A kind of pressure alternation type microporous inner surface cavitation shot peening equipment and working method

An inner surface and micro-hole technology, which is applied in the field of shot peening equipment and surface strengthening treatment of parts, can solve the problems of blind hole length-to-diameter ratio limitation, high processing cost, poor surface quality, etc., to reduce sharp edges and operate Convenience, effect of small surface roughness values

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

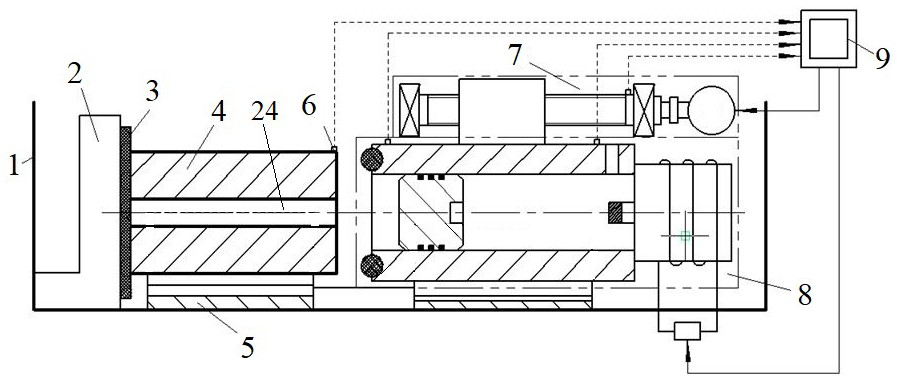

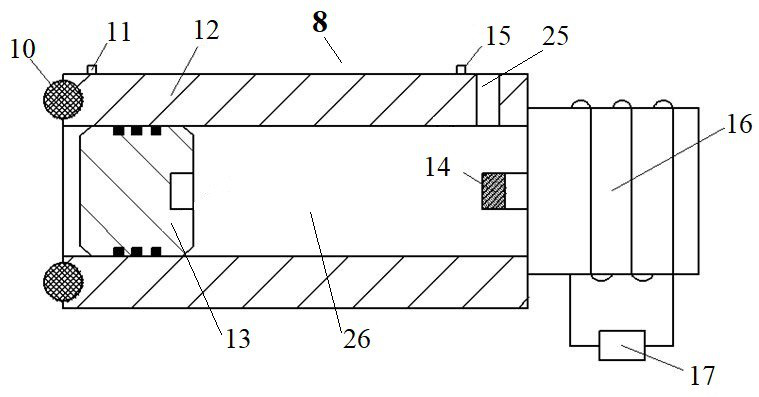

[0023] Such as figure 1 As shown, a pressure alternating microporous inner surface cavitation shot blasting equipment according to the present invention includes an oil tank 1 filled with oil. In the oil tank 1, a positioning device and a magnetic piston moving device 8 are installed, and the positioning device and the magnetic piston moving device 8 are installed facing each other left and right. Among them, the positioning device is used to fix the workpiece 4. The positioning device includes an L-shaped baffle 2, a gasket 3 and a composite V-shaped block 5. The L-shaped baffle 2 and the fuel tank 1 are fixedly connected together by screws. Below the right side of the baffle plate 2 is a composite V-shaped block 5, and the composite V-shaped block 5 is fixed on the bottom wall of the fuel tank 1 by screws. The workpiece 4 is placed on the composite V-shaped block 5, and the workpiece 4 is horizontally placed on the left and right sides, and the microhole 24 is opened on it,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com