Ultrasonic energy-gathering crushing method and device

A crushing device and ultrasonic technology, applied in grain processing and other directions, can solve the problems of poor crushing uniformity, serious energy dissipation and heat generation, insufficient impact crushing energy to achieve energy convergence and targeted positioning application, etc. The effect of improving controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings and examples.

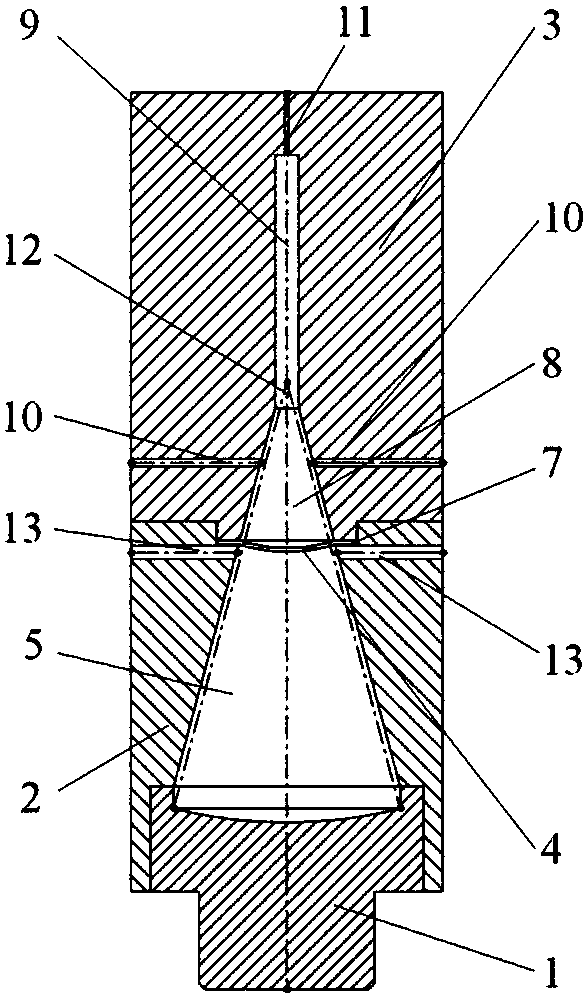

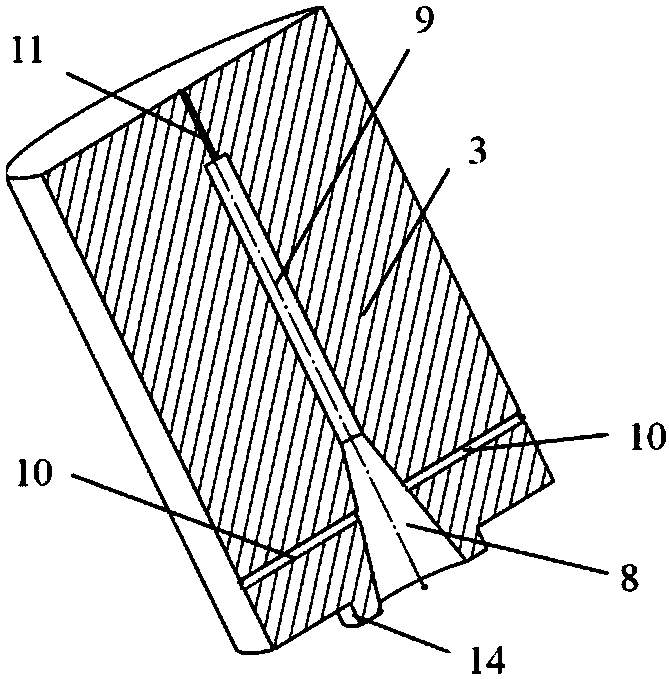

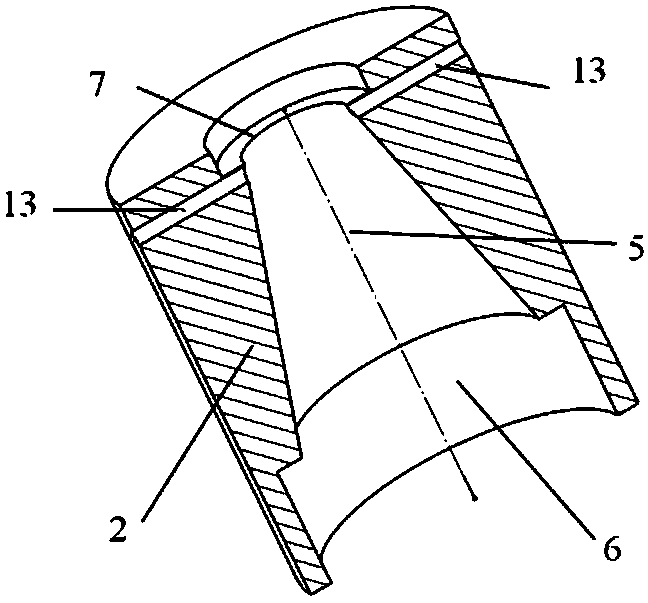

[0048] An ultrasonic energy-focused crushing device includes an ultrasonic transducer 1 , a coupling liquid cavity 2 , a concentrated-energy crushing cavity 3 , a diaphragm 4 and a diaphragm groove 7 . in,

[0049] The ultrasonic transducer 1 has a disc structure and includes a concave spherical transducing surface; the center of the concave spherical transducing surface is the concave spherical center 12 . The concave center 12 is located at the entrance of the crushing chamber 9 and on the axis of the ultrasonic energy-concentrating crushing device.

[0050] The coupling liquid cavity 2 is a hollow cylindrical structure, the hollow part is the coupling liquid cavity 5 , and the coupling liquid cavity 5 is in the shape of a truncated cone; The large end of the coupling liquid chamber 5 communicates with the fixing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com