Patents

Literature

34results about How to "Low processing efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

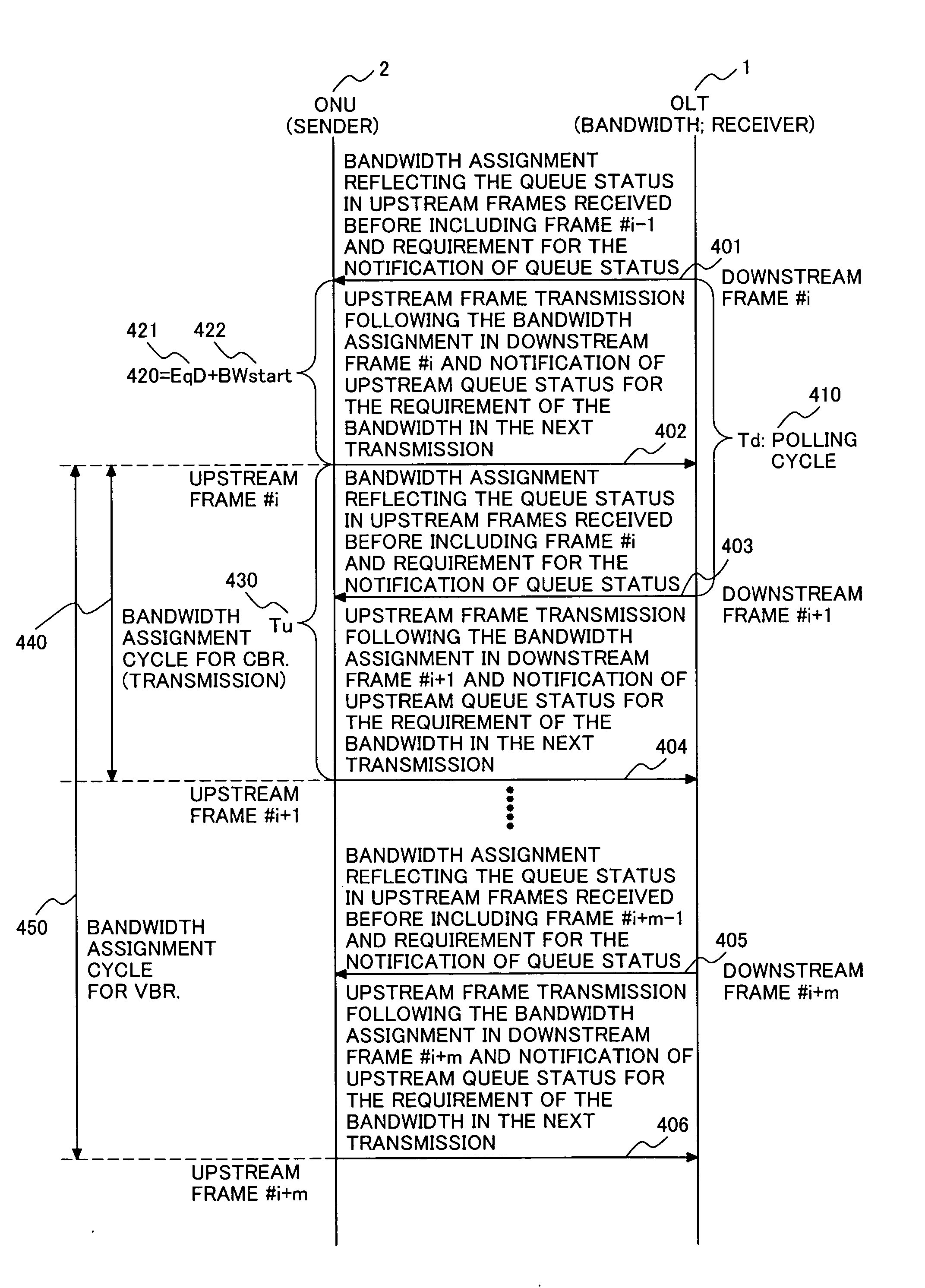

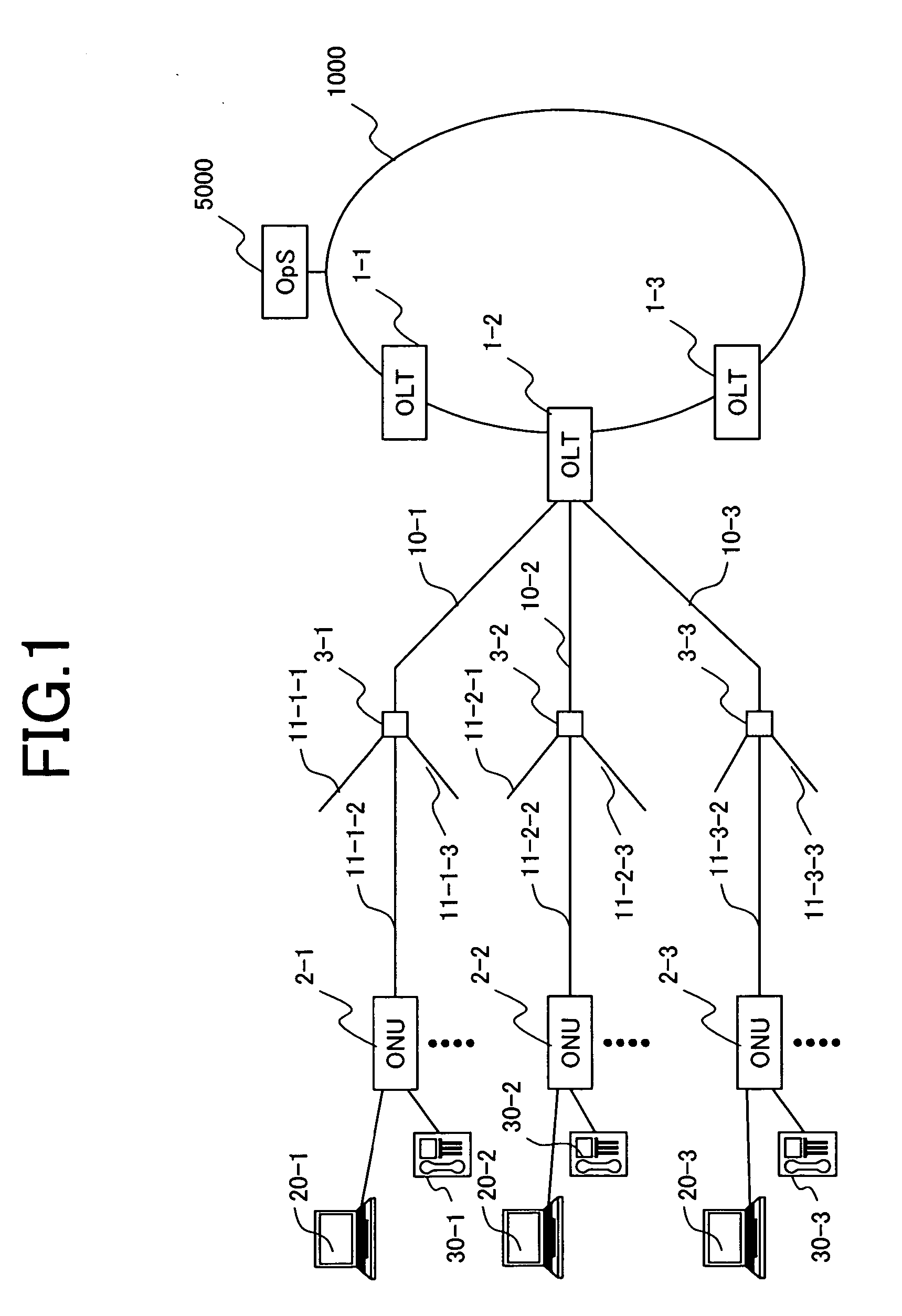

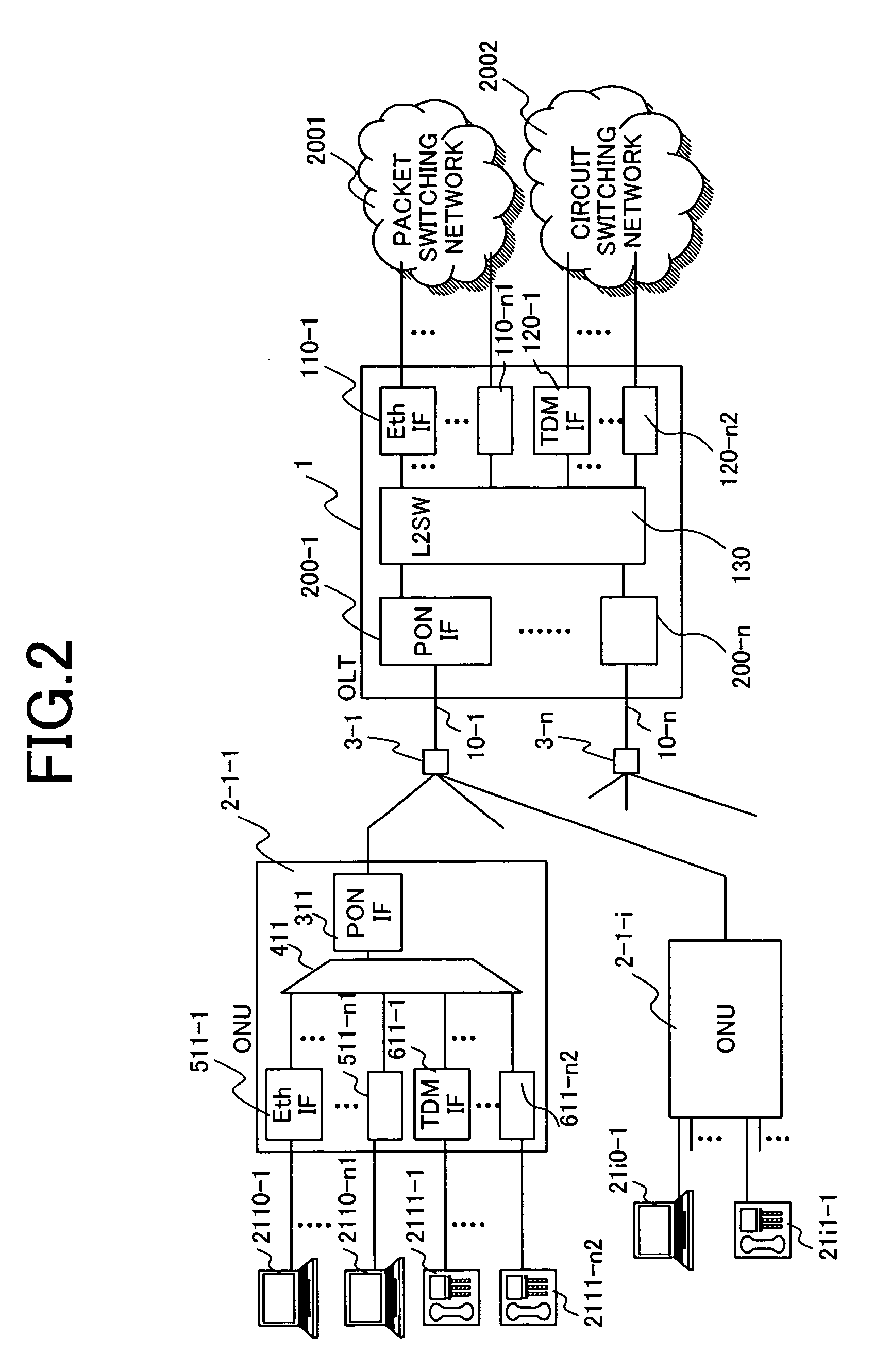

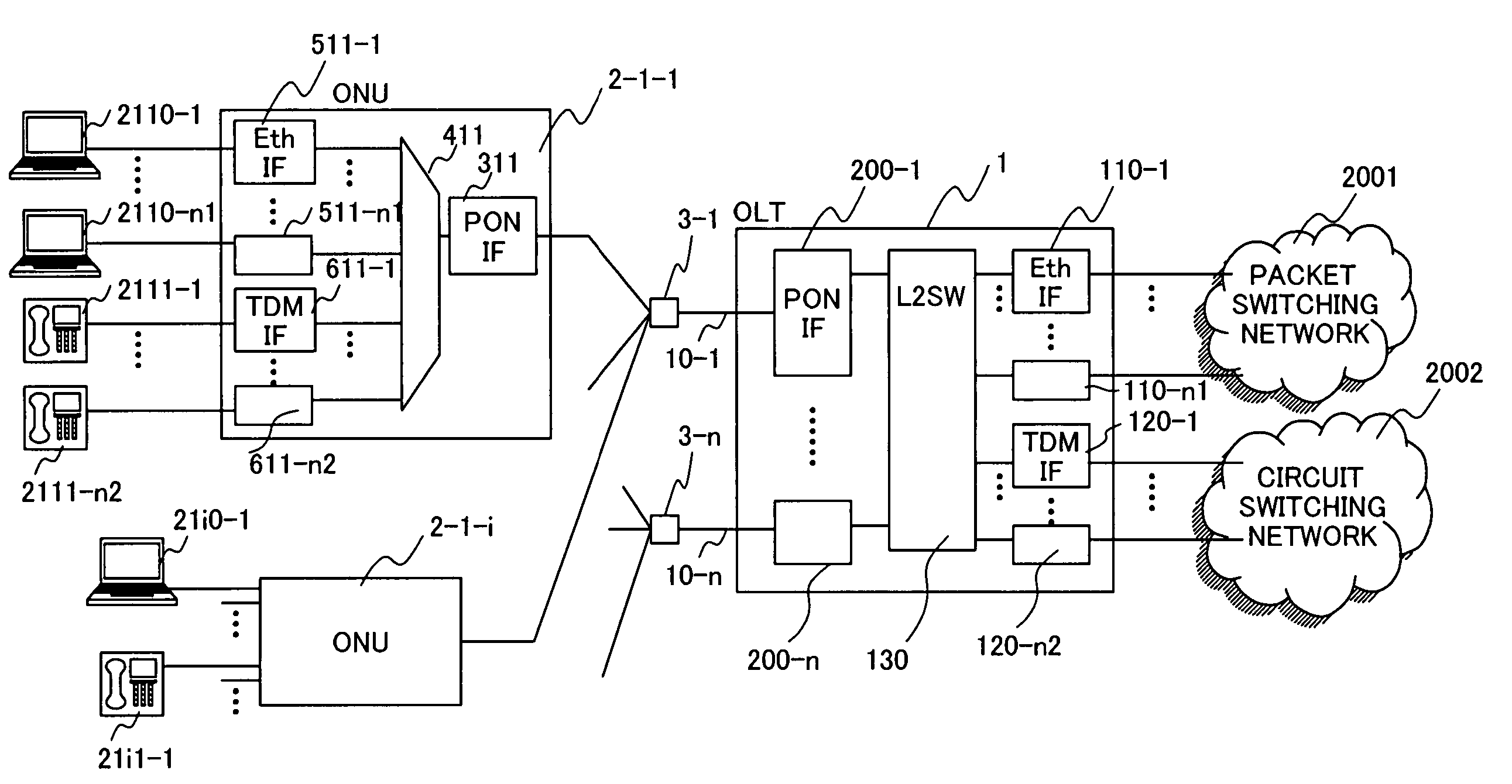

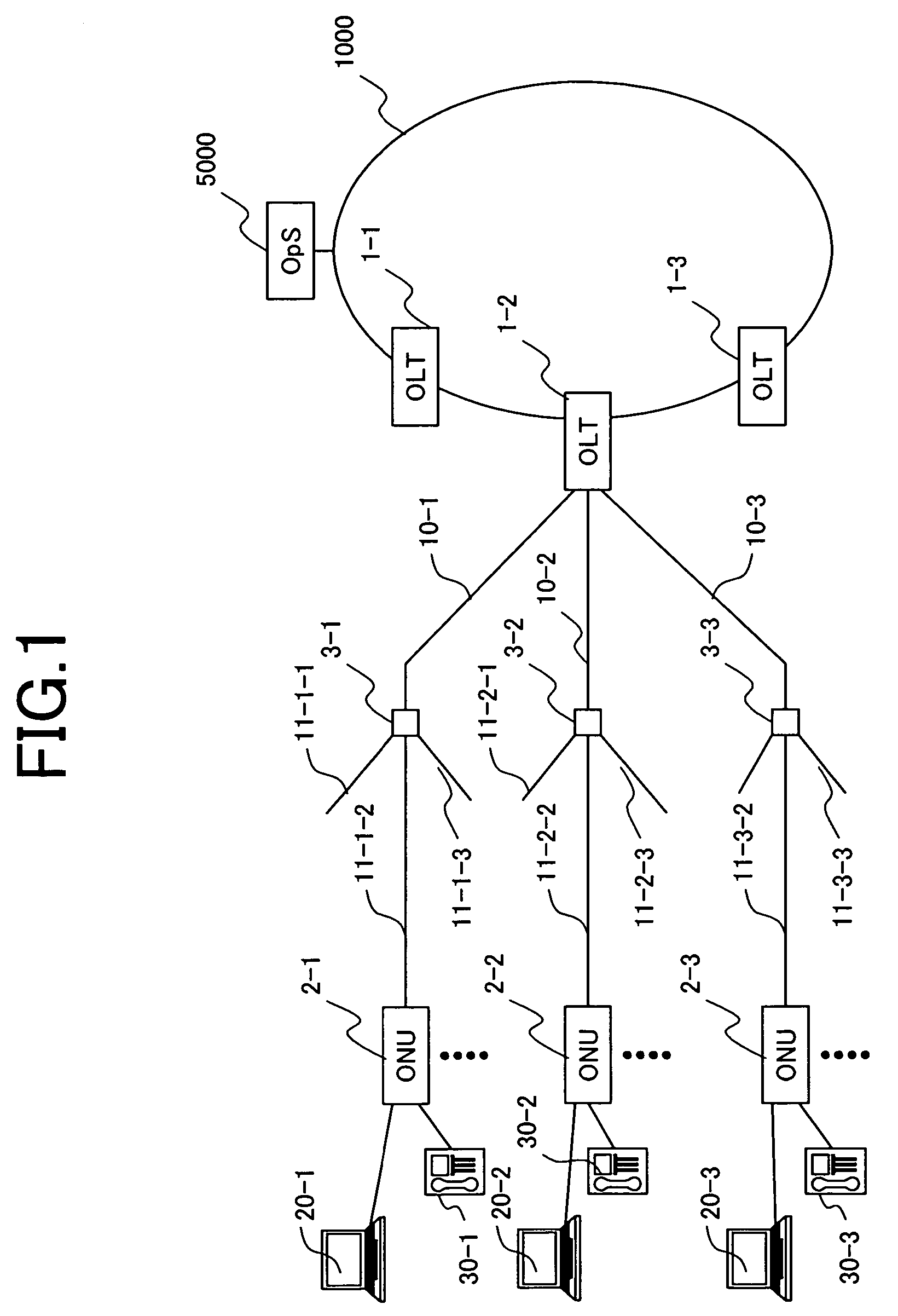

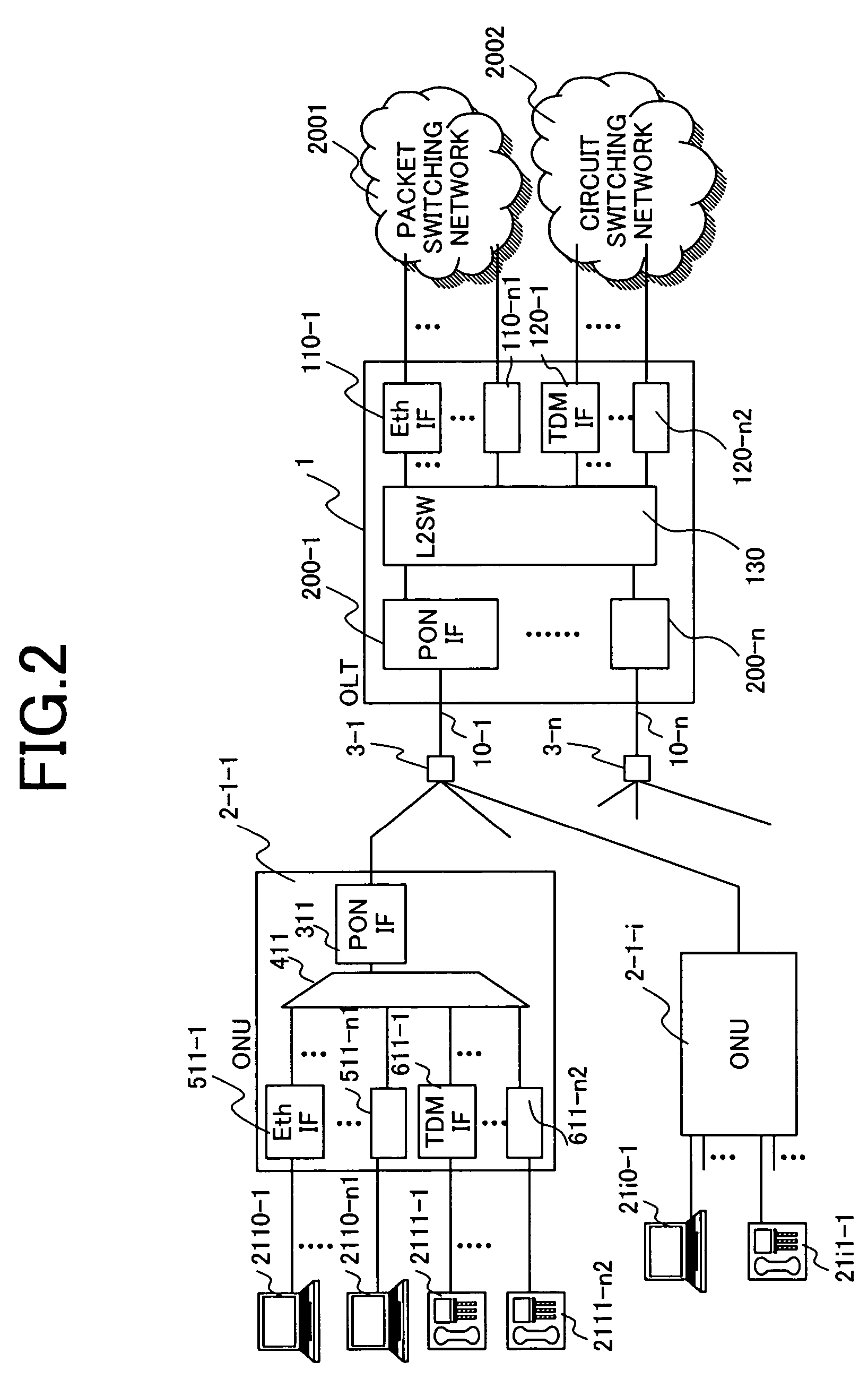

Transmission apparatus with function of multi-step bandwidth assignment to other communication apparatuses

InactiveUS20070064731A1Flexible bandwidth controlEliminating fluctuation in time slot positionTime-division multiplexStar/tree networksTerminal equipmentTransmission quality

Owner:HITACHI LTD

Transmission apparatus with function of multi-step bandwidth assignment to other communication apparatuses

InactiveUS7620325B2Low processing efficiencyLow efficiencyTime-division optical multiplex systemsTime-division multiplexTerminal equipmentTransmission quality

Owner:HITACHI LTD

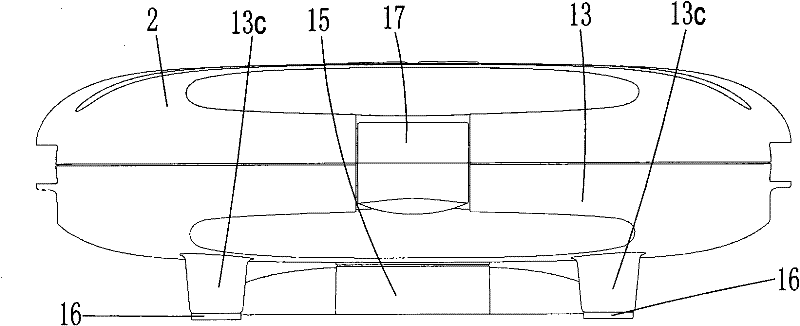

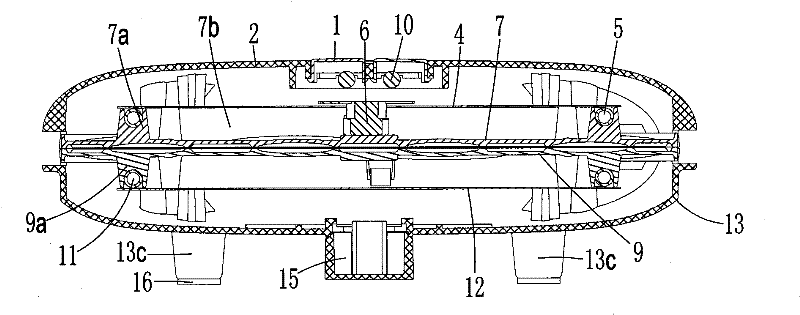

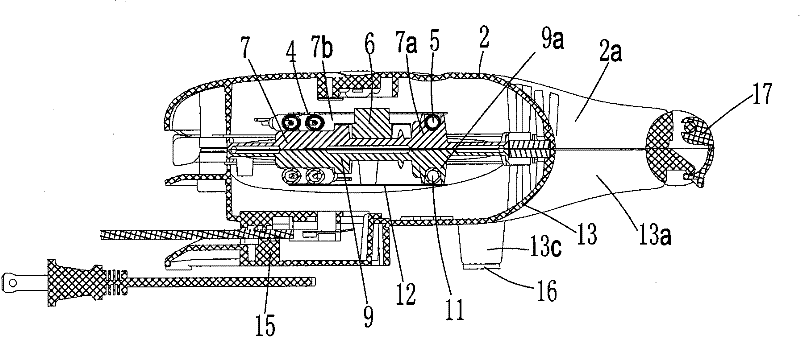

Splitting electrothermal waffle machine

InactiveCN102178465AEasy to carryReasonable structural designRoasters/grillsEngineeringTongue blades

The invention discloses a splitting electrothermal waffle machine, comprising an upper heating disc and a lower heating disc which are in joint fit with each other in a vertical direction and the right ends of which are articulated with each other, wherein the bottom of the lower heating disc is equipped with a lower casing, the top of the upper heating disc is equipped with an upper casing, the upper part of the upper heating disc is provided with an upper boss body which is equipped with an upper heating tube thereon; the lower part of the lower heating disc is provided with a lower boss body which is equipped with a lower heating tube thereon; the left end of the lower casing is provided with a lower tongue blade body stretching forwards, the tip of the lower tongue blade body is rotatably equipped with a latch; the left end of the upper casing is provided with an upper tongue blade body stretching forwards, and the other end of the latch can be fitted, in a buckled manner, with the tip of the upper tongue blade body; the entire splitting electrothermal waffle machine has the concise appearance of pointed tongue, and is convenient in carrying; the contact face of the upper and lower heating discs is provided with eight biscuit slots so that a plurality of biscuits can be baked at one time, so the processing efficiency is high; the biscuit slots are designed to be shallow, which is convenient for cleaning; the heating tubes are simultaneously disposed to achieve rapid heating, thus the effect of eating while baking can be realized; and two neon lamps are arranged transversely on the top surface of the upper casing, improving the operation of users.

Owner:宁波亿达电器有限公司

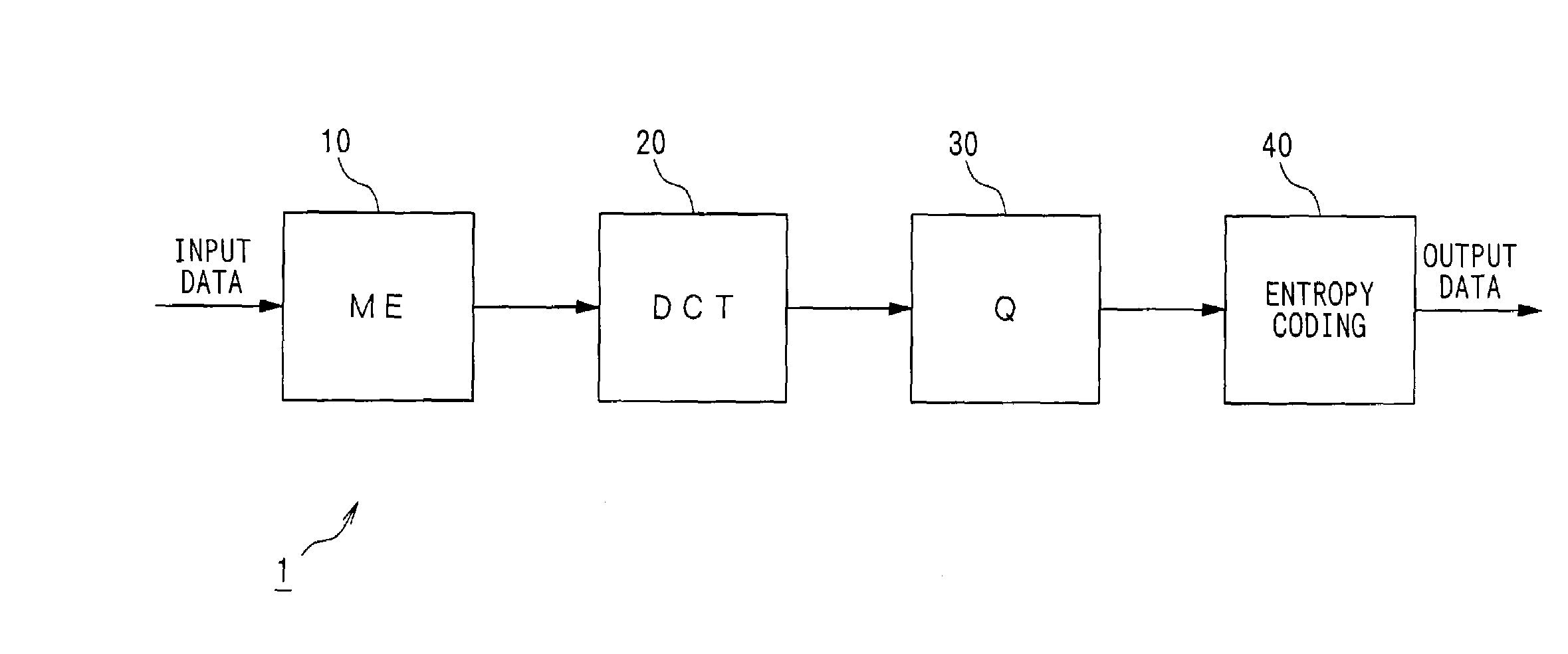

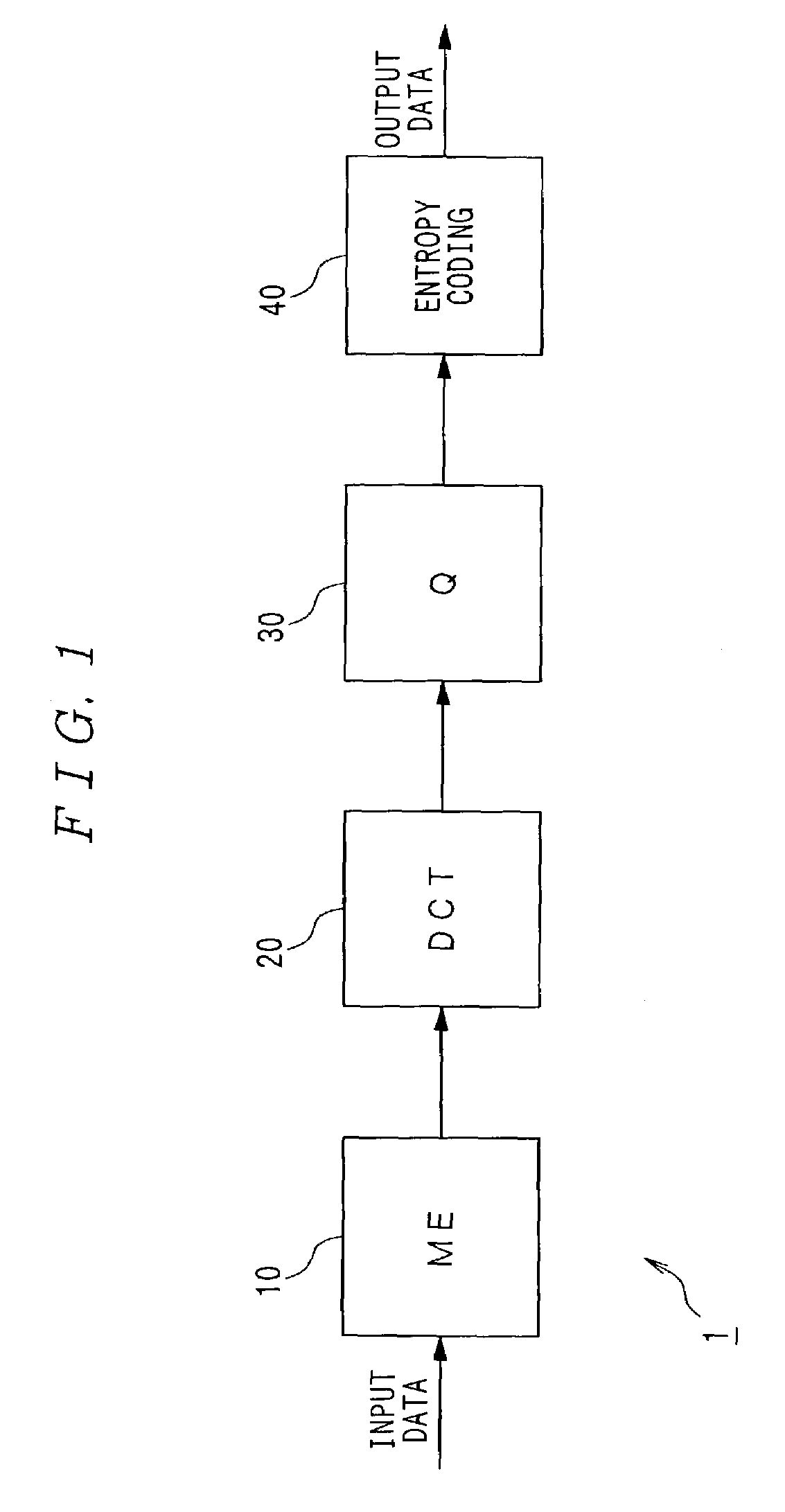

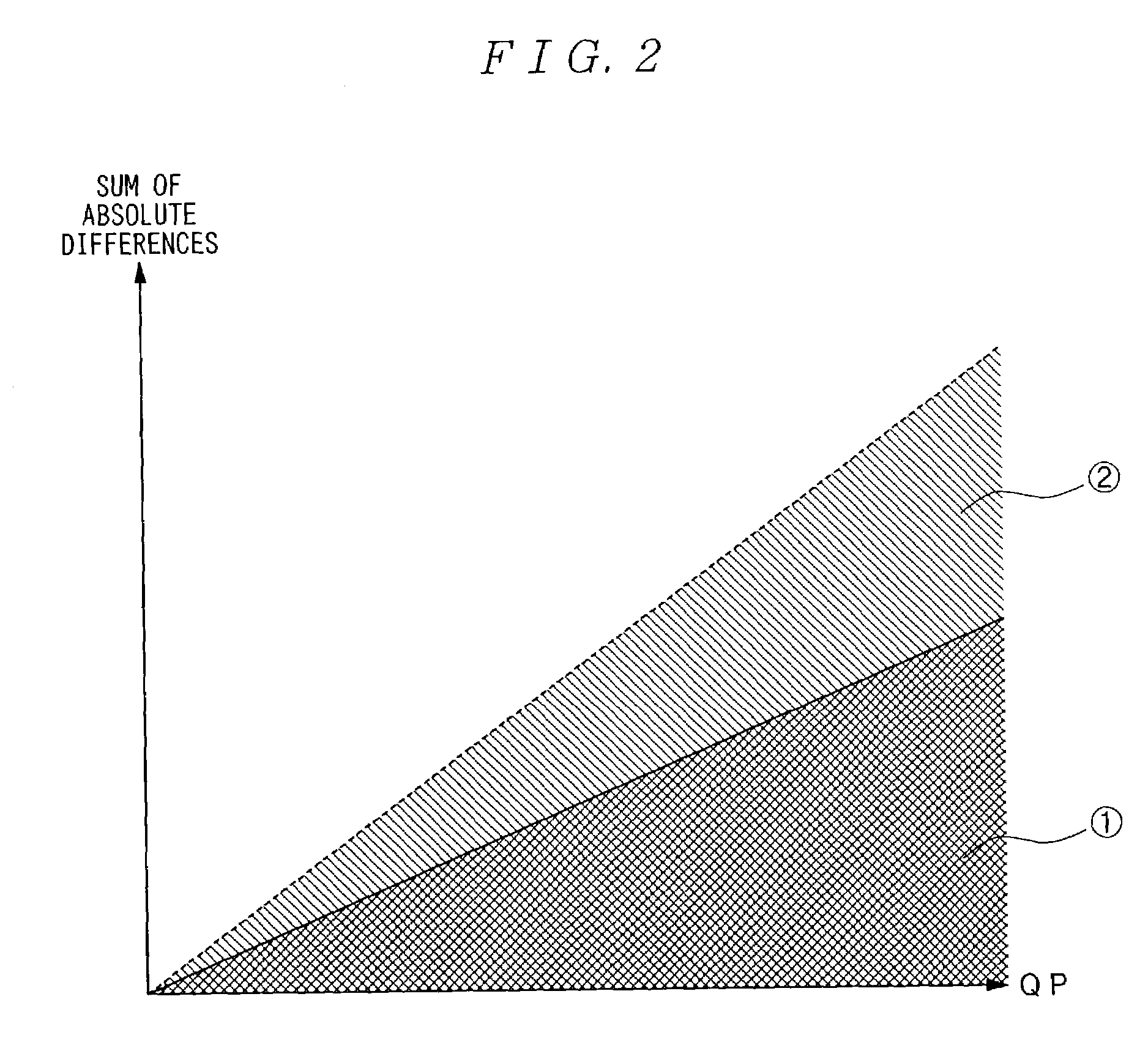

Moving picture coding method, moving picture coding apparatus, and moving picture coding program

ActiveUS7116713B2Efficiently determinedQuality improvementPicture reproducers using cathode ray tubesCode conversionMotion vectorComputer graphics (images)

To provide a process for coding the moving picture with higher speed and enhanced efficiency. The present invention provides a moving picture coding method for coding a moving picture of processing object through a predetermined process including a motion estimating process, determining whether or not the predetermined process (e.g., DCT process and quantization process) for a block of processing object can be omitted on the basis of the information regarding a difference between the block and a reference block of a frame to be referenced in coding (i.e., a frame to be referenced in making the motion vector detection), and a quantization parameter for use in a quantization process of the moving picture, performing the predetermined process if it is determined that the predetermined process can not be omitted, and omitting the predetermined process if it is determined that the predetermined process can be omitted and making a set defined value the result of the predetermined process for the block.

Owner:GK BRIDGE 1

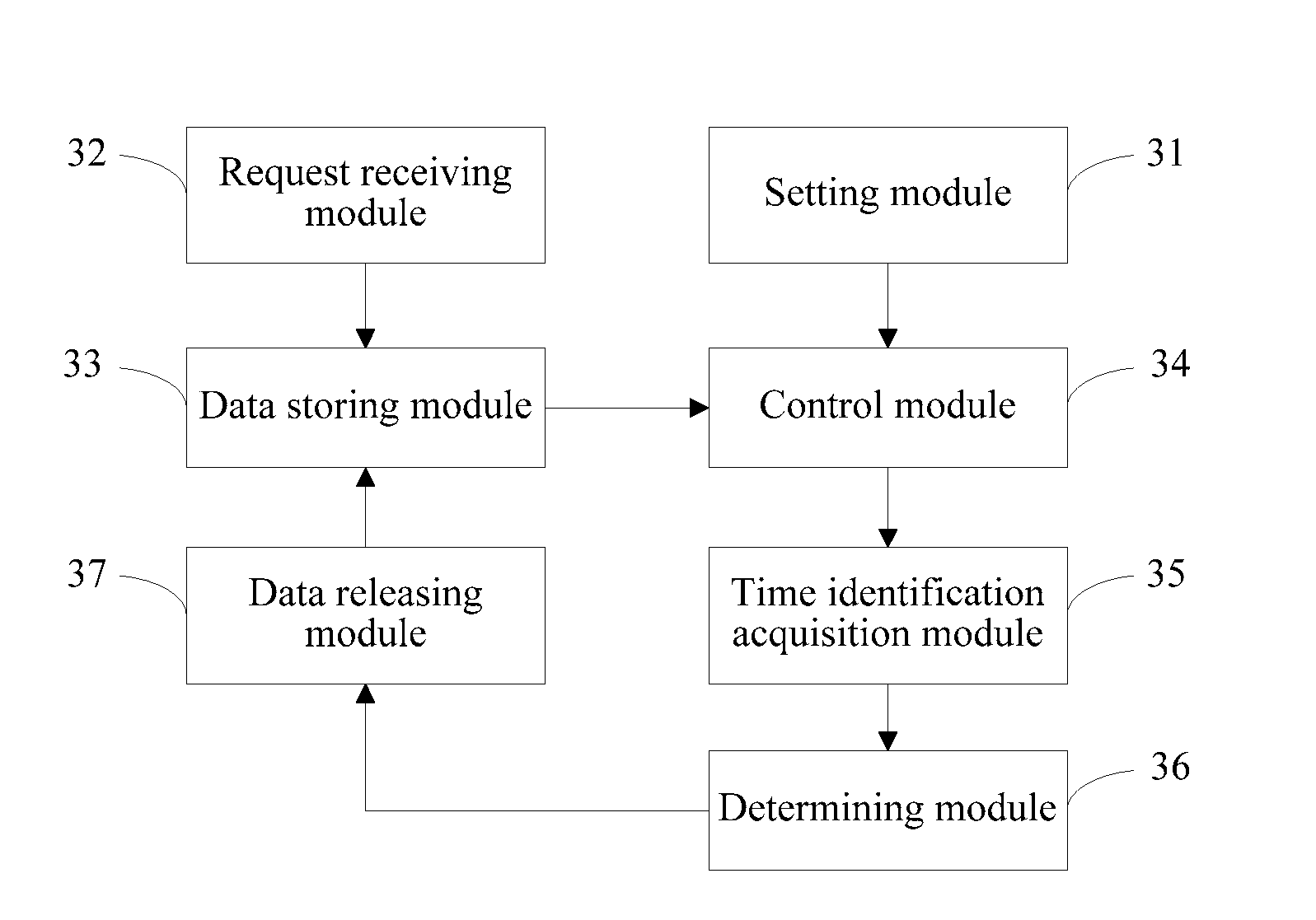

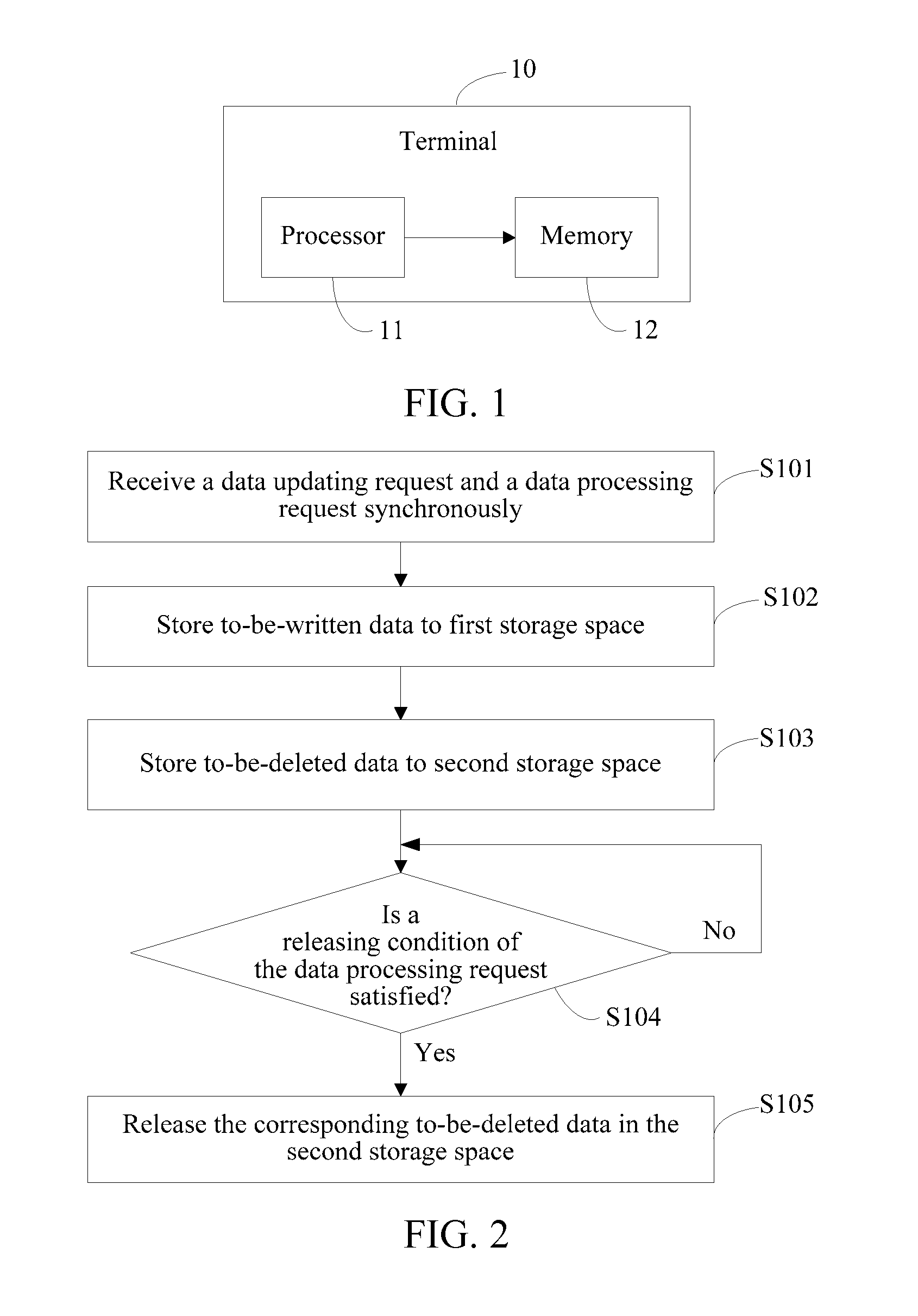

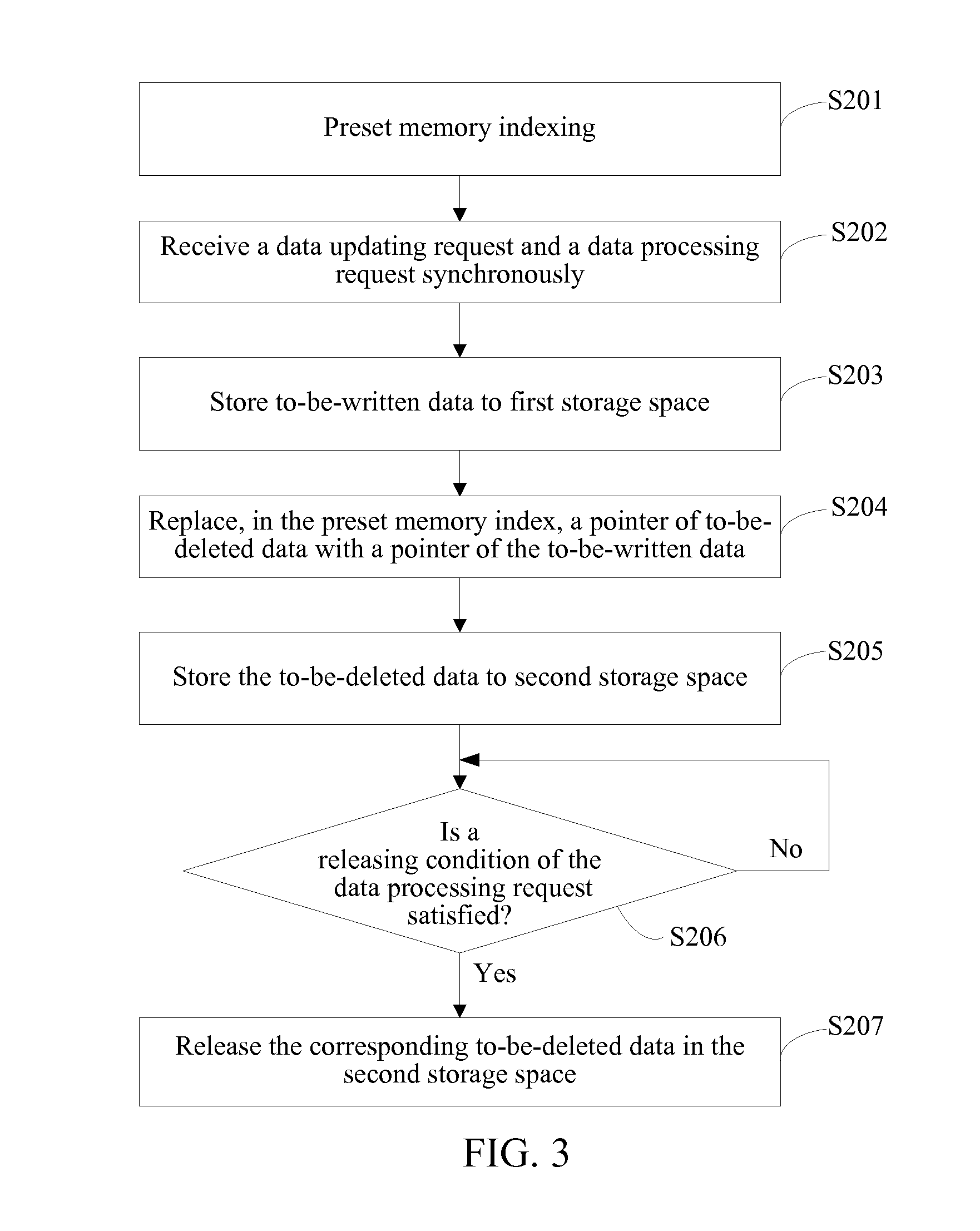

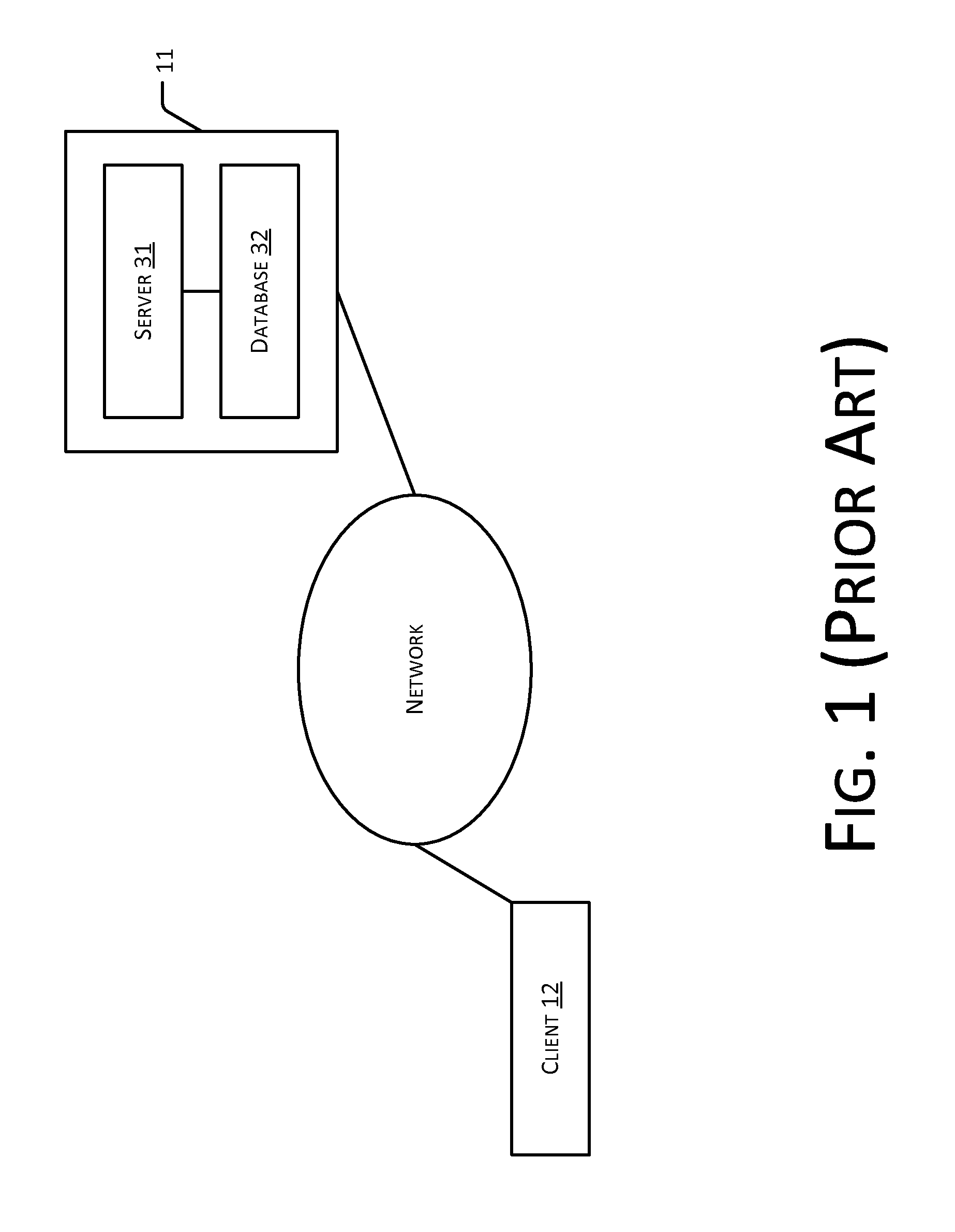

Data processing method, apparatus, and storage medium

InactiveUS20150213105A1Small footprintImprove processing effectivenessDatabase updatingDigital data processing detailsDocumentationData processing

A data updating request and a data processing request may be synchronously received. The data updating request may replace to-be-deleted data with to-be-written data, while the data processing request may operate using the to-be-deleted data. The solutions described throughout the present document facilitate execution of the two conflicting requests in parallel, substantially simultaneously, and synchronously, for example on respective threads. To facilitate the execution of the two requests, the to-be-written data may be stored to a first storage space, the to-be-deleted data may be stored to a second storage space, and the to-be-deleted data in the second storage space may be released if execution of the data processing request that meets a releasing condition is completed. The respective threads may synchronize with each other by postponing the release of memory. Thus, the two requests may execute synchronously and substantially simultaneously and consequently improving processing efficiency without occupying significant memory space.

Owner:TENCENT TECH (SHENZHEN) CO LTD

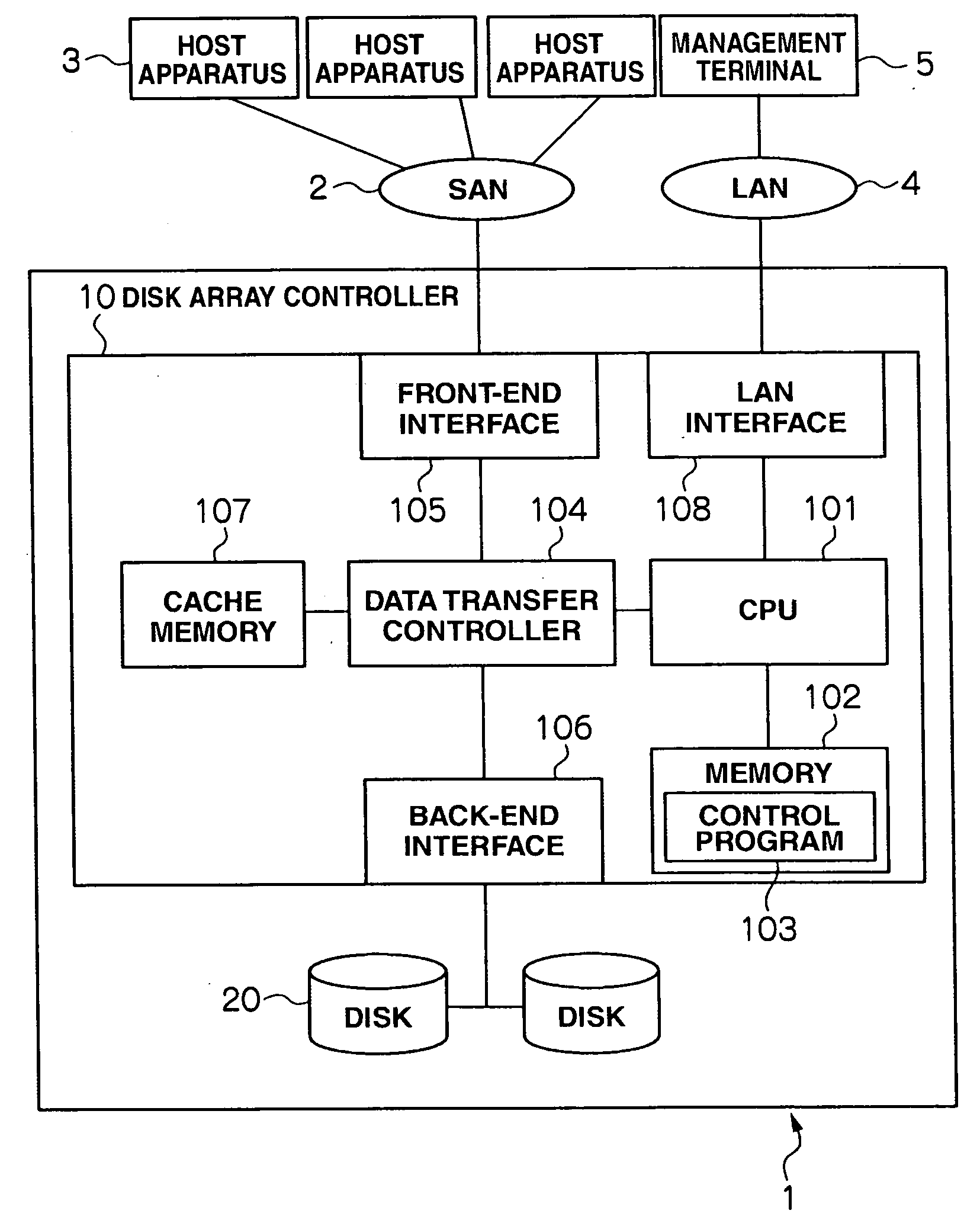

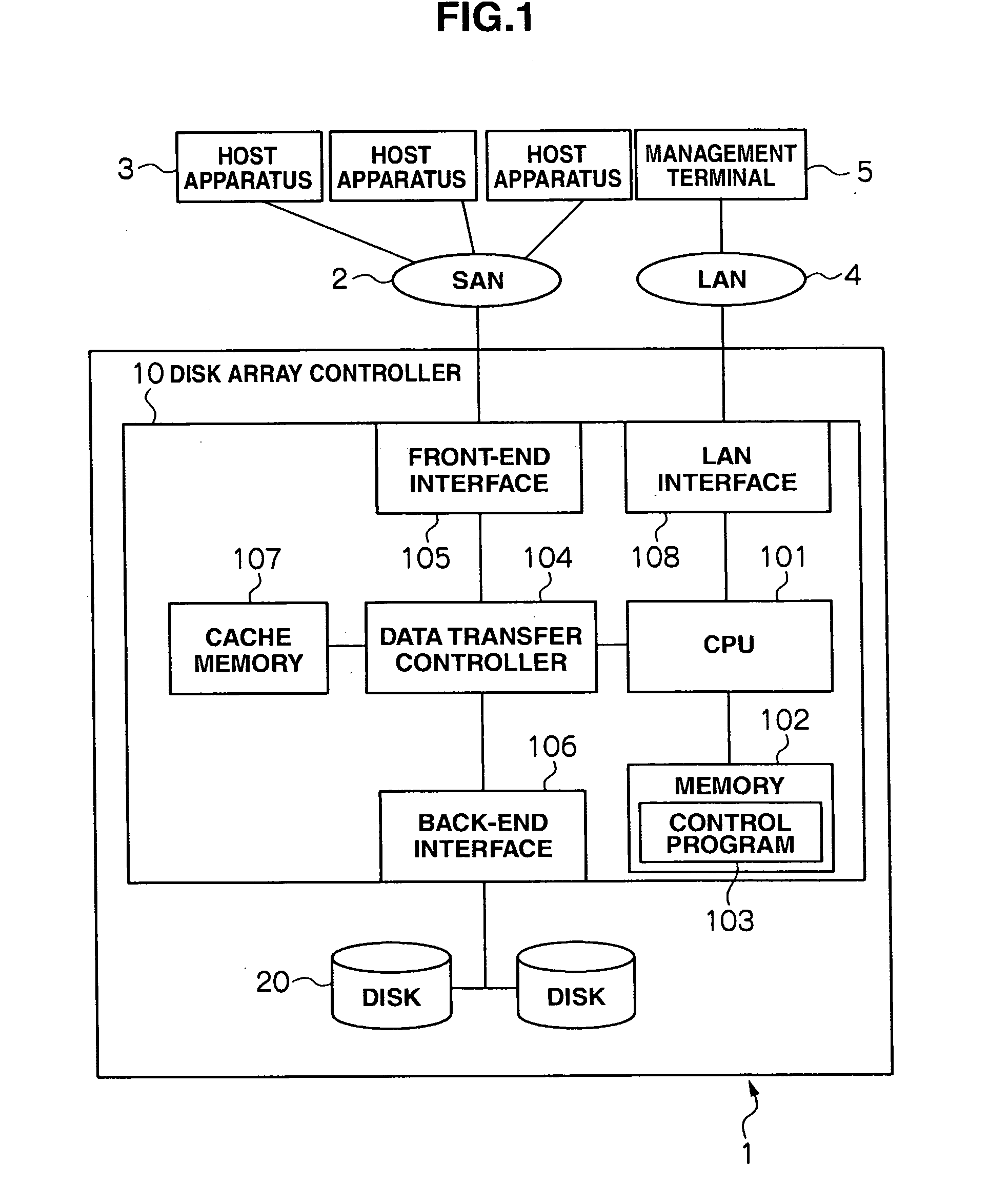

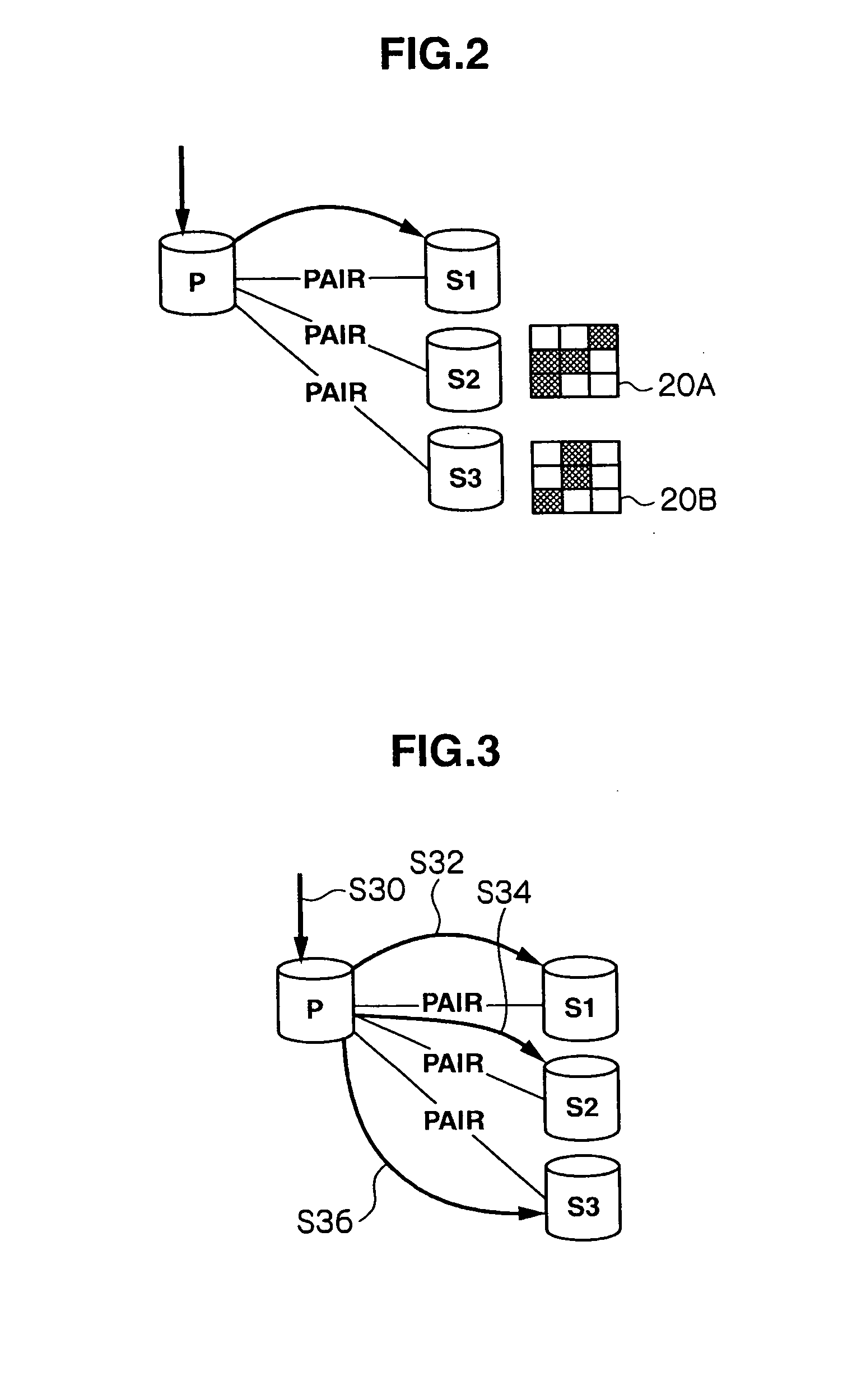

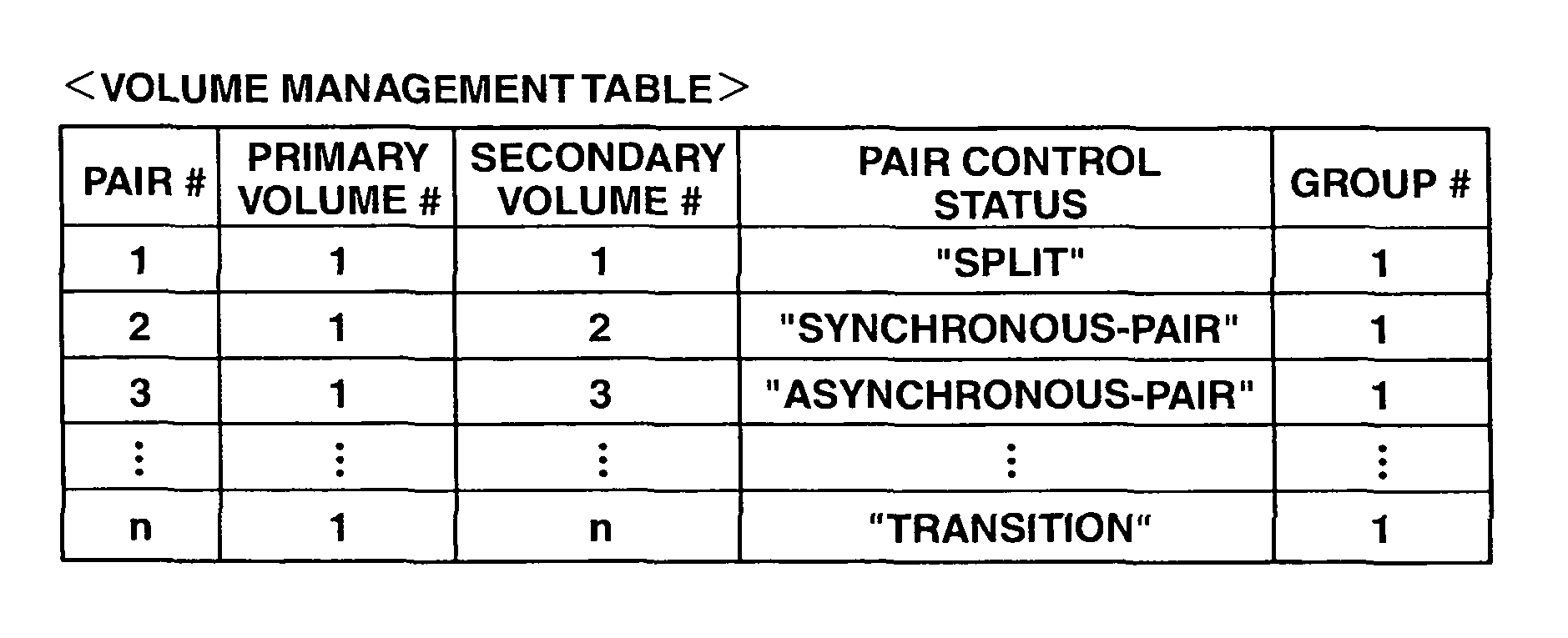

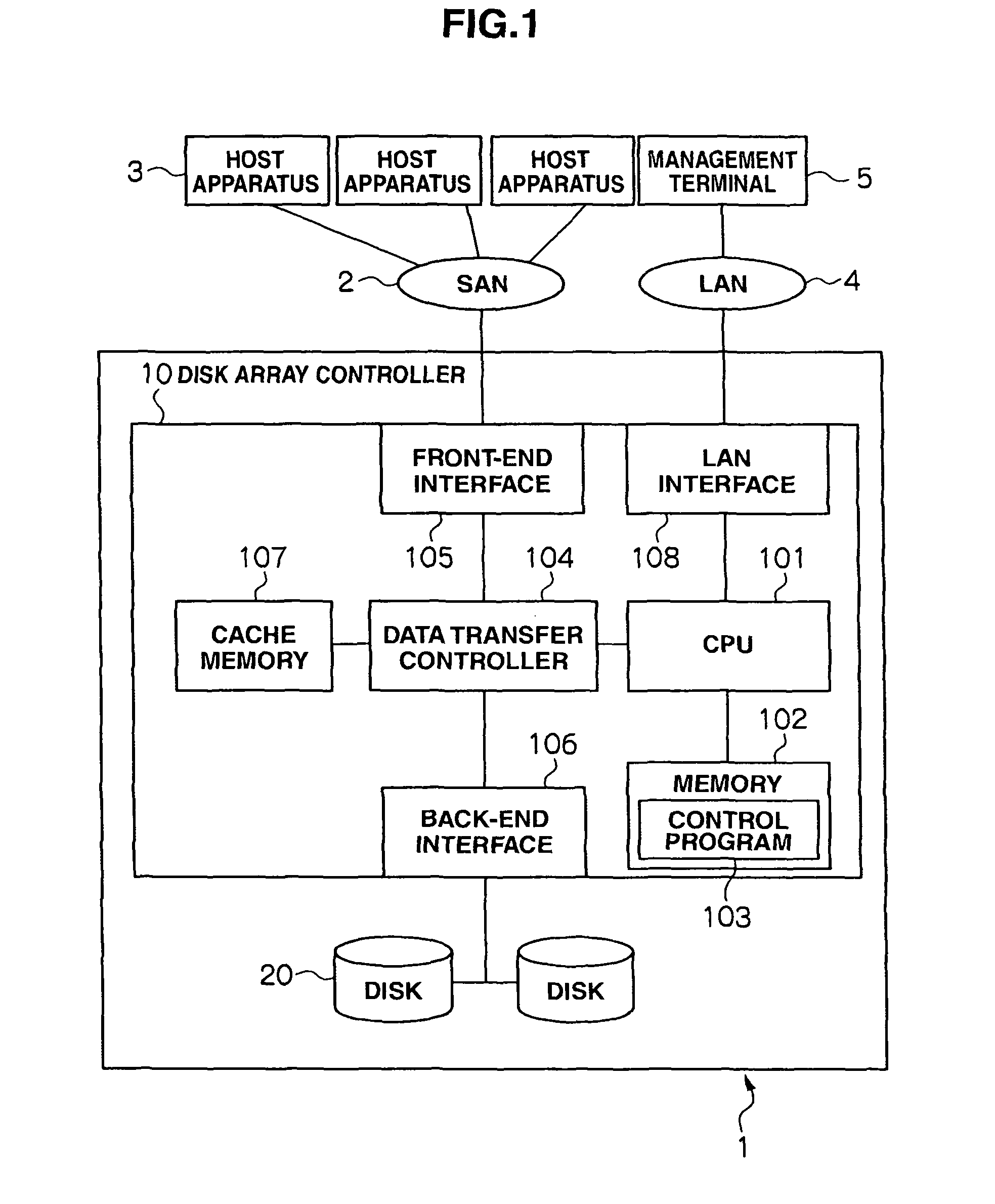

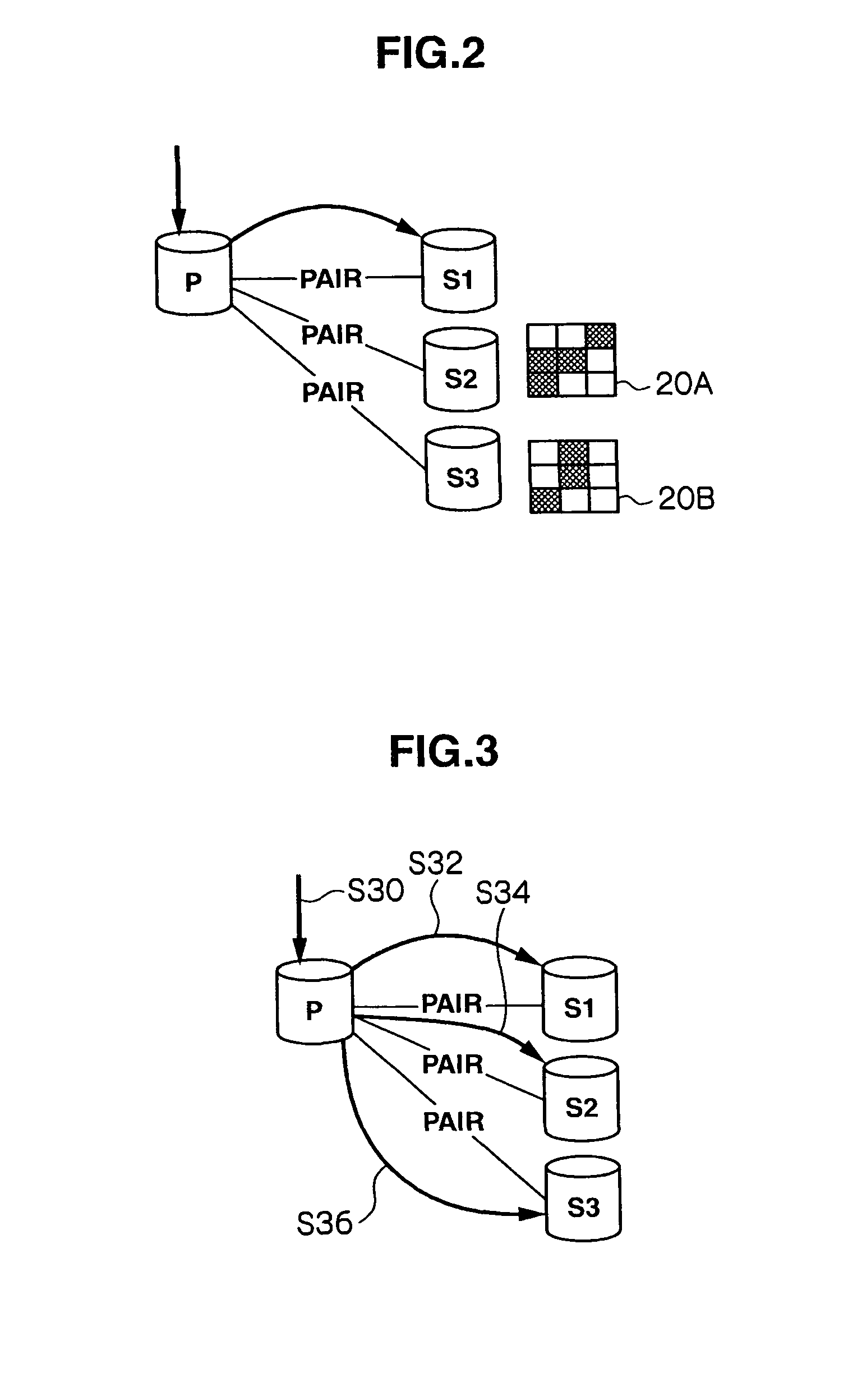

Storage apparatus, and storage control method using the same

InactiveUS20080168240A1Solve the processing efficiency is not highLow efficiencyError detection/correctionMemory systemsBitmapData consistency

The present invention aims at providing a storage apparatus that does not increase the I / O load on a primary volume, even if there are several secondary volumes for which data consistency with the primary volume should be guaranteed. A storage apparatus writes write data for write access directed to a primary volume P to a secondary volume S1. A controller in the storage apparatus copies that write data from the secondary volume S1 to secondary volumes. S2 and S3 in background processing. The storage apparatus uses bitmaps to manage data in the secondary volume S1 shared by each of the secondary volumes S2 and S3.

Owner:HITACHI LTD

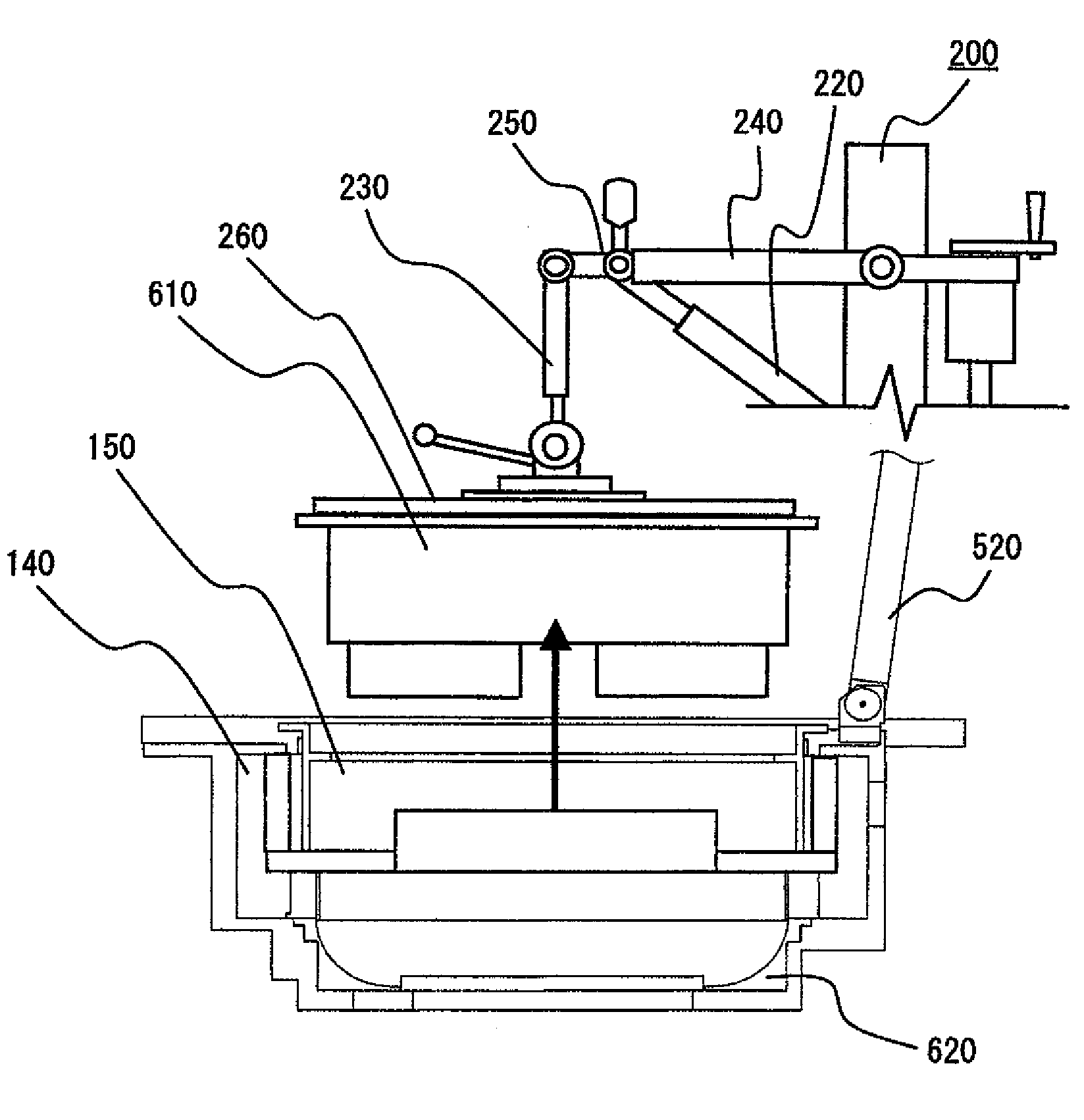

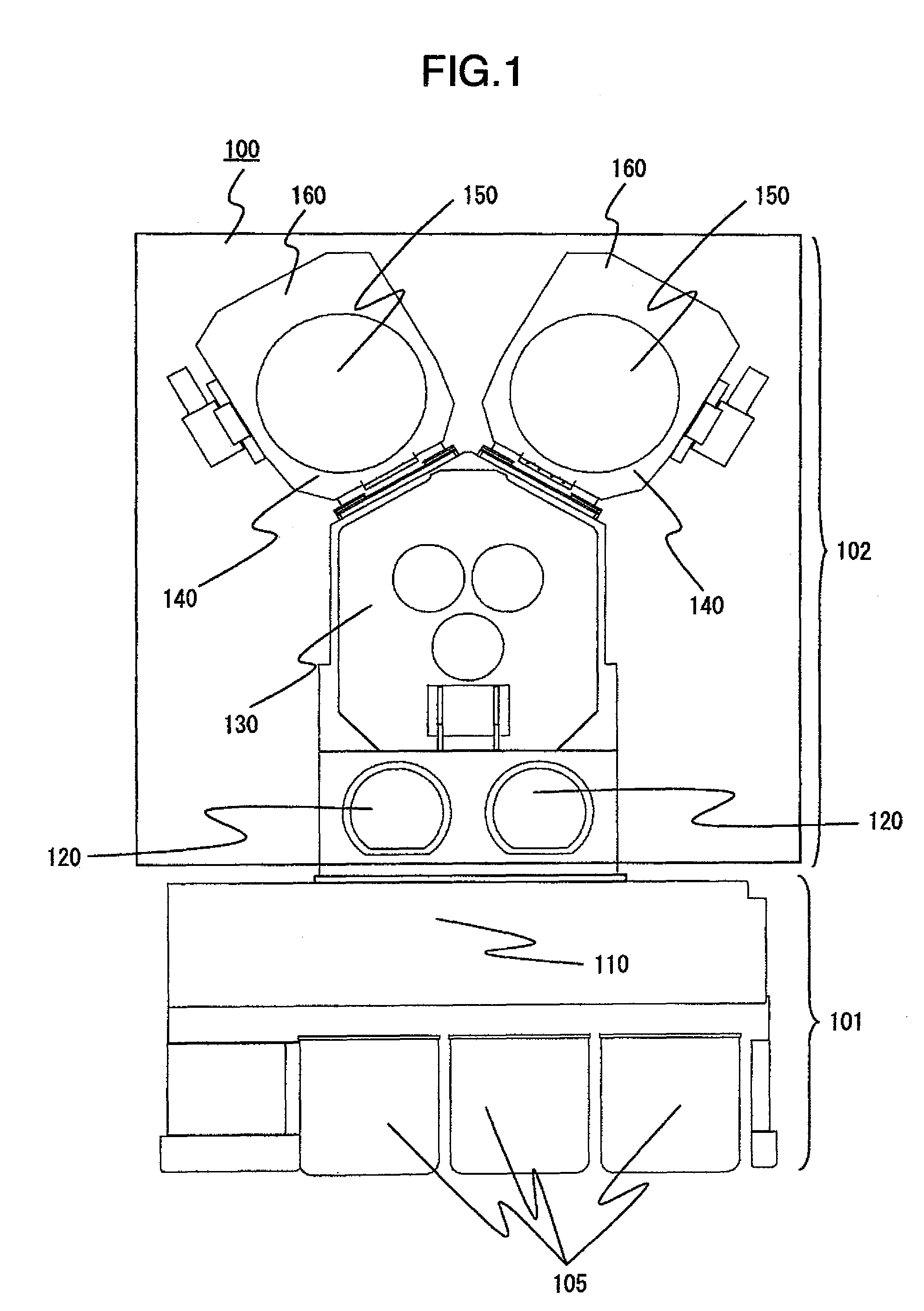

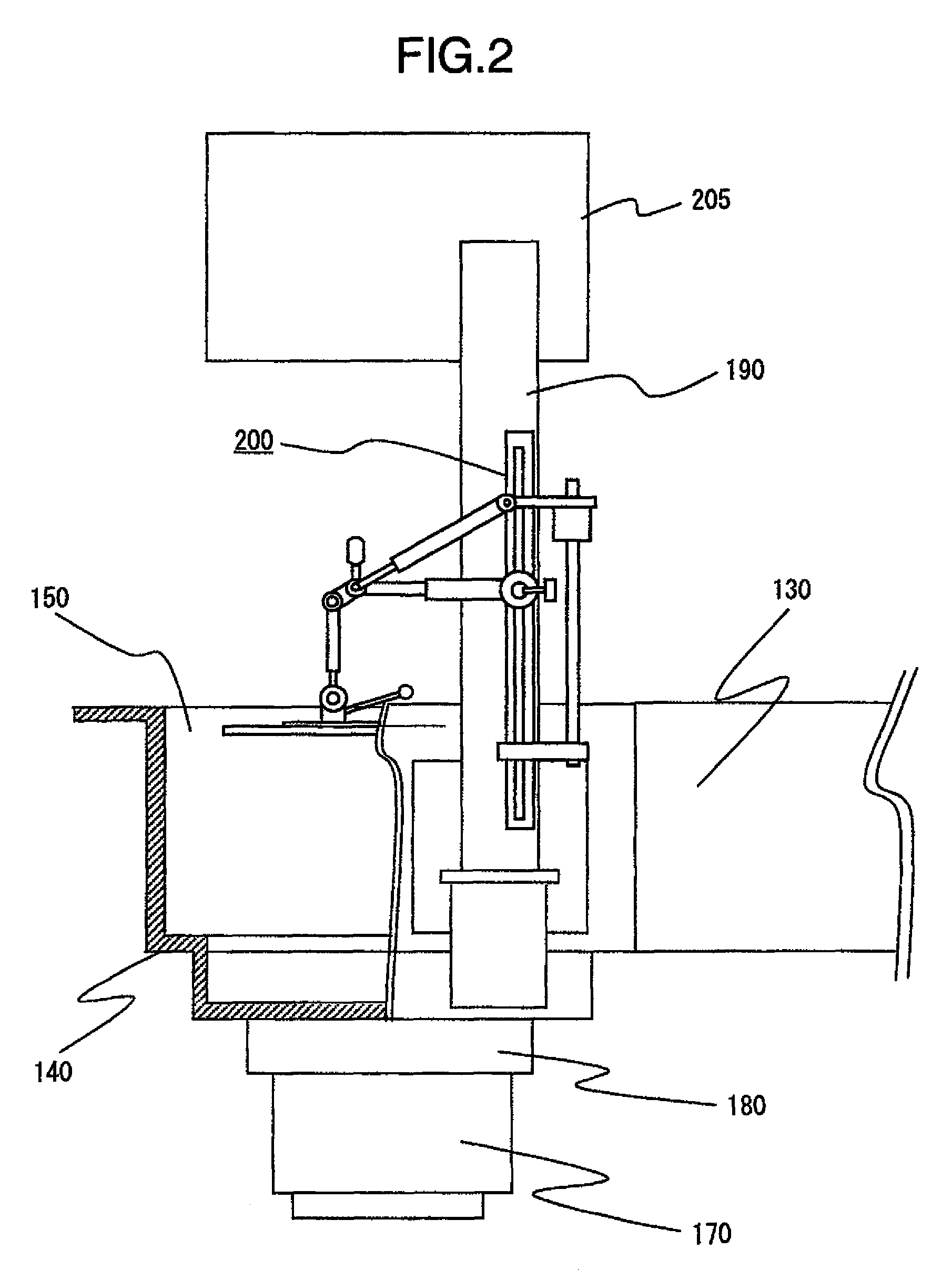

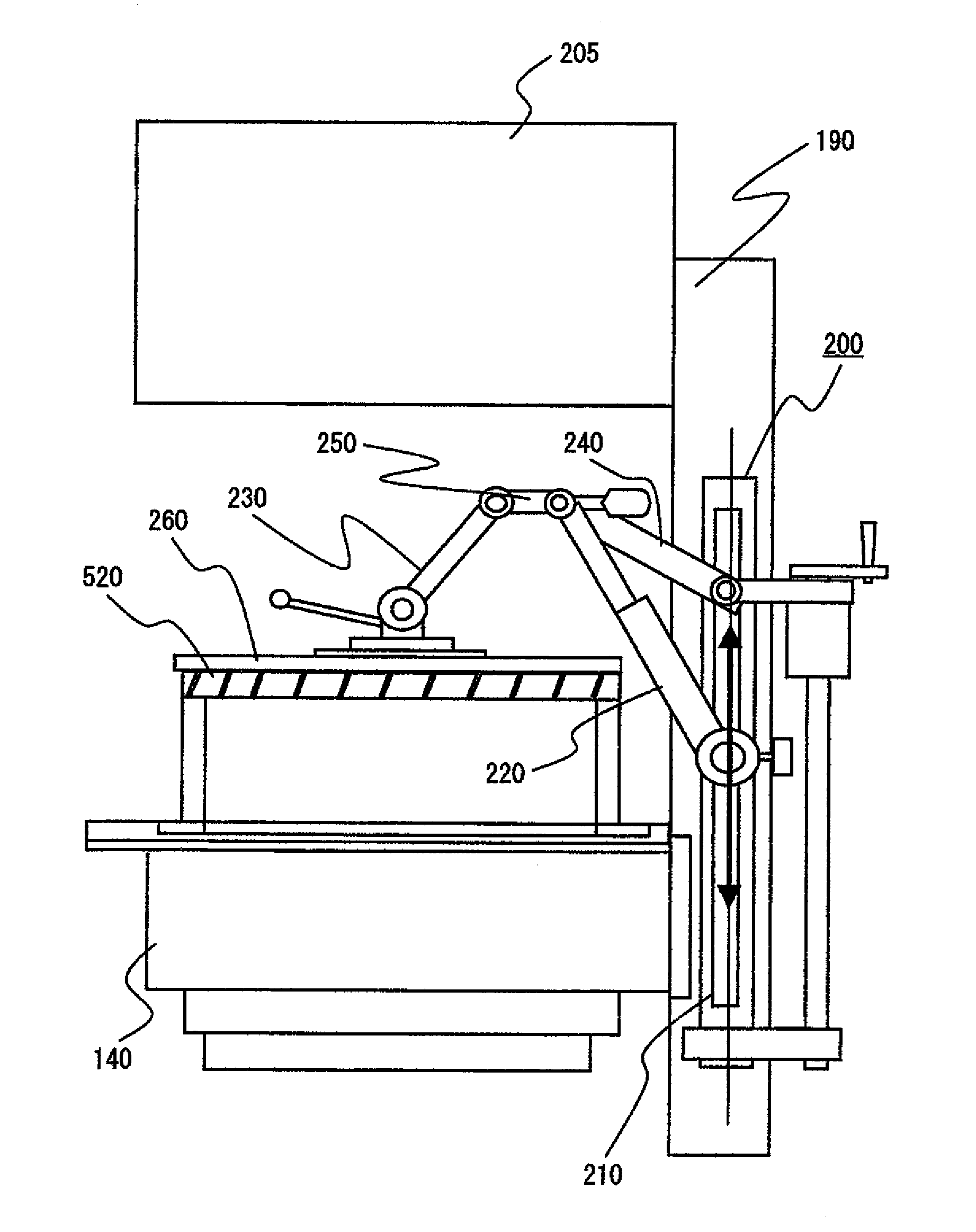

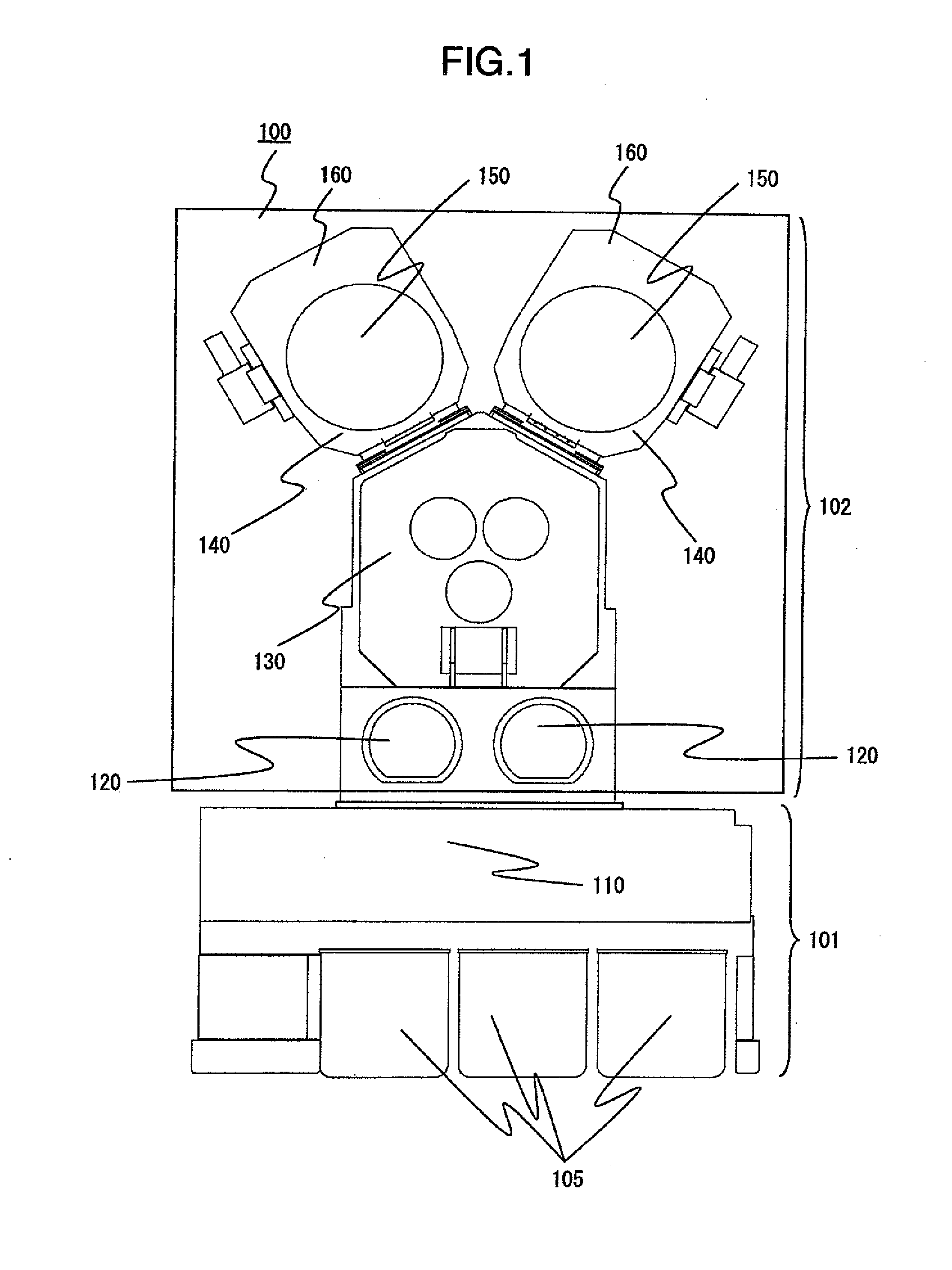

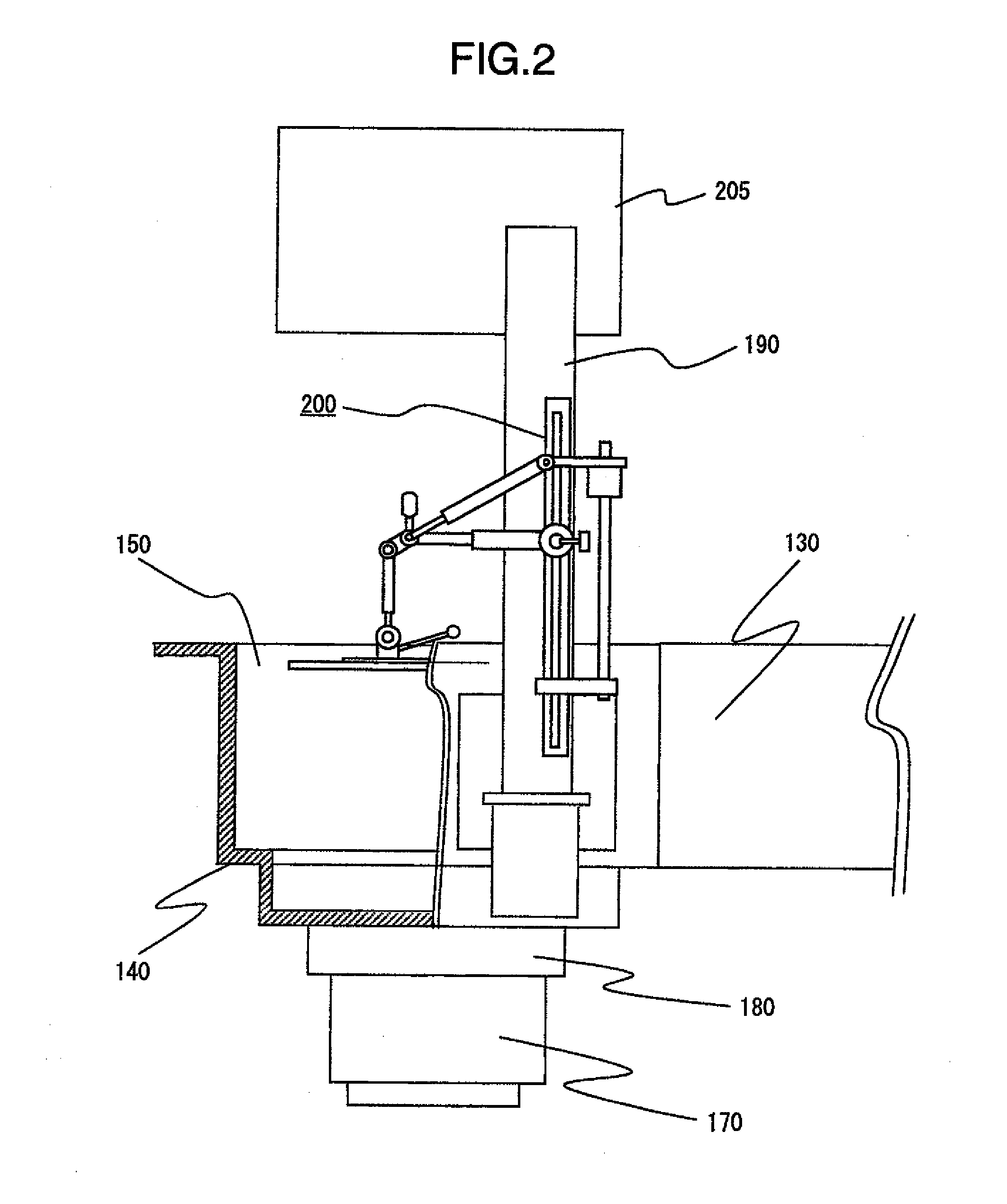

Vacuum processing apparatus

ActiveUS8366370B2Extended service lifeReduce CoC (cost of consumer)Semiconductor/solid-state device manufacturingConveyor partsHorizontal axisEngineering

Owner:HITACHI HIGH-TECH CORP

Vacuum processing apparatus

ActiveUS20110176893A1Extended service lifeReduce work efficiencySemiconductor/solid-state device manufacturingStorage devicesHorizontal axisEngineering

A vacuum processing apparatus includes a transfer container for transferring a wafer in the internal space thereof reduced in pressure, a vacuum vessel coupled to the side wall of the vacuum vessel and including a processing chamber having a sample stage therein on which a wafer to be processed is mounted, a lid member opened or closed by rotation above the vacuum vessel, an inner chamber member arranged in the vacuum vessel and making up the inner wall of the processing chamber, and a jig coupled to the side wall of the vacuum vessel to lift and hold the inner chamber member by being coupled thereto. The jig includes a first joint portion having vertical and horizontal shafts, an extensible arm portion rotatable around each shaft of the first joint portion, and a second joint portion with the inner chamber member adapted to rotate around the horizontal axis thereof.

Owner:HITACHI HIGH-TECH CORP

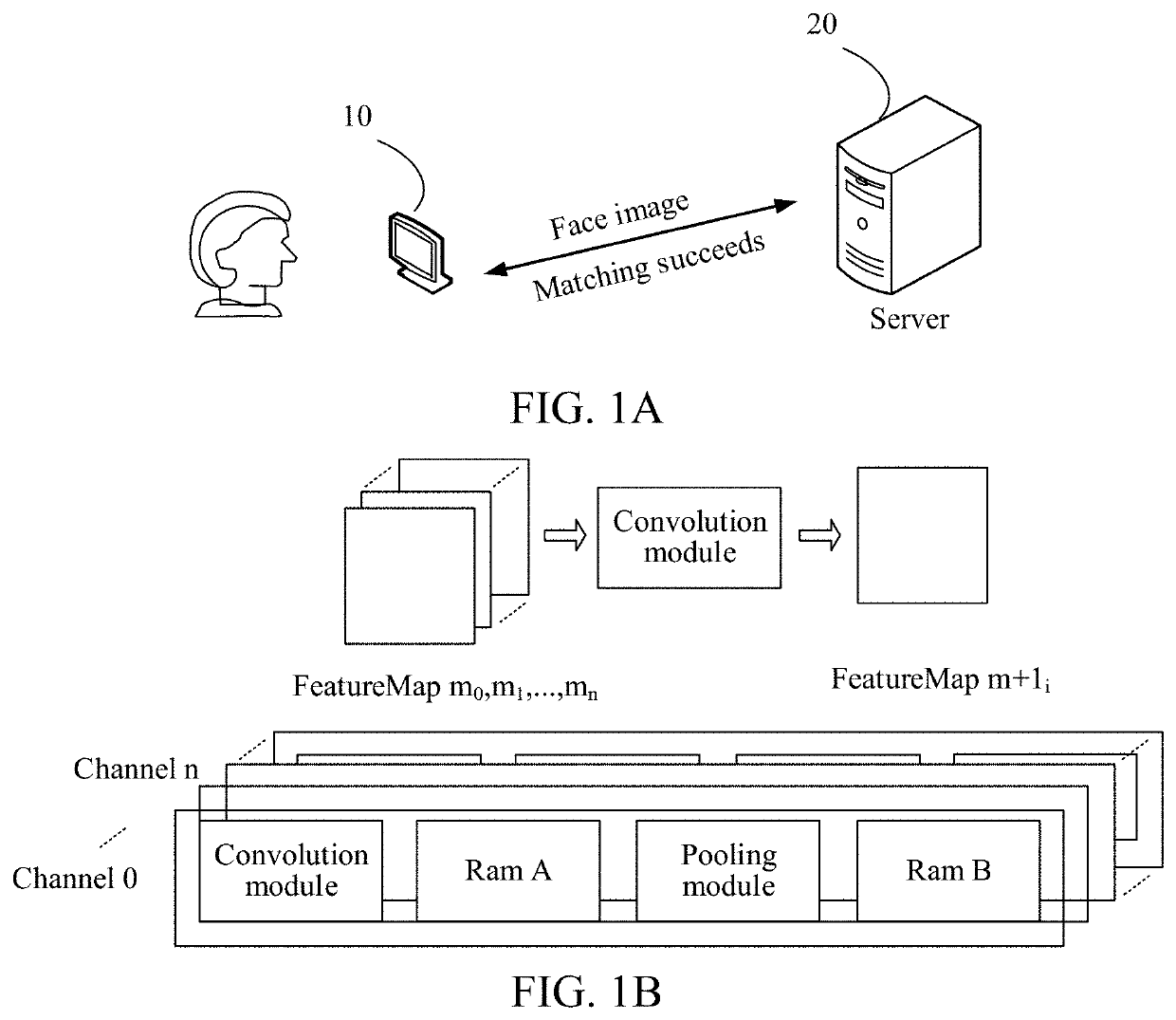

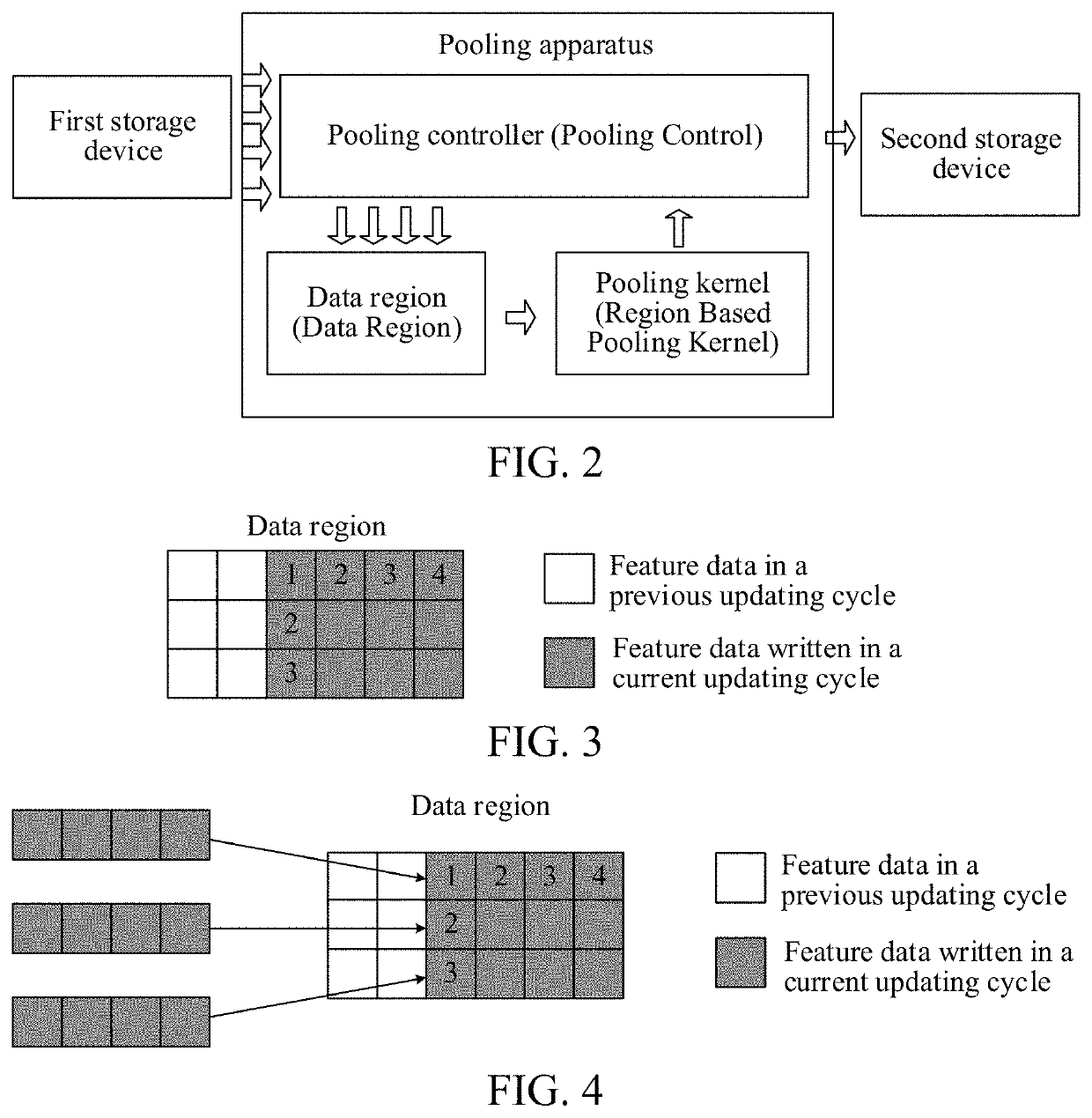

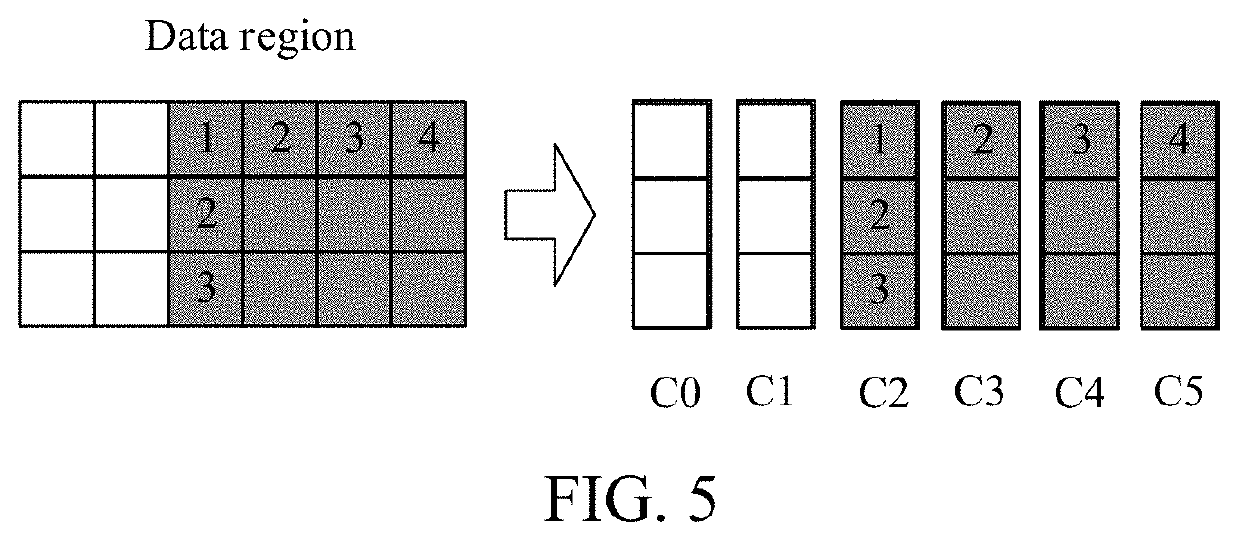

Pooling processing method and system applied to convolutional neural network

ActiveUS20200074289A1Reduce in quantityImprove pooling efficiencyGeometric CADDesign optimisation/simulationData packEngineering

This application discloses a pooling processing method, applied to a pooling processing system of a convolutional neural network. The pooling processing system includes a first storage device, a data region, a pooling computation kernel, and a pooling controller. The method includes: reading, by the pooling controller, k pieces of feature data from the first storage device in each reading cycle, the k pieces of feature data being components in a feature map generated by a convolution operation of the convolutional neural network, and k being an integer greater than 1; writing, by the pooling controller, the k pieces of feature data read from the first storage device into the data region, wherein the k pieces of feature data form one group among n groups of k pieces of data with each group arranged in a first dimension and the n groups arranged in a second dimension, wherein the n groups of k pieces of data are written into the data region in an updating cycle, wherein a duration of the updating cycle is n times a duration of the reading cycle, and wherein n cis an integer greater than 1; and transmitting, after the updating cycle is ended, data in the data region to the pooling computation kernel to perform a pooling operation, wherein the data in the data region comprises the n groups of k pieces of data and last m groups of data from a previous updating cycle with each group along the second dimension, wherein the last m groups of data are temporarily stored in the data region for use in pooling calculation by the pooling computation kernel in a next updating cycle. The technical solution in this application reduces the number of storage, numbers of reading and writing due to data reuses, and improves the efficiency of pooling processing.

Owner:TENCENT TECH (SHENZHEN) CO LTD

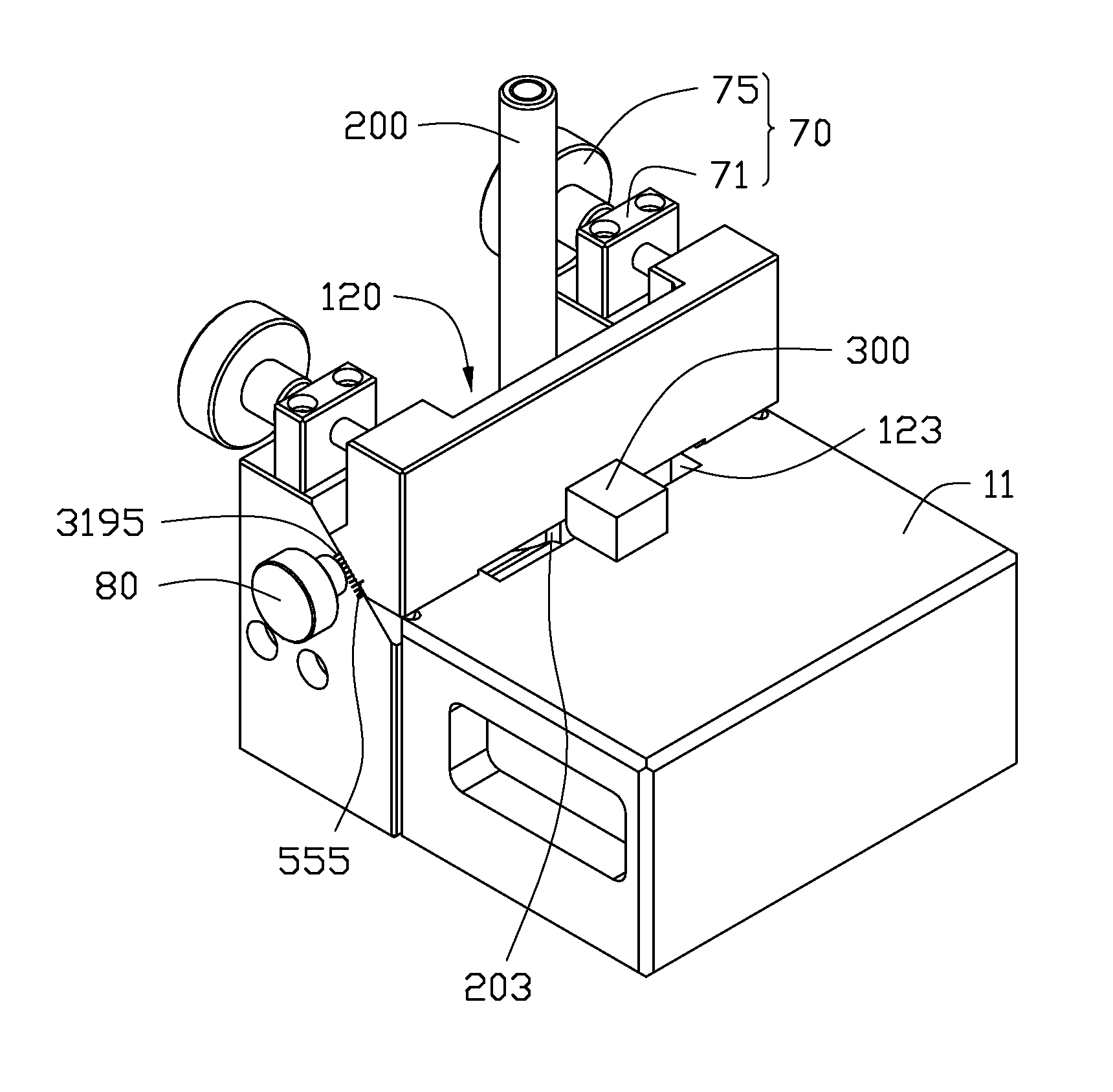

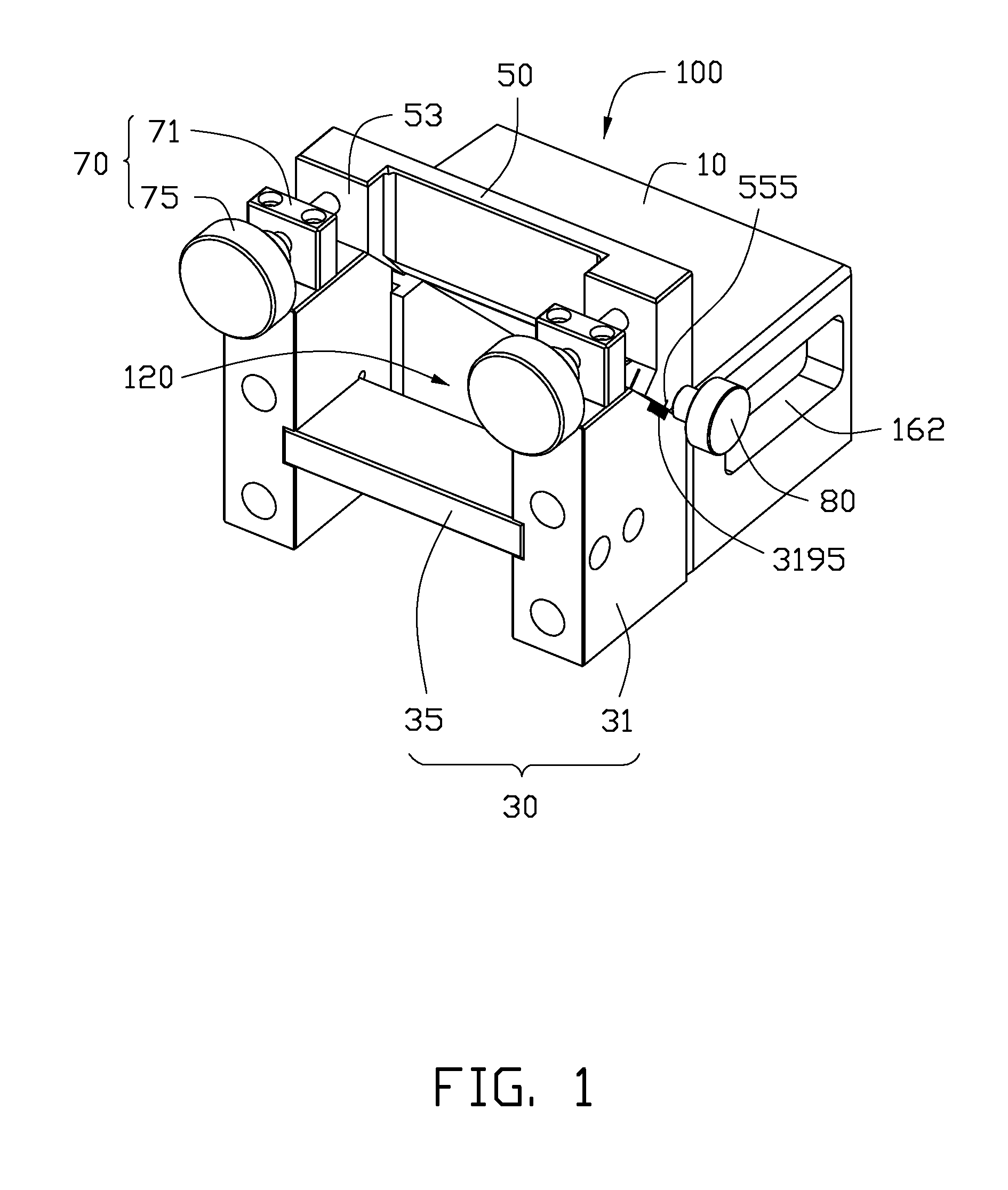

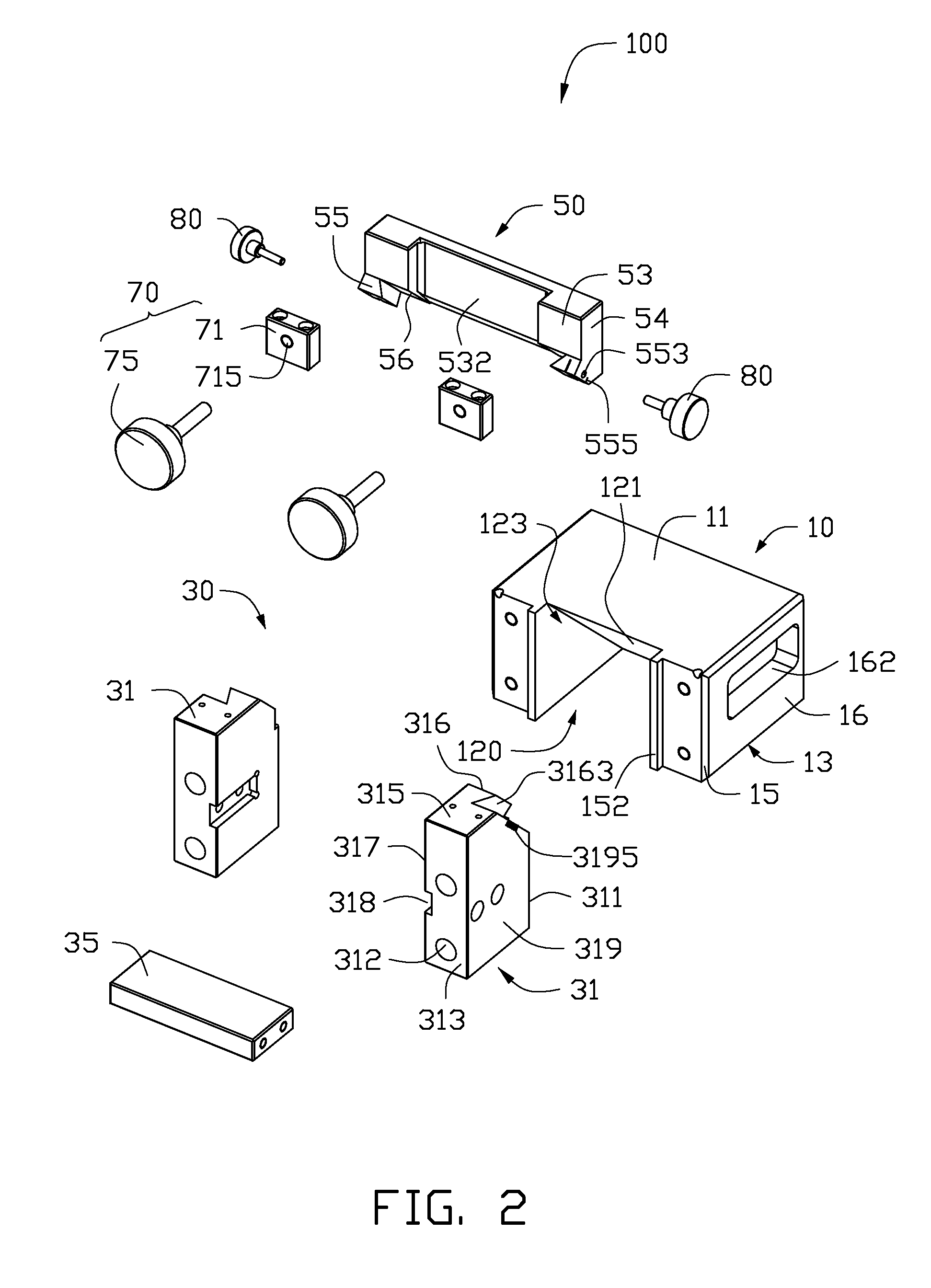

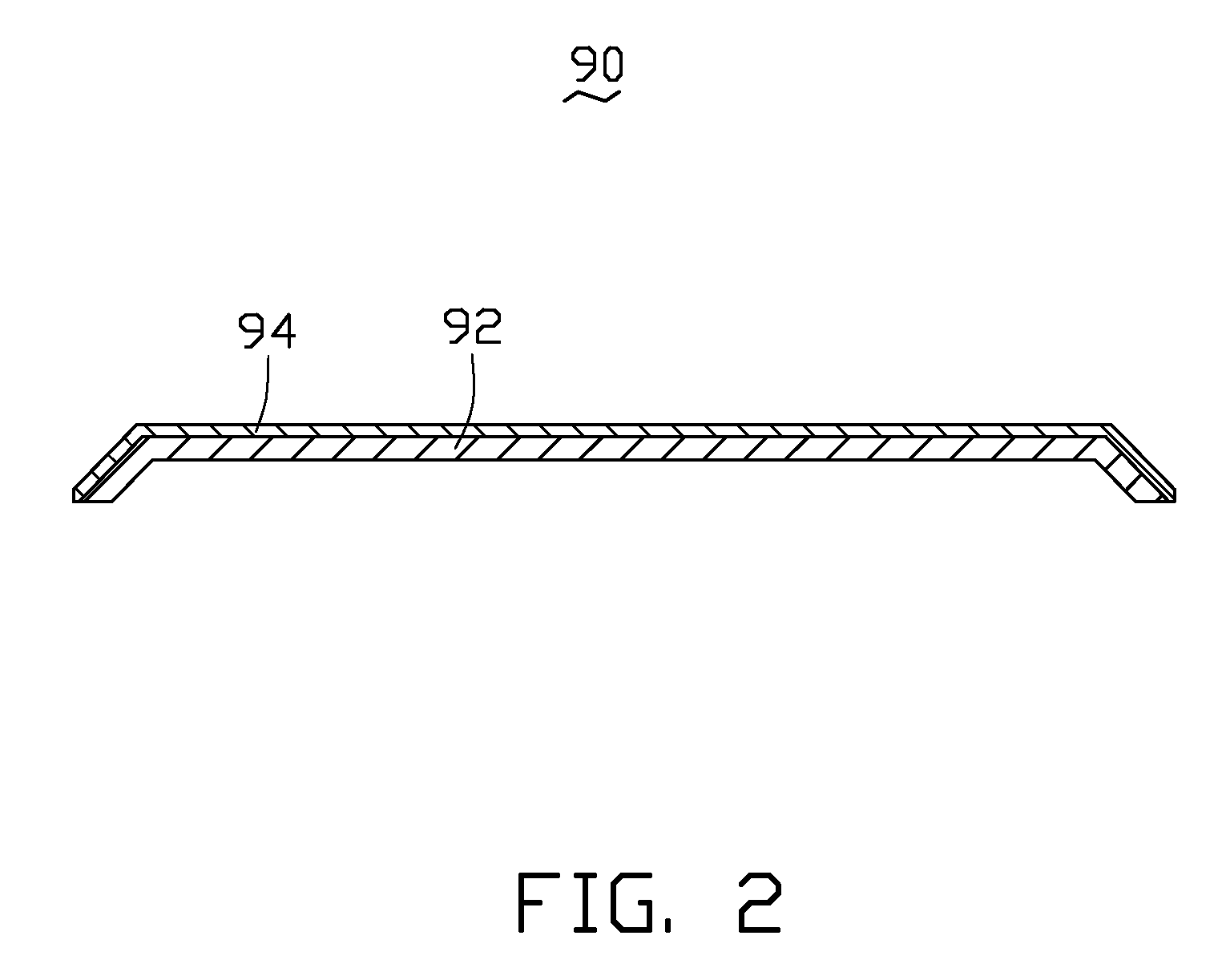

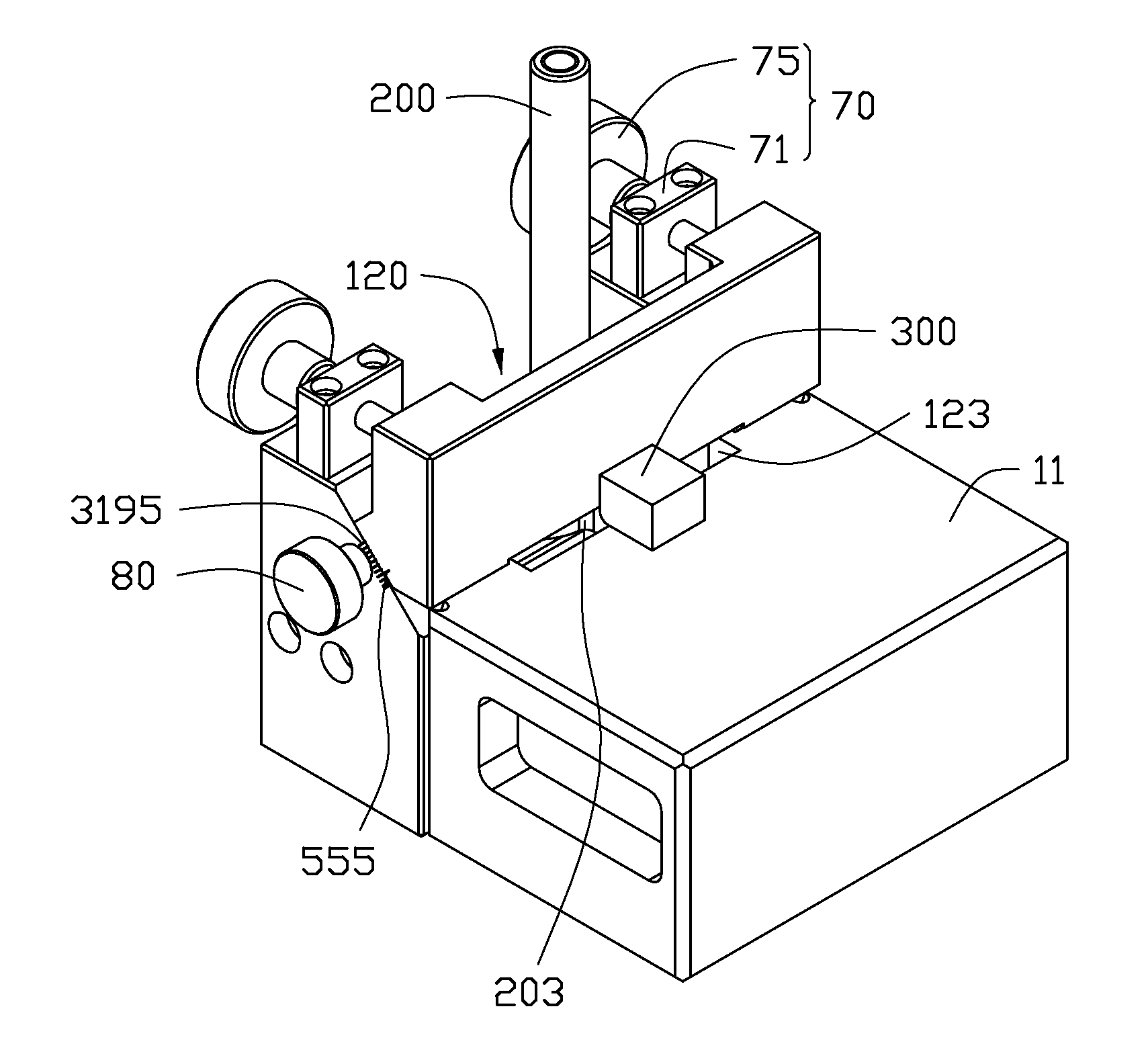

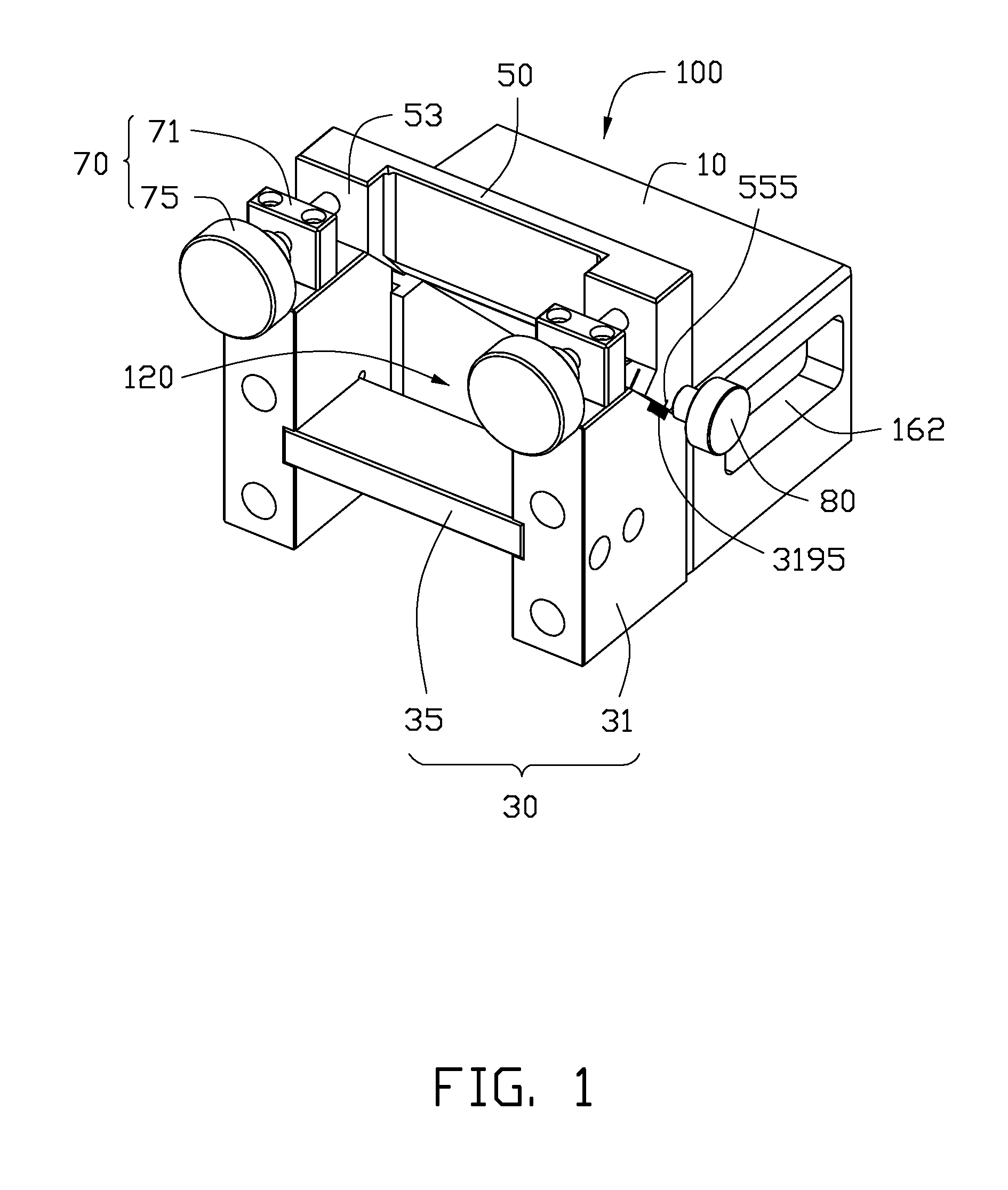

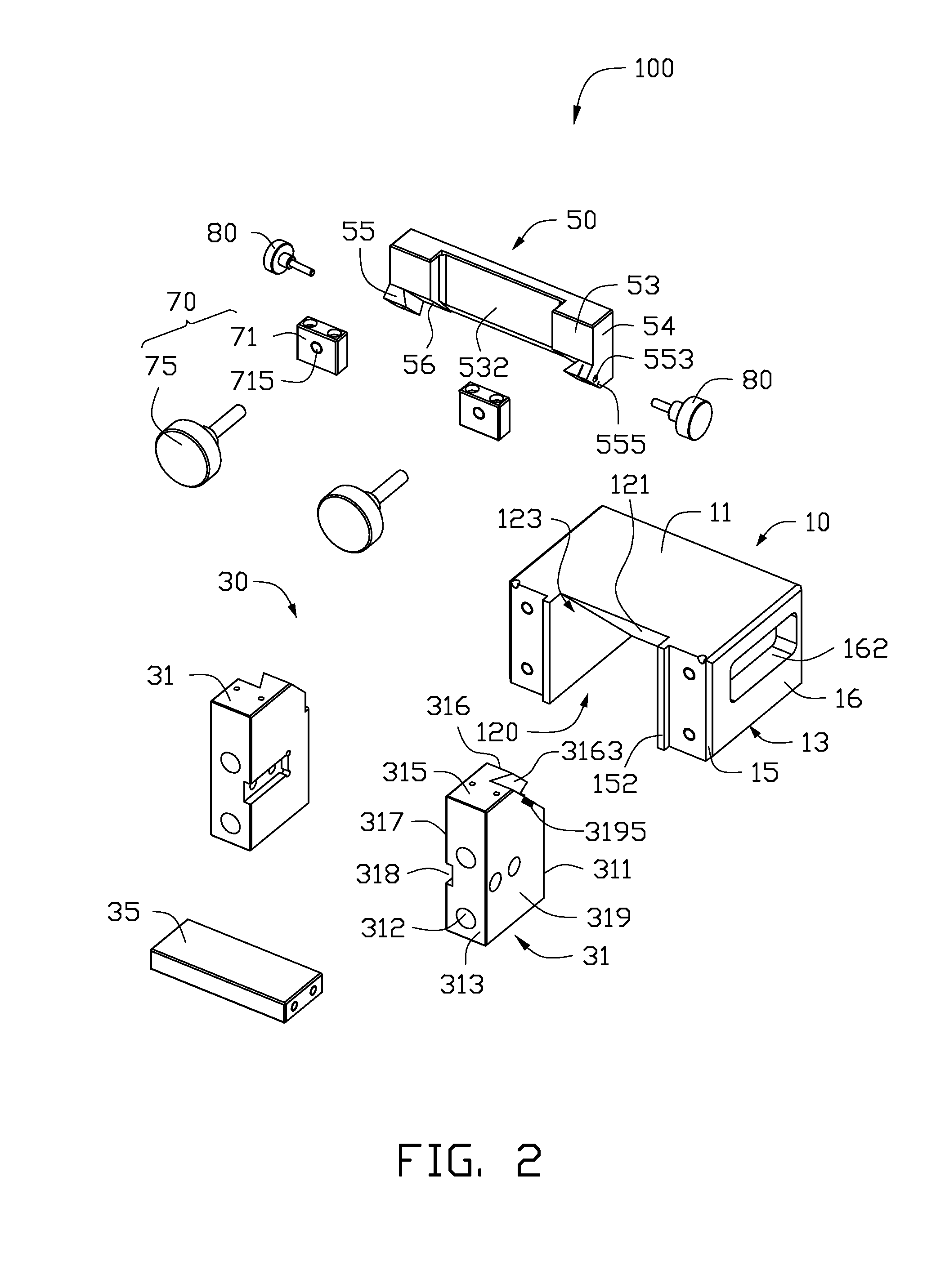

Arc surface milling assistant processing device

InactiveUS8905691B2Low processing efficiencyDifficult to operateGuide fencesProfiling/shaping machinesMechanical engineeringWedge shape

An arc surface milling machine includes a worktable, a base and a backup plate. The worktable is assembled adjacent to the base. The backup plate is adjustably mounted on the base and positioned adjacent to the worktable. The worktable includes a work surface, an opposite bottom surface, and a mounting end. The base is assembled to the mounting end of the worktable. The work surface defines a concave wedge-shaped receiving space adjacent to the mounting end and forms a milling opening communicating with the work surface and the mounting end.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

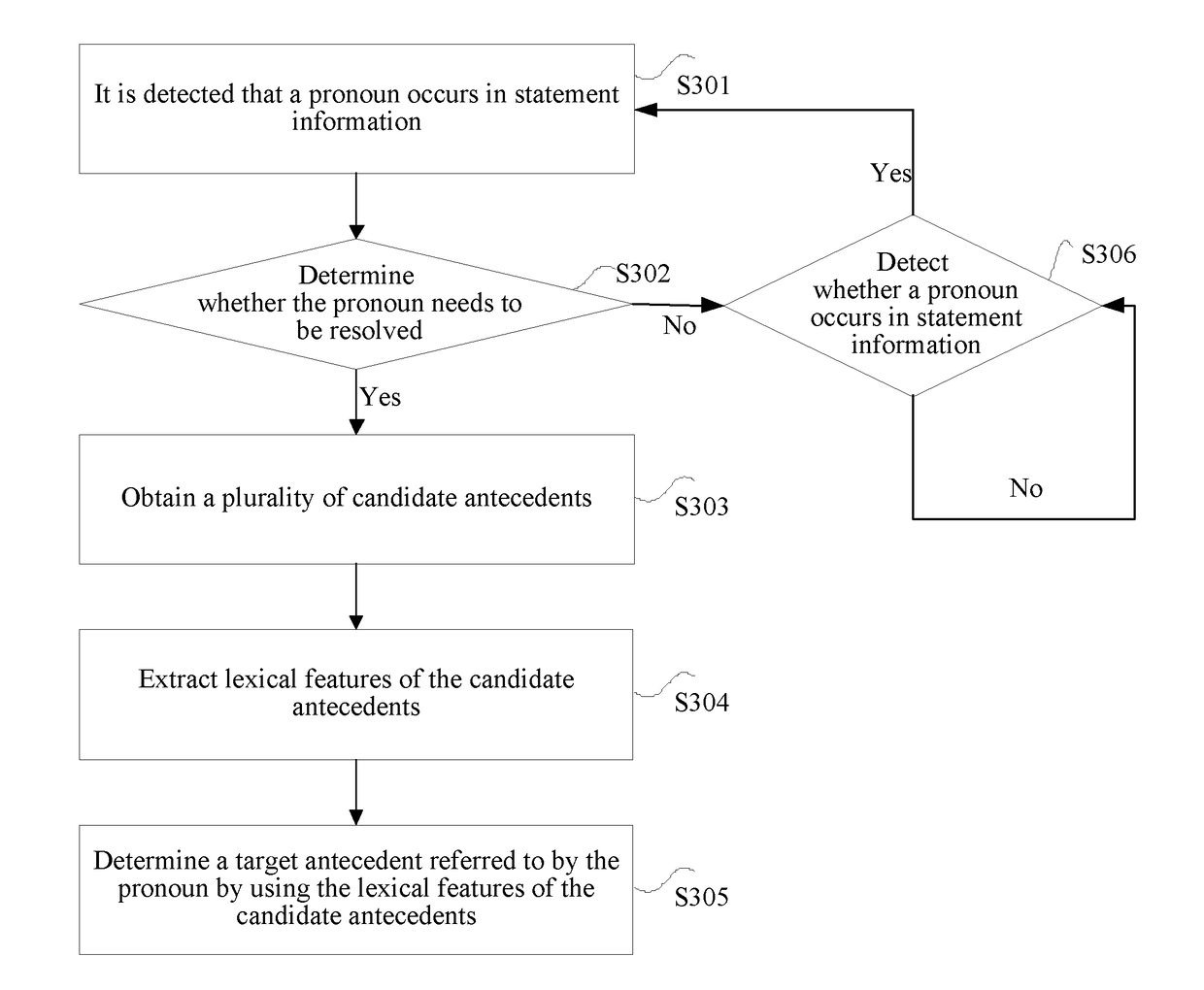

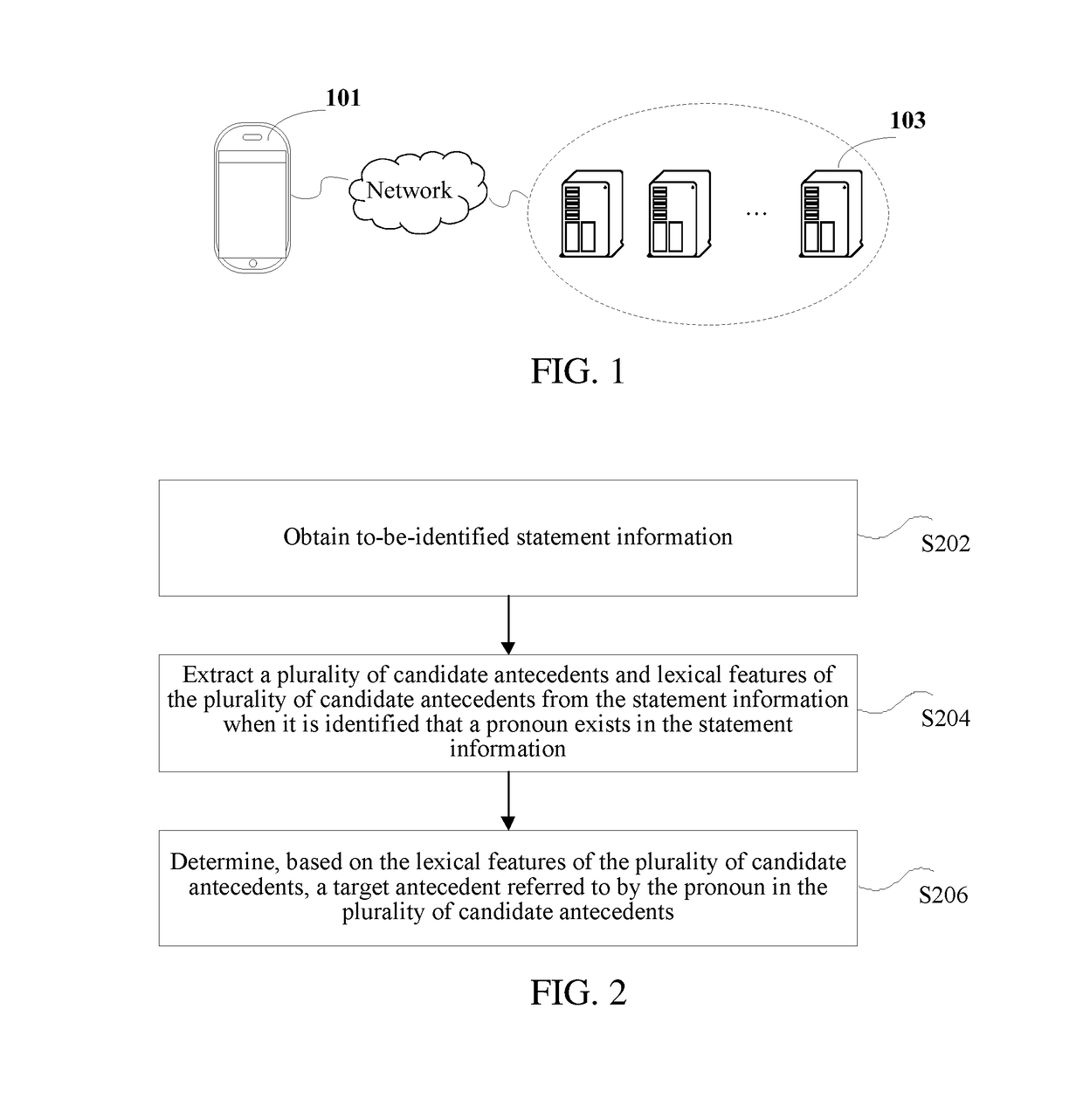

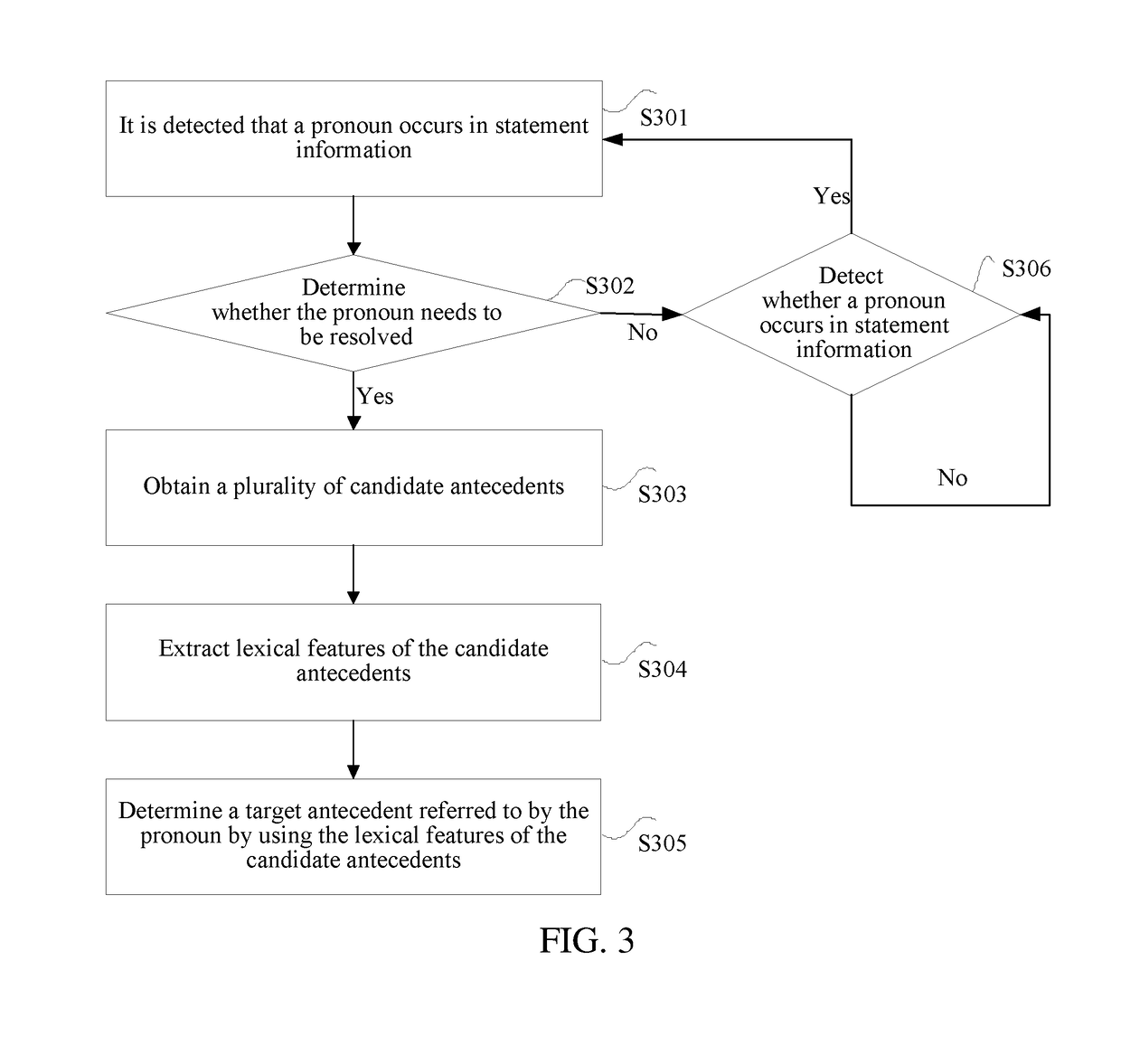

Antecedent determining method and apparatus

ActiveUS20180307671A1Accurately and high-efficiently determiningLow processing efficiencySemantic analysisSpecial data processing applicationsNatural language processing

Owner:TENCENT TECH (SHENZHEN) CO LTD

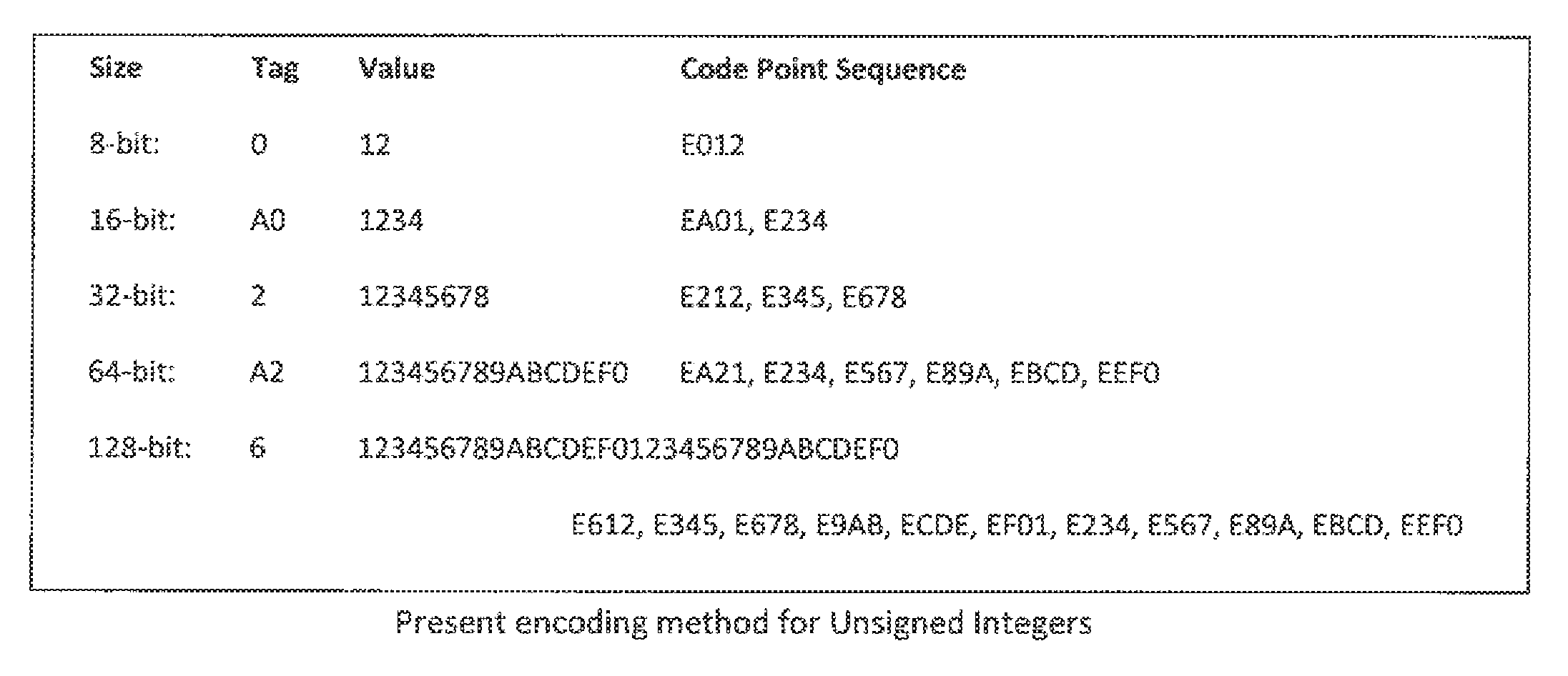

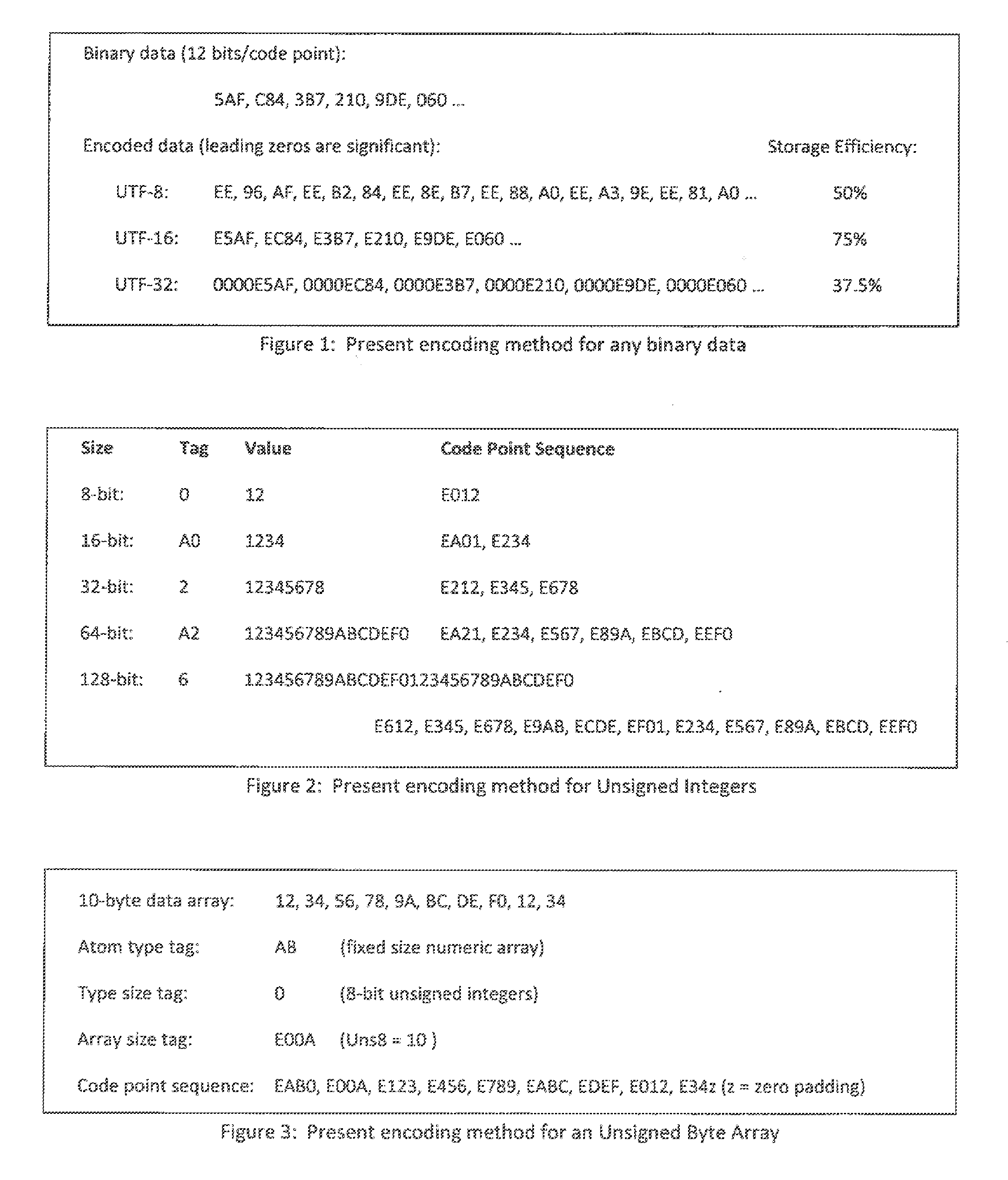

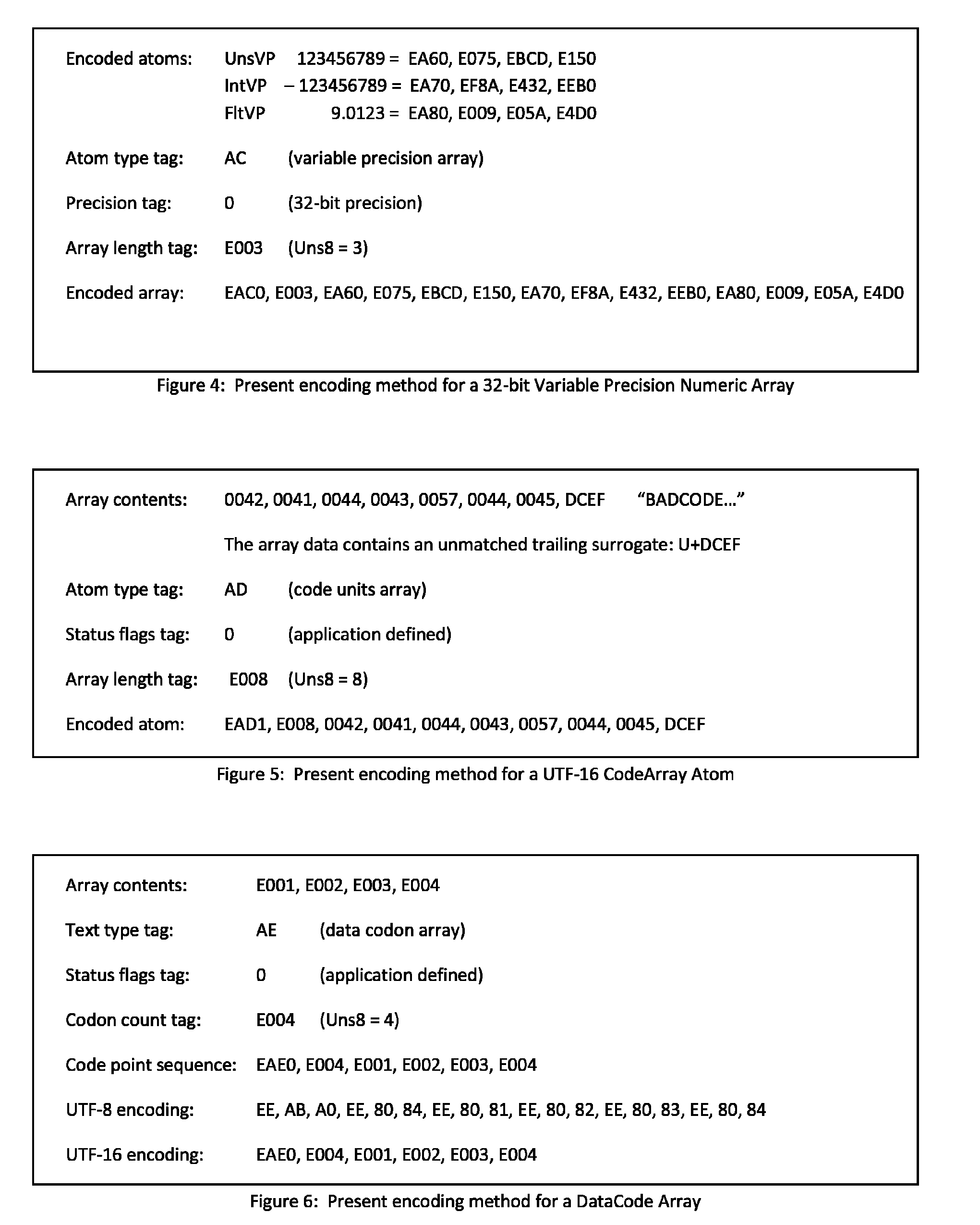

Data encoding method

InactiveUS7982637B2Maximize processing efficiencyMinimal of accessibilityIndividual digits conversionNatural language data processingUTF-16UTF-8

The present encoding method encodes binary data as sequences of code points occupying the Private Use Area of the Unicode Basic Multilingual Plane. The encoded data can be contained within a stream of UTF-8, UTF-16 or UTF-32 code units and subsequently decoded to yield the original binary data. This method requires minimal processing for both encoding and decoding operations, and yields a 75% storage efficiency limit. Each datum encoding sequence includes type and encoding length information, enhancing parse and search operation performance. The type system includes elements for creating complex structured data-text sequences, and a mechanism for application defined extensions.

Owner:JOYCE STEPHEN ALLYN

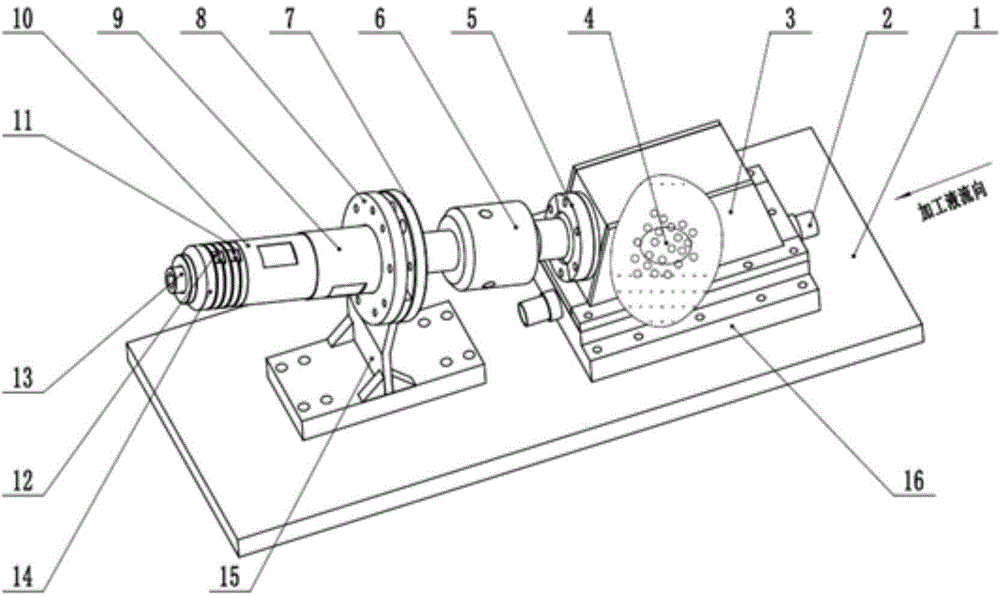

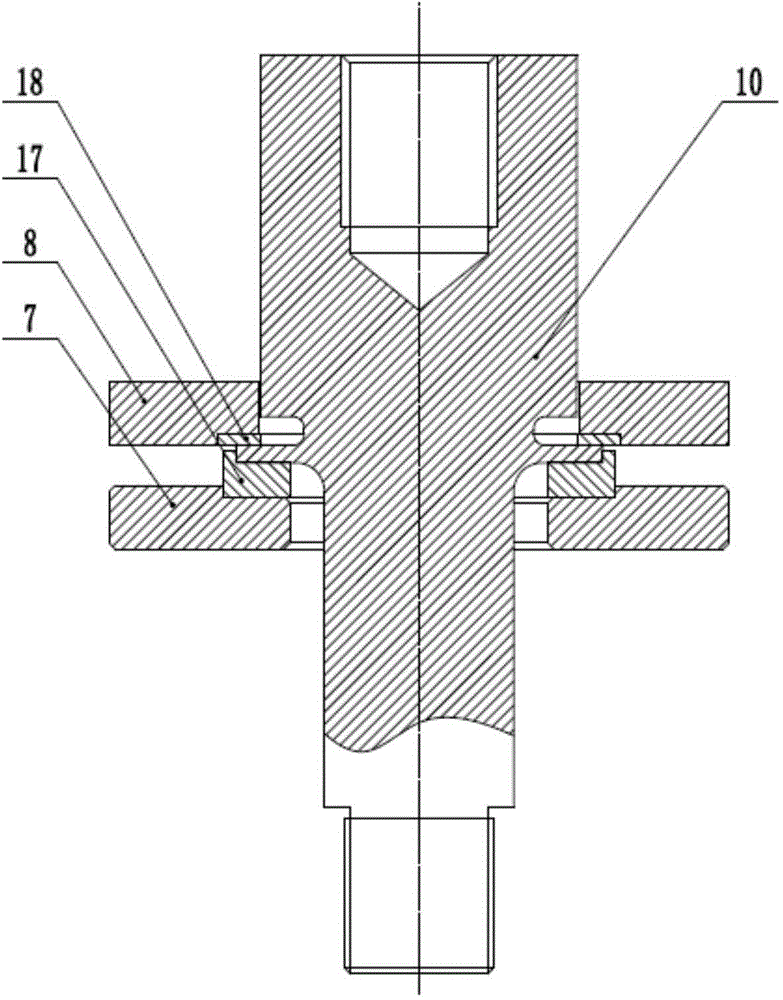

Reverse ultrasonic assisted gas-liquid-solid three-phase abrasive particle flow polishing processing method and device

ActiveCN104786153AIncreased chance of crashLow damageAbrasive machine appurtenancesAbrasive blasting machinesParticle flowShock wave

The present invention discloses a reverse ultrasonic assisted gas-liquid-solid three-phase abrasive particle flow polishing processing method and device, an ultrasonic generator is mounted in a position which is reverse in direction to abrasive particle flow, an included angle is formed between the abrasive particle flow direction and the position, a reverse ultrasonic is produced, the direction of the reverse ultrasonic is reverse to that of the abrasive particle flow, an included angle is formed between the abrasive particle flow direction and the reverse ultrasonic, the reverse ultrasonic can compress micro-sized bubbles near workpiece machining surface in an abrasive particle flow medium containing the micro-sized bubbles to collapse and perish the micro-sized bubbles, when the micro-sized bubbles are collapsed and perished, a reverse micro shock wave is produced, the direction of the reverse micro shock wave is reverse to that of the abrasive particle flow, the reverse micro shock wave allows the inner local area of the abrasive particle flow to produce a great pressure so as to produce microscopic explosion effect; two component forces are generated by the microscopic explosion effect, a vertical component force is used for improving the contact probability and acting force of abrasive particles and workpiece machining surface convex peaks, a reverse horizontal component force is used for forming relative block effect on the abrasive particles, the abrasive particle and workpiece action time is increased, and the abrasive particle flow polishing efficiency is greatly improved.

Owner:ZHEJIANG UNIV OF TECH

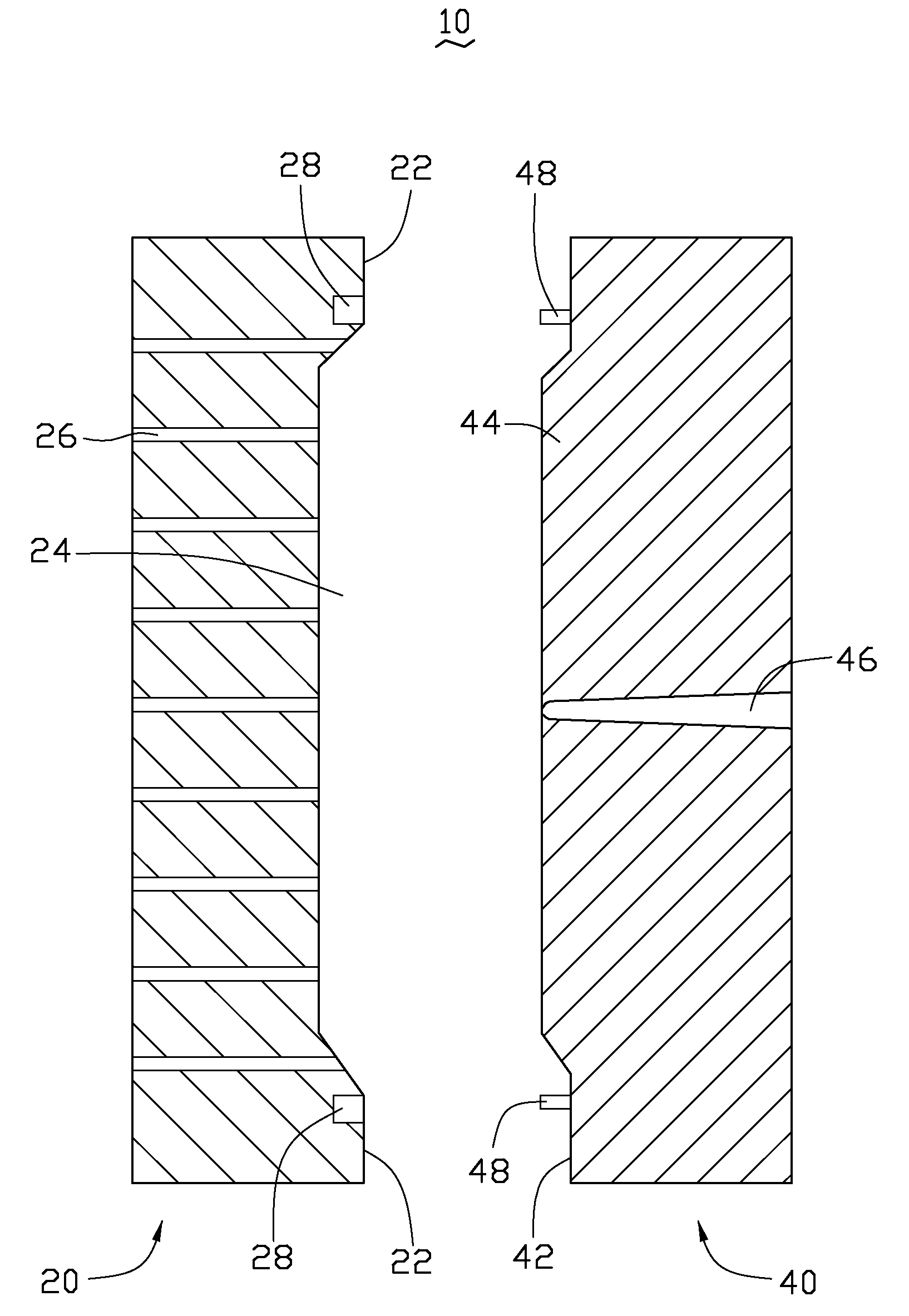

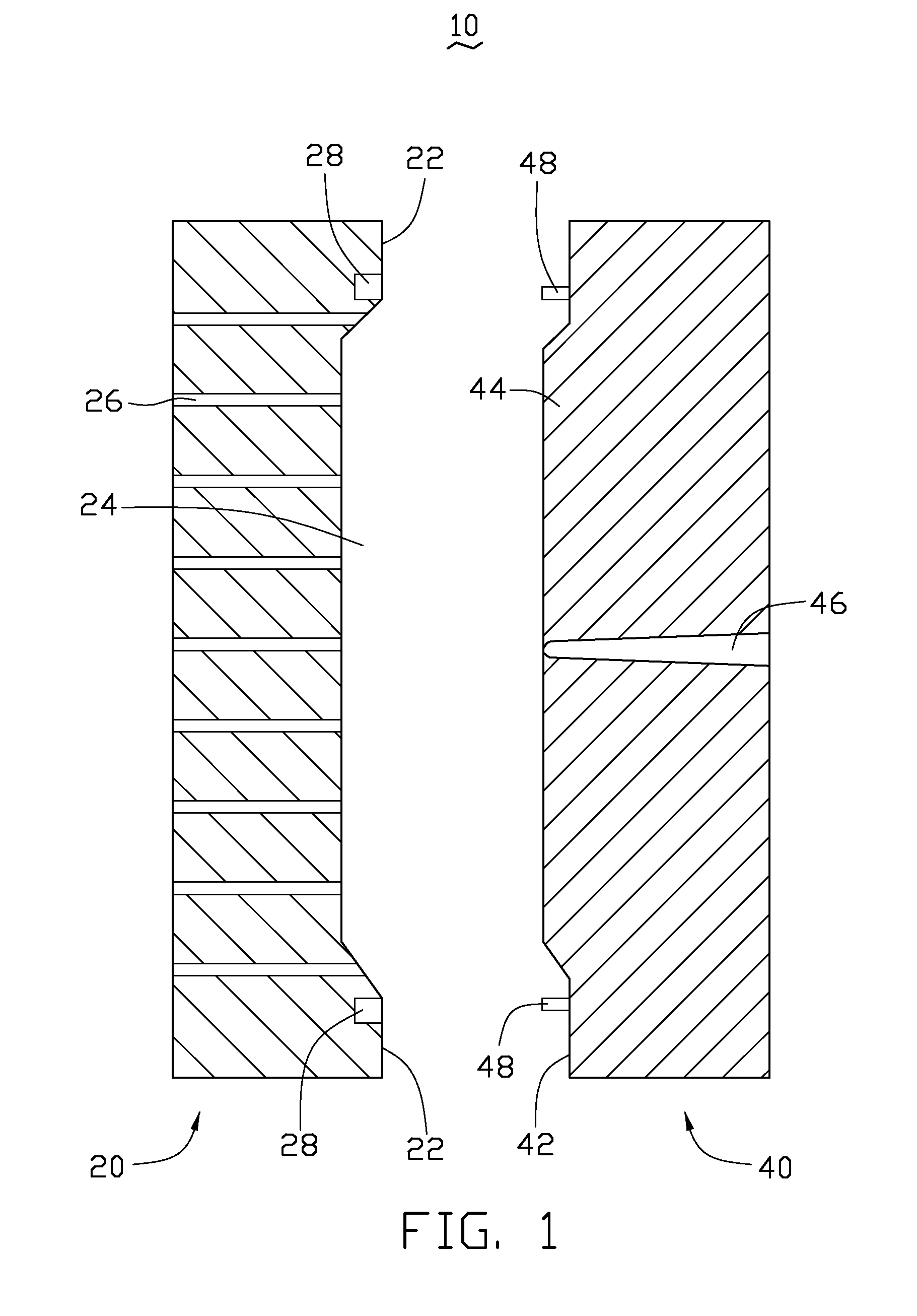

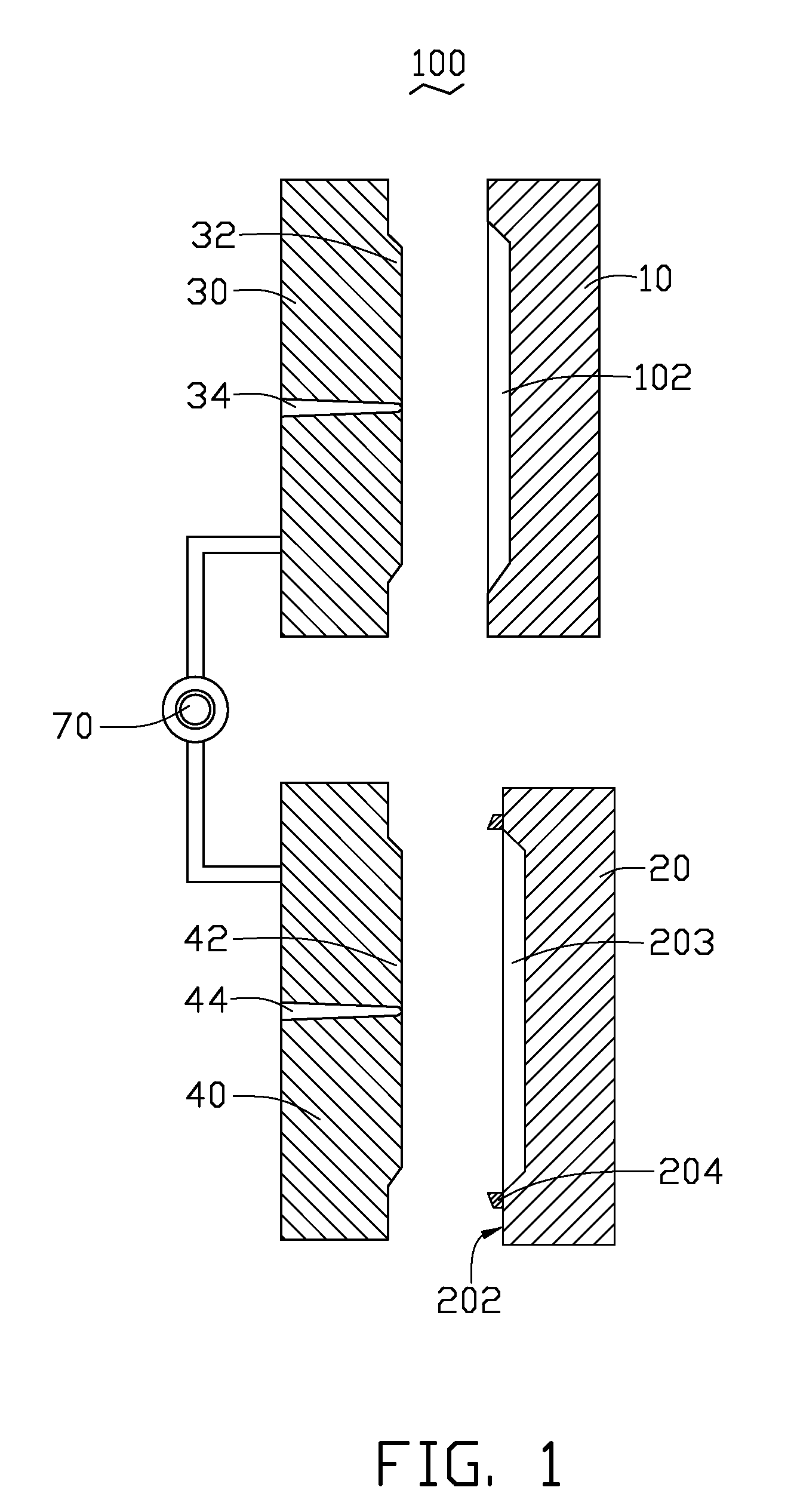

Injection mold and method for making a housing using the injection mold

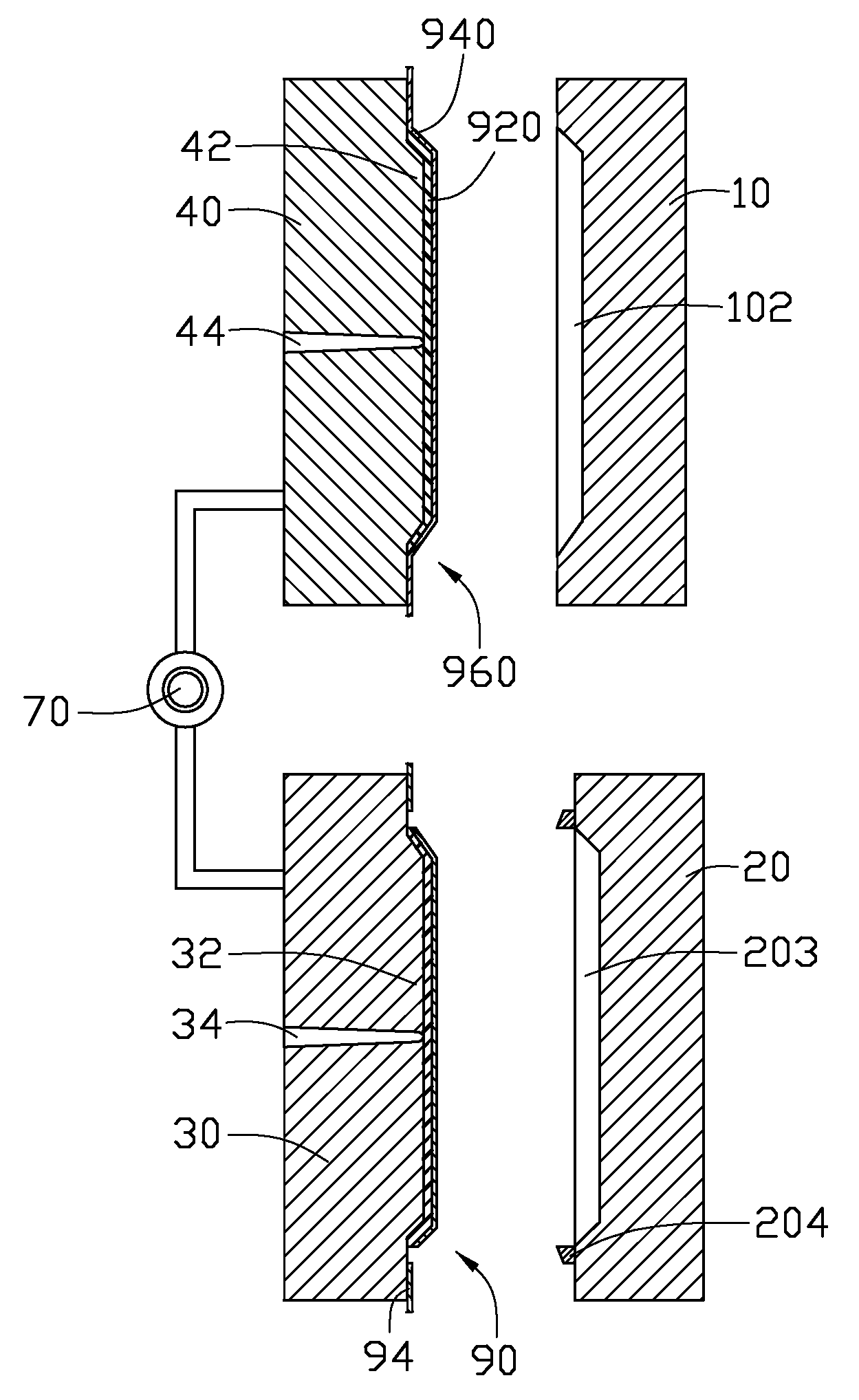

An injection mold (10) comprises a female mold (20), a male mold (40) matching with the female mold (20), and a cutting portion (48) is positioned on either the female mold (20) or the male mold (40) positioning, a receiving slot (28) is defined in another said mold for accommodating the cutting portion (48).

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD +1

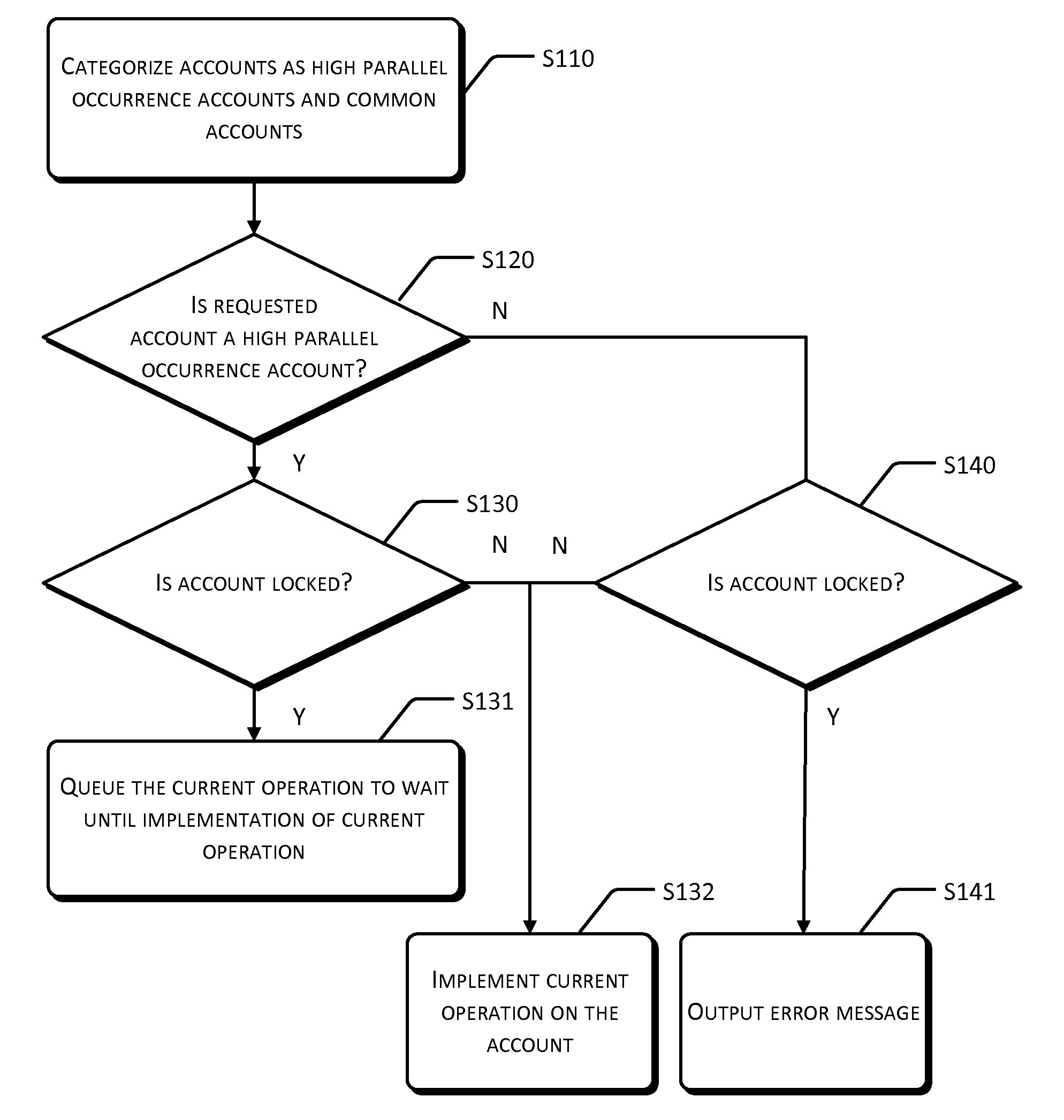

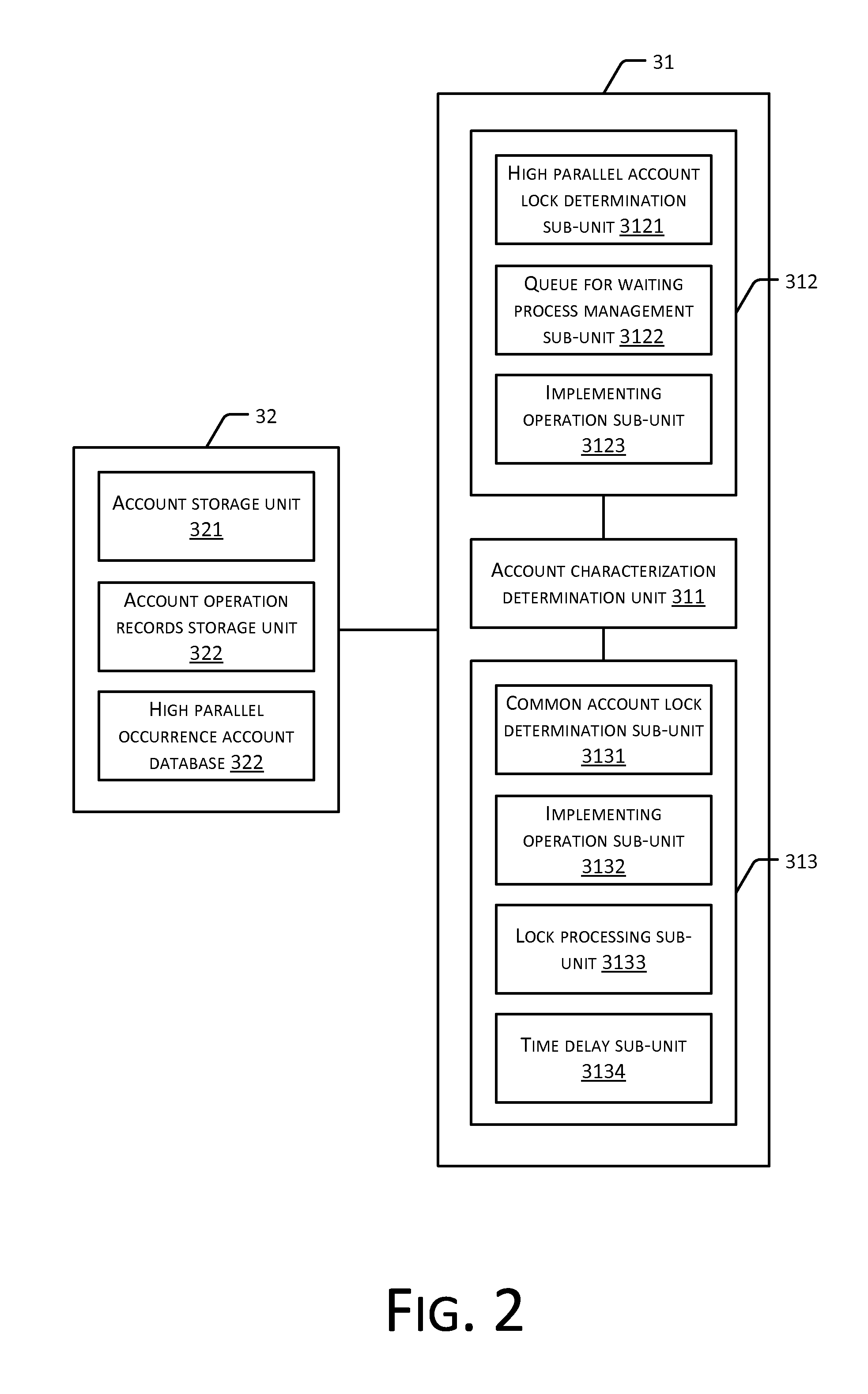

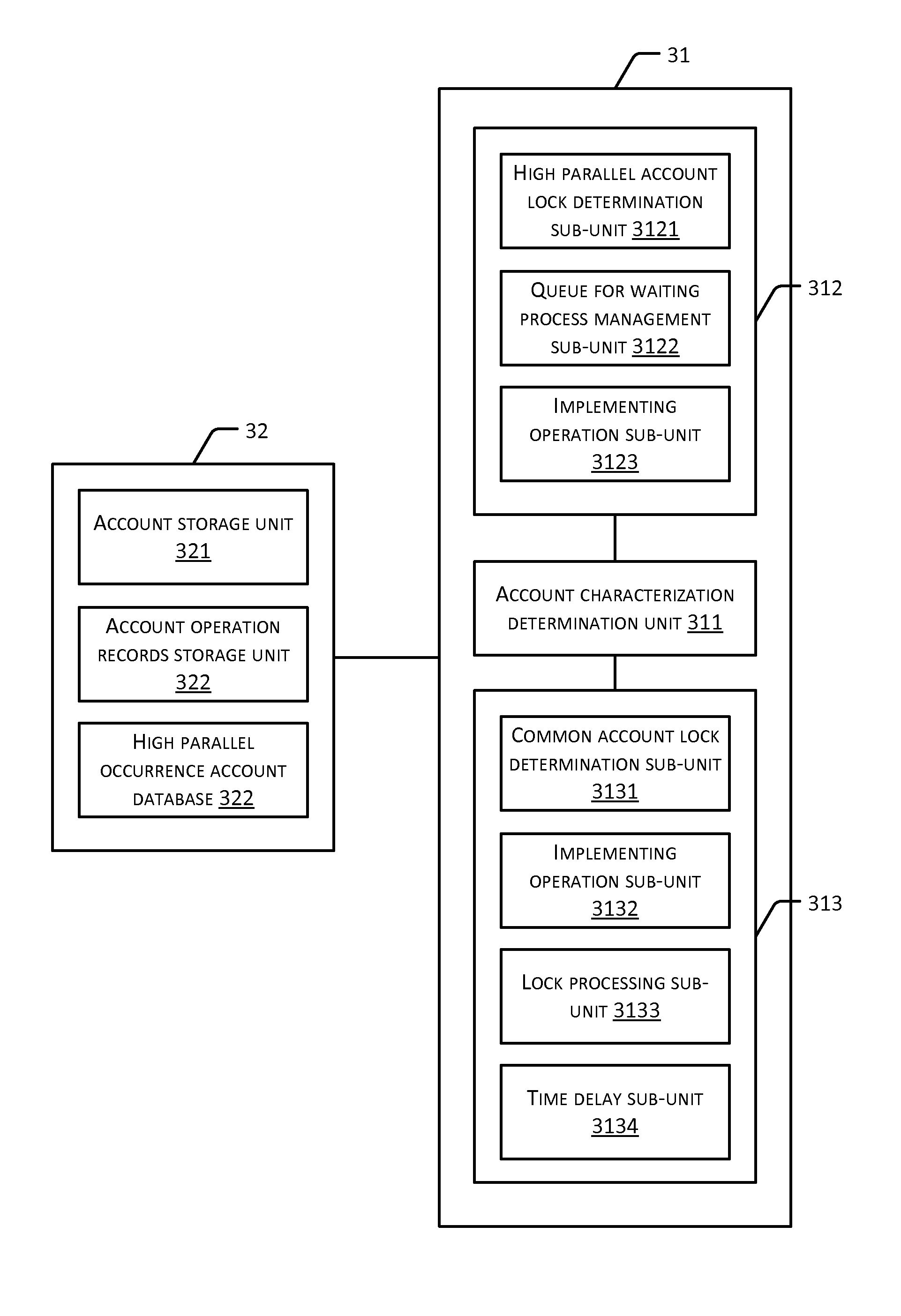

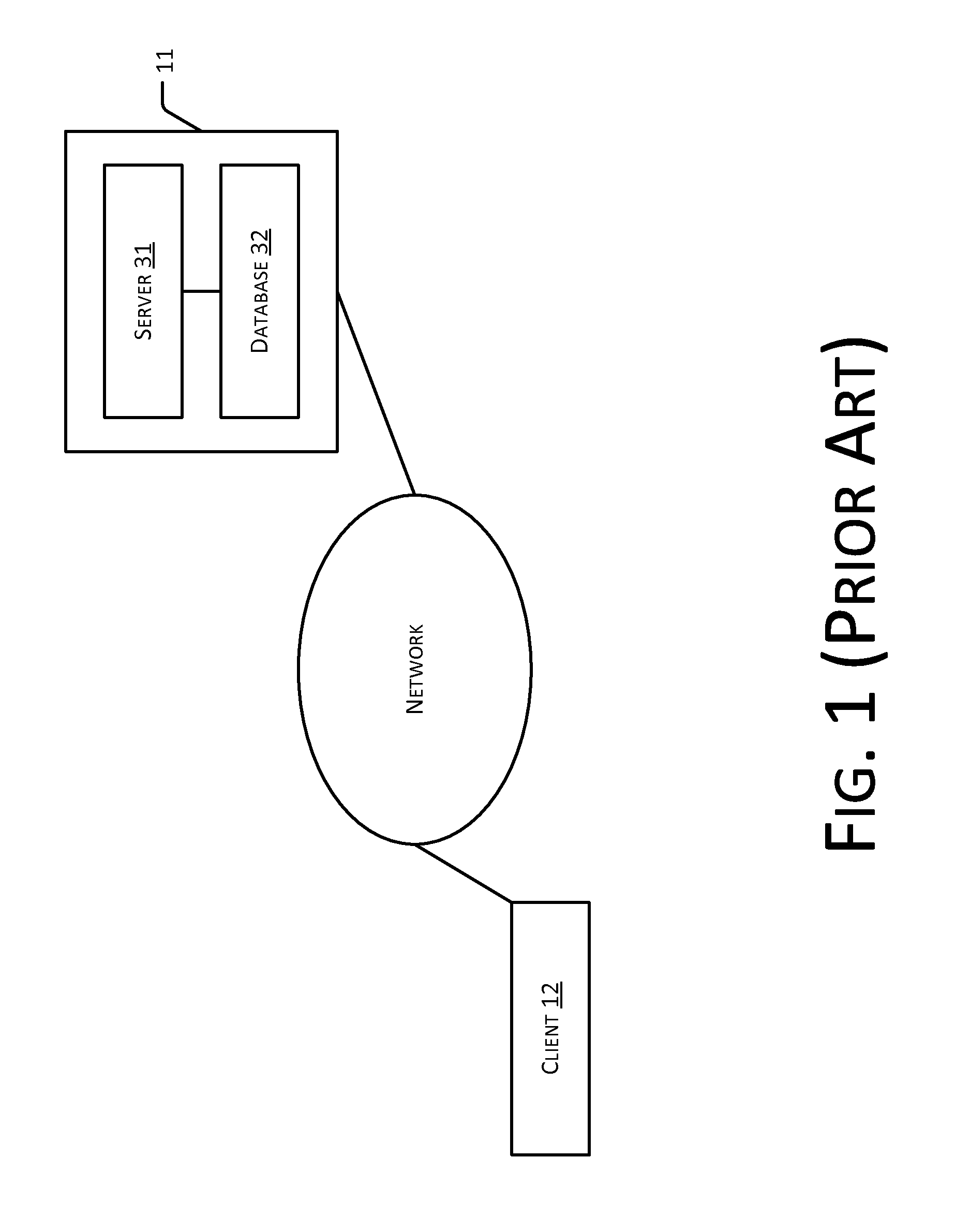

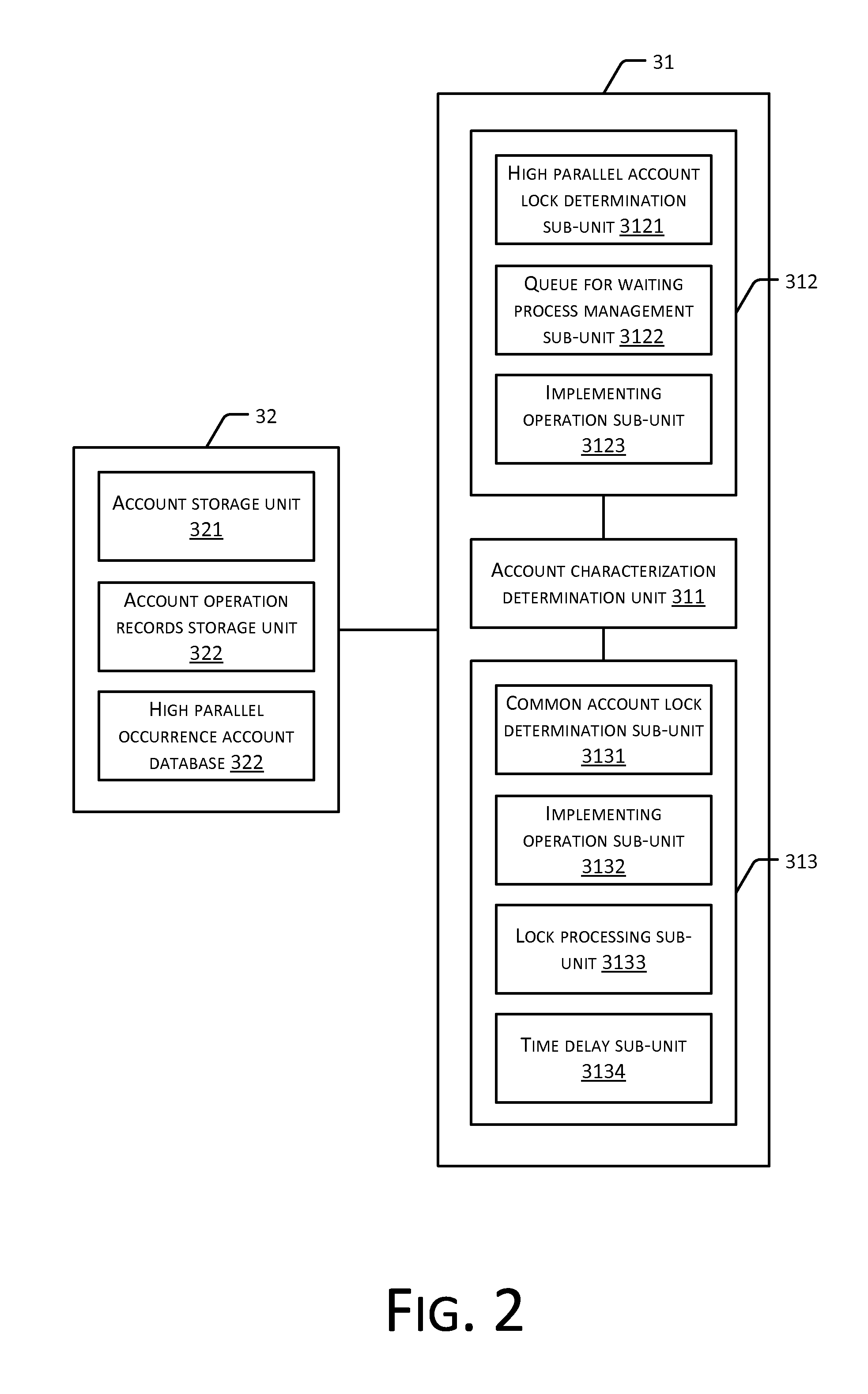

Method and System for Account Parallel Processing

ActiveUS20120123912A1Good serviceEffective controlComplete banking machinesFinanceParallel processingProcess operation

A method for account parallel processing used by an account processing center to process a request for account operation is disclosed. The method comprises: (1) categorizing accounts as high parallel occurrence accounts and common accounts; (2) when receiving the request from the client for processing operation of an account, firstly determining whether the account is a high parallel occurrence account; and if the account is a high parallel occurrence account, continuing to a step (3), otherwise, conducting a step (4); (3) if the account is locked, queuing a current operation to wait until implementation of the current operation; and (4) further determining, by the account processing center, whether the account is locked and outputting an error message when the account is locked, otherwise implementing the current operation. Such method provides more high quality services to the high parallel occurrence accounts. As for the common accounts, when there is a high volume of parallel transactions on the common accounts, the volume of parallel processing can be effectively controlled by outputting an error message to prevent comment accounts from causing damage the system.

Owner:ADVANCED NEW TECH CO LTD

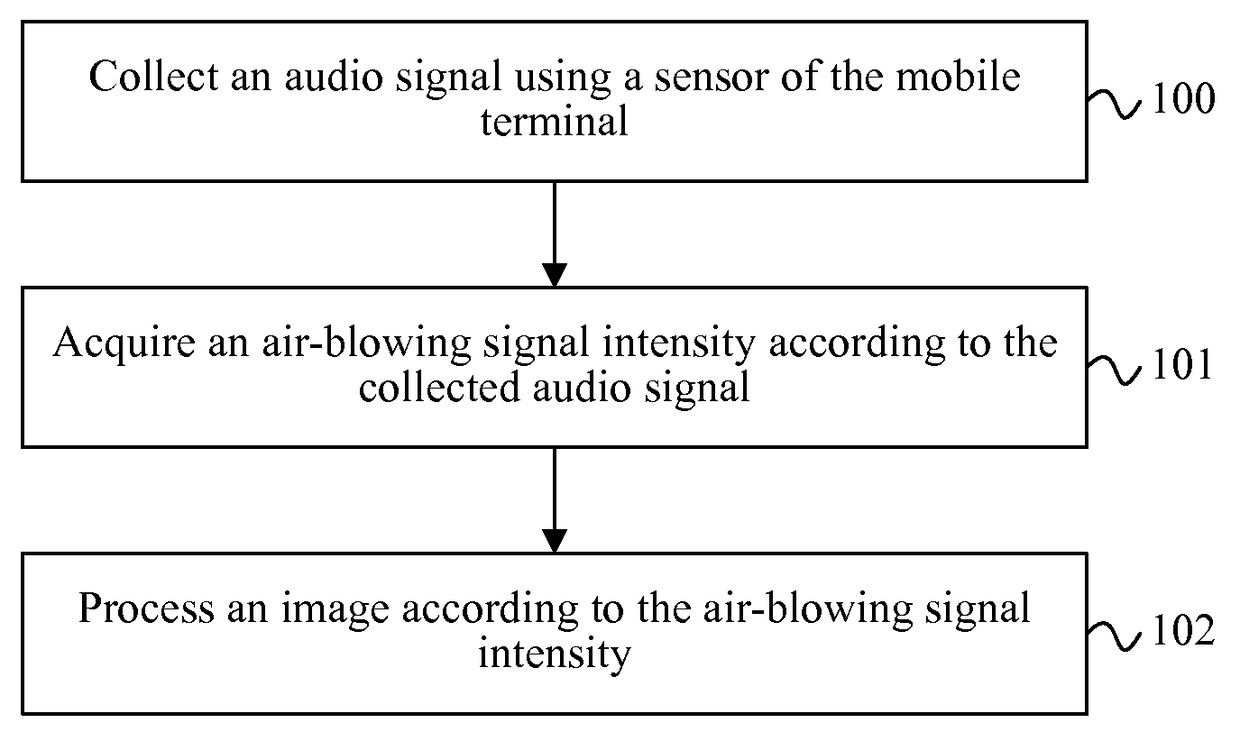

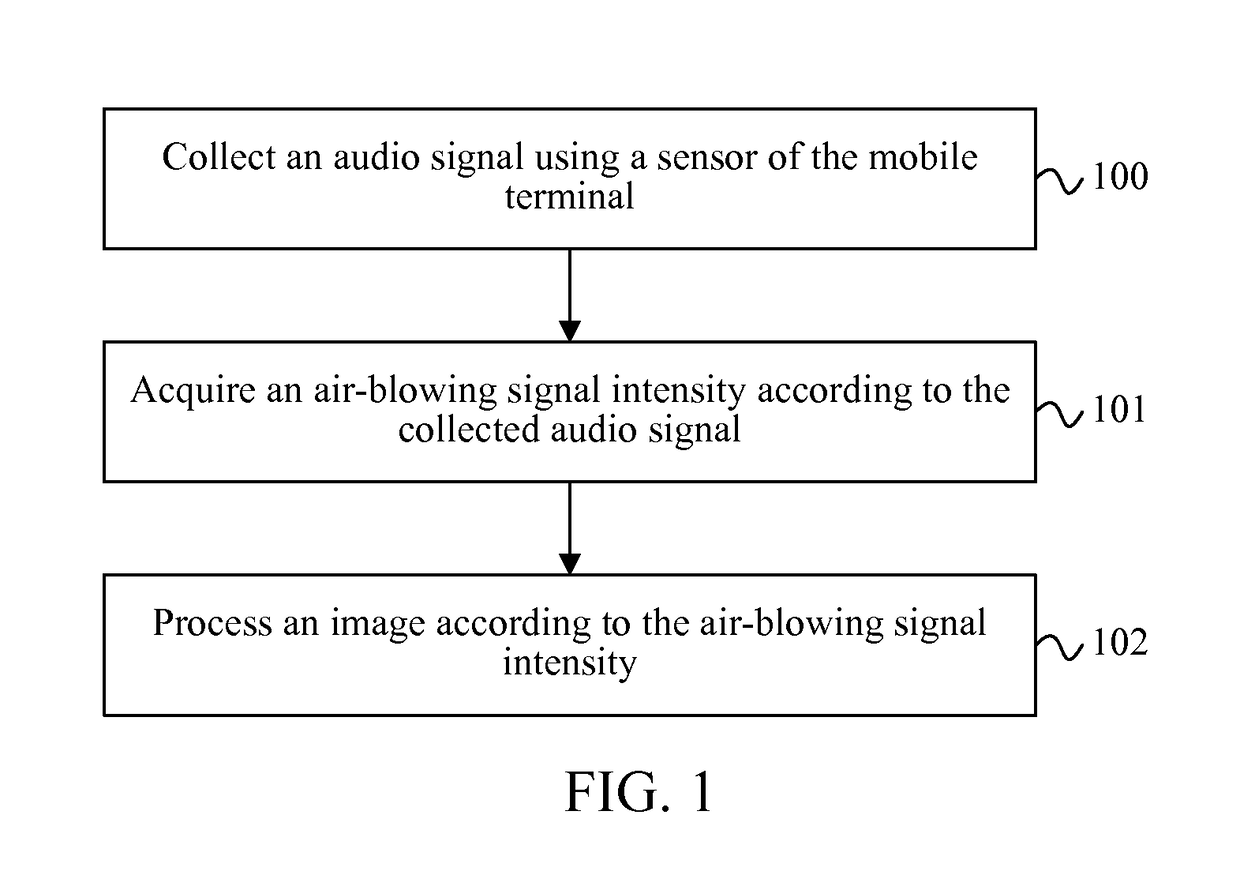

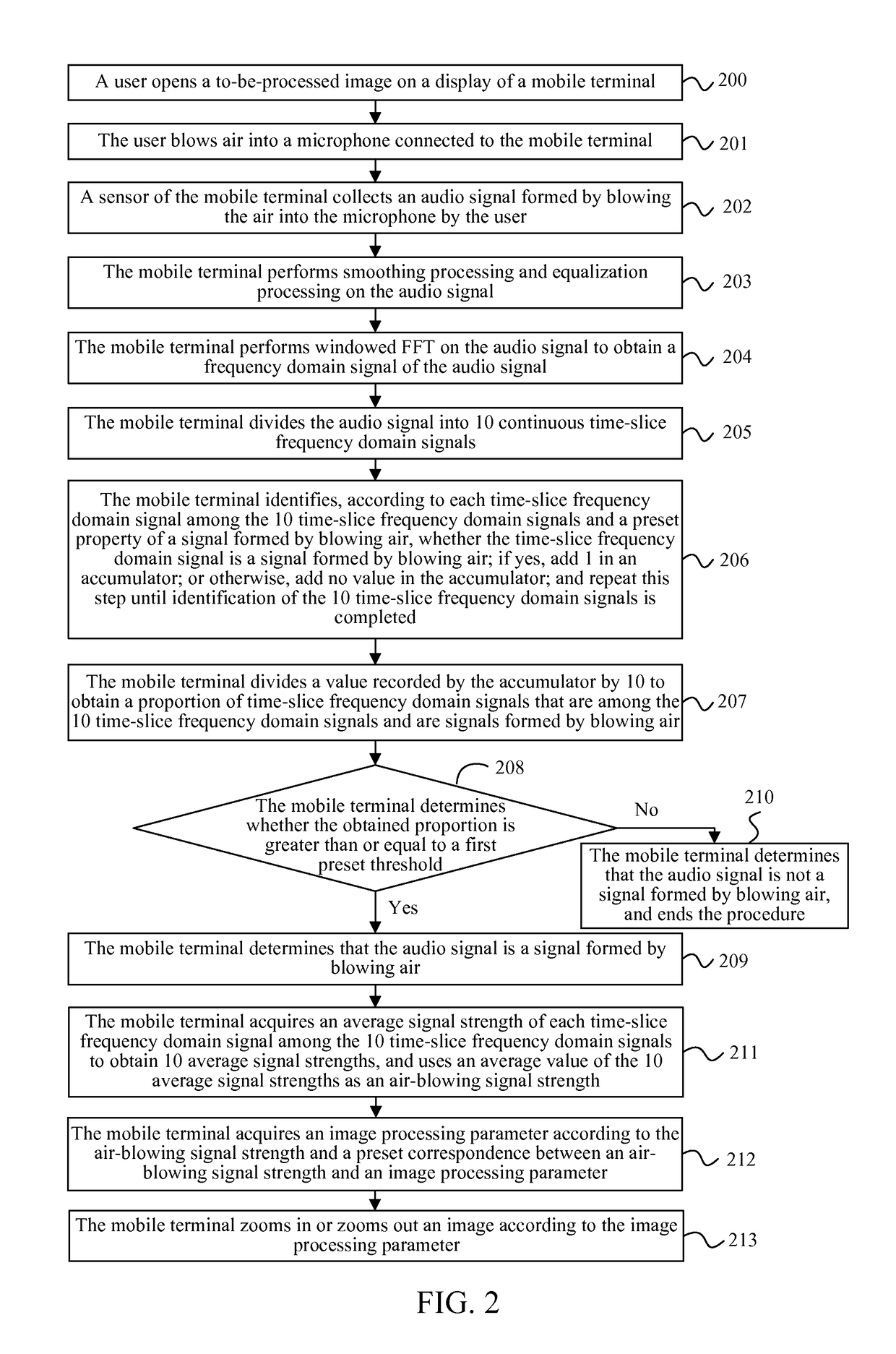

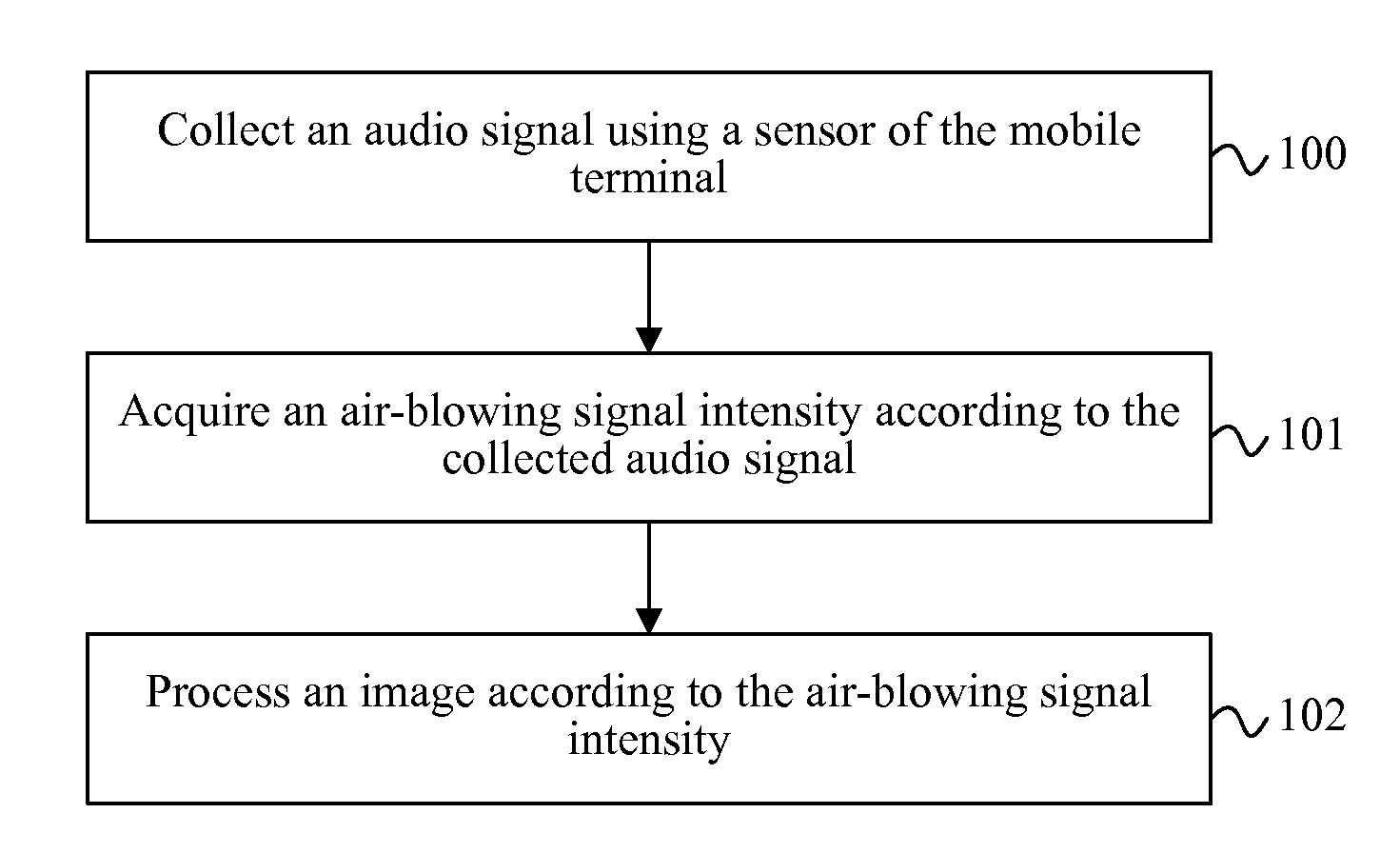

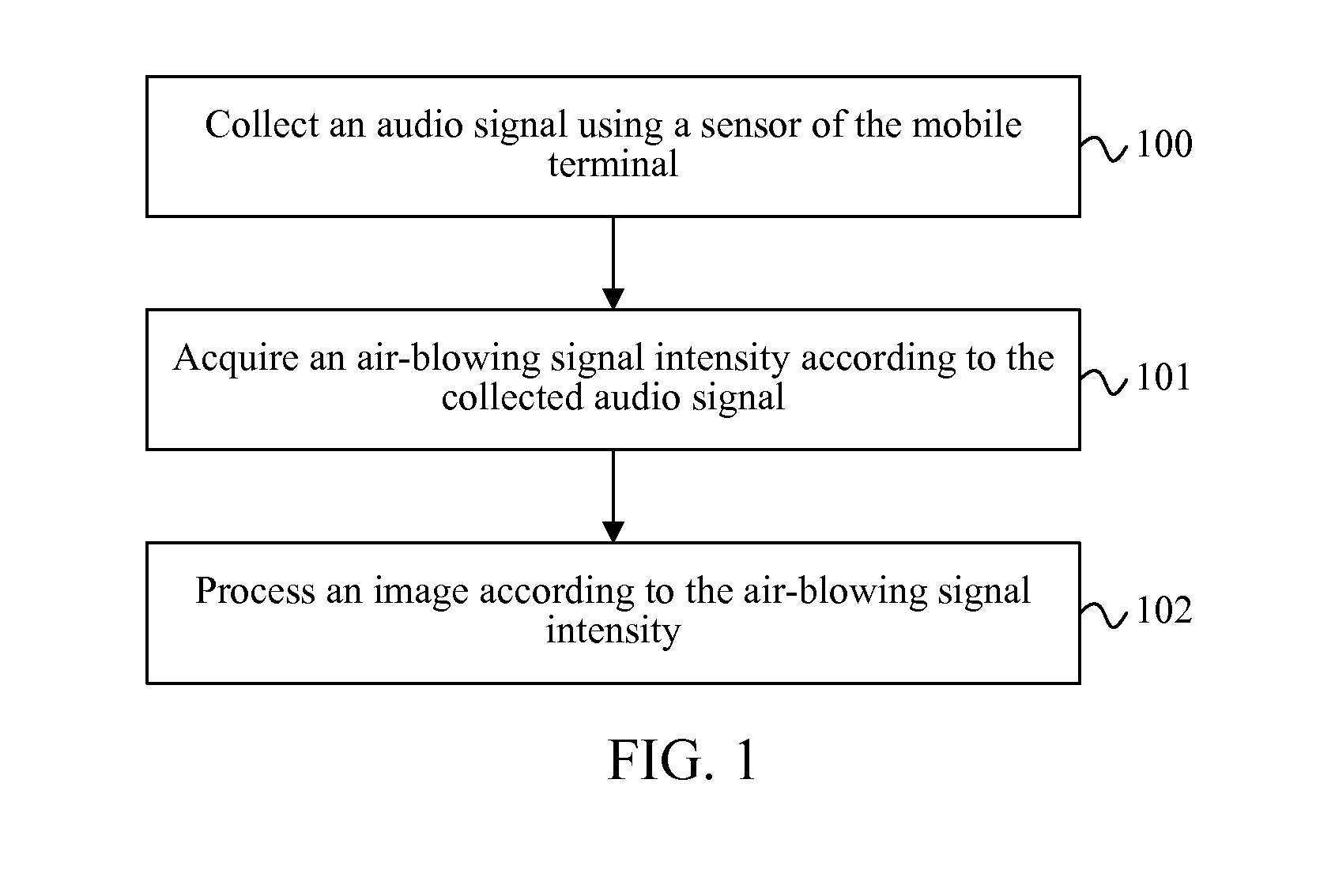

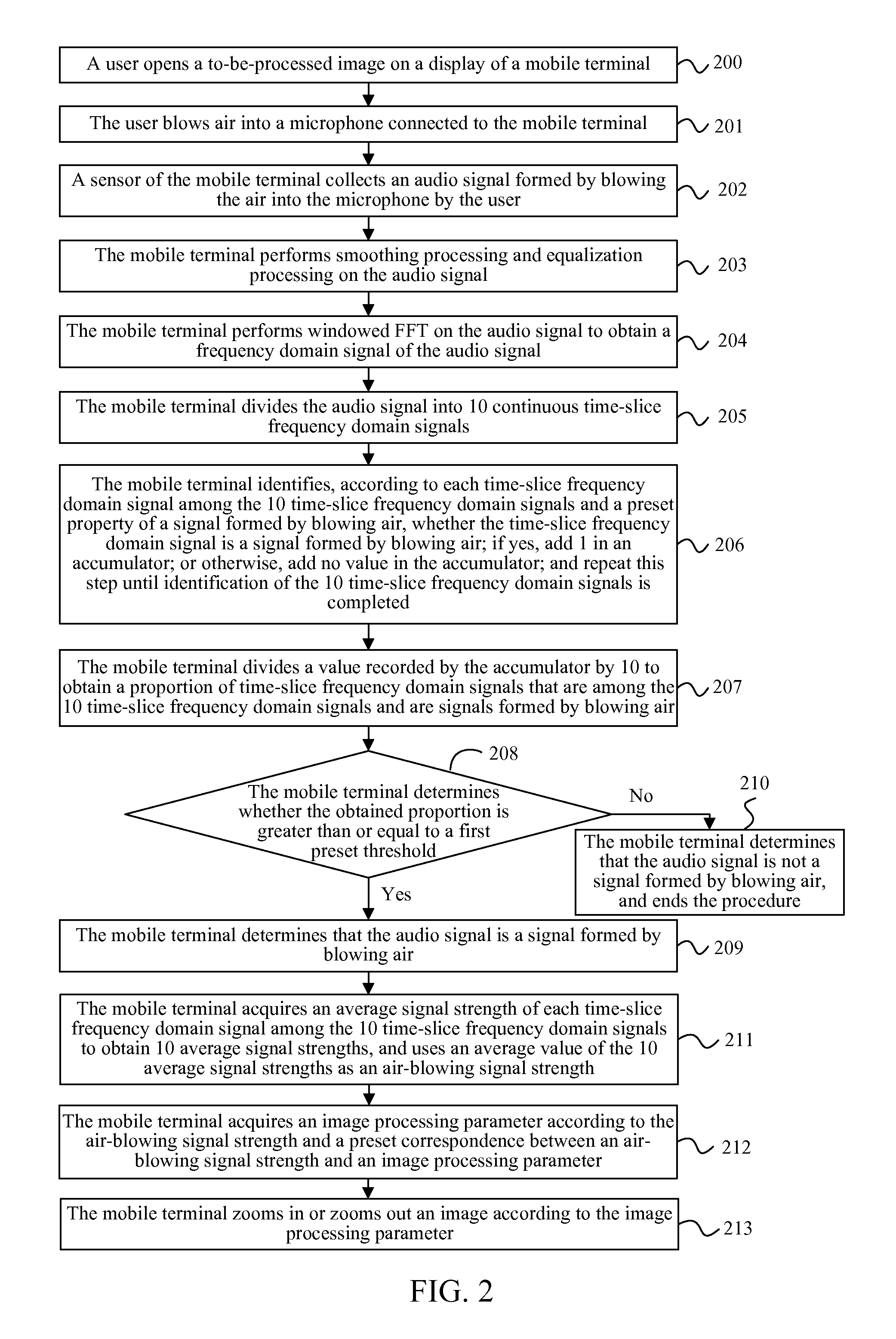

Mobile terminal and image processing method thereof

ActiveUS9977651B2Low processing efficiencyGuaranteed uptimeInput/output for user-computer interactionError detection/correctionFast Fourier transformImaging processing

The present disclosure discloses an image processing method of a mobile terminal, and a mobile terminal. To process an image, an audio signal is collected using a sensor of the mobile terminal. Air-blowing signal intensity is acquired by performing a windowed fast Fourier transform (FFT) on the audio signal to obtain a frequency domain signal of the audio signal. The frequency domain signal of the audio signal is divided into at least one time-slice frequency domain signal. It is then identified whether the audio signal is an air-blowing signal according to the at least one time-slice frequency domain signal and a preset property of the air-blowing signal. The air-blowing signal intensity is acquired according to the at least one time-slice frequency domain signal when the audio signal is identified as an air-blowing signal. An image is acquired according to the air-blowing signal intensity. In this manner, the image processing method using the air-blowing signal intensity may provide improved processing efficiency and simplified operation.

Owner:TENCENT TECH (SHENZHEN) CO LTD

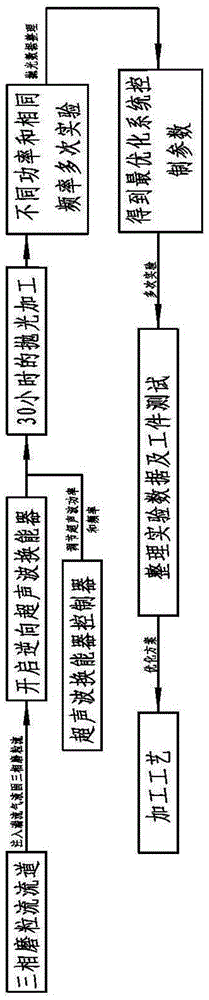

Laser sleeving-nesting type composite processing method

PendingCN111590194ARealize the processing effectEasy to processWelding/soldering/cutting articlesLaser beam welding apparatusLaser processingEngineering

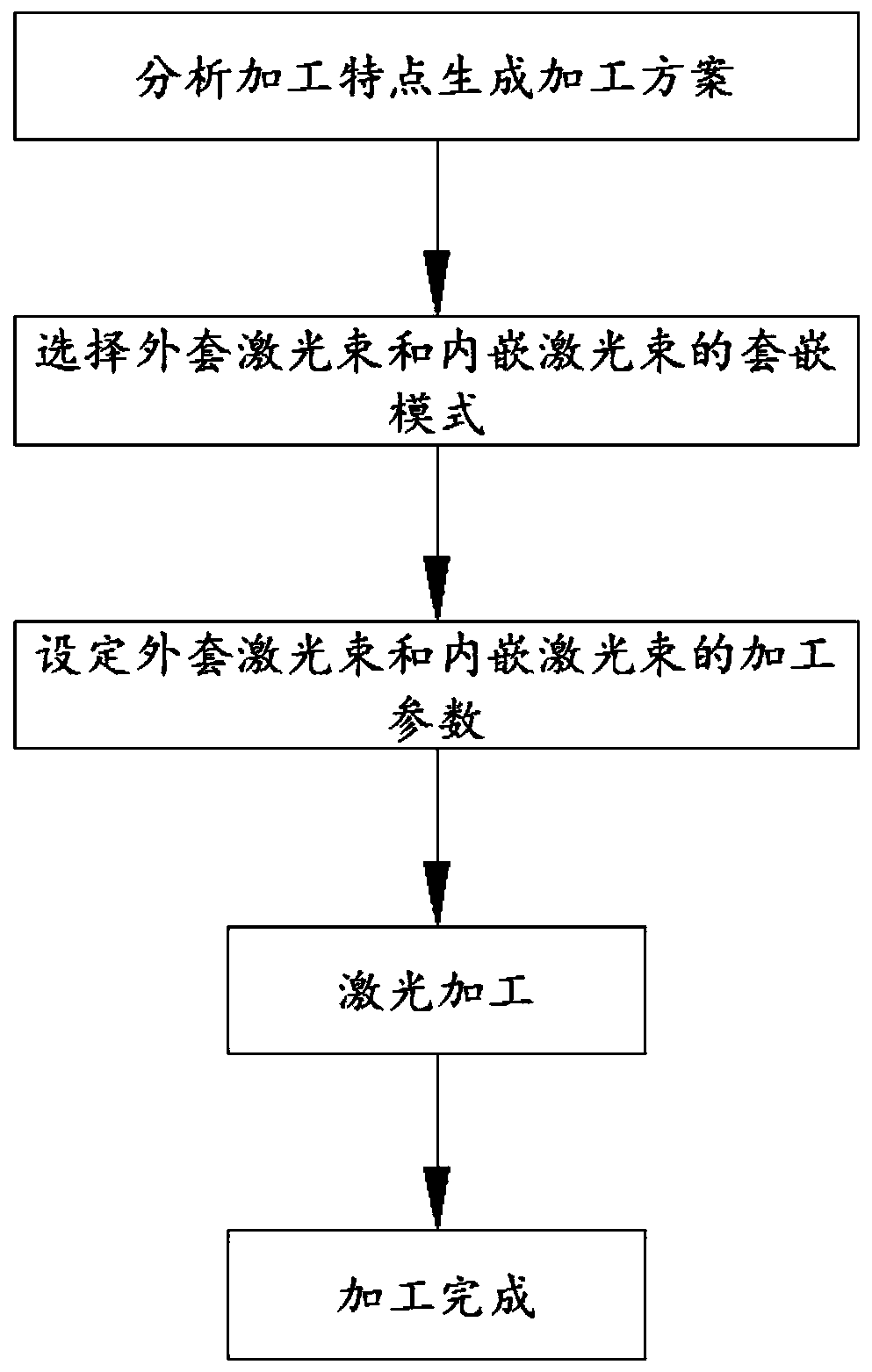

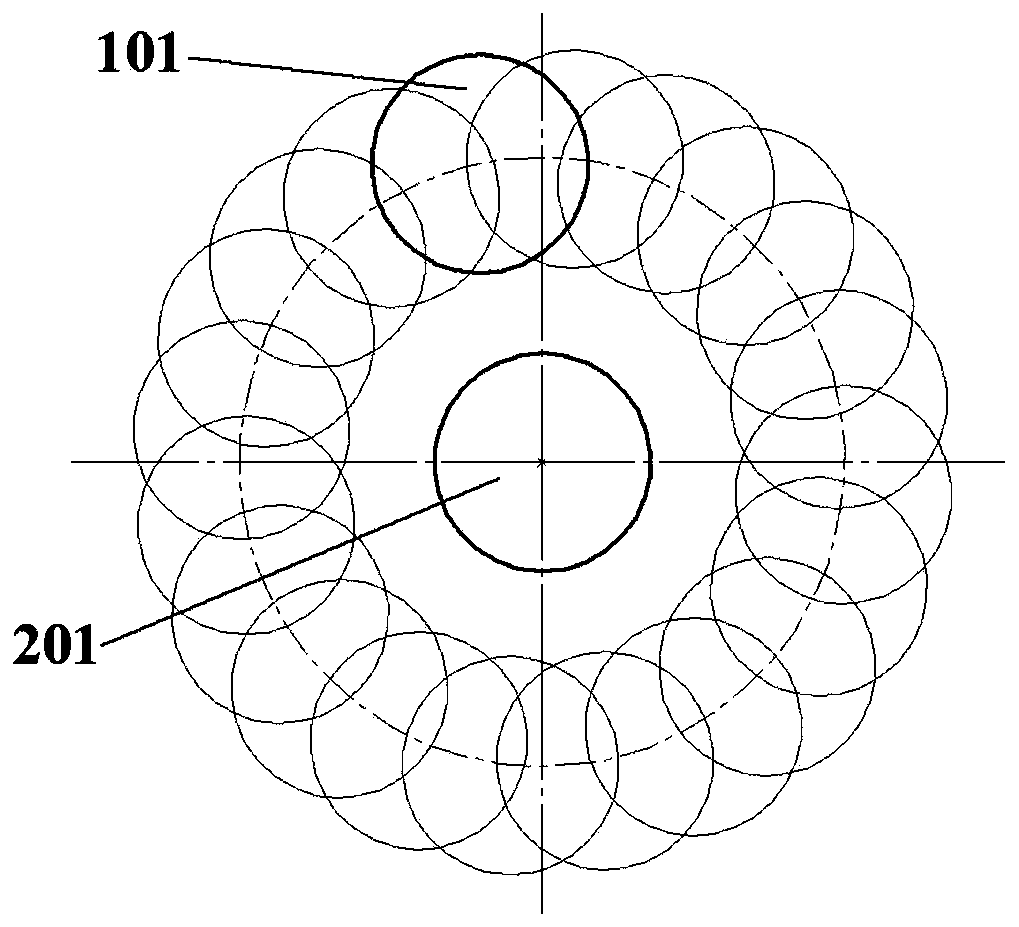

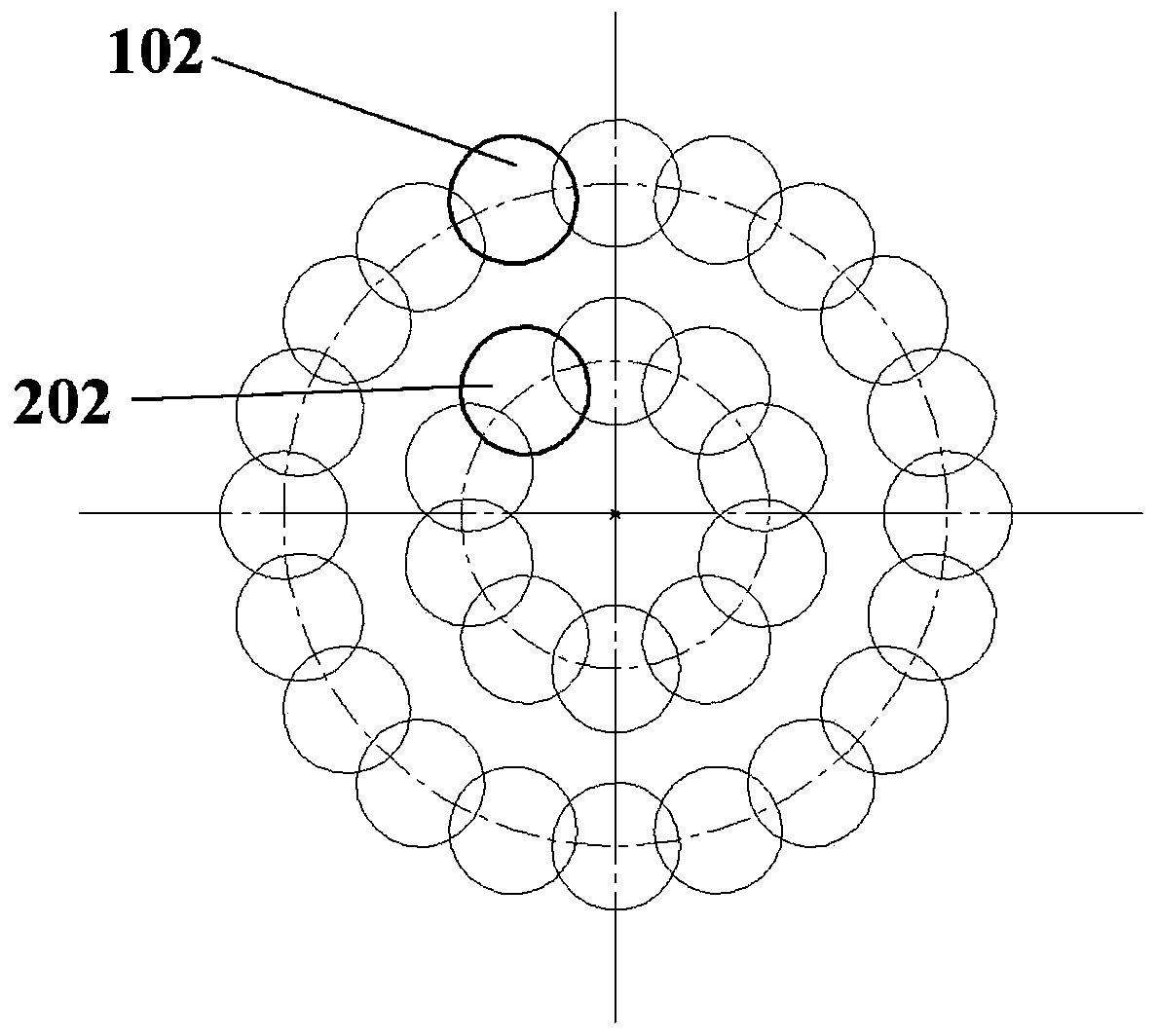

The invention relates to the technical field of laser processing, in particular to a laser sleeving-nesting composite processing method. The laser sleeving-nesting composite processing method comprises the following steps that (1) workpiece analysis is carried out, wherein processing characteristics of a workpiece are analyzed, and meanwhile, an optimal processing scheme suitable for the workpieceis generated; (2) a processing mode is set, and specifically a sleeving-nesting mode of a sleeving laser beam and a nested laser beam is selected; (3) processing parameters are set, and specificallyprocessing parameter setting is carried out on the sleeving laser beam and the nested laser beam which are set in the step (2); and (4) the workpiece is processed, and specifically, laser processing is carried out on the workpiece according to the set processing parameters in the step (3) and the optimal processing scheme in the step (1). According to the laser sleeving-nesting composite processing method, rough processing and finish processing of laser composite processing materials are achieved at a time through mutual nesting of different laser beams, the processing process is simplified, meanwhile, repeated clamping is not needed in one-time processing, and position errors caused by repeated clamping are reduced.

Owner:GUANGDONG UNIV OF TECH

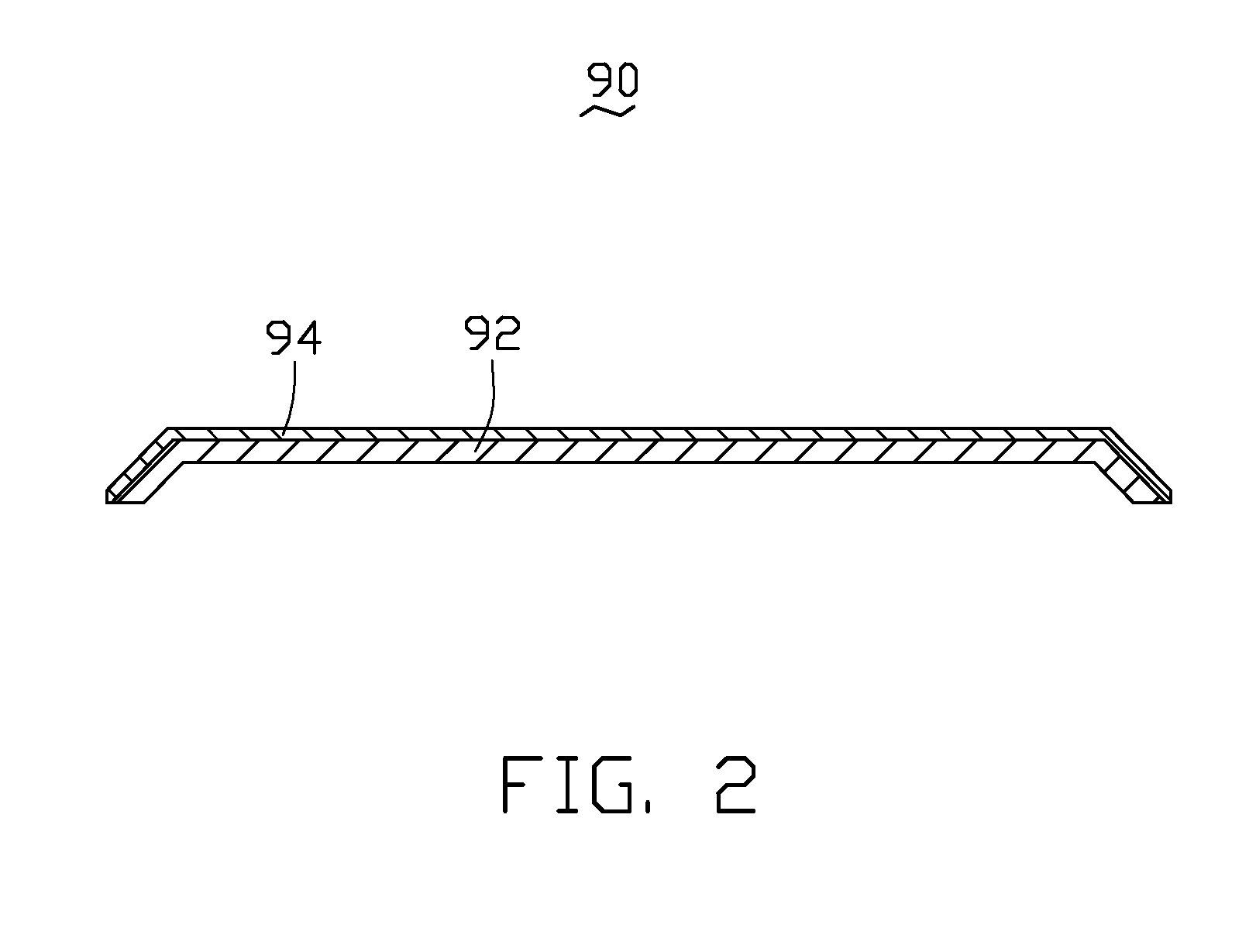

Injection mold and method for making a housing using the injection mold

An injection mold (100) comprises a first female mold (10), a second female mold (20), a first male mold (30) and a second male mold (40). The first male mold (30) and the second male mold (40) rotate to align with the first female mold (10) and the second female mold (20) selectively. One of the female molds defines a cutting portion. The injection mold (100) carries on the cutting process on a soft layer of a semi-finished product. The injection mold (100) can eliminate cutting process by using punching and cutting fixture on the soft layer and save lots of time on making the product, improve processing efficiency.

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD +1

Storage apparatus, and storage control method using the same

InactiveUS8108630B2Low processing efficiencyKeep for a long timeError detection/correctionMemory systemsBitmapData consistency

The present invention aims at providing a storage apparatus that does not increase the I / O load on a primary volume, even if there are several secondary volumes for which data consistency with the primary volume should be guaranteed. A storage apparatus writes write data for write access directed to a primary volume P to a secondary volume S1. A controller in the storage apparatus copies that write data from the secondary volume S1 to secondary volumes. S2 and S3 in background processing. The storage apparatus uses bitmaps to manage data in the secondary volume S1 shared by each of the secondary volumes S2 and S3.

Owner:HITACHI LTD

Arc surface milling assistant processing device

InactiveUS20120141222A1Low processing efficiencyDifficult to operateGuide fencesProfiling/shaping machinesEngineeringMechanical engineering

An arc surface milling machine includes a worktable, a base and a backup plate. The worktable is assembled adjacent to the base. The backup plate is adjustably mounted on the base and positioned adjacent to the worktable. The worktable includes a work surface, an opposite bottom surface, and a mounting end. The base is assembled to the mounting end of the worktable. The work surface defines a concave wedge-shaped receiving space adjacent to the mounting end and forms a milling opening communicating with the work surface and the mounting end.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

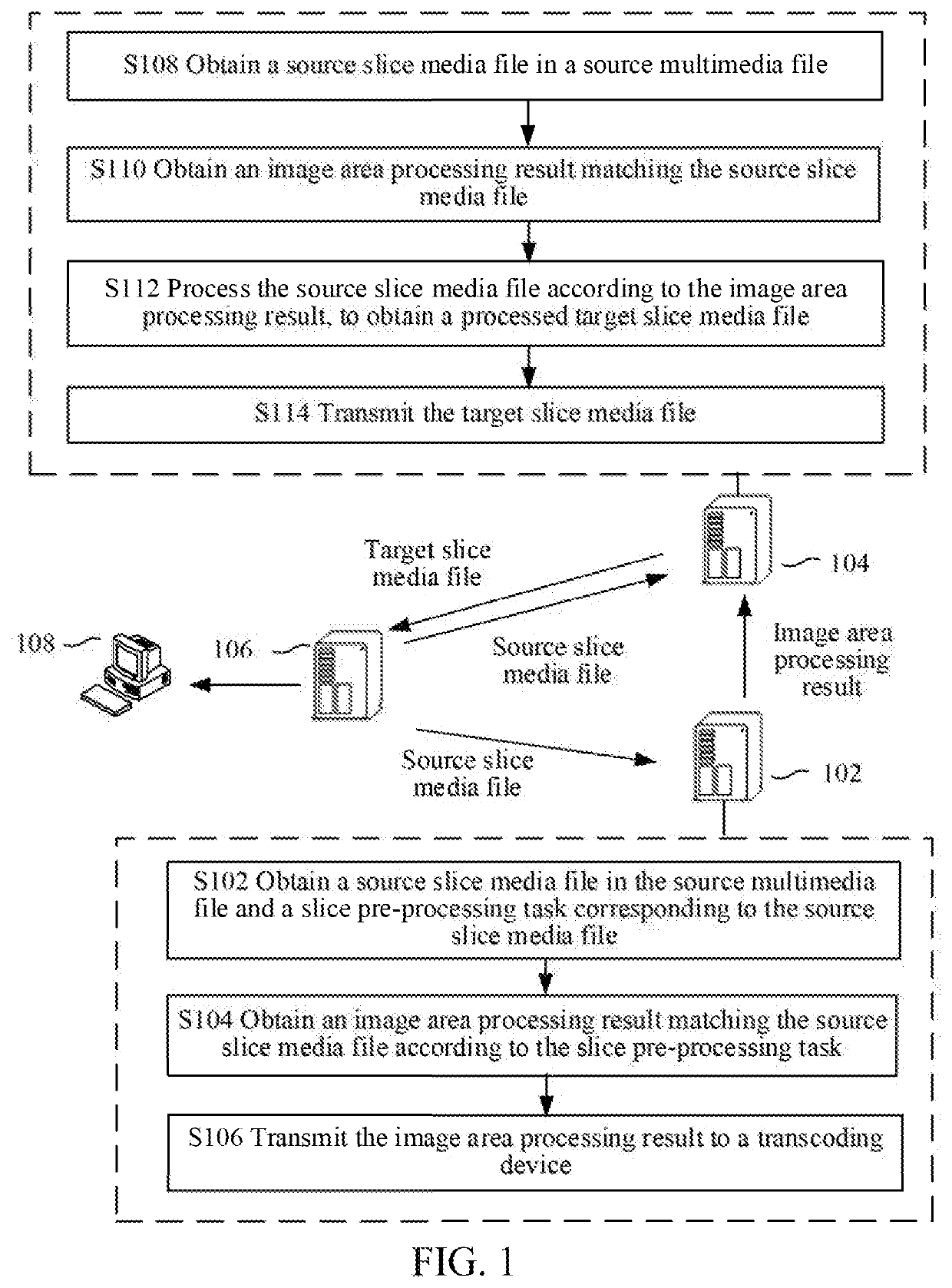

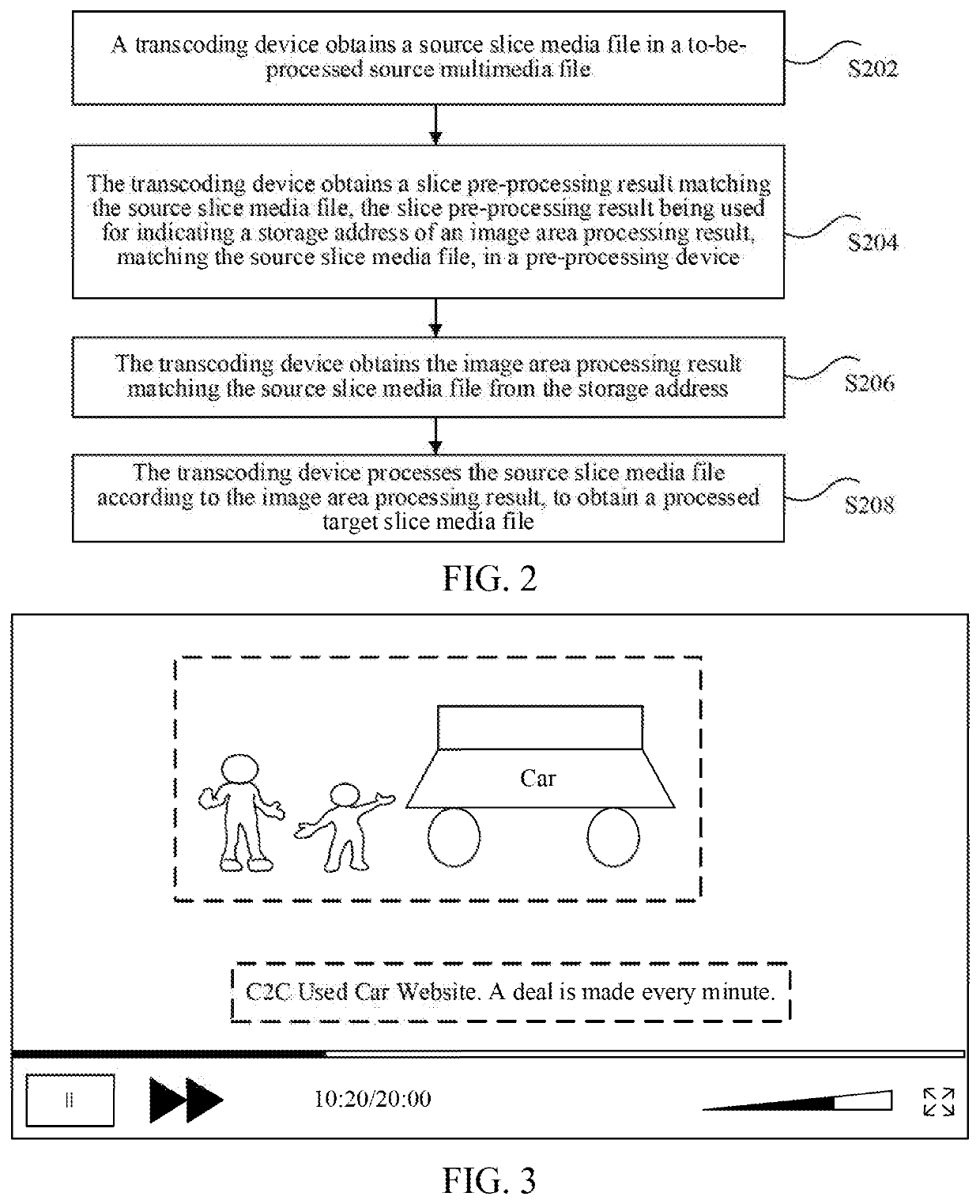

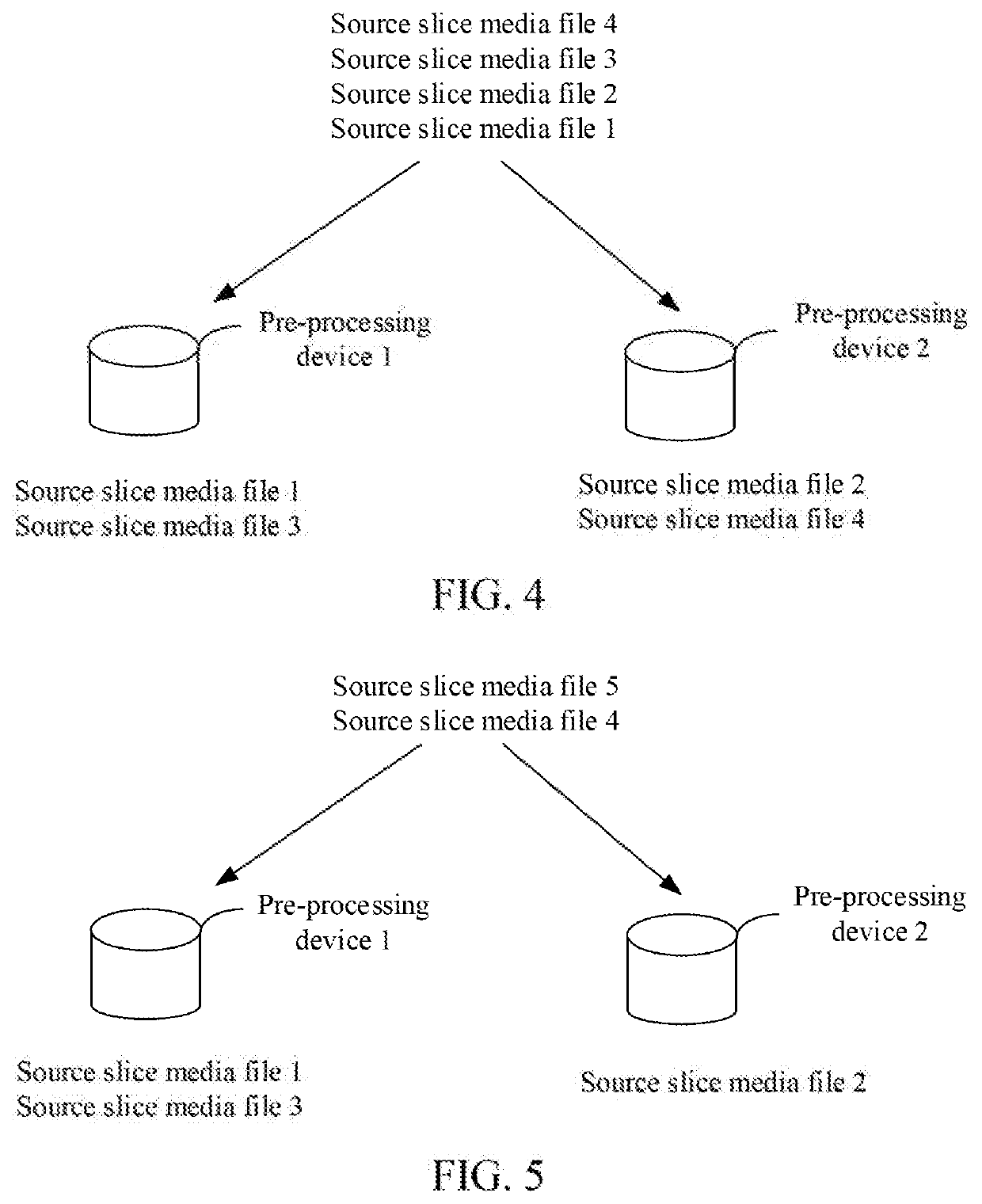

Method and apparatus for processing multimedia file, storage medium, and electronic apparatus

ActiveUS20200344497A1Improve efficiencyLow processing efficiencyDigital data information retrievalDigital video signal modificationComputer hardwareTranscoding

A method for processing a multimedia file is described. The method includes obtaining a source slice media file included in a source multimedia file, and obtaining, by processing circuitry of a transcoding device, a slice pre-processing result corresponding to the source slice media file, the slice pre-processing result indicating a storage address of an image area processing result of the source slice media file, in a pre-processing device. The method also includes obtaining, by the processing circuitry of the nanscoding device, the image area processing result of the source slice media file from the storage address. Finally, the method includes processing, by the processing circuitry of the transcoding device, the source slice media file according to the image area processing result, to obtain a processed target slice media file.

Owner:TENCENT TECH (SHENZHEN) CO LTD

Mobile terminal and image processing method thereof

ActiveUS20150212793A1Solve the processing efficiency is not highImprove image processing efficiency2D-image generationSound input/outputFast Fourier transformImaging processing

The present disclosure discloses an image processing method of a mobile terminal, and a mobile terminal. To process an image, an audio signal is collected using a sensor of the mobile terminal. Air-blowing signal intensity is acquired by performing a windowed fast Fourier transform (FFT) on the audio signal to obtain a frequency domain signal of the audio signal. The frequency domain signal of the audio signal is divided into at least one time-slice frequency domain signal. It is then identified whether the audio signal is an air-blowing signal according to the at least one time-slice frequency domain signal and a preset property of the air-blowing signal. The air-blowing signal intensity is acquired according to the at least one time-slice frequency domain signal when the audio signal is identified as an air-blowing signal. An image is acquired according to the air-blowing signal intensity. In this manner, the image processing method using the air-blowing signal intensity may provide improved processing efficiency and simplified operation.

Owner:TENCENT TECH (SHENZHEN) CO LTD

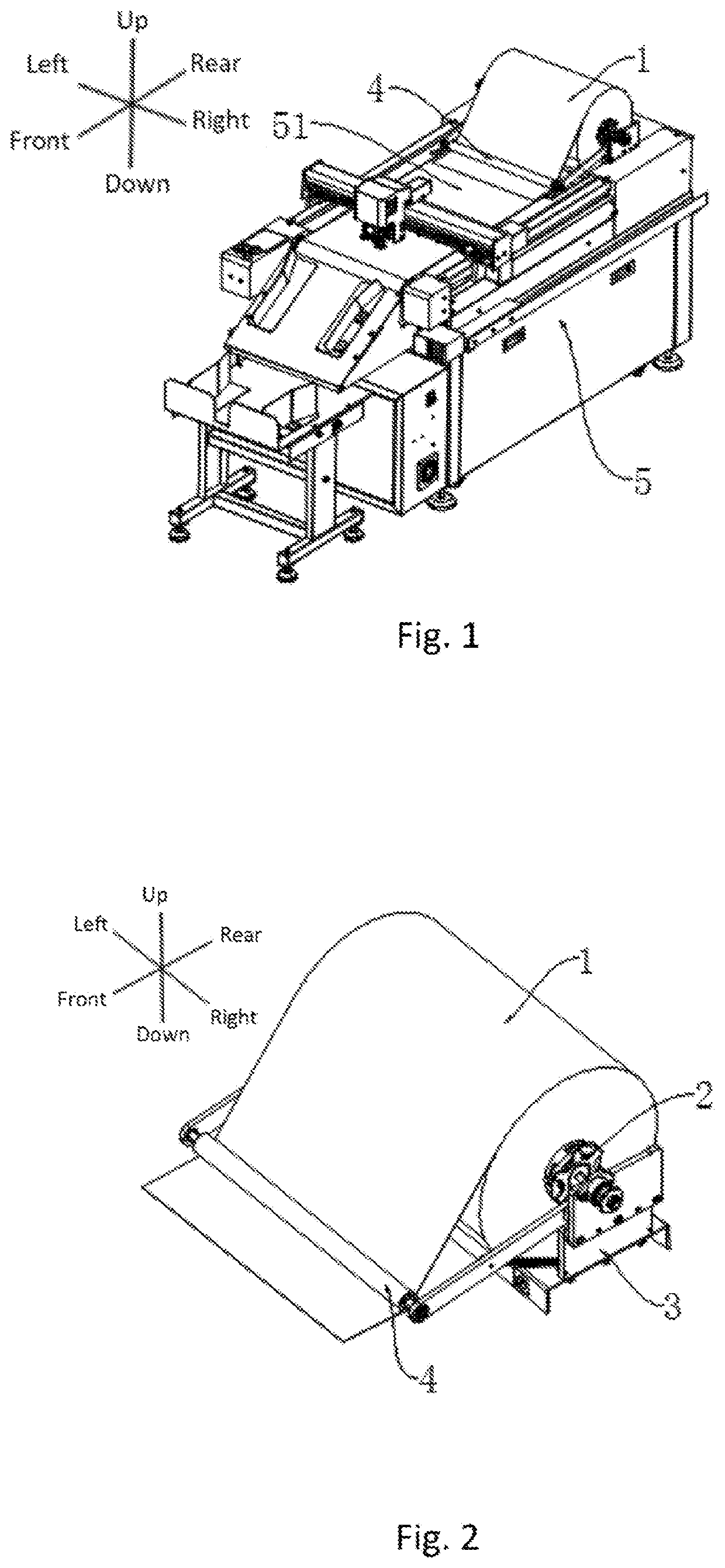

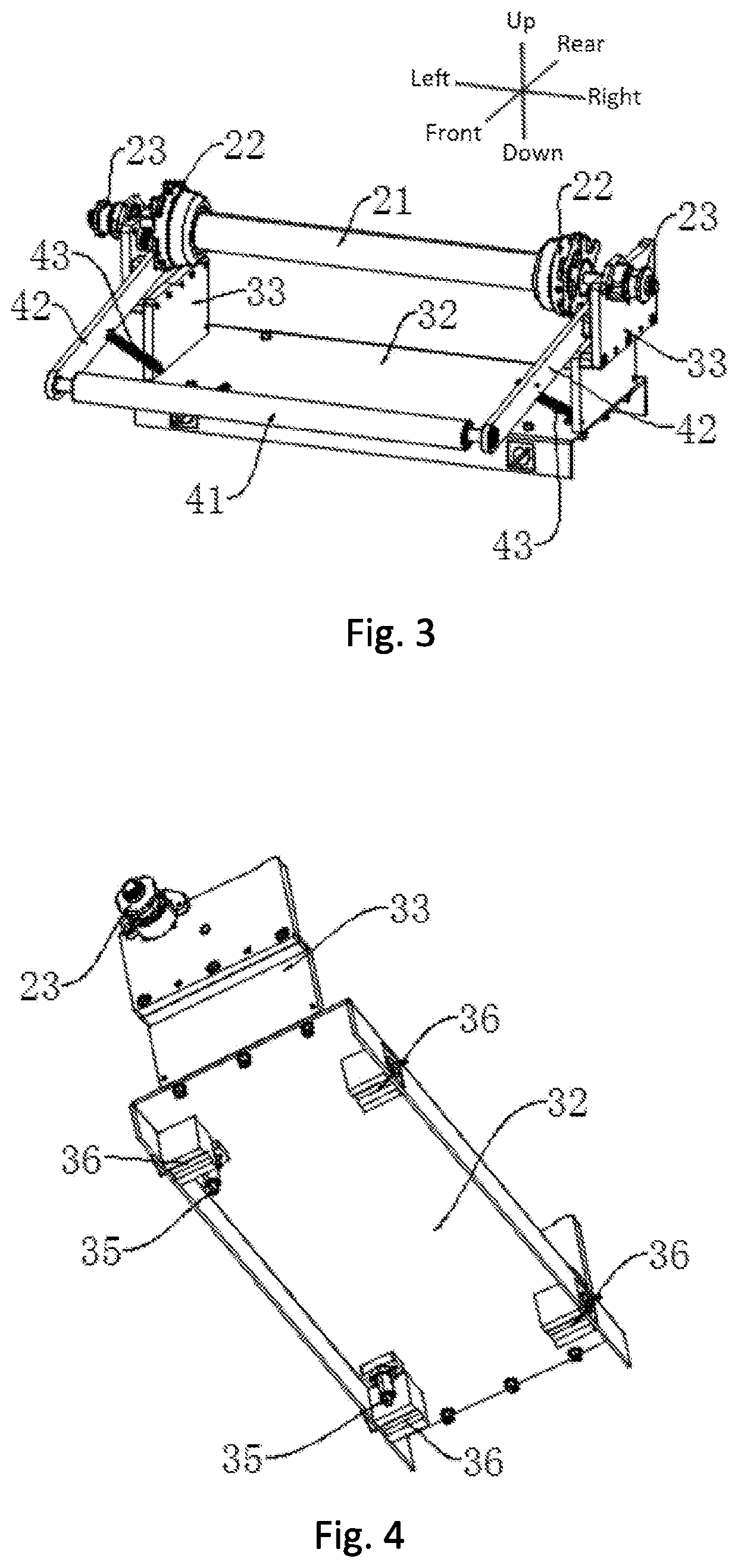

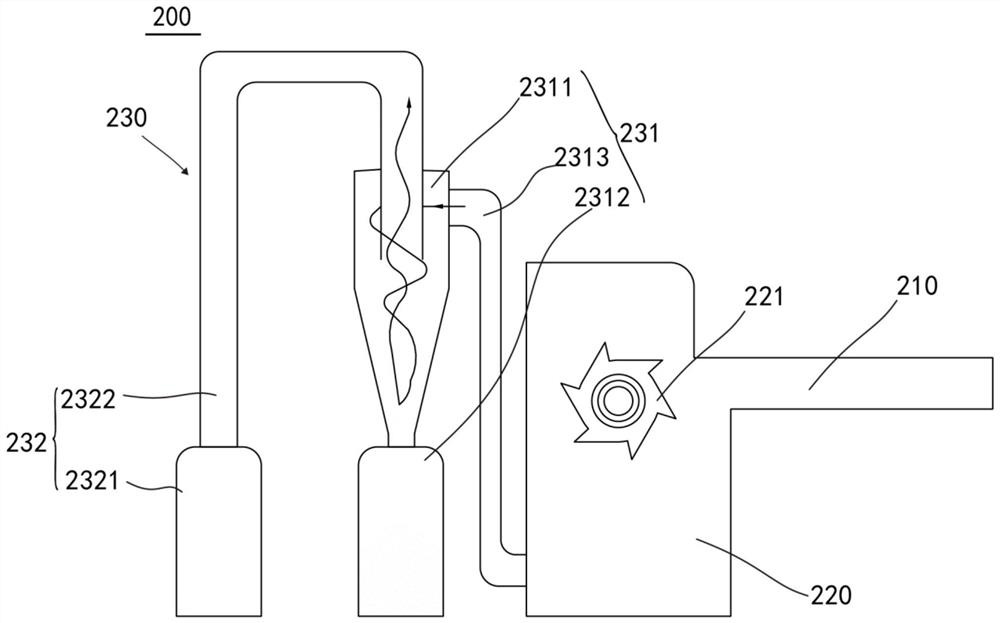

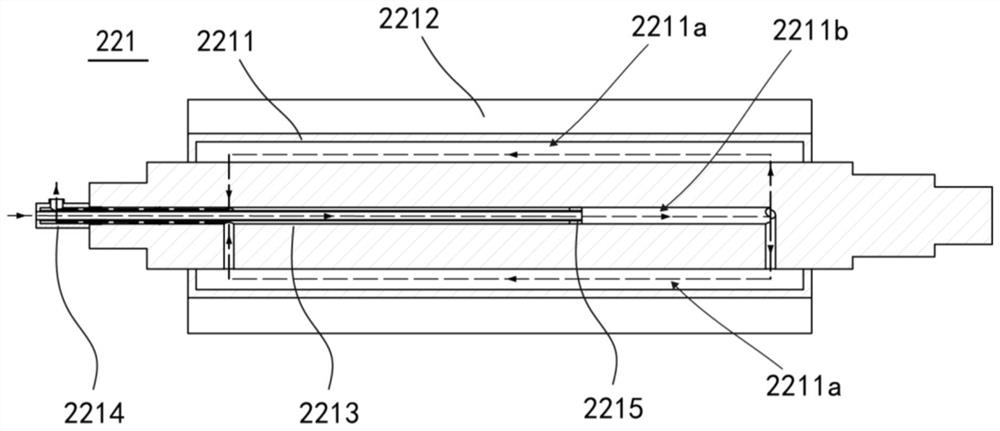

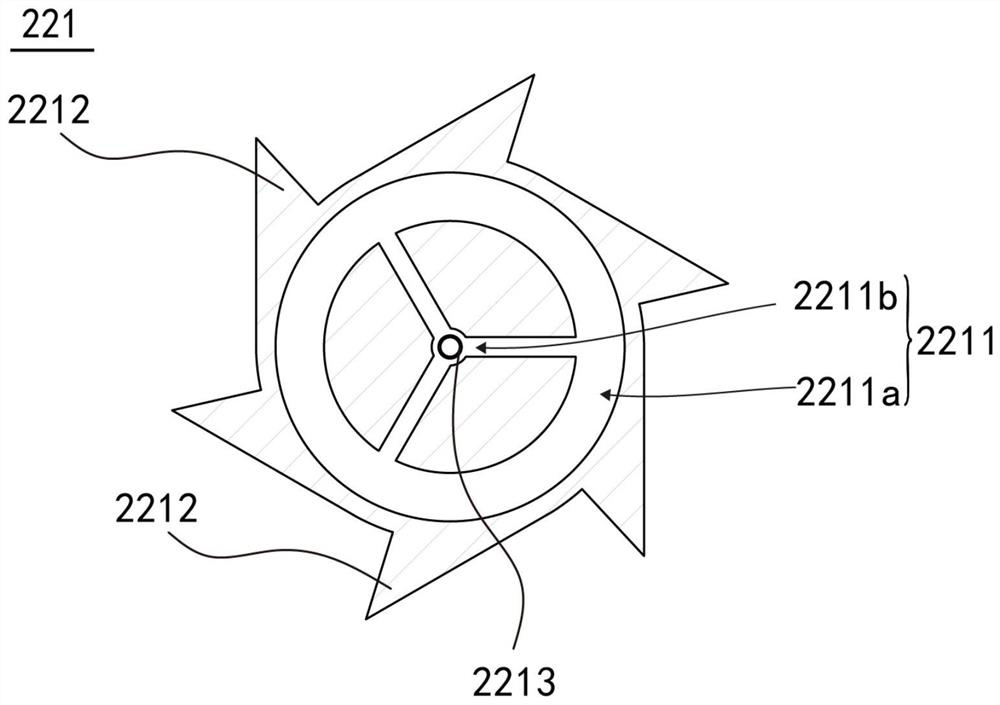

Coil feeding device and graphic machine thereof

ActiveUS20210107762A1Complex structureSolve the processing efficiency is not highFilament handlingWebs handlingGraphicsStructural engineering

A coil feeding device and a graphic machine thereof are provided. The coil feeding device includes a roller mechanism for carrying a coiled material, a base mechanism, and a compression rod mechanism. The roller mechanism includes a shaft penetrating through the shaft hole and a tension structure disposed on the shaft. The tension structure includes a first sleeve, a second sleeve and a tapered fixing member. When the first sleeve and the second sleeve are fixed to each other, the tapered fixing member holds the shaft to achieve mutual fixation of the coiled material and the shaft. By providing the second sleeve, the first sleeve and the tapered fixing member that cooperate with each other, the coiled material and the shaft are fastened to each other quickly, thereby improving production efficiency. Through the base mechanism, the coil feeding device is directly used on existing graphic machine for material processing.

Owner:NINGBO JINGWEI SYSTEMTECHNIK LTD

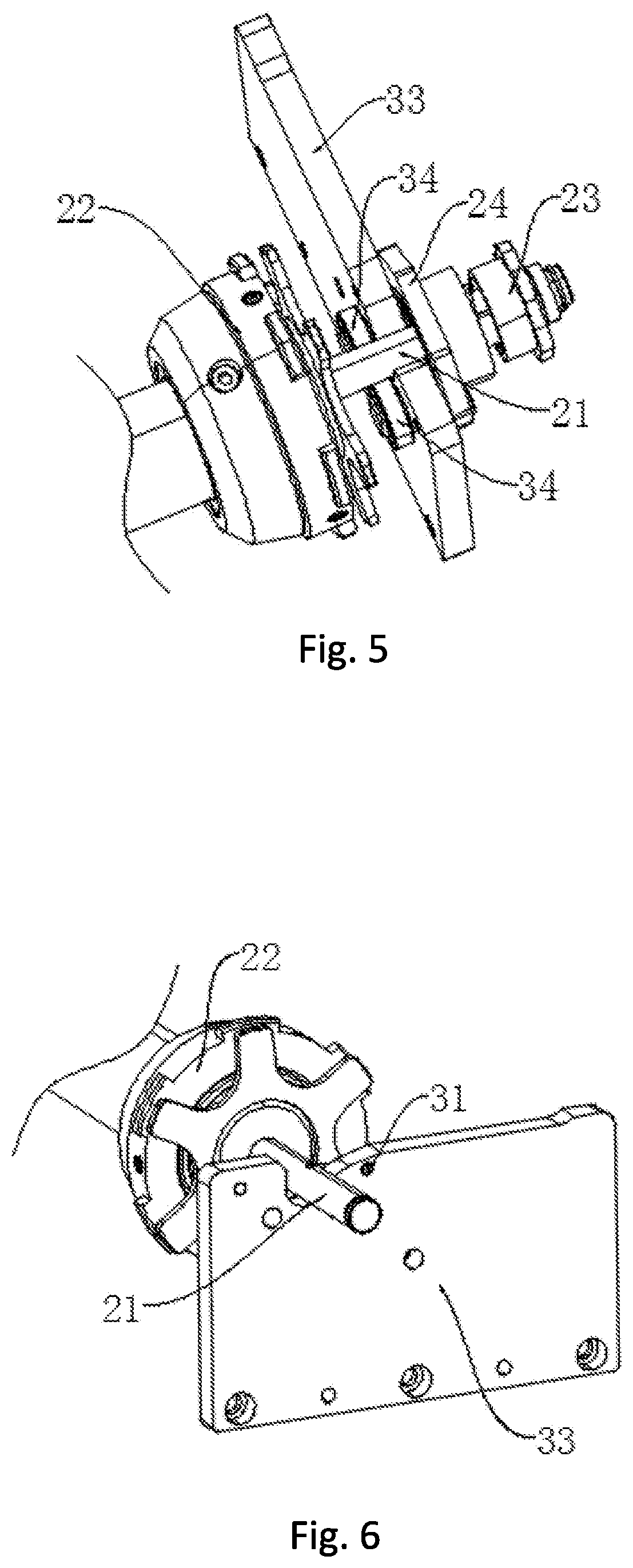

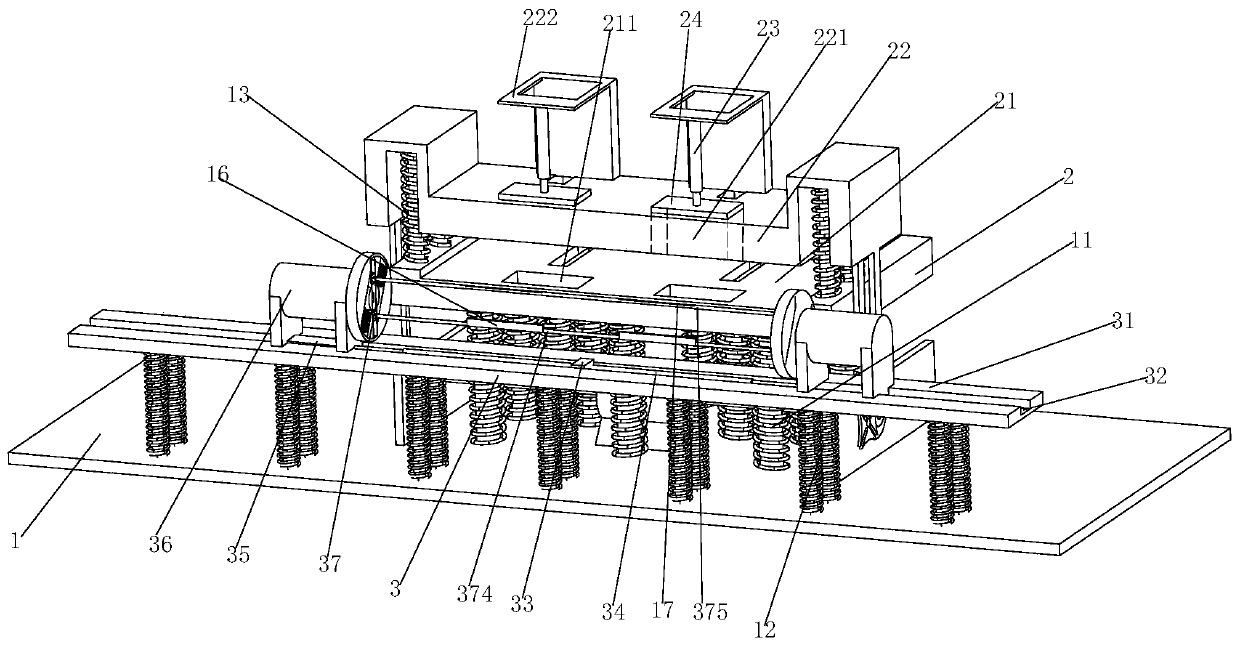

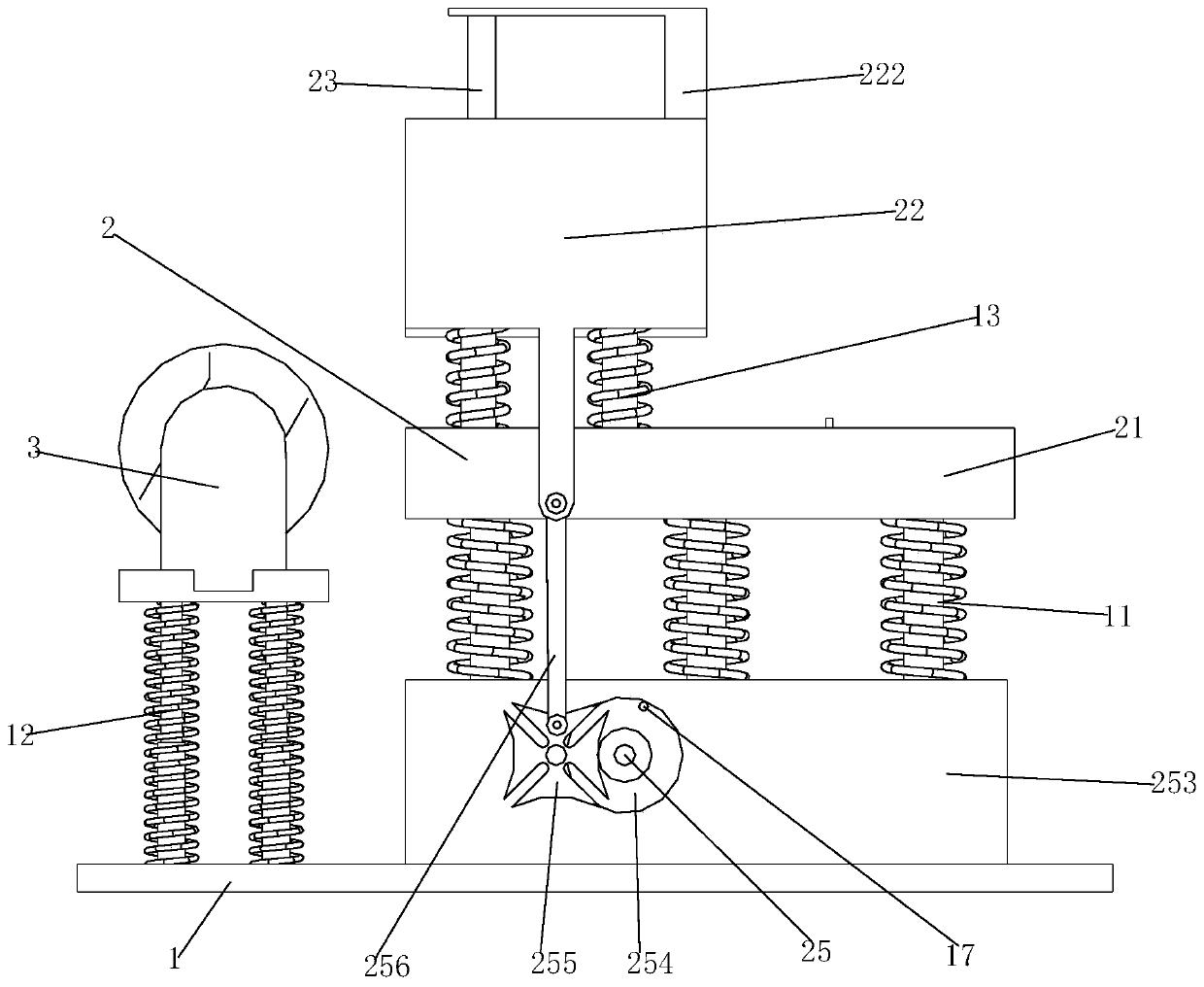

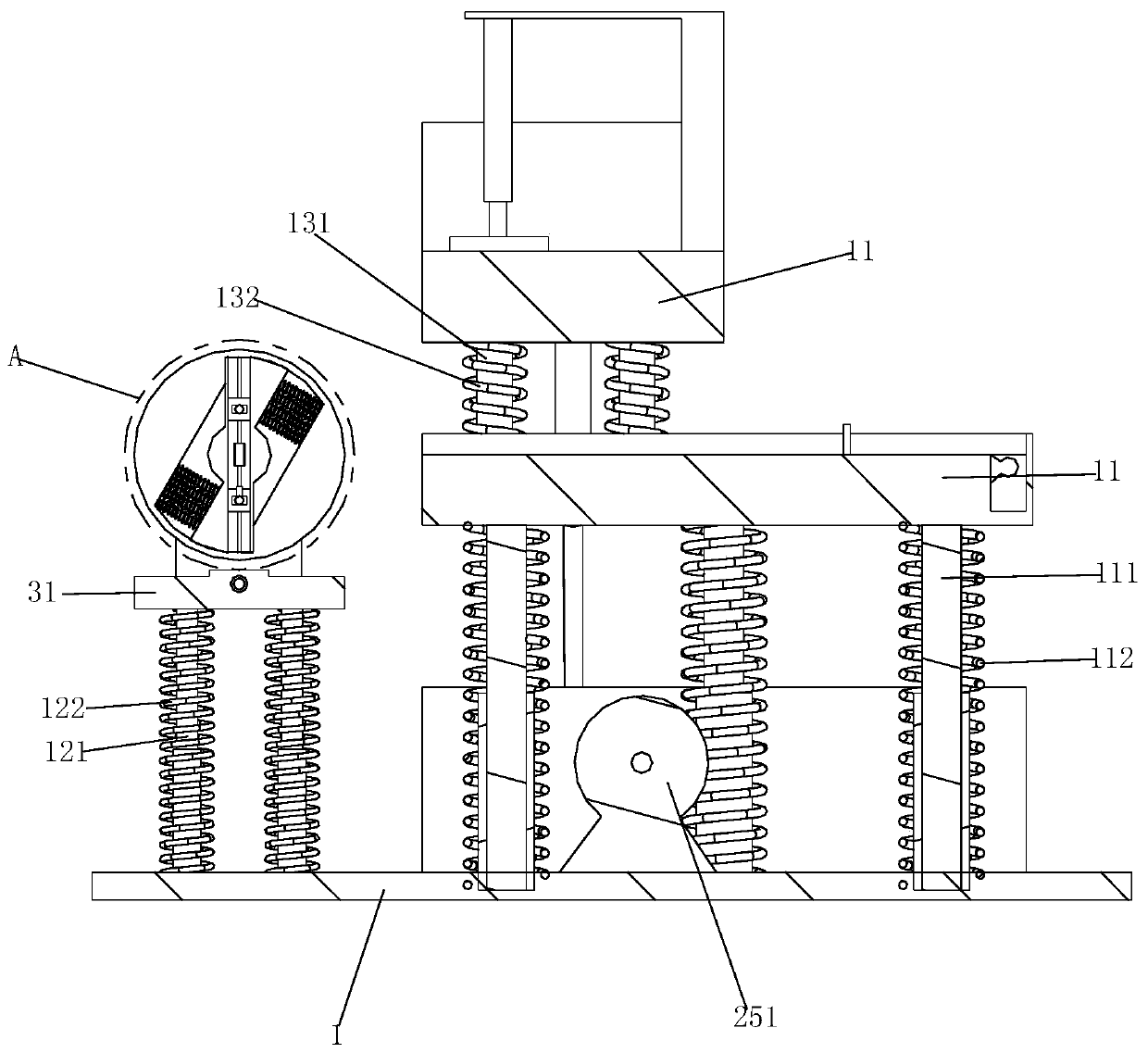

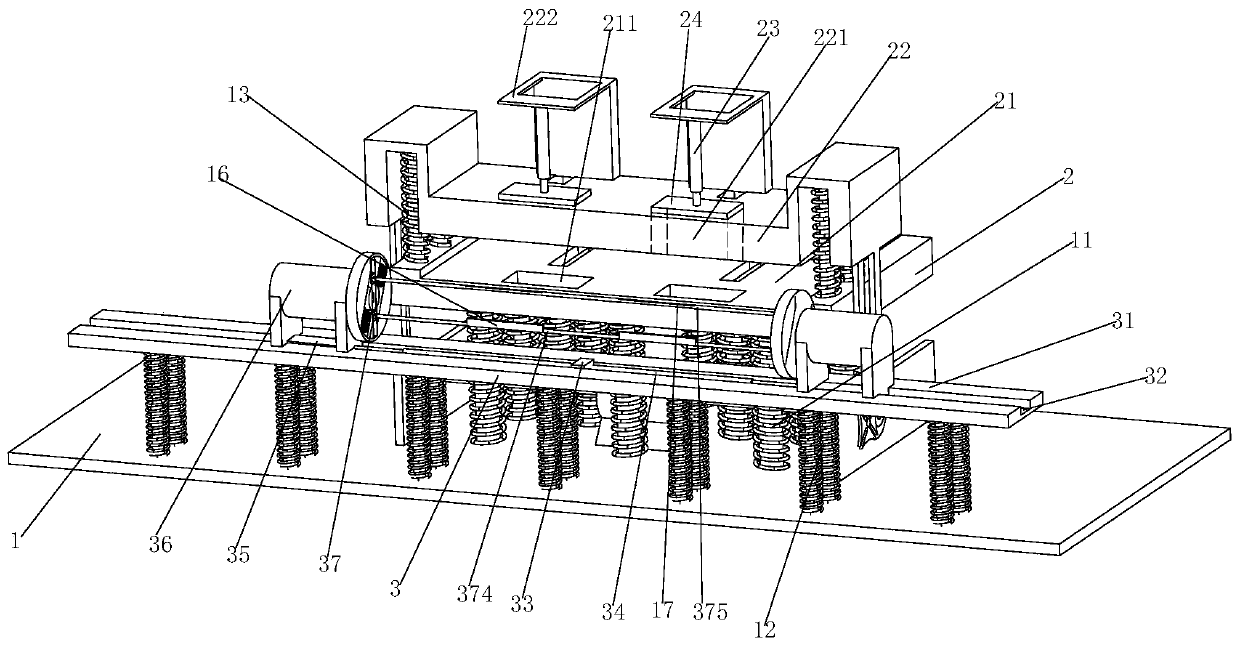

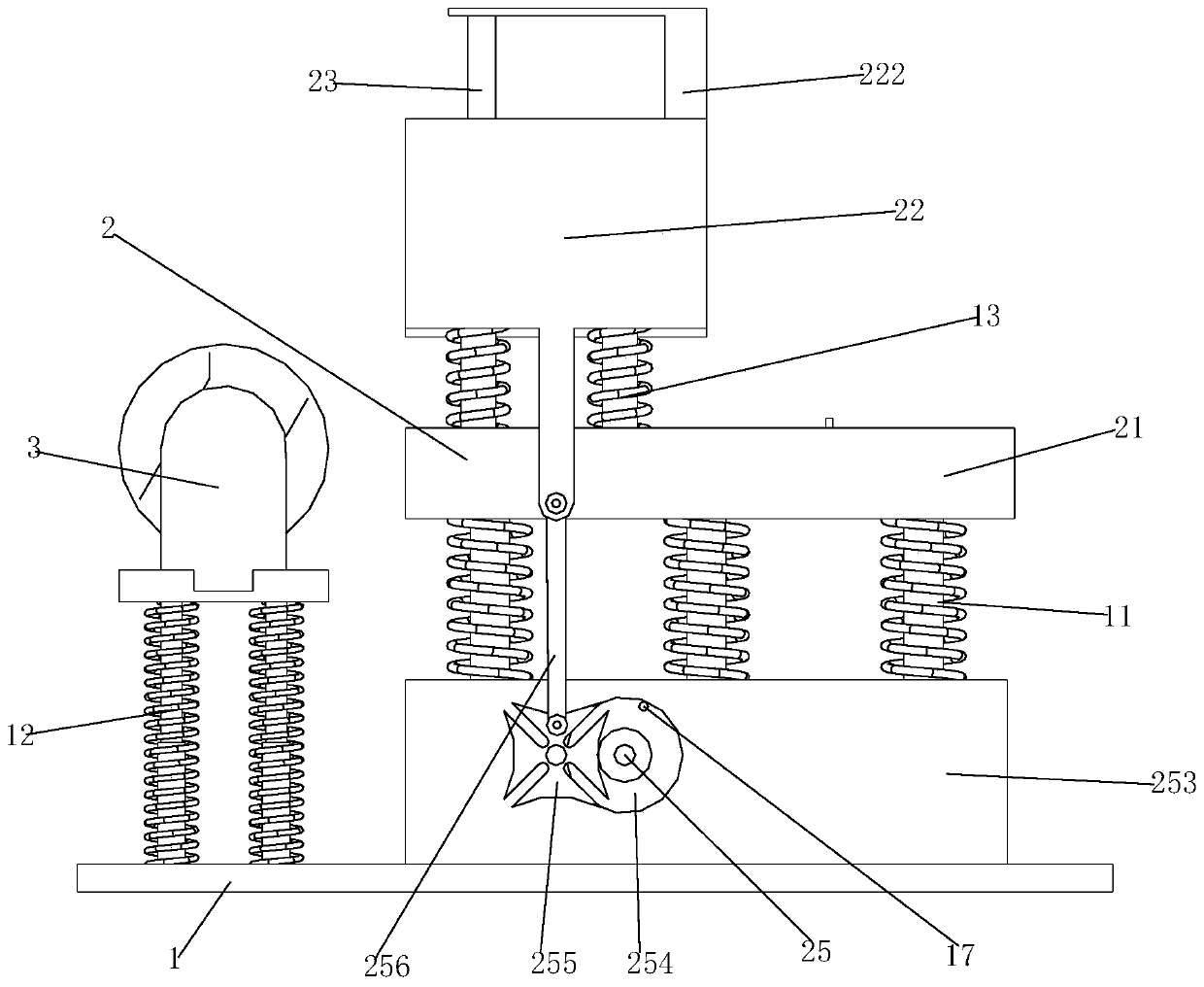

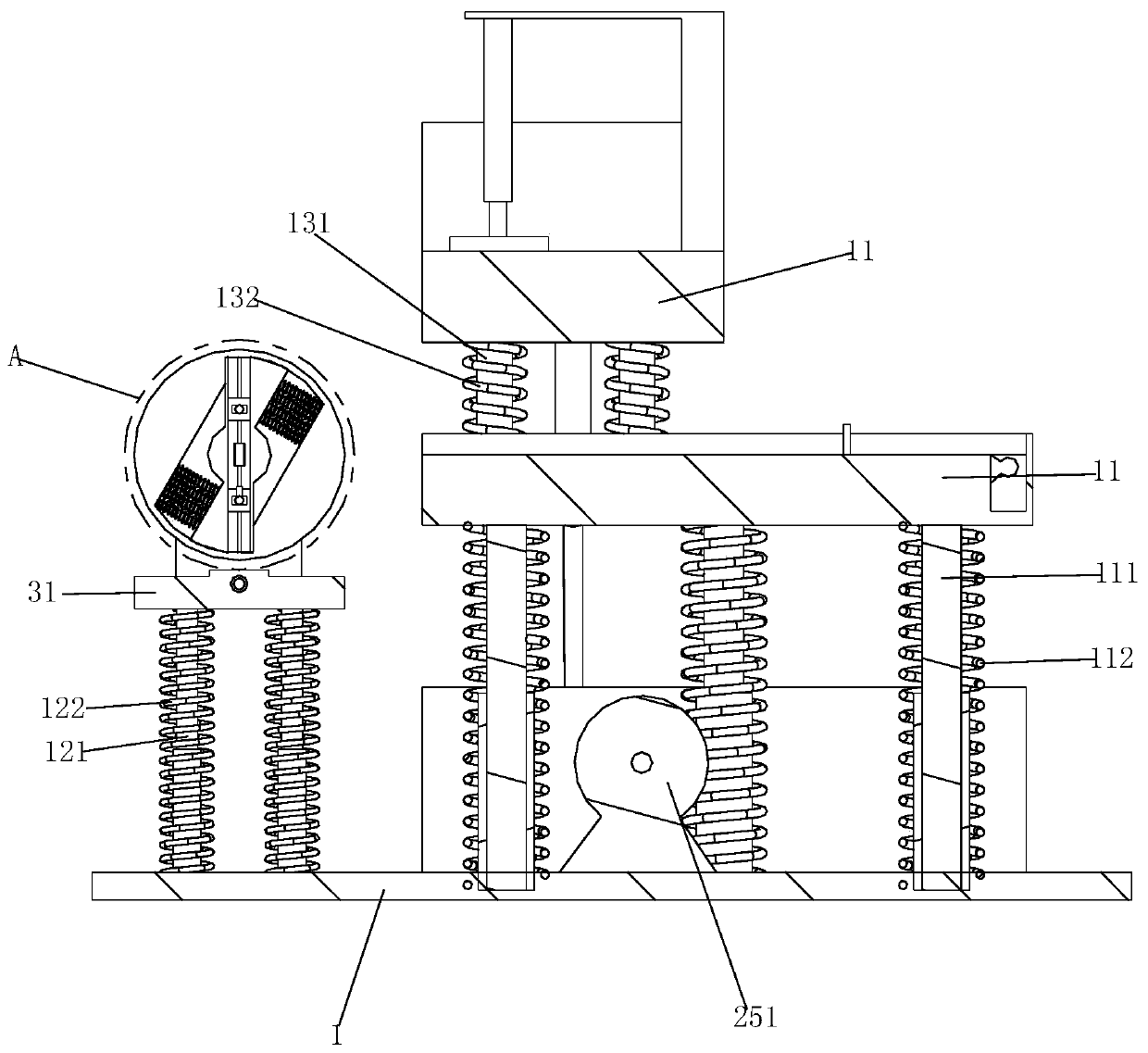

A kind of seam crimping machine and seam curling process for machining thin metal sheet

ActiveCN110899553BLow processing efficiencyLow degree of automationHingesVibration suppression adjustmentsThin metalEngineering

The invention relates to a seaming and hemming machine for machining a thin metal plate and the seaming and hemming process. The machine comprises a base, a grooving device and a hemming device, wherein a first damping mechanism and a second damping mechanism are evenly installed on the base, the first damping mechanism is located in front of the second damping mechanism, the grooving device is installed on the first damping mechanism, and the hemming device is installed above the second damping mechanism. The machine is advantaged in that when a lower hinge (hinge) machining machine is used for slotting and hemming a to-be-machined workpiece, the to-be-machined workpiece can be machined, in the prior art, machining of each station is usually achieved through single-machine operation, forexample, metal plates with the same size are cut out and placed on the side of a station of a grooving machine, the metal plates are grooved firstly, and then edge hemming machining of the next station is conducted on the grooved metal plates, so hinge pieces need to be machined through an assembly line device one procedure by one procedure, hinge piece machining production efficiency is low, theautomation degree is not high, and labor intensity is high.

Owner:江苏龙胜机床制造有限公司

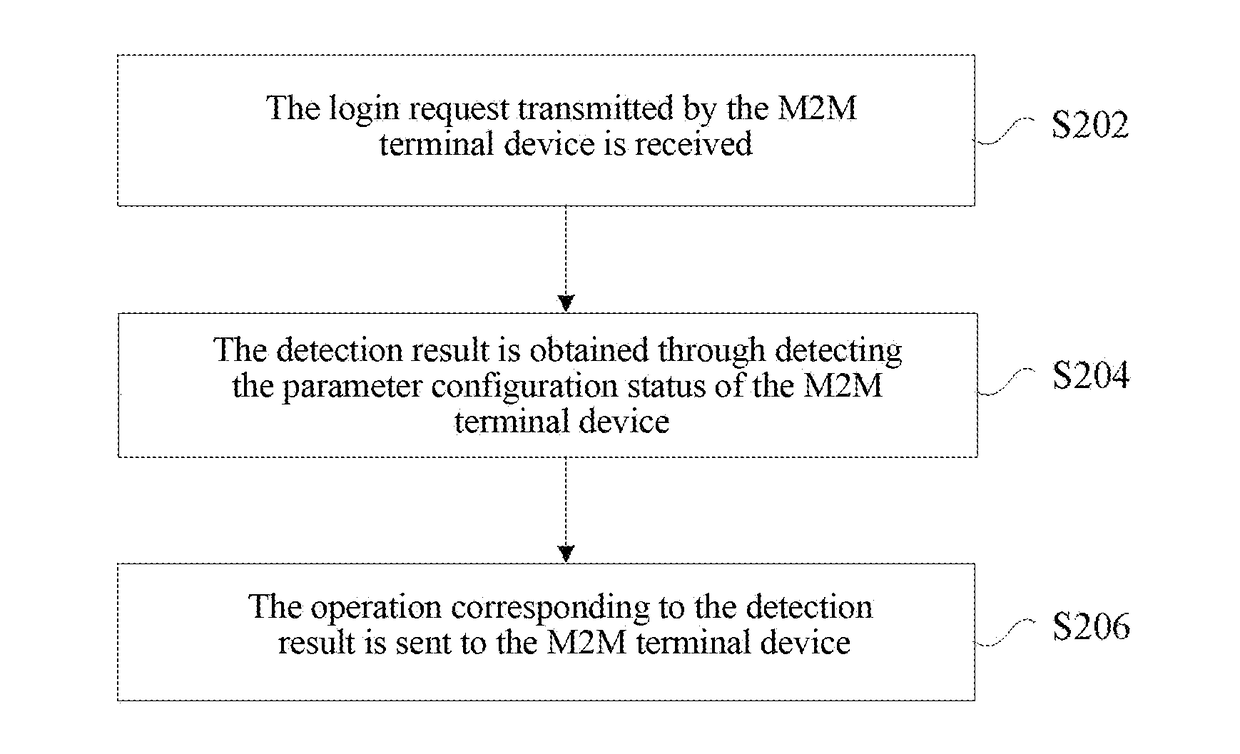

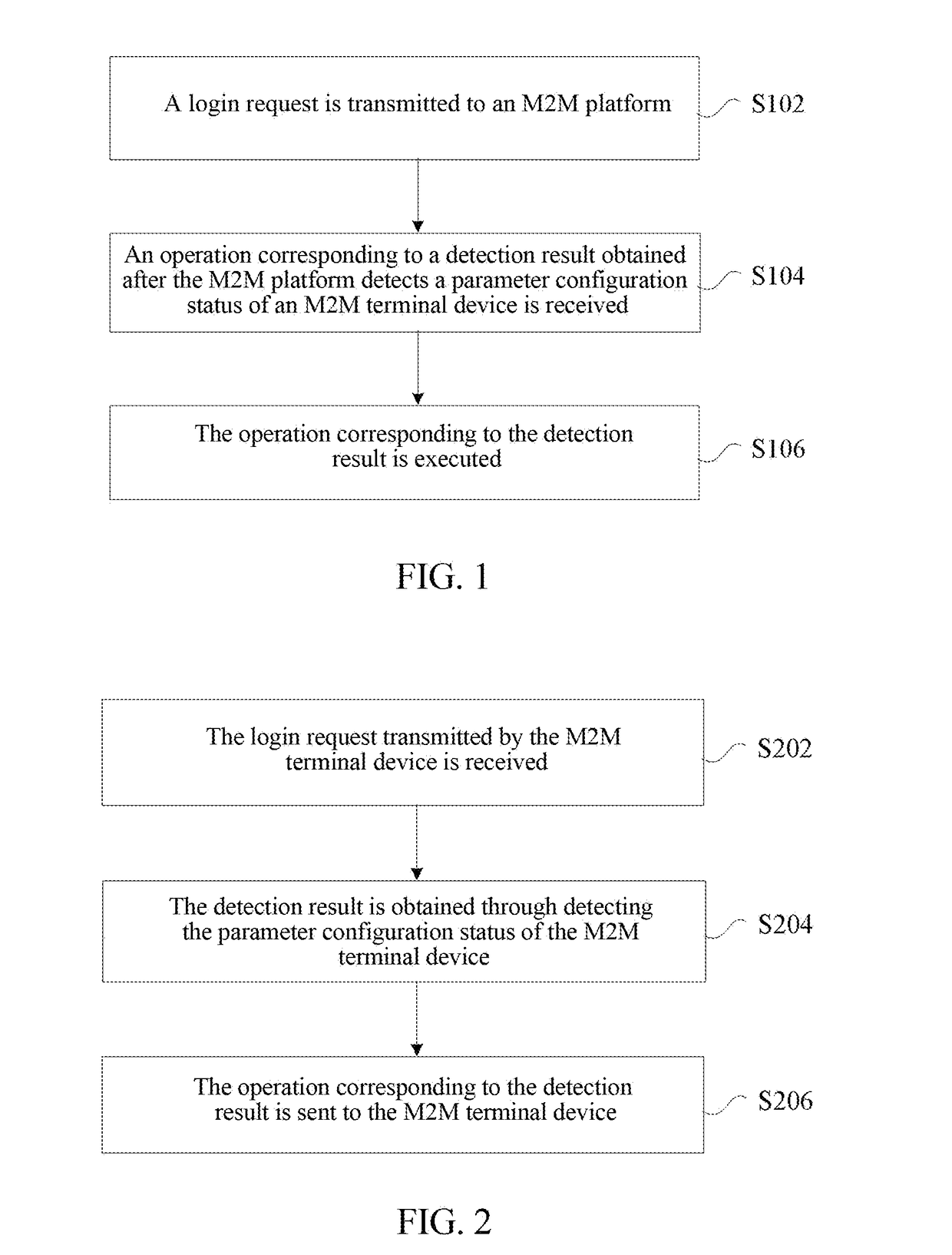

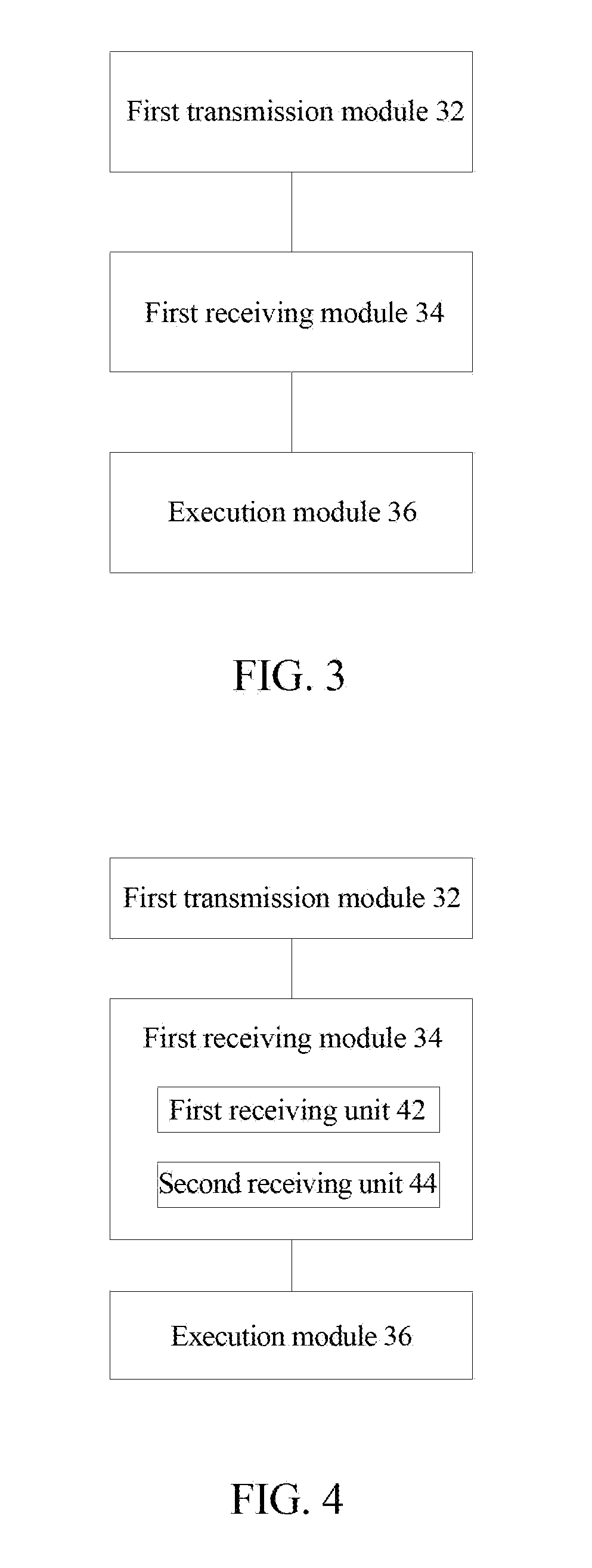

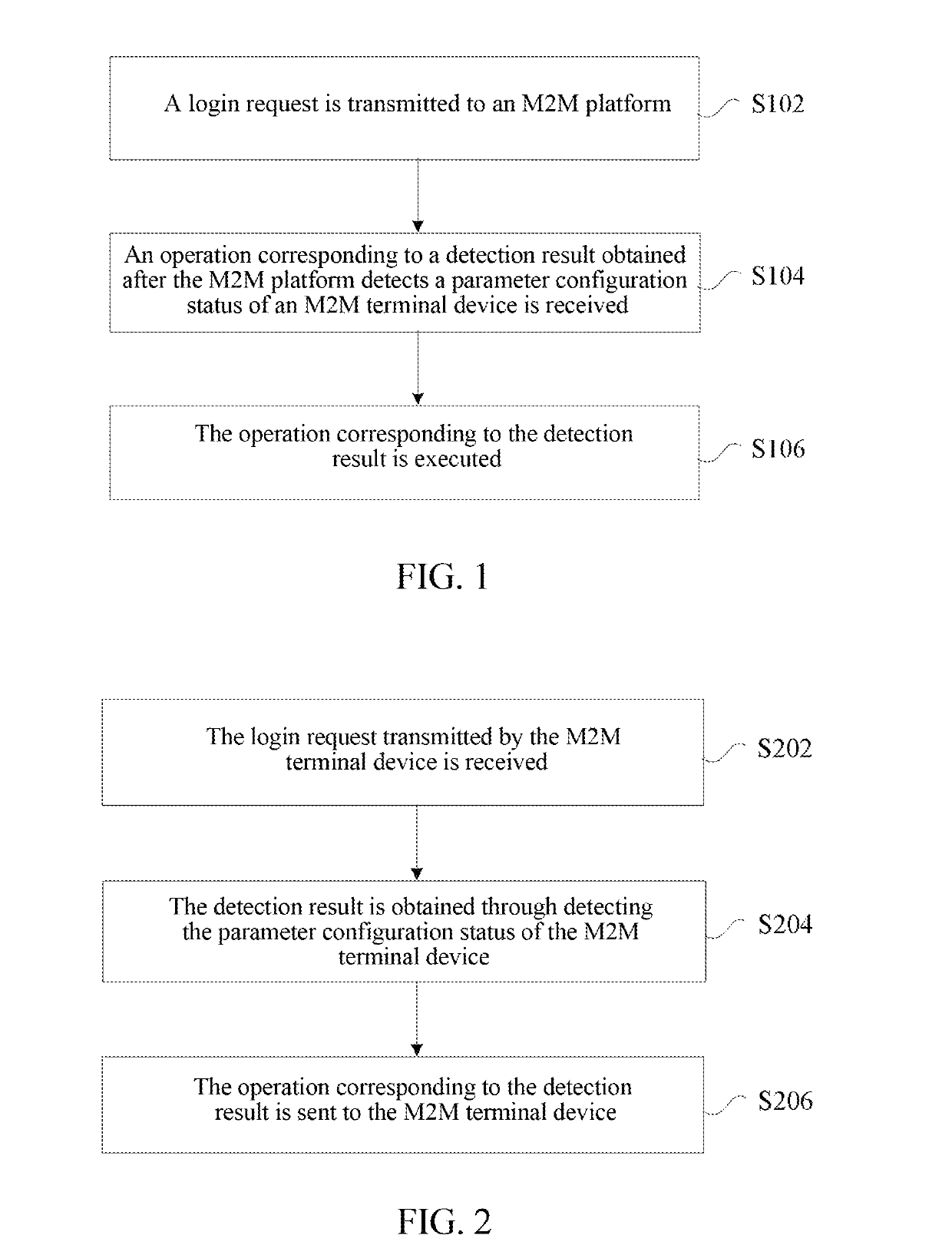

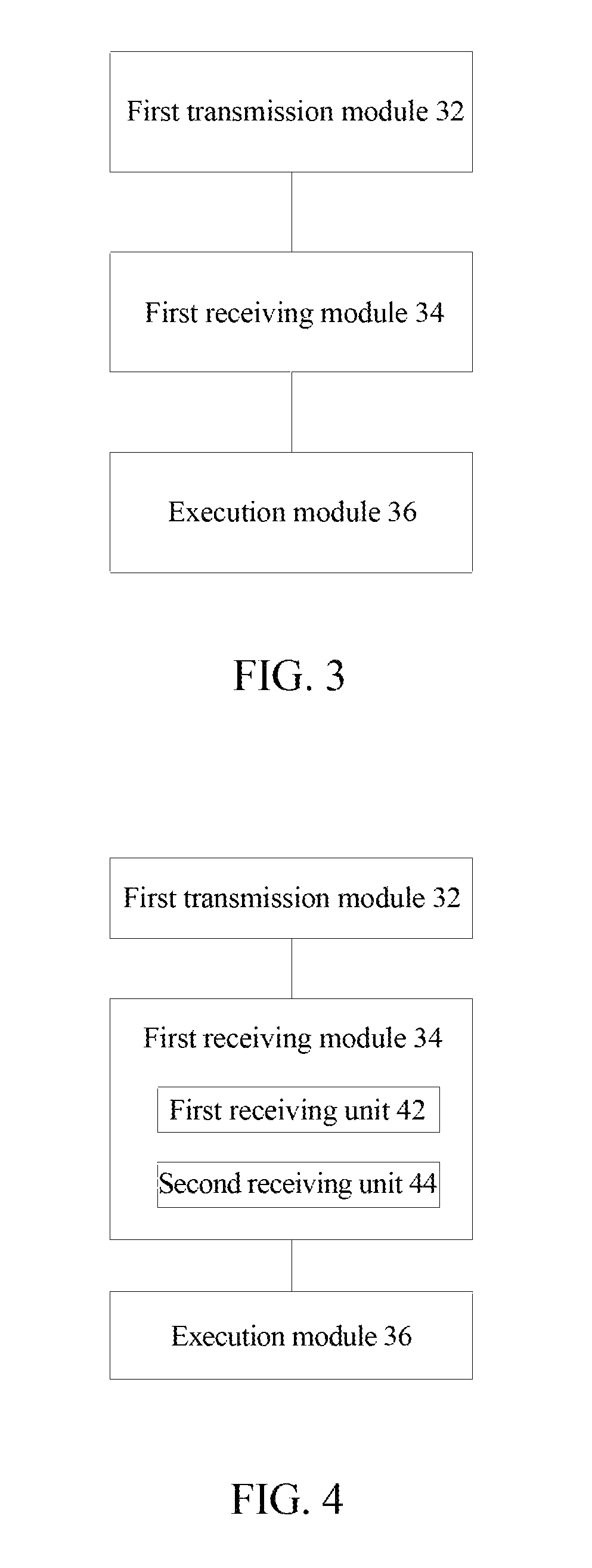

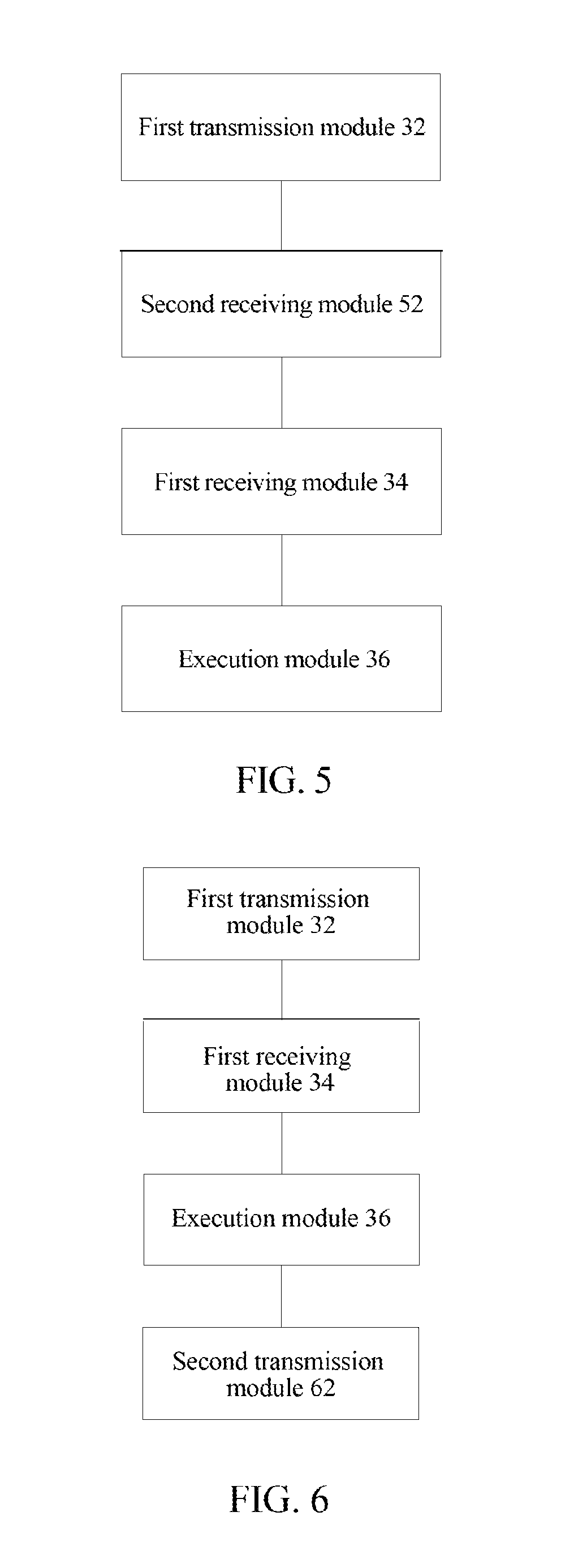

Login Processing Method and Device of Machine-to-Machine/Man Communication Terminal Equipment

ActiveUS20170149754A1Solve the processing efficiency is not highLow processing efficiencyData switching networksSecurity arrangementTerminal equipmentComputer terminal

The present document provides a method and apparatus for login processing of a Machine-to-Machine / Man (M2M) terminal device, herein, the method includes: transmitting a login request to an M2M platform; receiving an operation corresponding to a detection result obtained after the M2M platform detects a parameter configuration status of an M2M terminal device; and executing the operation corresponding to the detection result. The present document solves the problem of low login processing efficiency of an M2M terminal device in the related art, and then realizes processing the parameter configuration status of the M2M terminal during the login processing of the M2M terminal device.

Owner:ZTE CORP

Seaming and hemming machine for machining thin metal plate and seaming and hemming process

ActiveCN110899553ALow processing efficiencyLow degree of automationHingesVibration suppression adjustmentsThin metalEngineering

The invention relates to a seaming and hemming machine for machining a thin metal plate and the seaming and hemming process. The machine comprises a base, a grooving device and a hemming device, wherein a first damping mechanism and a second damping mechanism are evenly installed on the base, the first damping mechanism is located in front of the second damping mechanism, the grooving device is installed on the first damping mechanism, and the hemming device is installed above the second damping mechanism. The machine is advantaged in that when a lower hinge (hinge) machining machine is used for slotting and hemming a to-be-machined workpiece, the to-be-machined workpiece can be machined, in the prior art, machining of each station is usually achieved through single-machine operation, forexample, metal plates with the same size are cut out and placed on the side of a station of a grooving machine, the metal plates are grooved firstly, and then edge hemming machining of the next station is conducted on the grooved metal plates, so hinge pieces need to be machined through an assembly line device one procedure by one procedure, hinge piece machining production efficiency is low, theautomation degree is not high, and labor intensity is high.

Owner:江苏龙胜机床制造有限公司

Method and system for account parallel processing

ActiveUS8788374B2Low processing efficiencyGood serviceComplete banking machinesHand manipulated computer devicesParallel processingProcess operation

A method for account parallel processing used by an account processing center to process a request for account operation is disclosed. The method comprises: (1) categorizing accounts as high parallel occurrence accounts and common accounts; (2) when receiving the request from the client for processing operation of an account, firstly determining whether the account is a high parallel occurrence account; and if the account is a high parallel occurrence account, continuing to a step (3), otherwise, conducting a step (4); (3) if the account is locked, queuing a current operation to wait until implementation of the current operation; and (4) further determining, by the account processing center, whether the account is locked and outputting an error message when the account is locked, otherwise implementing the current operation. Such method provides more high quality services to the high parallel occurrence accounts. As for the common accounts, when there is a high volume of parallel transactions on the common accounts, the volume of parallel processing can be effectively controlled by outputting an error message to prevent comment accounts from causing damage the system.

Owner:ADVANCED NEW TECH CO LTD

Scrap processing device and system for protection of waste trademark brands

The invention discloses a scrap processing device and system for protection of waste trademark brands. The scrap processing device comprises a feeding mechanism, a cutting mechanism, and a collectionmechanism; the cutting mechanism is provided with a feeding port and a discharging port; the feeding mechanism is in communication with the feeding port; the collection mechanism comprises a first collection part and a second collection part; the first collection part is in communication with the discharge port; and the top of the first collection part is in communication with the second collection part. The scrap processing system comprises a processing workshop and the scrap processing device for the protection of the waste trademark brand. The scrap processing device for the protection of the waste trademark brands can achieve the purpose of isolating employees and dust when processing the waste trademarks. The processing efficiency is high, no delivery is required, and the processing cost is low. The scrap trademark brands can be processed on the same day without the need for being stacked on sites, which greatly reduces the processing cost.

Owner:广东康派环创科技有限公司

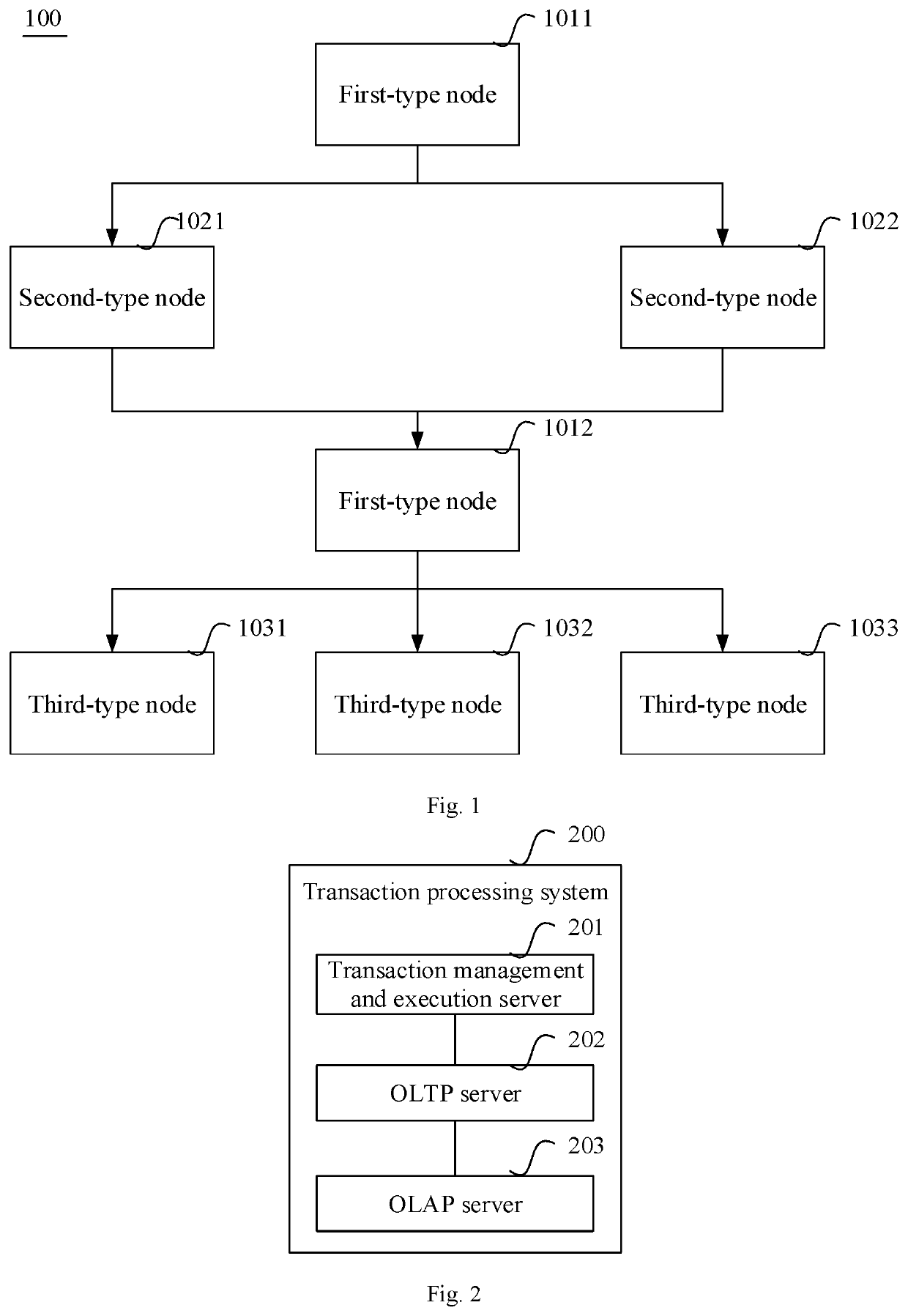

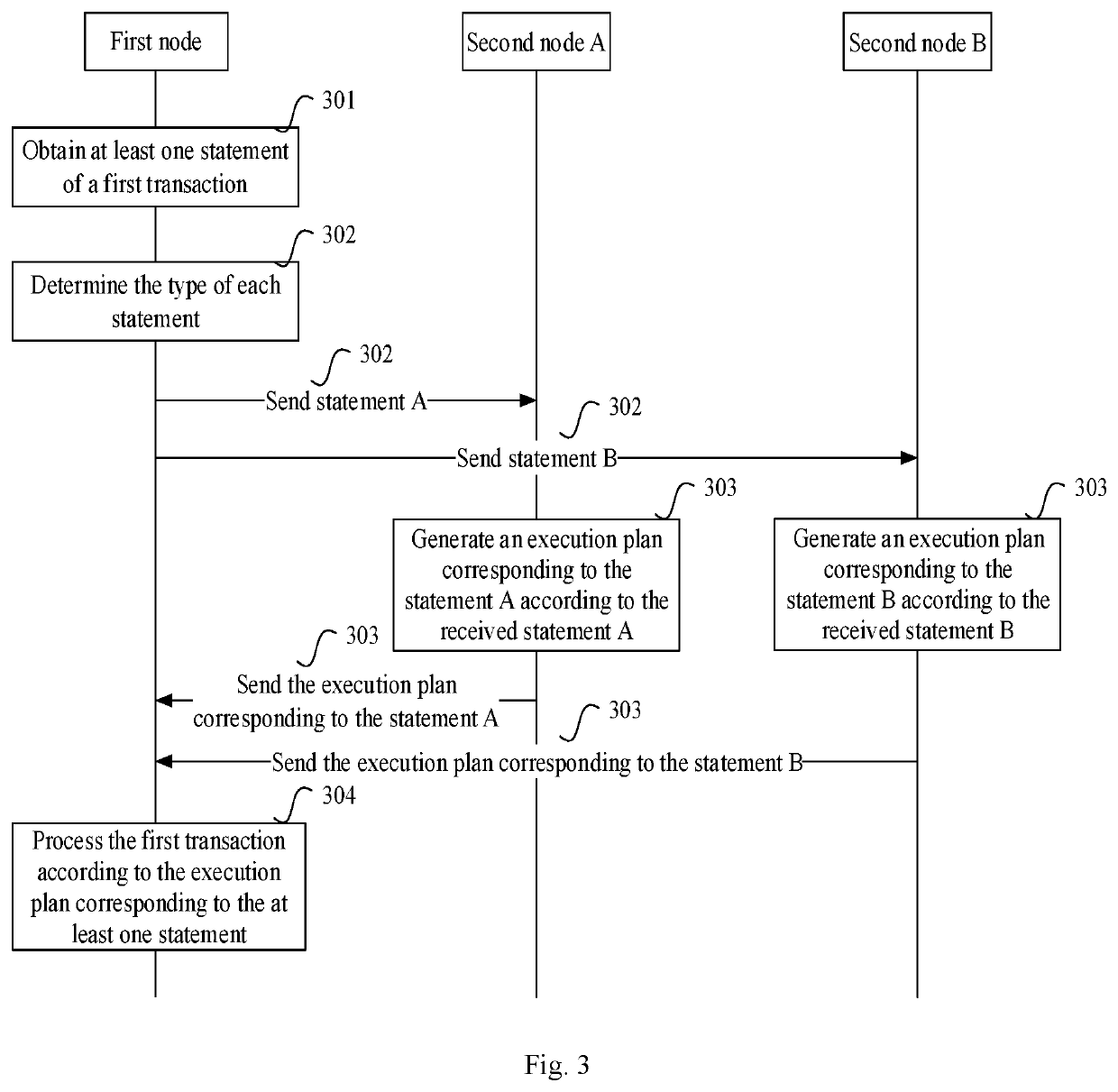

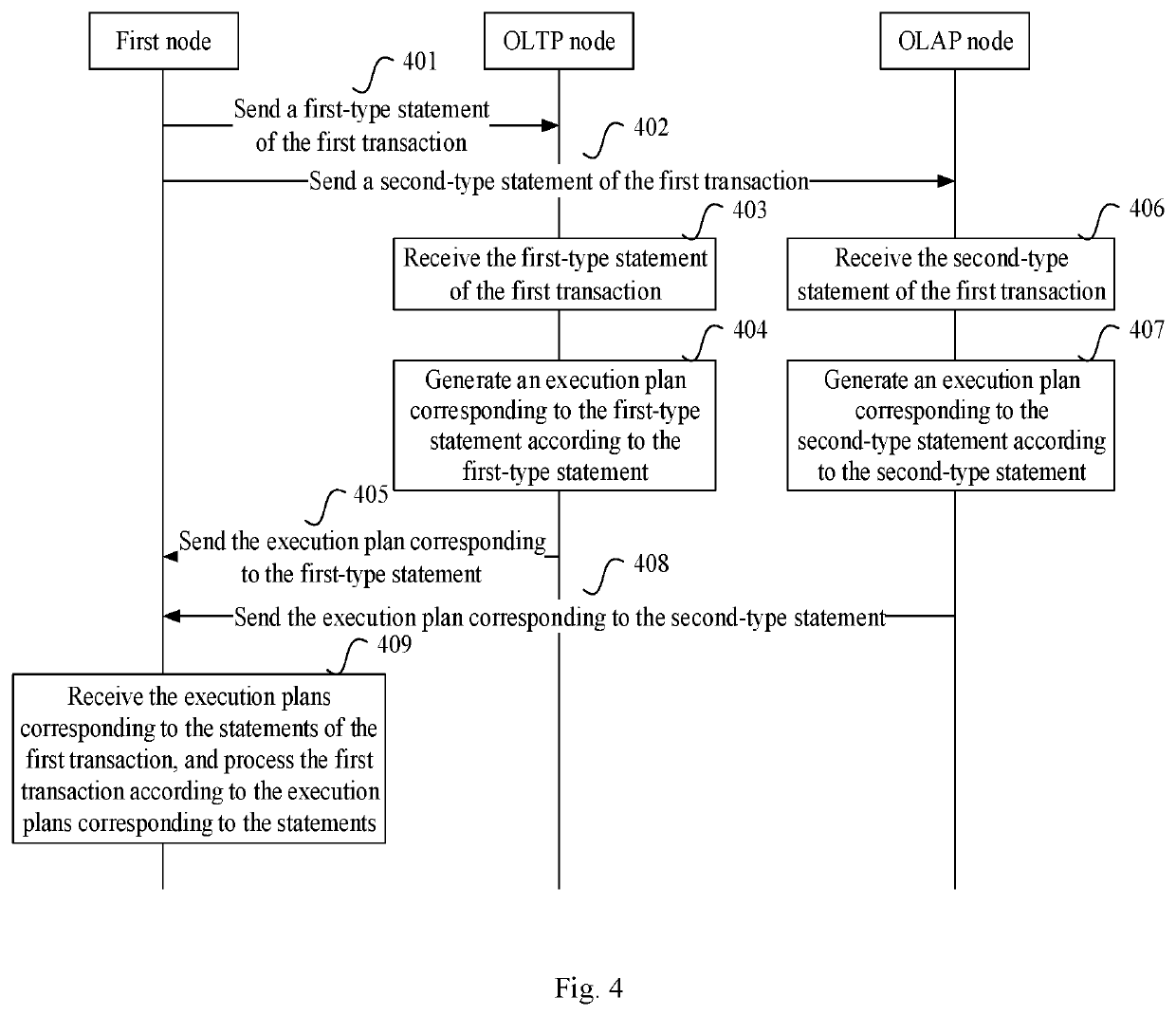

Transaction processing method and system, and server

ActiveUS20210026854A1Low processing efficiencyDatabase management systemsMulti-dimensional databasesExecution planTheoretical computer science

A transaction processing method and system, and a server. The method includes: after a first node obtains at least one statement corresponding to a first transaction, the first node may classify each statement, and send the at least one statement to at least one second node according to the type of each statement, respectively, so that the at least one second node generates an execution plan corresponding to the received statement according to the statement; then the first node may process the first transaction according to the received execution plan which corresponds to the at least one statement of the first transaction and is sent by the at least one second node. In this way, embodiments can process statements of multiple types at the same time, thereby effectively improving the processing efficiency of the system, reducing the operating burden of the system, and ensuring the transactionality of the system.

Owner:CHINA UNIONPAY

Login processing method and device of machine-to-machine/man communication terminal equipment

ActiveUS10356581B2Low processing efficiencyLow login processing efficiencyComputer security arrangementsData switching networksTerminal equipmentComputer terminal

The present document provides a method and apparatus for login processing of a Machine-to-Machine / Man (M2M) terminal device, herein, the method includes: transmitting a login request to an M2M platform; receiving an operation corresponding to a detection result obtained after the M2M platform detects a parameter configuration status of an M2M terminal device; and executing the operation corresponding to the detection result. The present document solves the problem of low login processing efficiency of an M2M terminal device in the related art, and then realizes processing the parameter configuration status of the M2M terminal during the login processing of the M2M terminal device.

Owner:ZTE CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com