Patents

Literature

394 results about "Production control system" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production Control Systems. The Production Control package is a closed-loop set of applications that control and monitor your production process, and incorporate the latest in Computer Integrated Manufacturing (CIM) technology.

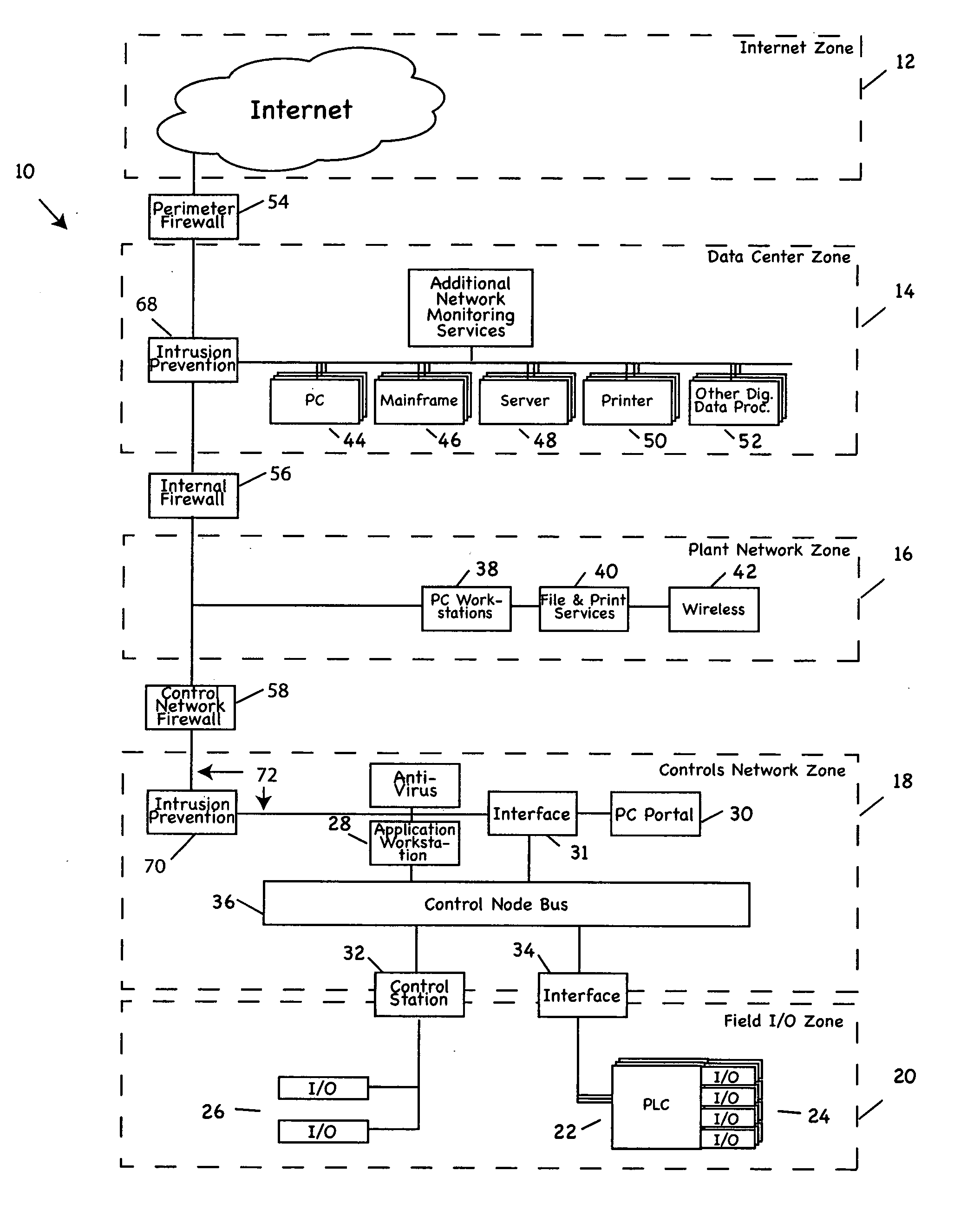

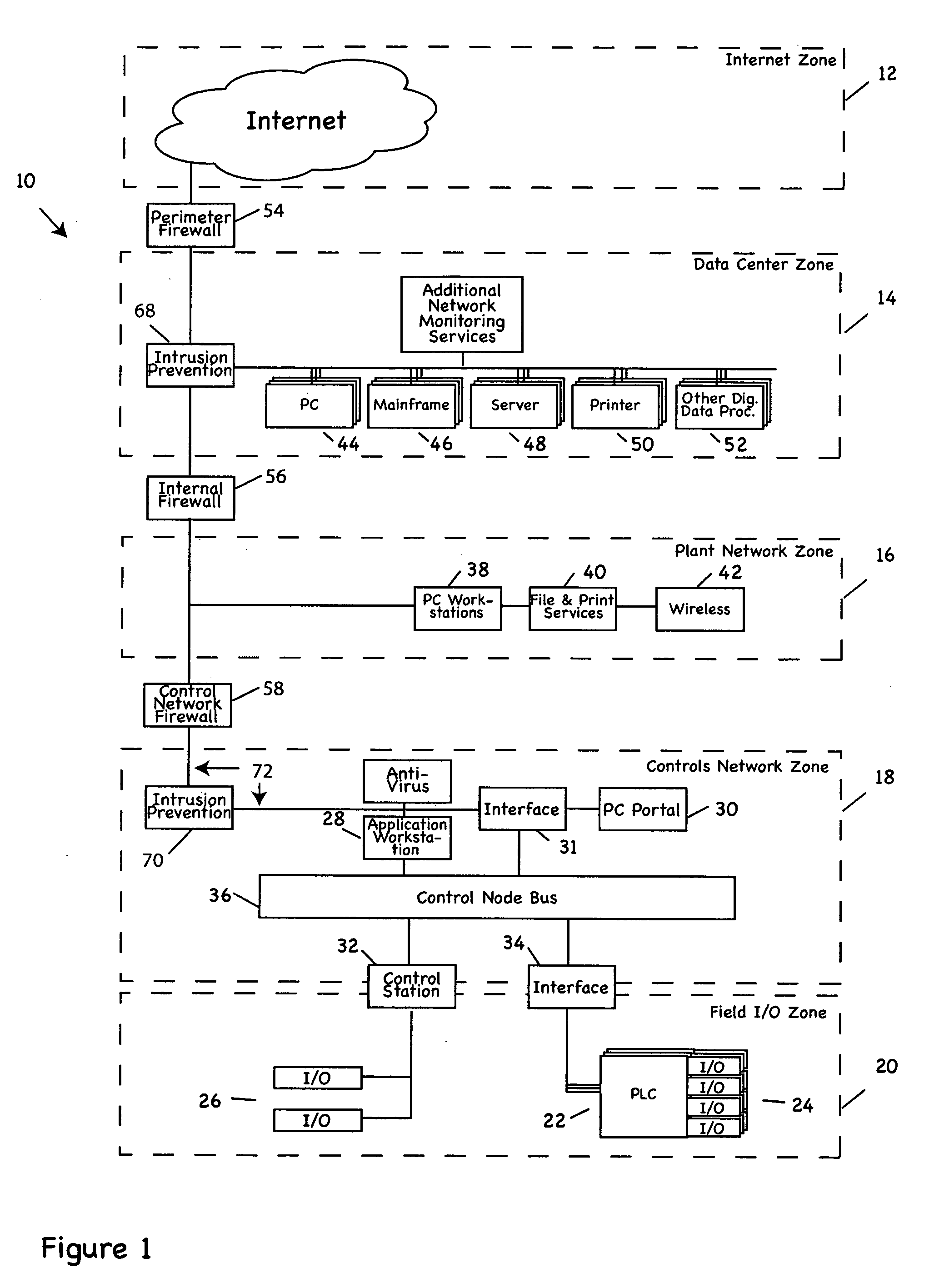

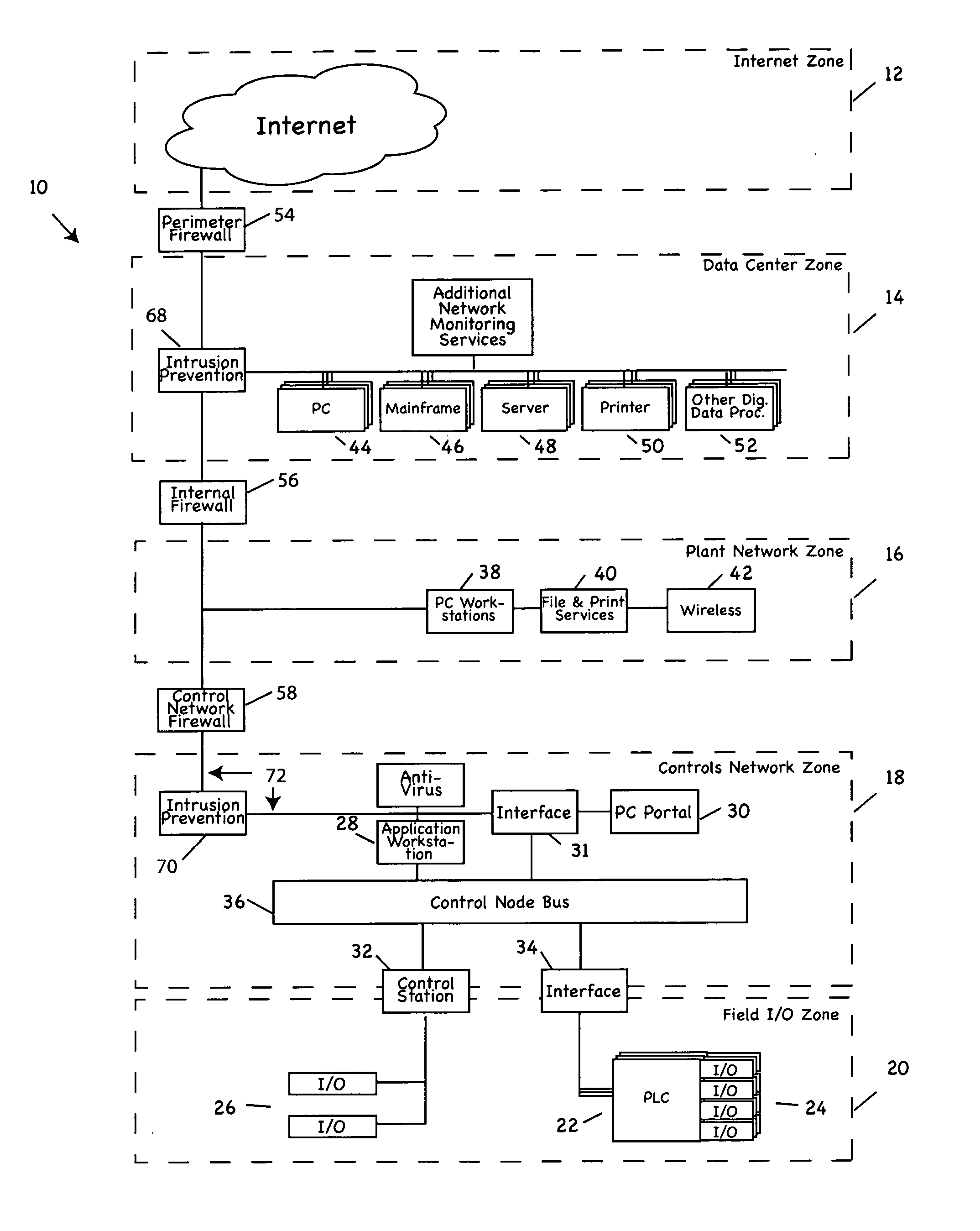

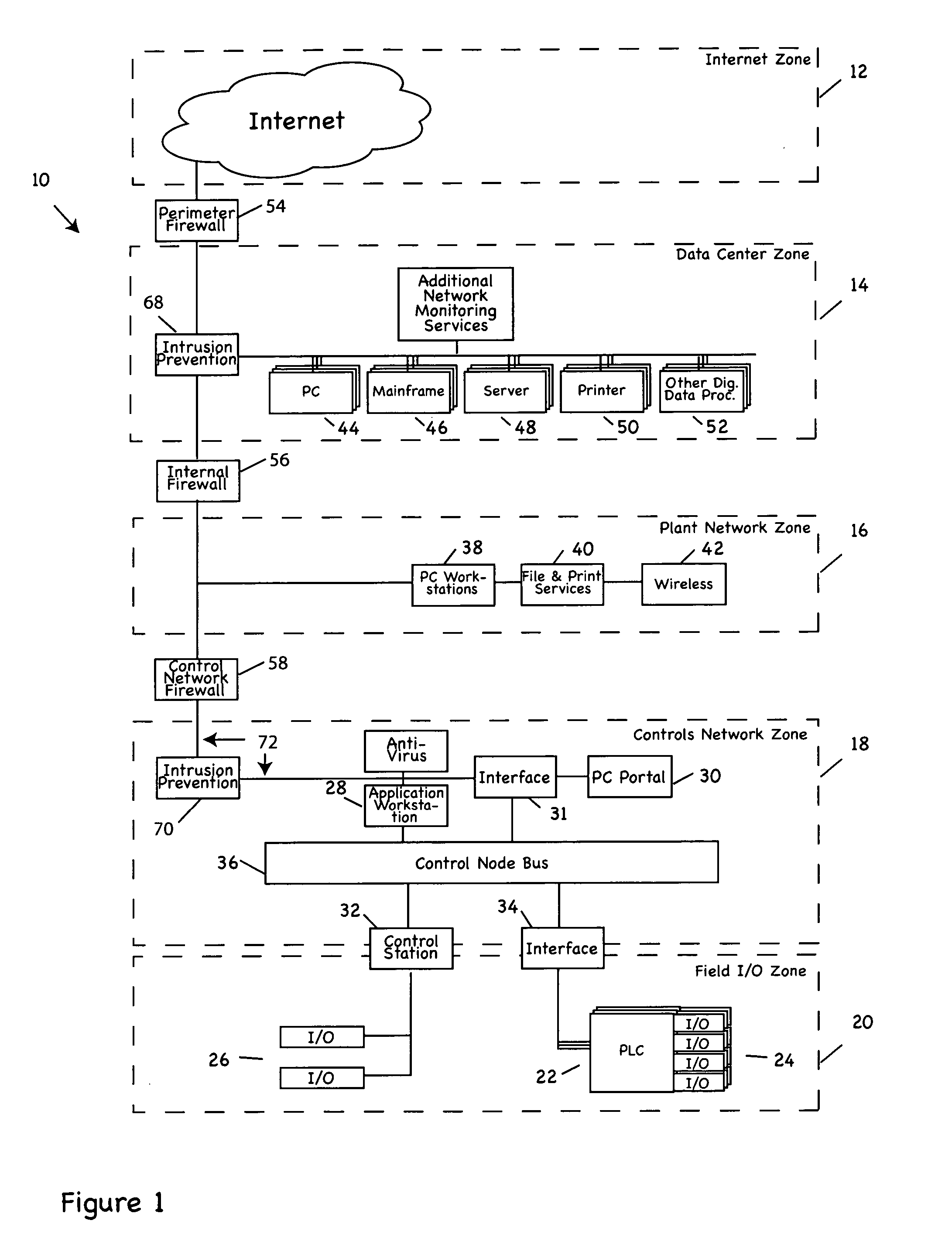

Process control methods and apparatus for intrusion detection, protection and network hardening

ActiveUS20060053491A1Memory loss protectionError detection/correctionEnvironmental control systemIntrusion prevention system

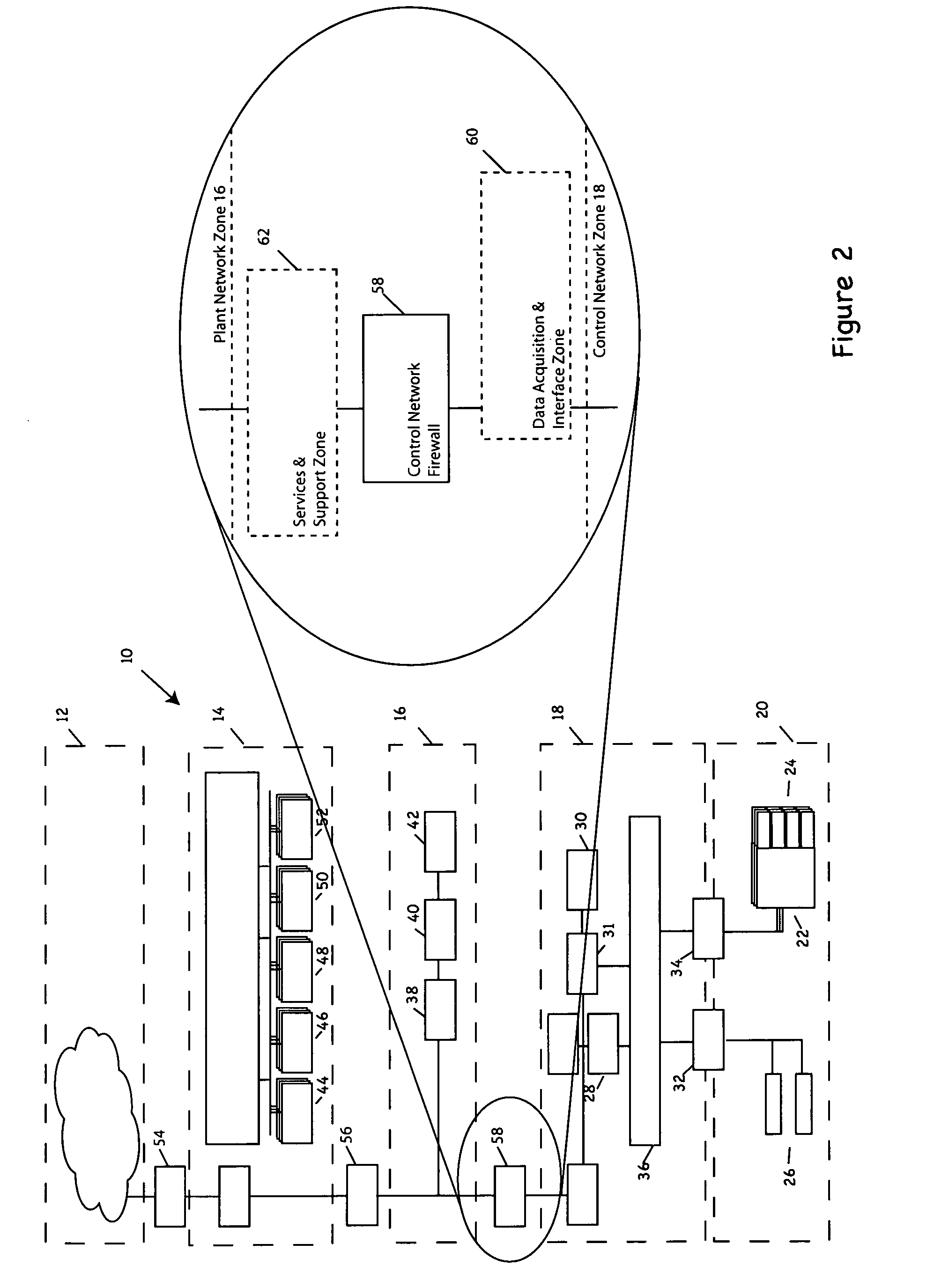

The invention provides an improved network and methods of operation thereof for use in or with process control systems, computer-based manufacturing or production control systems, environmental control systems, industrial control system, and the like (collectively, “control systems”). Those networks utilize a unique combination of firewalls, intrusion detection systems, intrusion protection devices and / or other devices for hardening (e.g., security against hacking, intrusion or other mischievous conduct) and / or intrusion detection. The networks and methods have application, by way of example, in plants, sites and other facilities in which networks that support control systems interface with corporate, business or other networks.

Owner:SCHNEIDER ELECTRIC SYST USA INC

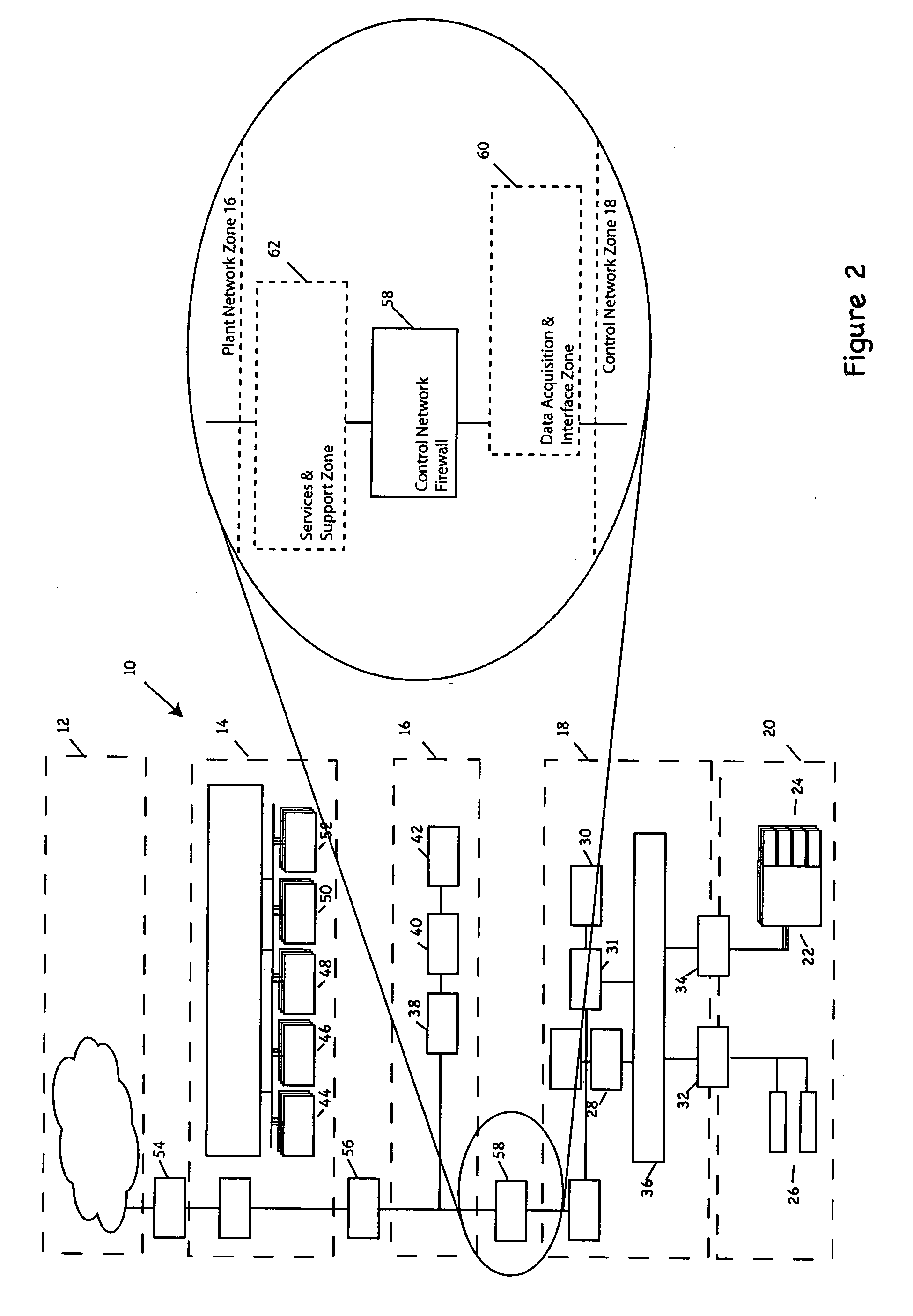

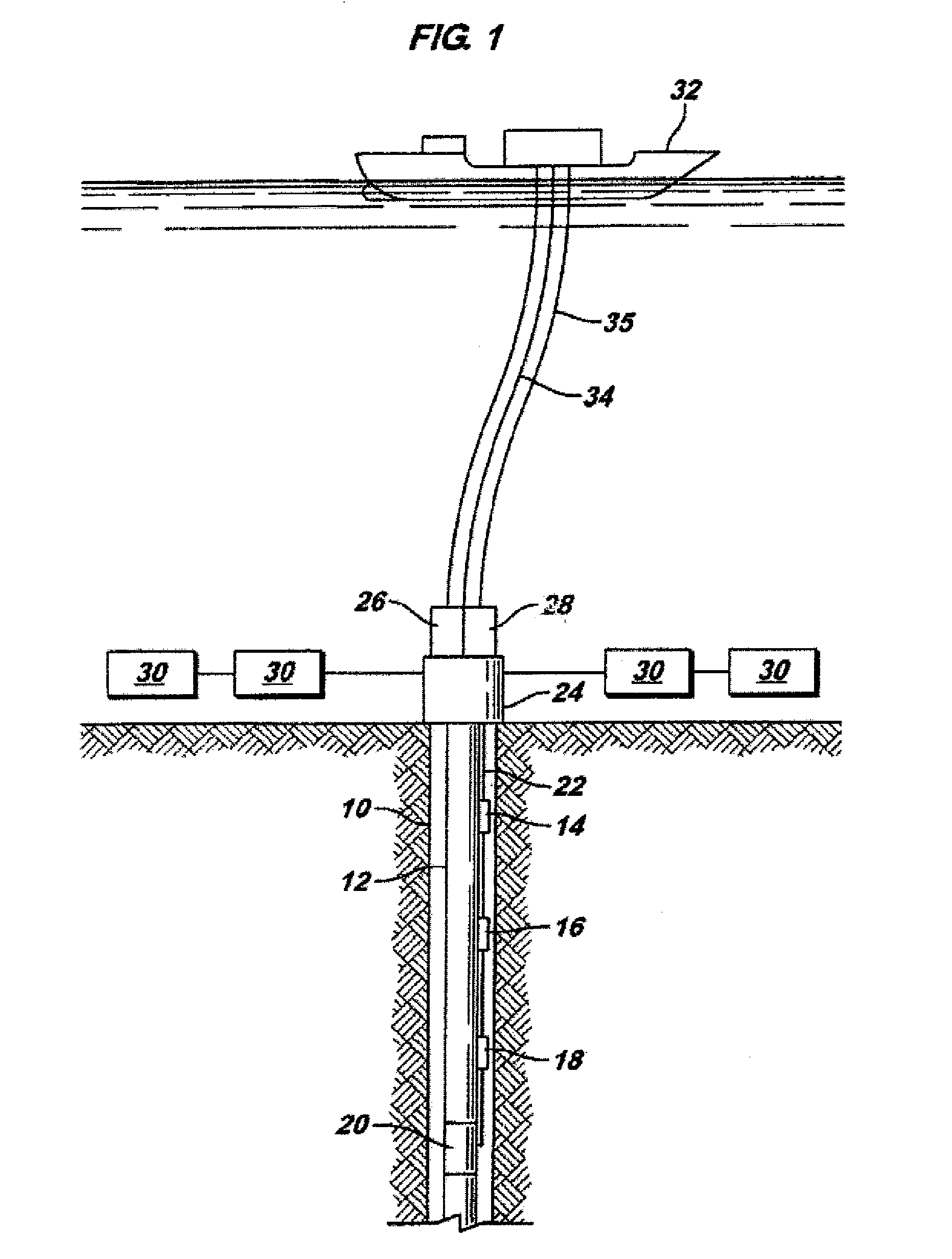

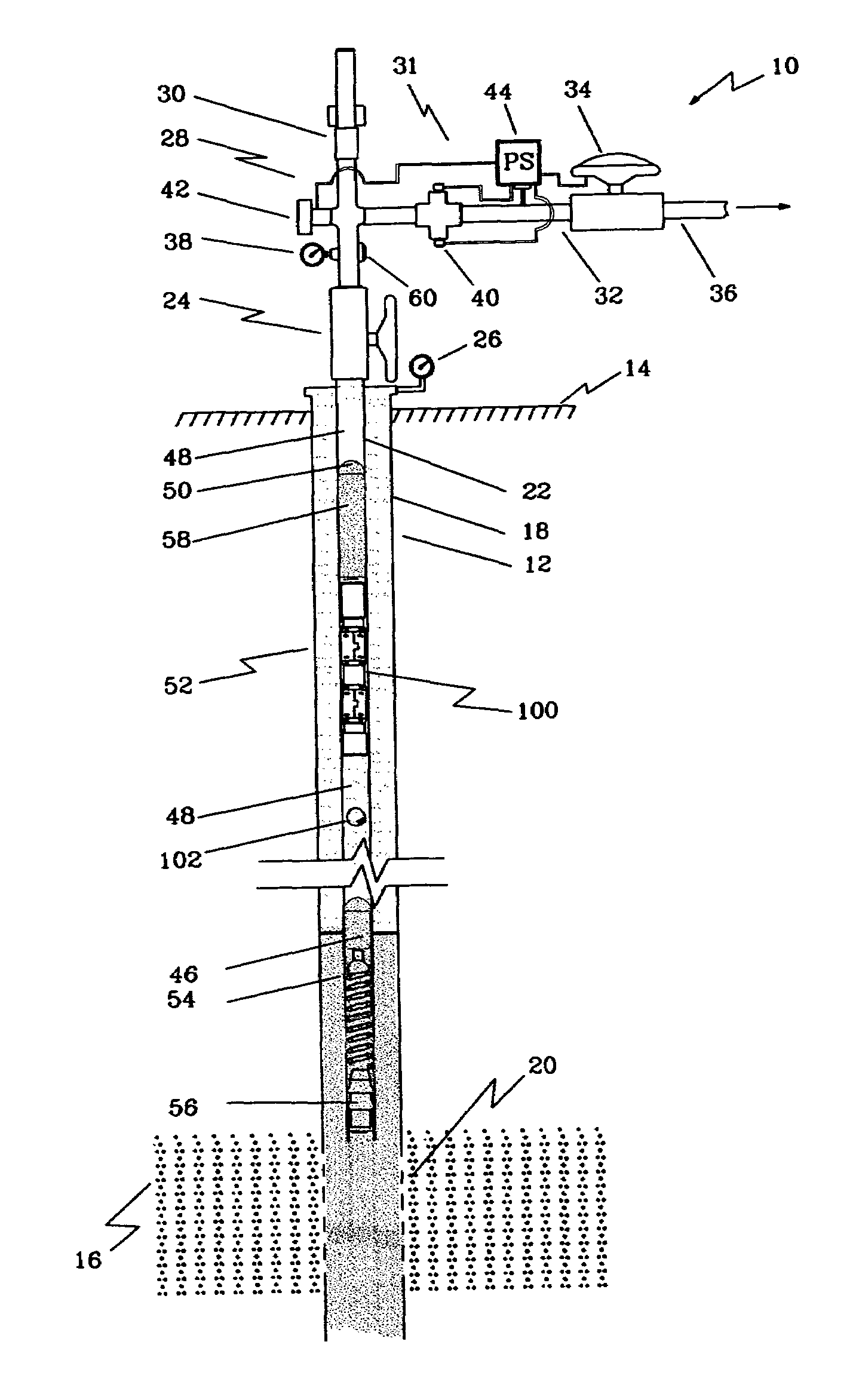

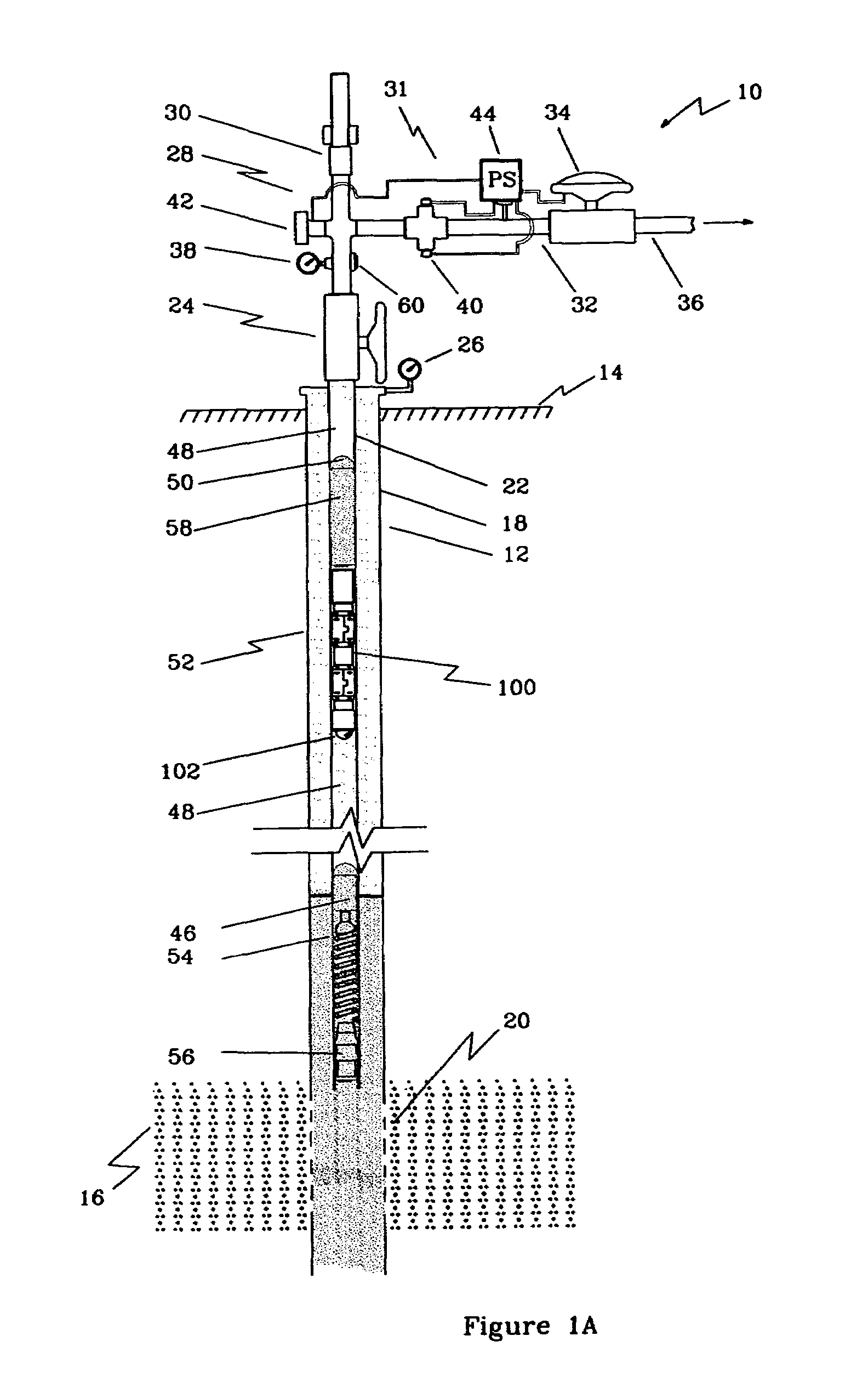

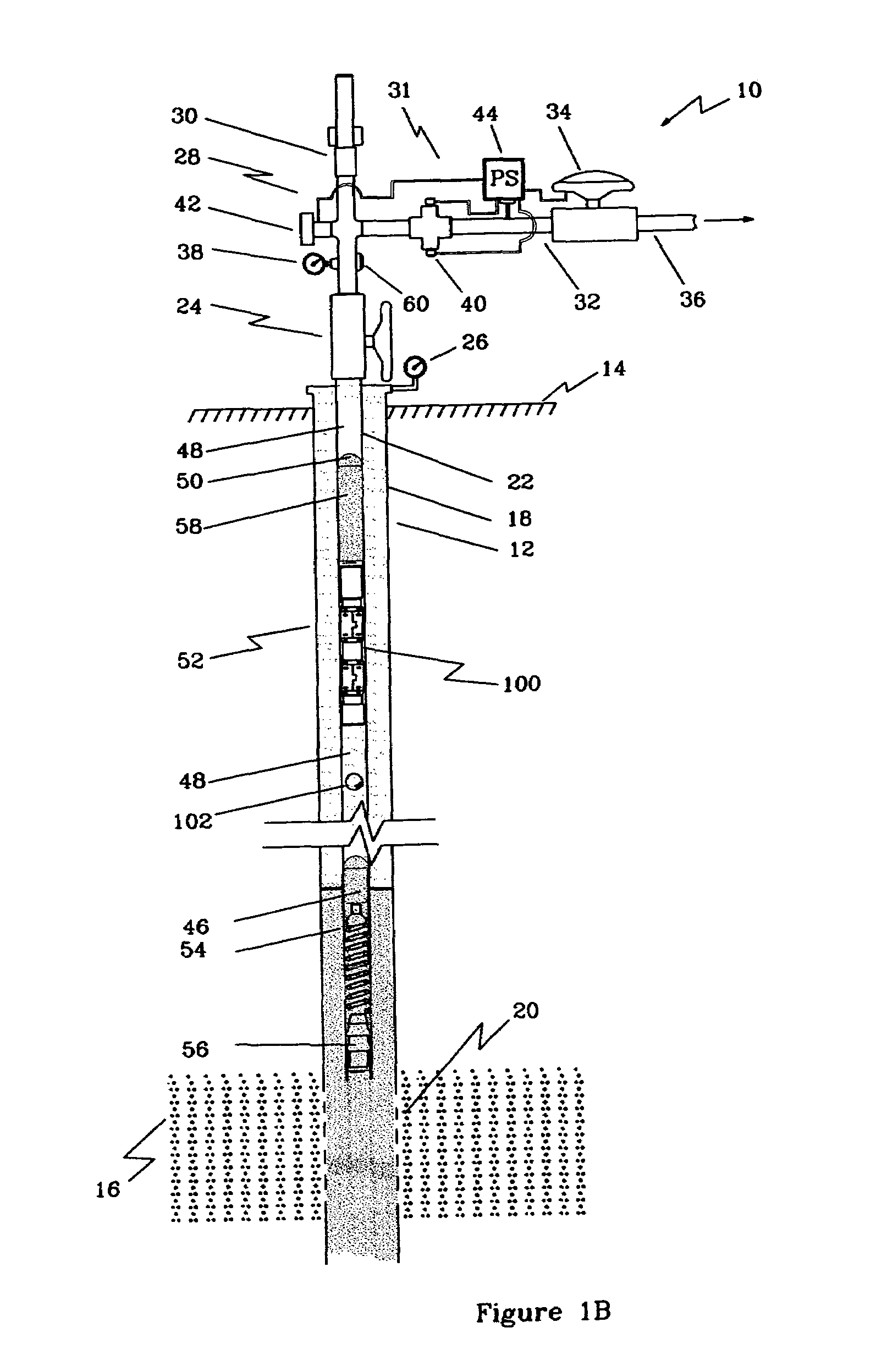

Wireless reservoir production control

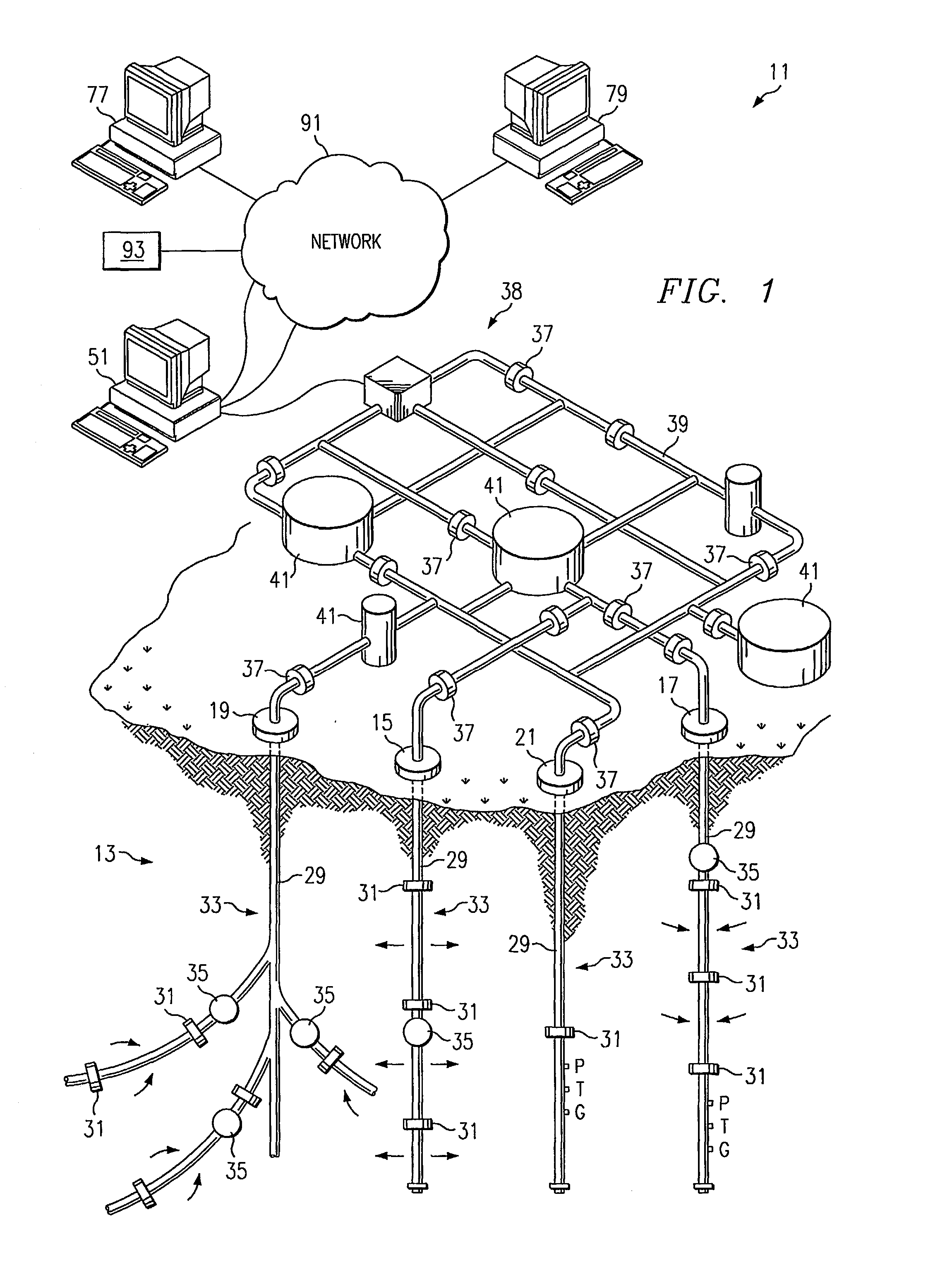

A reservoir production control system includes a plurality of wells for producing a reservoir linked to a central computer over a downhole communication network and a surface communication network. Both the downhole and the surface communication networks are wireless communications paths for transmitting downhole data and surface data to the central computer. Both networks include a series of interconnected tubing or pipe that allows transmission of data over electrically isolated portions of the pipe and tubing. After integrating and analyzing all relevant data and comparing the data with a reservoir model, the central computer initiates changes in a plurality of downhole control devices associated with the wells, thereby optimizing the production of the reservoir.

Owner:SHELL OIL CO

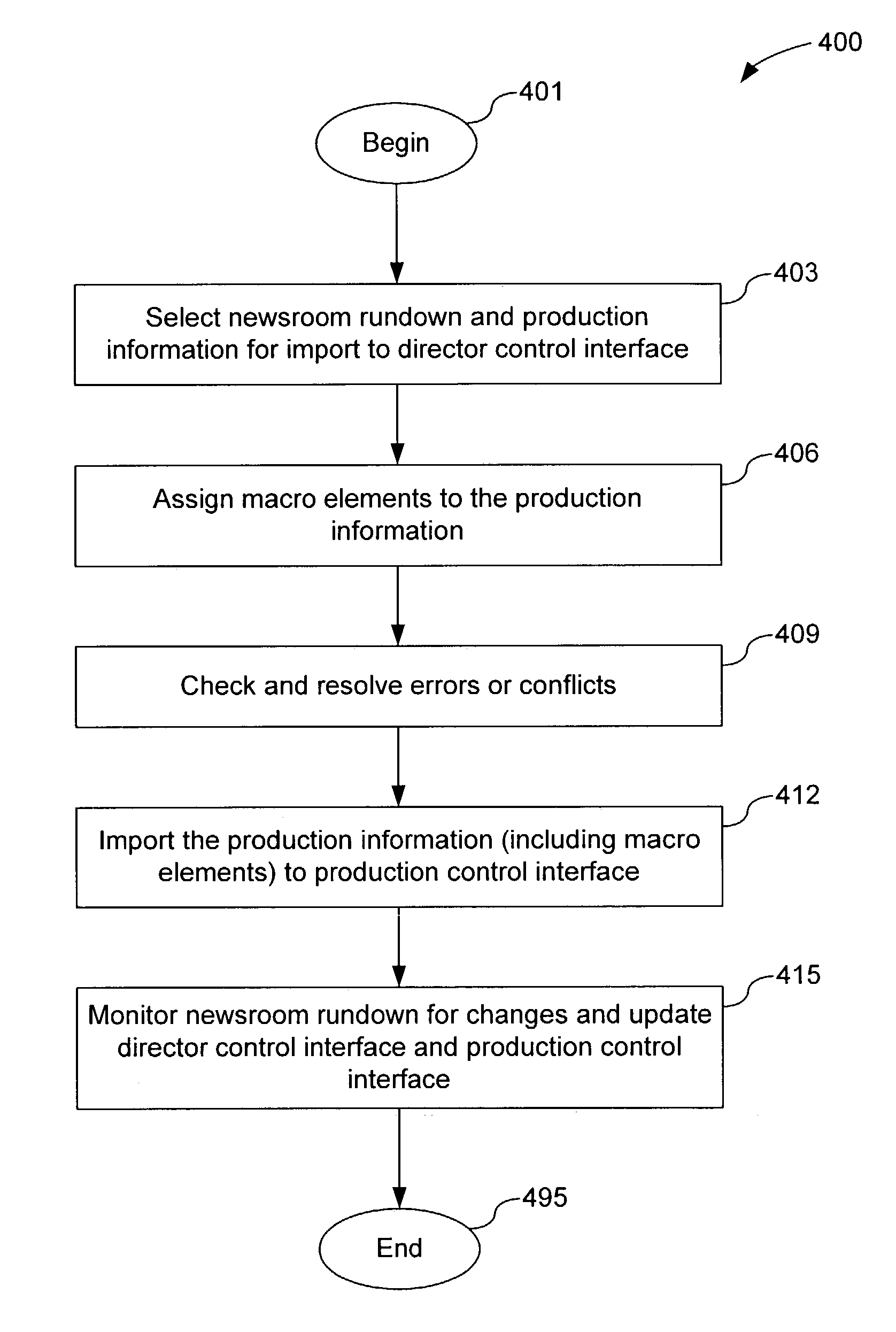

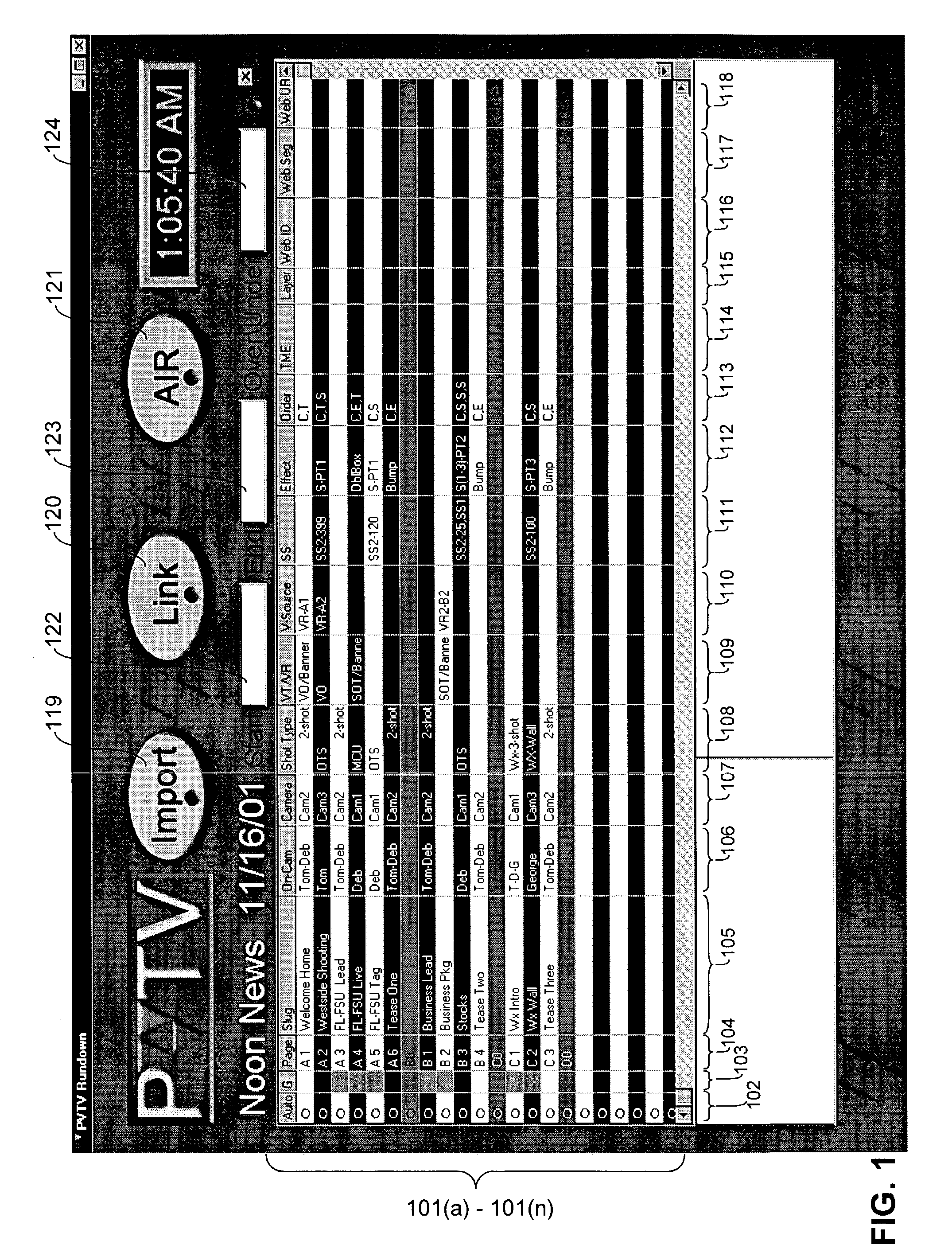

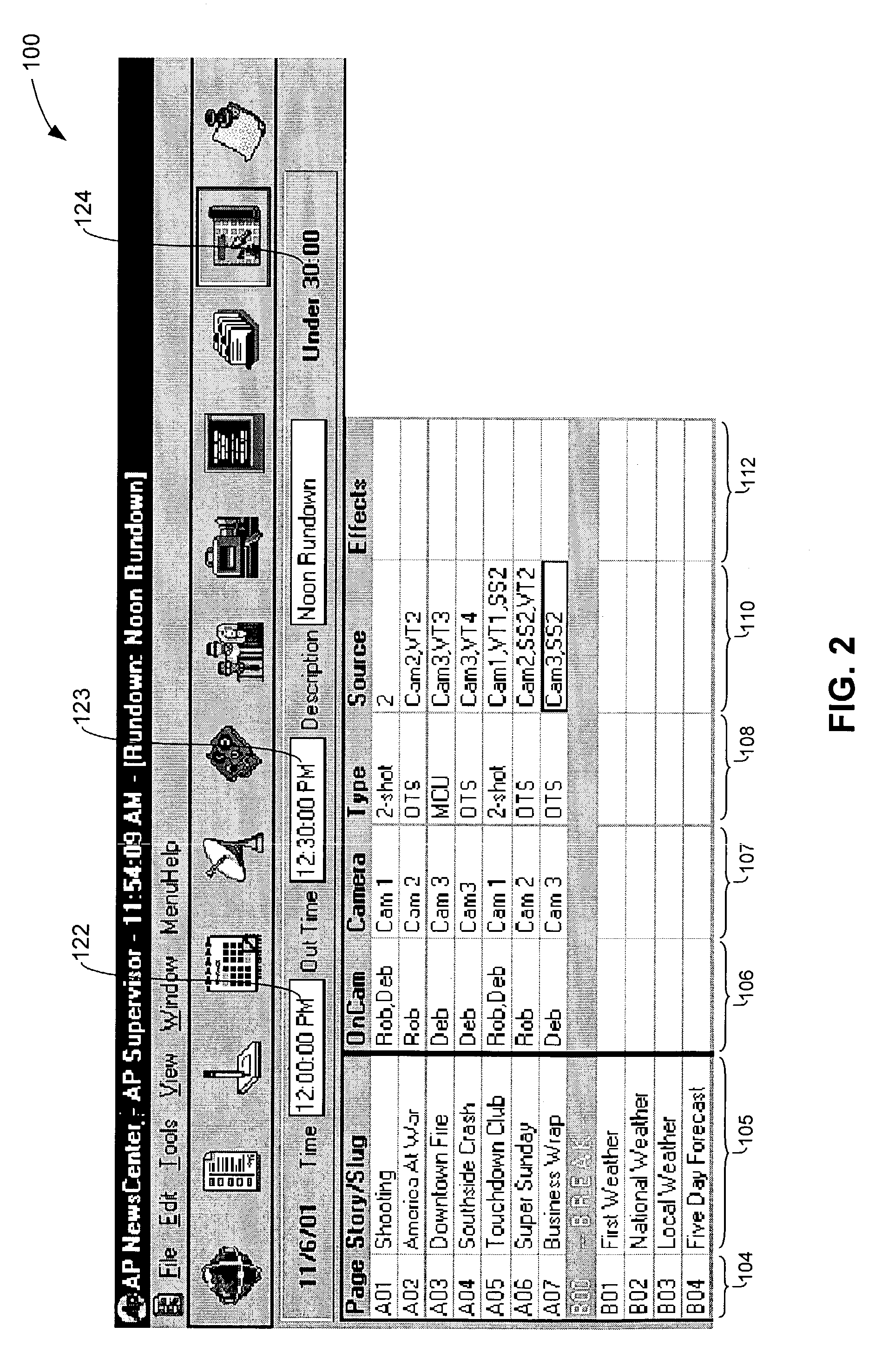

Director interface for production automation control

InactiveUS7835920B2Reduce errorsTelevision system detailsRecord information storageControl systemProduction control system

A director control interface is provided to extract production information from a newsroom information management system and populate a production control system. The director control interface enables the director to build a show, but mitigate errors and check for conflicts during the building process. In an embodiment, the director control interface automatically selects macro elements, which are executed on the production control system. The director can override the selection process and choose the macro elements. The director control interface monitors the newsroom information management system for rundown changes, evaluates the changes, and updates the production control system either automatically or with approval from the director. The director control interface is compatible with any type of newsroom information management system as long as it can extract the requisite information.

Owner:MAGNOLIA LICENSING LLC

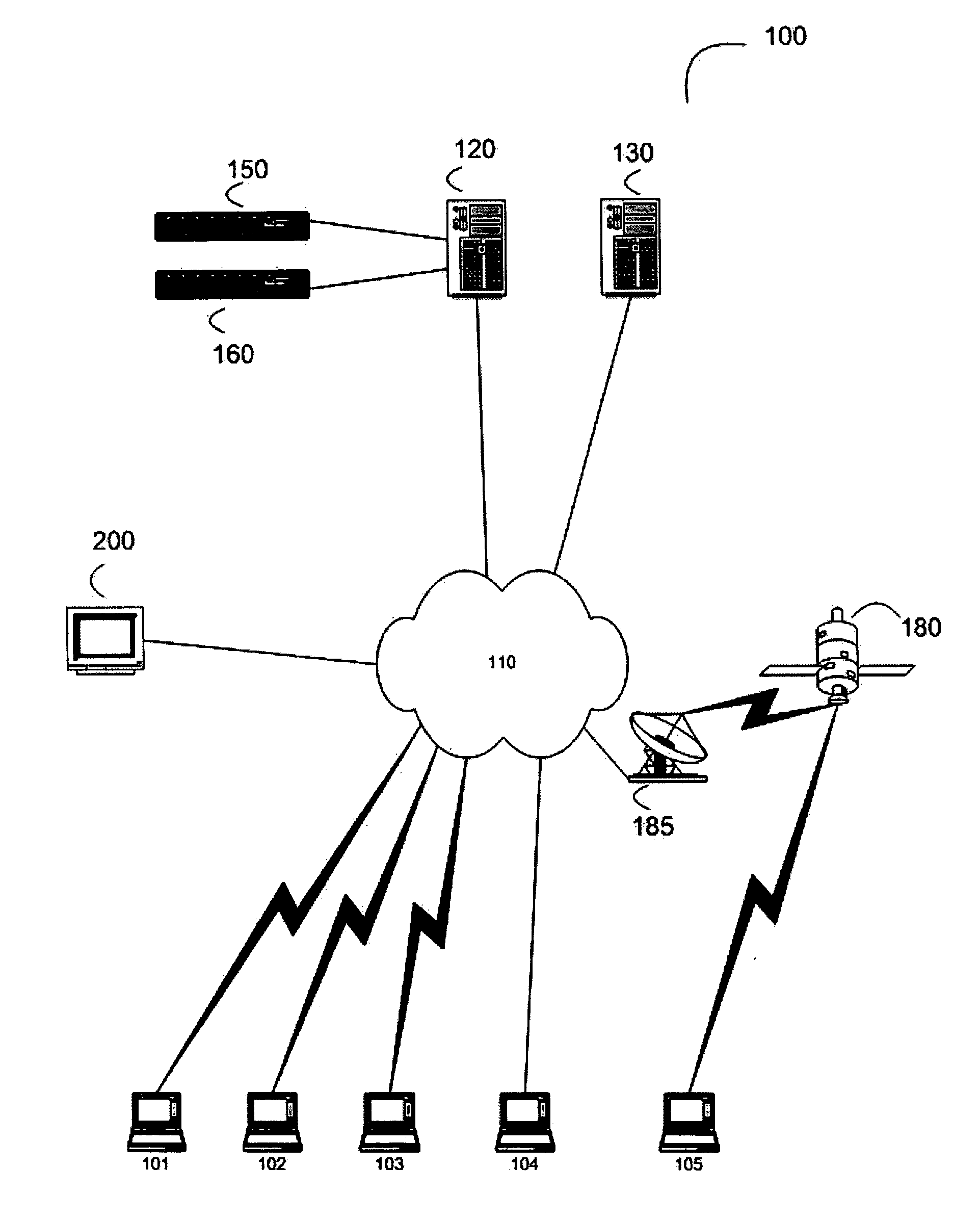

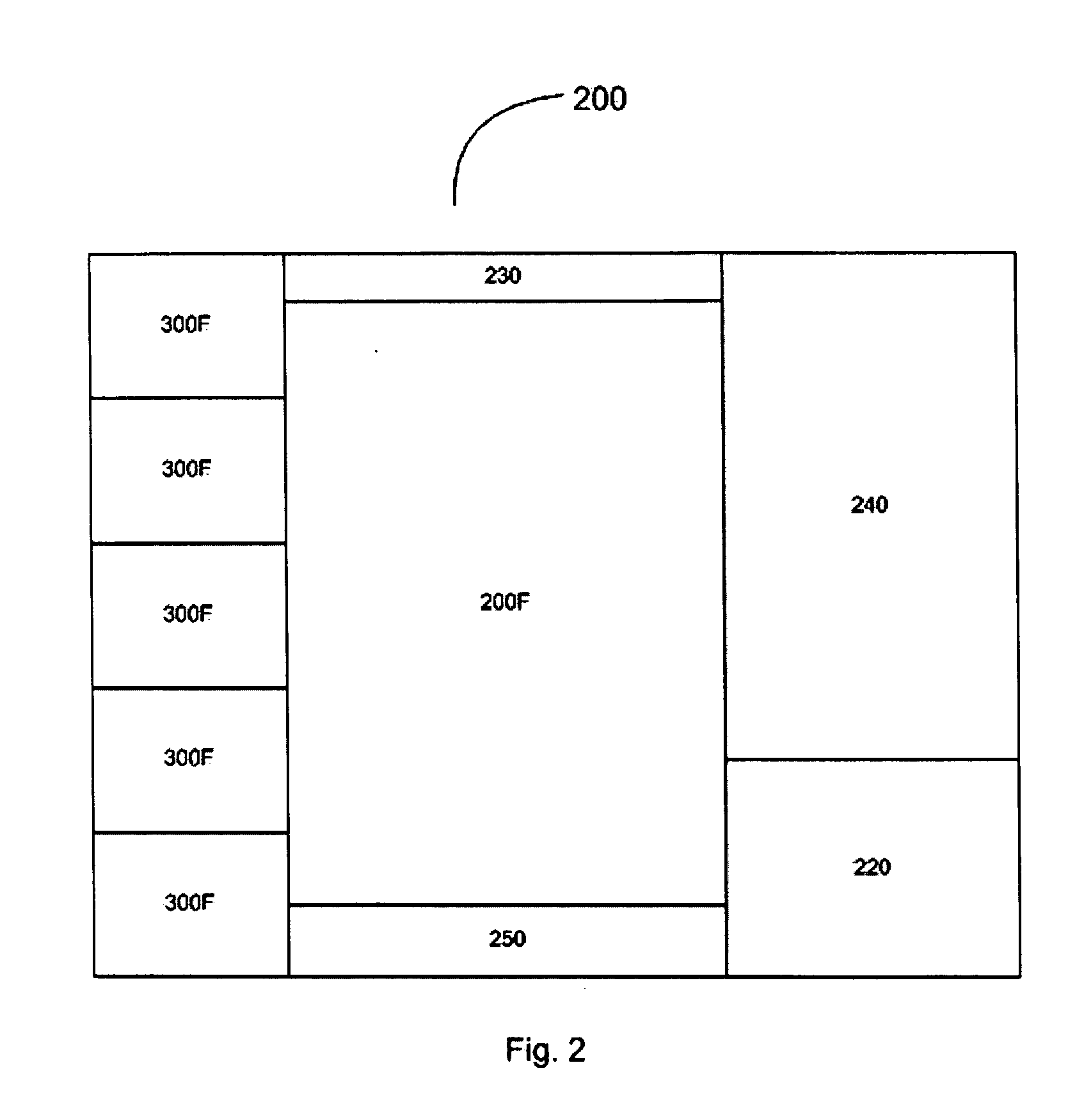

Interactive news gathering and media production control system

InactiveUS20070011710A1Easy to useTwo-way working systemsData switching networksWhiteboardWeb browser

A media production control system with built-in newsgathering and fact-checking tools, able to receive news feeds in multiple formats from many sources, and featuring geographic portability and low cost. The system allows a producer to select and queue individual feeds for broadcast or limited distribution, using either the system's software or an externally coupled device. Shared communications tools comprise a web browser, an instant-messaging package, a chat room, a headlines display, and a virtual whiteboard.

Owner:ERA DIGITAL MEDIA

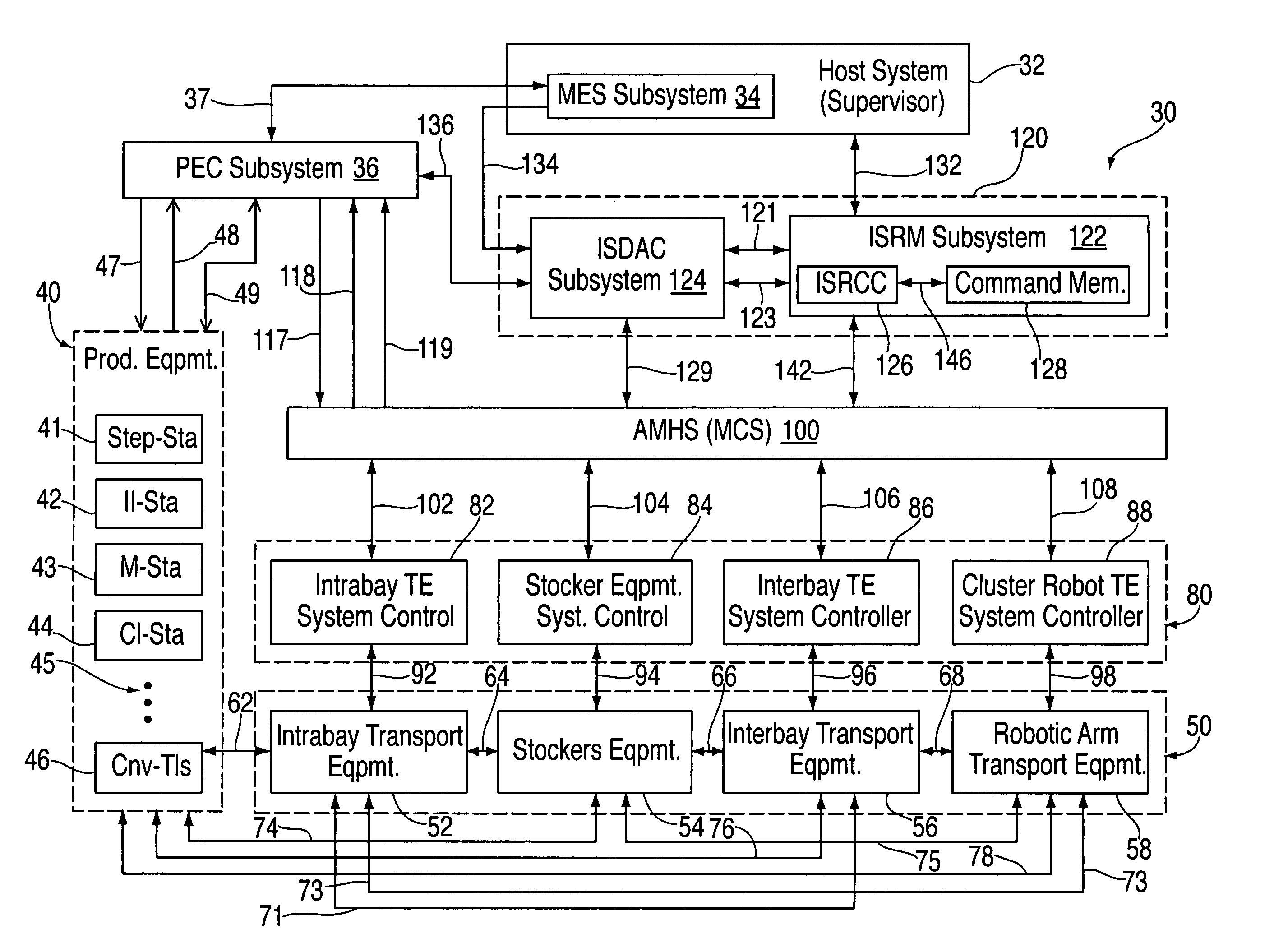

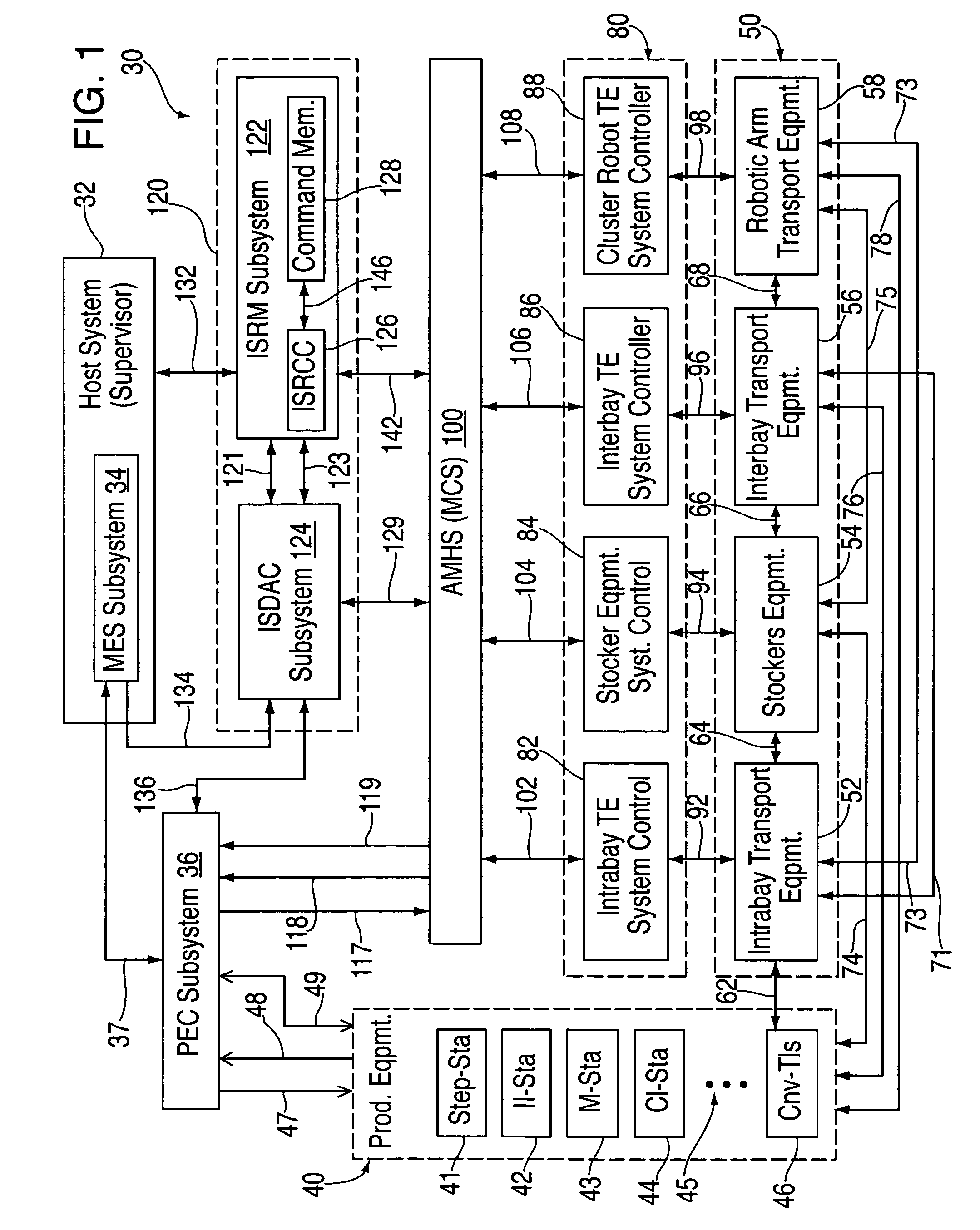

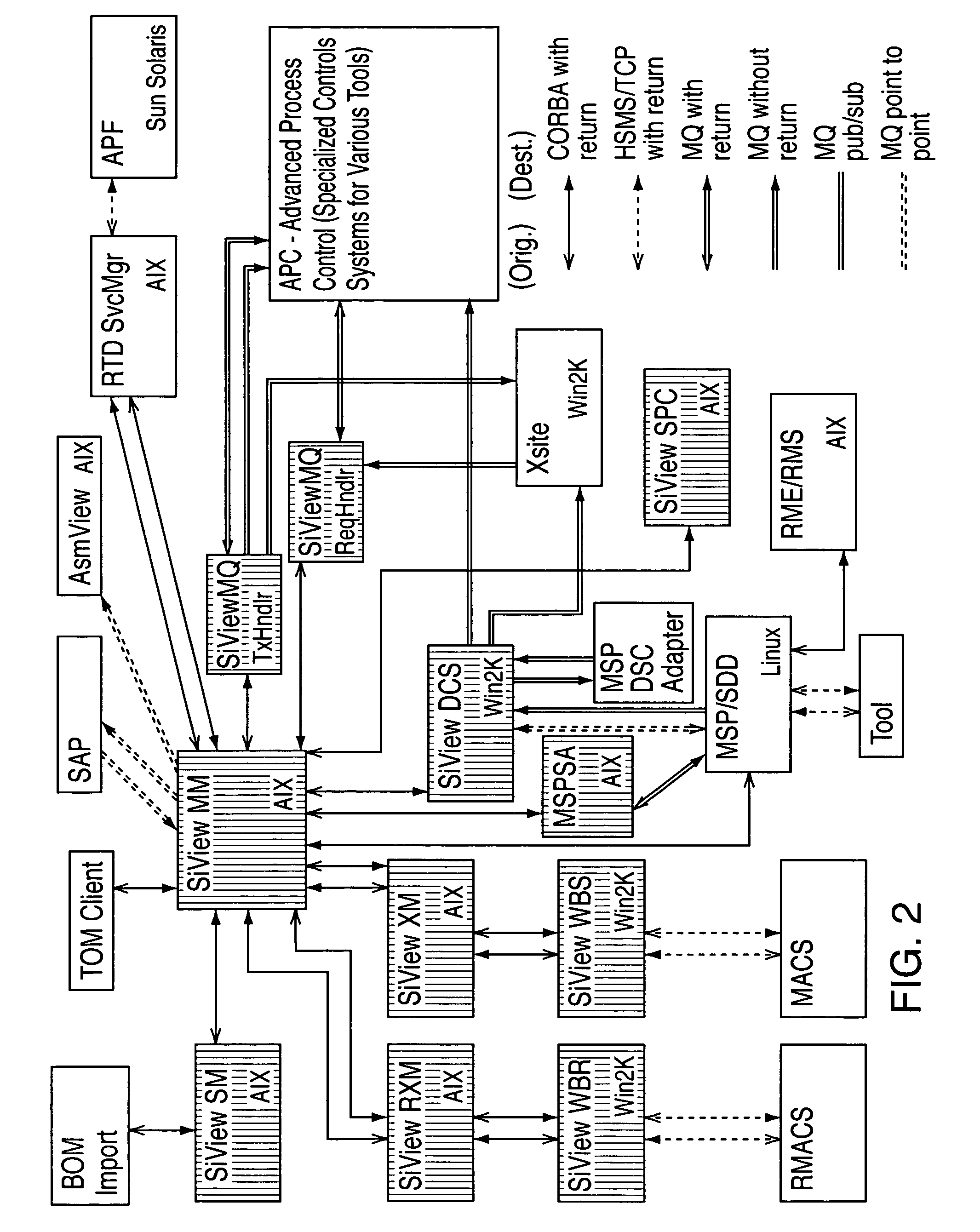

Method and system for automating issue resolution in manufacturing execution and material control systems

InactiveUS20050075748A1Decrease productivityImprove productivitySafety arrangmentsTesting/monitoring control systemsProduction rateImage resolution

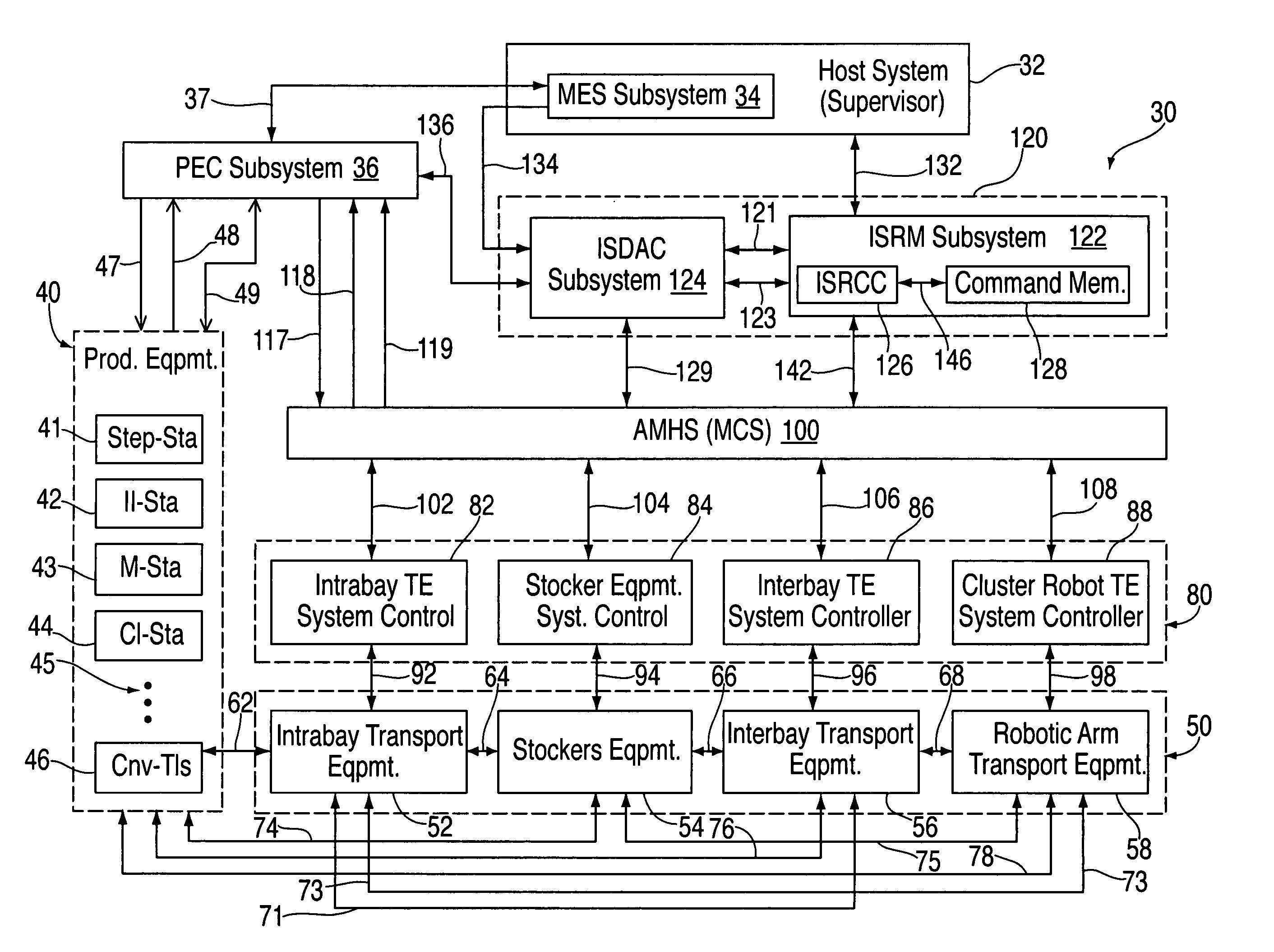

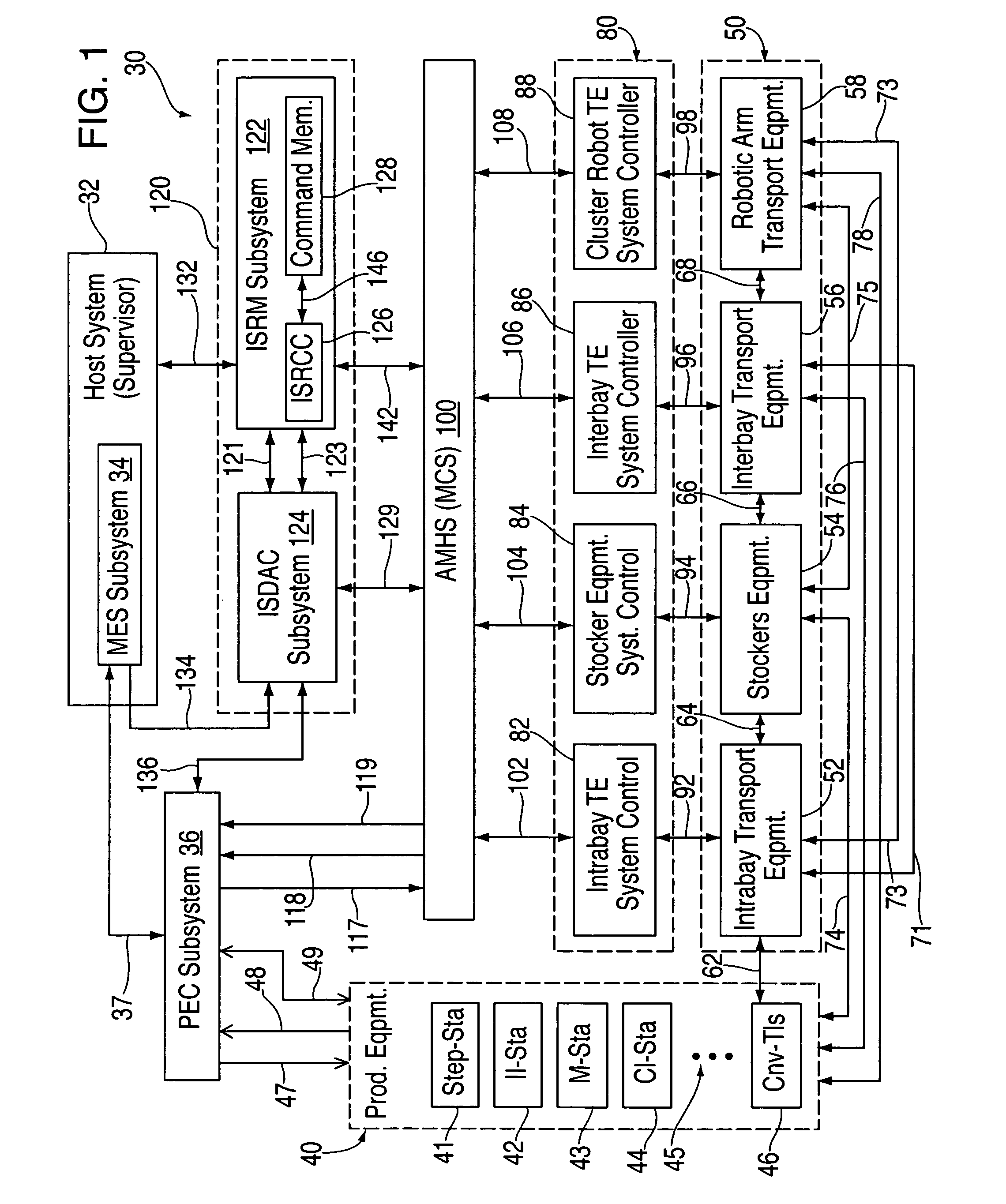

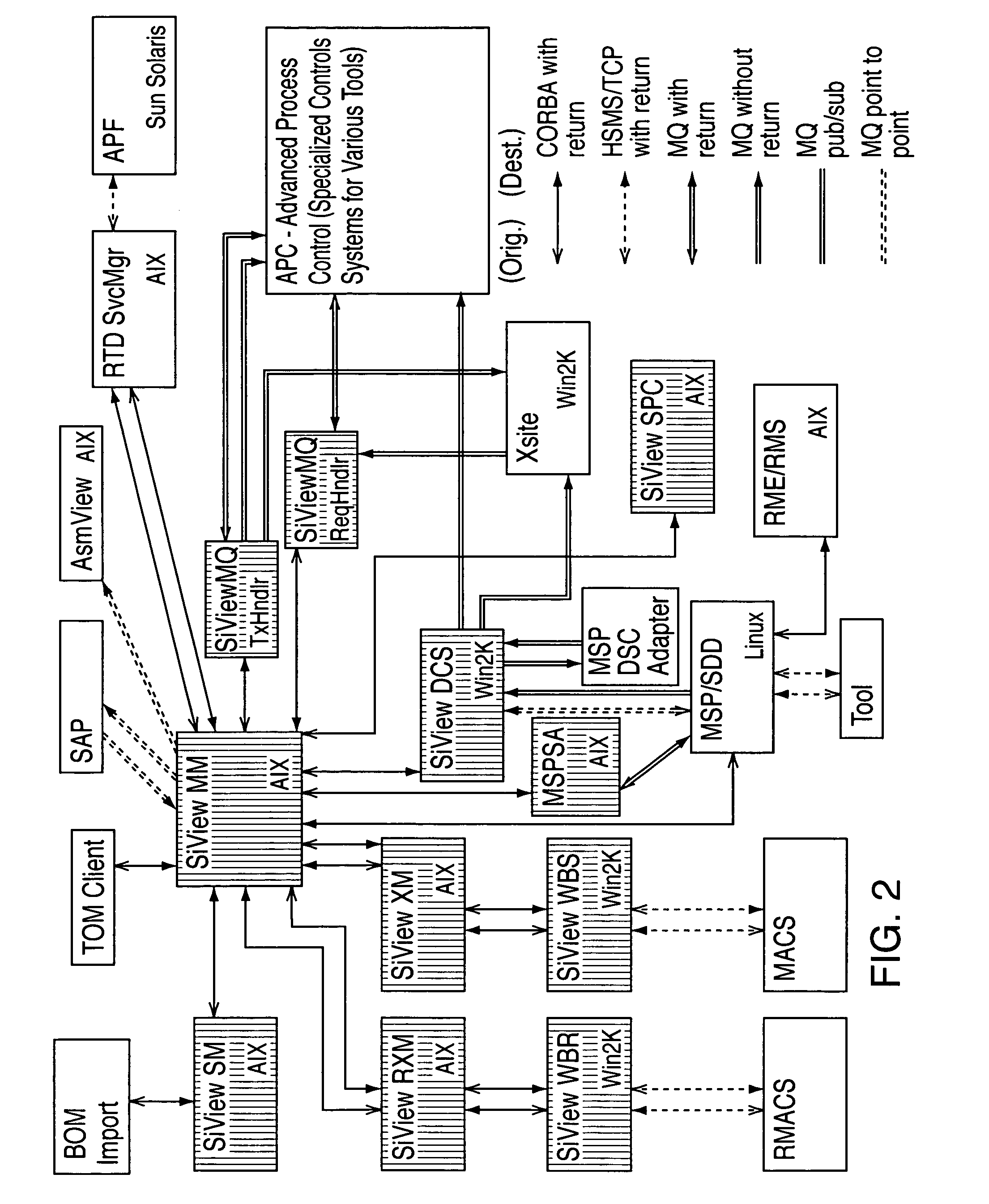

Automatic error recovery systems and methods for automated manufacturing plants and factories are disclosed. Such facilities normally have multiple automated control systems, including an automated material handling system (AMHS), all of which run automatically, typically under the control of a computerized manufacturing execution system (MES). The disclosed issue resolution (ISR) systems and methods involve providing components, which may be supervised and operated by an issue resolution management (ISRM) system, if desired, that interfaces with the MES, AMHS, and / or production control system(s) which operate the tools and other stations within the automated factory. The components, which may be considered customized logic cells, may each be written for handling a specific kind of incoming error condition, problem or other issue that might occur and which is amenable to automatic resolution or recovery. These errors often occur between or across the boundaries of the various interactive systems and automated equipment. Each cell may cycle through a sequence of possible error resolution or recovery steps until the specific issue is resolved or until the sequence of steps is exhausted. Other components of the ISR system may provide results-oriented messages and / or facilitate the collection of data as to whether and which corrective commands from the ISR system resolved the reported error conditions automatically. The disclosed ISR systems and methods for resolving errors and other issues automatically helps improve the overall productivity of automated factories by reducing downtime and the need for human intervention to correct problems, thereby increasing factory throughput.

Owner:IBM CORP

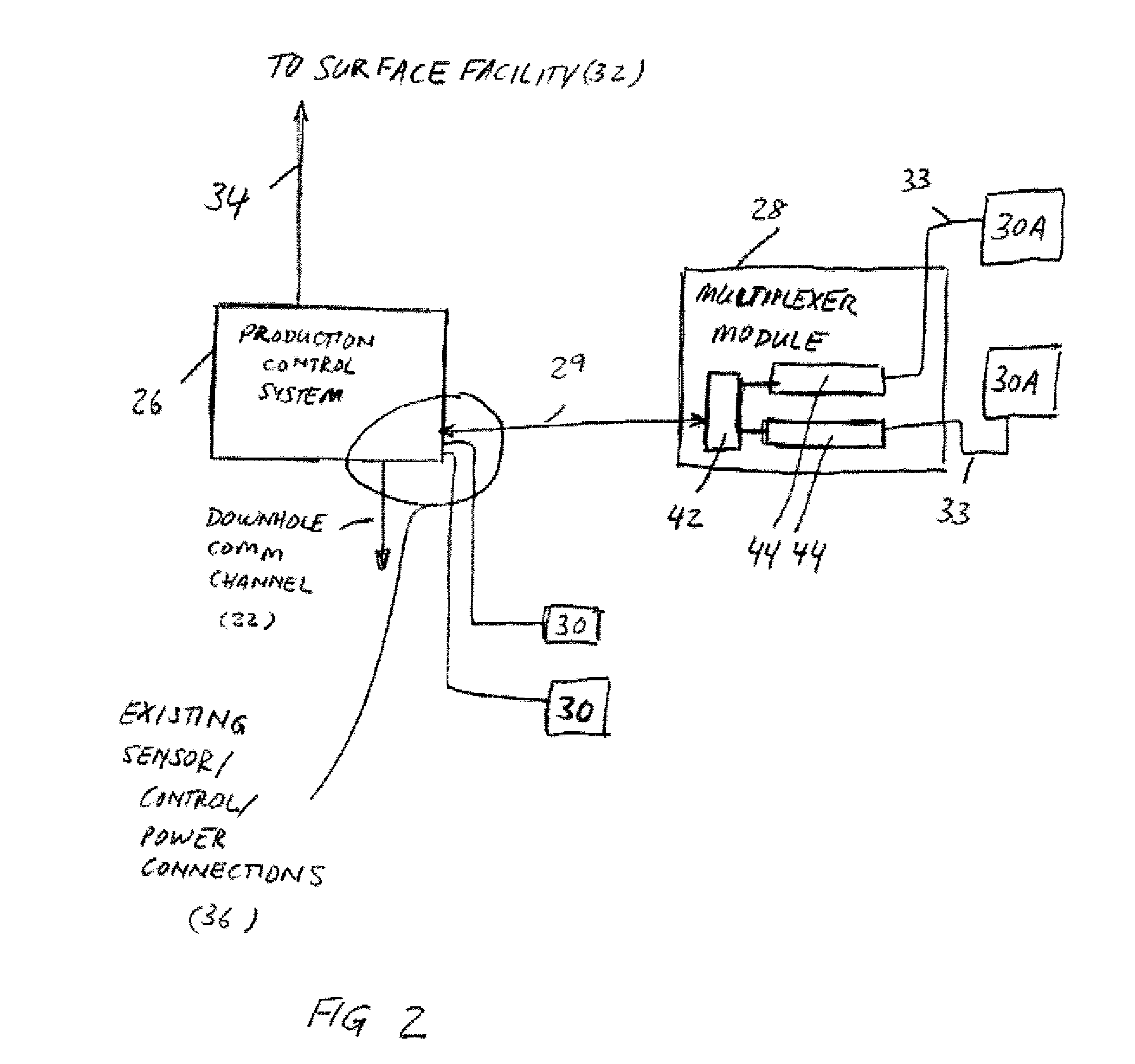

Subsea communications multiplexer

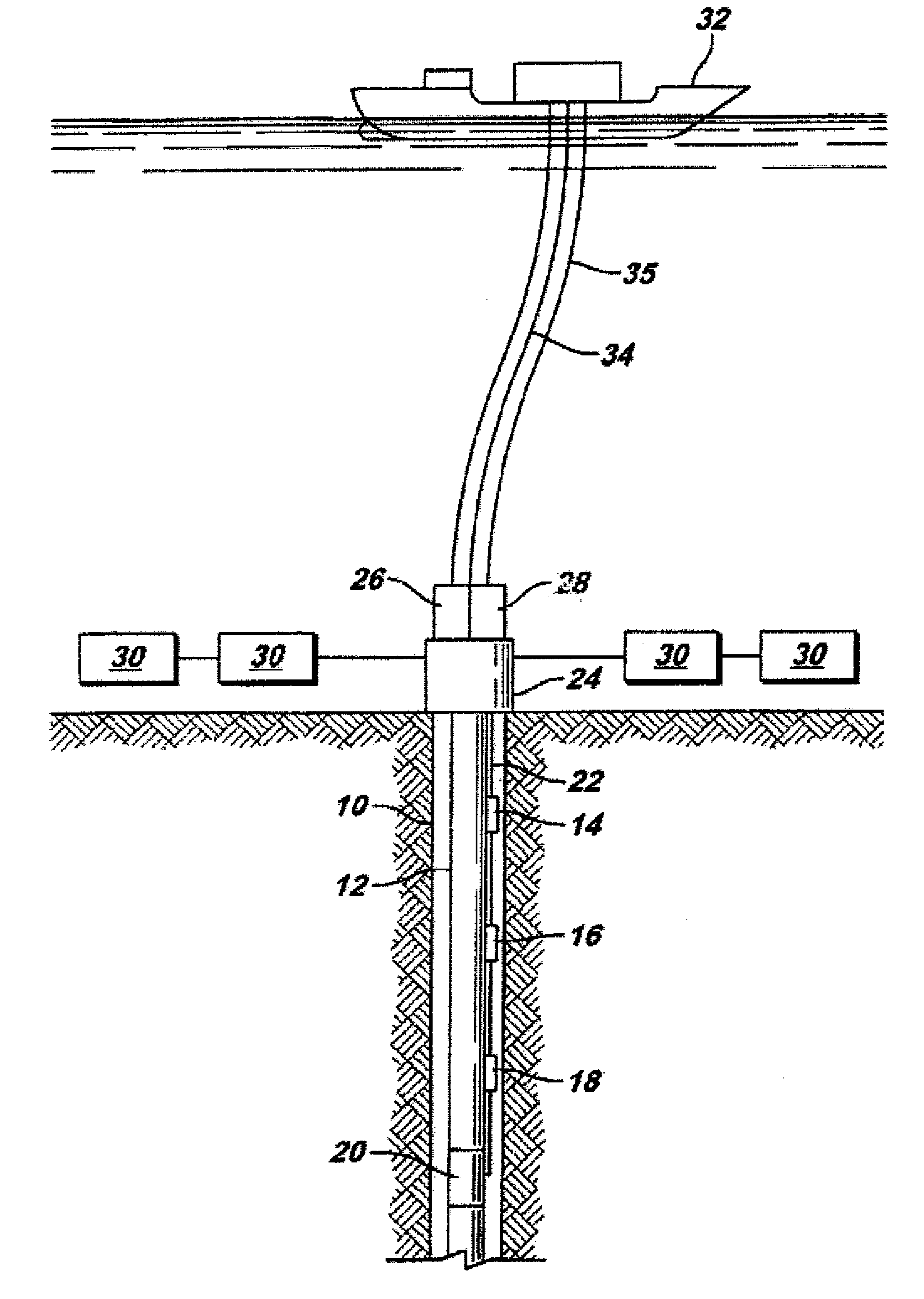

A system for communicating between a surface facility and a subsea production control system includes a communications device proximate the water surface. The water surface communications device has at least one communication interface. A communications device is functionally associated with a wellhead or subsea structure proximate the water bottom. The water bottom communications device has at least one communication interface. A communication channel extends between the surface communication device and the water bottom communication device. A multiplexer is functionally coupled to the communication interface on each of the surface and water bottom communication devices. At least two remote devices are functionally coupled to the water bottom multiplexer. The remote devices comprise at least one of a sensor and a control. At least two corresponding devices are coupled to the surface multiplexer. The corresponding devices include at least one of a signal acquisition device and a control signal generating device.

Owner:SCHLUMBERGER TECH CORP

Process control methods and apparatus for intrusion detection, protection and network hardening

ActiveUS20060294579A1Digital data processing detailsUser identity/authority verificationEnvironmental control systemProduction control system

The invention provides an improved network and methods of operation thereof for use in or with process control systems, computer-based manufacturing or production control systems, environmental control systems, industrial control system, and the like (collectively, “control systems”). Those networks utilize a unique combination of firewalls, intrusion detection systems, intrusion protection devices and / or other devices for hardening (e.g., security against hacking, intrusion or other mischievous conduct) and / or intrusion detection. The networks and methods have application, by way of example, in plants, sites and other facilities in which networks that support control systems interface with corporate, business or other networks.

Owner:SCHNEIDER ELECTRIC SYST USA INC

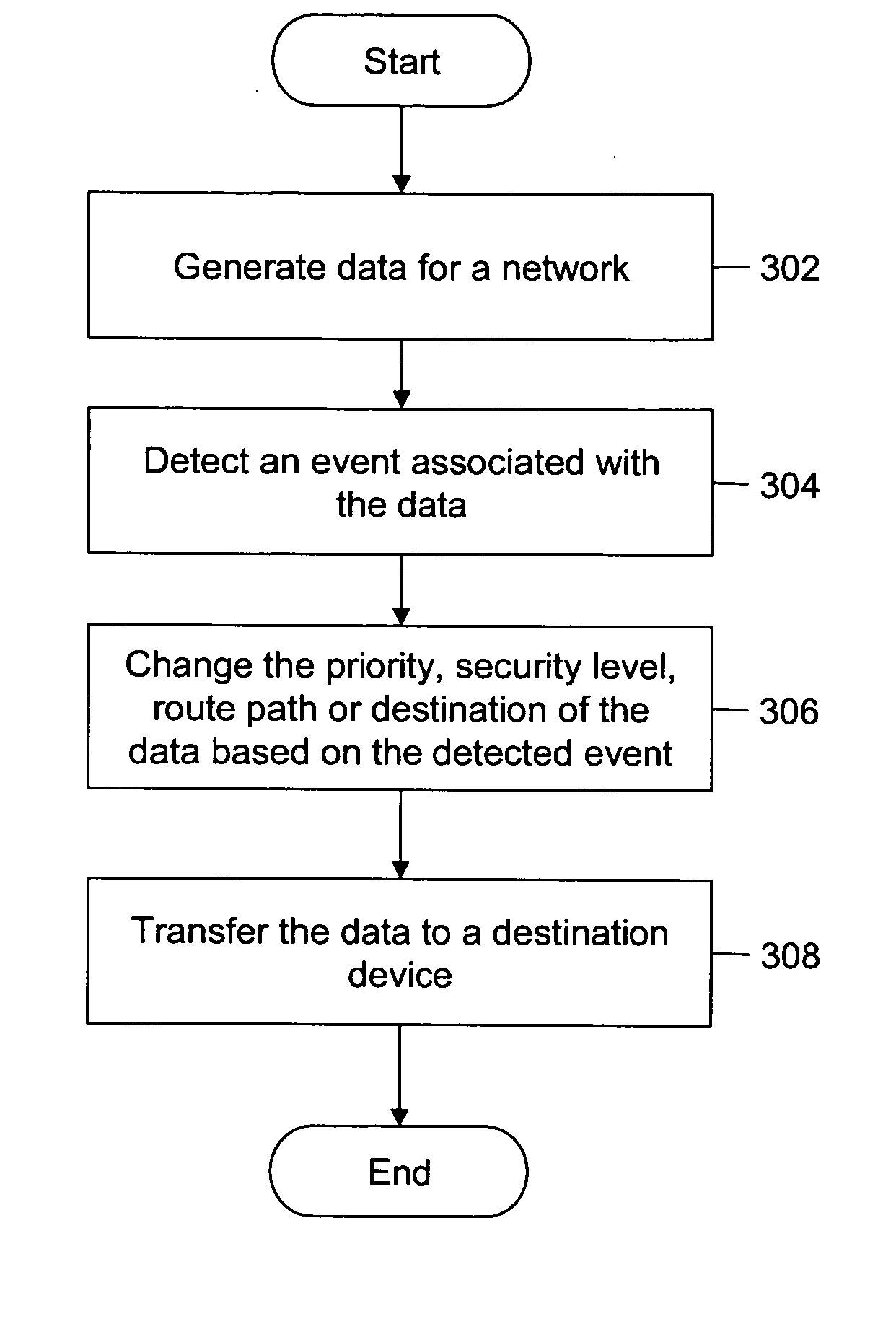

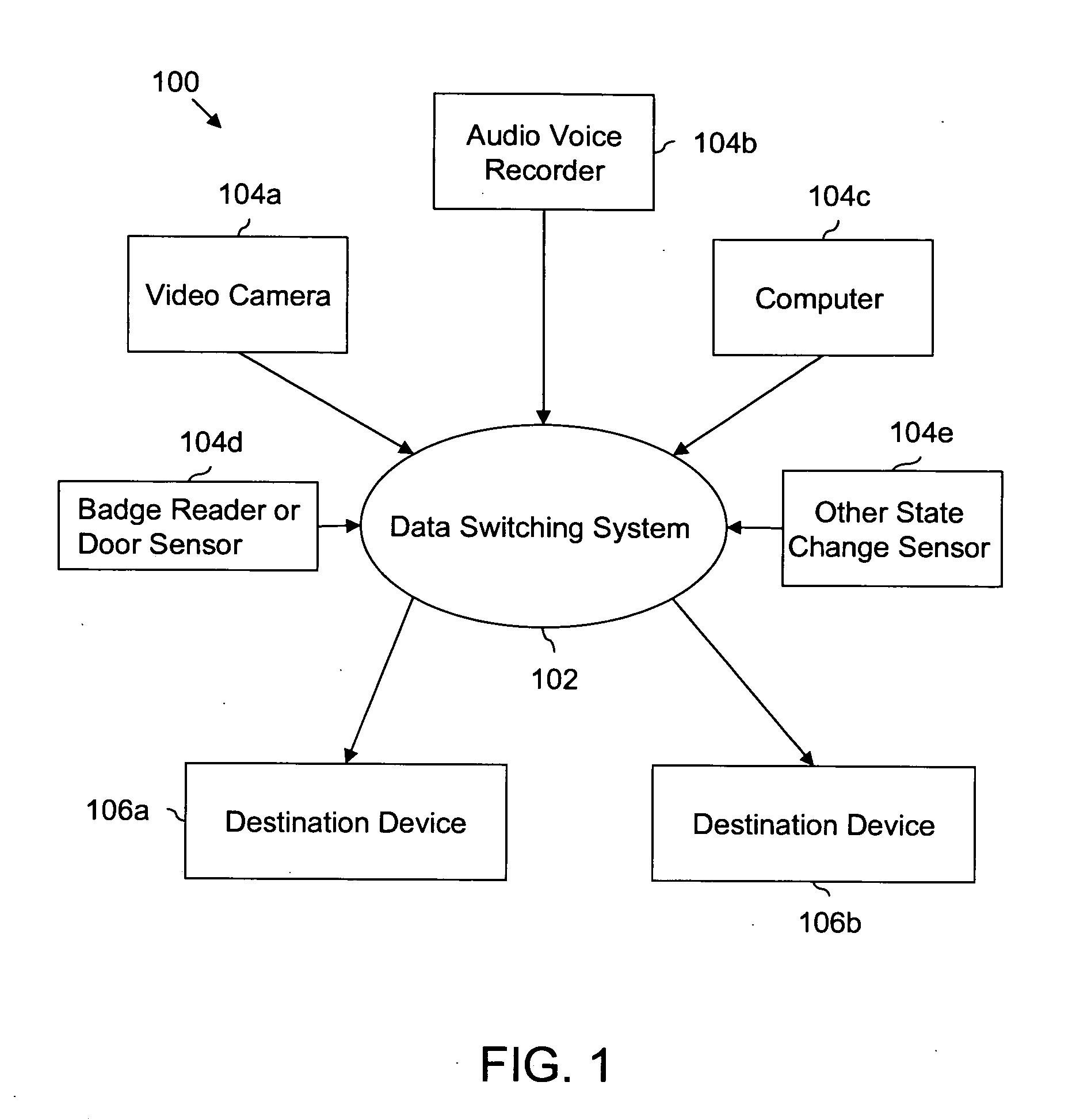

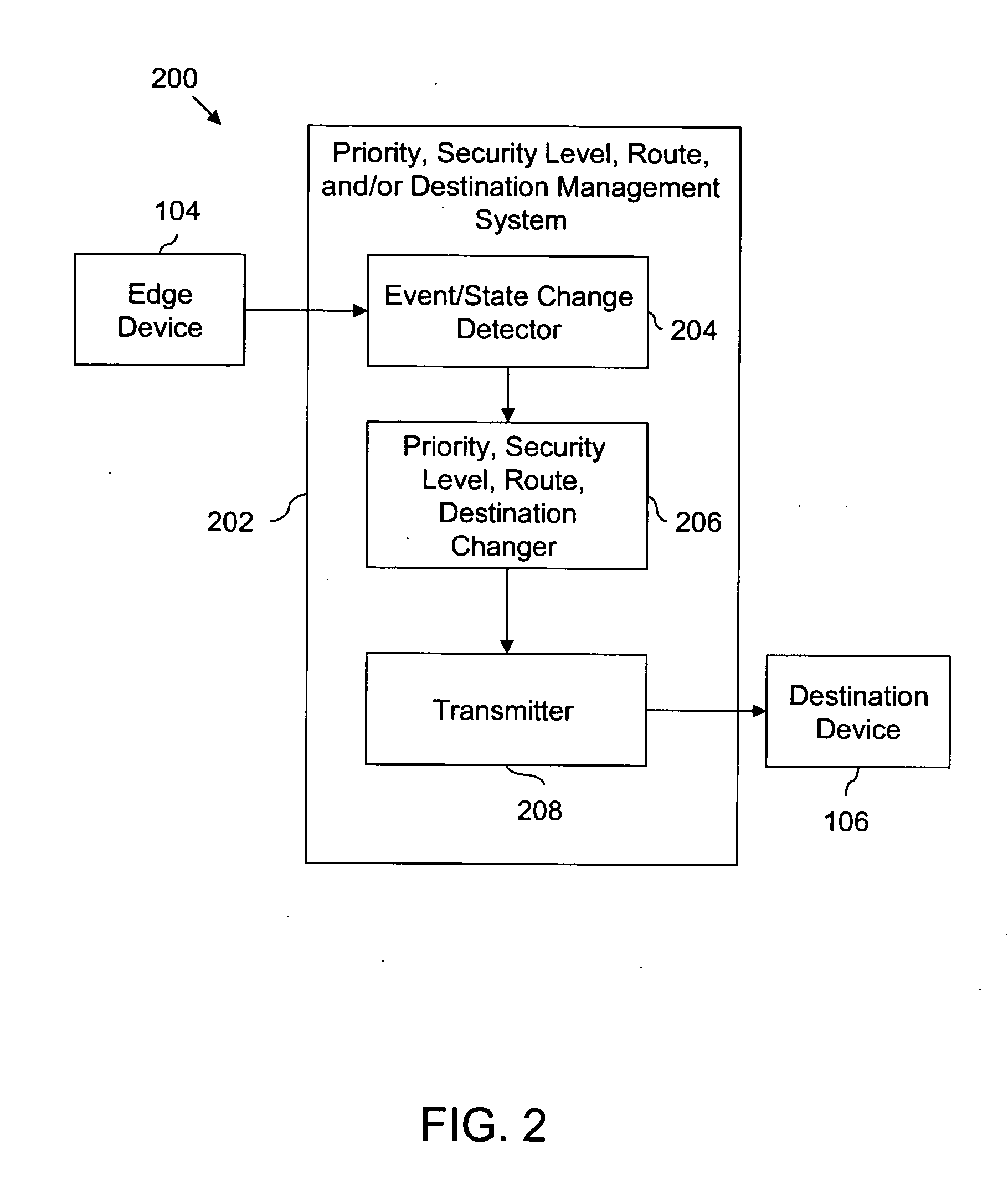

Method and system for transmitting data over a network based on external non-network stimulus

Method, system and apparatus are provided for transmitting data over a network based on external, non-network oriented (external to the network) stimulus. A facility's physical security, environment monitoring / management, or production control system utilizing a frame-based / packet-based network includes a number of edge devices, an event / state change detector, a priority, security level, route specification, destination changer, a transmitter, and a number of destination devices. Edge devices generate data for the network; the event / state change detector identifies an event associated with the data; the priority, security level, route specification, destination changer changes the priority, security level, route, destination of the data, based on the detected event or state change; and the transmitter then transmits the data to an intended destination device, based on the changed priority, security level, route, and destination.

Owner:CISCO TECH INC

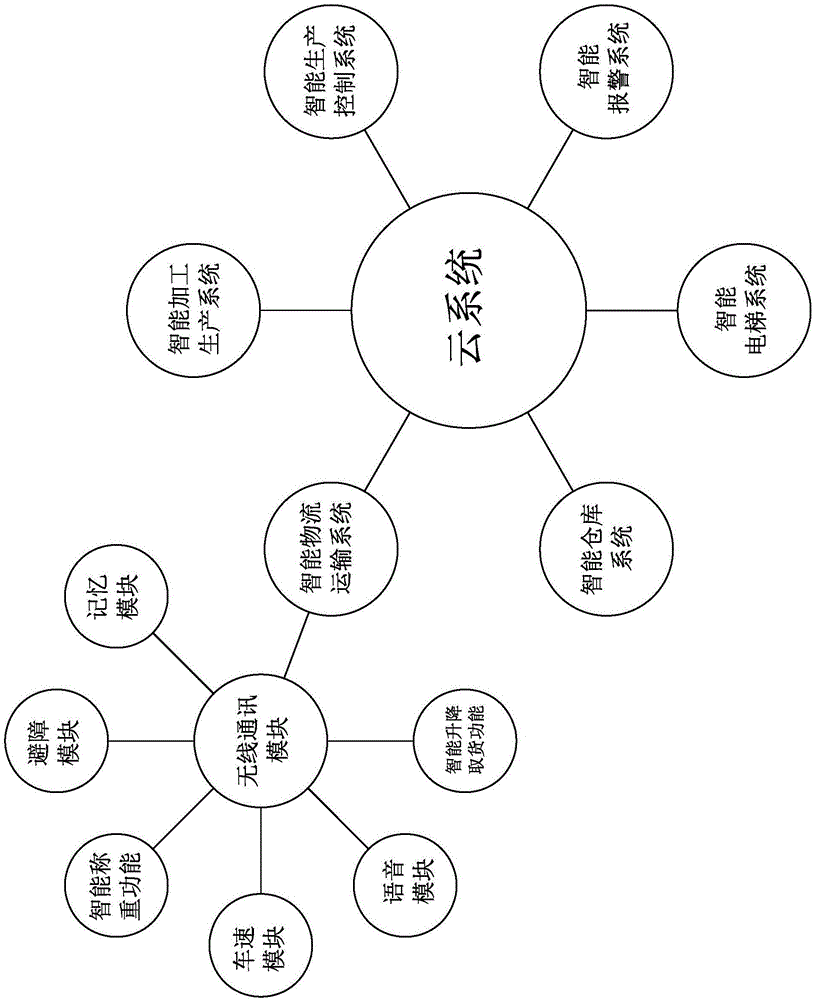

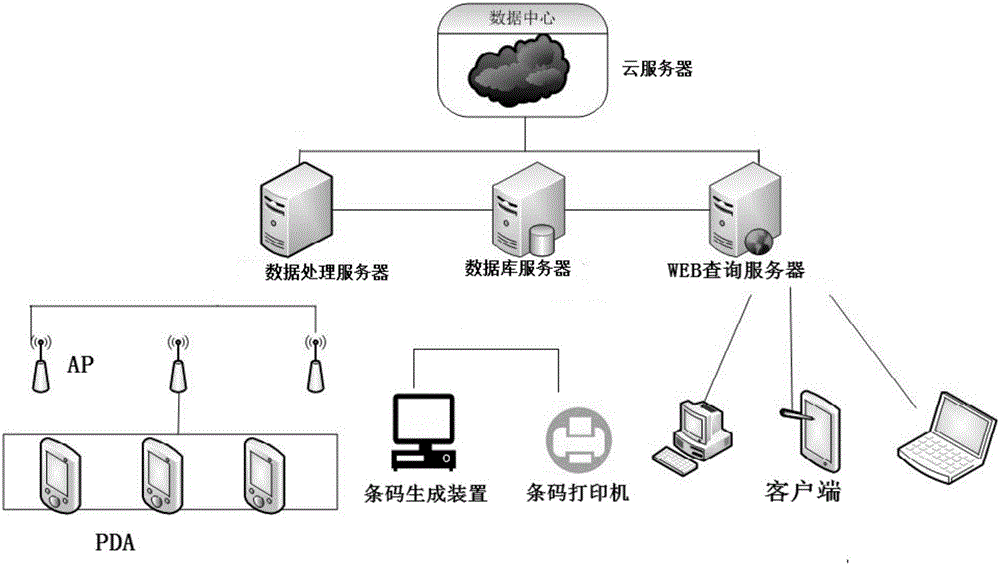

Factory intelligent workshop real-time scheduling system

ActiveCN106056298AIntelligent Management ScienceManagement scienceResourcesProduction control systemStorage garage

The invention relates to a factory intelligent workshop real-time scheduling system, and is designed to solve the technical problem that a management system of an existing factory intelligent workshop needs further improvement. The system is mainly characterized in that an intelligent processing production line of the scheduling system finishes research and purchase as well as installation and debugging of workshop machining equipment; an intelligent warehouse and logistics transportation system carries out scientific classification, storage and transportation on raw materials and substances, management of finished and semi-finished products, and analysis and management on storage data of the raw materials, the semi-finished products and the finished products; an intelligent production control system, by fully utilizing information technology, carries out control in multiple dimensions of production plan issuing, material delivery, production scheduling, completion confirmation, standard operation guidance, quality control and finished product bar code acquisition, and accurately conveys on-site information to a production manager and a decision maker in real time through a network; and an intelligent alarm system is used for monitoring environment and temperature and reminding a transfer robot to return, avoid obstacles and charge.

Owner:宁波赛夫科技有限公司

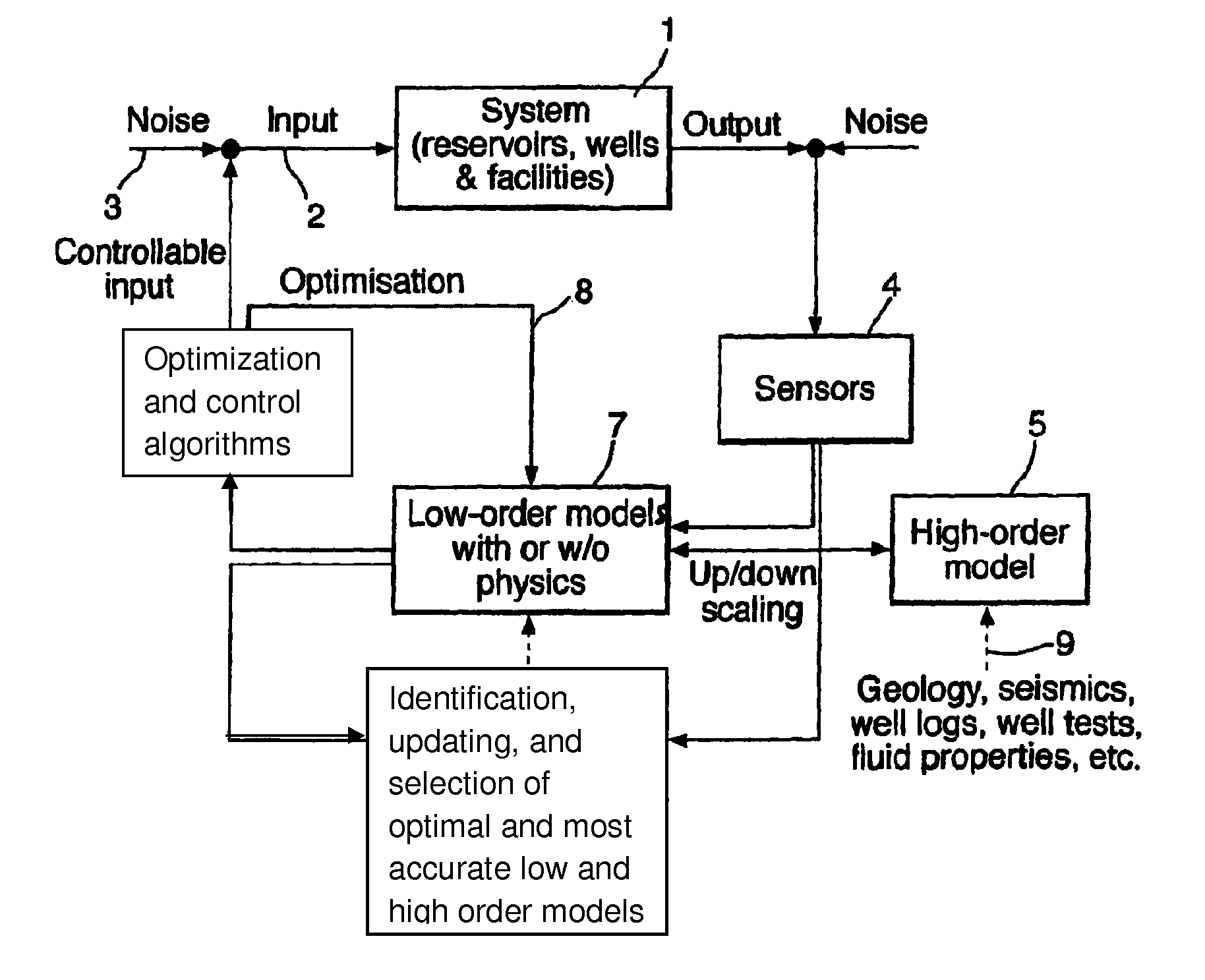

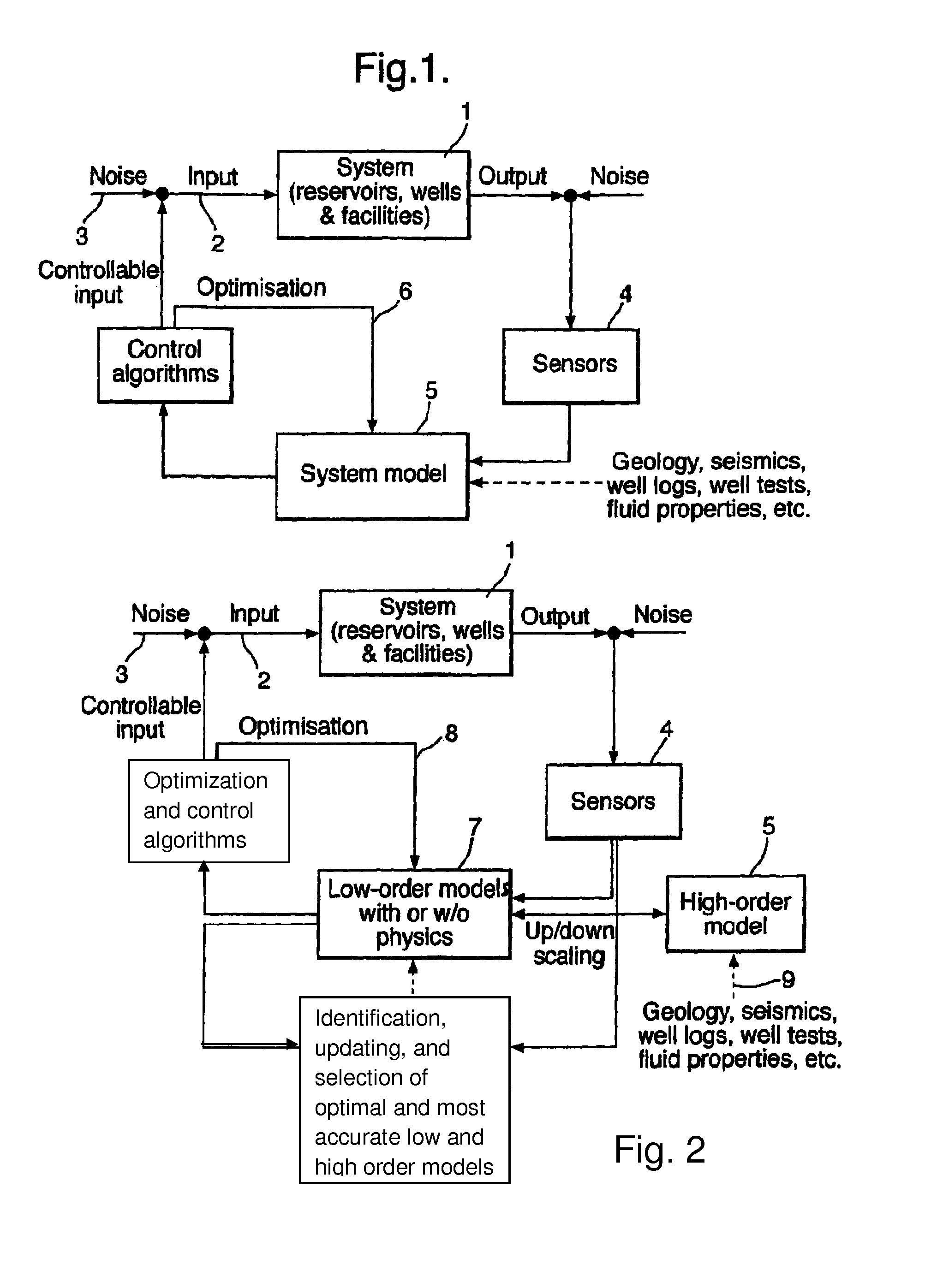

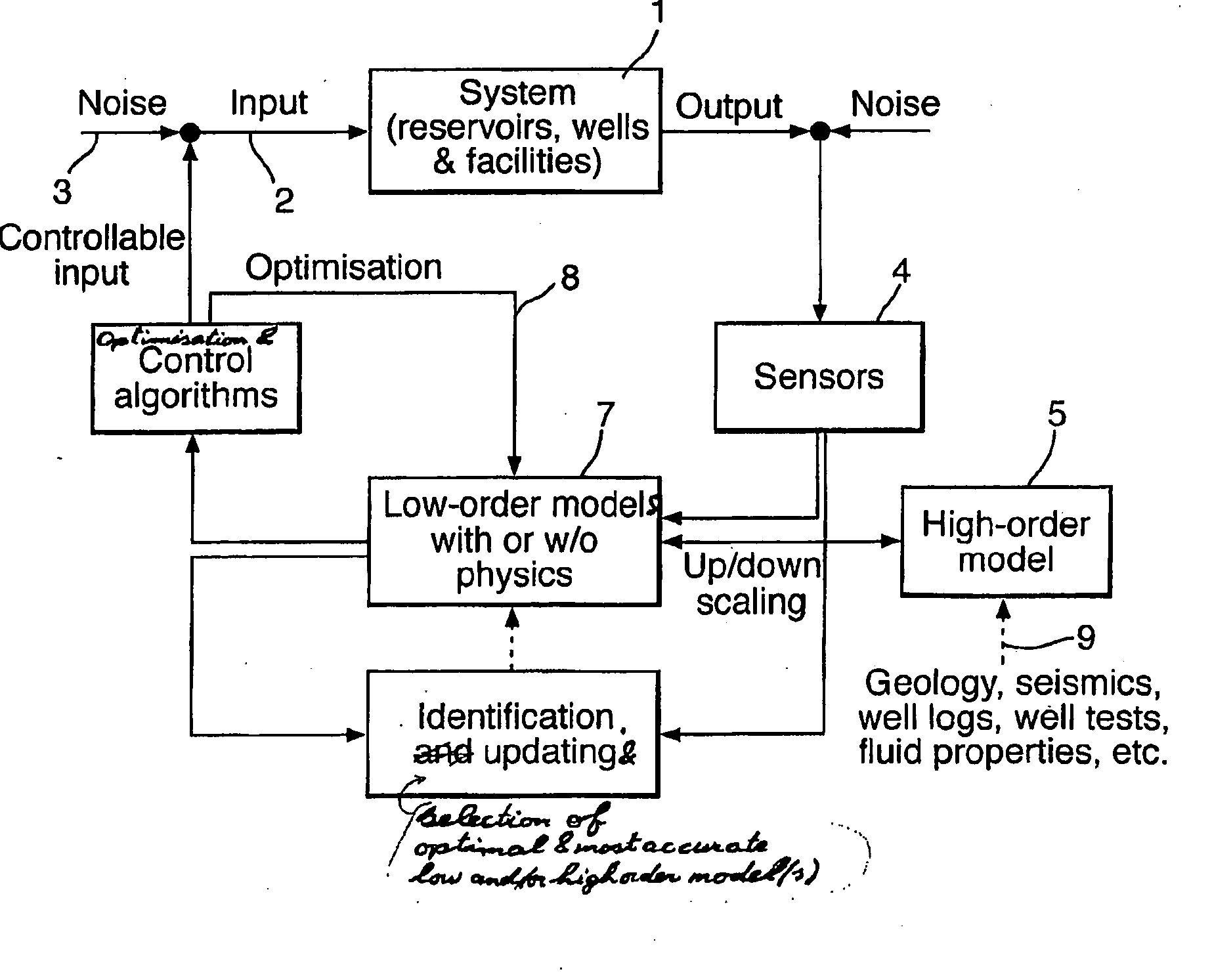

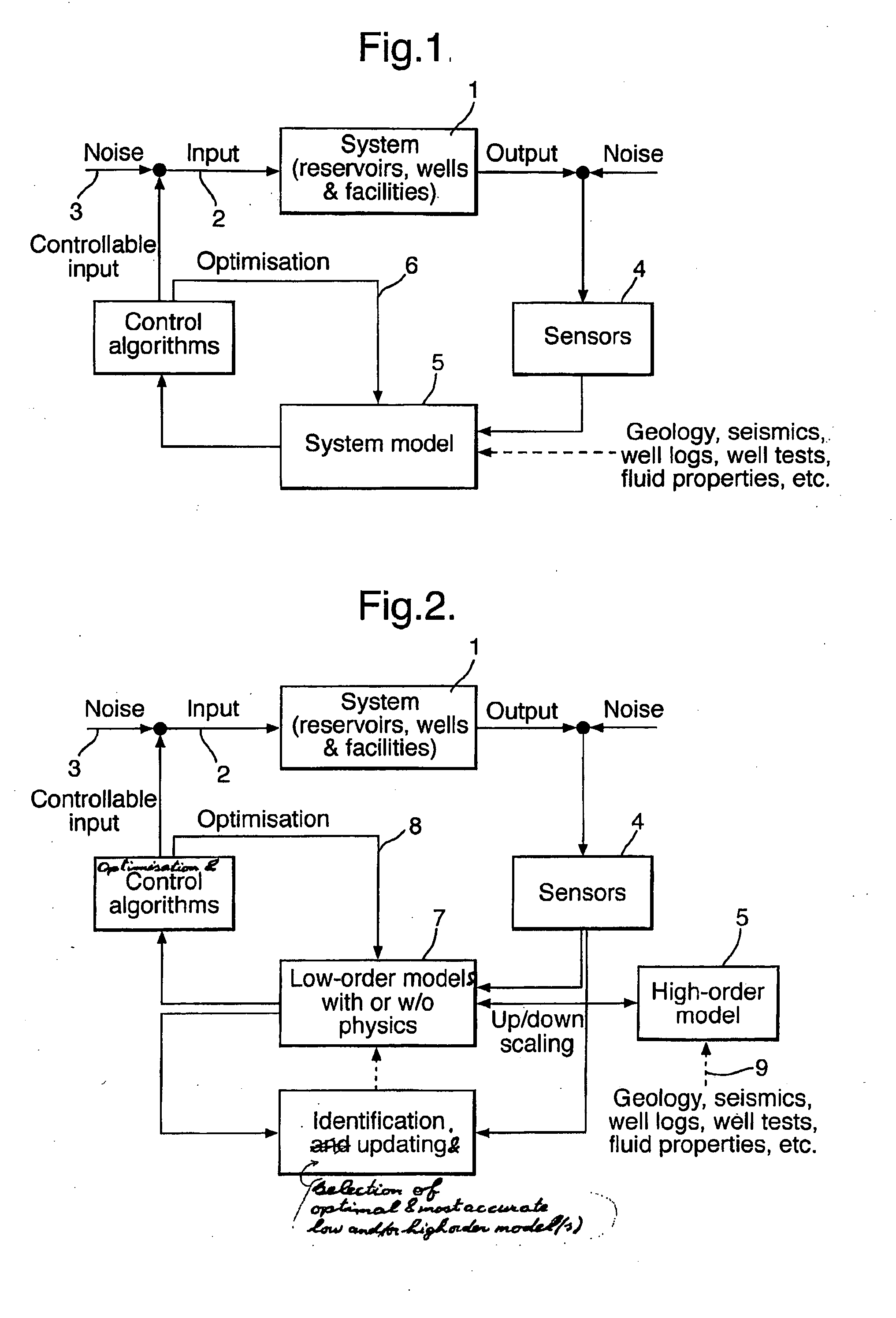

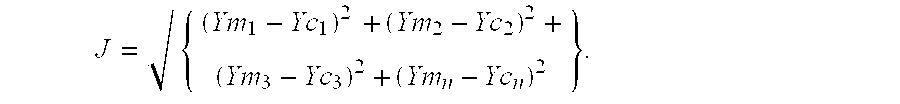

Closed loop control system for controlling production of hydrocarbon fluid from an underground formation

ActiveUS7672825B2Electric/magnetic detection for well-loggingComputation using non-denominational number representationControl systemClosed loop

Owner:SHELL USA INC

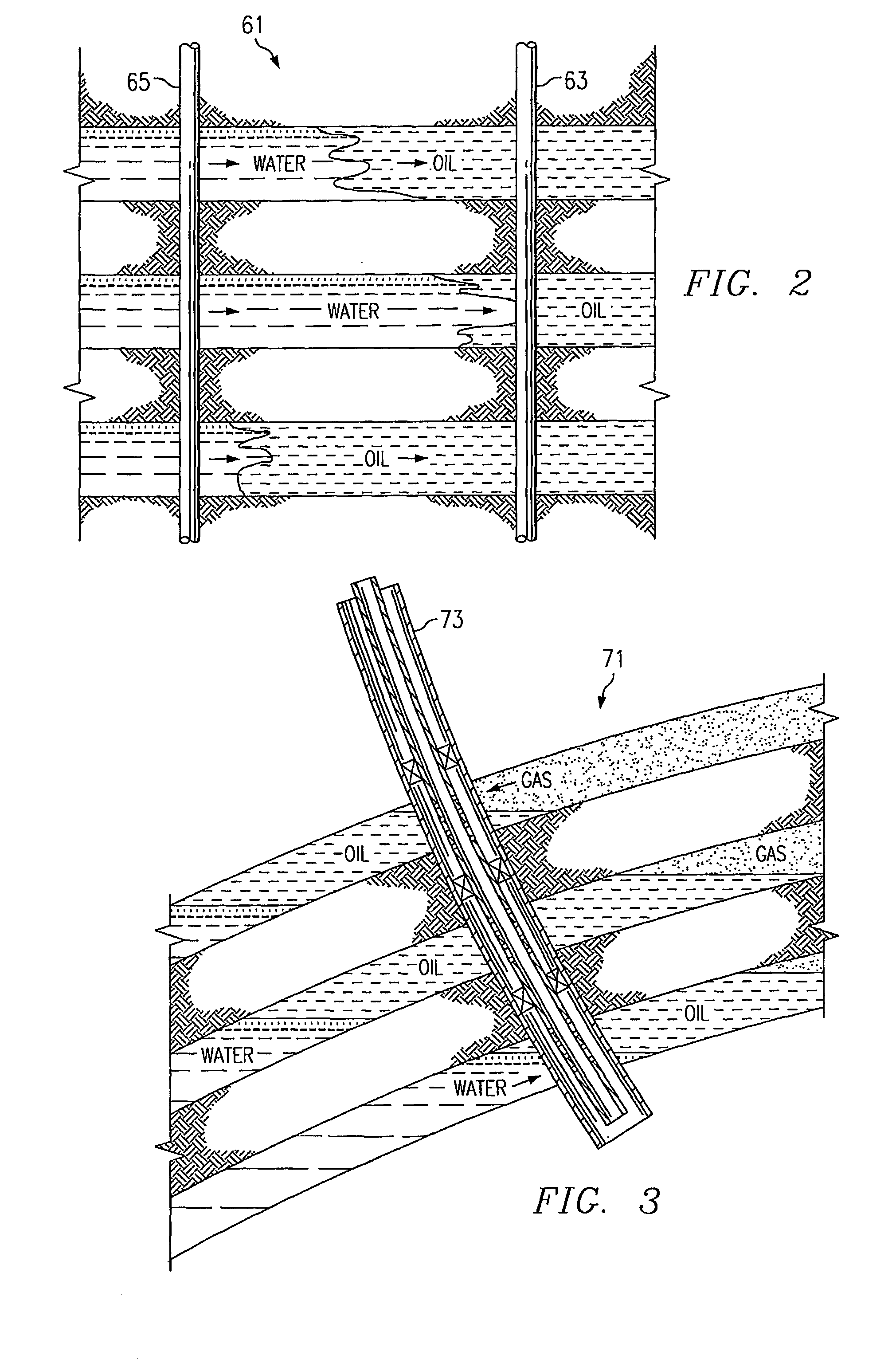

Closed loop control system for controlling production of hydrocarbon fluid from an underground formation

ActiveUS20090166033A1Electric/magnetic detection for well-loggingComputation using non-denominational number representationControl systemClosed loop

A method is disclosed for controlling production of oil and / or gas from an underground reservoir by means of a closed loop production control system, in which: —an assembly of monitoring sensors (4) monitor the physical properties of hydrocarbon and other fluids within the reservoir; —a plurality of high order and / or low order mathematical reservoir models (5, 7) calculate each an estimate of the physical properties of hydrocarbon and other fluids in the hydrocarbon containing formation and in the wells; —the mathematical reservoir models (5, 7) are iteratively updated in response to data provided by the assembly of sensors such that any difference between the properties monitored by the assembly of sensors and those calculated by each of the reservoir models is minimized; —an optimal mathematical reservoir model (5, 7) or an optimal combination thereof is selected during at least one updating step for which an averaged difference between the calculated properties and the properties monitored by the assembly of sensors (4) is minimal; and—an optimization algorithm (8) controls, on the basis of data provided by the selected optimal mathematical reservoir model or optimal combination thereof, production control assemblies of a plurality of wells which traverse the formation.

Owner:SHELL USA INC

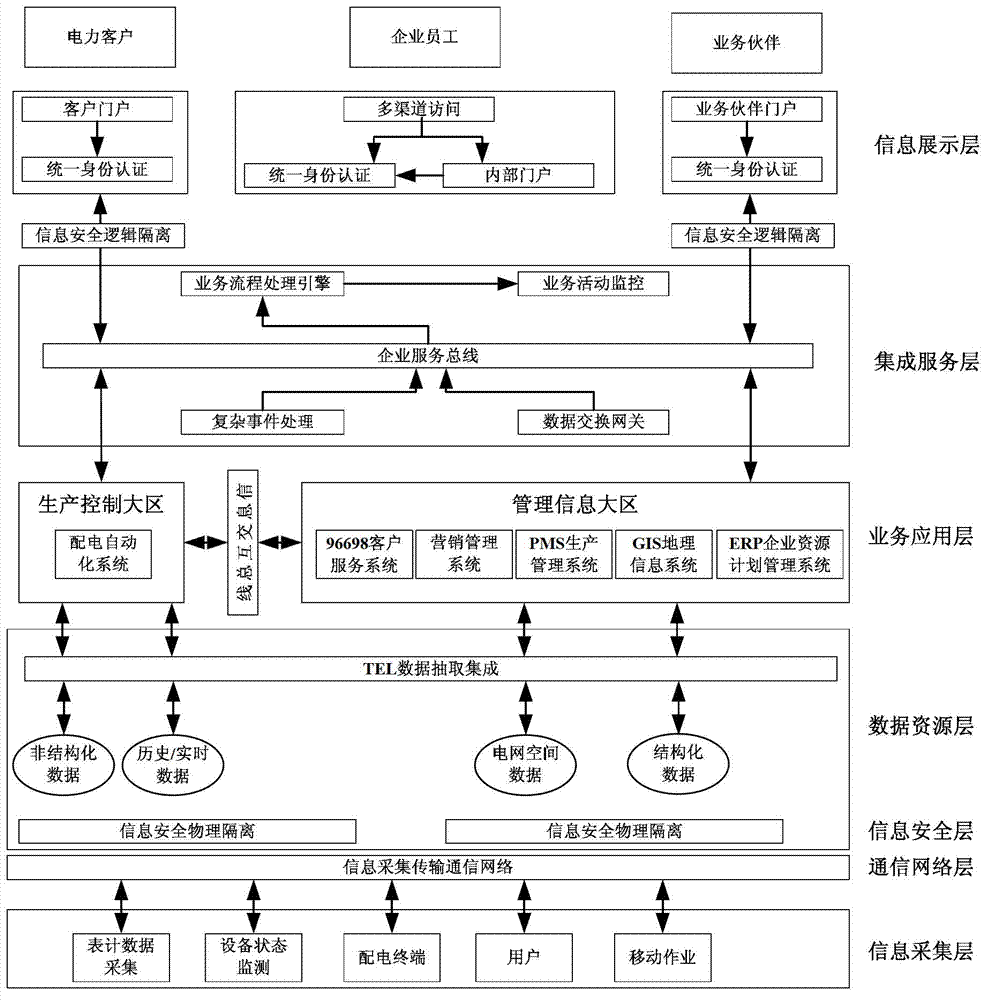

Multi-service system information fusion power grid comprehensive visualization method based on three-dimensional GIS

InactiveCN104240139AIntelligent Visual MonitoringRich Visual MonitoringData processing applicationsFusion powerSmart grid

The invention discloses a multi-service system information fusion power grid comprehensive visualization method based on the three-dimensional GIS. On the basis of comprehensively carding and analyzing all link service processes and data models of an intelligent power grid, related running and managing information in a production control system and a management information system is obtained through a distribution automation master station mirror image synchronous database server, wherein scheduling system data are obtained through an IEB information exchange bus crossing the production control region and the management information region. According to the method, by carding all the link service processes and the data models of the intelligent power grid and conducting deep excavation, analysis and comprehensive display on data on this basis, production running and managing personnel can be helped to more comprehensively, visually and effectively master the real-time running state of the power gird through a more intelligent and abundant power grid visualization monitoring, warning and analyzing method, and therefore intelligent auxiliary support is achieved when enterprise running and managing decisions are made.

Owner:STATE GRID CORP OF CHINA +2

Well production optimizing system

InactiveUS7243730B2Eliminating fluid flow through the passageFluid removalSealing/packingProduction optimizationEngineering

Owner:CASEY DAN

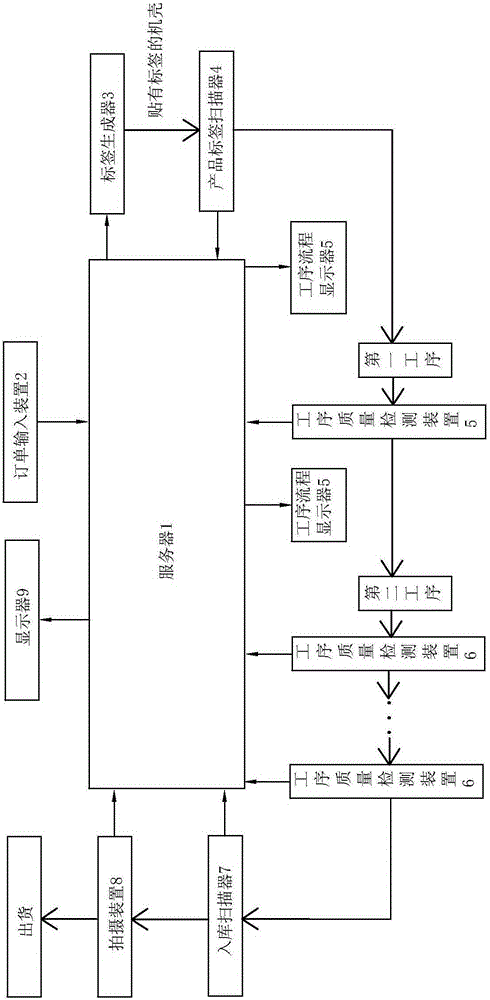

Product production control system and control method

ActiveCN105182935ARealize information production managementAchieve effectivenessProgramme total factory controlInformatizationProduct type

The invention discloses a product production control system which comprises a server. The server is connected with an order entry device for inputting product type information and quantity information, a label generator for generating corresponding product labels according to the product type information and quantity information, a product label scanner for scanning label information and reading the product process of the server according to the label information, a plurality of process flow displayers arranged at each process and used for displaying the corresponding process production, a plurality of process quality detection devices arranged at each process and used for detecting the quality of each process product, a warehousing scanner used for reading quality statistics information of each process of the server after all processes are finished so as to judge whether the finished products are qualified to be boxed, and a camera device for recording the appearance of the finished products and integrity of accessories before boxing. The steps of order placing, production processes in a workshop and cargo shooting and recording before boxing and the like are combined through the server, and thus informationized production management of the products is realized.

Owner:ZHONGSHAN WANJIN INTELLIGENT SCI & TECHCO LTD

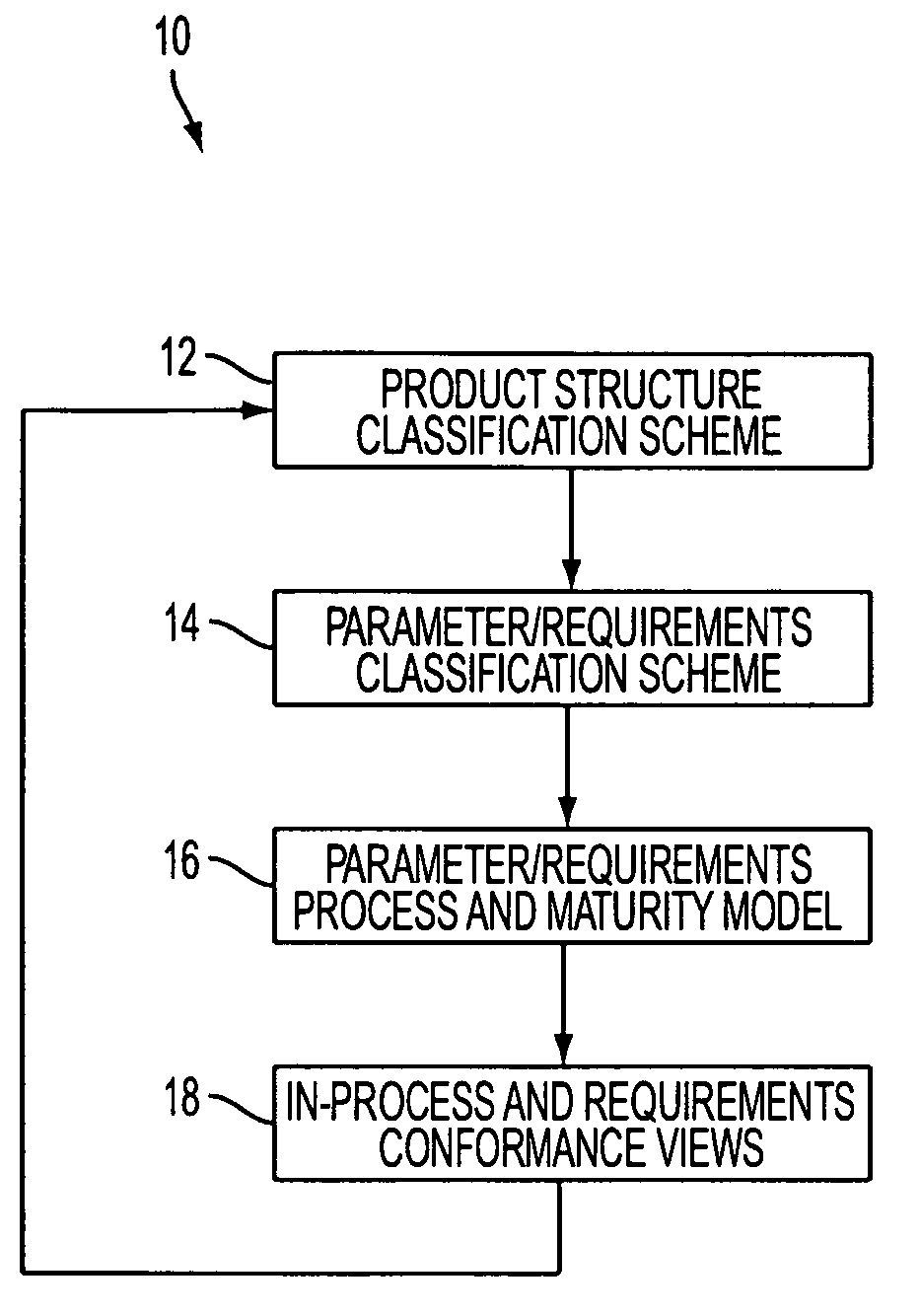

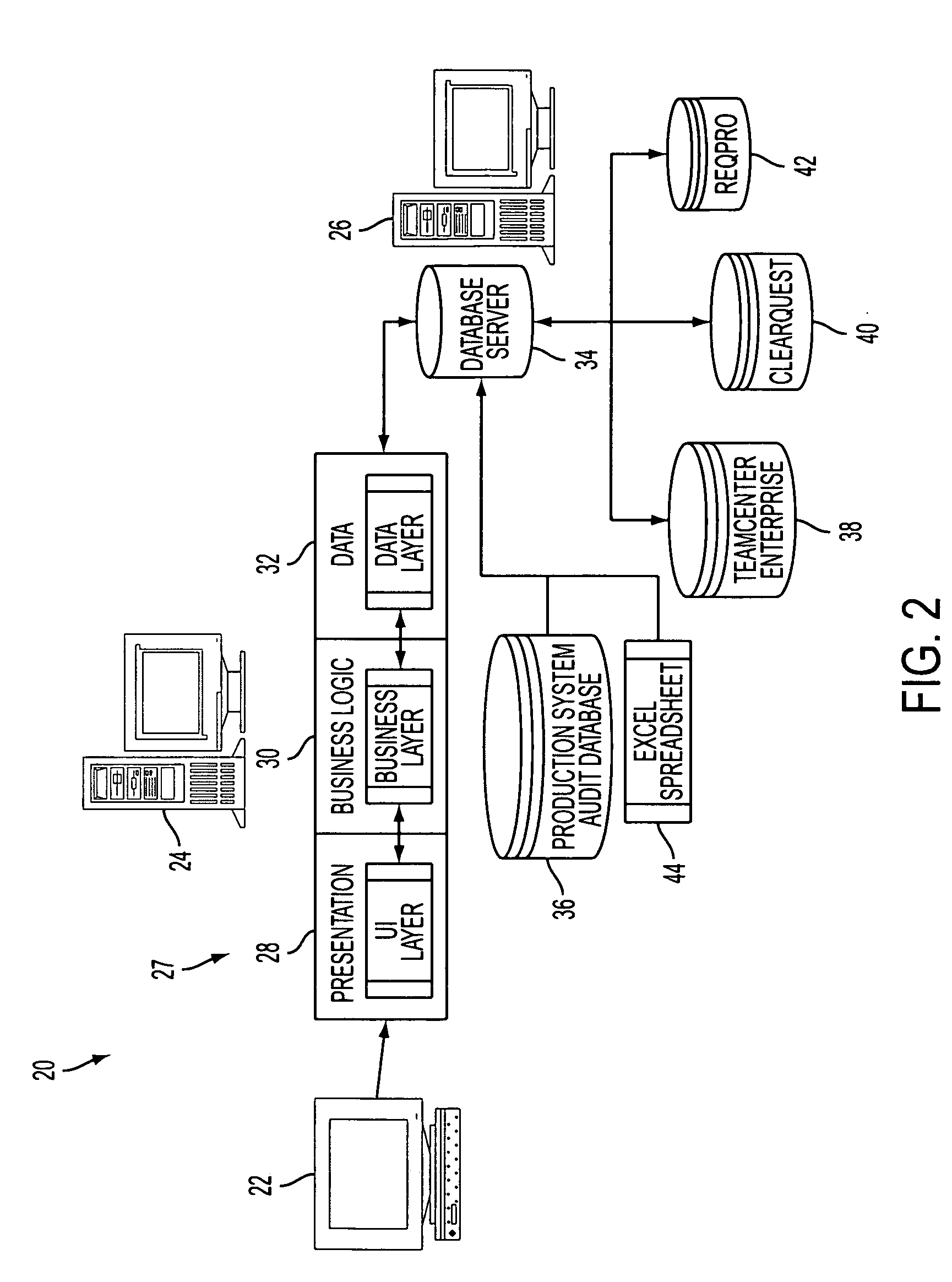

Critical parameter/requirements management process and environment

A critical parameter / requirements management process model for managing a development program for a product and an associated product structure-driven critical parameter / requirements management tool and environment is provided. In one embodiment, the process includes a product structure classification scheme, a parameter / requirements classification scheme, a parameter / requirements process and maturity model, and in-process and requirements conformance views. In one embodiment, the tool includes a user interface layer, a business layer, a data layer, and a database. The user interface layer may include a product structure feature group, an add / edit / link feature group, a manage maturity feature group, and a manage conformance feature group. The tool may be implemented as a web server accessible to user workstations operating as thin clients. The tool may be integrated with one or more other product development tools, such as a document-driven requirements management, configuration management, manufacturing / production control system, problem management, and phased product delivery process tools.

Owner:XEROX CORP

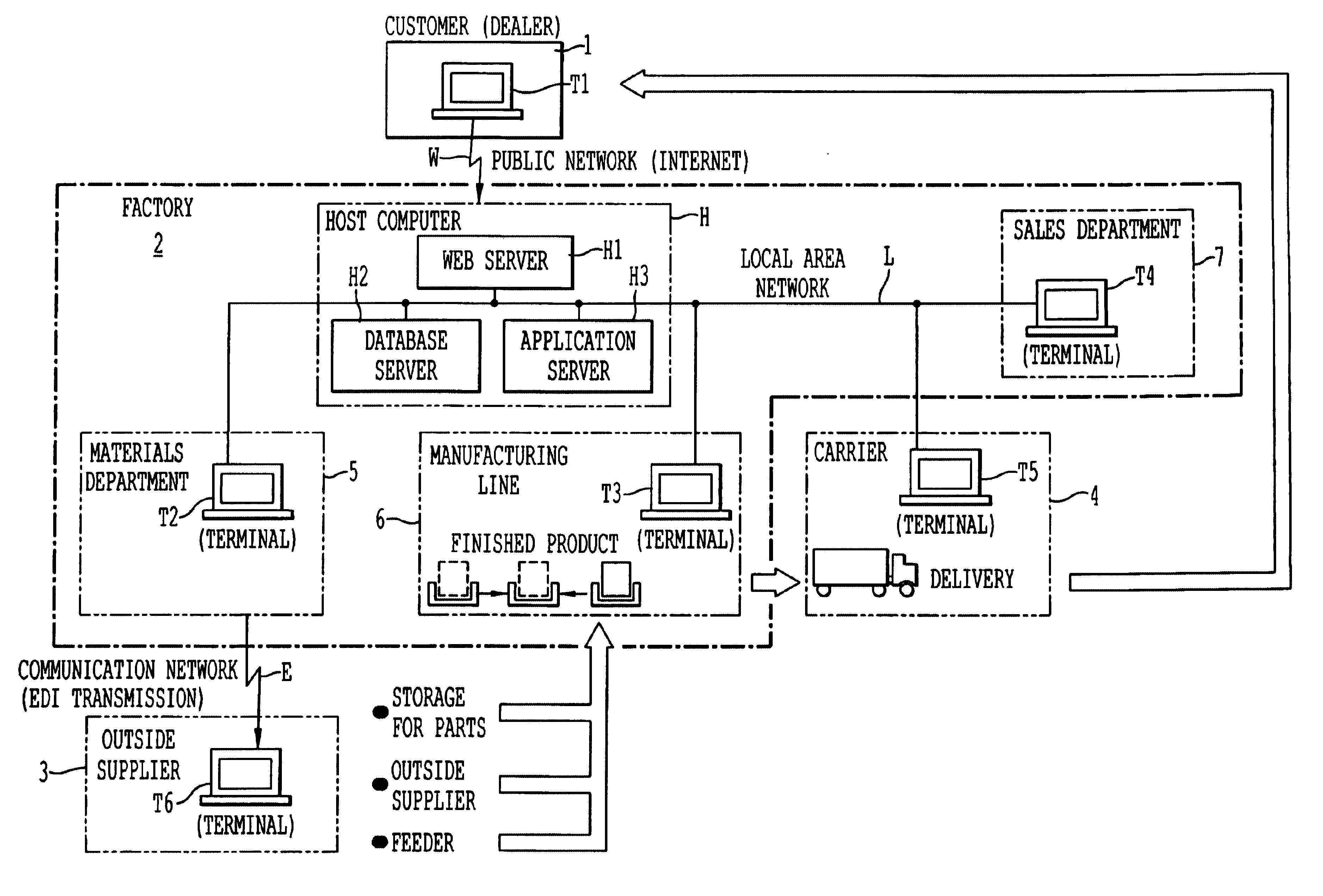

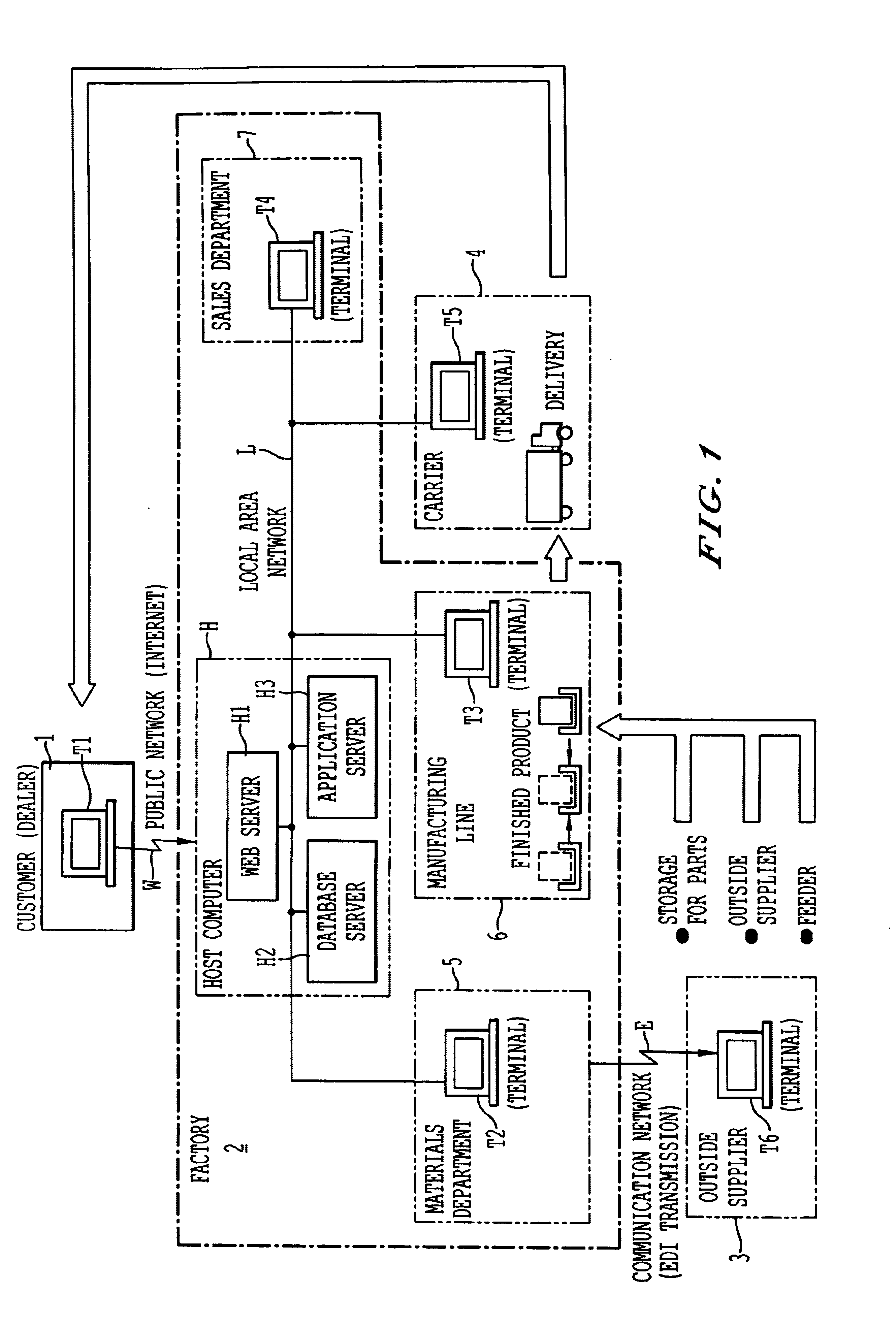

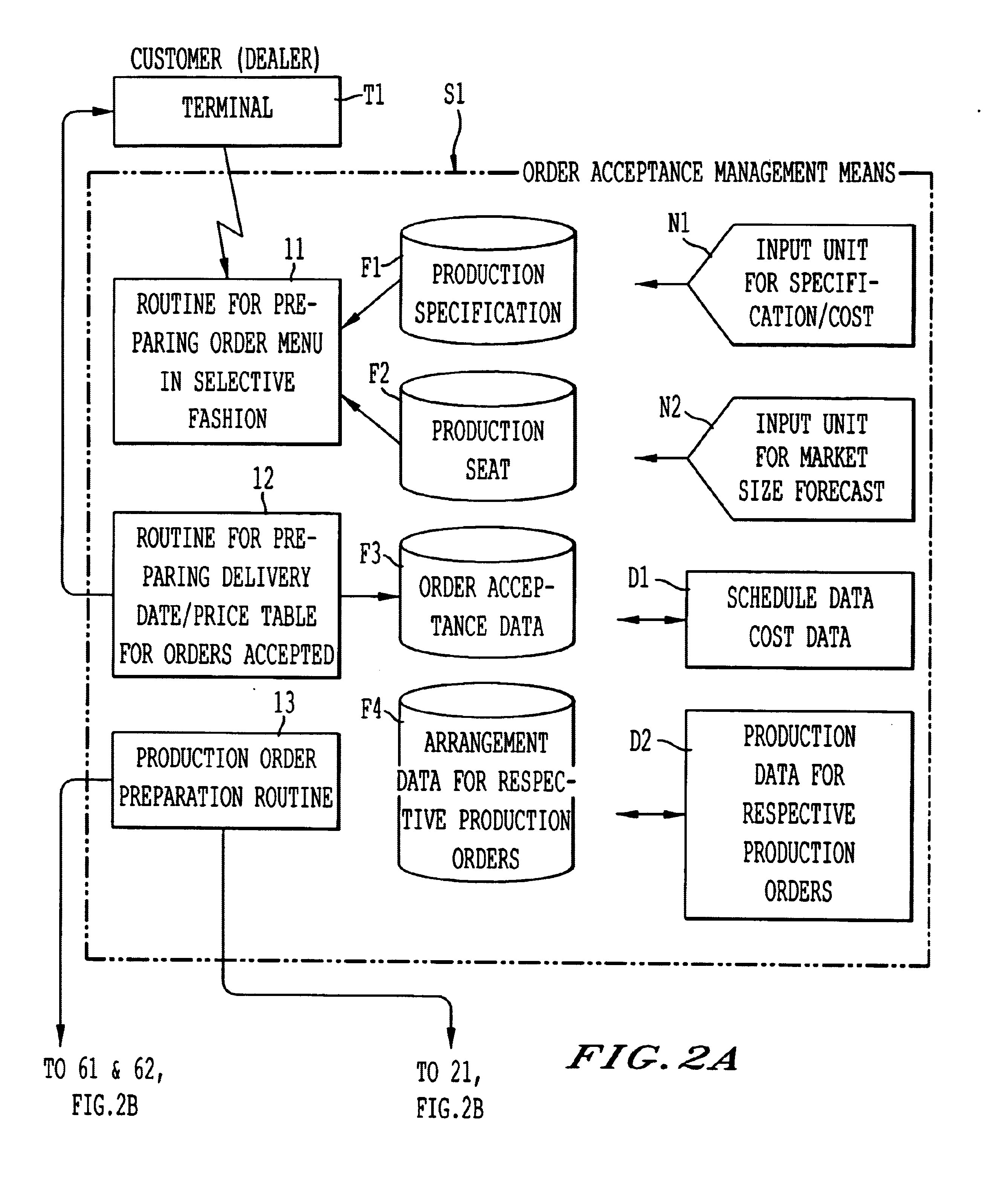

Production control system and method for producing air conditioners

InactiveUS6629008B2Preventing the stock of productsEfficiency acceptanceBuying/selling/leasing transactionsTransmissionControl systemThe Internet

An order menu that includes a plurality of specifications in respective functional blocks, into which a customized product is divided into, is provided from a factory through Internet. A customer selects a required specification from the order menu to determine the customized product. Based on data input through the order menu, material arrangement and directions for production can be dealt with on line, and data on the customized product are shared between the customer and a manufacturer.

Owner:MITSUBISHI ELECTRIC CORP

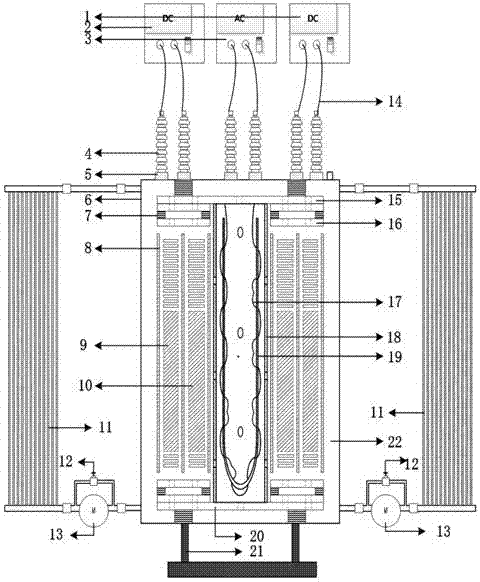

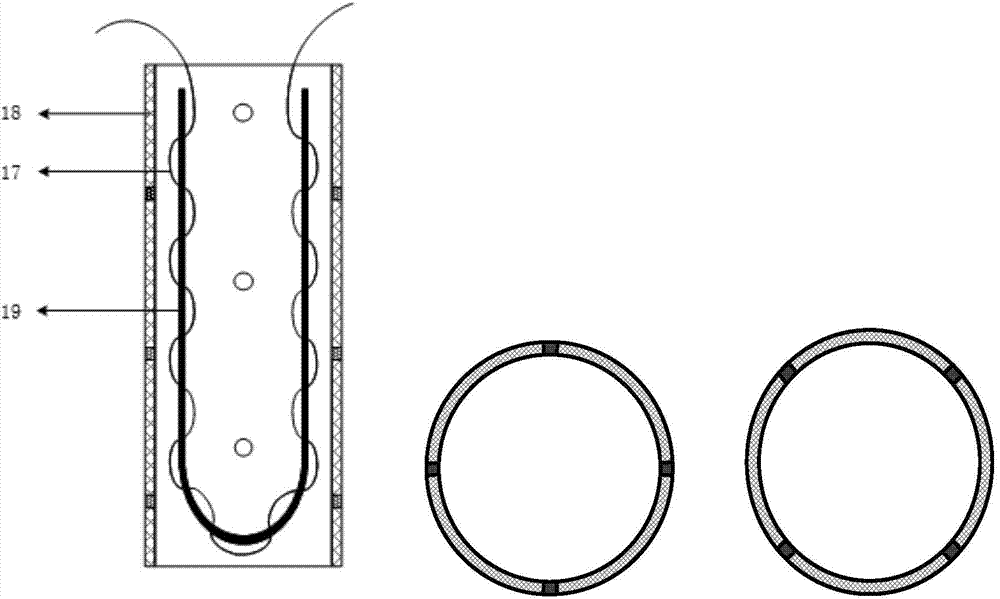

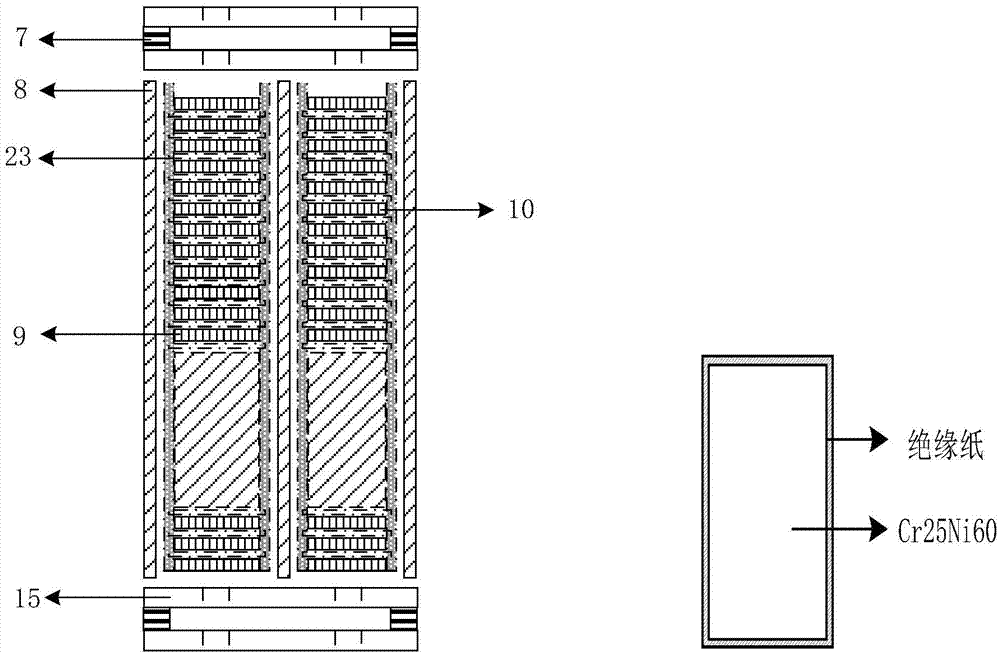

Experimental device and experimental method for simulating heat production of traction transformer

ActiveCN104766515AAvoid interferenceHigh measurement accuracyEducational modelsExperimental methodsDistribution transformer

The invention discloses an experimental device and experimental method for simulating heat production of a traction transformer. The experimental device is used for study experiments of the related properties of the temperature field and oil flow field of the traction transformer. The experimental device is composed of a transformer body, a heat production control system and an oil path cooling control system. According to the experimental device, the no-load loss and load loss of the transformer can be changed conveniently and fast under the conditions of needing no high voltage or high current, stable or time-varying loads in the transformer are simulated so that the stable or time-varying temperature field or oil flow field can be generated, subsequent measuring is facilitated, and meanwhile the influence of a strong magnetic field and a strong electrical field on a measuring instrument is reduced.

Owner:SOUTHWEST JIAOTONG UNIV

Method and system for automating issue resolution in manufacturing execution and material control systems

InactiveUS7440932B2Decrease productivityImprove productivitySafety arrangmentsTesting/monitoring control systemsProduction rateAutomatic control

Automatic error recovery systems and methods for automated manufacturing plants and factories are disclosed. Such facilities normally have multiple automated control systems, including an automated material handling system (AMHS), all of which run automatically, typically under the control of a computerized manufacturing execution system (MES). The disclosed issue resolution (ISR) systems and methods involve providing components, which may be supervised and operated by an issue resolution management (ISRM) system, if desired, that interfaces with the MES, AMHS, and / or production control system(s) which operate the tools and other stations within the automated factory. The components, which may be considered customized logic cells, may each be written for handling a specific kind of incoming error condition, problem or other issue that might occur and which is amenable to automatic resolution or recovery. These errors often occur between or across the boundaries of the various interactive systems and automated equipment. Each cell may cycle through a sequence of possible error resolution or recovery steps until the specific issue is resolved or until the sequence of steps is exhausted. Other components of the ISR system may provide results-oriented messages and / or facilitate the collection of data as to whether and which corrective commands from the ISR system resolved the reported error conditions automatically. The disclosed ISR systems and methods for resolving errors and other issues automatically helps improve the overall productivity of automated factories by reducing downtime and the need for human intervention to correct problems, thereby increasing factory throughput.

Owner:INT BUSINESS MASCH CORP

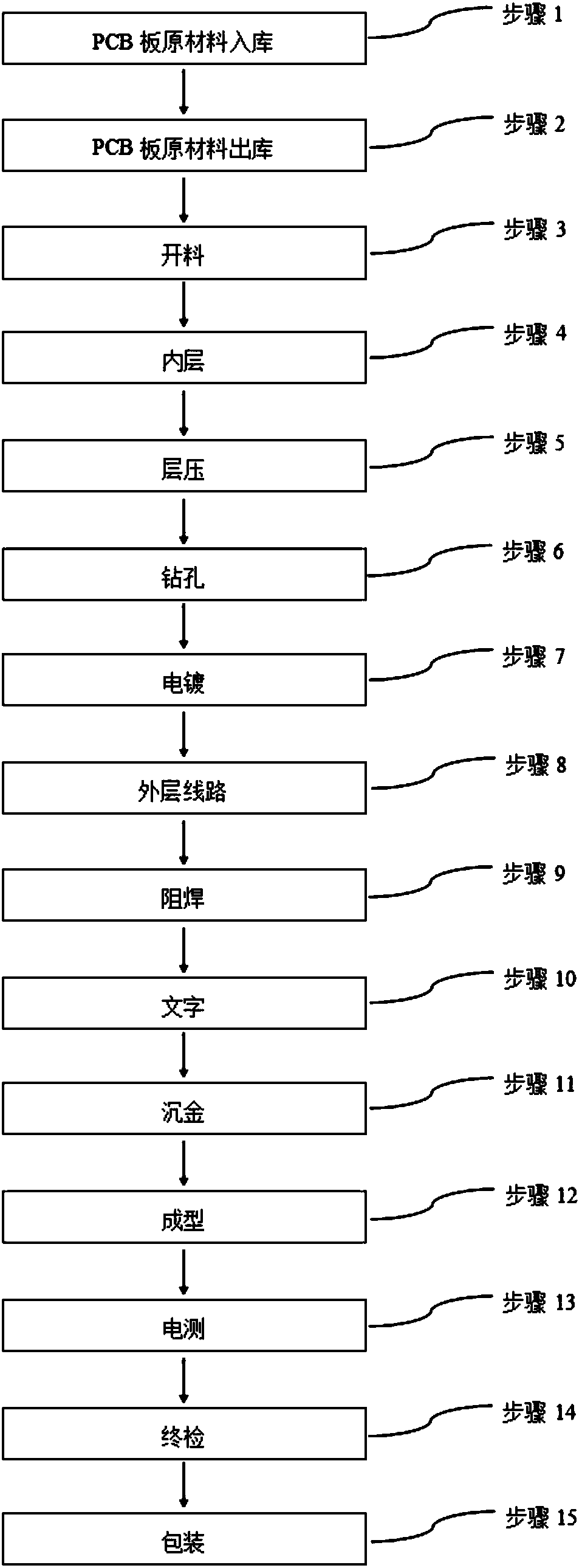

Intelligent manufacturing technique for printed circuit board

ActiveCN107817774ARealize intelligent productionRealize the whole process of automatic productionPrinted circuit manufactureElectric/hybrid propulsionElectricityControl system

The invention discloses an intelligent manufacturing technique for a printed circuit board, and the technique comprises the steps: PCB raw material warehousing, PCB raw material delivery, material splitting, inner layer, laminating, drilling, electroplating, outer circuit, welding, character, gold immersion, molding, electrical detection, final inspection, and packaging. The technique achieves theintelligent production from the PCB raw material warehousing, delivery, processing and packaging to delivery, enables all processes to be connected together, achieves the automatic linkage and regulation and control through a production control system, and achieves the automatic optimization of production parameters according to the testing conditions. An enterprise ERP system is connected, and the production arrangement is automatically carried out according to the delivery time of a customer. Cameras are respectively installed in key management and control regions of all processes, and theonline monitoring and remote monitoring can be achieved. All production information is enabled to automatically form a table, and is presented in a form of numbers. A production control system has functions of equipment automatic maintenance and management and fault automatic reporting.

Owner:JIAN MANKUN TECH

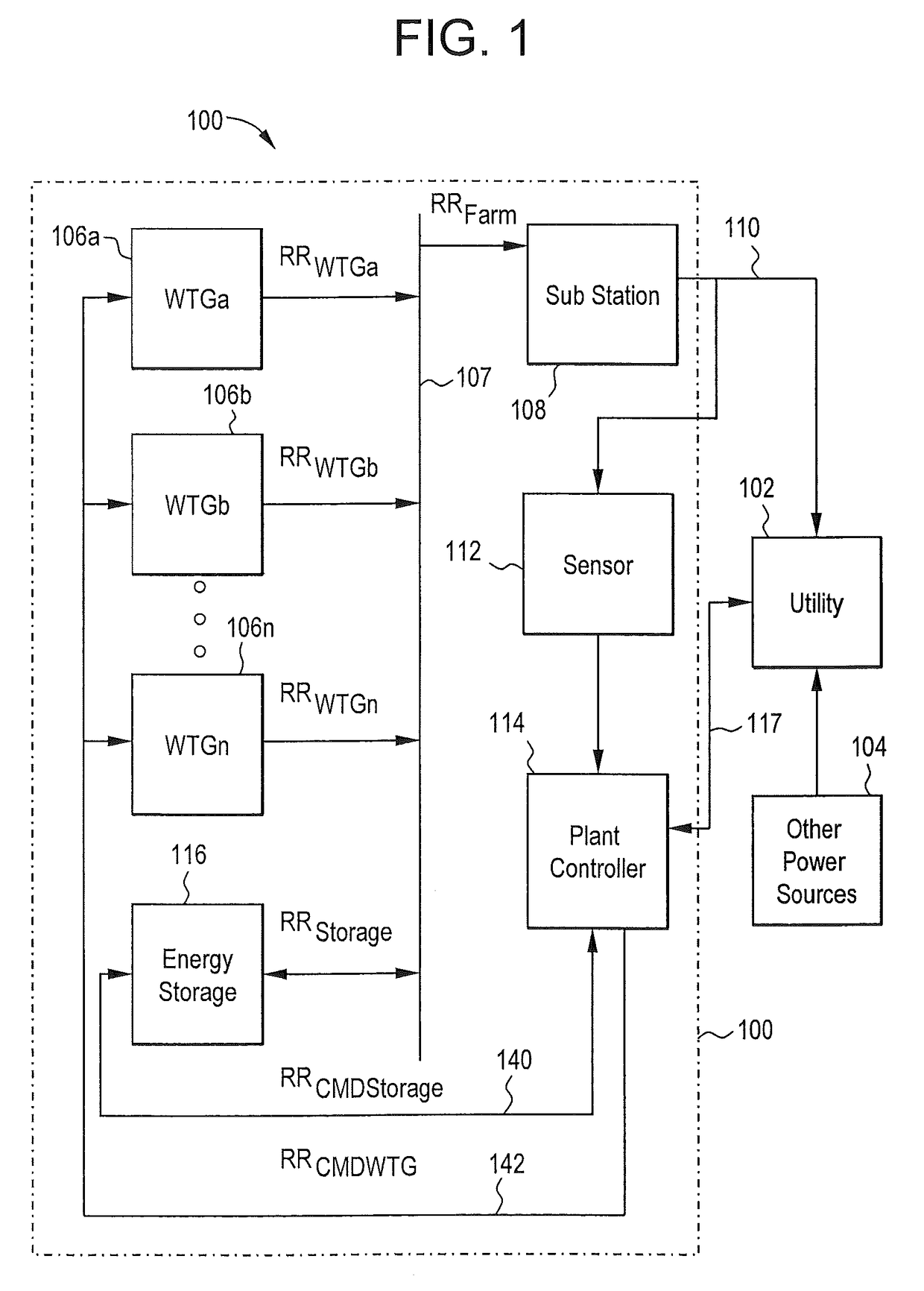

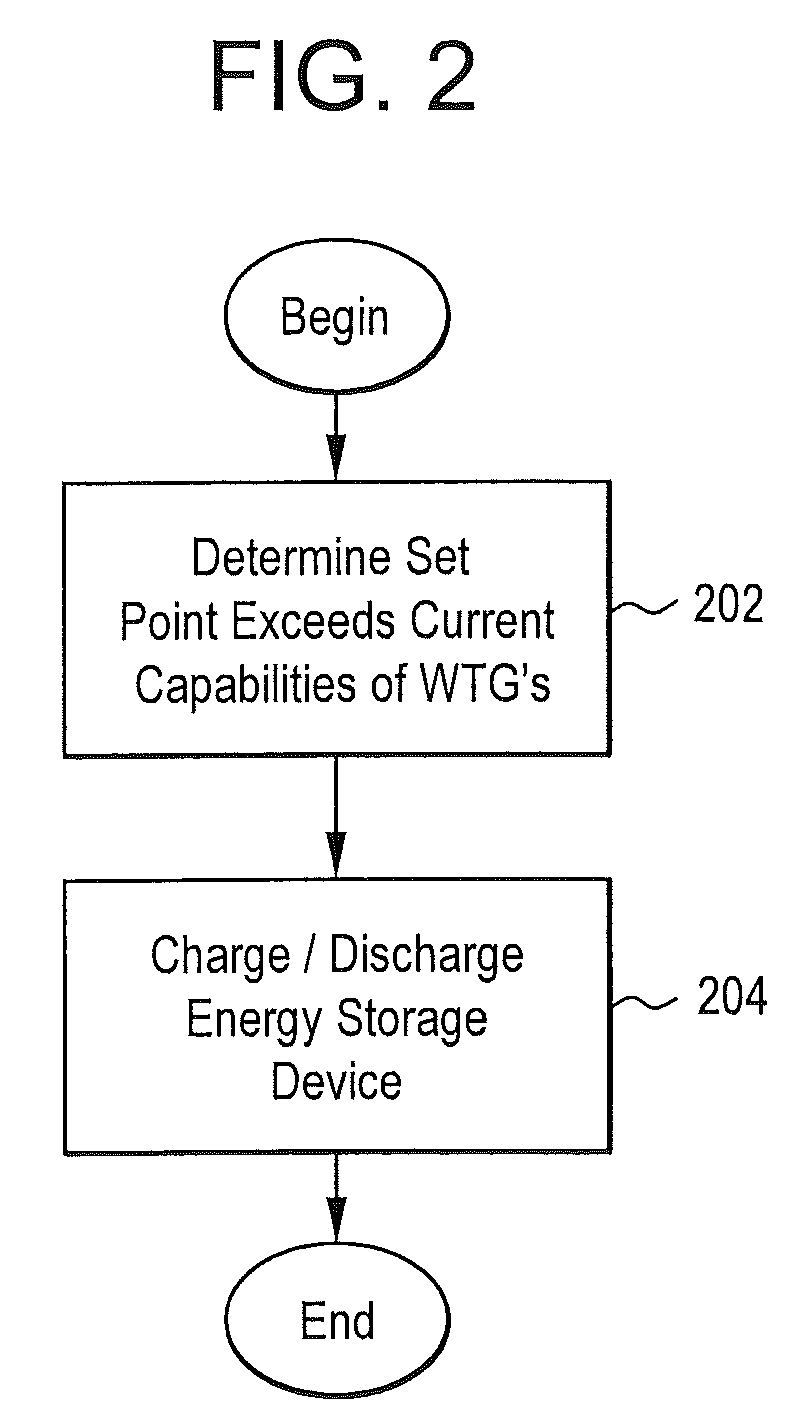

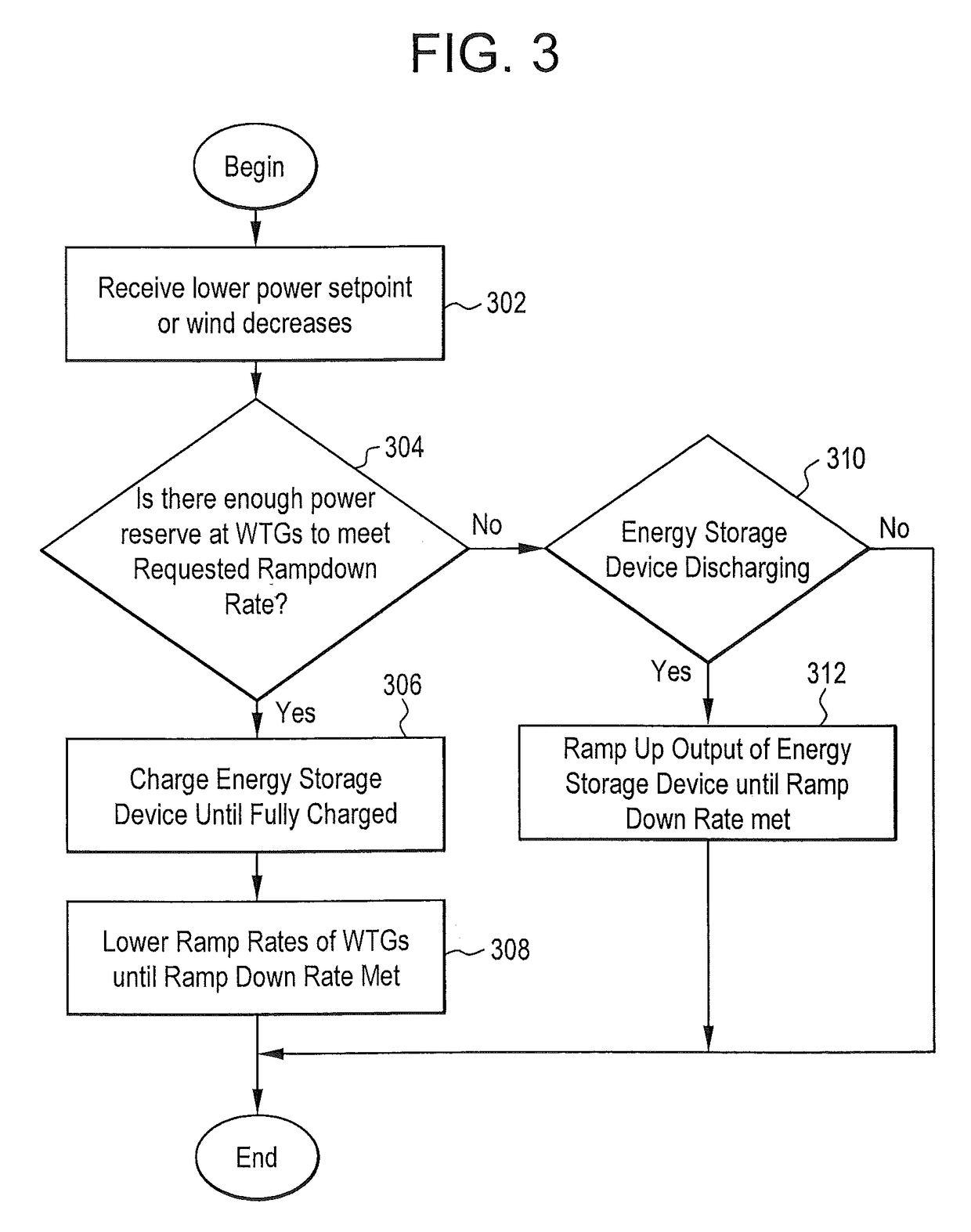

Power production control system and method

ActiveUS7908036B2Batteries circuit arrangementsWindings insulation shape/form/constructionPower capabilityControl system

A control system for an energy production facility includes a plant controller for receiving an indication of a measured power output of the energy production facility that includes power generators and produces output signals. The system also includes a processing unit operably coupled to the plant controller and responsive to executable computer instructions when executed on the processing unit cause the plant controller to: create an output signal that causes an energy storage device to discharge in the event power reserves of the power generators can not met the requested ramp down rate; and create an output signal that causes the energy storage device to charge up in the event that the power capability of the power generators can meet the requested ramp down rate.

Owner:GENERAL ELECTRIC CO

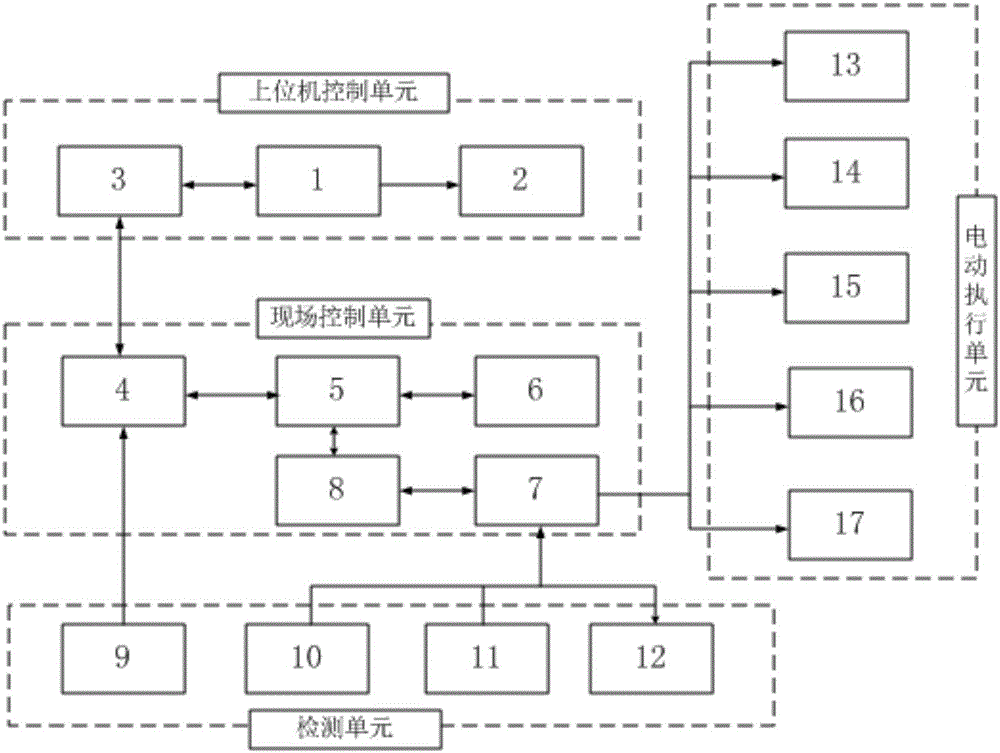

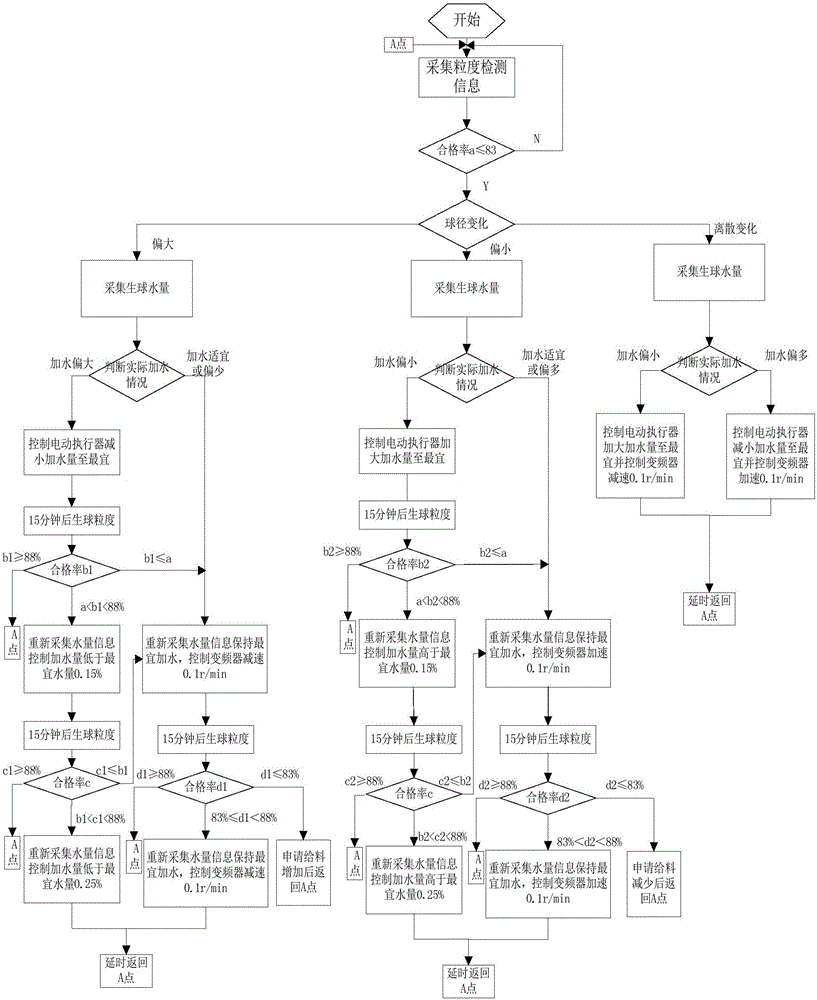

Disc pelletizing intelligent production system and control method thereof

ActiveCN106647663ATimely intelligent adjustmentRealize intelligent adjustmentGranulation in rotating dishes/pansTotal factory controlProgrammable logic controllerControl system

The invention discloses a disc pelletizing intelligent production system and a control method thereof, and the control system comprises an upper computer control unit, a field control unit, a detection unit, and an electric execution unit. The control system cooperates with the control method, carries out the processing of data and the setting of preset values through the upper computer control unit, and then transmits the data to the field control unit for production control. The detection unit is used for collecting a plurality of practical technological values related with the pelletizing qualified rate in a field disc pelletizing process, and transmitting a detection result to the field control unit for logic criterion in real time. According to the invention, the detection unit serves a data input unit of a production control system, and the electric execution unit serves as a data output unit. The system achieves the adjustment of the production technological parameters of a disc pelletizing device through a programmable logic controller, achieves a purpose of controlling the pelletizing qualified rate in a preset qualified range, and improves the product quality.

Owner:天津市三特电子有限公司

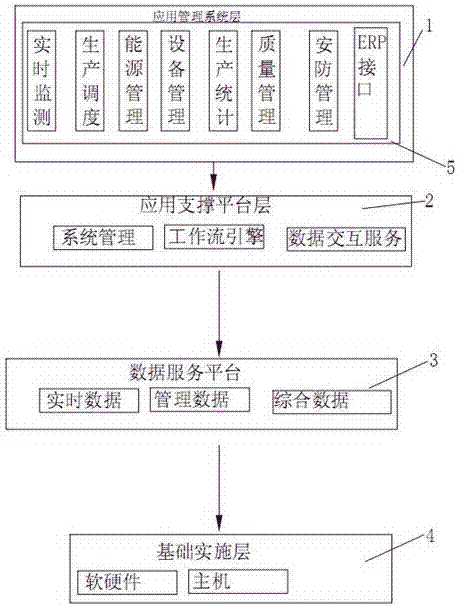

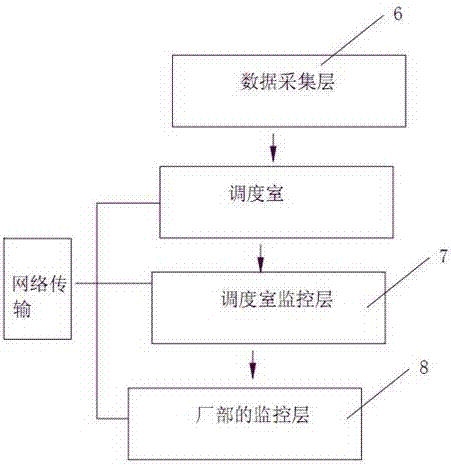

Energy automatic management and scheduling system

ActiveCN107065802AGood preventive maintenance mechanismImprove support capabilitiesEnergy industryTechnology managementInformatizationEnergy statistics

The invention discloses an energy automatic management and scheduling system. The energy management and scheduling system comprises four hierarchies from top to bottom, namely an application management system layer, an application support platform layer, a data service platform layer and an infrastructure layer. The energy automatic management and scheduling system realizes the real-time acquisition of field data through the unified acquisition and the integrated management of production control system data and various important monitoring instruments. Through the network transmission, the collected data are stored in a real-time database to be processed. Therefore, the actual production condition can be exactly mastered in an office or remotely by people and related leaders in scheduling and production management departments in the modes of flow chart monitoring, alarming, real-time reporting, trend searching and the like. Meanwhile, MES modules, including production monitoring, safety management, production scheduling, quality management, production statistics, equipment management, energy management, energy statistics and analysis and the like, is combined with a short message platform, so that a convenient and quick informatization management platform is provided for the production management and the scheduling command of a full company.

Owner:HENAN ZHONGHONG GRP COAL

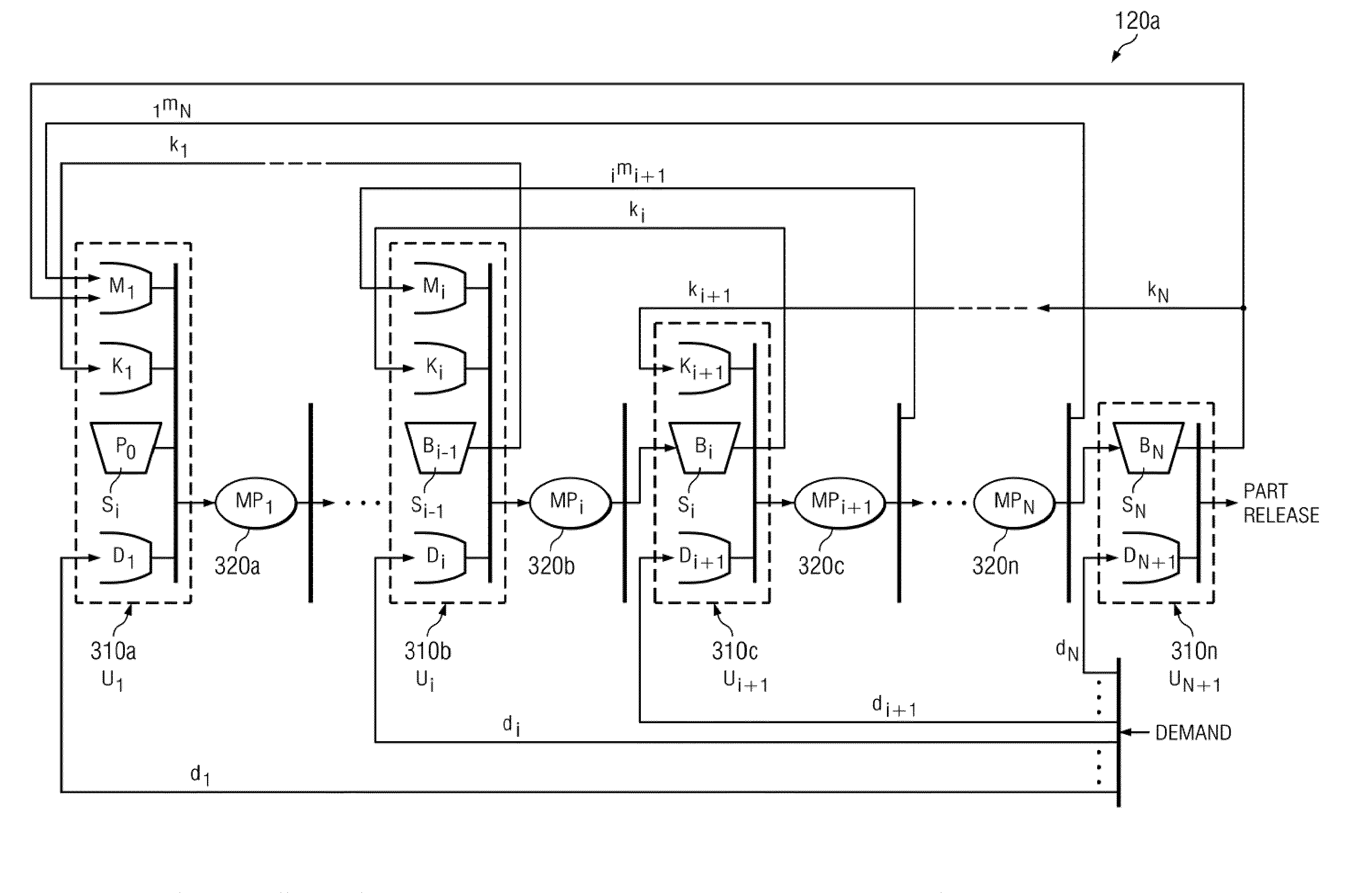

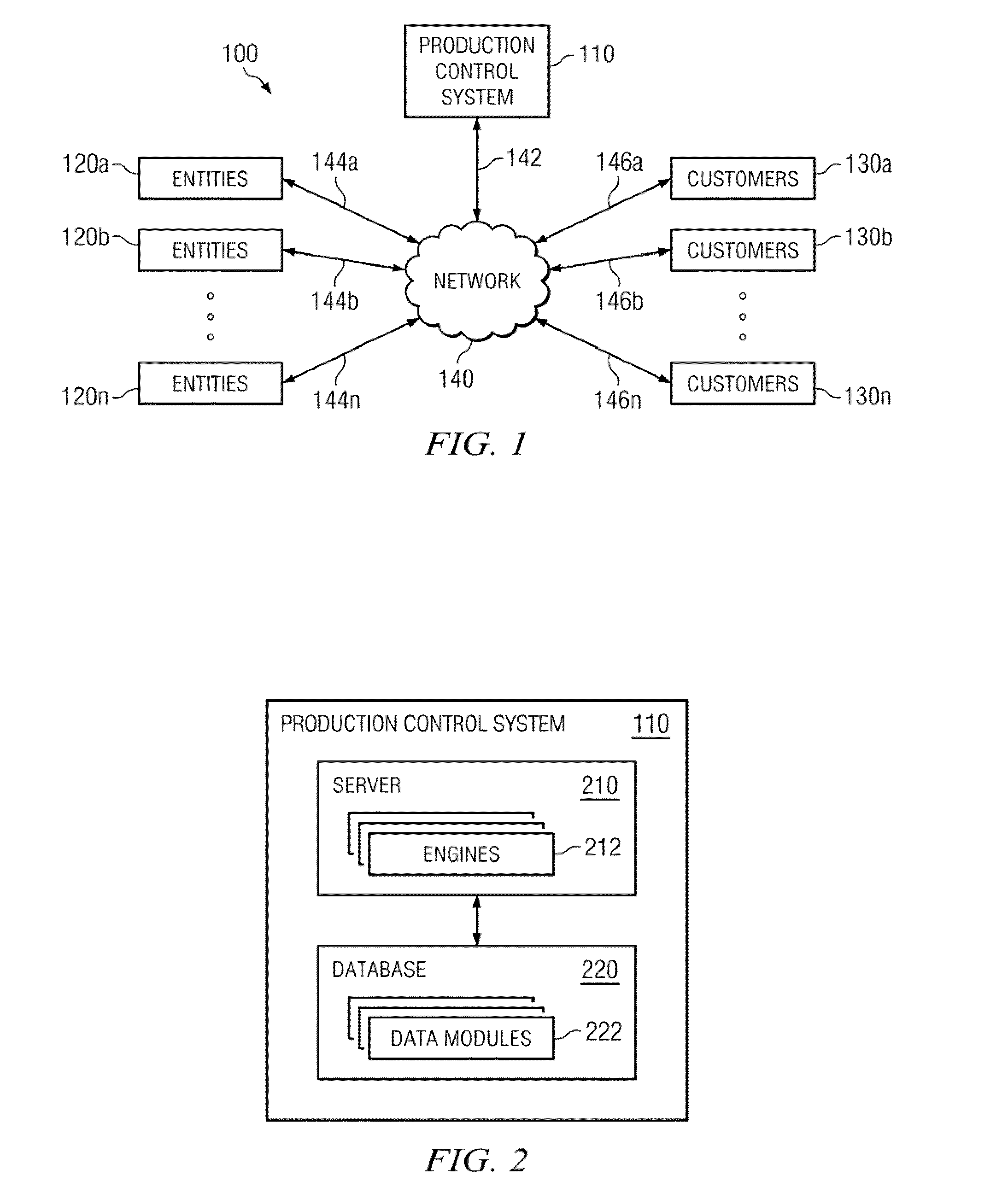

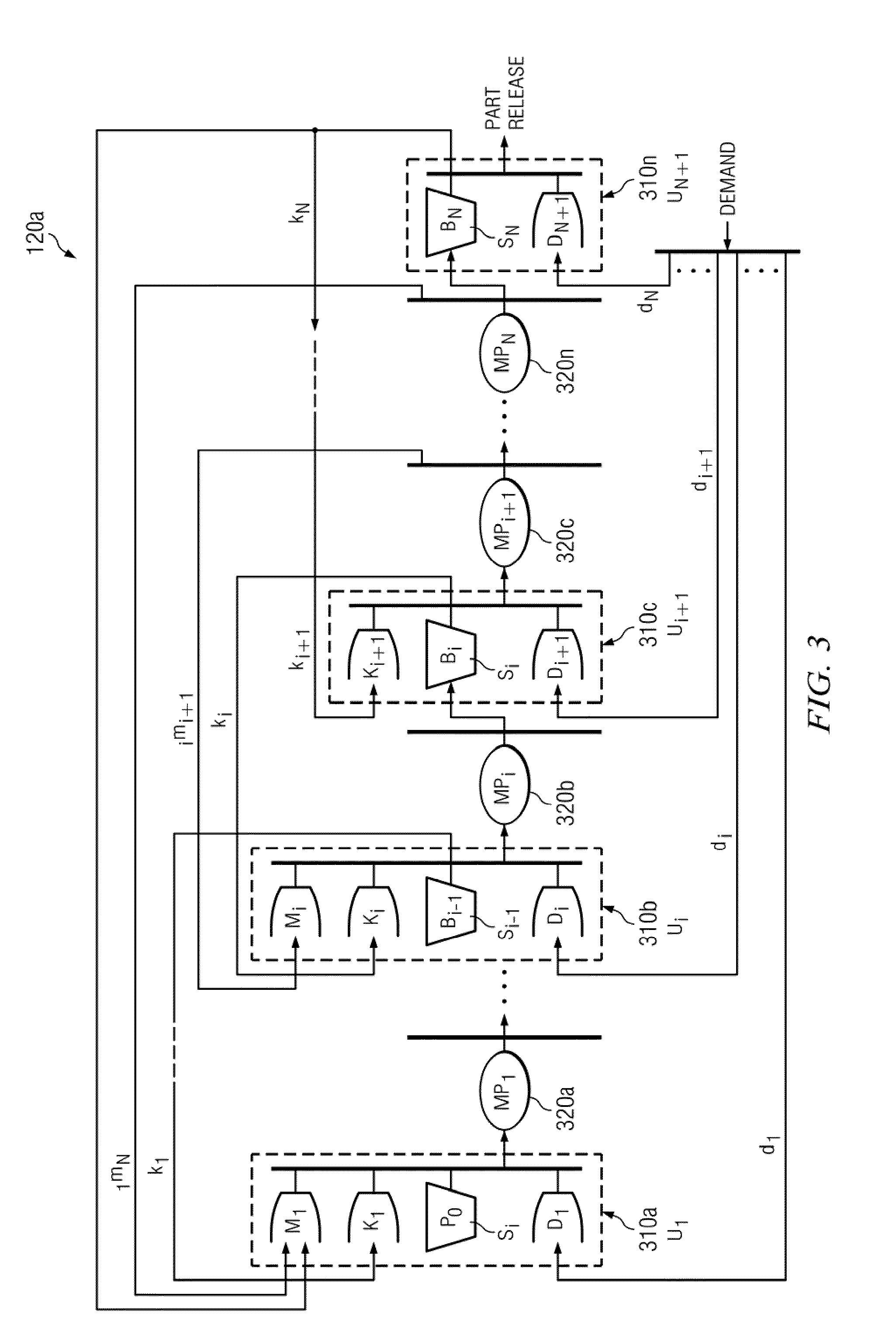

System and Method for a Demand Driven Lean Production Control System

A system is disclosed providing visualization of a production control framework. The system includes a database storing production control data associated with one or more entities and a production control system coupled with the database and configured to model a production control framework of the one or more entities. The production control system includes one or more work centers authorizing one or more tasks for one or more parts and one or more manufacturing processes that produce one or more finished parts using the one or more parts.

Owner:BLUE YONDER GRP INC

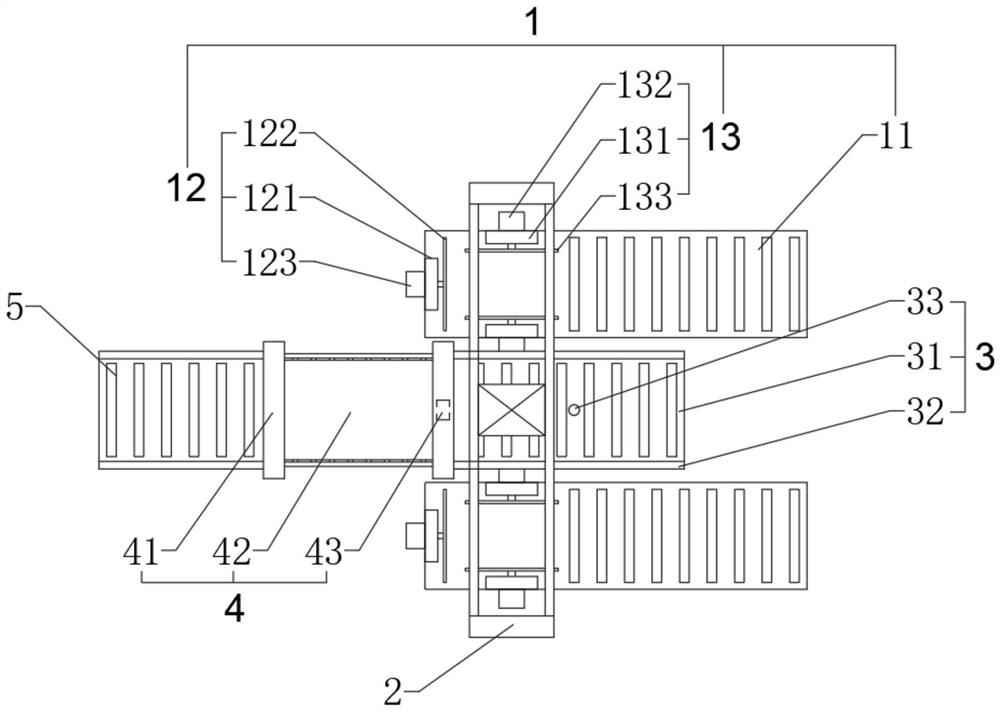

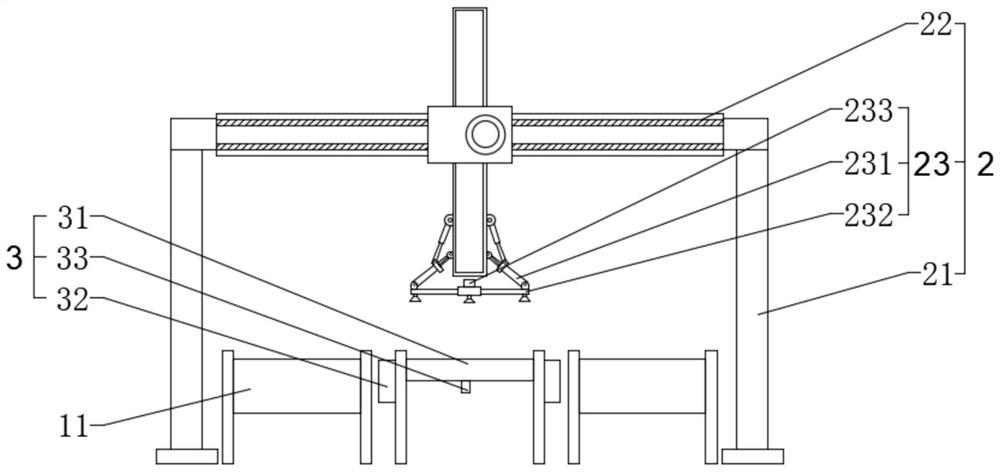

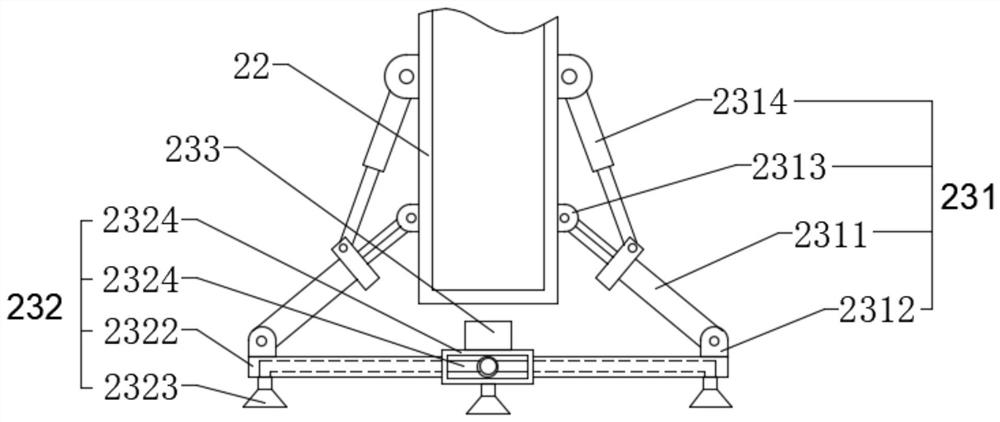

Intelligent feeding system and production control system

InactiveCN112978324AMaximize processing efficiencyImprove efficiencyControl devices for conveyorsRoller-waysProduction lineButt joint

The invention discloses an intelligent feeding system and a production control system. The intelligent feeding system comprises a left-right feeding roller way, a gantry suction cup mechanism, a plate feeding roller way, a plate turning device and an acceleration roller way which are sequentially arranged in a butt joint mode and used for conveying base plates. The left-right feeding roller way is used for correcting and conveying the base plates in batches through a left-right roller way structure, the gantry suction cup mechanism is matched with two sets of roller ways of the left-right feeding roller way to suck the base plates and conduct positioning and feeding on the plate feeding roller way in batches, the plate feeding roller way is in butt joint with the plate turning device and conveys the base plates at a low speed, the plate turning device turns over the base plates conveyed by the plate feeding roller way at intervals and conveys the base plates to the acceleration roller way, devices of all working sections on a gypsum plate production line are processed and controlled in a unified mode, so that it is guaranteed that the base plates are conveyed on all the working sections, the machining efficiency is maximized, and the devices of each working section are automatically switched to meet the processing and transporting specifications of the base plates of the corresponding specifications.

Owner:CHINA NAT BUILDING MATERIALS TECHCAL INNOVATION & RES INST LIMITED

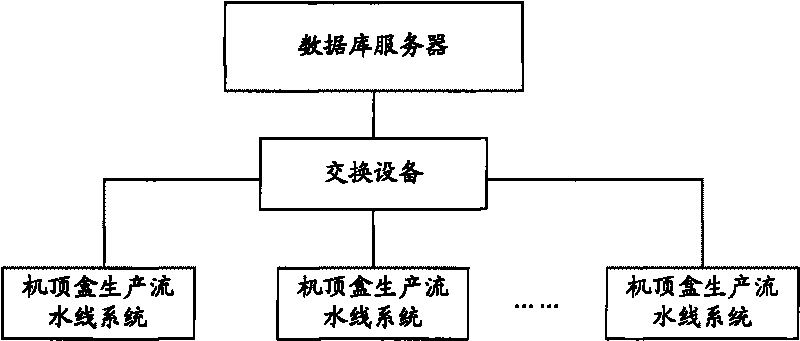

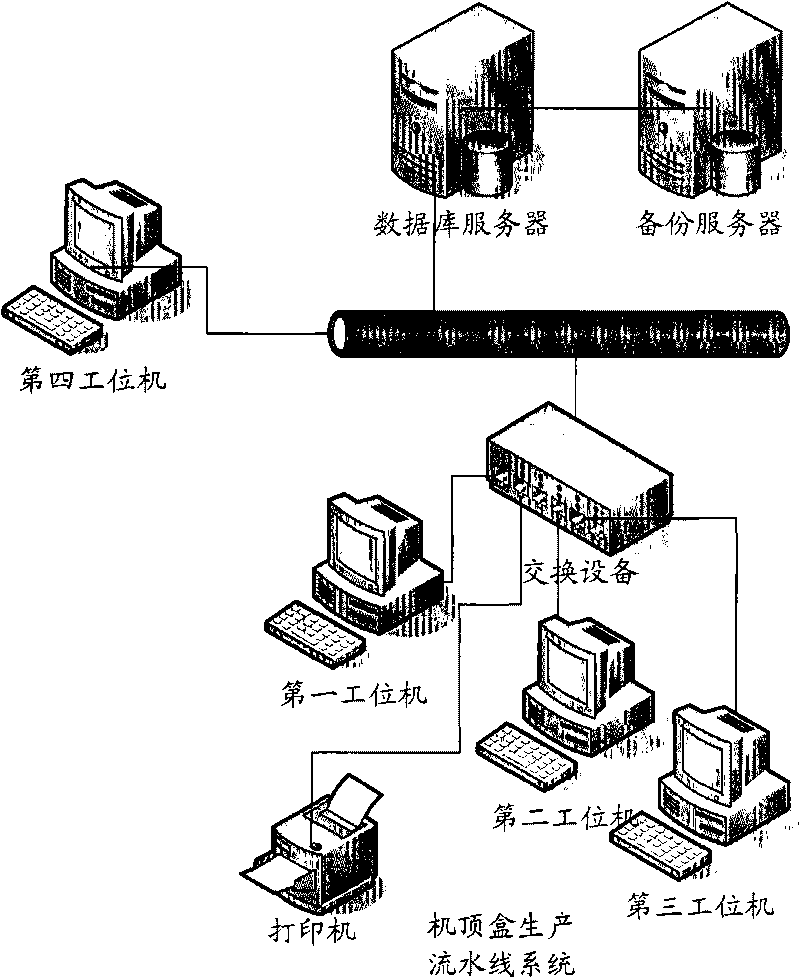

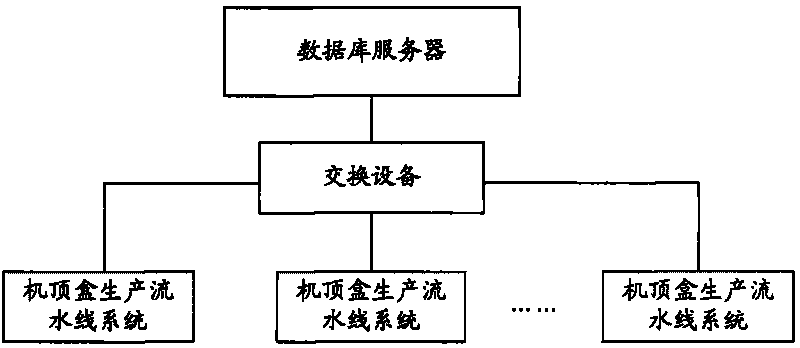

Set-top box production control system

InactiveCN101710240AGuaranteed uptimeRealize automatic collectionTelevision system detailsColor television detailsProduction lineControl system

The invention is suitable for the field of production control and provides a set-top box production control system. The system comprises at least one set-top box production line system, switching equipment and a database server, wherein the set-top box production line system is connected with the database server by the switching equipment so as to generate a serial number according to the read main chip ID number of the set-top box of an assembly line; the serial number is written into the set-top box and stored to the database server; a print label and the serial number written into the set-top box are checked, and the set-top box passing the check is performed with characteristic setup relative to advanced security; the set-top box is binned, and binning information is stored to the database server; the database server is used for storing the serial number generated by the set-top box production line system and the binning information of the set-top box to automatically collect set-top box production information, automatically print and bin so as to ensure normal and efficient operation of the assembly line.

Owner:SHENZHEN JIUZHOU ELECTRIC

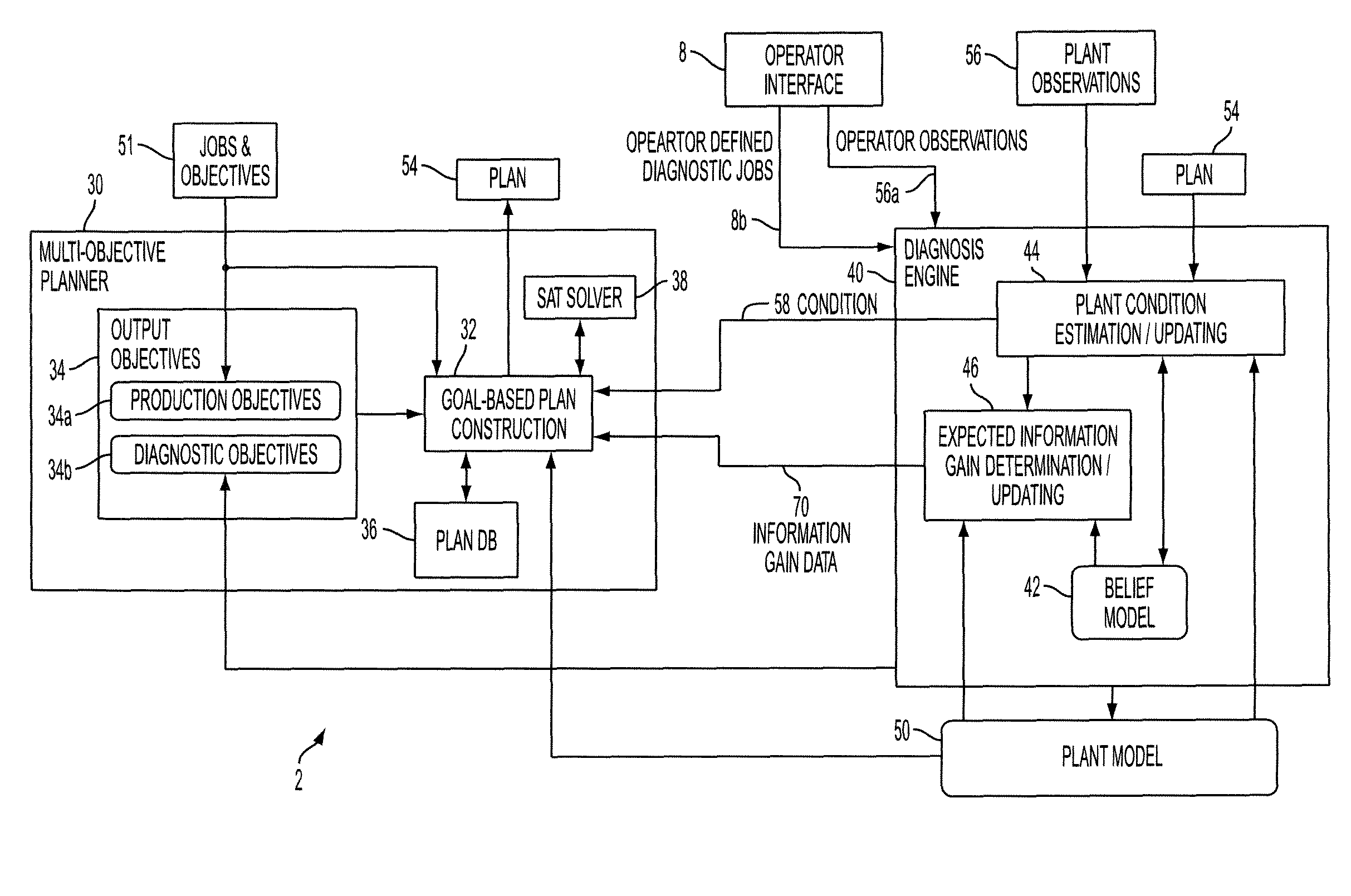

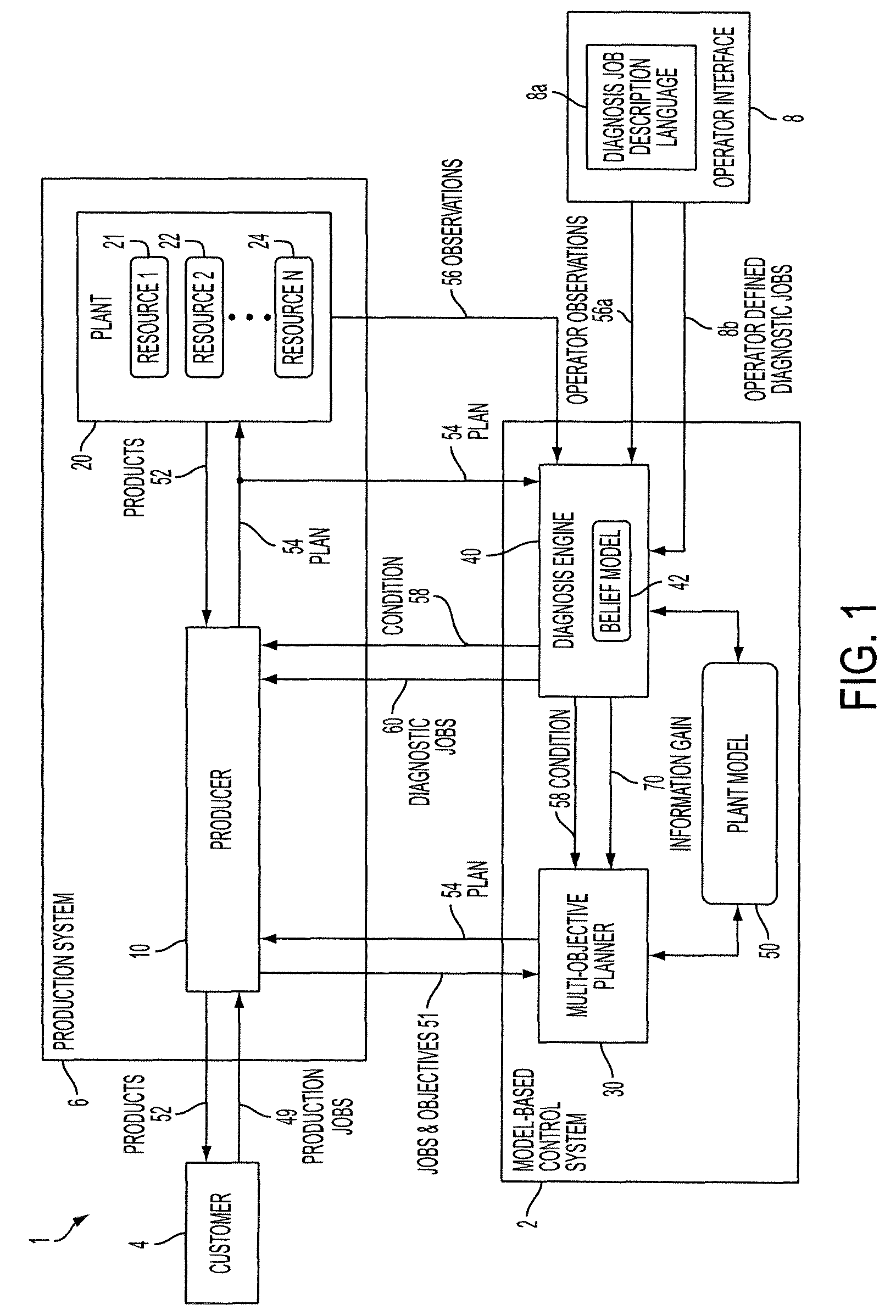

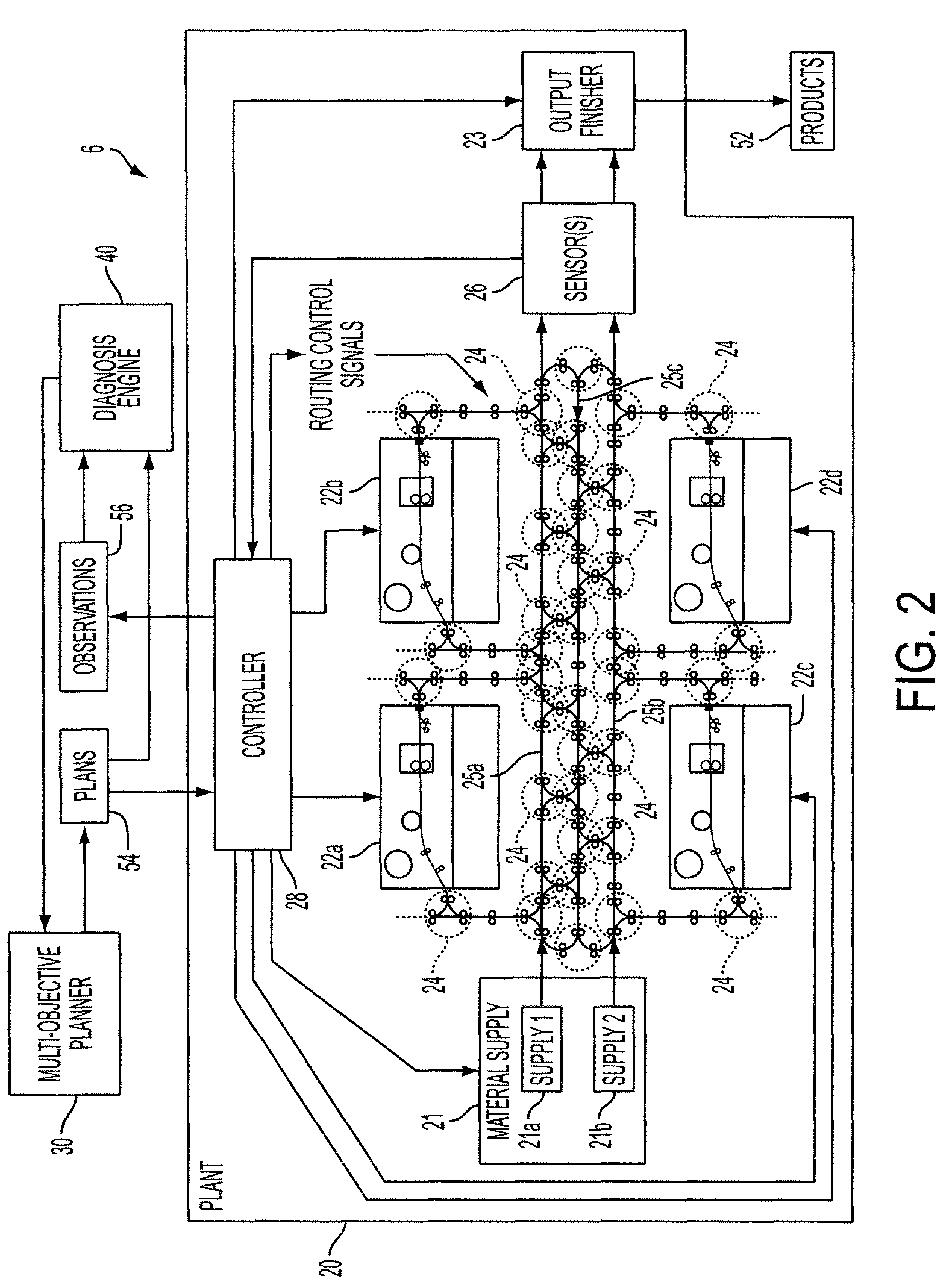

Methods and systems for pervasive diagnostics

ActiveUS7937175B2More cost-effectivelyLong productionProgramme controlTesting/monitoring control systemsProgram planningControl system

Owner:XEROX CORP

Marketing-distribution-dispatch business system information fusion and application method

The invention discloses a marketing-distribution-dispatch business system information fusion and application method. Power grid devices in a production management region and a management information region are unified to be coded, relevant operation and management information of a production control system corresponding to the production management region and a management information system corresponding to the management information region can be acquired in real time, and the production control system, the management information system and subsystems of the production control system and the management information system are integrated, loosely coupled and connected and subjected to data interaction and sharing, so that automatic data synchronization as well as processization, informatization and application integration of distribution data management are realized. Through fusing and integrating marketing-distribution-dispatch business system information, the method provided by the invention has the effects of breaking the information barrier among distribution, application and dispatch at a terminal, realizing the marketing-distribution-dispatch business collaboration and promotion and increasing the business flow efficiency.

Owner:NARI TECH CO LTD +2

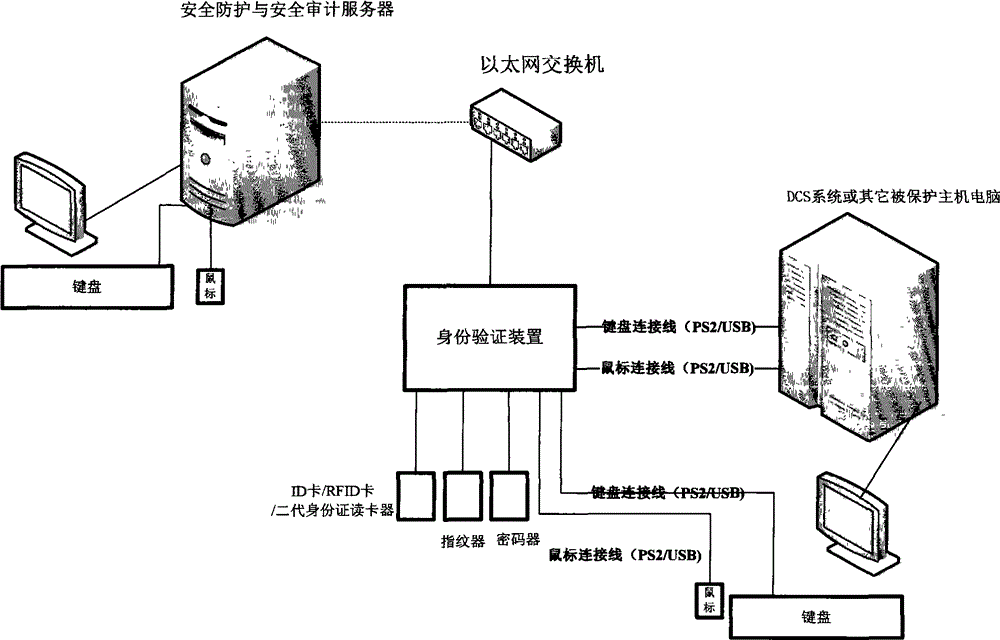

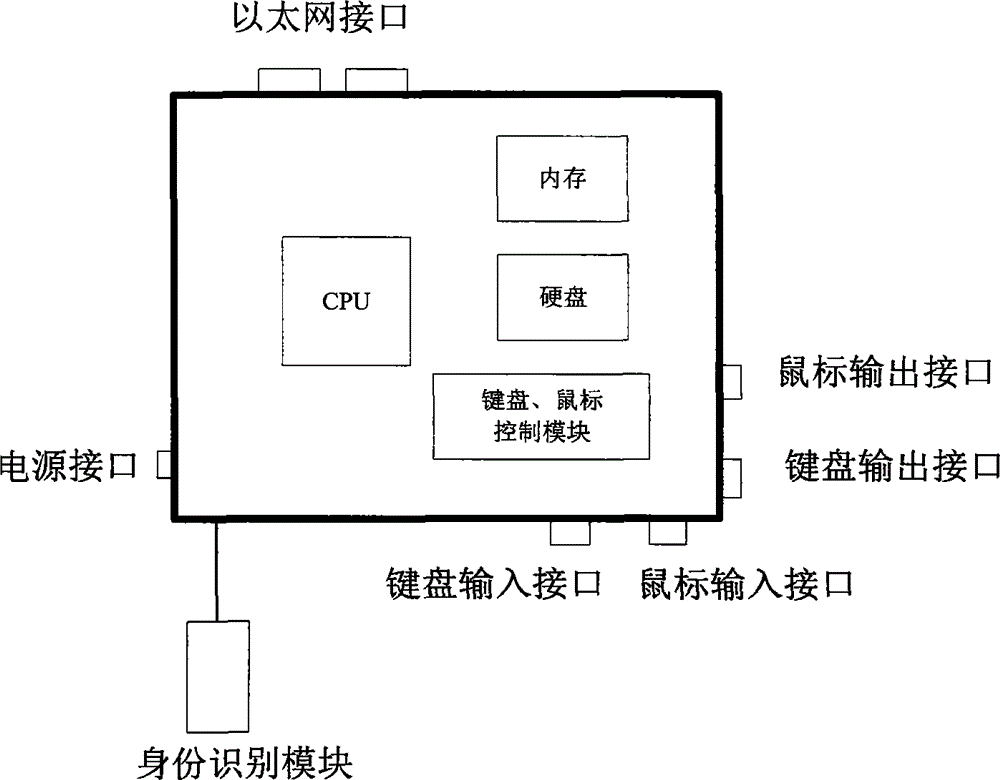

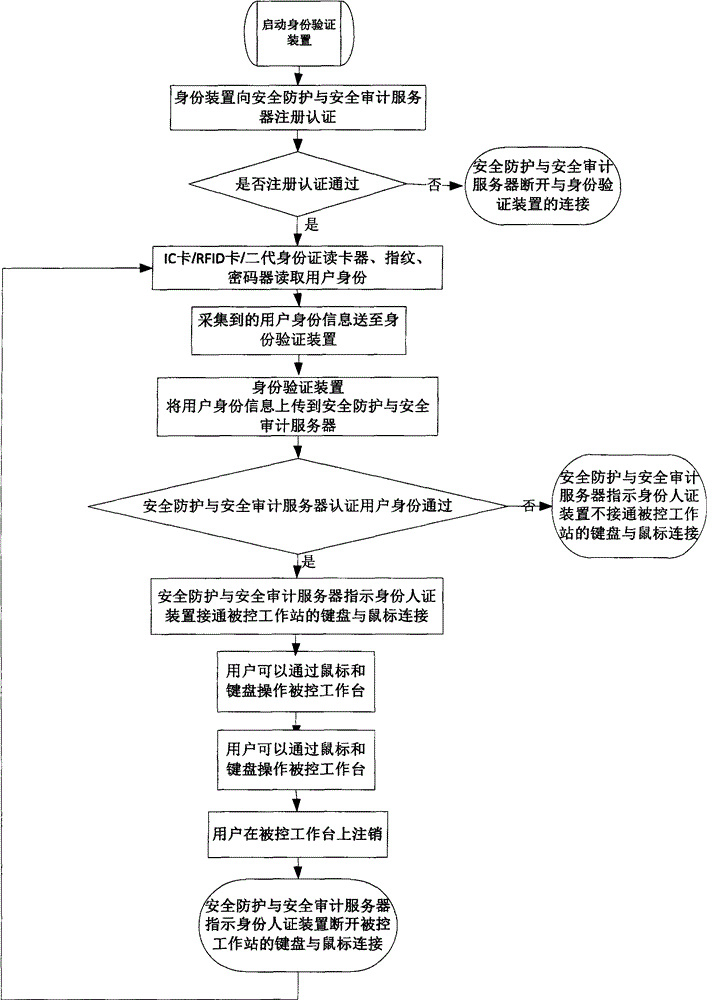

Method and device for identity verification and authority management

ActiveCN103942478ASecurity purposeUser identity/authority verificationDigital data authenticationIdentity recognitionControl system

The invention provides a method and device for identity verification and authority management, and relates to computer software, hardware and the network communication technology. Identity verification and a host which needs to be entered are separated, an IC card, or an RFID card, or an identity card, or a fingerprint identifier, or a cipherer or other identity identification means can be used, keyboard and mouse operation authorities are given to legal users according to flexible authority configuration, identities are recorded, and logs are checked. The identity verification and authority control device is independent, a computer can be more effectively prevented from being used illegally, and the requirement for operation and maintenance staff safety management and checking of a DCS production control system of important core enterprises like power generation enterprises and the state grid corporation of China and the industry field of petrochemical engineering and the like is met.

Owner:ZHEJIANG ANKE NETWORK TECH

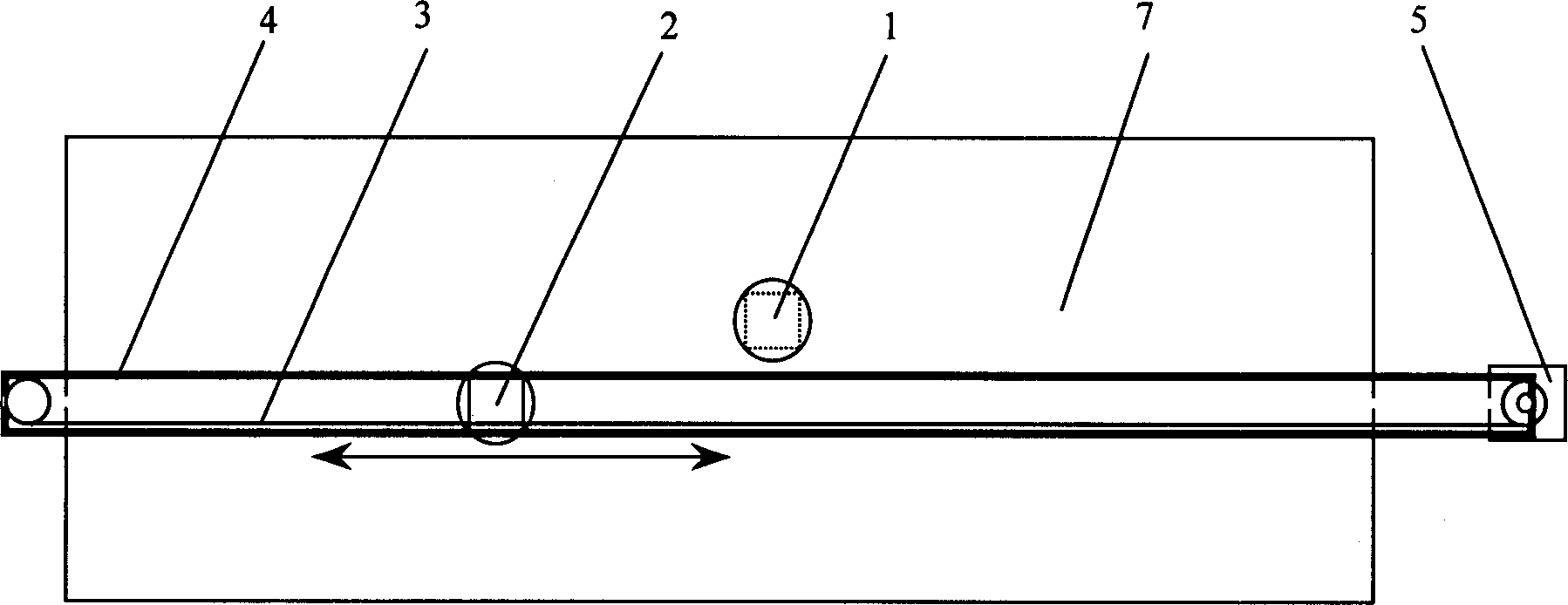

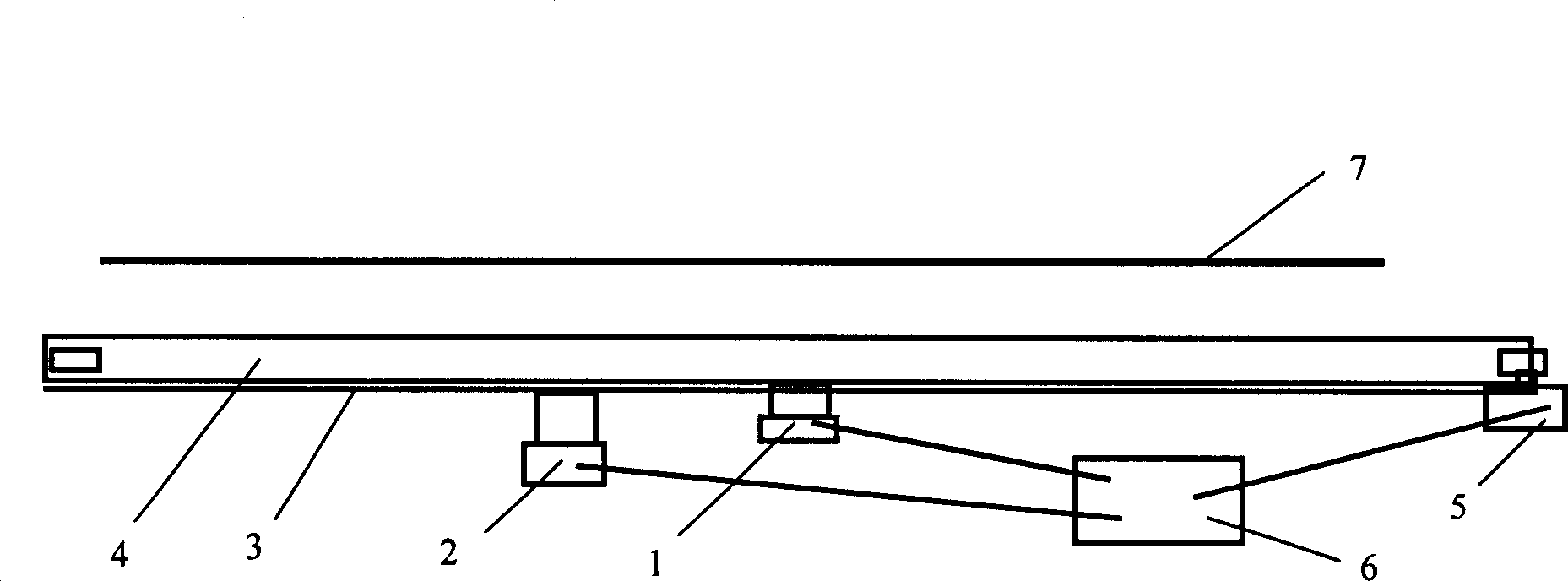

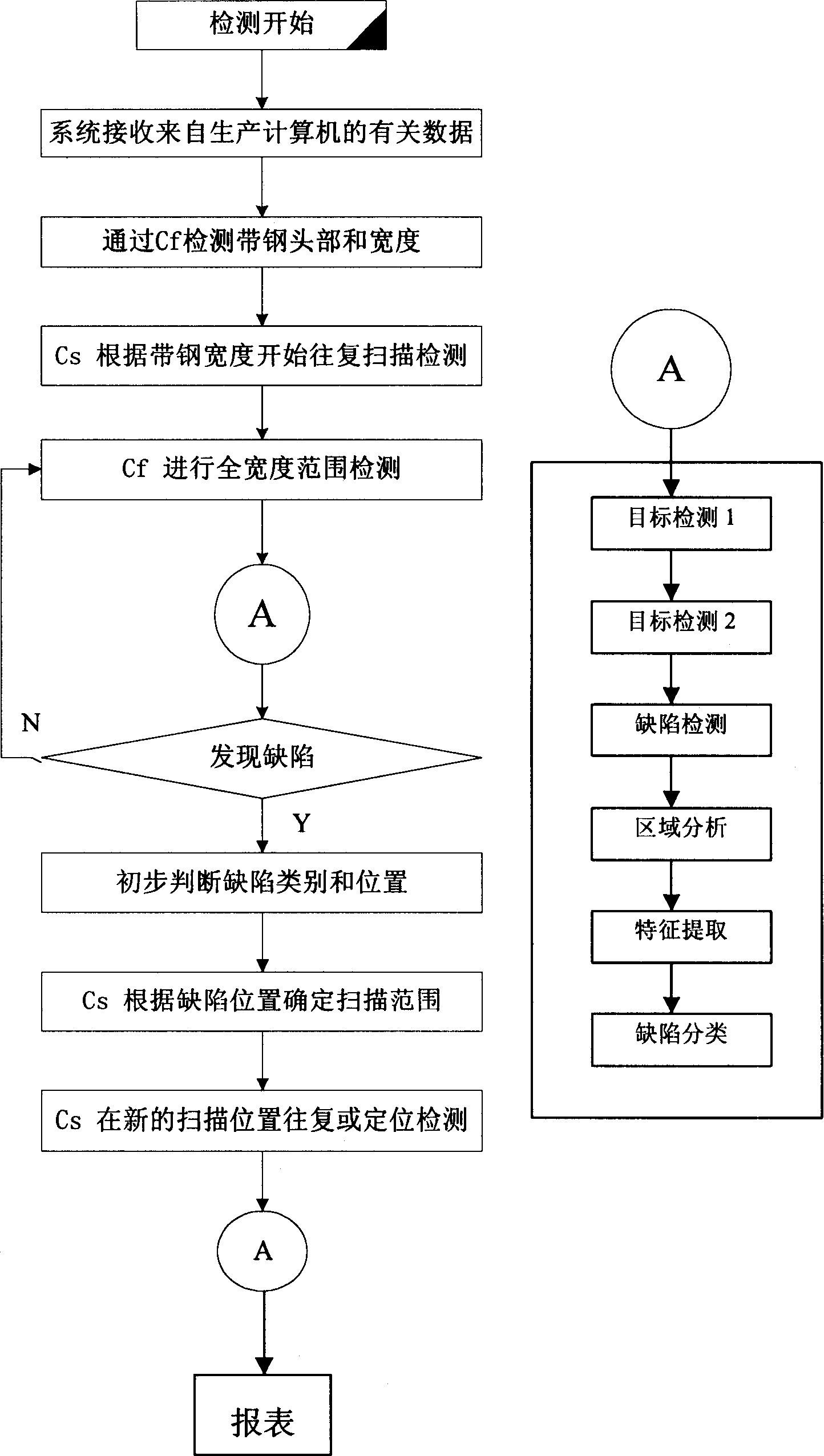

Scanning land steel surface detercting method and apparatus

InactiveCN1508535AImprove surface qualityImprove detection efficiencyInvestigating moving sheetsOptically investigating flaws/contaminationControl systemStrip steel

The invention refers to a measuring method and the device for steel surface, especially measuring large area steel surface defect and the continuous small defects. The invention uses the panoramic camera and high resolution scanning camera, uses panoramic camera to detect the global and the steel breadth, then uses the movable scanning camera to scan and amplify the local area, thus it can detect the obvious defect.

Owner:BAOSHAN IRON & STEEL CO LTD

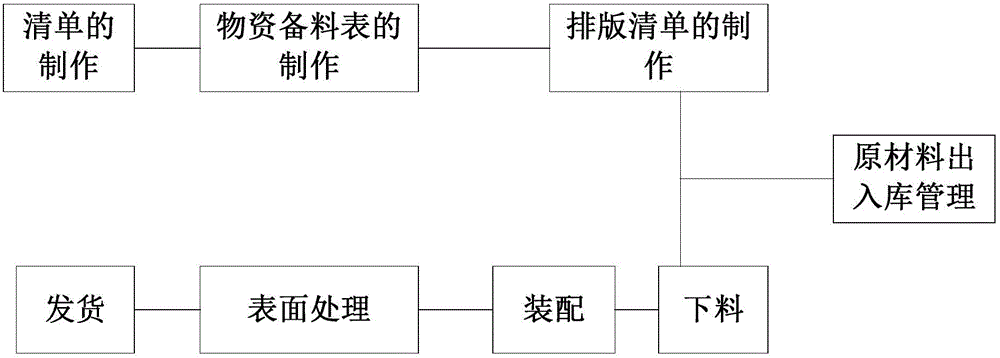

Steel structure product production control system and steel structure product production control method

ActiveCN106020141ATotal factory controlProgramme total factory controlMaterials preparationControl system

The invention discloses a steel structure product production control system and a steel structure product production control method. The control method comprises the following steps: (1) list generation; (2) material preparation table generation; (3) layout list compiling; (4) blanking; (5) assembly; (6) surface treatment; and (7) raw material warehousing-in and warehousing-out management. Through the system and the method, real-time monitoring of steel structure component production is realized, the production efficiency is improved greatly, the production quality is improved, and labor cost is saved.

Owner:HEBEI HANGXIAO STEEL STRUCTURE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com