Membrane structures and their production and use

A membrane structure, zeolite membrane technology, applied in membrane, membrane technology, semi-permeable membrane separation, etc., can solve the problems of laborious and slow methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

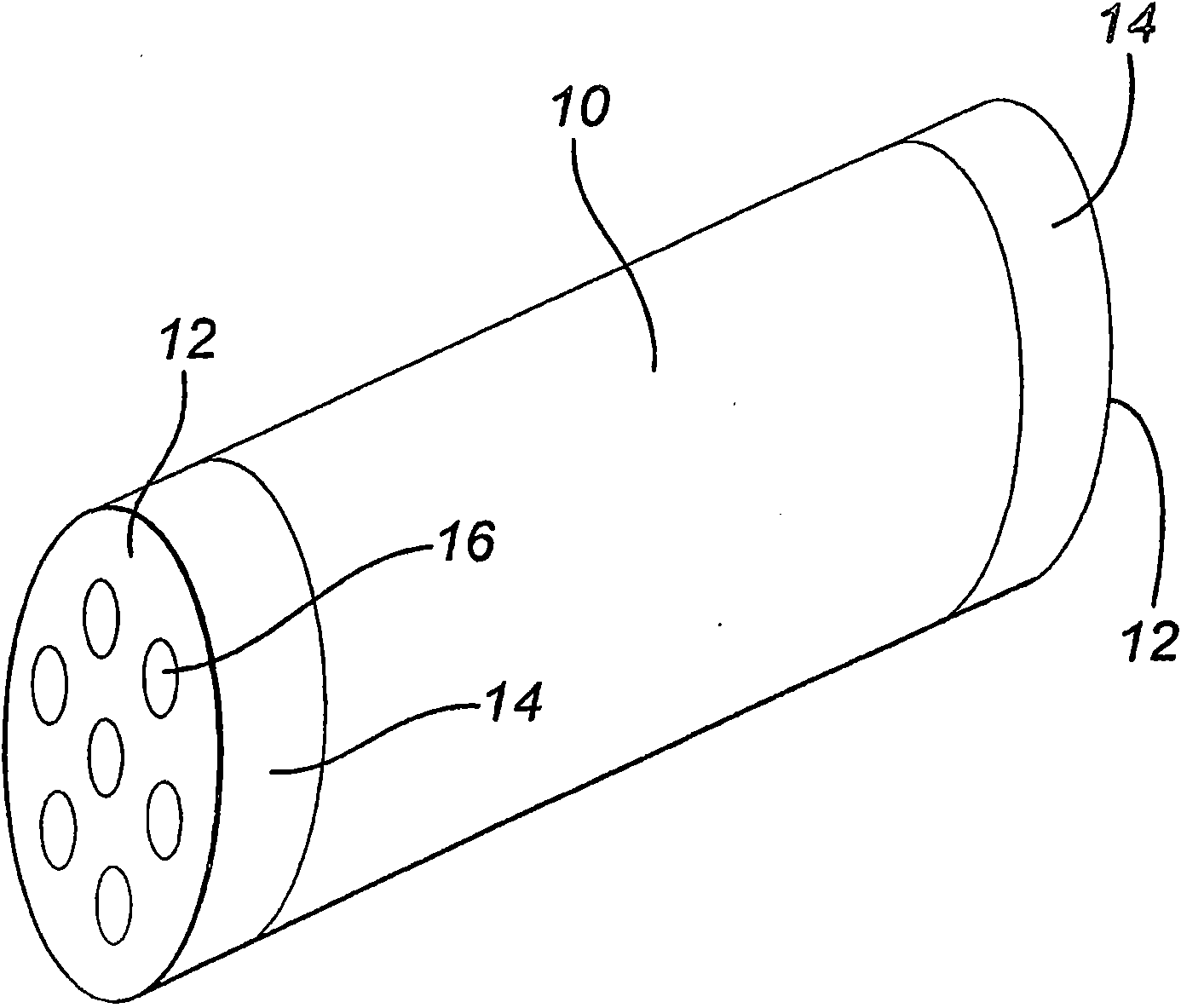

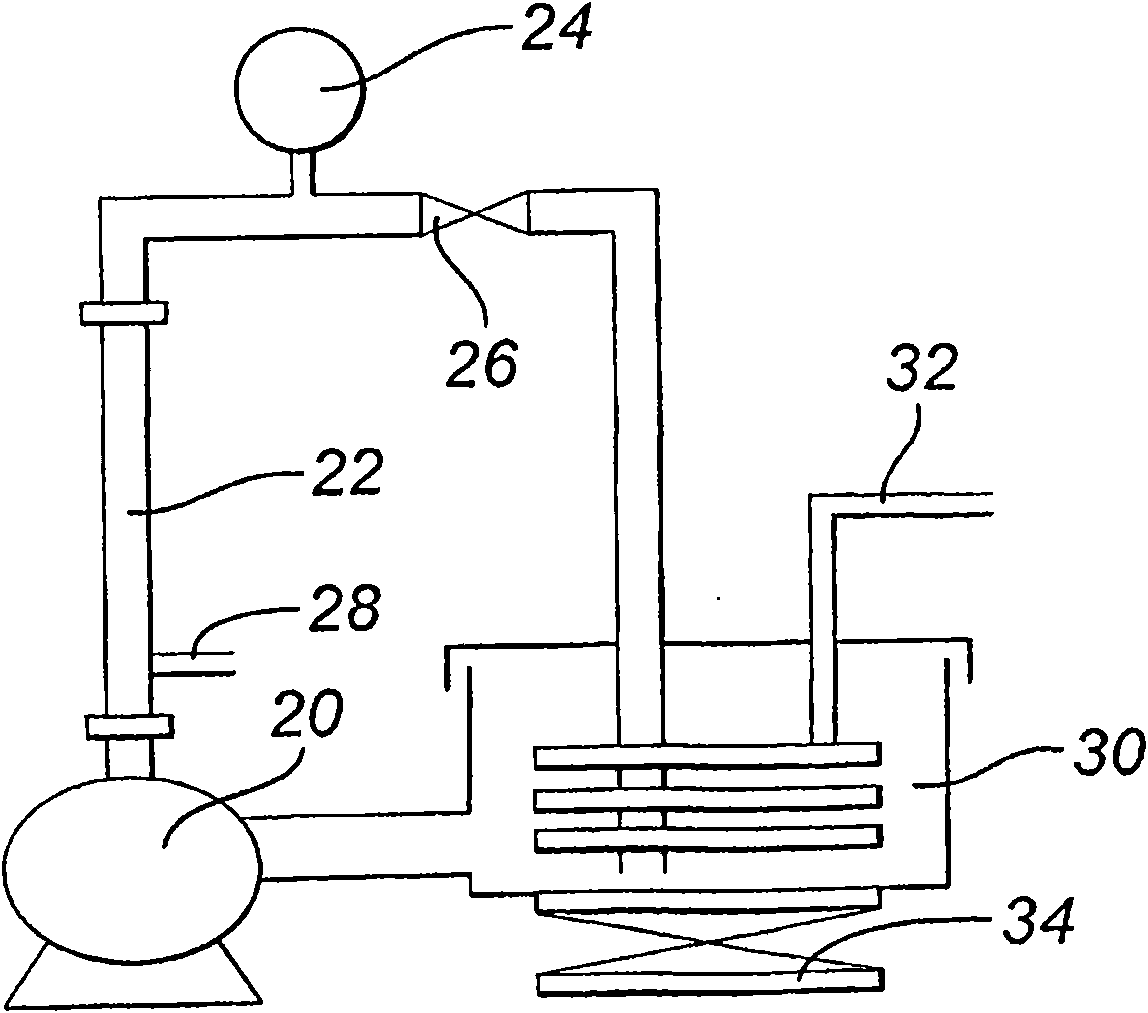

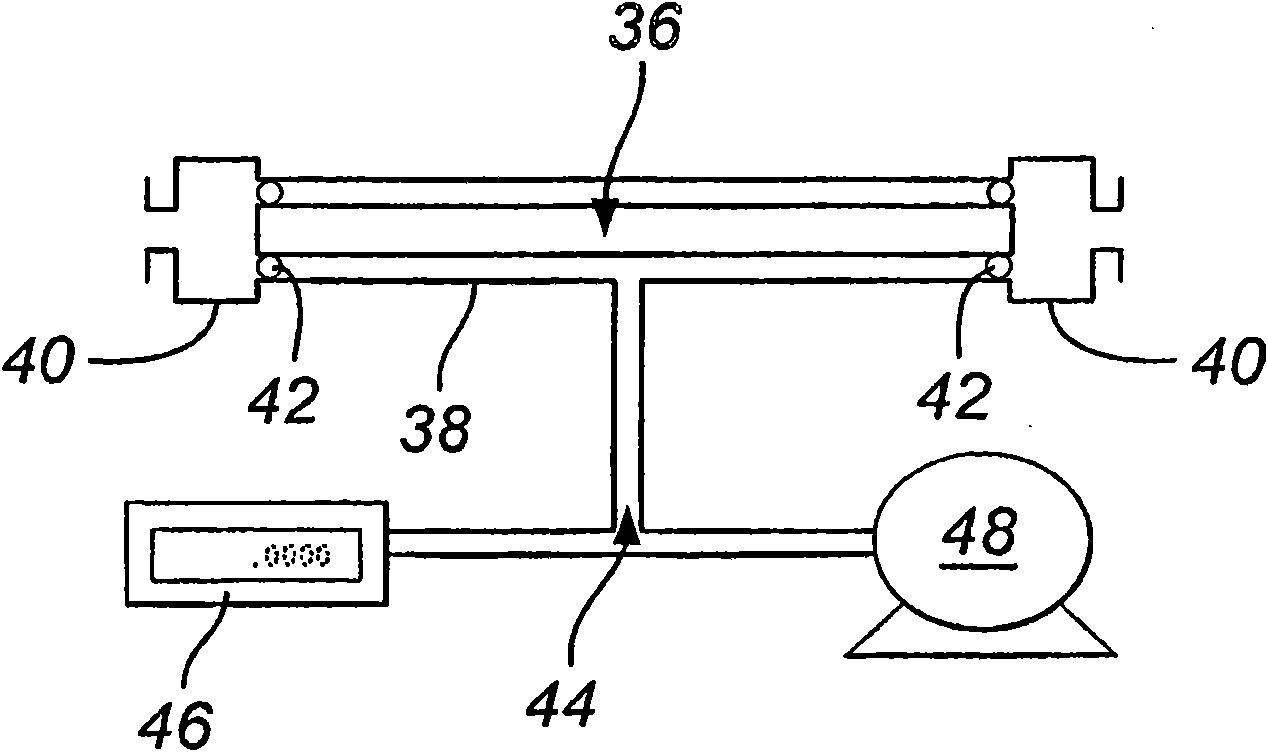

[0038] Embodiments of the present invention produce membranes of continuous zeolite membranes supported on porous alumina substrates. Membranes of zeolites in nature exhibit excellent solvent resistance. In an embodiment, an organic liquid or aqueous dispersed value or waste product can be dried and concentrated from any water level down to below 0.1% water and readily breaks the azeotrope. Liquids that can be treated include, but are not limited to, alcohols such as ethanol or butanol, ketones, ethers such as THF or diethyl ether, amines, DMF, mineral oils such as transformer oil, corn oil such as corn oil, and oils derived from other seeds Oils of biological origin, essential oils, agrochemicals, detergents and detergents, fragrances and fragrances, inks and adhesives, cosmetics and toiletry, waste water and water waste, beverages to be desalinated and Foods, biotechnological fluids, paints and dyes, and equilibrium reaction systems, for example where removal of water facil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com