Patents

Literature

46results about How to "Change movement speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

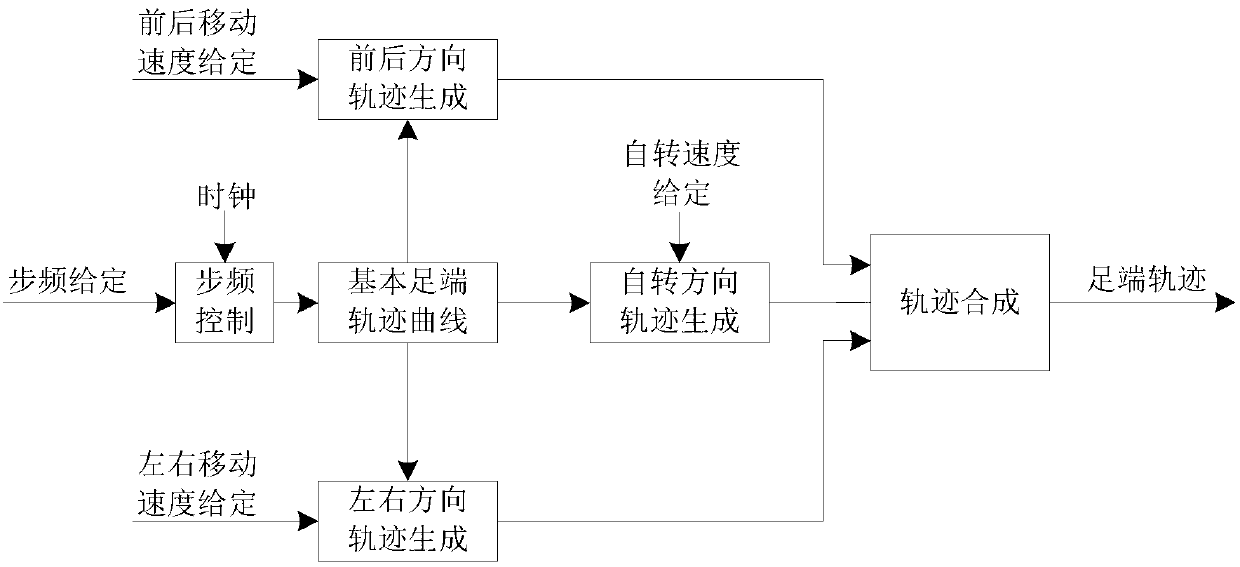

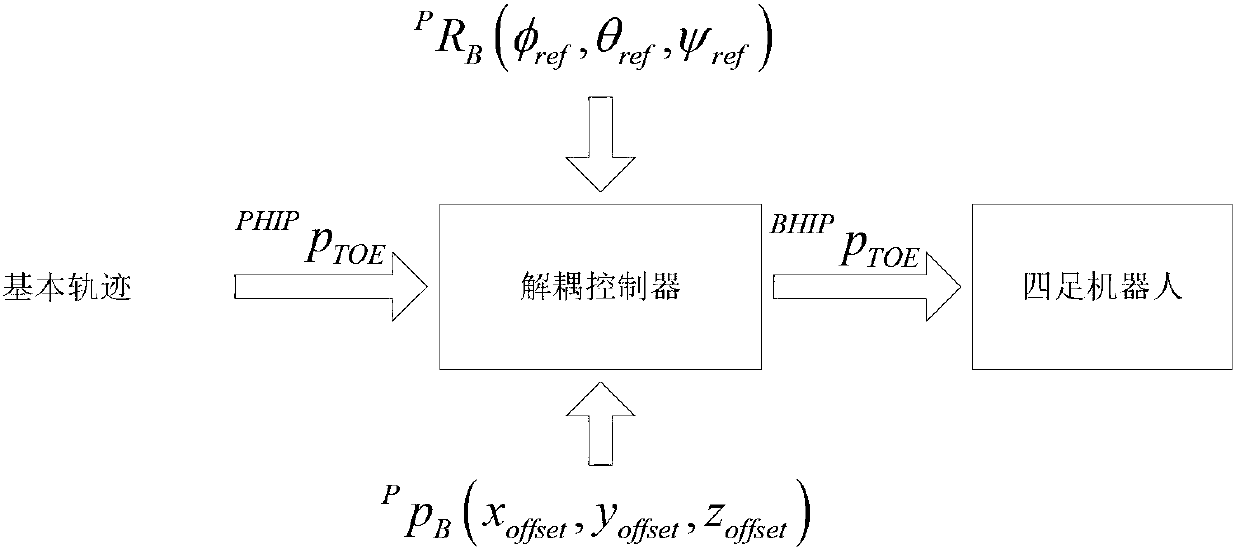

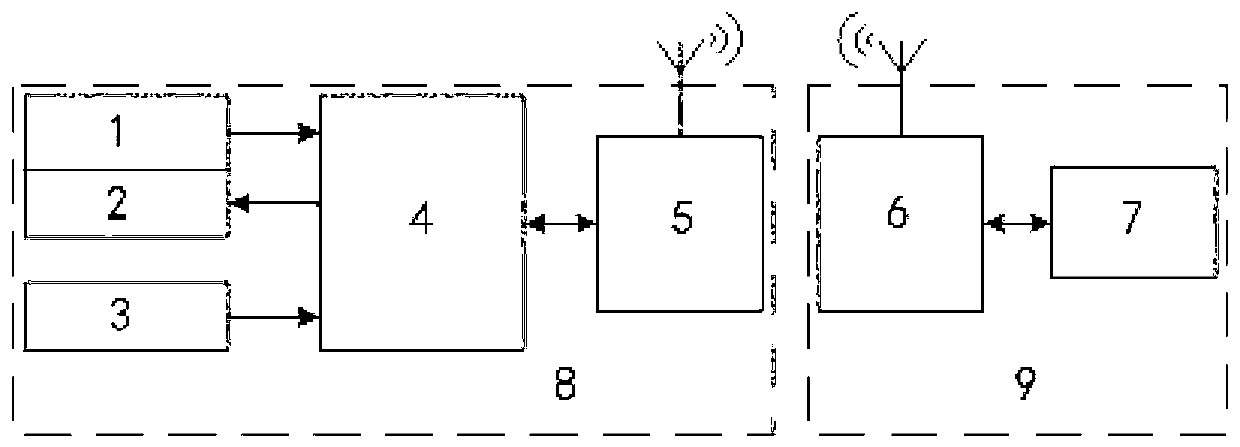

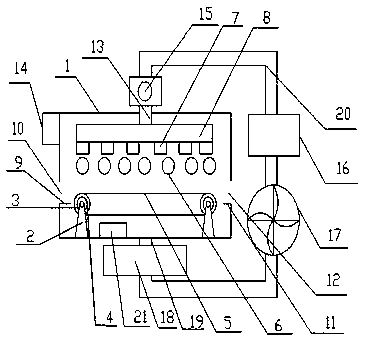

Quadruped robot remote control system and remote control method thereof

ActiveCN103345285ASimple and friendly interfaceChange movement speedTotal factory controlSimultaneous control of multiple variablesLiquid-crystal displayRemote control

The invention discloses a quadruped robot remote control system and a remote control method thereof. The remote control system comprises a controller I. The controller I receives and processes a touch screen and rocker signals and is communicated with a controller II of a quadruped robot through a wireless communication module I and a wireless communication module II of the quadruped robot, and the controller I also receives feedback information of the controller II and displays the feedback information of the controller II through a liquid crystal display screen. By means of the quadruped robot of the remote control system, the remote control method is simple and visualized, the remote control system is especially suitable for flexible control and state monitoring for the quadruped robot, can be interact with a user, then sends control commands and parameters, and setting and sending the commands and parameters to the quadruped robot, and finally displays the state fed back by the quadruped robot, and monitoring for the quadruped robot is achieved.

Owner:SHANDONG UNIV

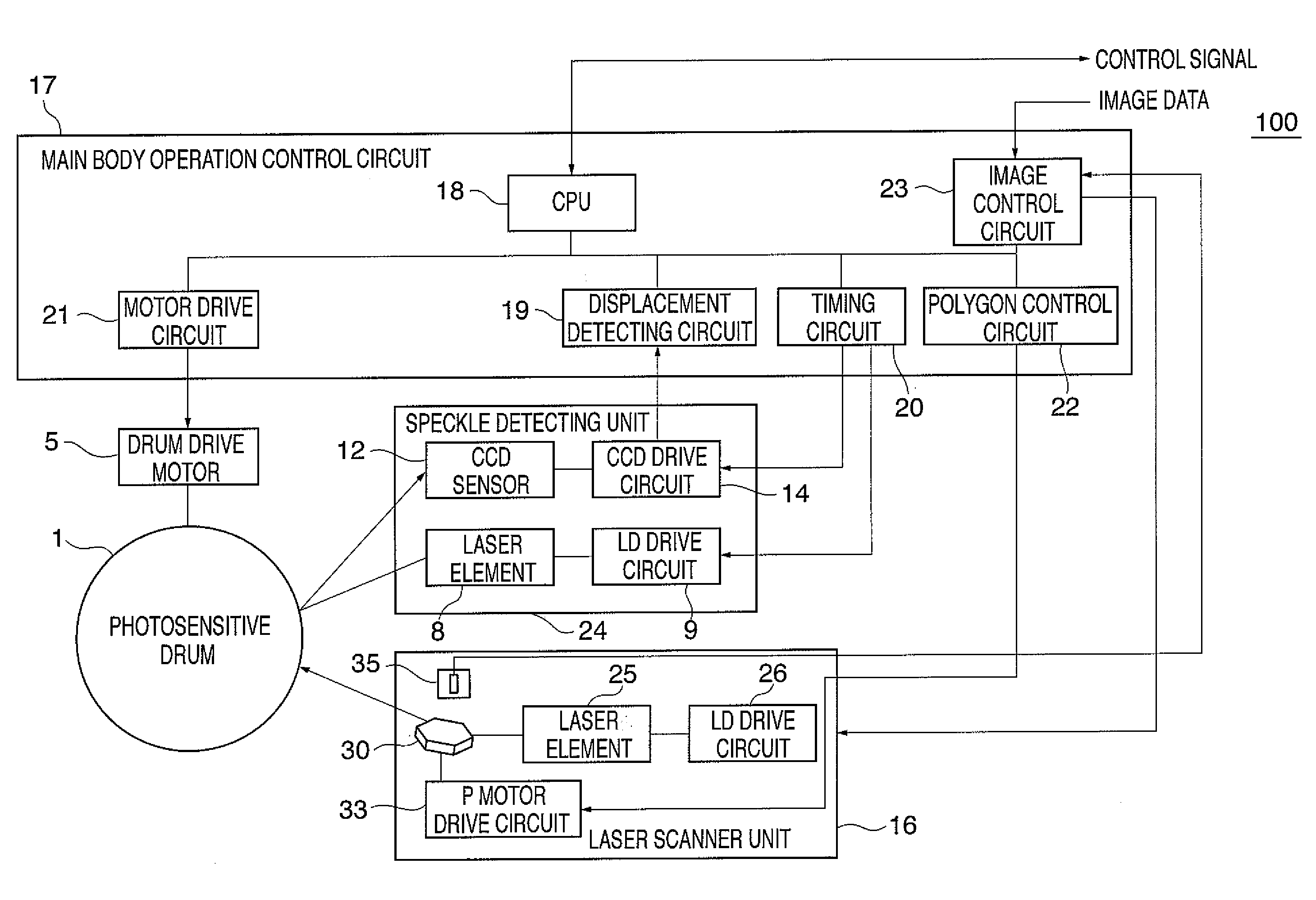

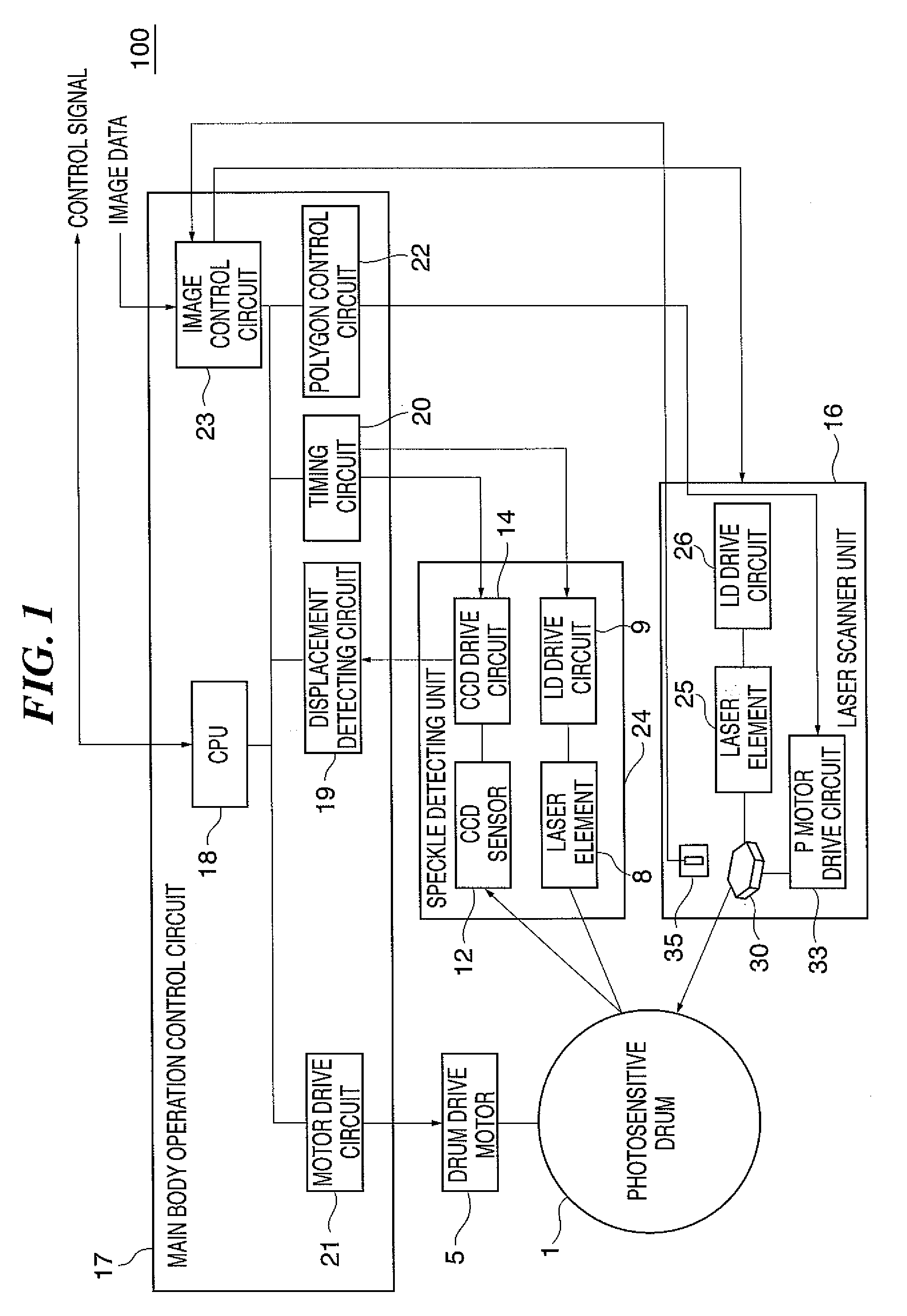

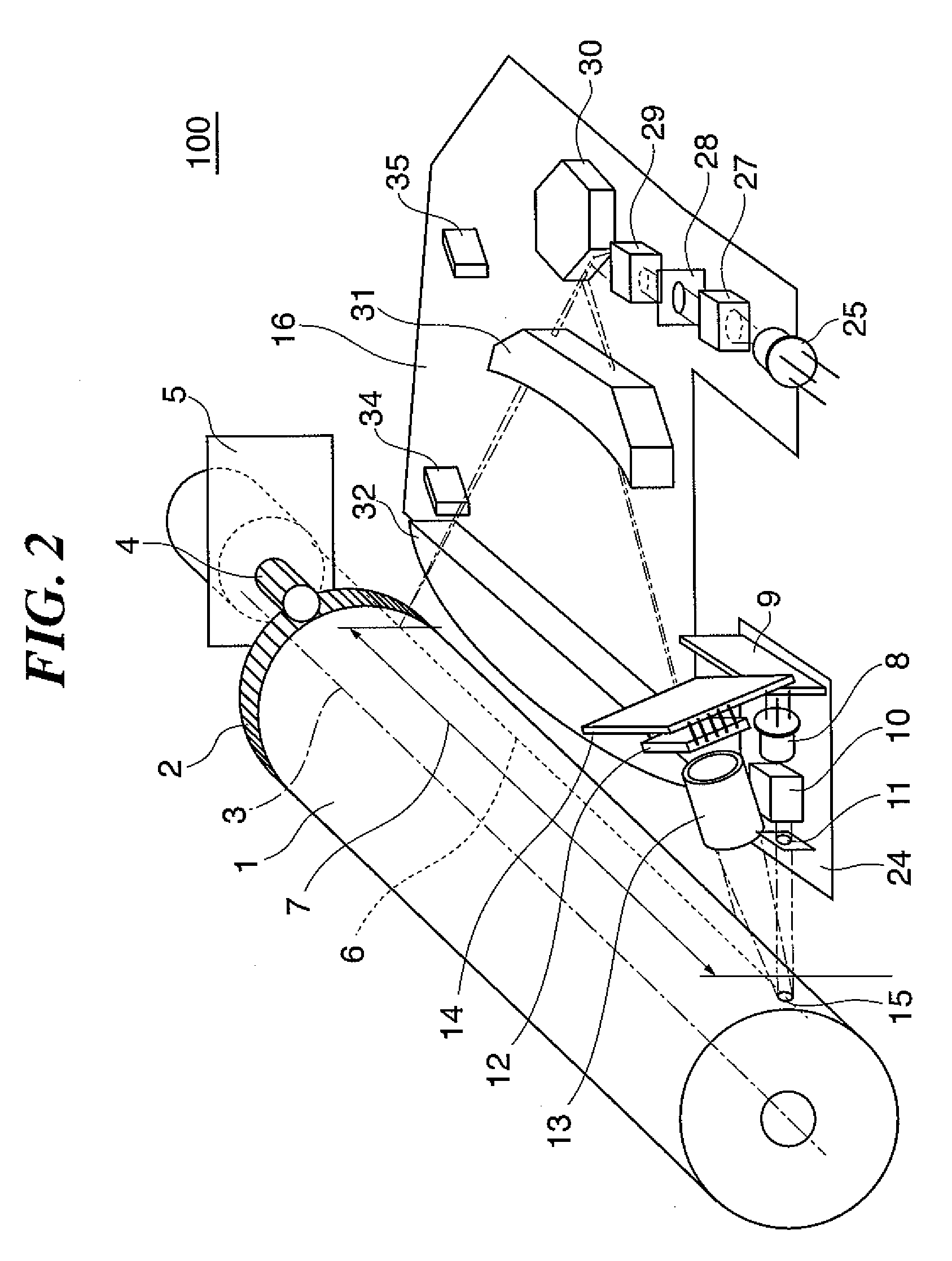

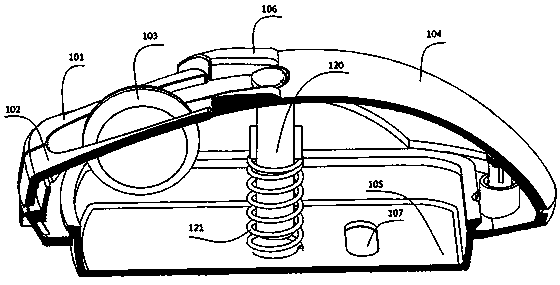

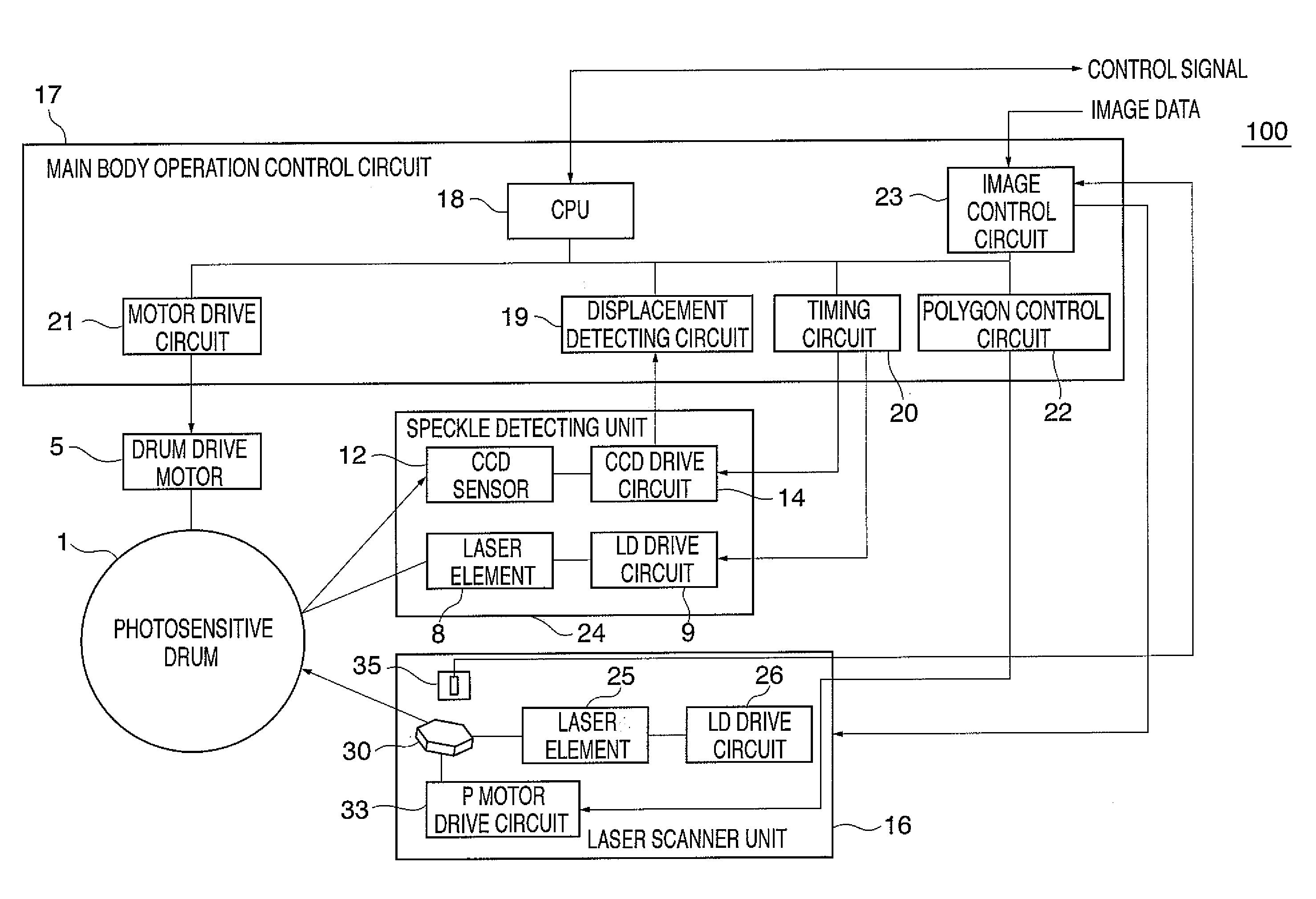

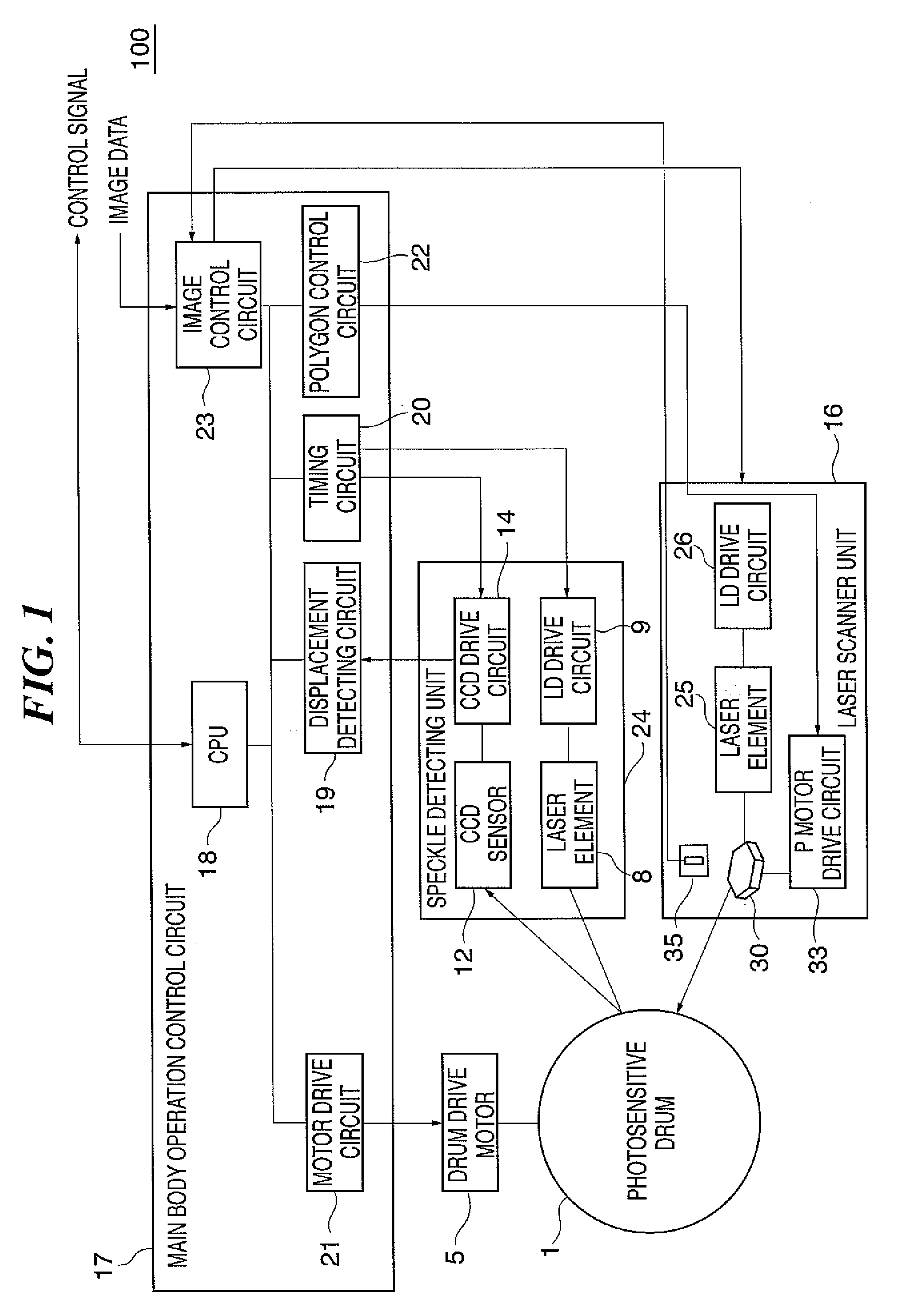

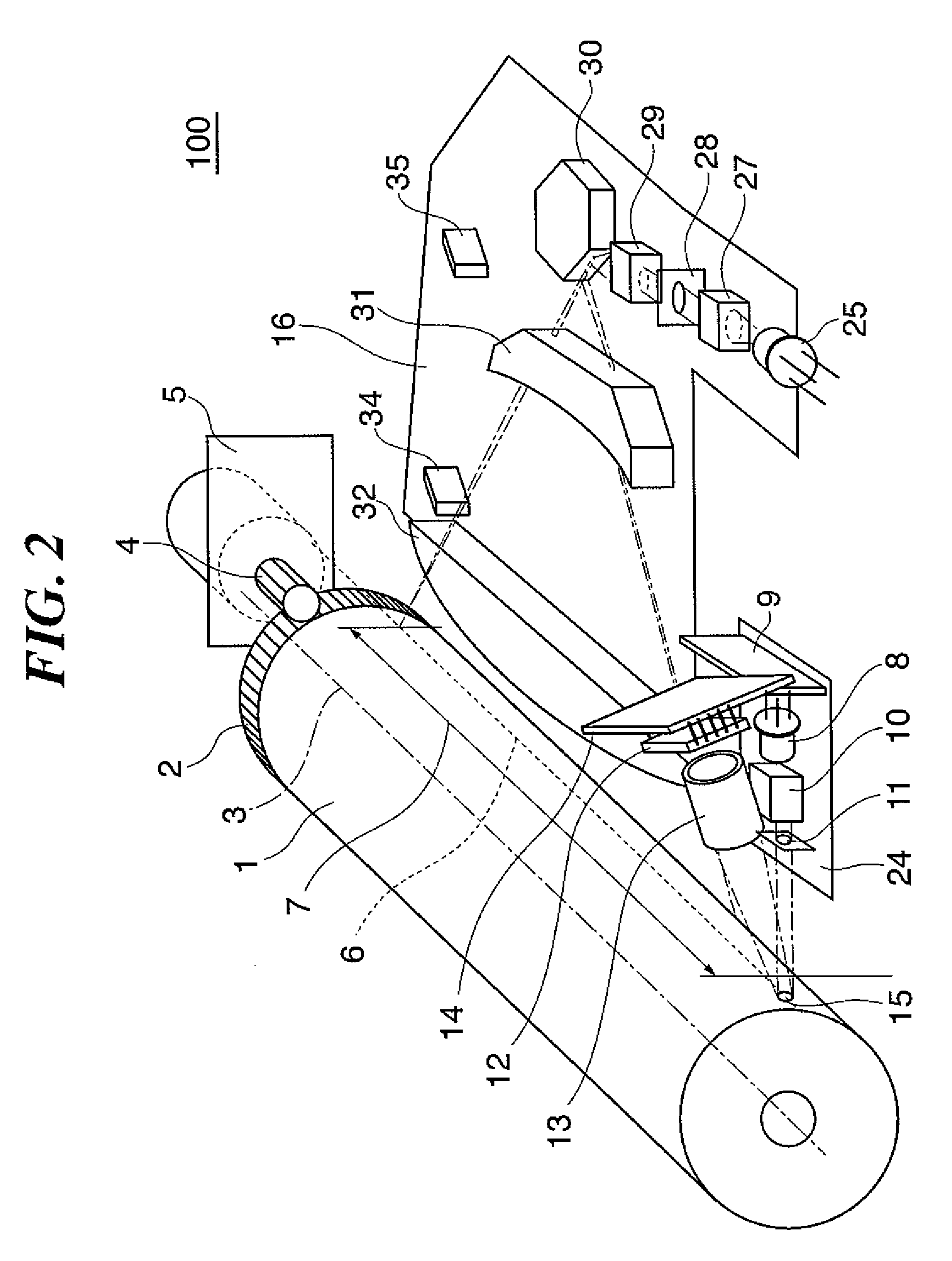

Image forming apparatus and image forming method

InactiveUS20070247636A1High resolutionChange movement speedUsing optical meansElectrographic process apparatusMotor driveImage formation

An image forming apparatus which can form an even image while maintaining high resolution. A speckle pattern detecting unit detects a speckle pattern on a surface of a photosensitive drum. A motor drive circuit controls the rotational speed of the photosensitive drum based on the detected speckle pattern on the surface of the photosensitive drum detected by the speckle pattern detecting unit.

Owner:CANON KK

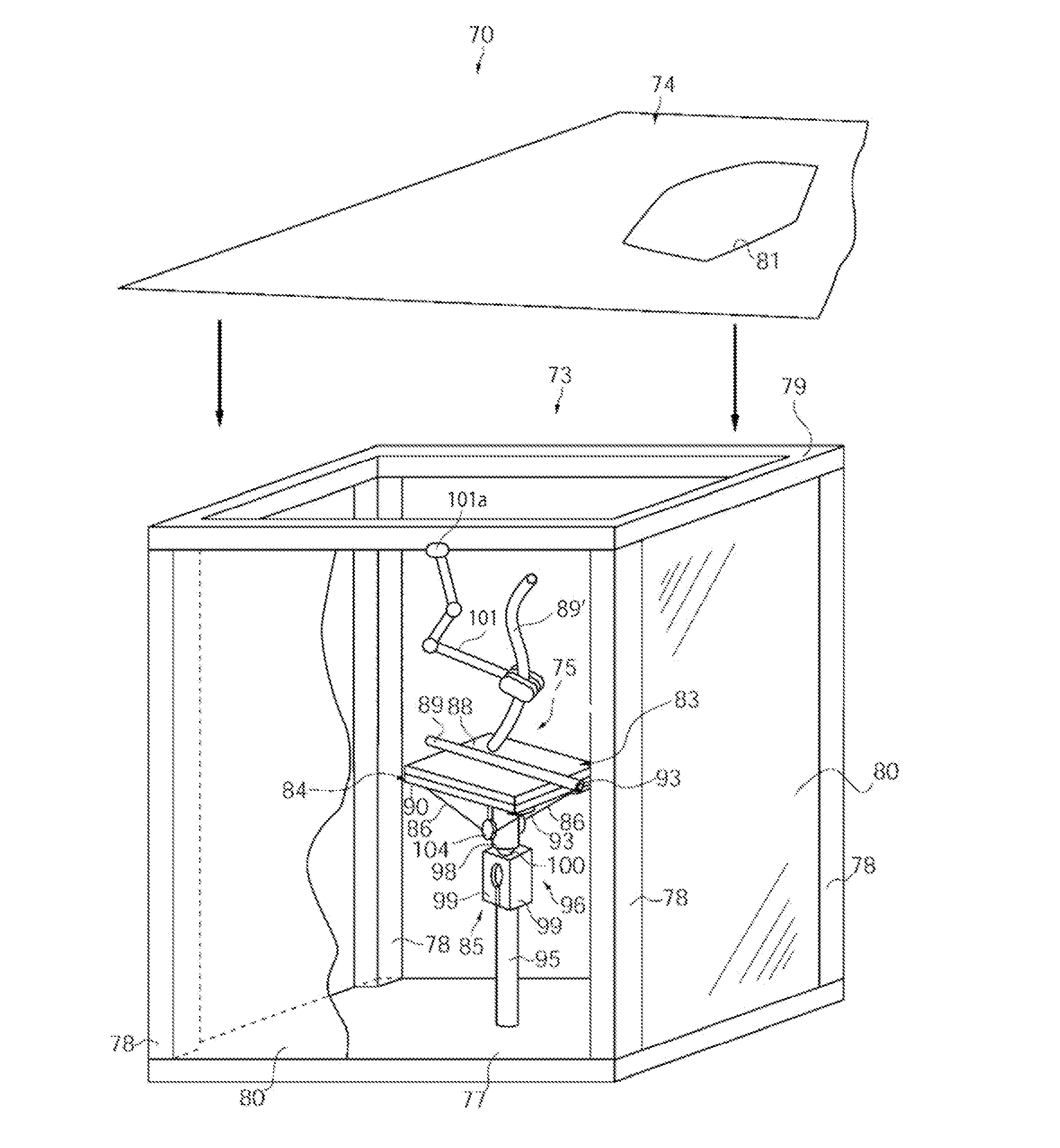

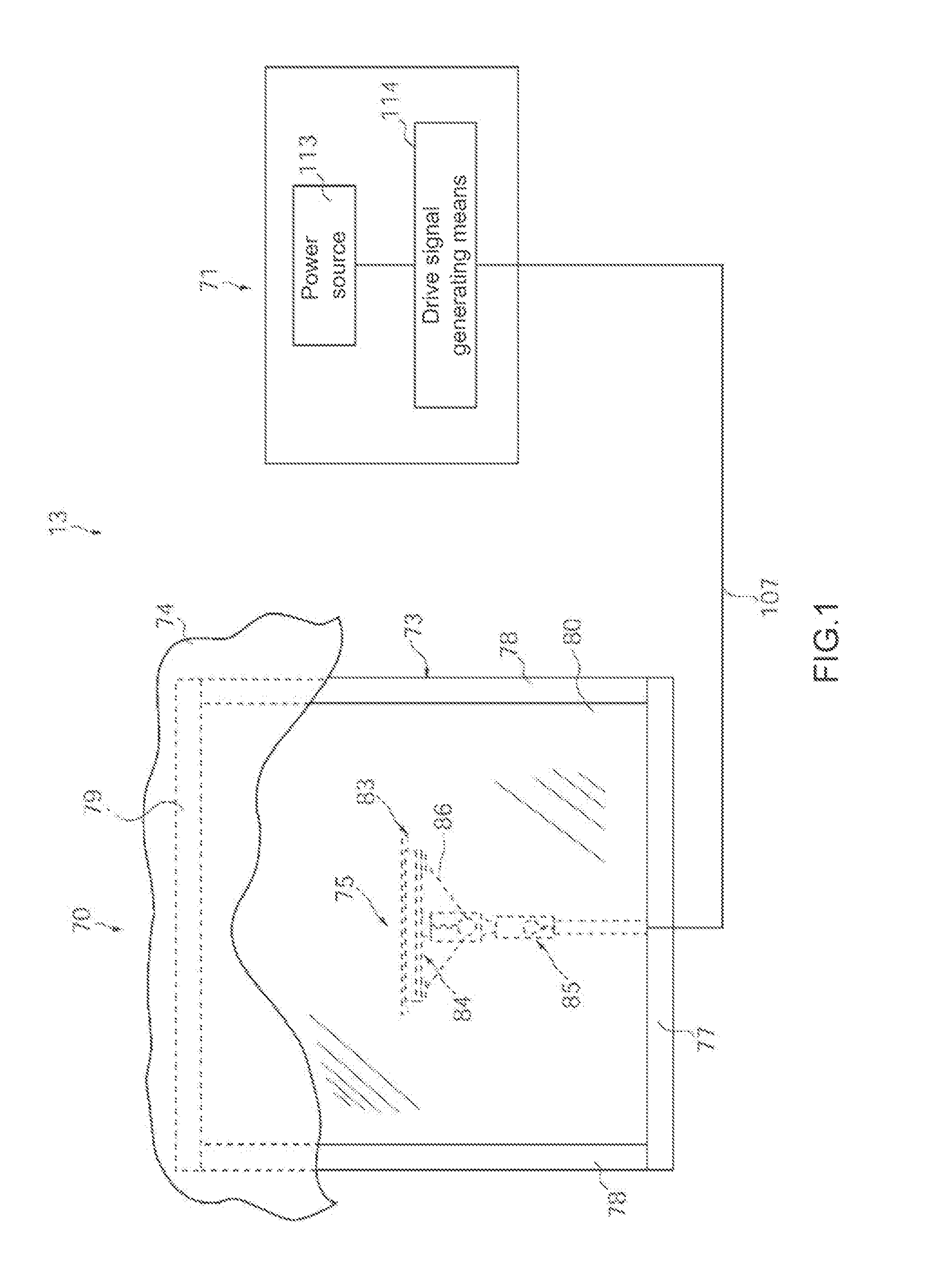

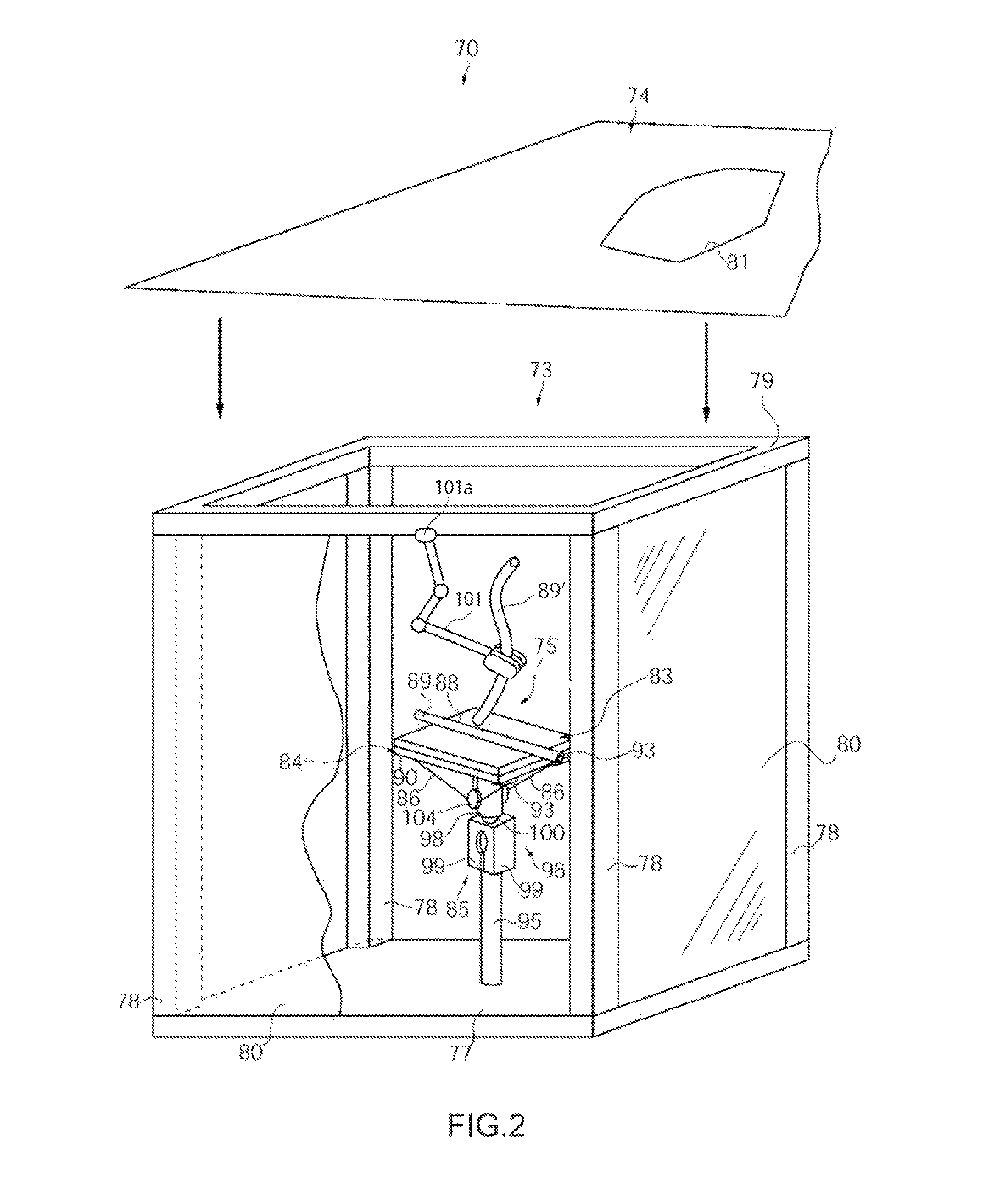

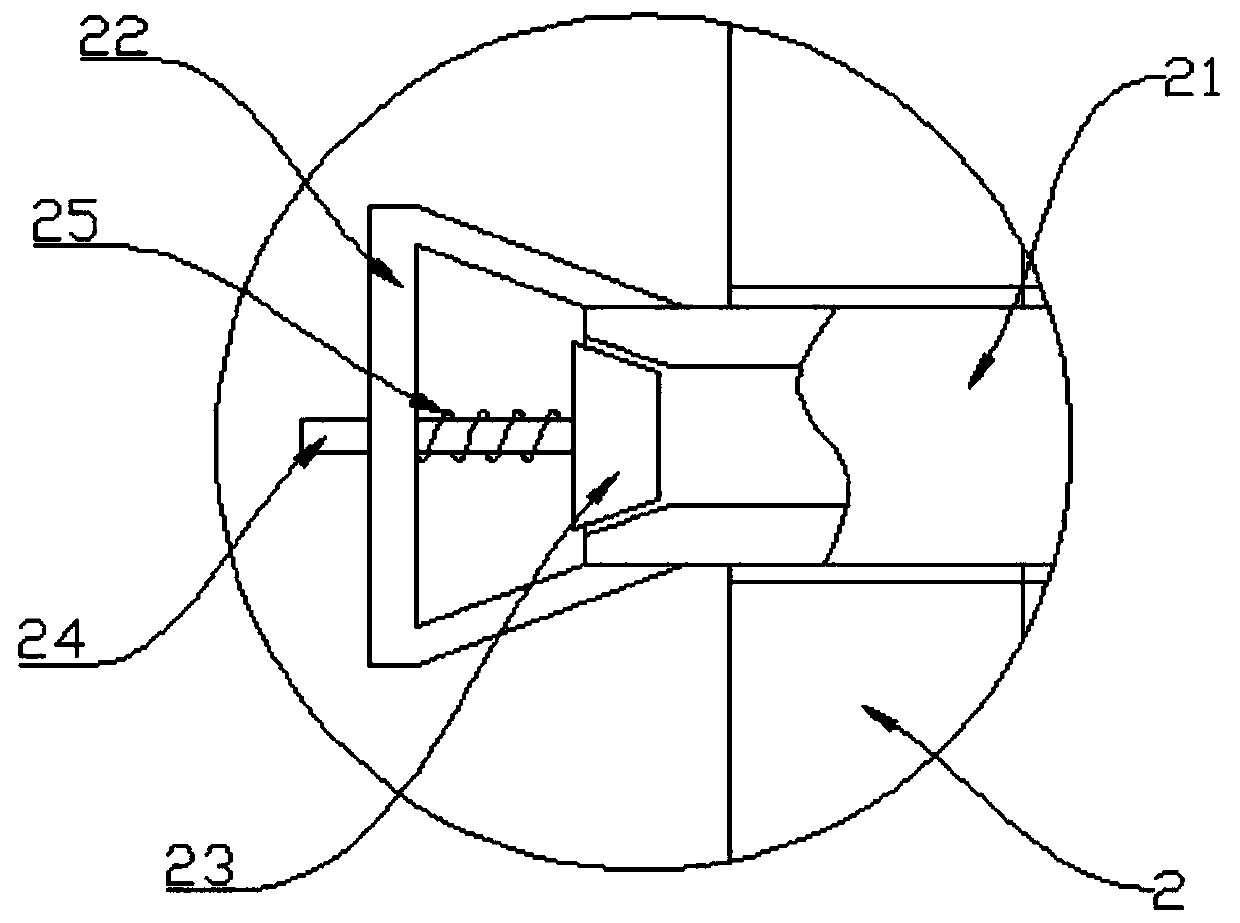

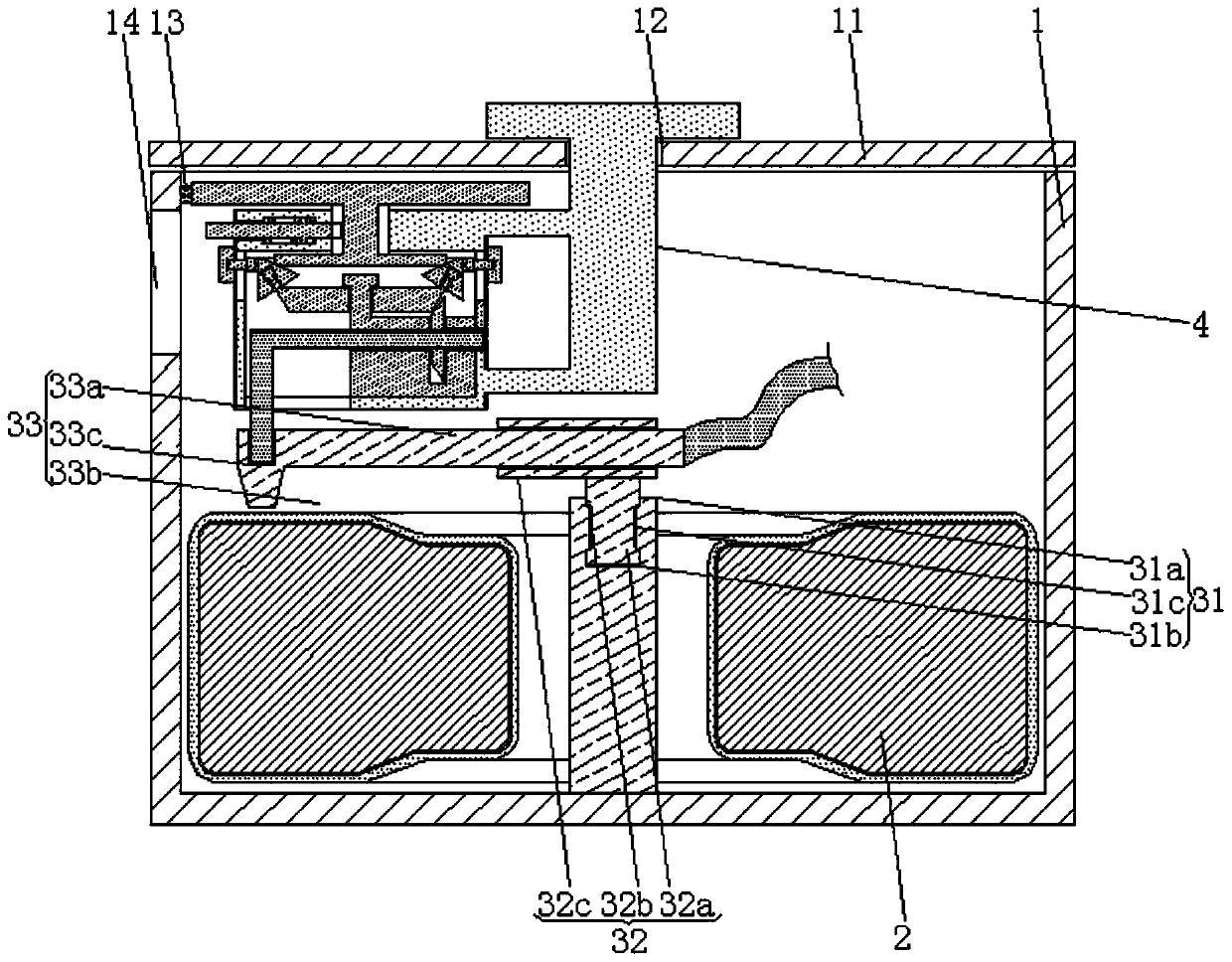

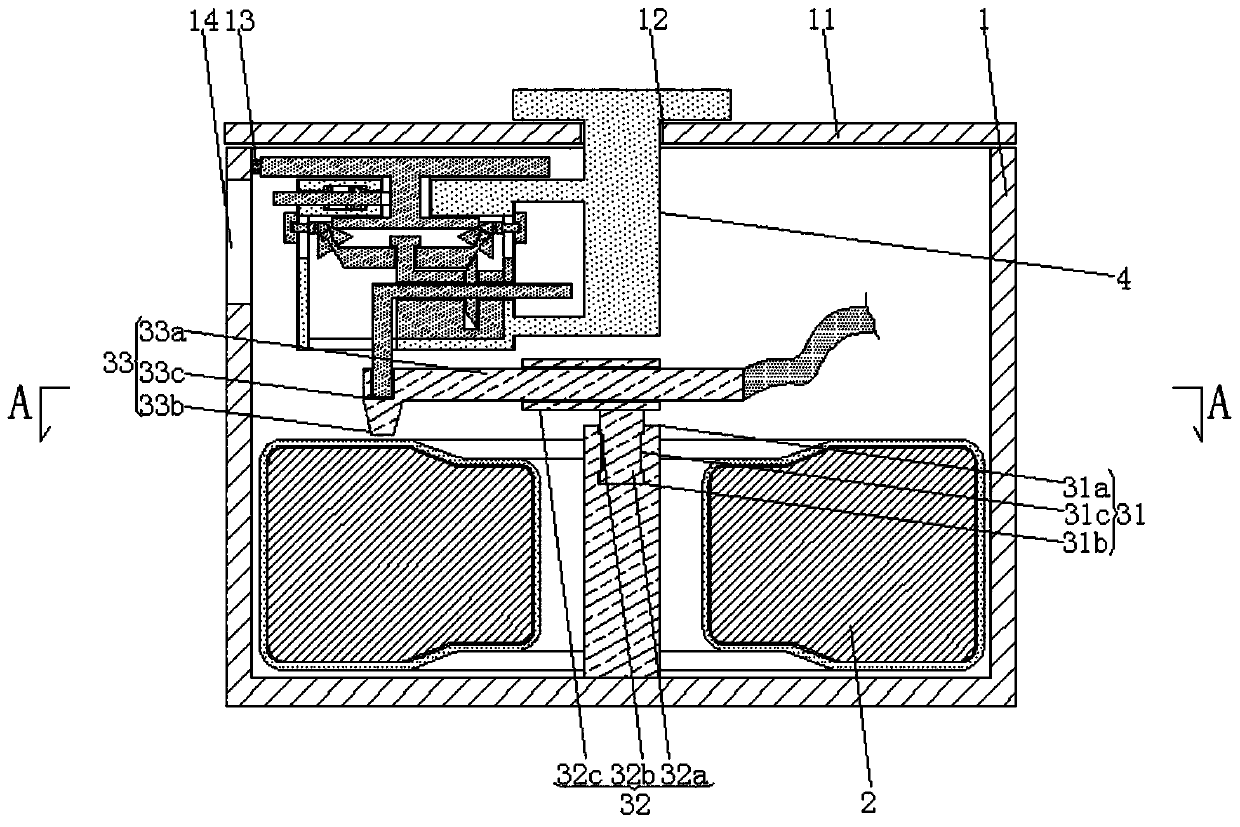

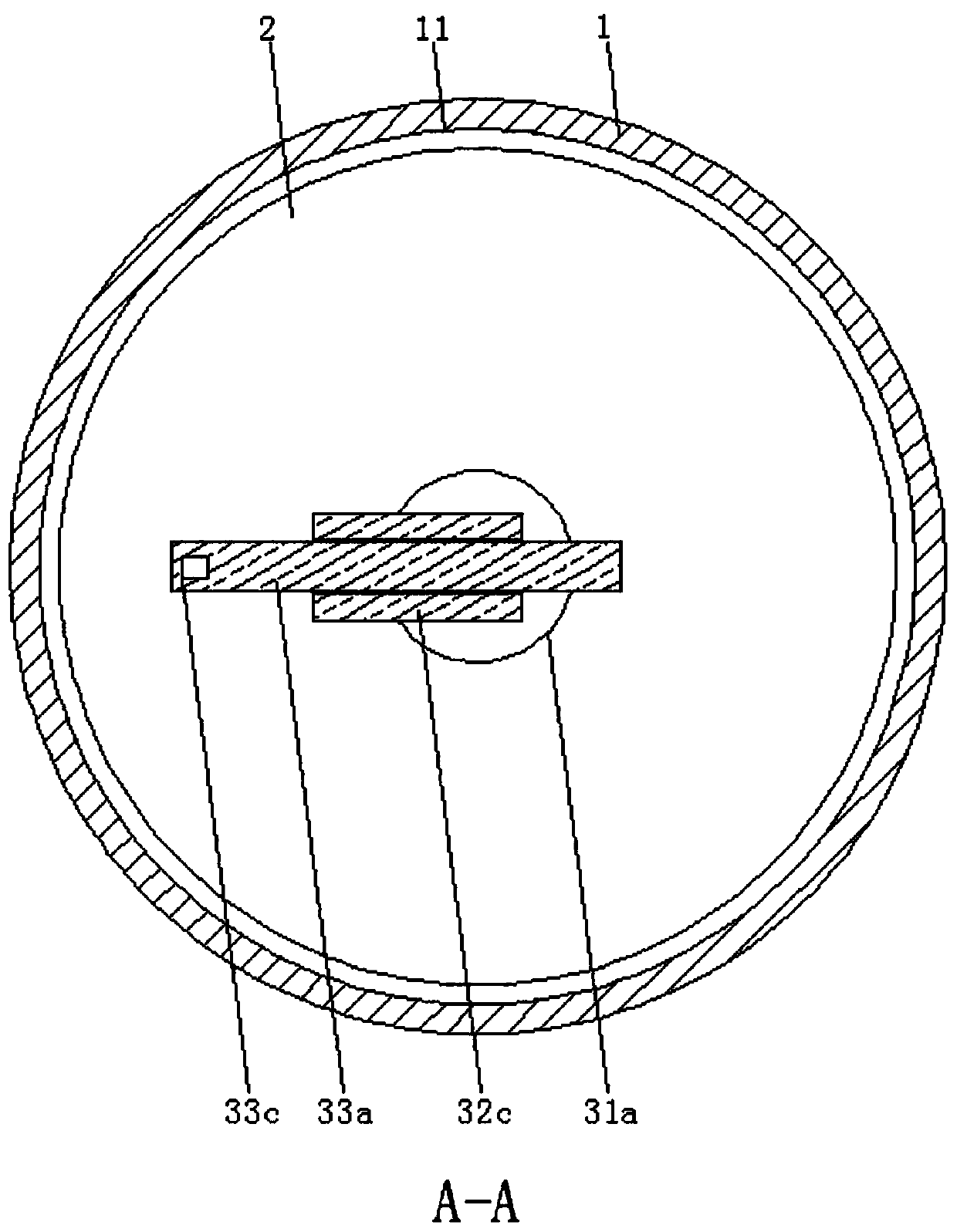

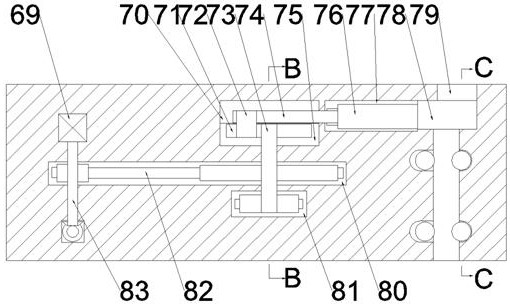

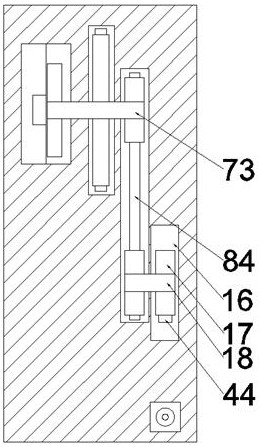

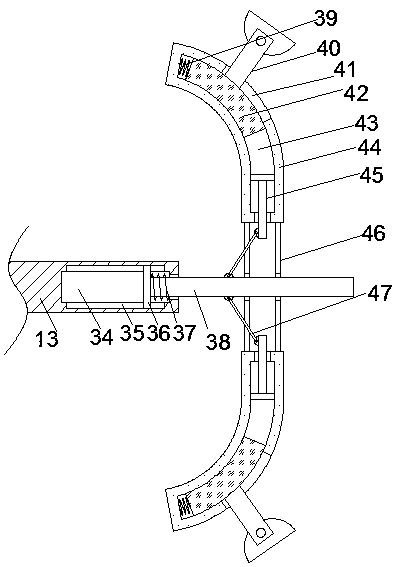

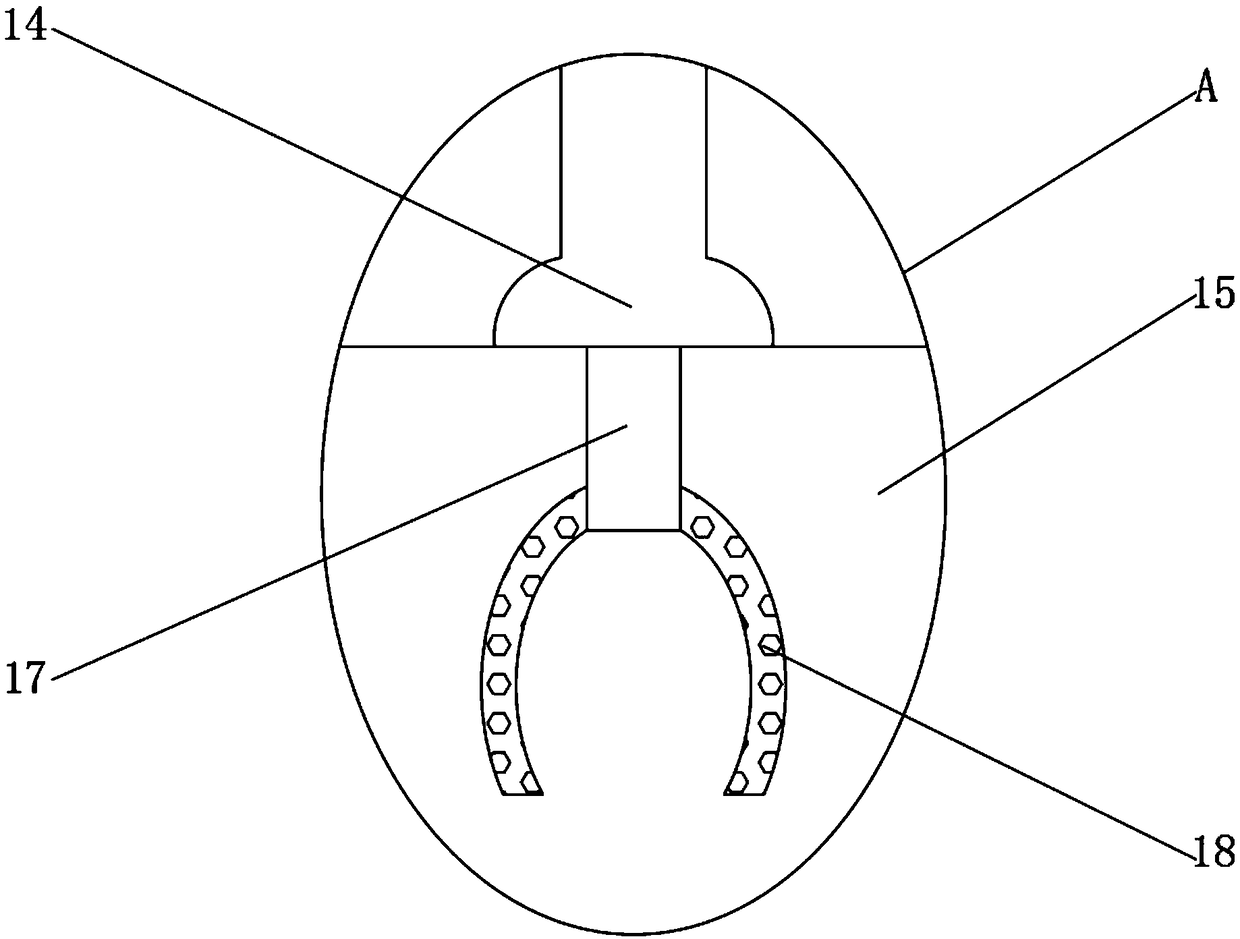

Surgical operation training device

ActiveUS20140349265A1Shorten the timeChange movement speedEducational modelsSurgical operationEngineering

A surgical operation training device 13 comprises a simulation body 83 subjected to a predetermined treatment during surgical operation training, a holder 84 for holding the simulation body 83 from below, a support 85 for supporting the holder 84 workably, a wire 86 for coupling the holder 84 with the support 85, and a control unit 71 for controlling operation of the holder 84. The wire 86 is formed of a shape memory material which can contract from an original shape when a current flows through the wire. The control unit 71 comprises a drive signal generating means 114 for supplying a current to the wire 86 at a predetermined timing and for performing operation control on the holder 84 with a change in the shape of the wire 86 by varying the supply state of current to the wire 86.

Owner:EBM

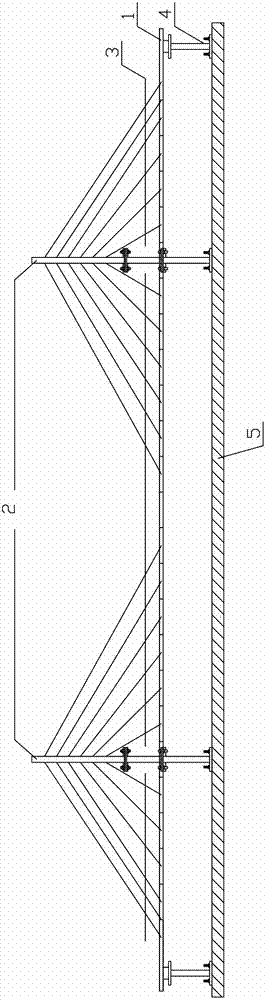

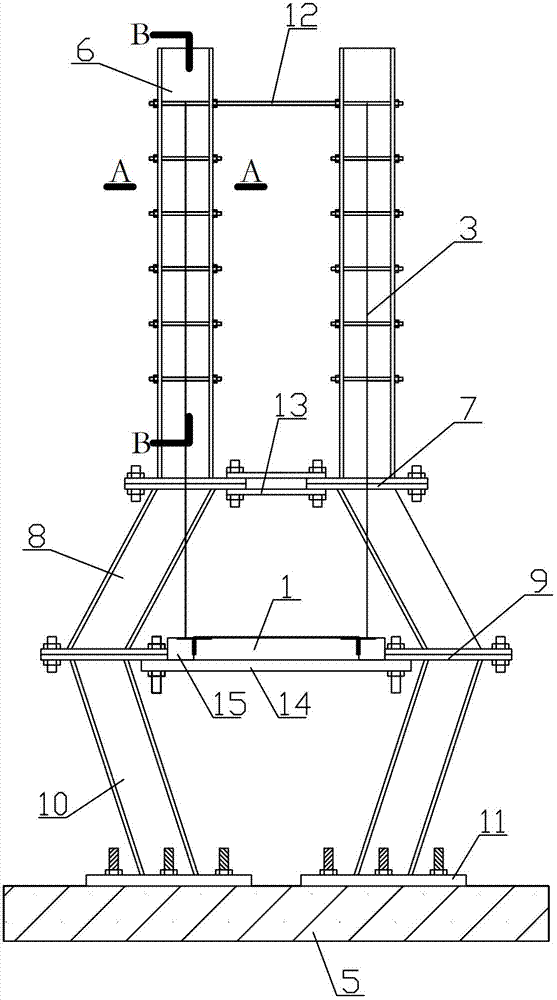

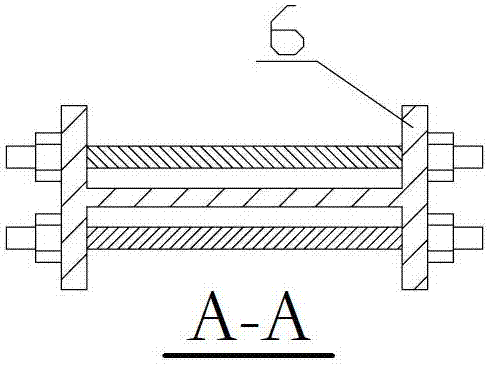

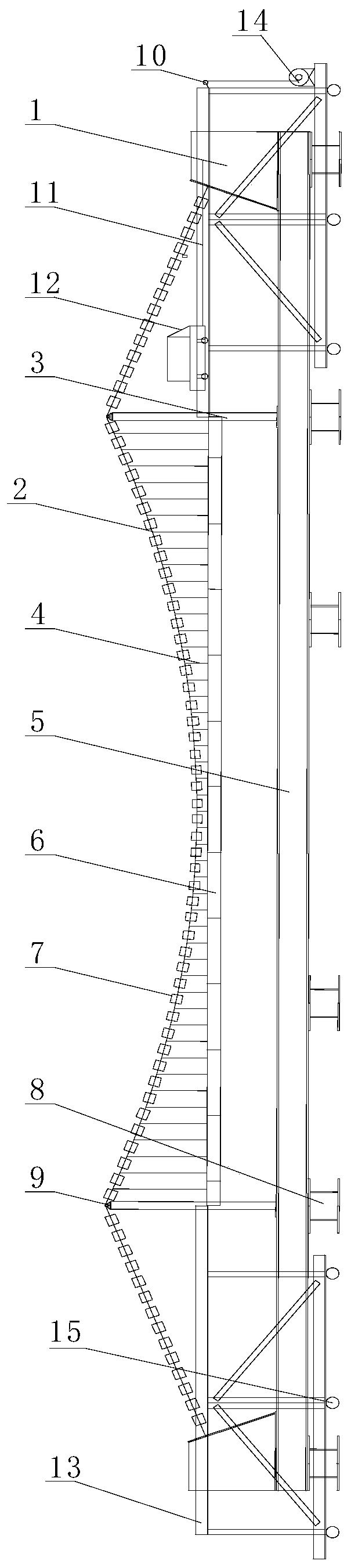

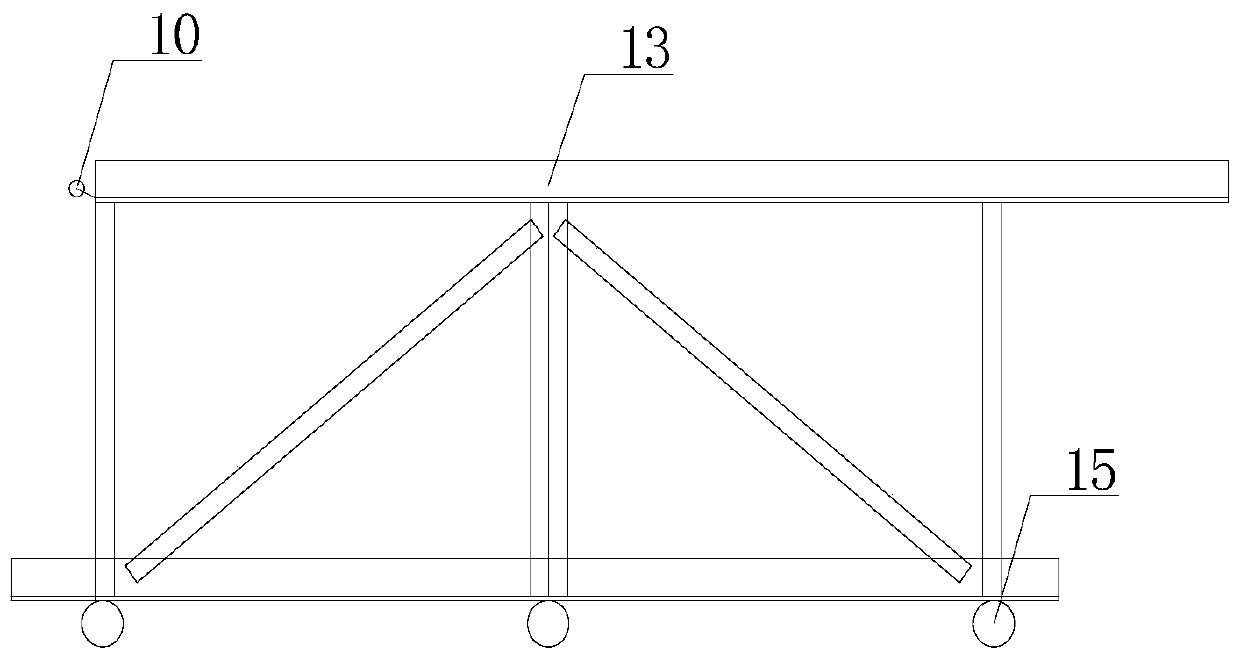

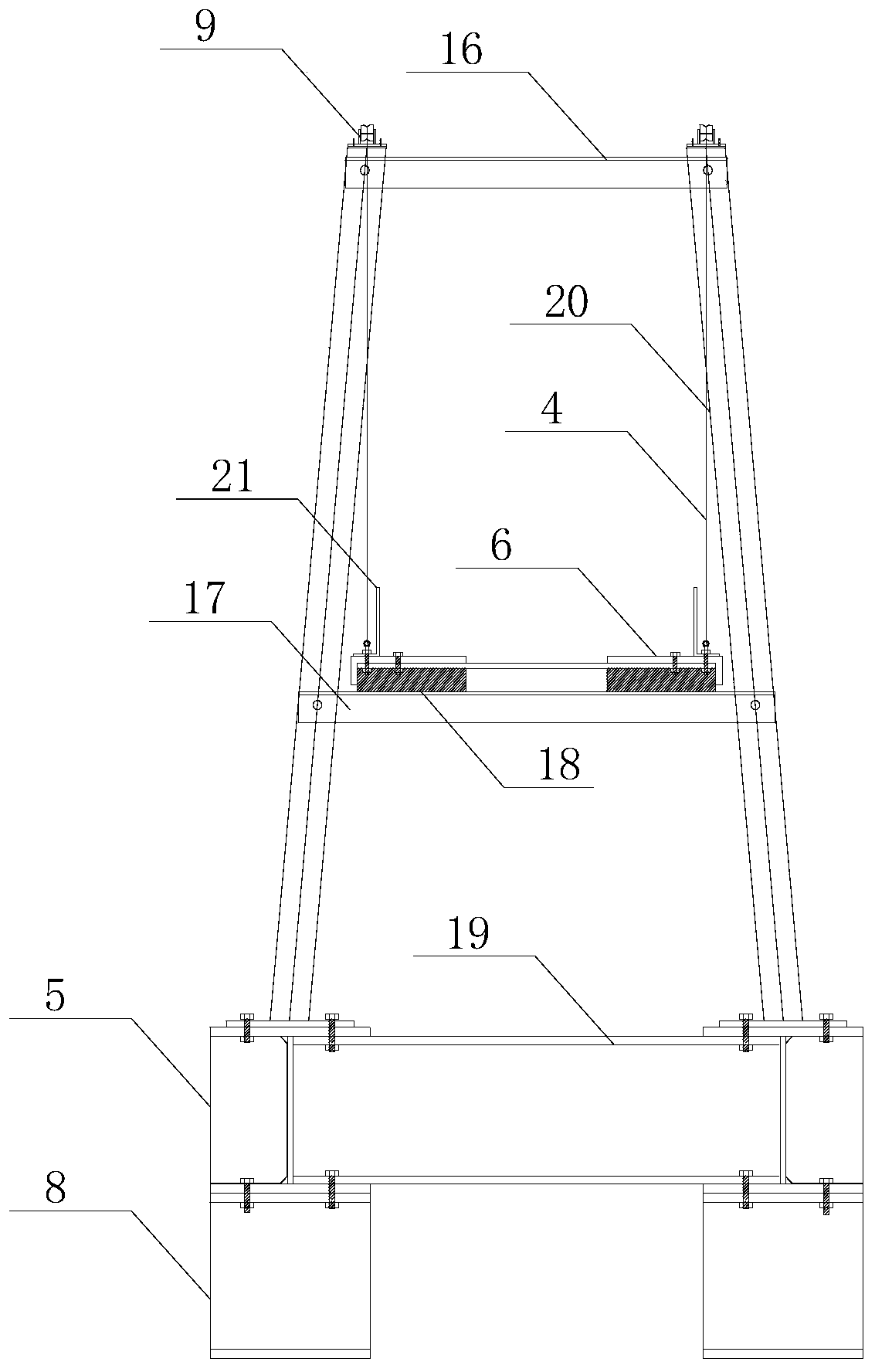

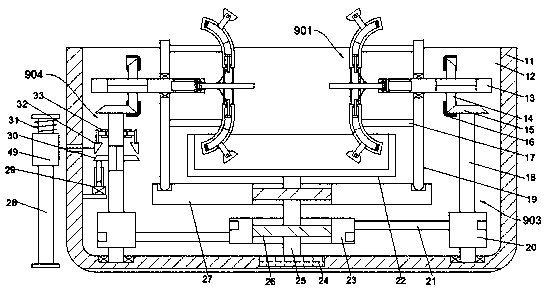

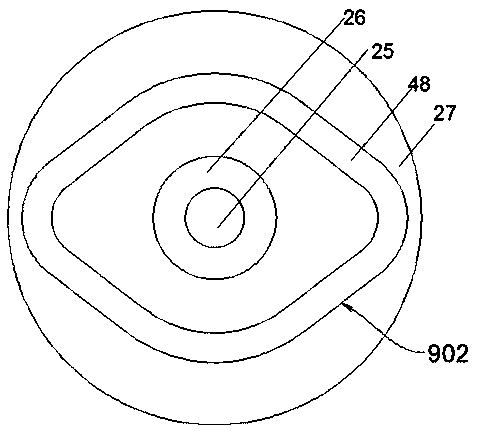

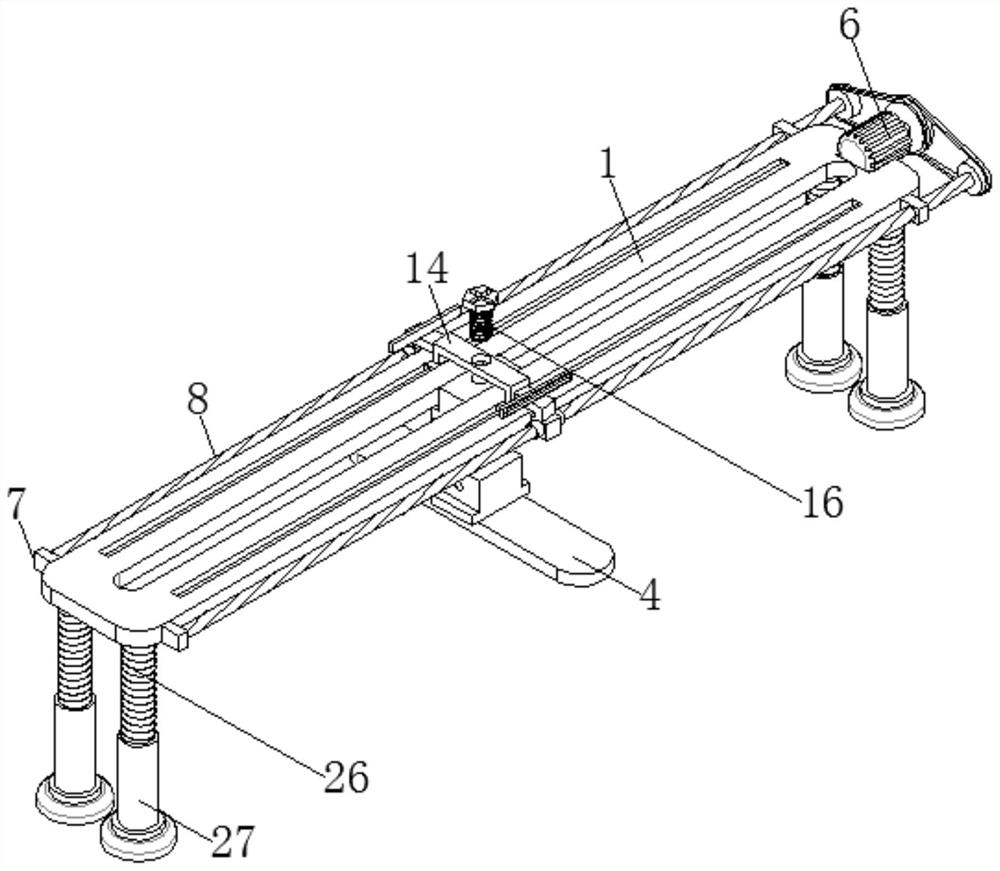

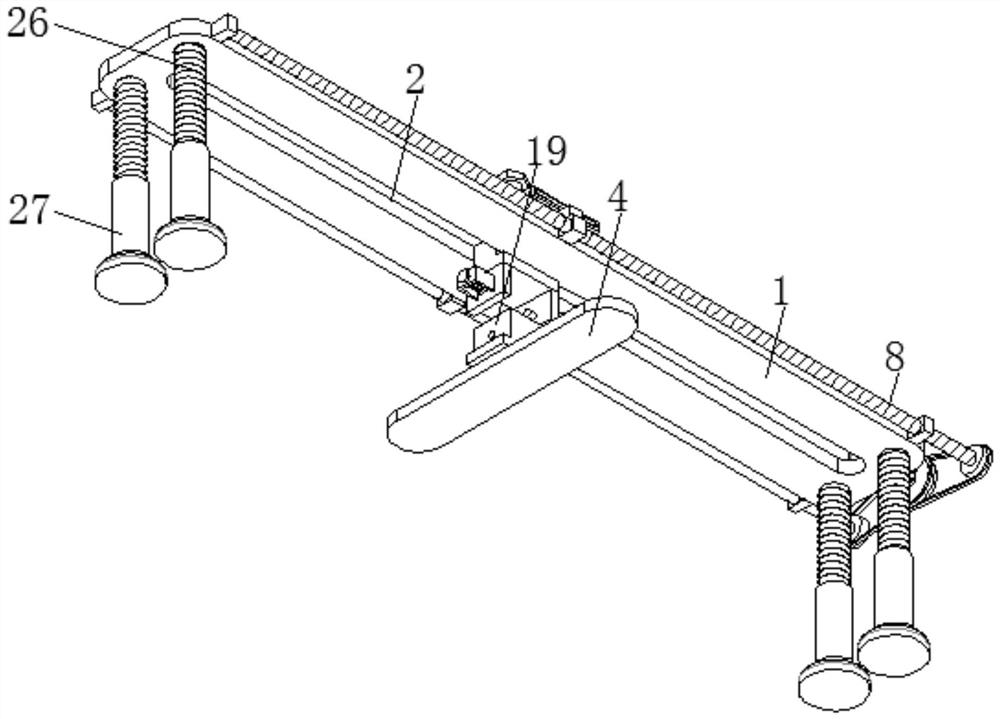

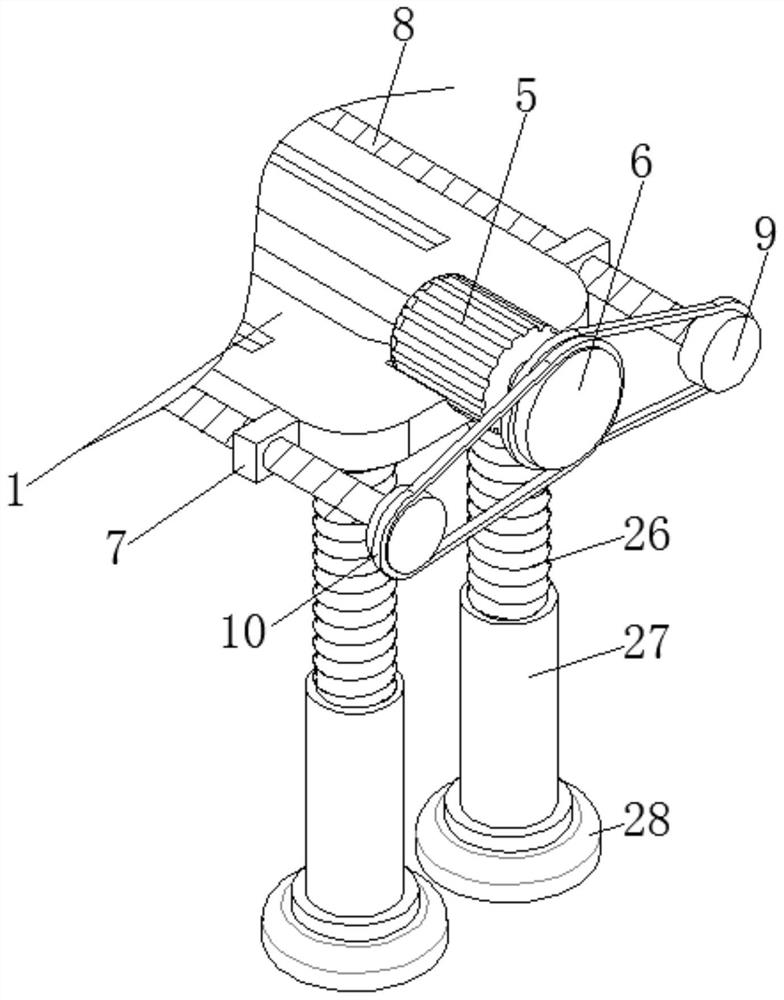

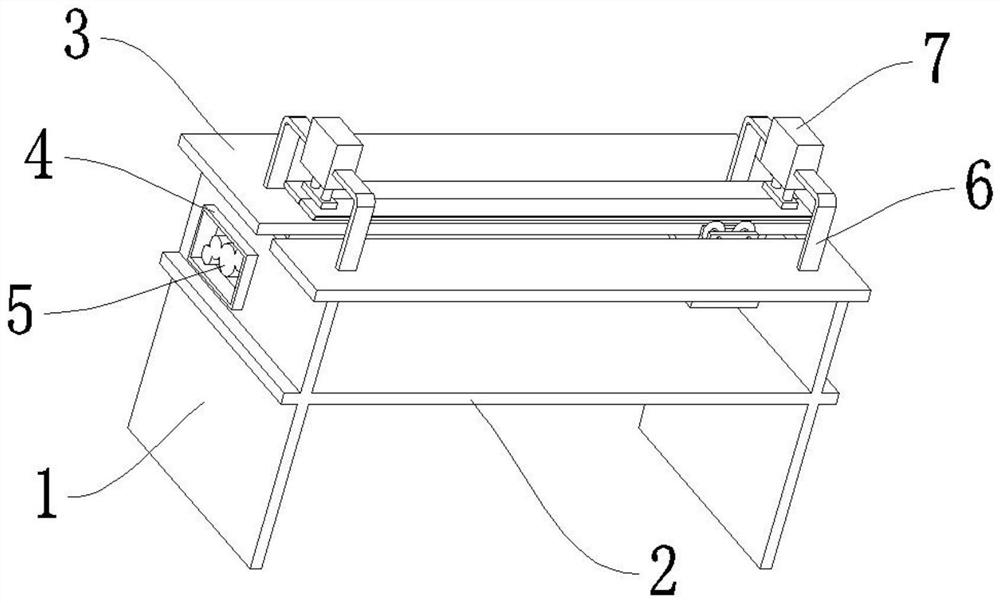

Assembled two-tower cable-stayed bridge damage identification test model system

InactiveCN102829990AHigh simulationEasy disassembly and assemblyStructural/machines measurementCable stayedRemote control

The invention discloses an assembled two-tower cable-stayed bridge damage identification test model system, which consists of a two-tower cable-stayed bridge test model, a moving load system and a data acquiring system, wherein the two-tower cable-stayed bridge test model consists of a girder, cable bent towers, stay cables, a support seat and bases, and the girder is formed by splicing sections with different lengths; the moving load system is a vehicle model controlled by a wireless remote control device, and weights are fixed on the moving load system; and the data acquiring system comprises a cable force testing system, a displacement testing system and an acceleration testing system. According to the system disclosed by the invention, the model experiments of dynamic and static performances of a cable-stayed bridge structure can be completed, and at the same time various damage states of the cable-stayed bridge structure under an actual situation can be conveniently simulated; the arrangement of counter weights can be adjusted according to the test requirement; an unsmooth driving situation of a vehicle on a bridge surface can be simulated; the loading of moving load is realized; and the data acquiring system is comprehensive, simple, convenient, economical, real-time and reliable in precision.

Owner:TIANJIN UNIV

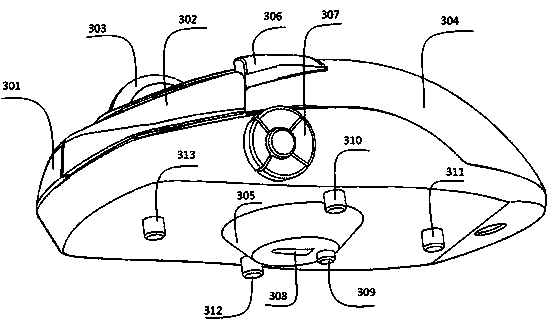

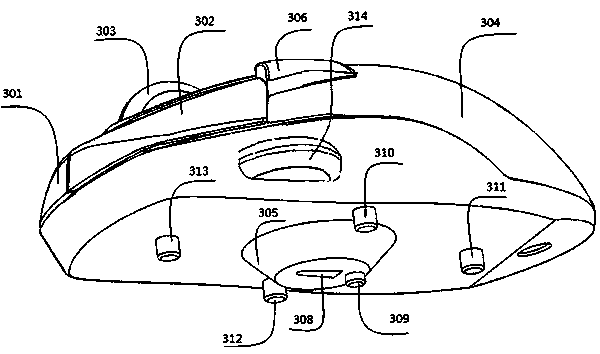

Three-dimensional control mouse and application method thereof

InactiveCN104199565AChange movement speedFlexible operationInput/output processes for data processingDimensional modelingHabit

The invention discloses a three-dimensional control mouse which comprises an upper shell body and a lower shell body; a left key, a middle-finger roller, a right key and a thumb roller are arranged on the upper shell body; an X-axis and Y-axis sensor and a deflection sensor are arranged on the lower shell body; the deflection sensor also comprises an angle sensing part; the upper shell body can deflect together with the added thumb roller relative to the lower shell body, so that the three-dimensional control mouse has more flexible and more convenient three-dimensional operation ability, can additionally carry out operation and control in more dimensions, and can provide convenient and flexible control which is more suitable for the habits of people for various conversion motion of three-dimensional scenes and three-dimensional objects compared with a two-dimensional mouse.

Owner:董礼貌

Image forming apparatus and image forming method

InactiveUS7535580B2High resolutionChange movement speedUsing optical meansElectrographic process apparatusMotor driveImage formation

An image forming apparatus which can form an even image while maintaining high resolution. A speckle pattern detecting unit detects a speckle pattern on a surface of a photosensitive drum. A motor drive circuit controls the rotational speed of the photosensitive drum based on the detected speckle pattern on the surface of the photosensitive drum detected by the speckle pattern detecting unit.

Owner:CANON KK

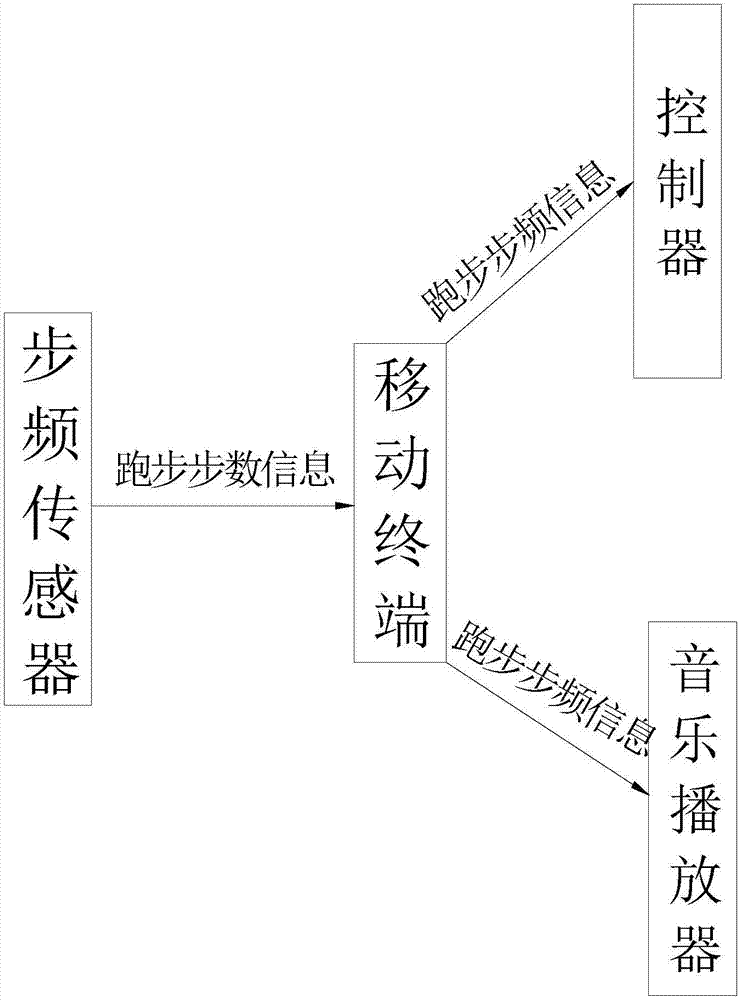

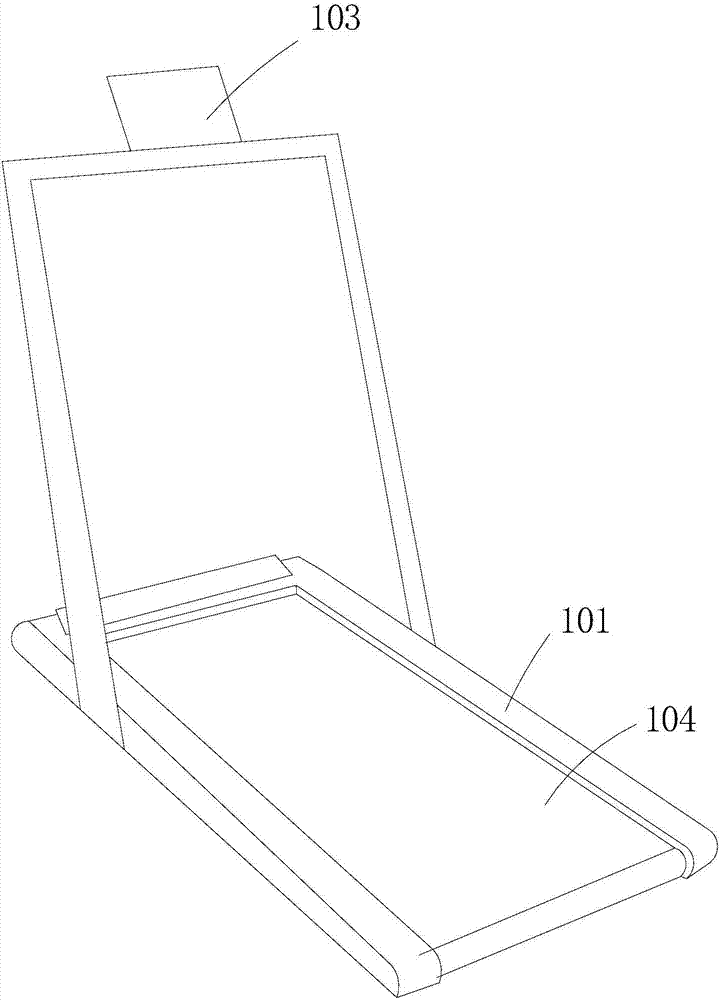

Control method for controlling speed on treadmill through adjusting music BPM by stride frequency

InactiveCN107875576AControl movement speedChange movement speedMovement coordination devicesCardiovascular exercising devicesMusic playerStep number

The invention relates to the technical field of treadmills, and discloses a control method for controlling speed on a treadmill through adjusting music BPM by stride frequency. When a runner runs on arunning belt of a treadmill, a stride frequency sensor on the treadmill acquires running step number information of the runner, and feeds the acquired running step number information back to a mobileterminal. The mobile terminal calculates running stride frequency information of the runner in short time, and feeds the calculated running stride frequency information back to a controller and a music player. The music player adjusts music BPM of music which is playing, to make the music BPM synchronize with the running stride frequency information of the runner. The controller controls a powerelement to drive moving speed of the running belt of the treadmill to be synchronous with the running stride frequency information of the runner. The runner synchronously changes music BPM played by the music player and the moving speed of the running belt of the treadmill according to running speed rhythm of the runner. The runner controls music and running speed according to stride frequency ofthe runner, so when the runner runs, running speed and the music are synchronously coordinated.

Owner:BEIJING KINGSMITH TECHNOLOGY CO. LTD.

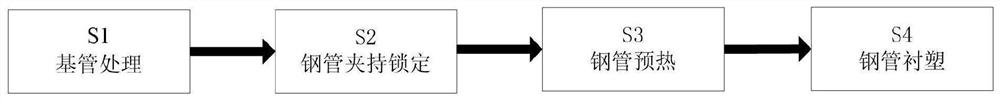

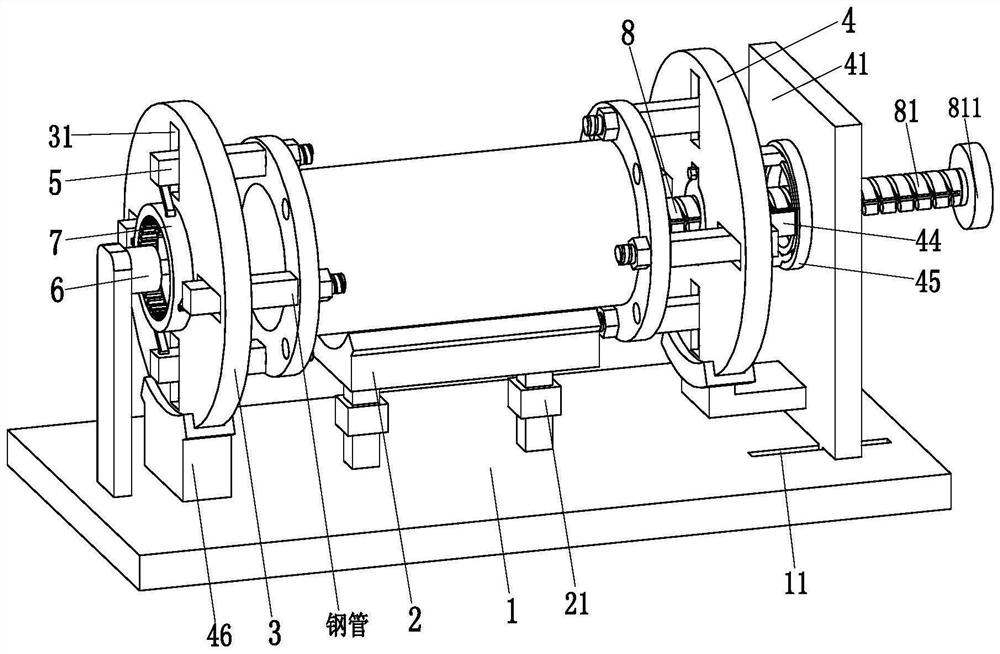

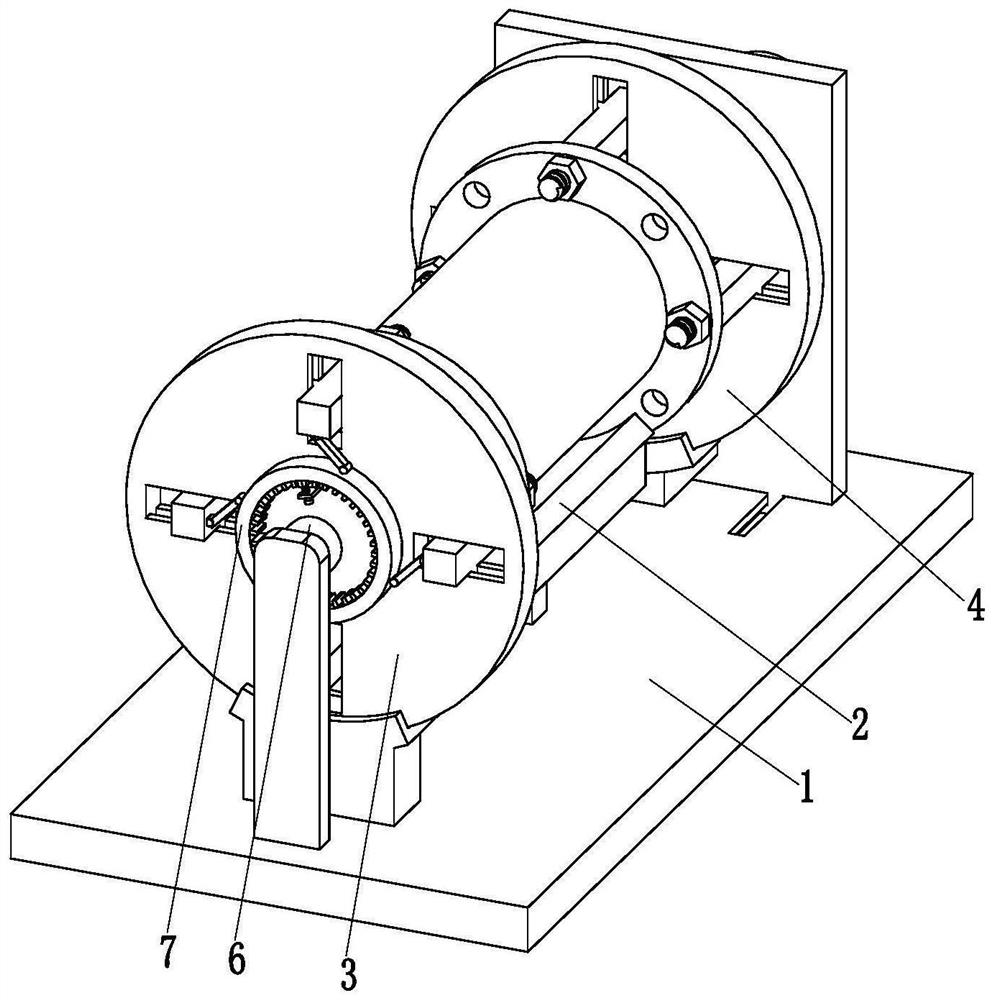

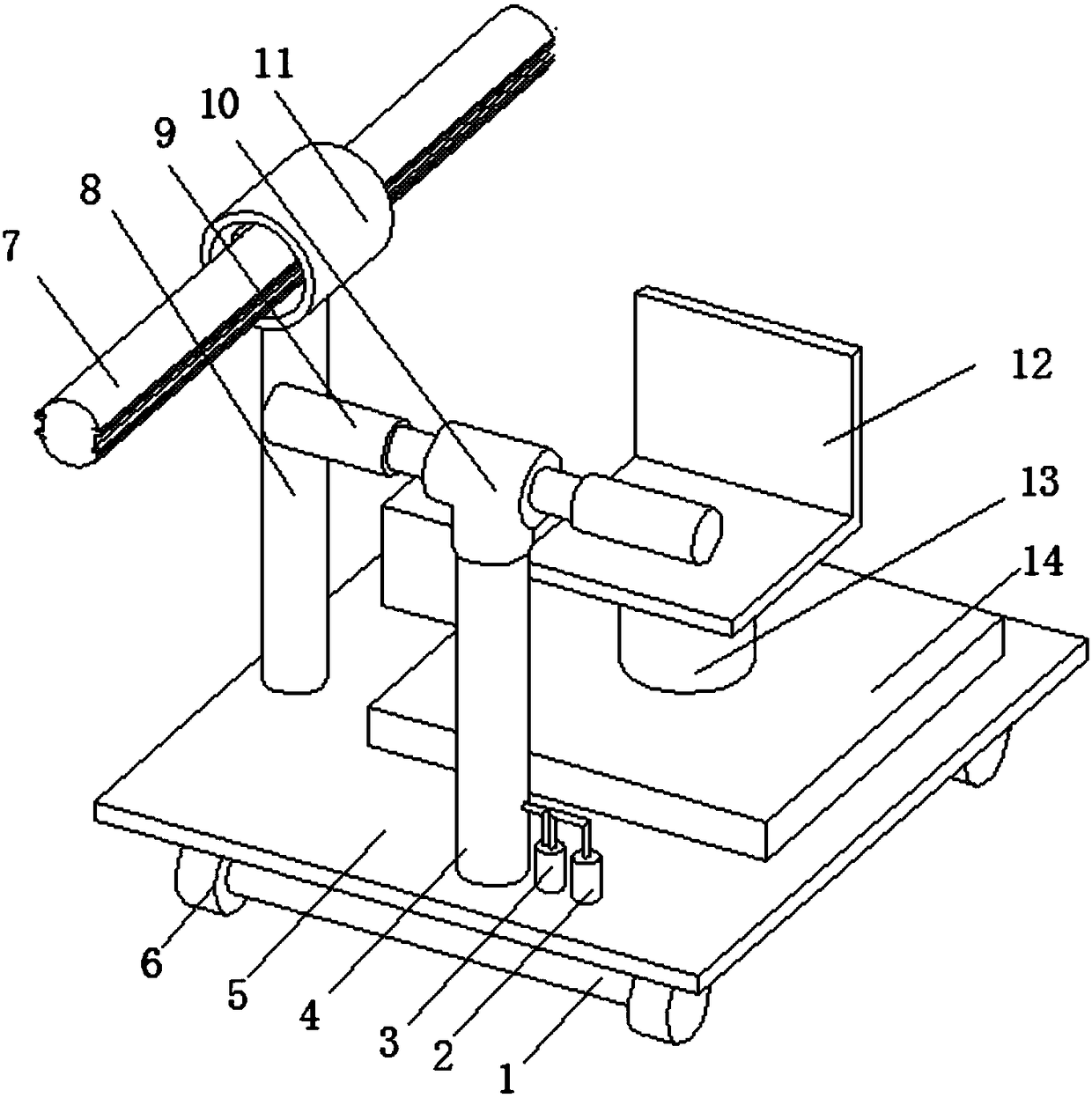

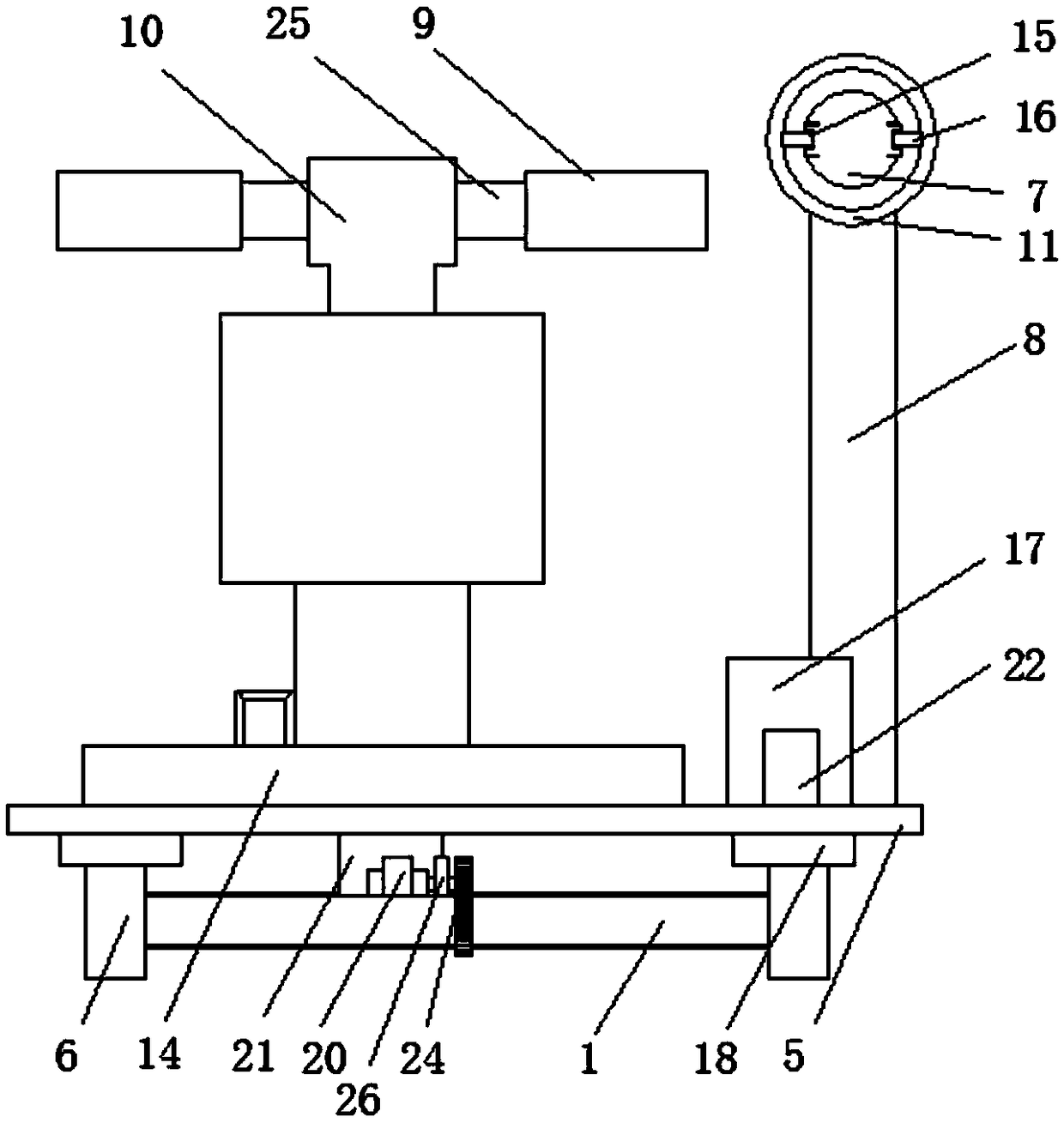

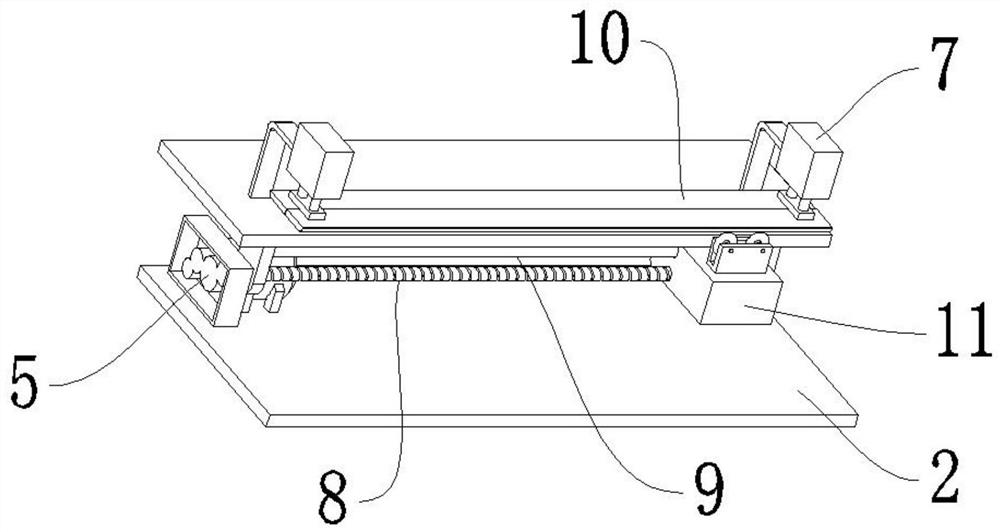

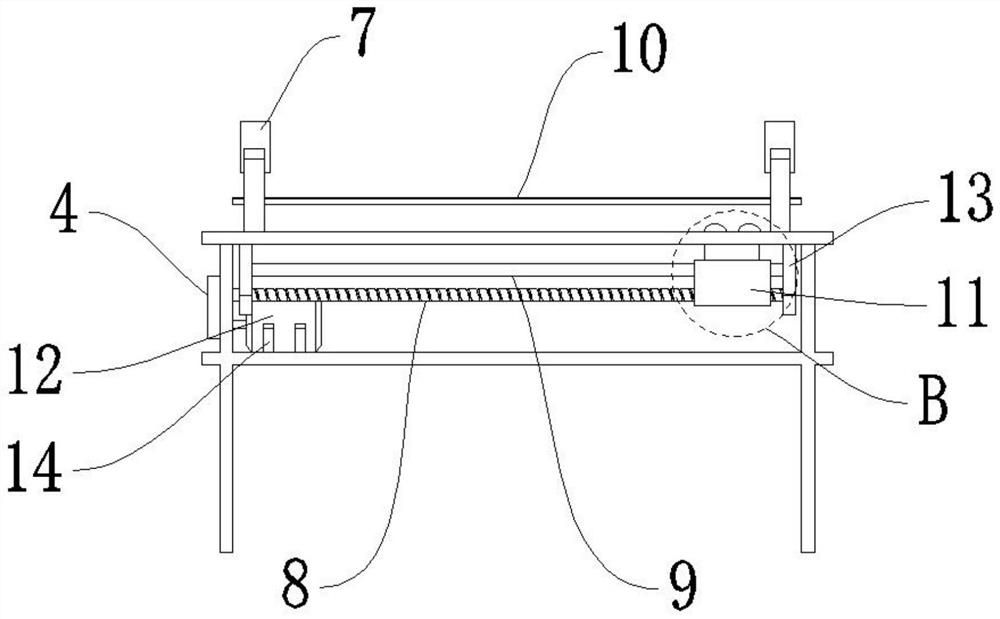

Chemical anti-corrosion steel pipeline manufacturing technology

InactiveCN112934646AImprove uniformityImprove applicabilityPretreated surfacesCoatingsSteel tubeEngineering

The invention relates to a chemical anti-corrosion steel pipeline manufacturing technology. A plastic-lined steel pipe forming device is adopted in the technology and comprises a bottom plate, a heating sleeve, a positioning plate, a sliding plate, a clamping rod, a rotating motor, an adjusting mechanism and an adhesion mechanism. The technology for manufacturing a chemical anti-corrosion plastic-lined steel pipeline by adopting the plastic-lined steel pipe forming device comprises the following steps of S1, base pipe treatment, S2, clamping and locking of a steel pipe, S3, preheating of the steel pipe and S4, plastic lining of the steel pipe. The problems that when an existing plastic-lined steel pipe is machined, a clamp for the plastic-lined steel pipe can only clamp the steel pipe of a specific model, the applicability is low, the steel pipe is unstable in rotation, and preheating of the steel pipe is uneven are solved, and the problems that when the inner side surface of the steel pipe is subjected to plastic lining treatment, a plastic injection machine cannot adjust the synchronous moving speed along with the rotating speed of the steel pipe, so that plastic lining on the inner wall of the steel pipe is uneven, and plastic on the inner wall of the steel pipe cannot be flattened are solved.

Owner:南京绪风科技有限公司

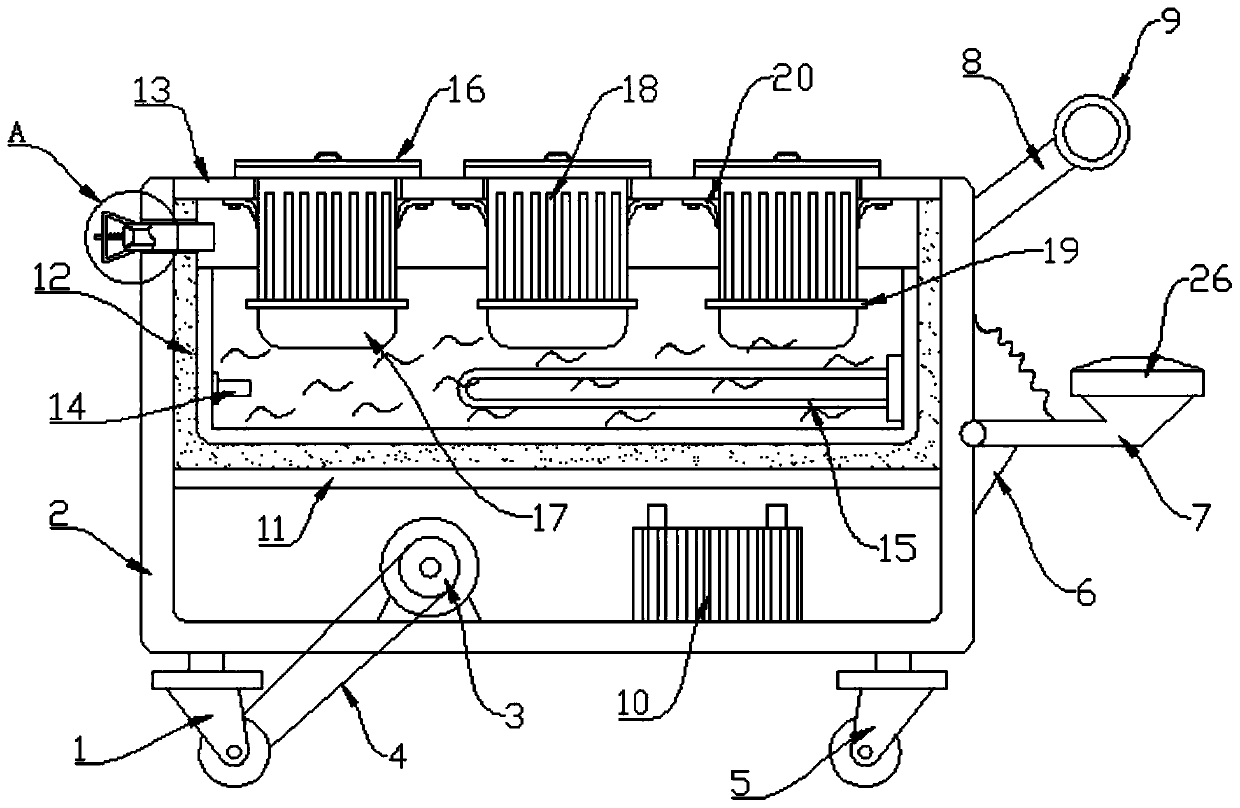

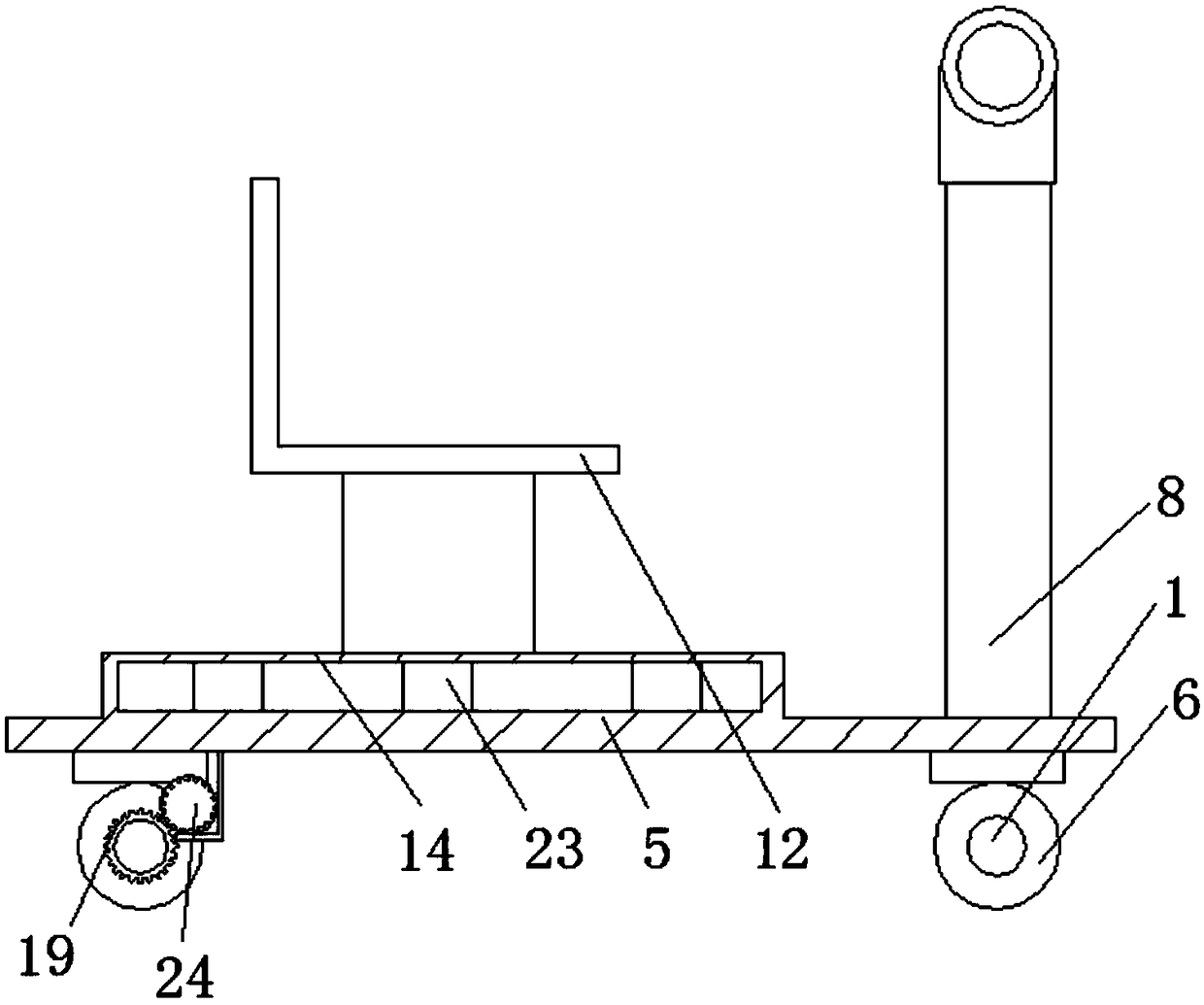

Electric steam heat preservation serving trolley

InactiveCN111265012ARealize heating and insulationReduce weightStorage heatersServing tablesElectric machineHeater Rod

The invention discloses an electric steam heat preservation serving trolley which comprises a carriage and a cover plate installed at the top of the carriage, a pot body is erected in a containing groove formed in the cover plate, an electric control moving device is installed at the bottom of the carriage, and the speed of the electric control moving device is adjusted through a speed regulator installed on one side. Water in the hot water tank is heated through the heating rod, and heating and heat preservation of food in the pot body are achieved; through the arrangement of transverse finsand vertical fins, heat of hot water is transferred upwards, the upper portion of the pot body can still be heated without adding much water, the water consumption is reduced, the weight of a vehiclebody can be reduced, the load is reduced, walking of a carriage is more convenient, and power consumption is reduced. When the carriage moves, the speed regulator on the handle can be rotated to adjust the rotating speed of the driving motor, and then the moving speed of the carriage is changed.

Owner:合肥人和节能环保设备制造有限公司

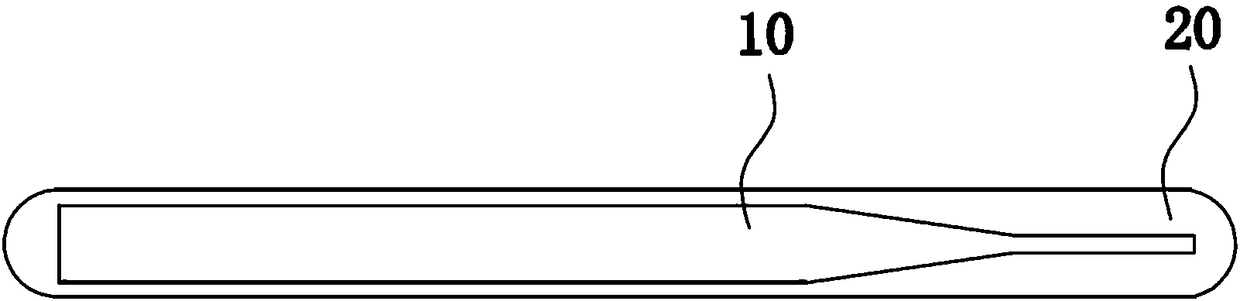

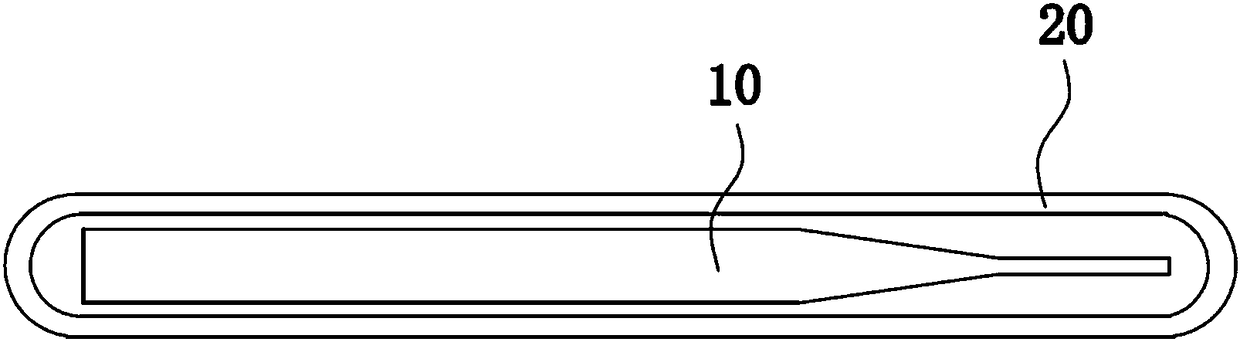

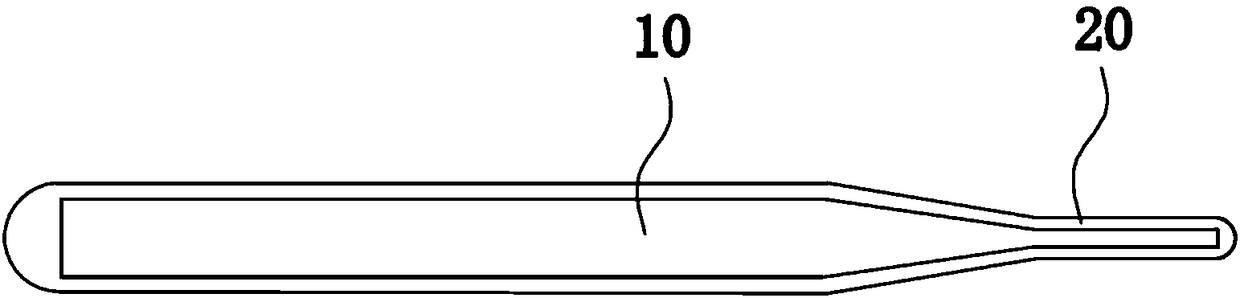

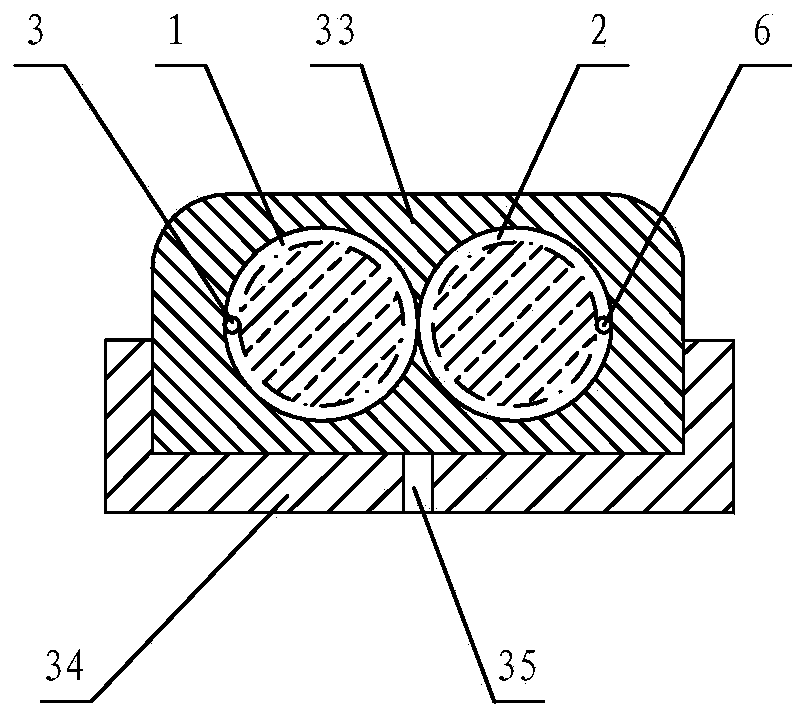

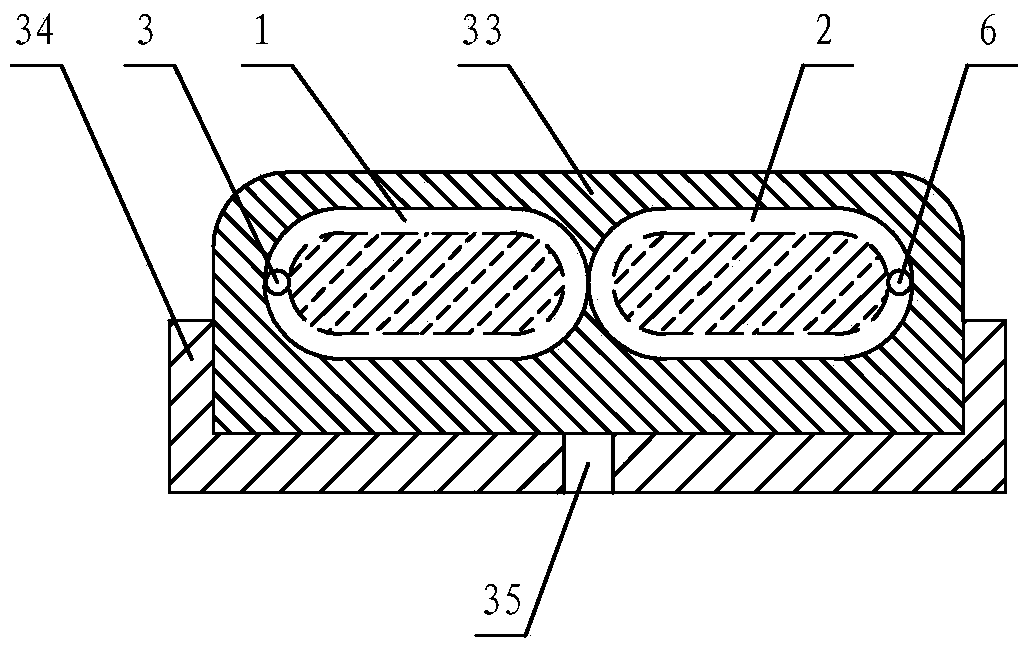

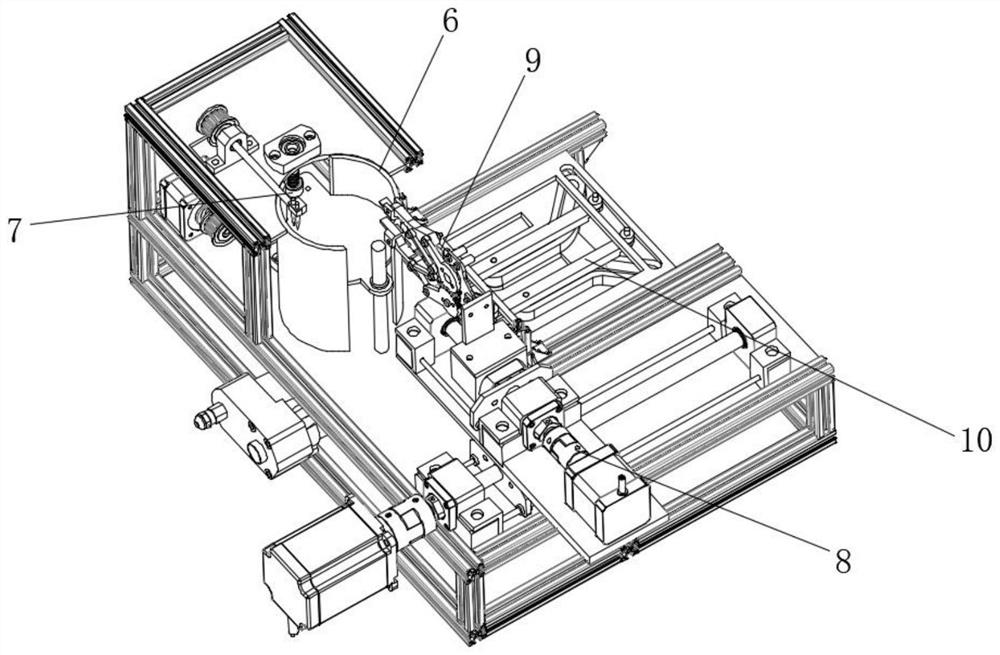

Super-slip guide wire outer wrapped layer solid solution molding device and wrapping method thereof

The invention discloses a super-slip guide wire outer wrapped layer solid solution molding device including a wrapping mold, a wrapping material supply device, a variable speed traction device and a cooling device; a molding channel for a core wire to pass through and a melt runner intersected with the molding channel are formed on the wrapping mold; the wrapping material supply device is used forproviding a wrapping material melt for the wrapping mold; the variable speed traction device is used for pulling a core wire out from the molding channel at different speeds according to the diametersizes of the core wire in different regions, wherein the core wire passes through the molding channel and is coaxial with a second molding channel of the molding channel; the cooling device is used for cooling the core wire removed out of the wrapping mold. The core wire is wrapped tightly by a solid solution way, so slipping is not easy, a head end of the core wire is prevented from puncturing the outer wrapping layer, and the risk of scrapping a chamber channel by a guide wire is reduced; at the same time, with adopting of the variable speed traction way, different-diameter regions of the core wire have more fit wrapping time and wrapping material melt amount, and uniform, smooth and reliable outer diameter of the guide wire after wrapping can be guaranteed.

Owner:SUZHOU HIGHWIRE MEDICAL DEVICES CO LTD

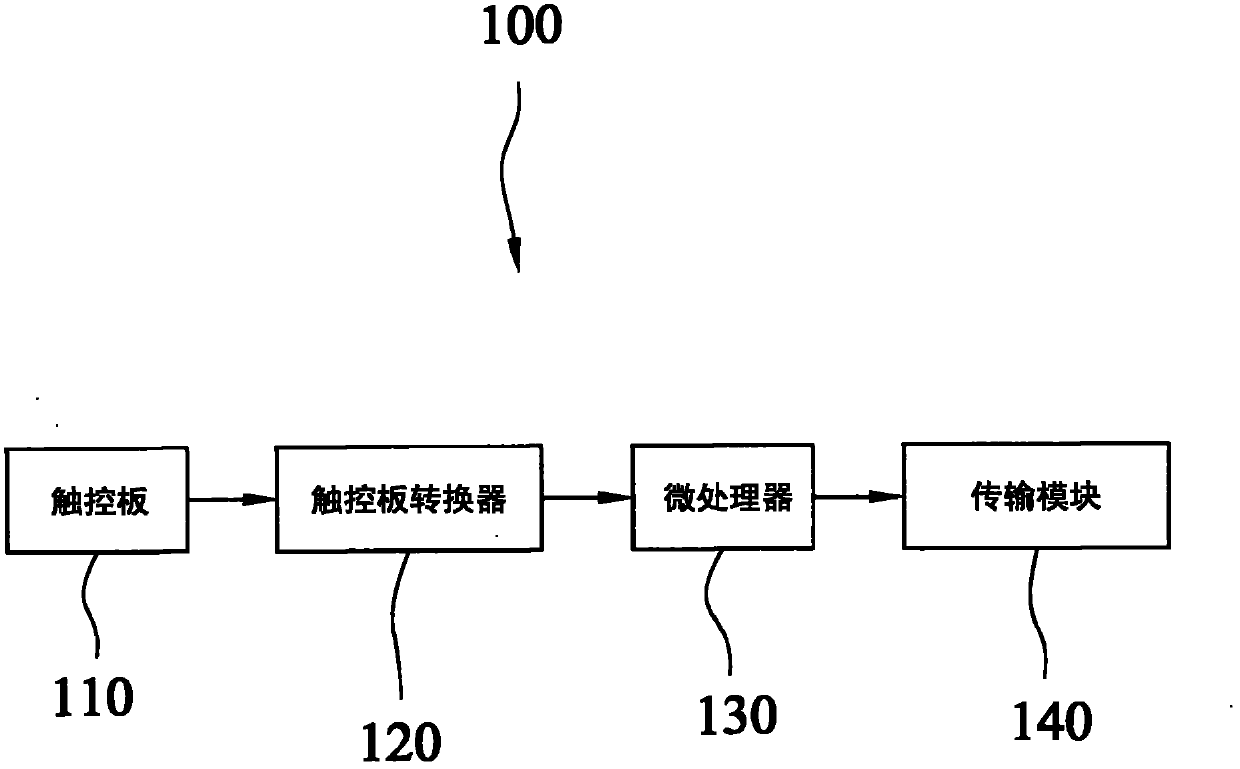

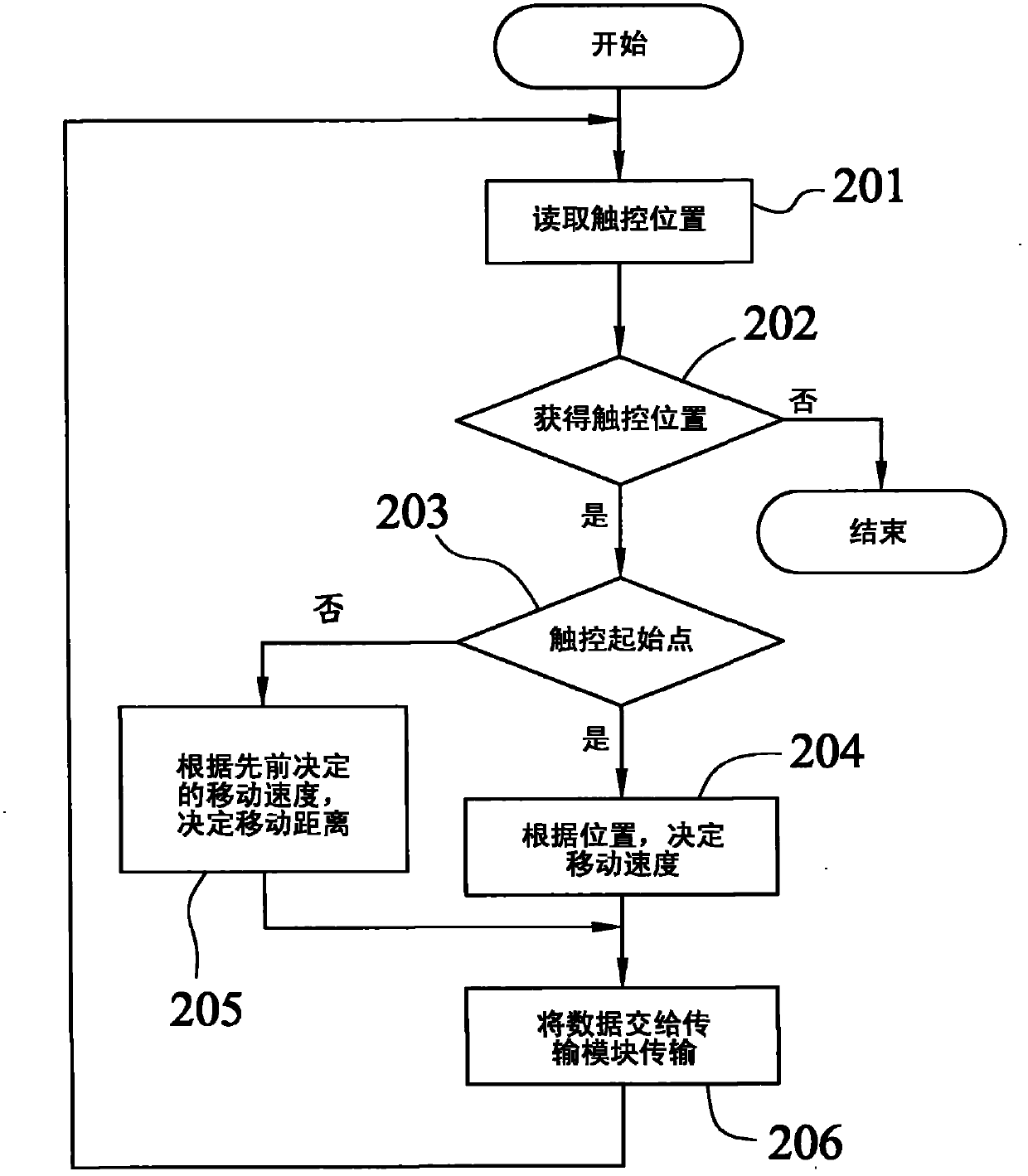

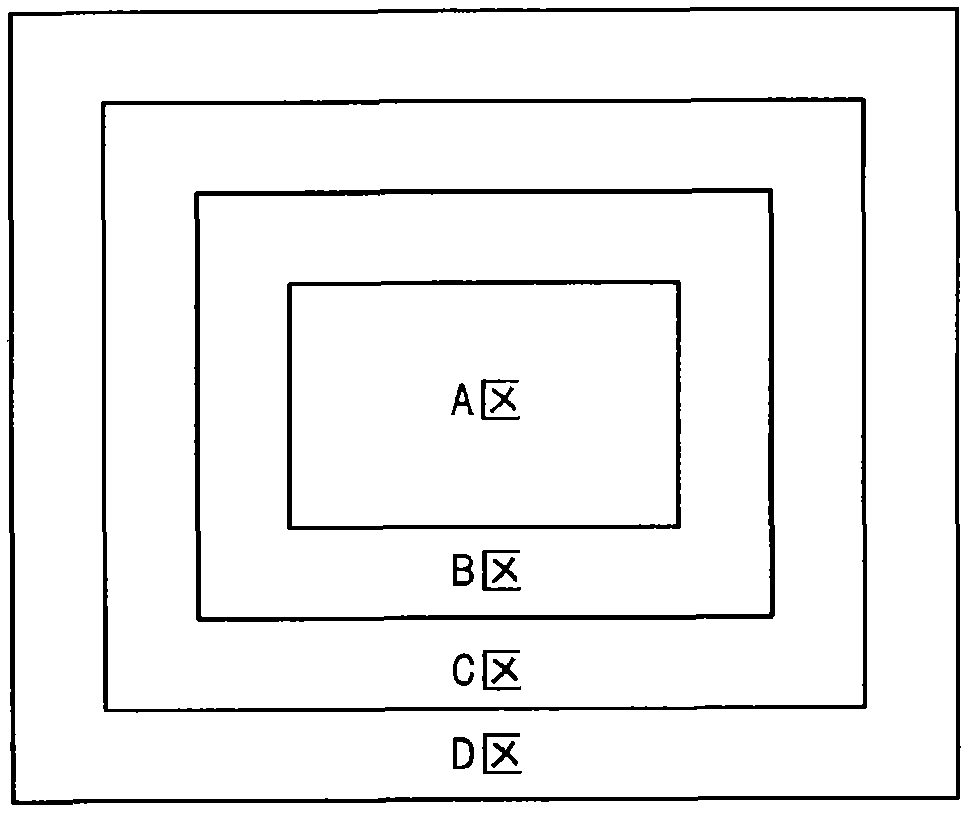

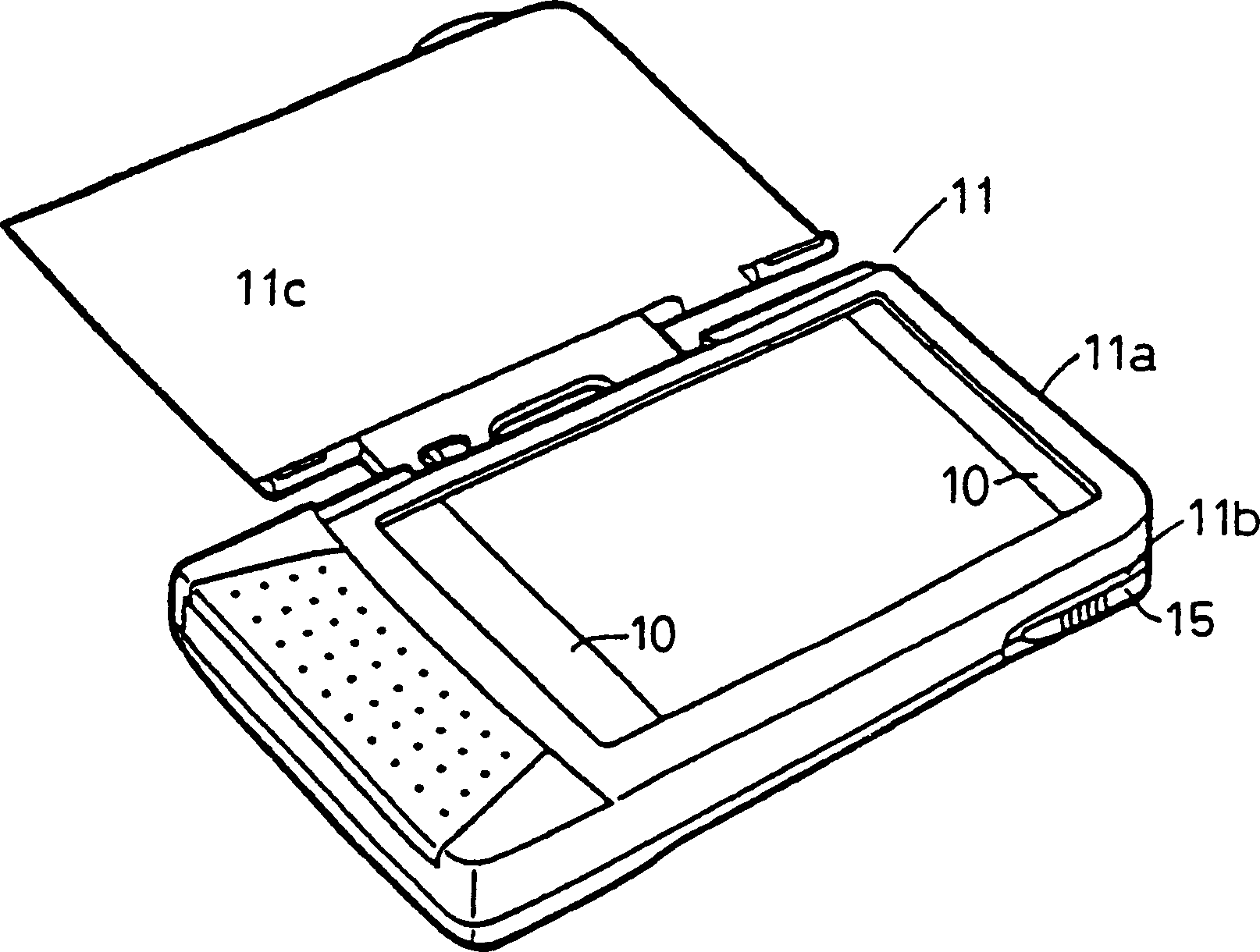

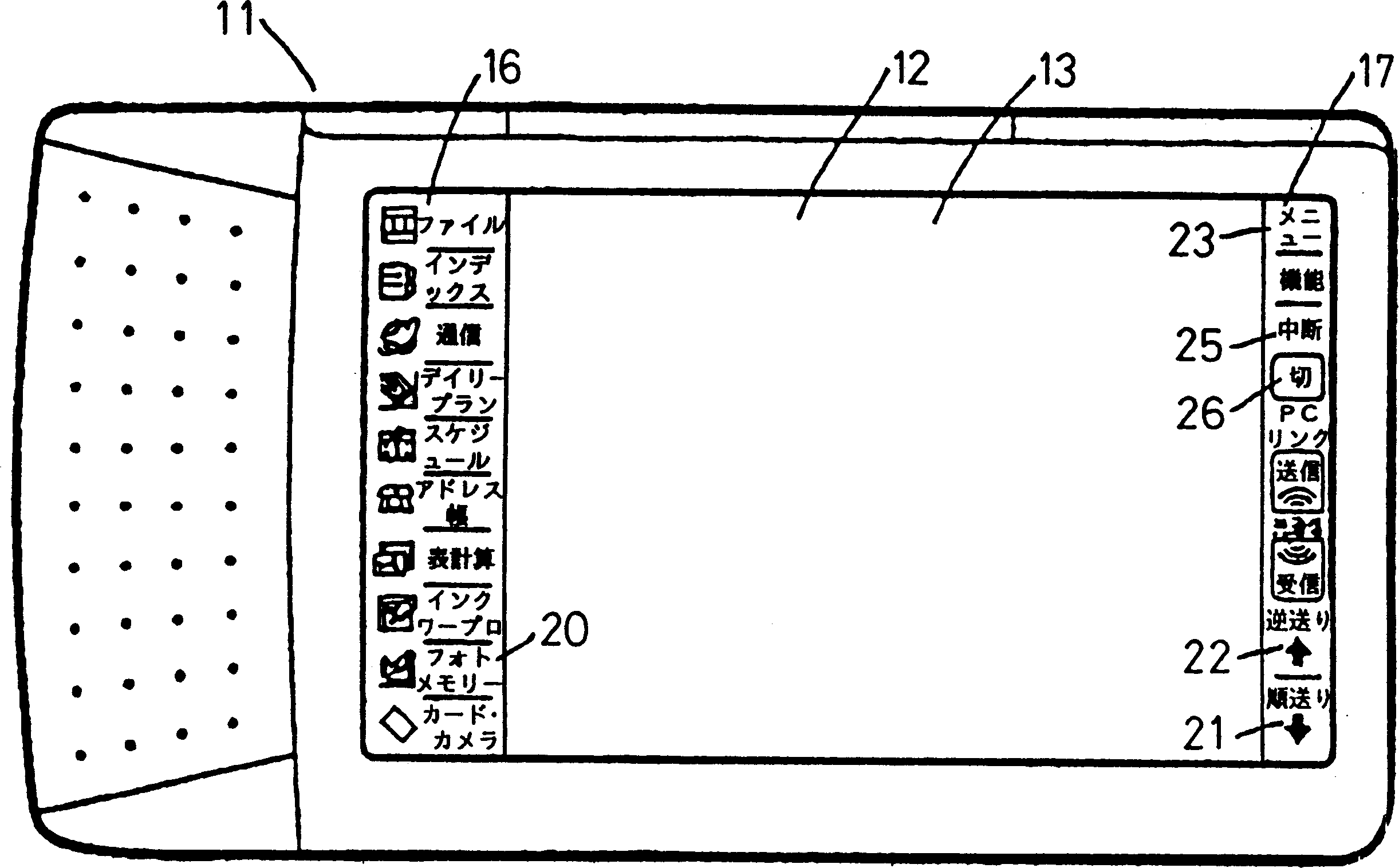

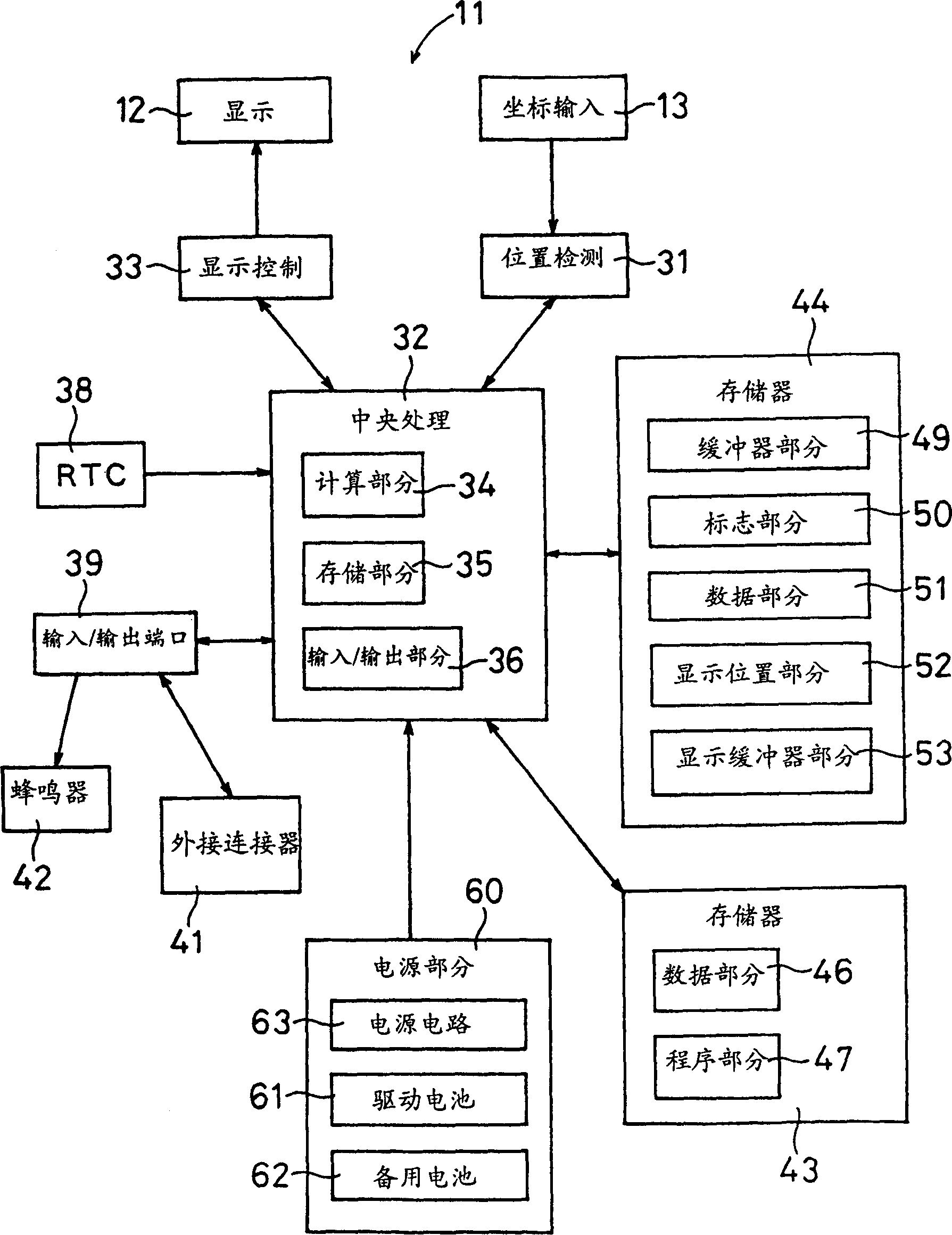

Touch input device and touch input method which are capable of changing movement speed

InactiveCN103309489AChange movement speedPrecise operation detailsInput/output processes for data processingRelevant informationDisplay device

The invention provides a touch input device and a touch input method which are capable of changing the movement speed. The touch input device comprises a touch panel, a touch panel converter, a microprocessor and a transmission module, wherein the panel surface of the touch panel is divided into multiple areas, each area can respectively correspond to one preset vernier movement speed, when the touch panel is operated by a user, the touch panel converter can be used for converting touch position on the touch panel by the user into coordinate related information and carrying out analysis and follow-up calculation by transmitting the coordinate related information to the microprocessor, and finally, the microprocessor is used for transmitting calculating results to an external display through the transmission module so as to control corresponding vernier movement speeds of the calculating result.

Owner:TRITAN TECH INC

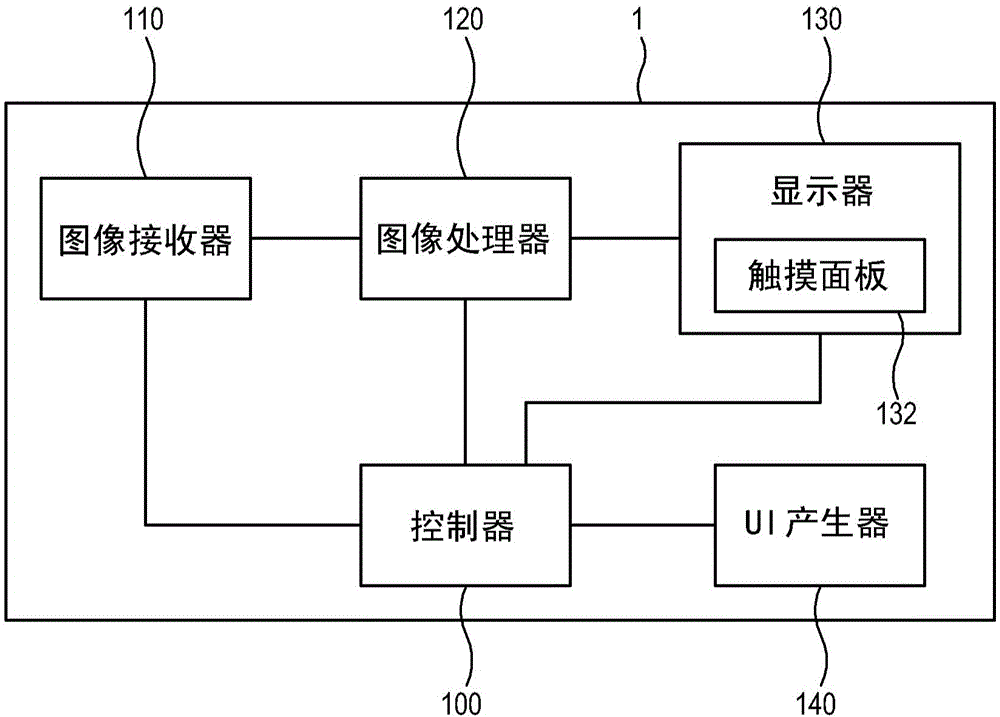

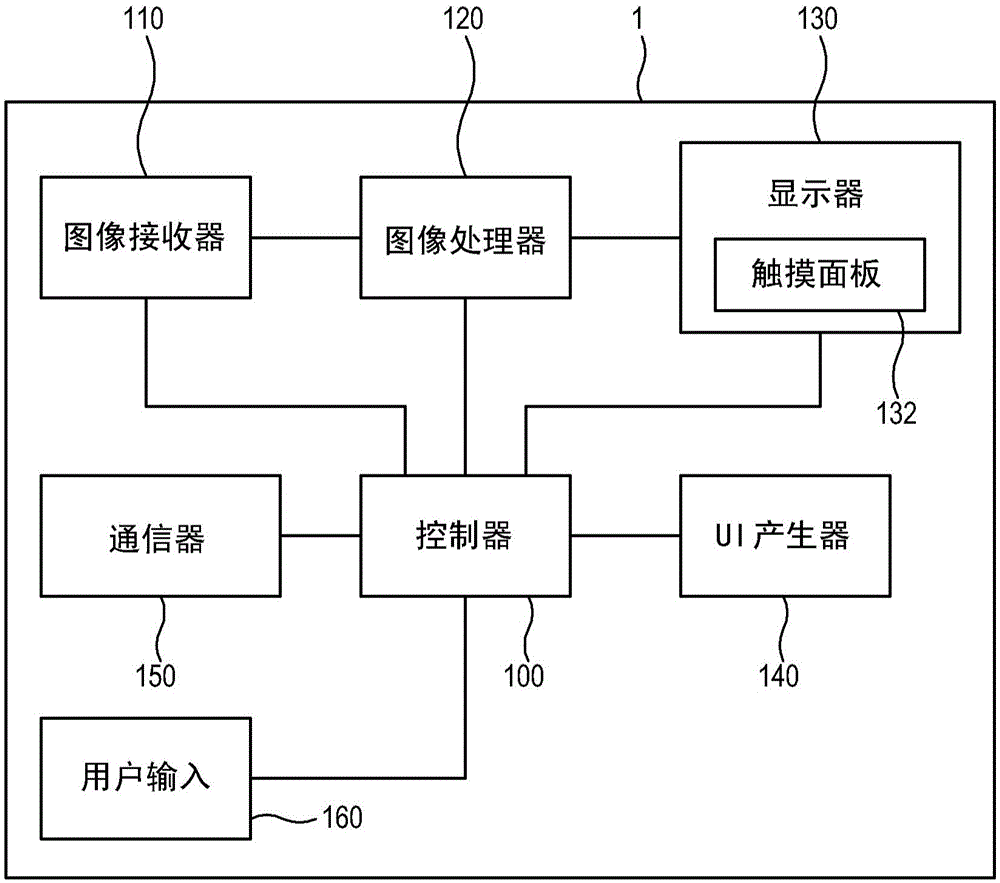

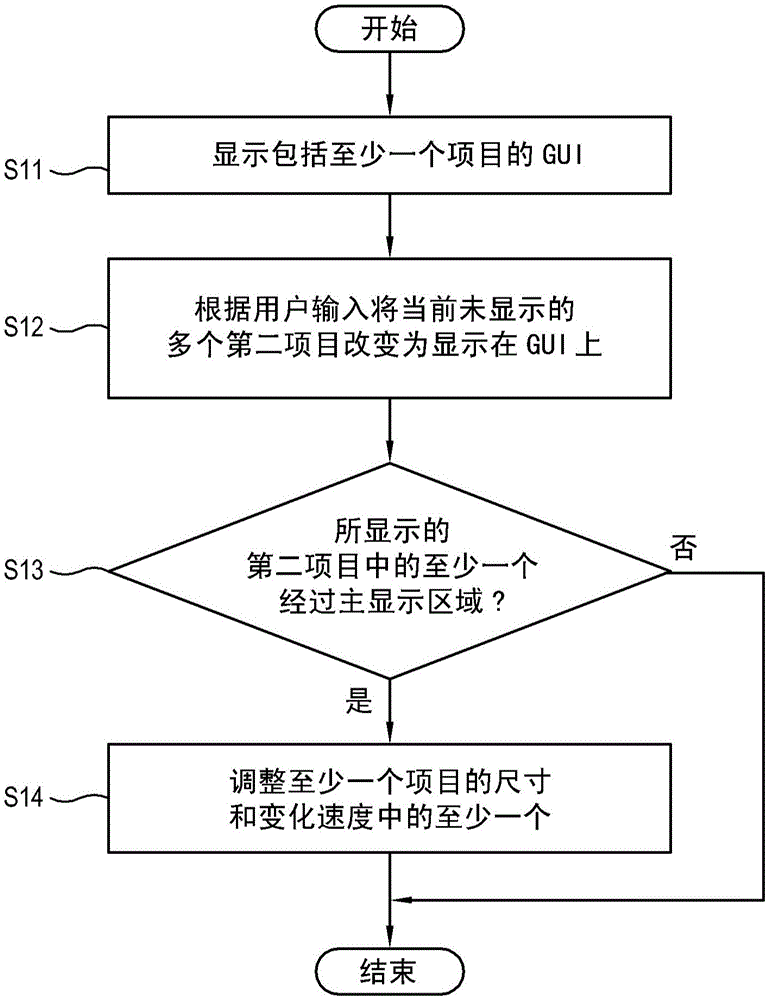

User terminal and control method thereof

InactiveCN104423834AAdjustable sizeAvoid excessive changesTelevision system detailsColor television detailsGraphicsGraphical user interface

Disclosed are a user terminal which includes: an image receptor to receive an image; an image processor to process the received image; a displayer to display the processed image; and a controller to display a graphical user interface (GUI) including at least one first item, to change a plurality of second items, not currently displayed, to be displayed on the GUI according to a user input, and to adjust at least one of size and display changing speed of at least one item of the displayed second items when the at least one item passes through a main display area.

Owner:SAMSUNG ELECTRONICS CO LTD

Suspension bridge test model system for damage identification and construction scheme verification

InactiveCN110044560ASimple simulation verificationEasy disassembly and assemblyElasticity measurementData acquisitionModel system

The invention discloses a suspension bridge test model system for damage identification and construction scheme verification. The system comprises a double-tower ground anchor type suspension bridge model, an approach bridge model, a mobile load system and a data acquisition system. The suspension bridge test model system is used to complete the model test of the dynamic and static performance ofthe suspension bridge structure, simulate an unsmooth condition during a vehicle driving on a bridge, simulate the damage simulation test of each key component of the suspension bridge structure conveniently, and simulate the construction process of the suspension bridge simply. Balance weight of a main cable and a main beam is realized, and the balance weight configuration can be adjusted according to test requirements. Loading of the moving load is realized. A data acquisition system is comprehensive, simple, convenient, economic, real-time and reliable in precision.

Owner:TIANJIN UNIV

Adjustable transformer

InactiveCN110098038AAvoid damageAvoid reciprocating frictionTransformers/inductances casingsTransformers/inductances coils/windings/connectionsTransformerConductor Coil

The invention relates to an adjustable transformer, which comprises a housing and an annular core and further comprises a carbon brush and an adjusting device. According to the adjustable transformerof the invention, the adjusting device drives the carbon brush to rotate in the circumferential direction and adjusts the position of the brush head in the radial direction; the reciprocating frictionbetween the brush head and a winding of the annular core on the same circular trajectory is avoided so as to prevent the damage of the winding of the annular core; the moving direction of a sliding brush rod can also be switched so as to enable the brush head to have two moving modes such as expansion and relaxation in the radial direction, and the brush head is enabled to be continuously used; the moving speed of the brush head is very slow, so that it is unnecessary to manually change the moving direction of the sliding brush rod for many times; and the moving speed of the sliding brush rodcan also be adjusted.

Owner:吕娜

Drying device for printing

InactiveCN110682678AControl work efficiencyChange movement speedPrinting press partsFrequency changerEngineering

The invention discloses a drying device for printing. The drying device comprises a shell body. Two sets of supporting seats are arranged at the bottom of an inner cavity of the shell body, electromotors and belts are arranged on the tops of the two sets of supporting seats, output shafts of the two sets of electromotors are connected with reels, a frequency converter is mounted on one sides of the supporting seats, the frequency converter is electrically connected with the electromotors, infrared heating lamp tubes are evenly arranged in the inner cavity of the shell body, an air inflow tubeis connected to the top of the inner cavity of the shell body in an inserted manner, a shunting tube is arranged at the bottom of the air inflow tube, drying tubes are evenly arranged at the bottom ofthe shunting tube, an air inflow valve is arranged on the top of the air inflow tube, a connecting tube is connected to the top of the air inflow valve in an inserted manner, a dryer is arranged at the bottom of the connecting tube, the bottom of the dryer is connected with an air blower through a pipeline, the bottom of the air blower is connected with a drying device through a pipeline, an airoutflow tube is arranged on the top of the drying device, the air outflow tube is connected to the bottom of the shell body in an inserted manner, and a control device is electrically connected with the electromotors, the frequency converter, the infrared heating lamp tubes and the air blower.

Owner:盐城丛林科技有限公司

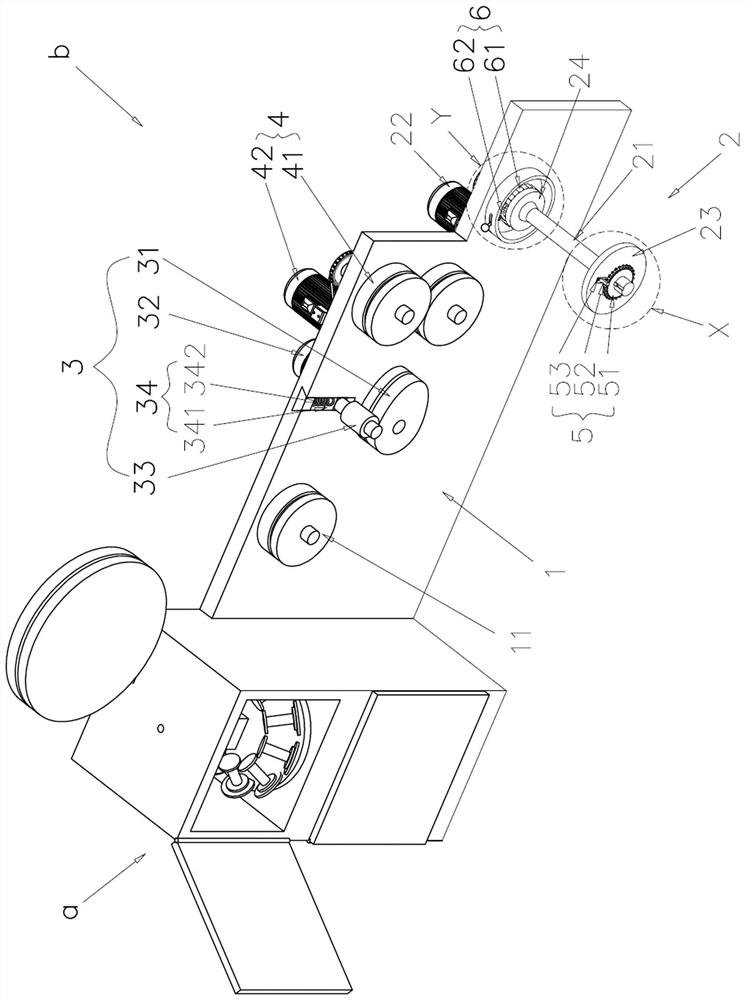

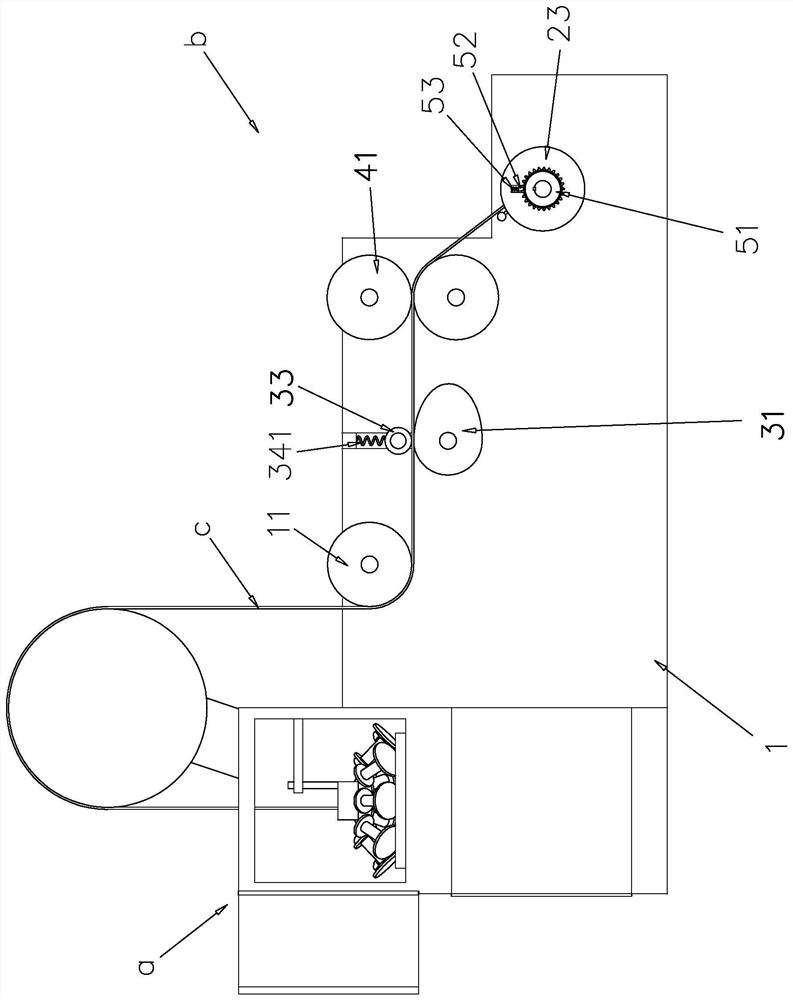

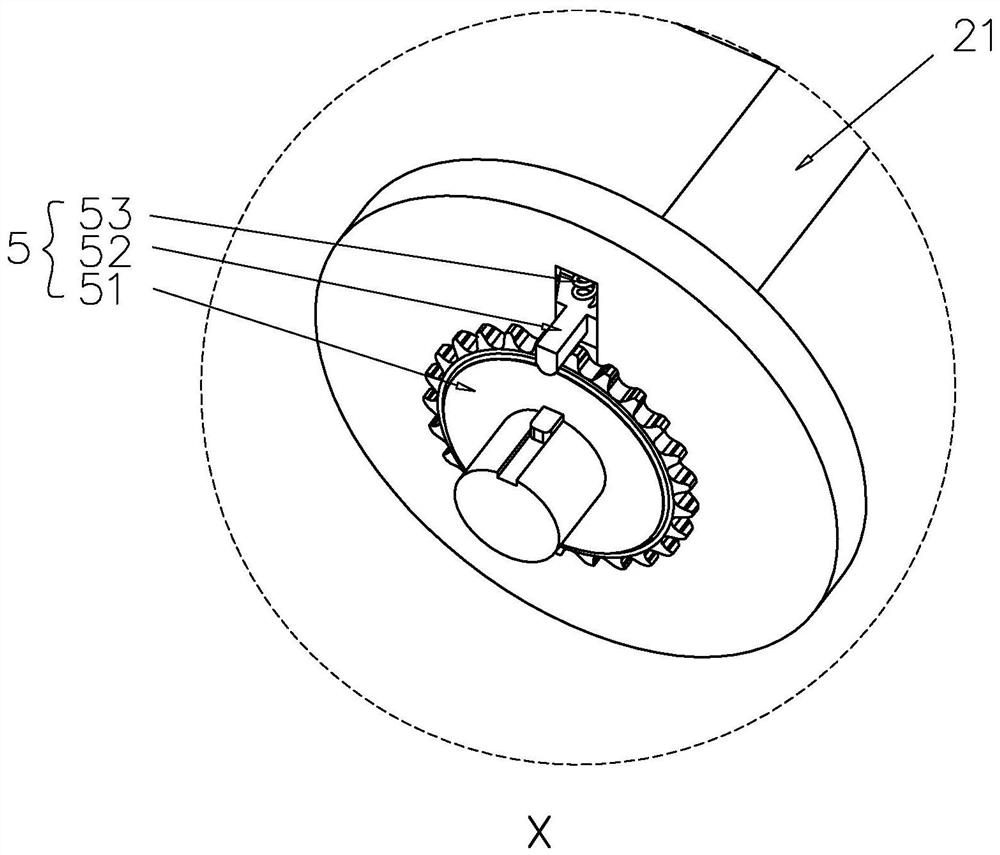

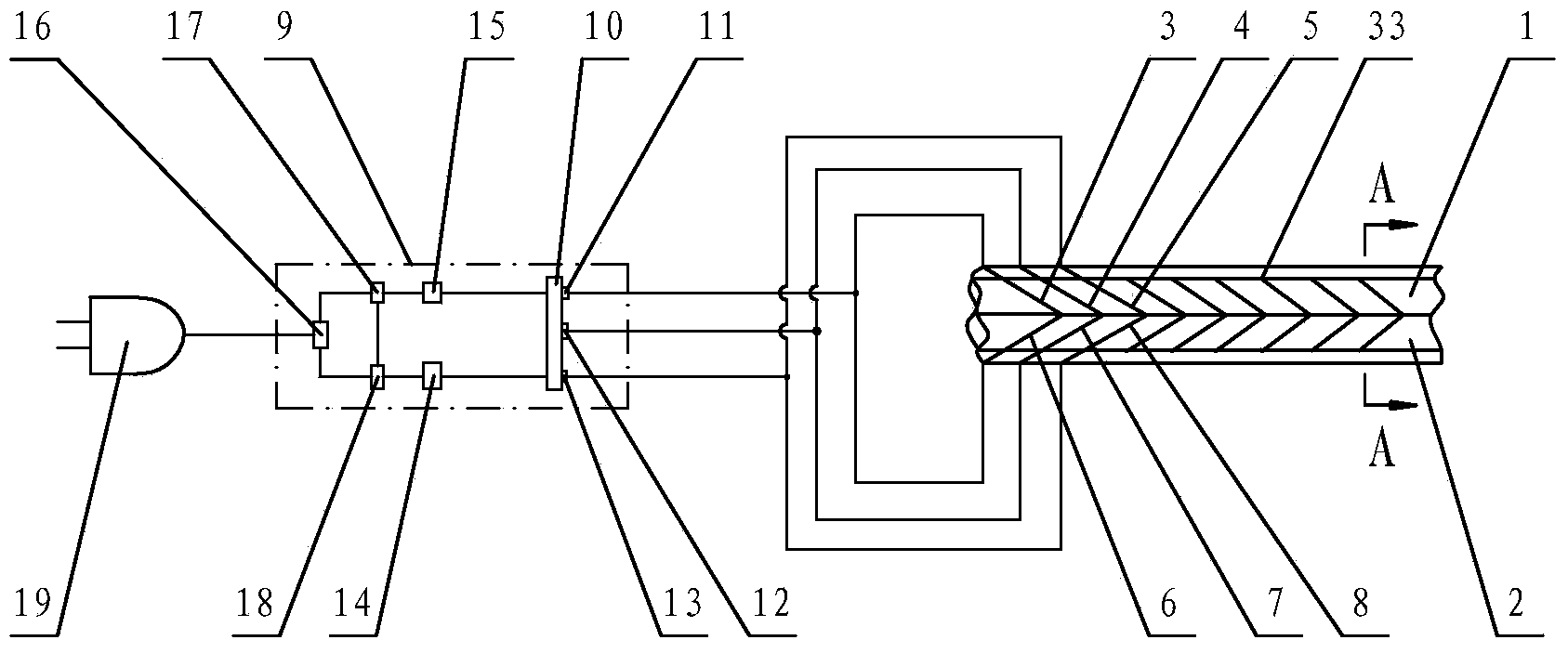

Braiding equipment for cable and process thereof

PendingCN111768933AChange movement speedReduced regularity reflexesCable/conductor manufactureCamStructural engineering

The application relates to braiding equipment for a cable and a process thereof. The braiding equipment for the cable comprises a braiding machine body and a take-up device. The take-up device comprises a base frame, a take-up mechanism and a speed adjusting mechanism used for adjusting the moving speed of the cable; the speed adjusting mechanism is arranged on the side, close to the braiding machine body, of the take-up mechanism; the speed adjusting mechanism comprises a direction adjusting cam, the direction adjusting cam is in an irregular oval shape and is rotationally connected with thebase frame, and the outer edge face of the direction adjusting cam abuts against and is attached to the cable. The outer edge surface of the direction adjusting cam is attached to the cable so as to guide the moving speed of the cable; when the direction adjusting cam rotates, the moving direction of the cable is changed along with the rotation of the direction adjusting cam; the change of the moving direction of the cable changes the moving speed of the cable, thereby driving the structure of the cable braided shielding layer to change, destroying the periodic change of the characteristic impedance of the cable in the braiding process, reducing the regular reflection of electromagnetic waves in the cable, and optimizing the voltage standing-wave ratio of the coaxial cable.

Owner:SHENZHEN SUPERLINK TECH CO LTD

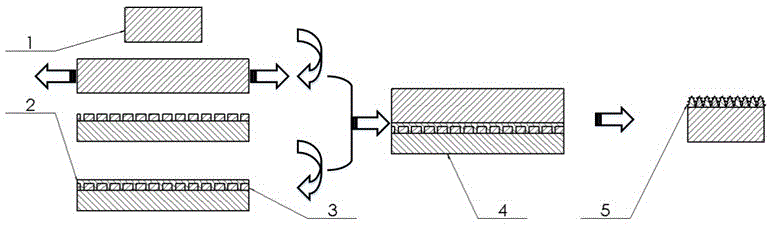

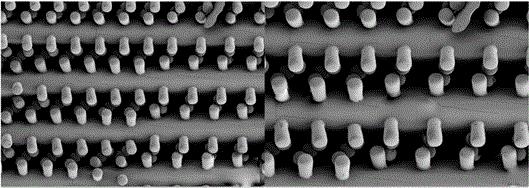

Surface preparation method of flexibility-controllable liquid drop self-driven multistage gradient structure

InactiveCN107177047AImprove hydrophobicityThe preparation method is simple and economicalChemistryAdhesive

The invention discloses a surface preparation method of a flexibility-controllable liquid drop self-driven multistage gradient structure. The method includes following steps: (1), preparing coating liquid; (2), preparing a covering plate; (3), preparing a multistage gradient structure surface having flexibility; (4), adjusting and controlling the flexible surface. On the basis that a flexible material is combined with a bent structure, and the coating liquid immerses into holes in a silicon template and solidifies to form a cylindrical structure. The preparation method is simple and efficient, and probability of directionally driving liquid drops is realized. The multistage structure is prepared by using a flexible VHB adhesive tape as a substrate, so that changing of arrangement density of the multistage structure can be realized by stretching the substrate, and control on liquid drop directional driving speed can be realized. Pre-stretching strain of the VHB adhesive tape can be changed properly, so that acquired bending and wrinkling amplitude is changed correspondingly.

Owner:ZHEJIANG UNIV OF TECH

Automatic-movement wall handrail used for nursing in geriatric department

The invention discloses an automatic-movement wall handrail used for nursing in the geriatric department. The automatic-movement wall handrail comprises a handrail body, sliding grooves are formed inthe left side face and the right side face of the handrail body respectively, and the automatic-movement wall handrail used for nursing in the geriatric department is simple in structure and convenient to use, enables aged people with disabled legs and feet in the geriatric department to move conveniently and to move without support with hands because electric idler wheels are arranged, relieves the burden of aged people, and enables the aged people disabled in action to move conveniently. A hydraulic telescopic rod is arranged to adjust the height of the handrail body and improve the comfortof the aged people when the automatic-movement wall handrail is used; the sliding grooves and sliding blocks which are slidingly connected with the sliding grooves are arranged on the handrail body, so that the wall handrail will not shake when moving; a gearbox is arranged, in this way, the moving speed of the handrail can be changed, and speed is more stable when the wall handrail is started andstopped; a shock absorption box and shock absorption plates are arranged to prevent the wall handrail from vibrating during movement; a handrail protective sleeve is arranged to prevent aged people from suffering hand slipping and falling.

Owner:任宪芳

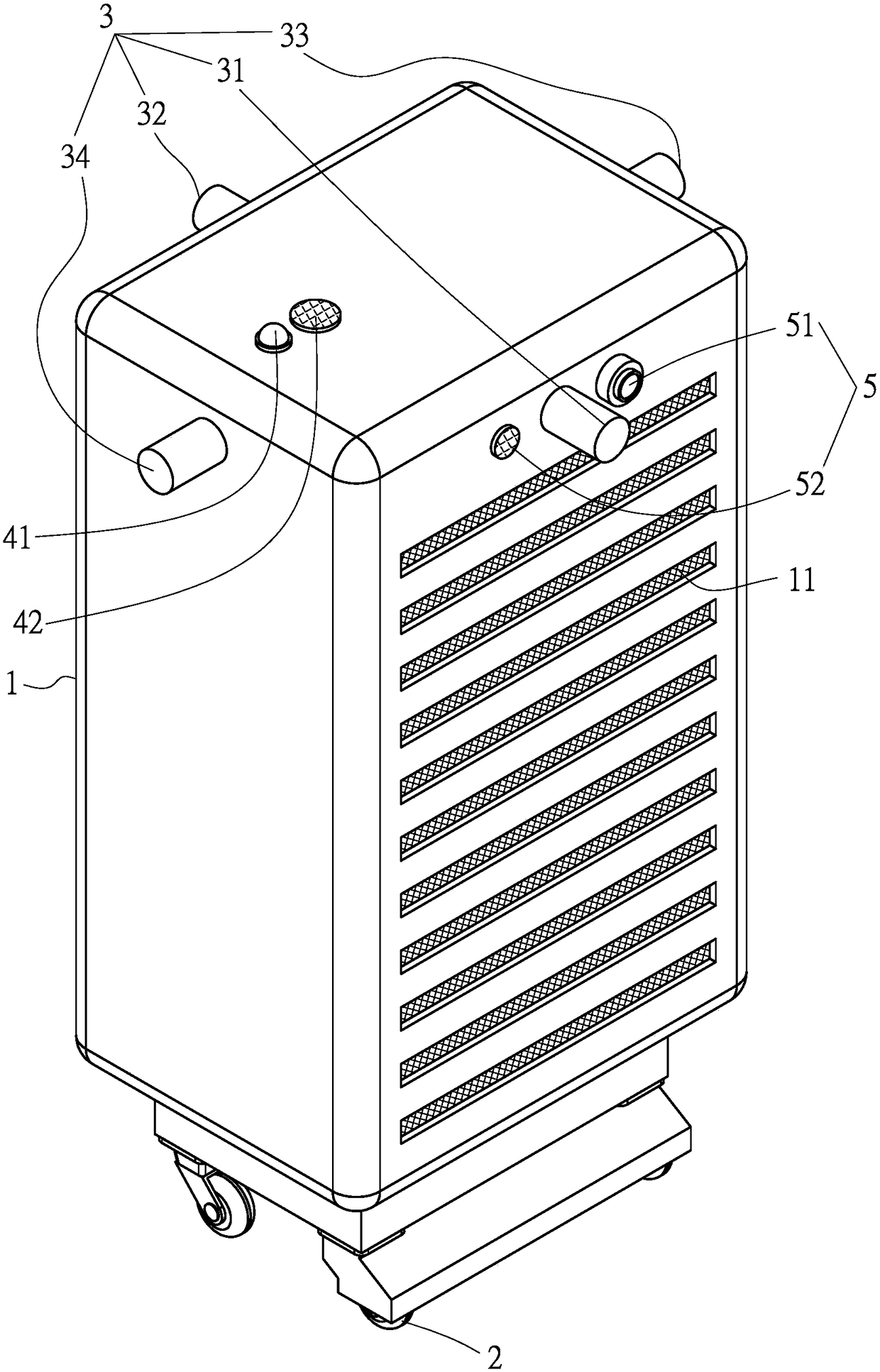

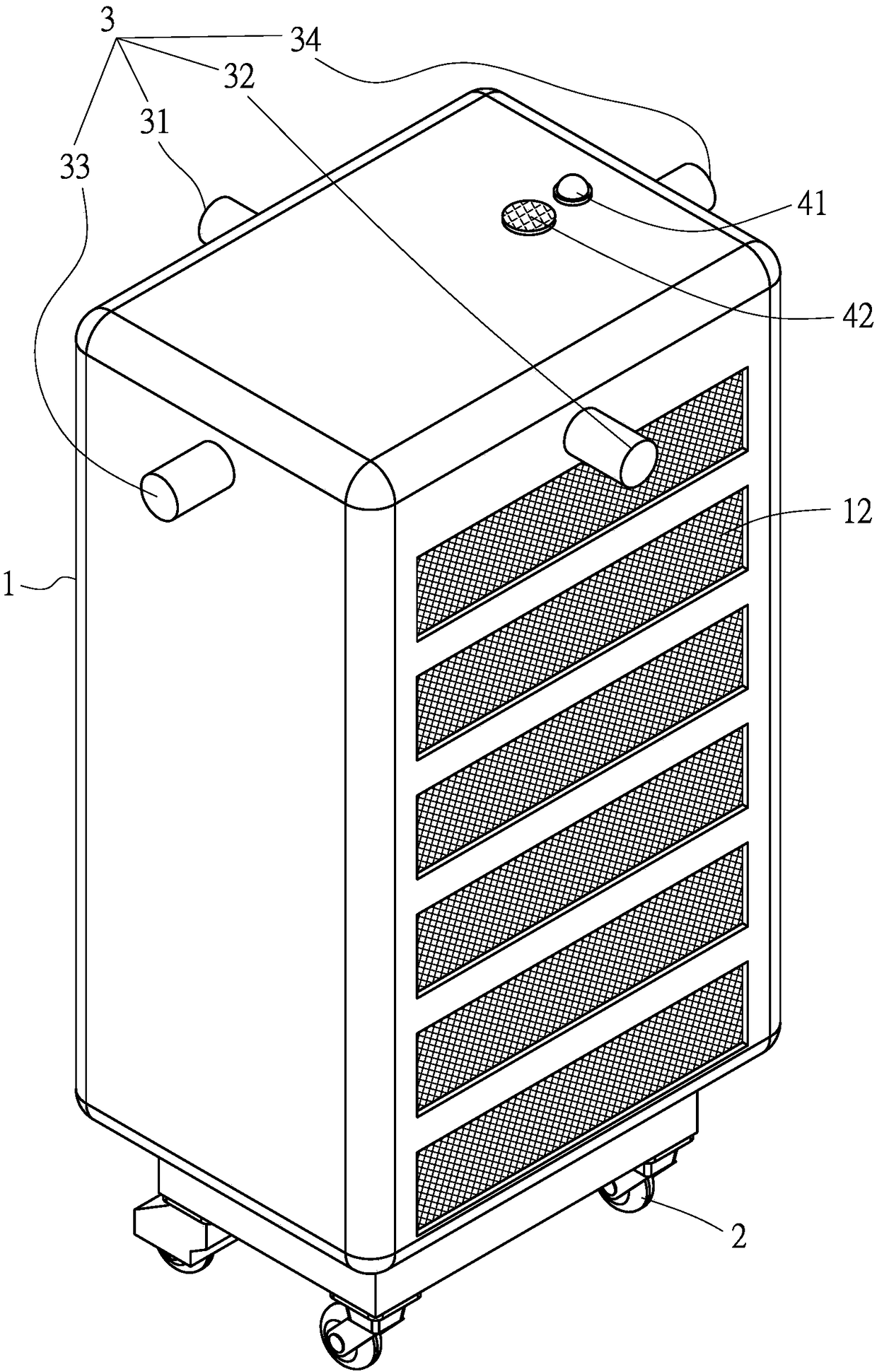

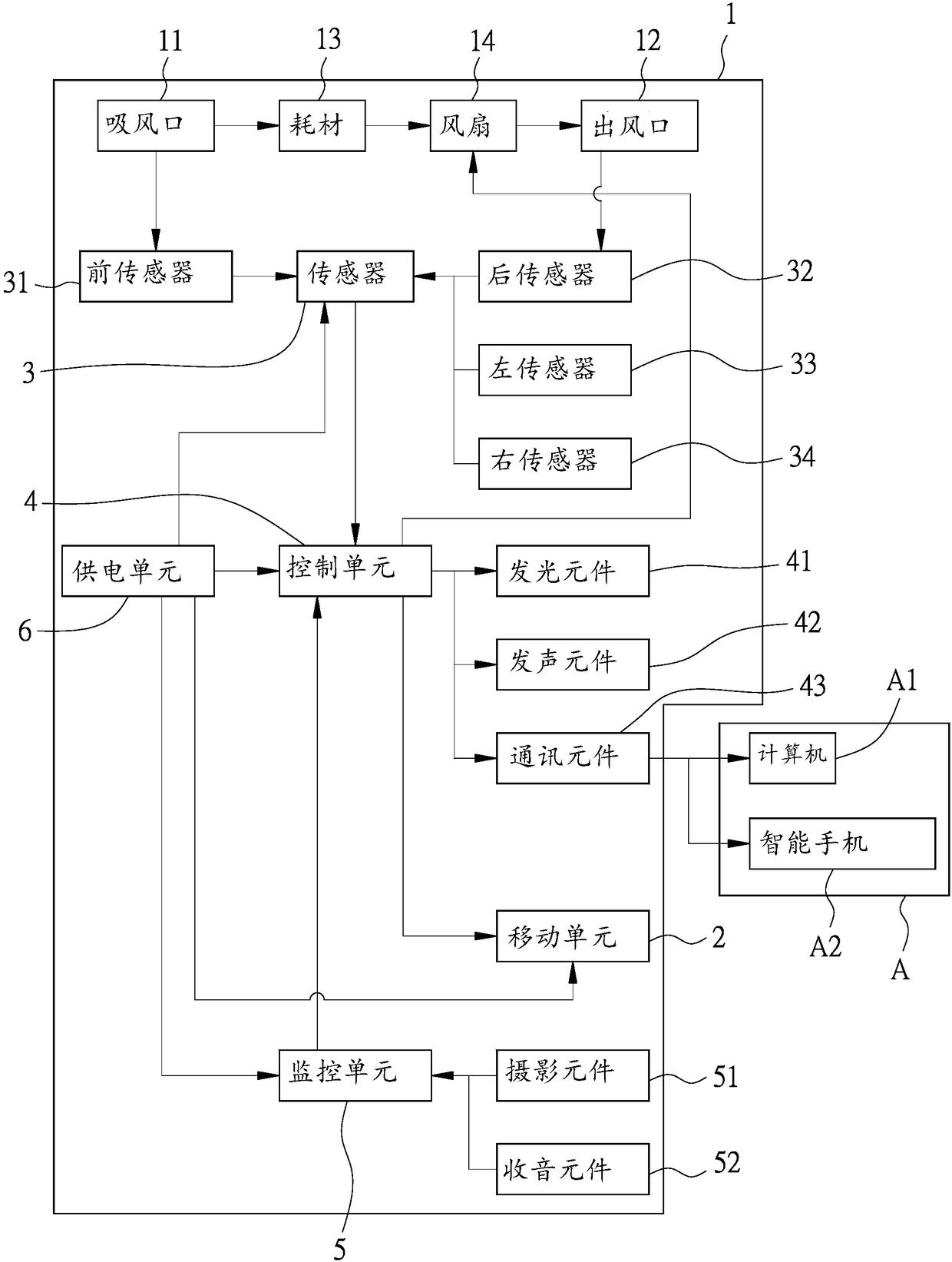

Intelligent air purifier

InactiveCN108916987AQuick purificationMaintain the performance of purifying air for a long timeMechanical apparatusSpace heating and ventilation safety systemsEngineeringAir purifier

The invention discloses an intelligent air purifier. A body is provided with an air suction opening, a consumable and an air outlet, wherein air is sucked in via the air suction opening, then is purified by the consumable, and is discharged via the air outlet; a moving unit is arranged on the body; at least one sensor is arranged on the body to detect pollution values of air in a space region; a control unit is separately connected to the moving unit and the sensors; the control unit has a preset pollution value; when the sensors detect that the pollution value of the air in an optional position in the space region is greater than the preset pollution value, controlling the moving unit to drive the body to move or rotate to the position, and enabling the air suction opening to face air ofwhich the pollution value is greater than the preset pollution value so as to achieve the purpose of rapidly purifying air.

Owner:蒋富成

Massage device for pediatric legs

The present invention relates to the field of pediatrics, and more specifically relates to a massage device for pediatric legs. The massage device can massage legs of children by a leg massage assembly, fix the legs of children by the legs of children, change a massage mode on the legs of children through the legs of children. The massage frequency of the device can be adjusted by an adjusting assembly. The massage device for pediatric legs comprises the leg massage assembly, a support body, the adjusting assembly and a tensioning assembly. By the legs of patients controlling compression on ahinged push spring 1, the fixing effect on different condition of legs of the patients can be completed through a leg arc rod under driving of a hinged horizontal rod. A semi-cam 1 drives a vertical plate 3 to drive sliding of a massage rod along the vertical plate 1, so that the massage rod slides along the vertical plate 1. The massage rod drives motion of press balls that are in contact with the legs of the patients, thereby completing massage on the legs of the patients.

Owner:漯河市第一人民医院

Steel bar cutting machine device

The invention relates to the field of steel bar shearing equipment, and discloses a steel bar cutting machine device. The steel bar cutting machine device comprises an intermittent transmission cavityformed in a box body, wherein an intermittent transmission belt cavity is formed in the rear side of the intermittent transmission cavity; an intermittent transmission main shaft extending forwards into the intermittent transmission cavity and extending backwards into the intermittent transmission belt cavity is connected into the front end wall of the intermittent transmission belt cavity in a manner of running fit; rotation of a variable-speed conical wheel is driven through rotation of a motor, and then a rotating speed of a variable-speed friction wheel is changed through a rotating knobto complete rotating speed adjustment for a friction wheel cavity; and then a moving speed of a steel bar is changed, so that the purpose of adjusting a cutting length is achieved; an intermittent touch rod is driven through the rotation of an intermittent rotating wheel to intermittently touch an intermittent sliding rod, and then a clutch spline sleeve is just separated from a clutch transmission block when a cutting block moves into a cutting cavity, so that the purpose of cutting the steel bar is achieved; and the steel bar compresses the friction wheel to enable a sliding push block to move backwards, so that the purpose of adjusting a cutting radius is achieved.

Owner:杭州圣埃蒂机械科技有限公司

Scroll controller

InactiveCN1139872CChange movement speedDigital output to display deviceLiquid-crystal displayReaction speed

There is provided a scroll controller which solves a problem that in scrolling an image at coordinates specified by a pen or the like to specific coordinates (e.g., the center), it is unable in a display such as a liquid crystal display having a slow display reaction speed to grasp the state of movement when a scroll quantity (scroll speed) per unit time is fast. The scroll controller calculates a difference between prefixed coordinates and the coordinate position specified by a position specifying device and on the basis of the calculation result, controls so that not only stepwise scroll quantities are obtained, but also scroll quantities in starting and ending of the scroll are different from that in the other time of the scroll.

Owner:SHARP KK

Safety guide device

InactiveCN103971612AGood and correct route guidanceClear and smooth movementSignalling system detailsVisible signalling systemsEngineeringLight-emitting diode

A safety guide device comprises two or more light emitting lines and a multi-path alternating current driver driving the light emitting lines to work. The light emitting lines which are arranged front and back or arranged left and right in parallel are of an arrow shape. The light emitting lines include the first light emitting line, the second light emitting line, the third light emitting line, the fourth light emitting line, the fifth light emitting line and the sixth light emitting line, wherein the first light emitting line, the second light emitting line and the third light emitting line rotate rightwards to be intertwisted or rotate rightwards to be sequentially wound around a first mandrel or a first core line so as to form a first cable emitting light sequentially section by section; the fourth light emitting line, the fifth light emitting line and the sixth light emitting line rotate leftwards to be intertwisted or rotate leftwards to be sequentially wound around a second mandrel or a second core line so as to form a second cable emitting light sequentially section by section; the first cable emitting light sequentially section by section and the second cable emitting light sequentially section by section are arranged left and right in parallel; the first light emitting line and the fourth light emitting line form an arrow. The safety guide device has the advantages of being simple and reasonable in structure, flexible in operation, clear in guiding and wide in application range.

Owner:SHENZHEN ZHUIGUANG ELECTRONICS TECH CO LTD

Milling machine tool table for assisting processing of non-planar cutting parts

InactiveCN110877219AChange movement speedRealize millingFeeding apparatusPositioning apparatusRotational axisFree rotation

The invention discloses a milling machine tool table for assisting the processing of non-planar cutting parts. The tool table includes a fixture body, a fixing cavity with an upward opening is arranged in the fixture body, left-right symmetrical adjustment plates are slidably connected to the inner walls of the front and rear sides of the fixing cavity, a rotation shaft is rotatably connected to each adjustment plate, and a buckle device is arranged on the side, close to the center of symmetry, of the rotation shaft. According to the tool table, a workpiece is fixed through symmetrical clamping structures in the up and down left and right directions, and clamping structures in the left and right directions can be freely rotated, so that the workpiece is driven to rotate to realize millingprocessing in the circumferential direction; and by using the principle of a detachable riveting structure, the structure of a wound rope can be actively controlled to rotate or stop, and through a wound rope moving device and structural design with a variable winding radius, the moving speed of the workpiece is changed to form processing techniques with a plurality of manners.

Owner:东阳温宾电子科技有限公司

Detector capable of rotating and moving

PendingCN113776568AAdjust the rotation rateAdjust movement speedMeasurement apparatus componentsControl theoryMechanical engineering

The invention is applicable to the technical field of detection equipment, and provides a detector capable of rotating and moving, which comprises a mounting mechanism, a device body and a detector body, wherein the device body is connected with the mounting mechanism, and the detector also includes a rotary moving mechanism which is movably connected with the device body and is used for driving the detector to move and rotate, wherein the rotary moving mechanism comprises a transmission part B, a driving assembly, a rotary moving assembly and a speed adjusting assembly; the rotary moving assembly comprises a sliding part A, a rotating part, a sliding groove A and a sliding part B. The sliding groove A is in sliding fit with the sliding part B. The rotating part is connected with the mounting mechanism. According to the invention, the rotational movement rate of the detector can be controlled.

Owner:TENGZHOU FEITIAN LASER AUTOMATION TECH

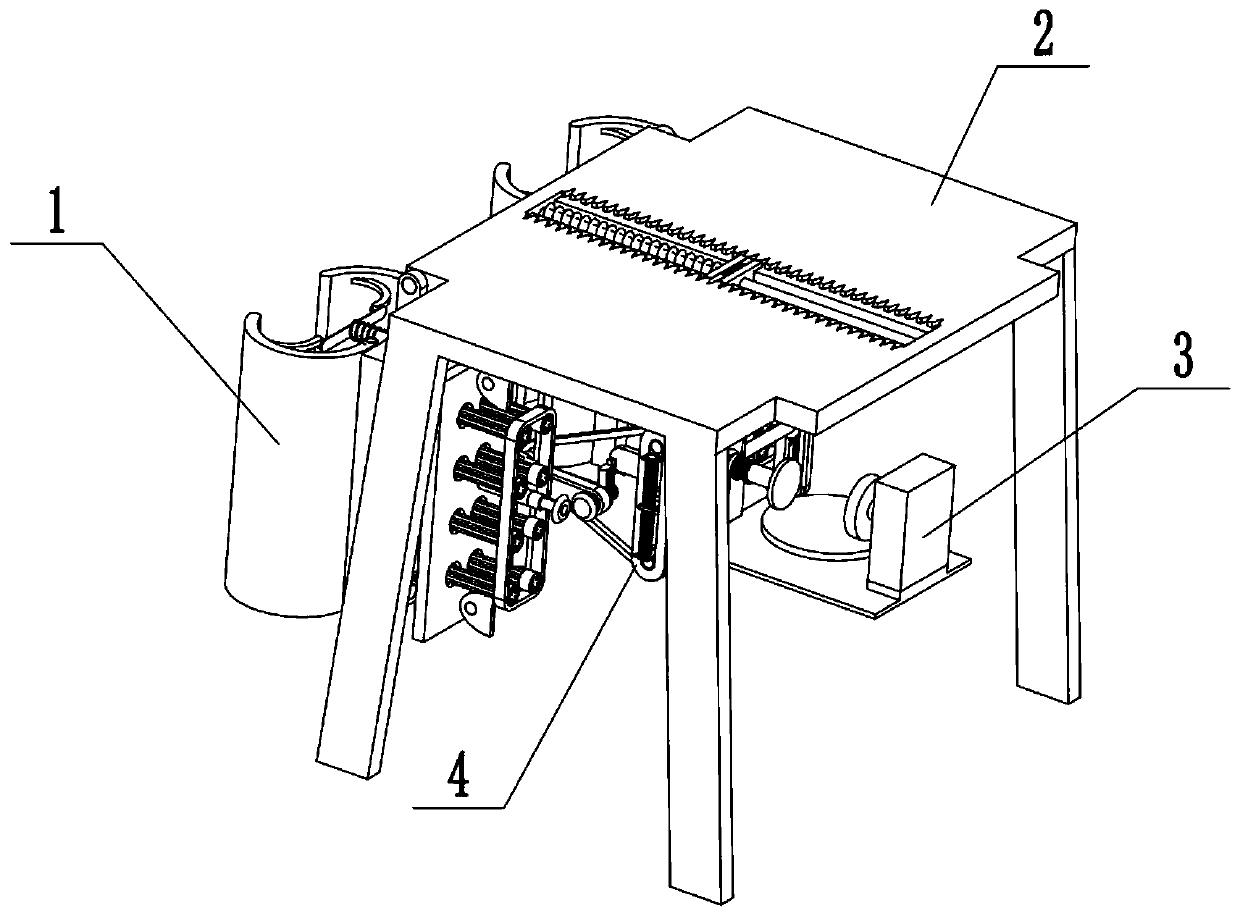

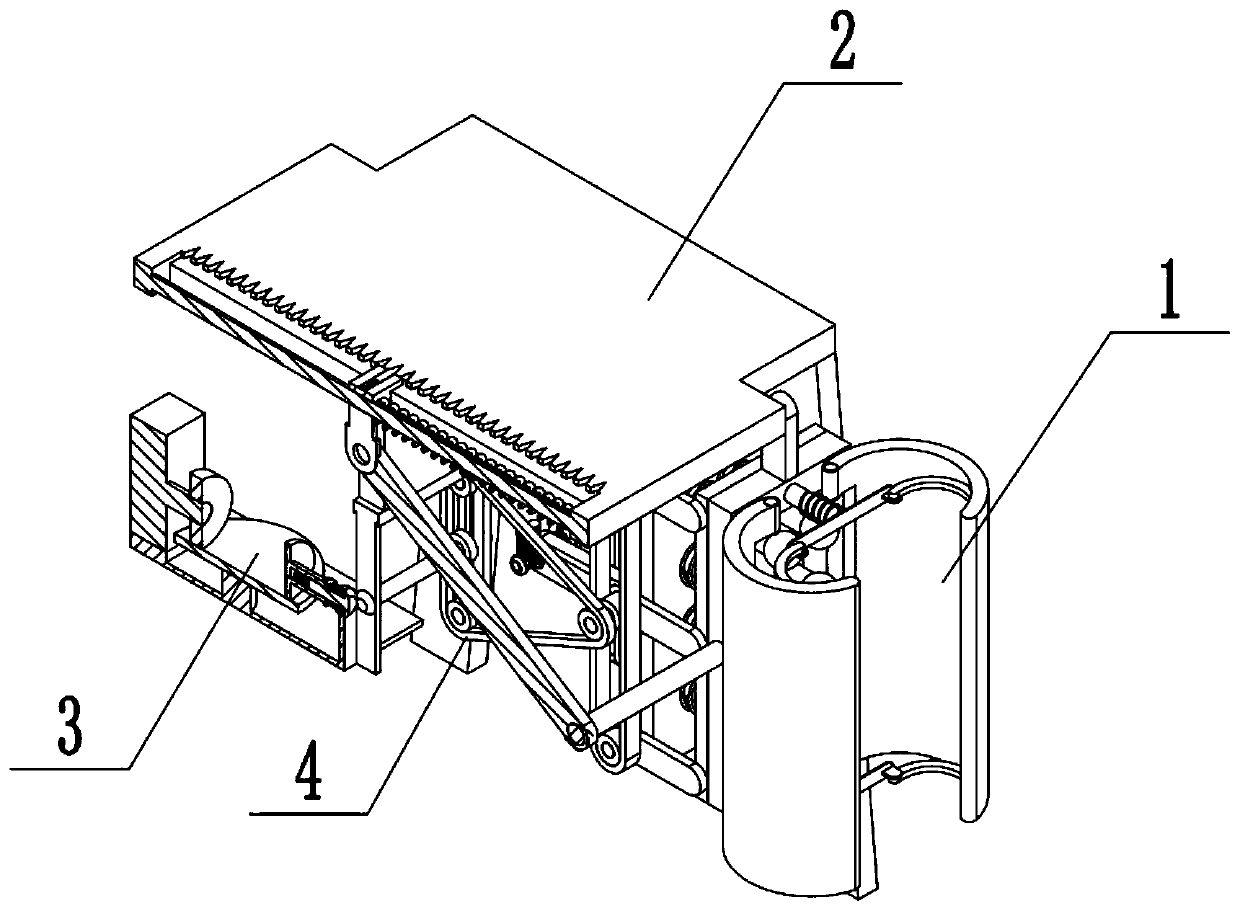

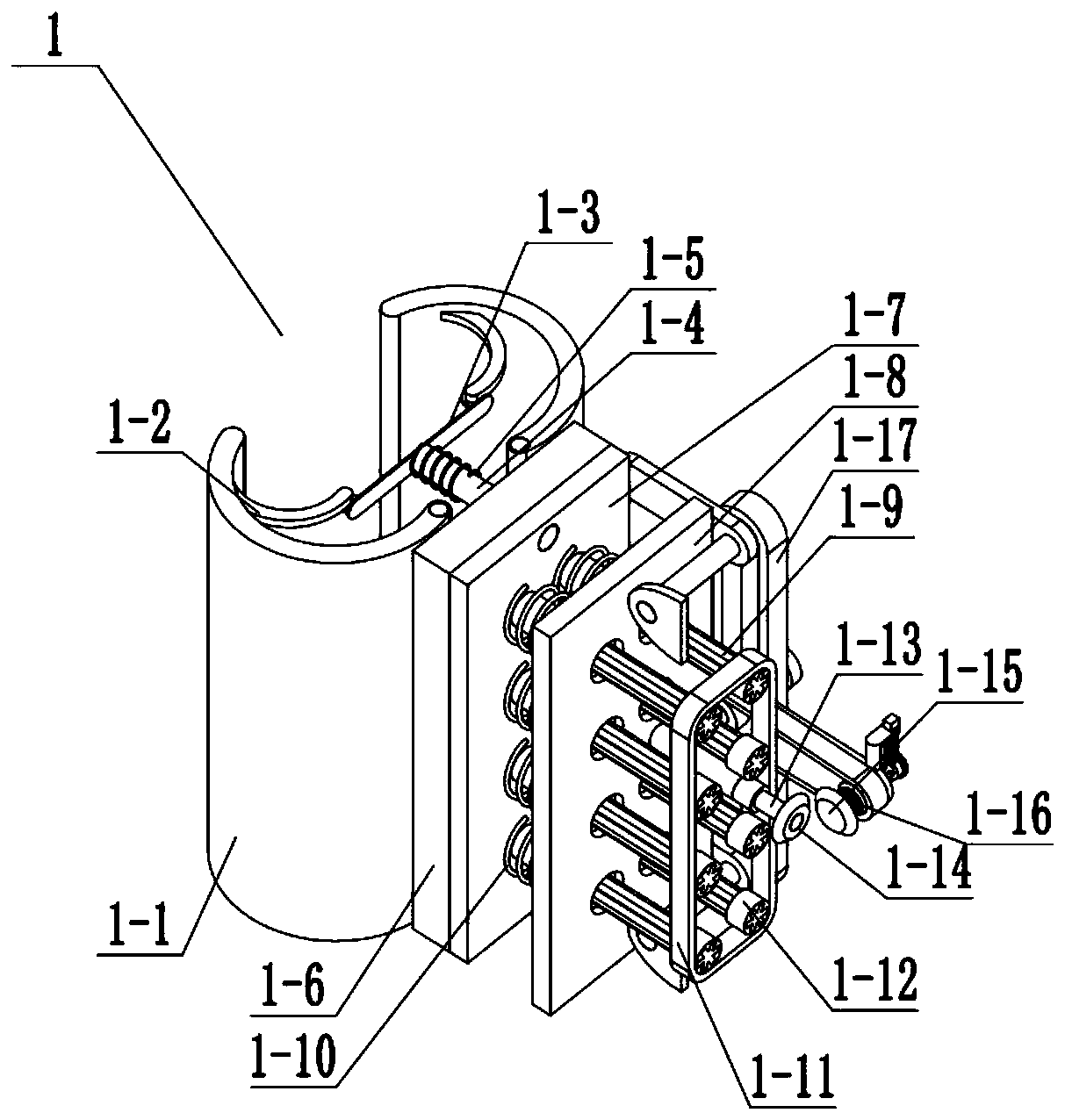

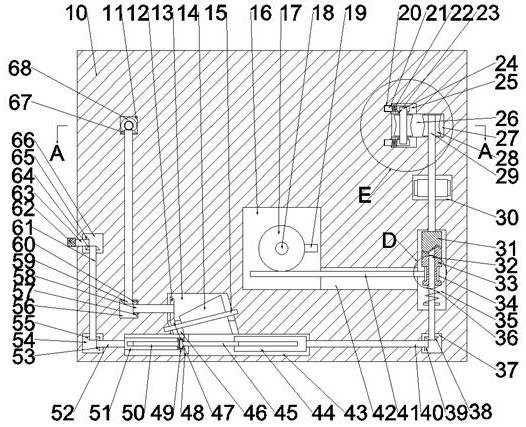

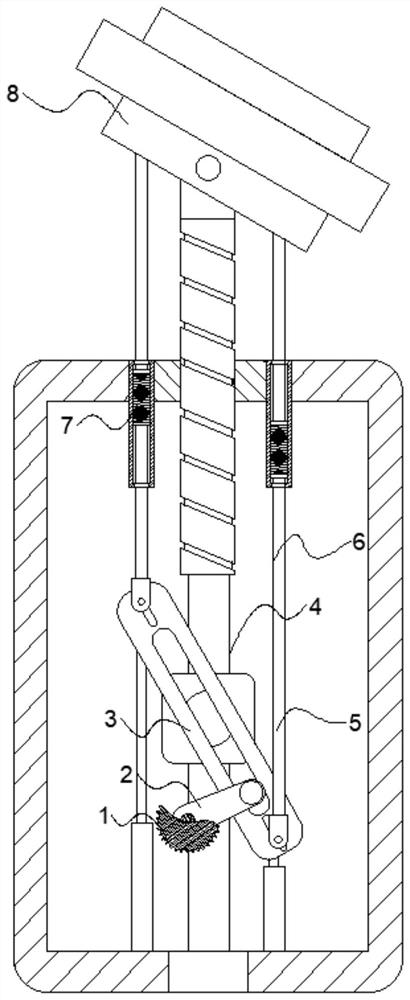

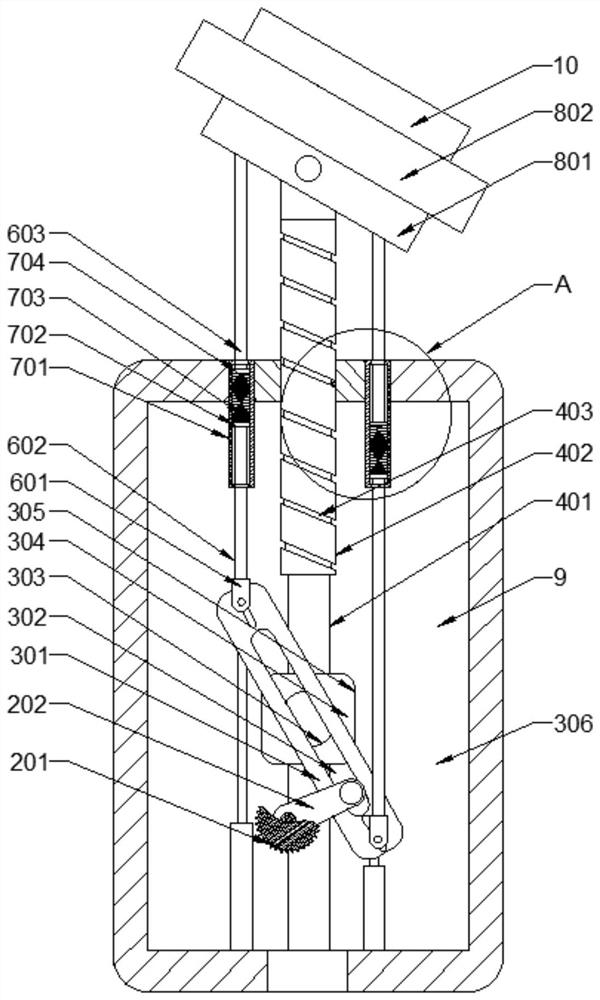

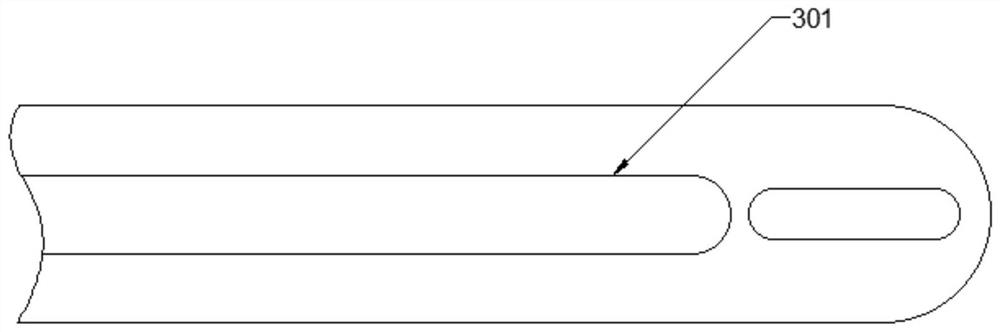

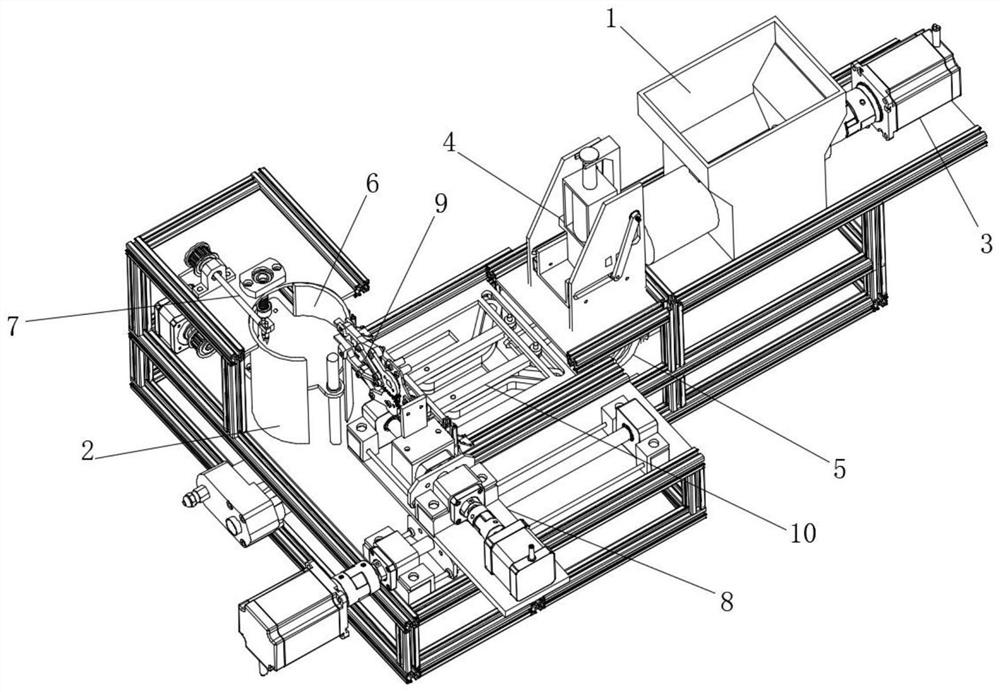

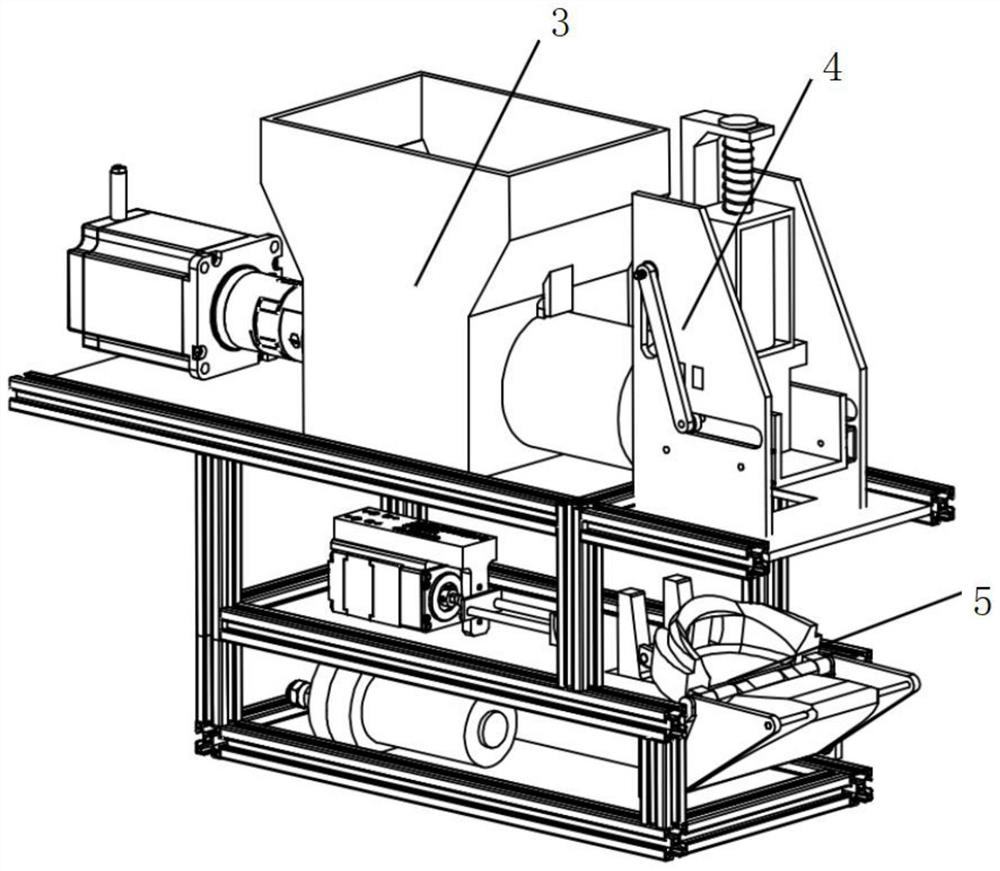

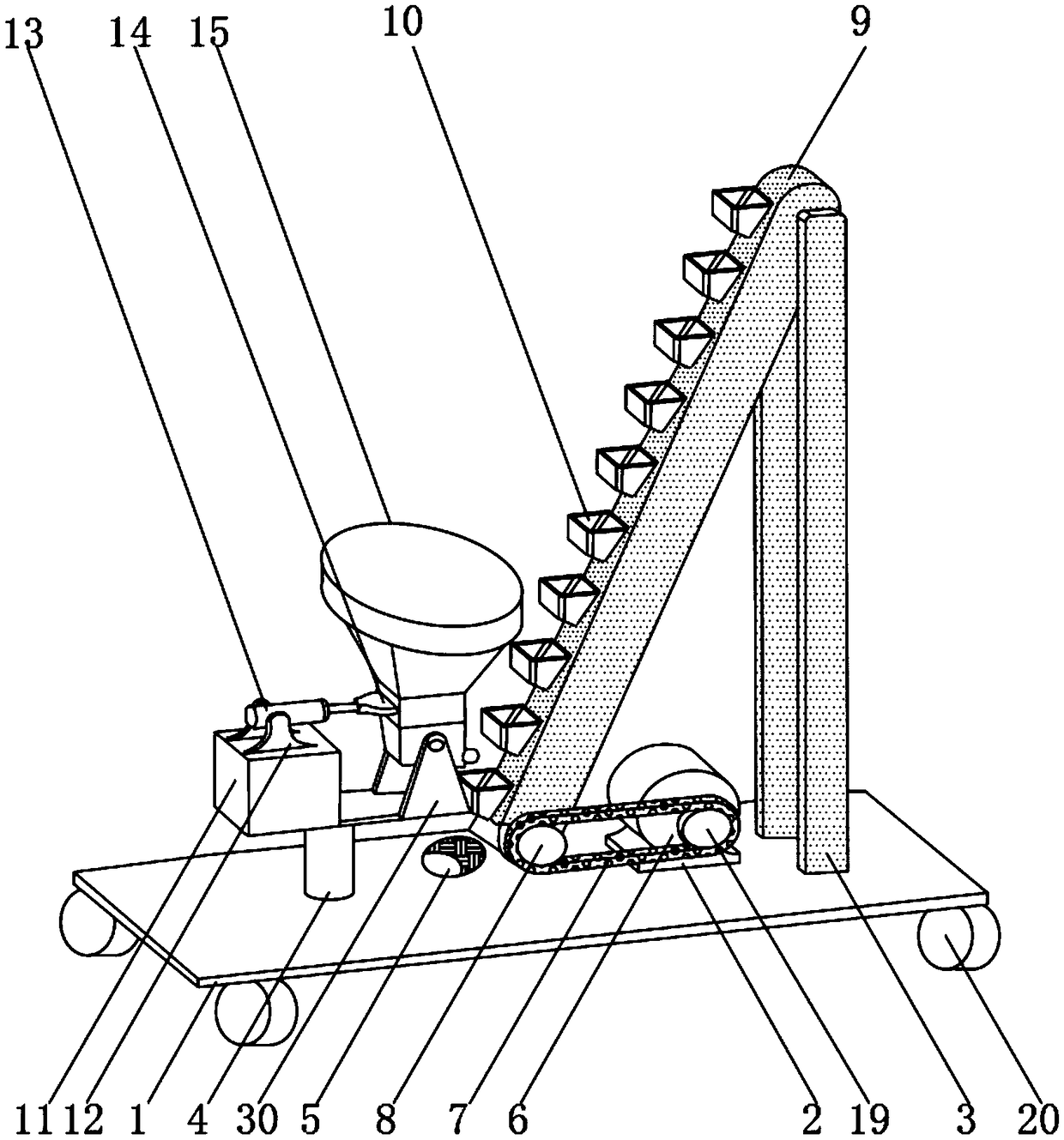

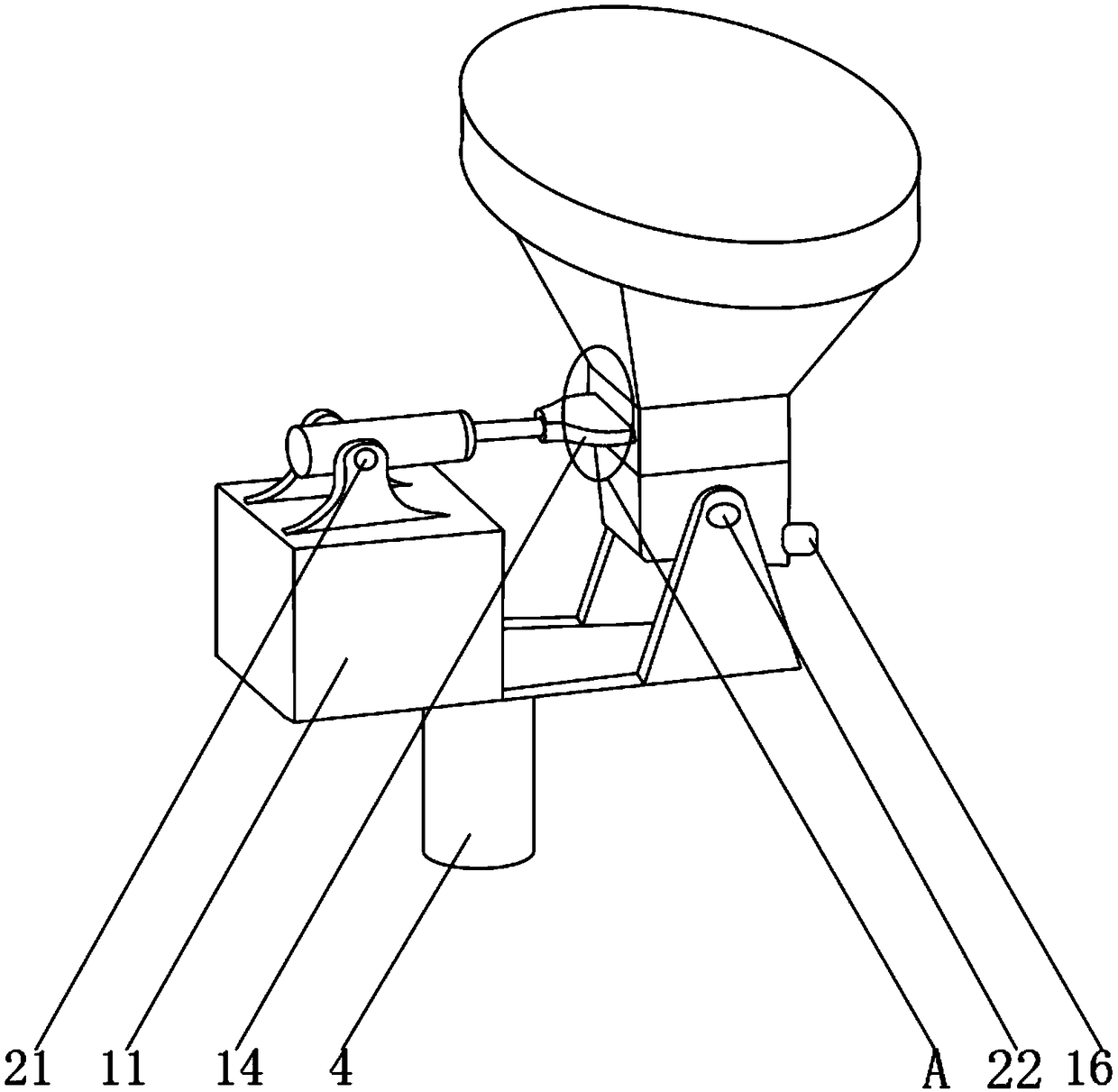

Automatic dumpling making machine and dumpling making method

ActiveCN113951293AImprove efficiencyHigh degree of automationDough processingProcess engineeringMechanical engineering

The invention discloses an automatic dumpling making machine and a dumpling making method. The automatic dumpling making machine comprises a frame body, and a spiral electromagnetic discharging, clamping and pressing device and a wrapper picking and transporting device are arranged on the frame body; the spiral electromagnetic discharging clamping and pressing device comprises a spiral feeding mechanism, a push-pull electromagnet discharging mechanism is arranged at the front end of the spiral feeding mechanism, and an electric push rod clamping and pressing mechanism is arranged below the push-pull electromagnet discharging mechanism; the wrapper picking and transporting device comprises a wrapper lifting device, and a teasing needle device is arranged on one side of the wrapper lifting device; the wrapper picking and transporting device further comprises a moving device located on one side of the wrapper lifting device, a mechanical claw is arranged on the moving device, and a wrapper transporting device is arranged on one side of the mechanical claw. The automatic dumpling making machine has the advantage of high automation degree, and can save labor cost and improve dumpling making efficiency.

Owner:WENZHOU UNIVERSITY

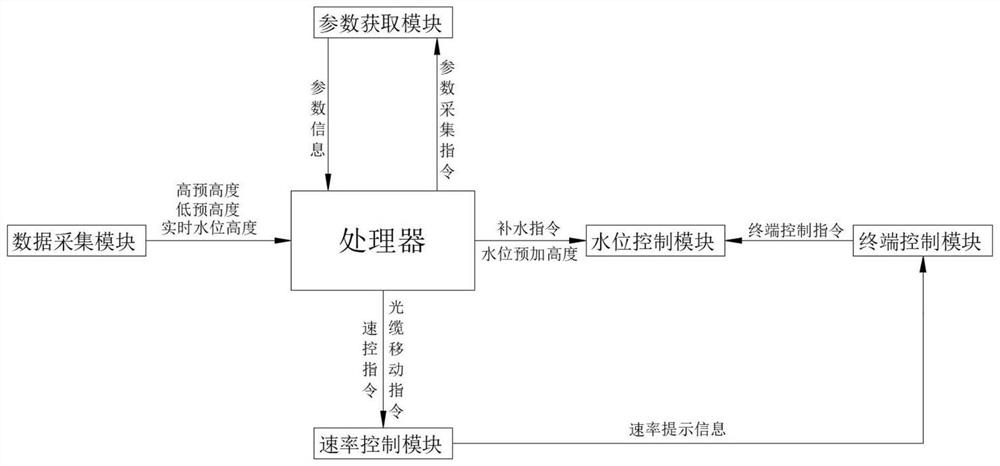

Multi-water-tank water level monitoring and analyzing system based on big data

PendingCN114485862AGuarantee the final qualityReduce lossMachines/enginesLevel indicatorsProcess engineeringData acquisition module

The invention relates to the field of optical cable production, and aims to solve the problems that the final quality of a finished product is affected due to the fact that water in an existing water tank is insufficient and the temperature of an optical cable cannot be reduced easily, and serious waste of water resources can be caused if a good cooling effect can be achieved if cooling water is continuously added into a cold water tank. The system comprises a data acquisition module, a processor, a parameter acquisition module, a rate control module, a water level control module and a terminal control module, the system controls the real-time water level height to continuously rise through the water level control module, and it is guaranteed that water in water tanks is sufficient; the temperature of the optical cable can be reduced, the final quality of a finished product is guaranteed, the water level in the water tank is increased in real time, the cooling effect can still be guaranteed when the water amount is small, and a large amount of cooling water is not used, so that water resource loss is reduced.

Owner:安徽天凯光通信技术有限公司

Engineering waste treatment equipment for construction field

InactiveCN109174910AReduce dust concentrationReduce volumeUsing liquid separation agentSolid waste disposalFrequency conversionTransmission belt

The invention relates to the technical field of construction engineering, and discloses engineering waste treatment equipment for the construction field. The equipment comprises a fixed base, whereina solder block, a supporting rack and a supporting shaft are soldered on the outer surface of the upper end of the fixed base; the supporting shaft is positioned on the other side of the solder block;a first groove is formed inside the fixed base, and is positioned between the solder block and the supporting shaft; a first motor is fixedly arranged on the outer surface of the upper end of the solder block; a frequency conversion mechanism is movably arranged on the outer surface of the front end of the solder block, and a transmission belt coats the outer surface of the frequency conversion mechanism; a first rotating shaft is arranged on one side of the frequency conversion mechanism; and a conveying belt is fixedly arranged on the outer surface of the solder block. The engineering wastetreatment equipment can be used for effectively removing dust, the working environment can be ensured, the inclined angle of the conveying belt can be adjusted at any time by workers conveniently, and the labor intensity of workers can be relieved.

Owner:FOSHAN QIANGWEI NEW ENERGY TECH CO LTD

Cement trowelling equipment for constructional engineering and use method thereof

ActiveCN113652930AMove at a constant speedChange movement speedRoads maintainenceLeather beltCement Material

The invention belongs to the technical field of cement trowelling equipment, and particularly relates to cement trowelling equipment for constructional engineering, the equipment comprises a frame fixing plate, a through groove and a first T-shaped block, a trowelling plate is arranged at the lower end of the first T-shaped block, a servo motor is fixedly mounted at the upper end of the frame fixing plate, and the output end of the servo motor is fixedly connected with a first belt pulley. A connecting block is fixedly installed on the periphery of the frame fixing plate and rotationally connected with a threaded rod through a bearing, one end of the threaded rod is fixedly connected with a second belt pulley, a linkage belt is wound around the outer surface of the first belt pulley and the outer surface of the second belt pulley, a containing groove is formed in the surface of the upper end of the frame fixing plate, and a transverse guide rod is fixedly connected to the interior of the containing groove. By arranging the servo motor, the threaded rod and the threaded cylinder, the movement of the whole trowelling plate can be more uniform, and the movement speed can be changed during the period so that the trowelling efficiency is improved.

Owner:华中伟业建设集团有限公司

Cutting device for cement woven bag processing

InactiveCN111941499AChange movement speedImprove cutting efficiencyMetal working apparatusKnife bladesIndustrial engineering

The invention belongs to the field of woven bag cutting, and particularly relates to a cutting device for cement woven bag processing. The cutting device for cement woven bag processing comprises a device main body, wherein an upper diaphragm plate is arranged at the upper end of the device main body; a support frame is arranged on the upper end face of the upper diaphragm plate; an air cylinder is arranged on the support frame; a push-out rod is arranged at the lower end of the air cylinder; a flattening plate is arranged below the push-out rod; a cutter groove is formed in the flattening plate; two transmission fixing blocks are arranged on the lower end face of the upper diaphragm plate; a lead screw and a polish rod are arranged between the two transmission fixing blocks; a movable boxis arranged on the lead screw and the polish rod; a transmission nut and a sliding sleeve are arranged in the movable box; a cutter rest is arranged on the upper end face of the movable box; a rotating pin is arranged on the cutter rest; circular blades and a spring are arranged on the rotating pin; and a lower diaphragm plate is arranged below the movable box. According to the cutting device forcement woven bag processing provided by the invention, the flattening plate and the two circular blades are designed, so that a notch of a woven bag can be kept flat, and the cutting efficiency is improved.

Owner:湖州友盛水泥制品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com