Patents

Literature

46results about How to "Improve collapse" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

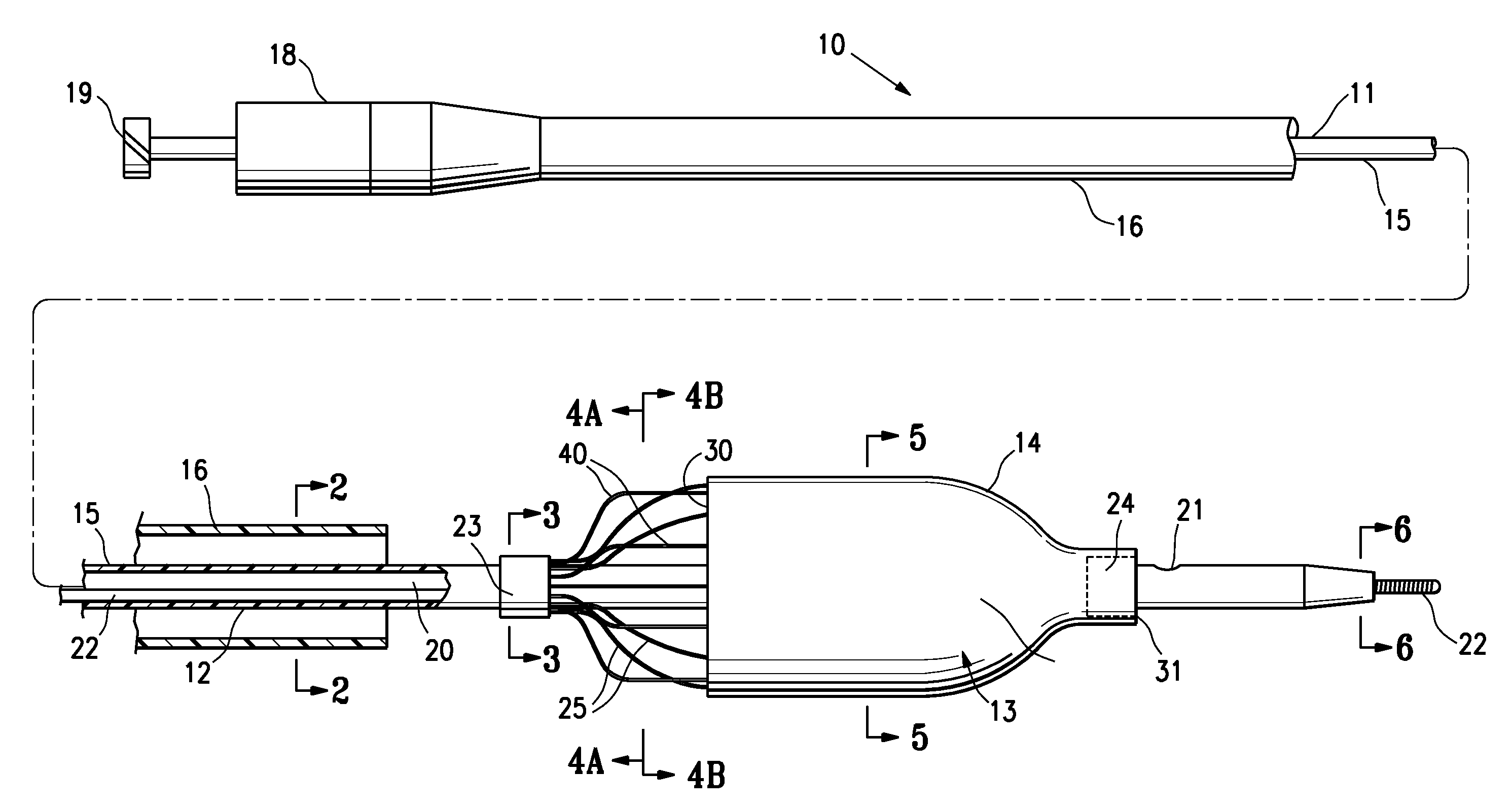

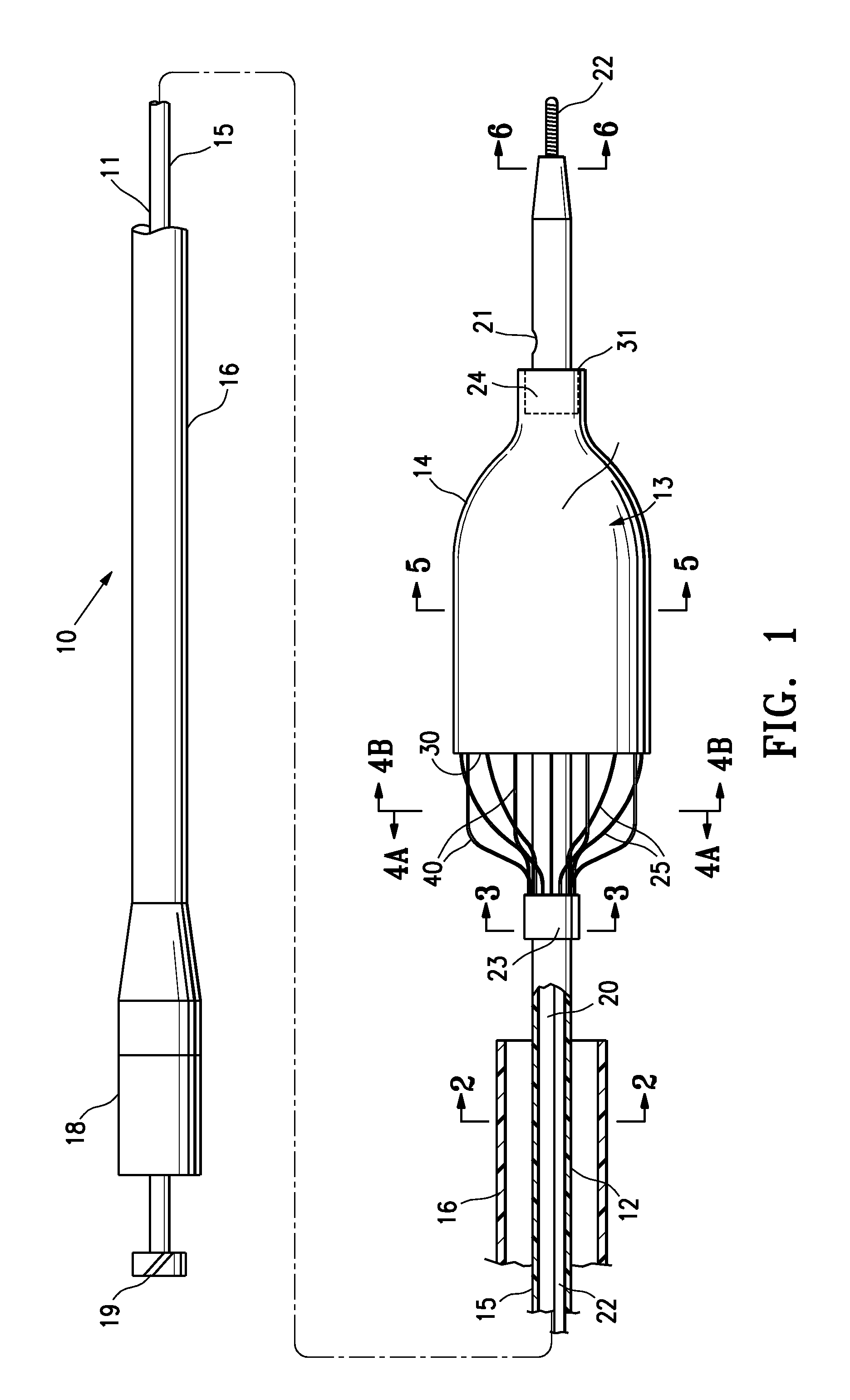

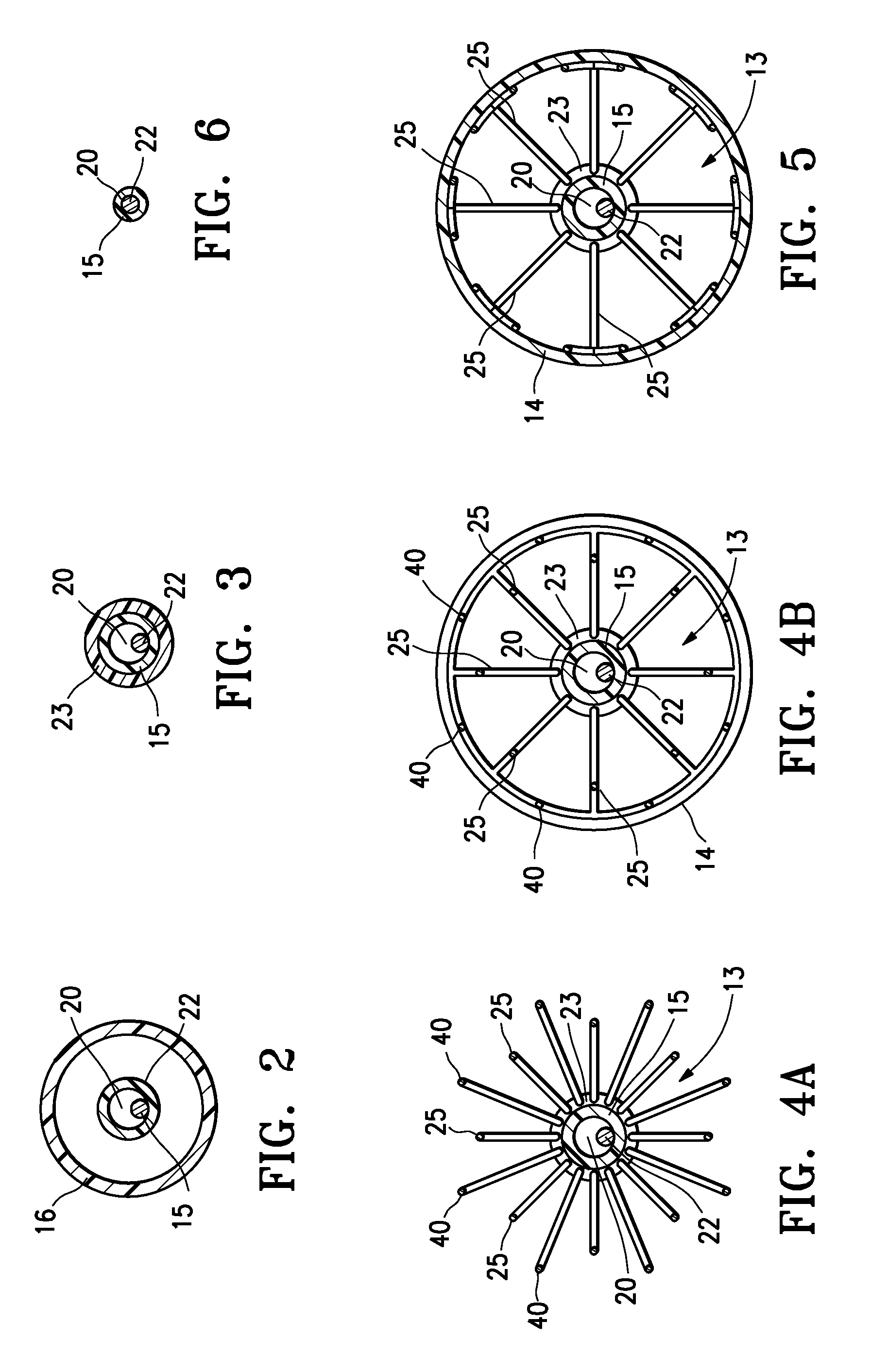

Intravascular medical device having a readily collapsible covered frame

InactiveUS20090105644A1Reduce deliveryExtended staySurgeryDilatorsMedical deviceIntravascular device

An elongated intravascular device having a frame configured for reversibly expanding in a patient's body lumen, which has a sleeve secured to the frame, and at least one sleeve-folding strut configured to fold the sleeve inwardly as the frame radially collapses in the patient's body lumen. Additional aspects of the invention are directed to methods of recovering such expanded frame type devices, and a recovery catheter configured for collapsing an expanded frame. The devices and methods of the invention facilitate the collapse of expanded frame devices, for repositioning or removal from the patient's body lumen.

Owner:ABBOTT CARDIOVASCULAR

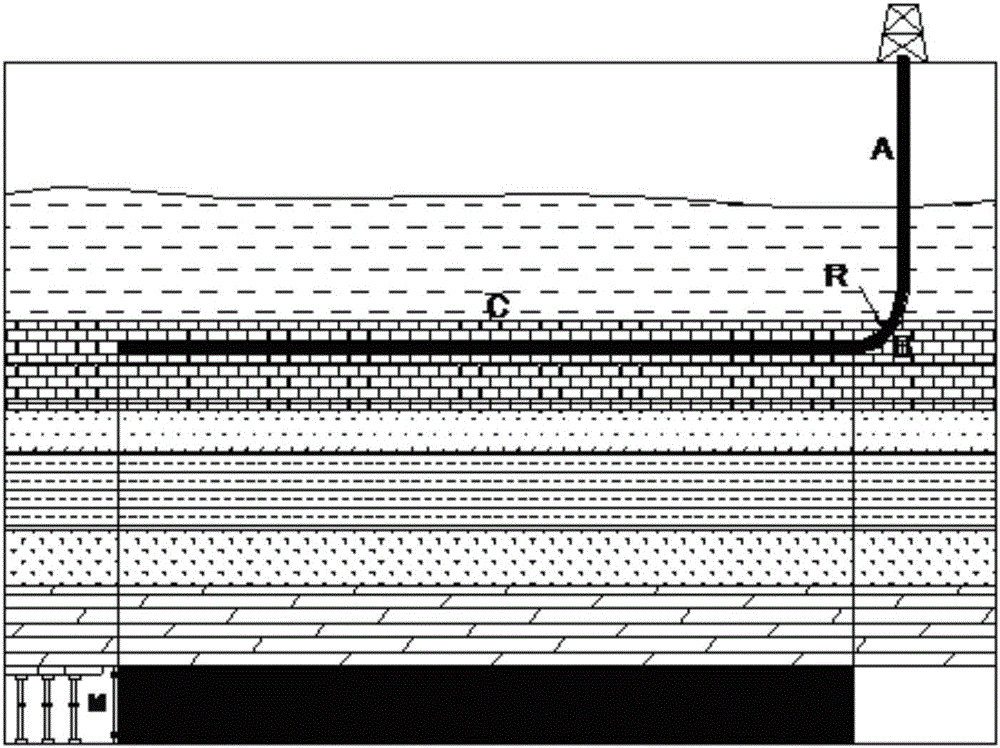

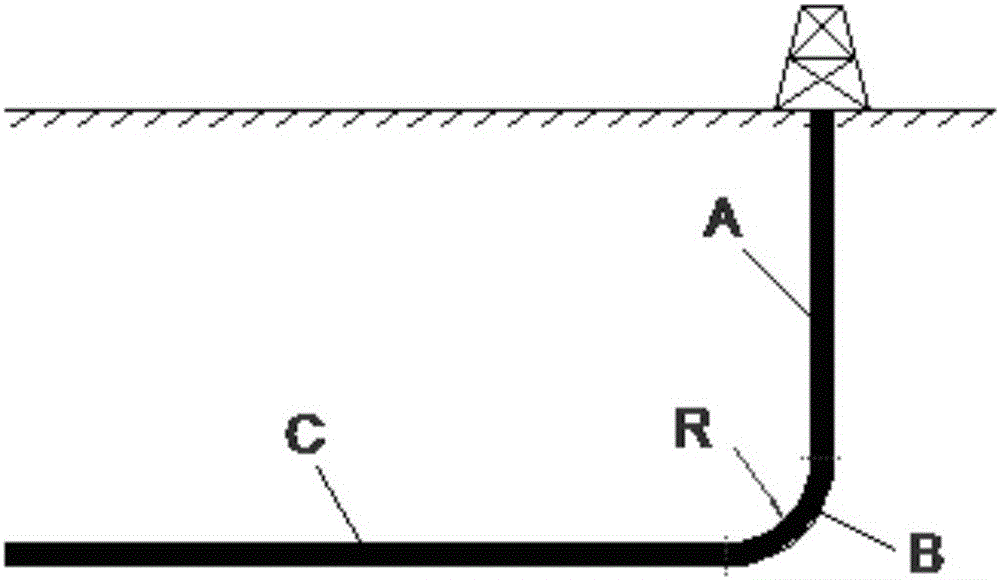

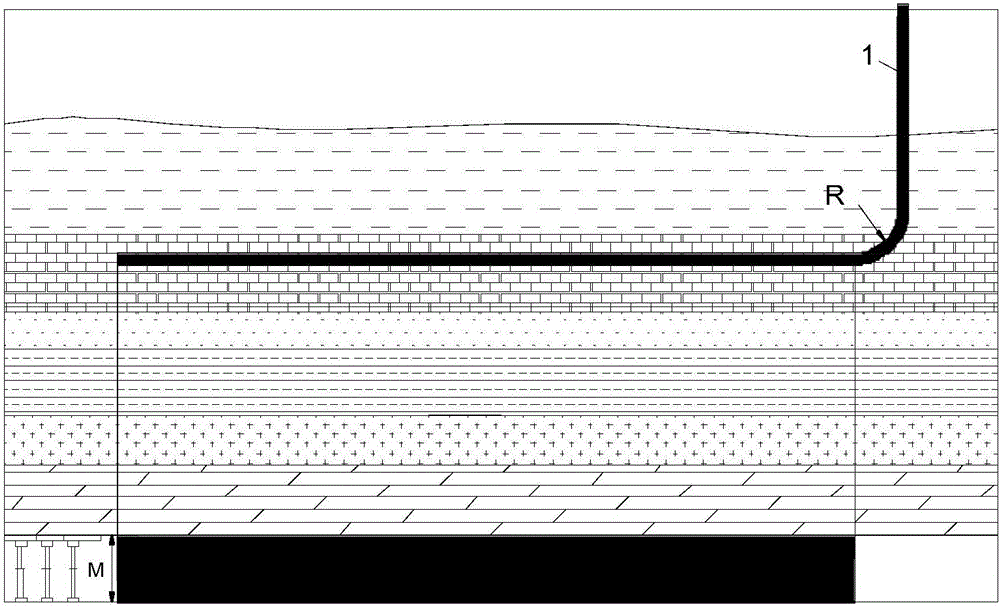

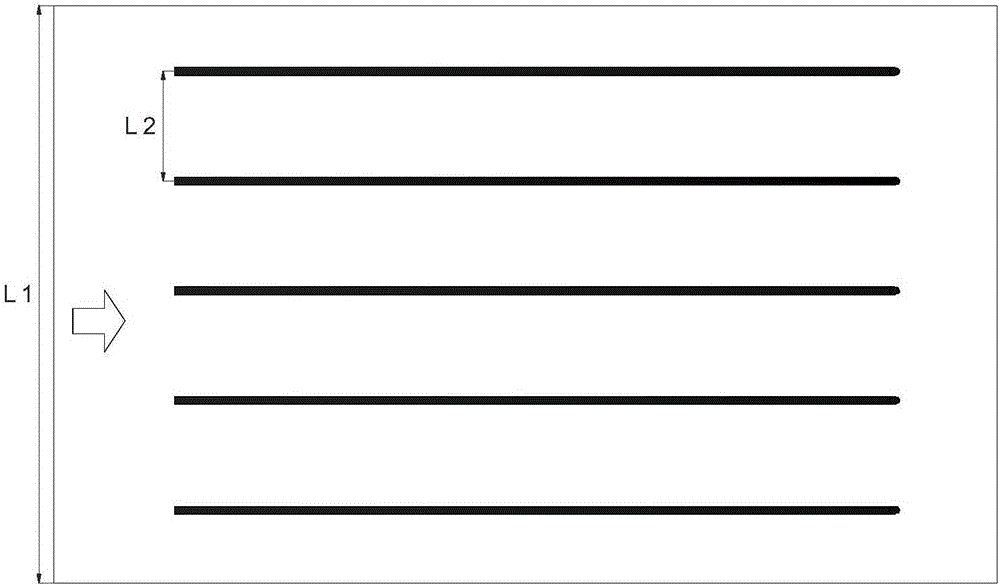

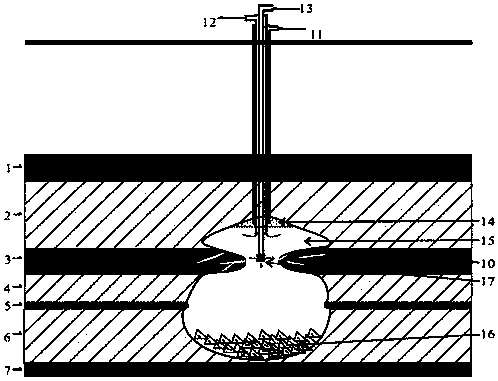

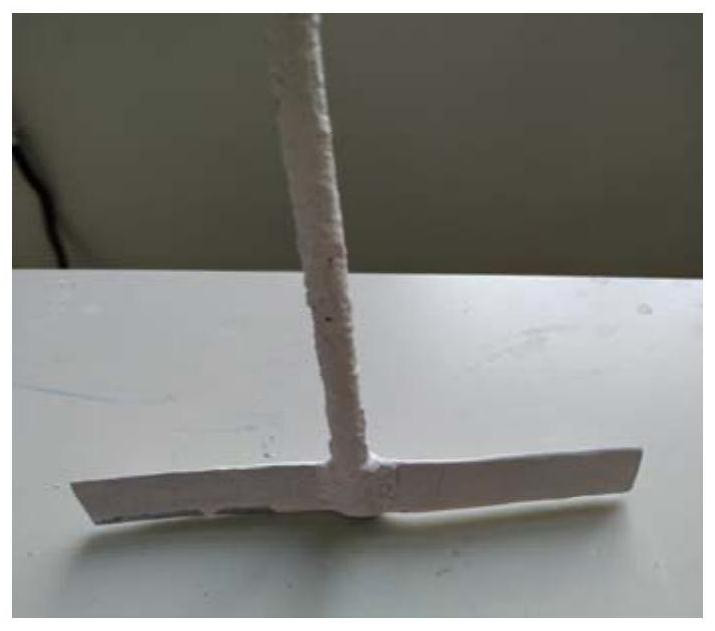

Gas extraction method for parallel hole arrangement of L-shaped drilling and fracturing weakening top plate

InactiveCN105927270ABreach of integrityReduce the appearance of strong mine pressureFluid removalGas removalExtraction methodsFissure

The invention relates to a gas extraction method for parallel hole arrangement of an L-shaped drilling and fracturing weakening top plate. The gas extraction method comprises the following steps: firstly, determining drilling positions and selecting drilling parameters on the ground corresponding to a working face of a coal mining seam; secondly, performing L-shaped fracturing drilling and L-shaped gas extraction drilling construction; thirdly, after the L-shaped fracturing drilling construction is finished, arranging a casing pipe and fracturing equipment in an L-shaped drilling hole; fourthly, after the L-shaped gas extraction drilling construction is finished, arranging a gas extraction pipe with air holes in L-shaped gas extraction drilling hole; fifthly, performing fracturing in advance on a coal seam top plate by using a hydraulic jet staged fracturing method; sixthly, extracting fissure zone gas by the gas extraction pipe while performing coal mining operation. According to the scheme, the problems of high mine pressure behavior and transfinite fissure zone gas in a goaf in a coal mining process in the prior art are solved.

Owner:CHONGQING UNIV

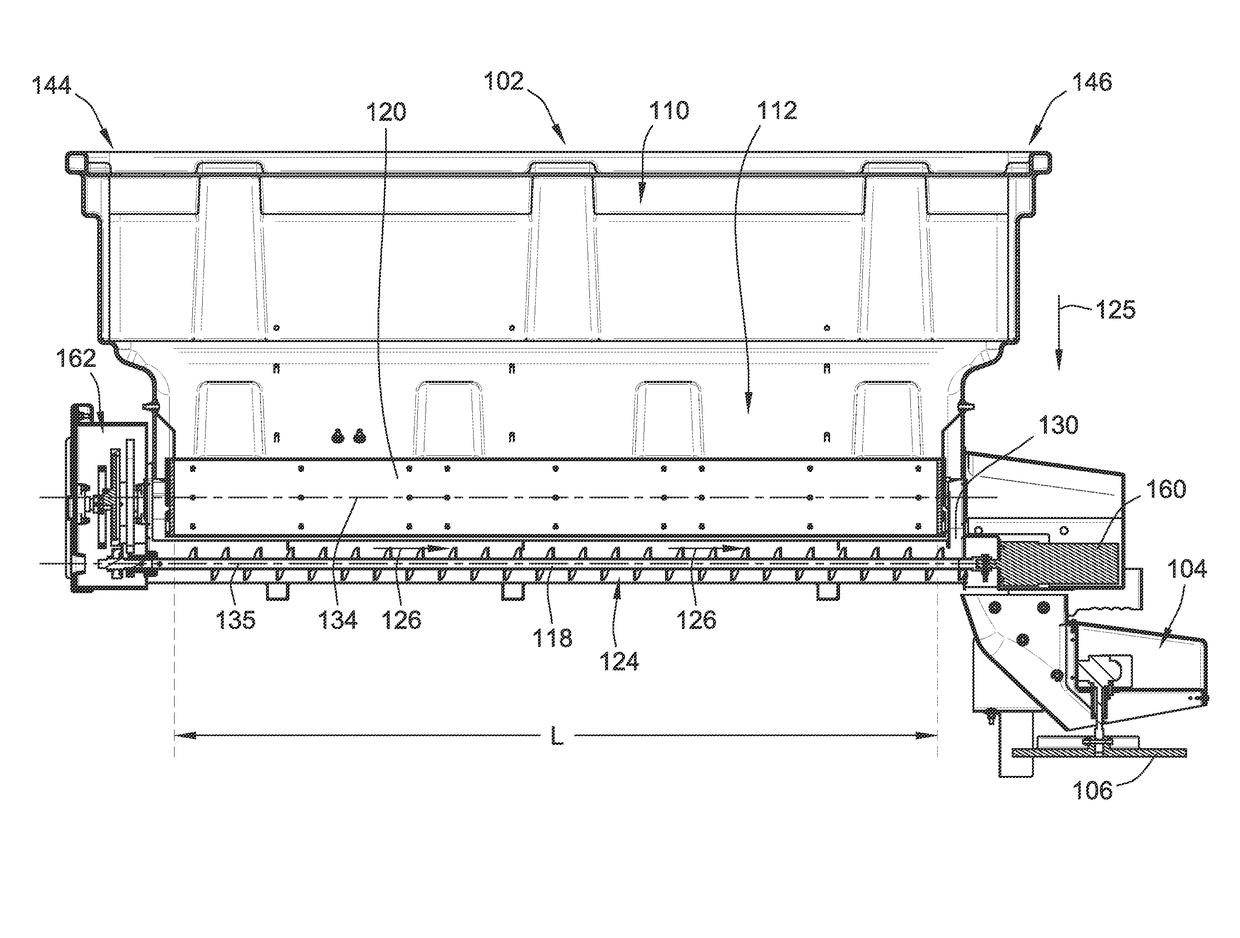

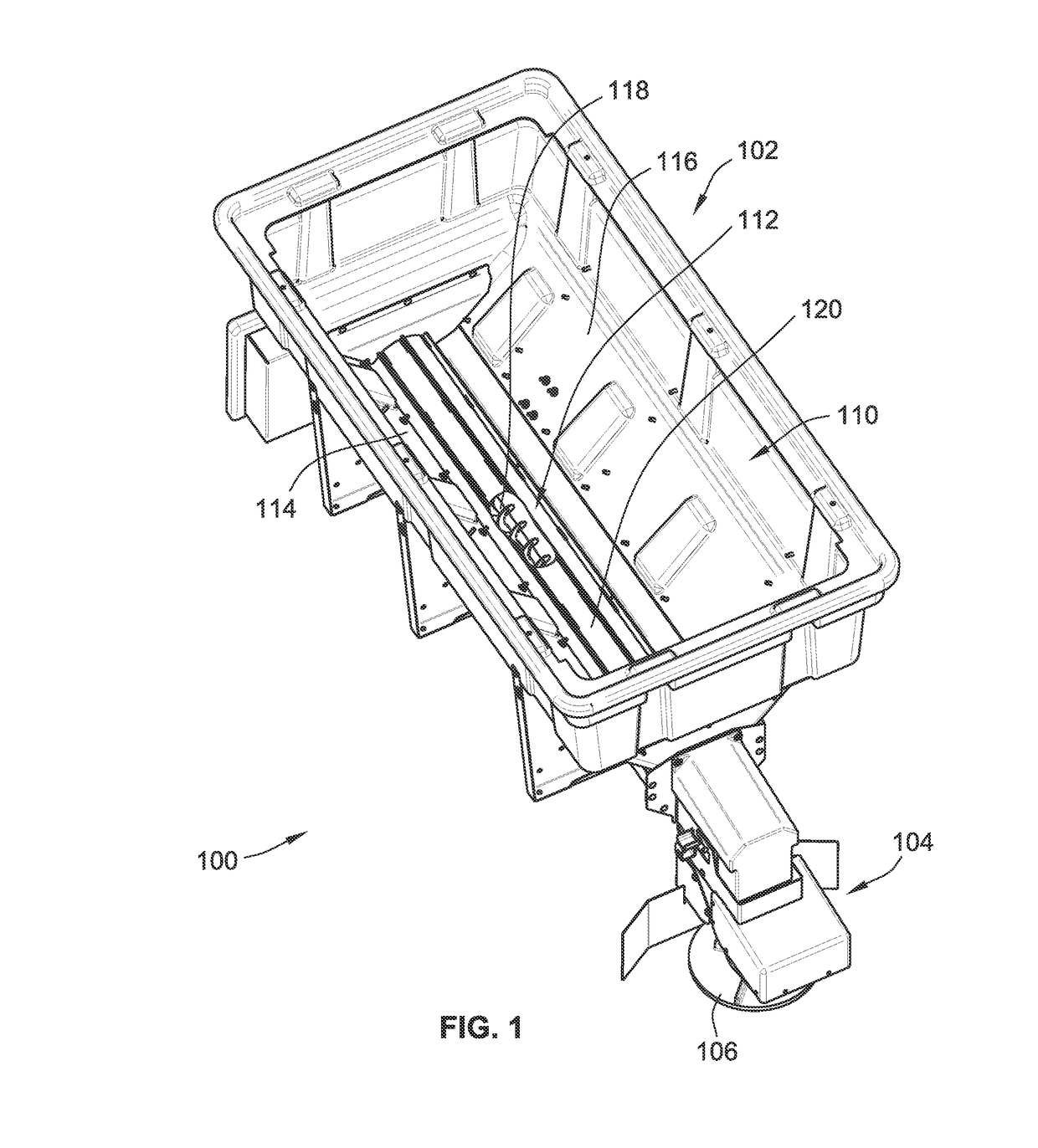

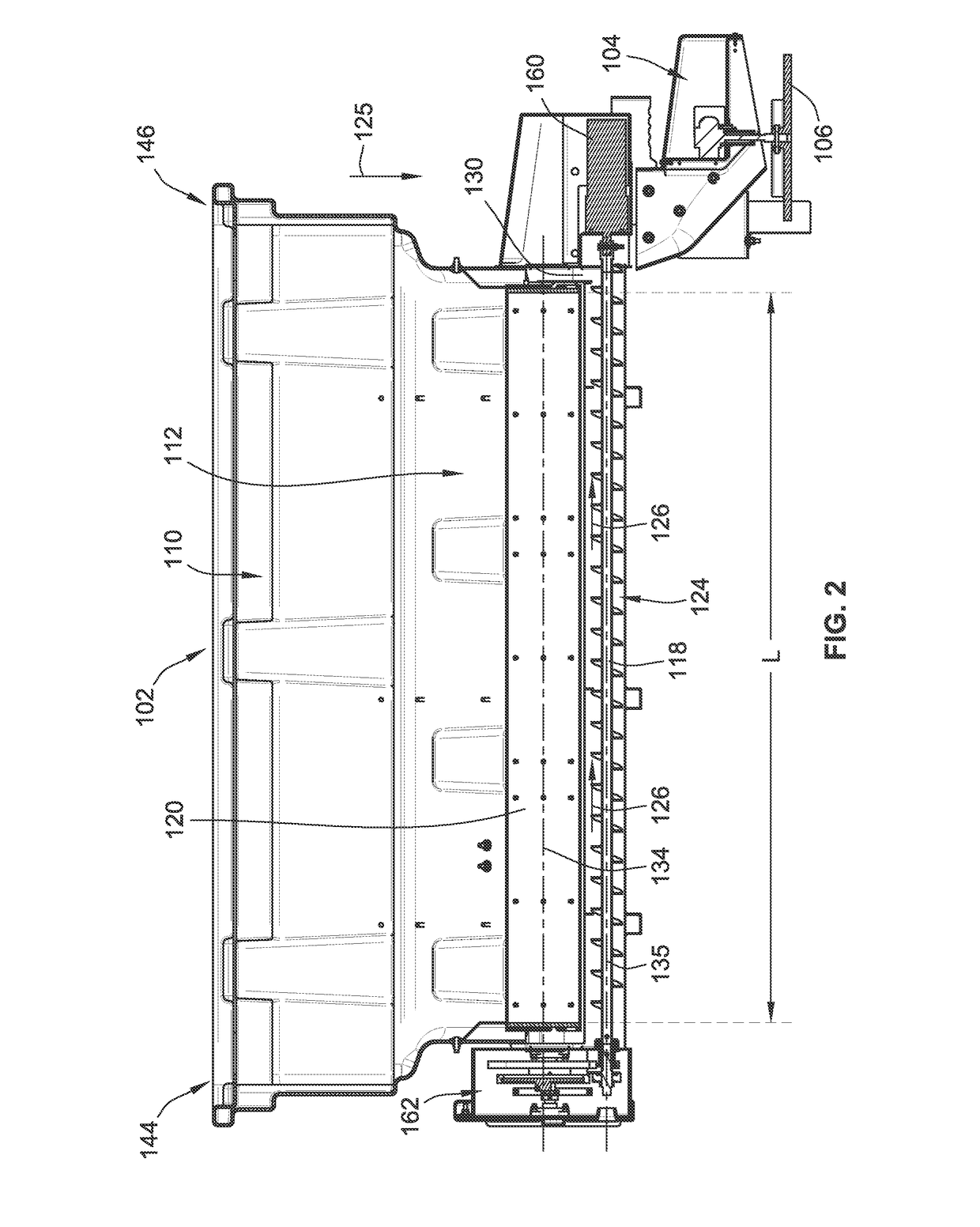

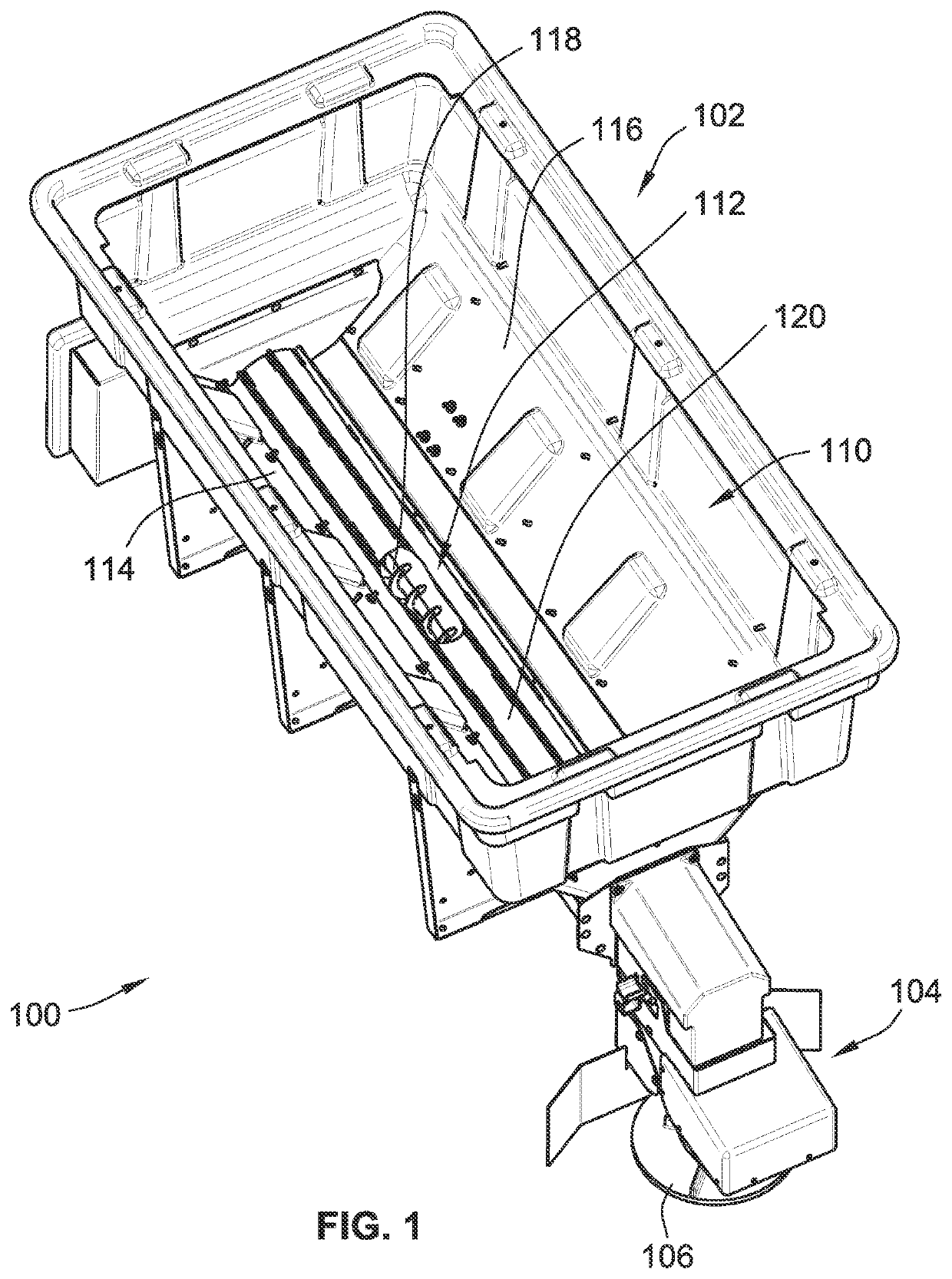

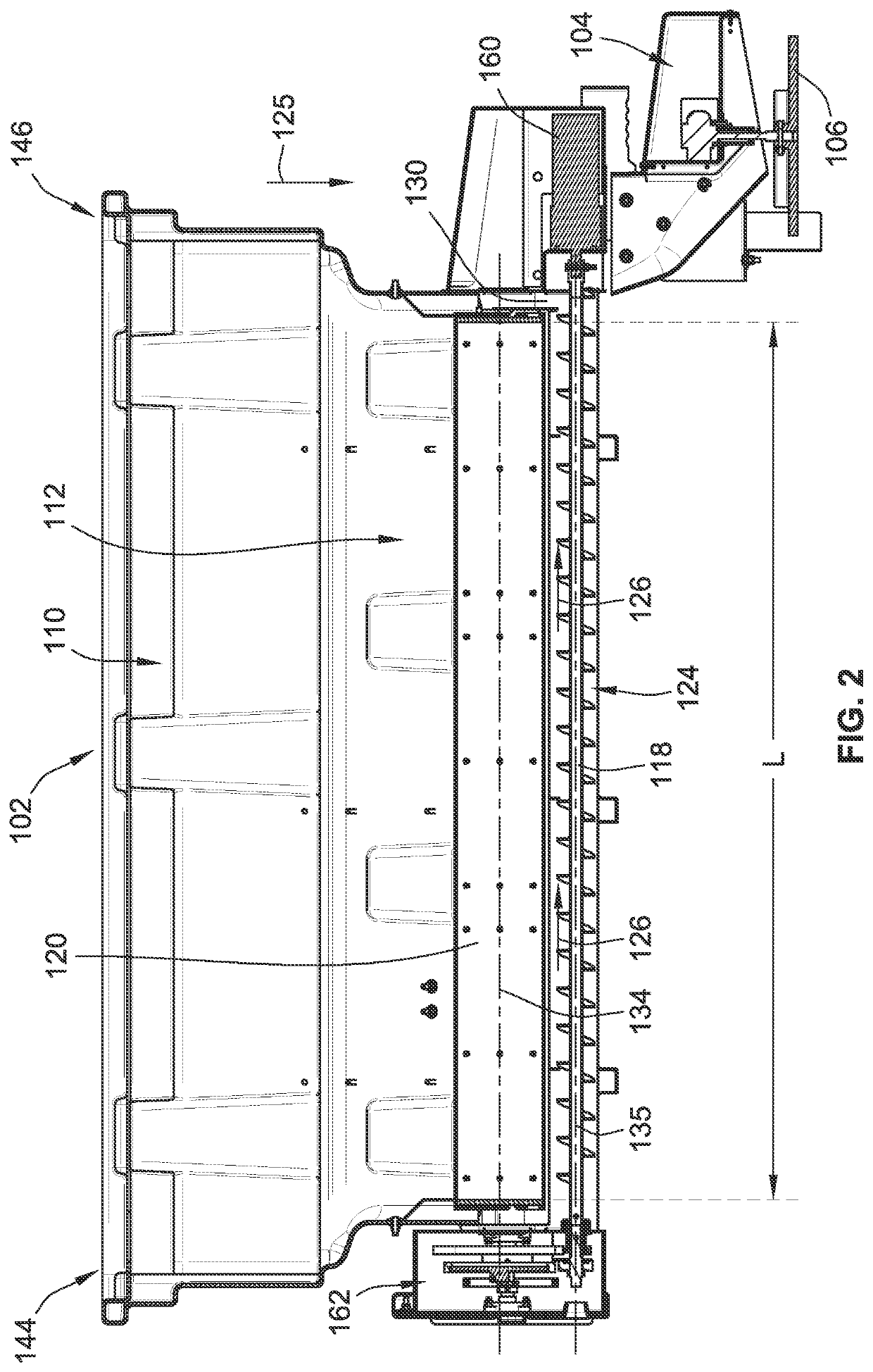

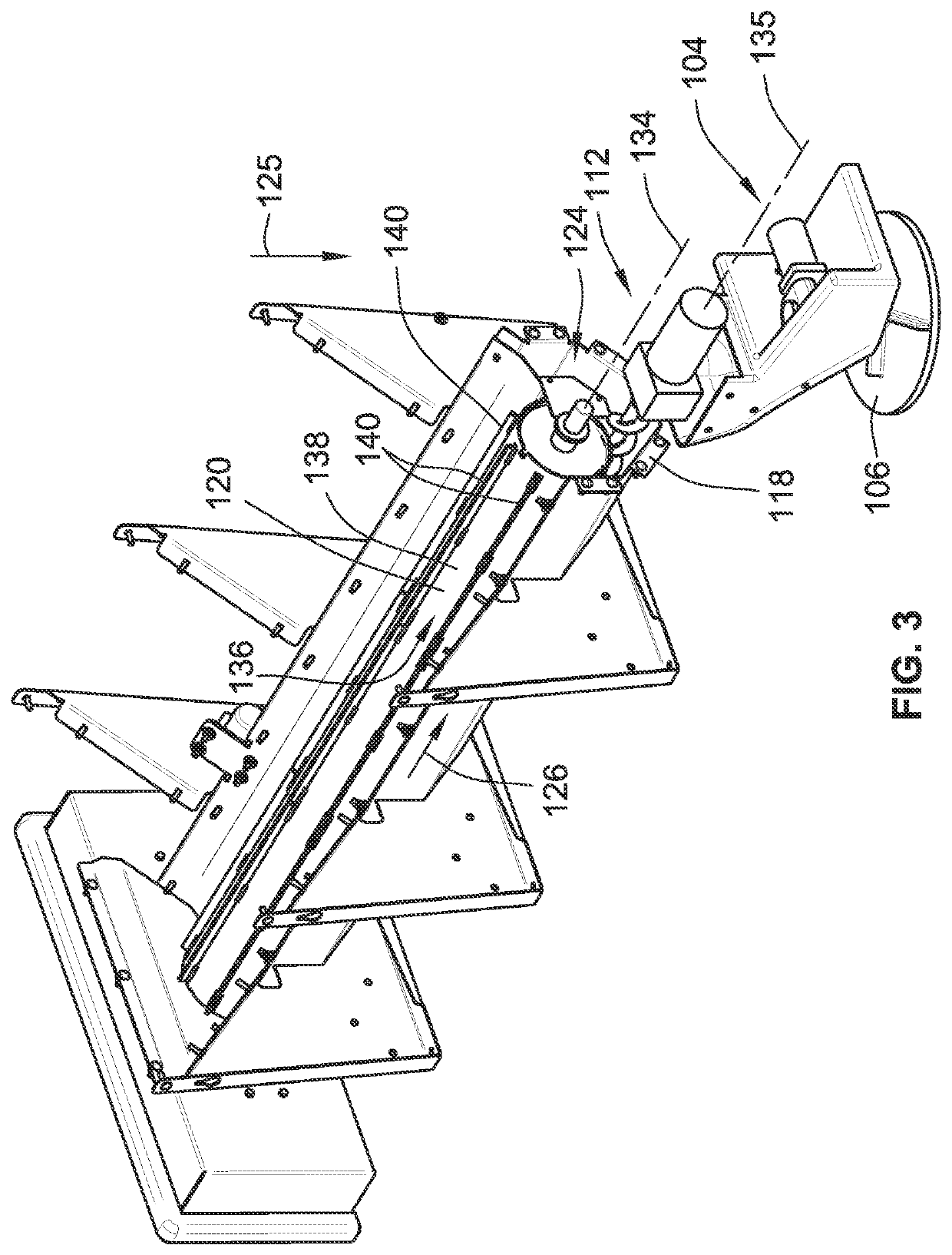

Spreader for spreading granular material and method of spreading granular material

ActiveUS20170107680A1Easy to handleImproved break-upThrowing machinesConveyorsEngineeringMechanical engineering

In one embodiment, a hopper spreader apparatus for spreading granular material is provided. The hopper spreader apparatus includes a hopper, a spreading unit, and a dispensing unit. The hopper has a storage cavity for storing the granular material to be spread. The spreading unit spreads the granular material. The dispensing system transports the granular material from the hopper to the spreading unit. The dispensing system includes a conveying unit and a rotating first roll. The conveying unit conveys the granular material toward the spreading unit. The rotating first roll controls a flow of granular material from the hopper to the conveying unit. The use of the rotating roll allows for control of high flow material (such as for example dry salt) while allowing for improved collapse and break-up of low flow material (such as for example wetted sand).

Owner:SNO WAY INT

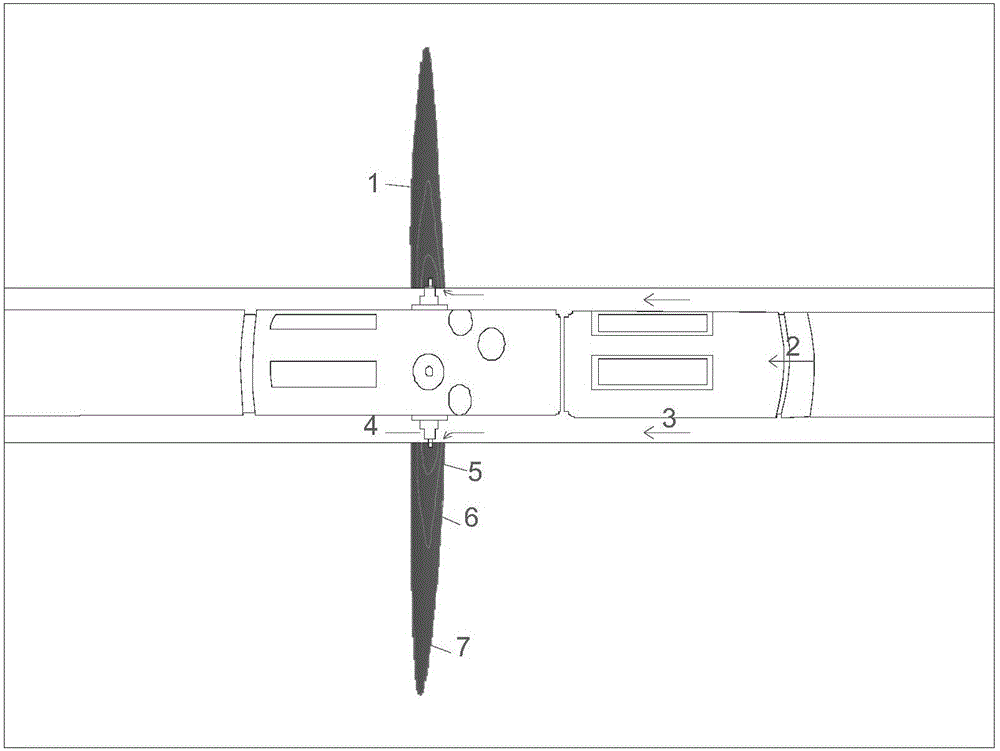

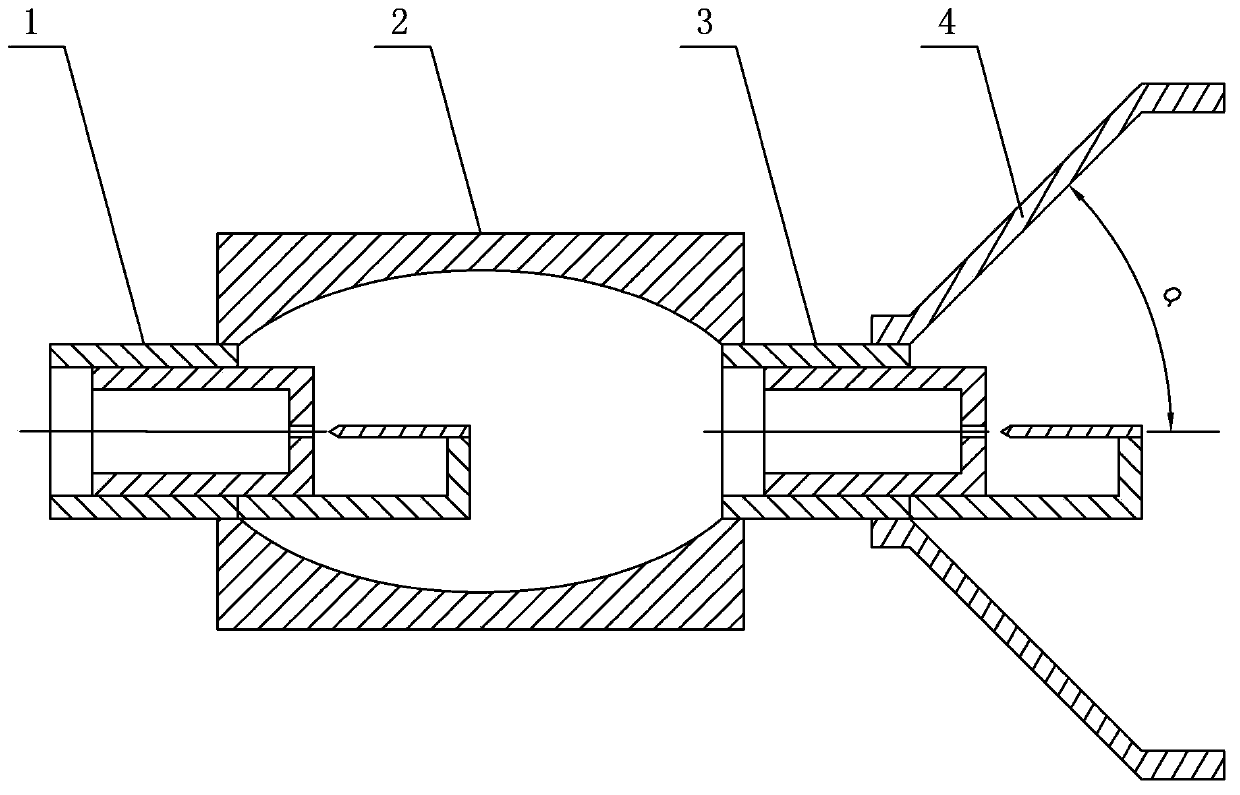

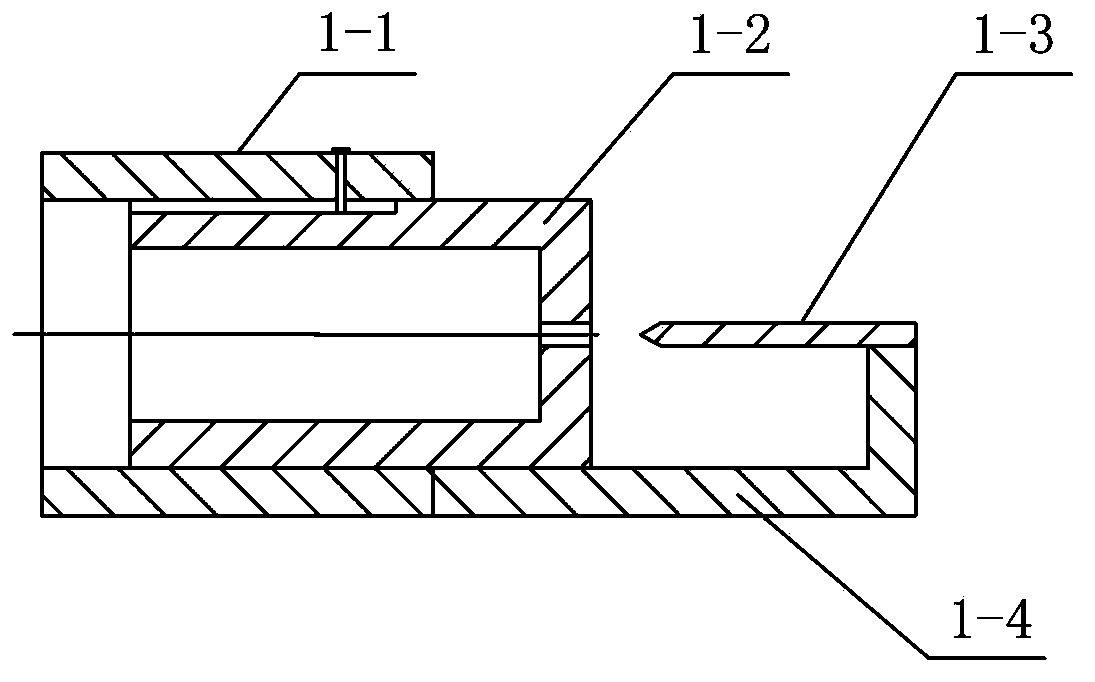

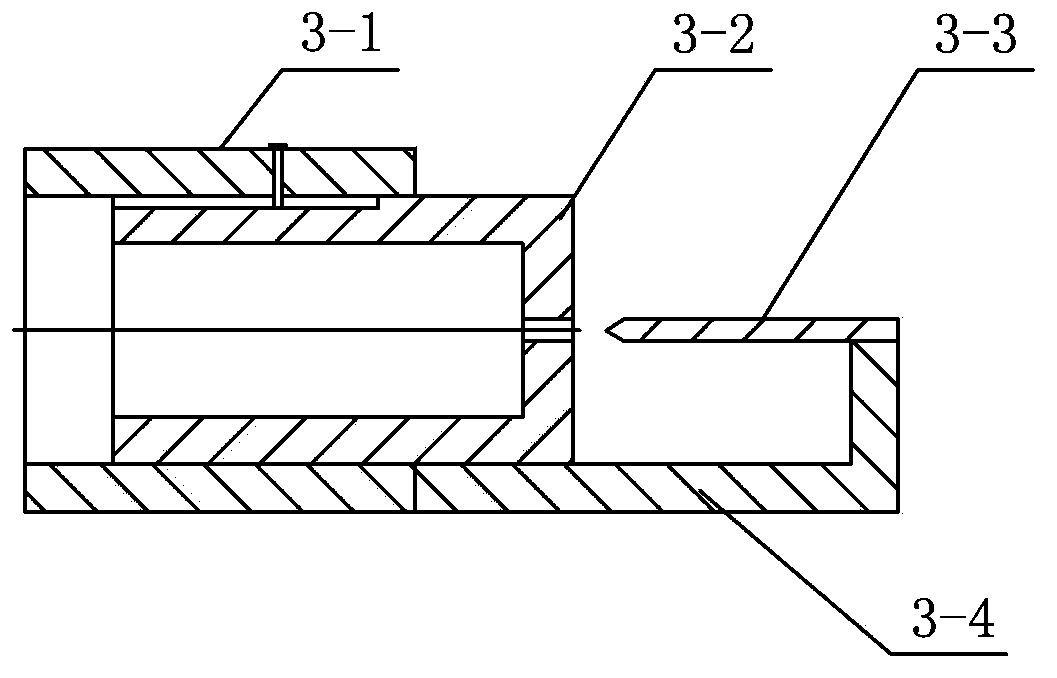

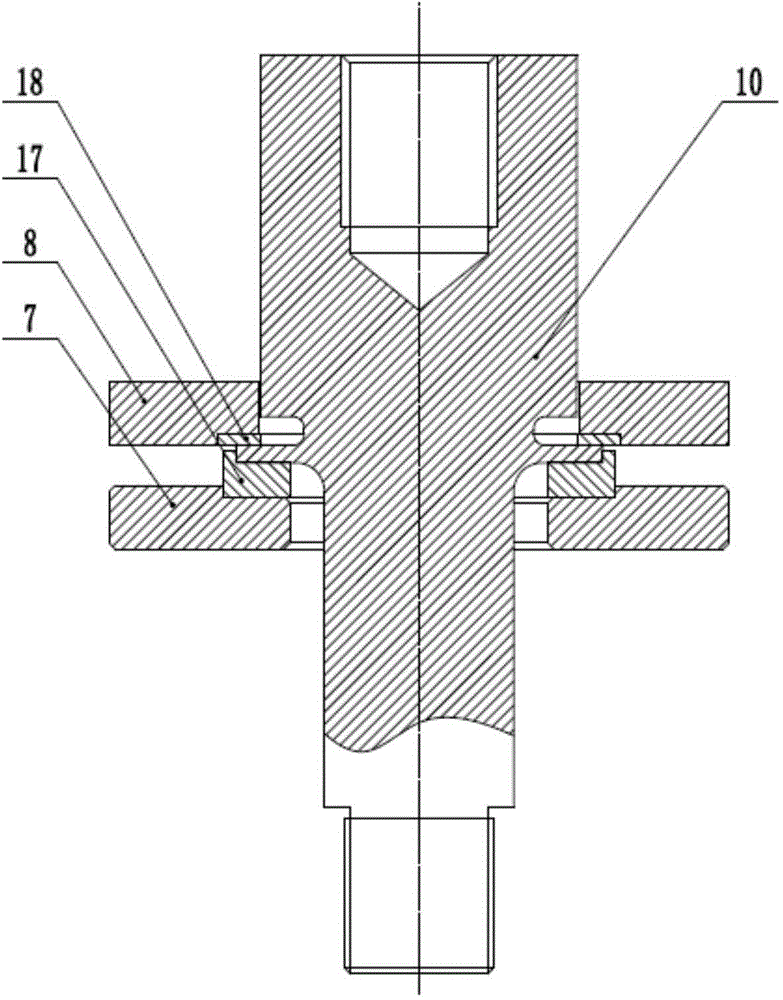

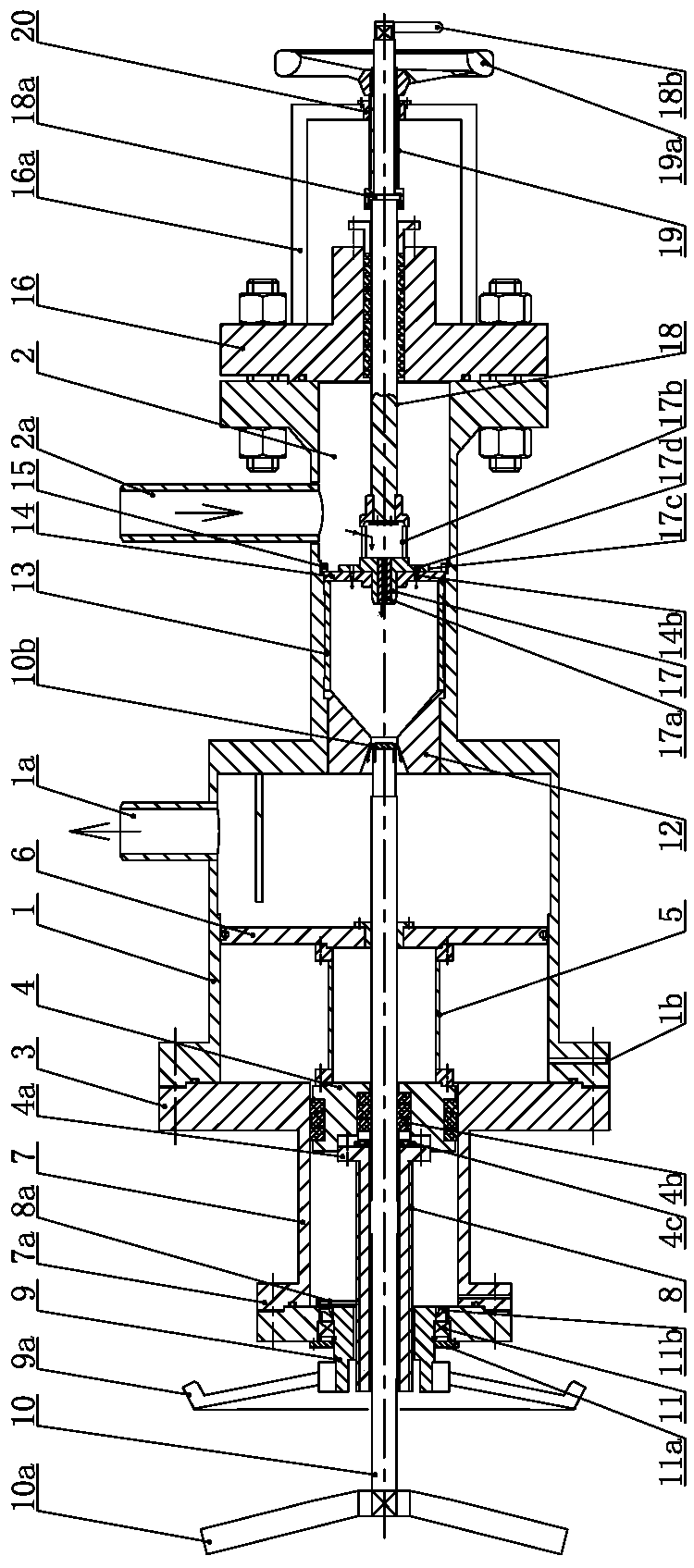

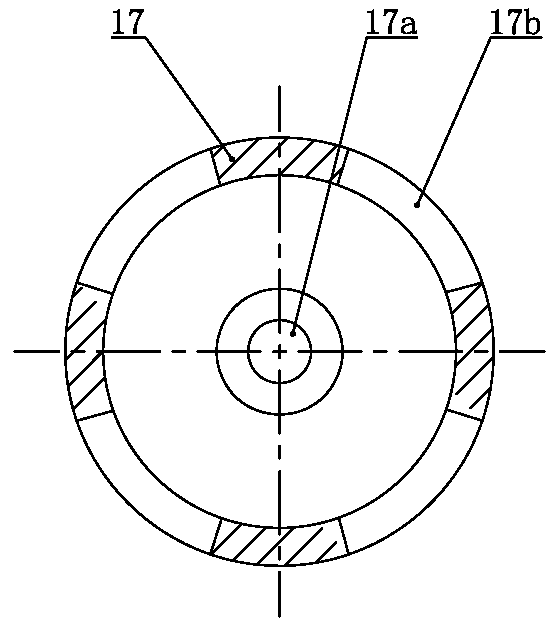

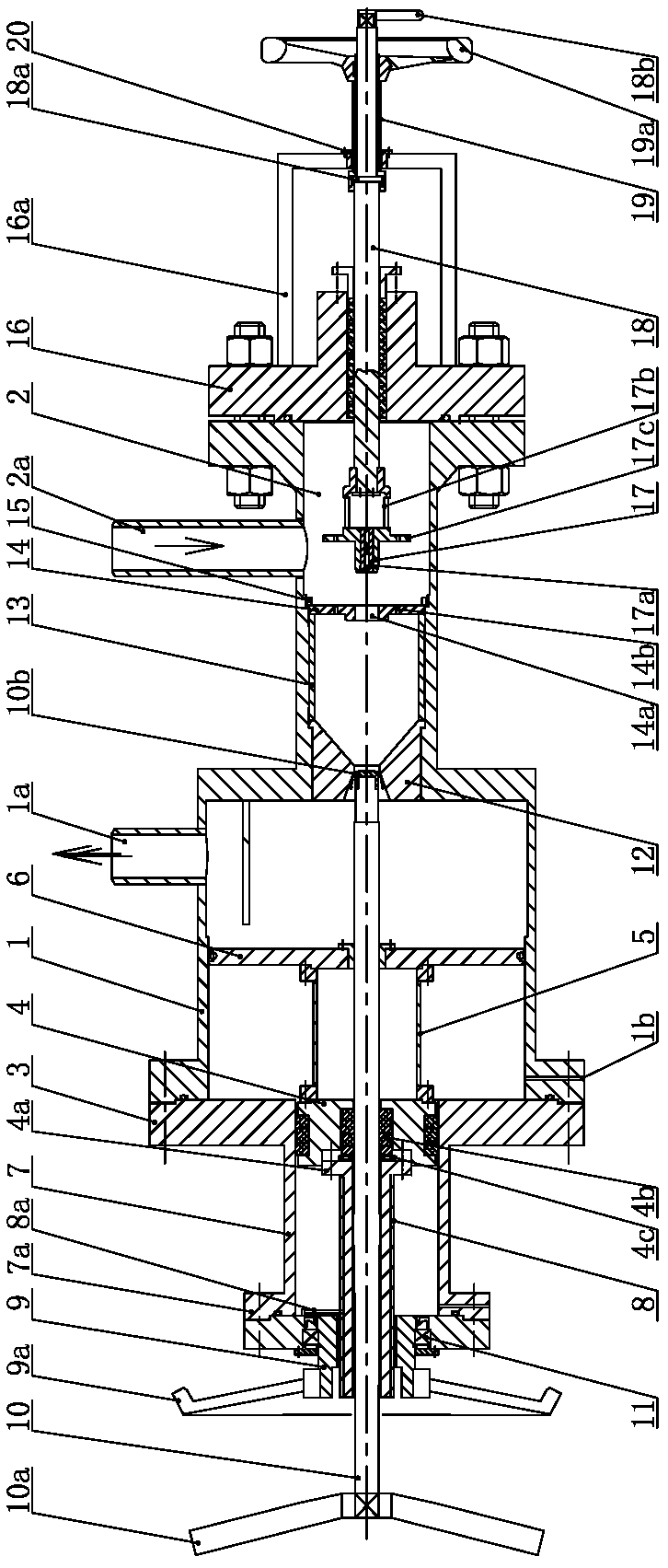

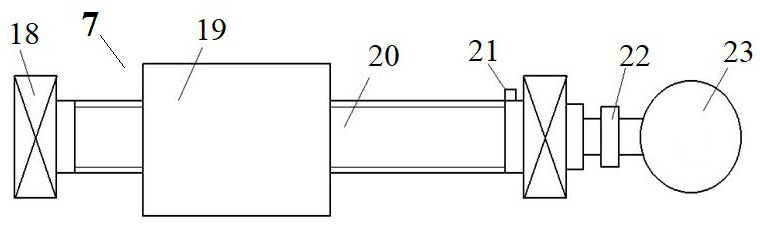

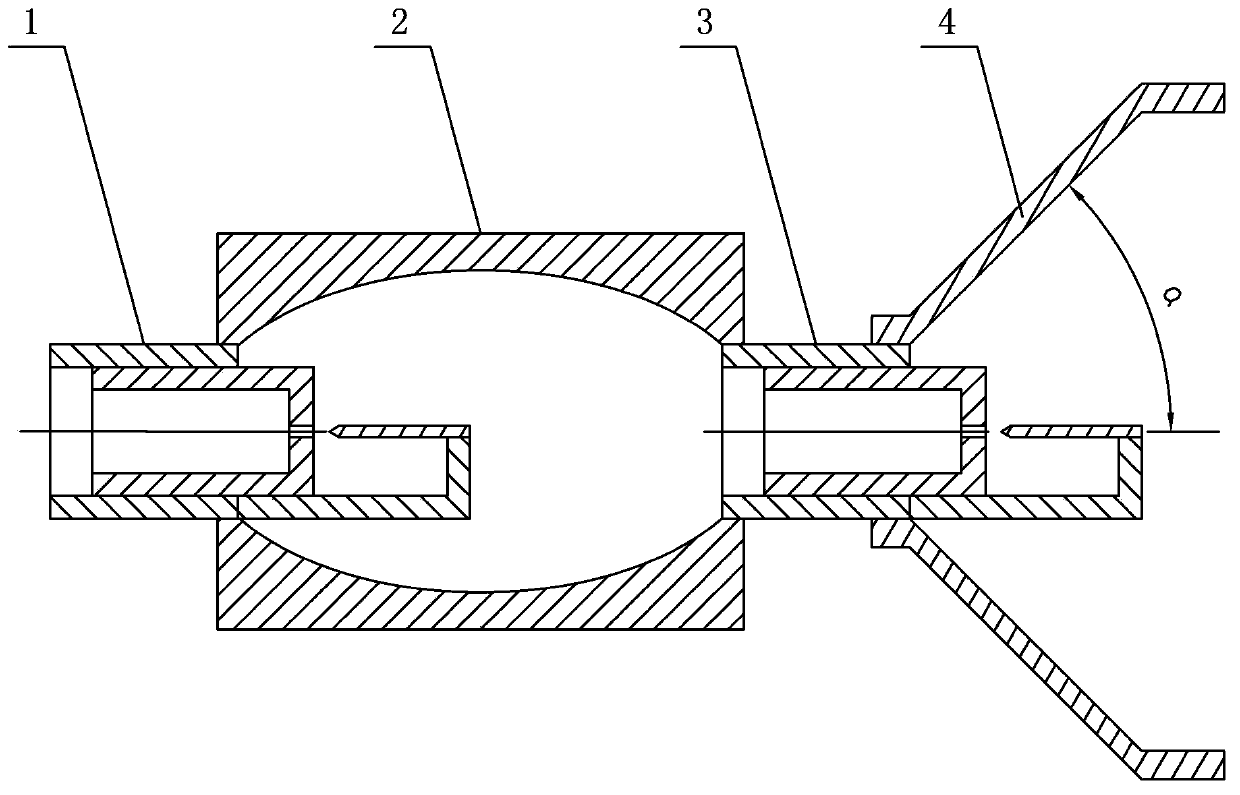

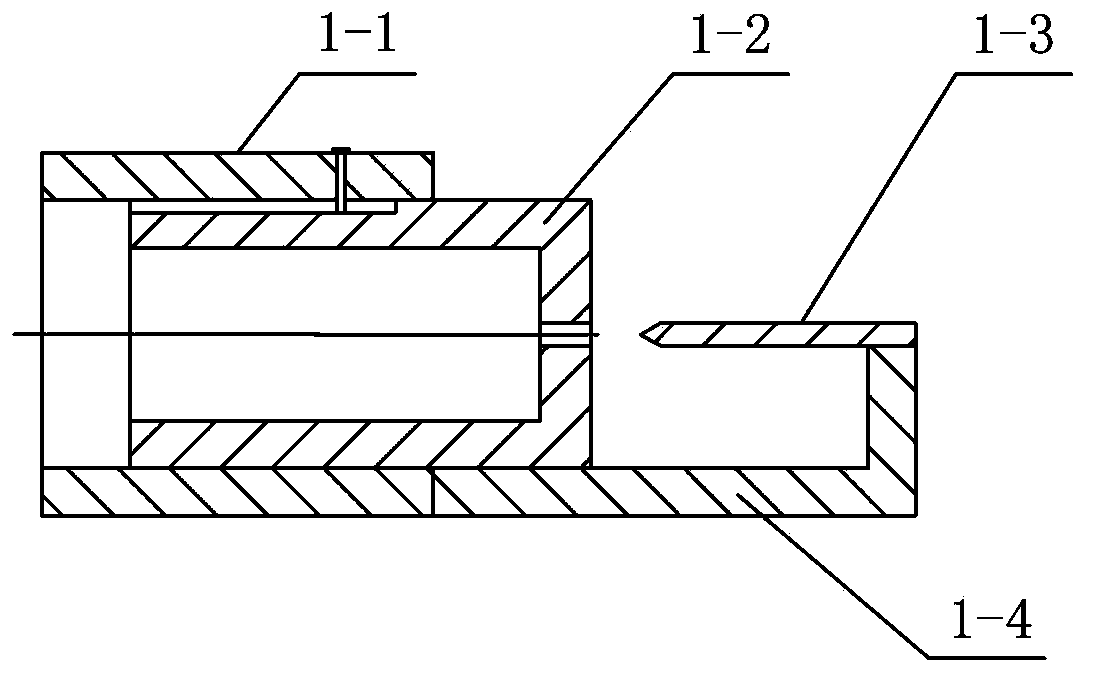

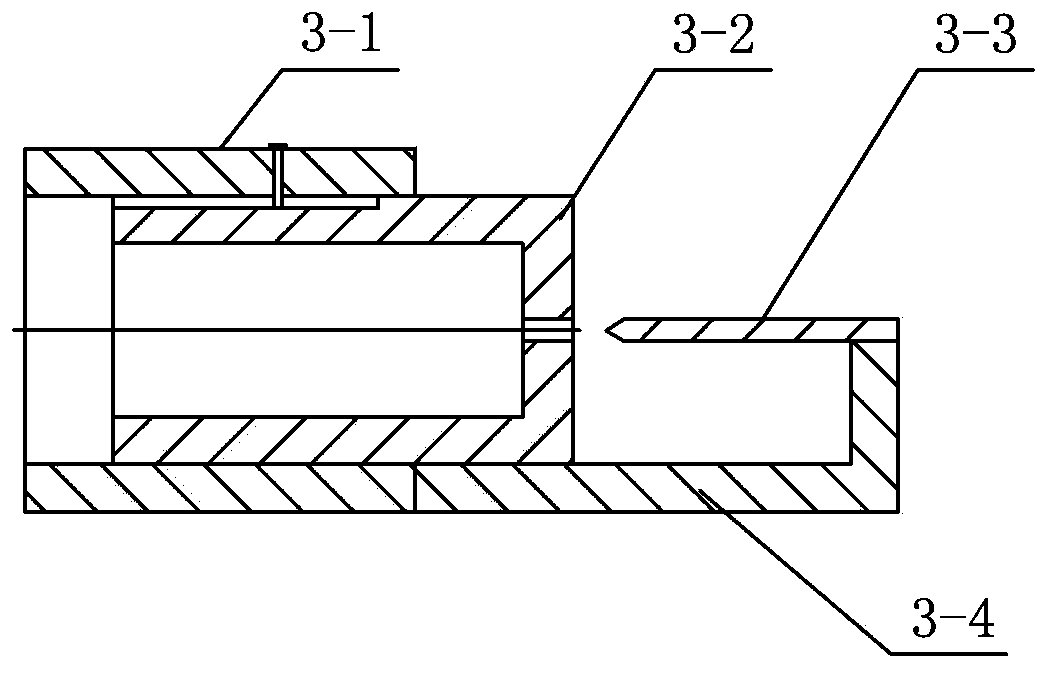

Tandem type hydrodynamic force sound wave generation device

InactiveCN103366727ADirectionalAdd depthShaking/oscillating/vibrating mixersMixing methodsCavitationSpray nozzle

The invention relates to a tandem type hydrodynamic force sound wave generation device. The tandem type hydrodynamic force sound wave generation device is characterized in that the front end of a cavity is provided with a first spray nozzle connected with a fluid pipeline, the back end of the cavity is provided with a second spray nozzle, the center lines of the first nozzle and the second nozzle are on the same straight line, and a divergent reflector is arranged on the outer wall of the second spray nozzle; the first spray nozzle and the second spray nozzle are connected in series through an oval cavity, two spring pieces can be used for generating different sound wave frequencies, and sound waves generated by the second spring piece are reflected by the inner wall of a reflector and then propagate along the divergent reflector, so that the generated sound waves have directivity. In addition, the tandem type hydrodynamic force sound wave generation device has the advantages of strong cavitation effect, high fluid mixing and emulsifying efficiency, simple structure, stable operation and relatively low cost; and as the movable spray nozzles can be changed and adjusted according to practical requirements, the tandem type hydrodynamic force sound wave generation device is suitable for industrialized application.

Owner:SHAANXI NORMAL UNIV

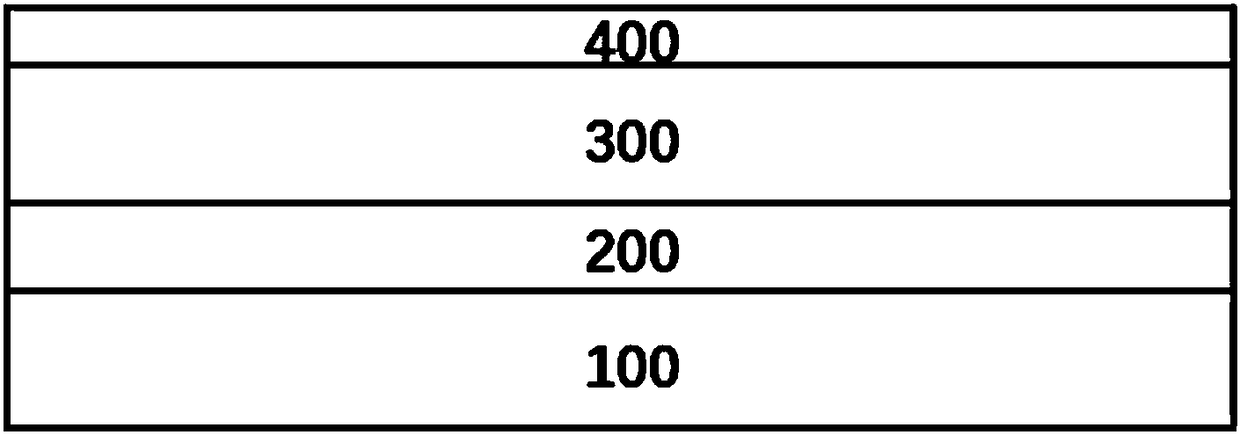

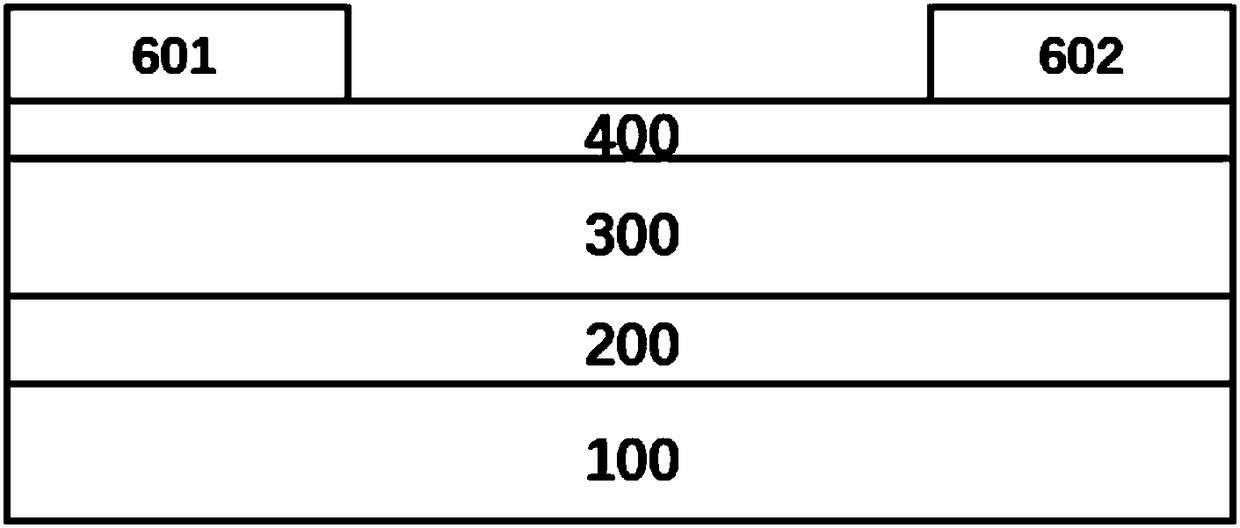

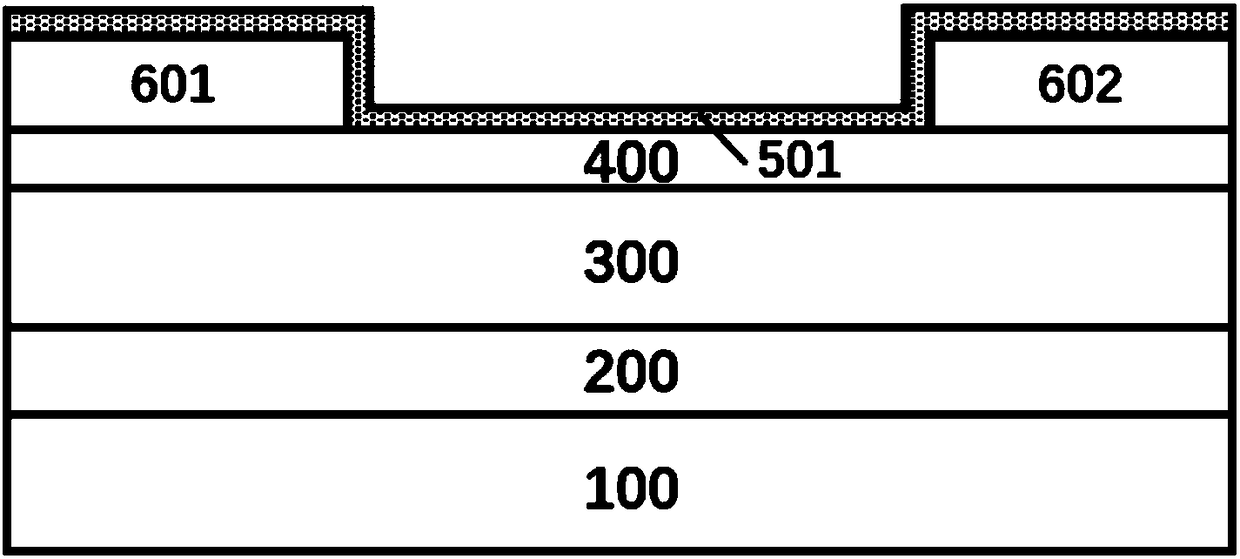

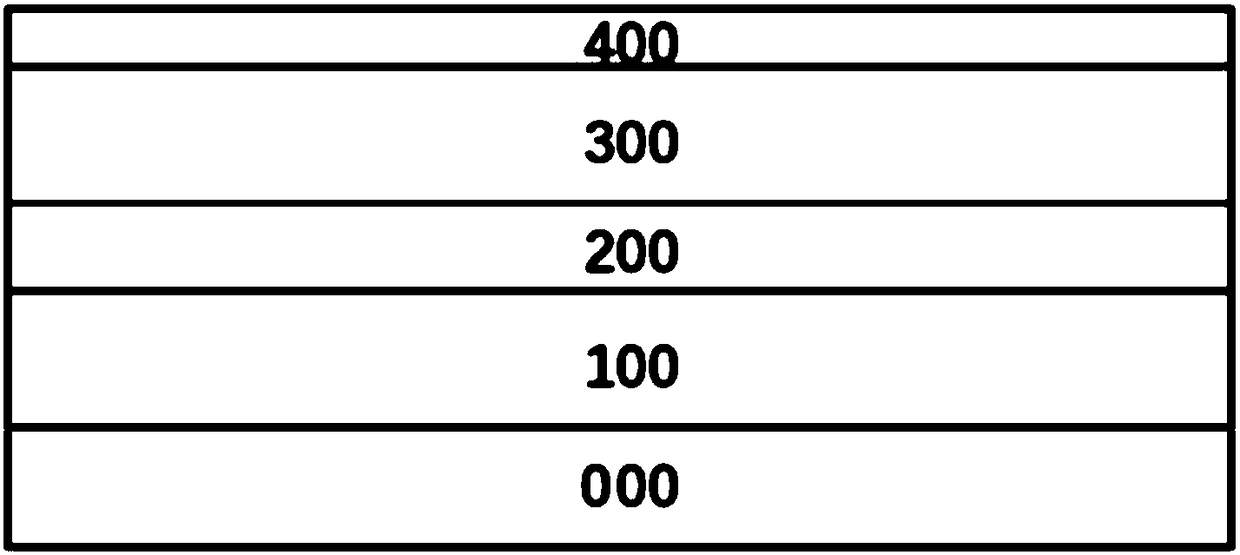

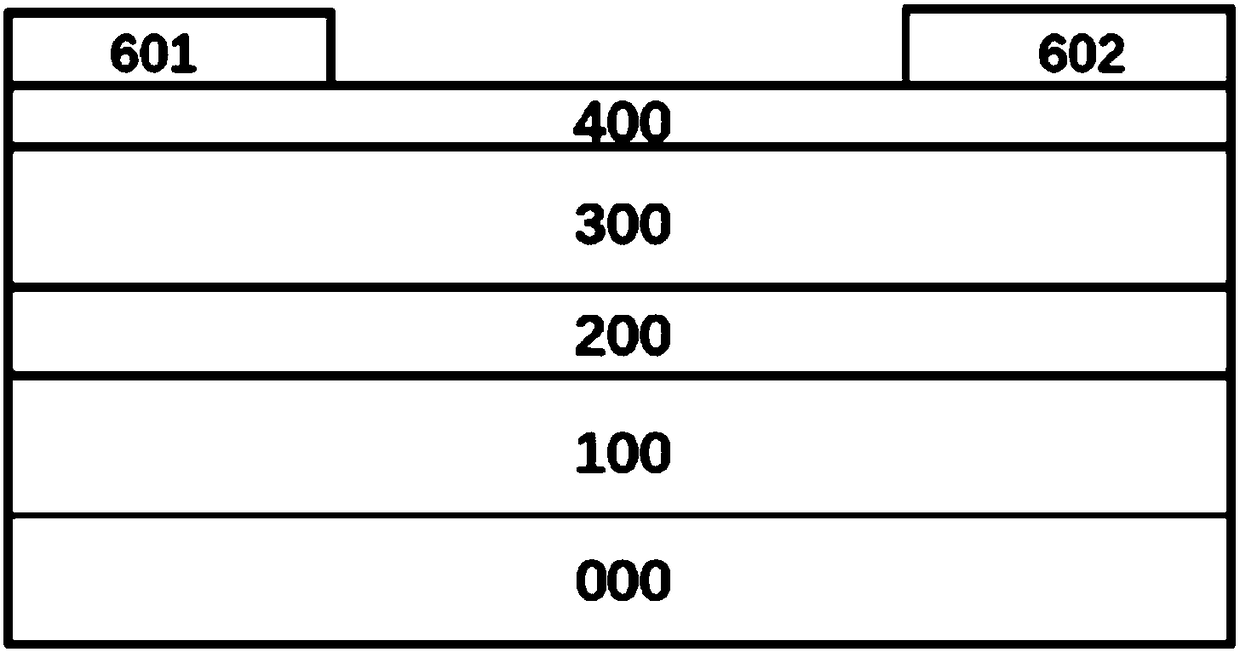

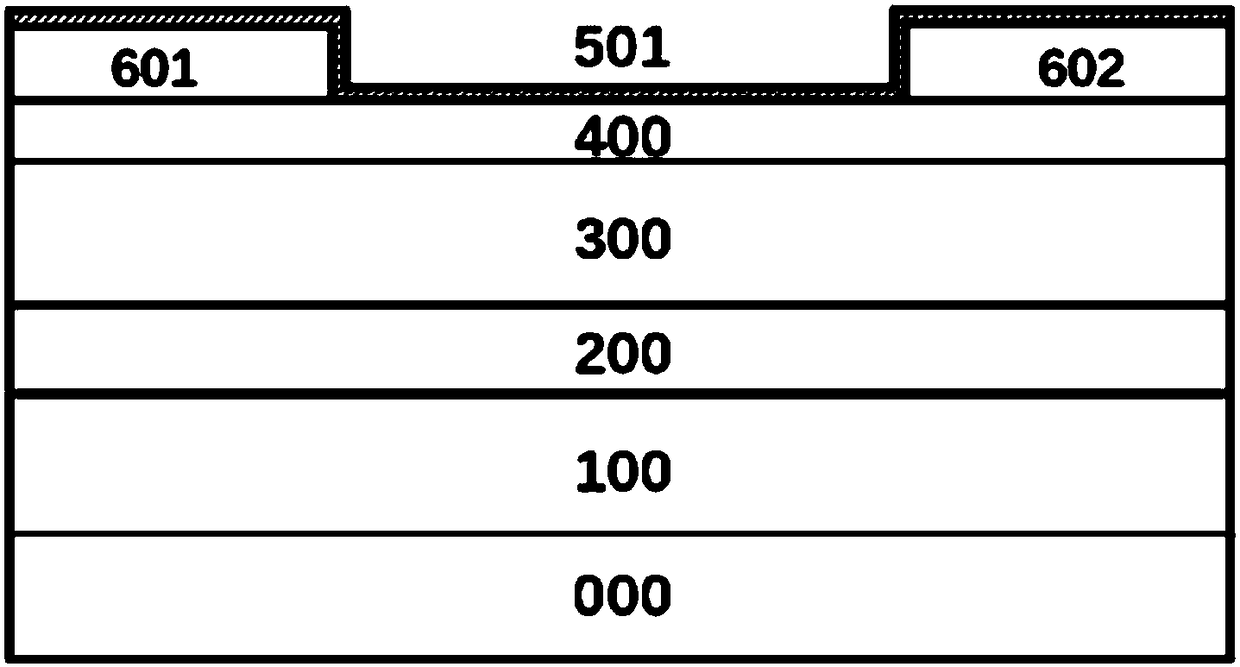

Method for preparing enhanced GaN field effect device

ActiveCN108305834AReduce leakageImprove collapseSemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductor materialsOxygen plasma

The invention provides a method for preparing an enhanced GaN field effect device structure. By inserting a layer of P-type two-dimensional semiconductor material under a gate metal, two-dimensional electron gas in a channel under a gate can be effectively depleted, and thus an enhanced GaN field effect device is prepared. The P-type two-dimensional semiconductor material of a contact region outside the lower part of the gate is etched and removed by using oxygen plasma, the contact resistance can be effectively reduced, and the device performance is improved. At the same time, by controllingan etching time and oxygen plasma concentration, an oxide film can be formed by a potential barrier layer by using the oxygen plasma, and the gate leakage of the device is reduced.

Owner:BEIJING HUATAN TECH CO LTD

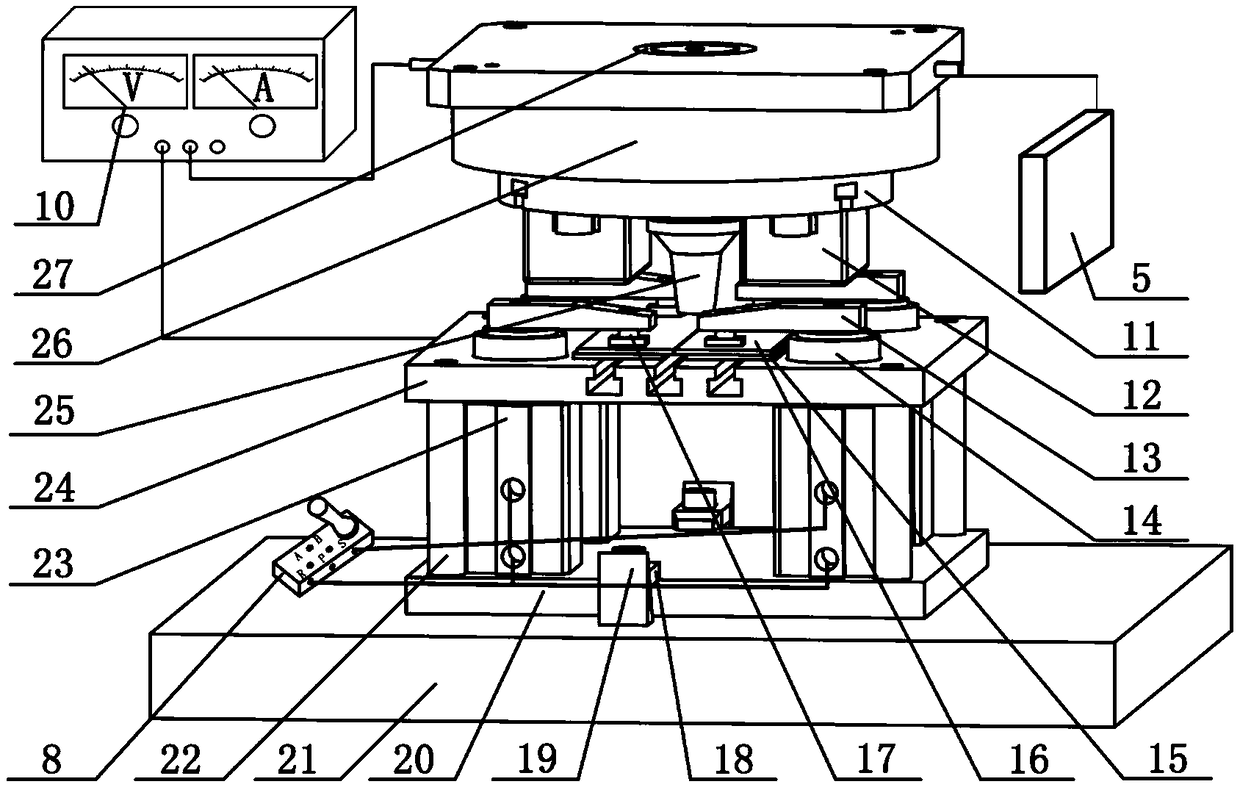

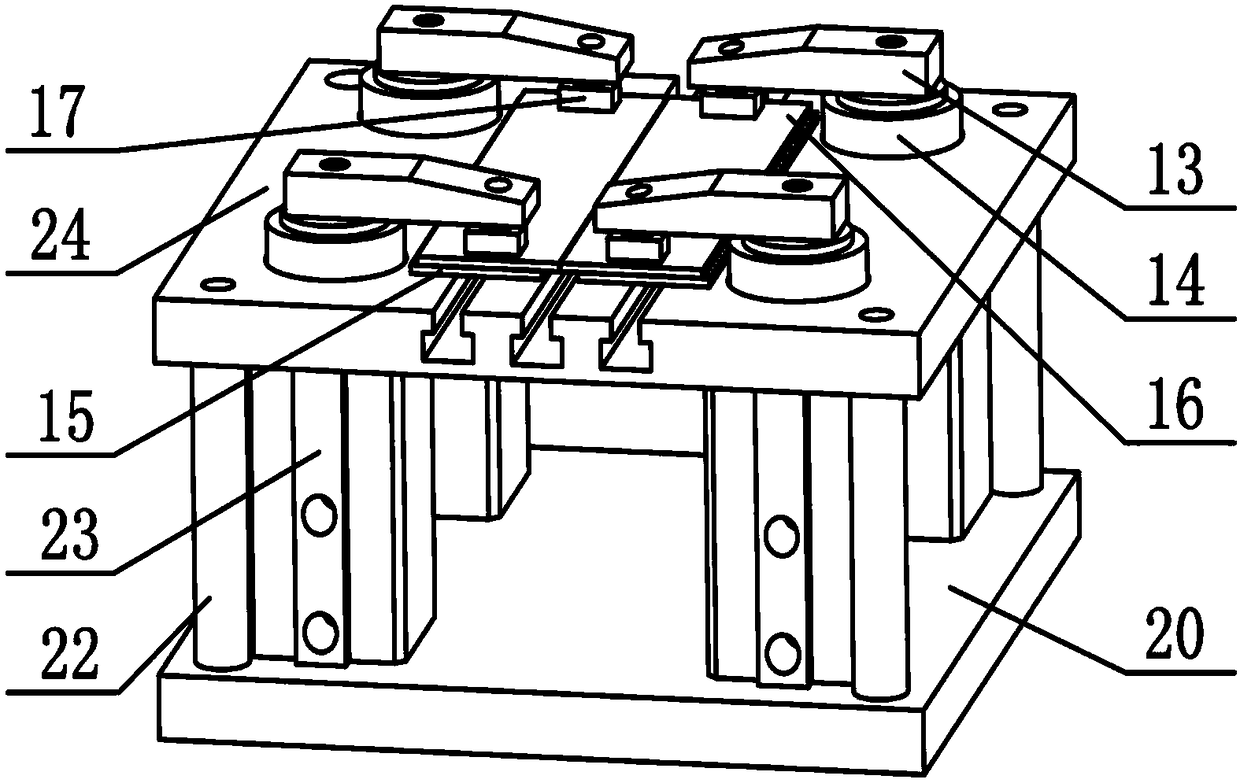

Rotary electric field and magnetic field synchronously assisted laser welding device and method

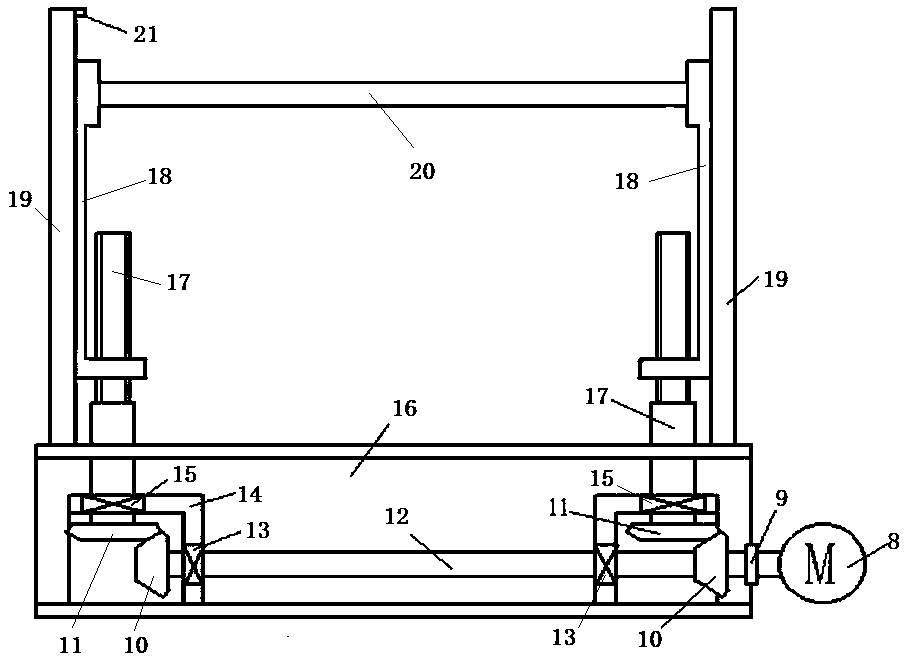

ActiveCN109128502AAchieve overlapEasy to adjustLaser beam welding apparatusElectric machineryDrive motor

The invention discloses a rotary electric field and magnetic field synchronously assisted laser welding device and method and belongs to the field of laser welding. The welding device comprises an electricity and magnet regulating device and a positioning and clamping tooling. Supporting columns and rotary air cylinders in the positioning and clamping tooling are mounted on a bottom plate. An electric field generation bottom plate is mounted on the supporting columns. Press blocks are mounted on the rotary air cylinders correspondingly. Neodymium iron boron permanent magnets in the electricityand magnet regulating device are fastened to a magnetic field regulating disc. Insulation sleeves, a welding laser head and the magnetic field regulating disc are mounted on a direct drive motor. Thedirect drive motor is mounted on a main shaft. The two poles of an electric field power source are connected to the electric field generation bottom plate and the welding laser head correspondingly.By means of the device and method provided by the invention, easy, convenient and fast regulation of a rotary magnetic field and a steady electric field can be achieved, continuous regulation of the intensity can be achieved, synchronous movement of the electric field and the magnetic field along with welding laser beams is guaranteed, and therefore, the forming quality of laser welding joints isimproved by setting the reasonable laser technological parameters including the power, the focal length, the defocusing amount, the helium protective gas flow rate and the like.

Owner:CHANGCHUN UNIV OF SCI & TECH

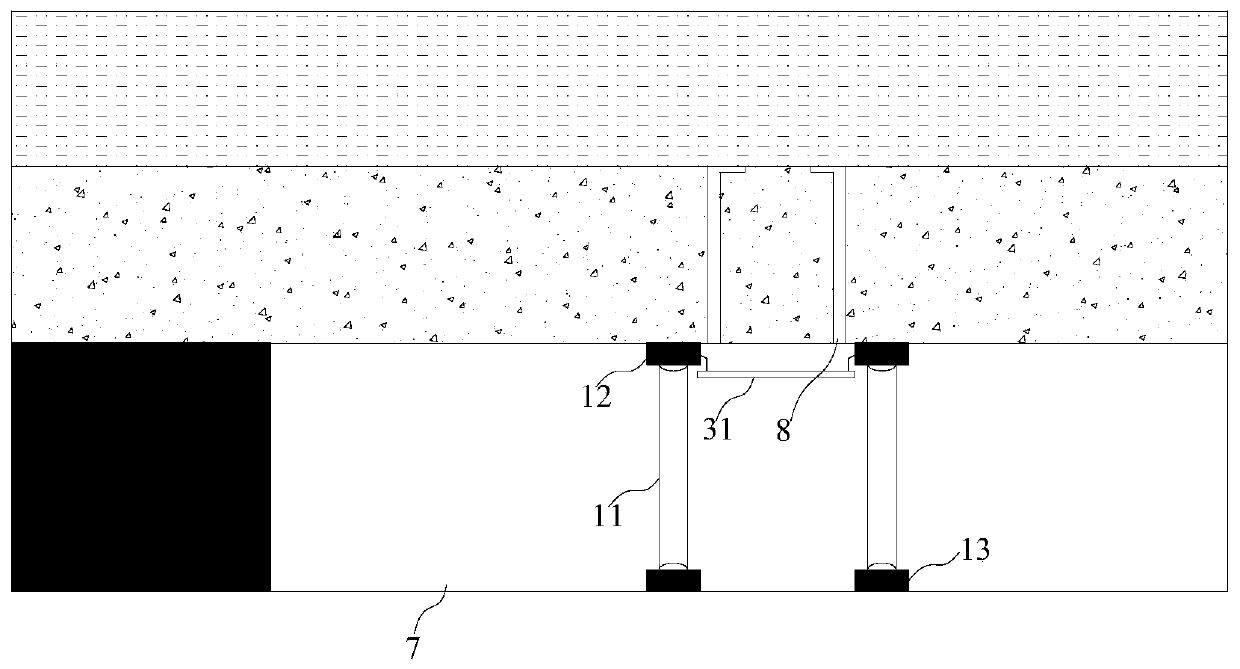

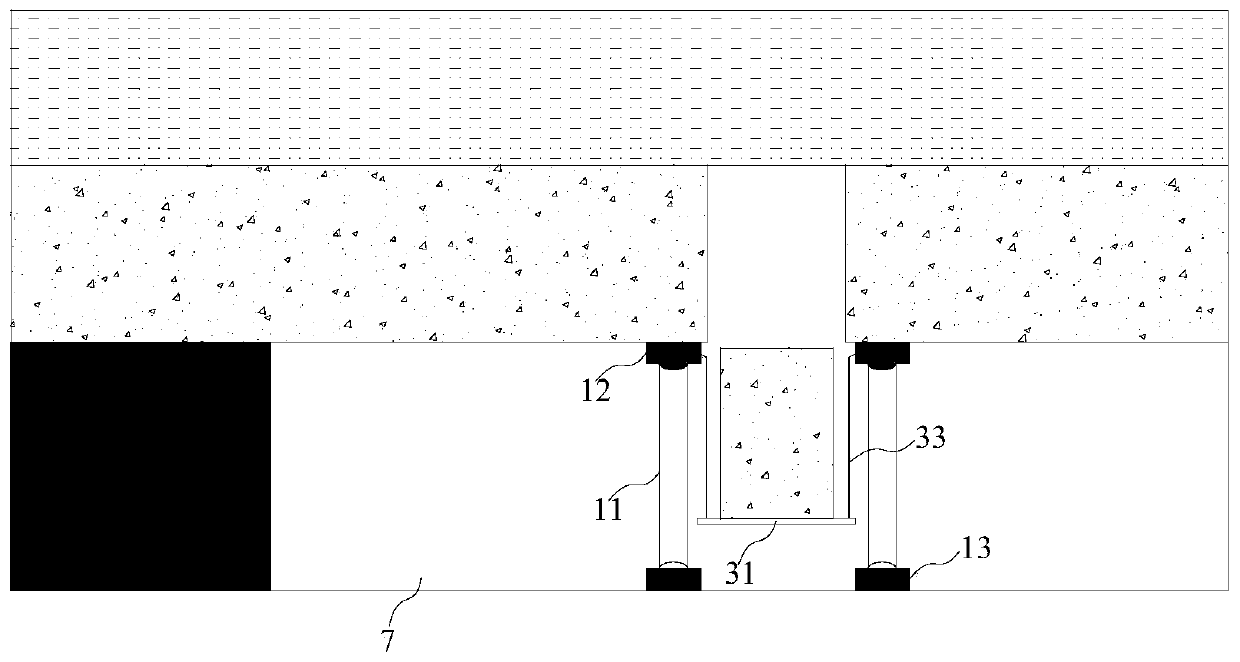

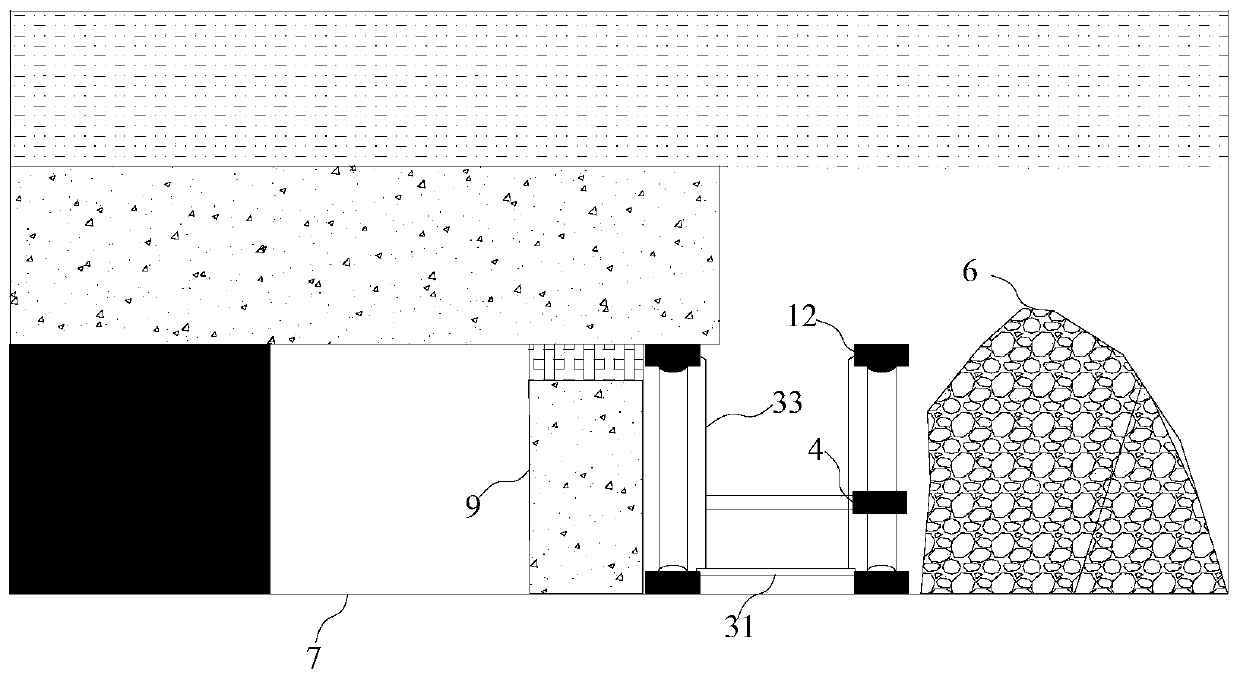

Method for gas extraction by coal seam roof weakening through L-shaped drilling staged fracturing

The invention relates to a gas extraction method for L-shaped borehole staged fracturing of a weakened coal seam roof, which comprises the following steps: 1) selecting the drilling position and parameters at the ground position corresponding to the working face of the coal seam to be mined, and constructing L 2) After the construction of the L-shaped borehole is completed, casings and fracturing equipment are arranged in the L-shaped borehole, and each preset fracturing site of the coal seam roof is fractured by means of hydraulic jet staged fracturing, to weaken the roof of the coal seam; 3) After the fracturing operation is completed, remove the fracturing equipment and connect the casing in the L-shaped borehole to the gas drainage device; 4) Start the coal mining operation at the coal mining face, and While the coal face is moving forward, the gas in the fracture zone is extracted through the gas extraction device. This solution solves the problems in the prior art that the amount of gas extraction is limited and the extraction intensity is not enough, and the coal seam gas cannot be extracted and utilized to a great extent.

Owner:CHONGQING UNIV

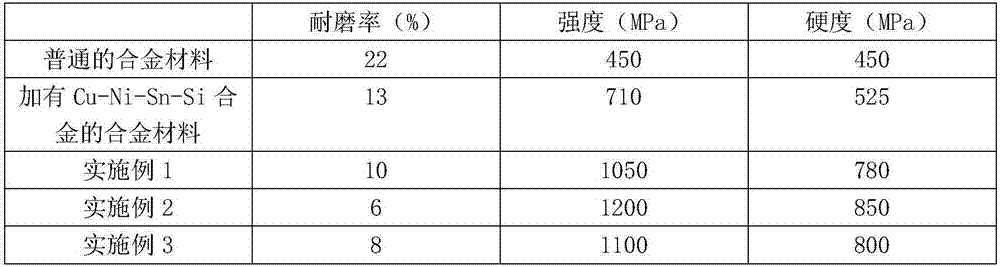

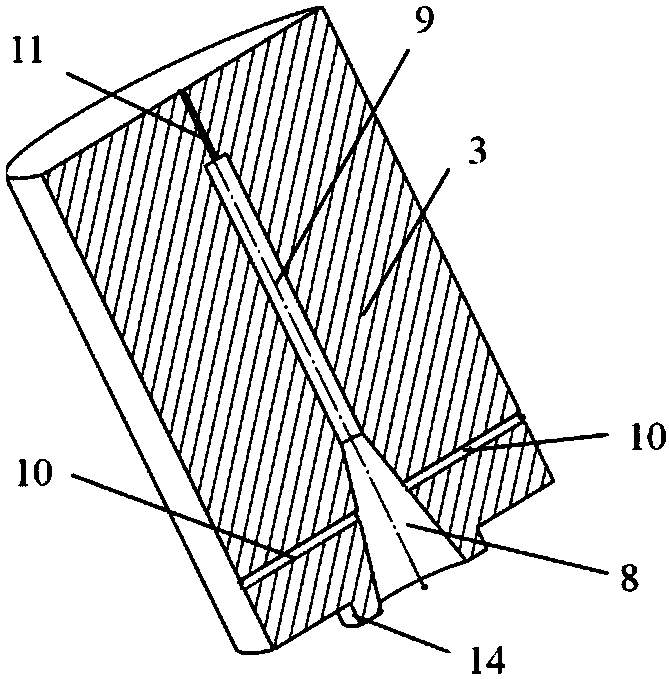

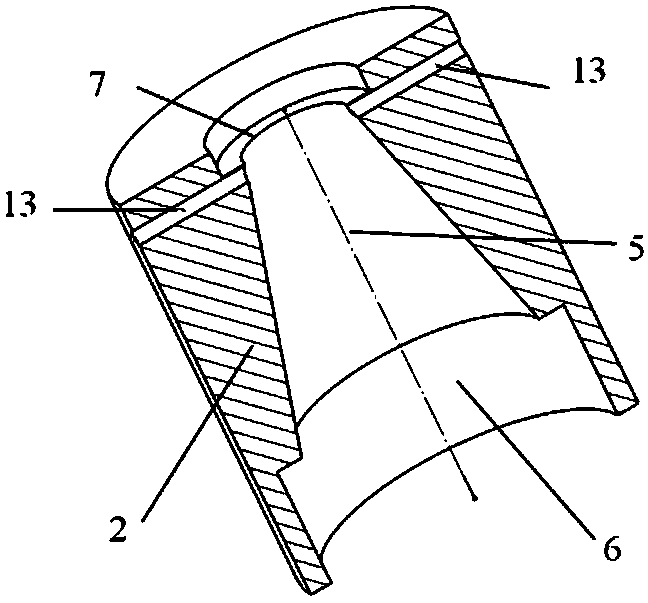

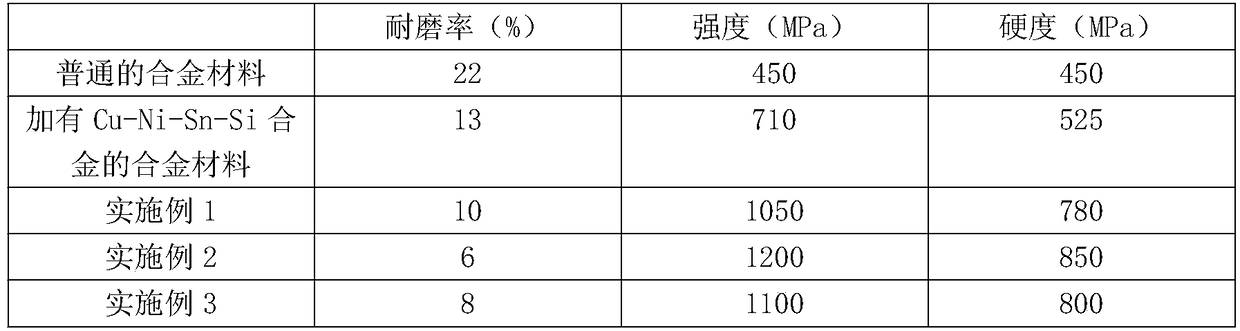

Non-stoichiometric ratio TiC reinforced copper-based composite and preparation method thereof

ActiveCN107119207AFacilitate deintercalation diffusionImprove collapseWear resistanceUltimate tensile strength

The invention discloses a non-stoichiometric ratio TiC reinforced copper-based composite and a preparation method thereof and belongs to the technical field of metallurgical composites. The composite is composed of, by mass percentage, 1-5% of non-stoichiometric ratio TiC particles and the balance a base body copper alloy. The base body copper alloy is a Cu-Ni-Sn-Si alloy. The preparation method comprises the following steps of 1, conducting vacuum in-situ reactive sintering on Ti2SnC, Ti3SiC2 and Cu powder to prepare a non-stoichiometric ratio TiC / Cu intermediate material; 2, placing Cu into a vacuum induction smelting furnace, after the Cu is fully molten, sequentially adding Ni, the TiC / Cu intermediate material, Sn and Si into the vacuum induction smelting furnace for smelting, so that a non-stoichiometric ratio TiC / Cu-Ni-Sn-Si powder material is obtained, and then conducting gas atomization treatment on the TiC / Cu-Ni-Sn-Si powder material, so that prealloy powder is obtained; and 3, conducting ball milling, cold pressing for blank production, vacuum sintering, extrusion and heat treatment on the prealloy powder, so that the TiC / Cu-based composite is obtained. The non-stoichiometric ratio TiC reinforced copper-based composite has the beneficial effects of being good in strength, low in friction coefficient, high in abrasion resistance and the like.

Owner:JIANGXI UNIV OF SCI & TECH

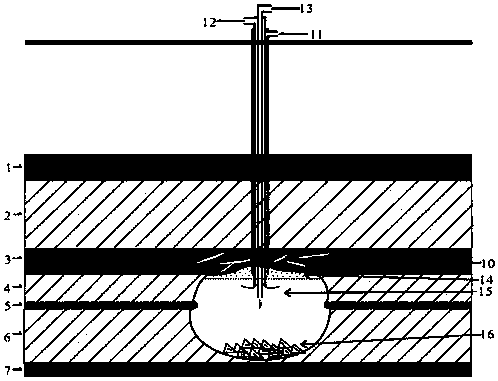

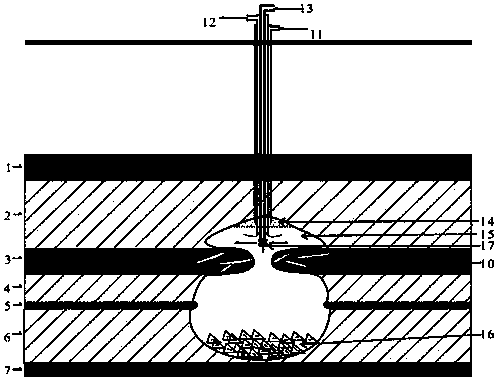

Layered rock salt selective solution mining cavity construction control process

ActiveCN110761766AAddressing impacts on salt chamber stabilityDifficult to peel off promotionFluid removalWell drillingChemistry

The invention relates to a layered rock salt selective solution mining cavity construction control process. The layered rock salt selective solution mining cavity construction control process specifically comprises the steps that during the construction of a salt cavern reservoir, first, drilling and fracturing are performed on an interlayer in a drilling stage, and the integrity of the interlayeris destroyed within a certain range; secondly, in the process of rock salt mining, an upper salt layer and a lower salt layer of the interlayer are first eroded to construct a cavity to enable the interlayer to be immersed in brine for a long time; meanwhile, the composition of a well injection water solution is changed to preferentially dissolve part of substances in the interlayer, and the interlayer structure is destroyed; and in addition, through a self-vibrating cavitating water jet device, the downhole water injection direction and water injection pressure are adjusted to increase the erosion effect on the interlayer and further promote the rapid denudation and collapse of the interlayer. Different mining schemes are adopted for different rock salt layer positions, the problem thatthe thick interlayer in layered rock salt is difficult to collapse is solved, and effective control over the shape of the solution cavity of the salt cavern reservoir is realized.

Owner:江苏省制盐工业研究所有限公司 +1

Preparation method of grid enhanced gallium nitride field effect device with P type 2D material

ActiveCN108365008AReduce leakageImprove collapseTransistorSemiconductor/solid-state device manufacturingGallium nitrideOhmic contact

The invention provides a preparation method of a grid enhanced gallium nitride field effect device with a P type 2D material. The method comprises the following steps that a buffer layer, a channel layer, a barrier layer and an interface control layer are arranged on a monocrystalline substrate successively in an epitaxy way to obtain an epitaxial substrate; source and drain metal are deposited insource and drain regions on the epitaxial substrate respectively to form ohmic contact; a 2D material layer is deposited on the epitaxial substrate; a grid metal region is defined, and grid metal isdeposited; and the 2D material between the grid and source and between the grid and drain is oxidized in the oxygen rich atmosphere; a medium passivation layer is deposited in the surface of the interface control layer; and contact holes between the source / drain and the grid are formed. The P type 2D material replaces a traditional P-GaN layer, and exhaust 2D electron gas thereunder to form an enhanced filed effect ransistor, etching is replaced by oxidation, damage on the surface of a barrier layer can be reduced, and difficulties in the prior art are overcome.

Owner:BEIJING HUATAN TECH CO LTD

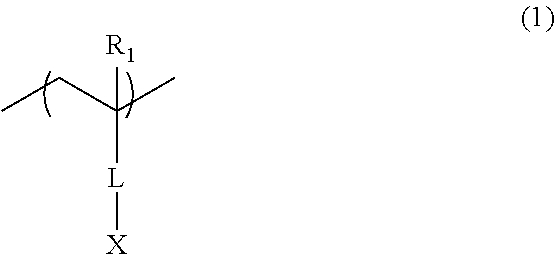

Additive for resist underlayer film-forming composition and resist underlayer film-forming composition containing the same

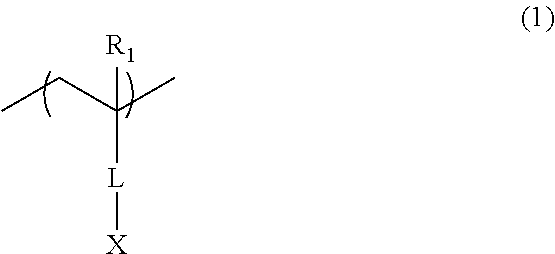

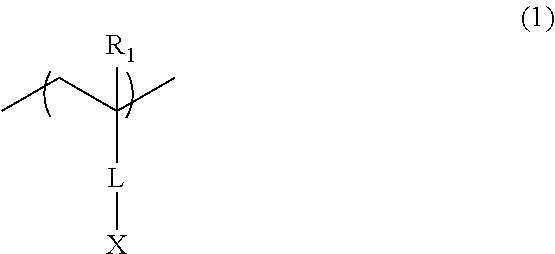

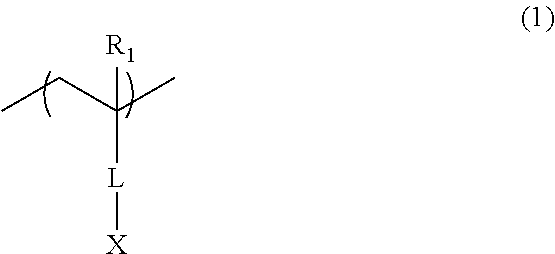

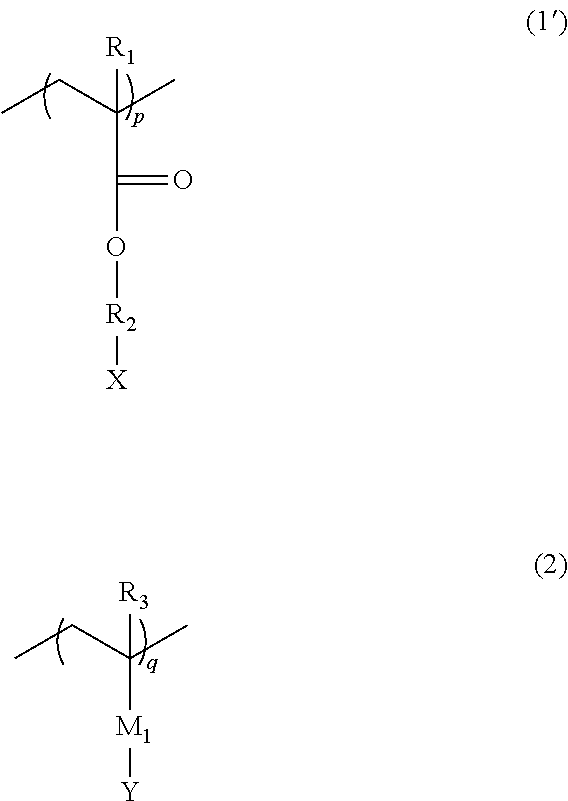

ActiveUS20140287589A1Less crashesImprove collapseSemiconductor/solid-state device detailsSolid-state devicesResistNitrogen

It is aimed to enhance adhesiveness between a resist pattern formed on a resist underlayer film and to reduce an undercut of the resist pattern. An additive for a resist underlayer film-forming composition, including: a polymer having a structural unit of Formula (1):(where R1 is a hydrogen atom or a methyl group; L is a divalent linking group; X is an acyloxy group having an amino group protected with a tert-butoxycarbonyl group or a nitrogen heterocycle protected with a tert-butoxycarbonyl group).

Owner:NISSAN CHEM IND LTD

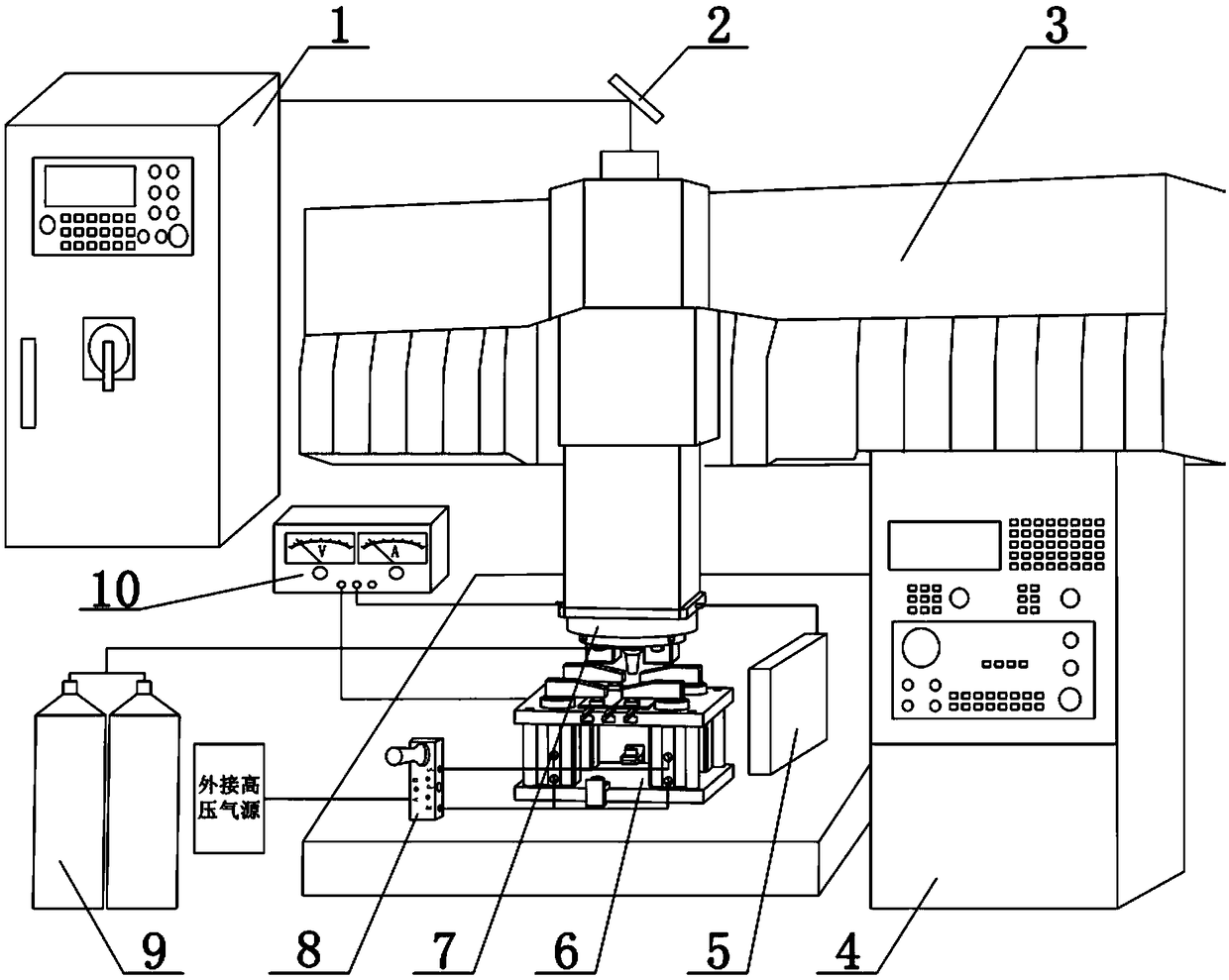

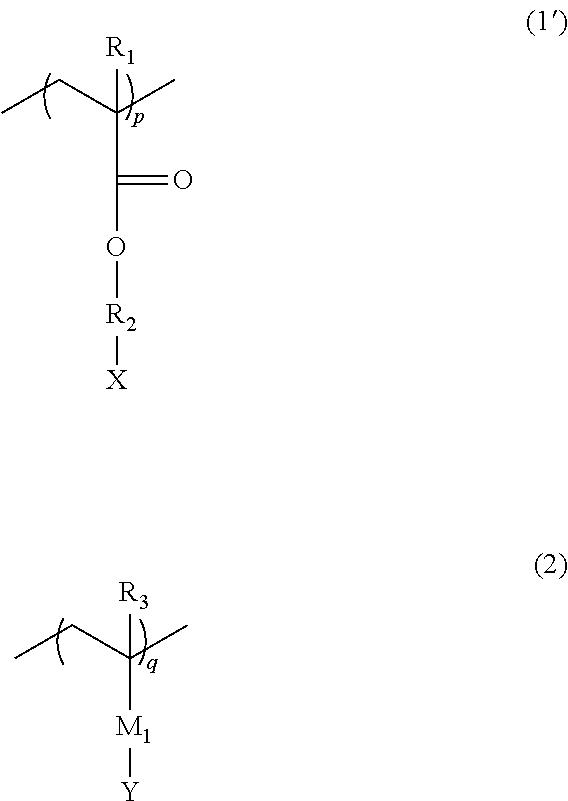

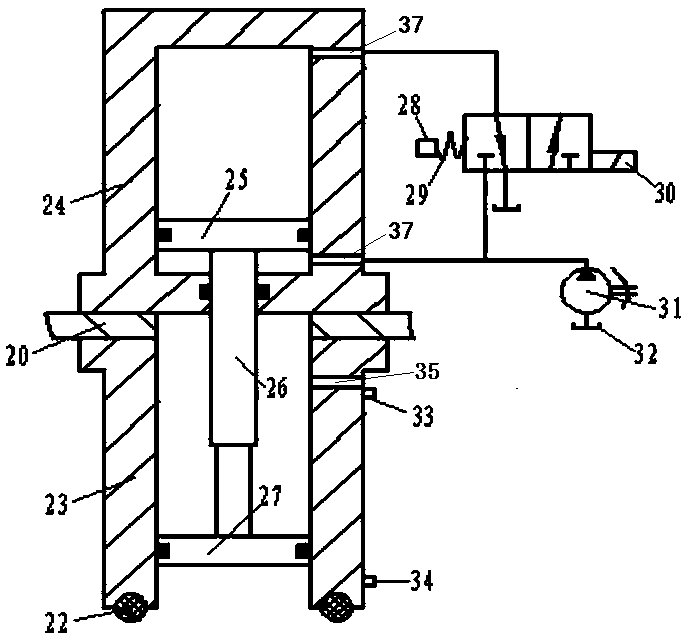

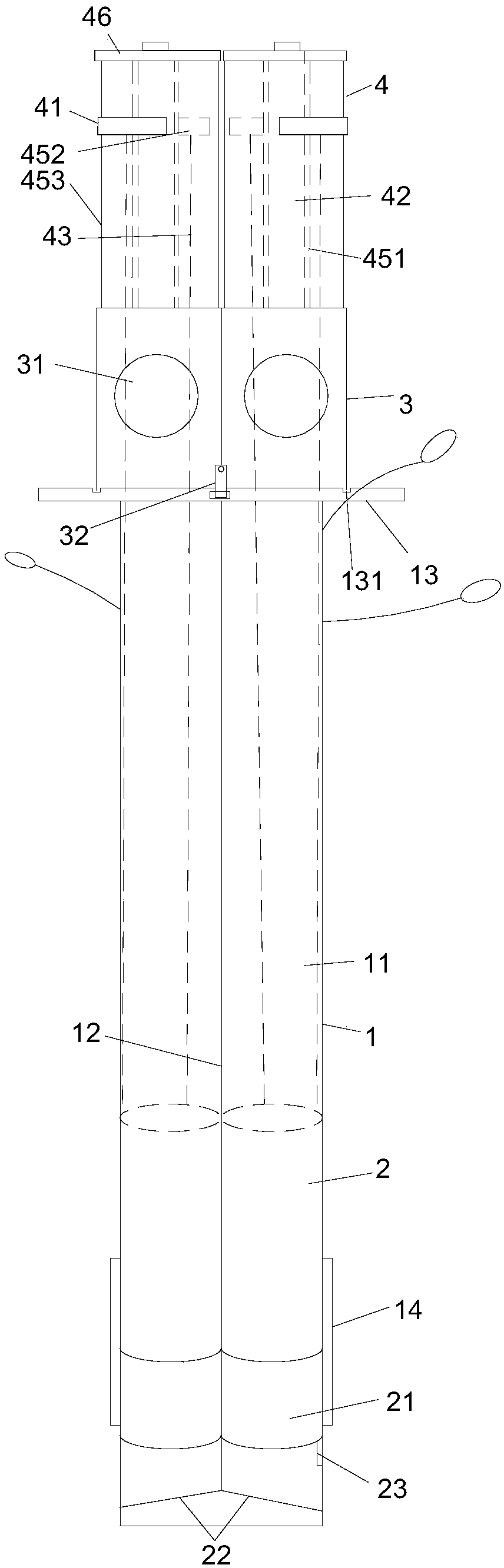

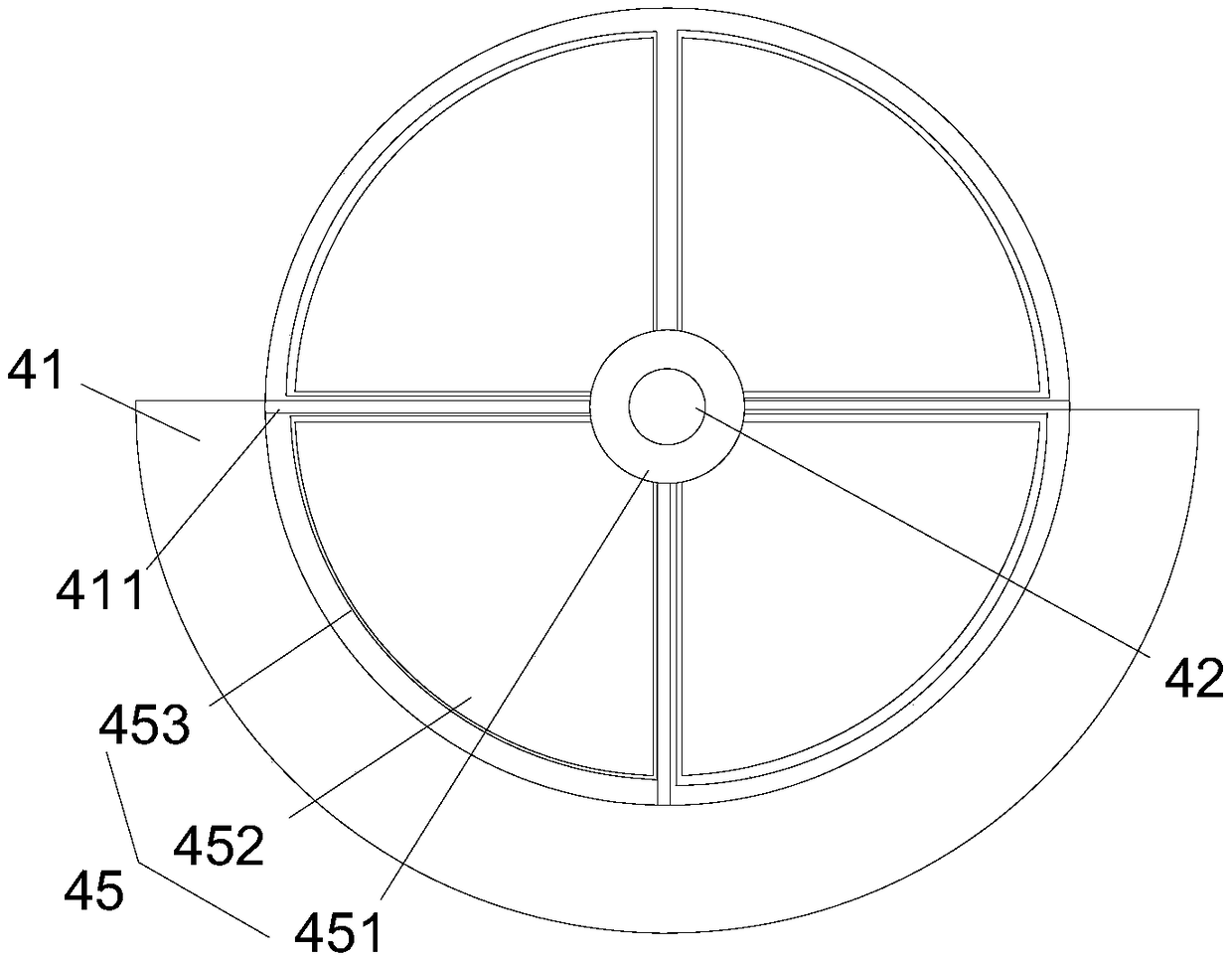

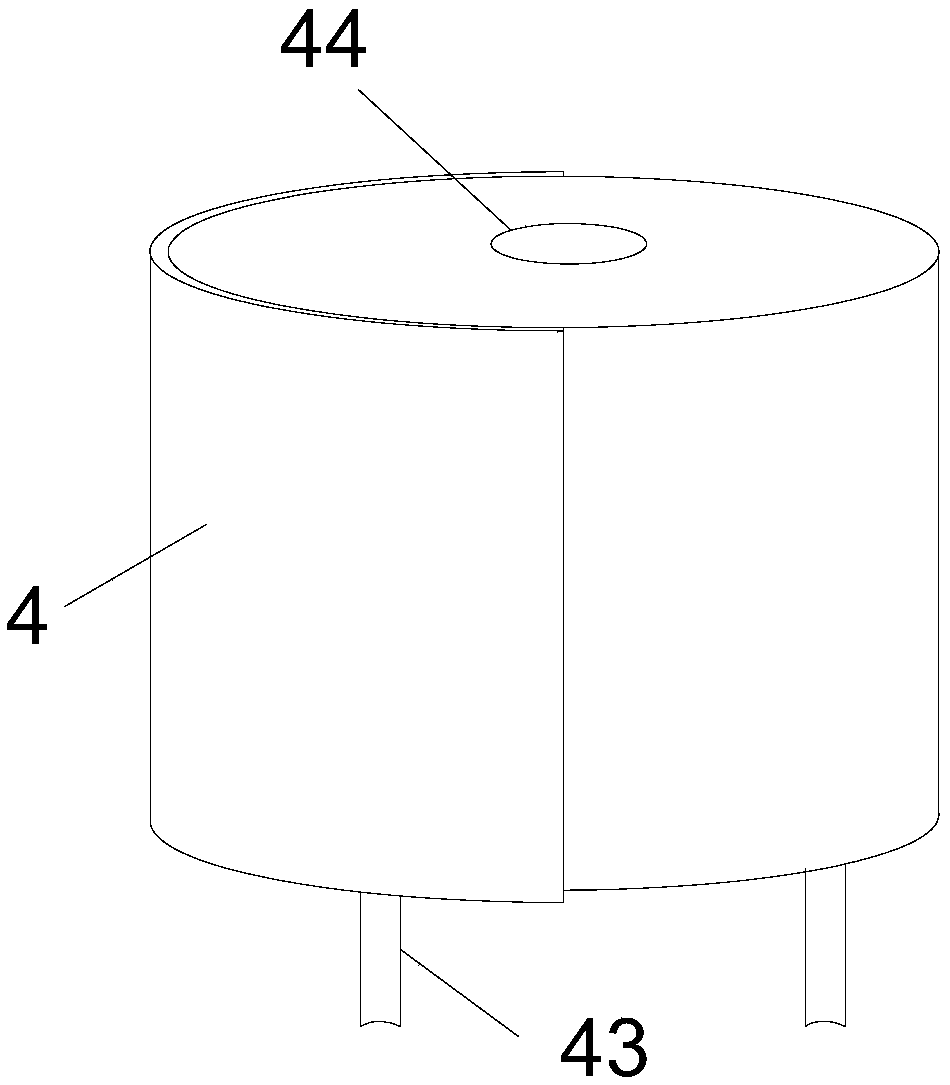

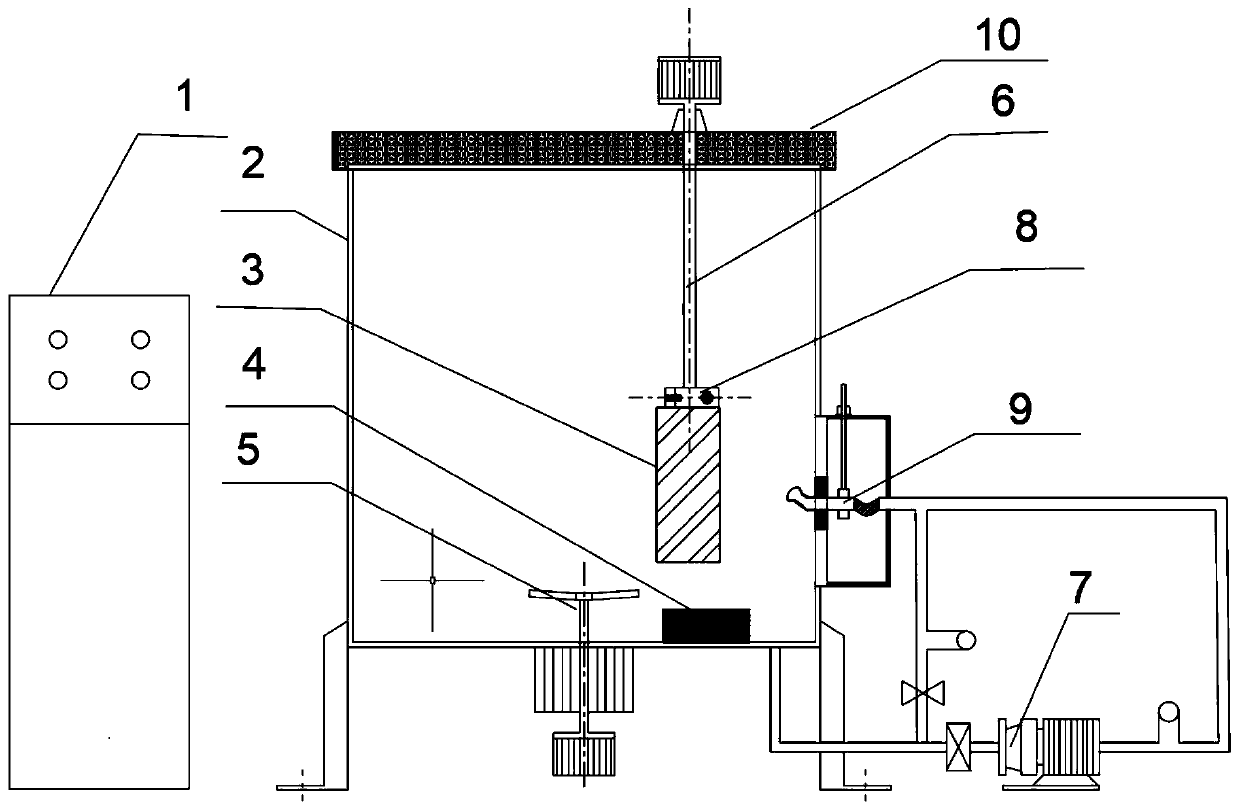

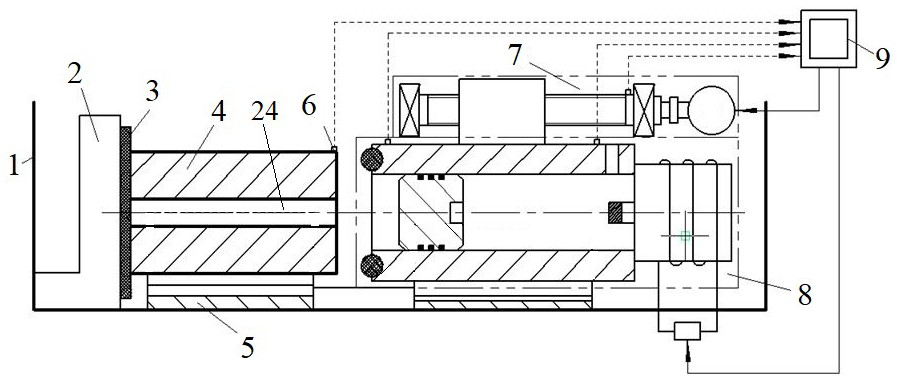

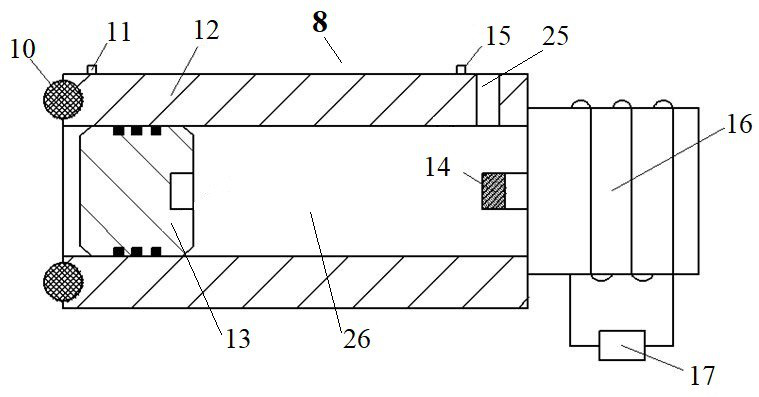

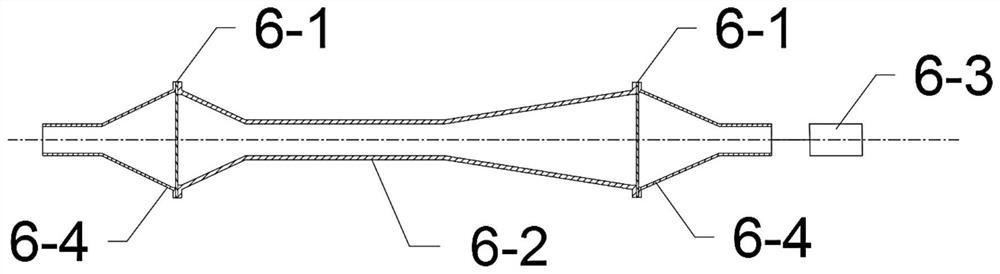

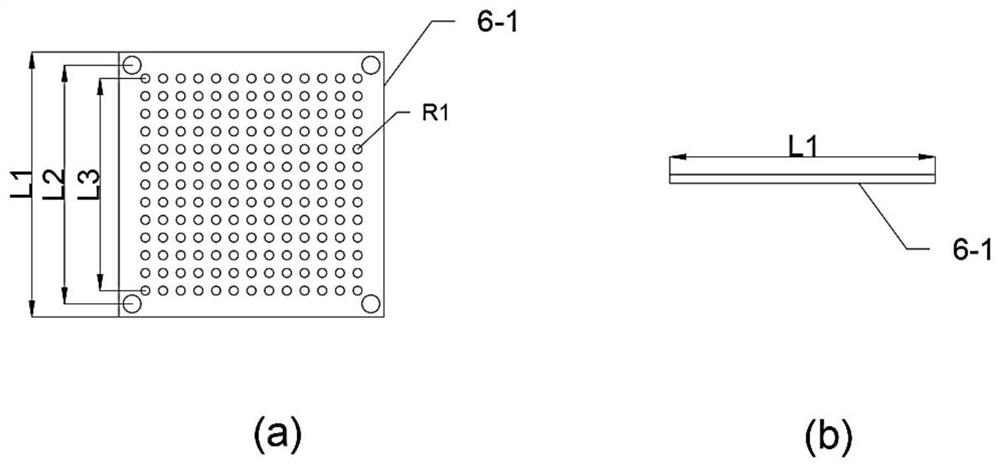

Hydraulic-driving type miniature tapered hole inner surface cavitation shot-blasting system and method

ActiveCN110144453AImprove collapseConsistent and smooth surface contourCavitationReciprocating motion

The invention discloses a hydraulic-driving type miniature tapered hole inner surface cavitation shot-blasting system and method. The two ends of a horizontal connecting rod are each fixedly connectedwith a first bevel gear. The lower segments of two vertical lead screws are each fixedly connected with a second bevel gear engaged with the corresponding first bevel gear. One end of the connectingrod is connected with a motor. A horizontal cover plate is connected between the upper ends of two sliding blocks. The lower end of each sliding block is connected with the corresponding lead screw through threads. A workpiece is vertically arranged on the bottom surface of the interior of a first oil tank. A cylinder is located over the workpiece. An oil cylinder is arranged over the cylinder. Anupper piston is arranged in an inner cavity of the oil cylinder. A lower piston is arranged in an inner cavity of the cylinder. A piston rod is fixedly connected between the upper piston and the lower piston. Oil holes are formed in the side walls of the upper end and the lower end of the oil cylinder correspondingly. The two oil holes are connected with reversing valves correspondingly. Throughreciprocating movement of the pistons, the volume of sealed liquid in a miniature tapered hole is continuously changed, a cavitation phenomenon is caused, shot blasting is performed on the inner surface of the tapered hole, and the good surface quality can be obtained.

Owner:JIANGSU UNIV

Method for producing colored veins for artware

ActiveCN106864153AImprove hydrolysis efficiencyPromote sheddingSpecial ornamental structuresVeinEnzyme

The invention discloses a method for producing colored veins for artware. The method comprises the following steps of 1, leaf selecting, wherein high-quality leaves are selected; 2, enzymolysis, wherein after the leaves are boiled with clear water, compound enzyme is added for enzymolysis; 3, bleaching, wherein after veins obtained after enzymolysis are aired to be half-dry, light-shielded bleaching is conducted with a hydrogen peroxide solution; 4, dying, wherein after the veins obtained after bleaching are cleaned, the veins are aired to be half-dry, and dying is conducted with a natural pigment, so that the dyed veins are obtained; and 5, shaping, wherein the colored veins are dried and shaped. According to the method for producing the colored veins for the artware, a compound enzymolysis method is adopted, and after being dried, the veins can still maintain to be soft and is not likely to be fractured; and later-stage processing and shaping of the artware can be conducted conveniently. Meanwhile, safety in the production process is improved; required production time is shortened; and production efficiency is improved.

Owner:YUNNAN RAINBOW BIO TECH

Reverse ultrasonic assisted gas-liquid-solid three-phase abrasive particle flow polishing processing method and device

ActiveCN104786153AIncreased chance of crashLow damageAbrasive machine appurtenancesAbrasive blasting machinesParticle flowShock wave

The present invention discloses a reverse ultrasonic assisted gas-liquid-solid three-phase abrasive particle flow polishing processing method and device, an ultrasonic generator is mounted in a position which is reverse in direction to abrasive particle flow, an included angle is formed between the abrasive particle flow direction and the position, a reverse ultrasonic is produced, the direction of the reverse ultrasonic is reverse to that of the abrasive particle flow, an included angle is formed between the abrasive particle flow direction and the reverse ultrasonic, the reverse ultrasonic can compress micro-sized bubbles near workpiece machining surface in an abrasive particle flow medium containing the micro-sized bubbles to collapse and perish the micro-sized bubbles, when the micro-sized bubbles are collapsed and perished, a reverse micro shock wave is produced, the direction of the reverse micro shock wave is reverse to that of the abrasive particle flow, the reverse micro shock wave allows the inner local area of the abrasive particle flow to produce a great pressure so as to produce microscopic explosion effect; two component forces are generated by the microscopic explosion effect, a vertical component force is used for improving the contact probability and acting force of abrasive particles and workpiece machining surface convex peaks, a reverse horizontal component force is used for forming relative block effect on the abrasive particles, the abrasive particle and workpiece action time is increased, and the abrasive particle flow polishing efficiency is greatly improved.

Owner:ZHEJIANG UNIV OF TECH

Double-lumen tube and intubation method

InactiveCN109224235AIncreases the chance of successful intubationEasy to adjustTracheal tubesTracheal tubeIntratracheal intubation

The invention provides a double-lumen tube and an intubation method. The double-lumen tube comprises a tracheal intubation tube, a partition plate arranged along the length direction of the tracheal intubation tube so as to partition the tracheal intubation lumen into two independent ventilation chambers, a tracheal tube inserted into the two ventilation chambers from the bottom of the tracheal intubation tube, and a ventilation device and an adjustment device arranged at the top of the tracheal intubation tube from the bottom to the top in turn; The ventilation device is in communication withan air source for supplying gas to the two ventilation chambers; The ventilator is fixedly connected with the partition plate; The adjusting device is fixedly connected with the tracheal tube; The tracheal tube is rotatable relative to the axis of the tracheal intubation through the ventilator. And / or at least one of the two tracheal tubes is rotatable relative to its axis by means of an adjusting device; The tracheal tube is telescopic with respect to the tracheal intubation by means of an adjusting device. As that split structure design is adopt, the tracheal tube can be telescoped and rotate, the accuracy of the intubation is improved, the success rate is high, the adjustability is good, and the damage of the tissue is reduced.

Owner:孙喜家

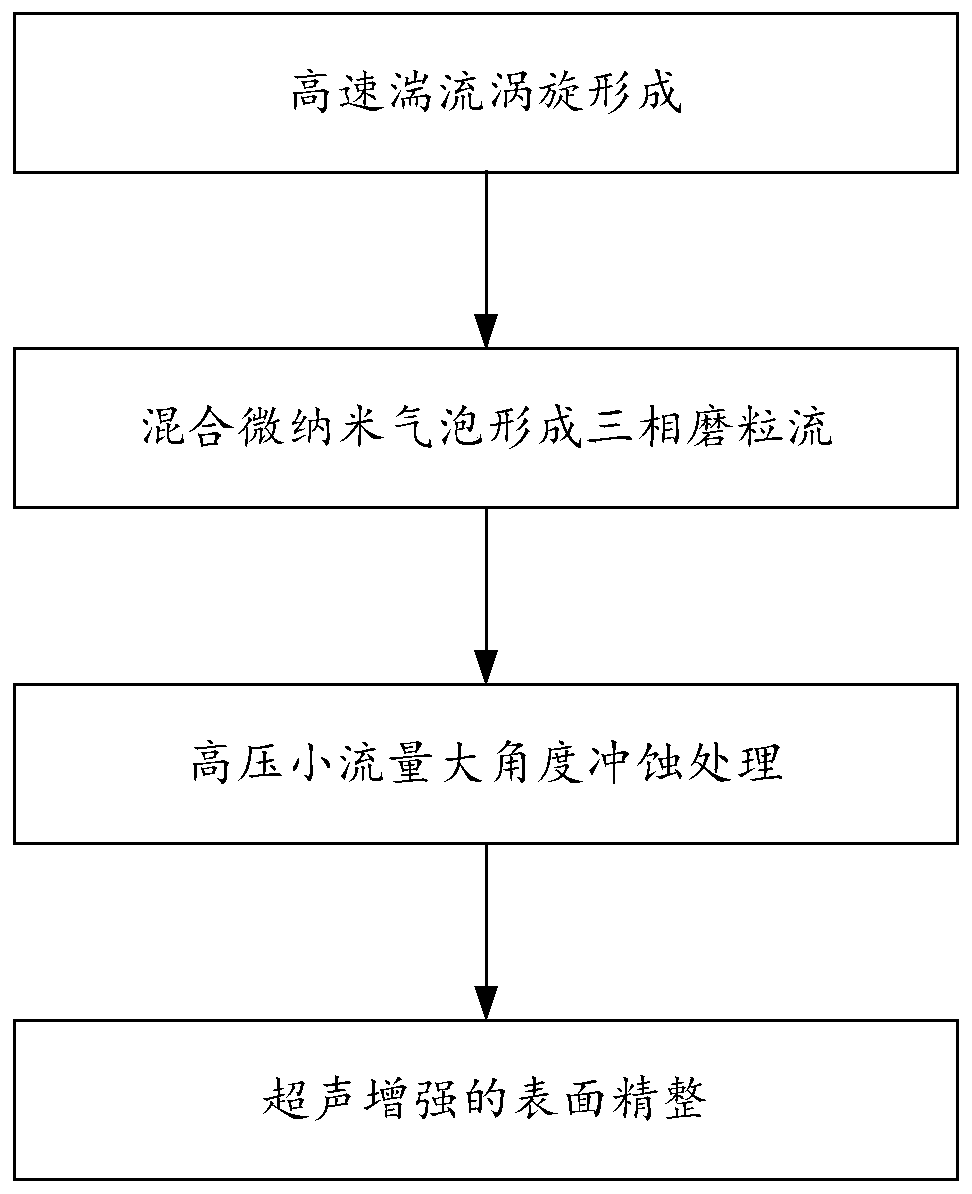

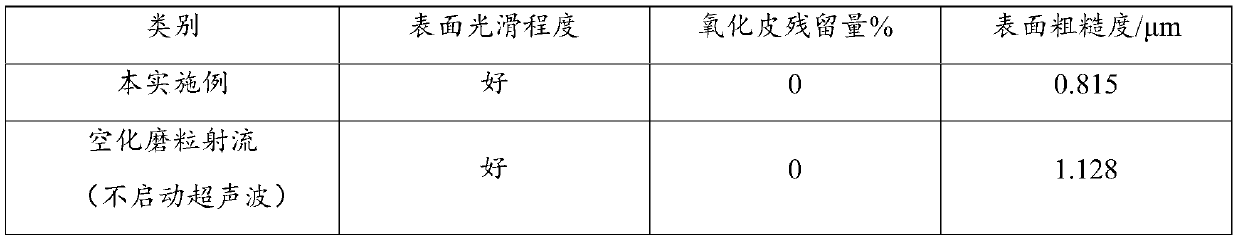

Ultrasonic-assisted cavitation abrasive grain flow finishing method for titanium alloy surface oxide layers

ActiveCN110948398AImprove removal efficiencyRealize integrated enveloping processingAbrasive feedersAbrasive machine appurtenancesMicro nanoUltrasonic assisted

The invention provides an ultrasonic-assisted cavitation abrasive grain flow finishing method for titanium alloy surface oxide layers. The method comprises the following steps: stirring a solid-liquidtwo-phase mixed fluid to form high-speed turbulence vortex; extracting the solid-liquid two-phase mixed fluid, mixing the solid-liquid two-phase mixed fluid with micro-nano bubbles to form a high-speed and high-pressure gas-liquid-solid three-phase abrasive grain flow; spraying the high-speed and high-pressure gas-liquid-solid three-phase abrasive grain flow to a workpiece in a tank body for staged surface treatment; meanwhile, emitting ultrasonic waves by an ultrasonic device configured below the workpiece to form an ultrasonic cavitation effect, and forming a negative fluctuation environment with positive and negative pressure alternating rapidly in the high-speed fluid in the tank body to cause expansion and compression of micro-nano bubbles in the high-speed fluid. Under the comprehensive action of turbulence, jet, cavitaiton and ultrasonic waves, a manner of combining cavitation abrasive grain jet and turbulence integrated surrounding type processing and ultrasonic enhancement isadopted, synchronous stripping of different in-situ defects of oxide scale and derivative and chain stripping of new defect points can be realized, the removal efficiency is high, and the processinguniformity is good.

Owner:SHANGI INST FOR ADVANCED MATERIALSNANJING CO LTD

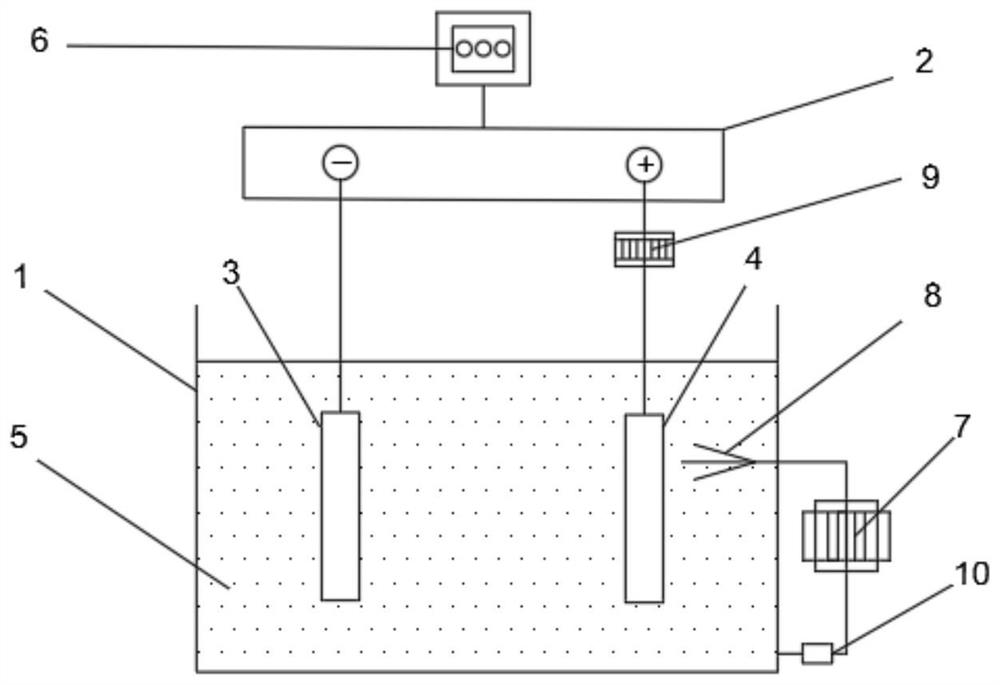

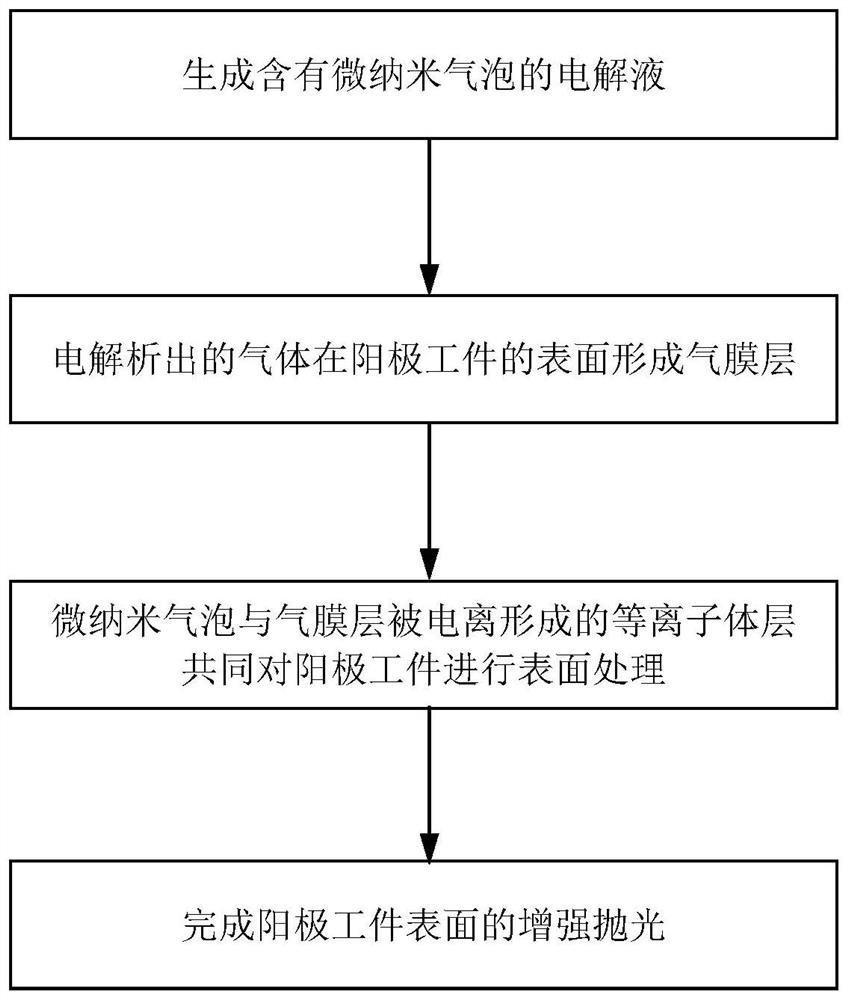

Micro-nano bubble enhanced plasma polishing method

The invention relates to the technical field of surface precision treatment, and particularly relates to a micro-nano bubble enhanced plasma polishing method. The method comprises the following steps that electrolyte containing micro-nano bubbles are conveyed into a working tank by utilizing a micro-nano bubble generating device; in the working tank of the electrolyte containing the micro-nano bubbles, a cathode tool is connected with a cathode of a power supply system, an anode workpiece is connected with an anode of the power supply system, the electrolyte is electrolyzed to separate out gas, and the gas forms a gas film layer on the surface of the anode workpiece; and a part of the gas film layer is punctured and ionized by electric field energy provided by the power supply system to form a plasma layer, and the micro-nano bubbles and the plasma layer jointly perform surface treatment on the anode workpiece. According to the micro-nano bubble enhanced plasma polishing method, by combining the comprehensive effect of the plasma layer and the micro-nano bubbles on the surface of the anode workpiece, the polishing effect on the surface of the anode workpiece is enhanced; and the micro-nano bubble collapse and the plasma layer discharge are mutually promoted and mutually beneficial, so that the polishing efficiency is greatly improved, and the polishing effect is improved.

Owner:SHANGI INST FOR ADVANCED MATERIALSNANJING CO LTD

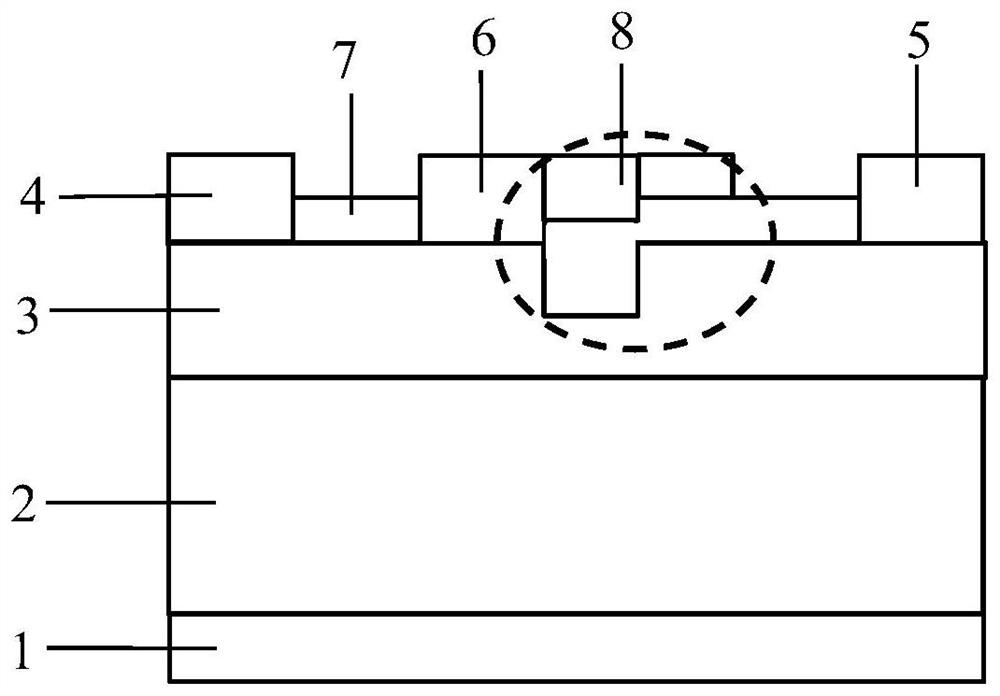

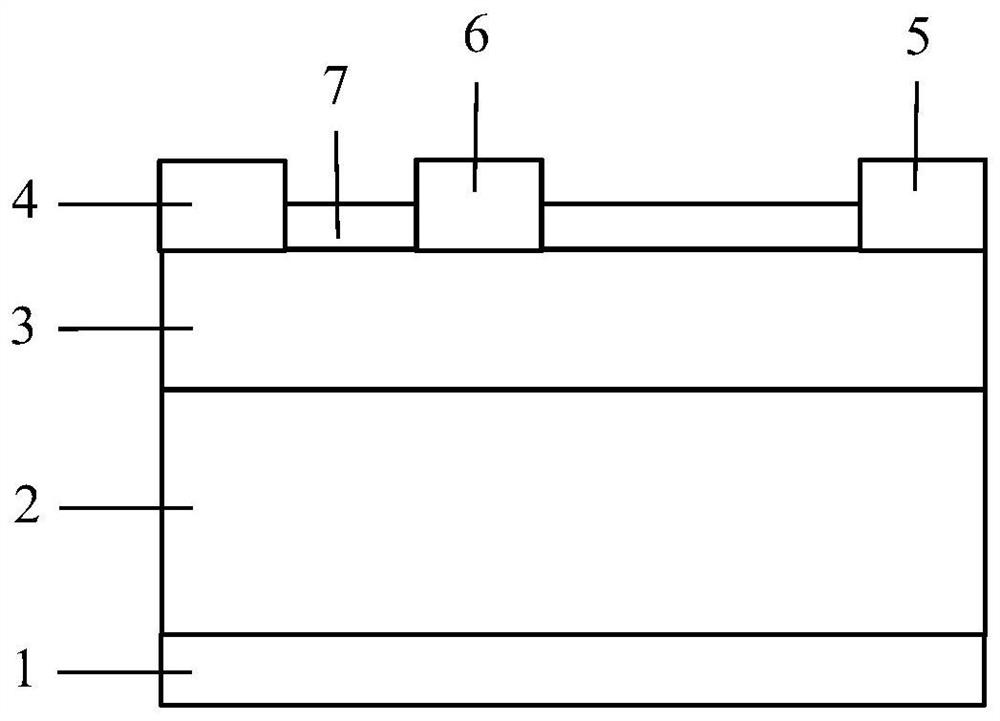

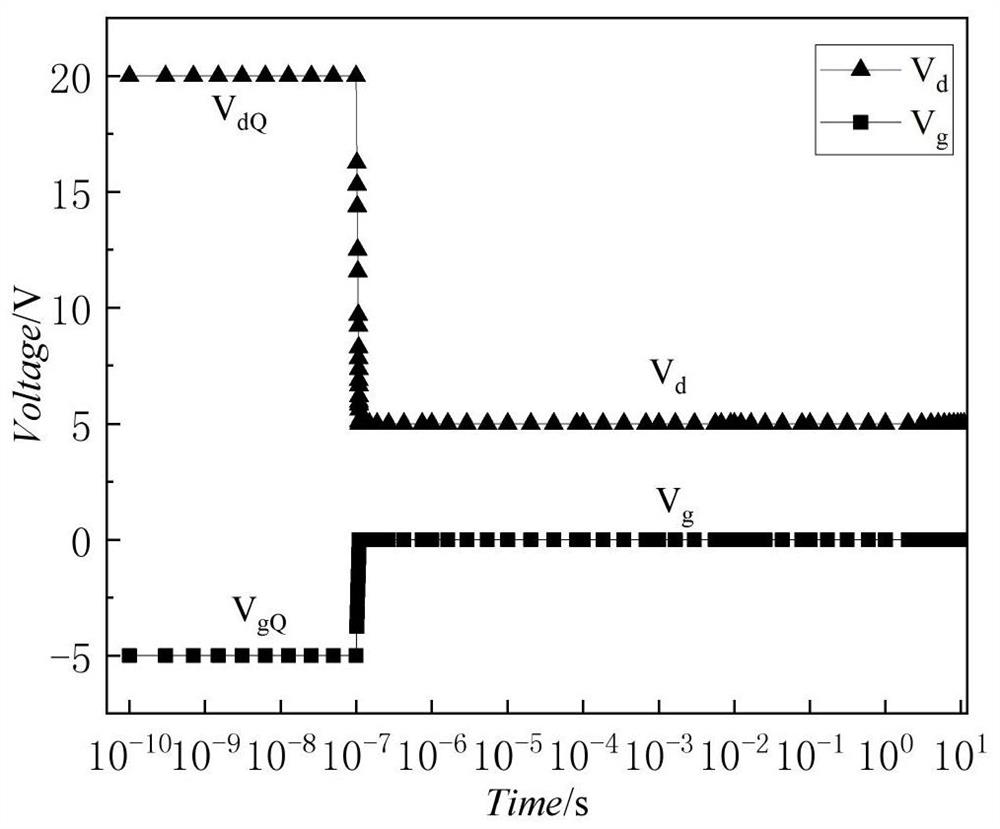

Groove double-field-plate AlGaN/GaN HEMT device

PendingCN113517340AReduce electric field peaksEvenly distributedSemiconductor/solid-state device manufacturingSemiconductor devicesDrain currentMaterials science

A groove double-field-plate AlGaN / GaN HEMT device comprises a substrate, a buffer layer, a barrier layer and a passivation layer which are sequentially arranged from bottom to top, and a source electrode, a drain electrode and a gate electrode which extend to the barrier layer, with the gate electrode located between the source electrode and the drain electrode. A groove double-field is arranged on the barrier layer and between the gate electrode and the drain electrode. The buffer layer is composed of GaN with the thickness of 2 microns, and the doping concentration is 1 * 10 < 15 > cm <-3 >. The barrier layer is composed of AlGaN with the thickness of 20 nm, and the doping concentration is 1 * 10 < 17 > cm <-3 >. The passivation layer is composed of Si3N4 with the thickness of 50 nm. The lengths of the gate electrode, the source electrode and the drain electrode are all 0.5 [mu]m. The length Lfp1 and the length Lfp2 of the groove double-field-plate structure are 0.3 [mu]m and 0.7 [mu]m respectively, the thickness H + Hfp1 and Hfp2 of the passivation layer below the field plates is 10 nm and 20 nm respectively, and the groove is filled with Si3N4. The electric field peak value is reduced, current collapse is improved, and meanwhile a saturated leakage current finally output by the device cannot be greatly reduced.

Owner:XIAN UNIV OF TECH

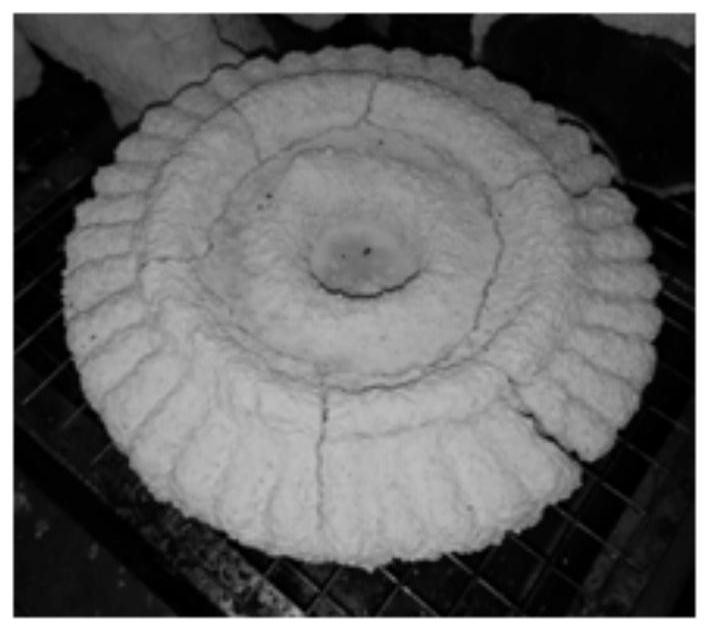

Variable and controllable cavitator

PendingCN110538626AReduce the effective volumeFavorable collapseChemical/physical/physico-chemical stationary reactorsWatercraft hull designCavitationSlide plate

The invention relates to a variable and controllable cavitator, which comprises a large jar body and a small jar body, wherein the small jar body is located on the right side of the large jar body, and is communicated to the large jar body, the left port of the large jar body is covered with a large jar end cover, the right port of the small jar body is covered with a right end cover, the right end of the small jar body is connected to a fluid inlet, the right end of the large jar body is connected to a fluid outlet, the left port of the small jar body is provided with a flow intercepting cone, a flow passing throat port is arranged along the axis of the flow intercepting cone, a sliding plate capable of axially sliding along the inner wall of the large jar body is arranged on the middle section of the inner cavity of the large jar body, the left side of the large jar end cover is connected to an end cover box, a piston is arranged in the center hole of the large jar end cover, is driven by a screw rod sleeve, and is connected to the sliding plate through a connecting cylinder, a screw rod shaft is screwed in the screw rod sleeve, a jet cone is fixed on the right end head of the screw rod shaft, and is inserted into the flow passing throat port of the flow intercepting cone, and a fixed pore plate is arranged on the right end of the flow intercepting cone, and is provided withan adjustable center hole and peripheral holes. According to the present invention, the cavitator can achieve multiple cavitation modes, and has characteristics of high raw material adaptability and good cavitation effect.

Owner:MYANDE GRP CO LTD

Additive for resist underlayer film-forming composition and resist underlayer film-forming composition containing the same

ActiveUS9165782B2Less crashesImprove collapseSemiconductor/solid-state device manufacturingPhotosensitive materials for photomechanical apparatusResistNitrogen

It is aimed to enhance adhesiveness between a resist pattern formed on a resist underlayer film and to reduce an undercut of the resist pattern. An additive for a resist underlayer film-forming composition, including: a polymer having a structural unit of Formula (1):(where R1 is a hydrogen atom or a methyl group; L is a divalent linking group; X is an acyloxy group having an amino group protected with a tert-butoxycarbonyl group or a nitrogen heterocycle protected with a tert-butoxycarbonyl group).

Owner:NISSAN CHEM IND LTD

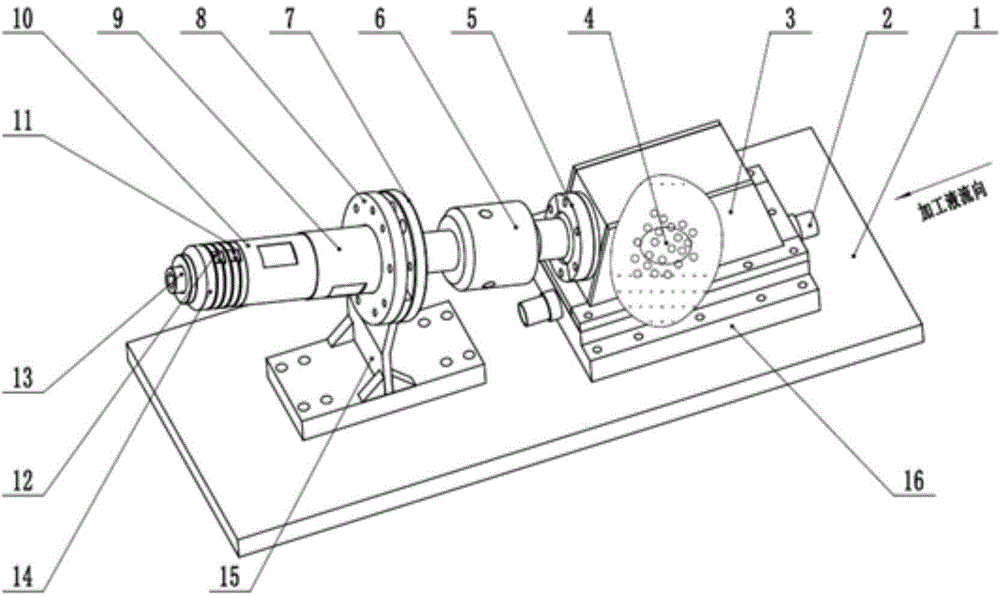

A kind of pressure alternation type microporous inner surface cavitation shot peening equipment and working method

ActiveCN110129537BImprove collapseConsistent and smooth surface contourReciprocating motionElectric machinery

The invention discloses pressure-alternated microhole inner surface cavitation and shot blasting equipment and a working method. A positioning device and a magnetic piston motion device arranged faceto face left and right are arranged in an oil tank; an L-shaped baffle plate of the positioning device is fixedly connected with the oil tank; a composite V-shaped block fixedly connected to the bottom wall of the oil tank is arranged under the right side of the L-shaped baffle plate; left and right horizontal workpieces are placed on the composite V-shaped block; the center axis of a cylinder ofthe magnetic piston motion device is collinear with the center axes of microholes; a piston is arranged in a center hole of the cylinder; a sealing cavity can be formed between the microholes and thecenter hole of the cylinder; the right end surface of the cylinder is fixedly connected with an electromagnet; a coil is wound on the electromagnet; two ends of the coil are connected with reversing switches; a driving device is above the magnetic piston motion device; a motor of the driving device can drive a lead screw to rotate; a slide block is matched with the lead screw through a thread; theslide block is fixedly connected with the cylinder; and the volume of liquid in the sealing chamber is continuously changed through a reciprocating motion of the piston for shot blasting reinforcement of the inner surfaces of the microholes so as to achieve high efficiency.

Owner:JIANGSU UNIV

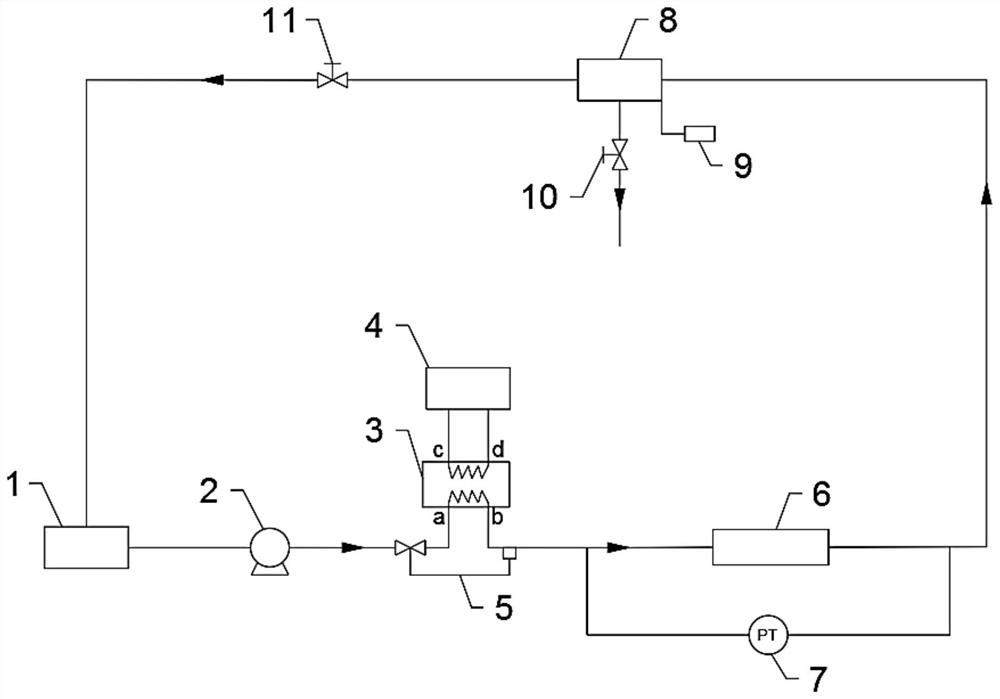

Device for carrying out cavitation treatment on sewage by utilizing ship waste heat and working method

PendingCN113023825AEasy to replaceImprove cavitation reaction efficiencySpecific water treatment objectivesWater/sewage treatment with mechanical oscillationsSewageWaste heat

The invention discloses a device for carrying out cavitation treatment on sewage by utilizing ship waste heat and a working method.The device comprises a first sewage tank, a centrifugal pump, a heat exchanger, an engine cylinder sleeve water tank, a combined cavitation device, a second sewage tank, a detection device, a first stop valve and a second stop valve, wherein the first sewage tank is connected with the centrifugal pump through a pipeline; the centrifugal pump is connected with a heat exchanger interface a through a pipeline, a heat exchanger interface b is connected with the combined cavitation device through a square and round pipeline, a heat exchanger interface c and a heat exchanger interface d are connected with the engine cylinder sleeve water tank through pipelines, the combined cavitation device is connected with the second sewage tank through a pipeline, the second sewage tank is connected with a detection device and a first stop valve through pipelines, and the second sewage tank is connected with the first sewage tank through a pipeline. The device has the function of efficiently treating sewage, the ship waste heat is effectively utilized, the sewage temperature can be increased, the cavitation efficiency and the sewage purification efficiency are improved, and the energy consumption is reduced.

Owner:JIANGSU UNIV OF SCI & TECH

A Crack Prevention Process for CF8C Castings

InactiveCN104532104BImprove collapseImprove thermal stabilityFoundry mouldsFoundry coresAlloySolid solution

The invention relates to a technology for preventing a cast piece made of a CF8C material from cracking. Due to the fact that cracks are generated easily when CF8C materials are produced, the rejection rate of products is high, and production cost is increased for enterprises. The technology for preventing the cast piece made of the CF8C material from cracking is characterized by comprising the steps that 1, the alkaline phenolic resin sand technology is used for shaping; 2, the carbon content is reduced and the chromium content is increased during alloy smelting; 3, the temperature of a welding area is controlled to range from 110 DEG C to 130 DEG C during welding repair, a small-diameter welding material is used, and multi-layer welding is conducted; 4, heat insulation is conducted for fifteen to twenty minutes when the temperature of quenching water rises to 960 DEG C during solid solution, and then the temperature is made to rise to 1080 DEG C after heat insulation for water quenching. By the adoption of the technology for preventing the cast piece made of the CF8C material from cracking, the number of cracks generated during production of cast pieces is reduced, the rejection rate is reduced, and production cost is reduced for the enterprises.

Owner:OUTONG GRP QINGTIAN WANXIN VALVE TECH CO LTD

Spreader for spreading granular material and method of spreading granular material

ActiveUS10745875B2Easy to handleImproved break-upThrowing machinesConveyorsEngineeringMechanical engineering

In one embodiment, a hopper spreader apparatus for spreading granular material is provided. The hopper spreader apparatus includes a hopper, a spreading unit, and a dispensing unit. The hopper has a storage cavity for storing the granular material to be spread. The spreading unit spreads the granular material. The dispensing system transports the granular material from the hopper to the spreading unit. The dispensing system includes a conveying unit and a rotating first roll. The conveying unit conveys the granular material toward the spreading unit. The rotating first roll controls a flow of granular material from the hopper to the conveying unit. The use of the rotating roll allows for control of high flow material (such as for example dry salt) while allowing for improved collapse and break-up of low flow material (such as for example wetted sand).

Owner:SNO WAY INT

Tandem type hydrodynamic force sound wave generation device

InactiveCN103366727BDirectionalAdd depthShaking/oscillating/vibrating mixersMixing methodsCavitationSpray nozzle

The invention relates to a tandem type hydrodynamic force sound wave generation device. The tandem type hydrodynamic force sound wave generation device is characterized in that the front end of a cavity is provided with a first spray nozzle connected with a fluid pipeline, the back end of the cavity is provided with a second spray nozzle, the center lines of the first nozzle and the second nozzle are on the same straight line, and a divergent reflector is arranged on the outer wall of the second spray nozzle; the first spray nozzle and the second spray nozzle are connected in series through an oval cavity, two spring pieces can be used for generating different sound wave frequencies, and sound waves generated by the second spring piece are reflected by the inner wall of a reflector and then propagate along the divergent reflector, so that the generated sound waves have directivity. In addition, the tandem type hydrodynamic force sound wave generation device has the advantages of strong cavitation effect, high fluid mixing and emulsifying efficiency, simple structure, stable operation and relatively low cost; and as the movable spray nozzles can be changed and adjusted according to practical requirements, the tandem type hydrodynamic force sound wave generation device is suitable for industrialized application.

Owner:SHAANXI NORMAL UNIV

Shell material used for pump valve type precision castings, and preparation process and application thereof

ActiveCN111790882ASolve the costEasy to operateFoundry mouldsFoundry coresMaterials preparationSilicic acid

The invention relates to the technical field of precision casting and material preparation, in particular to a shell material used for pump valve precision castings and preparation process and application thereof. The used base material is the electroquartz powder, the binder is ethyl silicate, and the reinforcing material is the white corundum powder. Firstly, the electroquartz powder and ethyl silicate are mixed in proportions and stirred evenly, and the viscosity of the slurry is adjusted through deionized water to form a slurry. Then, the slurry is coated on the back layer of the shell, the number of the coating layers is 1 to 3, and the thickness is 0.5 to 3 mm. Then, the conventional slurry is coated to make the pump valve type precision casting shell, which is used for pouring the castings. The pump valve precision casting shell prepared by using the shell material and process disclosed by the invention has good collapsibility, can be applied to the precision casting industry, and can effectively solve the long production cycle and cost increase caused by the difficulty of shelling and other problems, which has higher economic benefits and long-term application prospects.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

A gob-side entry retaining method for cutting and directly topping the roadside support wall

ActiveCN109882172BAvoid transportAvoid makingUnderground miningSurface miningHydraulic cylinderShotcrete

The invention provides a gob-side entryretaining method for cutting off a direct roof to make a roadside supporting wall body, and relates to the technical field of underground mining methods. The gob-side entryretaining method includes the steps that A, a gob-side entryretaining bracket is installed at the rear of a bracket of the end head of a working face, and the gob-side entryretaining bracket includes a supporting mechanism, a hole drilling mechanism, a descending mechanism, and a pushing and moving mechanism; B, after working face coal cutting, the gob-side entryretaining bracket is moved by a hydraulic cylinder, and a roof plate is drilled by the hole drilling mechanism; C, a drilling hole is internally filled with medicine and is sealed, and a lifting plate of the lifting mechanism is lifted below the roof plate; D, the roof plate above the gob-side entryretaining bracket is cut off in a blasting mode, and the lifting plate is lowered; E, after the lifting plate is descended to a bottom plate, the pushing and moving mechanism pushes the cut roof plate into a roadway of an gob-side entry through a hydraulic jack; and F, concrete is sprayed at gaps of the cut roof plate, andthe steps from A to F are repeated until the end of stoping. The technical problems of complicated and inefficient gob-side entryretaining construction under the condition of the medium and hard roofplate are solved, in addition, the gob-side entryretaining method further has the advantages of being low in labor intensity, low in entry forming cost and the like.

Owner:SHANDONG UNIV OF SCI & TECH

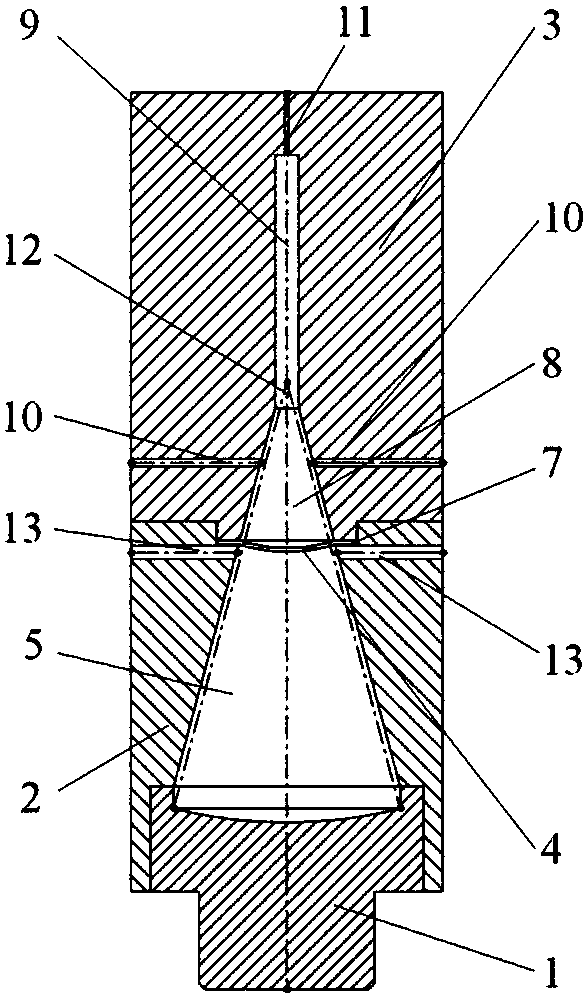

Ultrasonic energy-gathering crushing method and device

ActiveCN108014895AIncrease energy densityPromote formationPlastic recyclingGrain treatmentsUltrasonic sensorEnergy supply

The invention relates to the technical field of micronization processing, in particular to an ultrasonic energy-gathering crushing method and device. The device comprises an ultrasonic transducer (1),a coupling liquid cavity (2), an energy-gathering crushing cavity (3), a diaphragm (4) and a diaphragm groove (7). According to the device, the ultrasonic transducer with a concave spherical transduction surface is utilized for producing energy focusing, the cylindrical crushing cavity is utilized for guiding, recovering, reflecting and gathering secondary energy, and a feed liquid carrying particles is controlled to flow through various levels of energy enriching areas. According to the ultrasonic energy-gathering crushing method provided by the invention, energy gathering is favorable for improving the energy density and provides high-magnitude energy supply for crushing. According to the method, the energy magnitude and the energy utilization efficiency can be improved, and the controllability of a particle micronization process and the consistency of product particle size are improved.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

A kind of non-stoichiometric ratio tic reinforced copper matrix composite material and preparation method thereof

ActiveCN107119207BFacilitate deintercalation diffusionImprove collapseWear resistanceUltimate tensile strength

Owner:JIANGXI UNIV OF SCI & TECH

A method for making colored leaf veins for handicrafts

ActiveCN106864153BImprove hydrolysis efficiencyPromote sheddingSpecial ornamental structuresVeinEnzyme

The invention discloses a method for producing colored veins for artware. The method comprises the following steps of 1, leaf selecting, wherein high-quality leaves are selected; 2, enzymolysis, wherein after the leaves are boiled with clear water, compound enzyme is added for enzymolysis; 3, bleaching, wherein after veins obtained after enzymolysis are aired to be half-dry, light-shielded bleaching is conducted with a hydrogen peroxide solution; 4, dying, wherein after the veins obtained after bleaching are cleaned, the veins are aired to be half-dry, and dying is conducted with a natural pigment, so that the dyed veins are obtained; and 5, shaping, wherein the colored veins are dried and shaped. According to the method for producing the colored veins for the artware, a compound enzymolysis method is adopted, and after being dried, the veins can still maintain to be soft and is not likely to be fractured; and later-stage processing and shaping of the artware can be conducted conveniently. Meanwhile, safety in the production process is improved; required production time is shortened; and production efficiency is improved.

Owner:YUNNAN RAINBOW BIO TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com