Scanning land steel surface detercting method and apparatus

A surface inspection and scanning technology, applied in the direction of testing moving boards, optical testing flaws/defects, etc., can solve the problems of multiple cameras and computers, large investment, etc., and achieve low hardware cost, high detection efficiency, and stable surface quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

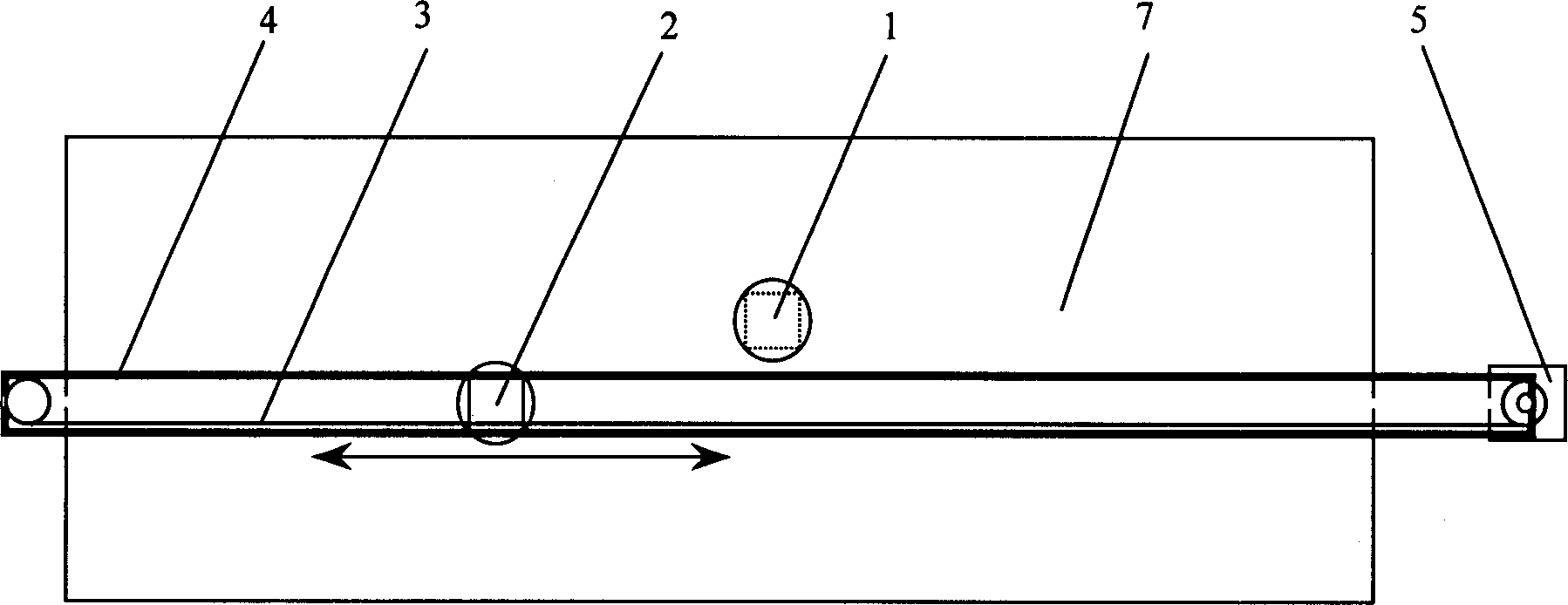

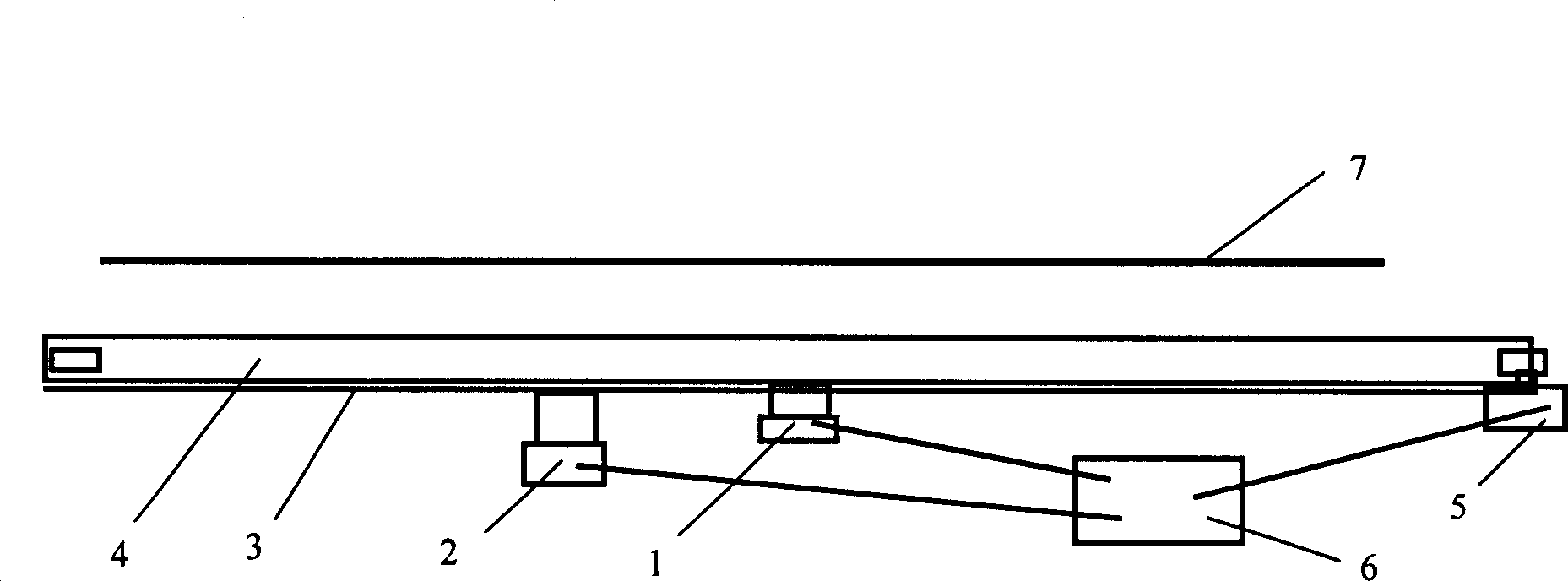

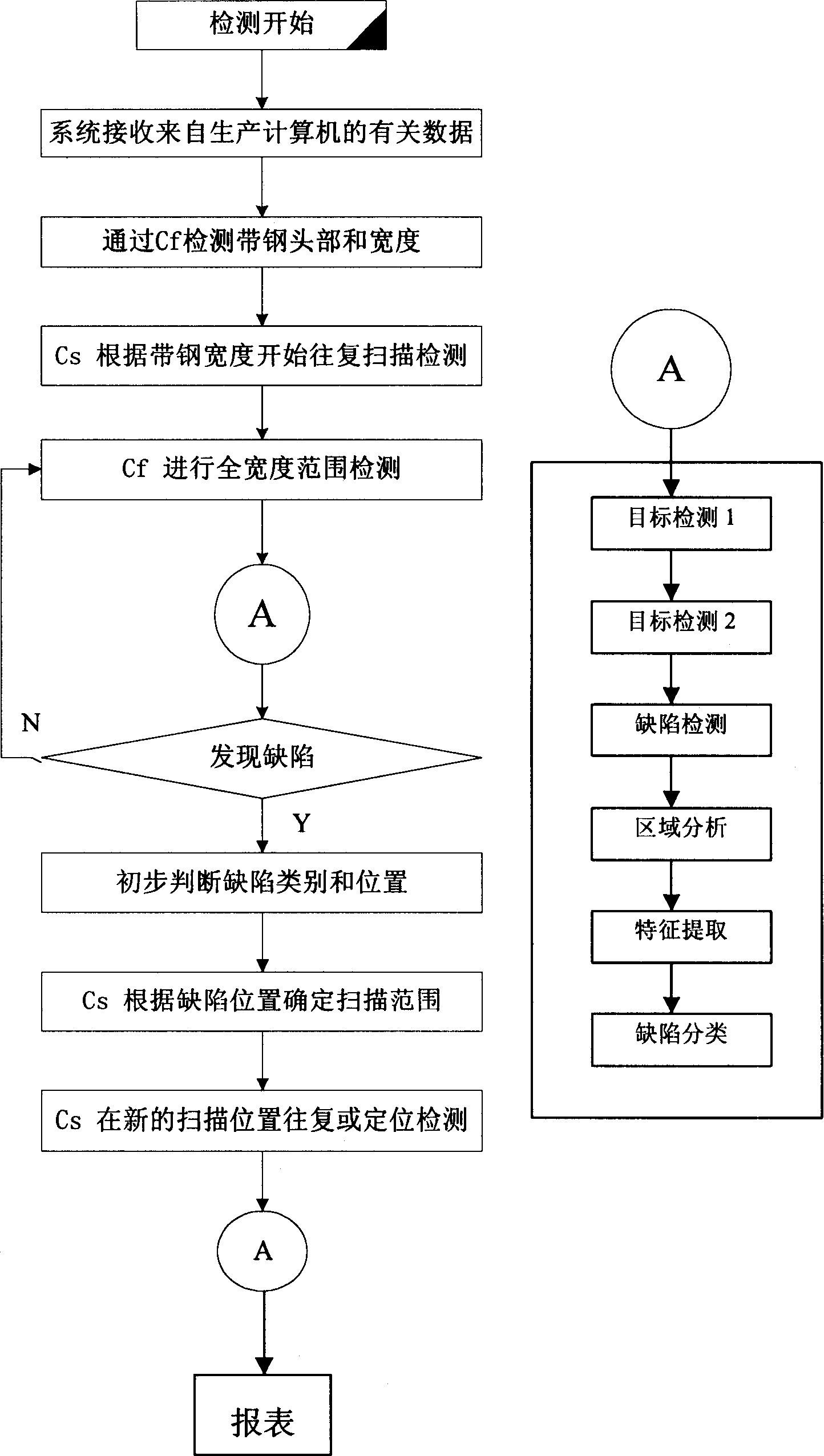

[0010] see figure 1 , figure 2 and image 3 , a scanning type steel strip surface detection method is that panoramic camera 1 carries out global range detection to the head and width of strip steel 7, obtains the detection image and inputs it into computer 6 through the image card, and scanning camera 2 starts reciprocating scanning according to the width of strip steel 7 Detection, the panoramic camera 1 performs full-width detection, and performs defect judgment after finding the target. If no, perform full-width detection again; yes, perform defect judgment. Perform defect detection, (3) perform area analysis on defects, (4) feature extraction, and (5) classify defects. Then make a preliminary judgment on the type and position of the defect, the scanning camera 2 determines the scanning range according to the defect position, and the scanning camera 2 performs reciprocating detection or positioning detection at the new scanning position, and performs local enlarged detec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com