Power-free rapid ventilation system of workshop

A ventilation system and power technology, which is applied in the field of unpowered rapid ventilation systems in workshops, can solve the problem that unpowered fans cannot meet working requirements, etc., and achieve the effects of ensuring air quality, increasing stability, and reducing size and number of teeth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to better understand the present invention, the implementation manner of the present invention will be explained in detail below in conjunction with the accompanying drawings.

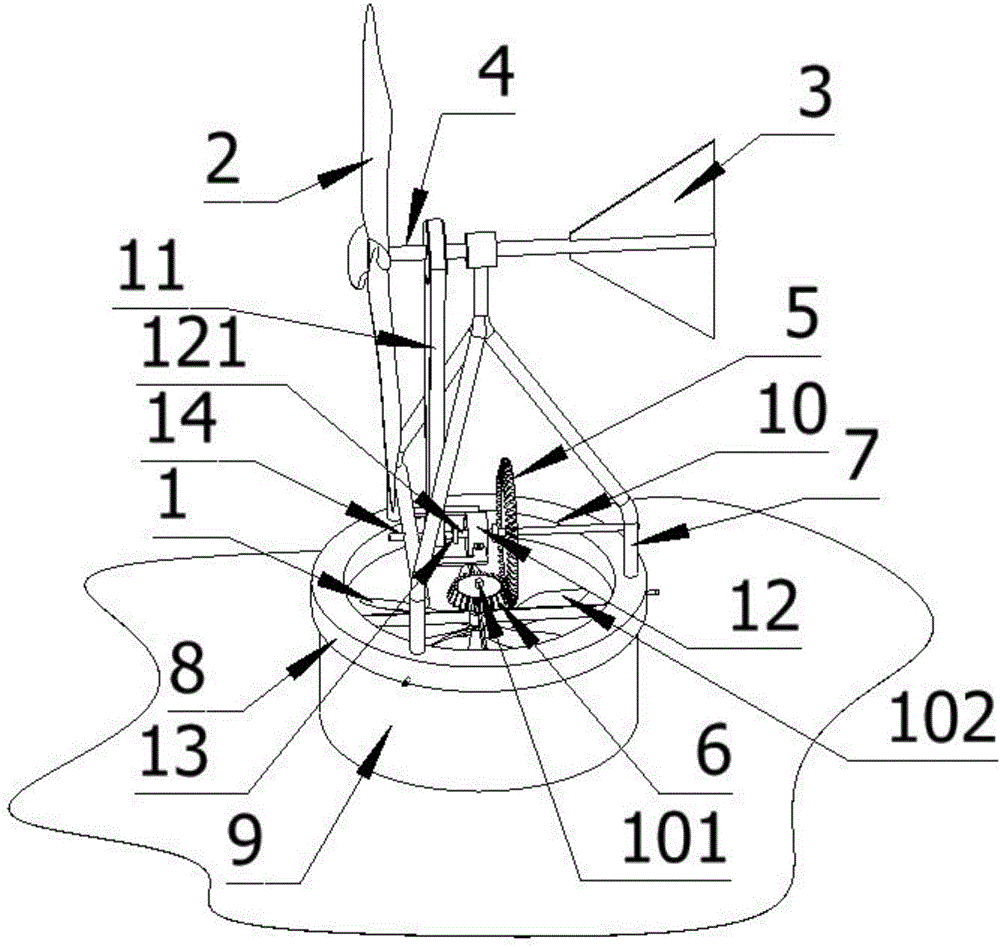

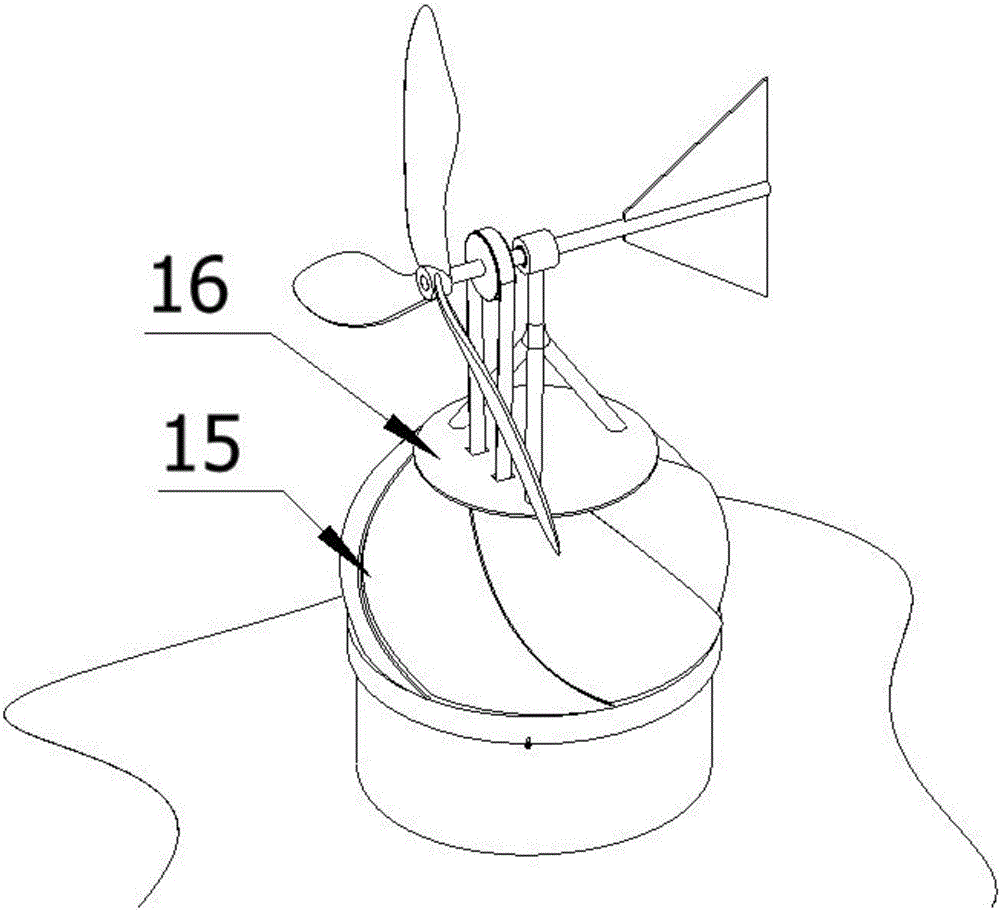

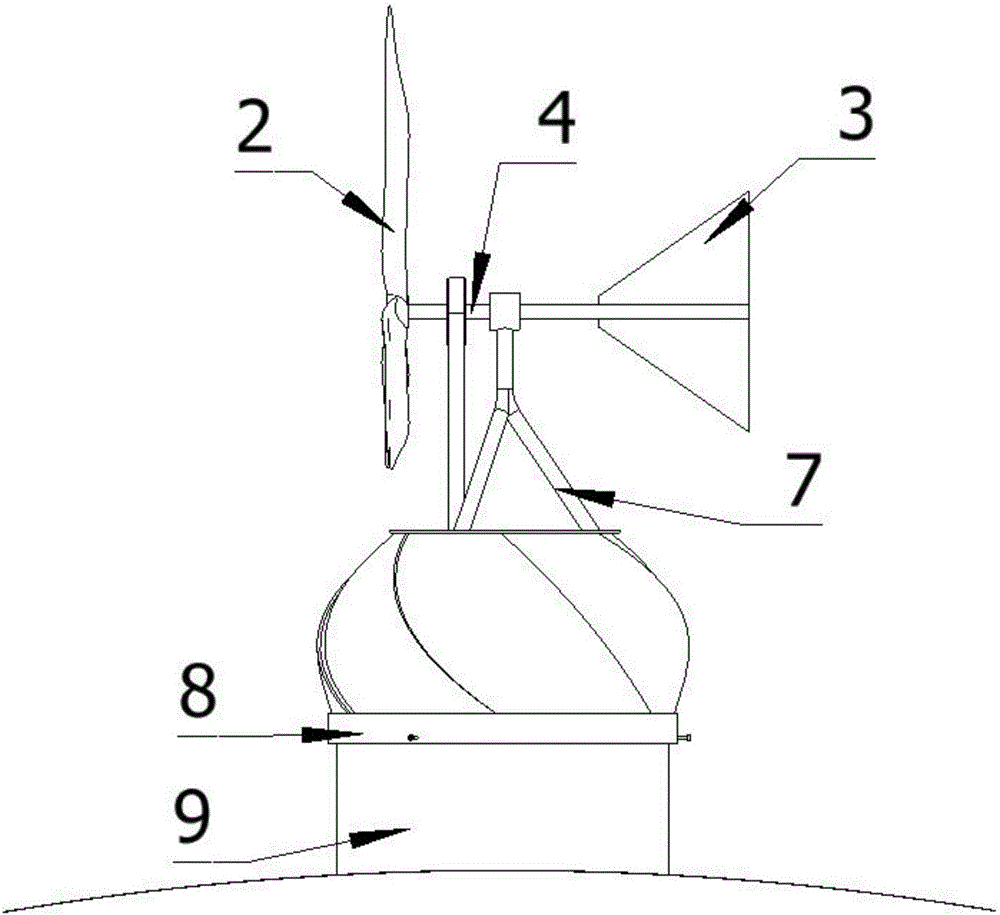

[0032] figure 1 It is the first embodiment of the present invention, such as figure 1 As shown, a non-powered rapid ventilation system for a factory building includes a ventilation fan 1, a wind drive wheel 2, a wind direction plate 3, a main shaft 4, a bevel gear a5, a bevel gear b6, a bracket 7, a rotating disc 8, a drive shaft 10, and a transmission mechanism c11 , barrel 12, overrunning clutch 13, transmission shaft 14, described ventilating fan 1 is installed in the ventilation passage 9 of factory building top, and the center of ventilating fan 1 is provided with fan shaft 101, and fan shaft 101 is installed on the fixed frame 102, and fixed frame 102 is fixed in the air duct 9, the bevel gear b6 is installed on the fan shaft 101, and the bevel gear a5 meshes with the bevel gear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com