Tandem type hydrodynamic force sound wave generation device

A technology of fluid dynamics and sound wave generation, which is applied in the direction of sound-generating equipment, shaking/oscillating/vibrating mixers, dissolution, etc., to achieve the effect of enhancing cavitation effect, simple structure, and promoting deep mixing or emulsification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

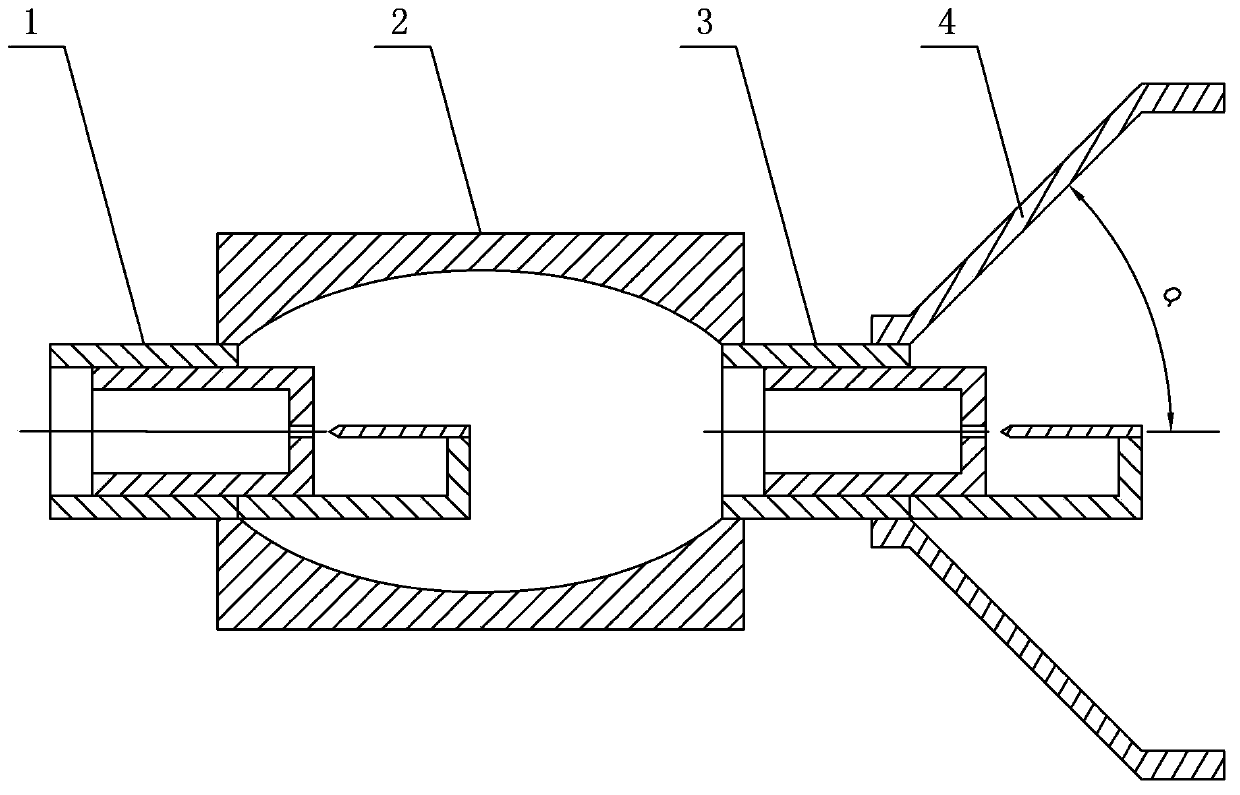

[0023] Depend on figure 1 It can be seen that the serial hydrodynamic sound wave generating device of this embodiment is composed of the first nozzle 1 , the cavity 2 , the second nozzle 3 and the reflector 4 .

[0024] The cavity 2 of this embodiment is a hollow cylinder with an elliptical inner cavity axial section, a first nozzle 1 is installed on the front port of the cavity 2, a second nozzle 3 is installed on the rear port of the cavity 2, and the second nozzle 3 is installed on the rear port of the cavity 2. The centerlines of one nozzle 1 and the second nozzle 3 are on the same straight line.

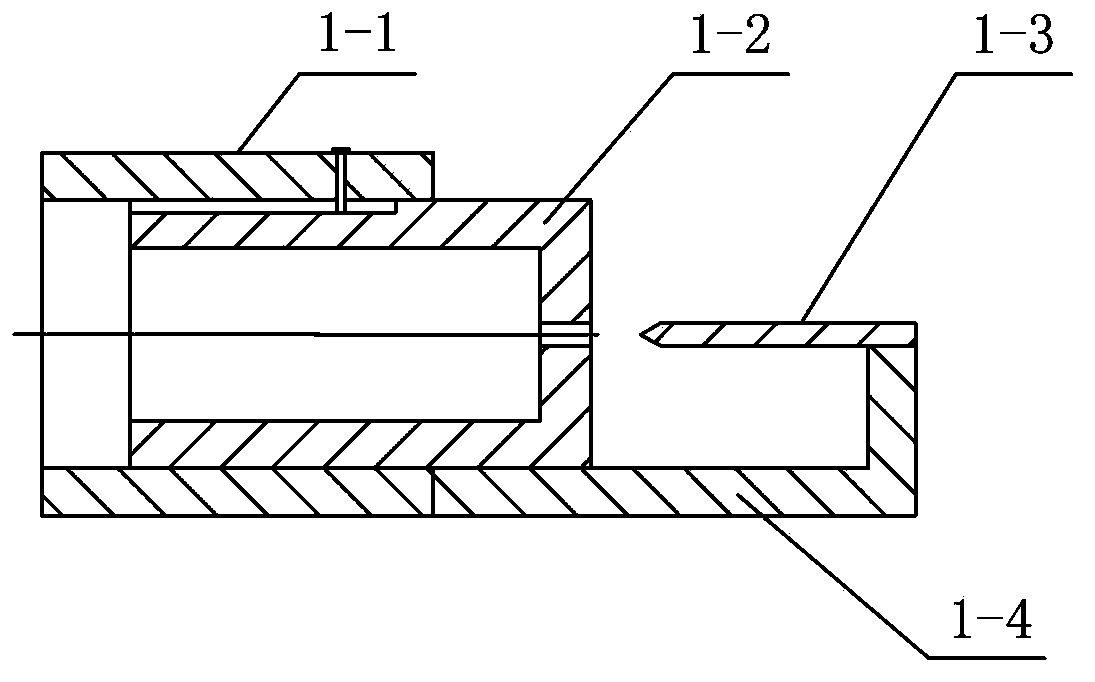

[0025] see figure 2 , the first nozzle 1 of this embodiment is composed of a first outer cylinder 1-1, a first inner cylinder 1-2, a first reed 1-3 and a first connecting rod 1-4. The first outer cylinder 1 -1 is fixedly connected with the front side wall of the cavity 2 by threads, the first inner cylinder 1-2 is sleeved on the inner wall of the first outer cylinder 1-1, and...

Embodiment 2

[0030] The bottom of the first inner cylinder 1-2 of this embodiment is processed with a first rectangular nozzle hole, which is located at the focal point of the long axis of the cavity body 2, and has a length of 15 mm, a width of 1.5 mm, and a depth of 5 mm. A first reed 1-3 is installed at a position of 2 mm outside the first rectangular spray hole, and the end of the first reed 1-3 is connected to the wall of the first outer cylinder 1-1 by the first connecting rod 1-4. Integral structure, the first reed 1-3 is made of ductile stainless steel, its length is 20mm, thickness is 1.2mm, the width is the same as the length of the first rectangular spray hole, the first reed 1-3 is the same as the first rectangular nozzle The top facing the nozzle hole is processed into an isosceles triangle with an apex angle of 25°.

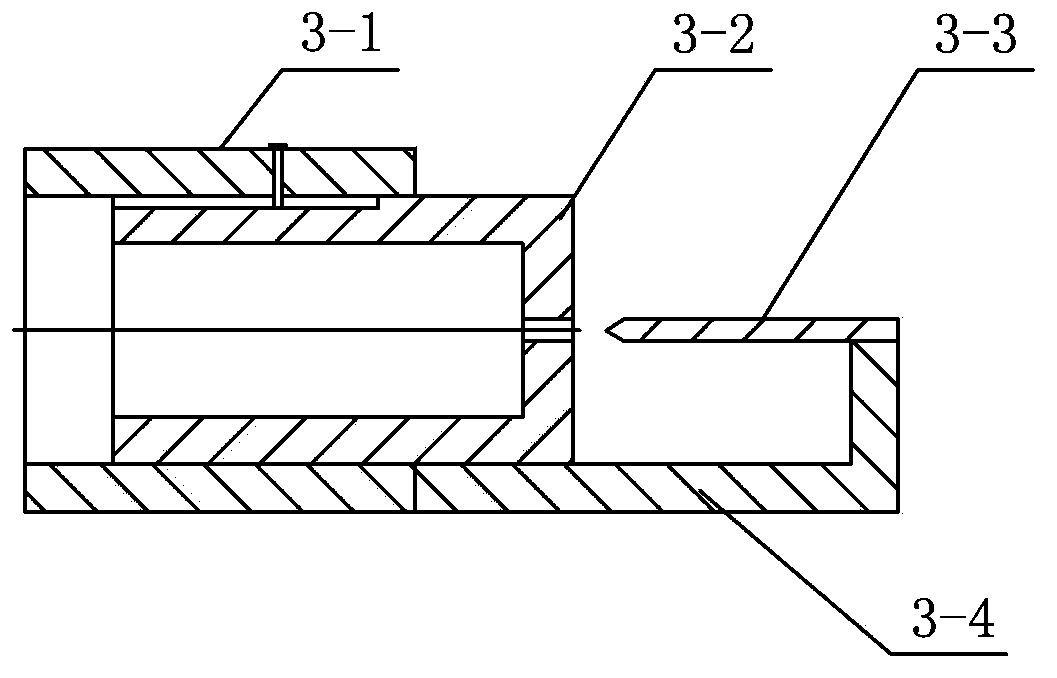

[0031] The bottom of the second inner cylinder 3-2 of the present embodiment is processed with a second rectangular spray hole, the length of the second rectang...

Embodiment 3

[0034] The bottom of the first inner cylinder 1-2 of this embodiment is provided with a first rectangular spray hole, the first rectangular spray hole is located at the focal point of the long axis of the cavity 2, and its length is 20mm, width is 2.0mm, and depth is 15mm. A first reed 1-3 is installed at a position of 10 mm outside the first rectangular spray hole, and the end of the first reed 1-3 is connected to the wall of the first outer cylinder 1-1 by the first connecting rod 1-4. Integral structure, the first reed 1-3 is made of tough stainless steel material, its length is 40mm, thickness is 2.0mm, the width is the same as the length of the first rectangular spray hole, the first reed 1-3 is the same as the first rectangular The top facing the spray hole is processed into an isosceles triangle with an apex angle of 35°.

[0035]The bottom of the second inner cylinder 3-2 of the present embodiment is provided with a second rectangular spray hole with a length of 20 mm,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com