Reverse ultrasonic assisted gas-liquid-solid three-phase abrasive particle flow polishing processing method and device

A technology of processing device and processing method, which is applied in the field of reverse ultrasonic-assisted gas-liquid-solid three-phase abrasive flow polishing processing method and device, can solve the problems such as the inconspicuous polishing effect of workpieces, increase the action time, reduce sewage discharge, improve Effect of Polishing Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing:

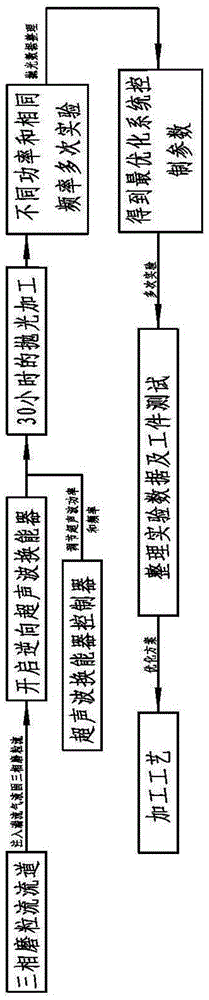

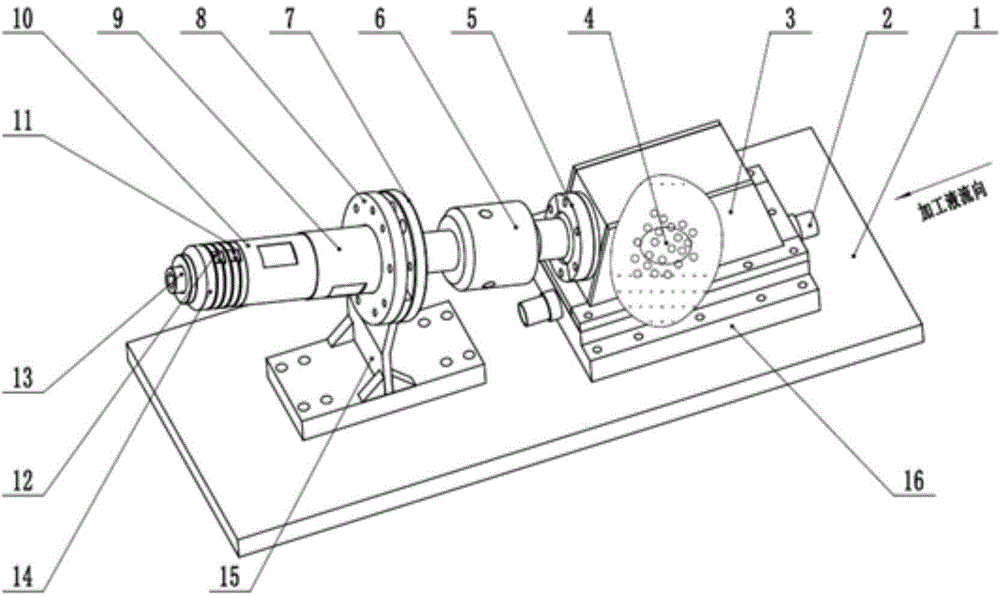

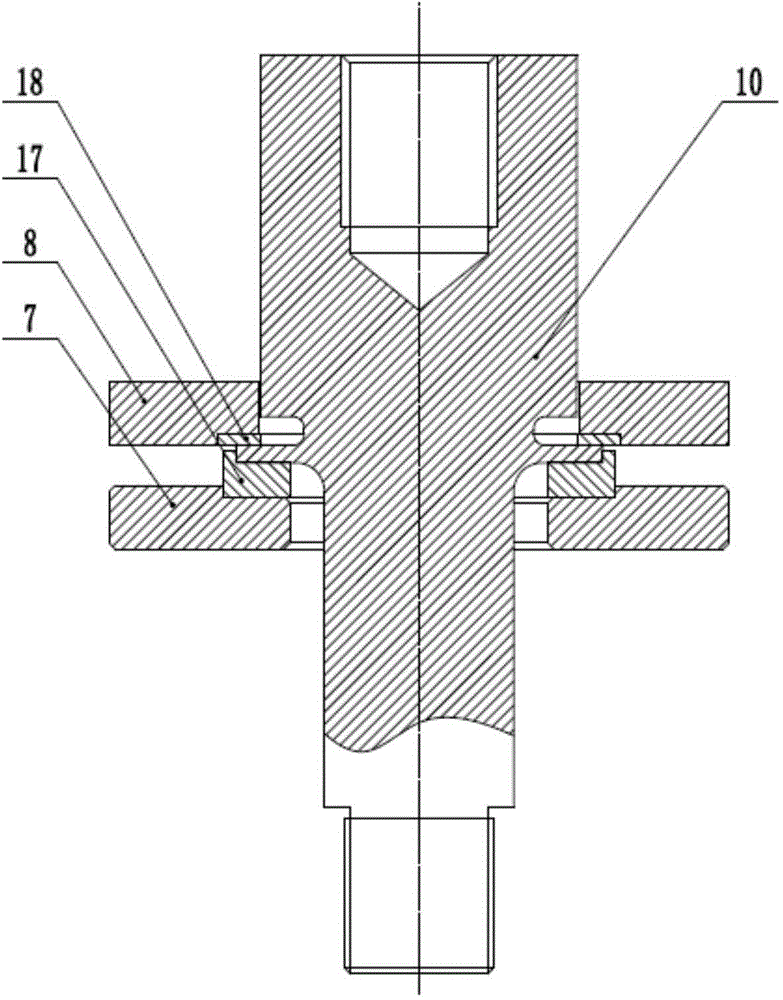

[0027] Refer to attached Figure 1~4 , a reverse ultrasonic-assisted gas-liquid-solid three-phase abrasive flow polishing process, the specific technical idea can be described as follows: the threaded pipe 2 in the polishing processing device is injected into the three-phase abrasive flow channel 16 in a turbulent state The gas-liquid-solid three-phase abrasive particle flow is turned on at the same time, and the power and frequency of the ultrasonic waves emitted by the ultrasonic transducer are adjusted by an external circuit and control system. After a certain period of continuous work, the workpiece 4 is taken out for measurement, and the processing Effect conclusion. Among them, under the adjustment of the external circuit and the control system, combined with the processing effect obtained from the measurement of the workpiece 4, multiple experiments were carried out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com