Wireless sensor network SMT manufacturing execution control system

A wireless sensor network and manufacturing execution technology, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problems of many required personnel, high operating costs, and error-prone, so as to improve production efficiency and reduce Tired work, the effect of improving production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

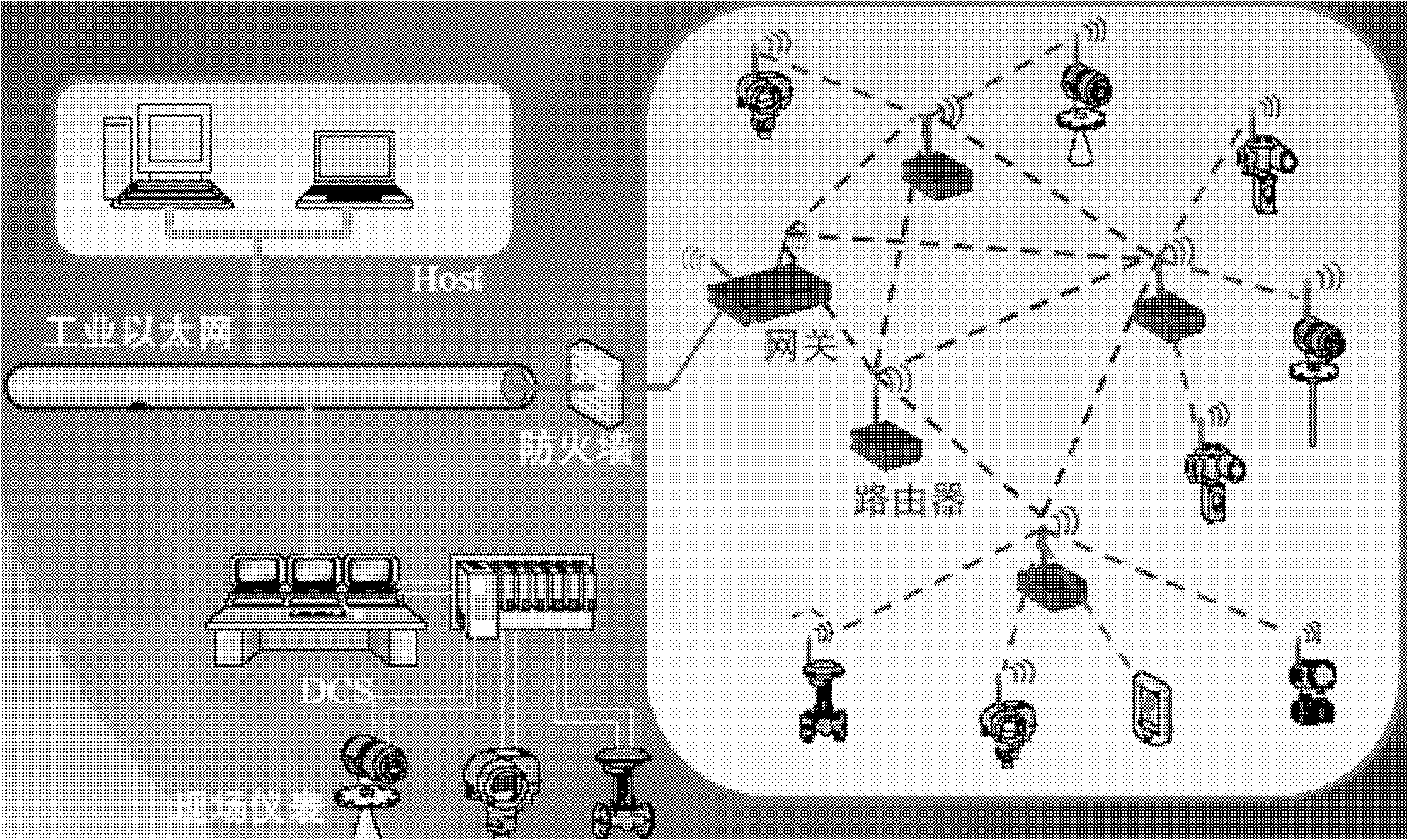

[0012] Such as figure 1 As shown, a specific application example of the present invention is illustrated.

[0013] In the system of the present invention, SMT placement machine is the placement machine of sa 6M620 of Panasonic Corporation, and this equipment itself contains computer, is operated by computer control, and the operation parameter of computer directly collecting this equipment is stored in computer, and these parameters are: SMT points, material loss rate, error information, material usage quantity and other process parameters, and there is a pressure sensor on the pressure tube of the placement machine, and the pressure data is also obtained by the computer; the computer has a serial port, and a wireless sensor is connected to the serial port The nodes of the network are preferably wireless sensor nodes using the Zigbee protocol in this embodiment. The wireless transmission network built with ZigBee technology mainly has the following advantages: 1. Low power co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com