Patents

Literature

95results about How to "Maximize processing efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

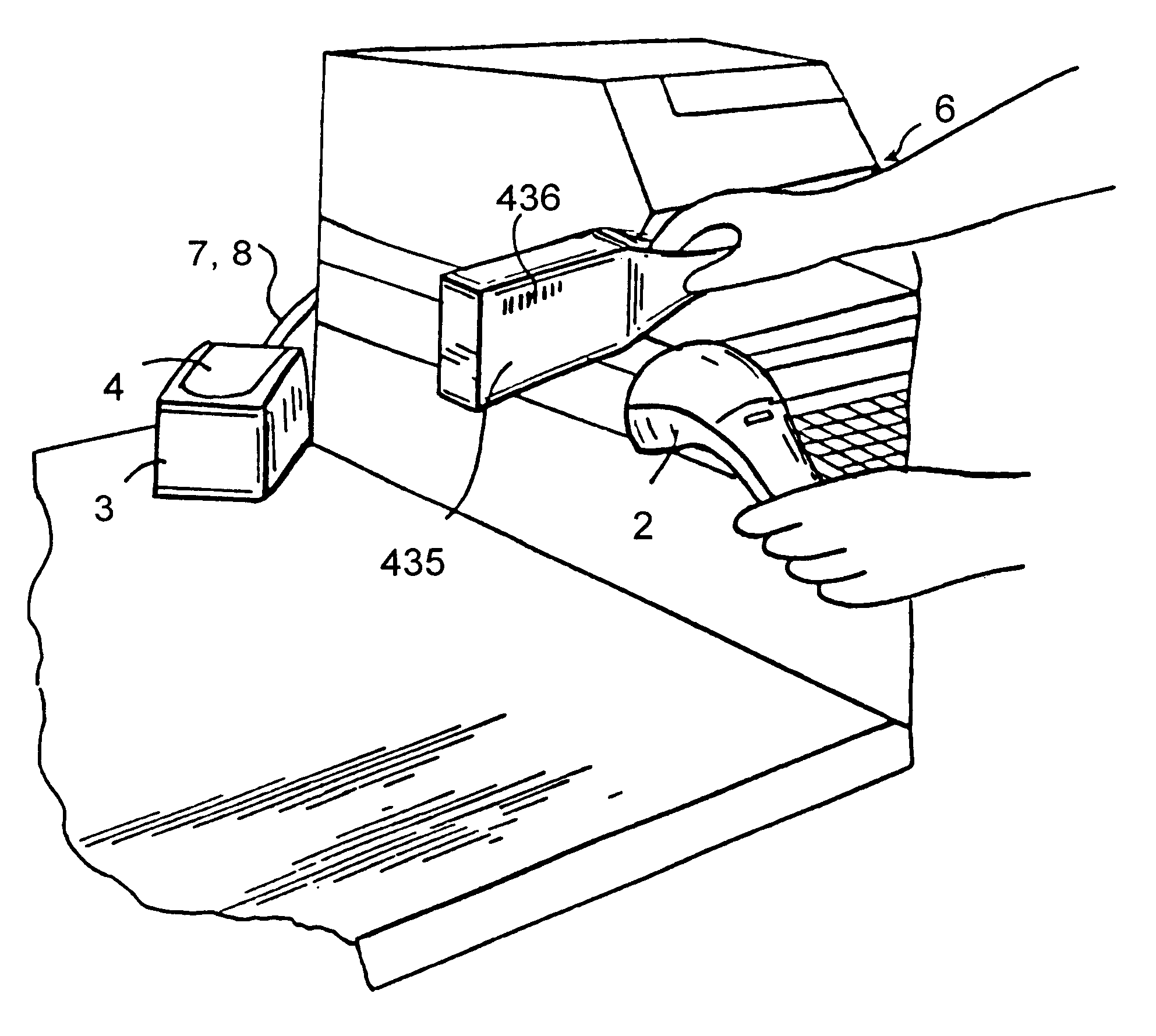

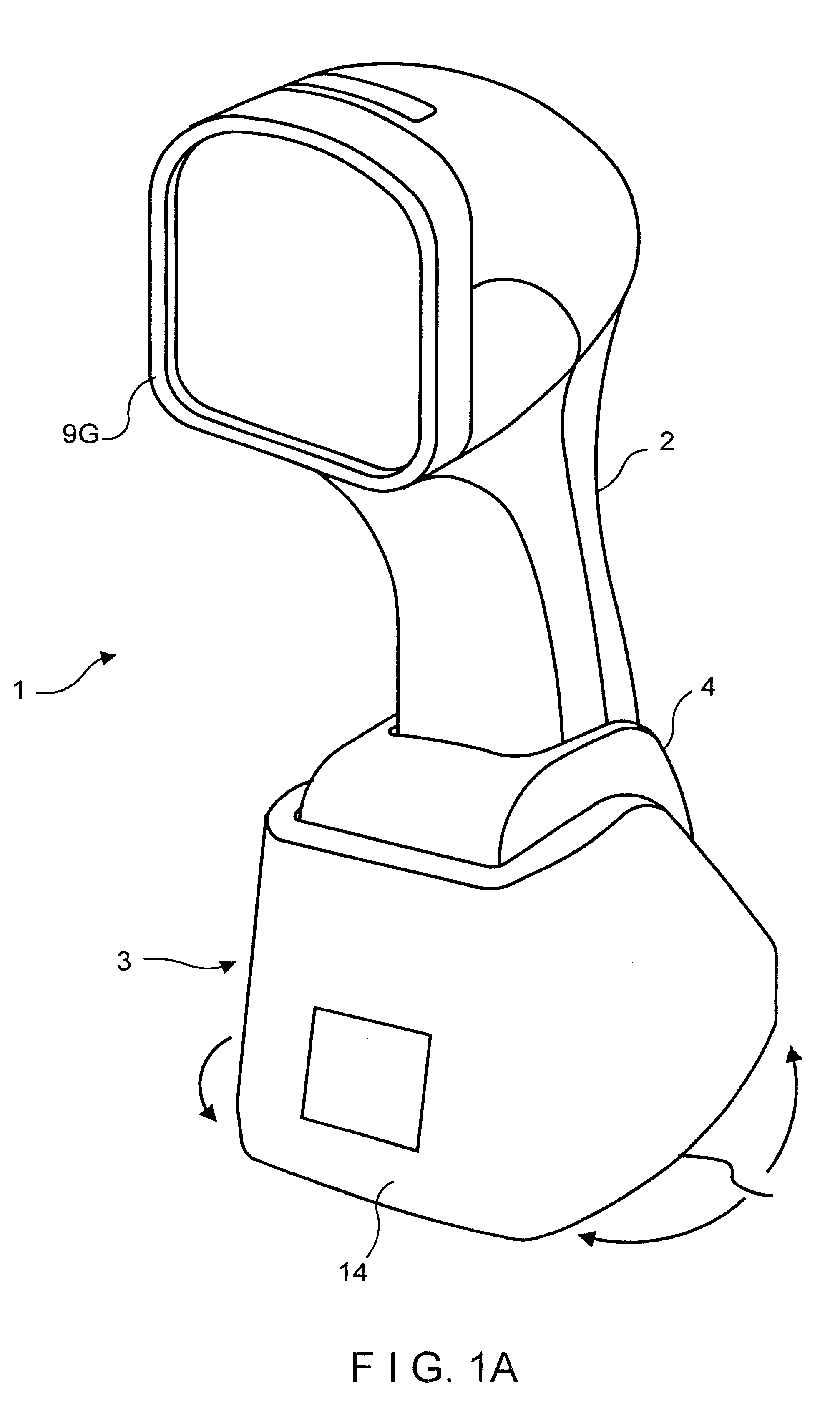

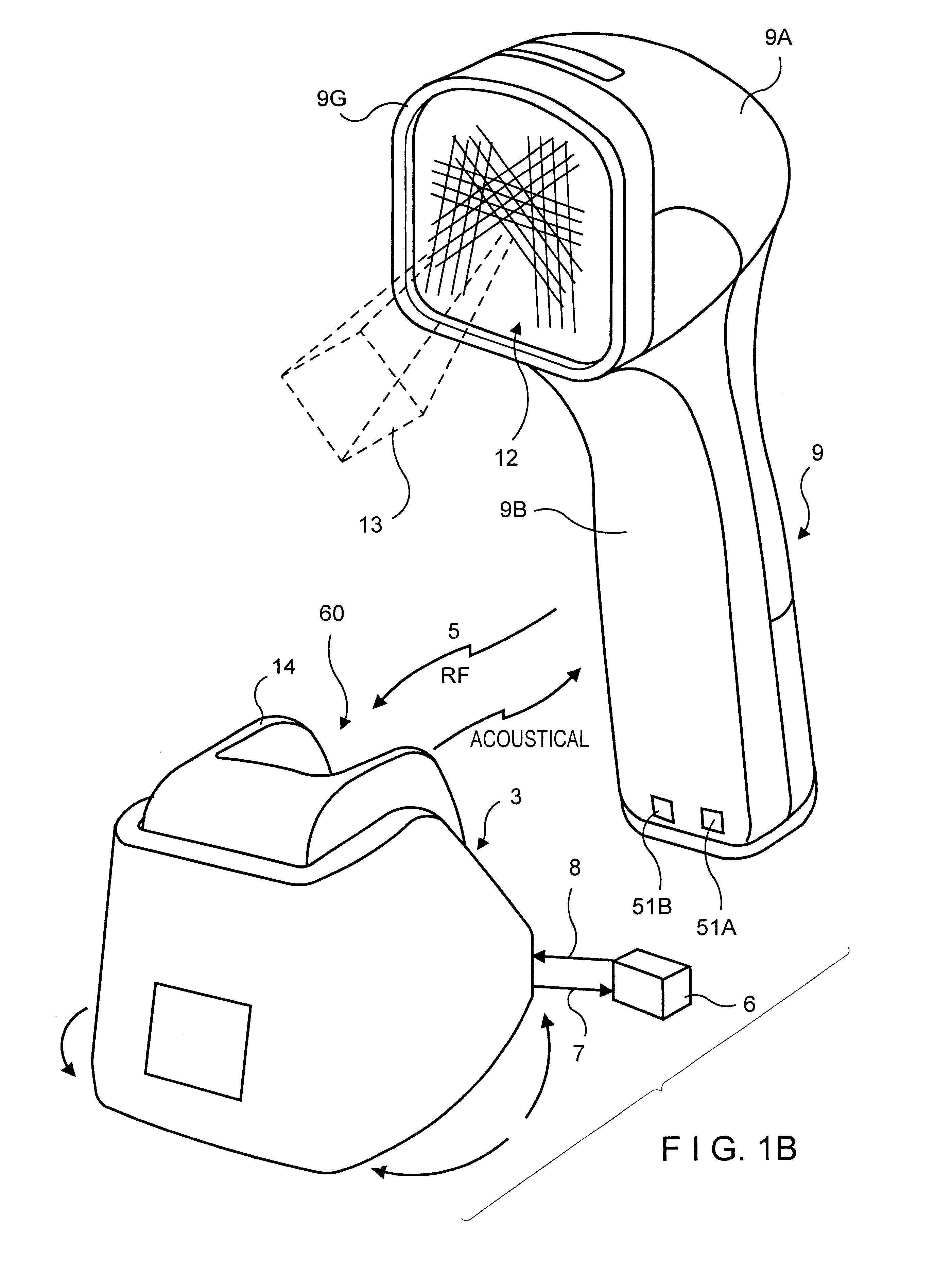

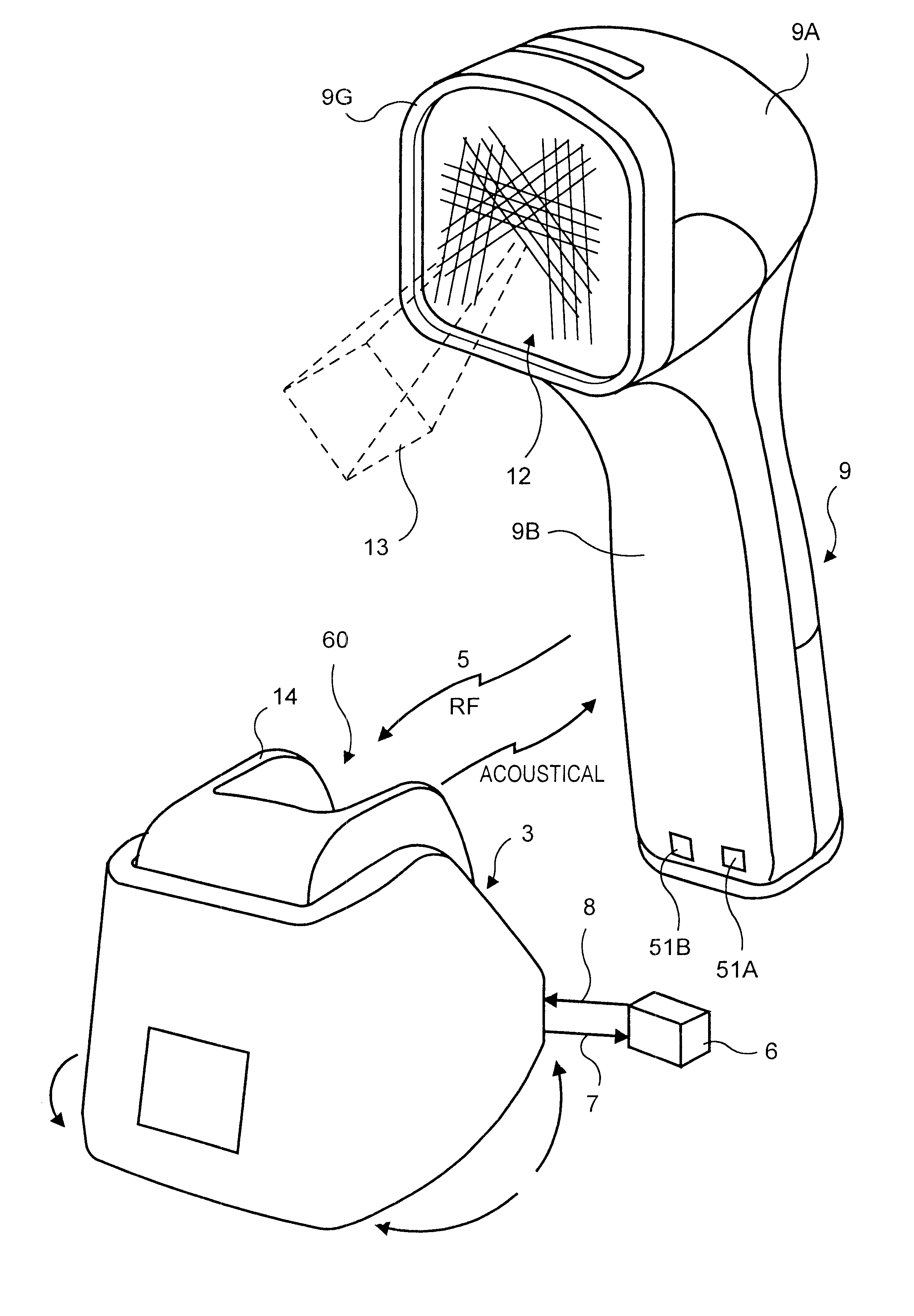

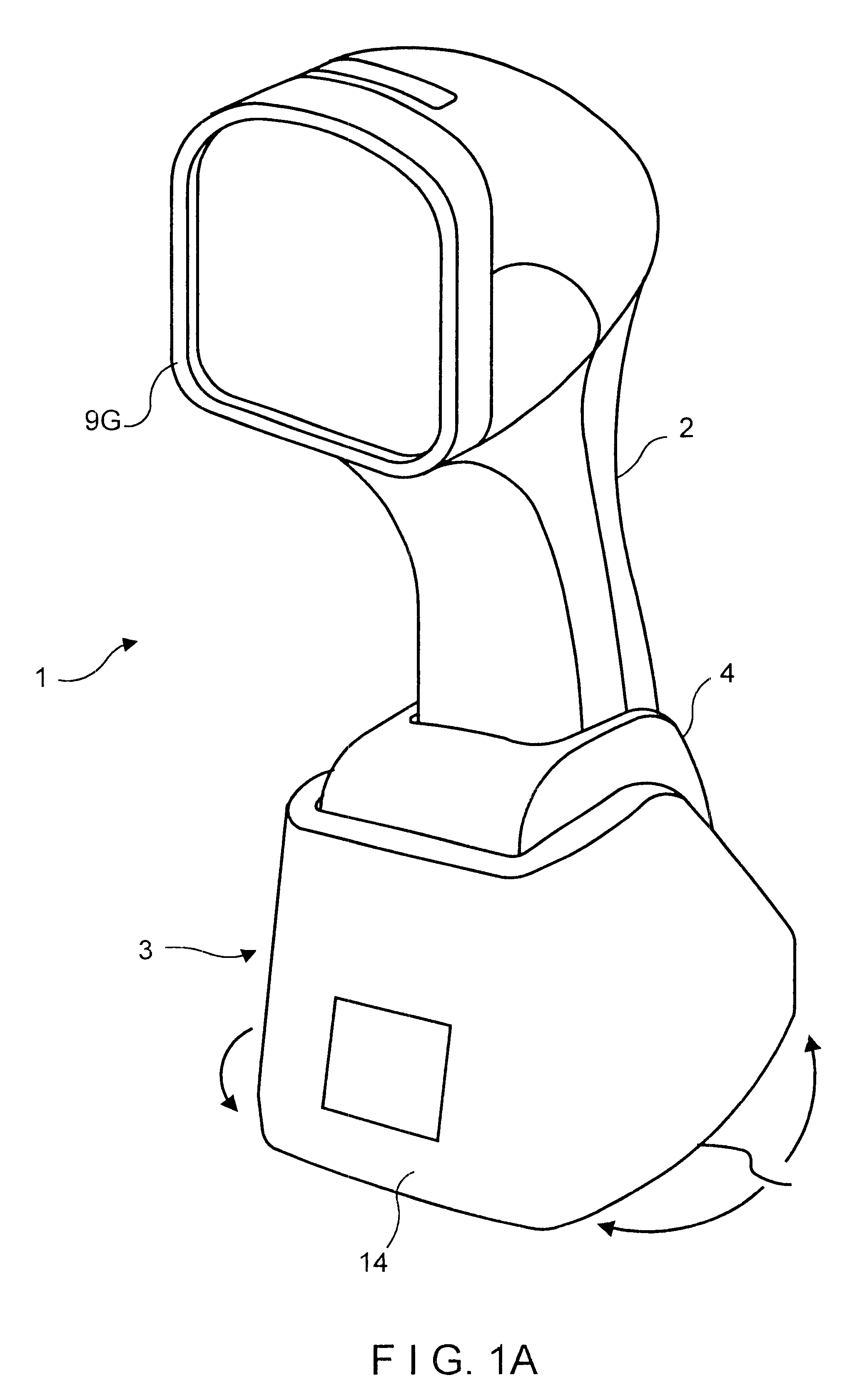

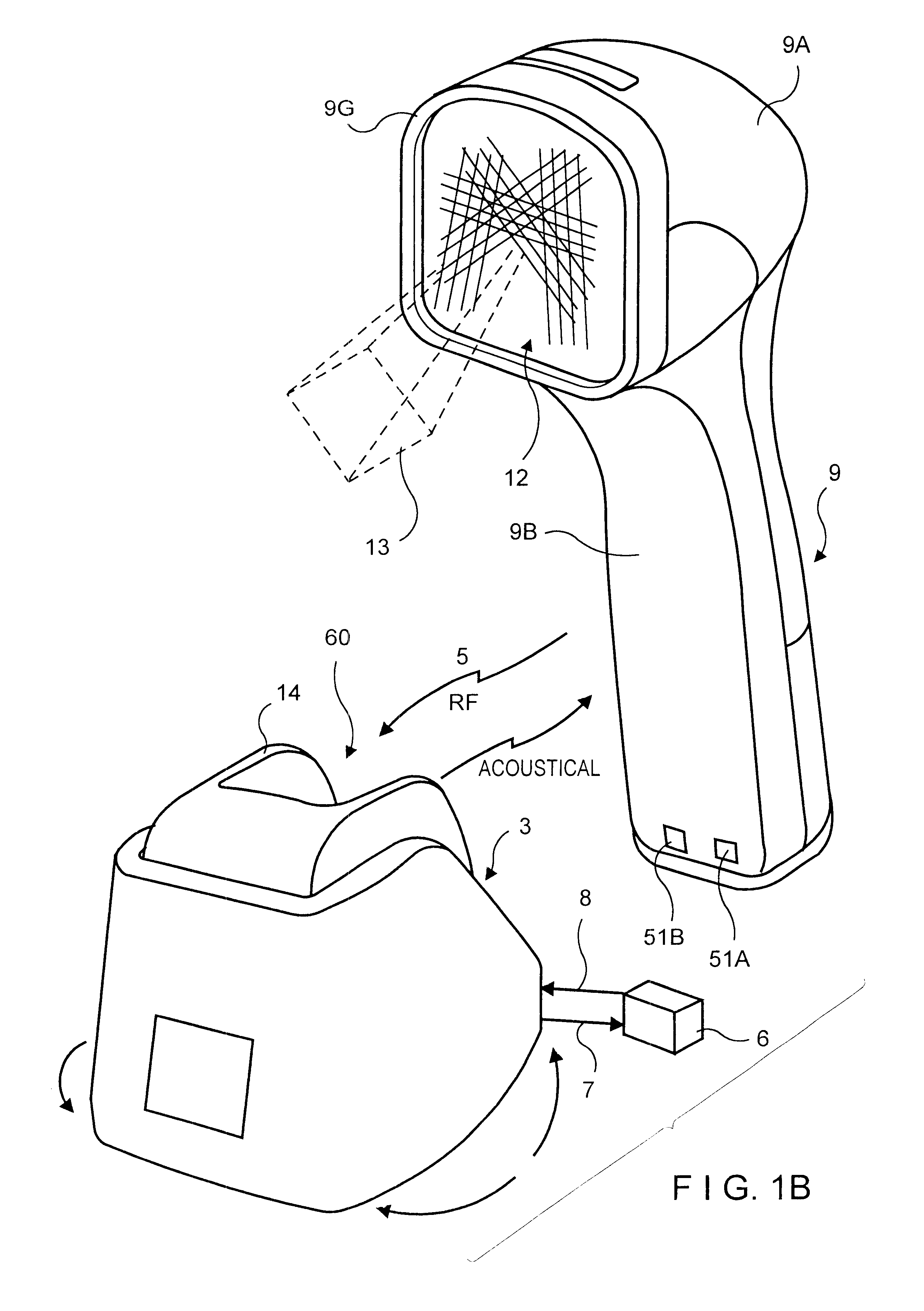

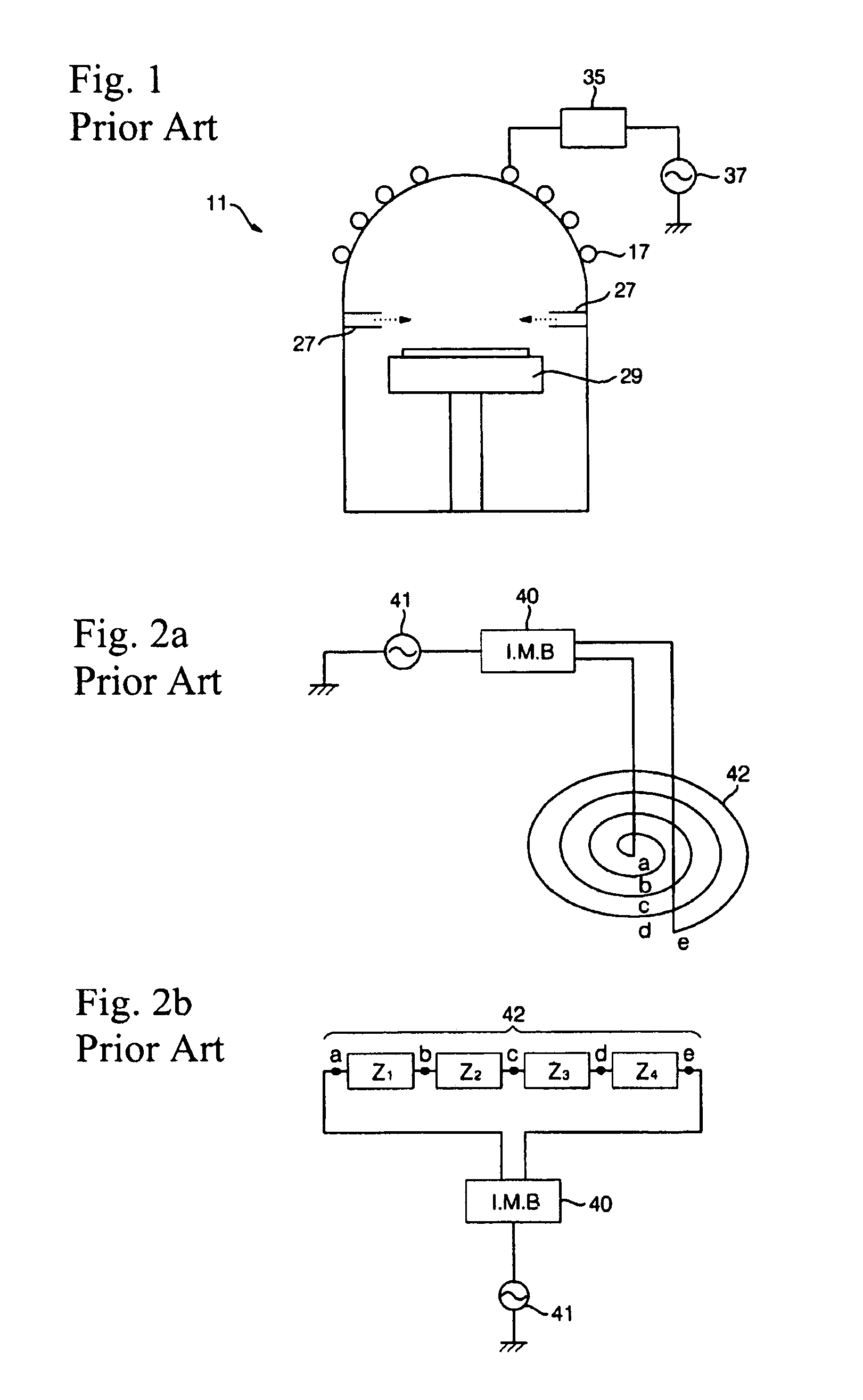

Automatic hand-supportable laser projection scanner for omni-directional reading of bar code symbols within a narrowly confined scanning volume

InactiveUS6286760B1Save power consumptionFacilitate rapid steady-state responseTelevision system scanning detailsCoin-freed apparatus detailsHand heldLaser scanning

A fully automatic bar code symbol reading system comprising an automatic (i.e., triggerless) portable bar code symbol reading device with an omni-directional laser scanning engine mounted within the head portion of its hand-supportable housing, and an associated base unit positioned within the data transmission range thereof without a physical wiring connection thereto.

Owner:METROLOTIC INSTR INC

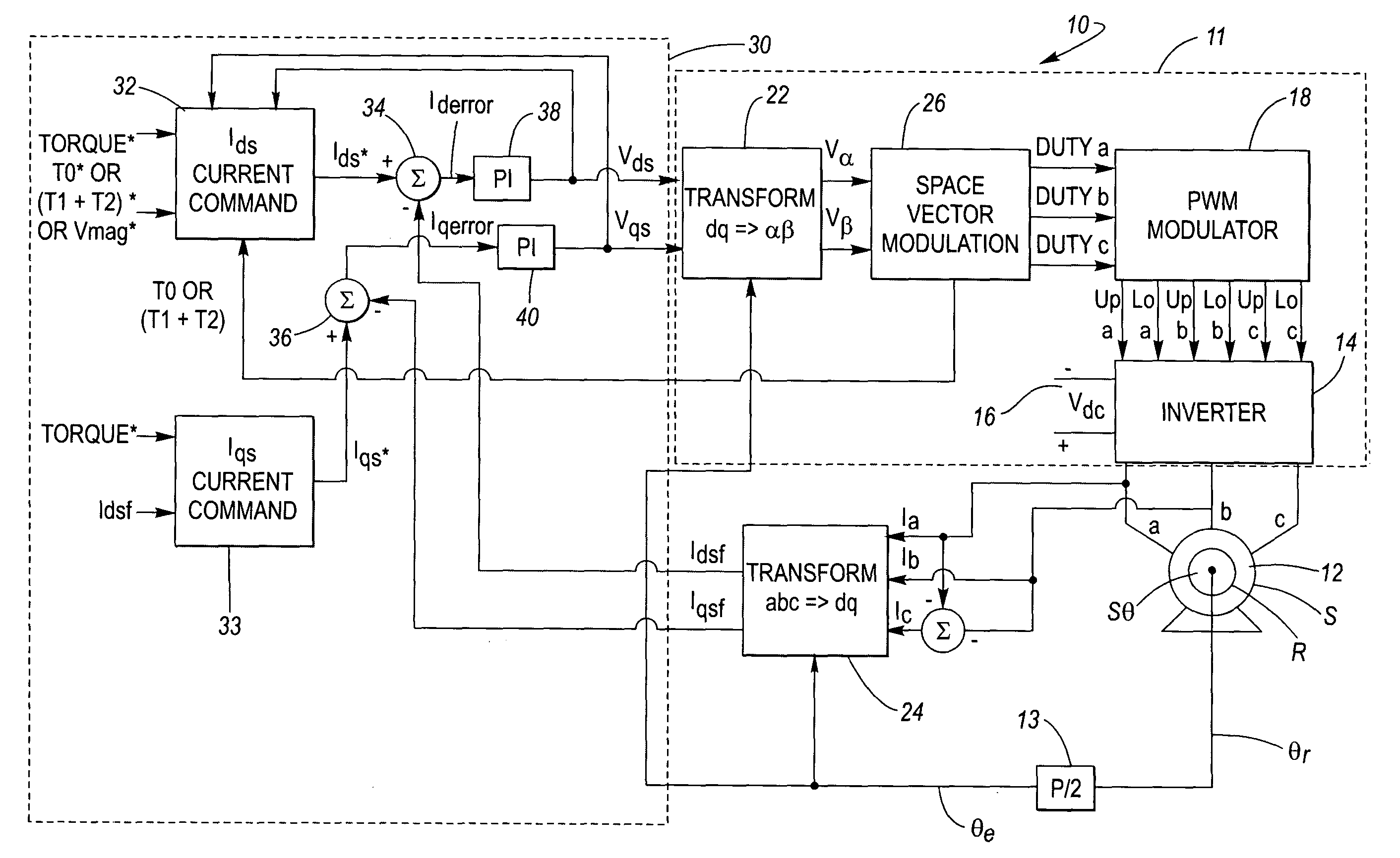

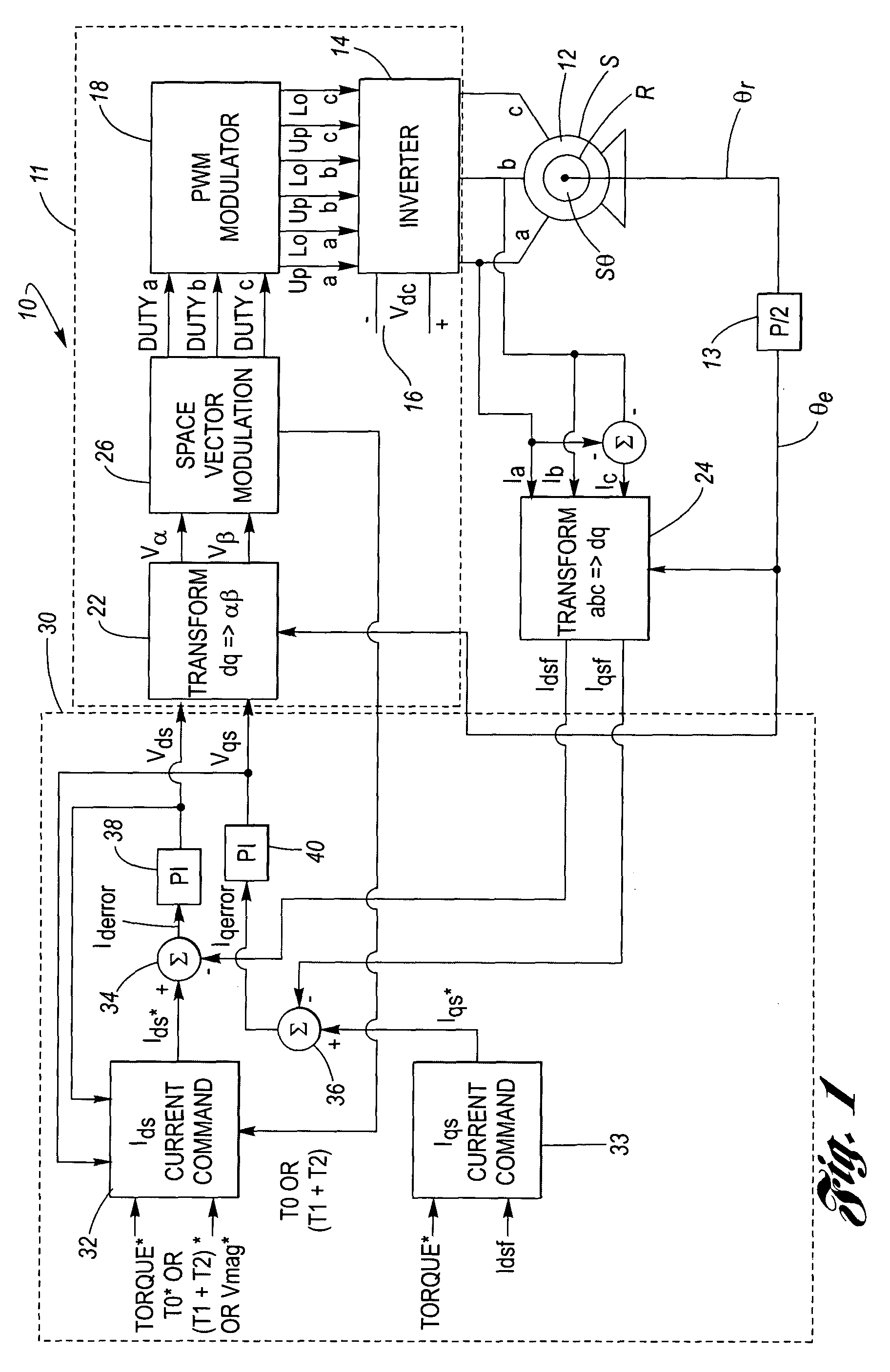

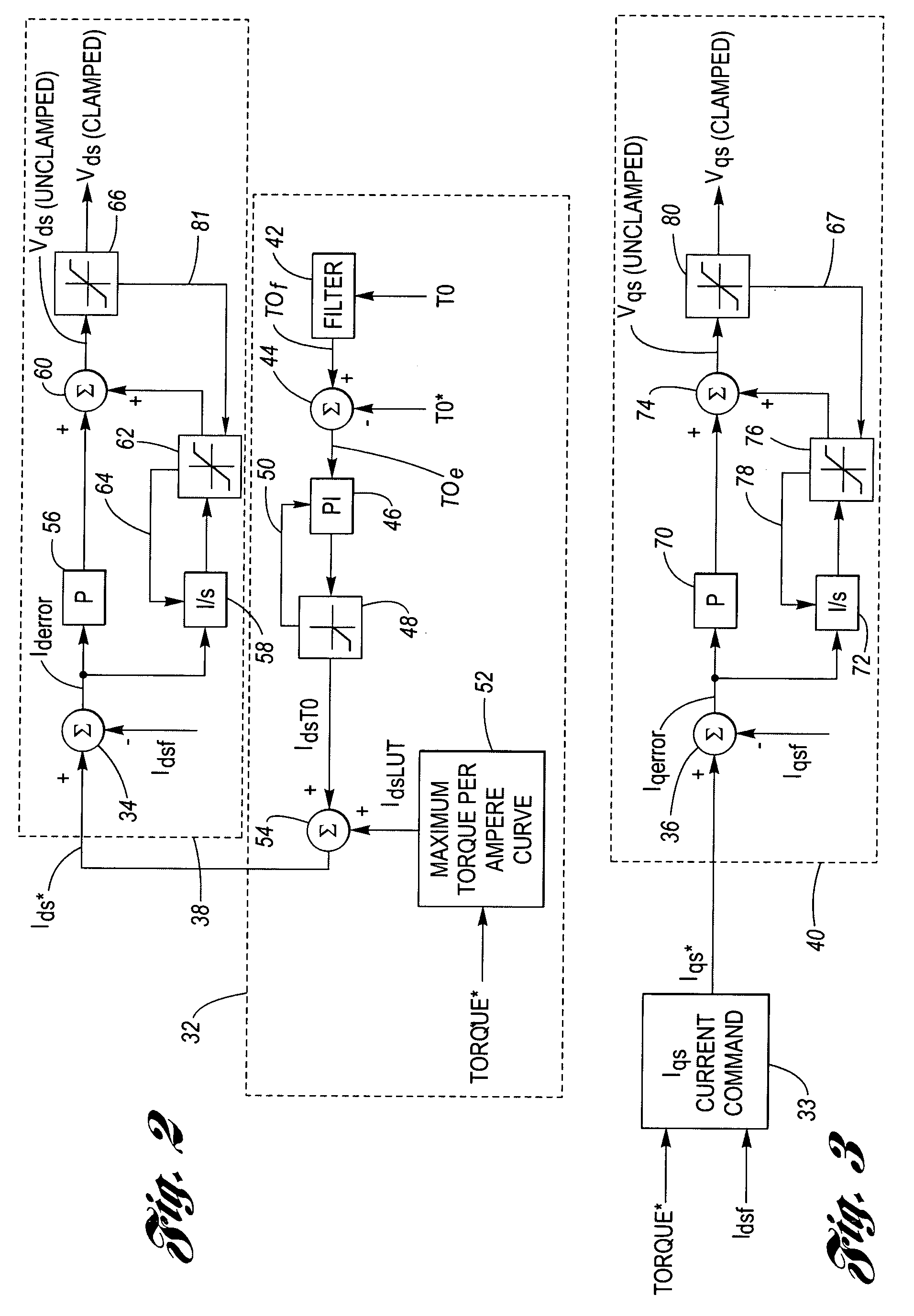

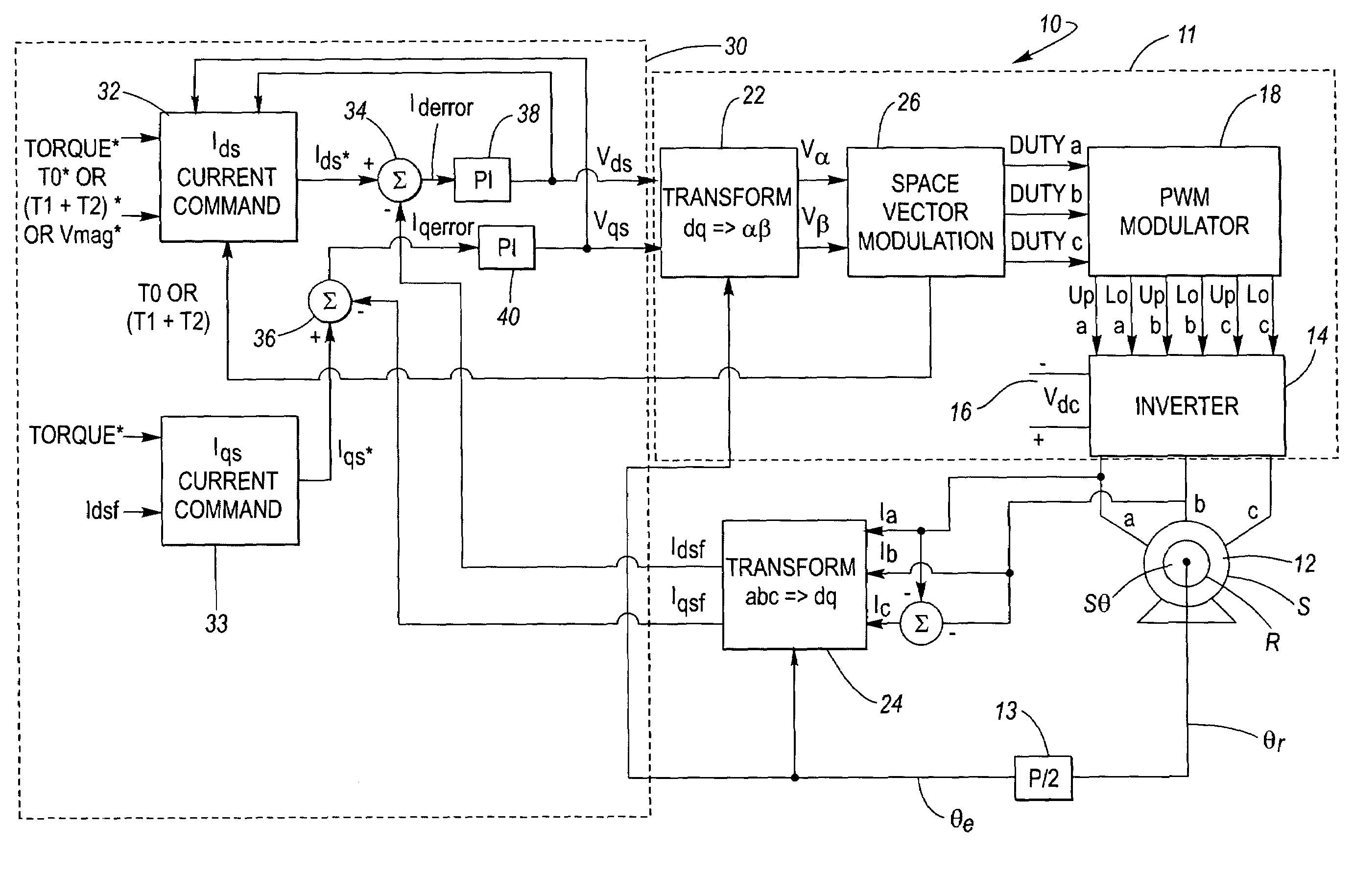

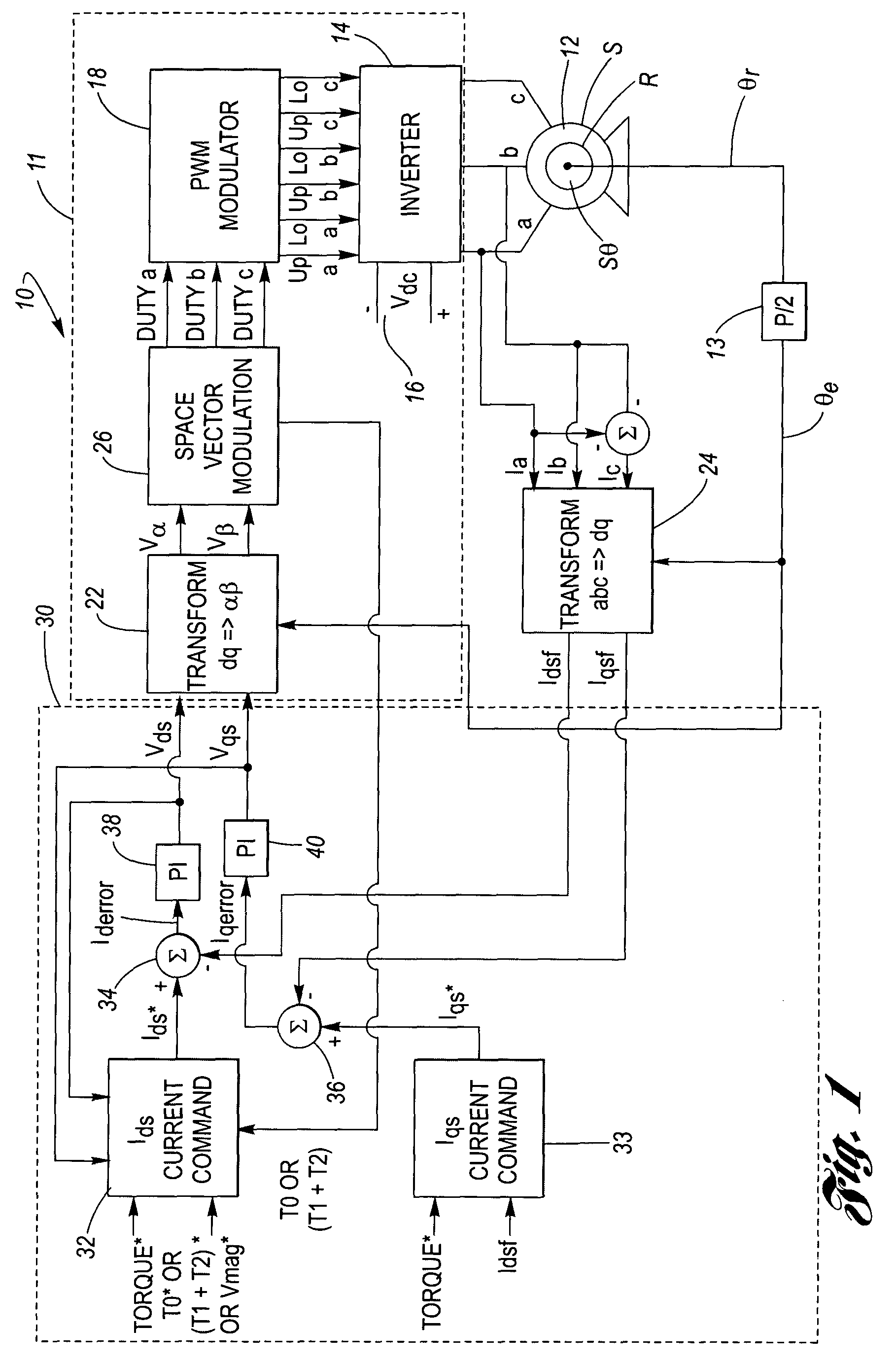

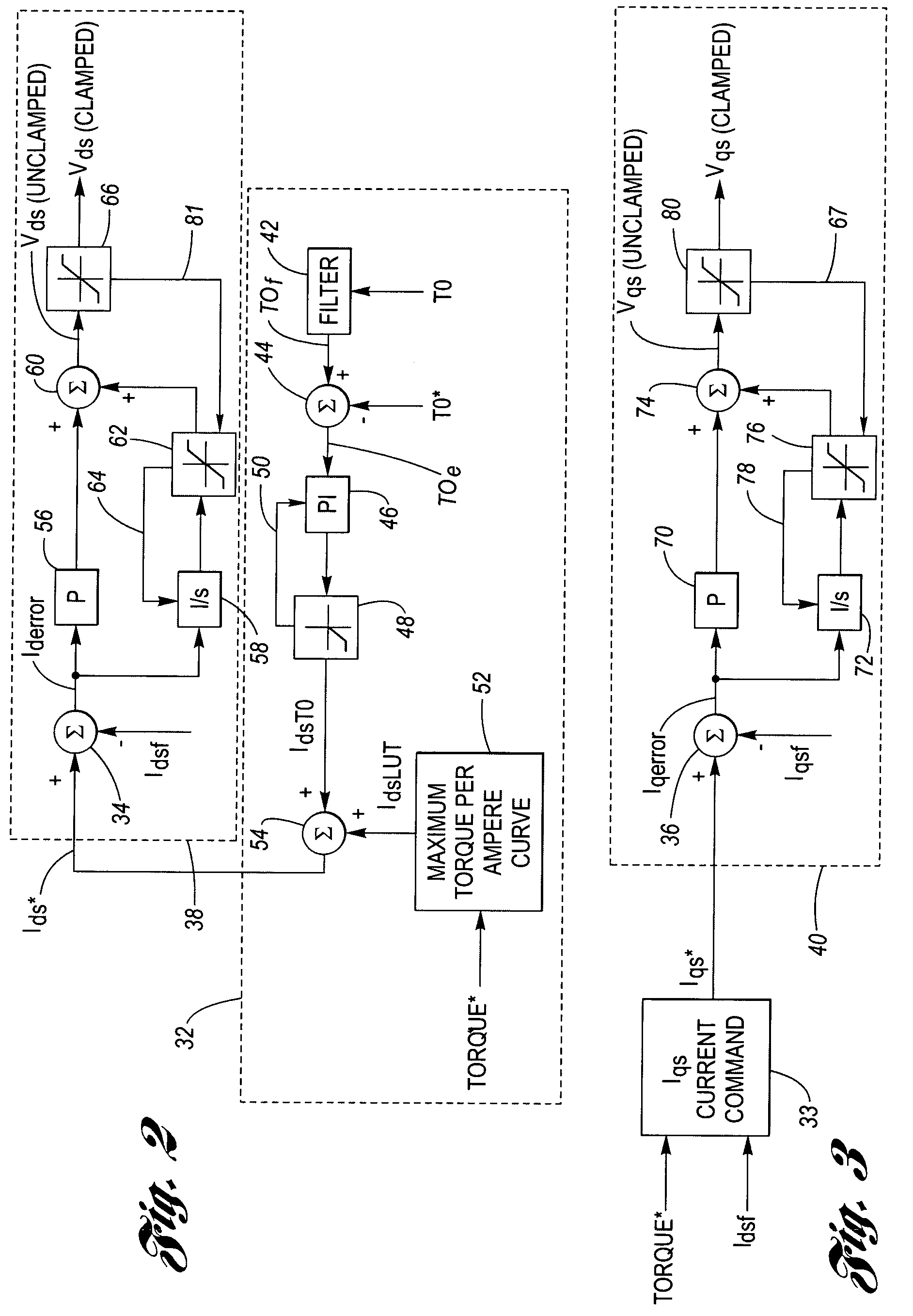

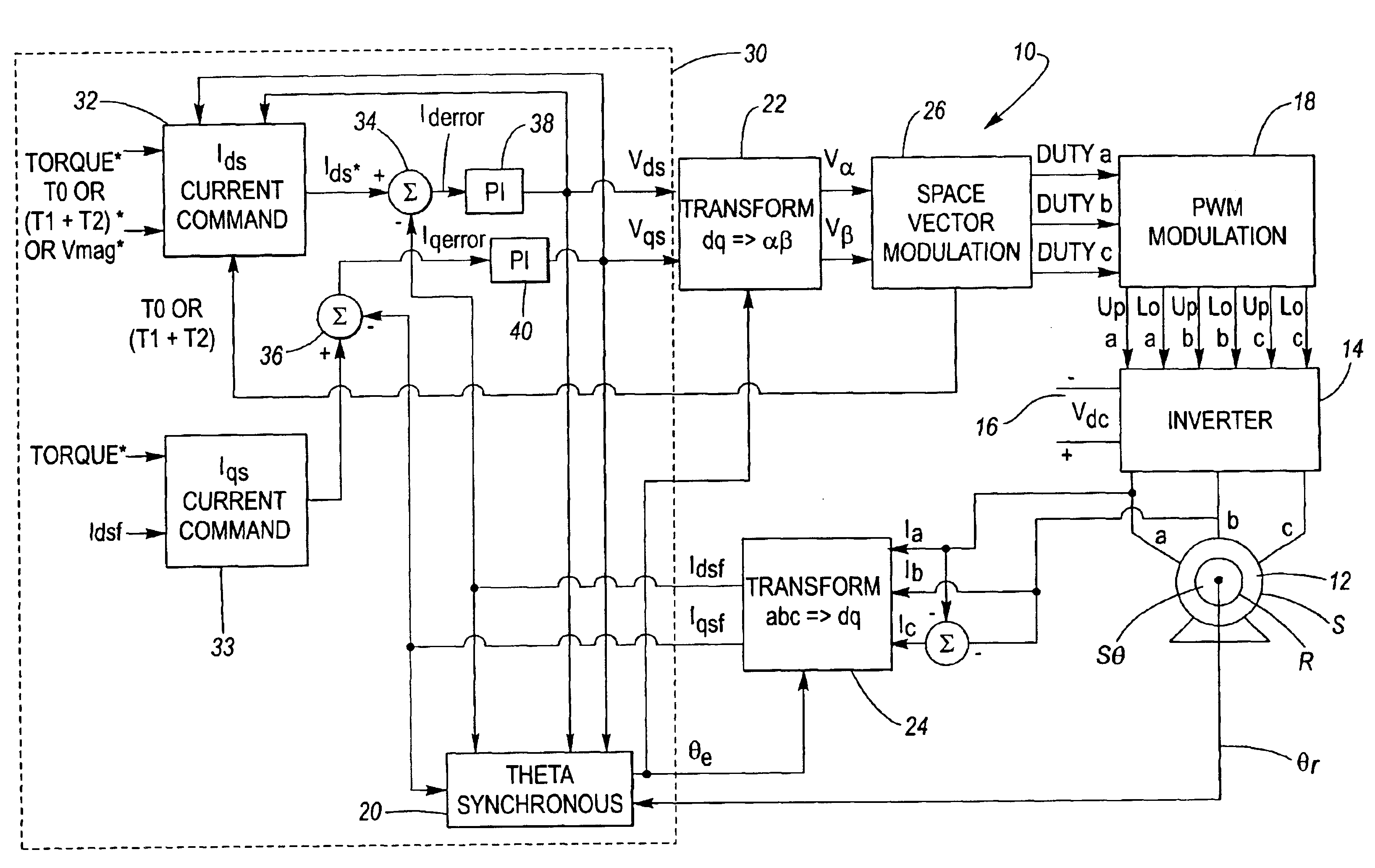

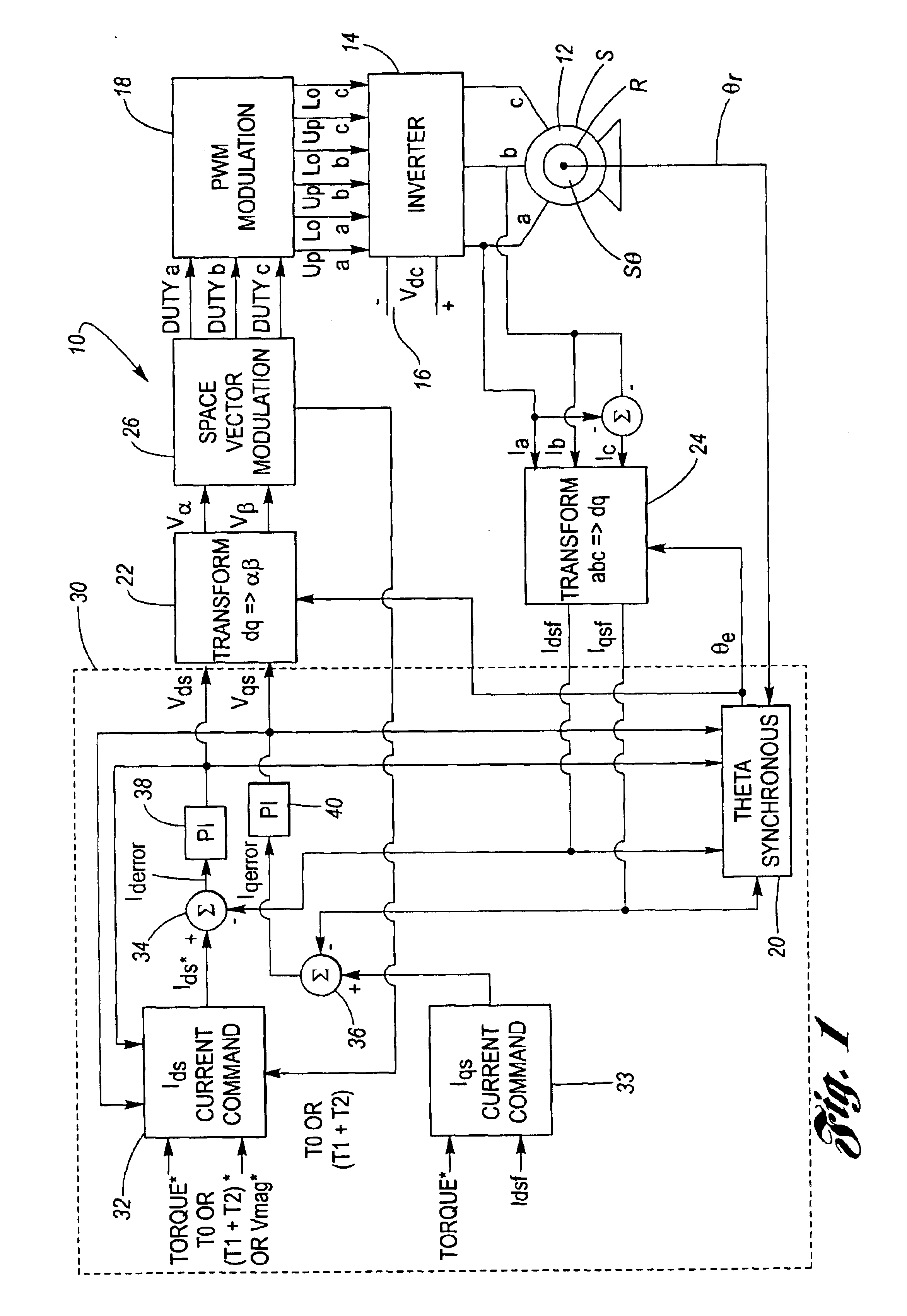

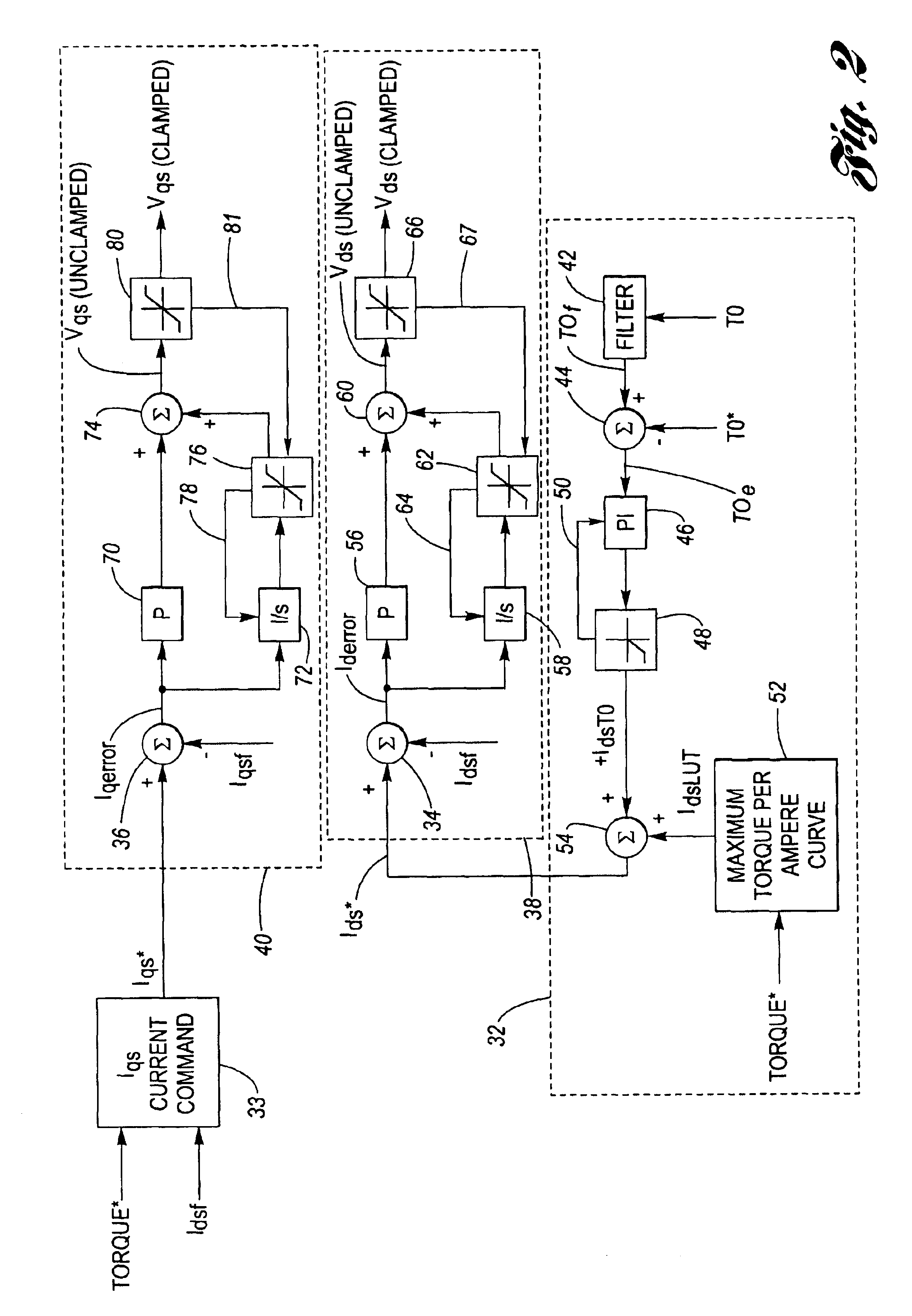

System and method for clamp current regulation in field-weakening operation of permanent magnet (PM) machines

ActiveUS20050046370A1Maximize processing efficiencyMaximum possible torqueAC motor controlDC motor speed/torque controlPhase currentsIntegrator

A device to regulate current produced by a permanent magnet machine responsive to a plurality of phase current signals. The motor produces torque for application on a shaft. A processing and drive circuit responsive to a direct current command signal and a quadrature current command signal produces phase current signals for input to the motor. A command circuit responsive to the phase current signals, an angular position of said shaft, and a voltage input command signal to produce a direct current error signal and a quadrature current error signal. A control circuit responsive to the direct and quadrature current error signals produces the direct voltage signal command and the quadrature voltage signal command. The control circuit has a direct and quadrature proportional gain, integrator and clamp circuits. An algorithm produces limited or clamped voltage modulation index signals to obtain maximum efficiency and maximum torque per ampere in the speed range. The algorithm ensures that the current regulator does not run out of voltage by limiting the voltage vector to the achievable voltage vector range that provides maximum torque per ampere and maximum efficiency.

Owner:DELPHI TECH IP LTD

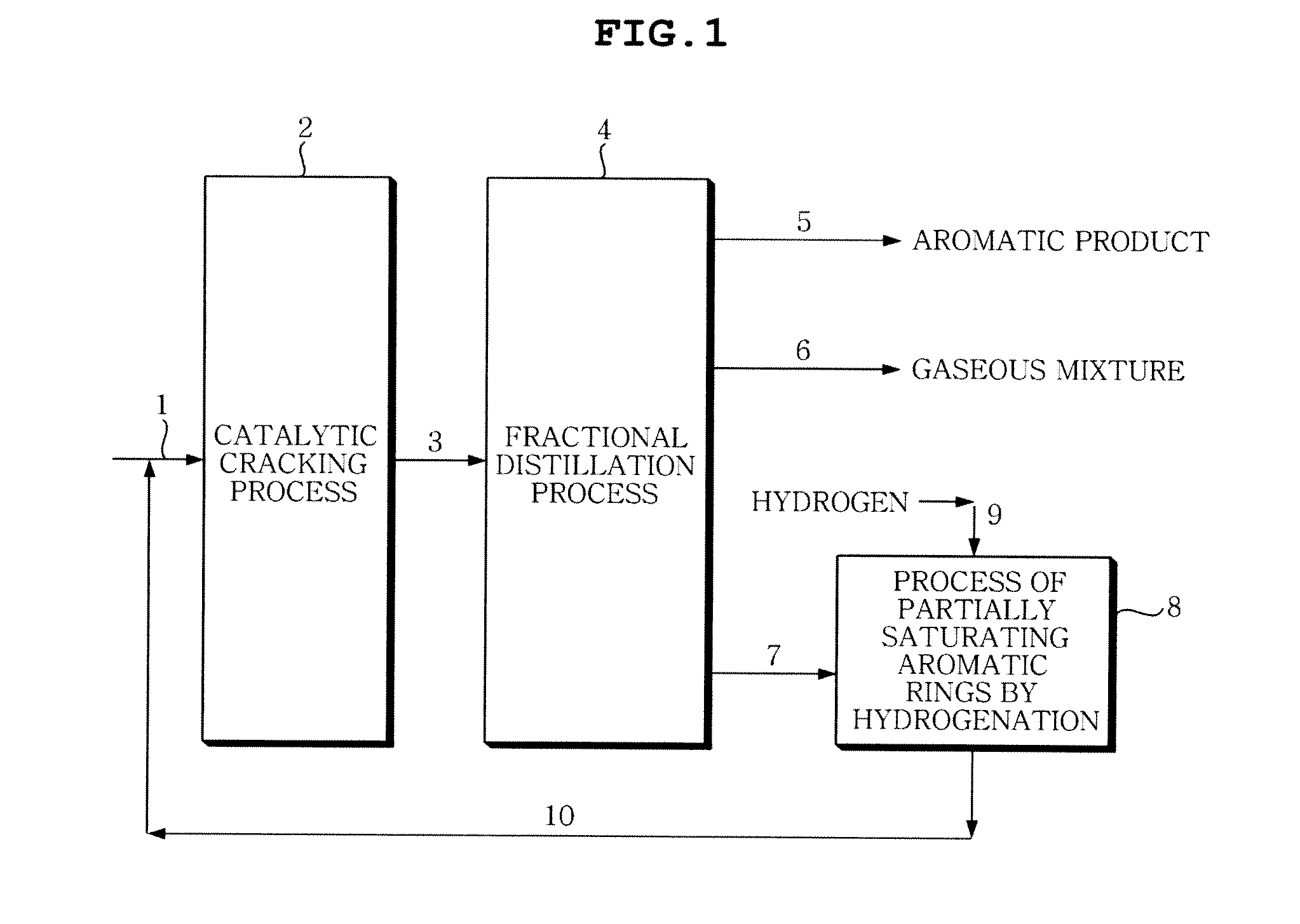

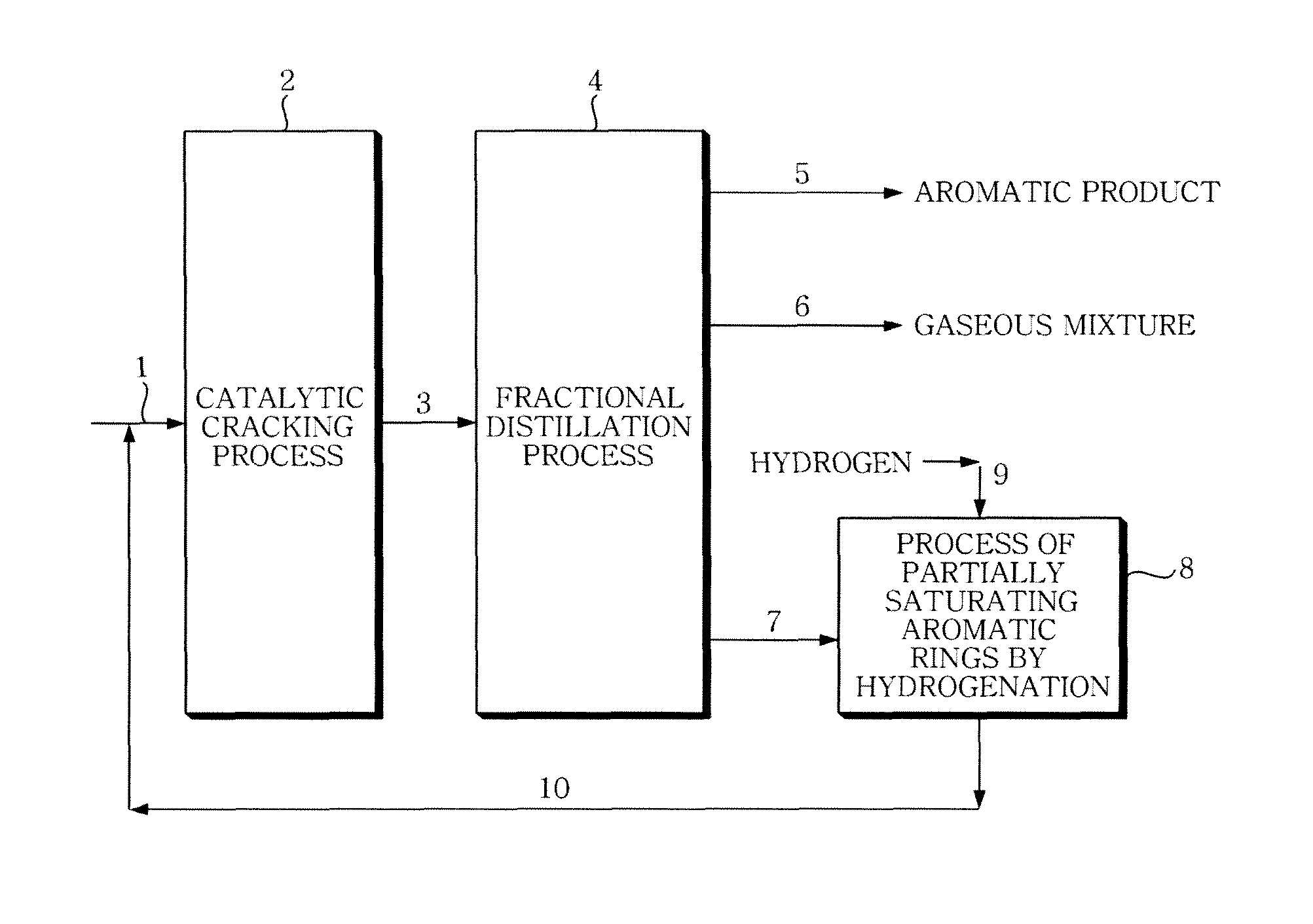

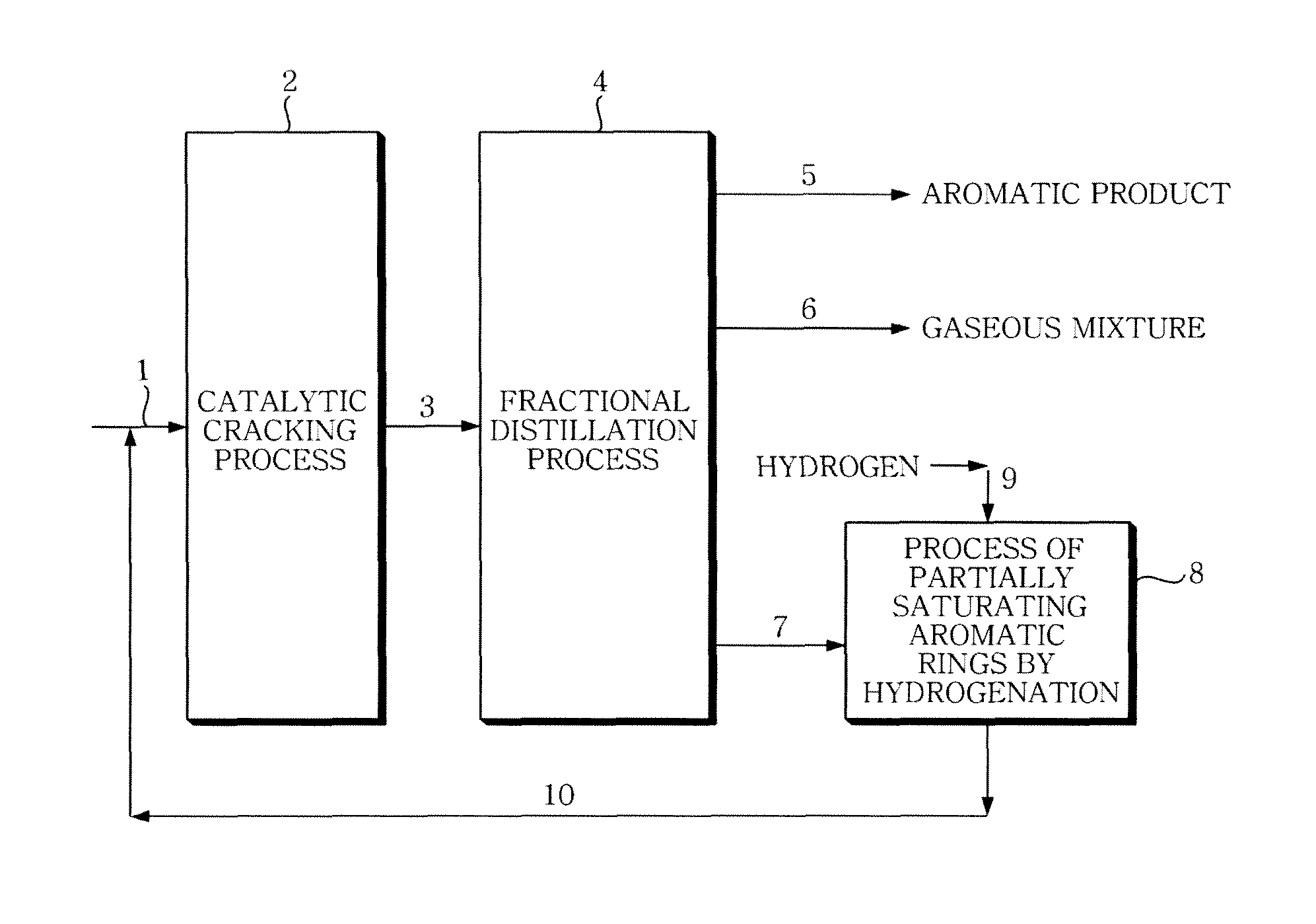

Method for producing high value aromatics and olefin from light cycle oil produced by a fluidized catalytic cracking process

ActiveUS20110207979A1Increase productionMaximize processing efficiencyCatalytic crackingHydrocarbonsHigh concentrationPetroleum

The present invention relates to a method of producing aromatic products (benzene / toluene / xylene) and olefin products from petroleum fractions obtained by fluid catalytic cracking, and, more particularly, to a method of producing products comprising high-concentration aromatic products and high value-added light olefin products from light cycle oil obtained by fluid catalytic cracking.

Owner:SK INNOVATION CO LTD

System and method for clamp current regulation in field-weakening operation of permanent magnet (PM) machines

ActiveUS7242163B2Extended speed rangeFunction increaseAC motor controlDC motor speed/torque controlPhase currentsVoltage vector

A device to regulate current produced by a permanent magnet machine responsive to a plurality of phase current signals. The motor produces torque for application on a shaft. A processing and drive circuit responsive to a direct current command signal and a quadrature current command signal produces phase current signals for input to the motor. A command circuit responsive to the phase current signals, an angular position of said shaft, and a voltage input command signal to produce a direct current error signal and a quadrature current error signal. A control circuit responsive to the direct and quadrature current error signals produces the direct voltage signal command and the quadrature voltage signal command. The control circuit has a direct and quadrature proportional gain, integrator and clamp circuits. An algorithm produces limited or clamped voltage modulation index signals to obtain maximum efficiency and maximum torque per ampere in the speed range. The algorithm ensures that the current regulator does not run out of voltage by limiting the voltage vector to the achievable voltage vector range that provides maximum torque per ampere and maximum efficiency.

Owner:DELPHI TECH IP LTD

Automatic optical projection scanner for omni-directional reading of bar code symbols within a confined scanning volume

InactiveUS6604684B1Save power consumptionFacilitate rapid steady-state responseTelevision system scanning detailsCoin-freed apparatus detailsBarcodeLaser scanning

An automatic bar code symbol reading system having an automatic laser scanning device which can be used at a point-of-sale (POS) station as either a portable hand-supported laser scanner when operated in its automatic hands-on mode of operation, or as a stationary laser projection scanner when operated in its automatic hands-free mode of operation. The bar code symbol reading system provides a collimated scanning pattern projected from the hand-supportable device about a projection axis. The collimated scanning pattern intersects the projection axis within a narrowly confined scanning volume so that bar code symbols disposed within this scanning volume can be read omnidirectionally, while inadvertent scanning of bar code symbols outside of the scanning volume is prevented.

Owner:METROLOGIC INSTR

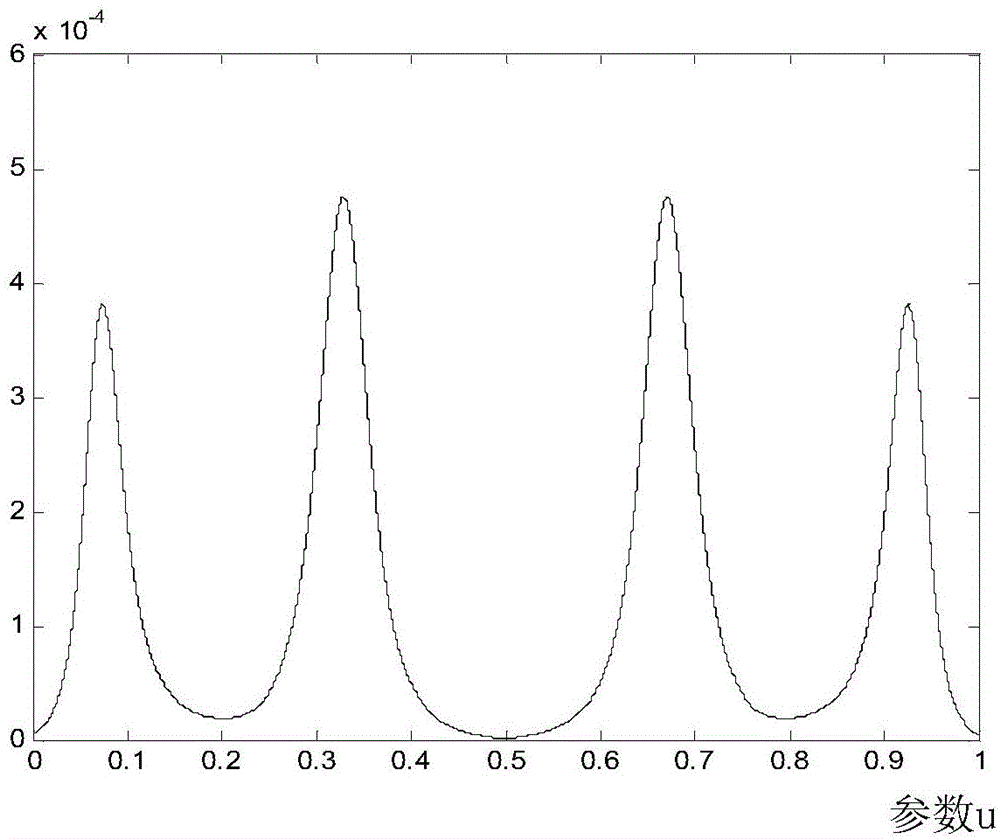

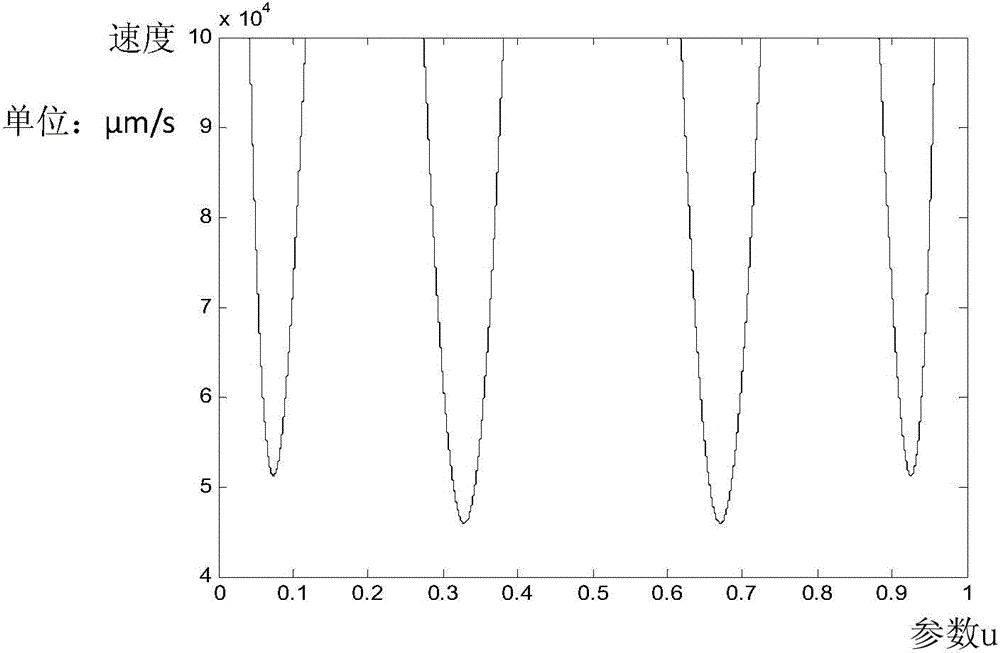

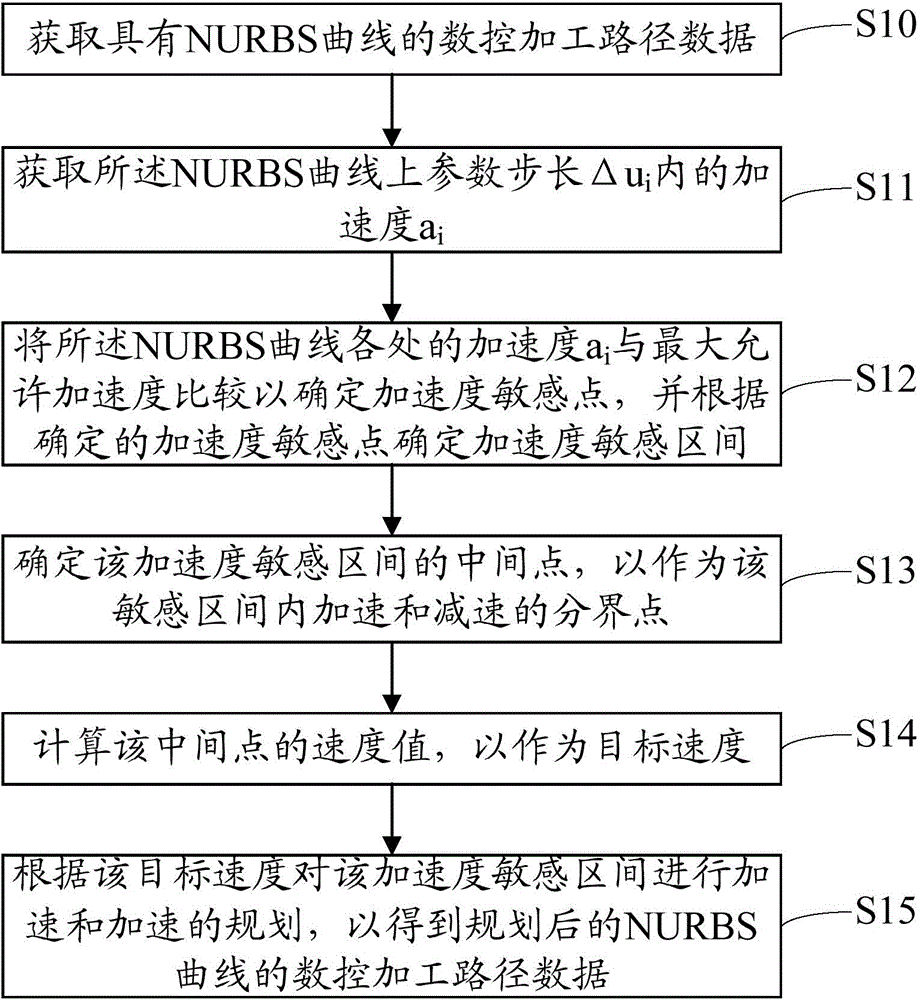

Curve velocity planning method and device, as well as numerical control machining path data processing method

ActiveCN104678899AMaximize processing efficiencySmall amount of computationNumerical controlNumerical controlComputer science

The invention discloses a curve velocity planning method and device, as well as a numerical control machining path data processing method, and provides an NURBS curve interpolation-based curve velocity planning method and device, as well as a numerical control machining path data processing method employing NURBS curve interpolation velocity planning. The processing method comprises the following steps: acquiring numerical control machining path data with an NURBS curve, and acquiring acceleration ai within a parameter step length deltaui on the NUBRS curve; comparing the acceleration with maximum allowable acceleration to determine acceleration-sensitive points and an acceleration-sensitive interval; determining a midpoint of the acceleration-sensitive interval as an acceleration and deceleration dividing point; calculating a velocity value of the midpoint as target velocity; performing acceleration and deceleration planning on the acceleration-sensitive interval according to the target velocity to obtain numerical control machining path data with a planned NURBS curve. According to the methods and the device, interpolation points at which acceleration exceeds a limit in a deceleration stage can be calculated in advance, so that the condition that acceleration exceeds the limit due to the fact that velocity at the end of an acceleration stage is excessively high is avoided.

Owner:BEIJING A&E TECH

System and method for clamp current regulation of induction machines

InactiveUS6850033B1Maximize processing efficiencyInhibit currentAC motor controlElectric motor control

A device to regulate current produced by an induction machine responsive to a plurality of phase current signals. The motor produces torque for application on a shaft. A processing and drive circuit responsive to a direct current command signal and a quadrature current command signal produces phase current signals for input to the motor. A command circuit responsive to the phase current signals, an angular position of said shaft, and a voltage input command signal to produce a direct current error signal and a quadrature current error signal. A control circuit responsive to the direct and quadrature current error signals produces the direct voltage signal command and the quadrature signal command. The control circuit has a direct and quadrature proportional gain, integrator and clamp circuits. An algorithm produces limited or clamped voltage modulation index signals to obtain maximum efficiency and maximum torque per ampere in the speed range.

Owner:DELPHI TECH IP LTD

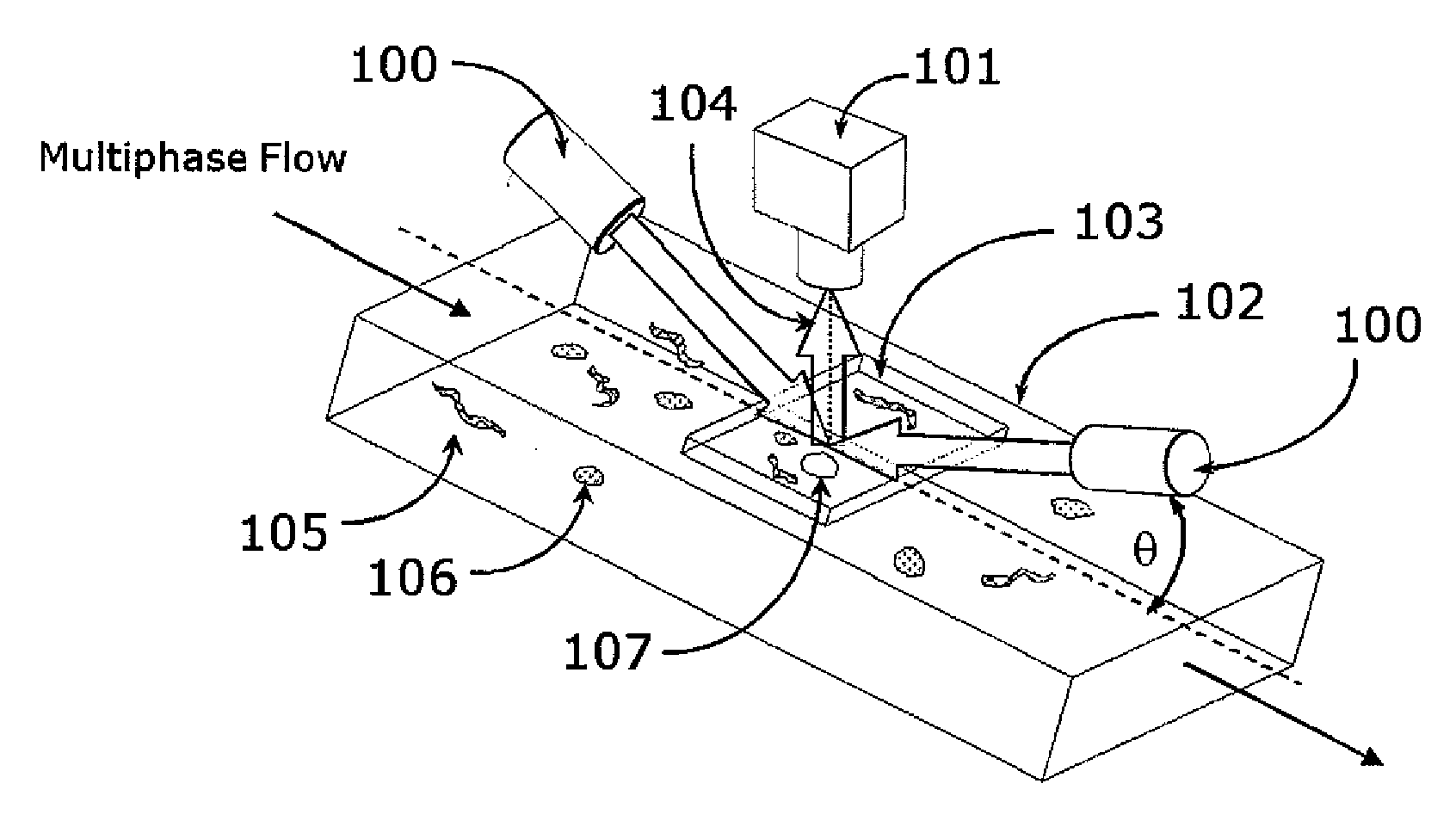

Method of monitoring macrostickies in a recycling and paper or tissue making process involving recycled pulp

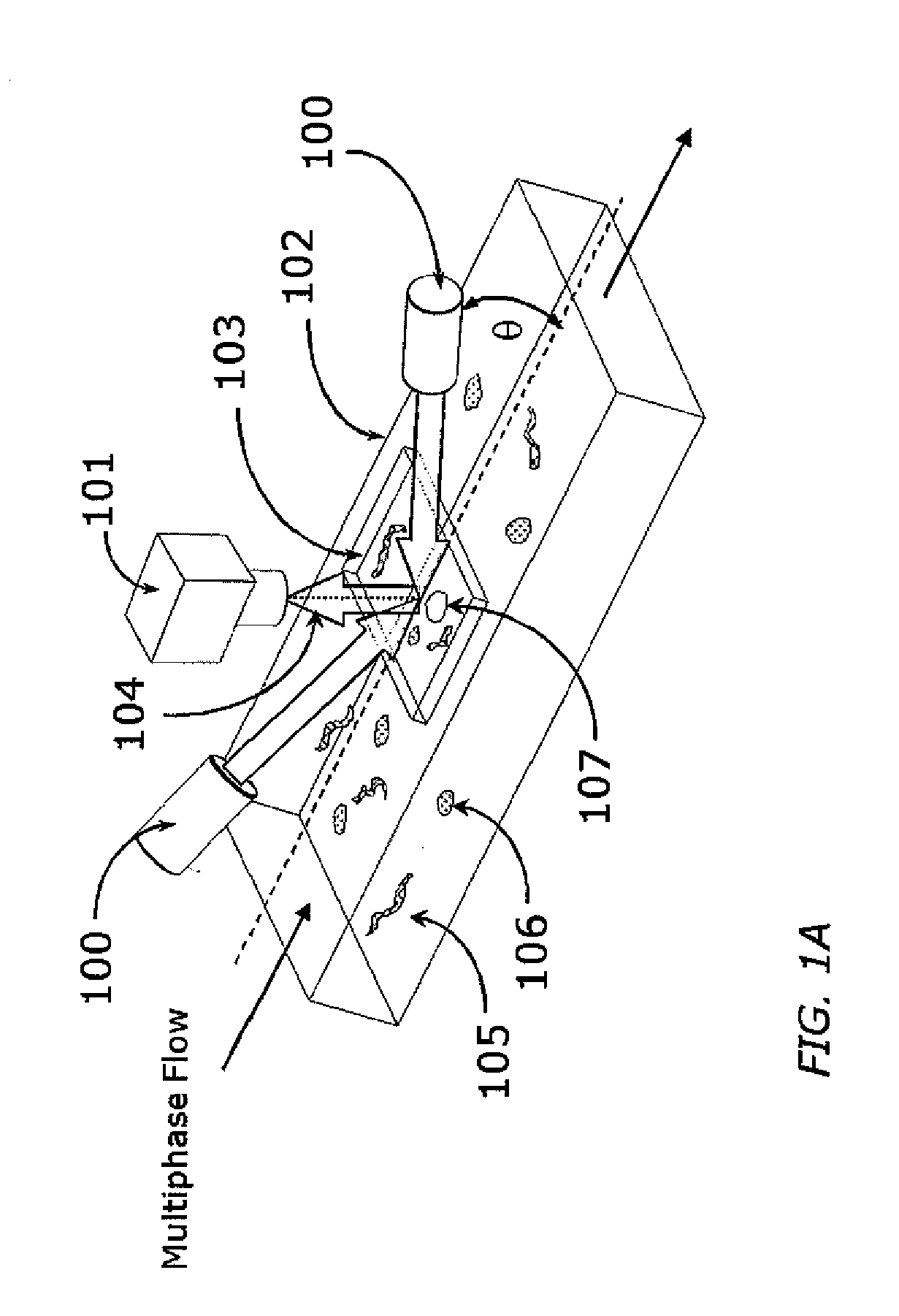

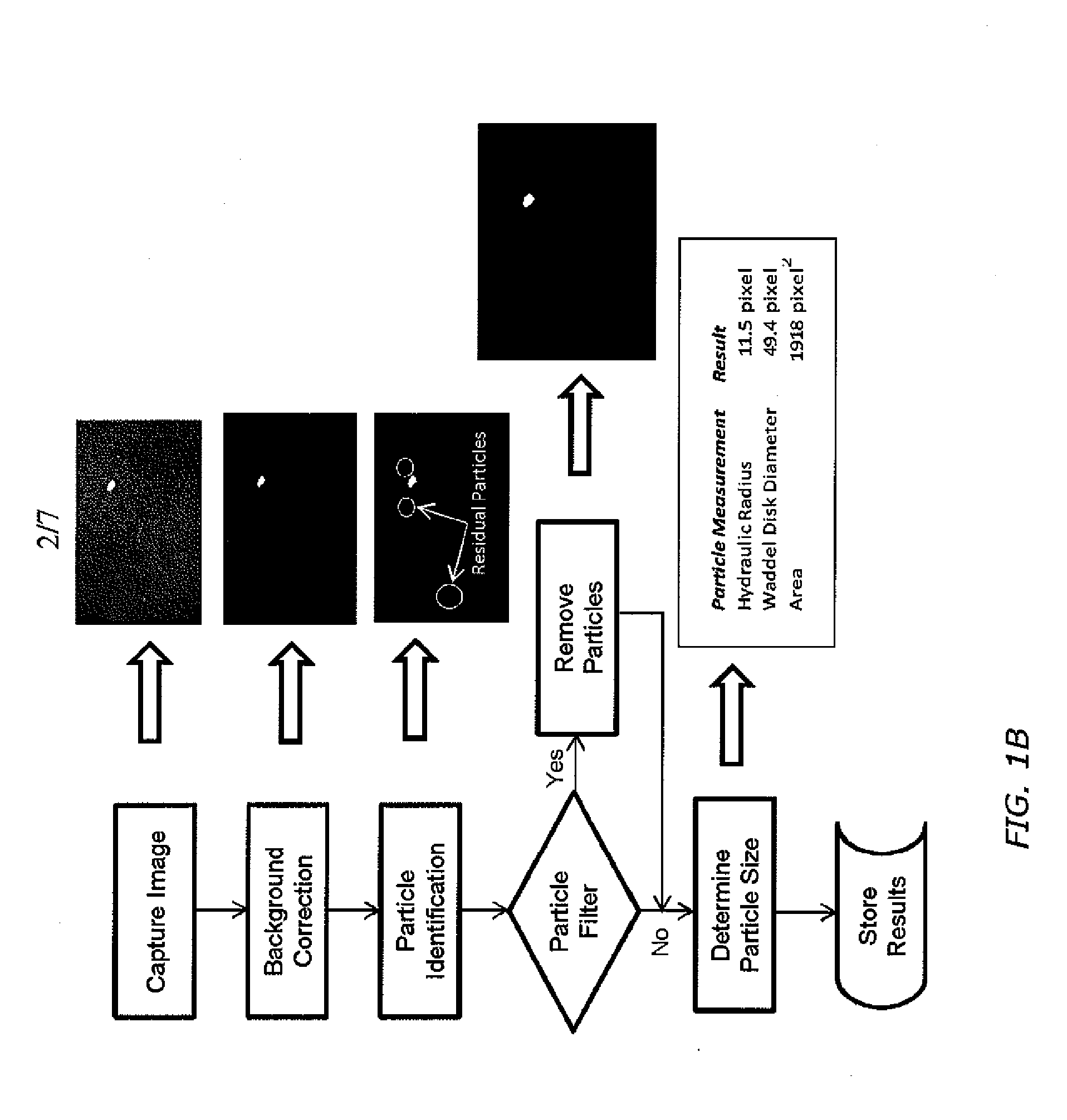

ActiveUS20120258547A1Maximize processing efficiencyReduce quality problemsCellulosic pulp after-treatmentWaste product additionImaging analysisFluorescence

A challenge in using recycled material in the papermaking process is the presence of hydrophobic organics with adhesive properties commonly known as “stickies.” Hydrophobic agglomerates can result in spots or defects in the final paper product or deposit on papermaking equipment resulting in poor runnability and downtime. Technologies for monitoring and controlling microstickies exist. However, a need exists for a technique to rapidly determine the size and content of macrostickies (diameter>100 microns) in recycled pulp process streams. The present invention is a device and method to perform real-time macrostickies and / or any visible hydrophobic particle analysis in an aqueous medium. Using the present invention, furnish quality can be monitored and treatment performance can be monitored and controlled. The technique is based on fluorescence image analysis to identify and count sticky particles as well as measure their size.

Owner:ECOLAB USA INC

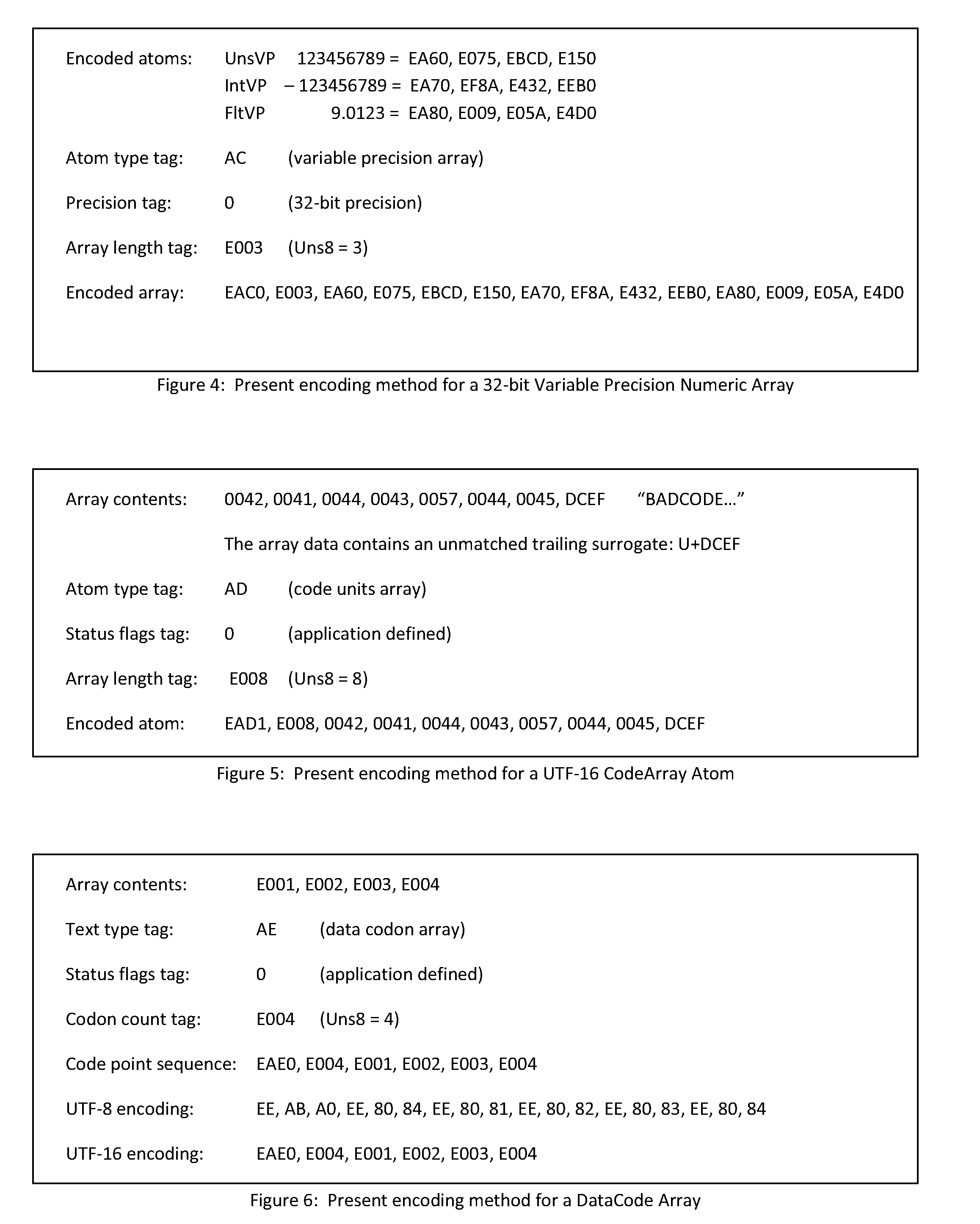

Data encoding method

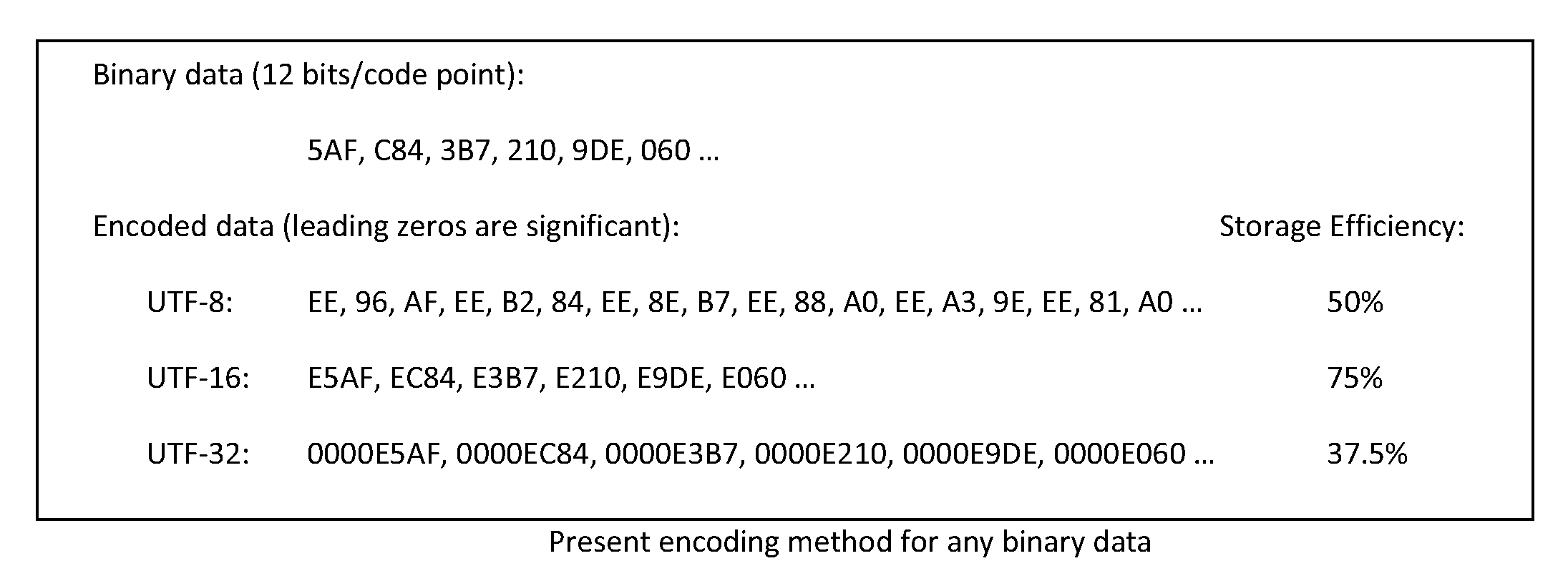

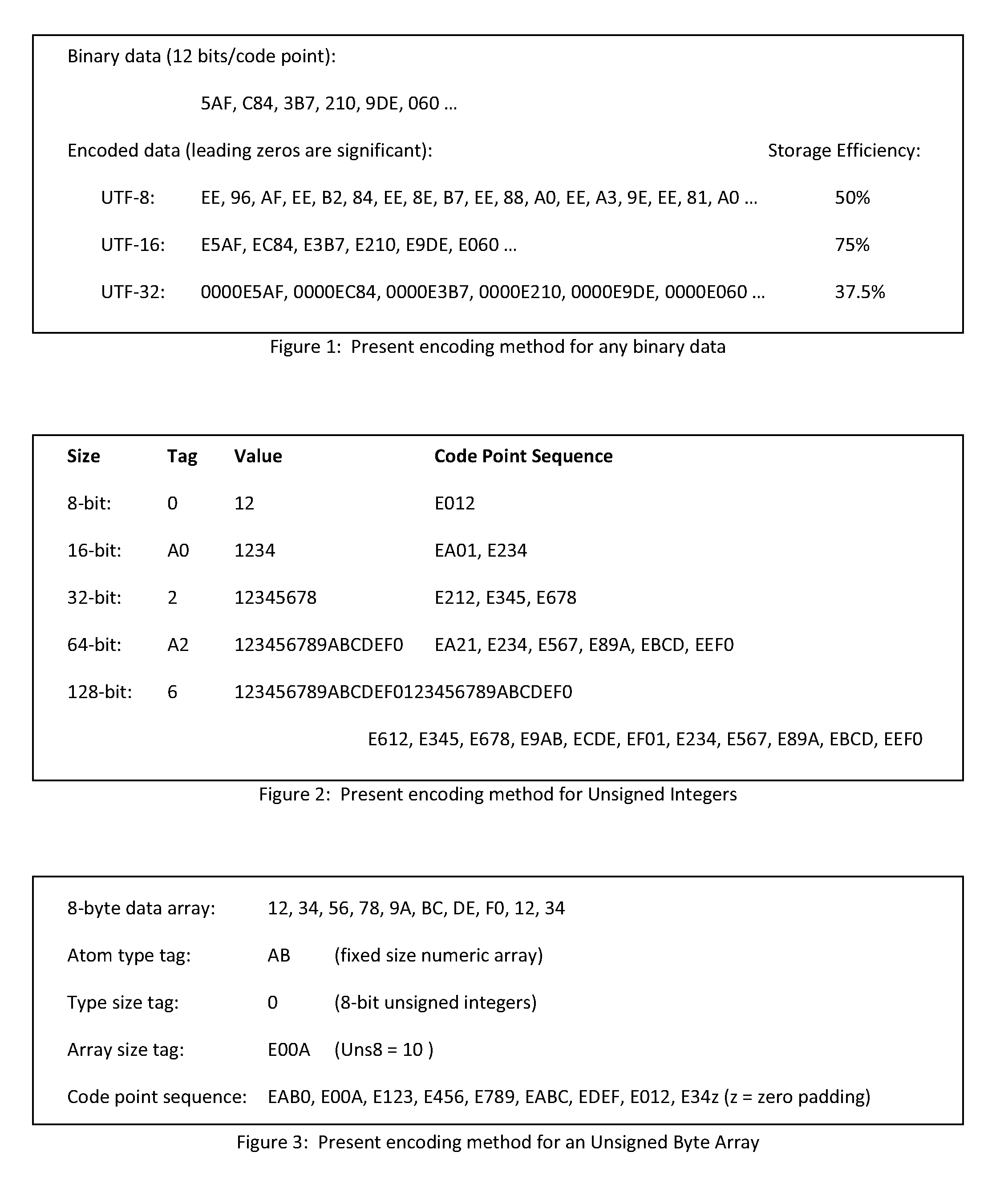

ActiveUS20110037625A1Efficient methodMaximize process efficiencyIndividual digits conversionNatural language data processingStorage efficiencyUTF-8

The present encoding method encodes binary data as sequences of code points occupying the Private Use Area of the Unicode Basic Multilingual Plane. The encoded data can be contained within a stream of UTF-8, UTF-16 or UTF-32 code units and subsequently decoded to yield the original binary data. This method requires minimal processing for both encoding and decoding operations, and yields a 75% storage efficiency limit. Each datum encoding sequence includes type and encoding length information, enhancing parse and search operation performance. The type system includes elements for creating complex structured data-text sequences, and a mechanism for application defined extensions.

Owner:JOYCE STEPHEN ALLYN

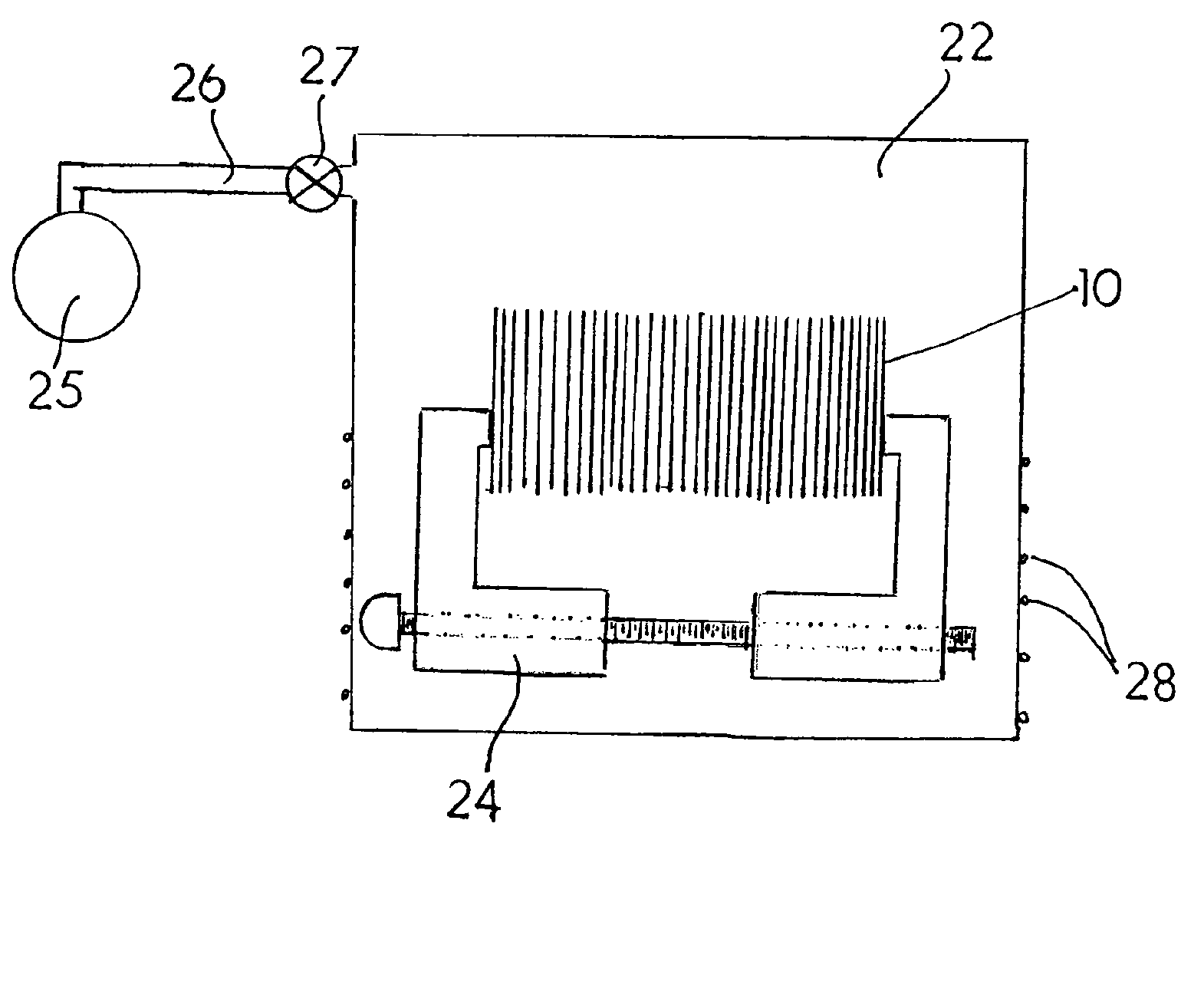

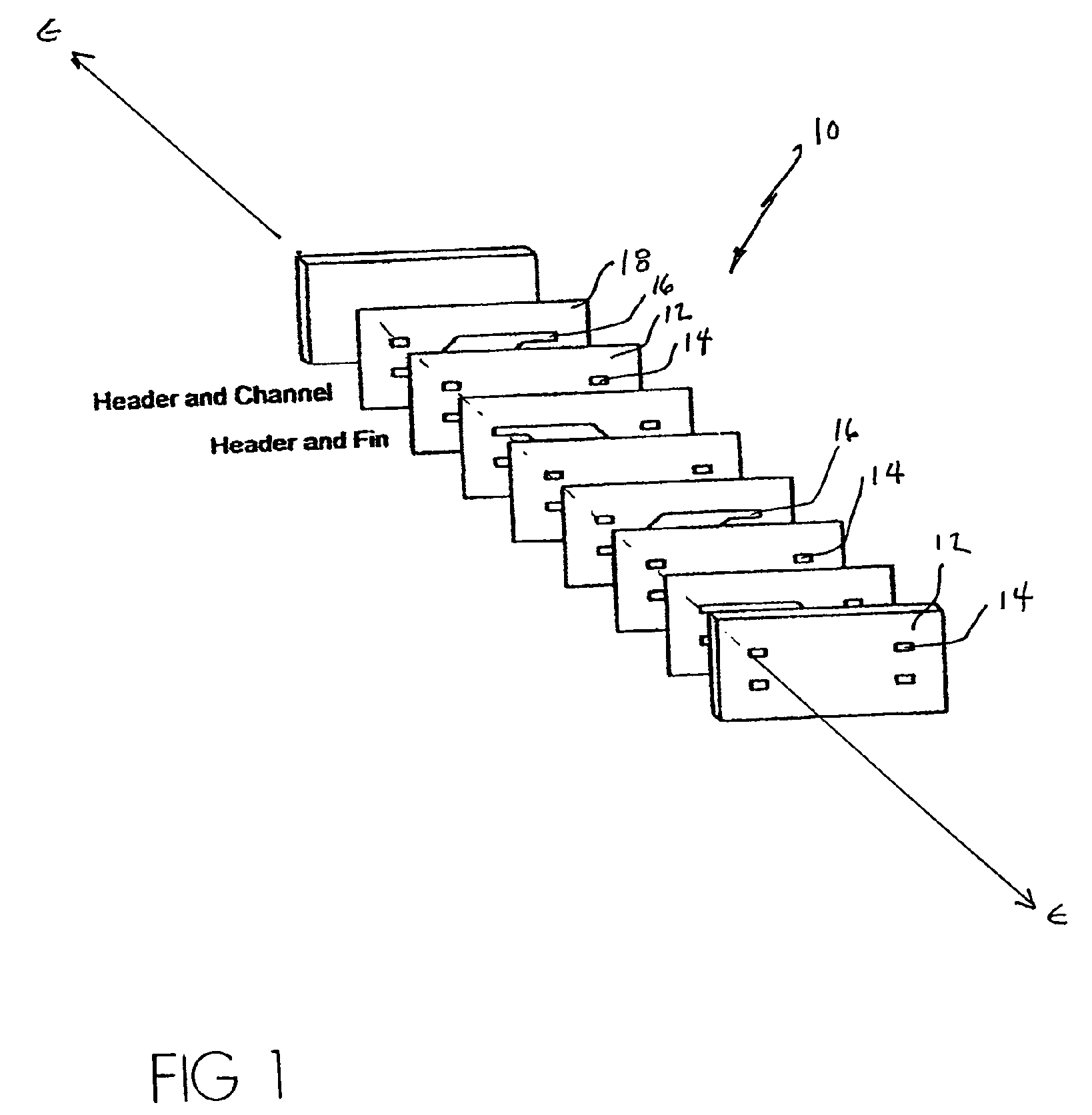

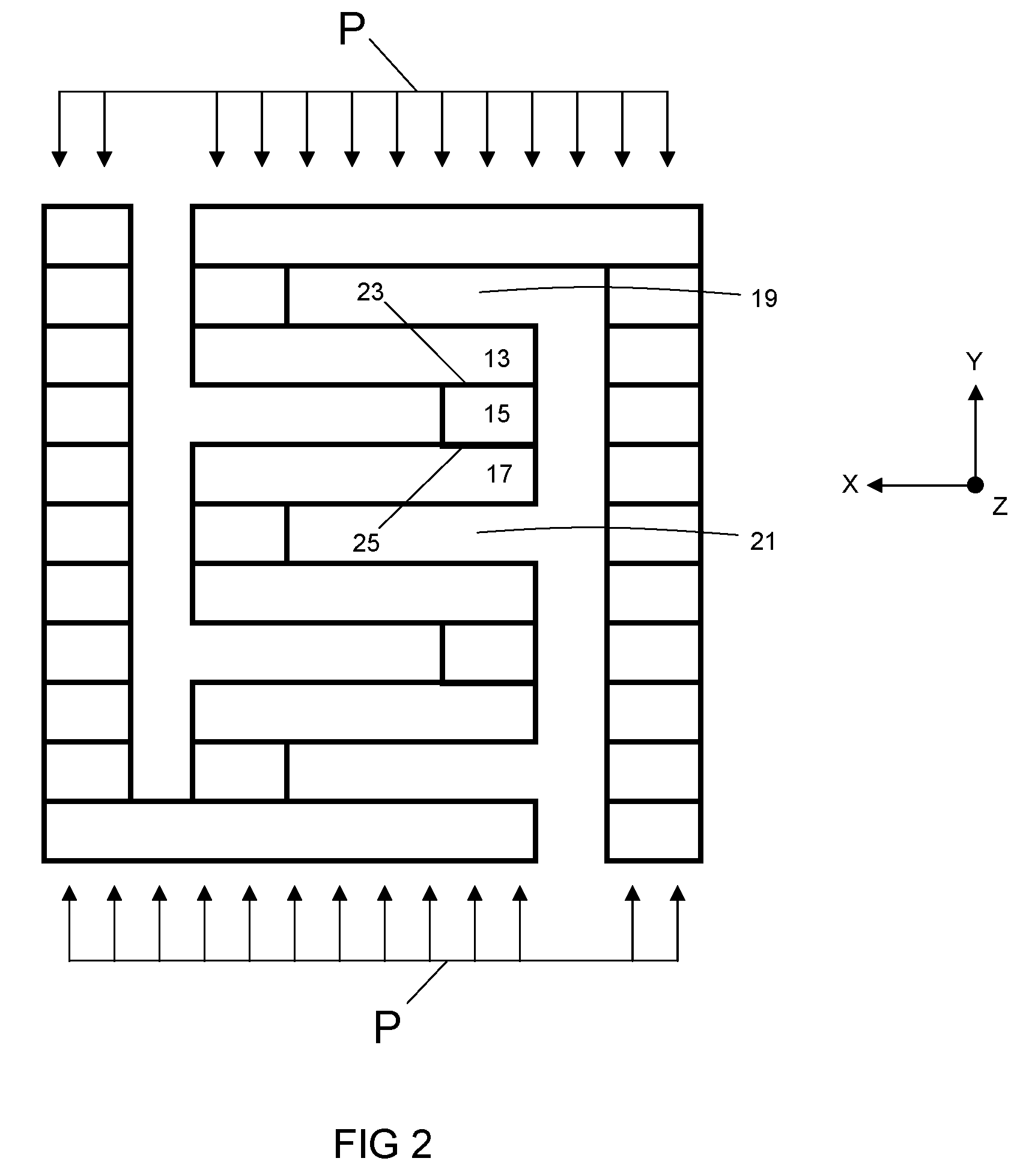

Method for producing components with internal architectures, such as micro-channel reactors, via diffusion bonding sheets

InactiveUS7900811B1Prevent collapseAvoid distortionAdhesive processesVegetable fibre separation from seedsCombustorChemical reactor

This invention relates to a method for producing components with internal architectures, and more particularly, this invention relates to a method for producing structures with microchannels via the use of diffusion bonding of stacked laminates. Specifically, the method involves weakly bonding a stack of laminates forming internal voids and channels with a first generally low uniaxial pressure and first temperature such that bonding at least between the asperites of opposing laminates occurs and pores are isolated in interfacial contact areas, followed by a second generally higher isostatic pressure and second temperature for final bonding. The method thereby allows fabrication of micro-channel devices such as heat exchangers, recuperators, heat-pumps, chemical separators, chemical reactors, fuel processing units, and combustors without limitation on the fin aspect ratio.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

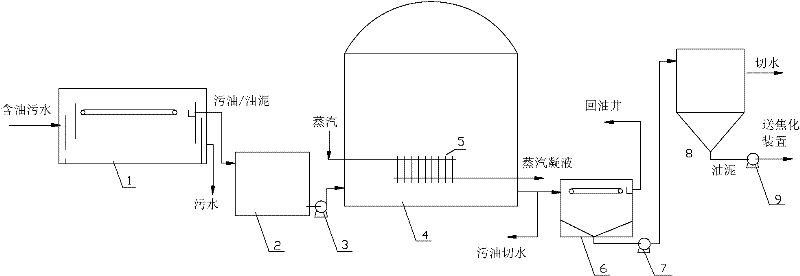

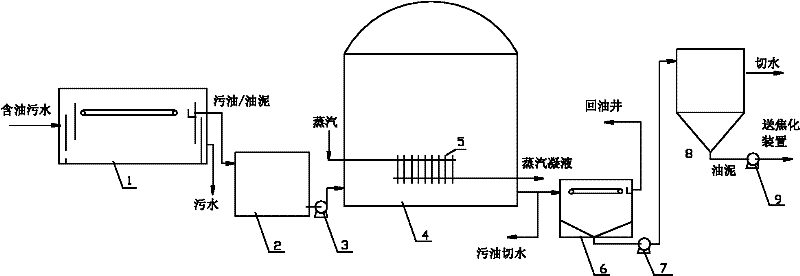

Greasy filth treatment process

ActiveCN102351389AAchieve efficiency and effectivenessNo secondary pollutionSludge treatment by pyrolysisWater/sewage treatmentPetrochemicalChemistry

The invention relates to a greasy filth treatment process, comprising the following steps of: heating water-containing polluted oil and greasy filth until the temperature rises to 85-90 DEG C, maintaining for 70-72 hours, destroying original oil / water / solid interface hydration film of greasy filth, simultaneously and effectively separating the three phases of oil / water / solid in greasy filth by the use of the extraction effect of lightweight polluted oil, sending oil recovered from greasy filth to an oil refining device for reprocessing, carrying out further condensation processing on greasy filth with low oil content, and sending to a coking device in refinery as coke cooling water or coke cut water. The above process provided by the invention has the following advantages of: (1) the process can be used to utilize effective components in sludge to the maximum and recover usable resources; (2) the process is used to realize classification (quality) processing of various sludge generated in petrochemical sewage processing fields and maximize the sludge processing efficiency and effect; (3) there is no secondary pollution during the sludge processing and disposal process.

Owner:贵州筑信水务环境产业有限公司

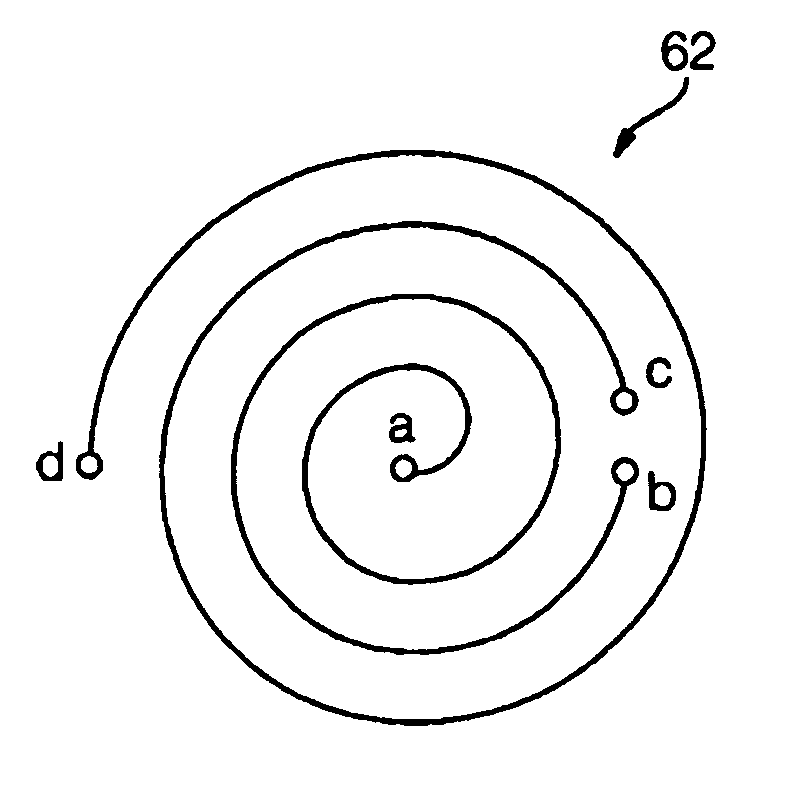

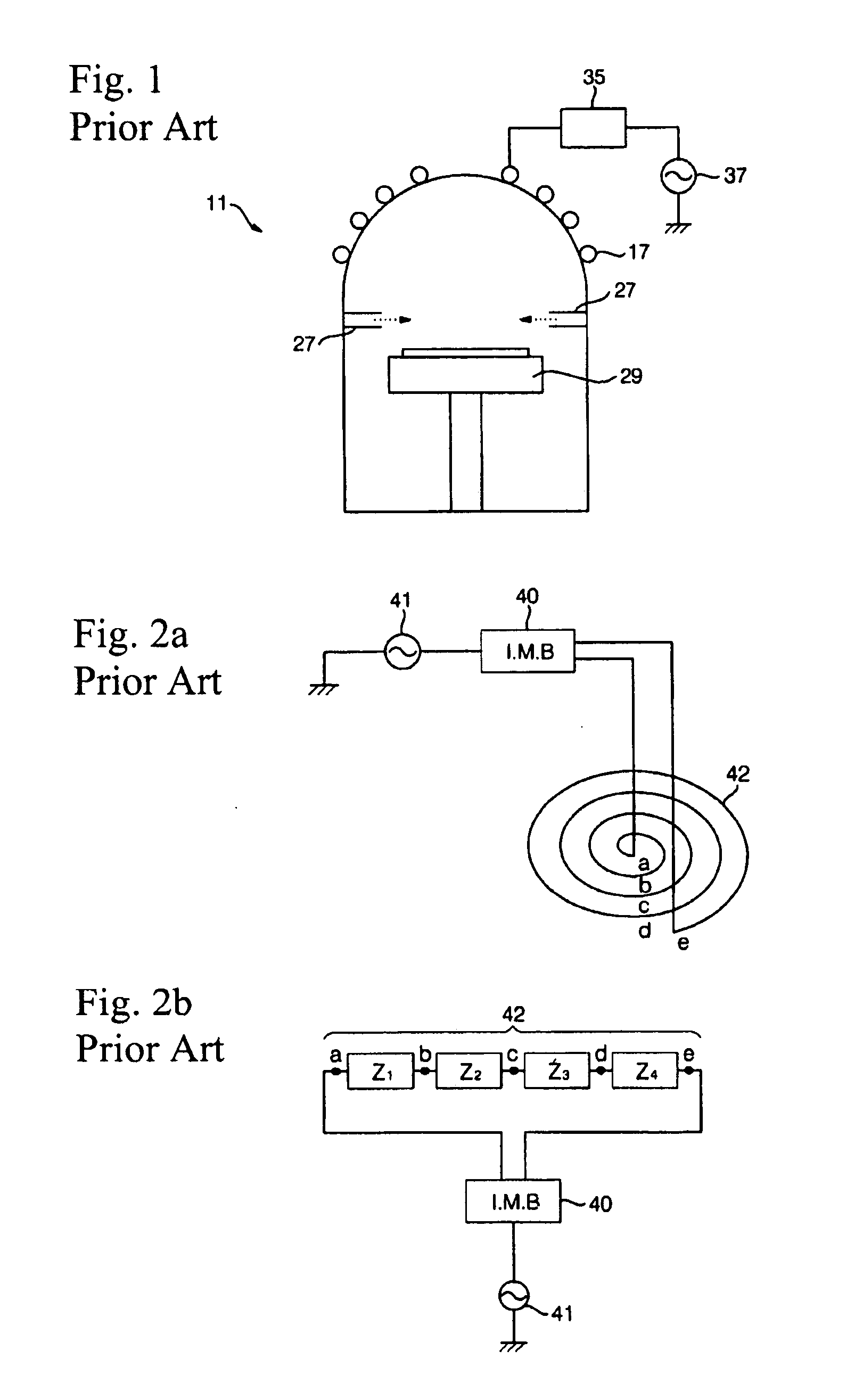

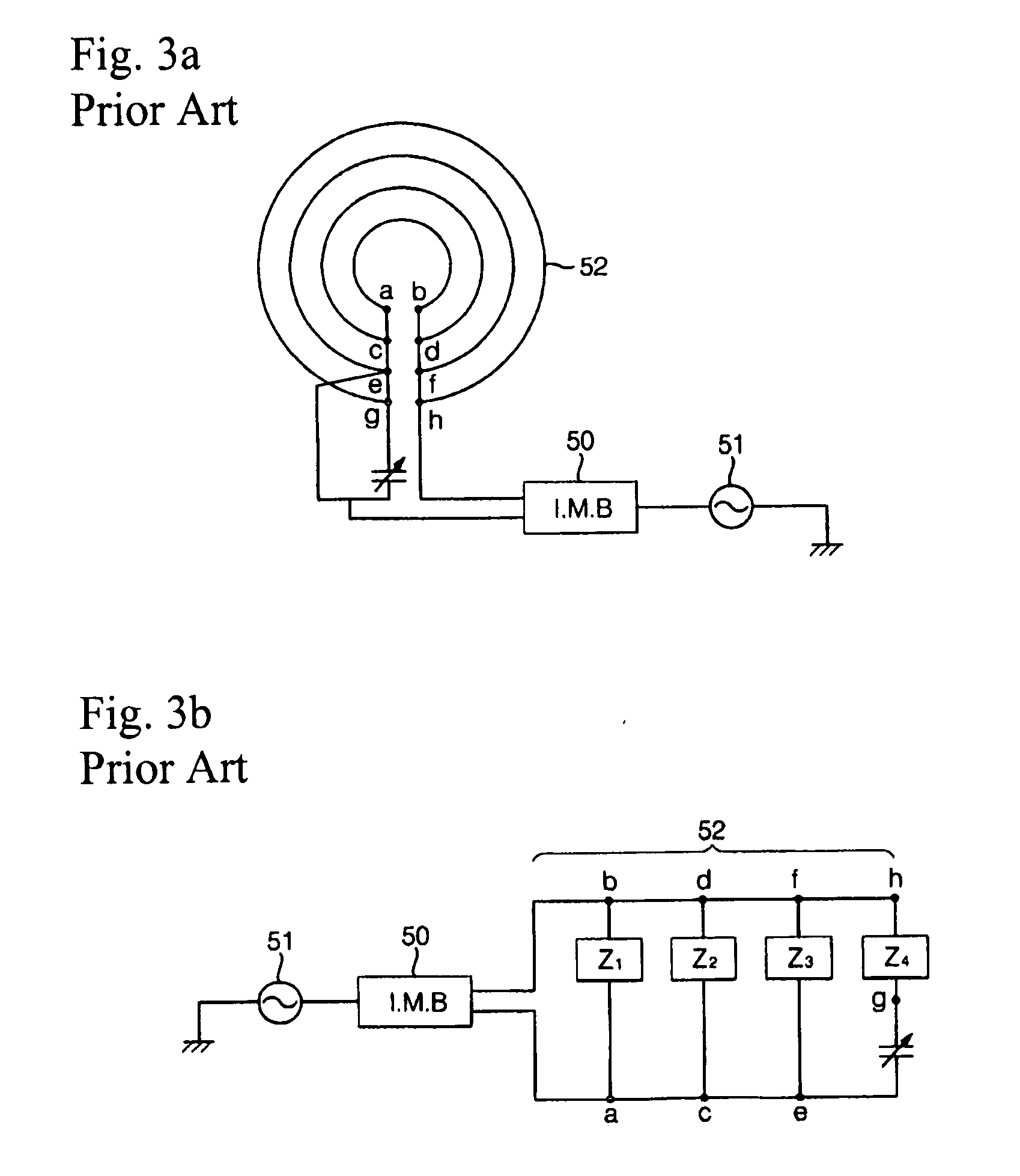

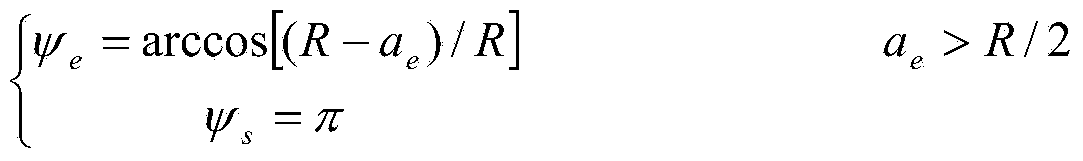

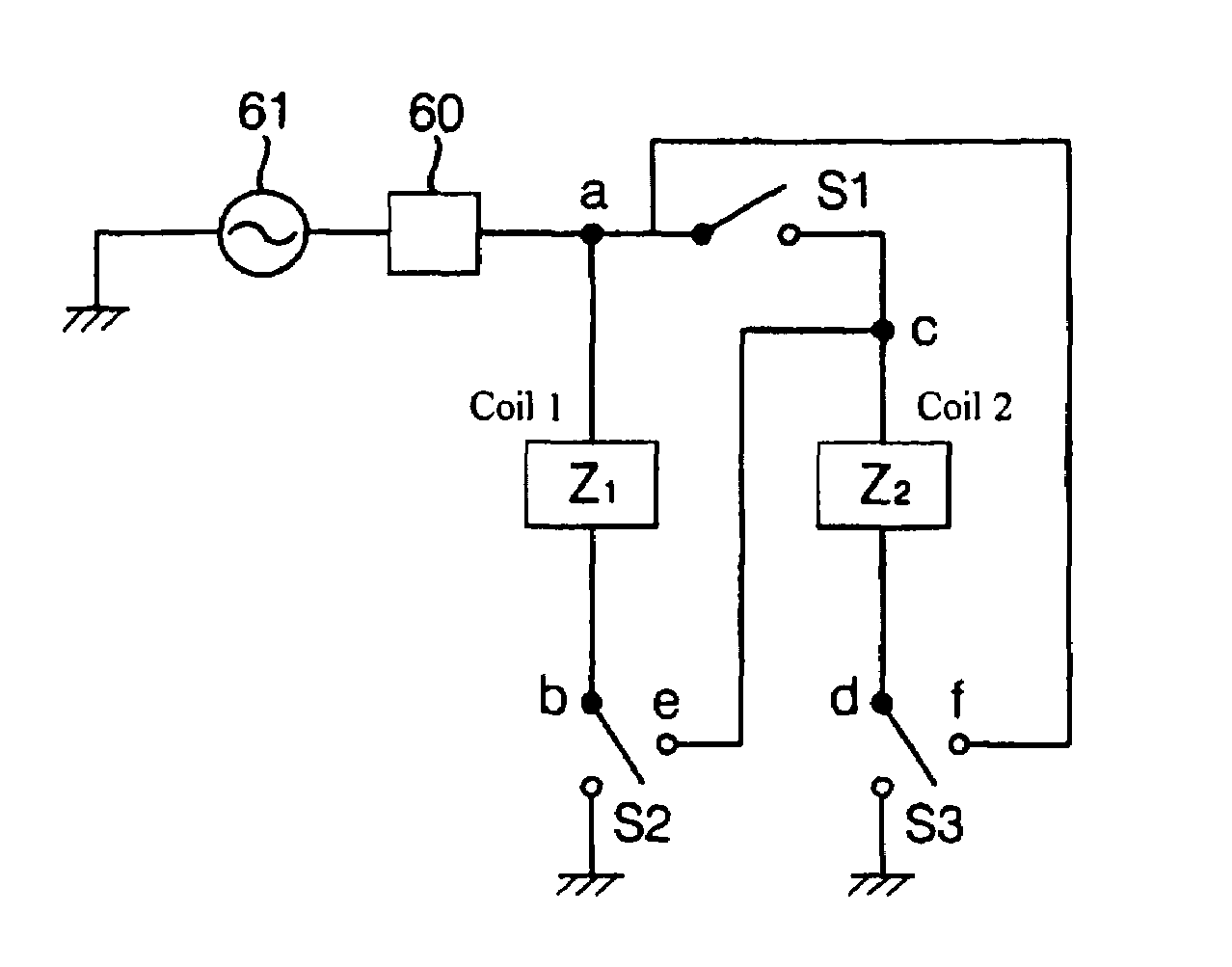

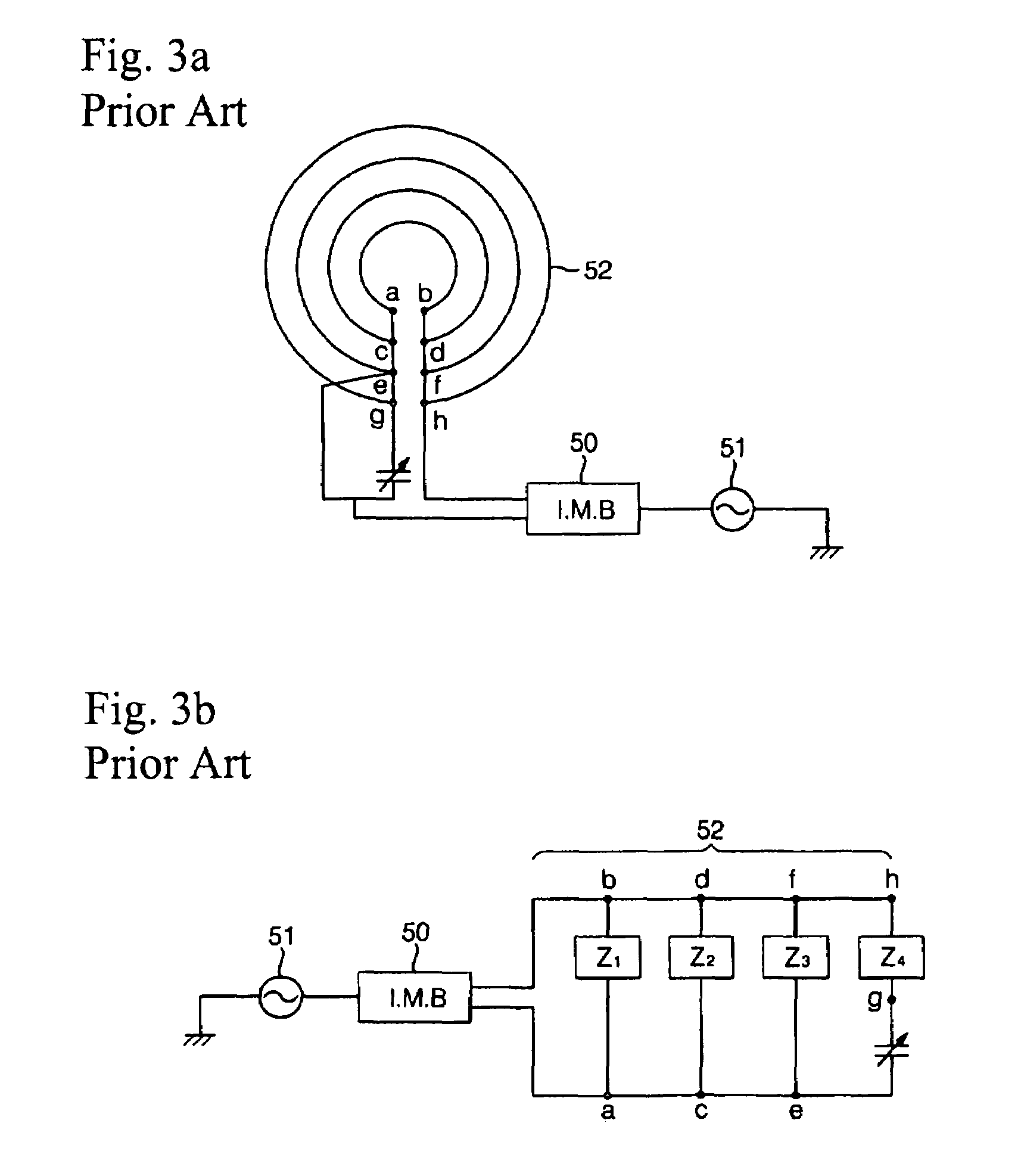

Plasma antenna

ActiveUS20050183668A1Maximize processing efficiencyElectric discharge tubesSemiconductor/solid-state device manufacturingCapacitanceConnection type

The plasma antenna is designed to allow connection between electric elements within the antenna to be varied without changing the construction of the antenna during a chemical vapor deposition process, thereby maximizing efficiency of a cleaning or deposition process. The plasma antenna comprises two or more coils to which RF power is supplied from an RF power source, respectively, and a switch connected to ends of the coils. The coils are constructed to have different impedances. The circuit construction of the plasma antenna can be changed on the basis of an inductive coupled plasma antenna so as to generate parallel connection type plasma, series connection type plasma, or capacitive coupled plasma according to the kind of process, such as cleaning or depositing, without changing the construction of the antenna, so that the process can be performed efficiently, thereby enhancing productivity through reduction in manufacturing costs attributed to the simple construction of the antenna.

Owner:JUSUNG ENG

Cutting force prediction method based on features

InactiveCN103439917ASave process modification timeMaximize processing efficiencyProgramme controlComputer controlEngineeringCutting force

A cutting force prediction method based on features is characterized in that feature recognition is carried out on a part based on a CAD three-dimensional model, and drive geometry recognizing the features is extracted according to a feature recognition result and is dispersed into some points. A primary process decision is carried out to obtain rotating speed, feeding, cutting depth, cutting width and other process parameters, a shearing force action coefficient and a cutting edge force coefficient are measured through experiments, a cut-in angle and a cut-out angle are calculated according to cutting parameters, and finally cutting force is calculated. According to cutting force prediction based on the features, the cutting force can be calculated according to the cutting parameter with different features in the part process decision process, and warning and process modification are carried out on the relatively large feature of the cutting force. Before post-processing, the cutting force can be predicted earlier. The predicted cutting force aims at each feature, that is, the modification is for a single feature, the processing efficiency of each feature of a plane structural component can be maximized, overall efficiency is accordingly maximized, and the number of simulation times is reduced.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

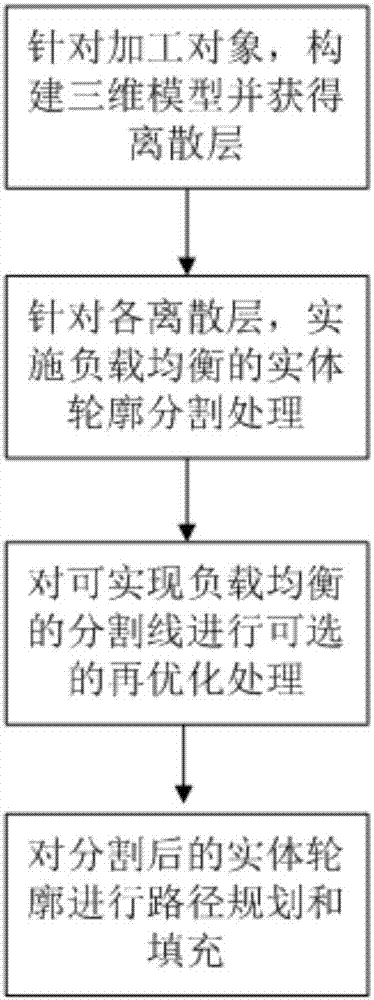

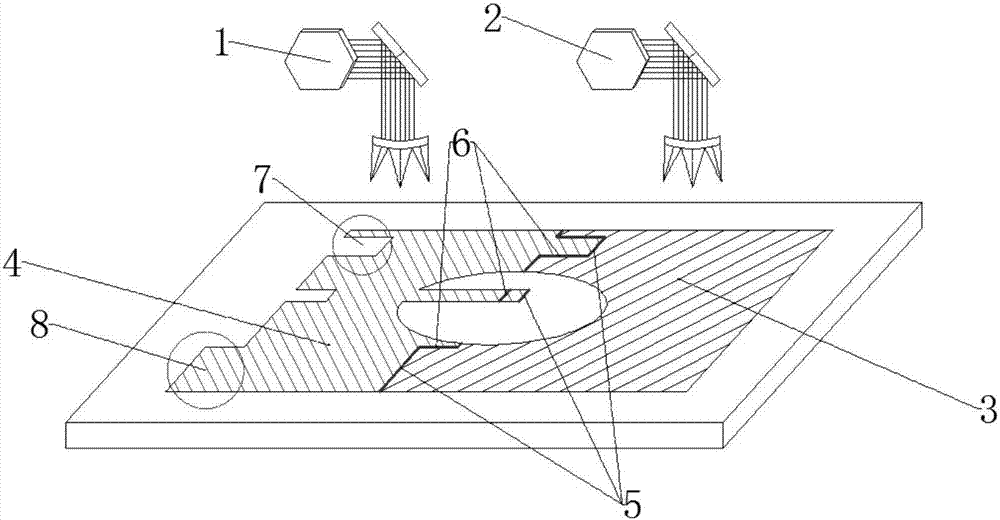

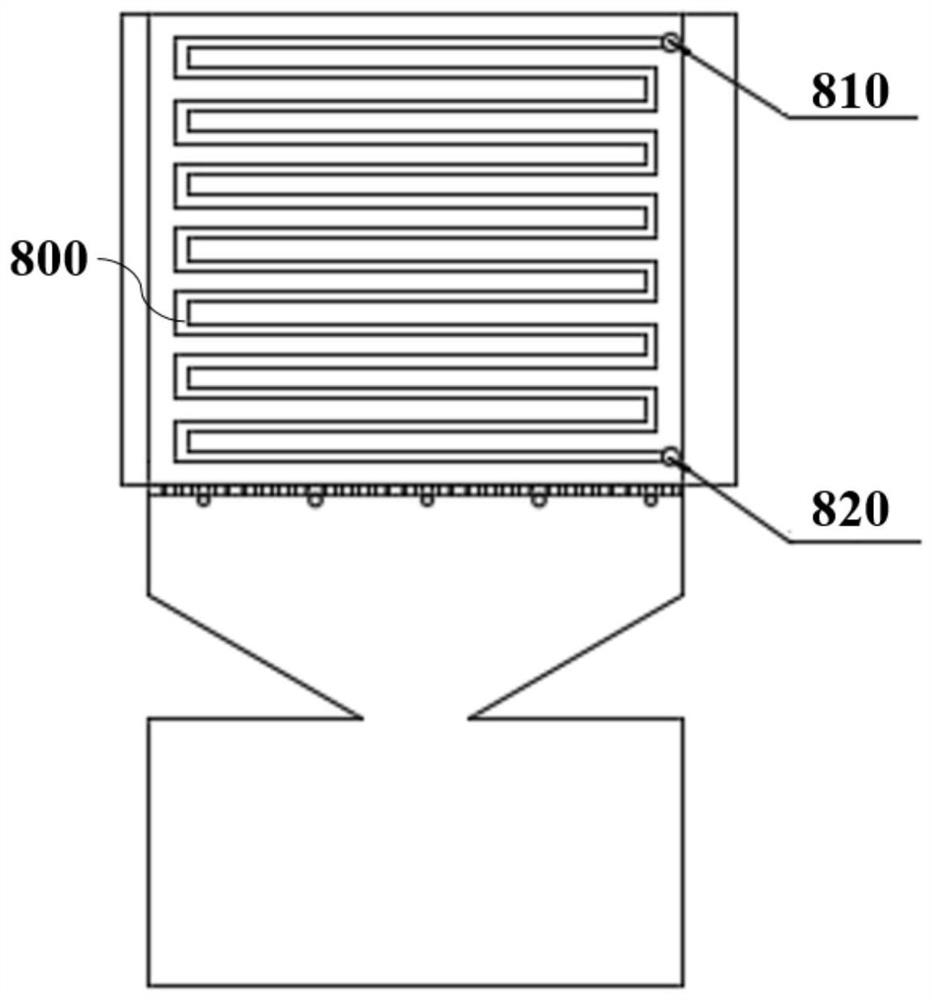

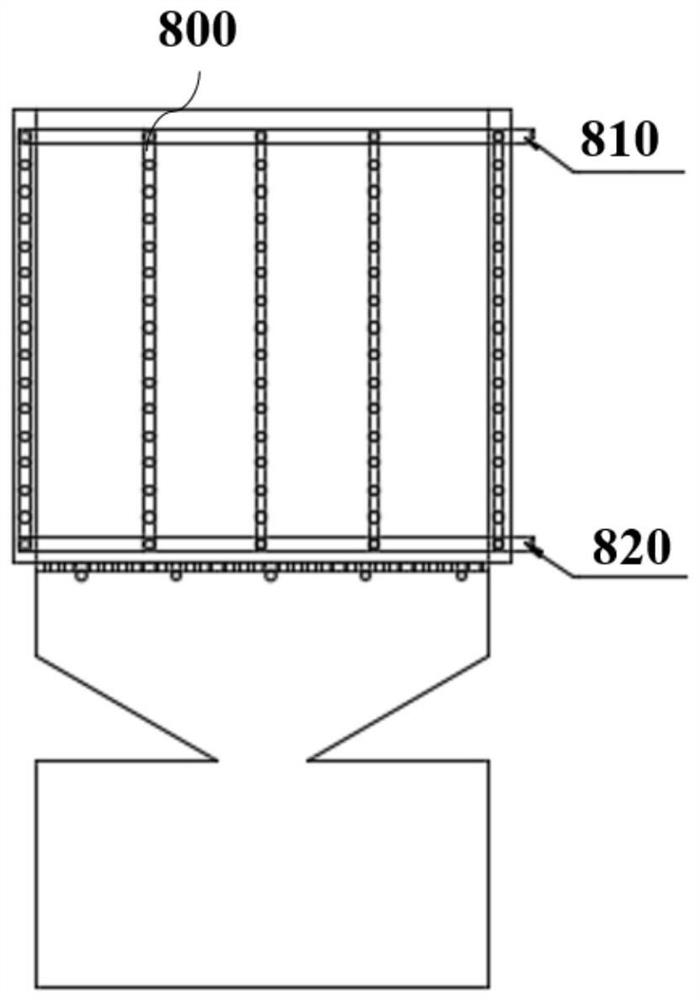

Load balancing scanning forming method used for multilaser selective laser melting (SLM) forming device

ActiveCN107498052AConsistent laser processing timeMaximize processing efficiencyAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingSplit lines

The invention belongs to the related technical field of additive manufacturing, and discloses a load balancing scanning forming method used for a multilaser selective laser melting (SLM) forming device. The method comprises the steps that (a) corresponding three-dimensional models are established for to-be-machined components, and the models are subjected to hierarchy slicing and discrete treatment to obtain model profiles of all discrete layers; (b) according to a certain algorithm, an optimized parting line is found out from an intermediate overlapping area between every two adjacent galvanometer scanning areas; and (c) all areas after optimized parting is completed are subjected to path programming and filling, and thus the whole load balancing scanning forming process is completed. Through the load balancing scanning forming method provided by the invention, the problems that currently, during machining of multilaser SLM forming equipment, the galvanometer set working efficiency is low, temperature field distribution is uneven, and the multilaser boundary area performance deteriorates can be effectively solved, and meanwhile, the method has the characteristics of high efficiency, high quality, convenient control and the like, so that the method is particularly suitable for manufacturing and application occasions of large-size workpieces of complex internal structures.

Owner:HUAZHONG UNIV OF SCI & TECH

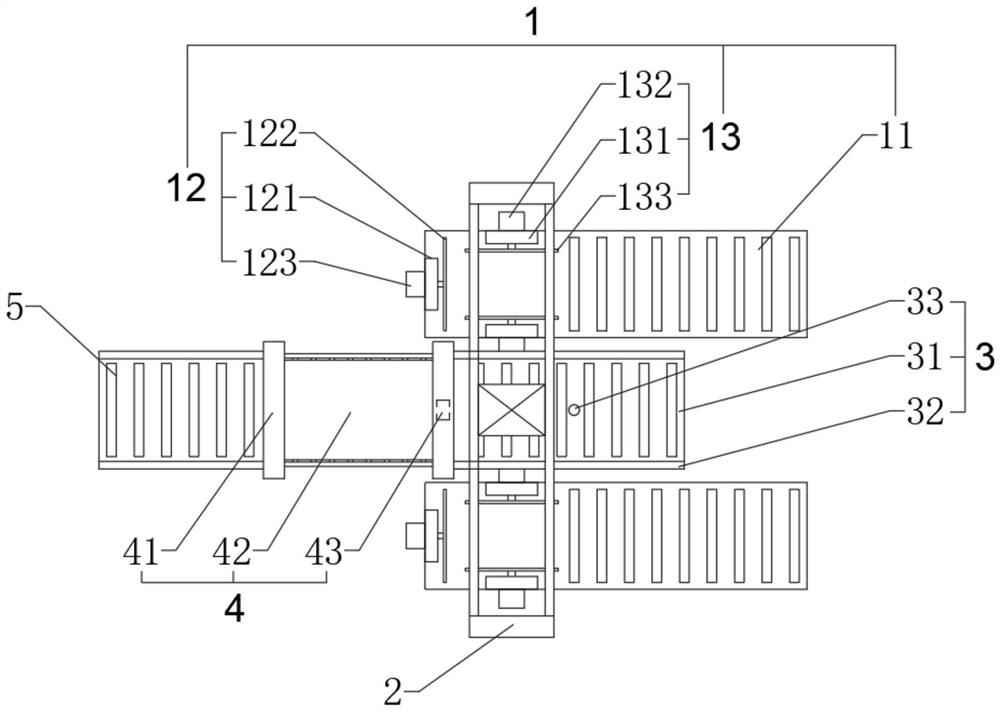

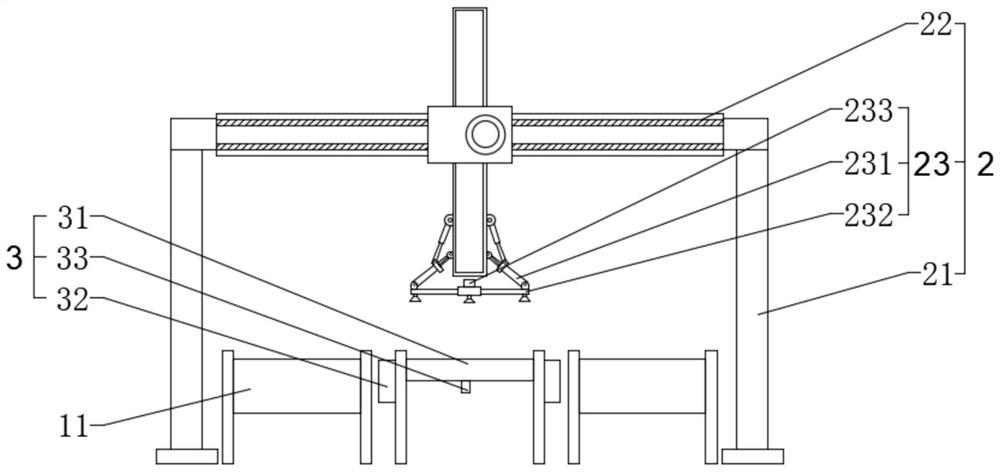

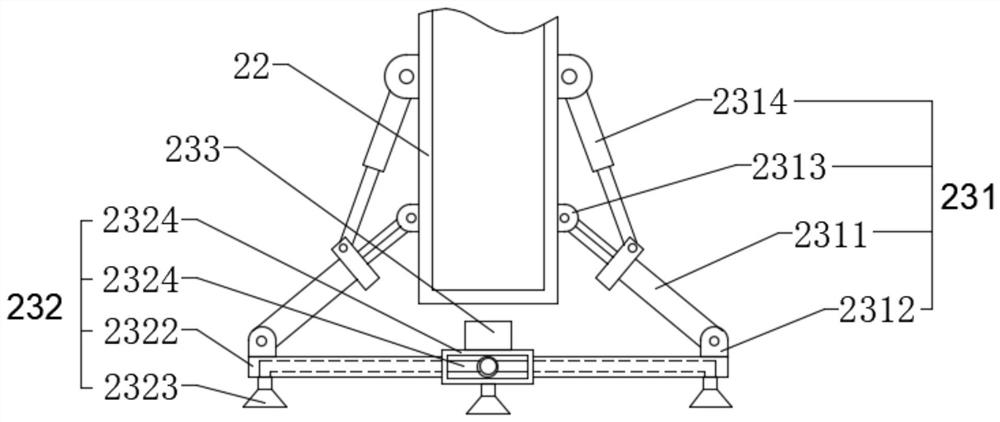

Intelligent feeding system and production control system

InactiveCN112978324AMaximize processing efficiencyImprove efficiencyControl devices for conveyorsRoller-waysProduction lineButt joint

The invention discloses an intelligent feeding system and a production control system. The intelligent feeding system comprises a left-right feeding roller way, a gantry suction cup mechanism, a plate feeding roller way, a plate turning device and an acceleration roller way which are sequentially arranged in a butt joint mode and used for conveying base plates. The left-right feeding roller way is used for correcting and conveying the base plates in batches through a left-right roller way structure, the gantry suction cup mechanism is matched with two sets of roller ways of the left-right feeding roller way to suck the base plates and conduct positioning and feeding on the plate feeding roller way in batches, the plate feeding roller way is in butt joint with the plate turning device and conveys the base plates at a low speed, the plate turning device turns over the base plates conveyed by the plate feeding roller way at intervals and conveys the base plates to the acceleration roller way, devices of all working sections on a gypsum plate production line are processed and controlled in a unified mode, so that it is guaranteed that the base plates are conveyed on all the working sections, the machining efficiency is maximized, and the devices of each working section are automatically switched to meet the processing and transporting specifications of the base plates of the corresponding specifications.

Owner:CHINA NAT BUILDING MATERIALS TECHCAL INNOVATION & RES INST LIMITED

Plasma antenna

ActiveUS7367281B2Maximize processing efficiencyElectric discharge tubesSemiconductor/solid-state device manufacturingCapacitanceProduction rate

The plasma antenna is designed to allow connection between electric elements within the antenna to be varied without changing the construction of the antenna during a chemical vapor deposition process, thereby maximizing efficiency of a cleaning or deposition process. The plasma antenna comprises two or more coils to which RF power is supplied from an RF power source, respectively, and a switch connected to ends of the coils. The coils are constructed to have different impedances. The circuit construction of the plasma antenna can be changed on the basis of an inductive coupled plasma antenna so as to generate parallel connection type plasma, series connection type plasma, or capacitive coupled plasma according to the kind of process, such as cleaning or depositing, without changing the construction of the antenna, so that the process can be performed efficiently, thereby enhancing productivity through reduction in manufacturing costs attributed to the simple construction of the antenna.

Owner:JUSUNG ENG

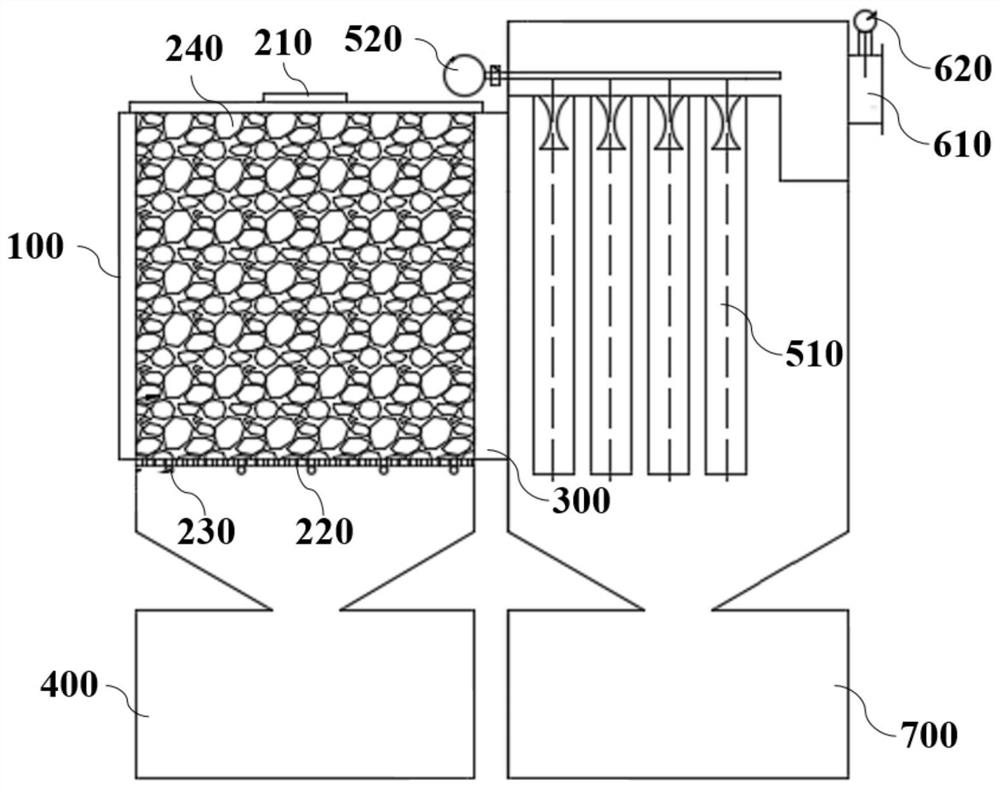

Fungus and algae rotary bio-membrane reactor system based on denitrification and phosphorus removal and application

ActiveCN108163972AMaximize processing efficiencyEfficient removalSustainable biological treatmentBiological water/sewage treatmentSludgeMembrane reactor

The invention discloses a fungus and algae rotary bio-membrane reactor system based on denitrification and phosphorus removal and application. Algae cells adhered to an adherent wall are fixed on a rotatable device, and rotate in waste water rich in nutrient substances and air rich in CO2, and when a microalgae membrane grows to a certain thickness, the microalgae membrane is harvested through a scraper to serve as a microalgae fertilizer, so that the microalgae harvesting cost can be reduced, and the economic benefit is improved. The rotary bio-membrane reactor system mainly comprises an active sludge system and a rotary algae bio-membrane system; on the basis of a traditional active sludge technology, a microalgae waste water treatment system is integrated, the nutrients such as COD, N and P inside waste water are removed efficiently, simultaneously the growth of microalgae can be promoted through CO2 generated by microbial metabolism inside active sludge, microalgae photosynthesis is used for providing O2 for microorganisms and partially reducing aeration cost, and the quantity of excess active sludge can be partially reduced due to the existence of microalgae.

Owner:NANCHANG UNIV

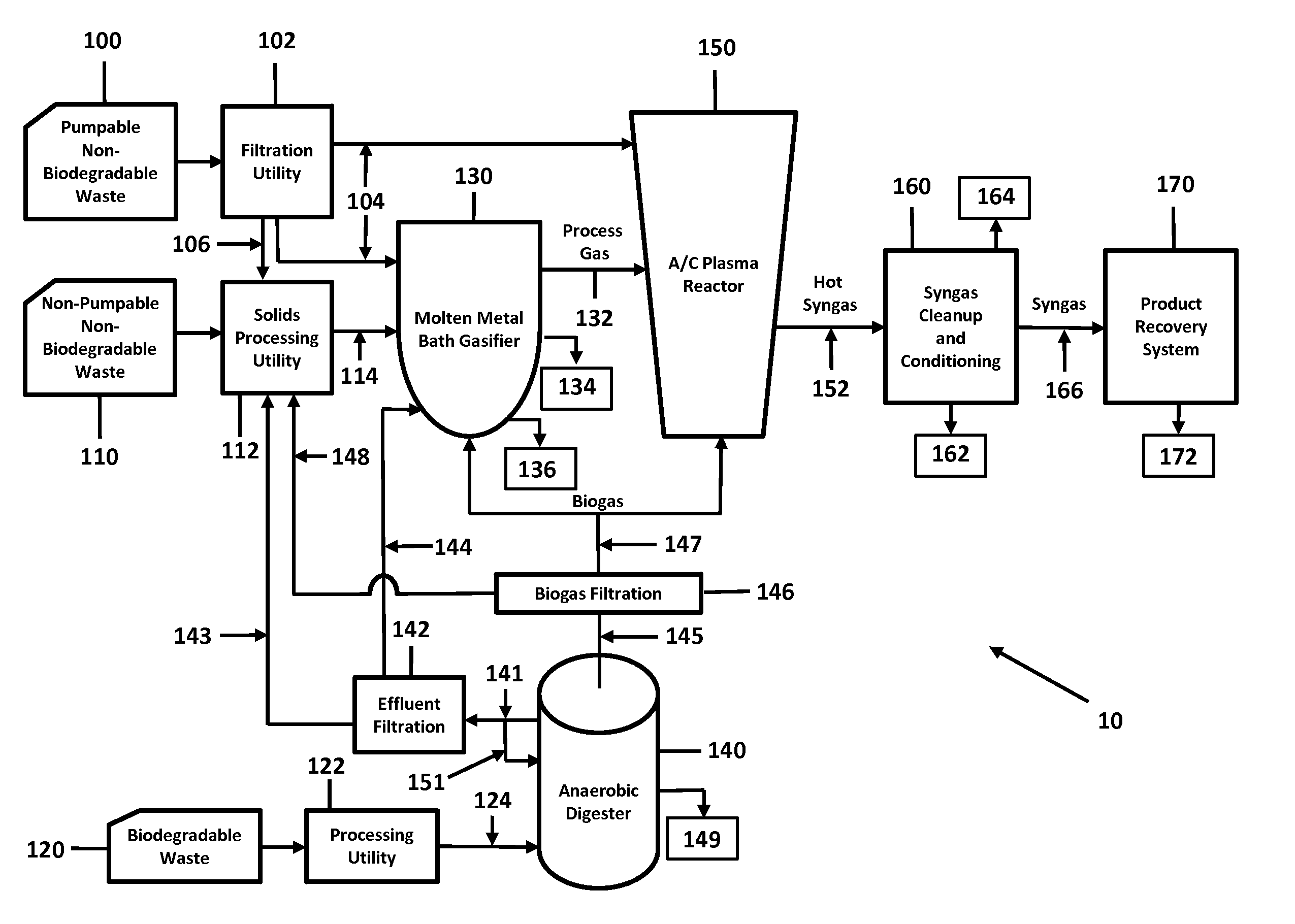

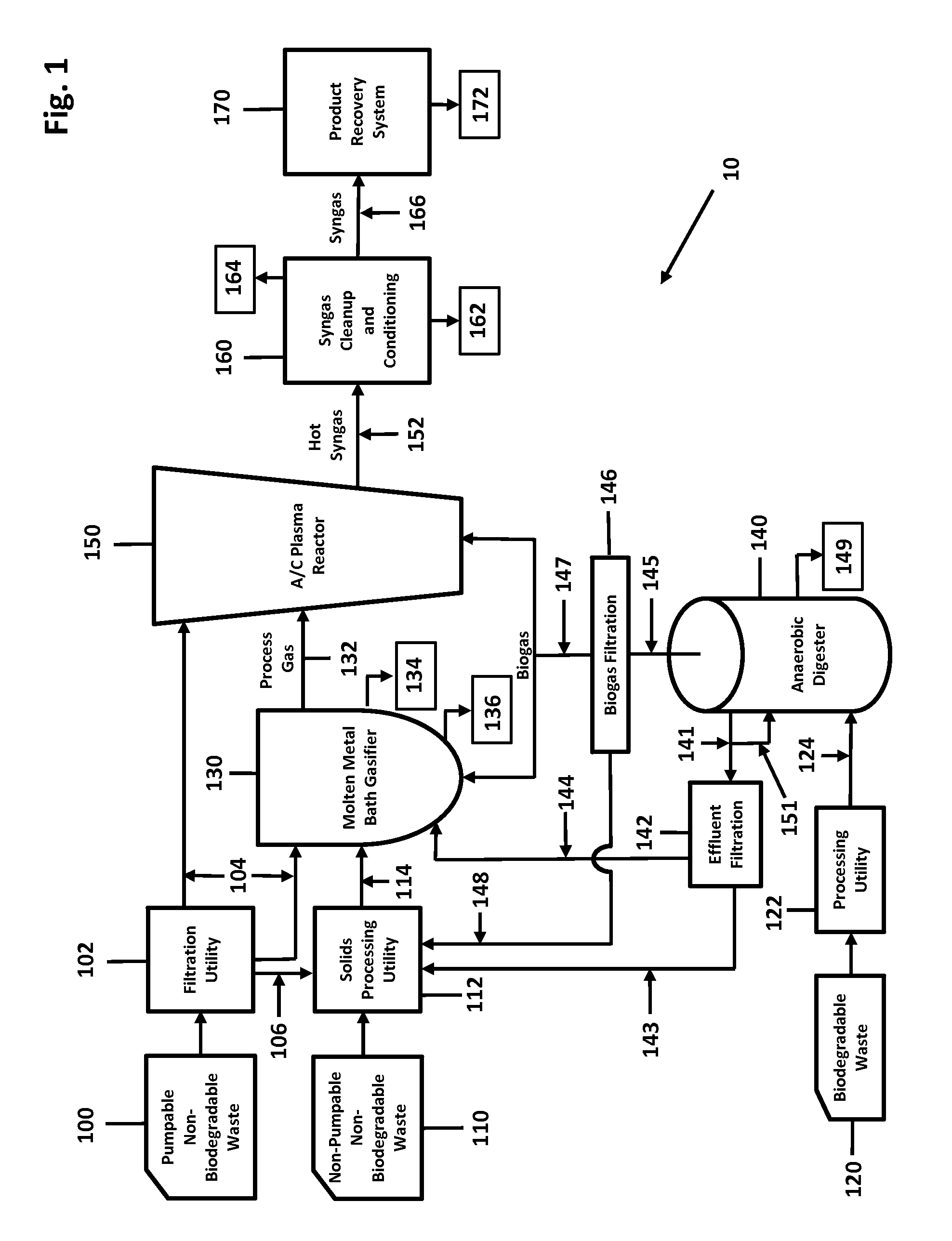

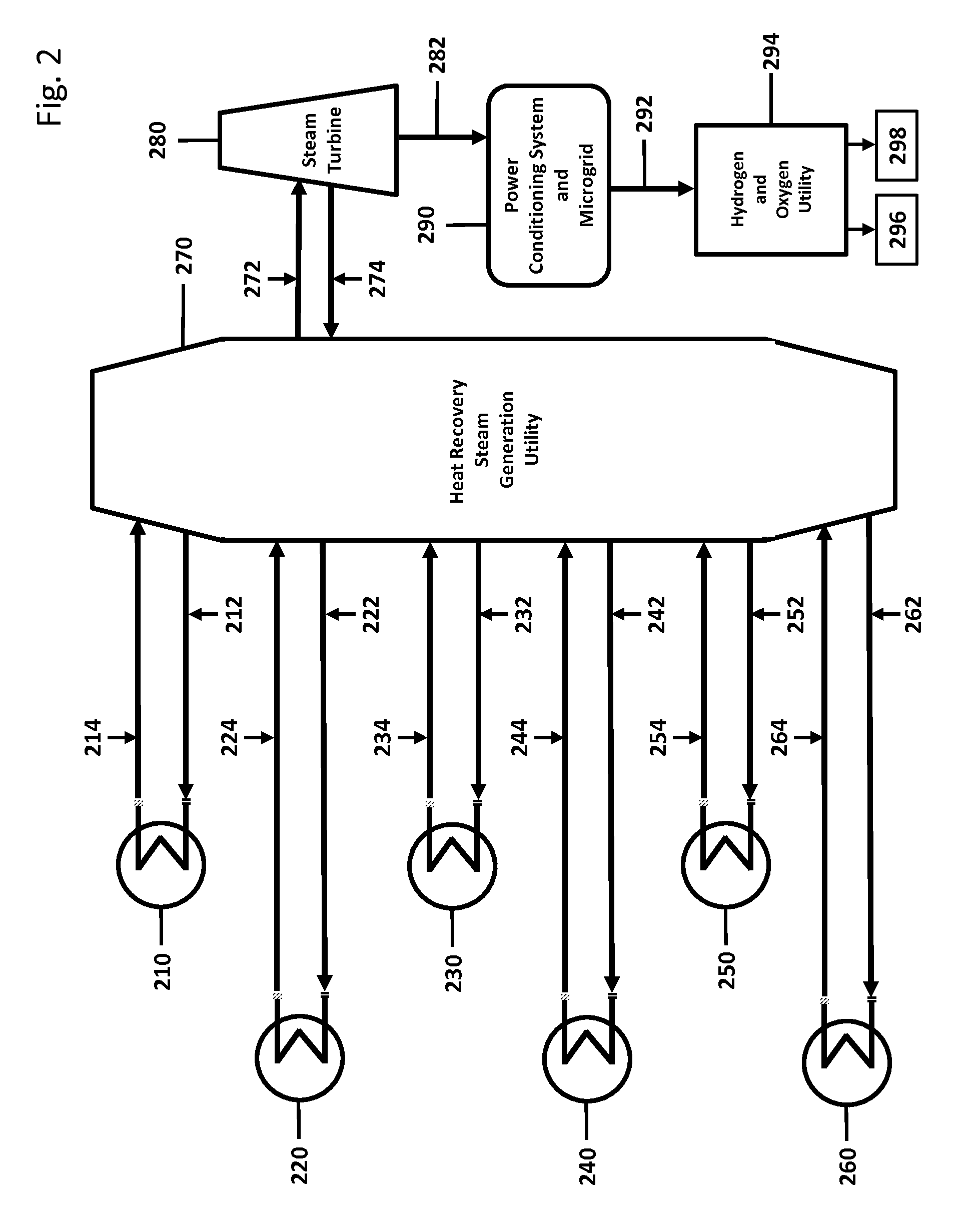

System and method for producing a consistent quality syngas from diverse waste materials with heat recovery based power generation, and renewable hydrogen co-production

ActiveUS9315735B2Processed effectively and safelyRisk minimizationDirect heating destructive distillationBiofuelsOxygenElectric power

A system and method for converting waste and secondary materials into synthesis gas (syngas) through the use of a molten metal bath gasifier for the initial breakdown of waste feeds and an A / C plasma reactor for complete dissociation of waste feeds into syngas, and an anaerobic digester. The system includes a heat recovery and steam power generation process for the production of electricity. The system produces a net output of electricity above plant load sufficient for the co-production of renewable Hydrogen and Oxygen. The process does not require the use of fossil fuels or fossil feedstocks during normal operations, and it eliminates combustion produced stack emissions or landfill residuals.

Owner:RENEWABLE OPPORTUNITIES

Method for producing high value aromatics and olefin from light cycle oil produced by a fluidized catalytic cracking process

ActiveUS8912377B2Increase productionMaximize processing efficiencyCatalytic crackingHydrocarbon by hydrogenationHigh concentrationPetroleum

The present invention relates to a method of producing aromatic products (benzene / toluene / xylene) and olefin products from petroleum fractions obtained by fluid catalytic cracking, and, more particularly, to a method of producing products comprising high-concentration aromatic products and high value-added light olefin products from light cycle oil obtained by fluid catalytic cracking.

Owner:SK INNOVATION CO LTD

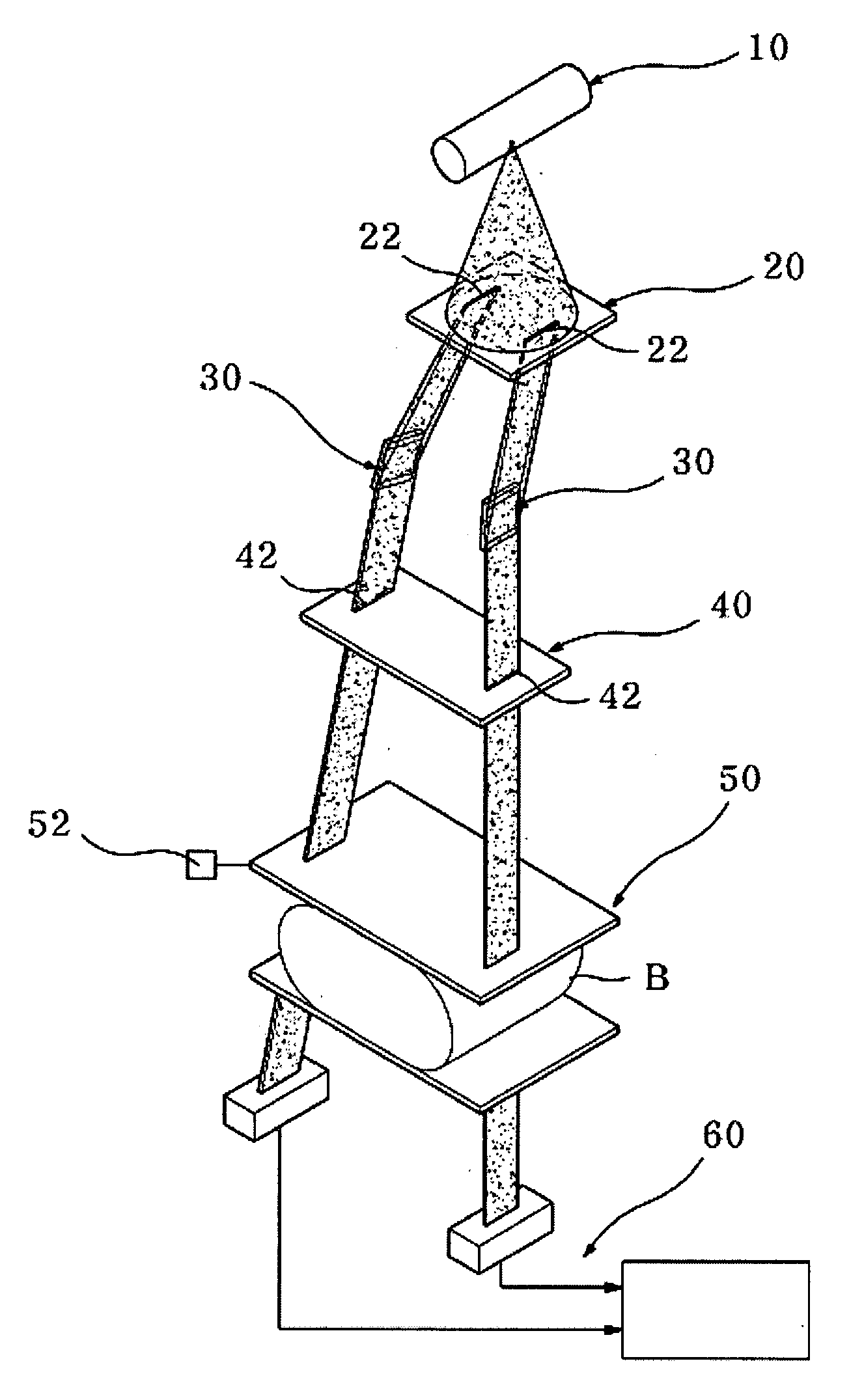

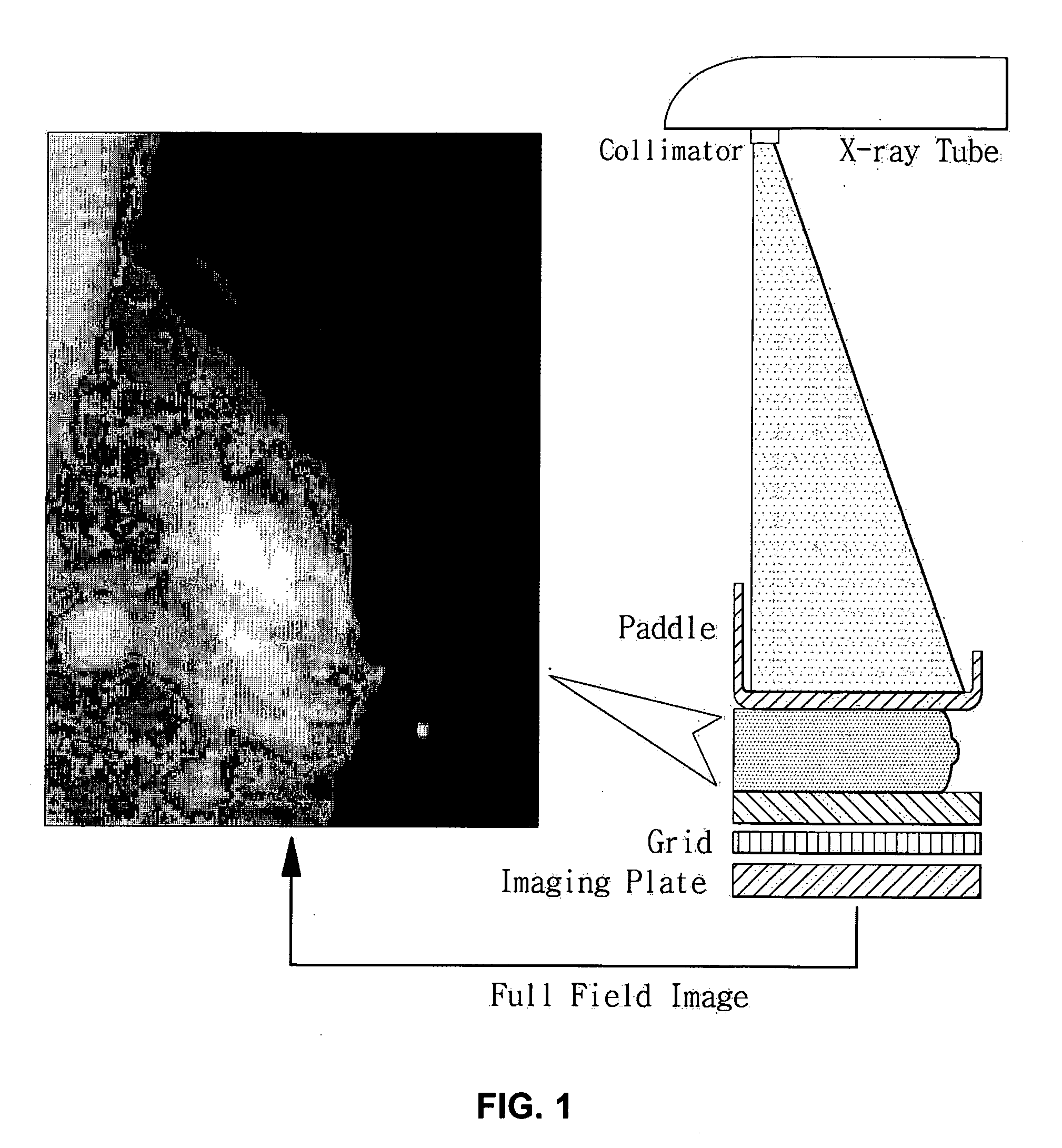

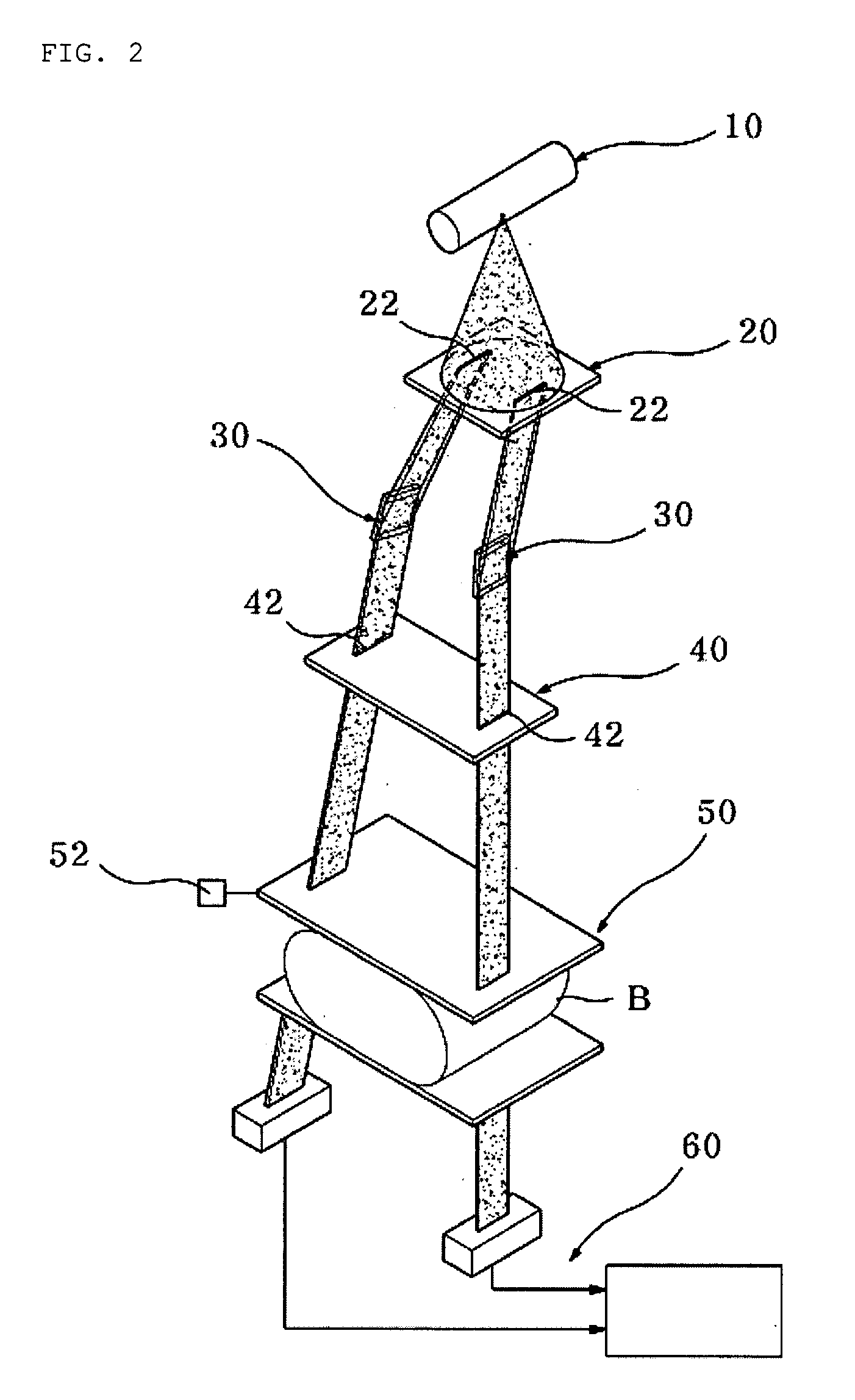

Dual-radiation type mammography apparatus and breast imaging method using the mammography apparatus

InactiveUS20080089472A1Easy to checkAccurately determinePatient positioning for diagnosticsMammography3d imageX-ray

A dual-radiation type mammography apparatus for examining a breast by taking a breast image using x-ray beams is provided. The mammography apparatus includes an x-ray generating unit generating the x-ray beams, a first collimator provided with transmission holes through which a solid angle beam generated from the x-ray beams radiated from the x-ray generating unit, in the course of which the solid angle beam is changed into a plurality of beams each having a predetermined size, a plurality of multi-layered filter units that filters off some of the beams passing through the holes of the first collimator to deflect only beams in a first specific energy band, a breast fixing unit fixing the breast B that will be scanned by the beams deflected by the multi-layered filter units, and a plurality of image output units provided for the respective beams scanning the breast fixed by the breast fixing unit and reforming two-dimensional images formed by the beams deflected at different angles into a three-dimensional image.

Owner:WONKWANG UNIV CENT FOR IND ACAD COOPERATION

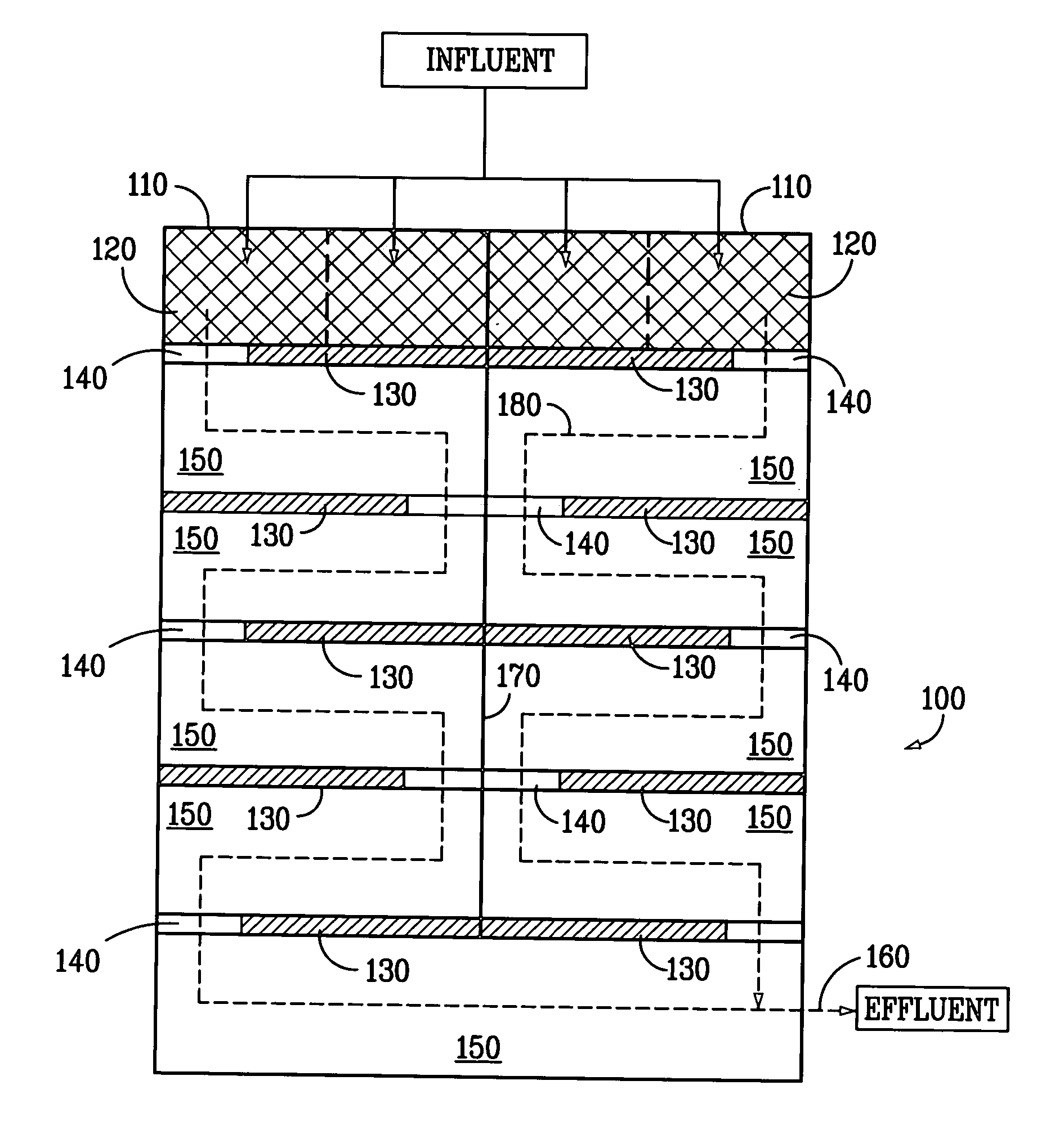

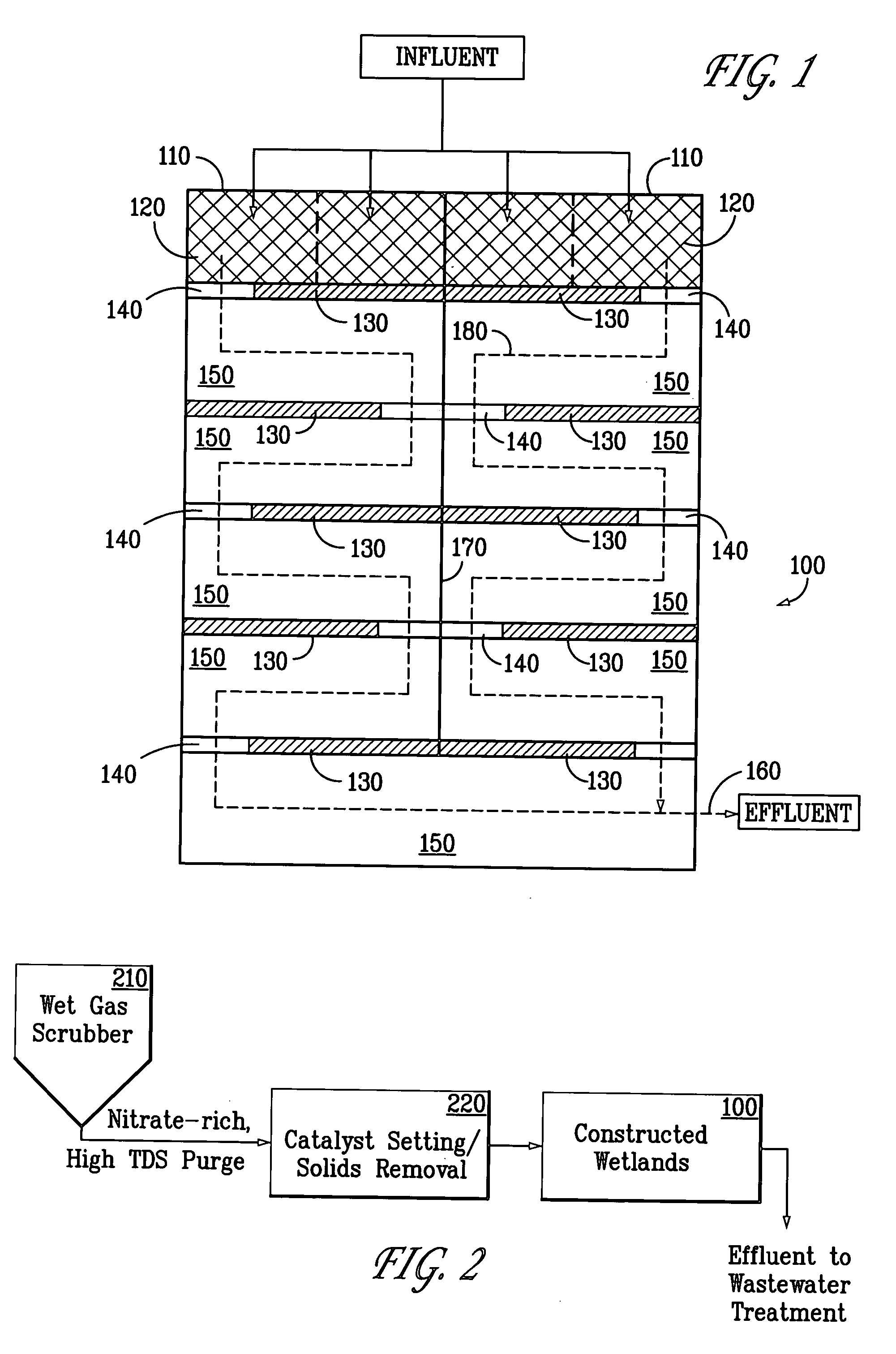

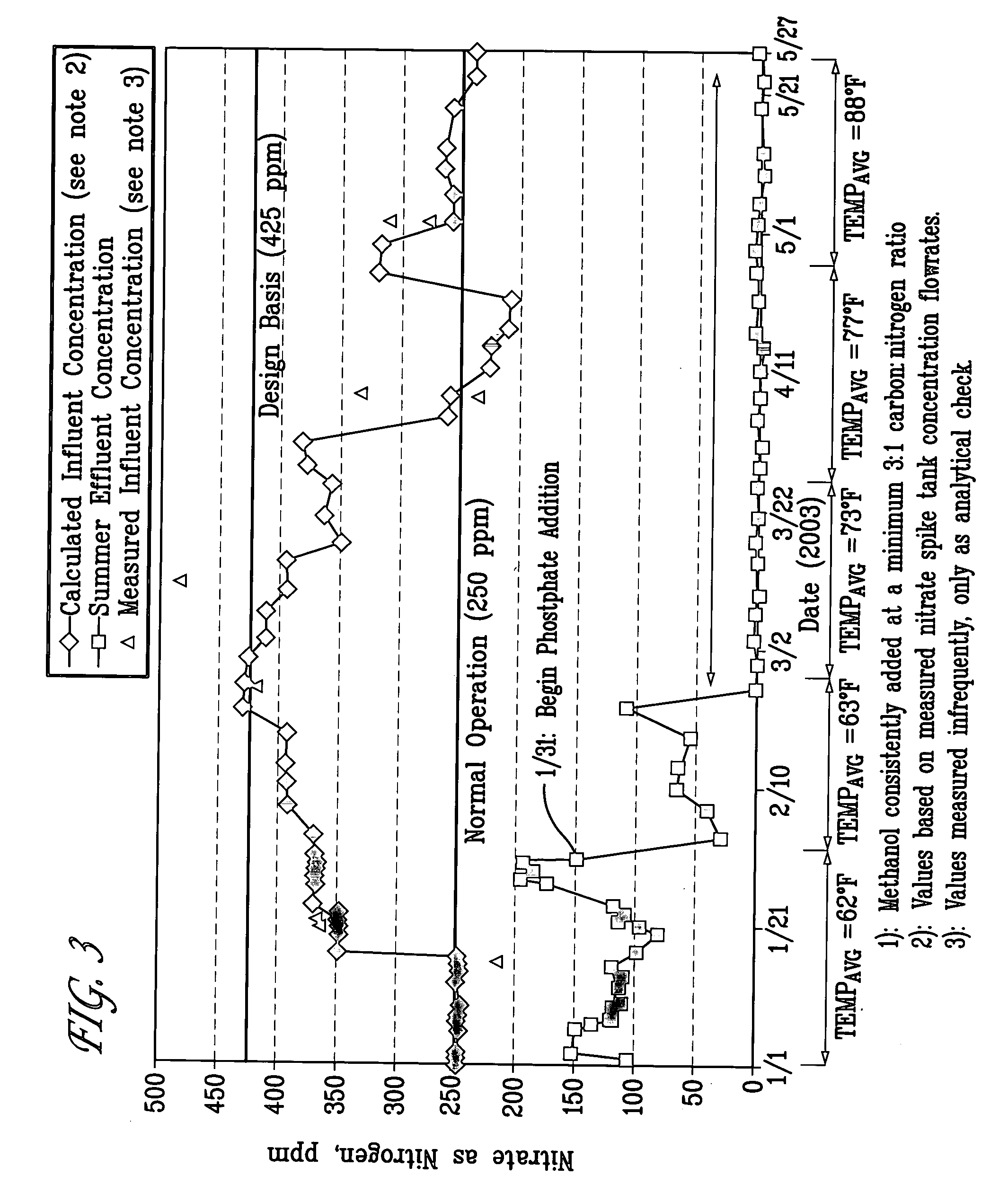

Nitrate removal in a purge stream using constructed wetlands

ActiveUS20060076290A1Requires minimizationMaximize processing efficiencyWater contaminantsSeparation devicesConstructed wetlandCost effectiveness

The present invention comprises a system and methodology for denitrification using constructed wetlands. The constructed wetlands of the present invention can be effectively applied as a wastewater point source treatment technology to any high total dissolved solids (e.g. sulfites and sulfates), carbon deficient wastewater stream for nitrate control. Pollutants are removed from the stream via a number of processes including plant uptake, volatilization, filtration and biological reduction. The present system and methodology offers an ability to reduce outflow stream nitrate concentrations in a cost-effective manner with minimal capital investment.

Owner:EXXON RES & ENG CO

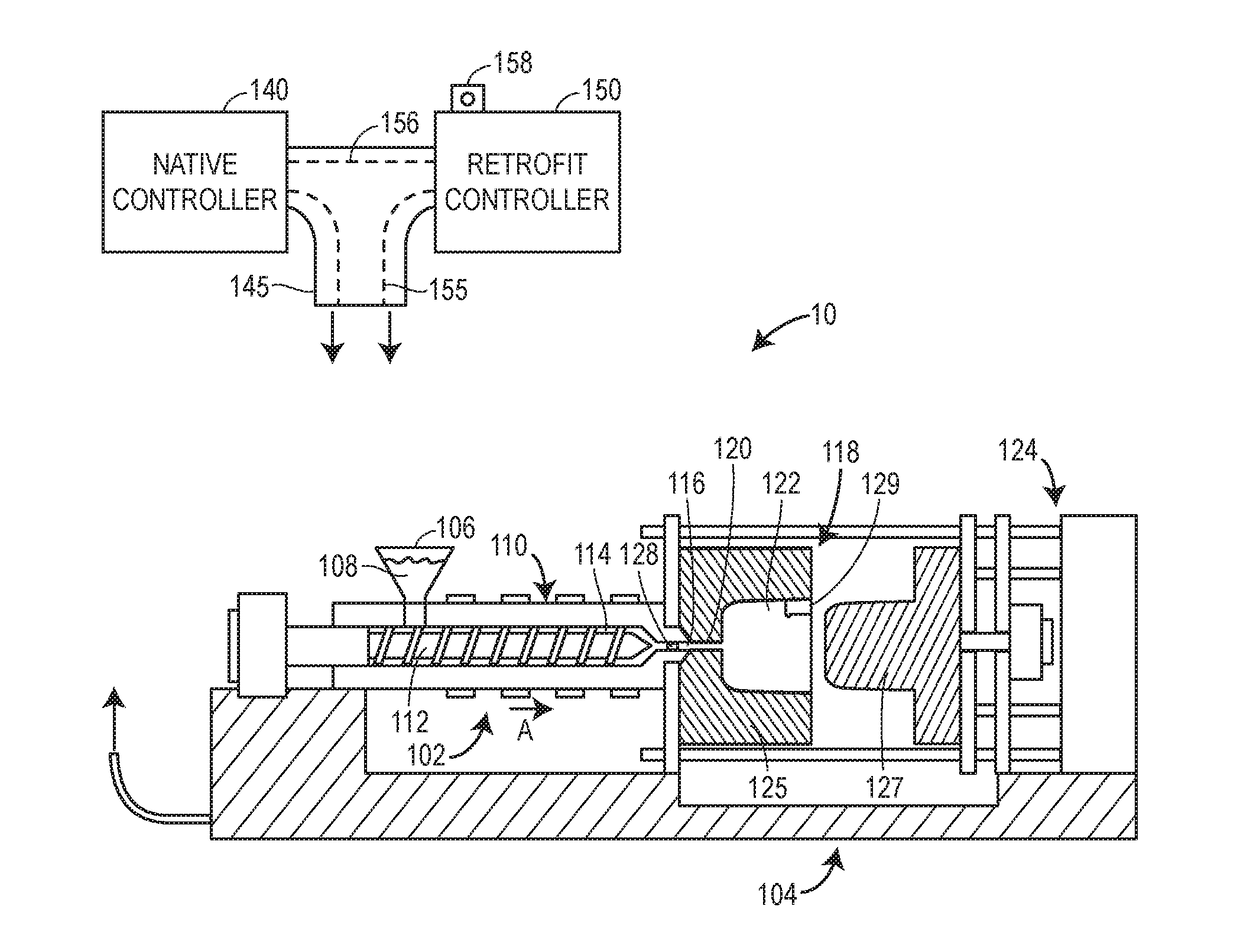

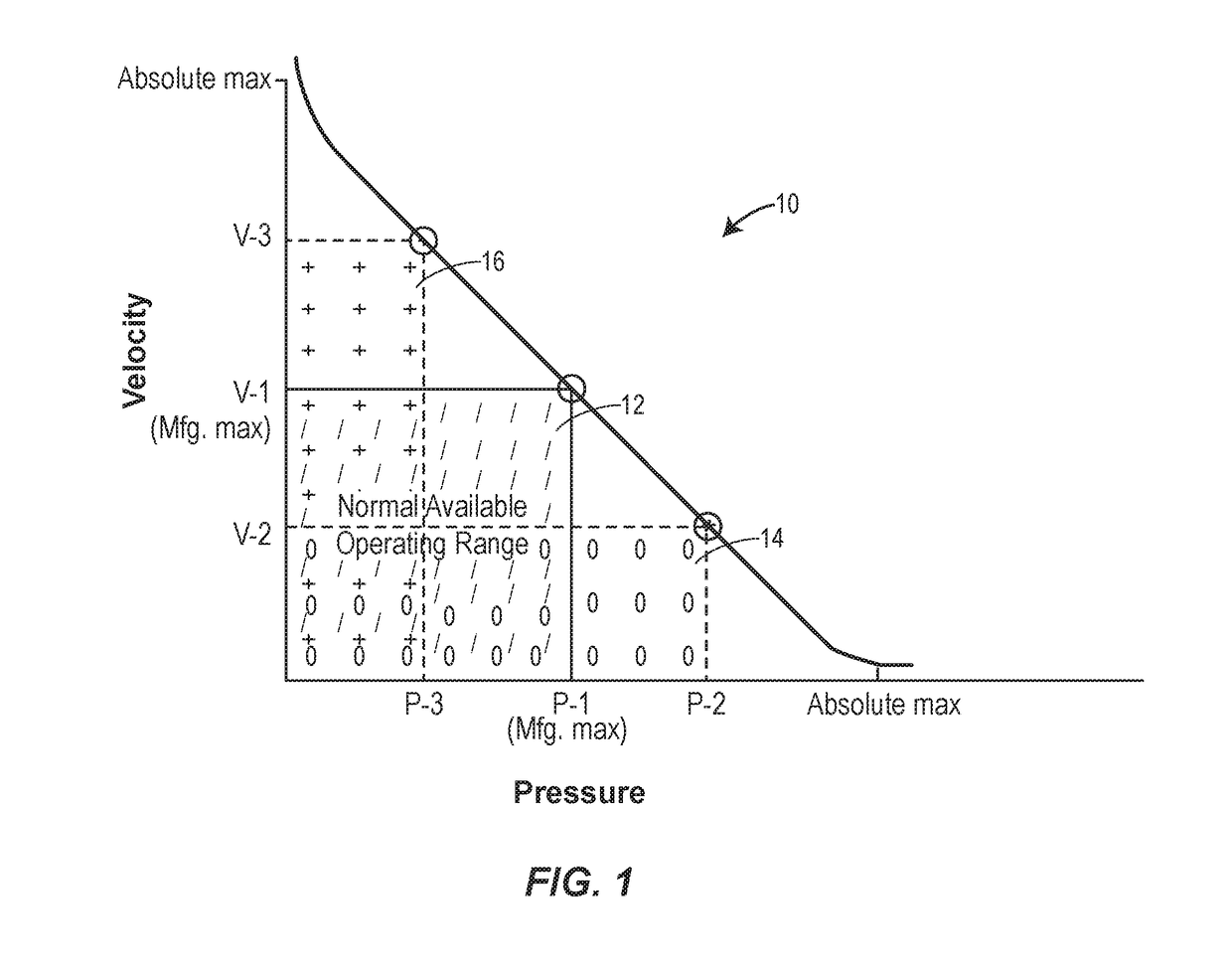

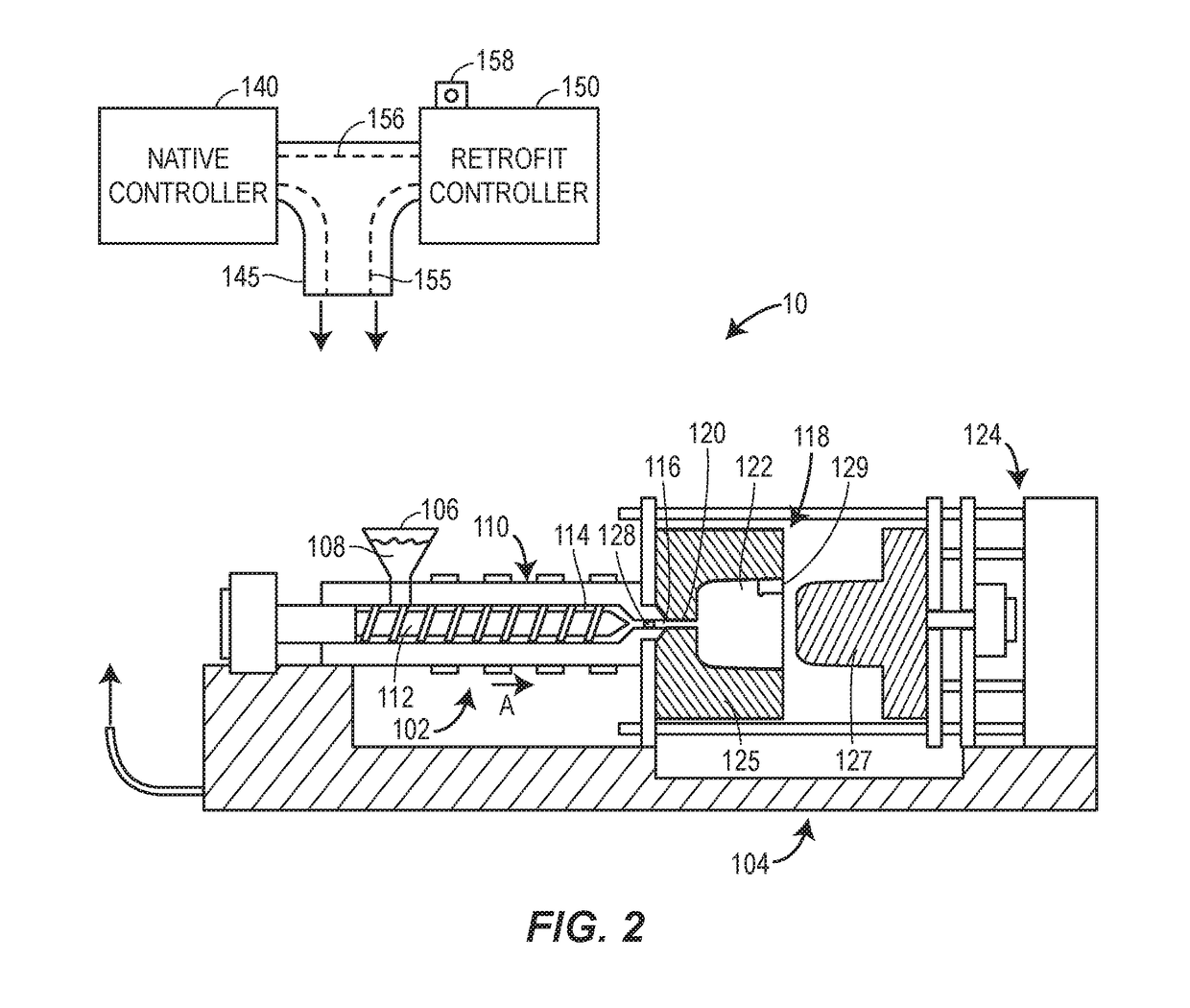

Injection molding controller interface with user-adjustable variables

ActiveUS20170274571A1Efficiently controlling operationImprove efficiencyMachine learningNumerical controlEngineeringInjection molding machine

An injection molding machine uses a native controller and a retrofit controller to effectively control its operation. The controllers may determine and / or receive information regarding the machine's maximum load capacity, and may also determine a current operational load value of the machine. The retrofit controller may cause the machine to operate at any number of combinations of settings of operational parameters which result in the machine operating at or below the maximum load value by adjusting any number of machine parameters associated with the injection molding machine based on feedback sensors measuring real-time operating conditions of the machine.

Owner:IMFLUX INC

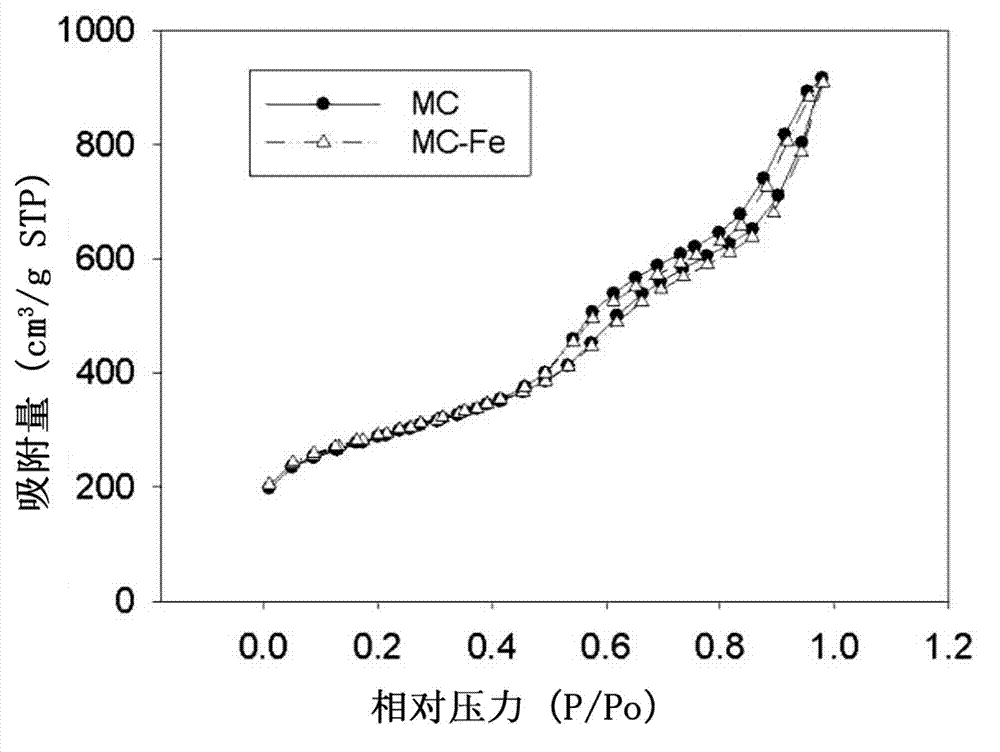

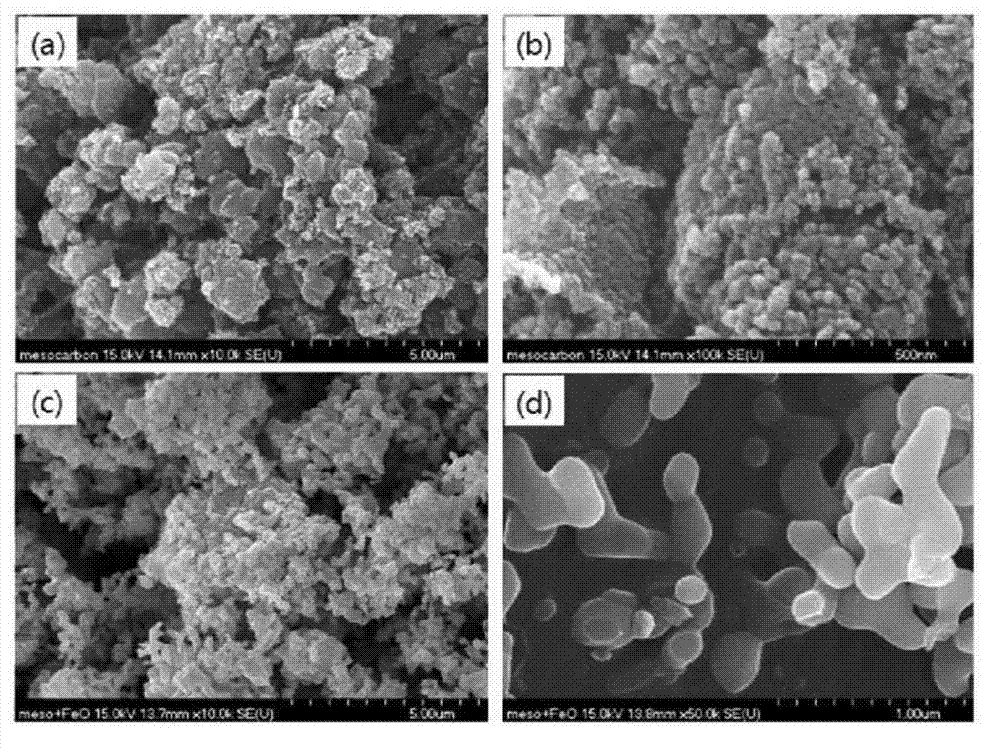

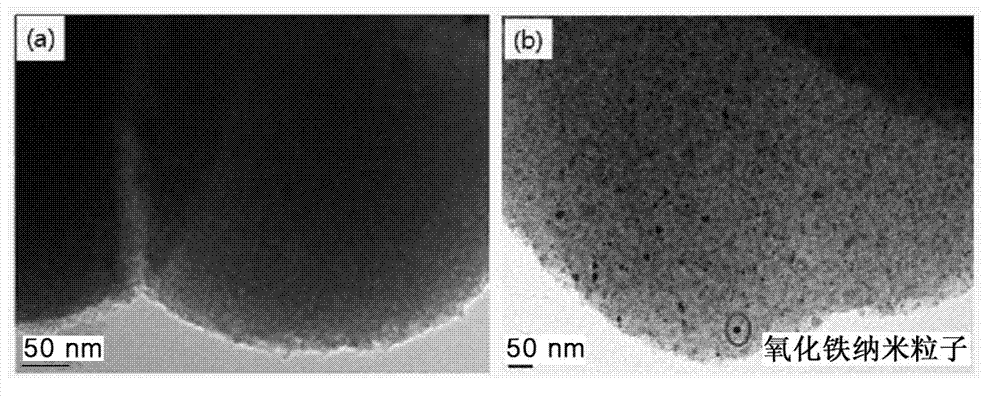

Method for preparing mesoporous carbon having iron oxide nanoparticles

InactiveCN102958833AMaximize processing efficiencyGood effectMaterial nanotechnologyCarbon compoundsSorbentIron oxide nanoparticles

The present invention relates to a method for preparing a mesoporous carbon having iron oxide nanoparticles, and the method for preparing a mesoporous carbon having iron oxide nanoparticles of the present invention comprises the steps of: 1) dispersing and saturing iron oxide nanoparticles on the surface of a mesoporous carbon; and 2) calcinating the mesoporous carbon. The mesoporous carbon having the iron oxide nanoparticles prepared according to the present invention displays excellent adsorption of organic substances, and is economic and convenient due to a shorter reaction time. Therefore, the mesoporous carbon having the iron oxide nanoparticles of the present invention can be applied to an adsorbent for maximizing contaminant treatment efficiency in water treatment.

Owner:GWANGJU INST OF SCI & TECH

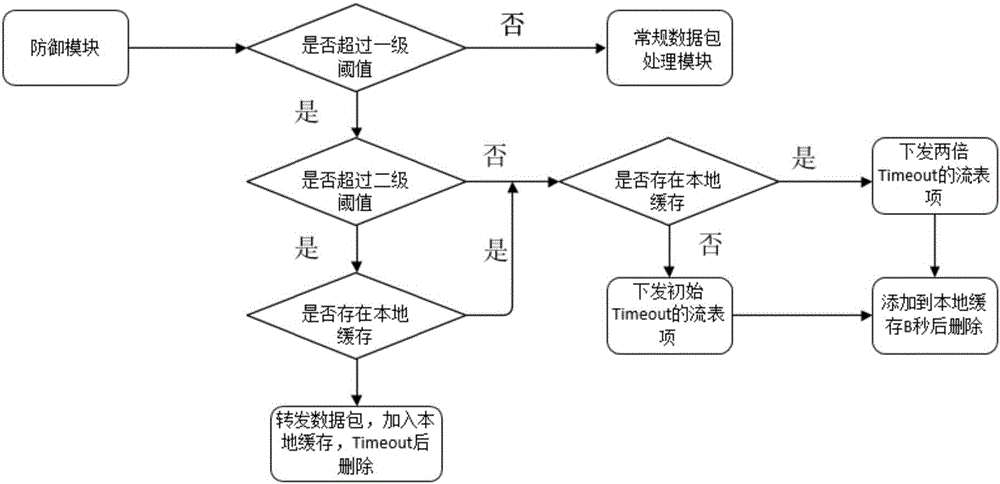

DoS/DDoS attack defense module and method based on SDN controller

ActiveCN107438066AMaximize processing efficiencyEnsure normal communicationTransmissionPacket communicationData pack

The invention discloses a DoS / DDoS attack defense module and a method based on an SDN controller. The DoS / DDoS attack defense module maintains a counter, the number of packets received by the SDN controller in the past n seconds is recorded, two thresholds, those are, a primary threshold and a secondary threshold, are set, and the secondary threshold is larger than the primary threshold. When the counter is smaller than the primary threshold, the data packets are transmitted to a default processing module for processing. When the counter exceeds the primary threshold, happening of a DoS / DDoS attack is meant, the data packets are firstly filtered through the DoS / DDoS attack defense module, and the controller at the time enters a defense mode. When the number of packets received per second exceeds the secondary threshold, happening of a stronger DoS / DDoS attack is meant. The module can effectively filter malicious attack packets and can ensure normal data packet communication, so that the module can resist DoS / DDoS attacks against SDN controllers to a certain extent.

Owner:ZHEJIANG UNIV

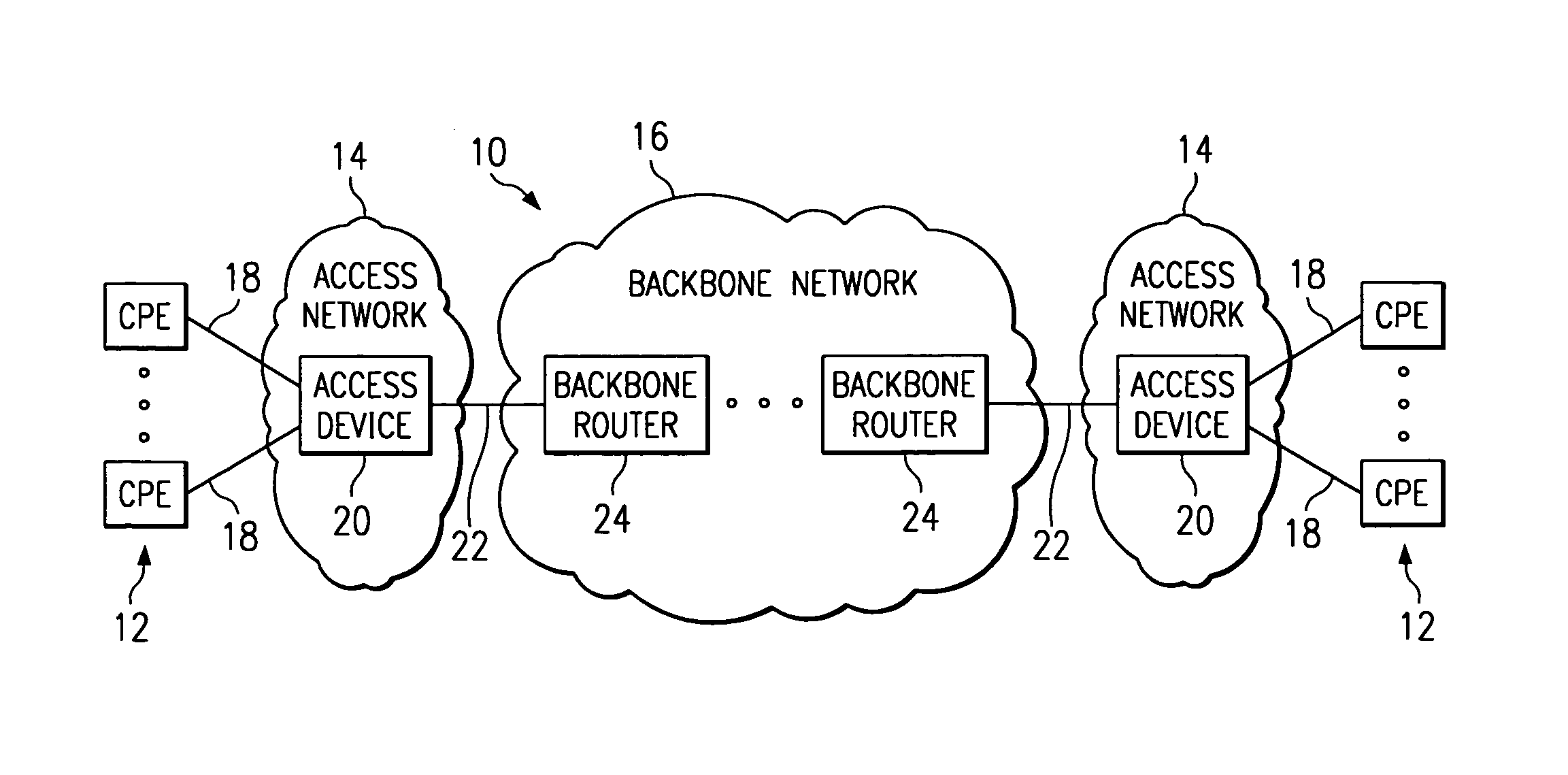

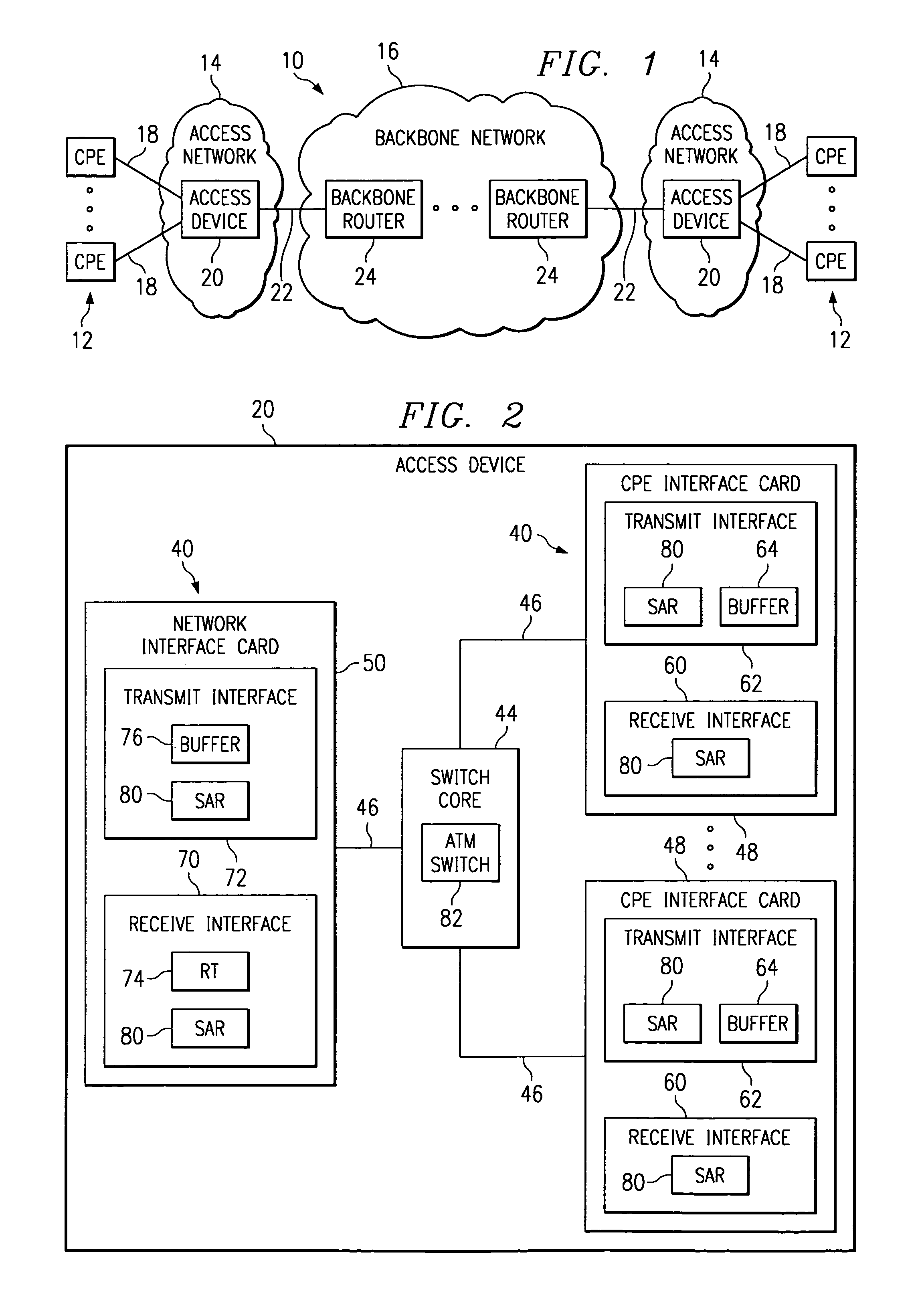

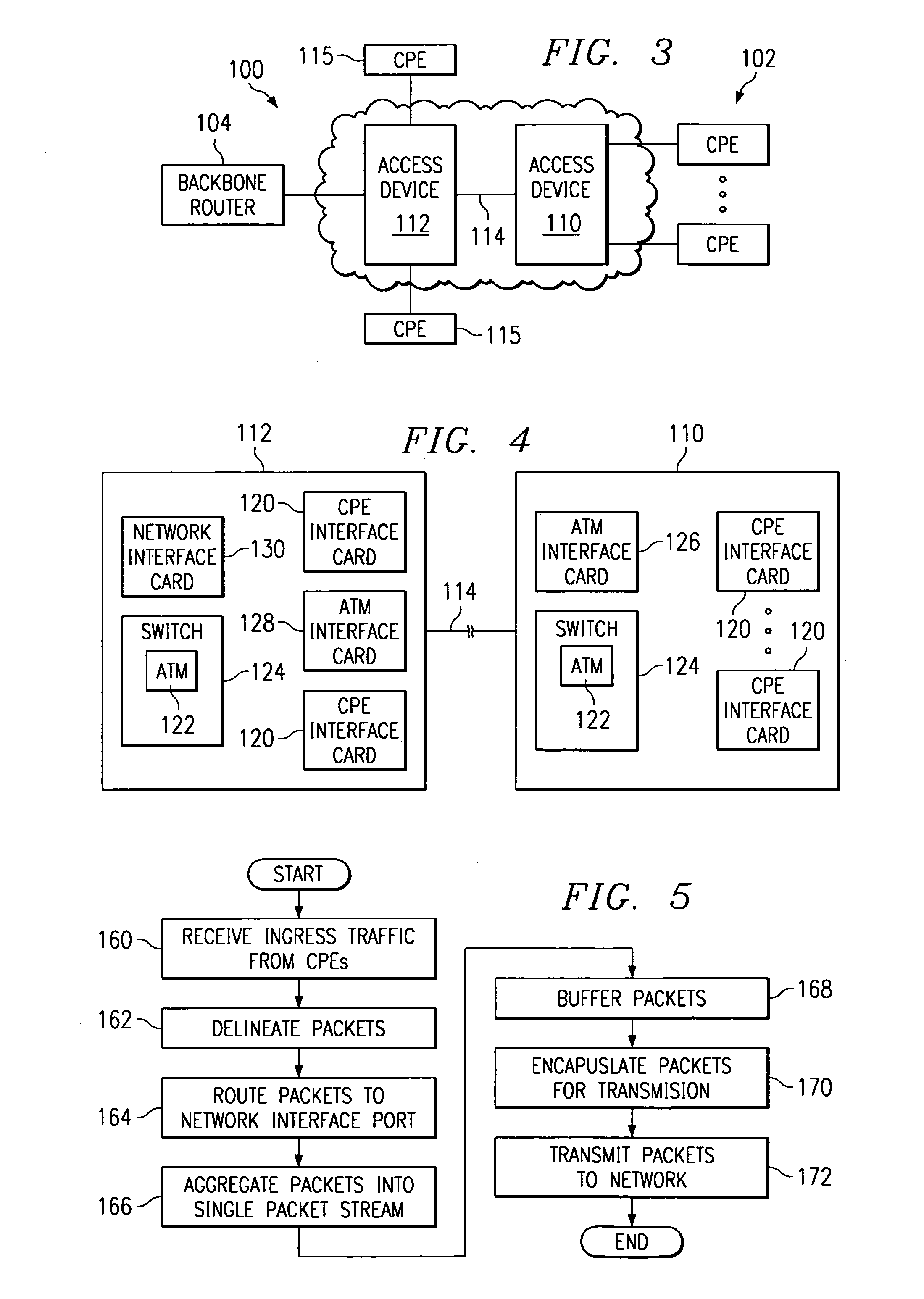

Method and system for processing traffic in an access network

ActiveUS8213460B1Efficient switchingMaintaining transport efficiencyTime-division multiplexNetwork connectionsAccess networkIp address

A method and system for processing traffic in an access network includes receiving a plurality of ingress traffic streams from customer premise equipment (CPE). Each ingress traffic stream includes a plurality of Internet Protocol (IP) packets having an IP address. The ingress traffic streams are aggregated into a combined traffic stream without regard to the IP addresses. The combined traffic stream is transmitted to a backbone network for routing based on the IP addresses. An egress traffic stream is received from the backbone network and includes a plurality of IP packets each having an IP address. A CPE port is determined for each IP packet based on its IP address. The IP packets are routed to their respective CPE ports and transmitted to their destination CPEs.

Owner:CISCO TECH INC

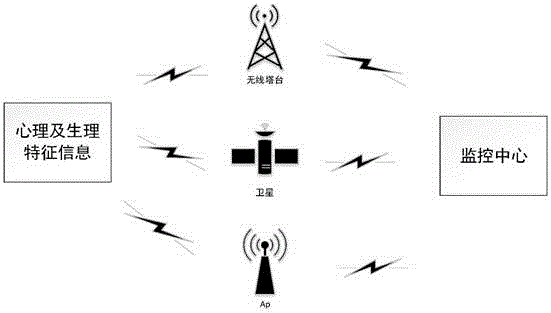

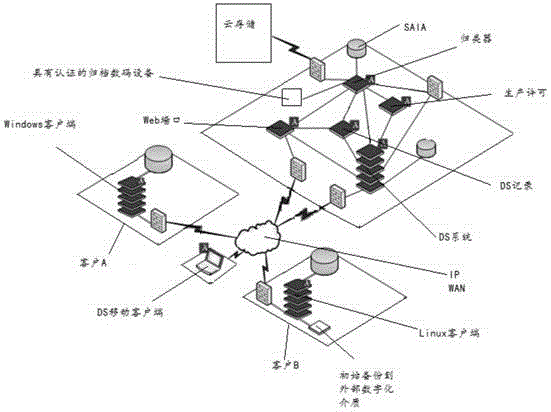

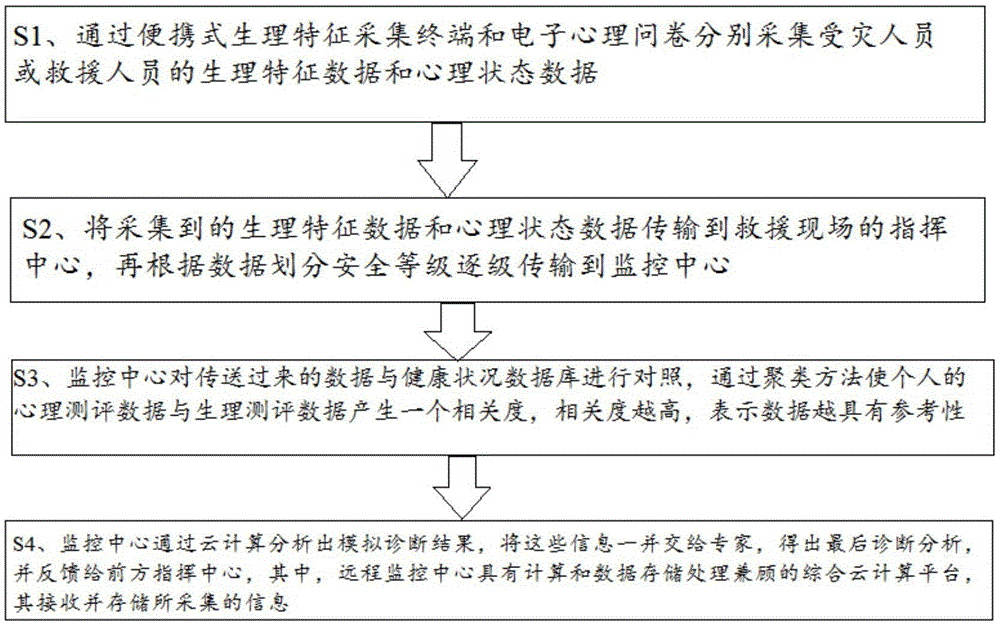

Method for conducting remote real-time psychological and physiological status monitoring

InactiveCN105574354AIncrease credibilityMaximize processing efficiency and accuracyTelemedicineSpecial data processing applicationsData transmissionTransfer mode

The invention discloses a method for conducting remote real-time psychological and physiological status monitoring. The method comprises the following steps that 1, physiological feature data and psychological state data of affected personnel or rescue personnel are collected through a portable physiological feature collection terminal and an electronic psychological scale respectively; 2, the collected data are transmitted to a rescue field managing center, and the data are transmitted level by level to a monitoring center according to the data partitioning safety level; 3, the remote monitoring center compares the data with a health status database and generates relevance between the personal psychological test data and physiological test data through a clustering method; 4, the monitoring center obtains the simulation diagnosis result through cloud calculation and analysis, delivers all information to experts, obtains final diagnosis analysis and feeds the result back to the rescue field managing center. By means of the method, the psychological and physiological feature tests under different rescue occasions can be conducted, multiple data transmission modes can be selected, and cloud platform data processing and guidance and feedback can be conducted.

Owner:GENERAL HOSPITAL OF PLA

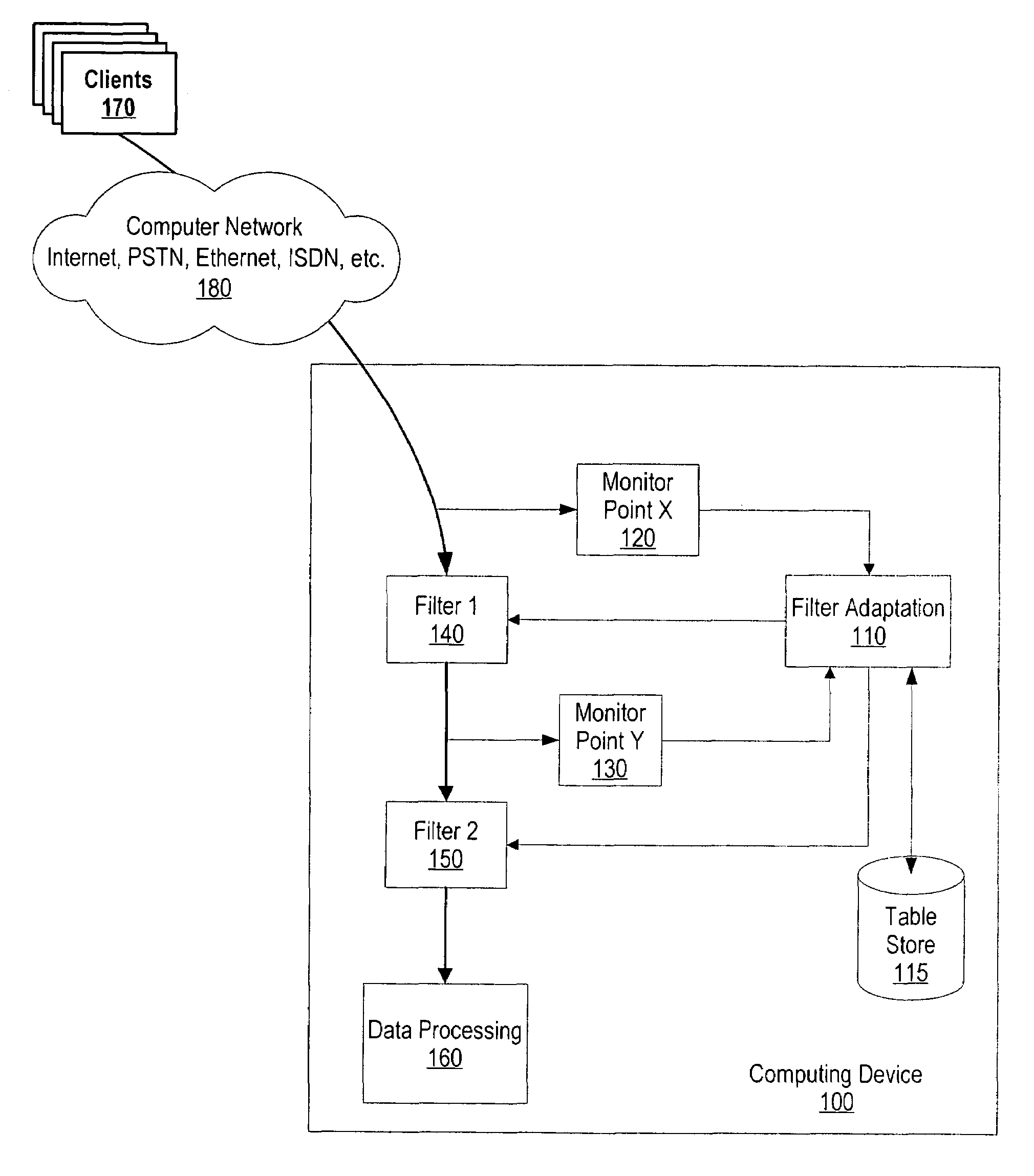

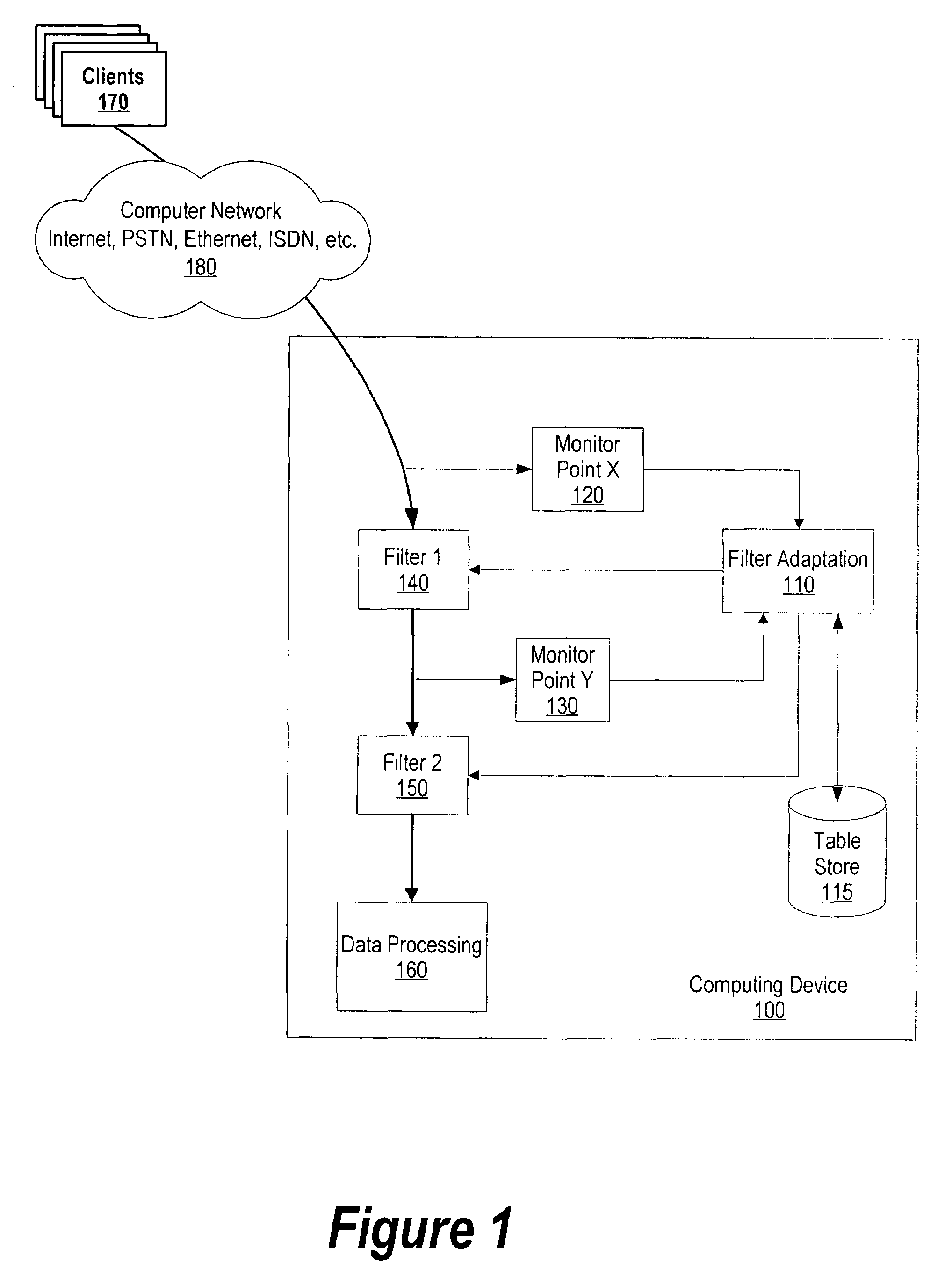

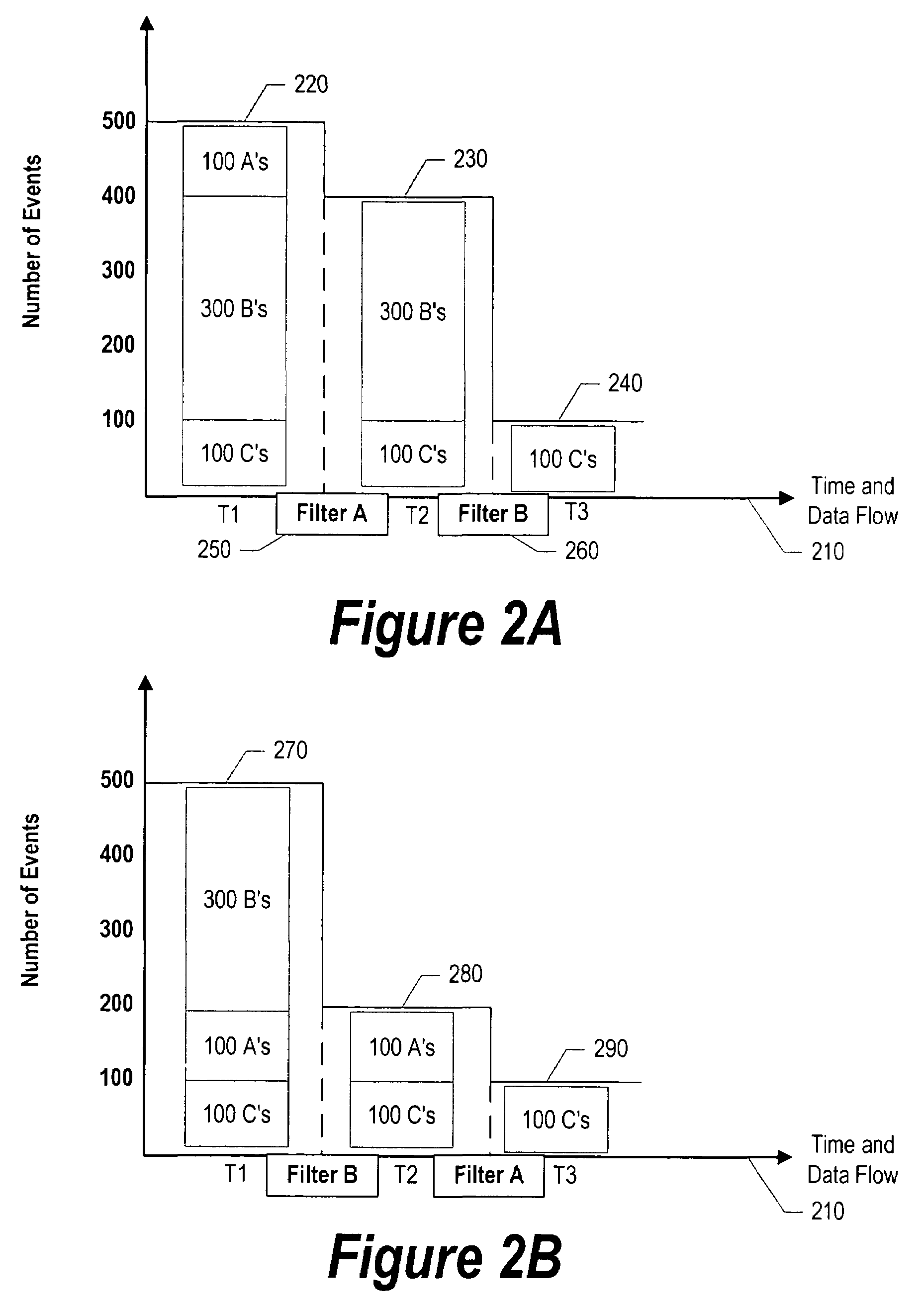

System and method for self-configuring and self-optimizing filters

InactiveUS7027962B2Maximize processing efficiencyDigital technique networkAmplifier modifications to reduce noise influenceEvent typeData stream

A system and method for self-configuring and self-optimizing filters is presented. A computing device monitors the number of occurrences of event types at particular stages in a data stream and adjusts filter properties in order to maximize processing efficiency based upon the number of event types that the computing device receives. The computing device may reconfigure, reorder, or create an exception filter based upon the analysis of the event types. The computing device may also pre-configure filter stages using historical data based upon a time of day, a time of month, or a time of year.

Owner:INT BUSINESS MASCH CORP

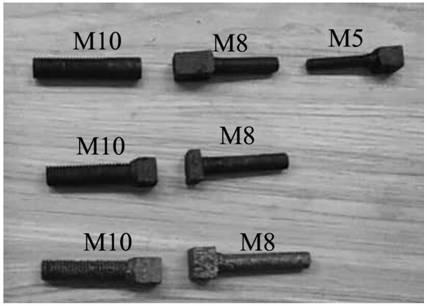

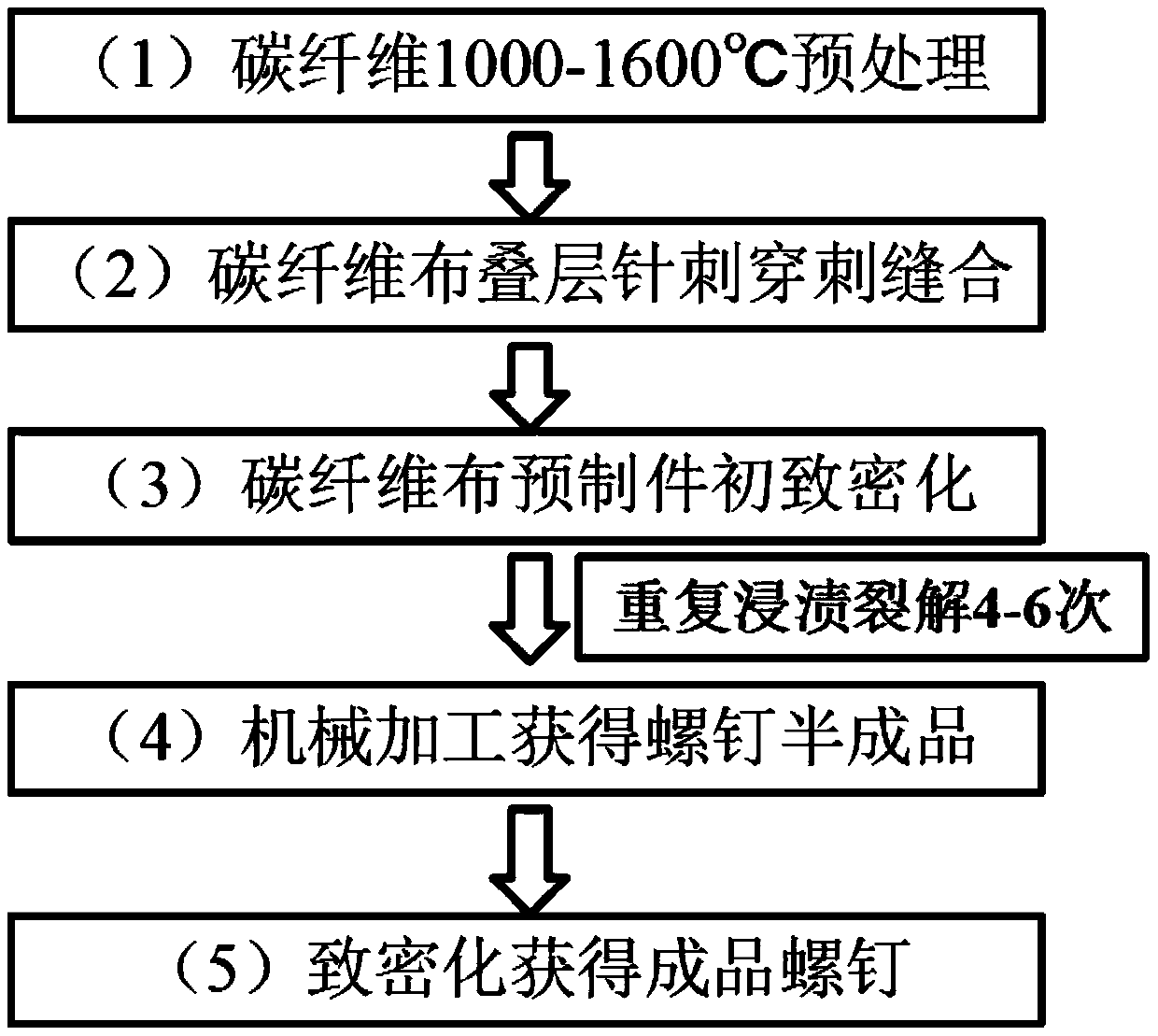

Ceramic-based composite material screw, and preparation method thereof

InactiveCN110194668AEasy to synthesize and collectLow costScrewsCeramic matrix compositeState of art

The invention discloses a ceramic-based composite material screw, and a preparation method thereof. The preparation method comprises five steps including carbon fiber cloth pretreatment, carbon fibercloth lamination needling sewing, carbon fiber cloth prefabricated component initial densification, machining, and densification. Compared with the prior art, the characteristics of the ceramic-basedcomposite material screw are that: the density is 1.60 to 1.70g / cm3, the room temperature tensile breaking strength is 152 to 175MPa, the room temperature shearing strength is 66 to 81MPa, the tensilebreaking strength after 1h of oxidation at 1000 DEG C is 81 to 96MPa, and the room temperature shearing strength is 41 to 60MPa. The preparation method technology is mature; production efficiency ishigh; preparation cost is reduced obviously; operation is simple; the preparation method is a promising effective method used for large scale production of the ceramic-based composite material screw in industrial industry; and the application prospect is promising.

Owner:NAT UNIV OF DEFENSE TECH

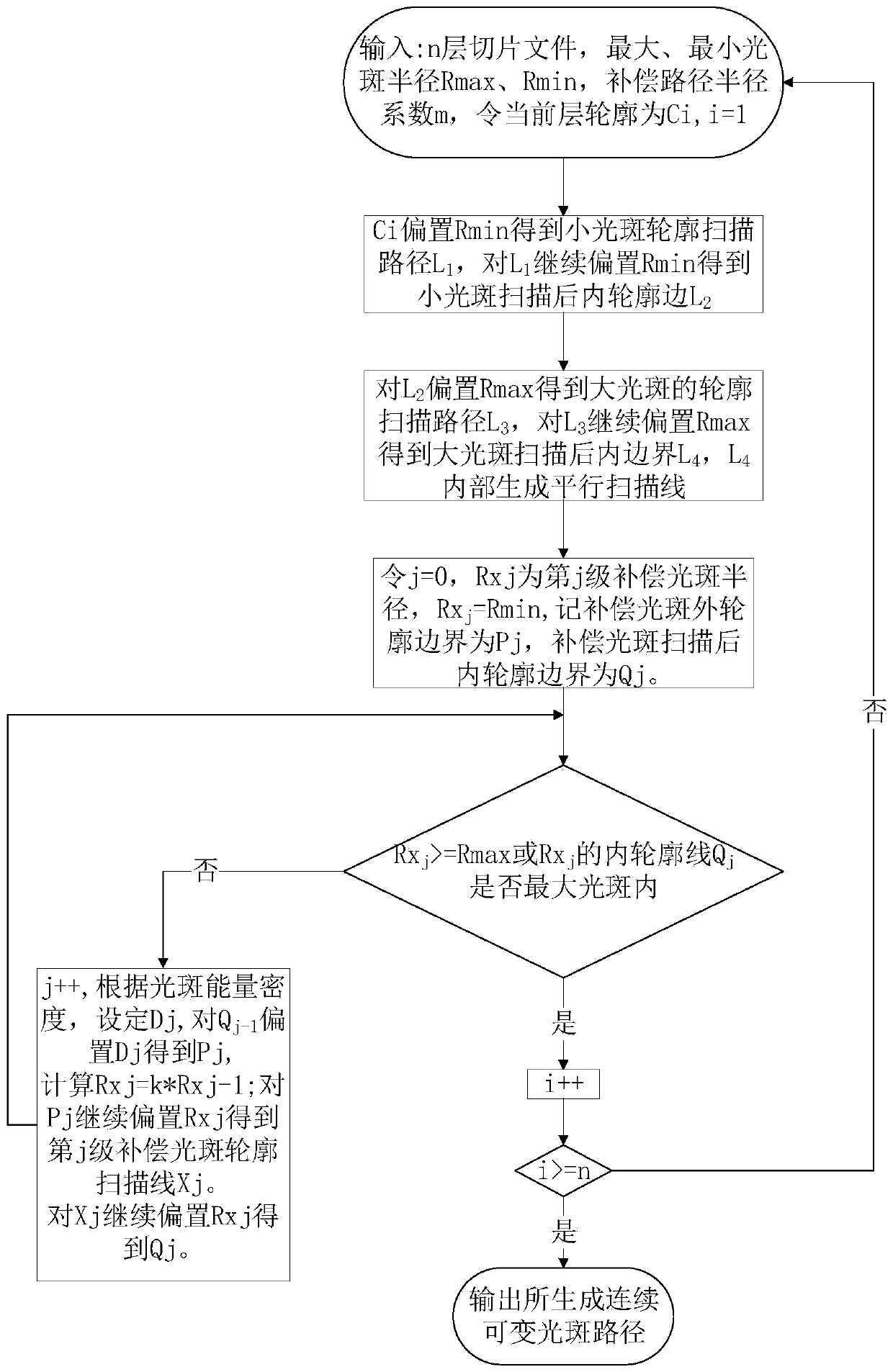

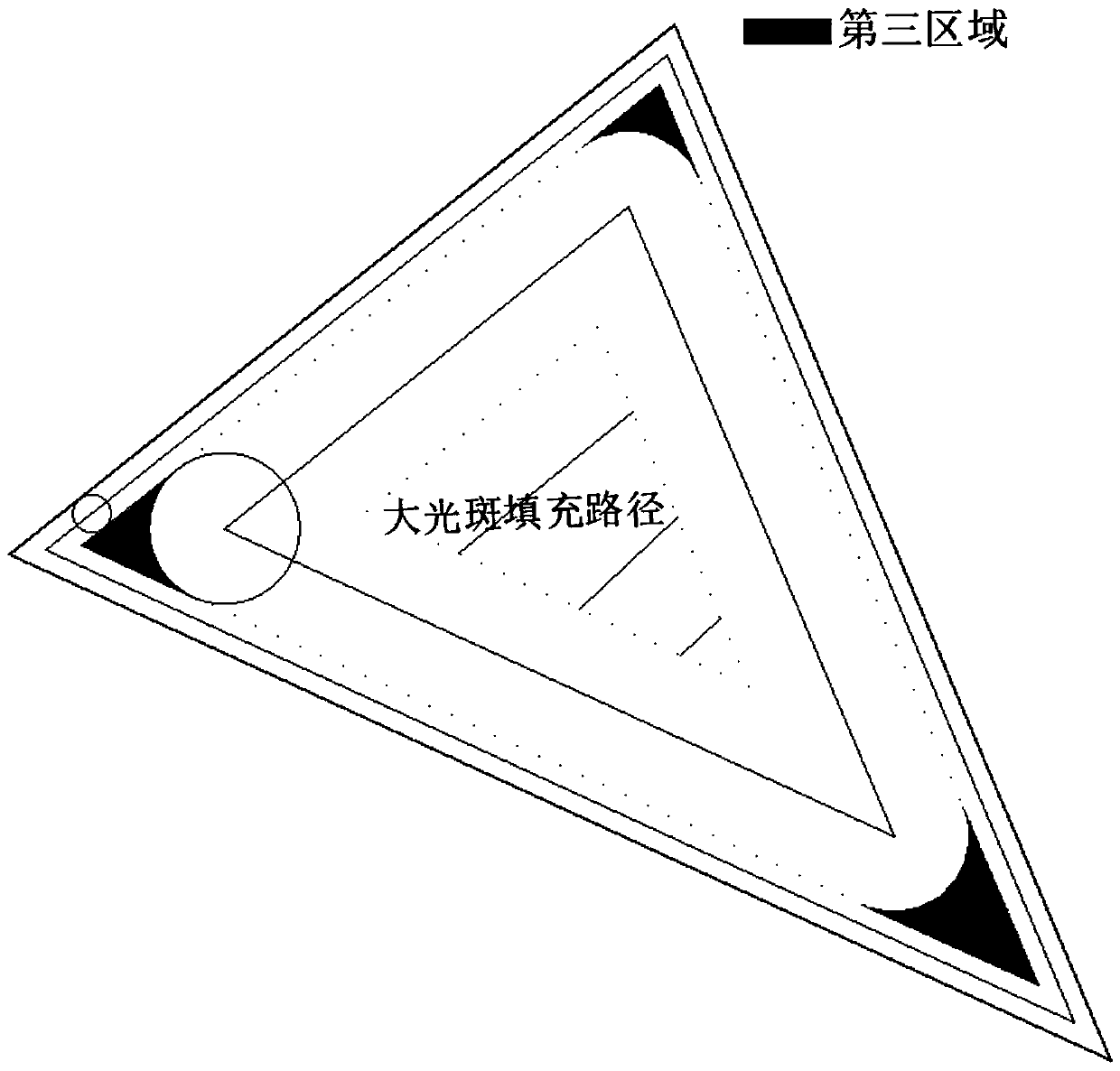

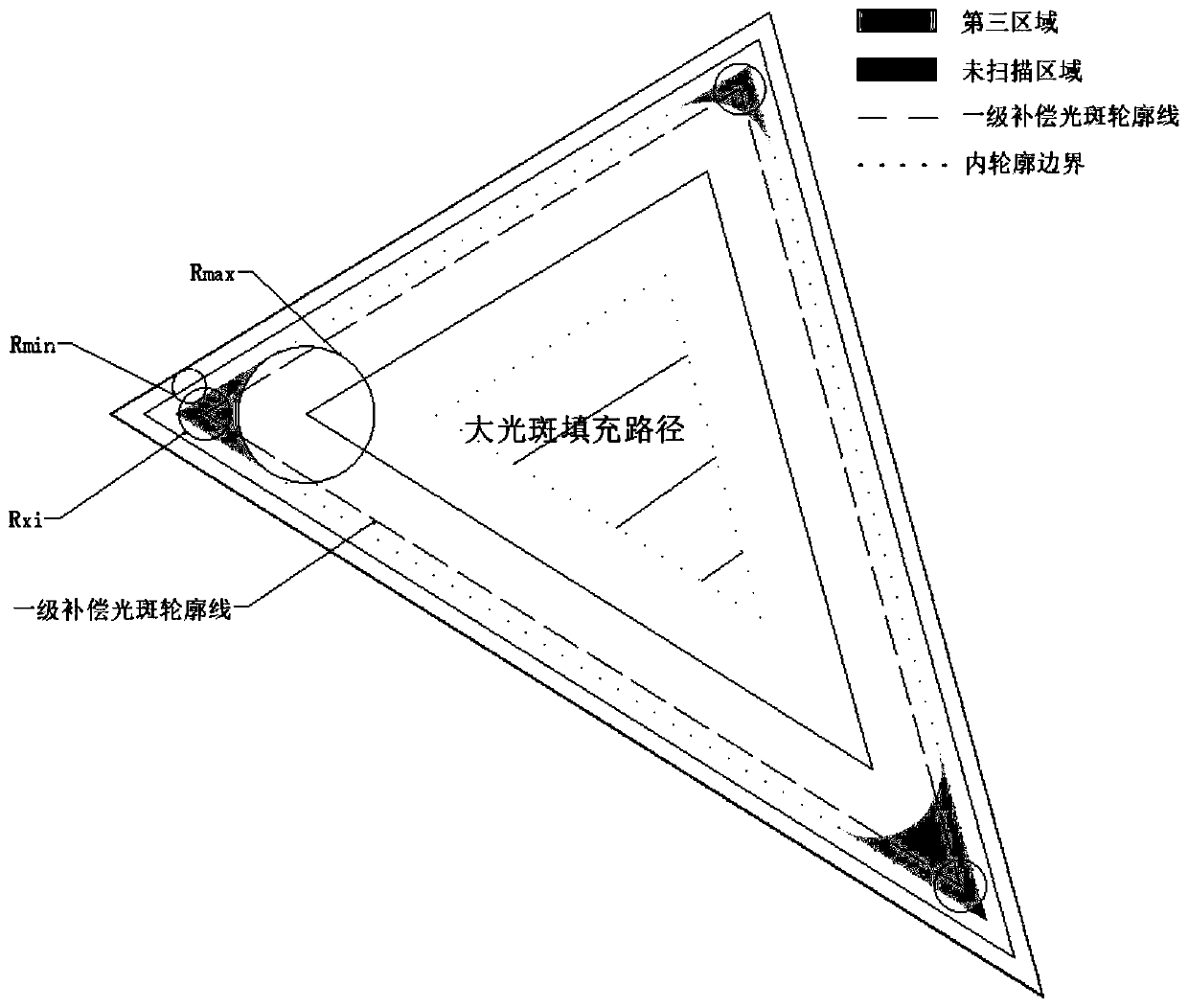

Method adopting continuous variable light spots for scanning processing in 3D printing

ActiveCN109878075AQuality improvementImprove scanning efficiencyAdditive manufacturing apparatus3D object support structuresLight spotLaser scanning

The invention belongs to the field of 3D printing, and particularly relates to a method adopting continuous variable light spots for scanning processing in 3D printing. The method comprises the following steps that for a single slicing layer in 3D printing, the maximum light spot radius and the minimum light spot radius of laser scanning processing are set, a to-be-scanned region is divided into afirst region, a second region and a third region, the first region is scanned and processed by adopting the minimum light spot, the second region is scanned and processed by adopting the maximum light spot, the third region adopts step-by-step compensation, namely the third region is scanned step by step by increasing the scanning radii of the light spots step by step, scanning processing of theregion is realized, and continuous variable light spot scanning processing is realized through continuous changing of the light spots in a way that the radii of the light spots are gradually increasedor reduced in the scanning process of the regions. According to the method, the scanning filling frequency is reduced, the forming efficiency is improved, and the local overheating curing of productsis avoided.

Owner:HUAZHONG UNIV OF SCI & TECH

Granular quicklime fixed bed dehydration and deodorization system and operation method thereof

ActiveCN112717666AReduce operating energy consumptionImprove the combination effectGas treatmentDispersed particle separationCalcium hydroxideTemperature control

The invention relates to the field of household garbage disposal, in particular to a granular quicklime fixed bed dehydration and deodorization system and an operation method thereof. The system comprises an alkali liquor absorption tower, a granular quicklime fixed bed, a forced ventilation module and a circulating water heat exchange module, the granular quicklime fixed bed comprises a quicklime drying room and a dust removal room, the quicklime drying room is mainly used for removing residual moisture in circulating air and increasing the temperature of the circulating air, and the dust removal room is mainly used for intercepting and separating calcium hydroxide powder generated by reaction of quick lime and water vapor. The circulating water heat exchange module is regulated and controlled through feedback of a temperature sensor, and then the composting environment of a subsequent aerobic composting reactor is regulated and controlled. The system integrates multiple functions of circulating water heat exchange accurate temperature control, circulating air, water content control and cyclic odor absorption and degradation, so that secondary pollution and zero emission in the domestic garbage biological treatment process are achieved, meanwhile, the operation energy consumption of the treatment system is greatly reduced, and the operation cost is effectively saved.

Owner:NANJING UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com