Environment-friendly cutting device for non-woven fabric

A cutting device and non-woven fabric technology, applied in textiles and papermaking, textile material cutting, etc., to achieve the effect of increasing strength, ensuring air quality, and constant cutting length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

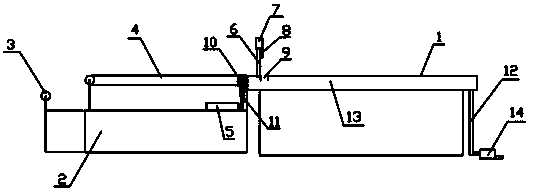

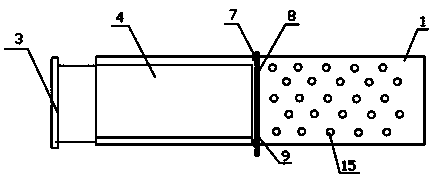

[0023] like figure 1 , figure 2 As shown, an environment-friendly non-woven fabric cutting device includes a cutting table 1 and a transmission device 2. The cutting table 1 is provided with a cutting groove 9 and a cutting device. Carry out cutting, and cutting device comprises cutter support 7, cylinder 7 and cutter 8, and described cutter 8 is a strip cutter, and cutter support 7 is vertically fixed on the cutting table 1, and cutter support 7 is two, Two cutter supports 7 are respectively arranged on both sides of the cutting table 1, the bottom of the cutter support 7 is fixed on the cutting table 1, the top of the cutter support 7 is provided with a cylinder 7, and the cylinder 7 is connected with the cutter 8. During cutting, The cylinder drives the cutting knife to cut the non-woven fabric downwards, and the cutting knife cooperates to cut into the cutting groove, and the cutting of the non-woven fabric is completed simultaneously by the strip-shaped cutting knife 8 ...

Embodiment 2

[0026] like figure 1 , figure 2 As shown, an environment-friendly non-woven fabric cutting device includes a cutting table 1 and a transmission device 2. The cutting table 1 is provided with a cutting groove 9 and a cutting device. Carry out cutting, and cutting device comprises cutter support 7, cylinder 7 and cutter 8, and described cutter 8 is a strip cutter, and cutter support 7 is vertically fixed on the cutting table 1, and cutter support 7 is two, Two cutter supports 7 are respectively arranged on both sides of the cutting table 1, the bottom of the cutter support 7 is fixed on the cutting table 1, the top of the cutter support 7 is provided with a cylinder 7, and the cylinder 7 is connected with the cutter 8. During cutting, The cylinder drives the cutting knife to cut the non-woven fabric downwards, and the cutting knife cooperates to cut into the cutting groove, and the cutting of the non-woven fabric is completed simultaneously by the strip-shaped cutting knife 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com