Gas extraction method for parallel hole arrangement of L-shaped drilling and fracturing weakening top plate

A gas drainage, L-shaped technology, applied in the direction of gas discharge, earth drilling, mining equipment, etc., can solve the problems of gas exceeding the limit, strong mine pressure, etc., to solve the problem of poor gas drainage and reduce strong mine pressure Appearing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0036] A gas drainage method for parallel arrangement of holes in a weakened roof by L-shaped drilling fracturing, comprising the following steps:

[0037] 1) On the ground corresponding to the working face of the coal seam to be mined, determine the drilling position and select the drilling parameters.

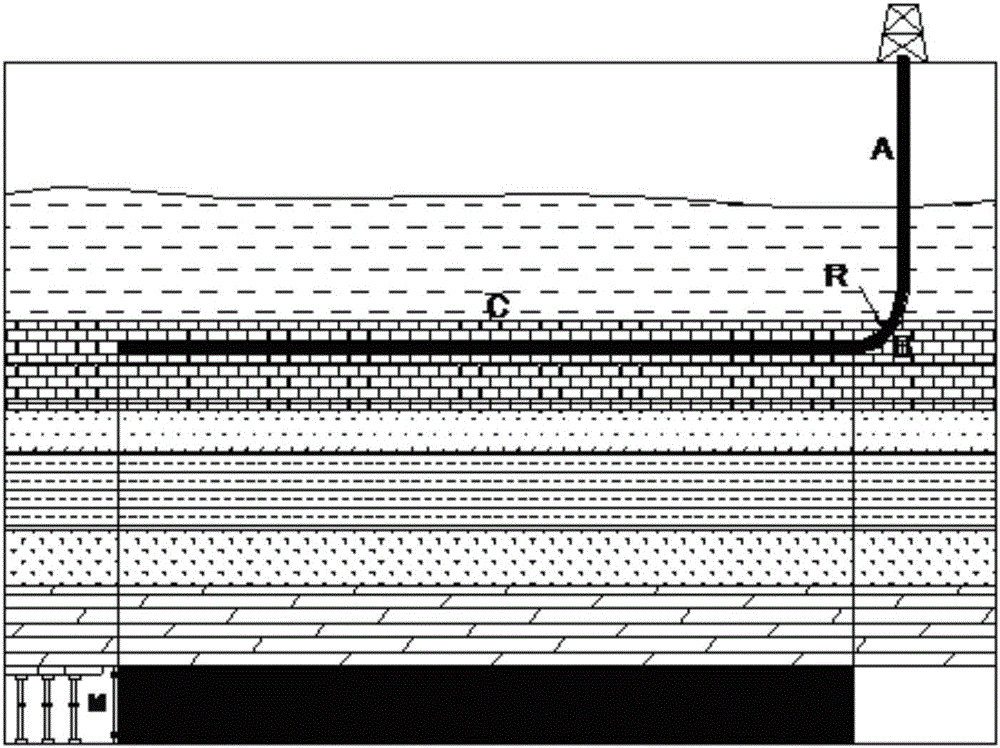

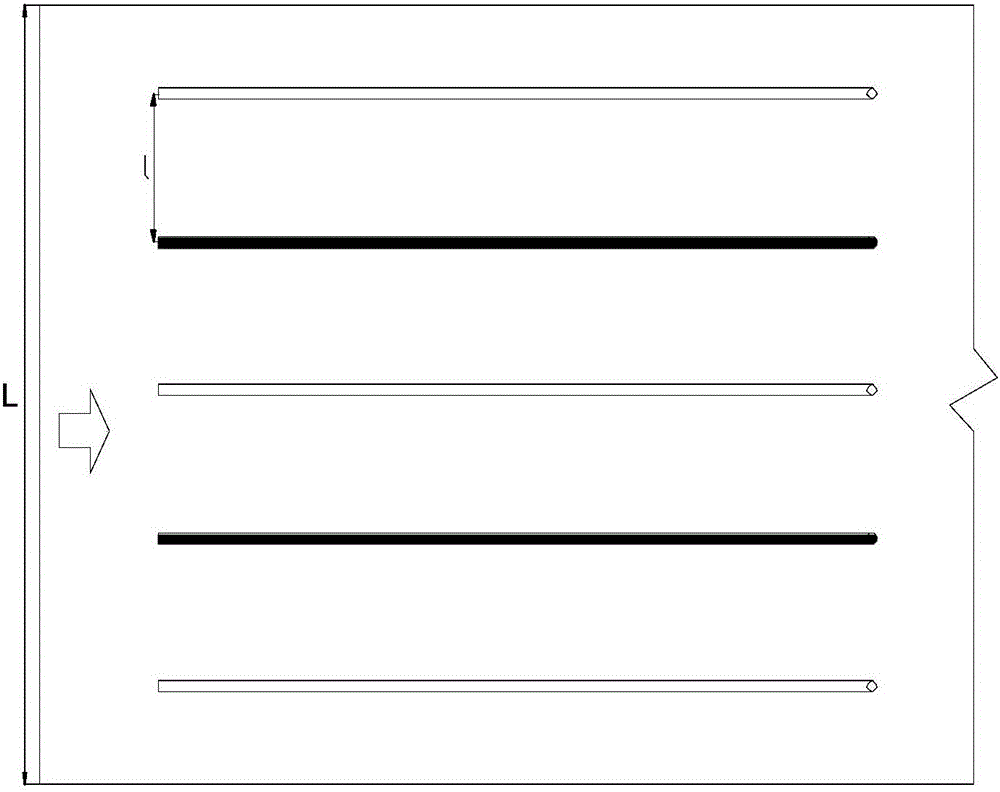

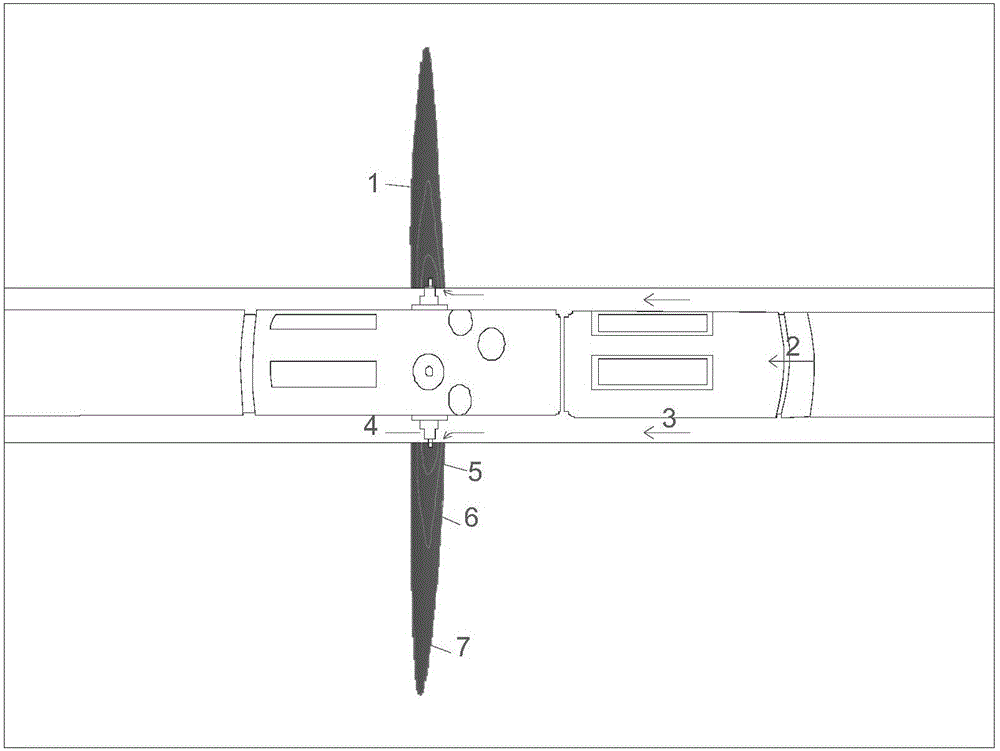

[0038] According to the up-and-down comparison map, corresponding to the ground position corresponding to the coal seam in the preparation work face, select a group of open, flat and convenient locations for construction to arrange L-shaped drilling holes. L-shaped drilling includes L-shaped fracturing drilling and L-shaped gas drainage drilling, L-shaped fracturing drilling and L-shaped gas drainage drilling include a straight hole section facing the coal seam roof and a horizontal section parallel to the coal seam roof , the straight hole section co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com