Multi-water-tank water level monitoring and analyzing system based on big data

A water level monitoring and analysis system technology, which is applied in the field of optical cable production, can solve problems such as insufficient water, failure of optical cable temperature to drop, waste of water resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

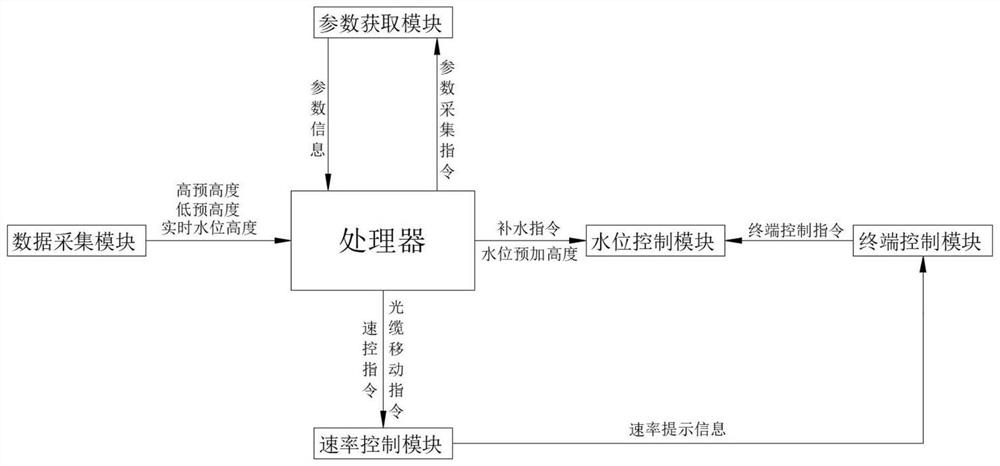

[0040] see figure 1 As shown, the present embodiment is a multi-sink water level monitoring and analysis system based on big data, including a data acquisition module, a processor, a parameter acquisition module and a water level control module;

[0041] The data acquisition module is used to collect the optical cable cooling information, the preset water level information, the real-time water level in the optical cable cooling water tank and send it to the processor. The optical cable cooling information includes the minimum height of the optical cable in the water tank and the inner cavity of the optical cable cooling water tank Top height, water level preset height information includes low preset height and high preset height, the specific process is as follows:

[0042] The data acquisition module collects the lowest height of the optical cable in the water tank and the top height of the inner cavity of the optical cable cooling water tank. The preset value above the lowes...

Embodiment 2

[0057] see figure 1 As shown, this embodiment is a multi-water tank water level monitoring and analysis system based on big data, which also includes a rate control module and a terminal control module;

[0058] The rate control module is used to control the moving rate of the optical cable, and the specific process is as follows:

[0059] When the speed control module receives the optical cable movement instruction, it controls the movement speed of the optical cable to be equal to the preset movement speed Vc;

[0060] After the processor receives the departure temperature W1, it compares the departure temperature W1 with the preset cooling temperature range of the optical cable, marks the upper limit of the preset cooling temperature range of the optical cable as Wmax, and marks the lower limit of the preset cooling temperature range of the optical cable as Wmin;

[0061] like (Wmin, Wmax), the processor generates a speed control instruction, and the processor sends the ...

Embodiment 3

[0067] see figure 1 As shown, in combination with Embodiment 1 and Embodiment 2, this embodiment is a working process of a multi-sink water level monitoring and analysis system based on big data, including the following steps:

[0068] Step 1: The data acquisition module collects the lowest height of the optical cable in the water tank and the top height of the inner cavity of the optical cable cooling water tank. 5cm is set as the high pre-height Hmax, the data acquisition module includes several water level sensors, and several water level sensors are respectively installed in the cavity of several optical cable cooling water tanks, and the data acquisition module uses the water level sensor to collect the real-time water level height Hs in the optical cable cooling water tank , the data acquisition module sends the low pre-height Hmin, the high pre-height Hmax and the real-time water level Hs to the processor;

[0069] Step 2: After the processor receives the low pre-heigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com