Patents

Literature

70results about How to "Change cutting length" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

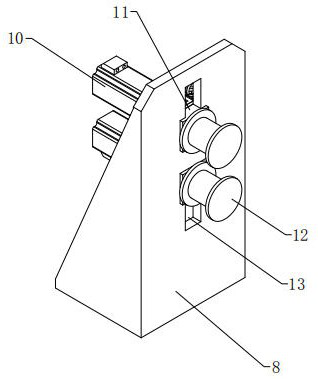

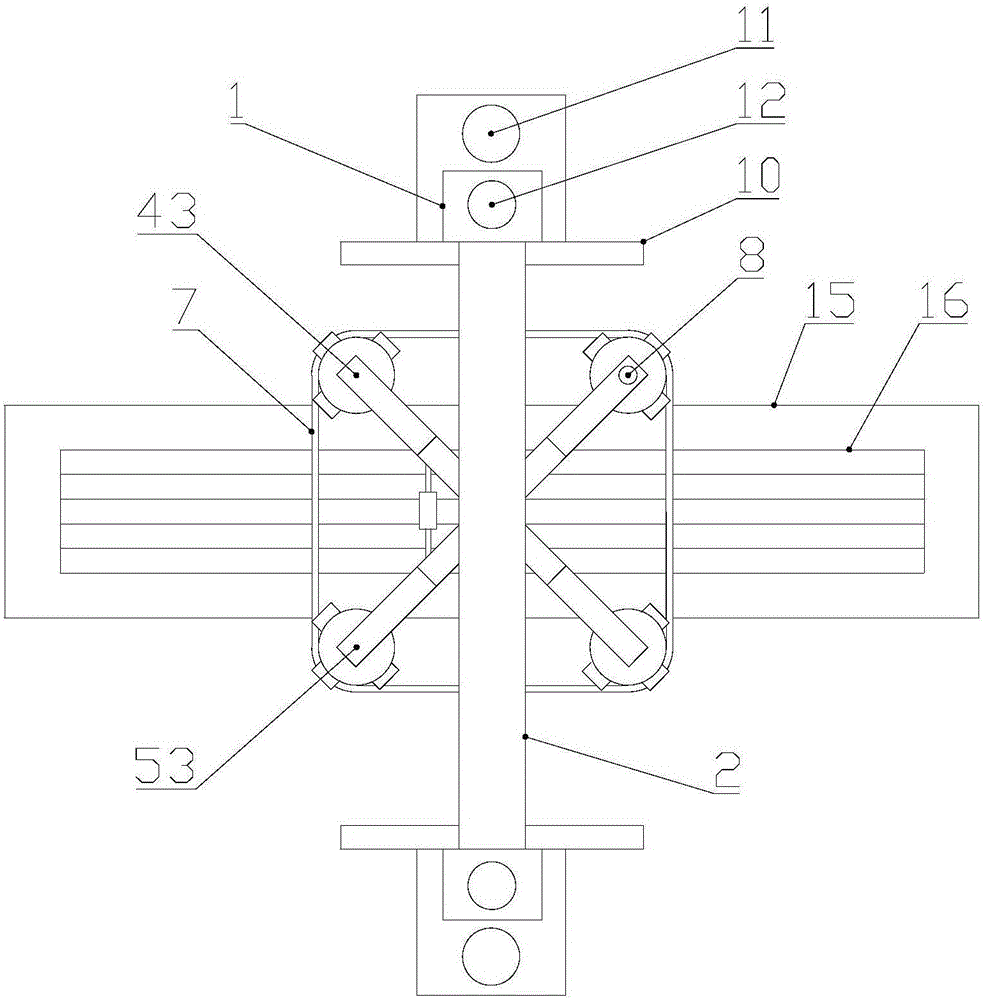

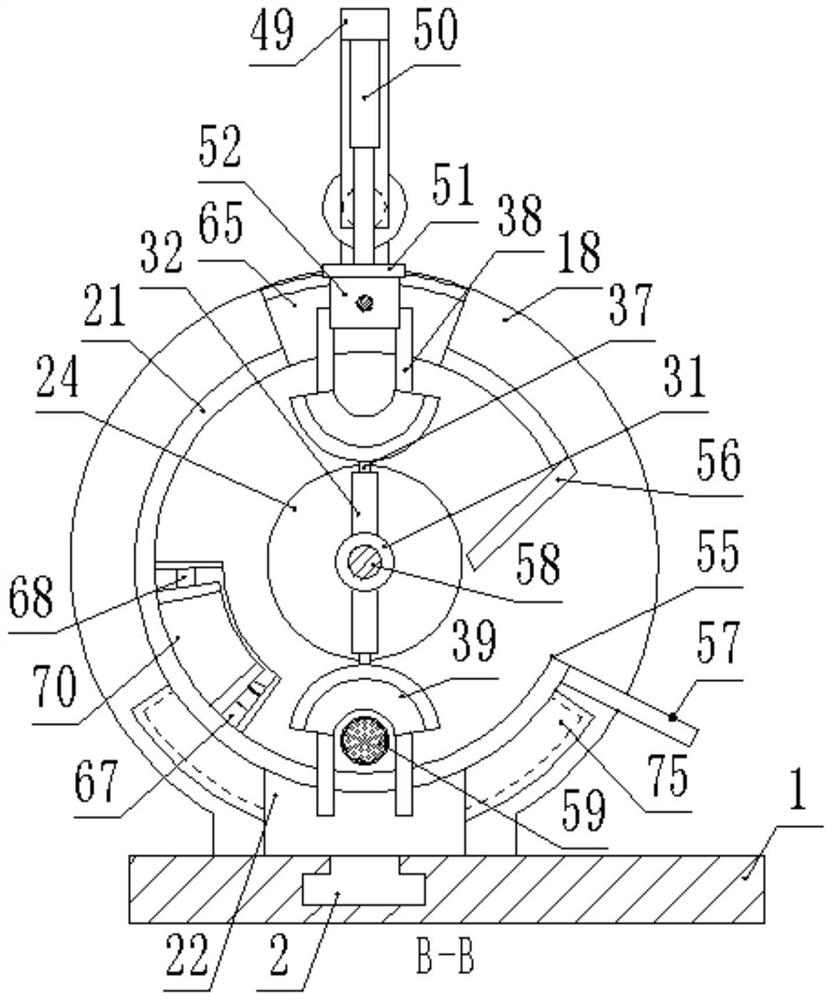

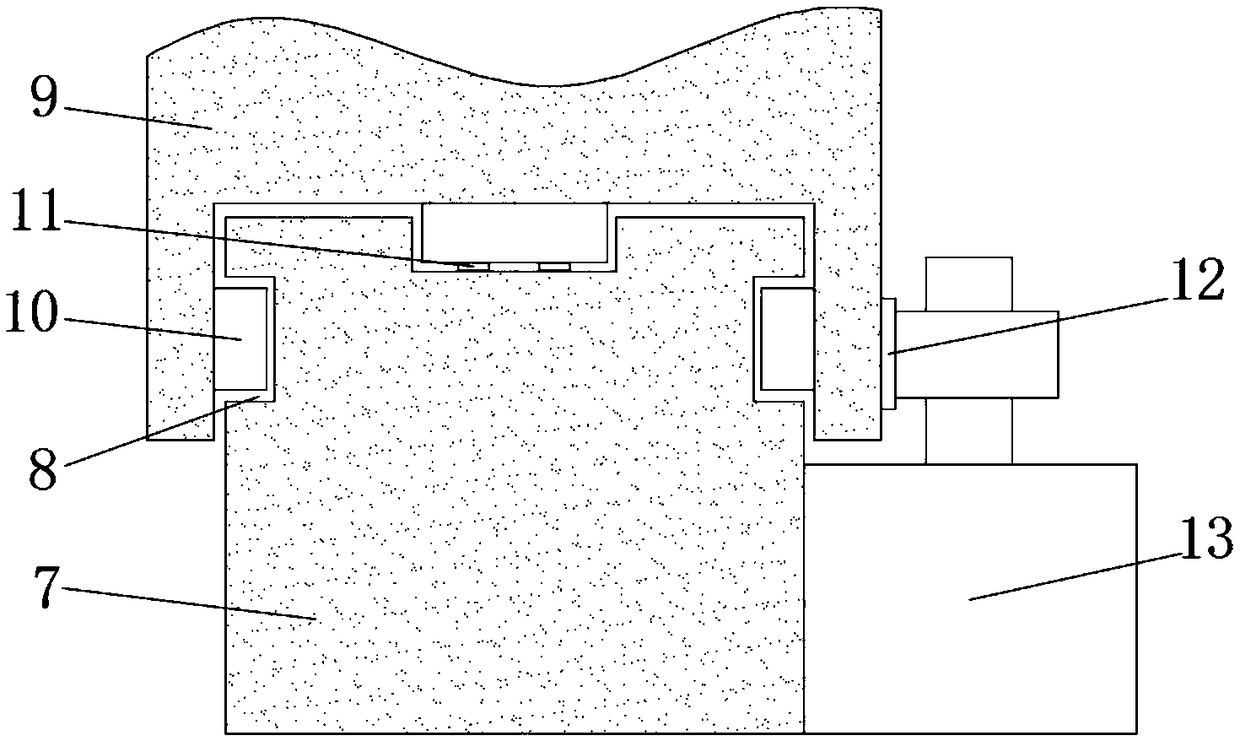

Cutting machine

InactiveCN106903371AChange cutting lengthImprove the inconveniencePositioning apparatusMetal-working holdersEngineeringMechanical engineering

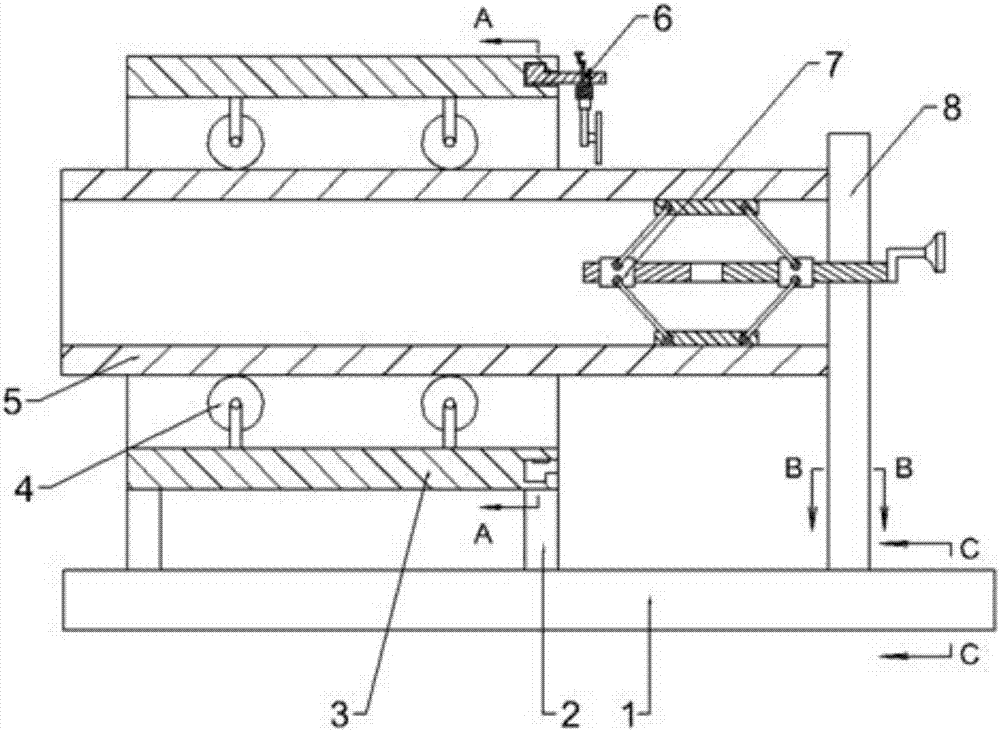

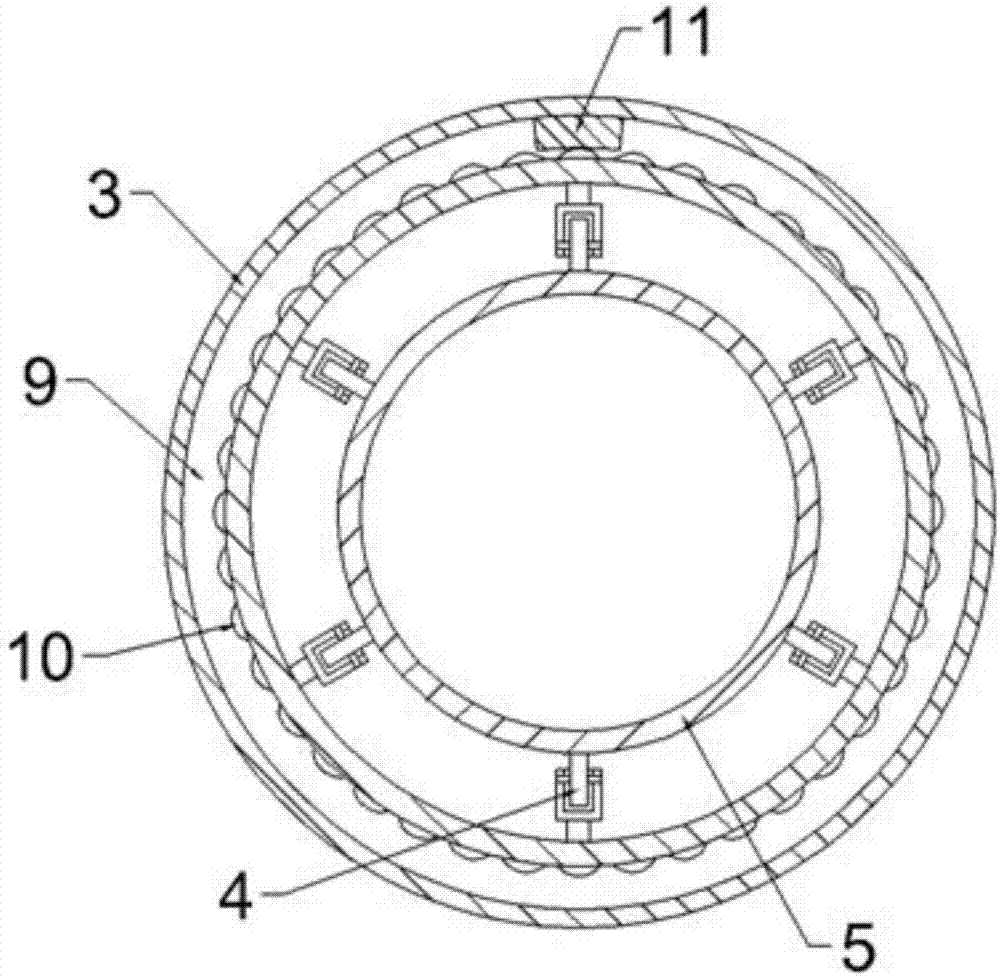

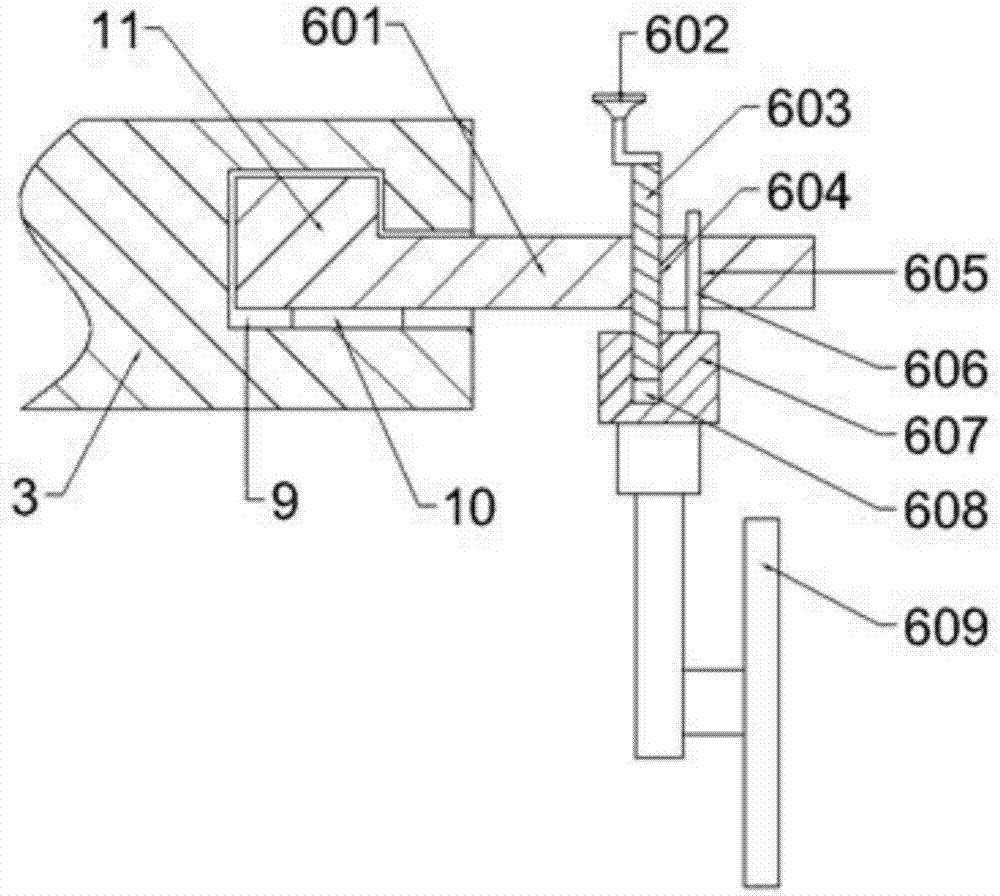

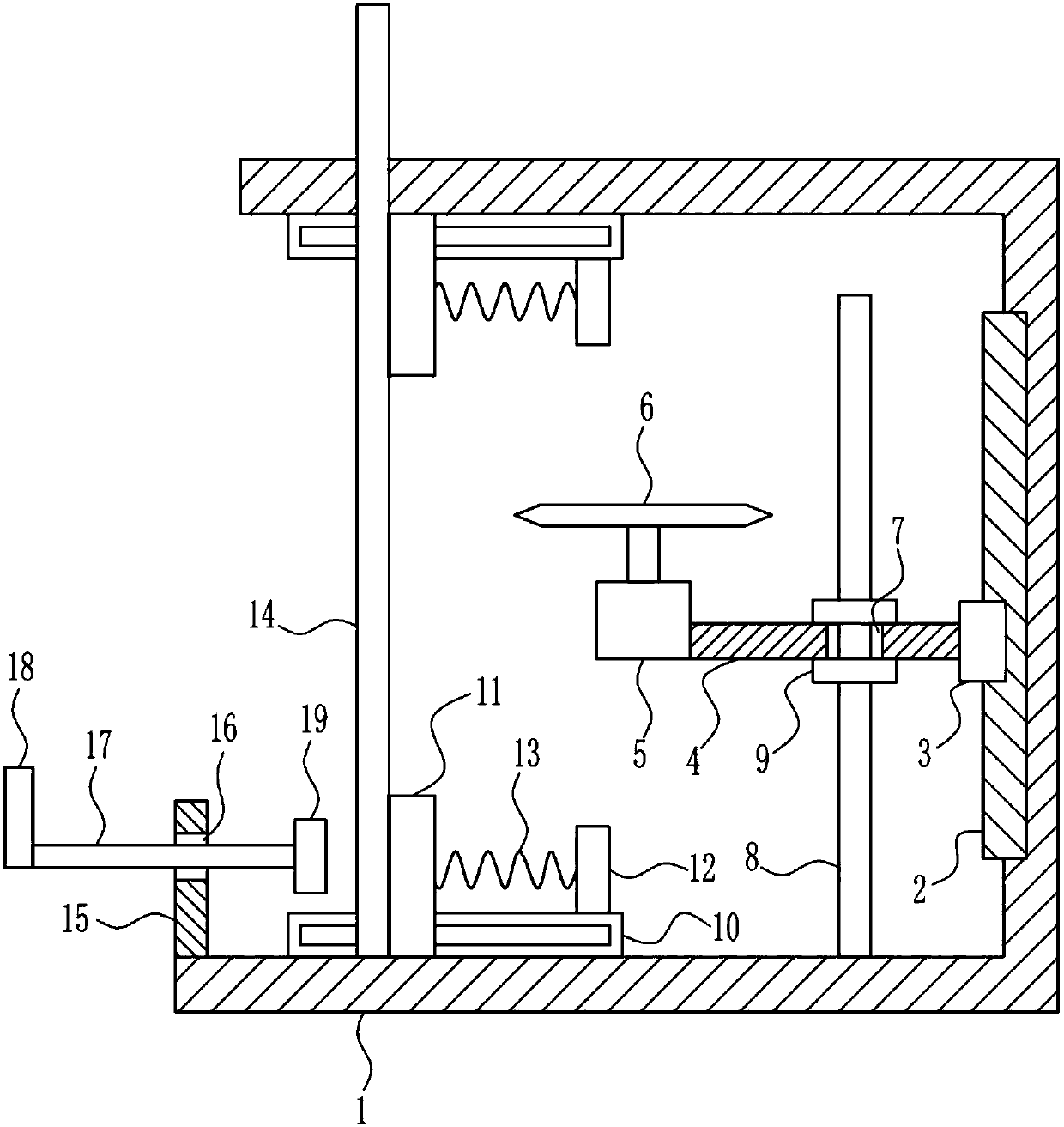

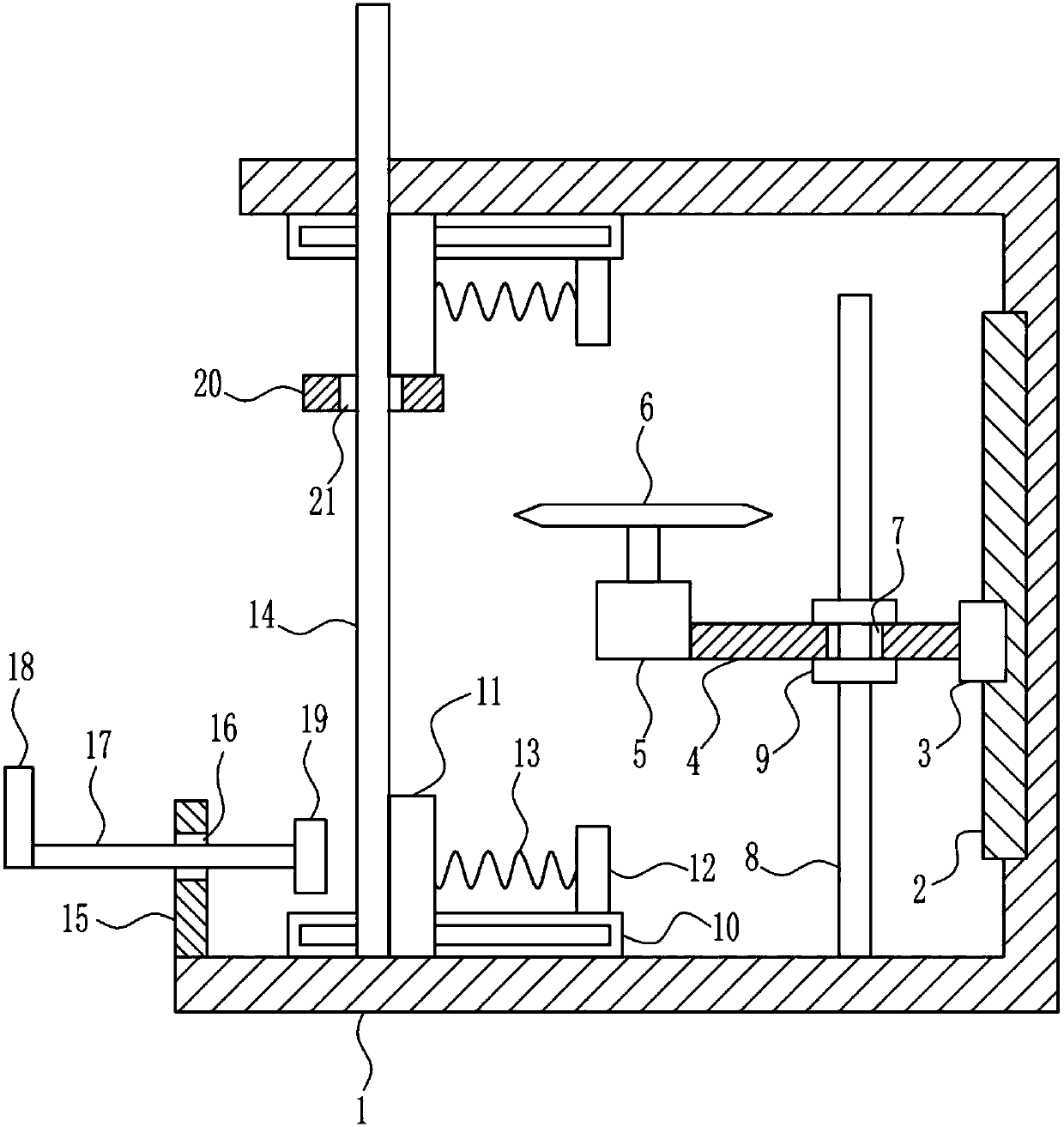

The invention relates to a cutting machine, comprising a base, two supporting frames are fixedly arranged on the upper side of the base, a supporting sleeve is fixedly arranged on the supporting frame, two sets of supporting rollers are fixedly arranged on the inner wall of the supporting sleeve, There is a pipeline between the roller groups, and the outer wall of the pipeline is in contact with the supporting roller group; a ring rotating groove is opened in the side wall of the right end of the supporting sleeve, and a rotating block is arranged in the ring rotating groove, and the outer end of the rotating block is fixed Connected with cutting machine lifting device. The beneficial effect of the present invention is that the cutting machine can cut the pipe around the pipe, which solves the problem of inconvenient cutting of larger pipes, which is convenient and fast; in addition, the position of the pipe during the cutting process is always kept unchanged by using the clamping device. The cutting blade of the cutting machine is protected from damage; and the position of the baffle can be adjusted, that is, the cutting length of the pipe can be adjusted conveniently.

Owner:安徽谢佑圣电子科技有限公司

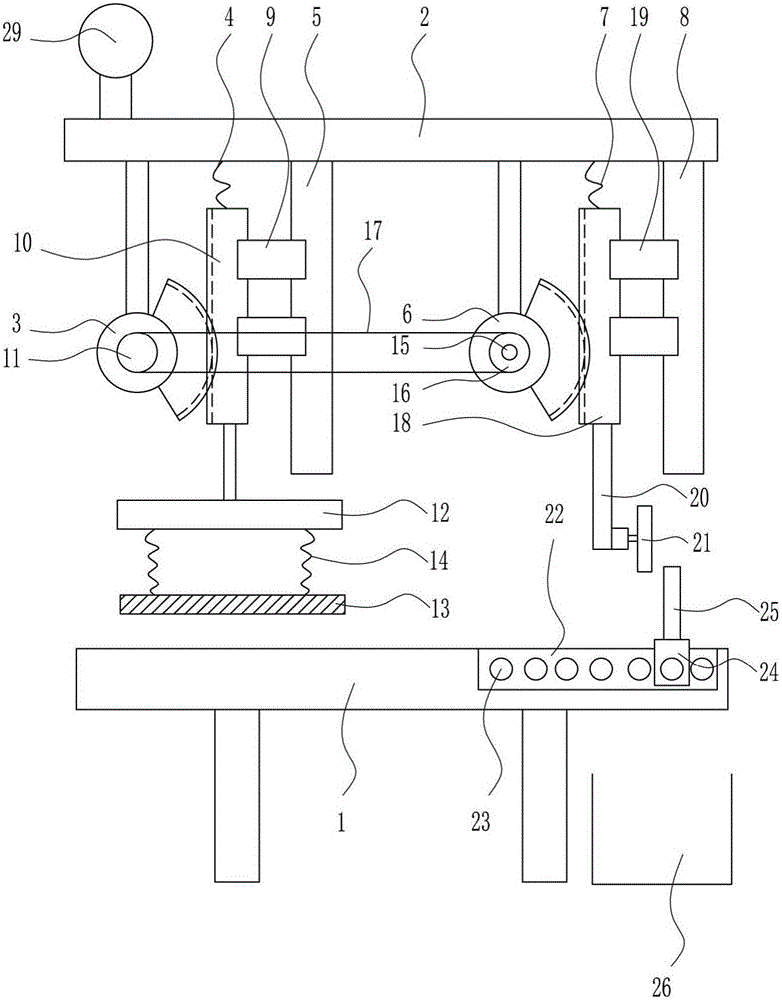

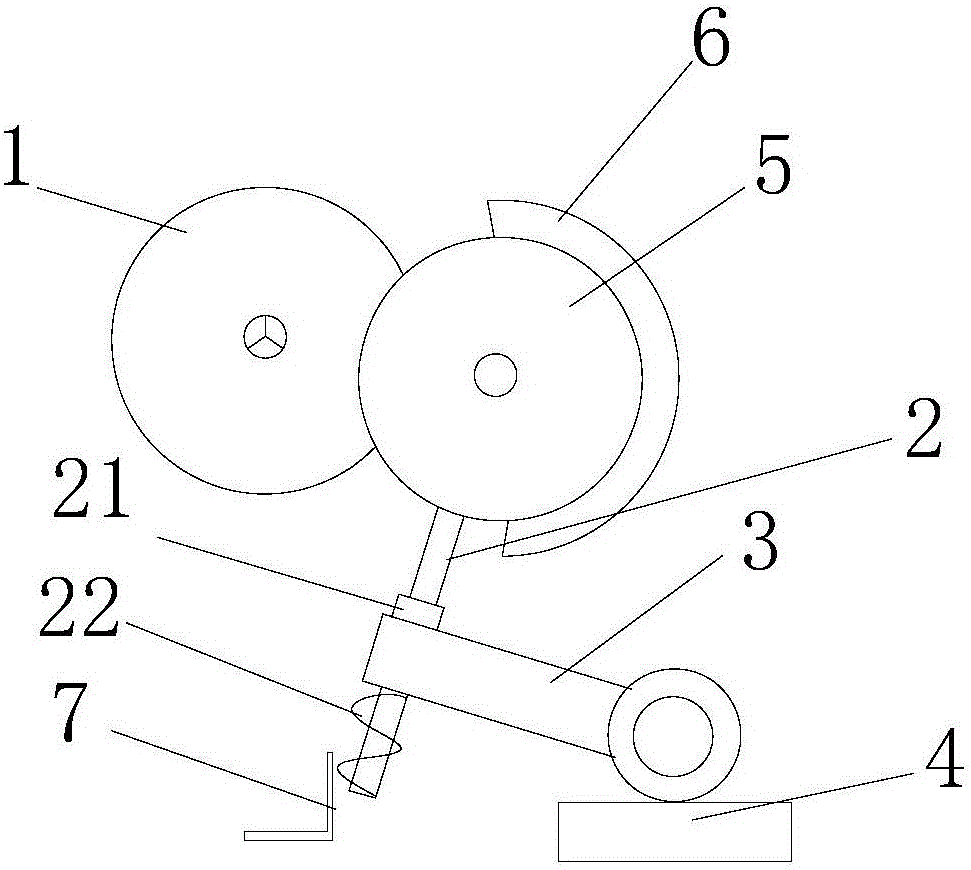

Aluminum material cutting device for hardware machining

ActiveCN106112099AReduce manufacturing costChange cutting lengthStock shearing machinesFeeding apparatusMachiningPulley

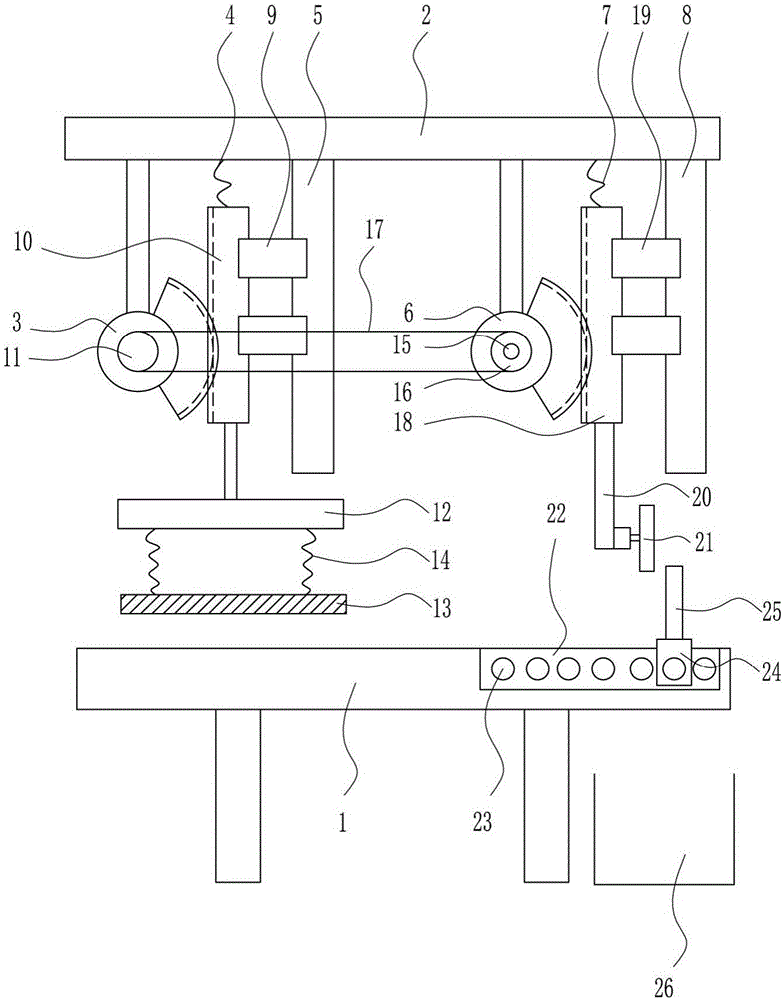

The invention relates to an aluminum material cutting device, in particular to an aluminum material cutting device for hardware machining. The aluminum material cutting device for the hardware machining aims to achieve the technical effects that the manufacturing cost is low, the cutting lengths of aluminum materials can be adjusted during cutting, and the cutting speed is high. In order to achieve the technical effects, the aluminum material cutting device for the hardware machining comprises a workbench, a top plate, a first sector gear, a first spring, a first sliding rail, a second sector gear, a second spring, a second sliding rail, a first sliding block, a first rack, a first belt pulley, a fixing plate, a rubber plate, a third spring, a motor, a second belt pulley, a flat belt, a second rack and the like. The top plate is arranged over the workbench. The aluminum material cutting device for the hardware machining has the technical effects that the manufacturing cost is low, the cutting lengths of aluminum materials can be adjusted during cutting, and the cutting speed is high.

Owner:奋安铝业股份有限公司

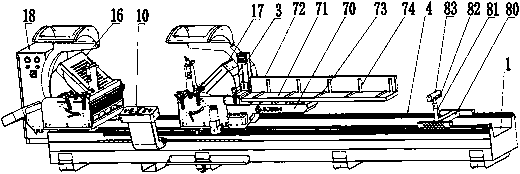

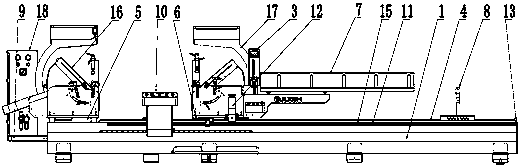

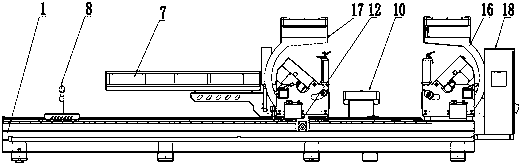

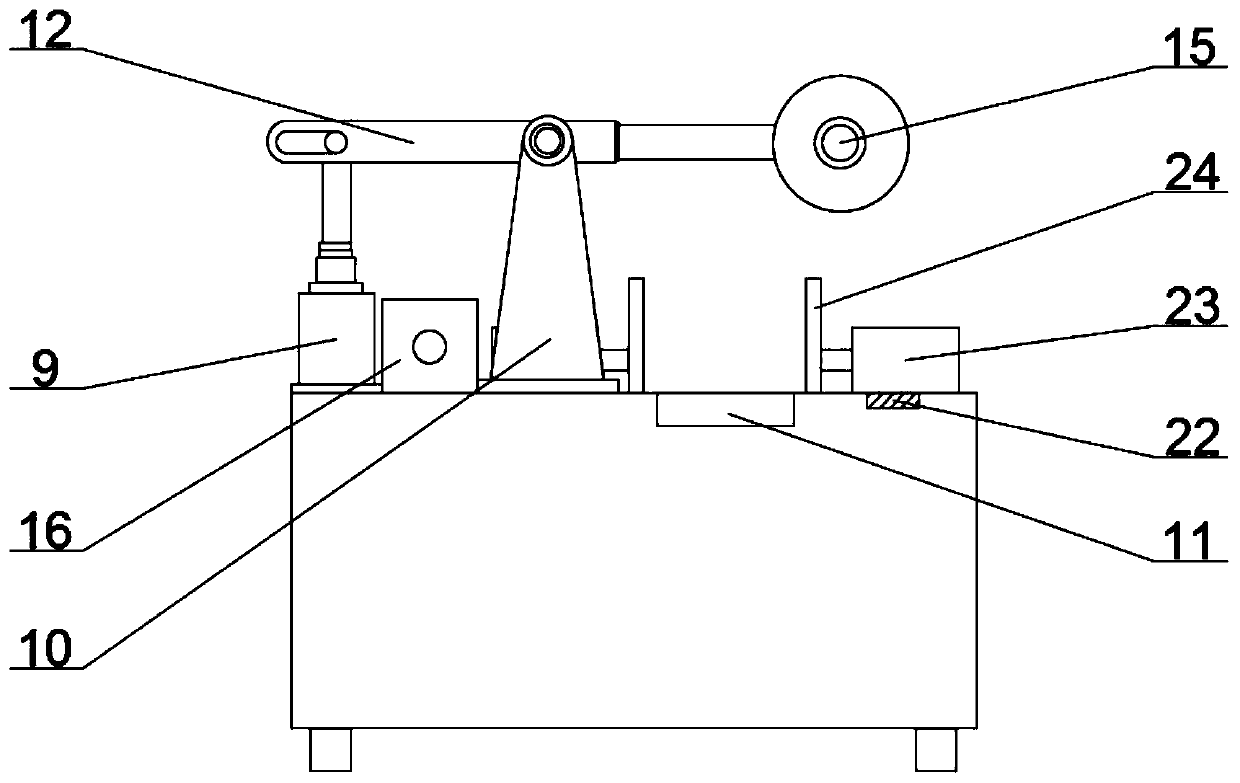

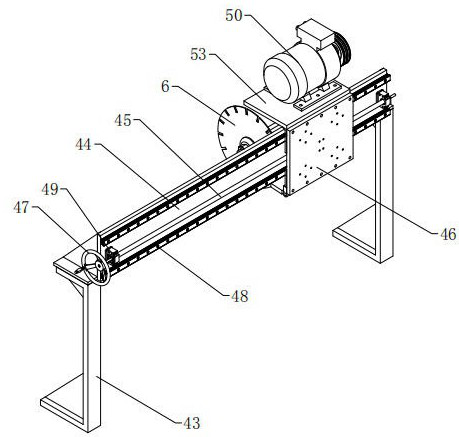

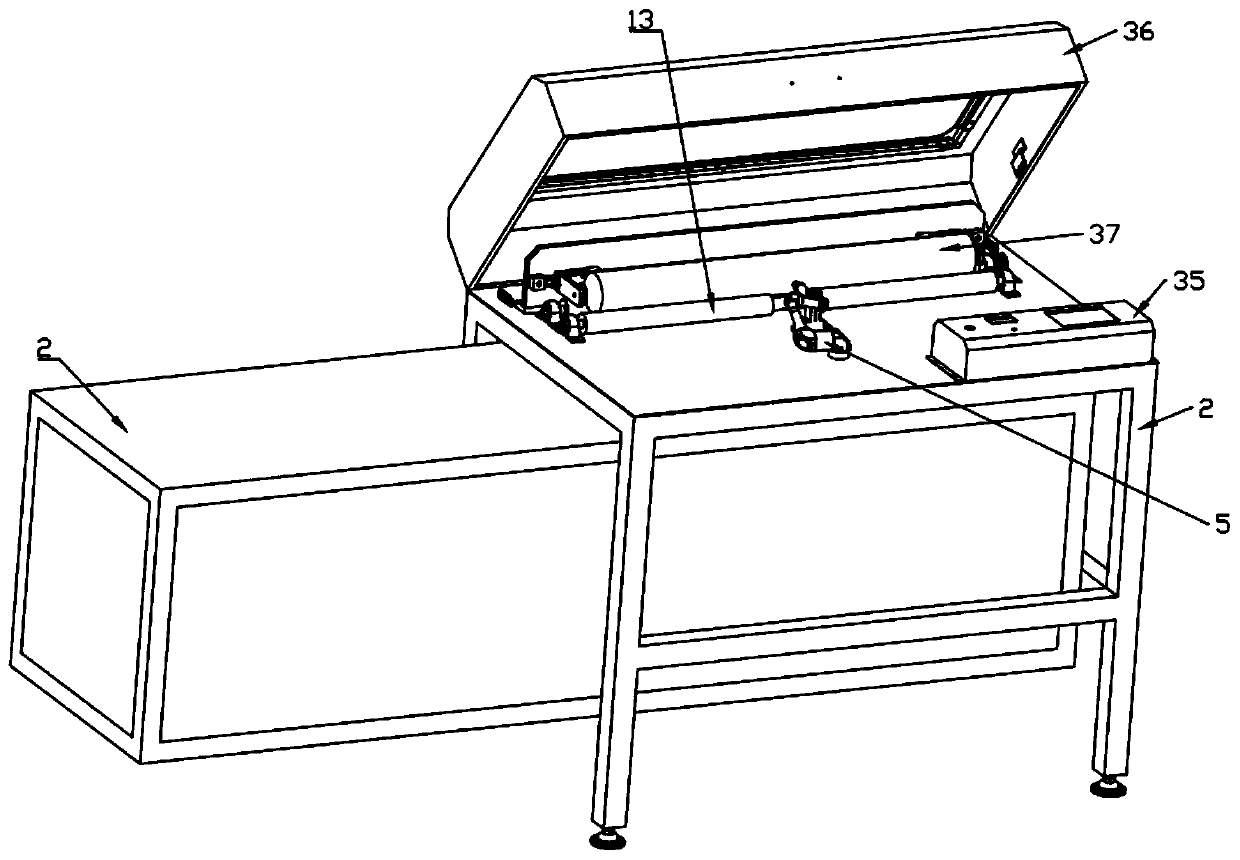

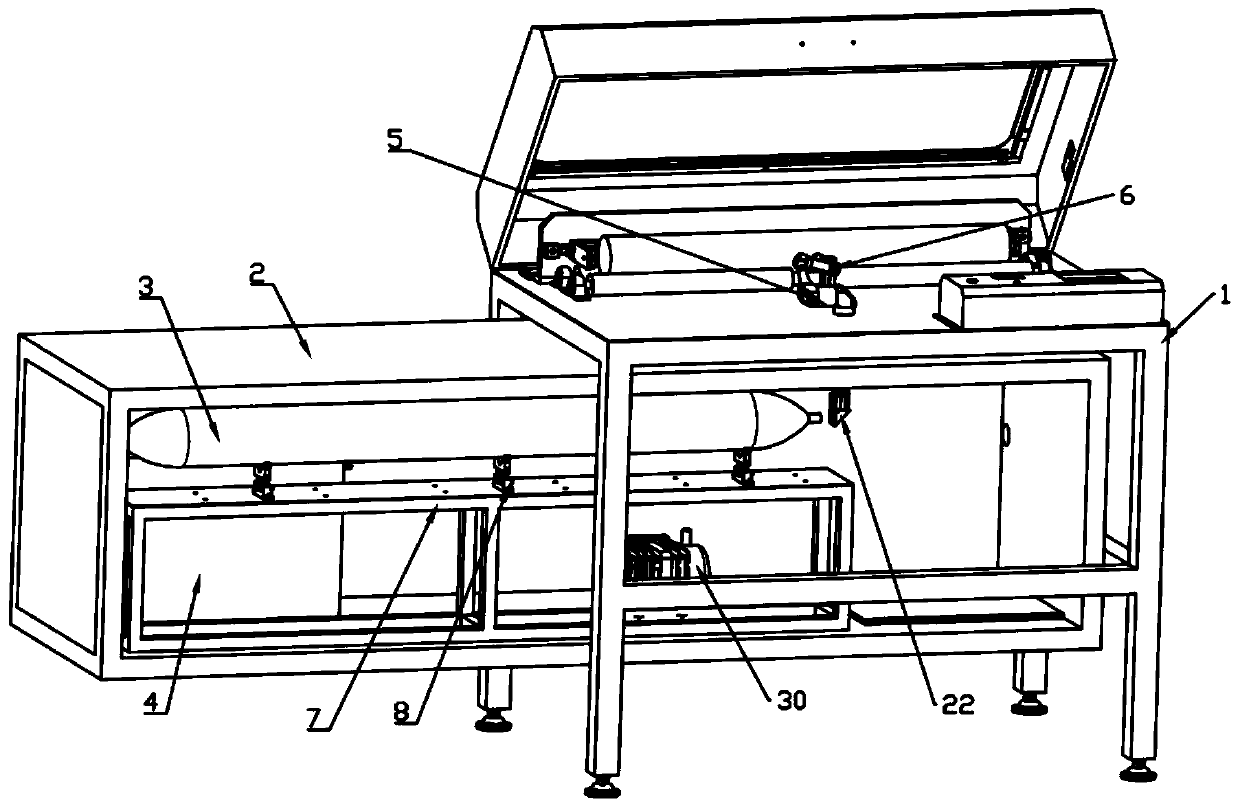

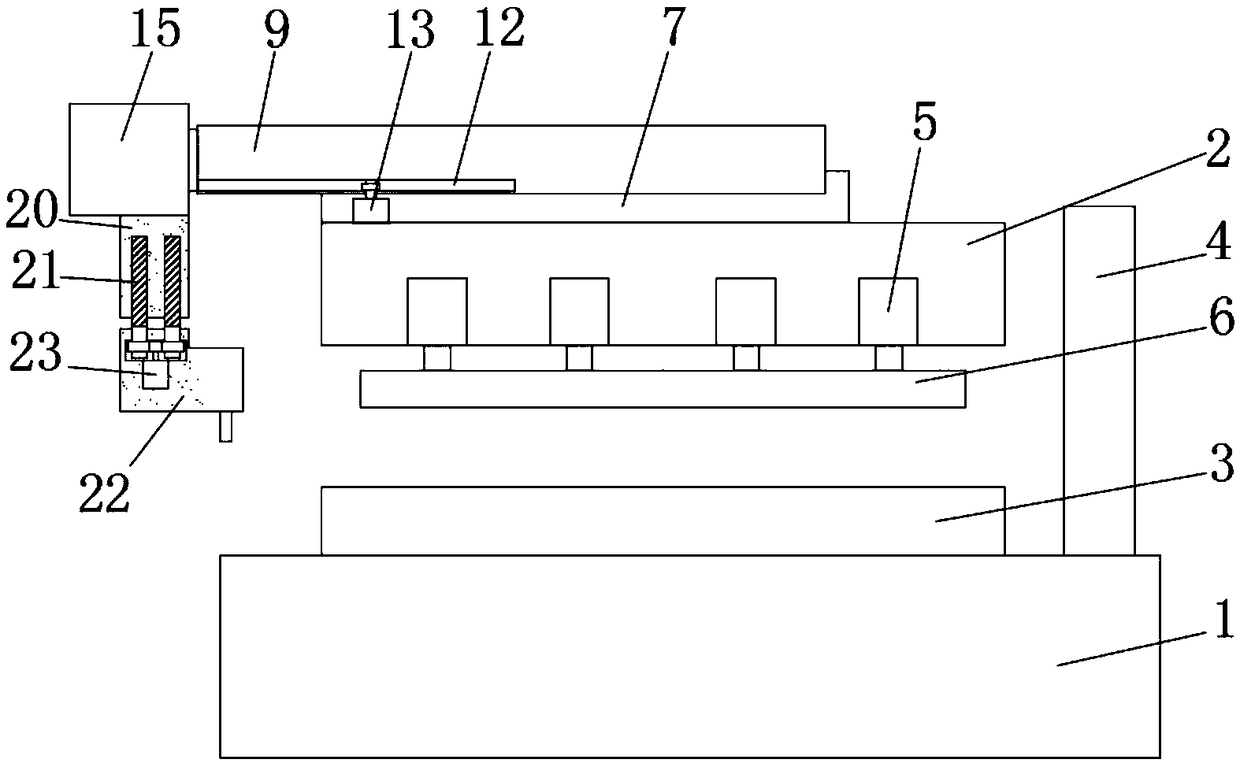

Double-ended saw cutter

InactiveCN110434396AAdjustable cutting angleChange cutting lengthMetal sawing devicesMetal sawing accessoriesEngineeringMechanical engineering

The invention discloses a double-ended saw cutter. The double-ended saw cutter comprises a horizontal type lathe rack, wherein a linear horizontal rail is arranged on the top of the horizontal type lathe rack; a slide base is arranged on the linear horizontal rail in a sliding mode; a fixed base is fixedly arranged at the left end of the horizontal type lathe rack; a transmission frame is jointedto the outer side of the horizontal type lathe rack; a transmission rack is arranged in the transmission frame; two groups of saw blade cutting units are oppositely arranged on the horizontal type lathe rack left and right; a height measuring device and a supporting frame are arranged at the right side of the slide base; a movable rack can be arranged on the right part of the linear horizontal rail in a sliding mode, and is opposite to the supporting frame horizontally; a drive device is arranged at the outer side of the slide base; and the transmission rack drives the slide base to slide leftand right on the linear horizontal rail. The double-ended saw cutter has the characteristics of being compact and scientific in structure, being adjustable in cutting angle of a saw blade cutting assembly, being capable of supporting relatively long section bar workpieces, being adjustable in cutting length of section bar workpieces, and being capable of measuring top side length parameters of the section bar workpieces on line; and the saw blade cutting assembly does not have intermediate transmission link, is high in transmission efficiency, and facilitates energy conservation and environment protection.

Owner:佛山市金立星机械设备有限公司

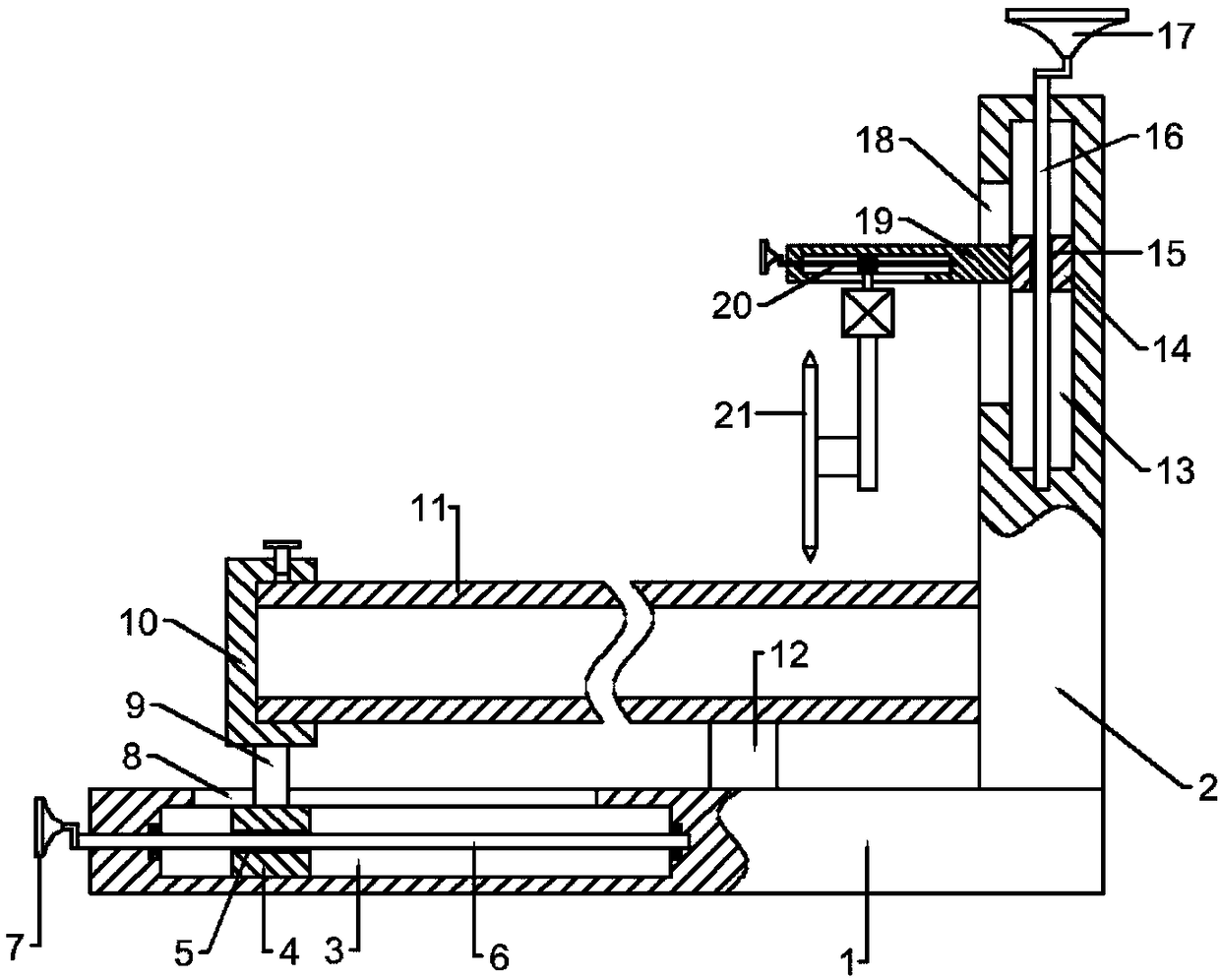

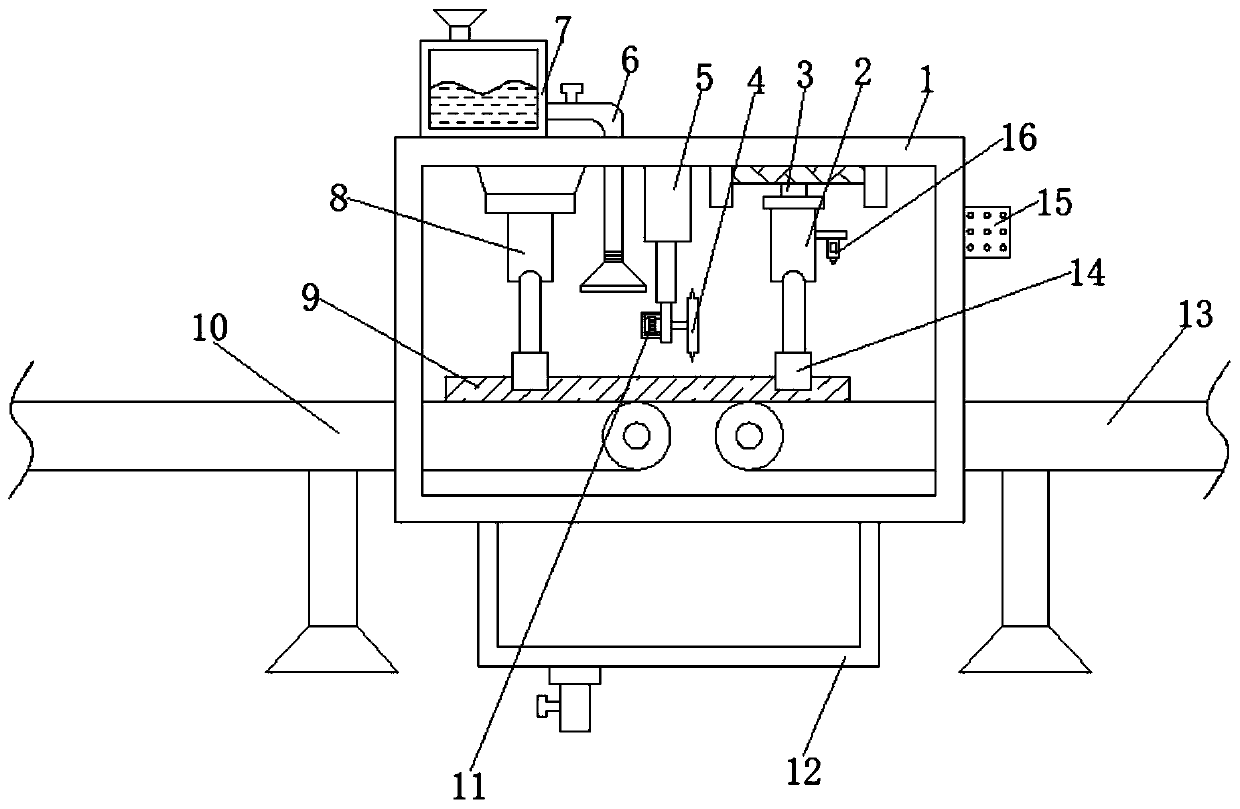

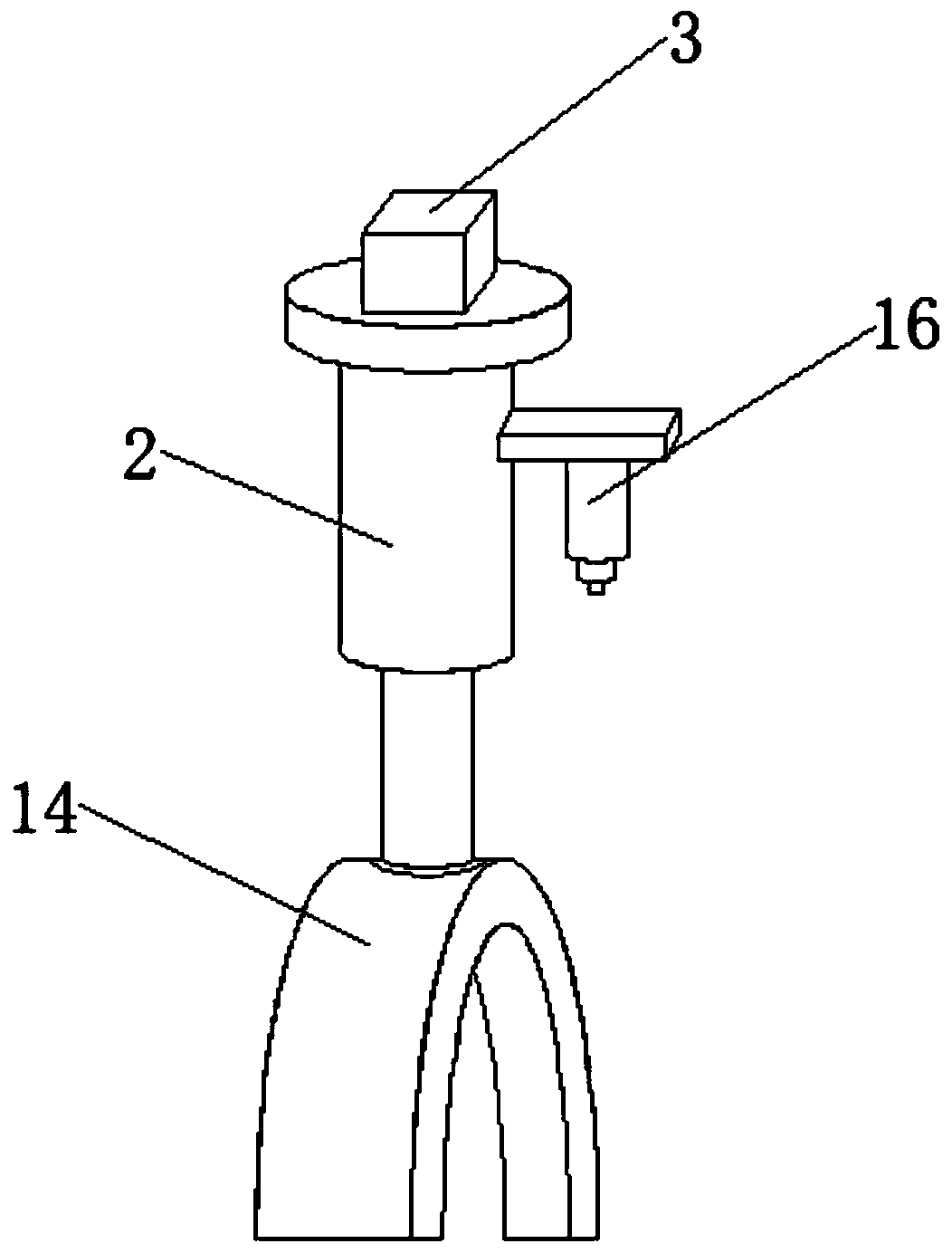

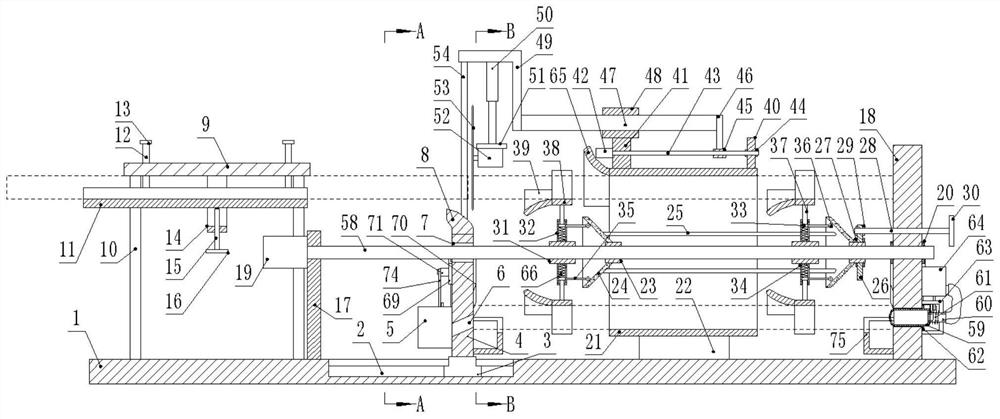

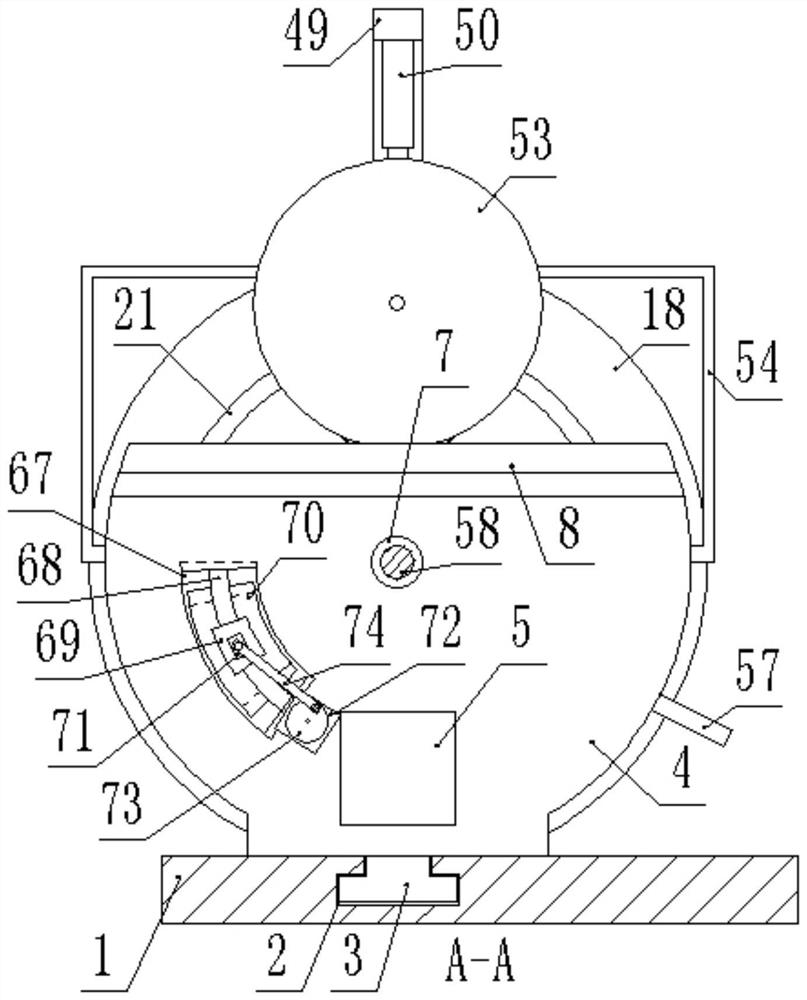

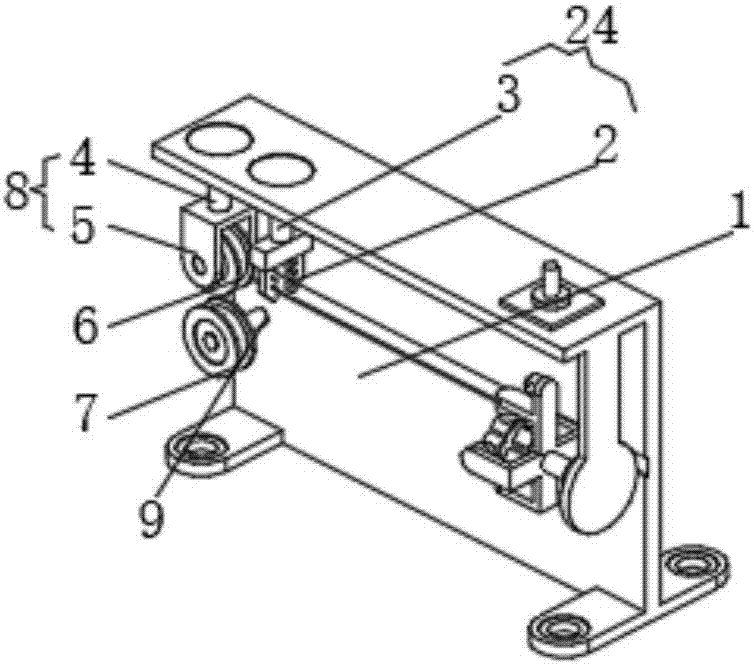

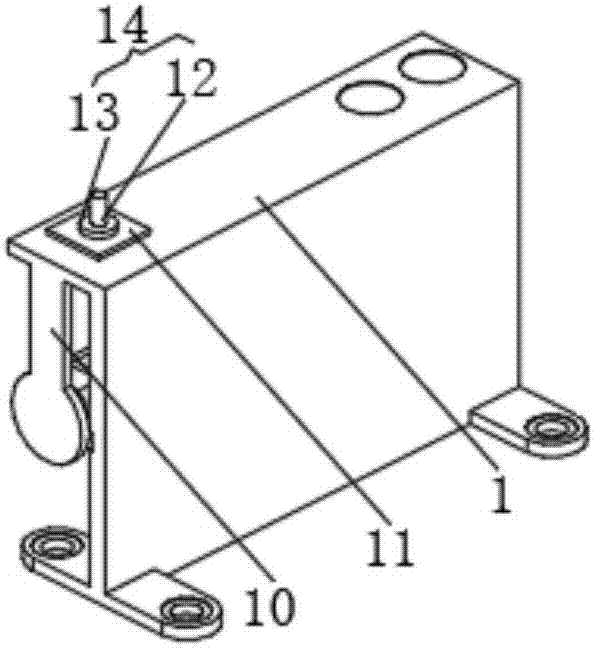

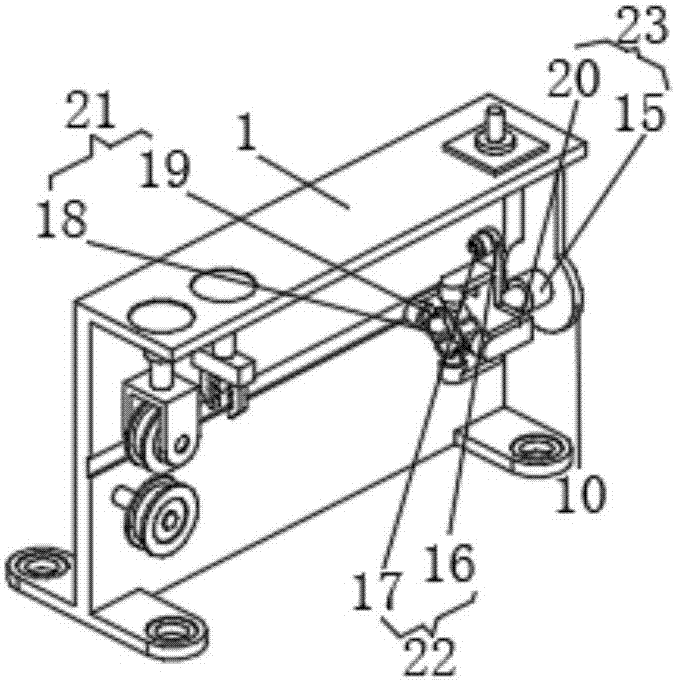

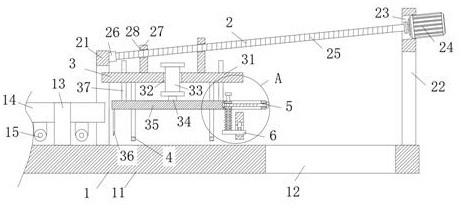

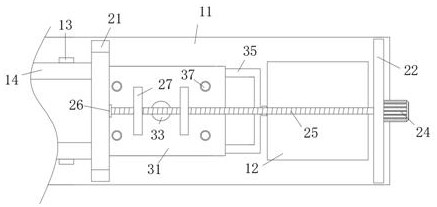

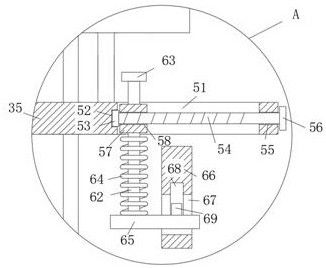

Composite plastic pipe fitting forming processing equipment and forming processing method

ActiveCN113427528AEnsure clamping limitEasy to handleMetal working apparatusPipe fittingStructural engineering

The invention relates to composite plastic pipe fitting forming machining equipment and a forming machining method, the composite plastic pipe fitting forming machining equipment comprises a bottom plate, a clamping device, a distance adjusting device, a cutting device and a driving device, wherein the clamping device is mounted at the upper end of the bottom plate, the distance adjusting device is arranged on the right side of the clamping device, and the distance adjusting device is fixedly connected with the bottom plate. The composite plastic pipe fitting forming machining equipment can solve the problems that when existing equipment is used for cutting a composite plastic pipe fitting, the composite plastic pipe fitting can only be clamped and limited from the uncut end, the composite plastic pipe fitting cannot be limited from the cut end, the composite plastic pipe fitting is prone to being bent under gravity when being about to be cut, the problems that the surface of a notch is uneven, the surface of the composite plastic pipe cannot be cleaned before cutting, stains on the surface of the composite plastic pipe easily affect cutting, the flatness of the notch cannot be kept during cutting, the condition that the notch is inclined easily occurs, and the cutting effect is poor are solved.

Owner:新沂市鼎丽塑胶制品有限公司

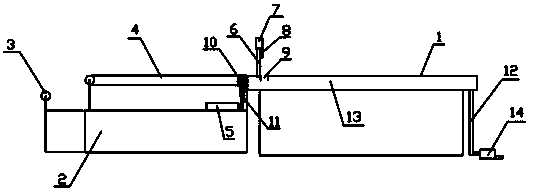

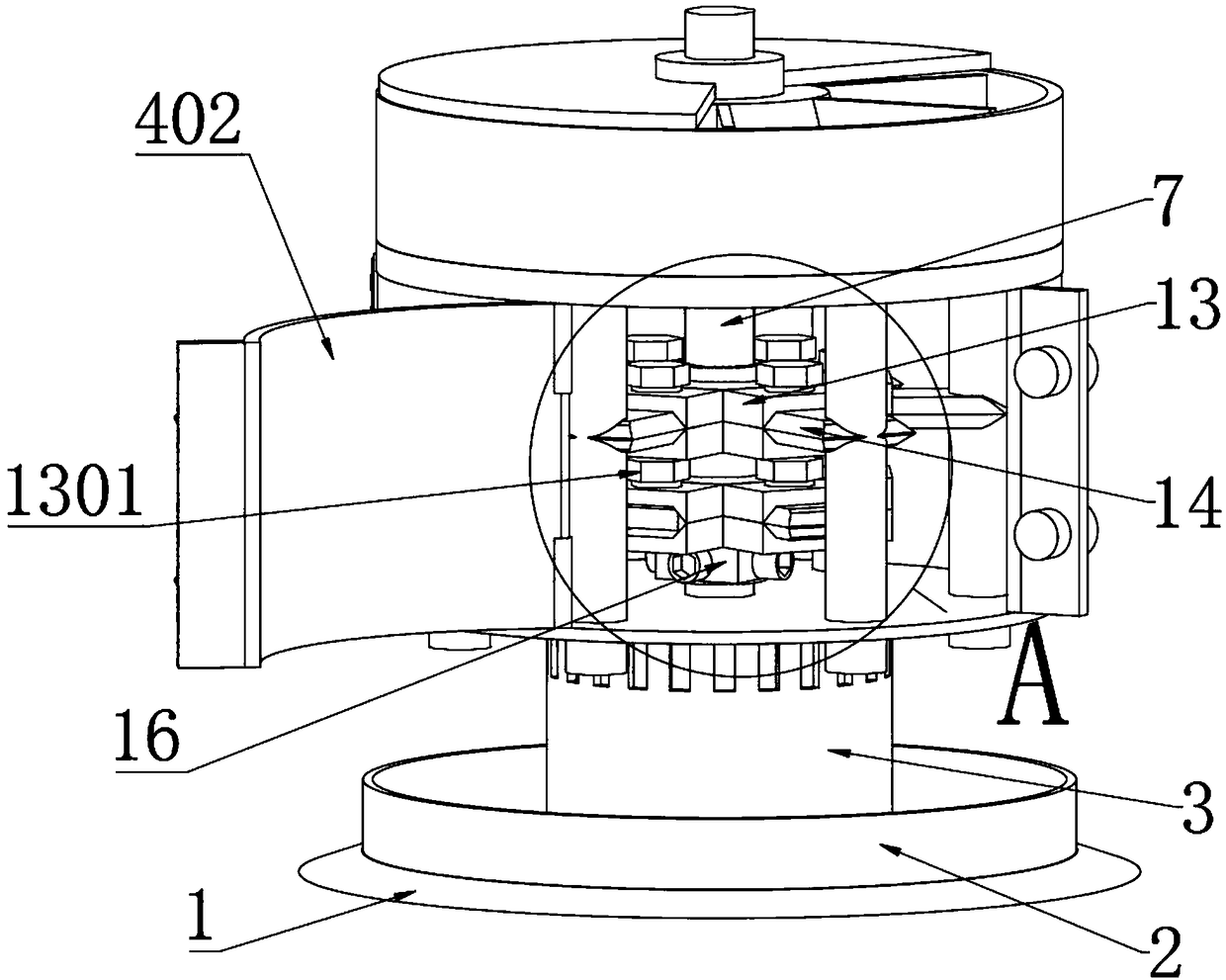

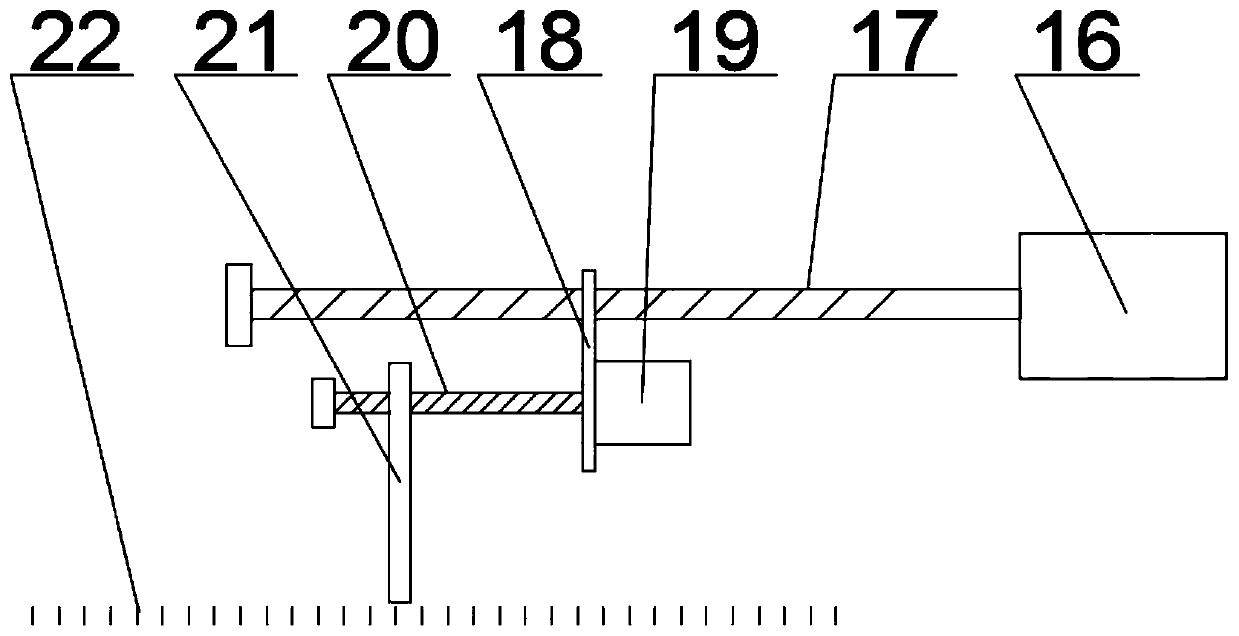

Pipe cutting system

InactiveCN104028830ASave human effortChange cutting lengthTube shearing machinesMachiningPiston cylinder

The invention discloses a pipe cutting system, relates to the technical field of pipe machining, and aims to solve the problem that the existing pipe cutting is inconvenient in length- cutting adjusting, low in machining efficiency, and the like. The pipe cutting system comprises a receiving device and a length adjusting device. By the receiving device, the cut pipes can be received and taken out without manual operation, and manpower is saved greatly. The length adjusting mechanism comprises a fixing plate and a piston cylinder fixed on the fixing plate. The piston rod of the piston cylinder is connected with a positioning plate. A ruler is fixed on a base. A limit device is slidably disposed on the ruler. The limit device is slid to the position of required length, when a positioning plate driven by the piston rod moves to the position of the limit device, the positioning plate stops, and a pipe can be conveyed to the positioning plate to acquire the required cutting length. By the arrangement, cutting length of pipes can be adjusted conveniently.

Owner:浙江地球管业有限公司

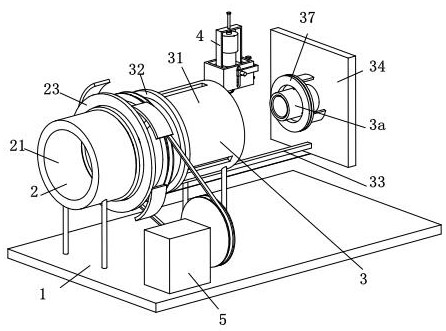

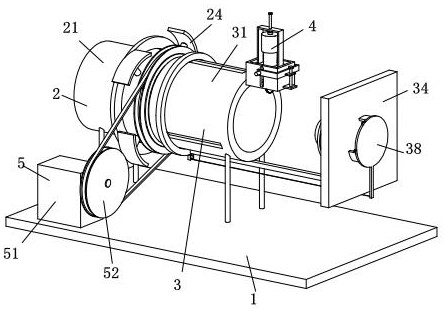

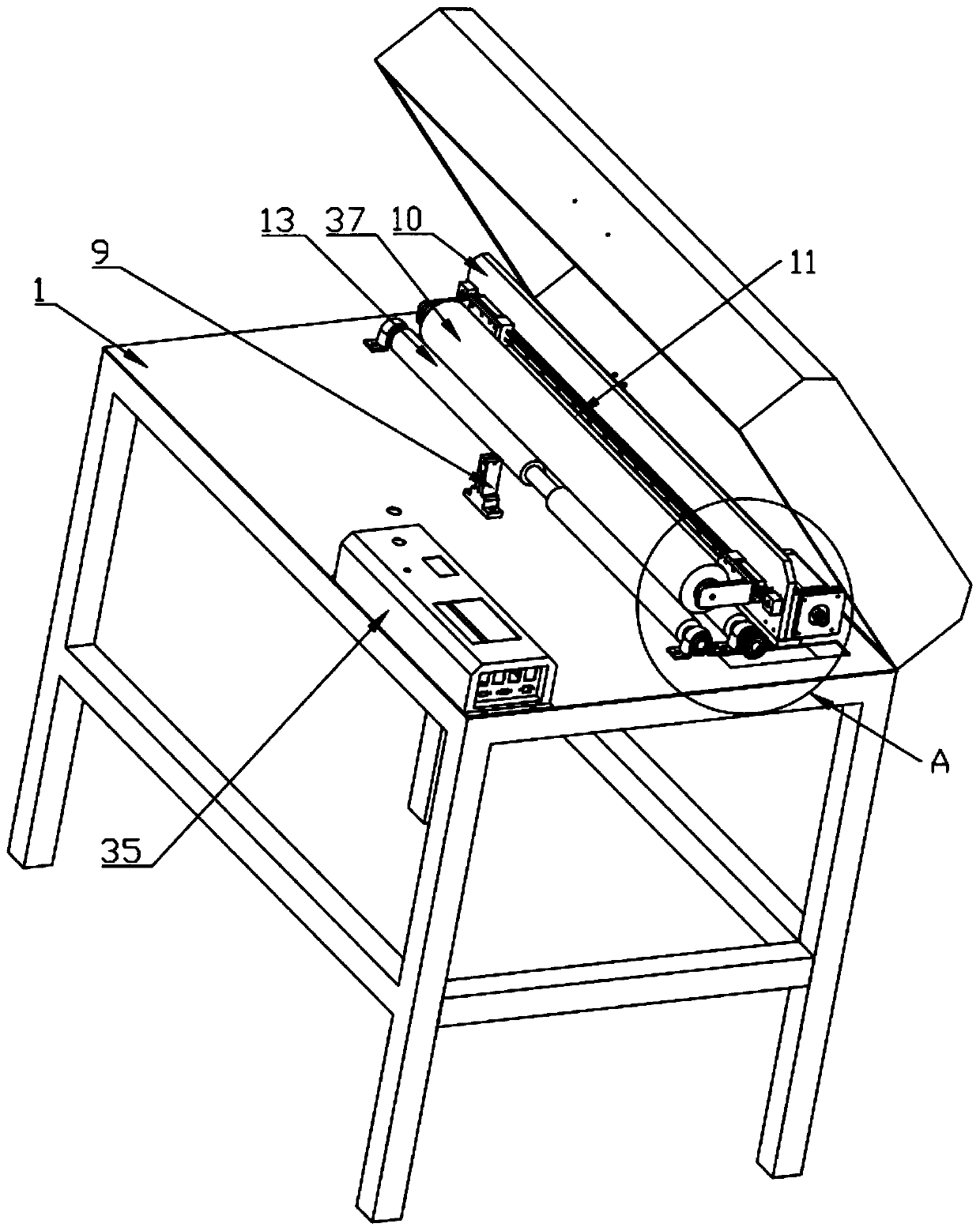

Flexible bar cutting machine

ActiveCN108994884AEasy to achieve cutting functionChange cutting lengthMetal working apparatusEngineeringCam

The invention discloses a flexible bar cutting machine which is a high precision automatic cutting device for the cylindrical surface of the two ends of a bar with certain rigidity. The flexible bar cutting machine comprises a feeding system, a jacking system and a rolling-cutting system. A cam disk on a first camshaft is driven to rotate by a motor of the feeding system, and a push plate is driven by the cam disk for achieving forward feeding, so that the bar falls into a V-shaped groove; a cam and the V-shaped groove are driven by a second camshaft to move up and down; the rolling-cutting system comprises a cutting table and a rolling plate, and the cutting table is provided with blades of which the distance and inclination can be regulated; the bar is driven by the rolling plate under the driving of a crank to roll forwards; when the bar is rolled to come into contact with the blades, the end starts to cut; and the bar is continuously rolled for a circle so that the end cutting is finished. The three transmission systems can be reset automatically, and the reciprocating end cutting is achieved. The pressure of the rolling plate is adjustable, and the problems that the bar is soft and liable to deform during clamping, and the cutting accuracy of the end face is low are solved; the structure is simple, and the flatness of the cut end face and the cutting accuracy requirement can be better ensured.

Owner:HUBEI UNIV OF TECH

Building construction machining device with cutting-off length adjustable function

InactiveCN108941748AAchieve fixationChange cutting lengthTube shearing machinesShearing machine accessoriesArchitectural engineeringBlock match

The invention discloses a building construction machining device with the cutting-off length adjustable function. The device comprises a bottom plate, a supporting plate is fixedly connected to the upper side of the right end of the bottom plate, a first moving groove is formed in the upper side of the bottom plate, a first moving block is arranged in the first moving groove, a first thread through hole is formed in the first moving block, a first thread rod is in threaded connection into the first thread through hole, the right end of the first thread rod is fixedly connected with a first handle, a first connecting plate is fixedly connected to the upper side of the first moving block, and the first connecting plate penetrates through a first through groove formed in the bottom plate. Thedevice has the beneficial effects that a locking thread rod is used for locking a pipeline, the pipeline is fixed, a third handle is rotated, the third handle drives the third thread rod to rotate, athird moving block matched with the thread rod moves in a third moving groove, the third moving block drives a cutting motor to be subject to position changing, and the cutting length is changed.

Owner:龙仕银

Environment-friendly cutting device for non-woven fabric

InactiveCN107904921AGuarantee air qualityOvercome the defects of rough edgesSevering textilesCircular discWorking environment

The invention discloses an environment-friendly cutting device for a non-woven fabric. The device comprises a cutting table and a transmission device, the cutting table is provided with a cutting groove and a cutting device body, and the cutting device body comprises a cutter support, an air cylinder and a cutter; the cutter is a strip-shaped cutter, the lower portion of the cutter support is fixed to the cutting table, and the air cylinder is arranged on the upper portion of the cutter support; the air cylinder is connected with the cutter, a collection bin which is used for collecting non-woven fabric soft flocks is arranged below the cutting table, and the cutting groove is communicated with the collection bin; an air suction pipe is connected to the side wall of the collection bin andcommunicated with the collection bin, and an exhaust fan is connected to the other end of the air suction pipe. According to the environment-friendly cutting device for the non-woven fabric, the detect is overcome that disc cutters can generate burrs, and meanwhile the cutting efficiency is also improved. In cutting, under the effect of negative pressure of the exhaust fan, the soft flocks which are generated due to cutting are sucked into the collection bin and sucked away by the exhaust fan along the air suction pipe, the quality of air in a workshop is guaranteed, and the pollution to working environment is prevented.

Owner:DEYANG YONGSHENG NONWOVEN PROD

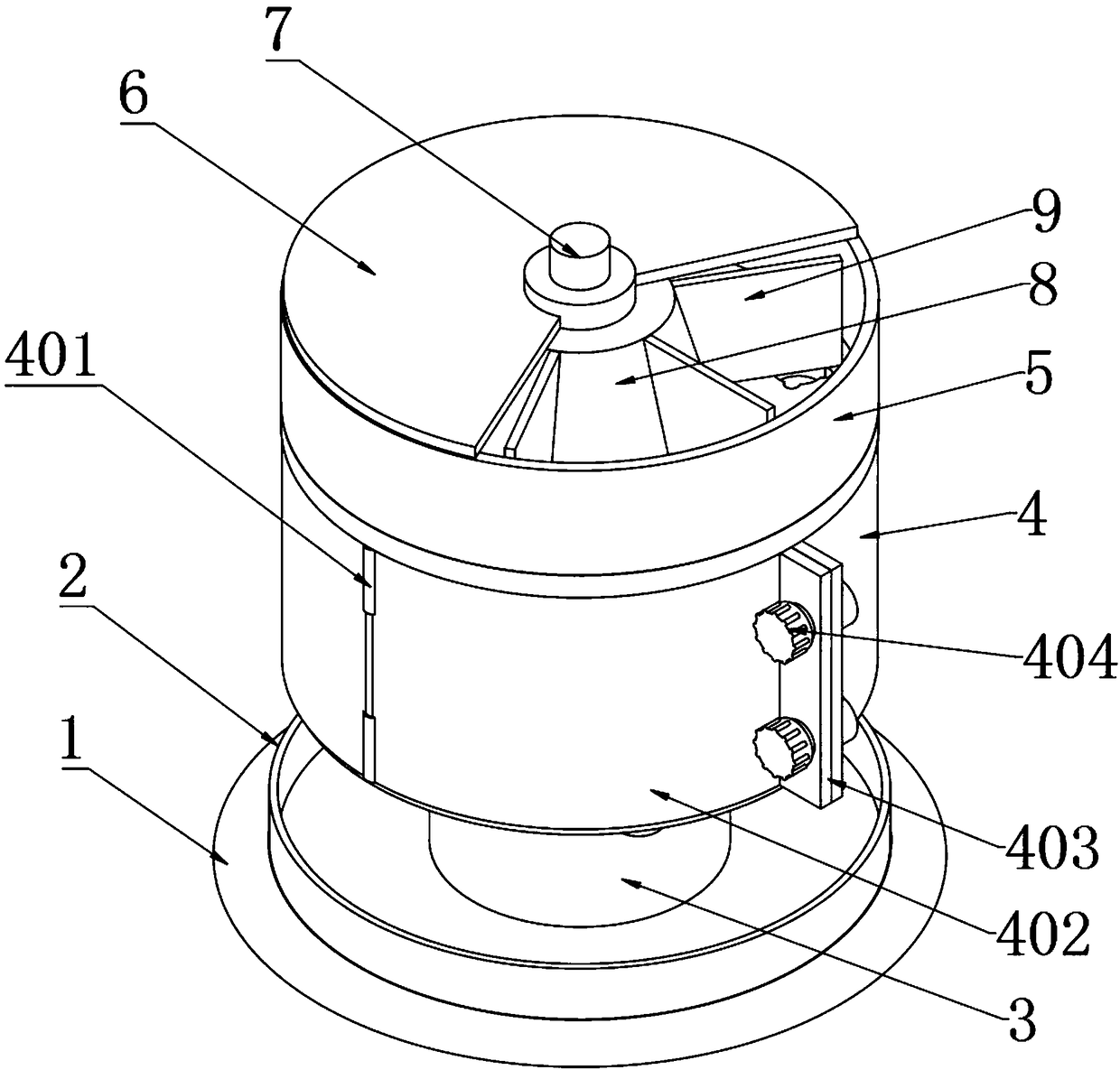

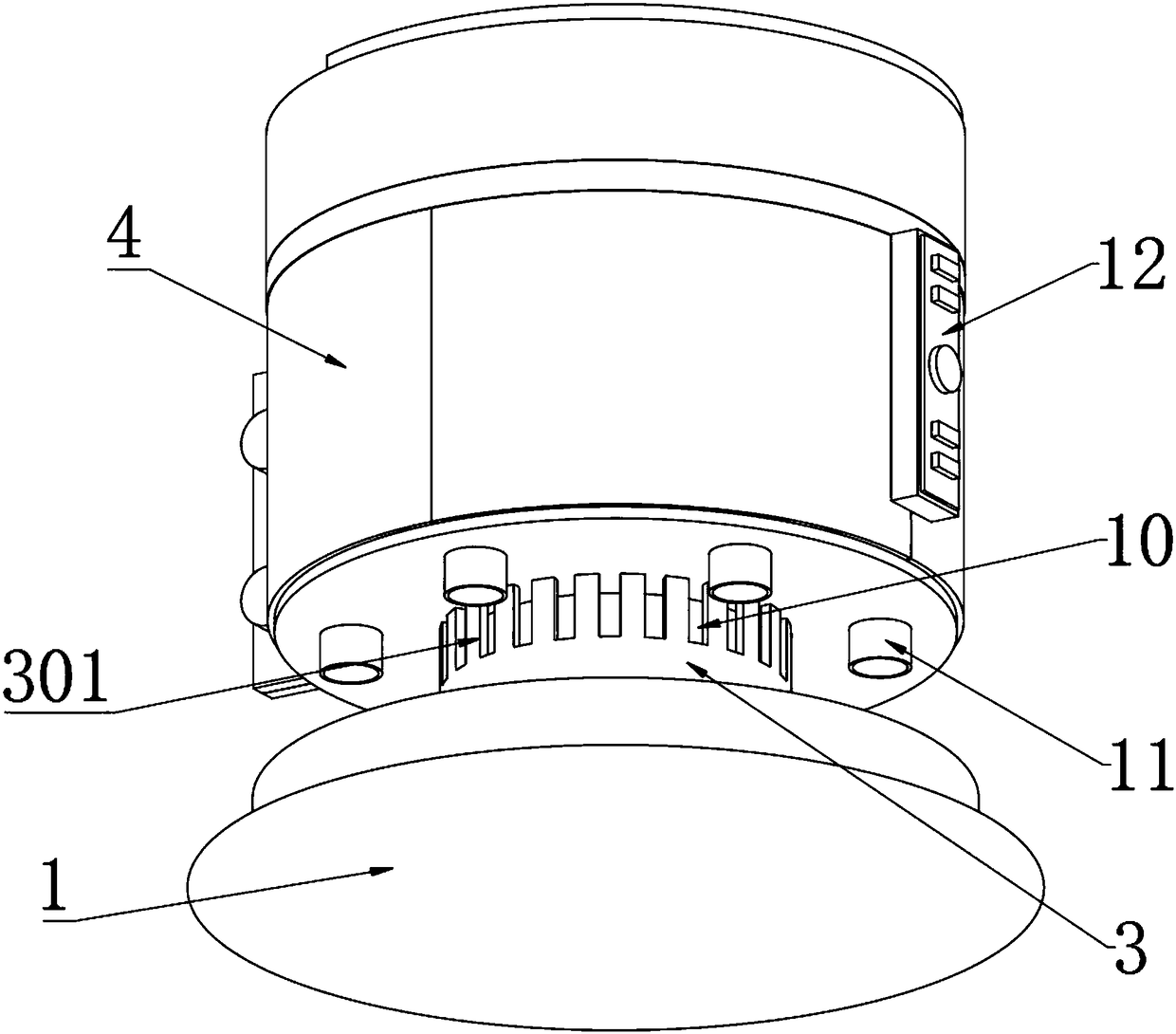

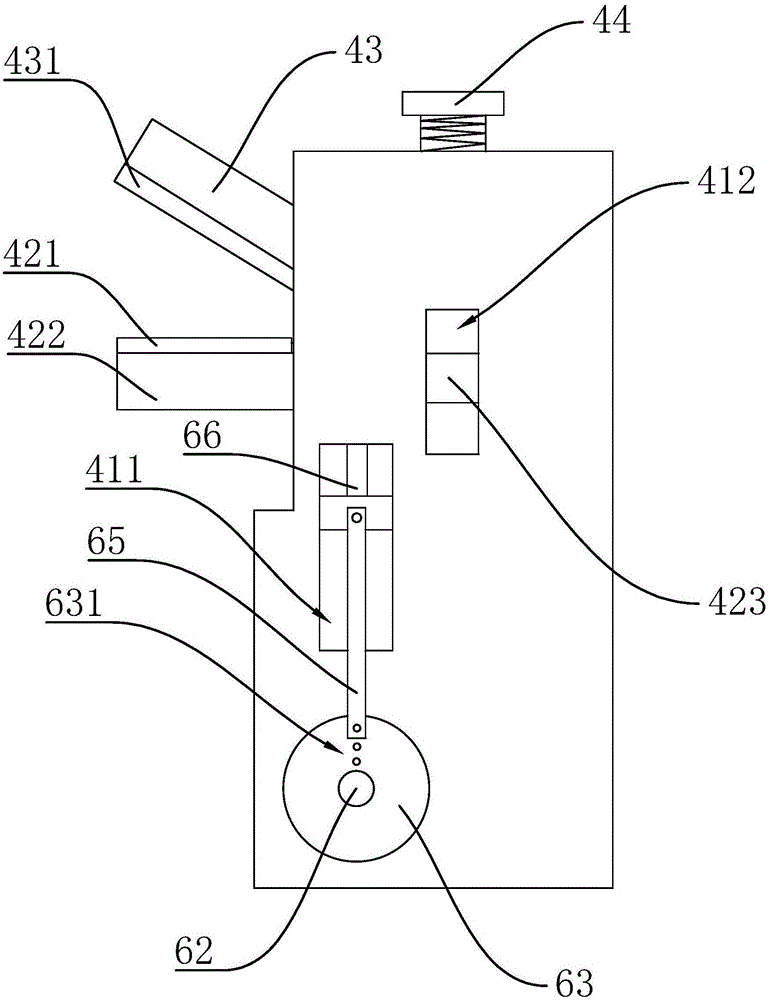

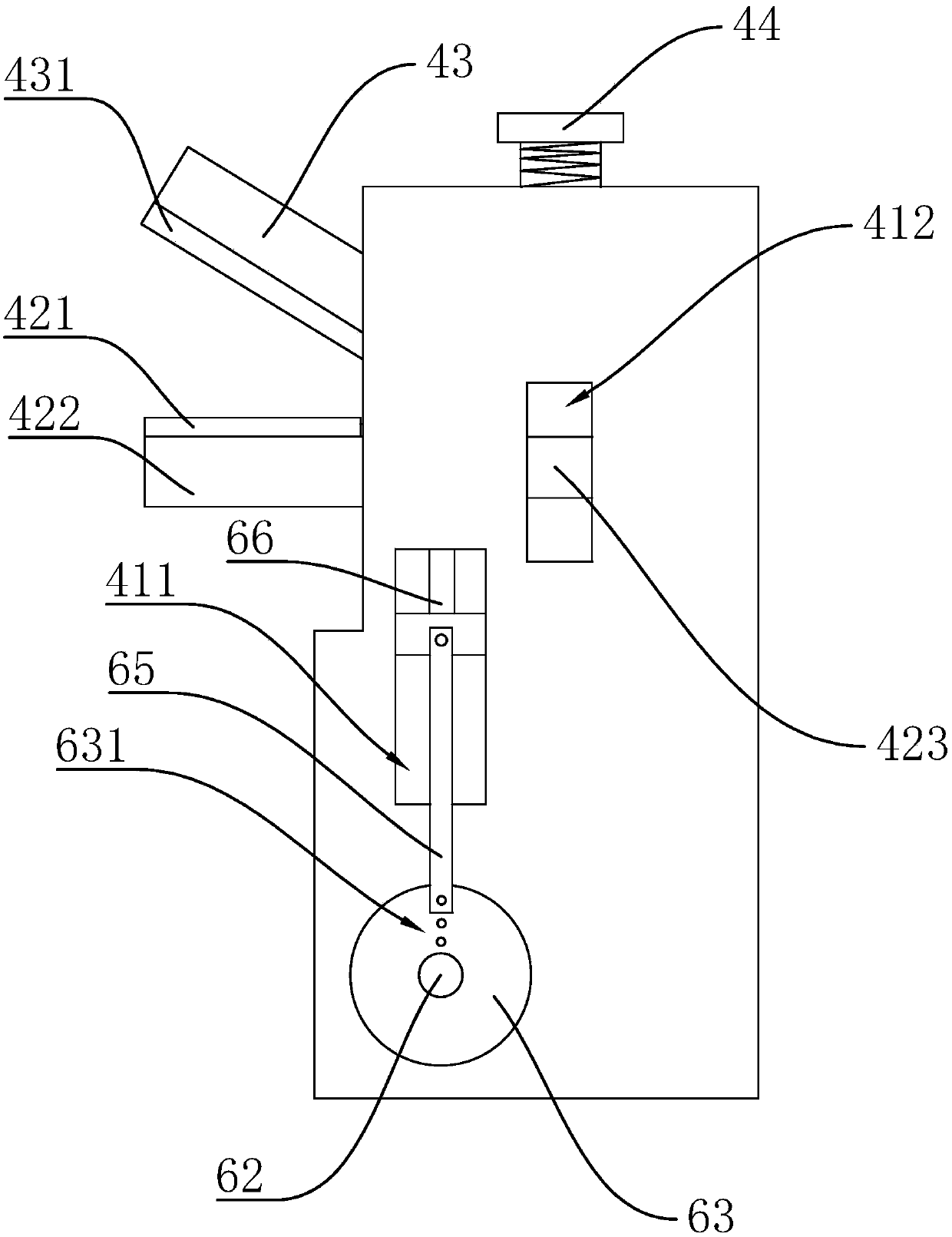

Rotary type herbal medicine slicing machine

InactiveCN108501072AEasy to cutAvoid vibrationMetal working apparatusSupports/enclosures/casingsEngineeringTraditional Chinese medicine

The invention provides a rotary type herbal medicine slicing machine which comprises a base, a cutting edge and an internal hexagon nut; a motor is fixedly arranged in the center of the top of the base; an accepting ring plate is fixedly arranged on the outer edge of the top of the base upward; the top of the motor is fixedly connected to the bottom of a casing main body; a motor shell annularly sleeves the external of the motor between the casing main body and the base; an upper protective plate is fixedly arranged on the outer edge of the top of the casing main body upward; the top of the upper protective plate is covered with a top cover plate in a sealing manner; and a rotation portion of the motor penetrates through the casing main body above the top the of the motor and penetrates out from the center of the top cover plate above the motor. By adopting the rotary type herbal medicine slicing machine provided by the invention, through mutual matching of various structures, an efficient rotary type herbal medicine slicing machine is comprehensively realized; and traditional Chinese medicines can be rapidly and uniformly cut through the herbal medicine slicing machine, and an amount of cutter heads can be changed to perform regulation of cutting lengths with relatively large spans, and two groups of cutter heads are provided and can be selected to be used through stretching of the cutter heads.

Owner:ANHUI KECHUANG PRODUCTIVITY PROMOTION CENT CO LTD

Rapier loom

ActiveCN106048864AImprove surface qualityAccurate and fast resetLoomsAuxillary apparatusPush and pullMotor drive

The invention provides a rapier loom which comprises a workbench, a warp let-off mechanism, a weft let-off mechanism, a slitter edge cutting mechanism and a rolling mechanism. The slitter edge cutting mechanism comprises a cutter rest, a fixed cutter body and a movable cutter body, the fixed cutter body is provided with a first blade, the movable cutter body is provided with a second blade, the fixed cutter body is fixed to the cutter rest in a height-adjustable mode, the movable cutter body is hinged to the fixed cutter body, and the first blade and the second blade abut against each other to form a cutting opening; the slitter edge cutting mechanism further comprises a motor driving the movable cutter body to rotate, a transmission shaft and a rotating disc, and the transmission shaft is controlled by the motor and fixedly connected to the center of the rotating disc; the cutter rest is provided with a longitudinal sliding groove, a sliding block is arranged in the sliding groove, a first connecting rod used for driving the sliding block to rise and fall is arranged between the sliding block and the rotating disc, a second connecting rod used for pushing and pulling the movable cutter body is arranged between the sliding block and the movable cutter body, one side of the sliding block is fixedly connected with the second connecting rod, and the second connecting rod is hinged to the movable cutter body; the other side of the sliding block is hinged to the first connecting rod, and the first connecting rod is hinged to the eccentric position of the rotating disc.

Owner:LANGXI YUANHUA TEXTILE

Device for quickly pruning urban environmental sanitation green belt

ActiveCN109258165AChange cutting lengthQuick smashHedge trimming apparatusPlant waste comminutingPruningEngineering

The invention discloses a device for quickly pruning an urban environmental sanitation green belt. The device comprises a pruning frame, wherein the pruning frame is formed by fixedly connecting the ends of two L-shaped plates through a first hydraulic cylinder, the two sides of the inside of the first hydraulic cylinder are fixedly connected with first connecting blocks, and first rotary shafts are rotatably connected in the two first connecting blocks through bearings. The device has the advantages that by adopting the design that first cutting chains on two sides of the inside of the pruning frame are driven by second electric telescopic rods to telescope and second cutting chains are driven by first electric telescopic rods to telescope, the cutting lengths of the corresponding cuttingchains can be effectively changed through telescoping of the corresponding electric telescopic rods when the green belt is cut, accordingly the requirement of pruning different volumes and sizes of green belts is met, and the processing efficiency is higher; by adopting the design of a spiral cavity and a smashing cavity, pruned branches and leaves are quickly smashed effectively, plant absorption is facilitated, meanwhile the branches and leaves are prevented from floating and landing on the roadsides.

Owner:曾金玉

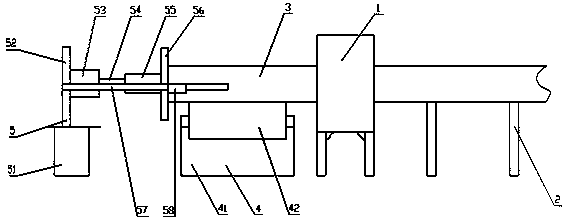

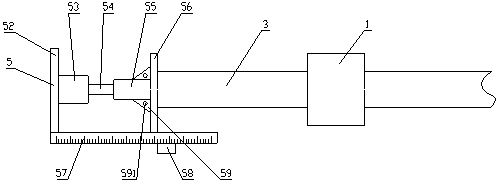

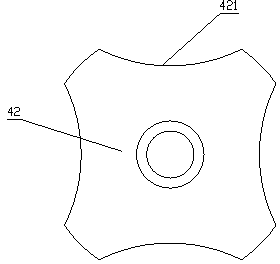

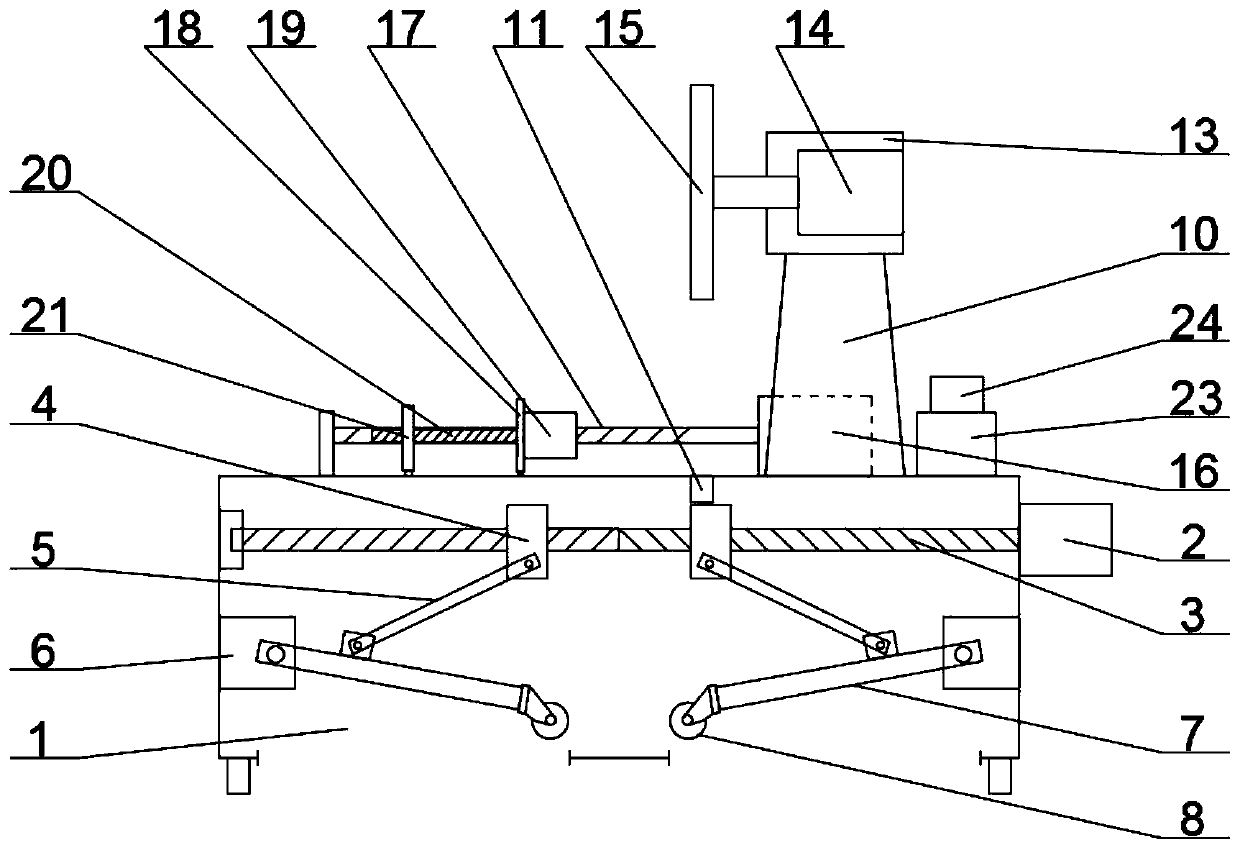

Cutting machine for fitness equipment production

InactiveCN110524055AAccurate adjustment of cutting lengthChange cutting lengthMeasurement/indication equipmentsFeeding apparatusHydraulic cylinderEngineering

The invention discloses a cutting machine for fitness equipment production. The cutting machine comprises a base; a motor D, a double-rotation-direction lifting lead screw, a nut, a connecting rod A,a connecting rod B, moving wheels, a hydraulic cylinder A, a support, a cutting groove, a movable rod, a motor B, a cutting blade, a measuring and positioning device and a workpiece clamping device are arranged on the base. By arranging the connecting rods, the lifting lead screw and the motor D, the machine is convenient to move; meanwhile, due to the arrangement of the measuring and positioningdevice, the cutting length of a steel pipe can be accurately adjusted, the accuracy is high, and the working efficiency is improved; and finally, the workpiece clamping device can clamp the workpiece,and reduction of the cutting quality caused by sliding of the workpiece during cutting is avoided.

Owner:TIANJIN XINGKAI SPORTS INSTR

Steel pipe cutting device and cutting method thereof

PendingCN108380963AChange cutting lengthSimple cutting methodTube shearing machinesArchitectural engineering

The invention provides a steel pipe cutting device and a cutting method thereof. The device comprises a workbench, a fixing clamping plate and an adjustment clamping plate are oppositely arranged on the workbench, and a mounting hole is formed in the fixing clamping plate; an adjustable mold for supporting a steel pipe to be cut is coaxially arranged in the mounting hole, a sliding groove is formed in the workbench, and two guide holes are formed in the bottom of the adjustment clamping plate; a guide rod penetrates through the guide holes, the two ends of the guide rod are fixed to the side wall of the sliding groove separately, and the guide rod is parallel to the axis of the mounting hole; the adjustment clamping plate is connected with a first retractable rod, the first retractable rodis parallel to the guide rod, and multiple annular grooves which are coaxial with the mounting hole are formed in the surface of the adjustment clamping plate opposite to the fixing clamping plate; acutter is arranged over the steel pipe to be cut and fixed to a rotation shaft of a rotation motor, the rotation motor is fixed on a retractable device, and a Y-shaped rack is arranged on the portion, between the cutter and the adjustment clamping plate, of the workbench. According to the steel pipe cutting device, the adjustment clamping plate can move horizontally along the guide rod to adjustthe length of the steel pipe to be cut.

Owner:TIANJIN PIPELINE ENG GROUP

Cutting device for log machining

InactiveCN110625700AChange cutting lengthMeet the needs of different cutting lengthsProfiling/shaping machinesBark-zones/chip/dust/waste removalEngineeringMachining

The invention discloses a cutting device for log machining. The device comprises a box body, a first conveyor belt and a second conveyor belt, wherein a second electric push rod is arranged on the inner wall of the top of the box body, a fixing plate is connected to the outer wall of one end of the second electric push rod, a protective shell is arranged on the outer wall of one side of the fixingplate, a motor is arranged on the inner wall of one side of the protective shell, a cutting wheel is arranged on the outer wall of one end of a motor output shaft, a liquid storage box is arranged onthe outer wall of the top of the box body, a connecting pipe is inserted into the outer wall of one side of the liquid storage box, one end of the connecting pipe extends into the box body, and an atomizing nozzle is in threaded connection with the outer wall of one end of the connecting pipe. According to the device, when the cutting wheel cuts a log, a first electric push rod and a third electric push rod are started, the first electric push rod and the third electric push rod drive a fixing ring to move downwards, a wood body can be effectively fixed, the cutting work stability is guaranteed, and the cutting efficiency of the device is improved.

Owner:湖北华诺木业有限公司

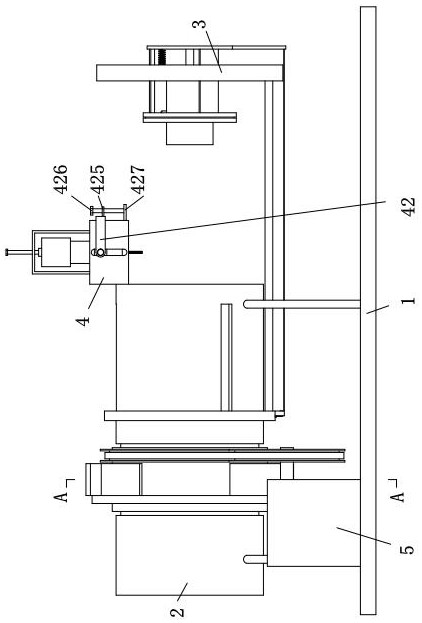

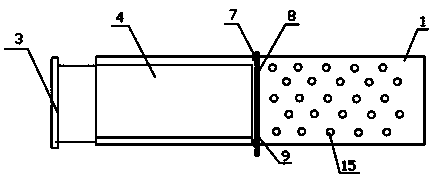

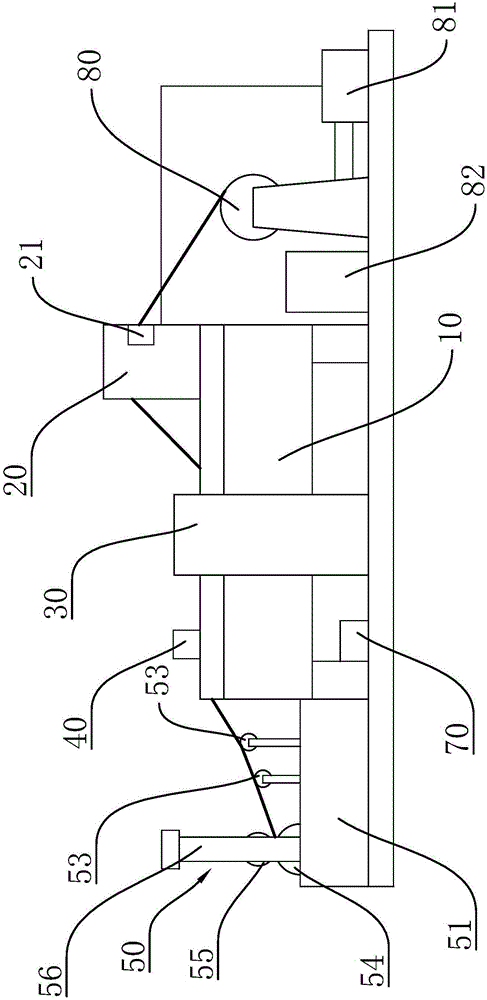

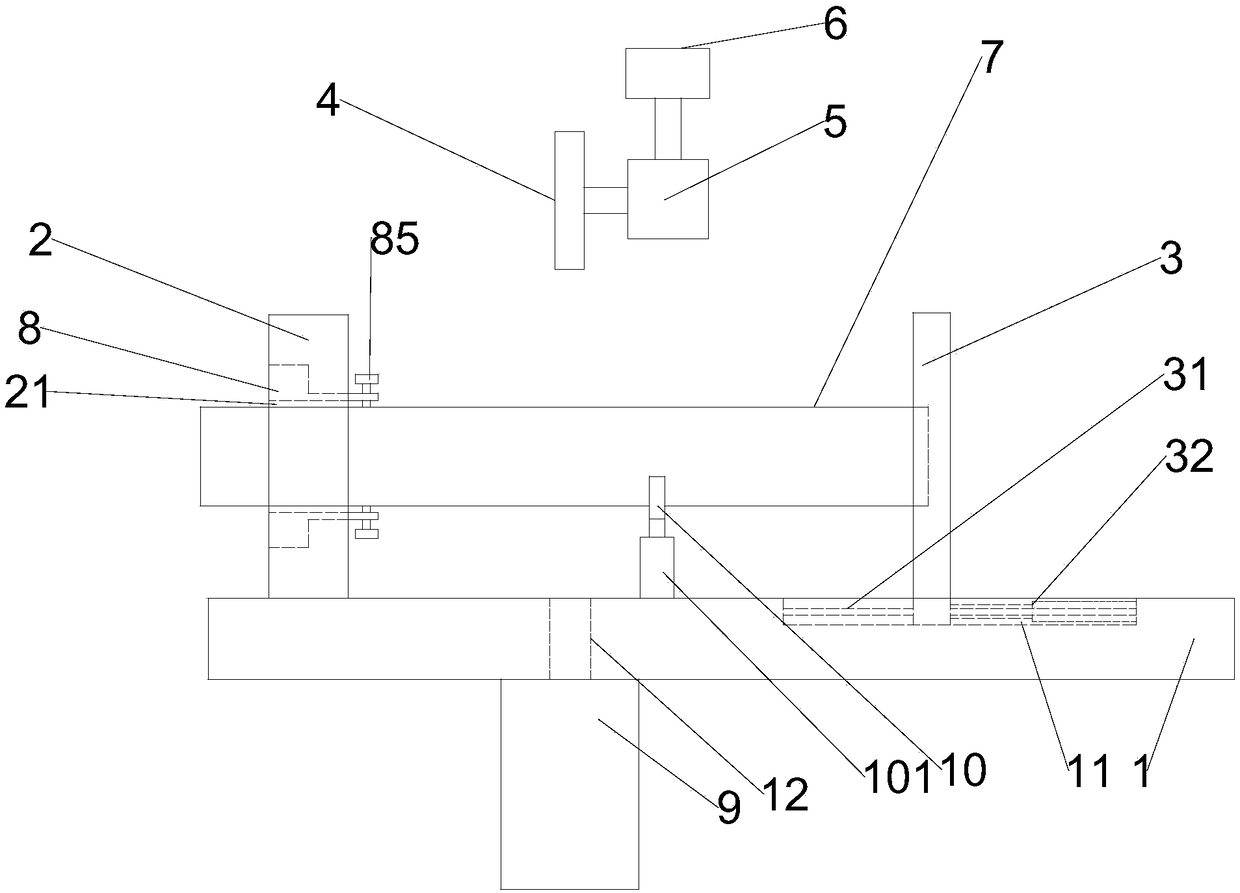

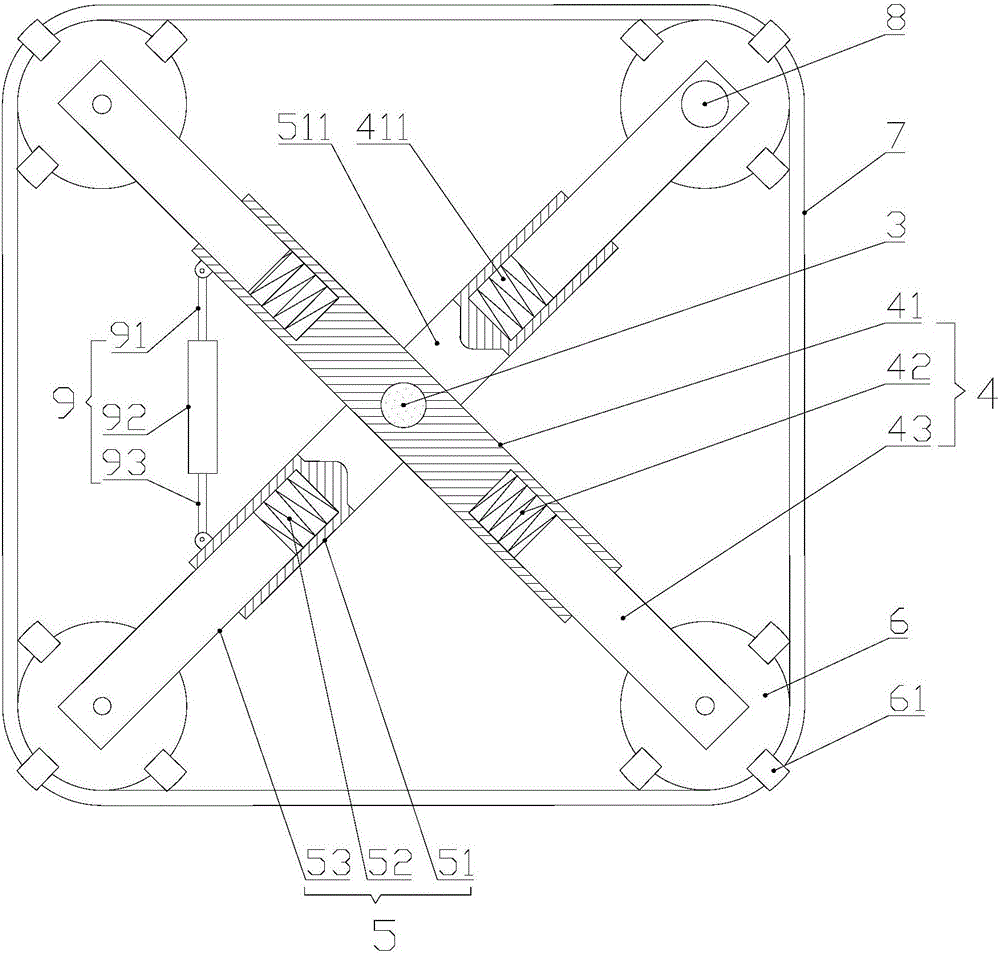

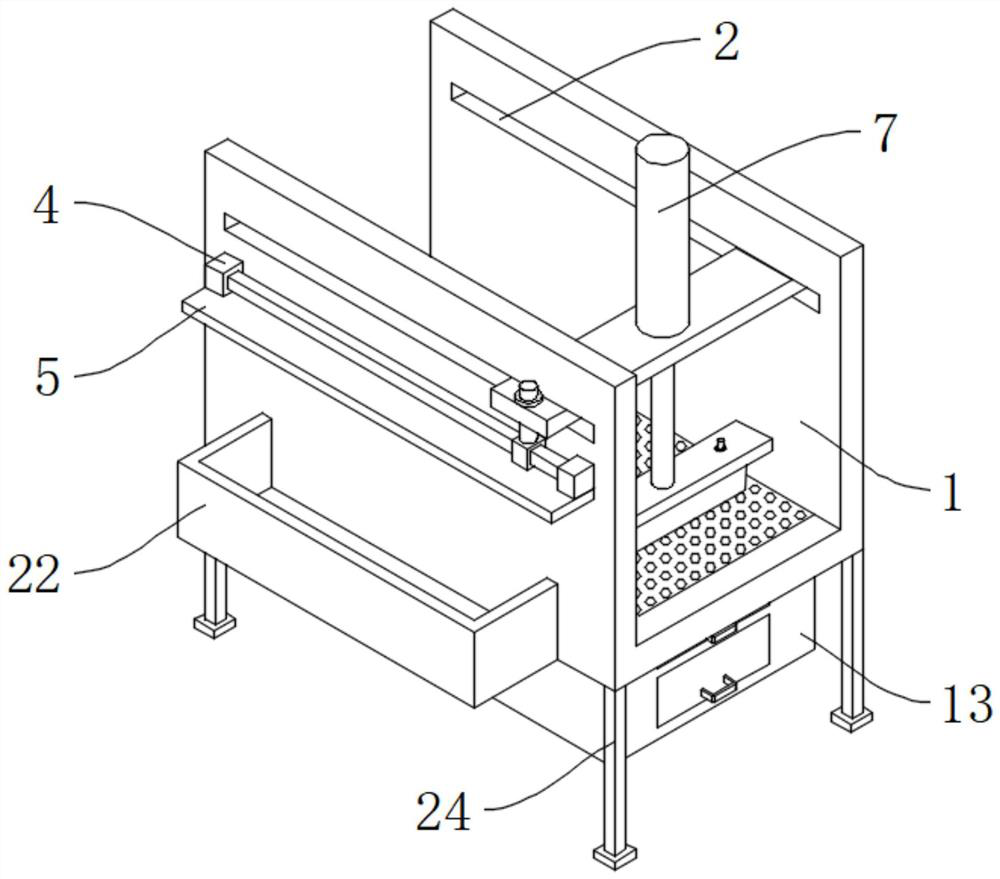

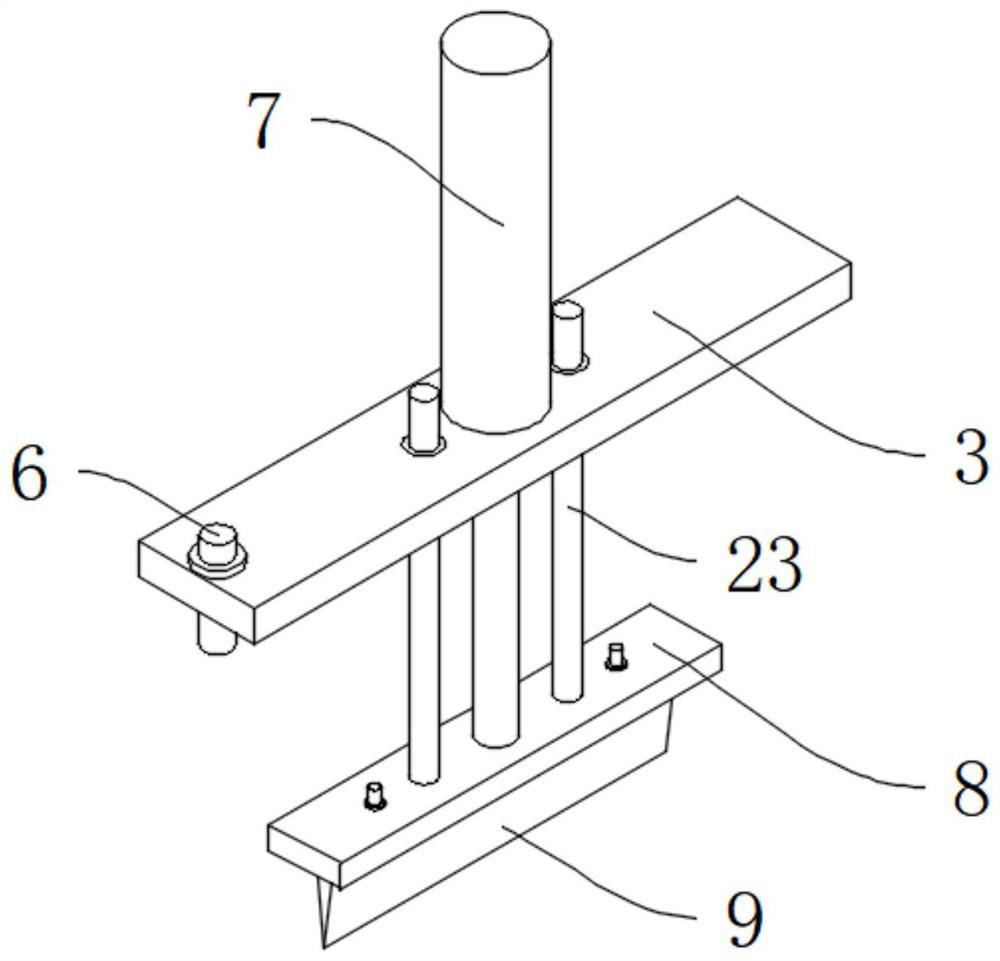

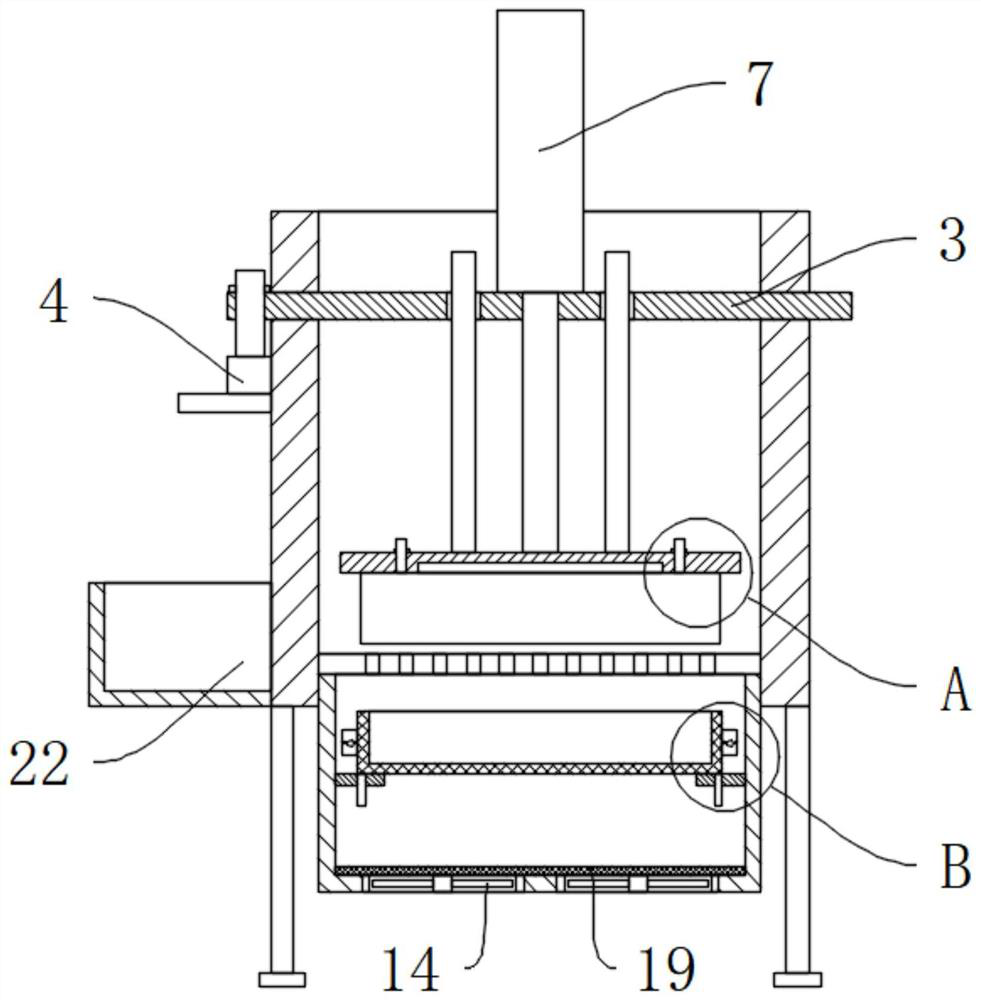

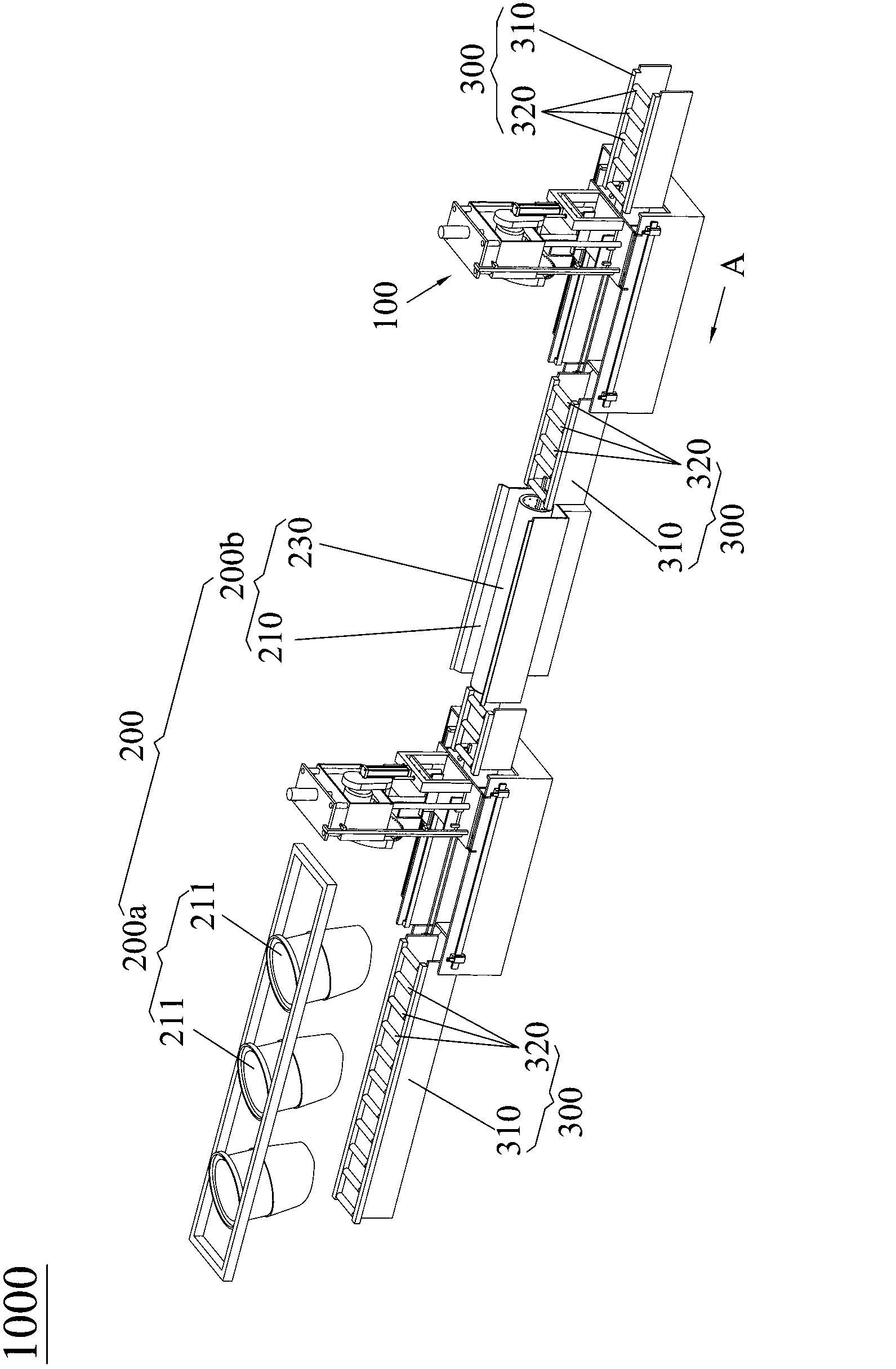

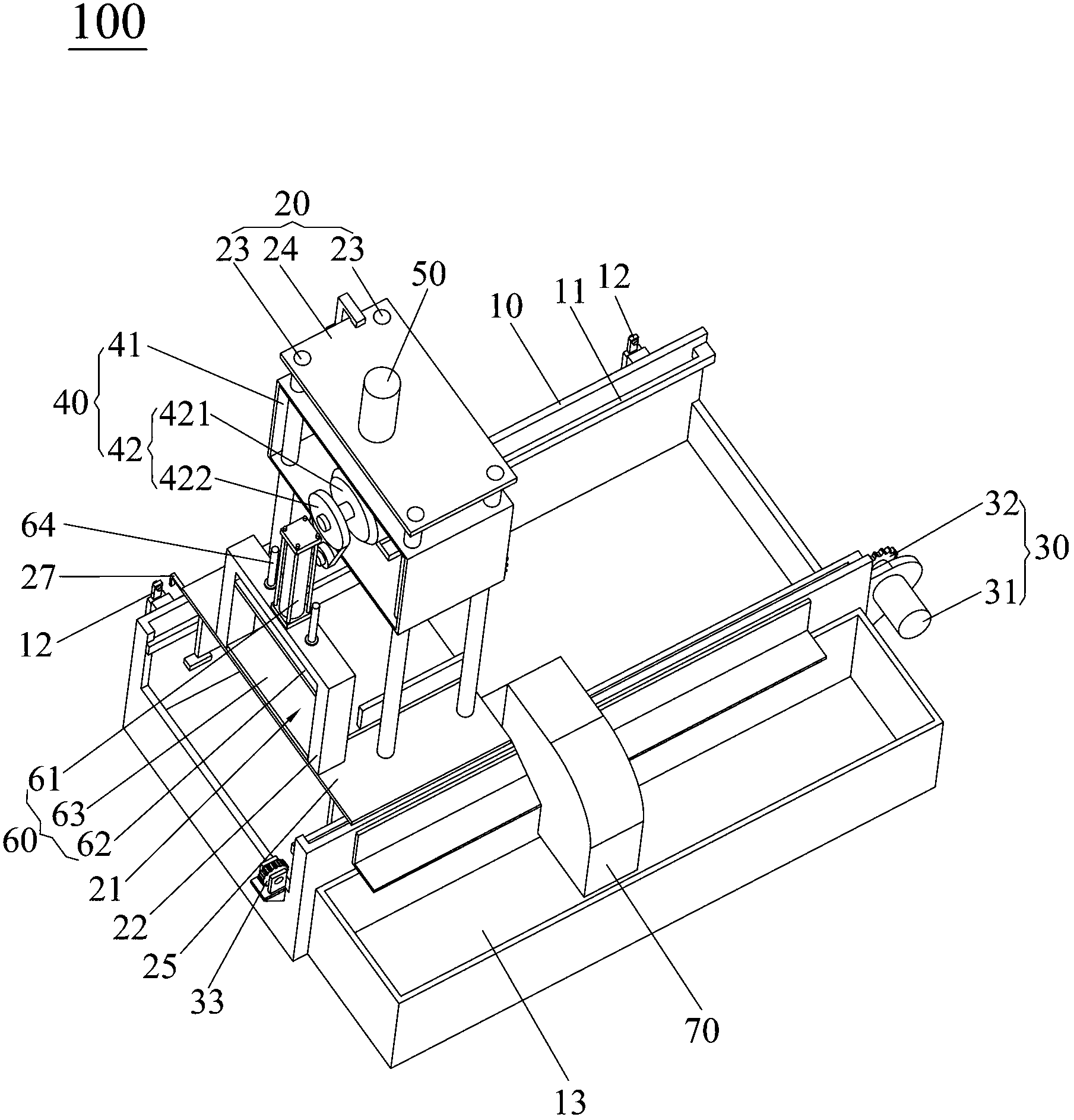

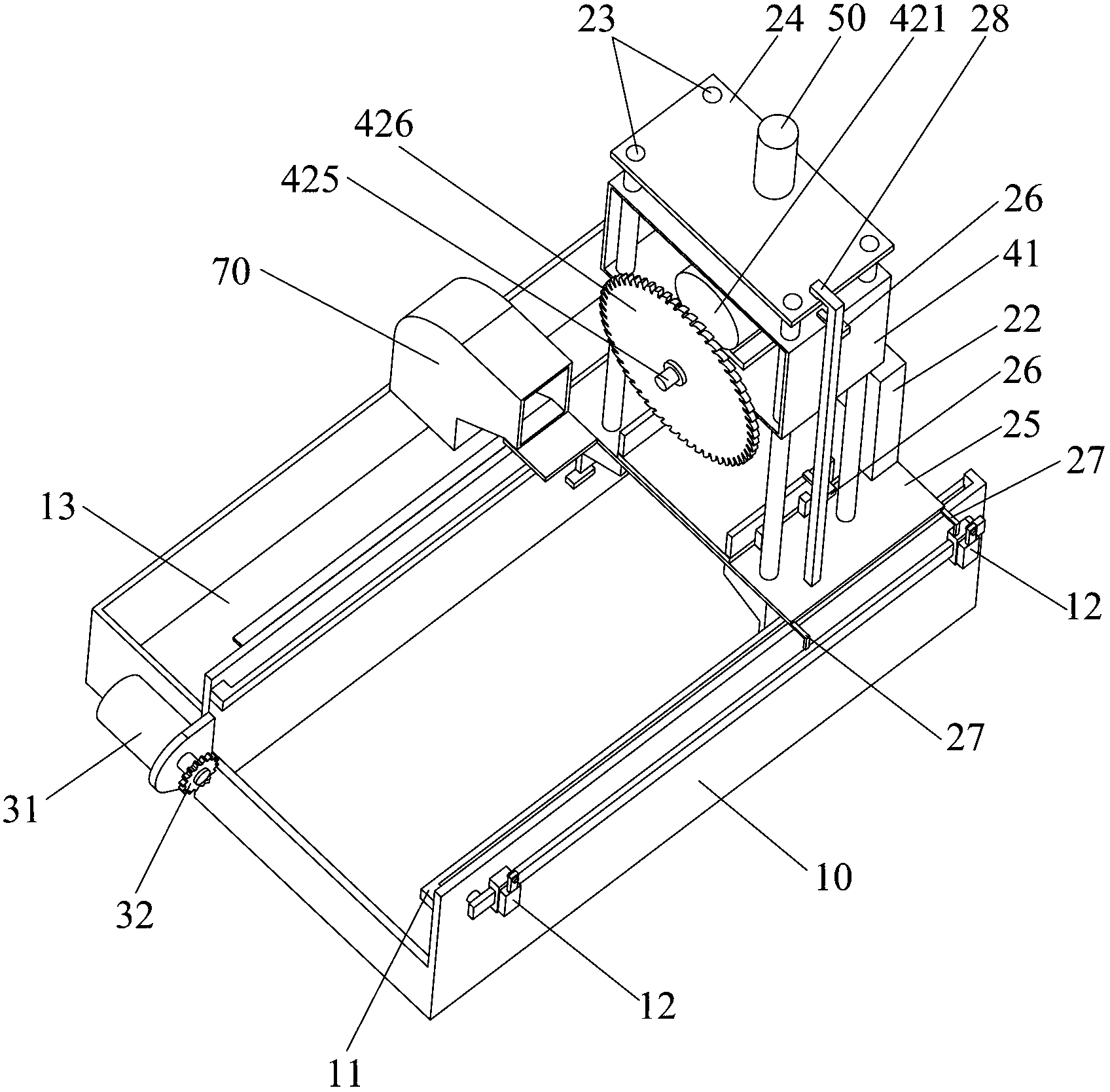

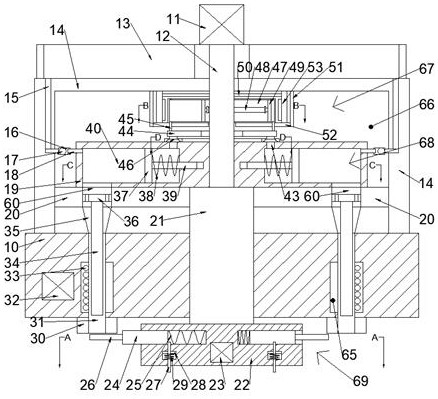

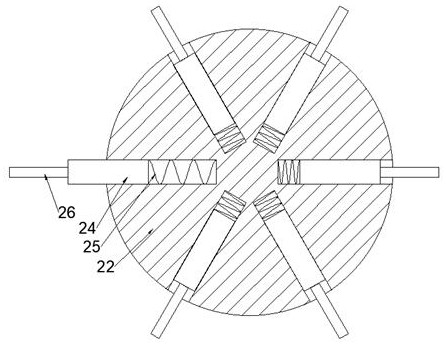

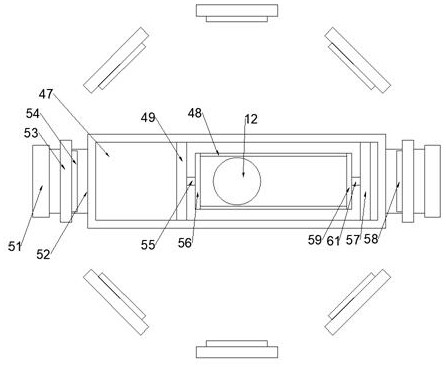

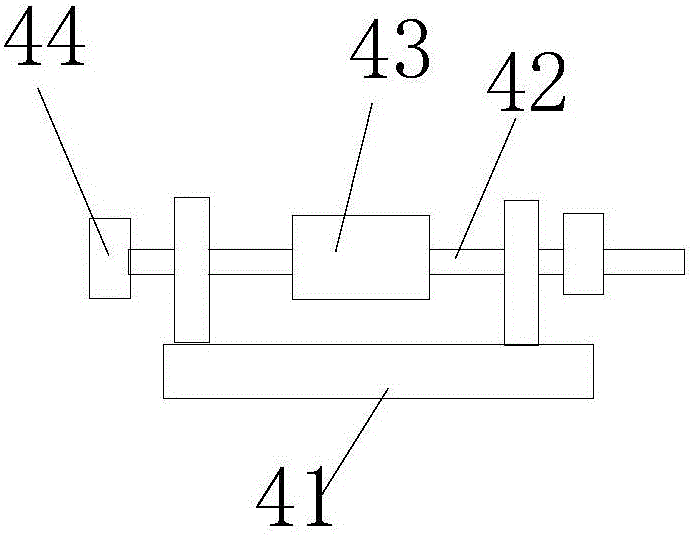

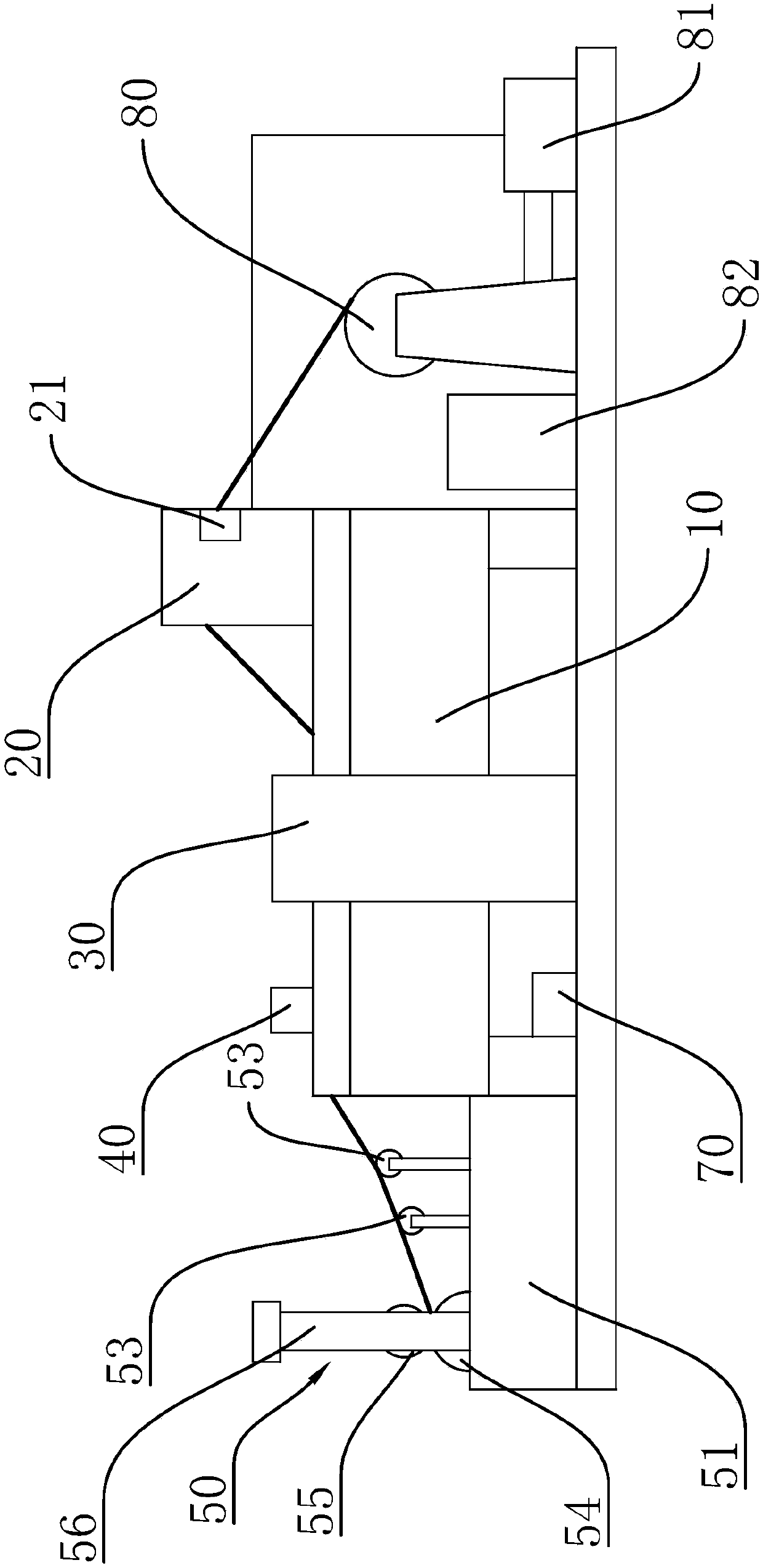

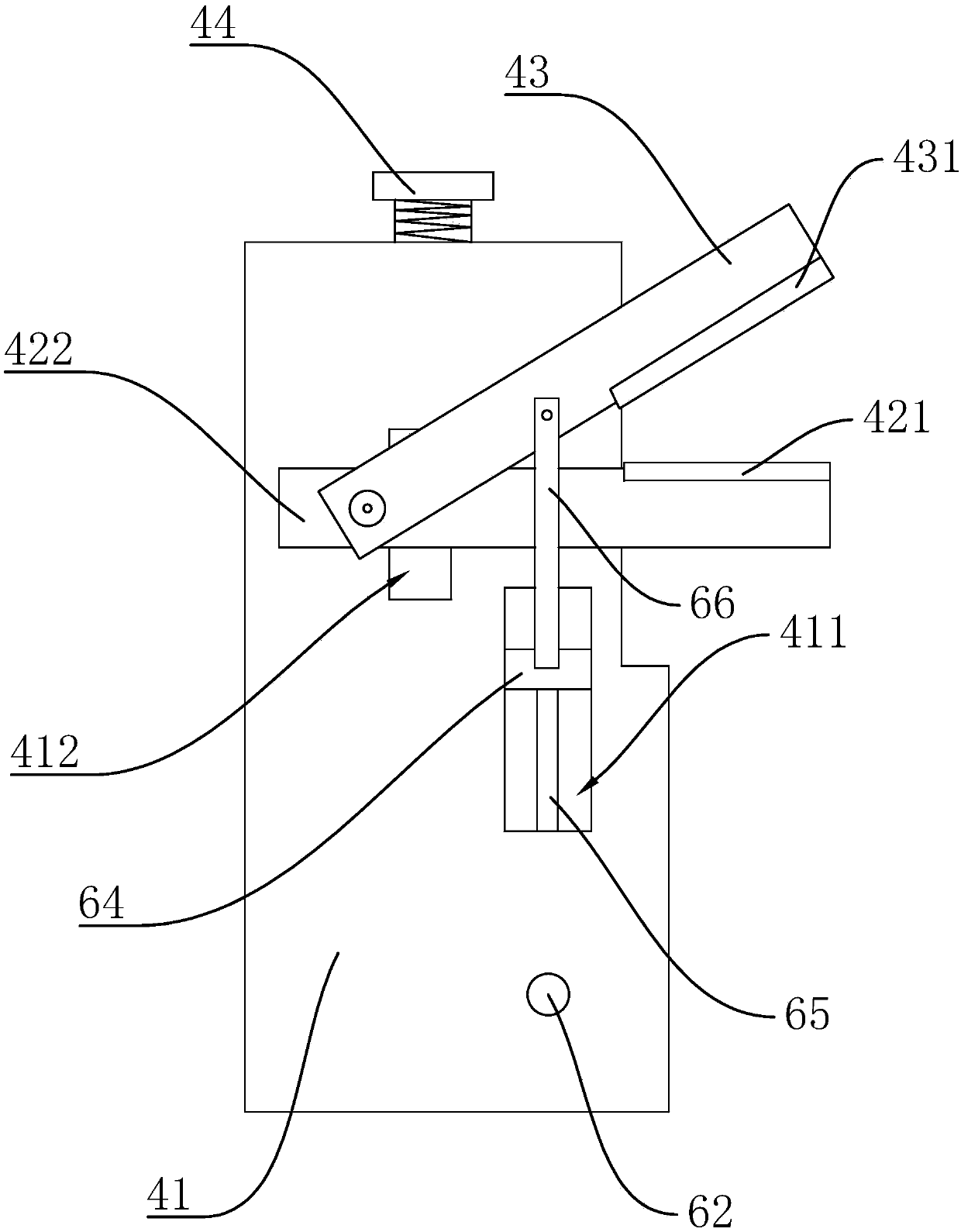

Integrated equipment for square pipe drilling and fixed length cutting

InactiveCN111791064AHighly integratedStable structureWork clamping meansOther manufacturing equipments/toolsEngineeringStructural engineering

The invention relates to the field of pipe machining, in particular to integrated equipment for square pipe drilling and fixed length cutting. The equipment comprises a conveying assembly, a perforating assembly, a locating assembly, a cutting assembly and a clamping assembly which are linearly and sequentially arranged. The conveying assembly comprises a rubber wheel conveying mechanism for conveying a square pipe forward. The perforating assembly is provided with a bearing platform. The locating assembly comprises a third supporting seat and a hole locating mechanism. The hole locating mechanism is fixedly arranged on the top of the supporting seat. The cutting assembly comprises a saw disk, wherein the position of the saw disk can be adjusted transversely. The square pipe sequentially penetrates the rubber wheel conveying mechanism, the bearing platform, the hole locating mechanism and the clamping assembly. The saw disk is located over the square pipe. According to the integrated equipment for square pipe drilling and fixed length cutting, functions such as conveying, drilling and cutting are integrated into one, the integration degree is high, the structure is reliable, and land occupying space is little; and in the meantime, the cutting length can be adjusted freely, and the use is flexible.

Owner:姚国成

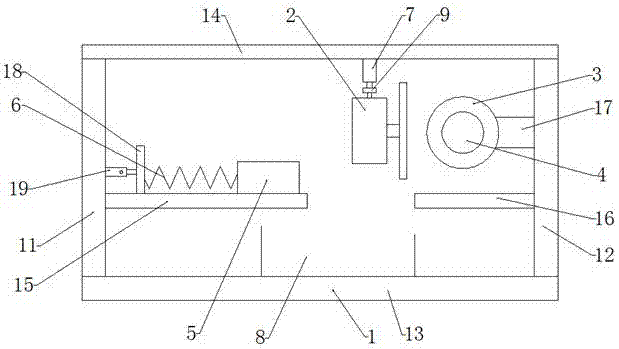

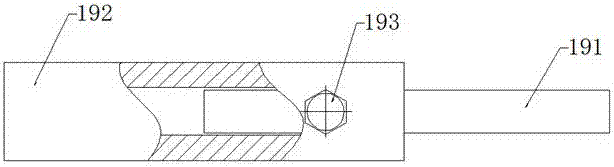

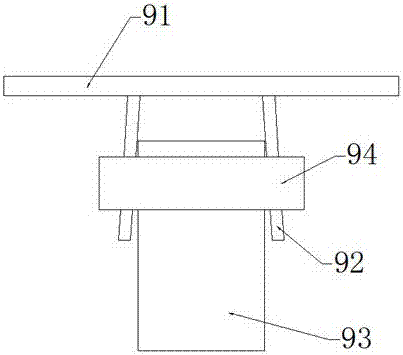

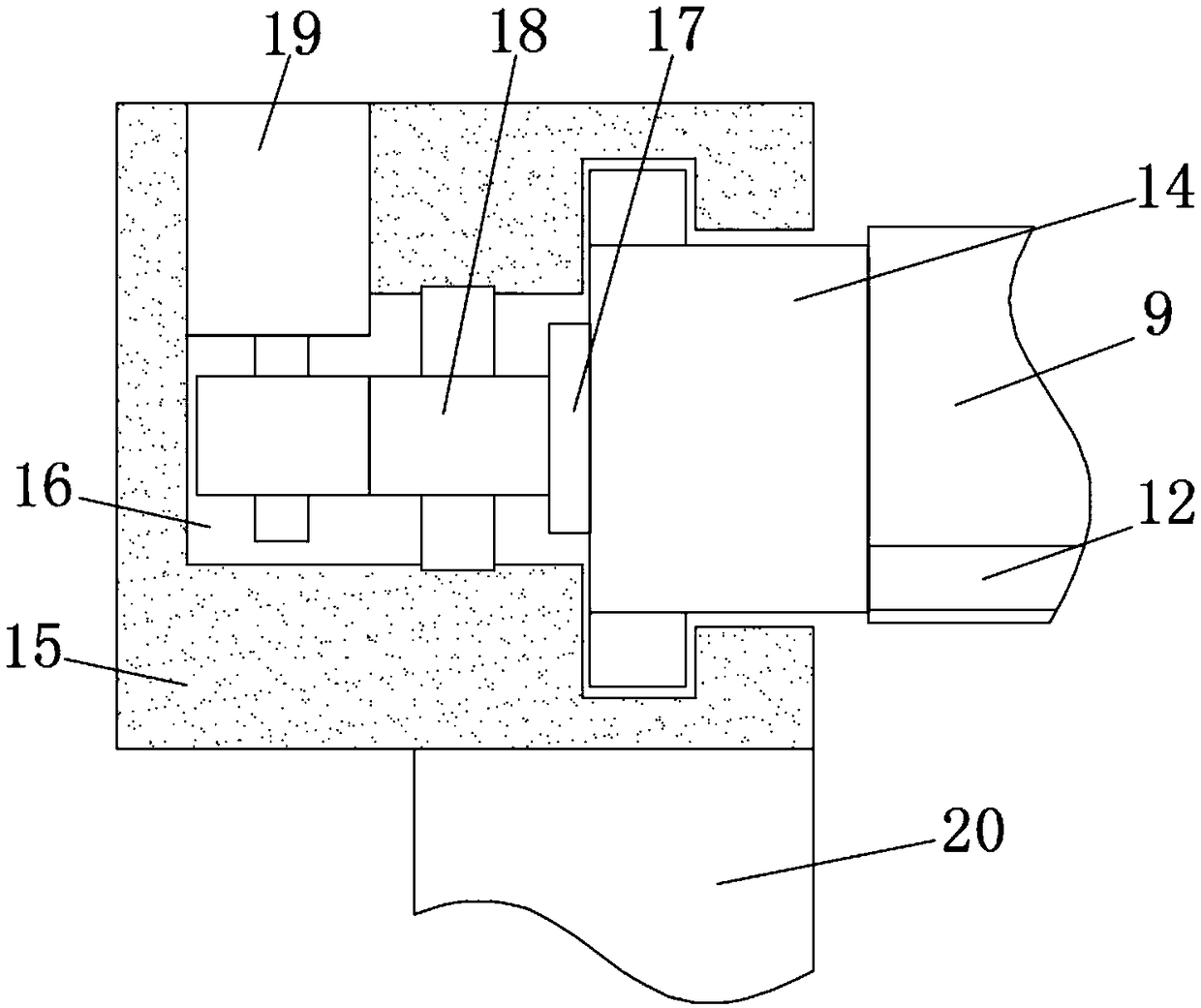

Automatic cutting device for door-window manufacturing material

InactiveCN106863403ASimple structureChange cutting lengthMetal working apparatusHydraulic cylinderSlide plate

The invention discloses an automatic cutting device for door and window materials. A limit slide is installed on the left side plate. The limit slide is installed on the limit slide and can move freely along the left and right directions. A compression spring is installed between the left side plates; a force sensor is installed at the end of the compression spring; a placement plate is installed on the right side plate, the height of the placement plate is the same as that of the limit slide plate; A motor bracket is arranged above the placing plate, the motor is fixedly installed on the motor bracket, and a pressure roller is fixedly installed on the output shaft of the motor; a hydraulic cylinder is installed on the top plate, and the tail of the hydraulic cylinder is fixedly installed on the top plate. The push rod portion of the hydraulic cylinder is fixedly connected with a cutting machine, and the cutting piece on the cutting machine is parallel to the right side plate. The invention has the advantages of simple structure, can adjust multiple different cutting lengths and cutting certificates, and can also cut oblique angles.

Owner:响水县泽州开发有限公司

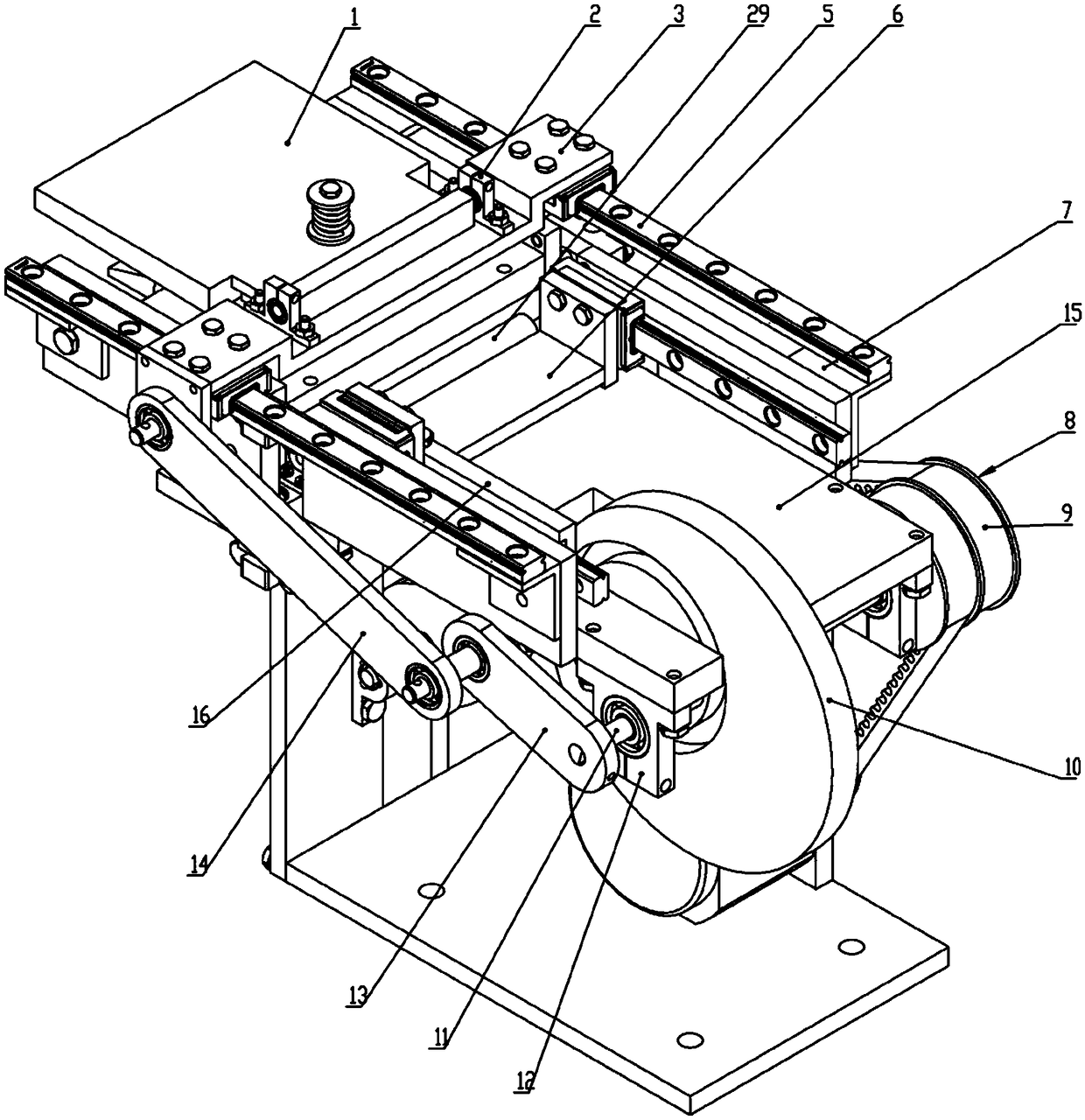

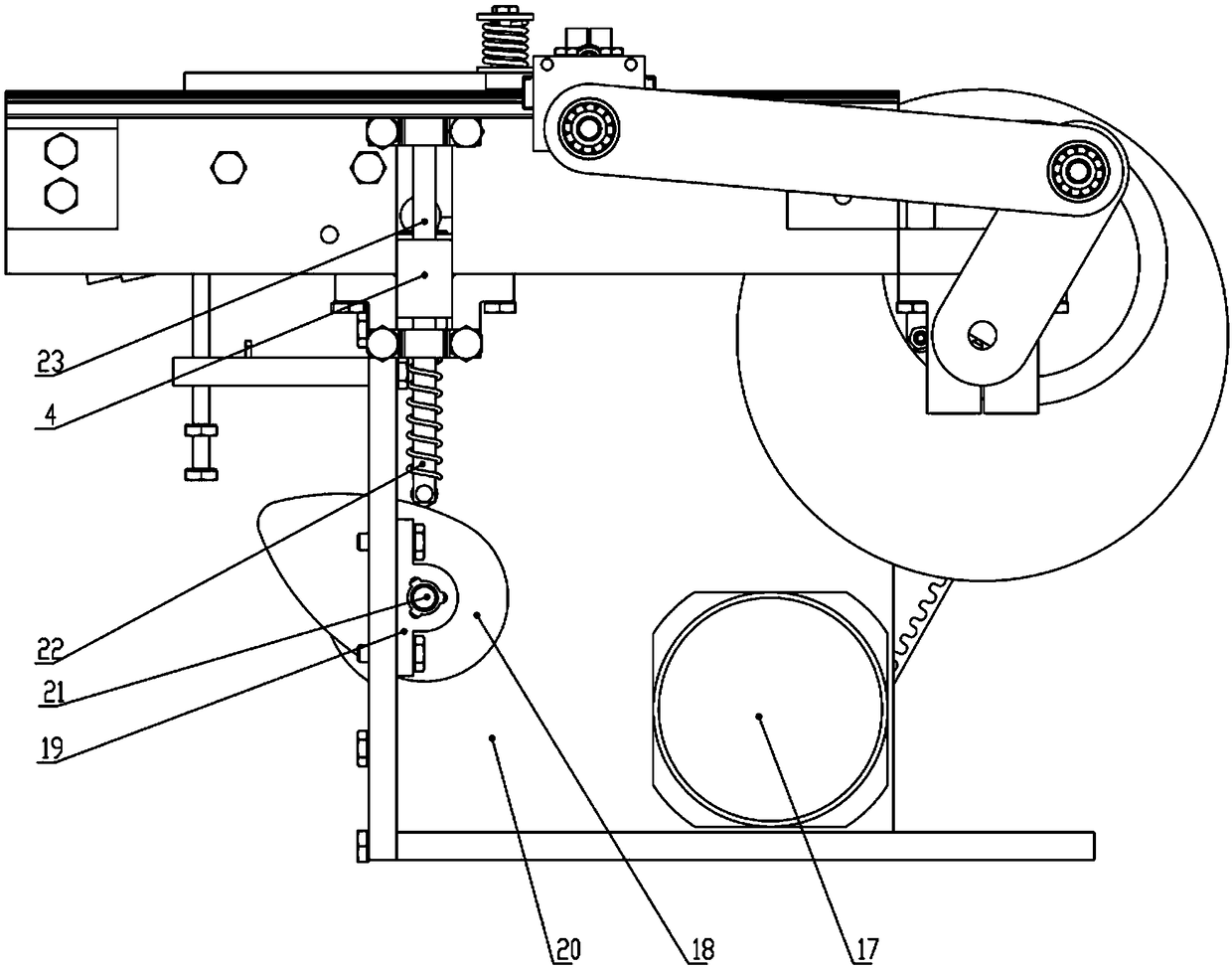

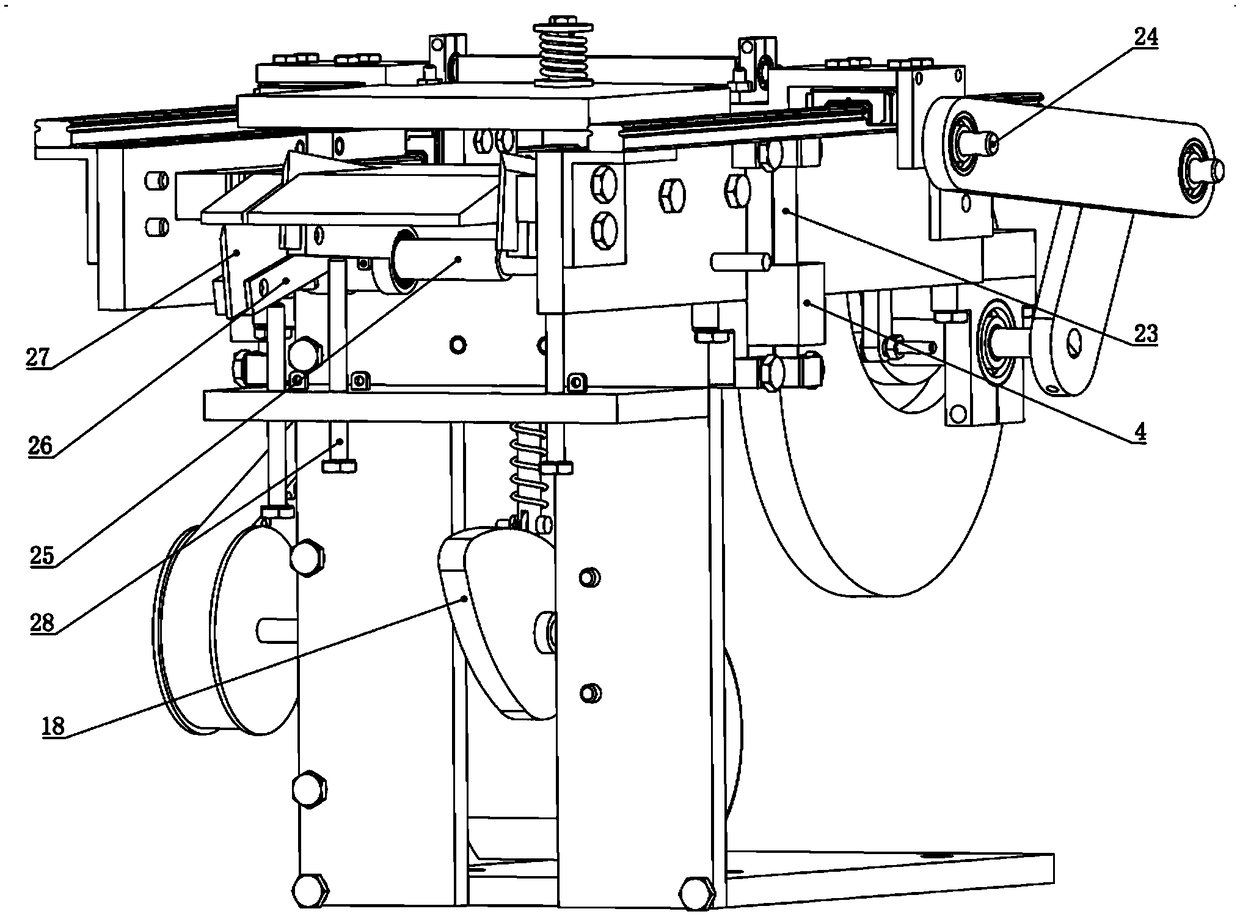

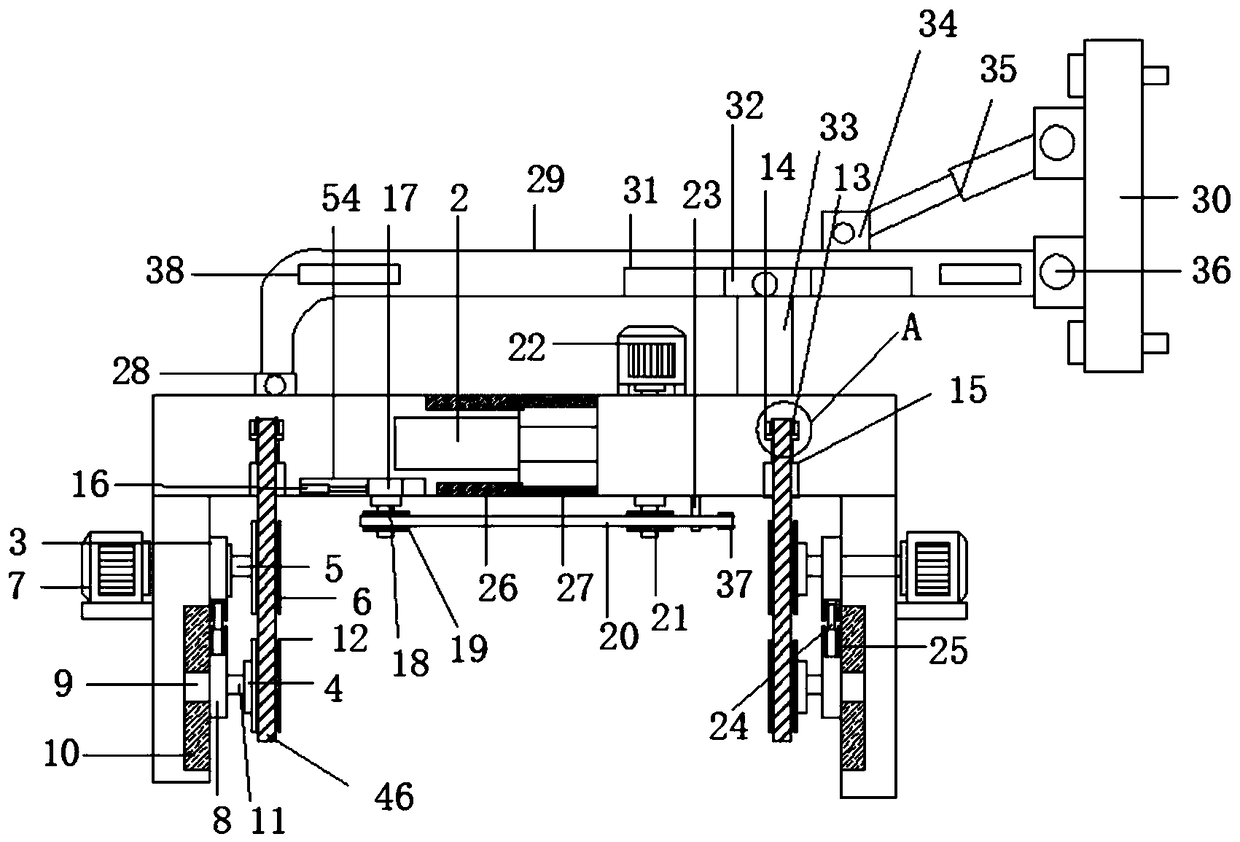

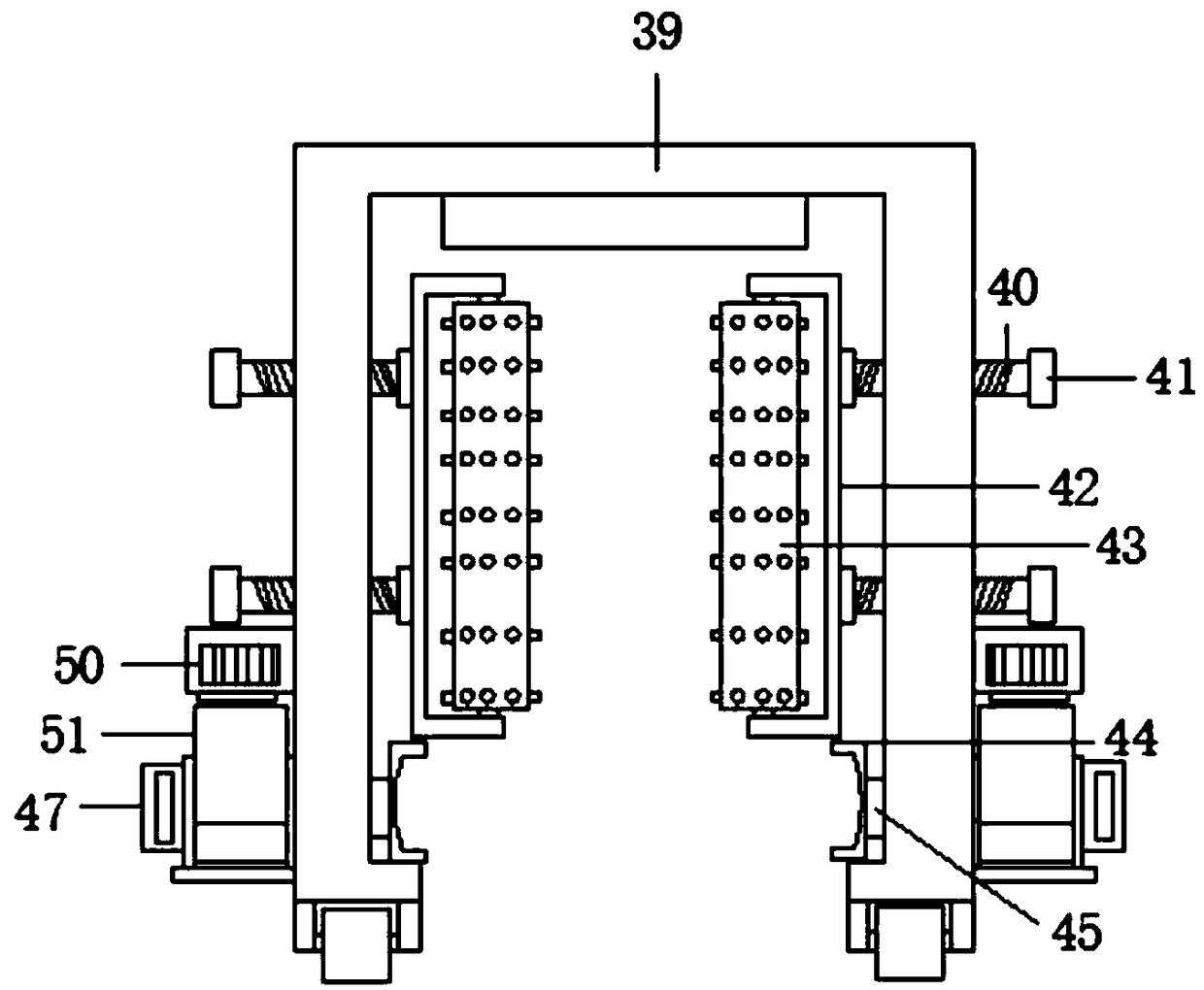

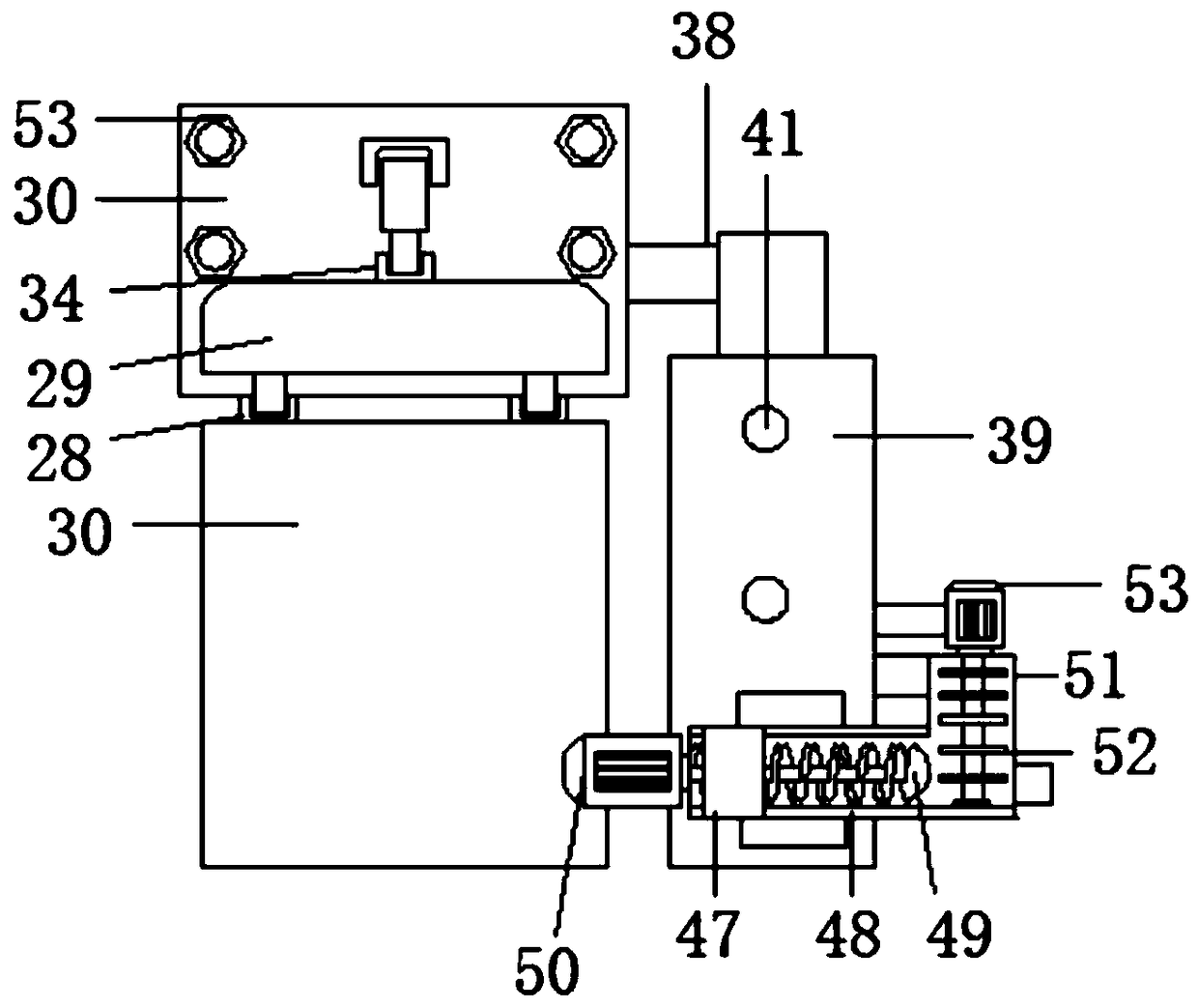

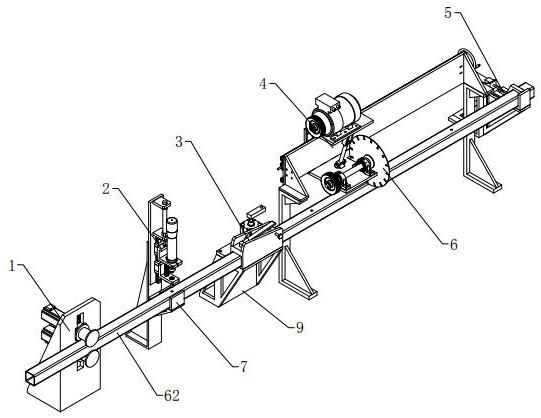

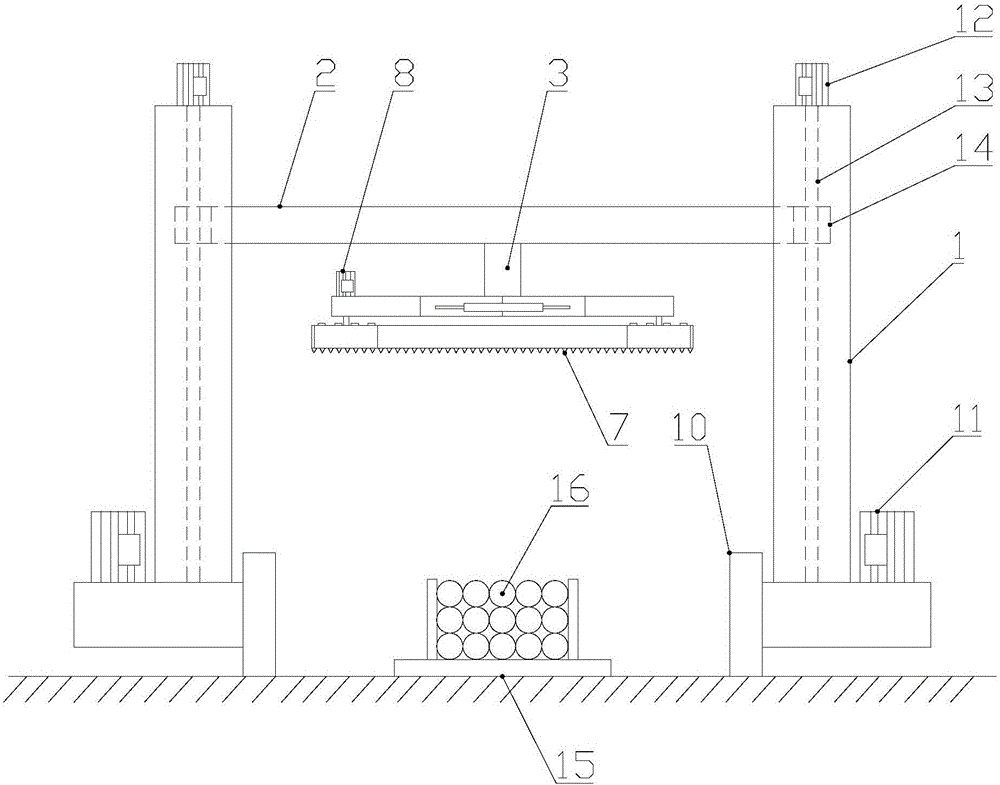

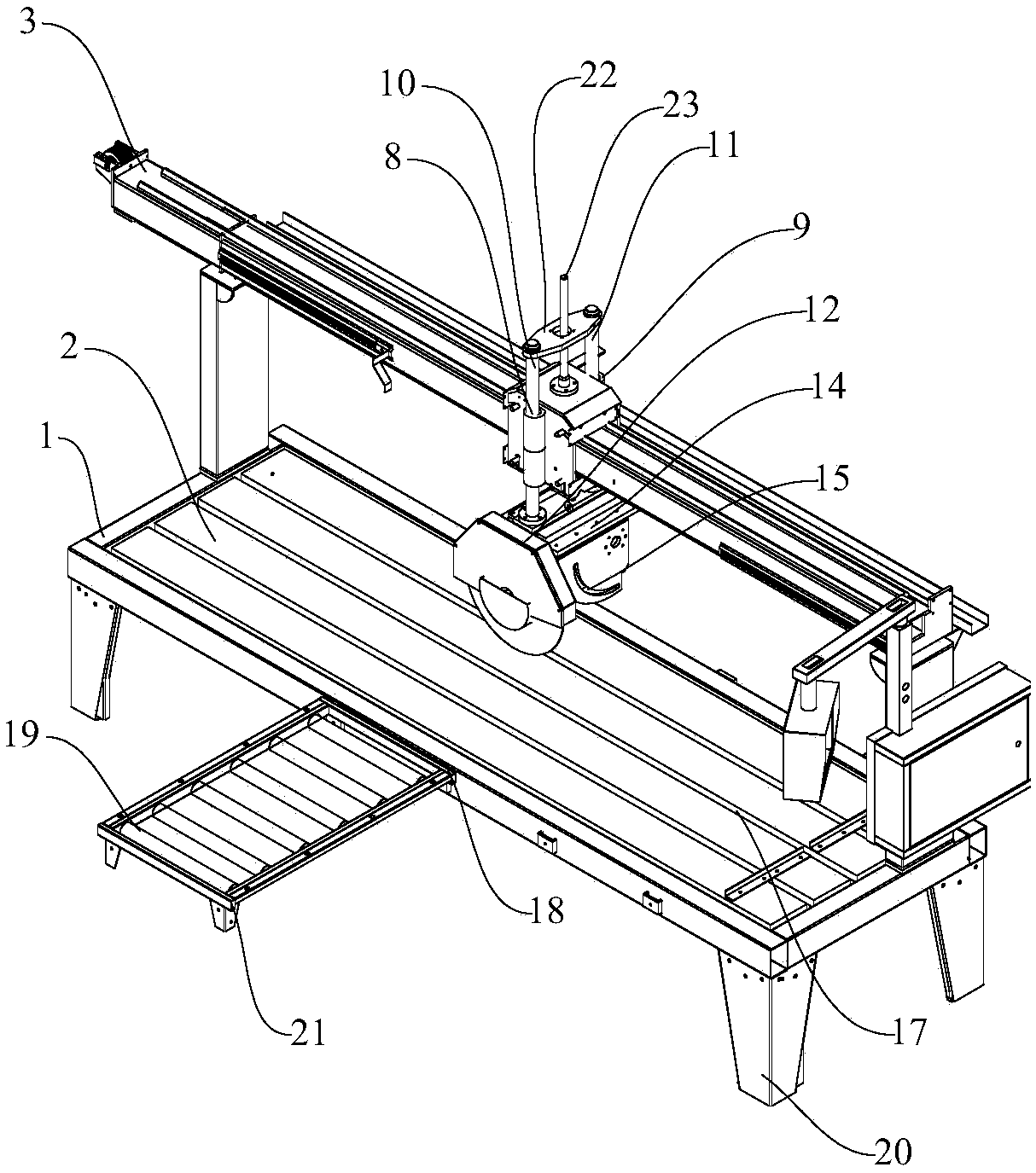

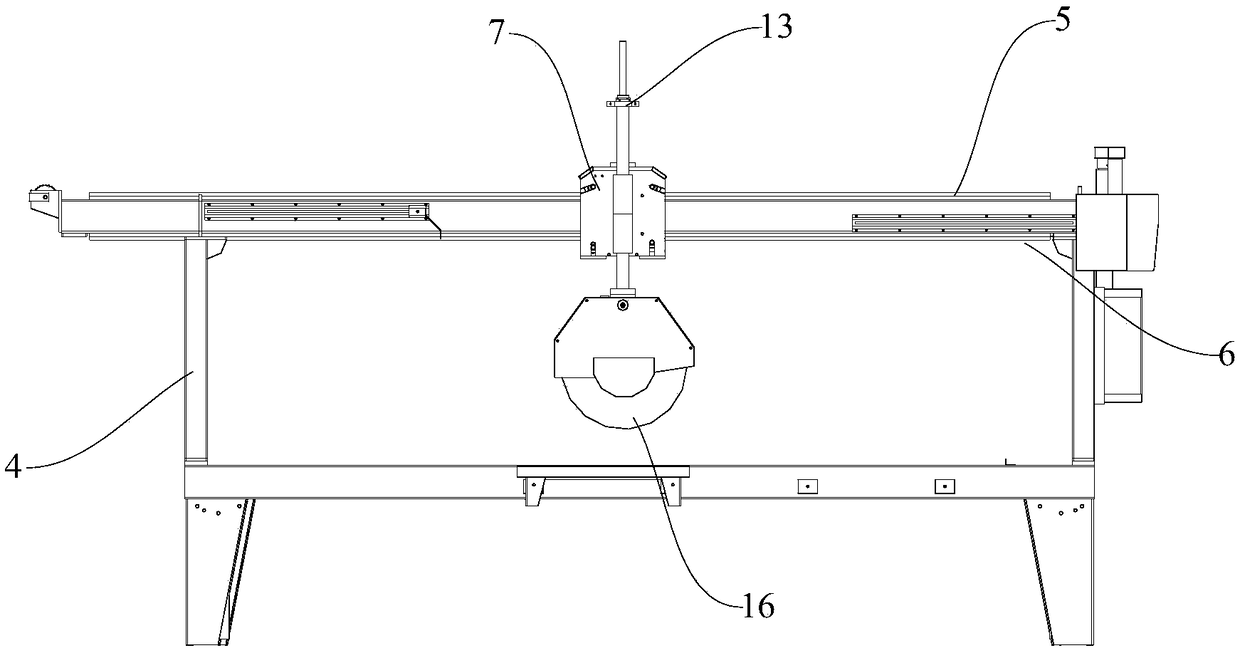

Gantry-type bar cutting machine allowing cutting length to be adjustable

The invention discloses a gantry-type bar cutting machine allowing the cutting length to be adjustable. The gantry-type bar cutting machine comprises a gantry framework, a cutting mechanism, a running mechanism, a feeding mechanism and a work table, wherein the gantry framework is provided with two gantry stand columns and a gantry cross beam which is used for connecting the two gantry stand columns and can move up and down; the cutting mechanism comprises a first support, a second support, four guide wheels, band saw strips, a cutting motor and an adjusting mechanism, the first support and the second support are transversely arranged below the gantry cross beam and are equal in length, the four guide wheels are arranged at the two ends of the first support and the two ends of the second support correspondingly, the band saw strips are arranged on the outer sides of the four guide wheels in a sleeving manner, and the cutting motor drives any guide wheel to rotate; the running mechanism is arranged at the lower ends of the gantry stand columns and used for driving the gantry stand columns to move left and right; the feeding mechanism is arranged on the gantry stand columns and used for driving the gantry cross beam to move up and down; and the work table is located between the two gantry stand columns. According to the bar cutting machine of the structure, two sections of bars can be cut out from one single bar through cutting motion each time, moreover, the cutting mechanism is moved to carry out cutting of the next time, and the cutting efficiency is improved greatly compared with that of traditional cutting equipment.

Owner:CHONGQING JIEJIATAI MACHINE MFG CO LTD

Steel pipe cutting and port grinding integrated device for building construction

InactiveCN112621237AEffective grindingChange cutting lengthHollow article cleaningOther manufacturing equipments/toolsElectric machineConstruction engineering

The invention discloses a steel pipe cutting and port grinding integrated device for building construction. The steel pipe cutting and port grinding integrated device for building construction comprises a transverse plate, and supporting legs are fixed to the four corners of the bottom face of the transverse plate correspondingly. According to the device, through the arrangement of an arc-shaped plate and a U-shaped supporting plate, the purpose of stably fixing a steel pipe can be effectively achieved, through the arrangement of a motor, a dust collector and an air blower, the cut-off steel pipe can be driven by the motor to just move to the position between a through hole and a barrel body, and then the cleanliness of an inner cavity of the cut-off steel pipe is effectively guaranteed; in addition, through the arrangement of an arc-shaped frosted plate, burrs generated when the end of the steel pipe is cut can be effectively removed through grinding, at the moment, two U-shaped supporting plates originally located at the lower end of a rotating shaft can rotate to the upper end of the rotating shaft, and at the moment, the steel pipe to be cut can be continuously pushed towards the direction of a circular plate; and when the motor is started again, the cut steel pipe can fall into a pre-placed collecting groove through an opening in the barrel body, and then the purpose of conveniently collecting the cut steel pipe is achieved.

Owner:乌云毕力格

Rotary ice-cutting laser machine

PendingCN110434482ARealize automatic cuttingChange cutting lengthLaser beam welding apparatusLight guideEngineering

The invention provides a rotary ice-cutting laser machine. The rotary ice-cutting laser machine comprises a working frame, a thermostat, a laser tube, a water tank, a light guide arm assembly, a laserhead body and a supporting assembly. The supporting assembly comprises an L-shaped support, a locked type sliding rail, a driving rubber roller, a driven rubber roller and a driving motor; the L-shaped support is fixed on the working frame; the locked type sliding rail is horizontally arranged on one side of the L-shaped support; two locked type sliding blocks are arranged on the locked type sliding rail; two slide rail locking blocks are further arranged between the two locked type sliding blocks; ice column baffle blocks are fixed on the slide rail locking baffle blocks; a rubber coating bearing is further arranged on the opposite side of the two ice column locking blocks; a first synchronous pulley is connected to one end of a roller shaft of the driving rubber roller; a second synchronous pulley is connected to a motor shaft of the driving motor; and the first synchronous pulley and the second synchronous pulley are transmitted through a belt. According to the rotary ice-cutting laser machine, the normal automatic cutting of cylindrical ice products can be realized under a low-temperature working condition, and the cutting lengths of ice columns can be adjusted more flexibly.

Owner:SUZHOU CHANXAN LASER TECH

Copper foil plate shearing machine for bimetallic material plate

PendingCN114147274AChange cutting lengthAutomatic control devicesShearing machinesElectric machineMetallic materials

The invention discloses a copper foil plate shearing machine for a bimetallic material plate, and belongs to the technical field of copper foil processing, the copper foil plate shearing machine comprises a mounting frame, a plate shearing assembly is mounted on the inner side of the mounting frame, and a recycling assembly is mounted at the bottom of the mounting frame; the plate shearing assembly comprises sliding grooves symmetrically formed in the two sides of the mounting frame and a sliding plate movably inserted between the two sliding grooves, a linear guide rail motor is mounted on the outer wall of one side of the mounting frame, and a first threaded rod is in threaded connection between the top of the output end of the linear guide rail motor and the corresponding side of the sliding plate; a hydraulic rod is installed in the center of the top of the sliding plate, the output end of the hydraulic rod penetrates through the top of the sliding plate and is connected with a connecting plate, and two guide rods are symmetrically connected to the top of the connecting plate. According to the copper foil plate shearing machine for the bimetallic material plate, the cutting length of copper foil can be conveniently and stably adjusted, and excess materials and waste residues generated by cutting can be classified and recycled.

Owner:苏州牧喆电子有限公司

Strip wood equal-length cutting equipment

InactiveCN107932637AReduce work accidentsChange cutting lengthProfiling/shaping machinesCouplingPulp and paper industry

The invention relates to cutting equipment, in particular to strip wood equal-length cutting equipment. The strip wood equal-length cutting equipment can adjust wood cutting lengths, and can cut woodsby the same lengths. The strip wood equal-length cutting equipment comprises a mounting frame, a first slide rail, a first slide block, a connecting plate, a motor, a cutting wheel and the like; thefirst slide rail is arranged in the middle part of the inner side of the right wall of the mounting frame; the first slide block is slidingly arranged in the first slide rail; the connecting plate isarranged on the left side of the first slide block; the motor is mounted at the left end of the connecting plate; the cutting wheel is connected to an output shaft on the upper side of the motor through a coupling; and a first through hole is formed in the middle part of the connecting plate. The strip wood equal-length cutting equipment achieves the effects of capability of adjusting the wood cutting lengths and capability of cutting the woods by the same lengths, and enables the cutting wheel to move up and down through screwing a nut so as to achieve the effect of adjusting the wood cuttinglengths.

Owner:钟清

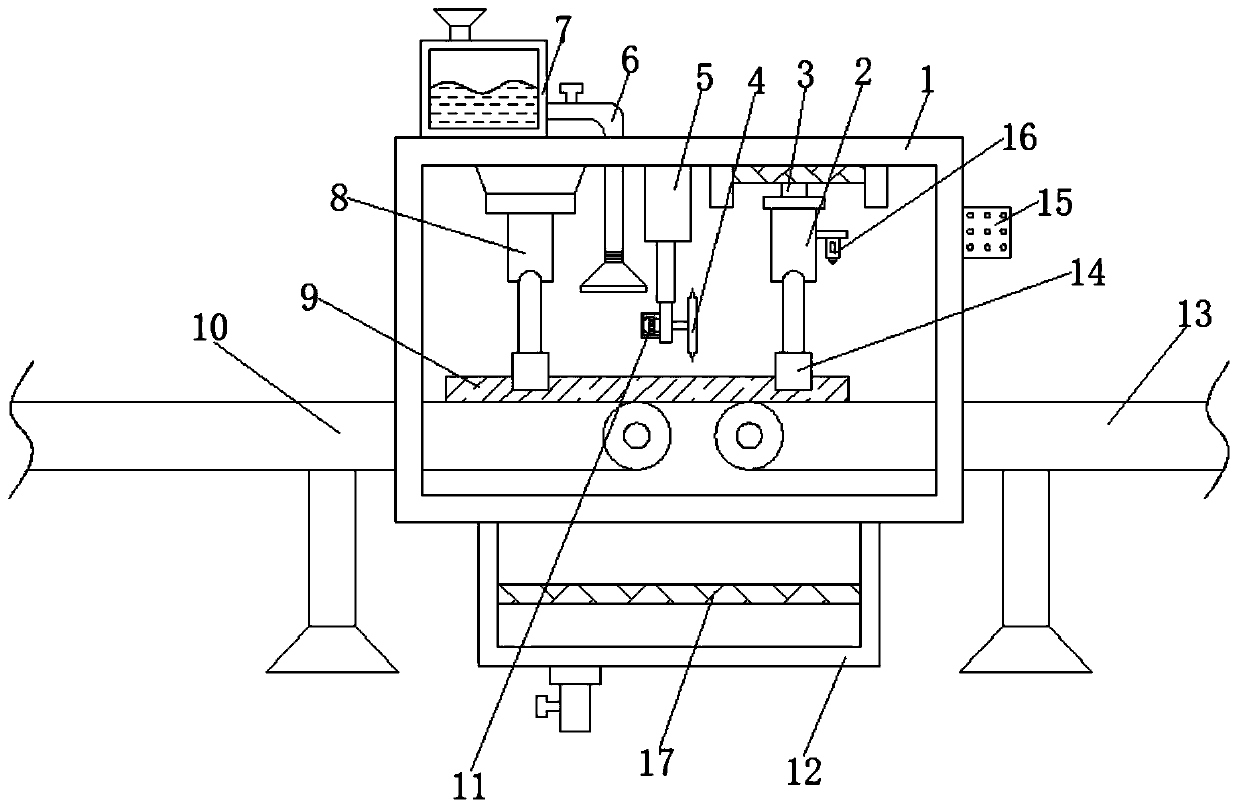

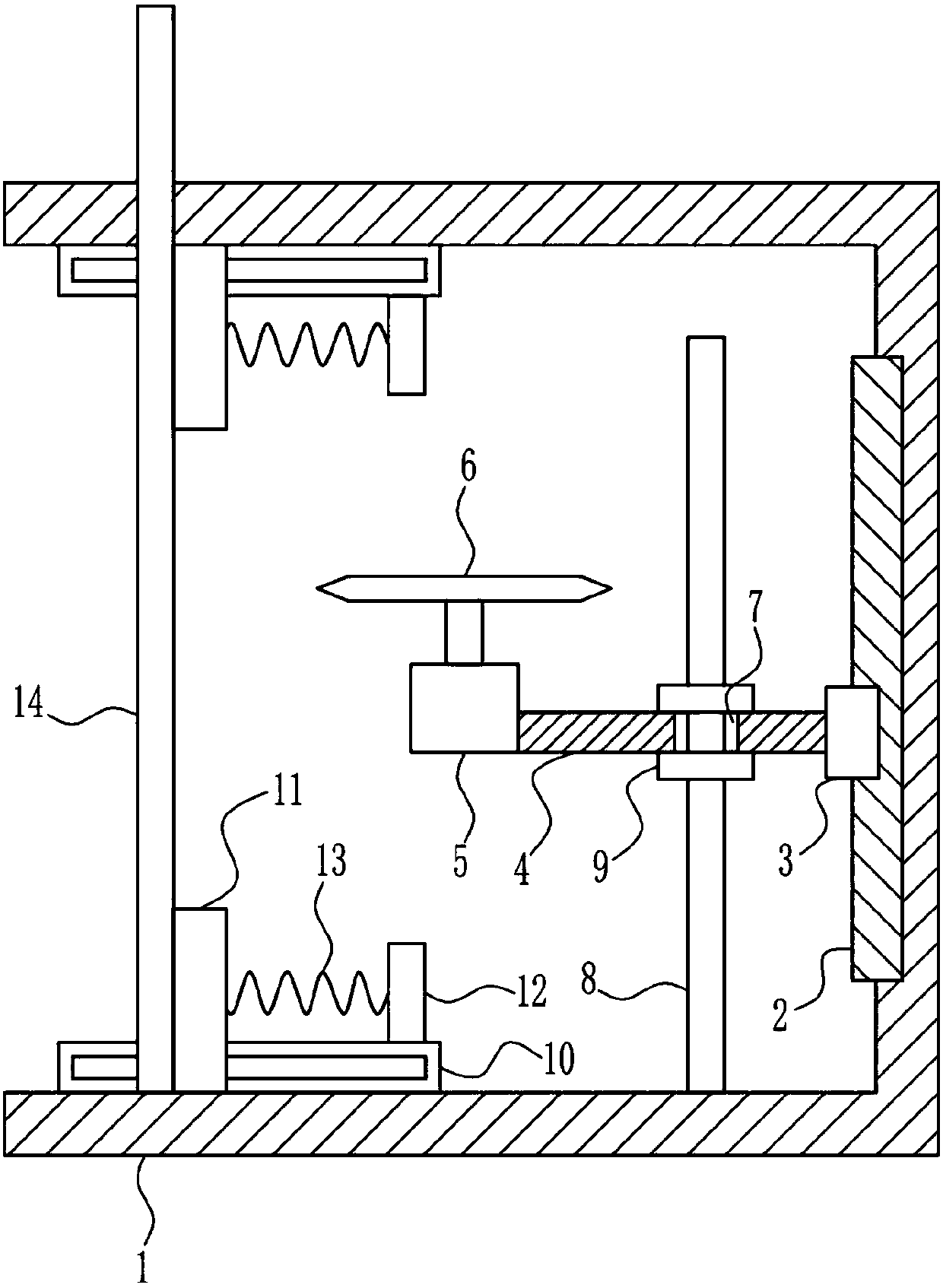

Work-piece cutting and cooling system

InactiveCN102699439AIncrease productivityReduce manufacturing costMetal sawing devicesMetal sawing accessoriesProduction lineEngineering

The invention discloses a work-piece cutting and cooling system electrically connected with a controller. The work-piece cutting and cooling system comprises a work-piece cutting device and a cooling device, wherein the work-piece cutting device comprises a bed body which is mounted on a production line, a sliding frame body which is arranged on the bed body in a sliding manner and provided with a conveying channel, a driving mechanism which is arranged on the bed body and drives the sliding frame body to slide on the bed body, a cutting mechanism which is arranged on the sliding frame body and cuts a work-piece entering into the conveying channel into work-piece sections and a cutting driver which is arranged on the sliding frame body and drives the cutting mechanism to move towards the place where the work-piece inside the conveying channel exists; the cutting driver, the driving mechanism and the cutting mechanism are electrically connected with the controller; and the cooling device is located behind the work-piece cutting device along the direction in which the production line conveys the work-piece. The work-piece cutting and cooling system, disclosed by the invention, can perform cutting process and cooling on the conveying work-piece without stopping the production line. Therefore, the work-piece cutting and cooling system, disclosed by the invention, has the advantages of improving work efficiency and changing cutting length of the work-piece to satisfy with different requirements according to the need.

Owner:东莞市润华铝业有限公司

Rapid production cutting equipment for plastic pipes

ActiveCN112519174ARapid productionEfficient productionMetal working apparatusElectric machineAir pump

The invention discloses rapid production cutting equipment for plastic pipes. The equipment comprises a machine body; a supporting body is fixedly arranged on the upper side face of the machine body;a storage box is fixedly arranged on the upper side face of the supporting body; molten plastic is stored in the storage box; a main motor is fixedly arranged on the upper side of the storage box; themain motor is in power connection with a motor shaft; a rotary supporting column is rotatably connected into the machine body; a cutting body is fixedly arranged on the lower side of the rotary supporting column; an air pump is fixedly arranged in the cutting body; six fixed blocks are fixedly arranged on the lower side face of the machine body in a circumferential array mode; six cooling cavities corresponding to the fixed blocks are formed in the machine body; a pressure device pushed through magnetic force is arranged on the upper side of a power cavity; a pushing device for producing theplastic pipes is arranged in the middle of the power cavity; and a cutting device for cutting the pipes is arranged in the cutting body. The rapid production cutting equipment has the advantages thatthe plastic pipes can be quickly produced, efficient production of the plastic pipes is achieved, automation and batch production can be realized, operation can be reduced, and manual labor can be reduced.

Owner:广东保通管业科技有限公司

Wire cutting equipment with adjusting mechanism

PendingCN107321886AChange cutting lengthEasy to adjustMetal working apparatusMicrocontrollerWire rod

The invention discloses a wire cutting device with an adjustment mechanism, which includes a frame, and the side of the frame is sequentially installed with a guide mechanism, a cutting device and a length adjustment device from left to right, and the length adjustment device is connected with the connecting frame through the connecting frame The frame is connected, and the end of the length adjusting device is respectively equipped with a fixing device and a measuring device. An open-source single-chip microcomputer is installed on the top of the frame, and an IoT device is installed on the top of the open-source single-chip microcomputer. The input terminal of the open-source single-chip microcomputer is connected to the The output end of the external power supply is connected. This wire cutting equipment with an adjustment mechanism measures the length of the wire through the measuring device, which is convenient for the length adjustment device to adjust the cutting length of the wire. It has strong adjustability and can meet different production needs. , The wire cutting equipment is remotely controlled through the Internet of Things device, which has a high degree of intelligence, convenient control, and is safe and reliable.

Owner:张家辉

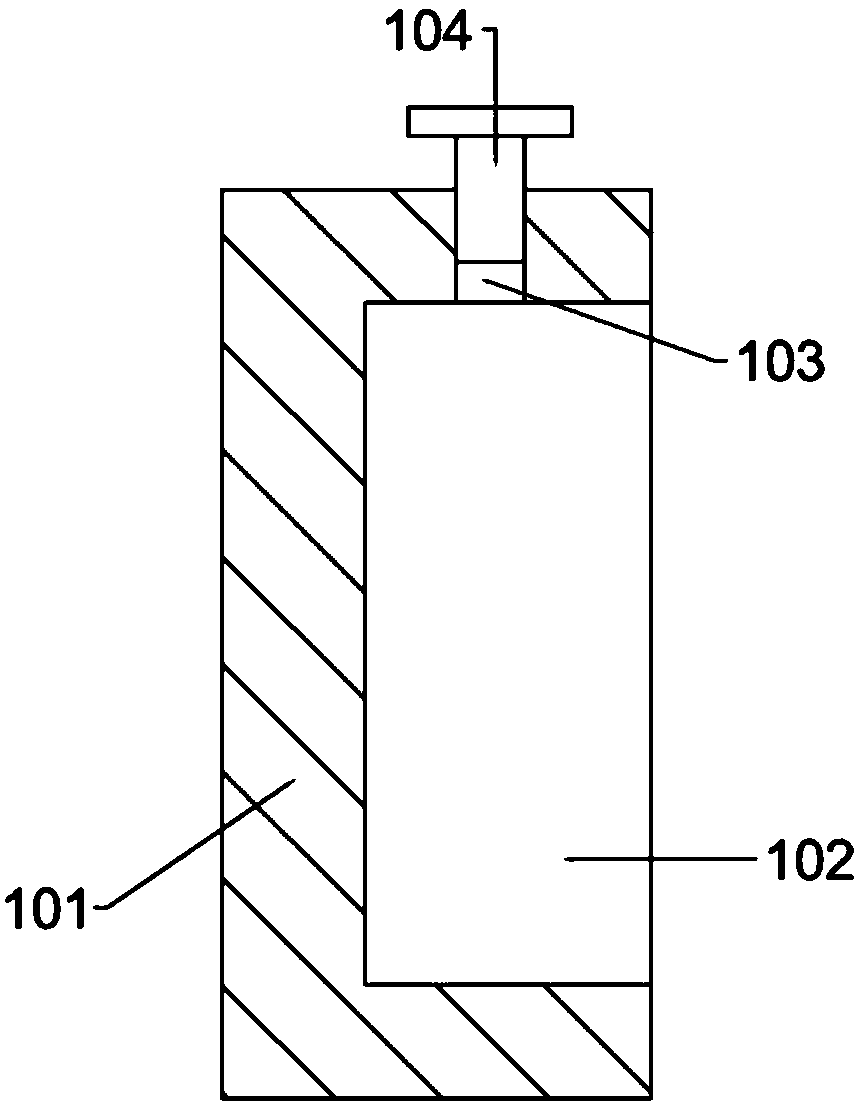

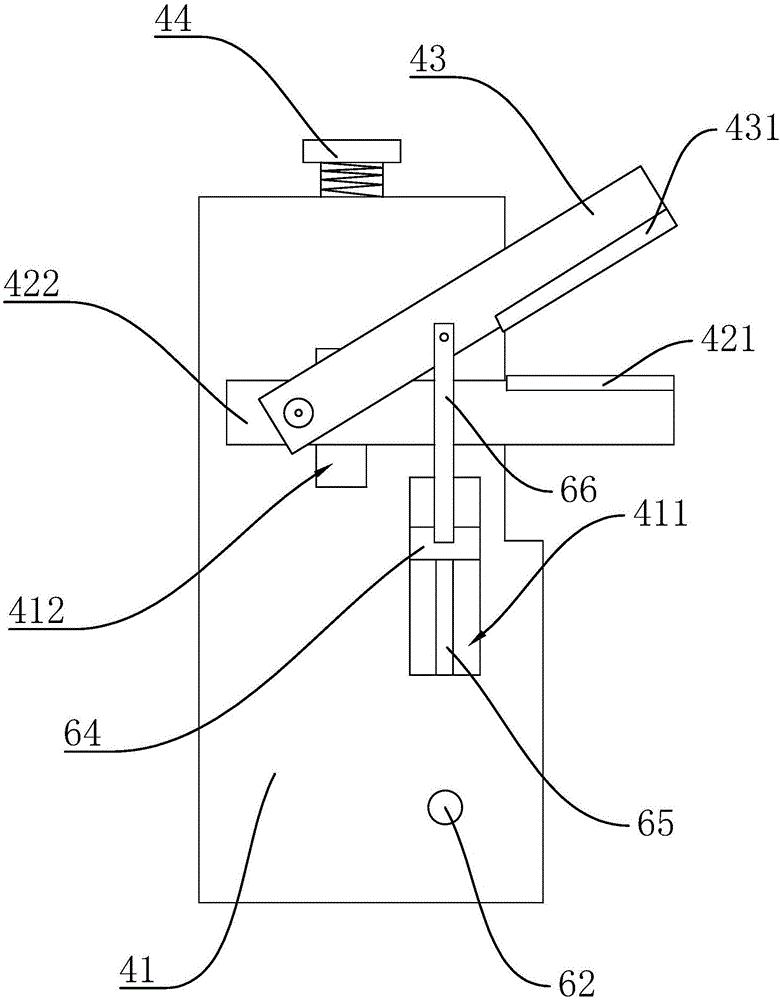

Cutting device for capsule hand sample

ActiveCN105922307AEnsure cutting thicknessEnsure cutting heightMetal working apparatusBiomedical engineering

The invention discloses a cutting device for a capsule hand sample. The cutting device for the capsule hand sample comprises a rotational clamping workpiece, a cutting workpiece, a limit rod workpiece, a support arm and a support. The capsule hand sample is clamped on the rotational clamping workpiece; one end of the support arm is hinged to the support; the other end of the support arm is connected with the limit rod workpiece which is arranged on the support arm in a threaded mode; the head end of the limit rod workpiece is connected with the cutting workpiece, and the tail end of the limit rod workpiece is suspended; the height between the tail end of the limit rod workpiece and the center of the cutting workpiece is matched with the height of the center of the rotational clamping workpiece; and an elastic workpiece is arranged in the position from the portion, where the support arm is located, of the limit rod workpiece to the tail end of the limit rod workpiece. According to the cutting device for the capsule hand sample, positioning can be conducted through the limit rod workpiece, the cutting height is determined, and it is ensured that the cutting thickness and the cutting height of the capsule hand sample meet requirements; the cutting length adjustment is achieved by adjusting of an adjustment rod; and the whole cutting device for the capsule hand sample is simple in structure, convenient to use, and capable of effectively cutting the capsule hand sample.

Owner:ANHUI HUANGSHAN CAPSULE CO LTD

Corrugated paper processing cutting device with a material receiving structure

InactiveCN112518855AAvoid warpingImprove crop qualityMetal working apparatusPaper productionStructural engineering

The invention relates to the field of corrugated paper production, in particular to a corrugated paper processing cutting device with a material receiving structure. The structure comprises a transmission mechanism, wherein the transmission mechanism comprises an operation base table, and a hollow groove is formed in one end of the surface of the operation base table. A pressing mechanism is arranged to press a corrugated board, edge warping during cutting is prevented, the cutting quality is improved, a length of the cut corrugated board can be limited after a length limiting baffle makes contact with the operation base table, a cutting length is adjusted through an adjusting mechanism, the production efficiency is improved conveniently, by arranging a material grabbing mechanism, grabbing can be completed in a cutting process, four inclined sliding grooves drive corresponding inclined rods to horizontally move, in a cutting process, a square plate moves downwards, the inclined rods on the two sides slide towards the middle, and after the inclined rods move towards the middle, a cut corrugated paper board is clamped between a grabbing plate and a pressing block at the bottom ends,material receiving and stacking are facilitated, full-automatic completion is achieved, and the labor cost is reduced.

Owner:李保峰

Integrated cutting machine

The invention discloses an integrated cutting machine. An object stage is arranged on the top part of a main working table; a cross rod parallel to the main working table is arranged above the objectstage; two ends of the cross rod are connected with the main working table through connecting rods; an upper guide rail and a lower guide rail are arranged on the top part and the bottom part of the cross rod; a first guiding hole and a second guiding hole arranged downwards vertically are formed in the front side and the rear side of a moving mechanism; grooves in the upper end and the lower endin the moving mechanism are matched with the upper guide rail and the lower guide rail; a first moving rod and a second moving rod are arranged in the first guiding hole and the second guiding hole along the upper guide rail; a cutting mechanism is connected to the bottom parts of the first moving rod and the second moving rod; fastening pieces are arranged on the top parts of the first moving rodand the second moving rod; and the first moving rod and the second moving rod move up and down so as to adjust a position of the integrated cutting machine, and are fixed through a fixing mechanism on the top part of the moving mechanism. The integrated cutting machine provided by the invention is stable in structure, and not only can the cutting depth be changed, but also the cutting length canbe changed.

Owner:YANCHENG CITY HAITONG MACHINERY MFG PLANT

A rapier loom

ActiveCN106048864BFinished product quality impactAccurate and fast resetLoomsAuxillary apparatusPush and pullDrive shaft

The invention provides a rapier loom which comprises a workbench, a warp let-off mechanism, a weft let-off mechanism, a slitter edge cutting mechanism and a rolling mechanism. The slitter edge cutting mechanism comprises a cutter rest, a fixed cutter body and a movable cutter body, the fixed cutter body is provided with a first blade, the movable cutter body is provided with a second blade, the fixed cutter body is fixed to the cutter rest in a height-adjustable mode, the movable cutter body is hinged to the fixed cutter body, and the first blade and the second blade abut against each other to form a cutting opening; the slitter edge cutting mechanism further comprises a motor driving the movable cutter body to rotate, a transmission shaft and a rotating disc, and the transmission shaft is controlled by the motor and fixedly connected to the center of the rotating disc; the cutter rest is provided with a longitudinal sliding groove, a sliding block is arranged in the sliding groove, a first connecting rod used for driving the sliding block to rise and fall is arranged between the sliding block and the rotating disc, a second connecting rod used for pushing and pulling the movable cutter body is arranged between the sliding block and the movable cutter body, one side of the sliding block is fixedly connected with the second connecting rod, and the second connecting rod is hinged to the movable cutter body; the other side of the sliding block is hinged to the first connecting rod, and the first connecting rod is hinged to the eccentric position of the rotating disc.

Owner:LANGXI YUANHUA TEXTILE

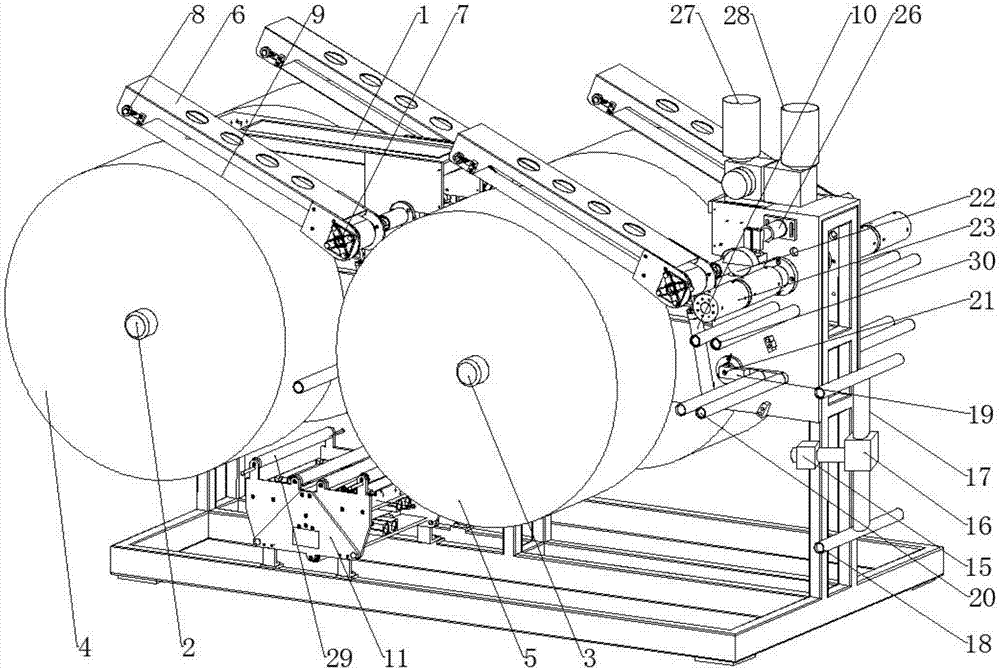

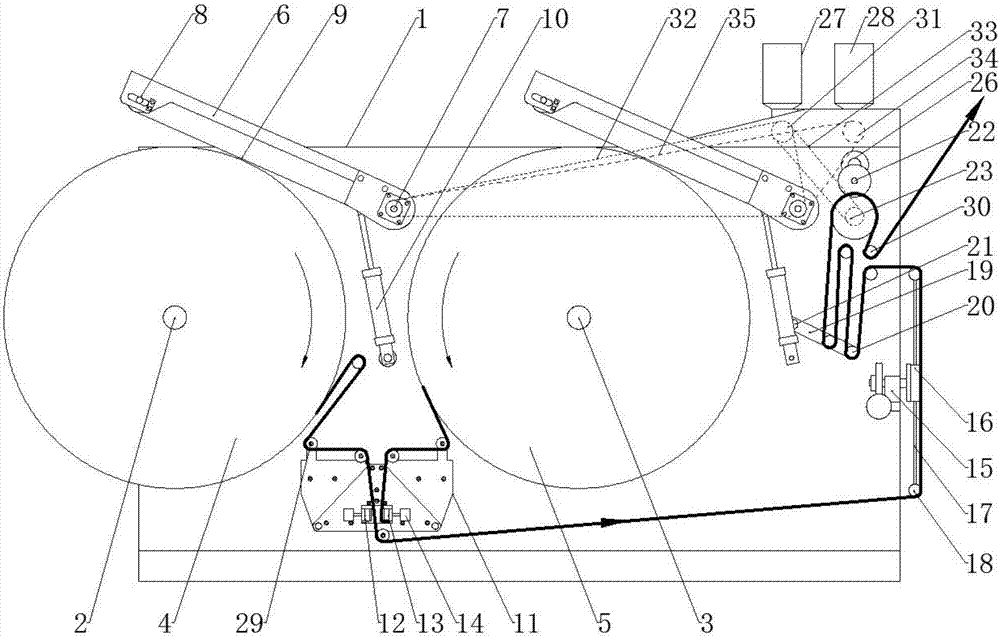

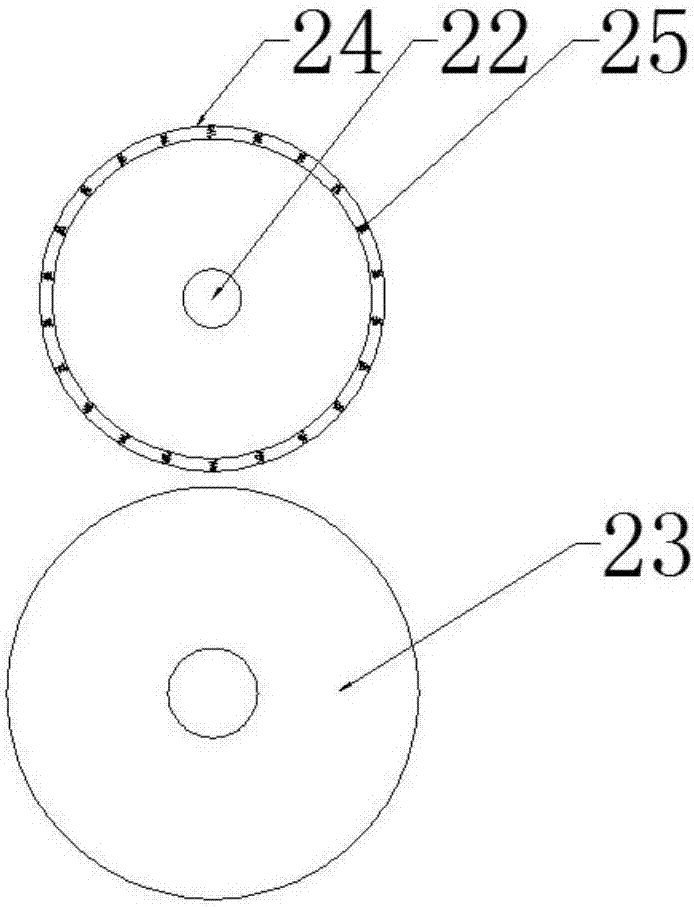

Automatic roll changing and cloth releasing device

InactiveCN107529506AEasy to operateEasy to controlArticle deliveryWebs handlingEconomic benefitsEngineering

The invention relates to an automatic roll changing and cloth releasing device. The automatic roll changing and cloth releasing device comprises a rack, cloth feeding mechanisms, a head and tail rebutting device, a deviation rectifying device, a floating and rolling tension control device and a slitting device, wherein the front side and the rear side of the rack are arranged in a symmetrical structure, and a primary cloth releasing frame and a secondary cloth releasing frame are arranged at the front side of the rack; four cloth feeding mechanisms are respectively arranged above two primary non-woven fabric rolls and above two secondary non-woven fabric rolls; the head and tail rebutting device is arranged below a central position between the primary cloth releasing frame and the secondary cloth releasing frame; the deviation rectifying device is arranged at the right end of the rack and comprises a mounting block and a mounting sleeve; the floating and rolling tension control devicecomprises a control rod, a compensation roller used for conveying non-woven fabrics and a control rod driving part used for driving the control rod to move; and the slitting device comprises a rollingroller and a cutter roller which are arranged up and down. Two rolls of non-woven fabrics can be full-automatically processed every time, continuous processing is carried out on the non-woven fabricswithout halt, both time and labor are saved, operation is easy, control is precise, labor cost is greatly reduced, and working efficiency is improved, so that the automatic roll changing and cloth releasing device provided by the invention has good economic benefit.

Owner:天津比朗德机械制造有限公司

Extrusion shaping and edge cutting device for processing bamboo products

InactiveCN108858508ARealize the purpose of extrusion shapingChange cutting lengthWood compressionCane mechanical workingHydraulic pumpSlide plate

The invention discloses an extrusion shaping and edge cutting device for processing bamboo products, and relates to the technical field of bamboo product processing. The extrusion shaping and edge cutting device for processing the bamboo products comprises a base and an installation frame, wherein a placement plate is fixedly connected to the middle of the upper end of the base; a baffle plate isfixedly connected to one side of the upper end of the base; the inner part of the installation frame is fixedly connected with one end of a hydraulic pump; the other end of the hydraulic pump penetrates through the installation frame and is fixedly connected with a pressing plate; a fixed plate is fixedly connected to the top end of the installation frame; a first sliding plate is arranged at theupper end of the fixed plate; sliding chutes are formed in the middle parts of the upper ends and the top ends of two sides of the fixed plate. According to the extrusion shaping and edge cutting device for processing the bamboo products, through arranging the hydraulic pump and the pressing plate, the aim of extrusion shaping the bamboo products can be achieved; through arranging the baffle plate, one ends of the bamboo products can be aligned, so that two ends of the cut bamboo products are ensured to be smooth; through arranging the fixed plate and a first sliding plate, the cutting lengthof the cutting device can be adjusted; through arranging a second sliding plate and a movable block, an effect on feeding is achieved.

Owner:安吉县欧阳竹木工艺品厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com