Rapier loom

A technology of rapier loom and connecting rod, applied in looms, textiles, textiles and papermaking, etc., can solve the problems of uneven winding, additional manual work, inability to adjust shear force and shear length, etc. The adjustment method is simple, improving the cutting effect, and stabilizing the effect of the cutting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

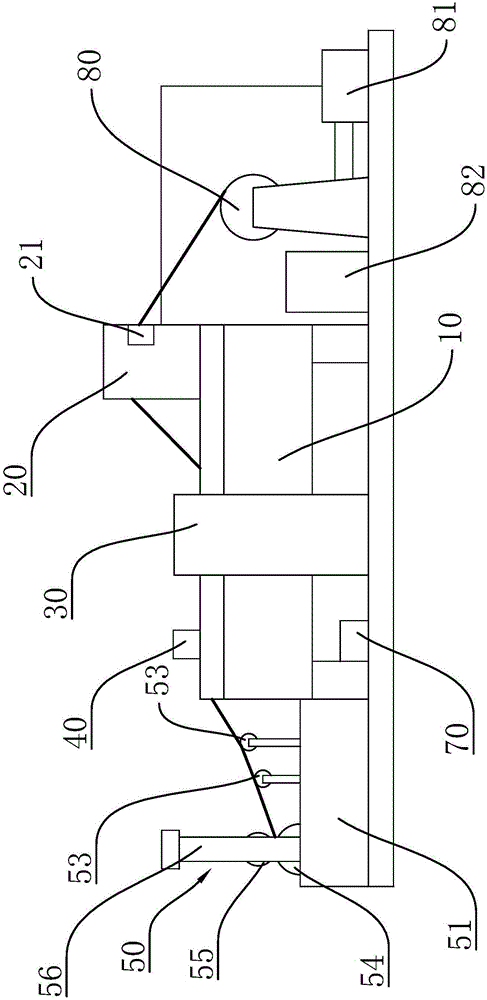

[0033] Such as Figure 1 to Figure 5 As shown, the present invention provides a kind of rapier loom, comprises workbench 10, warp let-off mechanism 20, weft feed mechanism 30, waste edge cutting mechanism 40 and winding mechanism 50, the place ahead of warp let-off mechanism 20 is provided with Warp beam 80 of warp yarn, warp beam 80, warp let-off mechanism 20, workbench 10, winding mechanism 50 are arranged in sequence from front to back according to the process direction, weft feeding mechanism 30 is arranged on one side of workbench 10, waste edge cutting mechanism 40 Installed on top of the workbench 10.

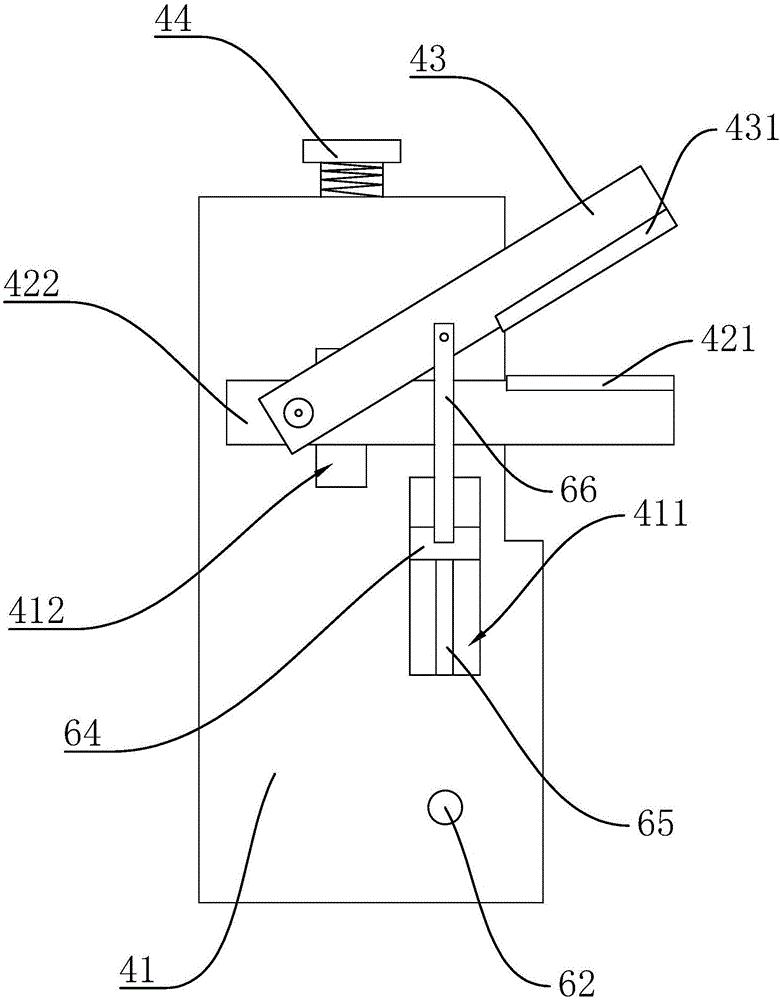

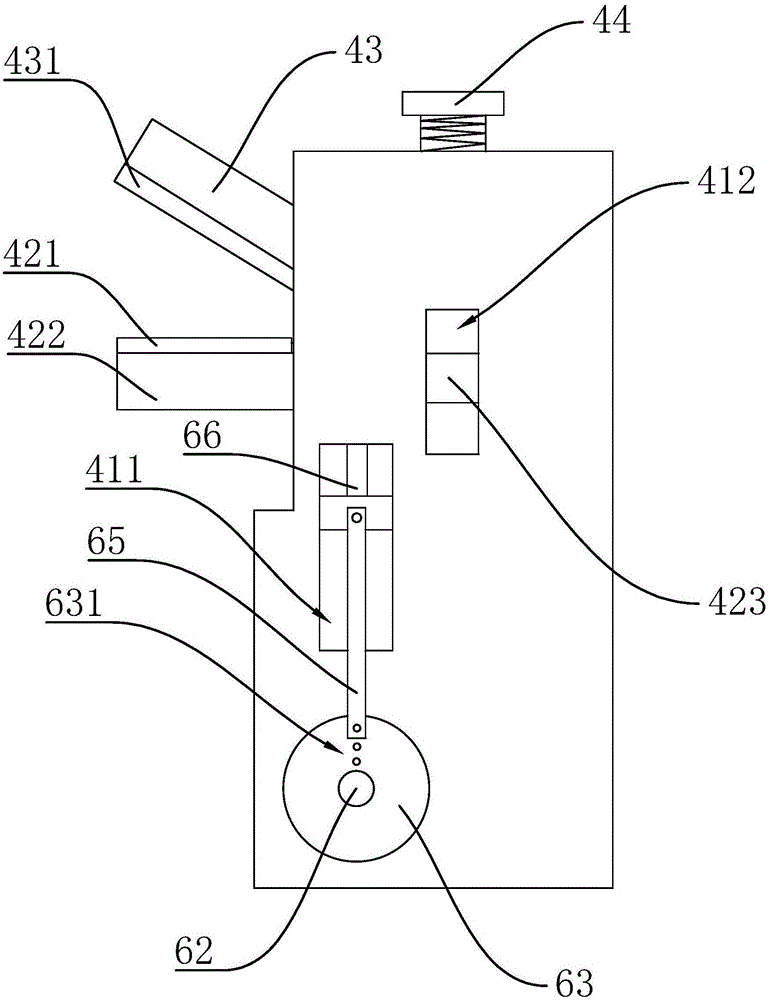

[0034]The waste edge cutting mechanism 40 comprises a knife rest 41, a fixed knife body and a movable knife body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com