Mussel byssus removal method and device

A mussel and shredded technology, which is applied in the field of mussel shredded and desiccated devices, can solve the problems of low cleaning rate and damage to the integrity of shellfish meat, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] 1. A method for removing shredded mussels. The harvested mussels are cleaned and classified first, and then soaked in hot water. When the temperature of the mussels rises above 50°C, they are sent to the shredder device for removal. wire. The temperature of the hot water used is 60-70°C, and the mussel temperature is kept above 50°C when removing the silk. Because the connection between the mussel foot thread and the shell meat at this temperature is loose, a slight separation force (such as the brush movement) can separate the foot thread from the mussel.

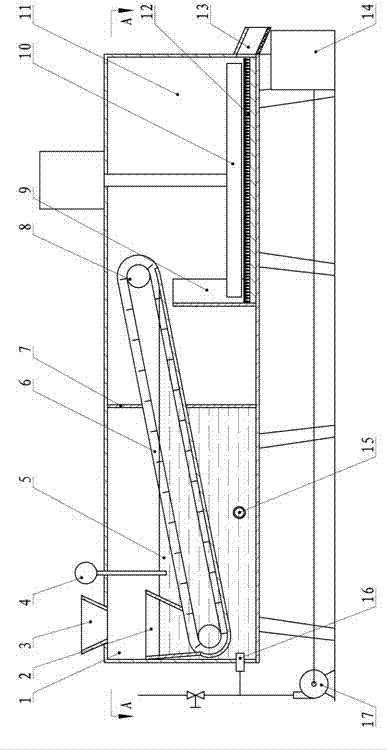

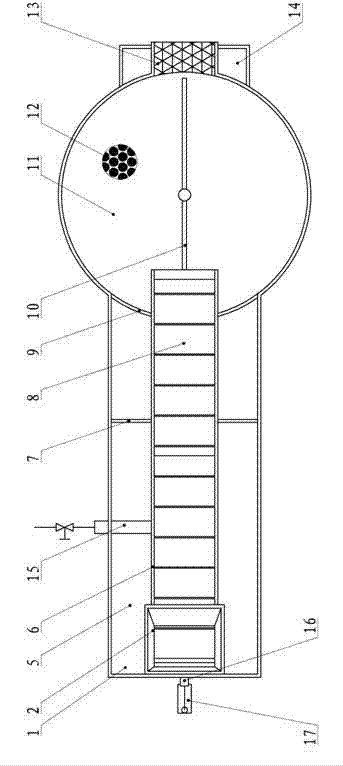

[0016] 2. A mussel shredded device, such as figure 1 , 2 As shown, it is composed of a water scalding device 1 and a wire removing device 11. The two parts have a common shell, and the shell is formed by a rectangular parallelepiped and a cylindrical body connected laterally. The hot water scalding device has an independent rectangular box 7 in the outer shell, which is divided from the rectangular parallelepiped in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com