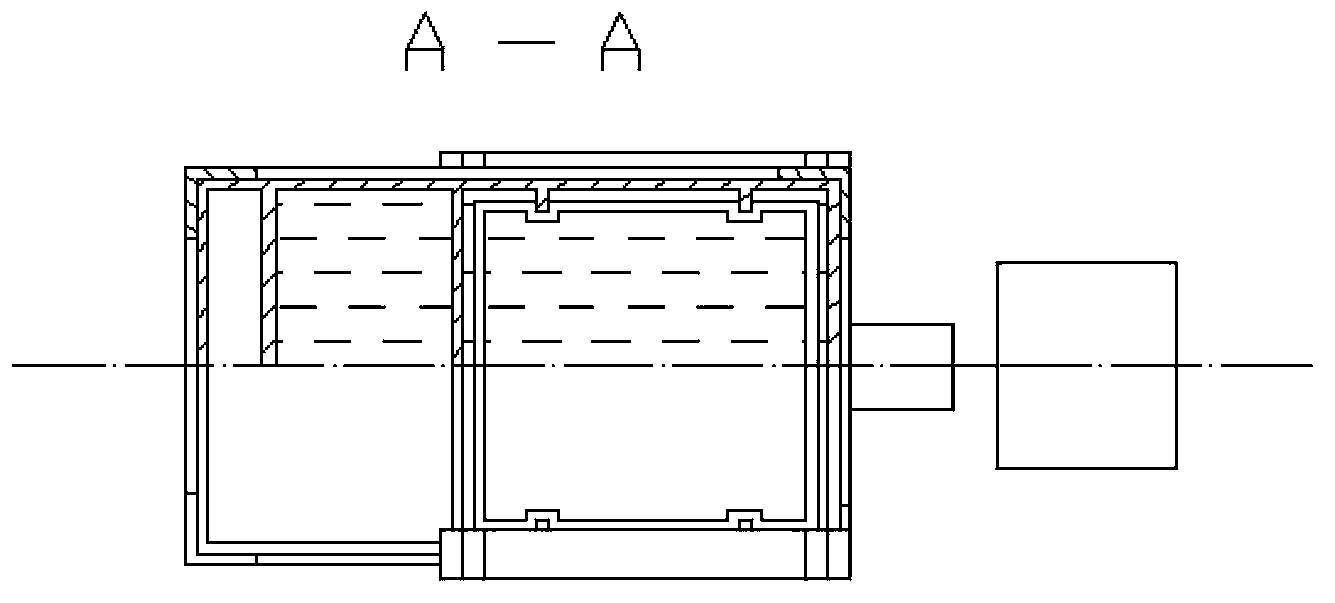

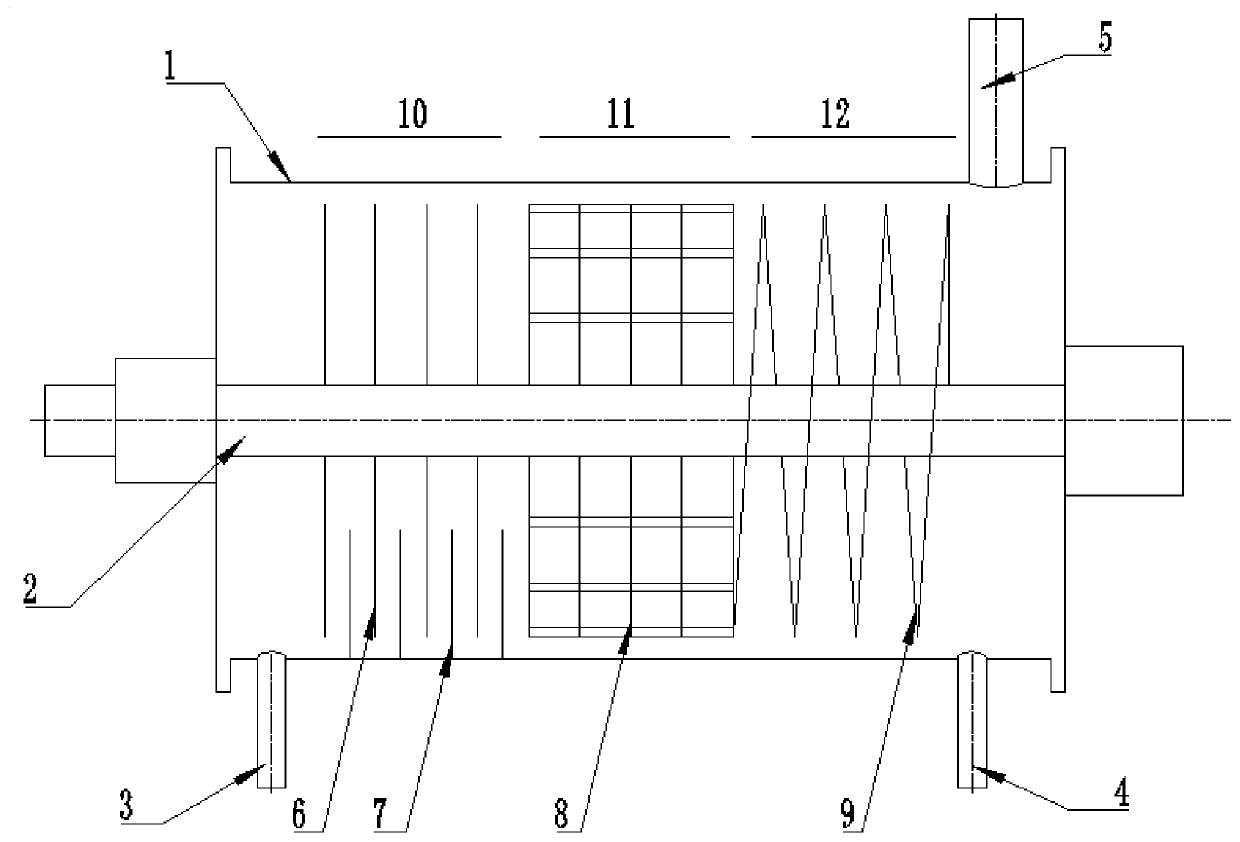

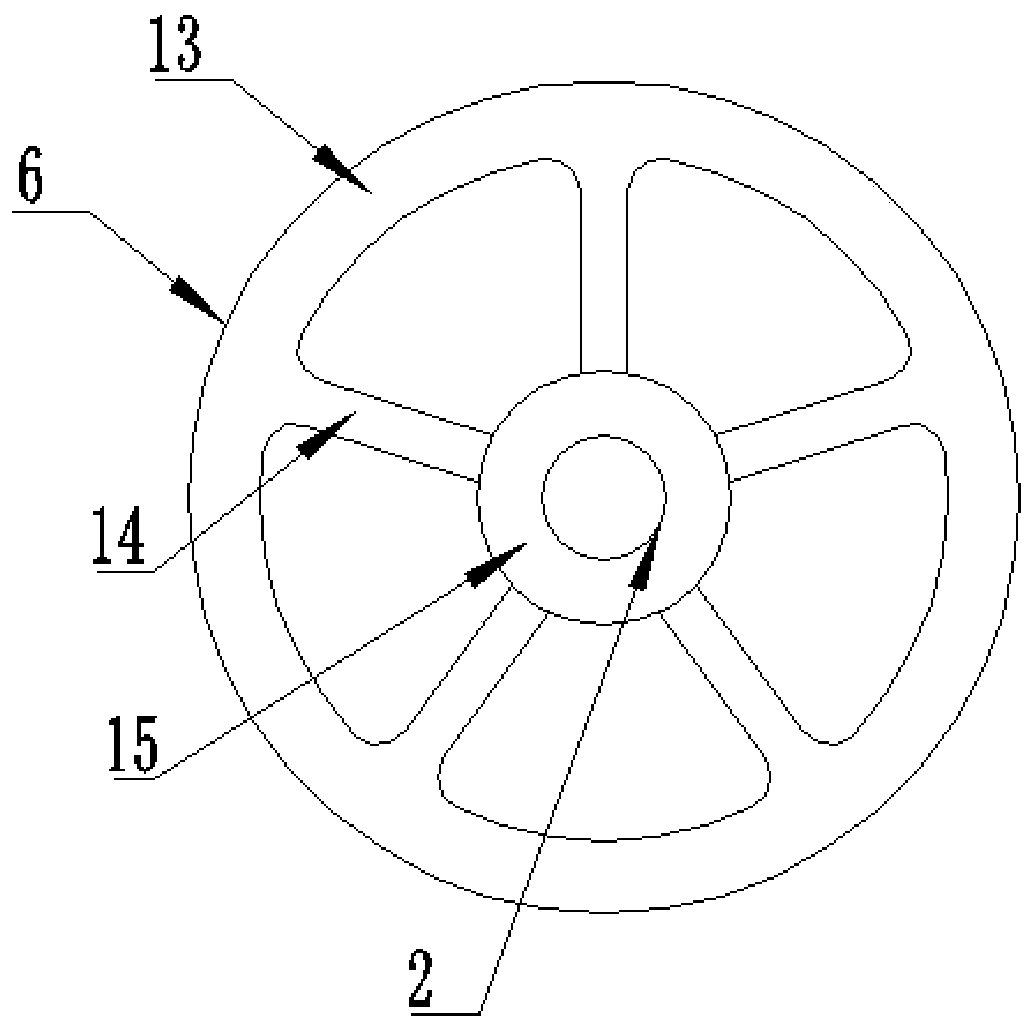

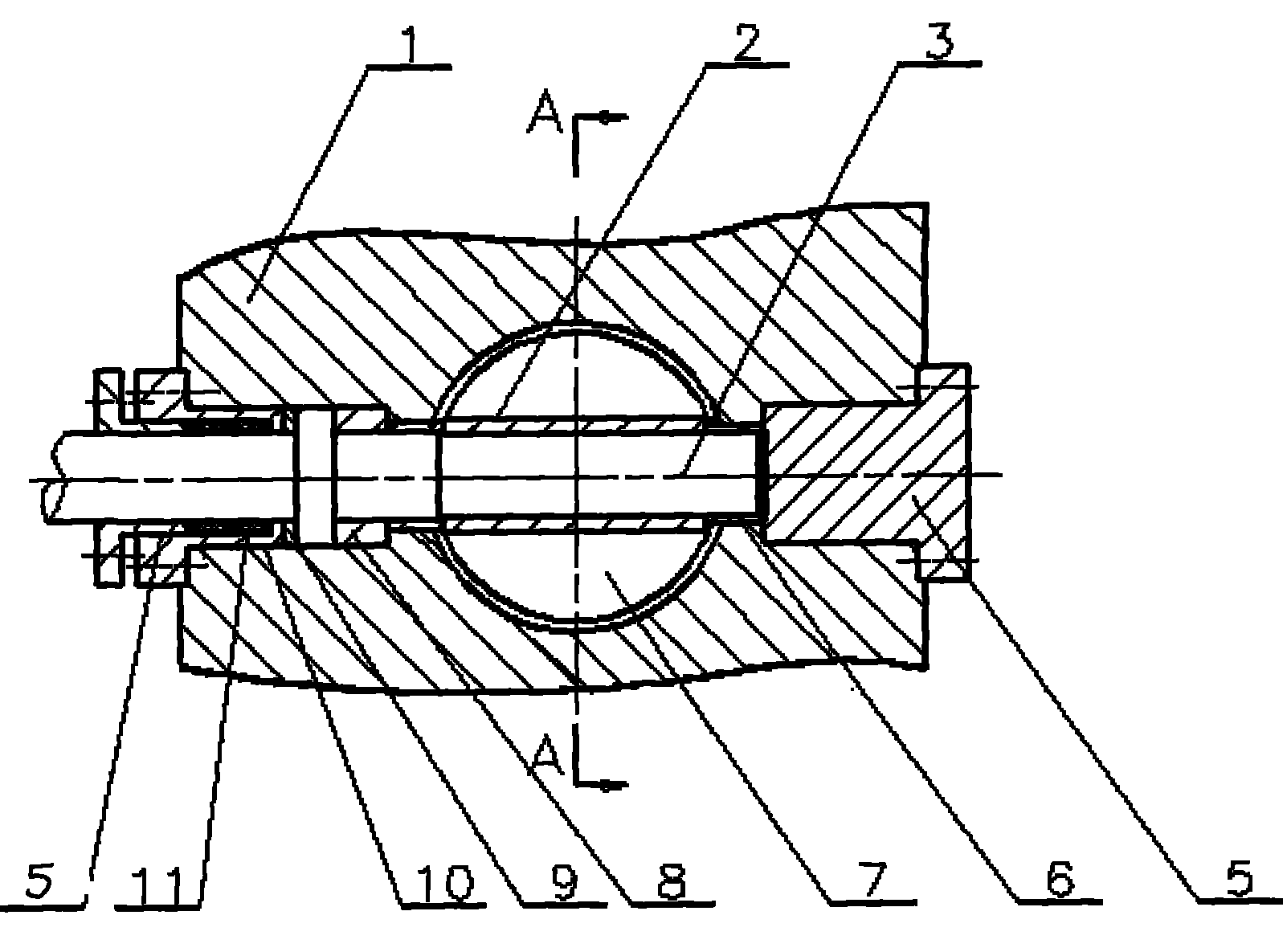

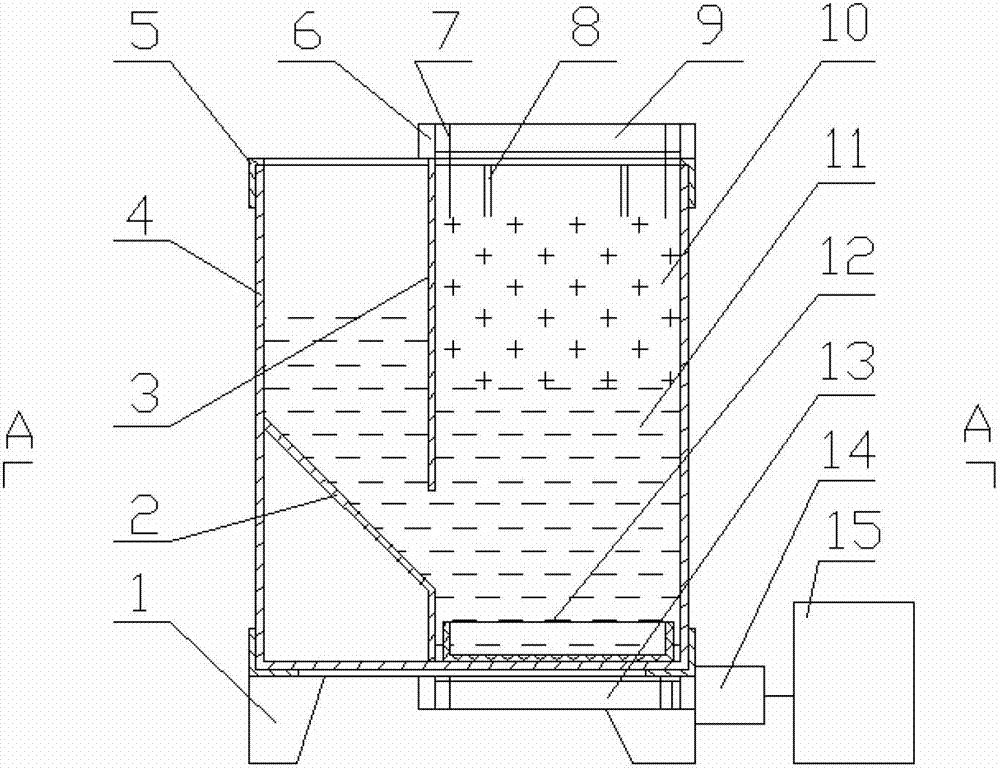

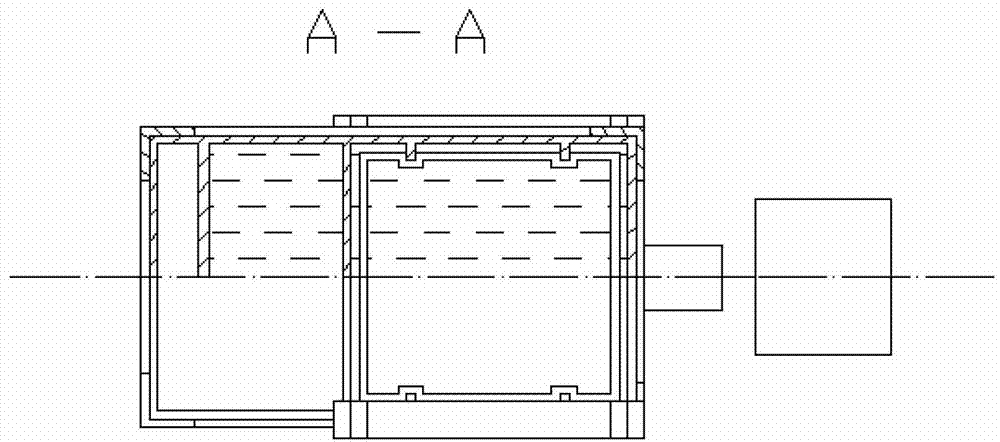

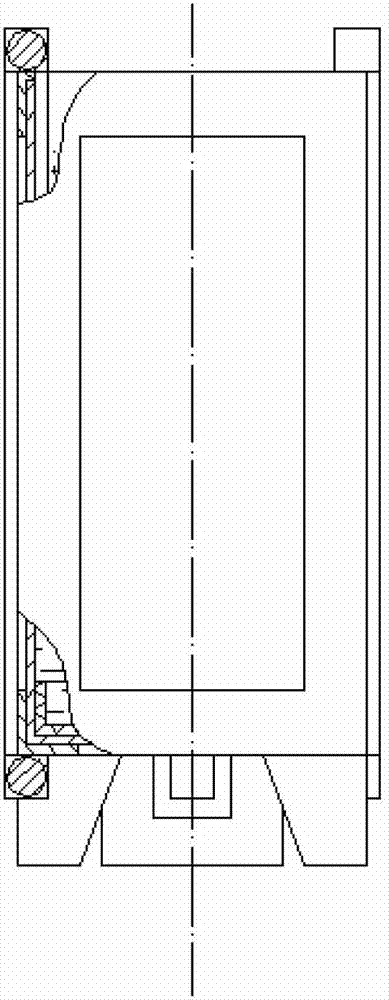

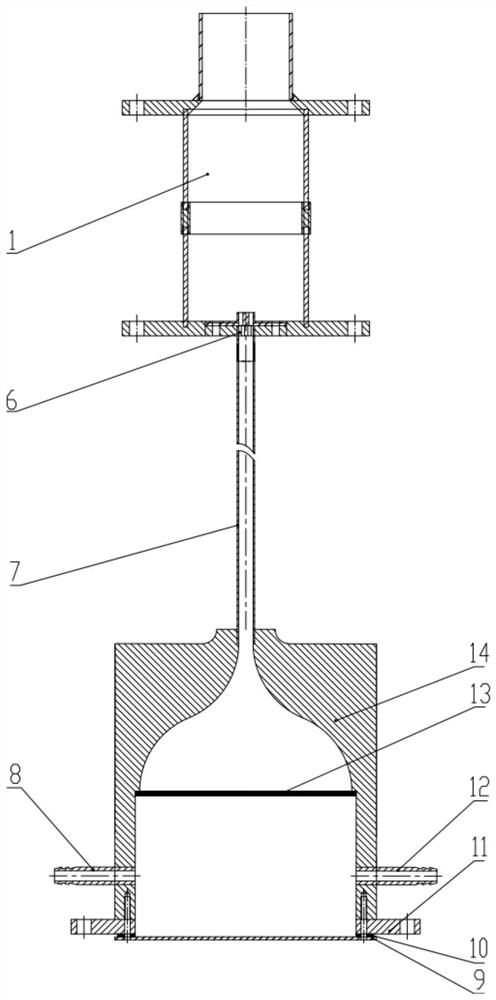

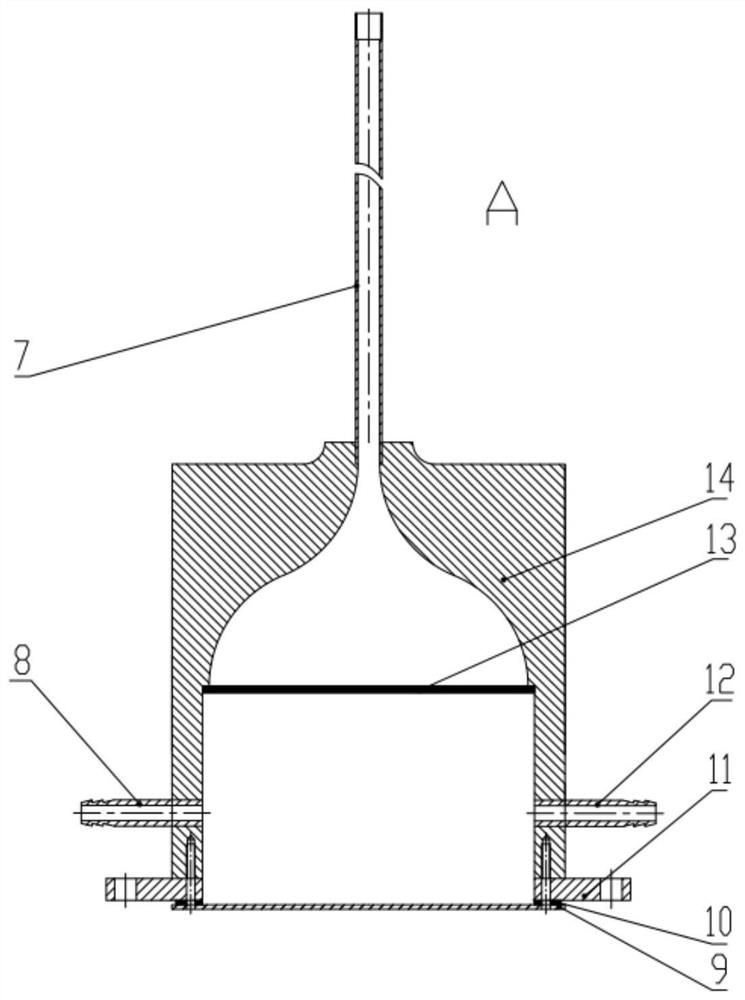

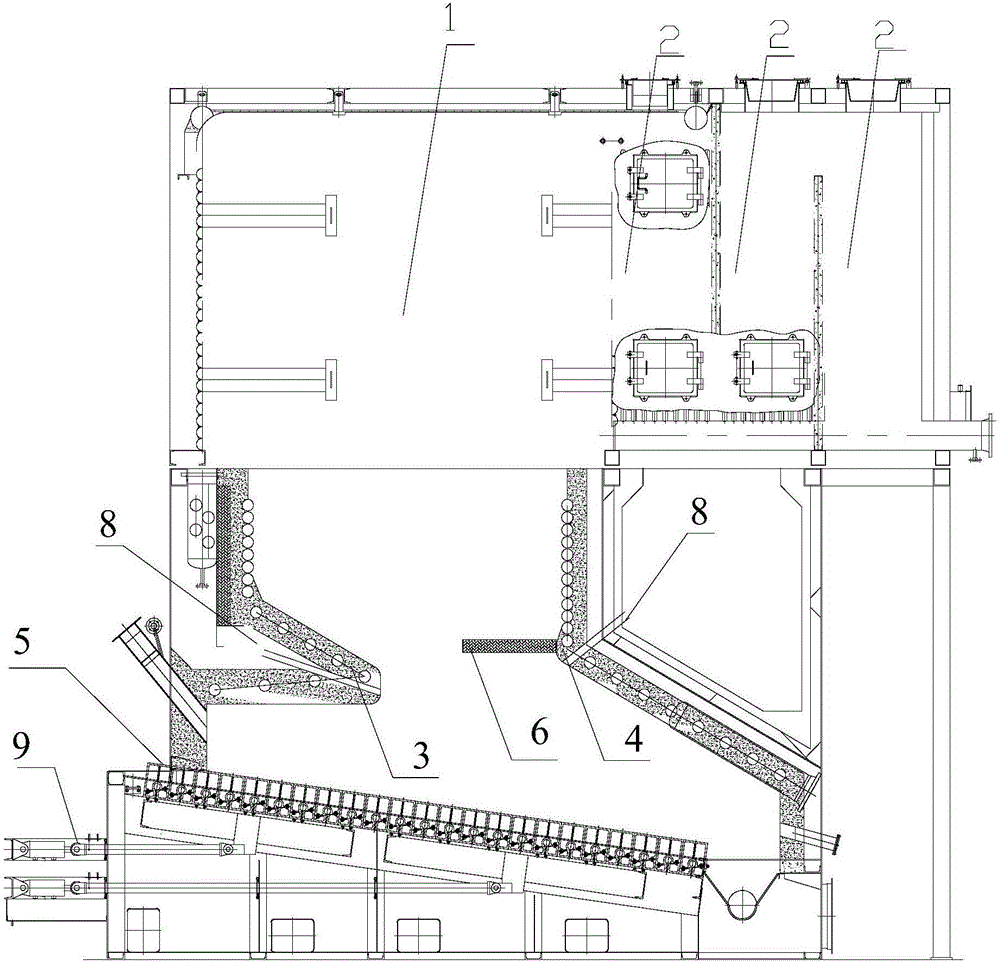

Special equipment for two-medium quenching heat treatment and cooling and technology of equipment

InactiveCN103436671AChange dwell timeSpeed up coolingQuenching agentsQuenching devicesSlide plateOil cooling

The invention relates to special equipment for two-medium quenching heat treatment and cooling and a technology of the equipment. The equipment comprises landing legs, a sliding plate, a separation plate, a box plate, a slotted-angle shelving, a roller seat, a pull rope, guide rails, a guide roller, a net basket, a rope reeling roll, a stepping motor and a control cabinet, wherein the box plate and the slotted-angle shelving are welded to form a quenching cooling tank; the quenching cooling tank is supported by the landing legs; the separation plate is welded in the quenching cooling tank, and divides the quenching cooling tank into a water tank and an oil tank with the lower parts communicated; the lower part the water tank is welded with the sliding plate; the sliding plate is placed obliquely; steel is heated and subjected to heat preservation to form austenite, then is put in the water tank, and enters the net basket via the sliding plate; and the net basket and the steel in the net basket move up into oil from water through a lifting mechanism under control of the control cabinet, so that the water quenching and oil cooling two-medium quenching technology is achieved. According to the equipment and the technology, quenching deformation and cracking of the steel can be avoided effectively; an automation degree is high; the labor intensity is low; brine and oil two-medium quenching and brine-oil-air three-medium quenching can be achieved; and the equipment and the technology have broad market prospects.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

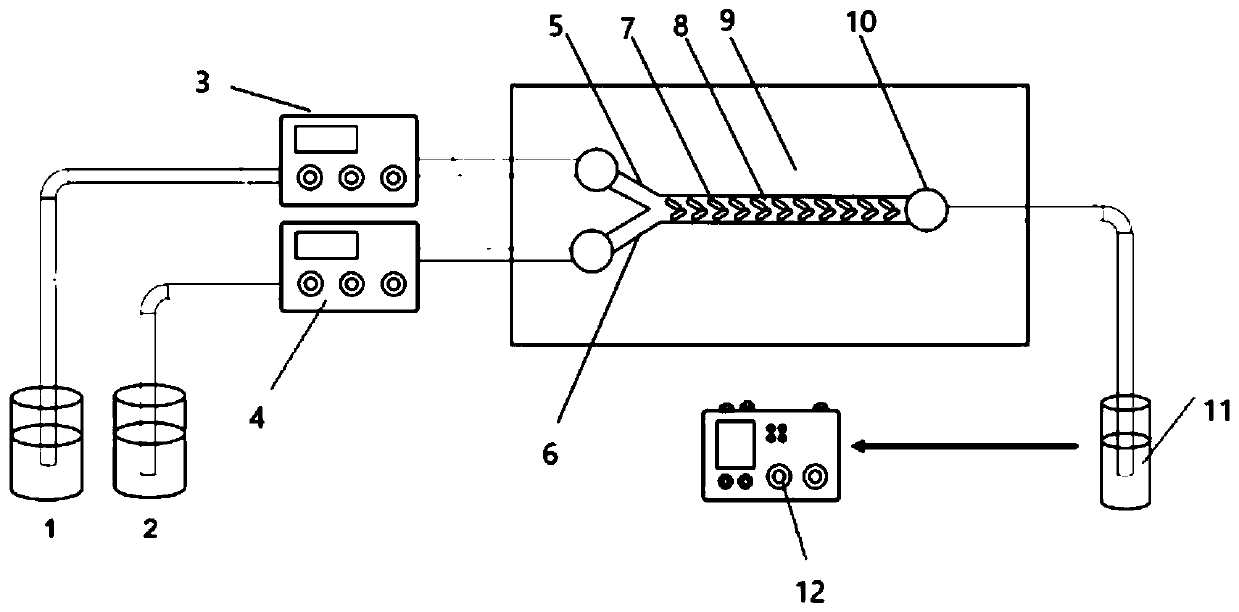

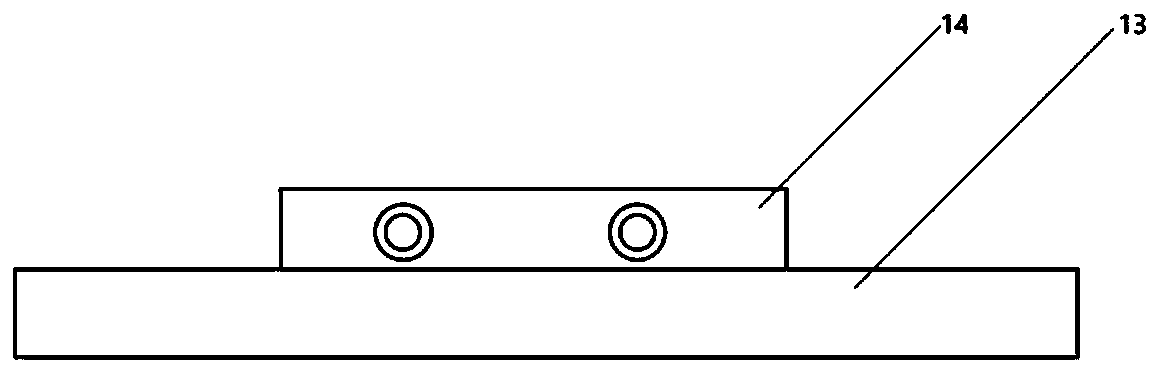

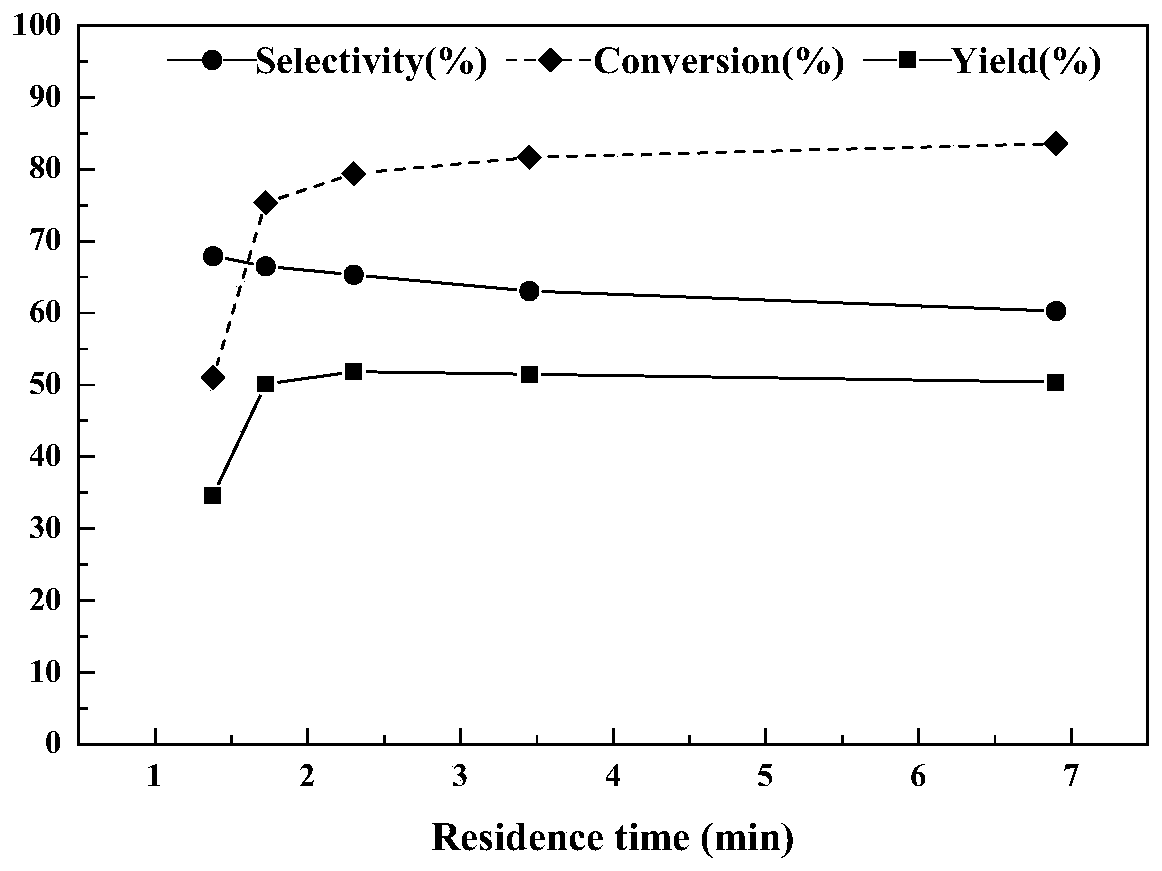

System and method for synthesizing methyl ethyl oxalate based on micro-channel reactor

ActiveCN110283071AHigh yieldHigh selectivityPreparation by ester-hydroxy reactionChemical/physical/physico-chemical microreactorsOxalateOrganic synthesis

The invention belongs to the field of organic synthesis, and particularly discloses a system and method for synthesizing methyl ethyl oxalate based on a micro-channel reactor. The system comprises a first raw material bottle, a second raw material bottle, the micro-channel reactor and a collecting device. The micro-channel reactor comprises a first inlet micro-channel, a second inlet micro-channel, a micro-channel and a channel outlet. The first inlet micro-channel and the second inlet micro-channel are connected with the first raw material bottle and the second raw material bottle respectively. The other end of the first inlet micro-channel and the other end of the second inlet micro-channel are connected with the micro-channel. The channel outlet is connected with the collecting device. Through the efficient mixing and process strengthening of the micro-reactor, through an ester exchange method, the high methyl ethyl oxalate yield can be realized, and the selectivity is high; compared with a traditional kettle type reactor micro-reactor, continuous feeding can be realized, the production efficiency of the product is greatly improved, the process is safe and controllable, and human error accidents are reduced.

Owner:NANJING UNIV OF SCI & TECH

Oxygen-enriched burner and air distribution method thereof

InactiveCN106439795AChange the combustion atmosphereChange dwell timeFluegas recirculationDirect carbon-dioxide mitigationCombustion chamberCombustor

The invention relates to the technical field of energy, and discloses an oxygen-enriched burner and an air distribution method thereof. The burner comprises a combustion chamber, wherein a burnout air port, primary air ports and secondary air ports are formed in the wall of the chamber so as to form a line of air ports, the primary air ports and the secondary air ports are vertically formed below the burnout air port in the height direction of the combustion chamber at intervals, and the primary air ports are located between adjacent secondary air ports. The air distribution method of the oxygen-enriched burner comprises the steps of closing the burnout air port, and opening the primary air ports and the secondary air ports in the working condition of oxygen-enriched combustion; adjusting the volume of circulating smoke which enters a boiler and injected oxygen so as to adjust the oxygen partial pressure of the boiler; controlling a part of the injected oxygen to enter the primary air ports and the other part of the injected oxygen to enter the secondary air ports, and adjusting the oxygen partial pressure of primary air or secondary air; and controlling the momentum of the primary air to be the same as that of the primary air in the working condition of air combustion. According to the oxygen-enriched burner and the air distribution method, the high efficiency and stability of pulverized coal combustion are increased in the working condition from air combustion to oxygen-enriched combustion.

Owner:CHINA SHENHUA ENERGY CO LTD +3

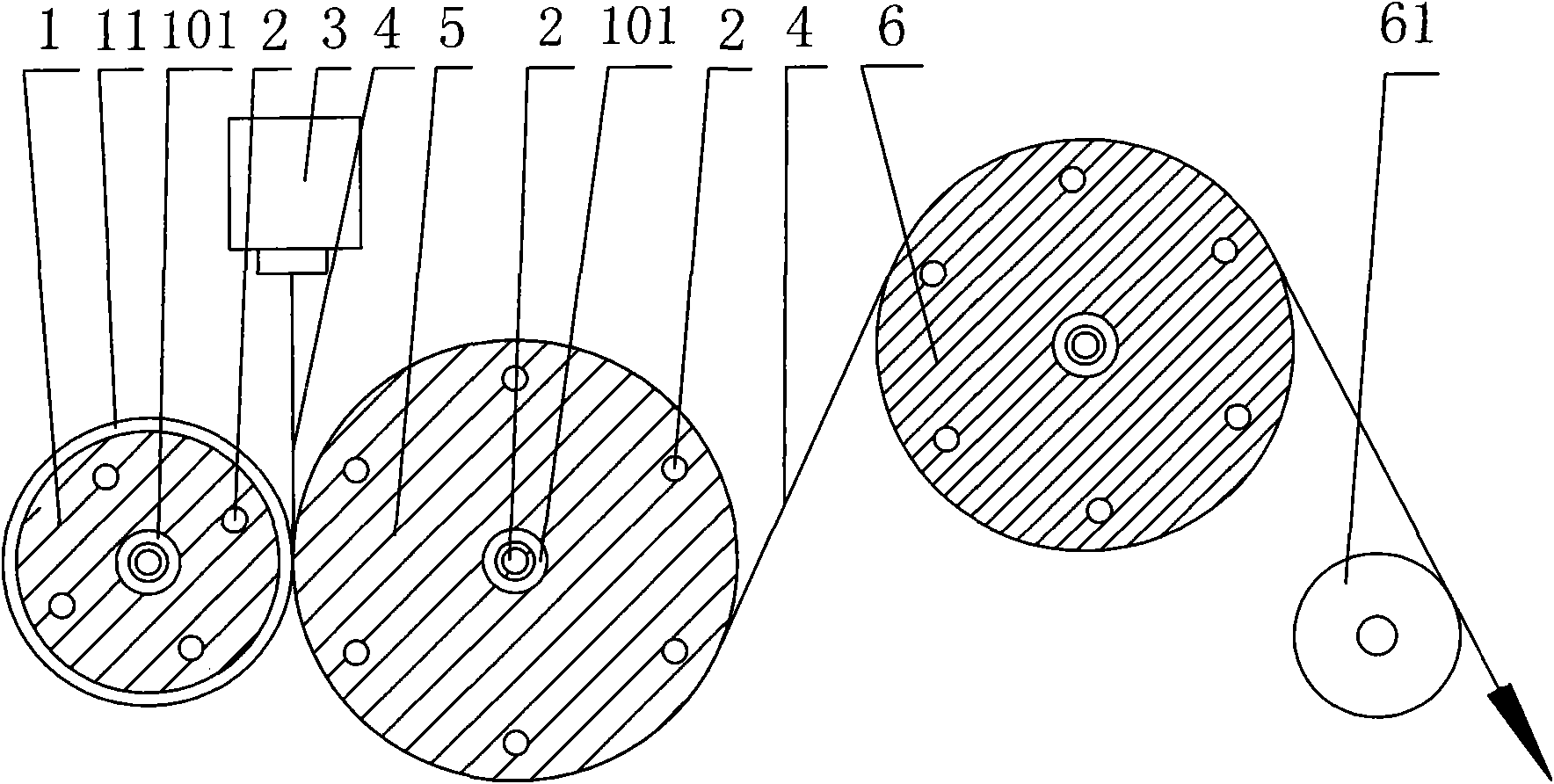

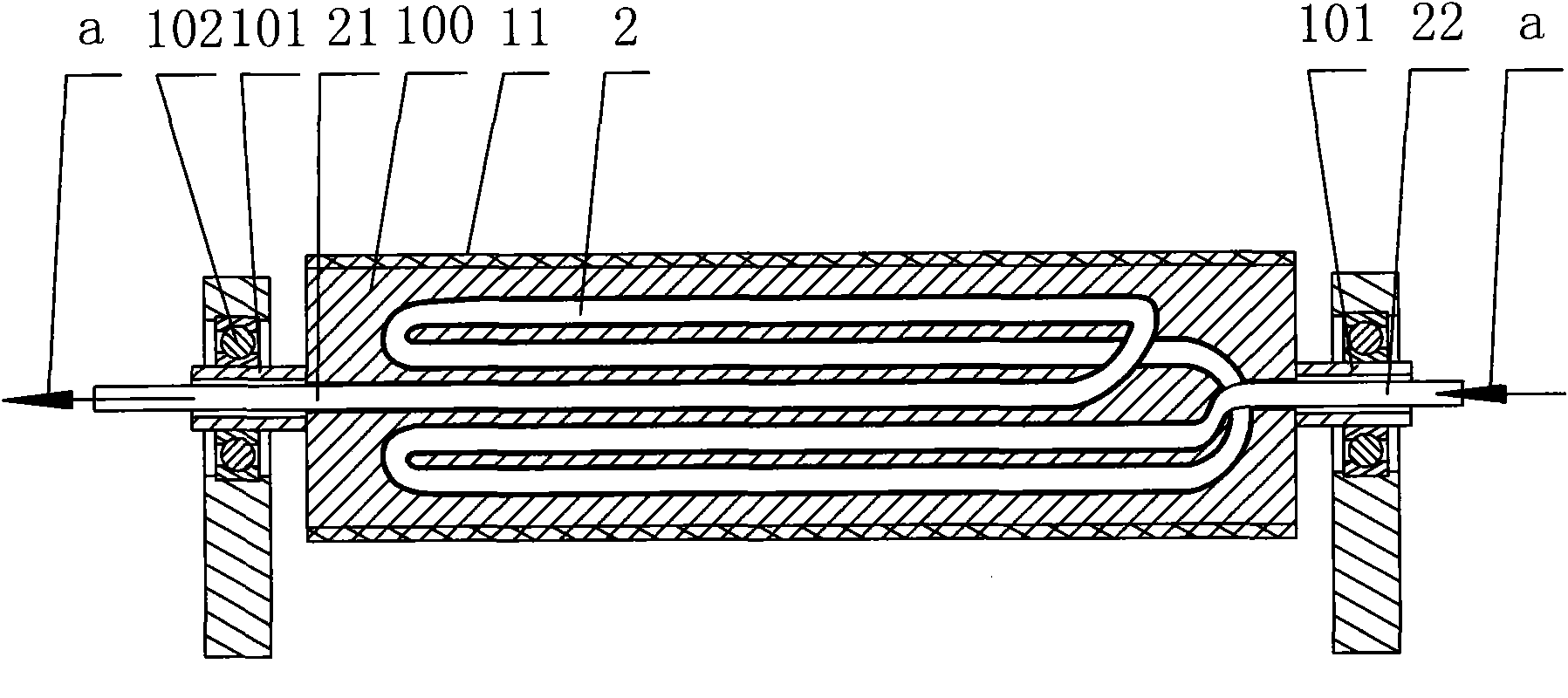

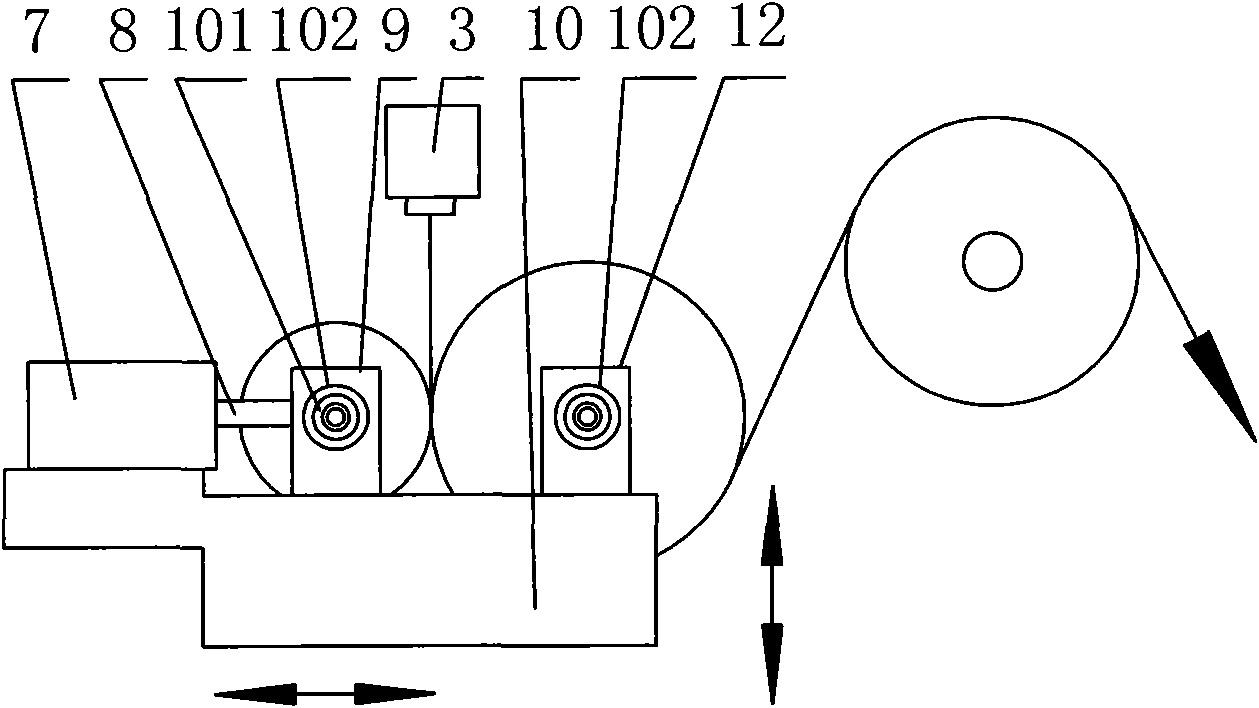

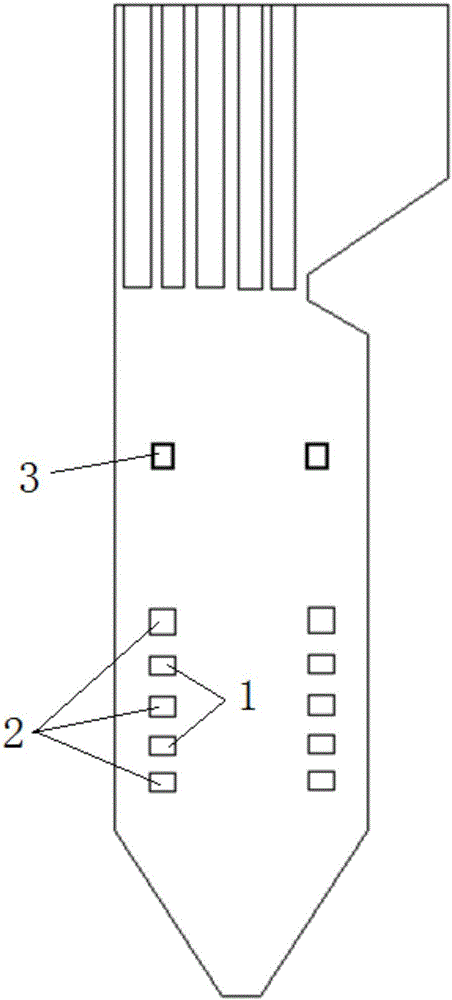

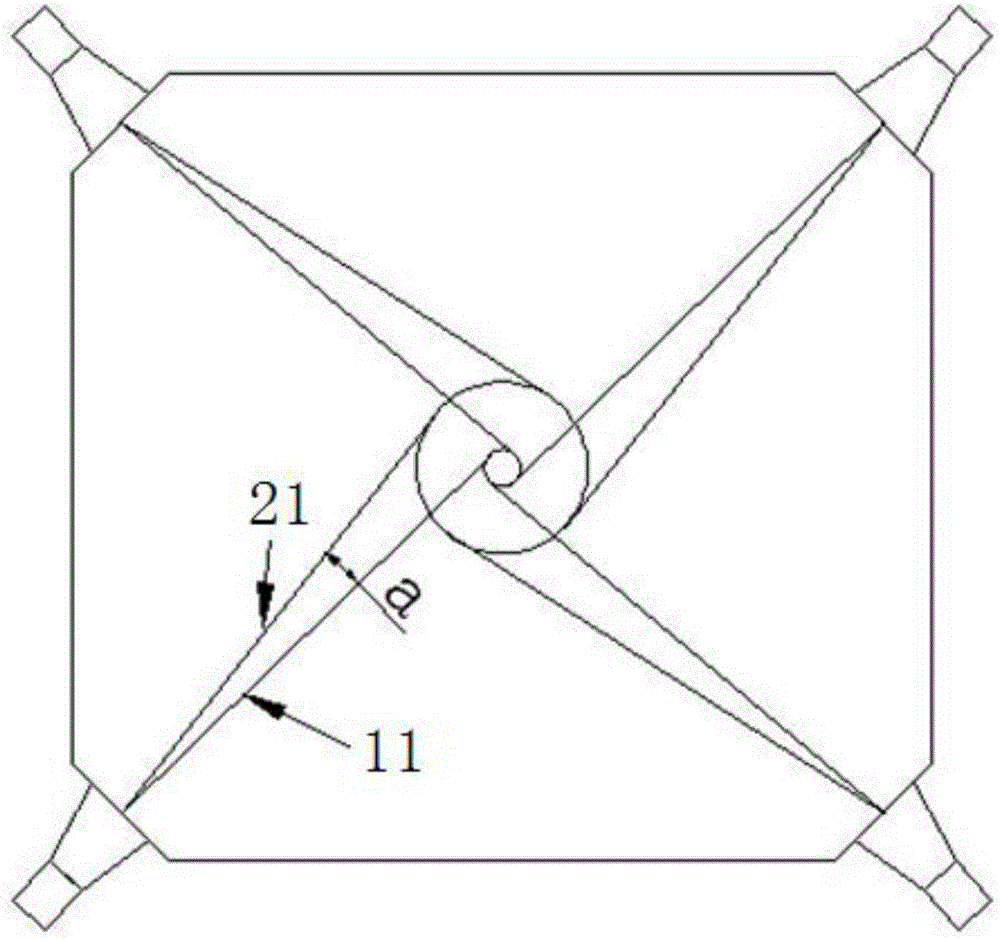

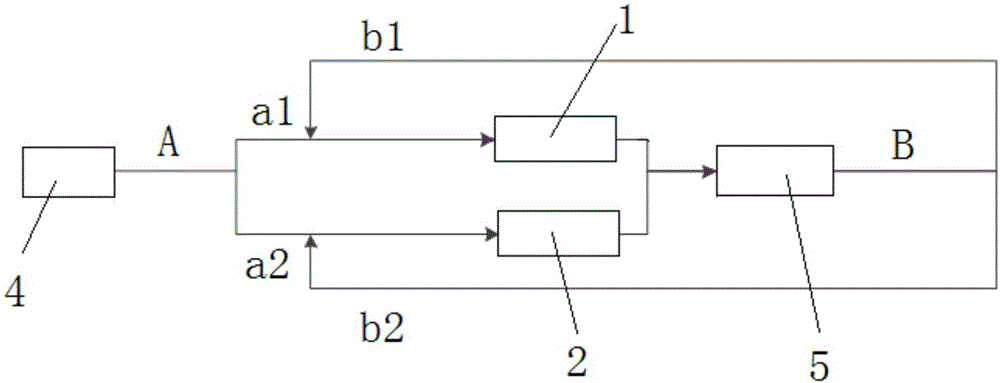

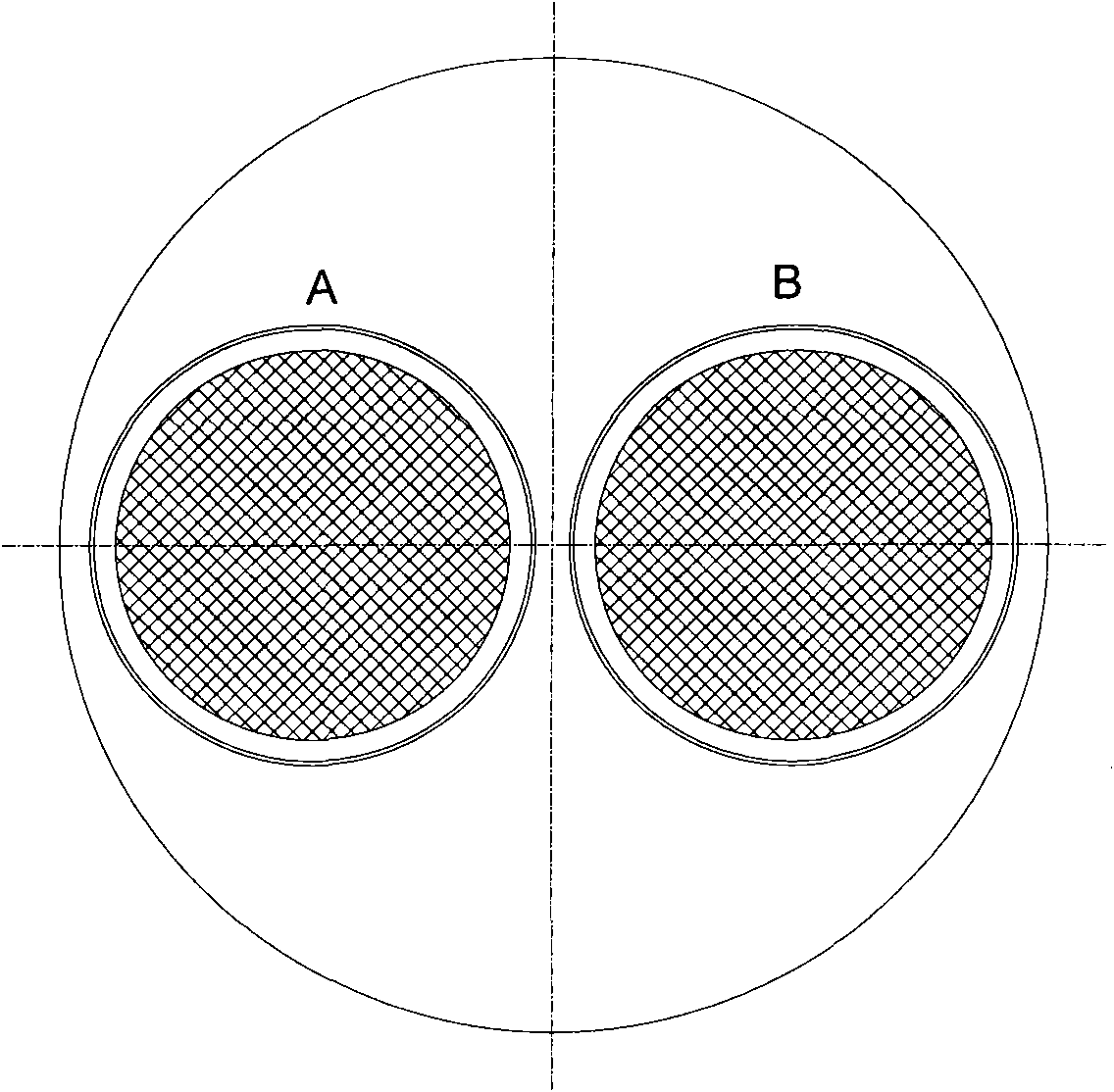

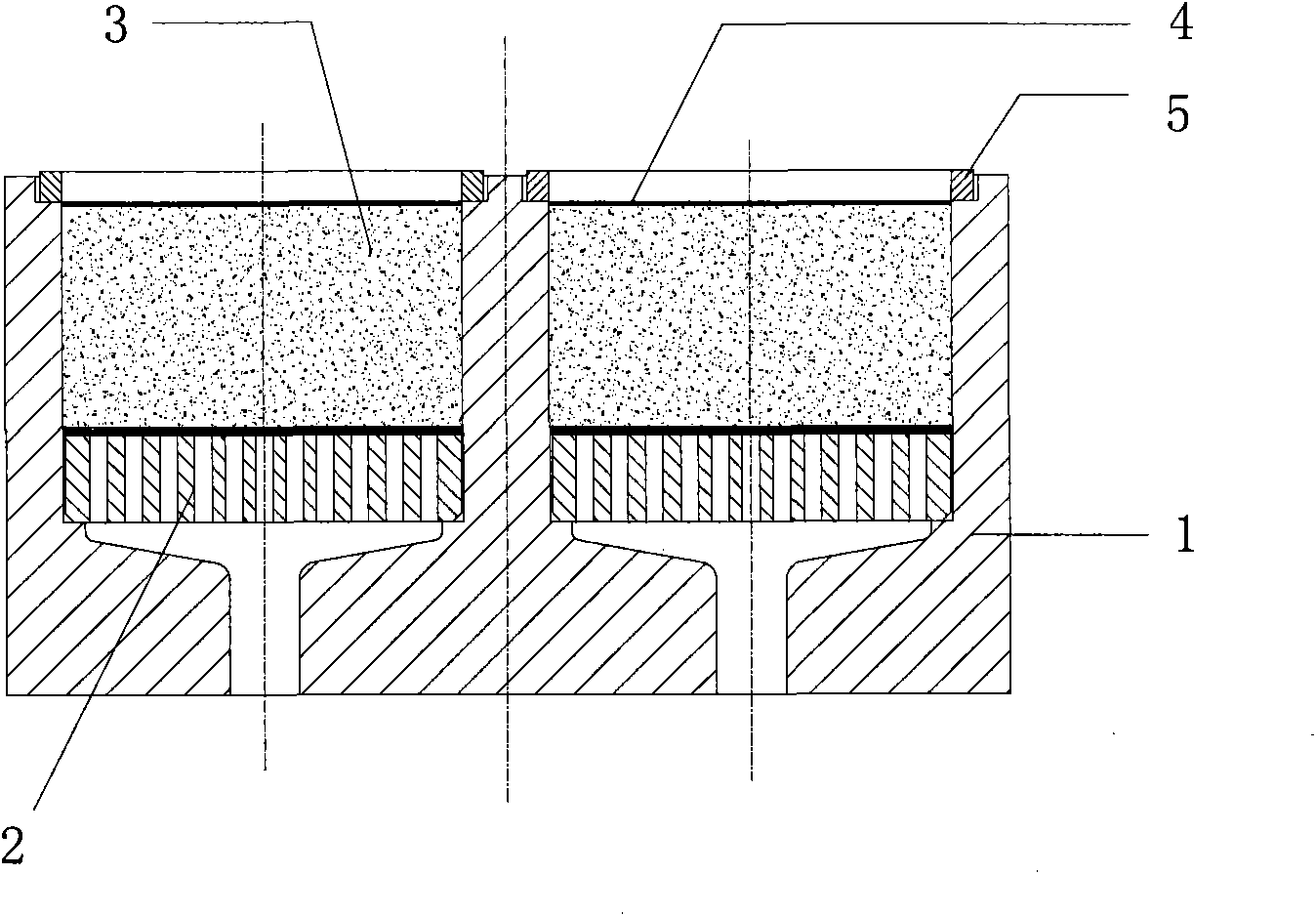

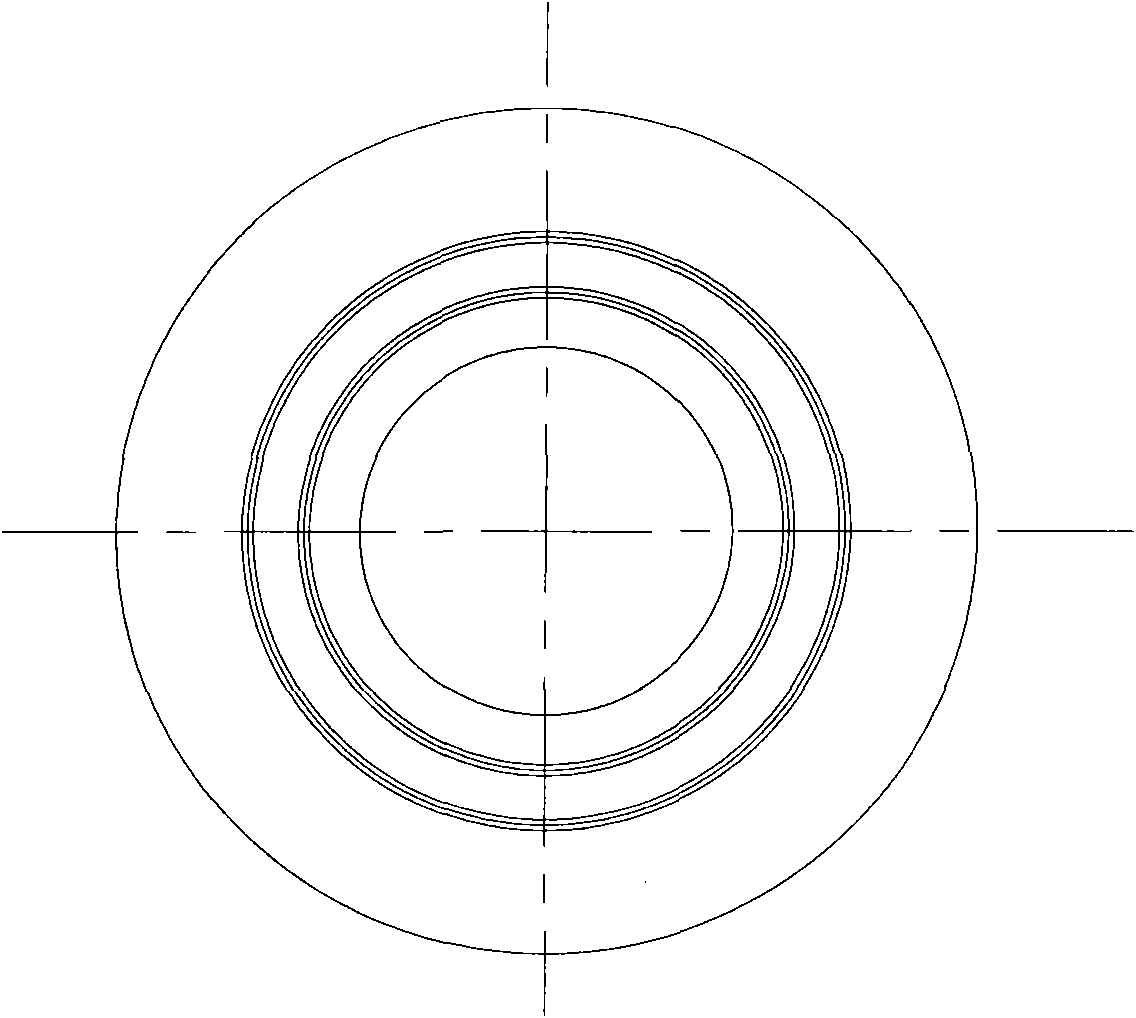

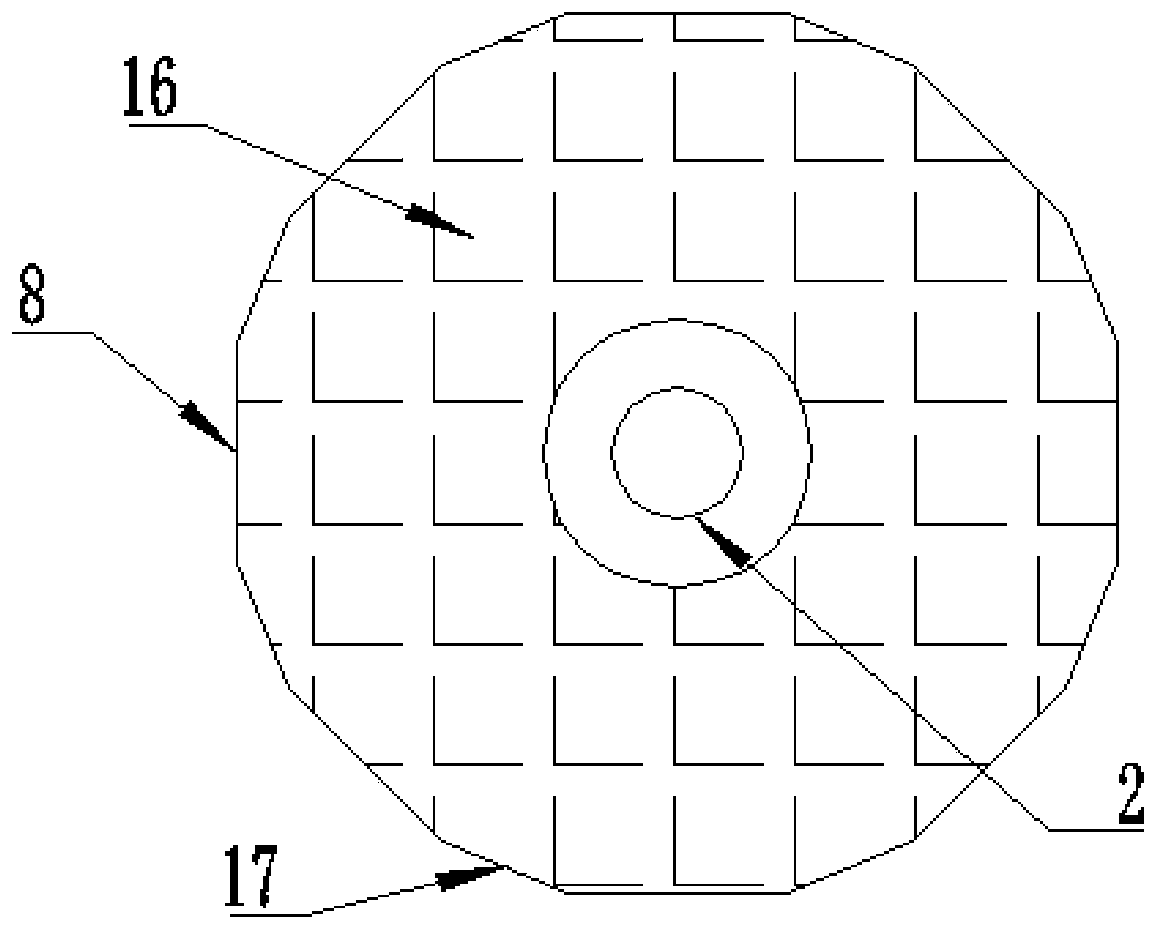

Compound spinning assembly with replaceable sand cavity inner sleeve and application thereof

ActiveCN101768787AChange volumeChange dwell timeSpinnerette packsSpinning head liquid feederRetention timeSand filter

The invention relates to a compound spinning assembly with a replaceable sand cavity inner sleeve and application thereof. The assembly comprises a sand cavity body 1, a sand cavity internal distribution block 2, a metal sand filter 3, a metal filter screen 4, a metal sealing ring 5 and a movable sand cavity inner sleeve 6, wherein the sand cavity body 1 comprises a component A sand cavity and a component B sand cavity, and the movable sand cavity inner sleeve 6 is matched with the component A sand cavity or the component B sand cavity. The compound spinning assembly provided by the invention can reduce the volume of the sand cavity by times so as to reduce the retention time of the components with smaller pumping power in the sand cavity, thereby finally and obviously reducing the fusant degradation and realizing spinning in a steady state. The sand cavity inner sleeve is replaceable, can be set with different inner diameters and can be used or not used according to the technological requirements, thereby realizing the control on the retention time of the fusant without replacing the sand cavity.

Owner:CTA HIGH TECH FIBER

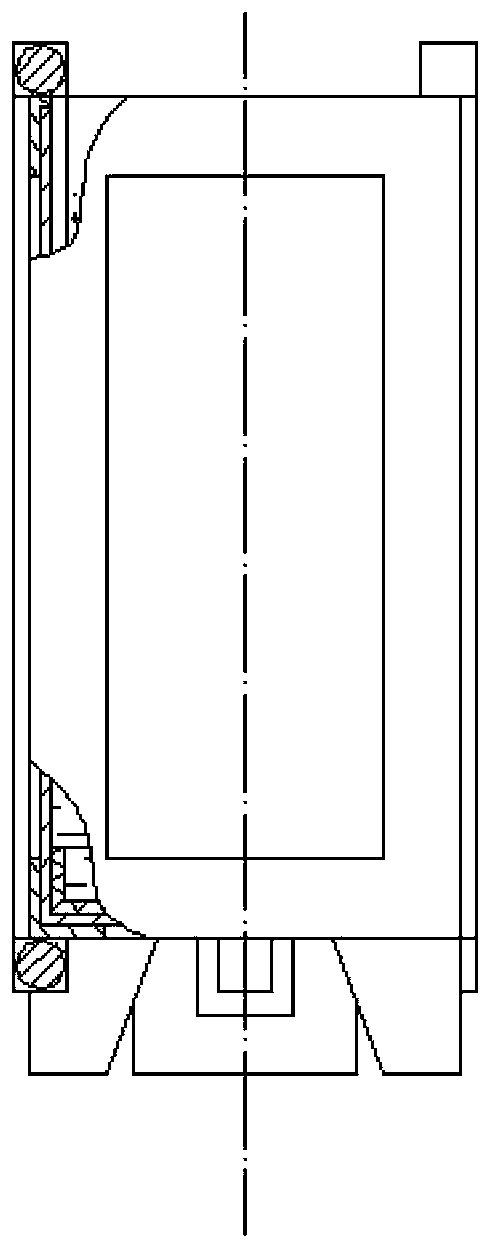

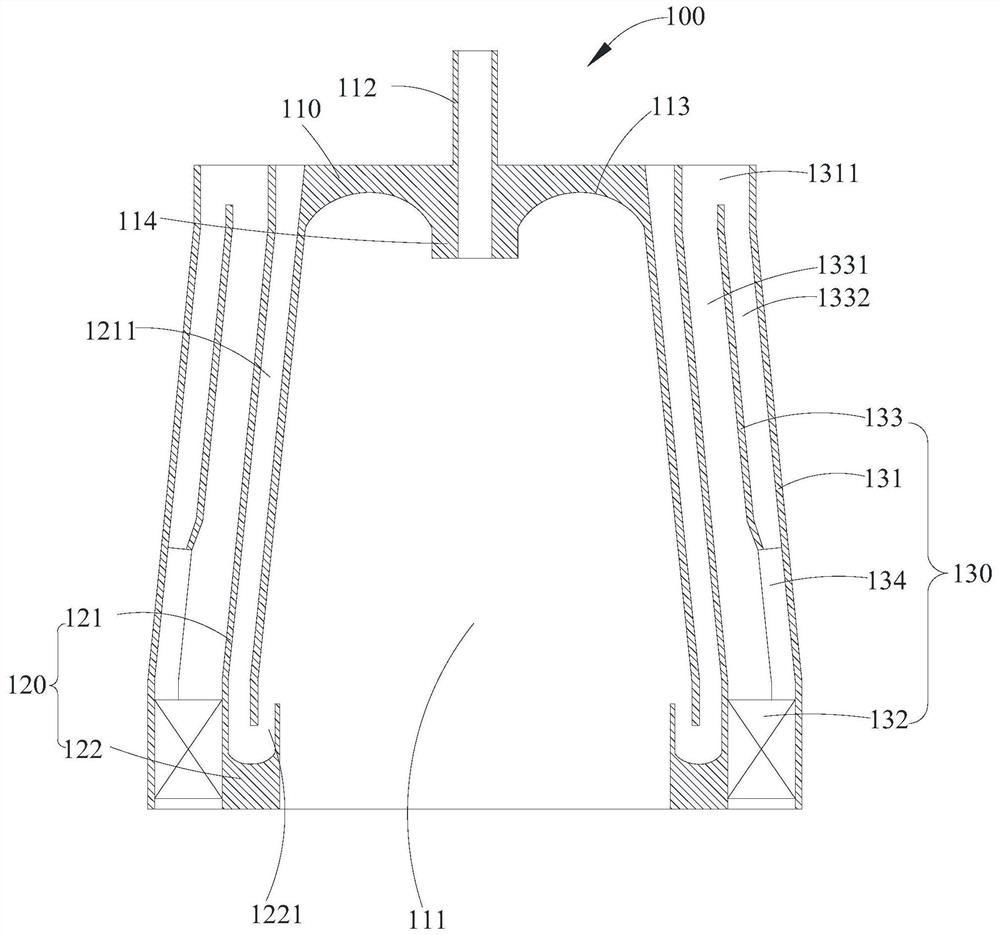

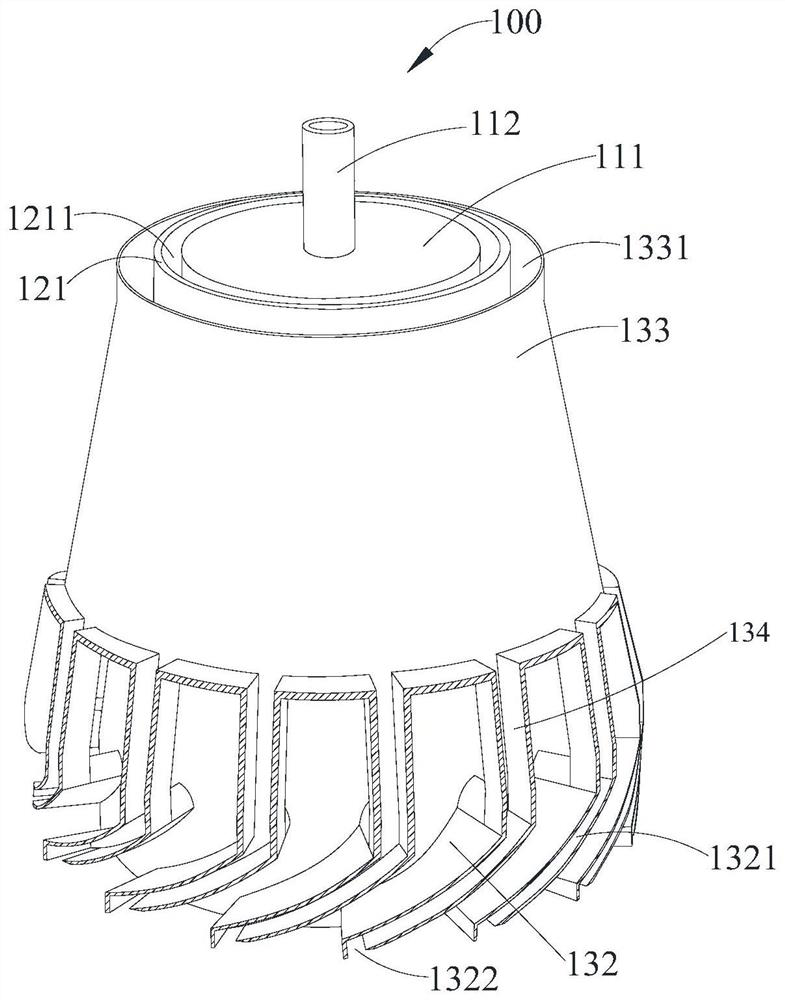

Final polycondensation reactor for preparing polycarbonate(PC)

ActiveCN110280202AImprove responseAvoid side effectsChemical/physical/physico-chemical stationary reactorsPolycarbonateSide reaction

The invention provides a final polycondensation reactor for preparing polycarbonate. The reactor includes a horizontal cylindrical body, a feeding port, a discharging port and a vacuum port; a driving shaft is arranged inside the horizontal cylindrical body, a feeding port, a discharging port and a vacuum port, a low viscosity area, a medium viscosity area and a high viscosity area are arranged inside the horizontal cylindrical body from the feeding port to the discharging port in sequence, disc blades, screen frame blades and spiral belt ring blades are installed on the driving shaft, the disc blades are lower than the low viscosity area, the screen frame blades are located in the medium viscosity area, and the spiral belt ring blades are located in the high viscosity area. According to the final polycondensation reactor for preparing polycarbonate, by arranging different types of blades, the reactor adapts to the change of material properties of different areas, which is beneficial to improving the reaction effect; the spiral belt ring blades of the high viscosity area can change the stay time of high viscosity PC, side effects are prevented, and the product quality is improved. The novel reactor is provided with the combined blades, an axial membrane and a radial membrane with a certain angle can be formed, certain driving force can be applied to the high viscosity PC at the end of the cylindrical body, the stay time can be effectively controlled, and a superheated side reaction is prevented.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

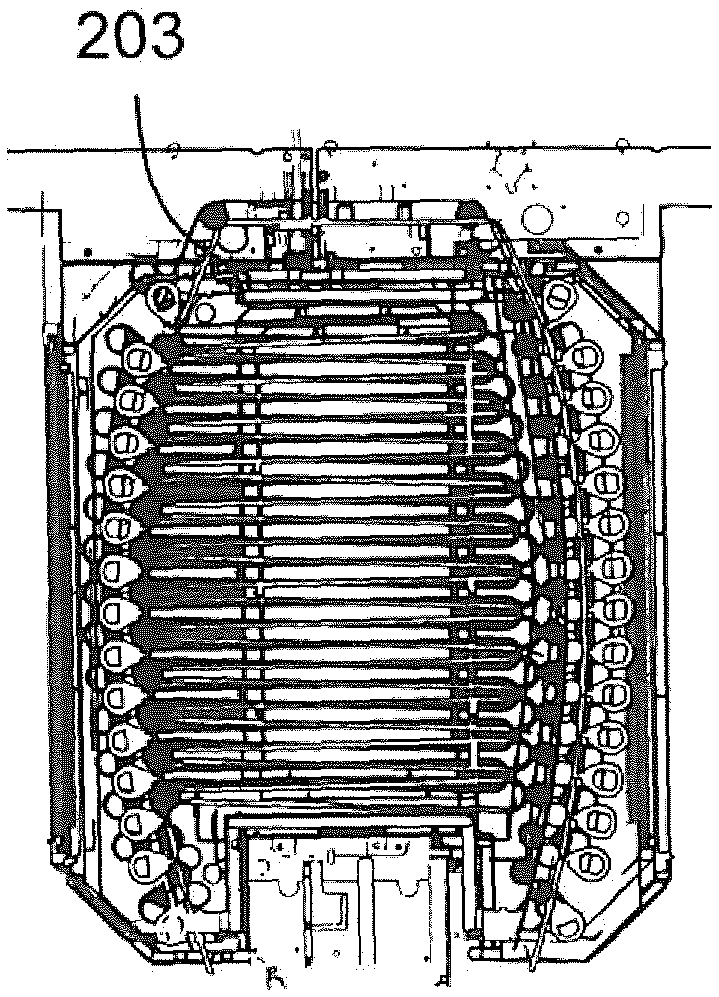

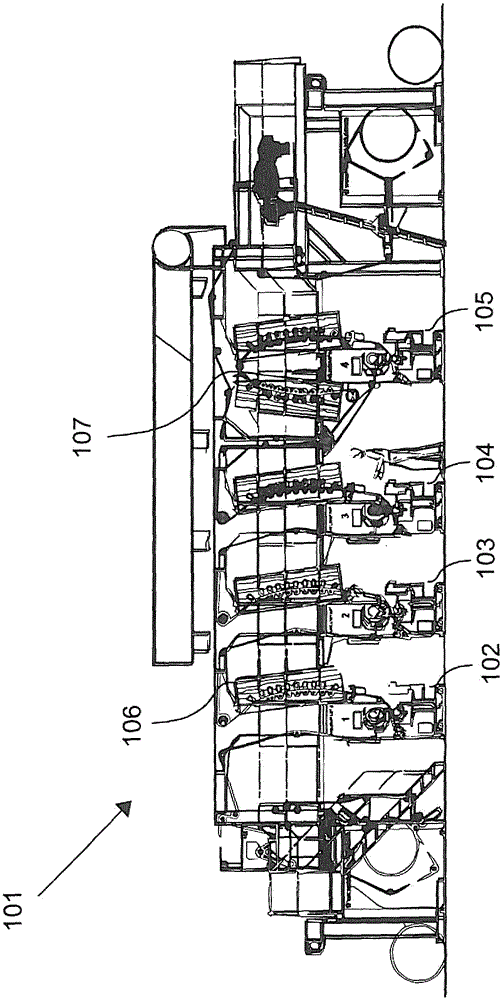

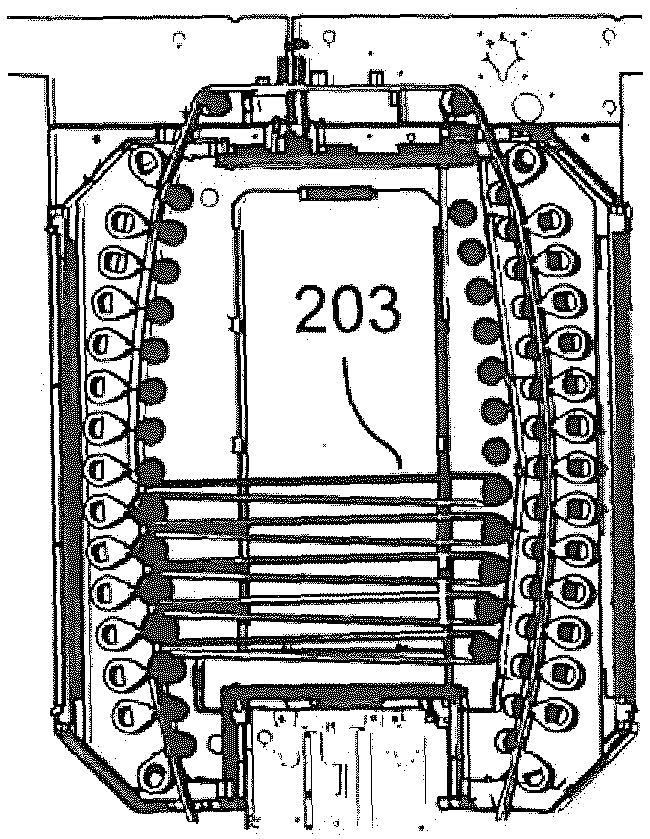

Dryer for drying a material web

InactiveCN105658434AChange dwell timeSwitch reachedDrying solid materials with heatFunction indicatorsEngineeringPrinting press

The invention relates to a dryer for drying a material web, in particular a material web (203) printed with inking units of a printing machine (101). In order to create a dryer for drying a material web that is run optimally for the task currently in progress, the dryer according to the invention comprises a drying section, in which the material web (203) is guided by deflection bodies (206), wherein the deflection bodies can be adjusted and / or the deflection bodies can be introduced into the web path and / or the deflection bodies can be removed from the web path in such a manner that the dwell time of the material web (203) in the drying section changes.

Owner:WINDMOELLER & HOELSCHER GMBH

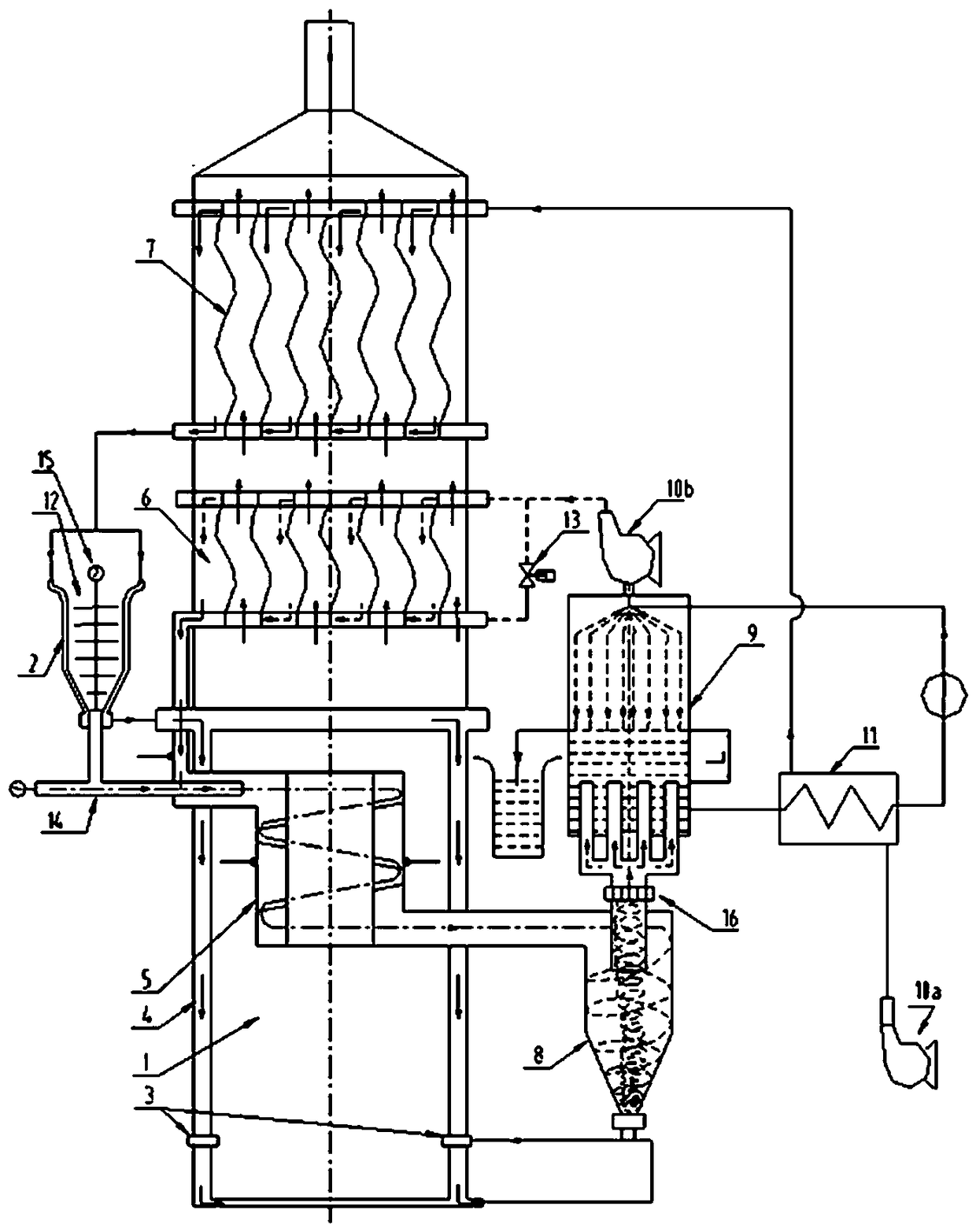

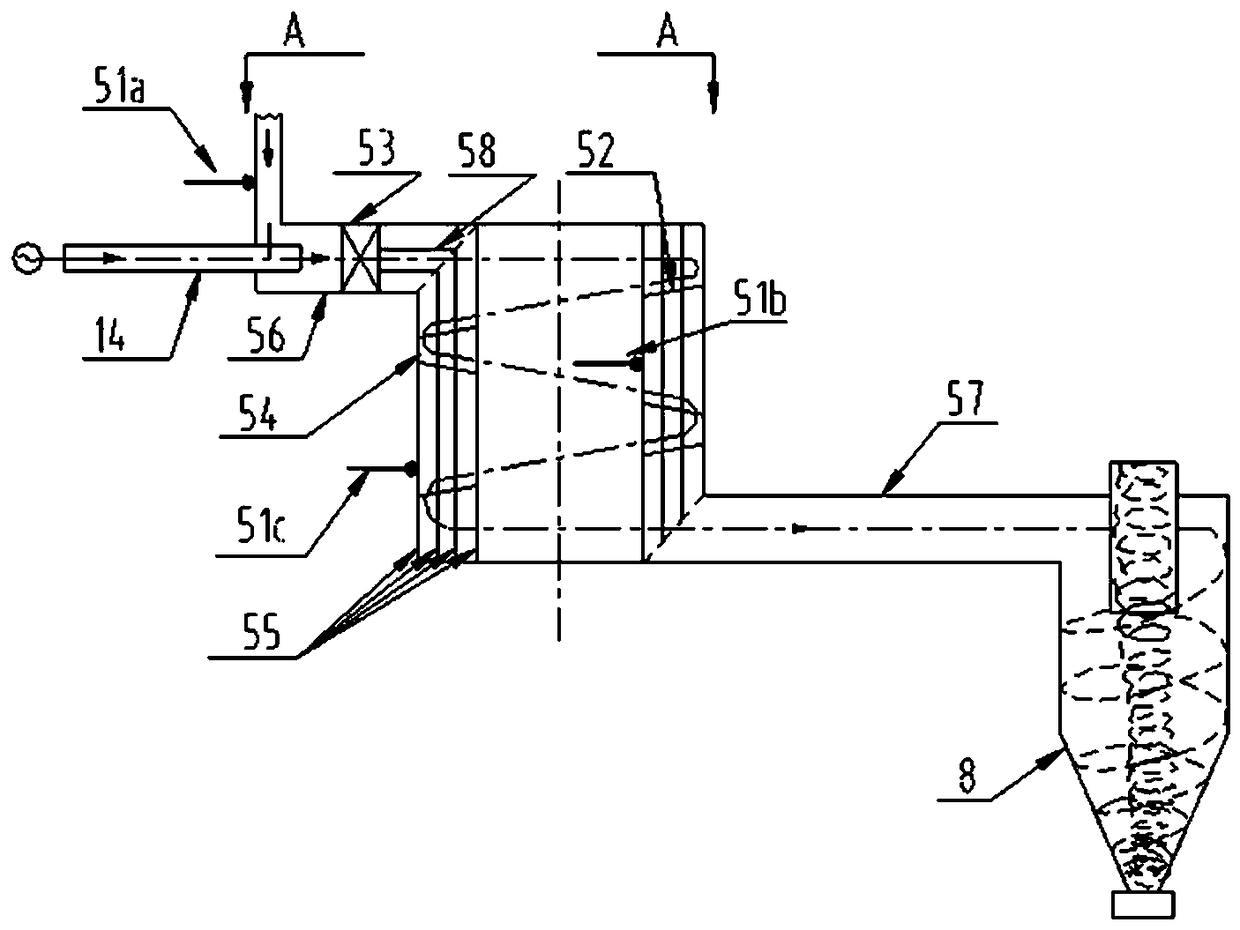

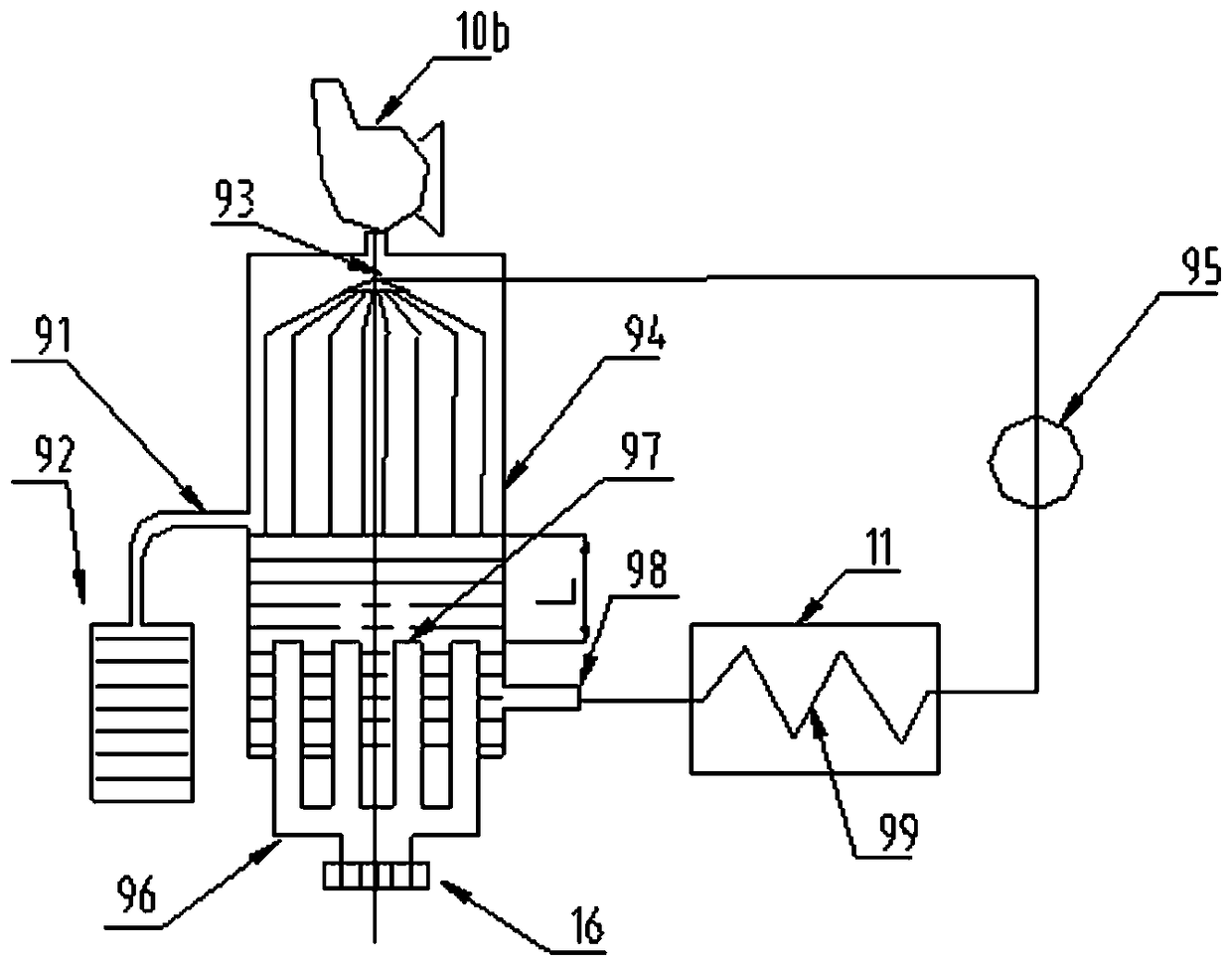

Method for drying and desolventizing cottonseed meal and special drying and desolventizing equipment of method

InactiveCN104479860AQuality improvementChange dwell timeDrying gas arrangementsFatty-oils/fats productionBiotechnologyProcess engineering

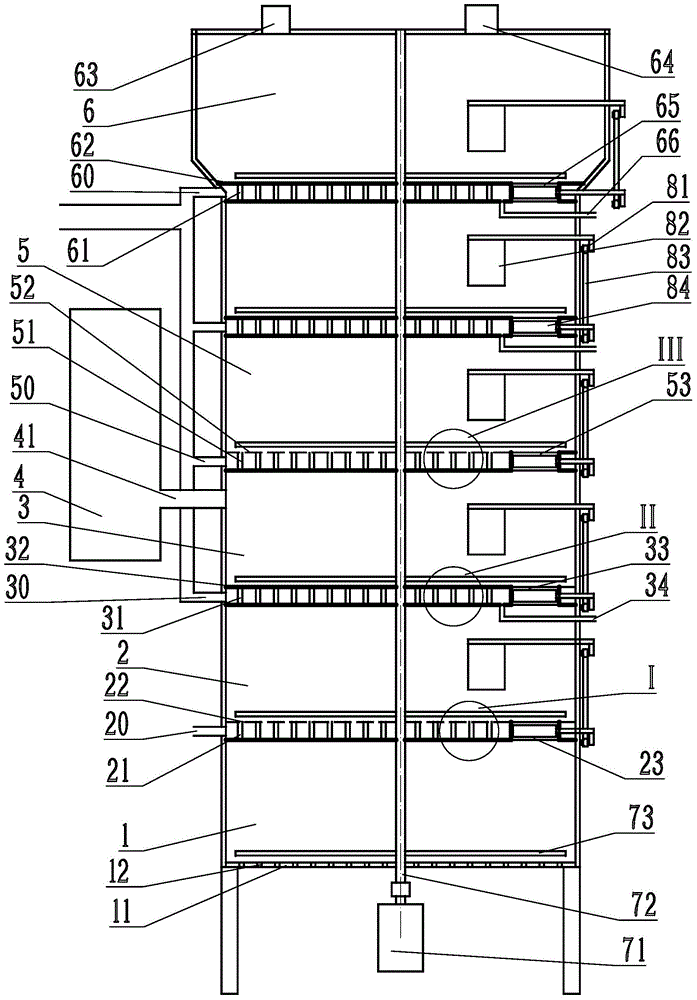

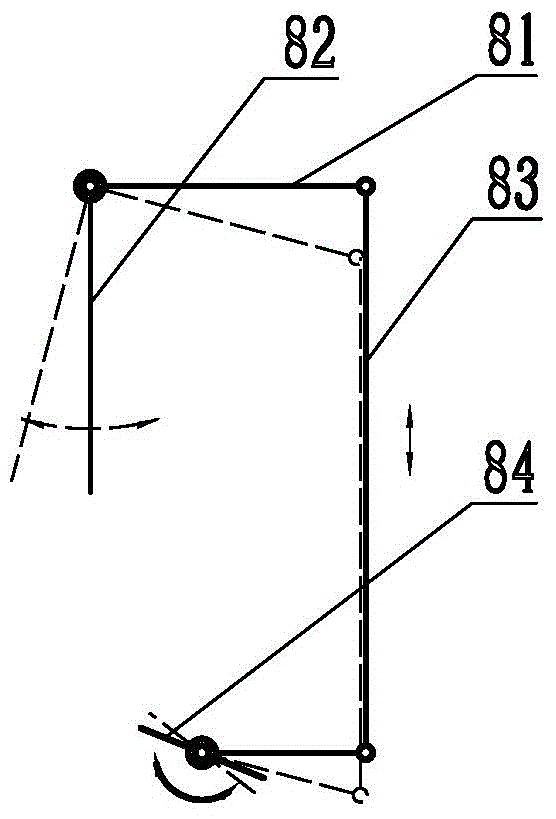

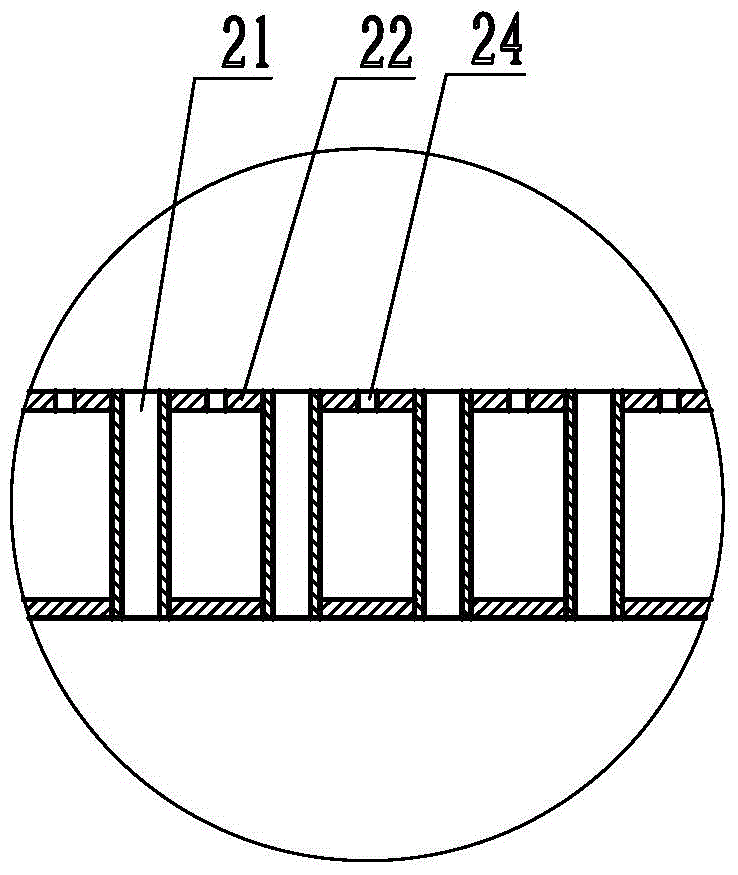

The invention discloses a method for drying and desolventizing cottonseed meal and special drying and desolventizing equipment of the method. The cottonseed meal is dried and desolventized by virtue of a drying tower, wherein the drying tower comprises a tower body and a stirring mechanism; the interior of the tower body comprises at least 5 layers, namely a discharging layer (1), a cooling layer (2), a drying layer (3), a ventilating layer (5) and a pre-desolventizing layer (6) sequentially; a partition board below the cooling layer (2), the drying layer (3), the ventilating layer (5) and the pre-desolventizing layer (6) is a sandwich hollow sheet; steam is directly input from the ventilating layer (5) and cooling gas is directly input from the cooling layer (2); the drying layer (3) and the pre-desolventizing layer (6) are used for indirectly heating by virtue of steam; and various layers are formed with material level regulating holes and corresponding material level regulating mechanisms for regulating the height of a material layer. Compared with the prior art, the drying and desolventizing method and the drying and desolventizing equipment disclosed by the invention can be used for effectively solving problems of an existing cottonseed meal protein treatment process which is instable in product, poor in color, high in residual oil, high in solvent consumption and the like, and the stable quality of the cottonseed meal protein is guaranteed.

Owner:BOLE JIALE GREASE

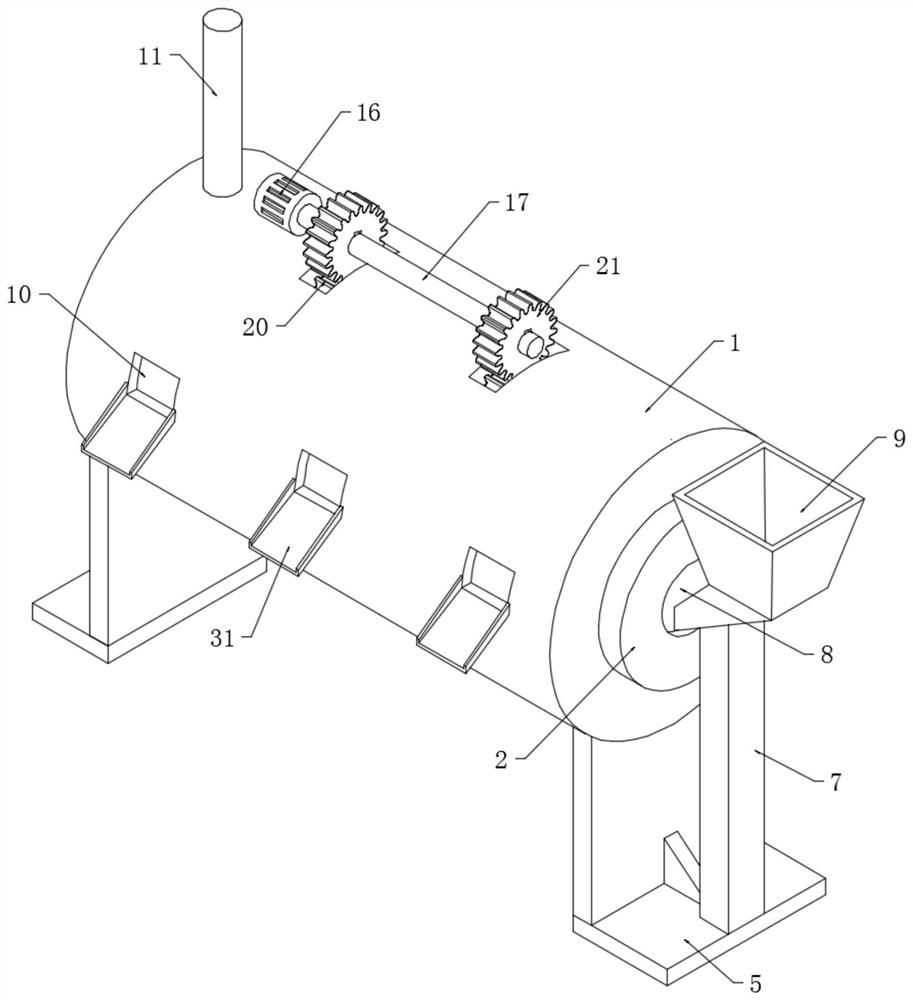

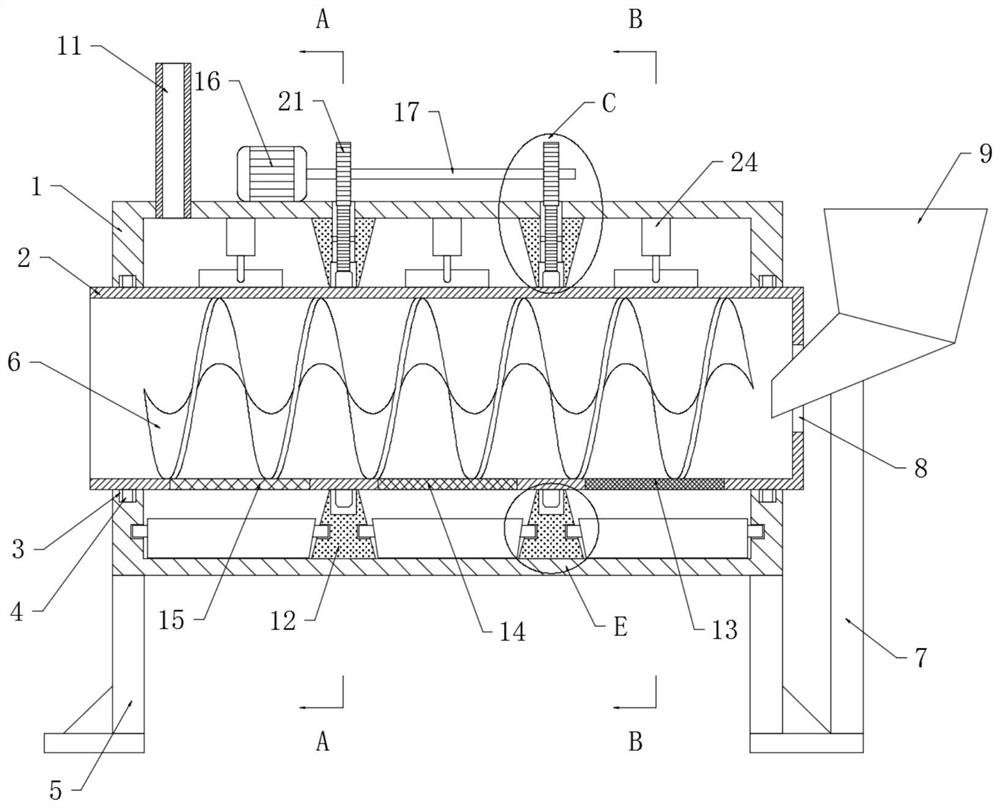

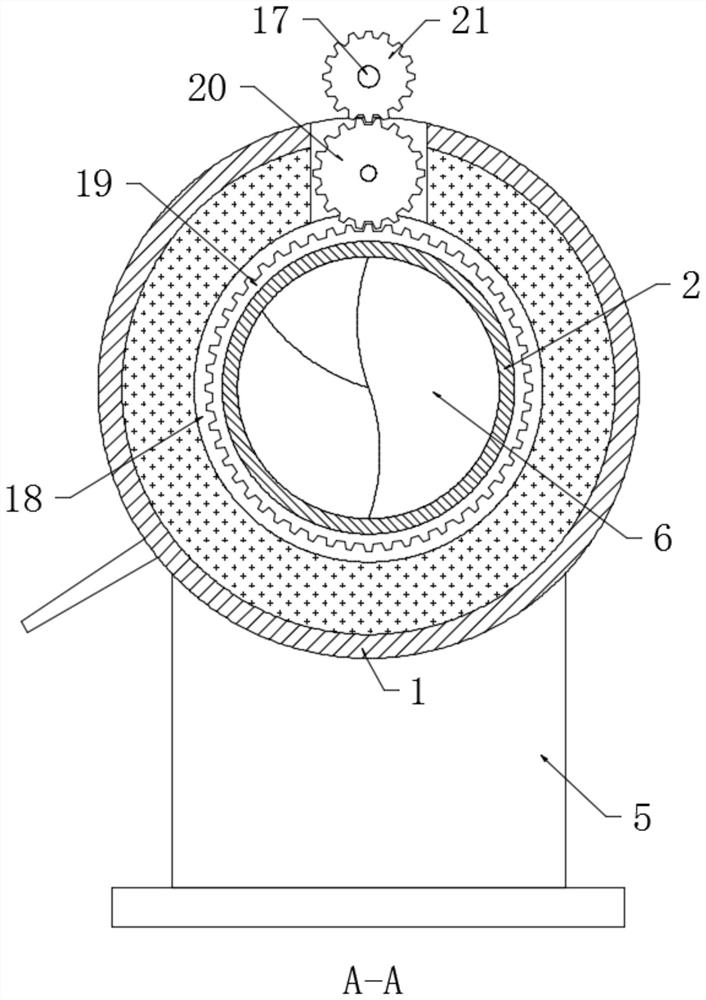

Multi-stage screening and drying integrated equipment for food machining

InactiveCN113522719AGood screening effectImprove screening efficiencySievingScreeningStructural engineeringIndustrial engineering

The invention discloses multi-stage screening and drying integrated equipment for food machining. The equipment comprises a transversely-arranged cylindrical machine box, wherein two supporting legs are fixedly connected to the outer wall of the bottom of the machine box, a cylindrical material screening box is rotationally connected to the box walls of the two sides of the machine box in a penetrating mode, the machine box and the material screening box are located on the same axis, guide rails are arranged on the positions, connected to the material screening box, of the box walls of the machine box, and a plurality of rolling wheels are arranged on the outer box wall of the material screening box and connected with the guide rails in a sliding mode. The equipment has the advantages that in a rotary material screening process of the material screening box, an inclined table on the outer wall of the material screening box can continuously rotate to the position below a push rod, an inclined face on the inclined table can continuously lift the push rod and then fall down, materials stuck on meshes of a screen mesh are vibrated to fall off through impact force and vibration generated when the push rod falls down to just collide with the screen mesh, subsequent material screening is prevented from being affected, the time for cleaning the stuck materials on the screen mesh is saved, and the screening efficiency is further improved.

Owner:ZHEJIANG SHENGNA INTELLIGENT TECH CO LTD

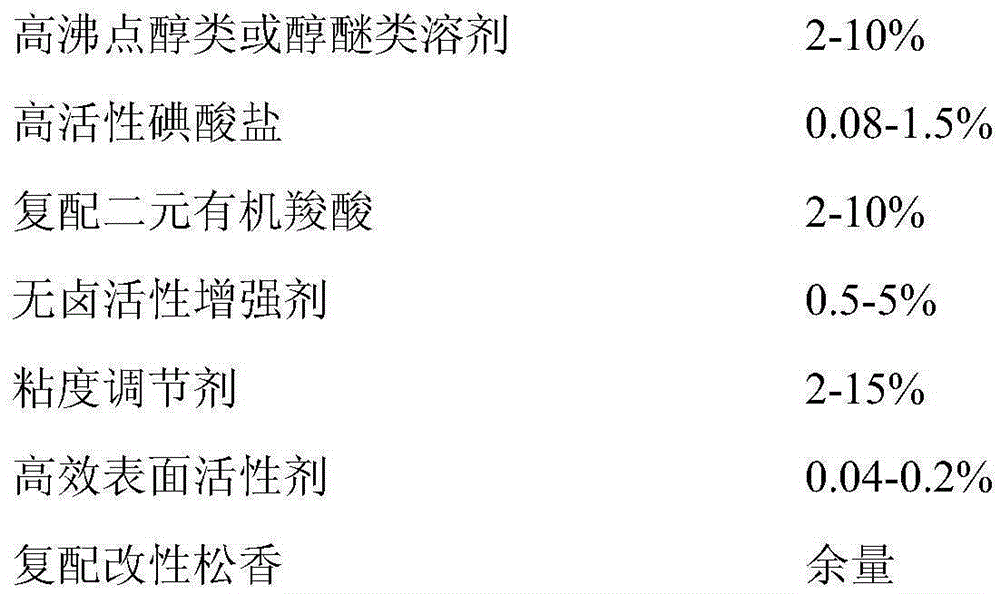

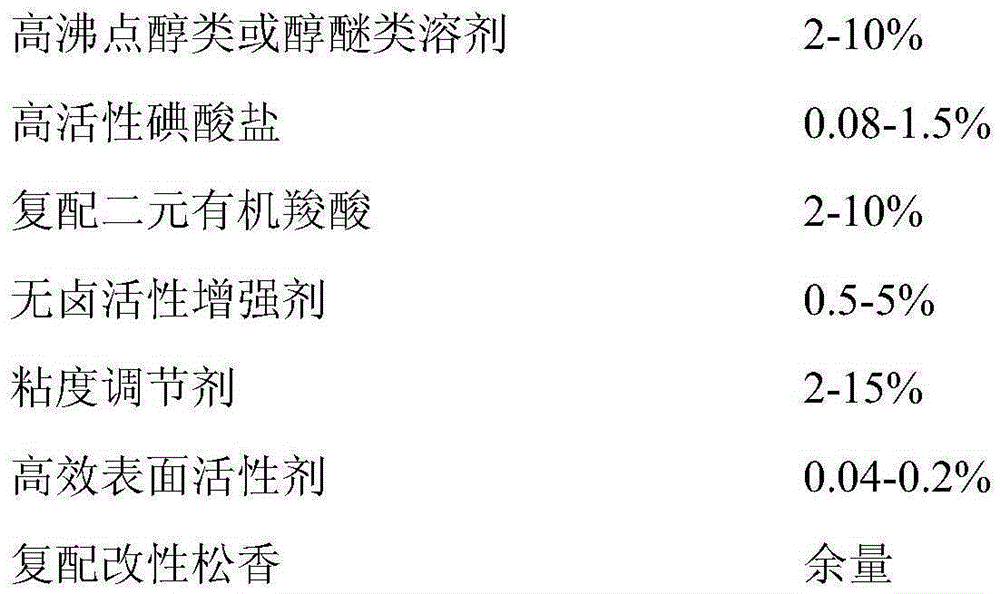

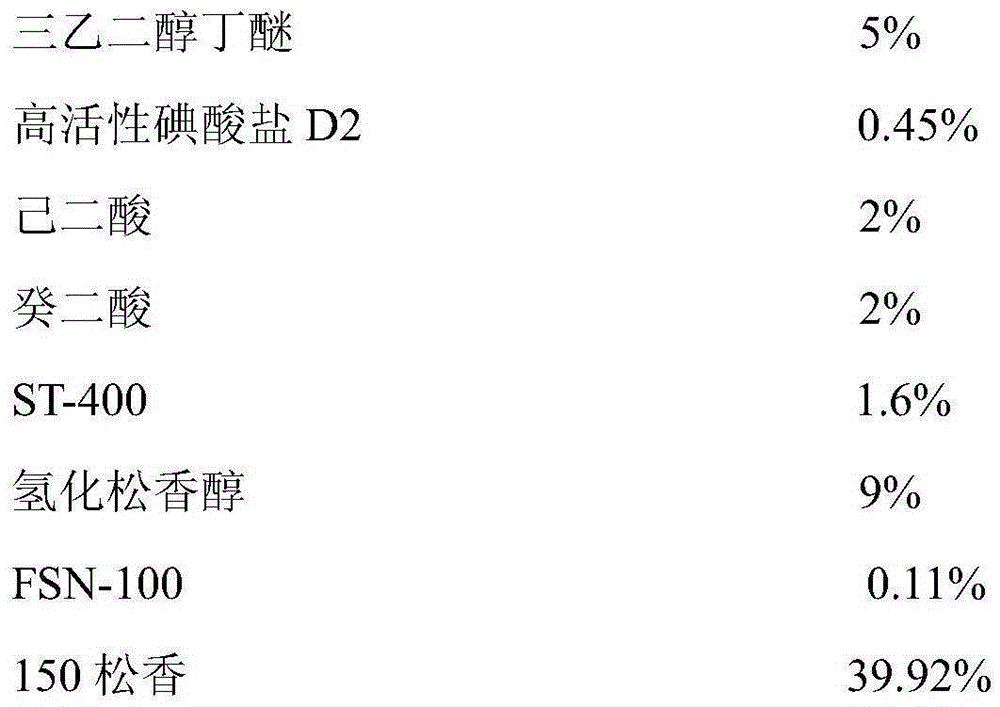

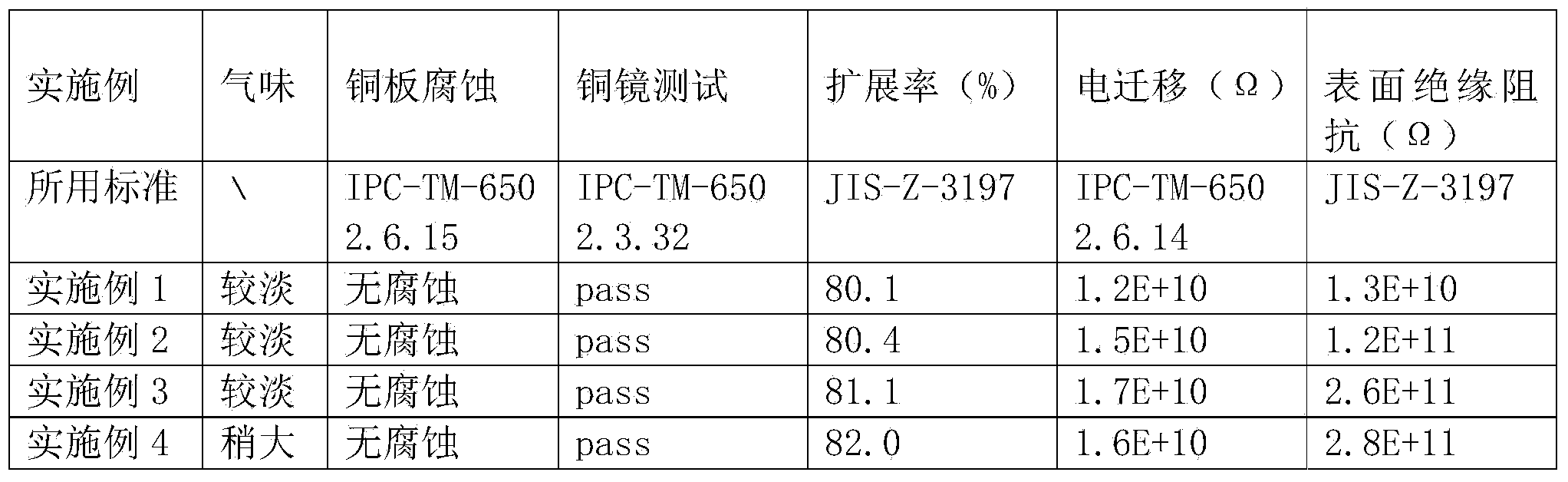

A halogen-free high-activity low-spatter solder wire flux and preparation method thereof

InactiveCN104191108BHalogenatedFast tinningWelding/cutting media/materialsSoldering mediaSurface-active agentsSolvent

The invention discloses halogen-free high-activity low-splatter solder wire soldering flux and a preparing method thereof. The halogen-free high-activity low-splatter solder wire soldering flux comprises, by mass, 2-10 percent of alcohol or alcohol ether high-boiling-point solvent, 0.08-1.5 percent of high-activity iodate, 2-10 percent of compound binary organic acid, 0.5-5 percent of halogen-free activity enhancer, 2-15 percent of viscosity modifier, 0.04-0.2 percent of efficient surface active agent and the balance modified rosin and rosin derivatives. The preparing method includes the steps that the compound rosin and the viscosity modifier are added into a container to be heated and stirred until the compound rosin and the viscosity modifier are completely melted down, the organic acid, the novel high-activity iodate, the efficient surface active agent and the high-boiling-point solvent are added to be stirred continuously, and therefore the soldering flux is prepared. The prepared halogen-free soldering flux for solder wires is free of halogen compounds, tin is easy to apply in the soldering process, splatter is little, smells are light, soldering spots are bright and full, damage to the health and the environment is avoided, and the post-soldering reliability effect of an electronic product is ensured.

Owner:SOUTH CHINA UNIV OF TECH +1

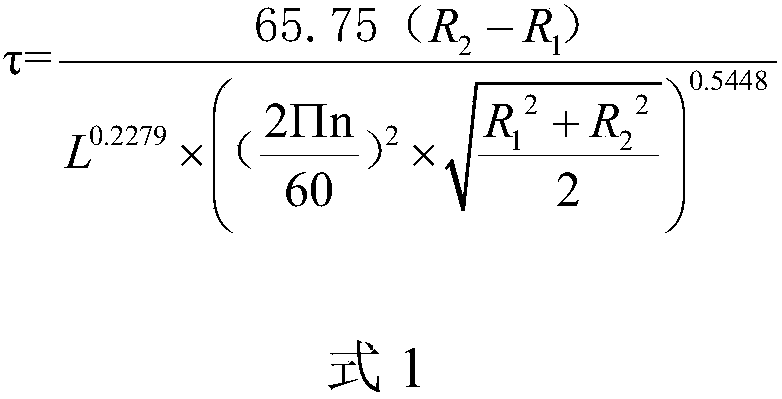

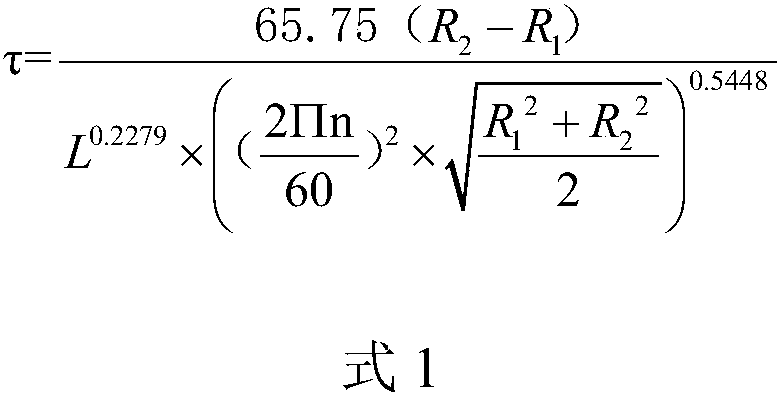

Method for synthesizing acetone condensation compound from acetone and hydrogen

ActiveCN110903179AChange selectivityHigh selectivityOrganic compound preparationChemical industryPtru catalystLiquid state

The invention belongs to the field of chemical engineering, and discloses a method for synthesizing an acetone condensation compound from acetone and hydrogen. The method comprises the following steps: mixing acetone and hydrogen, introducing into a supergravity rotating bed, contacting a catalyst bed layer arranged on the rotor of the supergravity rotating bed, and reacting to obtain a liquid-phase component containing the acetone condensation compound and a gas-phase component, wherein the residence time tau of the liquid-phase component in the catalyst bed layer is less than or equal to 20s. According to the invention, the supergravity rotating bed reactor is introduced into the reaction for one-step synthesis of the acetone condensation compound from acetone and hydrogen, so that theretention time of the liquid-state product in the catalyst bed layer is remarkably shortened, the phenomenon of carbon deposition and coking in the catalyst along with the prolonging of the reaction time is relieved / eliminated, the service life of the catalyst is prolonged, and the conversion rate of reactants and the selectivity of the product are changed.

Owner:CHINA PETROLEUM & CHEM CORP +1

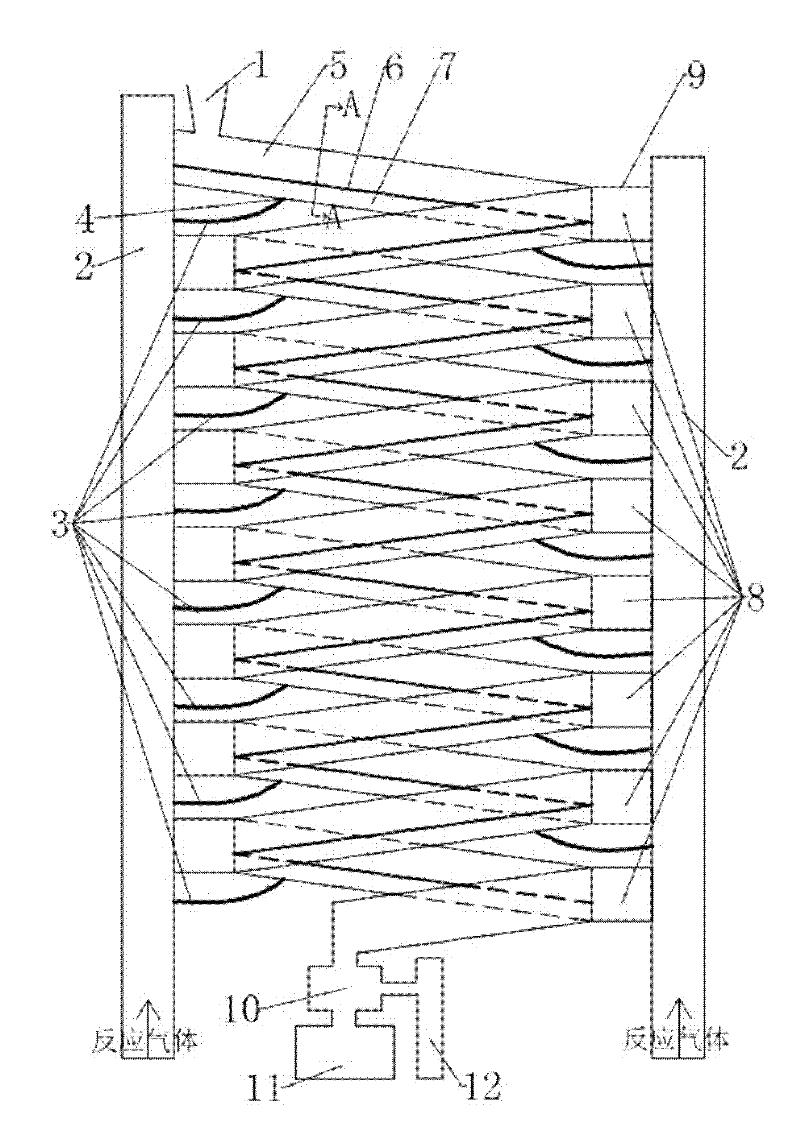

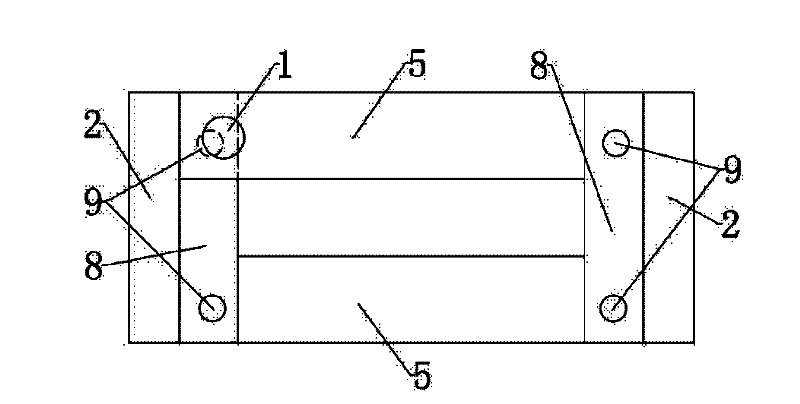

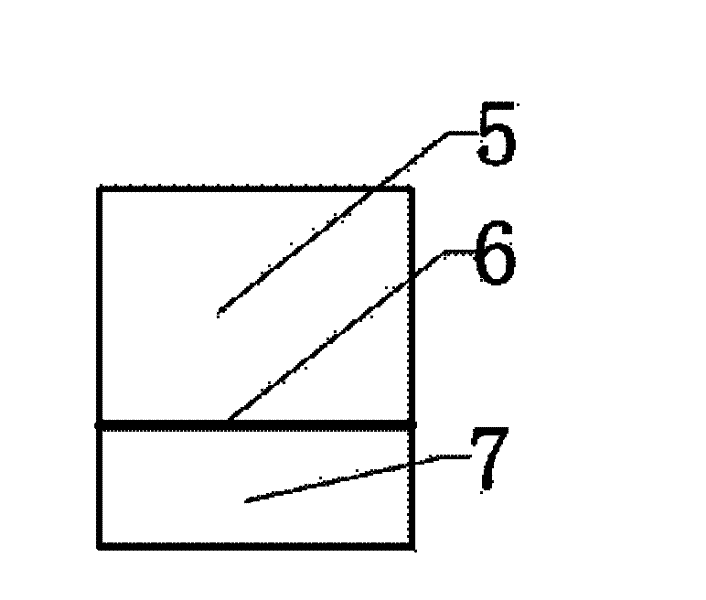

Dense phase transport bed reactor

InactiveCN102247793AAchieve high concentration inputAdjust densityChemical/physical/physico-chemical stationary reactorsGas solidIndustrial gas

A dense phase transport bed reactor belongs to the technical field of chemical industrial gas-solid two phase reaction equipment. The dense phase transport bed reactor comprises a top feeding port, gas transport passages, transport beds, a separator, a solid collector and a gas collector, wherein the transport beds contain multiple levels, and each level of transport bed, which slants down, is composed of a transport groove, an air distribution plate disposed on the lower portion of the transport groove and an air compartment; two adjacent level of transport beds are connected end to end by a horizontal transition section; the gas transport passages lead out a plurality of gas branches, and the air compartment of each level transport bed is connected with the gas transport passages by the gas branches. According to the dense phase transport bed reactor, the transport beds are utilized to carry out the gas-solid two phase reaction. The transport process is stable, the concentration of a solid reactant is high, and the reaction speed of a mixture can be regulated by adjusting the inclination angle. The dense phase transport bed reactor has advantages of high concentration of the reaction solid, stable reaction process, easily controllable reaction time, simple structure and the like, and especially is suitable for the gas-solid two phase reaction with high concentration of the solid reactant.

Owner:TSINGHUA UNIV +1

Annular wall heat type reverse-spraying pulverized coal burner

ActiveCN112050203ASimple structureStrong reliabilityFuel supply regulationPulverulent fuel combustion burnersThermodynamicsCombustor

The invention provides an annular wall heat type reverse-spraying pulverized coal burner. The burner comprises a pre-burning structural body, a reverse-spraying assembly and a secondary air assembly,wherein the pre-burning structural body is provided with a pre-heating burning chamber and a central injection air pipe which communicates with the pre-heating burning chamber; the reverse-spraying assembly comprises a main pulverized coal pipe and a groove-shaped baffle ring, the main pulverized coal pipe is arranged on the outer side of the pre-burning structural body in a sleeving mode, a mainpulverized coal airflow channel is defined by the main pulverized coal pipe, and the groove-shaped baffle ring is connected to the end portion of the main pulverized coal pipe and partially located atthe outlet end of the pre-burning structural body; a reverse-spraying channel is defined by the groove-shaped baffle ring and the end portion of the pre-burning structural body; and the secondary airassembly comprises a secondary air pipe and hollow swirl starting blades, the secondary air pipe is arranged on the outer side of the main pulverized coal pipe in a sleeving mode, a secondary air channel is defined by the secondary air pipe and the main pulverized coal pipe, and the hollow swirl starting blades are arranged at the outlet end of the secondary air channel. Other pipelines and accessory structures do not exist in the pre-heating burning chamber, so that the annular wall heat type reverse-spraying pulverized coal burner is simple in structure and high in operation reliability.

Owner:TSINGHUA UNIV

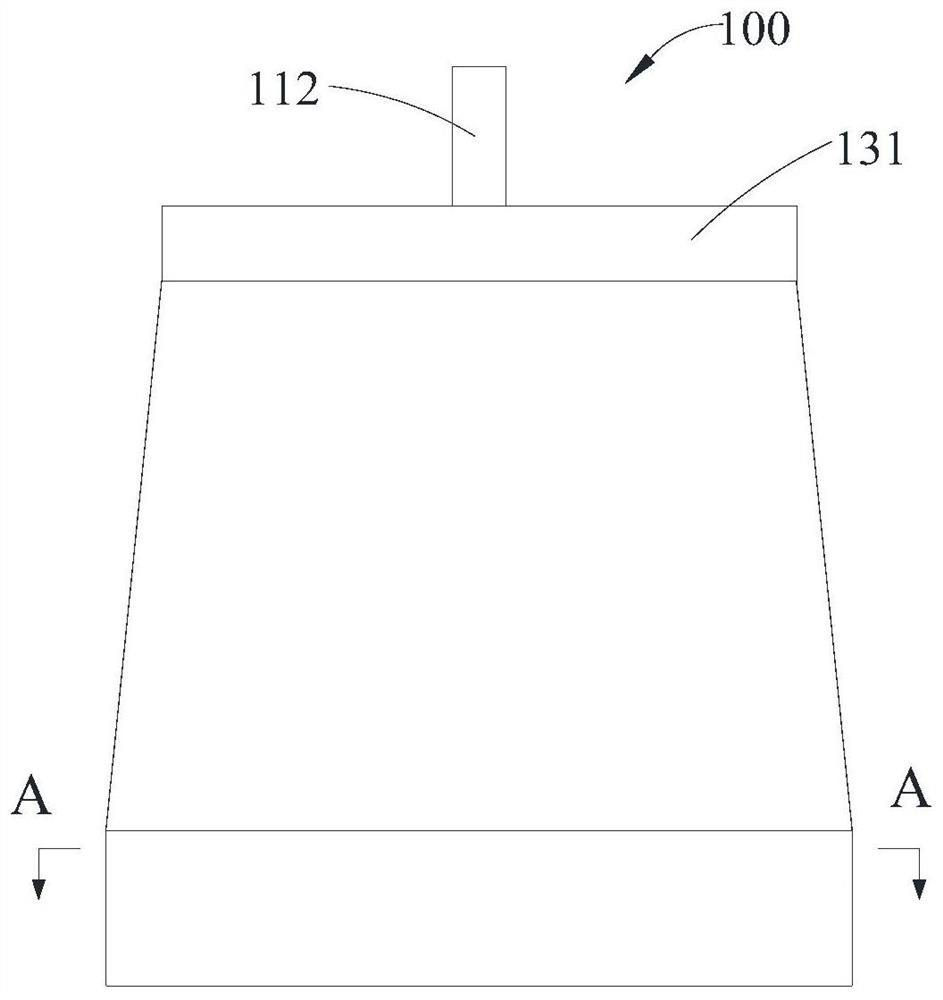

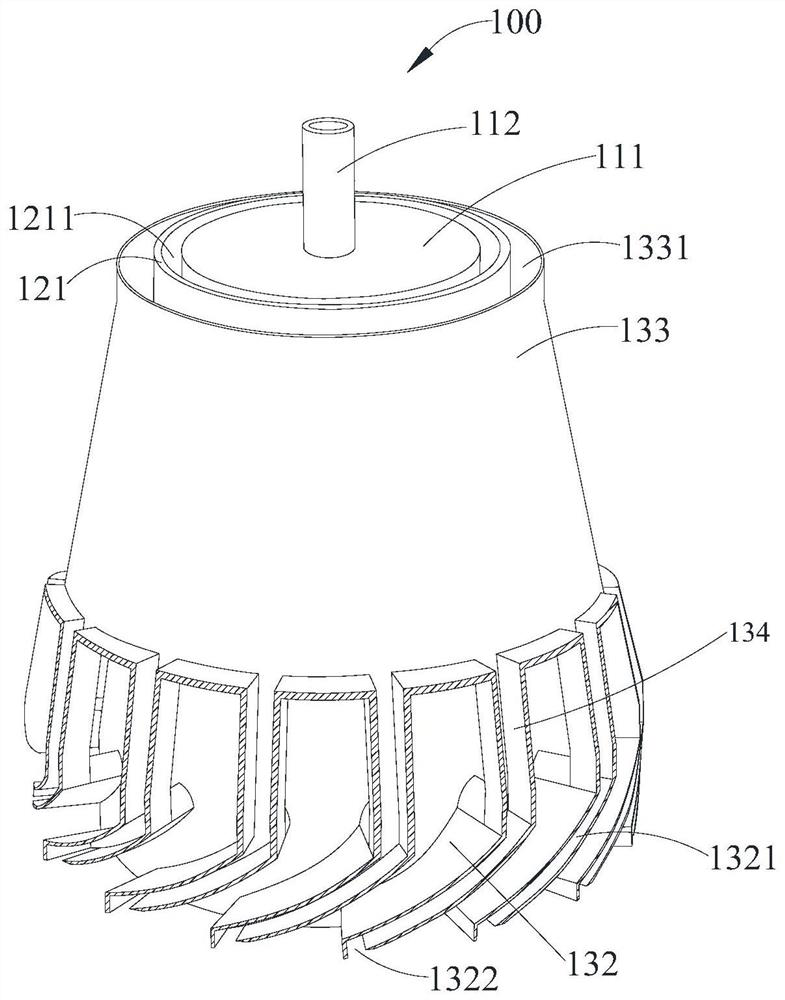

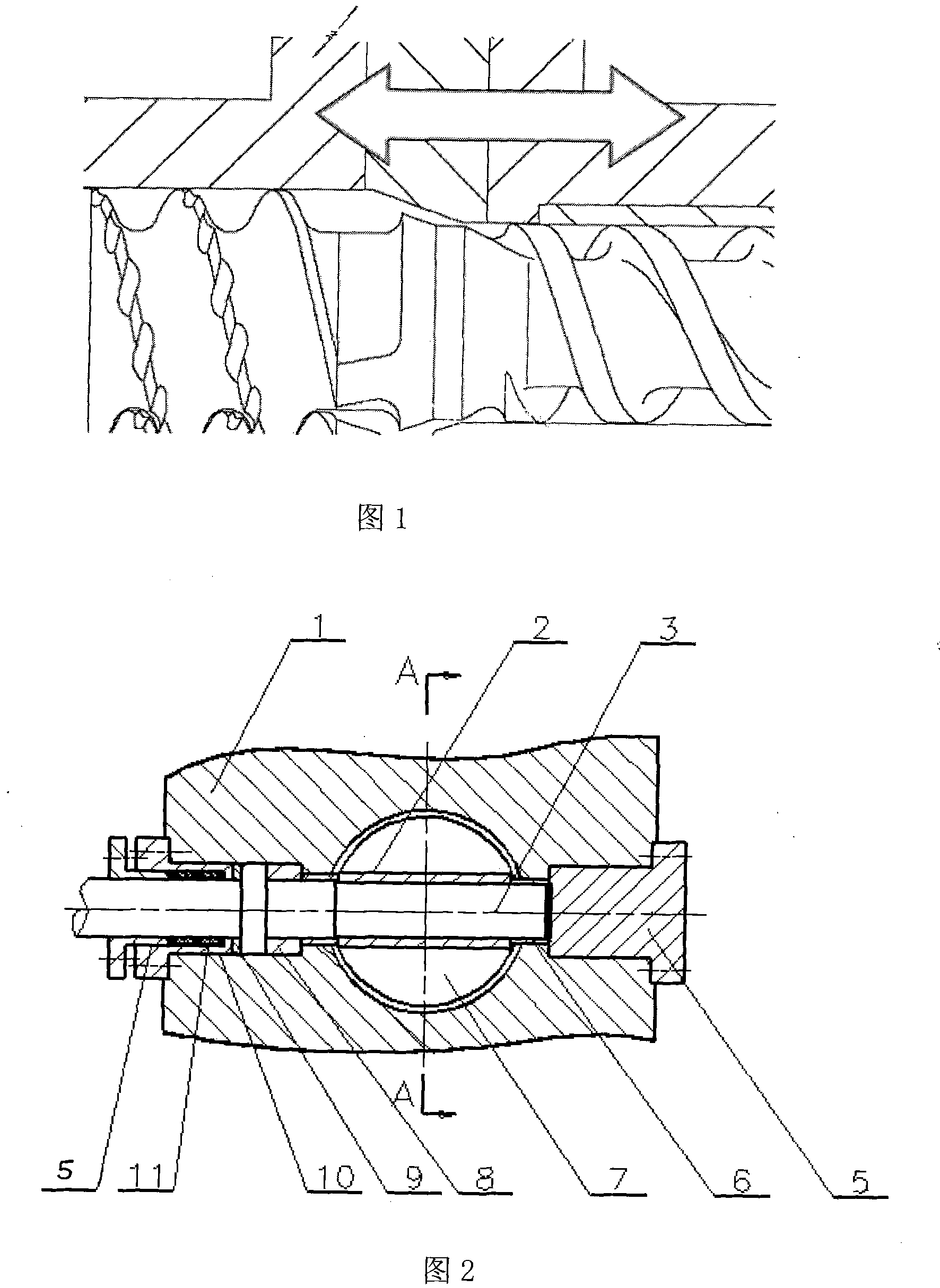

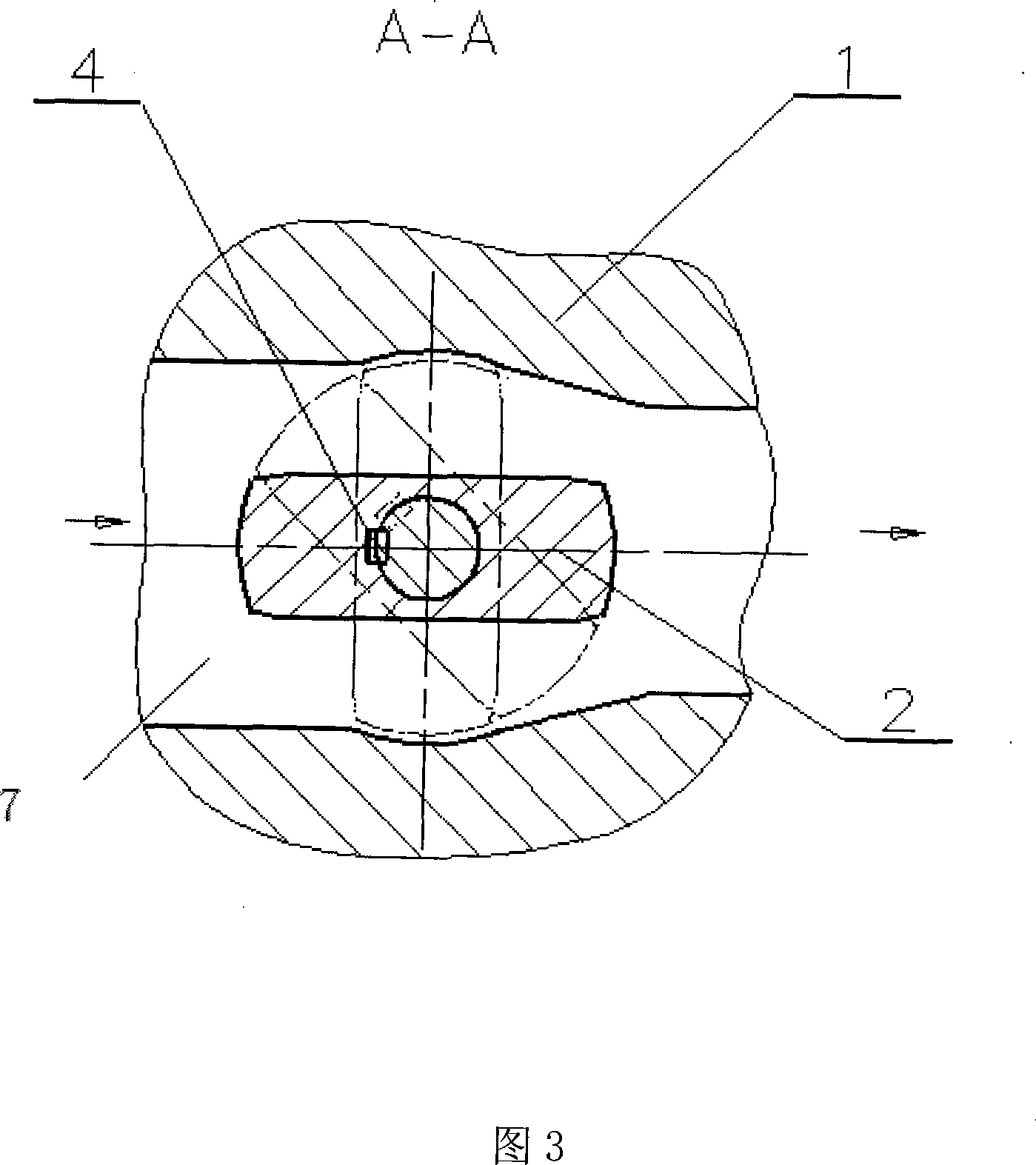

Fondant milling degree regulating device of milling extrusion pressing granulation machine group

The invention relates to a mixing and extruding granulator set. The melt mixing degree adjusting device of the mixing granulator set is characterized in that a valve is provided with a material channel, and that the material channel is provided with a rotatable valve core or valve plate, the flow areas of which vary with the rotation angle. The invention has novel structure, small volume and the mixing degree can be adjusted through the valve, the material channel area of which can be adjusted. The valve has simple structure, and with the angle between the rotatable valve core or valve plate in the material channel and the horizontal plane of the material channel changes, the flow area of material changes correspondingly, thus adjusting the flow resistance of the material from the mixing transmission part in the channel, changing the resident time of material in the channel, achieving the goal of increasing the mixing effect of the material, adjusting the back pressure of the materialin the mixing transmission system and changing the actual power consumption of the main drive motor of the set.

Owner:大连橡胶塑料机械有限公司

Halogen-free low-splash solder wire and preparation method of halogen-free low-splash solder wire

InactiveCN103071944BSmall smellReduce splashWelding/cutting media/materialsSoldering mediaOrganic acidActive agent

The invention discloses a halogen-free low-splash solder wire and a preparation method of the halogen-free low-splash solder wire. The halogen-free low-splash solder wire comprises the following ingredients in percentage by mass: 97.4 percent to 98.2 percent of welding fluxes and 1.8 to 2.6 percent of soldering fluxes, wherein the welding fluxes are selected from one of materials including Sn-0.7Cu, Sn-3.0Ag-0.5Cu and Sn-0.3Ag-0.7Cu, and the soldering fluxes consist of the following ingredients in percentage by mass: 12 to 22 percent of rubber, 6.5 to 8.5 percent of organic acid, 2 percent of benzotriazole, 2 percent of imidazole substances, 3 percent of oxidation resistant oil, 3.5 to 4.5 percent of composite active agents and the balance of rosin. The preparation method is characterized in that firstly, the soldering fluxes are prepared according to the proportion, and then, the solder wire is obtained through work procedures of wire extrusion, wire pulling and wire winding. The characteristic indexes of the solder wire respectively meet the requirements of JIS-Z-3197 and IPC-TM-650 standards. After the welding, welding spots are bright and full, the odor is low, the splash is little, and green and environment-friendly effects are realized.

Owner:JIANGSU UNIV OF SCI & TECH

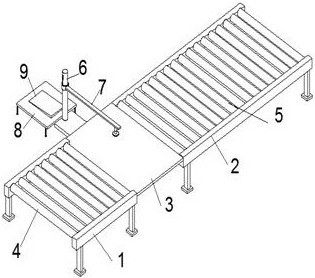

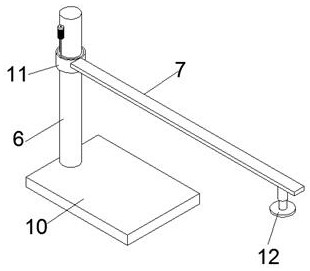

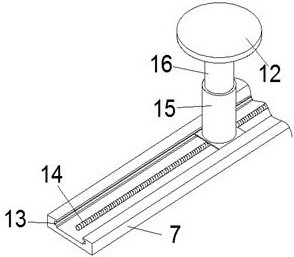

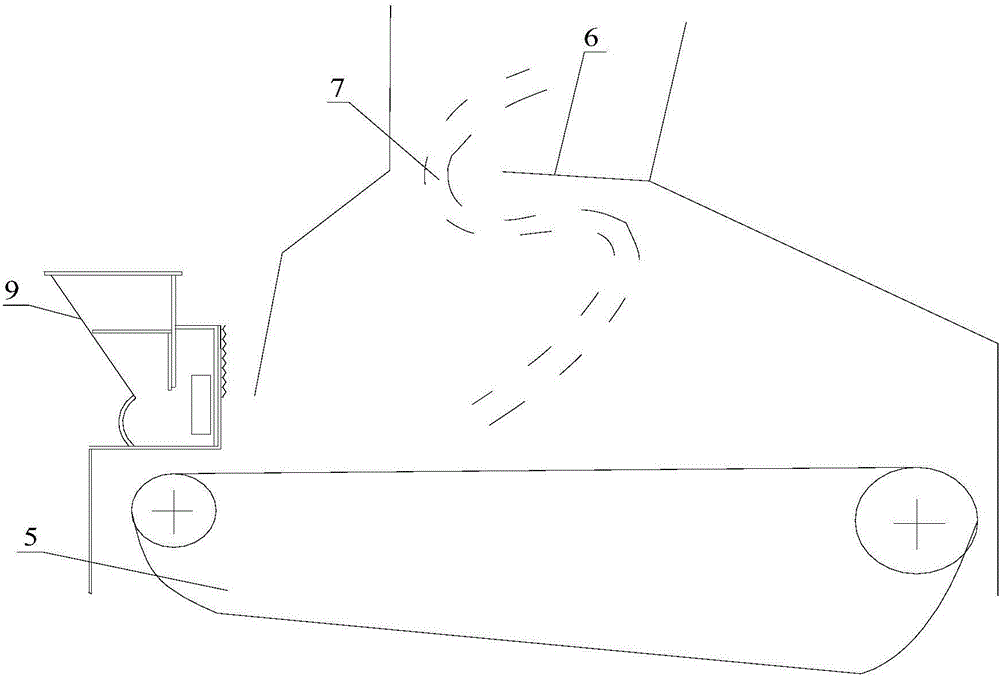

Material purchasing quality inspection analysis device

InactiveCN112374022AReasonable designChange dwell timeSupporting framesRoller-waysElectric machineryLap joint

The invention discloses a material purchasing quality inspection analysis device. The device comprises a first frame, a second frame, a lap joint plate, a front rolling shaft, a rear rolling shaft, astand column, a cross rod, an analysis platform and an analyzer, supporting legs are welded to the bottom of the first frame and the bottom of the second frame, the first frame and the second frame are fixed to the ground through the supporting legs, the lap joint plate is installed between the first frame and the second frame, the front rolling shaft is installed in the first frame, the rear rolling shaft is installed in the second frame, the front rolling shaft and the rear rolling shaft are driven by a motor, the stand column is arranged on one side of the lap joint plate, the cross rod isinstalled on the stand column, the cross rod extends to the position above the lap joint plate, the analysis platform is installed behind the stand column, the analyzer is fixed to the analysis platform, and purchased materials are iron materials. According to the material purchasing quality inspection analysis device, and the design is reasonable; and the materials can be rapidly transported through the design of the first frame and the second frame, and the materials are easy to select through the design of the lap joint plate.

Owner:ZAOZHUANG POWER SUPPLY COMPANY OF STATE GRID SHANDONG ELECTRIC POWER +1

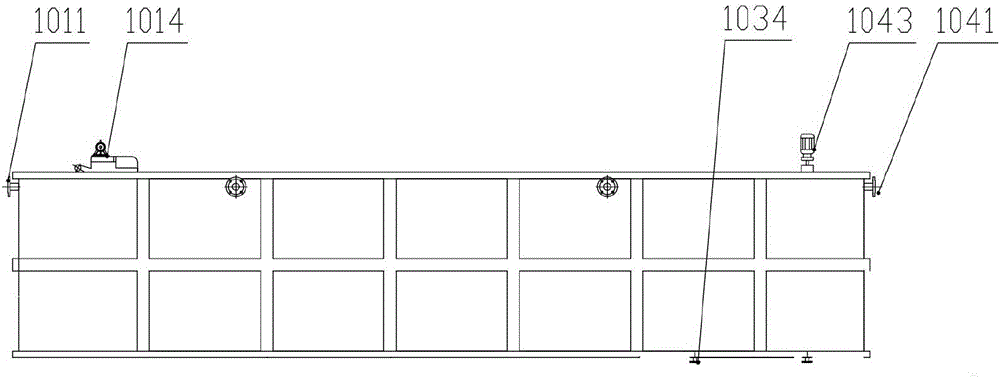

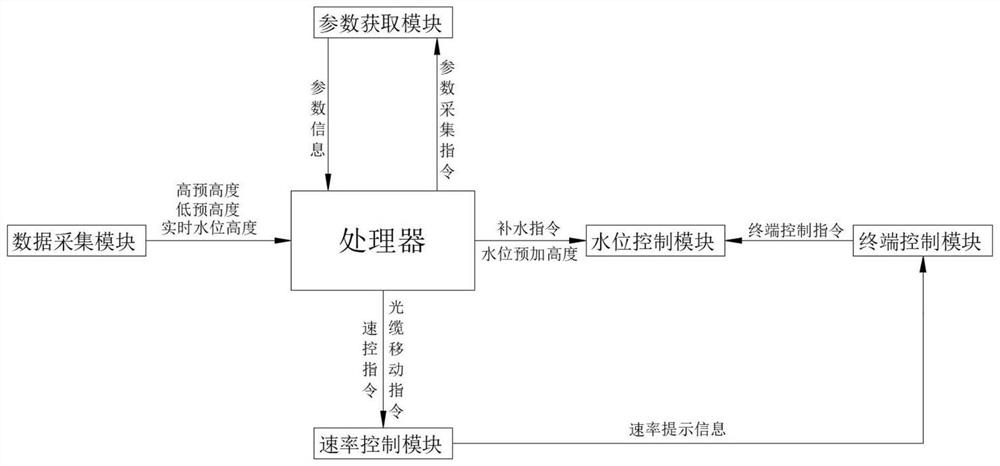

Multi-water-tank water level monitoring and analyzing system based on big data

PendingCN114485862AGuarantee the final qualityReduce lossMachines/enginesLevel indicatorsProcess engineeringData acquisition module

The invention relates to the field of optical cable production, and aims to solve the problems that the final quality of a finished product is affected due to the fact that water in an existing water tank is insufficient and the temperature of an optical cable cannot be reduced easily, and serious waste of water resources can be caused if a good cooling effect can be achieved if cooling water is continuously added into a cold water tank. The system comprises a data acquisition module, a processor, a parameter acquisition module, a rate control module, a water level control module and a terminal control module, the system controls the real-time water level height to continuously rise through the water level control module, and it is guaranteed that water in water tanks is sufficient; the temperature of the optical cable can be reduced, the final quality of a finished product is guaranteed, the water level in the water tank is increased in real time, the cooling effect can still be guaranteed when the water amount is small, and a large amount of cooling water is not used, so that water resource loss is reduced.

Owner:安徽天凯光通信技术有限公司

Special equipment for two-medium quenching heat treatment and cooling and technology of equipment

InactiveCN103436671BChange dwell timeSpeed up coolingQuenching agentsQuenching devicesSlide plateOil cooling

The invention relates to special equipment for two-medium quenching heat treatment and cooling and a technology of the equipment. The equipment comprises landing legs, a sliding plate, a separation plate, a box plate, a slotted-angle shelving, a roller seat, a pull rope, guide rails, a guide roller, a net basket, a rope reeling roll, a stepping motor and a control cabinet, wherein the box plate and the slotted-angle shelving are welded to form a quenching cooling tank; the quenching cooling tank is supported by the landing legs; the separation plate is welded in the quenching cooling tank, and divides the quenching cooling tank into a water tank and an oil tank with the lower parts communicated; the lower part the water tank is welded with the sliding plate; the sliding plate is placed obliquely; steel is heated and subjected to heat preservation to form austenite, then is put in the water tank, and enters the net basket via the sliding plate; and the net basket and the steel in the net basket move up into oil from water through a lifting mechanism under control of the control cabinet, so that the water quenching and oil cooling two-medium quenching technology is achieved. According to the equipment and the technology, quenching deformation and cracking of the steel can be avoided effectively; an automation degree is high; the labor intensity is low; brine and oil two-medium quenching and brine-oil-air three-medium quenching can be achieved; and the equipment and the technology have broad market prospects.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

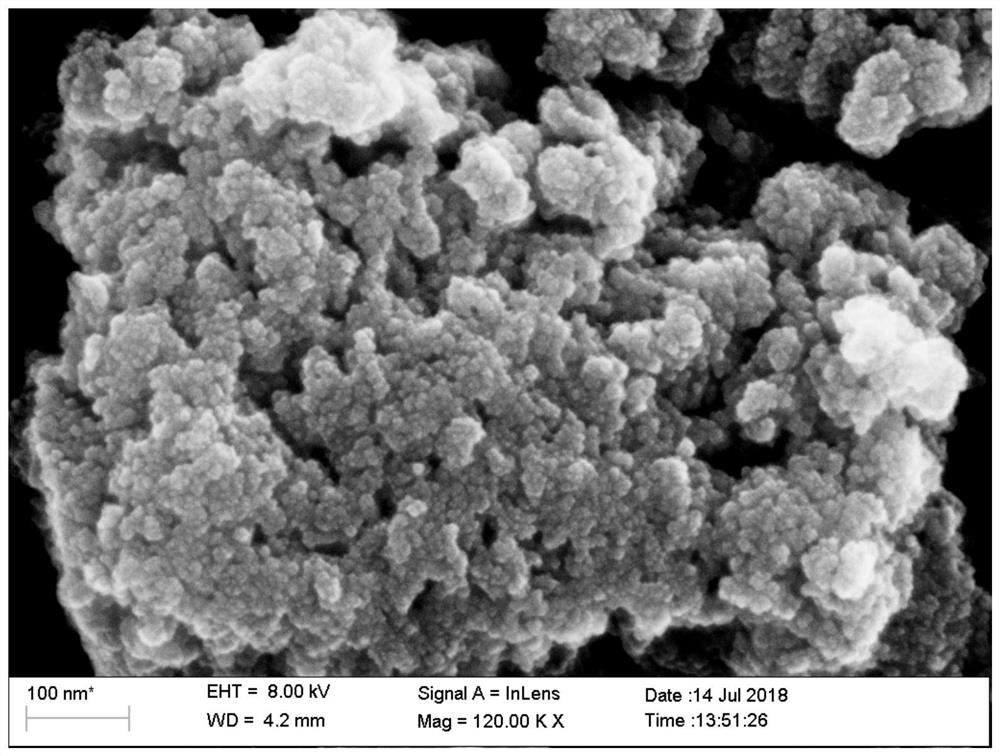

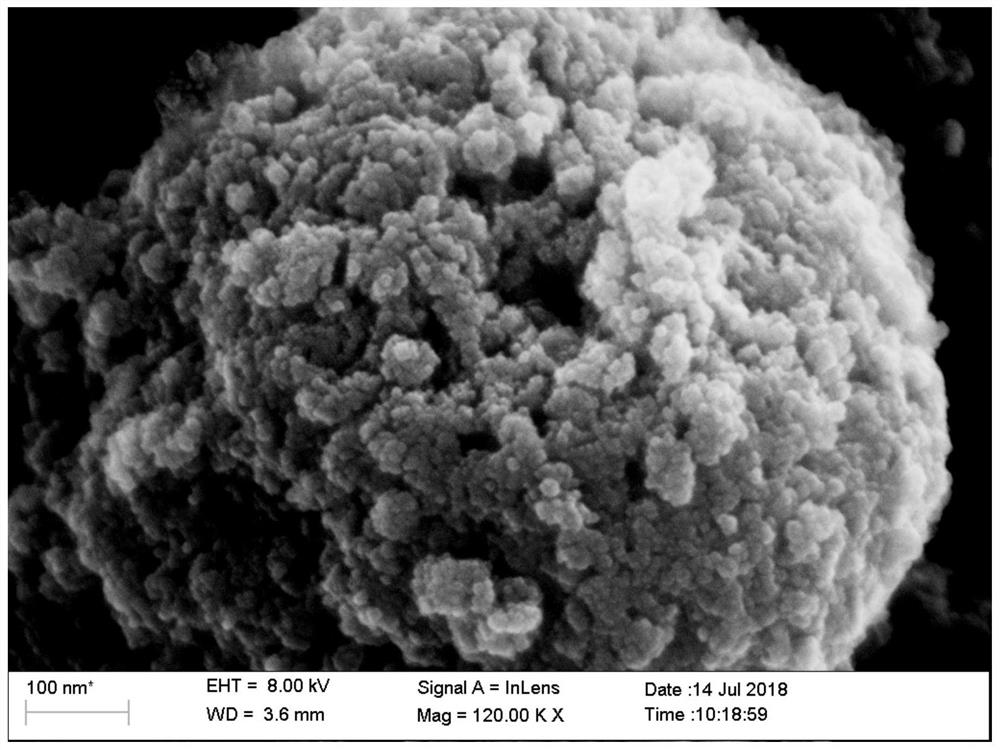

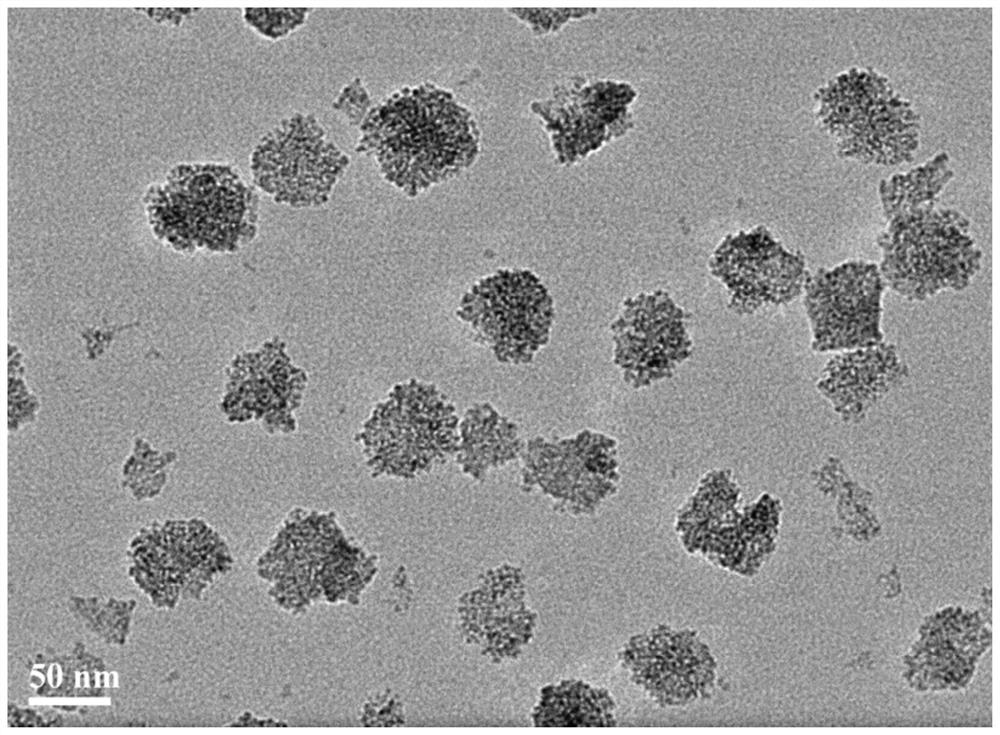

A method for realizing regularization of particle size of titanium dioxide

ActiveCN111573722BChange dwell timeRegulate growth rateTitanium dioxideChemical physicsPhysical chemistry

Owner:EAST CHINA UNIV OF SCI & TECH +1

Staged combustor with two radial rotating inflow channels

PendingCN113960242AEasy to disassembleEasy to replaceChemical analysis using combustionGaseous fuel burnerThermodynamicsCombustion chamber

The invention discloses a staged combustor with two radial rotating inflow channels. The combustor comprises a combustion chamber, a mixed gas inlet pipe and a fuel and air inflow mixing device, wherein the combustion chamber is arranged at a top end of the staged combustor, and the fuel and air inflow mixing device is arranged at a bottom end of the staged combustor in a communicating mode; the bottom of the combustion chamber is communicated with the fuel and air inflow mixing device through a mixed gas inlet pipe, and a fuel inlet pipe and an air inlet pipe are arranged at the bottom of the fuel and air inflow mixing device. According to the combustor, mixed staged combustion of multiple fuels can be achieved, the equivalence ratio and the mixing degree of mixed gas in a channel can be controlled at the same time, and defects in an existing combustion test bed device are overcome.

Owner:JIANGSU UNIV

Fondant milling degree regulating device of milling extrusion pressing granulation machine group

The invention relates to a mixing and extruding granulator set. The melt mixing degree adjusting device of the mixing granulator set is characterized in that a valve is provided with a material channel, and that the material channel is provided with a rotatable valve core or valve plate, the flow areas of which vary with the rotation angle. The invention has novel structure, small volume and the mixing degree can be adjusted through the valve, the material channel area of which can be adjusted. The valve has simple structure, and with the angle between the rotatable valve core or valve plate in the material channel and the horizontal plane of the material channel changes, the flow area of material changes correspondingly, thus adjusting the flow resistance of the material from the mixing transmission part in the channel, changing the resident time of material in the channel, achieving the goal of increasing the mixing effect of the material, adjusting the back pressure of the material in the mixing transmission system and changing the actual power consumption of the main drive motor of the set.

Owner:大连橡胶塑料机械有限公司

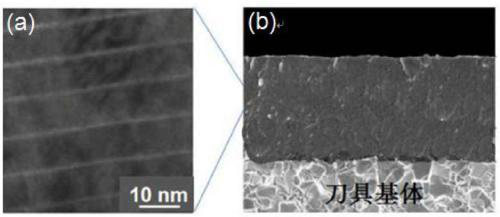

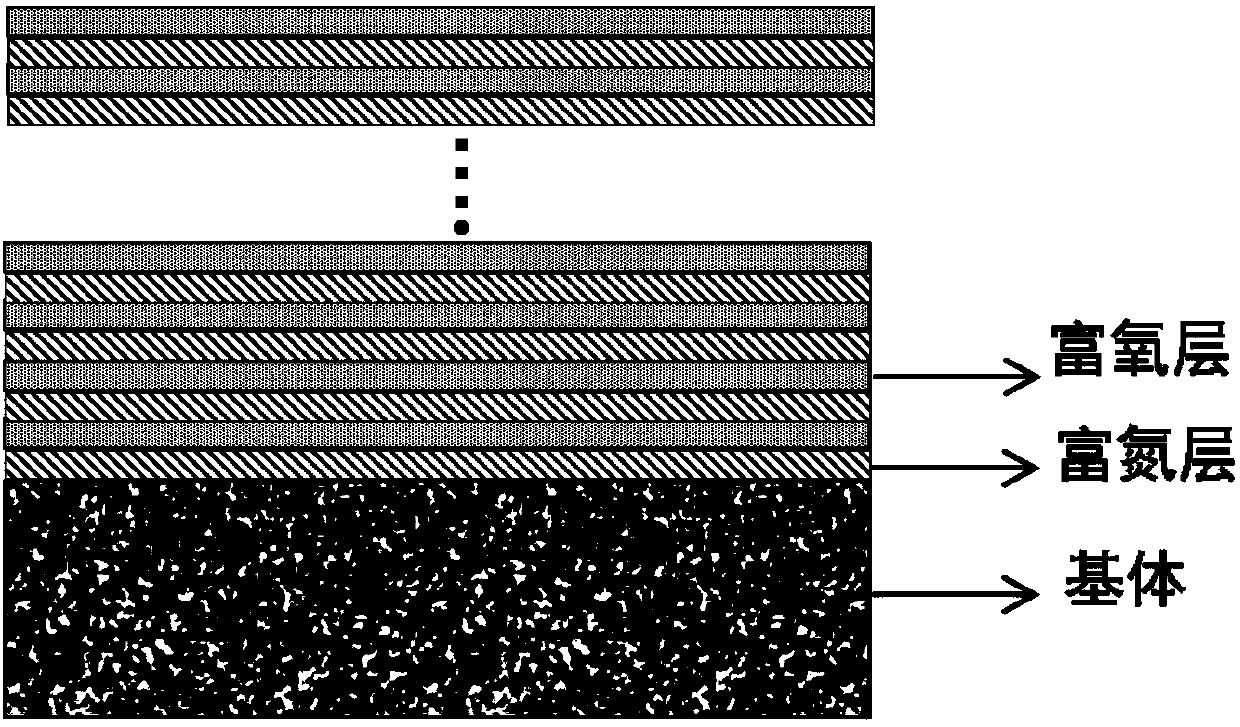

A self-assembled nano-oxynitride coating and its preparation method and application

ActiveCN107287555BOvercoming the disadvantages of manufacturing difficultiesSimple processVacuum evaporation coatingSputtering coatingRetention timeSelf-assembly

Owner:GUANGDONG UNIV OF TECH

Injectable hyaluronic acid/polyethylene glycol hydrogel and its preparation method and application

ActiveCN106519072BEasy to prepareHigh yieldPharmaceutical delivery mechanismProsthesisClick chemistryCross linker

The invention discloses injectable hyaluronic acid / polyethylene glycol hydrogel as well as a preparation method and application thereof, and belongs to the fields of plastic and cosmetic biological materials. The method is characterized in that a cyclooctyne-modified hyaluronic acid (HA) solution is mixed with a nitrine-modified polyethylene glycol (PEG) solution, a hydrogel precursor solution with favorable flowability is formed, and the hydrogel precursor solution can be quickly cross-linked through a ring tension promoted click chemical reaction to form the hydrogel after being injected into a body, so as to play roles in water retention, plastic and the like. The preparation process of the material is simple; the additional addition of a cross-linking agent is not needed; the heating is not needed; the ultraviolet treatment or the radiation and the like are not needed; one-step cross-linking is adopted; the injectable hyaluronic acid / polyethylene glycol hydrogel is non-toxic and has no stimulation; therefore, the made hydrogel is good in biocompatibility, and is insignificant in inflammatory reaction. Meanwhile, the gel is slower in degradation speed, and is excellent in mechanical performance; therefore, the material is good in durability and molding performance, is quite applicably used as a face-lifting filling material in the fields of wrinkle resisting, breast enlargement, nose augmentation, filling-padding and the like.

Owner:深圳浦瑞健康科技有限公司

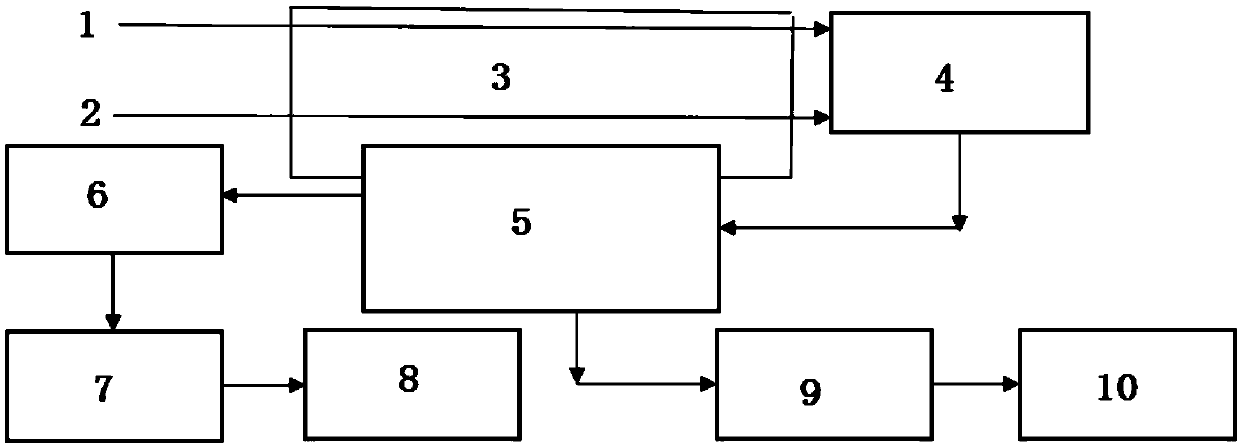

Low energy consumption biomass liquefying device

ActiveCN109161394AMeet heat absorption needsImprove utilization efficiencyLiquid hydrocarbon mixture productionAir preheaterMultiple stages

The invention belongs to the field of biomass fast pyrolysis liquefaction, particularly relates to a low energy consumption biomass liquefying device, and solves the problems of overhigh energy consumption and relatively low output proportion in the biomass pyrolysis liquefaction process. The device mainly comprises a feed bin heating jacket, a carbon powder burner, a multistage air preheater, a biomass pyrolysis reactor, a plate-type nitrogen preheater, a gas-solid cyclone separator, a fast condensing system, a metal filter and the like. According to the low energy consumption biomass liquefying device disclosed by the invention, the heating rate of biomass is greatly improved by use of rotating centrifugal force and a honeycomb channel; due to gas-liquid bubbling mixing, quick condensingis realized and the generation proportion of biomass oil is increased. Meanwhile, heat required by pyrolysis is mainly provided by burning biomass carbon particles, so that the self sufficiency of energy is realized; in addition, the heat of flue gas is recovered by multiple stages, so that heat loss of exhausted smoke is reduced, and heat efficiency of the whole set of device is improved. By adopting the low energy consumption biomass liquefying device disclosed by the invention, the oil yield of biomass fast pyrolysis liquefaction can be improved to 65 percent or above.

Owner:SHANXI UNIV

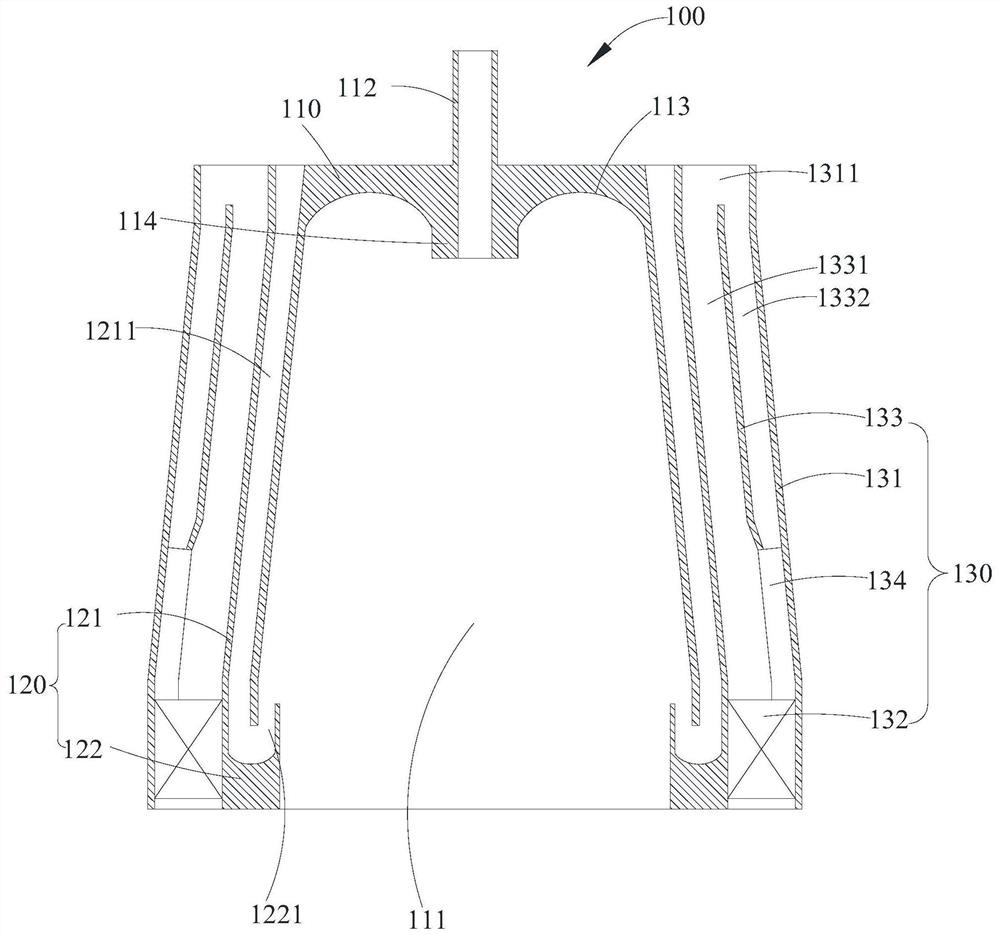

Annular wall heat reverse injection pulverized coal burner

ActiveCN112050203BSimple structureStrong reliabilityFuel supply regulationPulverulent fuel combustion burnersThermodynamicsCombustion chamber

The invention provides an annular wall-heating type reverse injection pulverized coal burner, comprising: a pre-combustion structure, the pre-combustion structure has a preheating combustion chamber and a central ejection air pipe communicating with the preheating combustion chamber; a reverse injection The assembly includes a main pulverized coal pipe and a grooved retaining ring. The main pulverized coal pipe is sheathed on the outside of the pre-combustion structure and surrounds the main pulverized coal flow channel. The grooved retaining ring is connected to the The end of the main pulverized coal pipe is partly located at the outlet end of the pre-combustion structure, and the groove-shaped retaining ring and the end of the pre-combustion structure are surrounded by a reverse injection channel; and the secondary air assembly , including a secondary air pipe and a hollow opening blade, the secondary air pipe is sleeved on the outside of the main pulverized coal pipe, and is surrounded with the main pulverized coal pipe to form a secondary air channel, the hollow opening The rotary vane is arranged at the outlet end of the secondary air passage. There are no other pipelines and auxiliary structures inside the preheating combustion chamber, which makes the structure of the annular wall heat reverse injection pulverized coal burner simple and reliable in operation.

Owner:TSINGHUA UNIV

Biomass boiler system capable of lengthening flue gas combustion path

The invention discloses a biomass boiler system capable of lengthening a flue gas combustion path. The biomass boiler system capable of lengthening the flue gas combustion path comprises a radiation section, convection sections, a front arch, a rear arch and a fire grate. A protruded baffle plate is arranged on the rear arch, and is located above a secondary tuyere; the front arch, the rear arch and the protruded baffle plate form a flue gas channel which is an S-shaped channel; an inlet of the S-shaped channel communicates with the fire grate; and an outlet of the S-shaped channel communicates with the radiation section. The biomass boiler system capable of lengthening the flue gas combustion path provided by the invention is provided with the S-shaped channel, so that the flue gas combustion path in a hearth can be lengthened.

Owner:SUZHOU DISEN BIOLOGICAL ENERGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com