Method for gas extraction by coal seam roof weakening through L-shaped drilling staged fracturing

A coal seam roof and staged fracturing technology, which is applied to gas discharge, earthwork drilling, mining equipment, etc., can solve the problems of insufficient drainage and limited gas extraction volume, and achieve large drainage volume and gas drainage High concentration, effect of promoting roof slump

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below with reference to the drawings and embodiments.

[0030] The steps of the present invention are as follows:

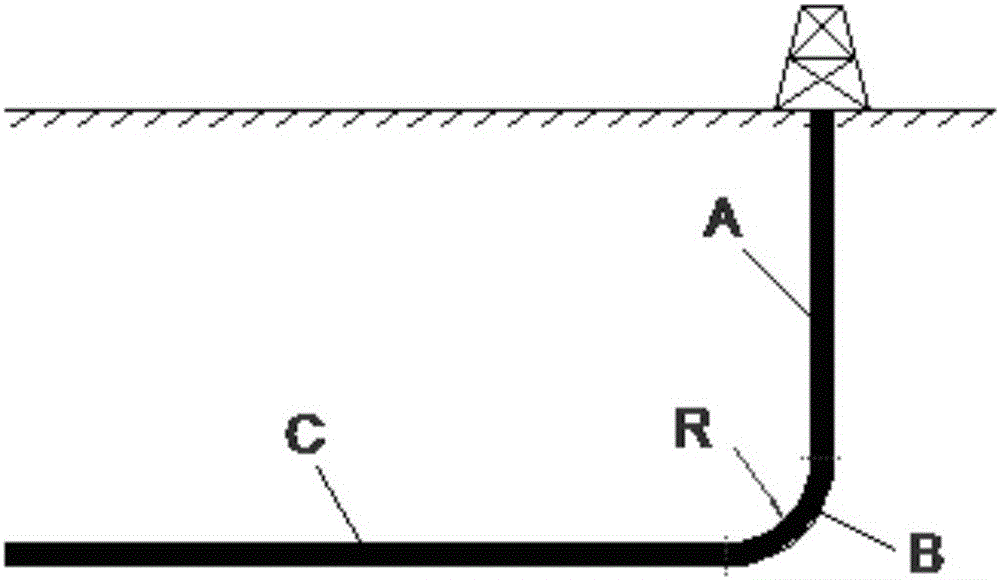

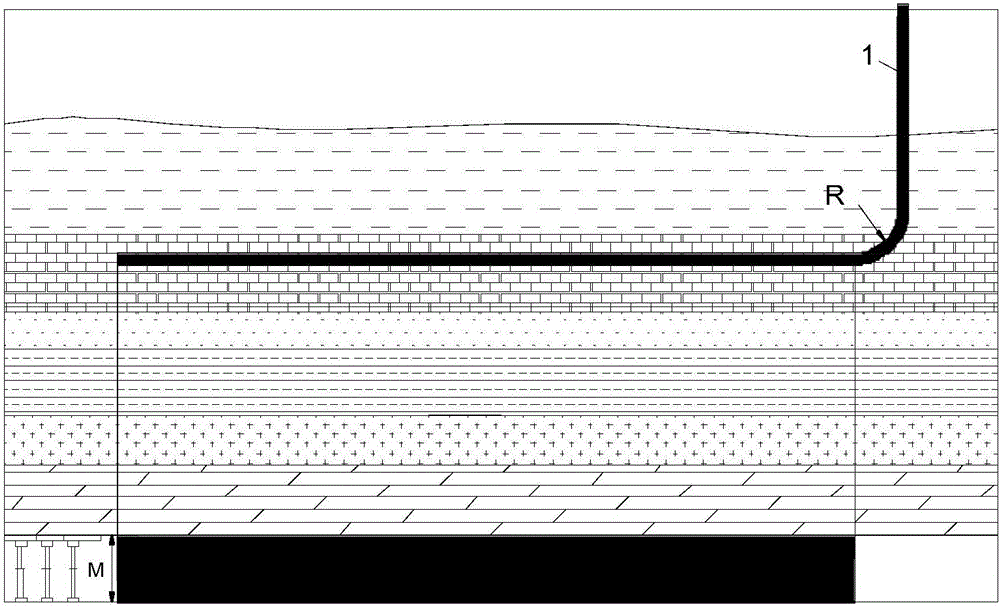

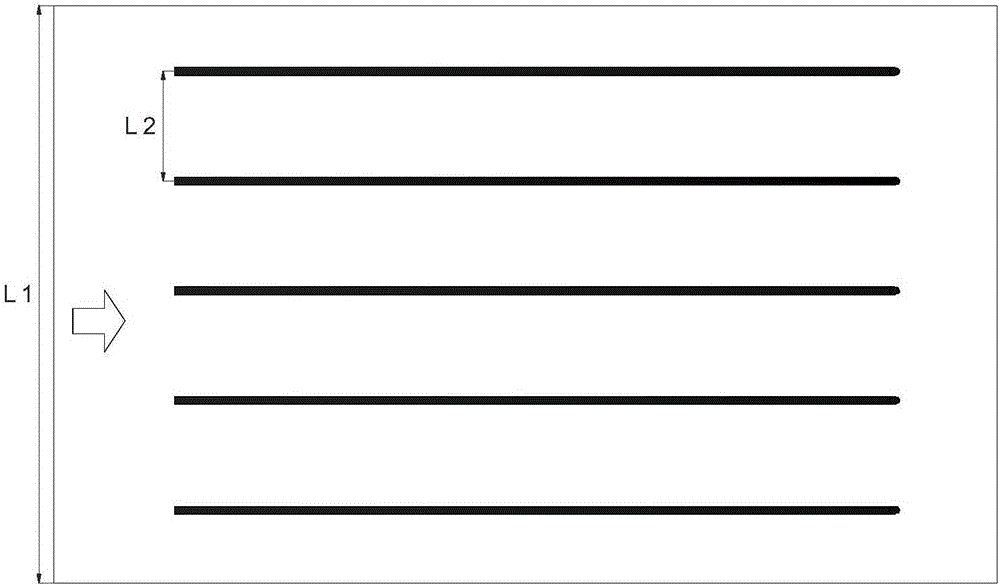

[0031] 1) Select the drilling location and parameters at the ground position corresponding to the working face of the coal seam, and construct the L-shaped drilling 1.

[0032] According to the up and down comparison chart of the well, find the corresponding ground position of the coal seam at the preparation working face, and select a group of construction sites that are flat, open, convenient for transportation and construction, and not threatened by natural disasters such as floods, fires and landslides for L-shaped drilling Hole construction. TD2000 / 600 hydraulic top drive drilling rig is selected, and advanced directional drilling technology is used to carry out straight hole construction at the selected ground drilling position, and then adjust the angle of the gyrator to carry out the construction of the inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com