Patents

Literature

161 results about "Horn structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

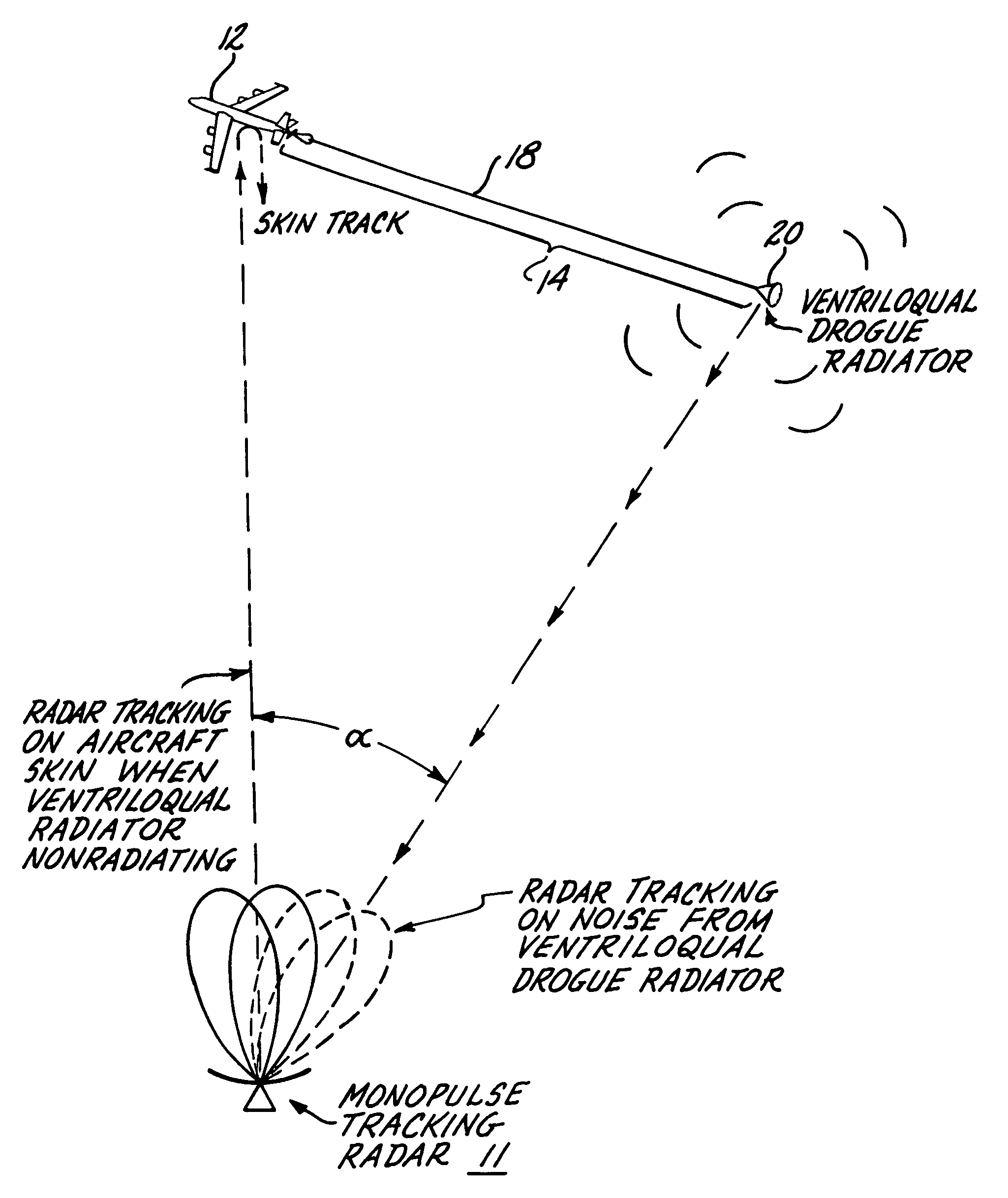

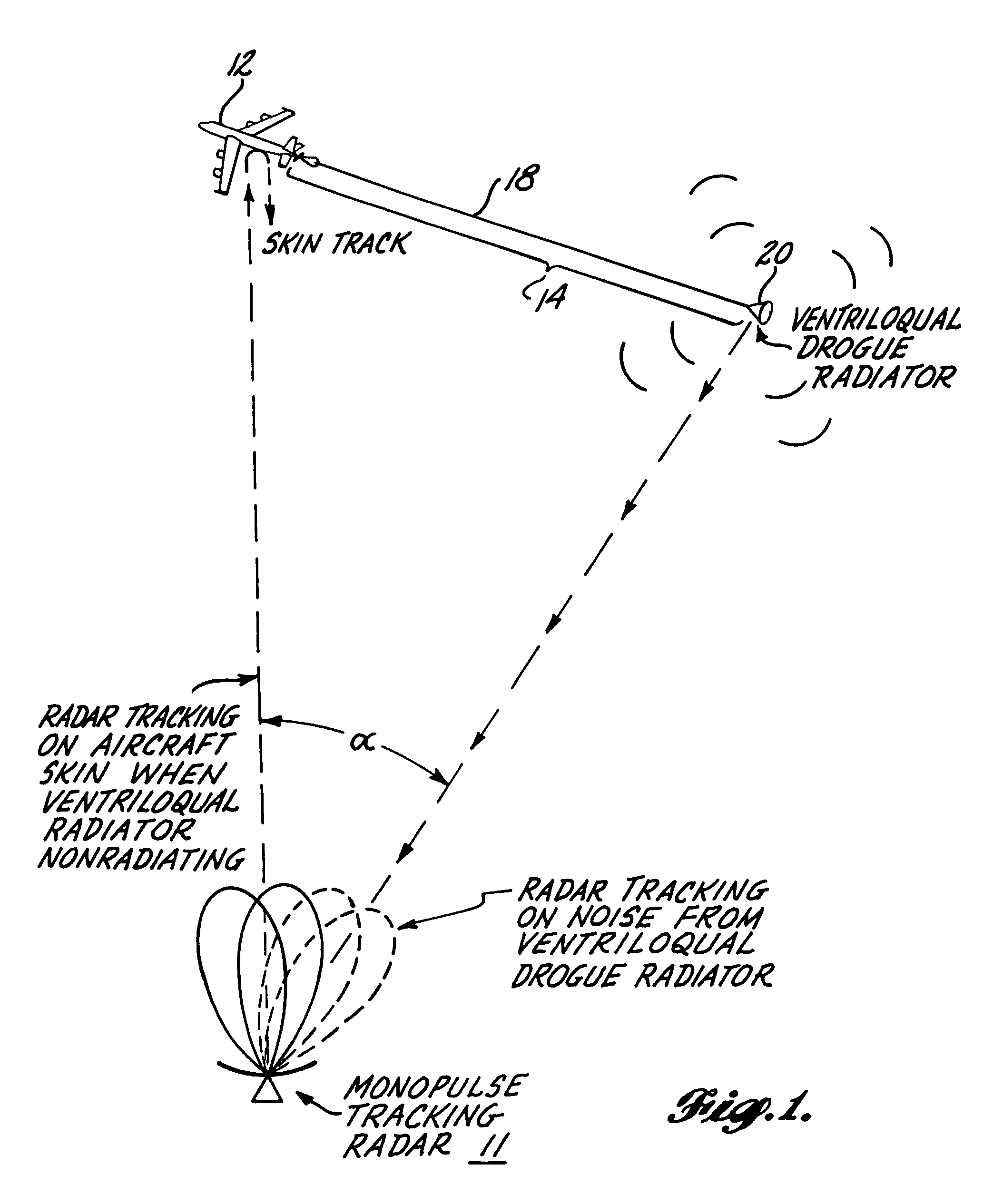

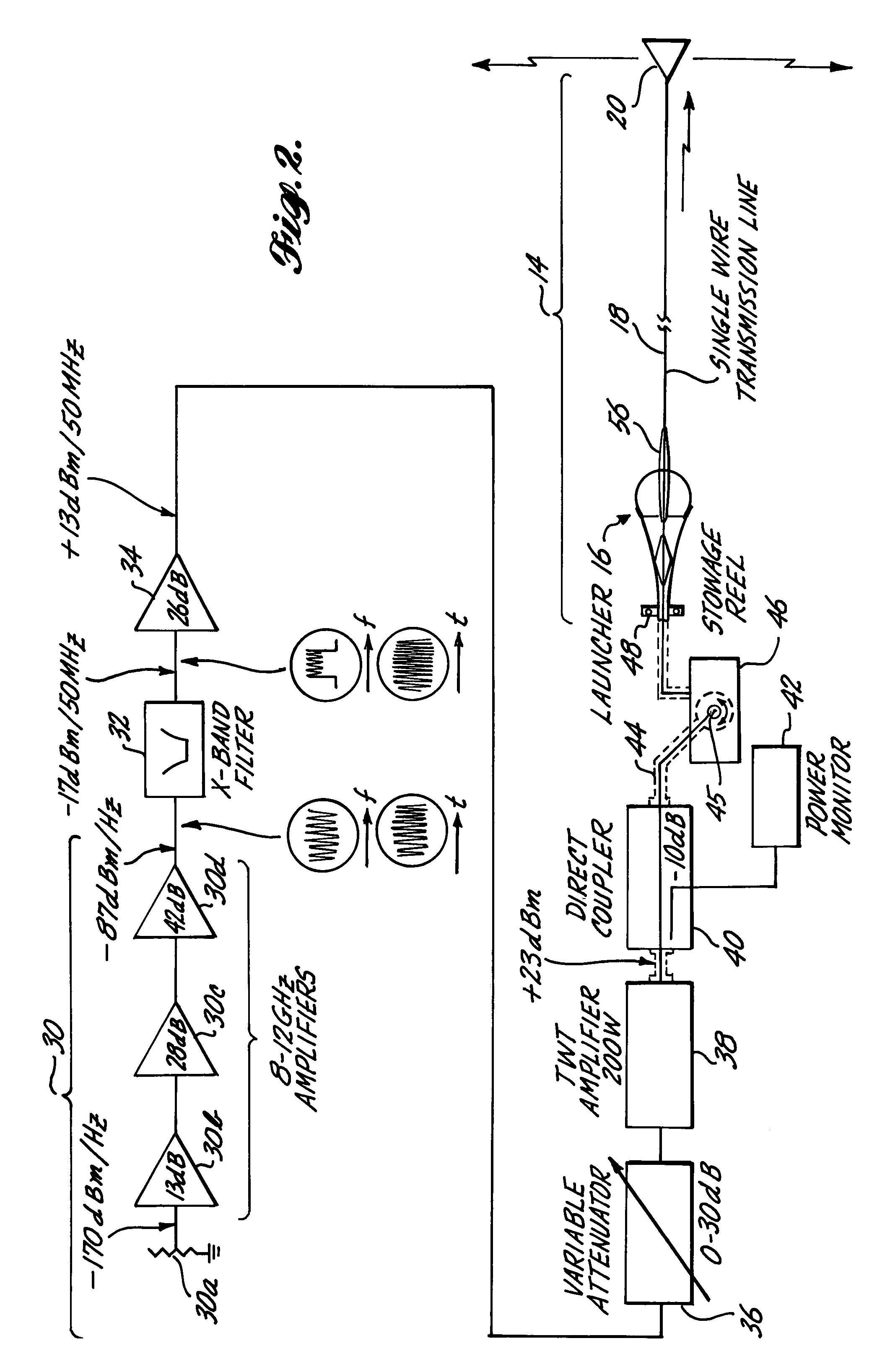

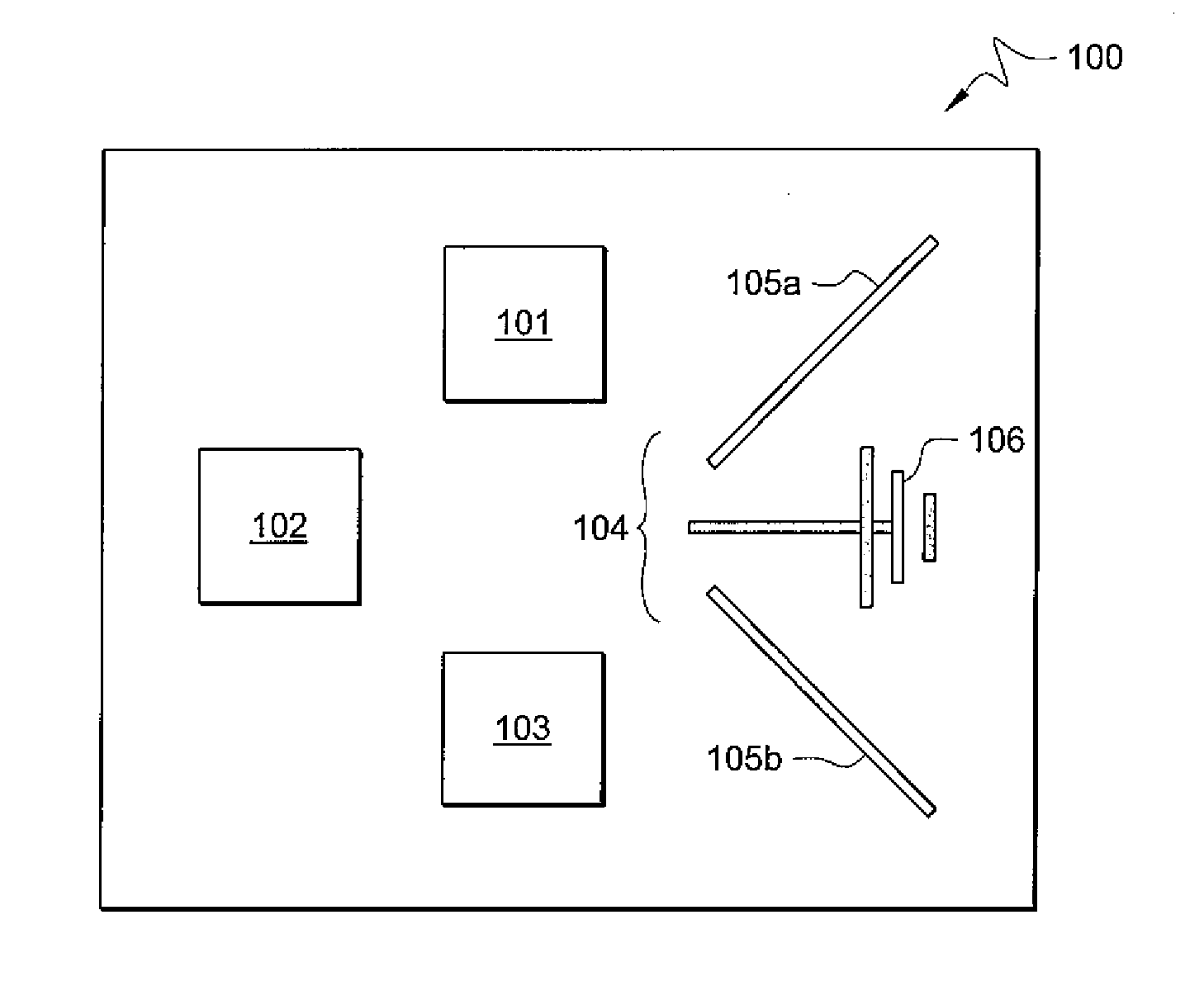

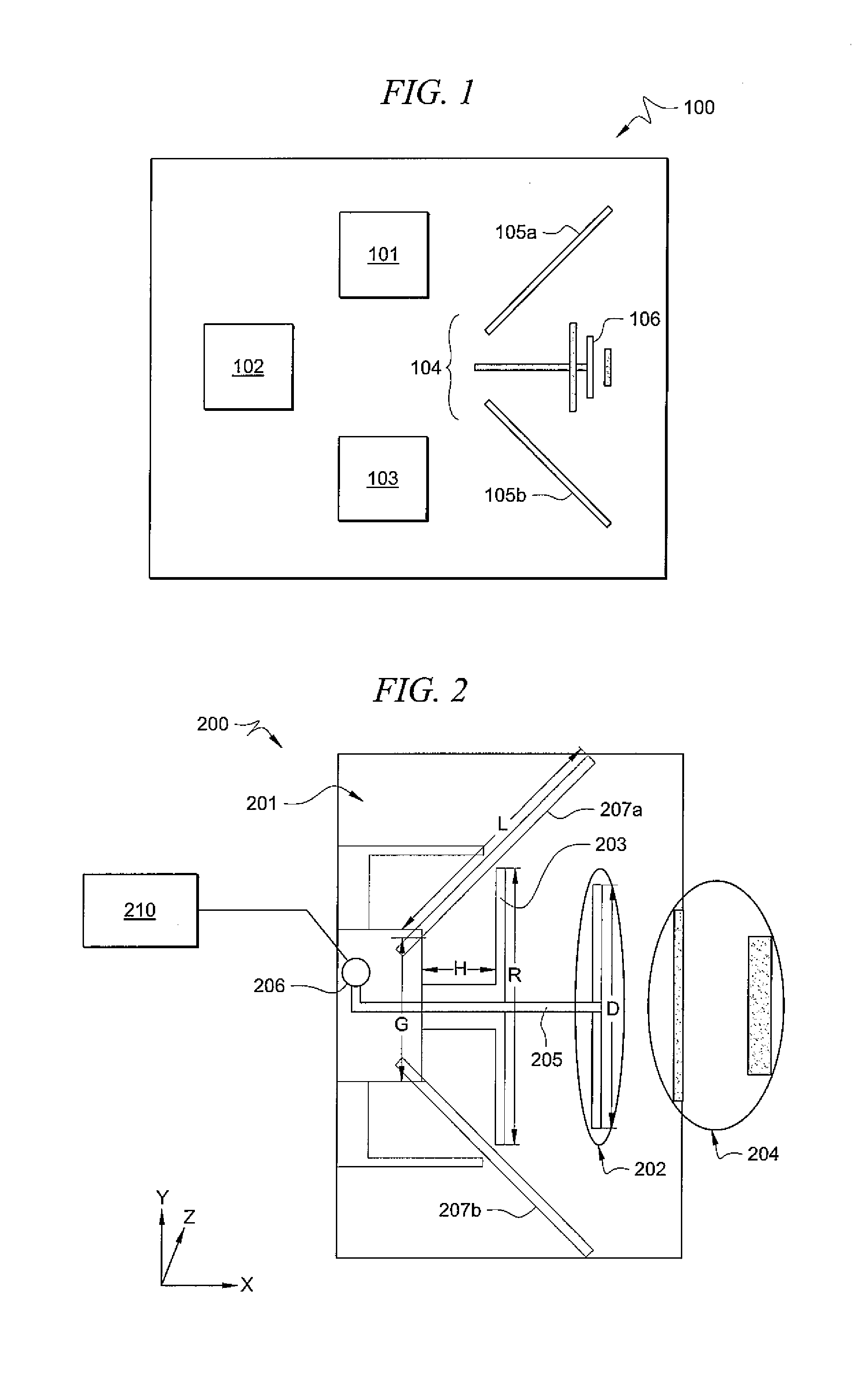

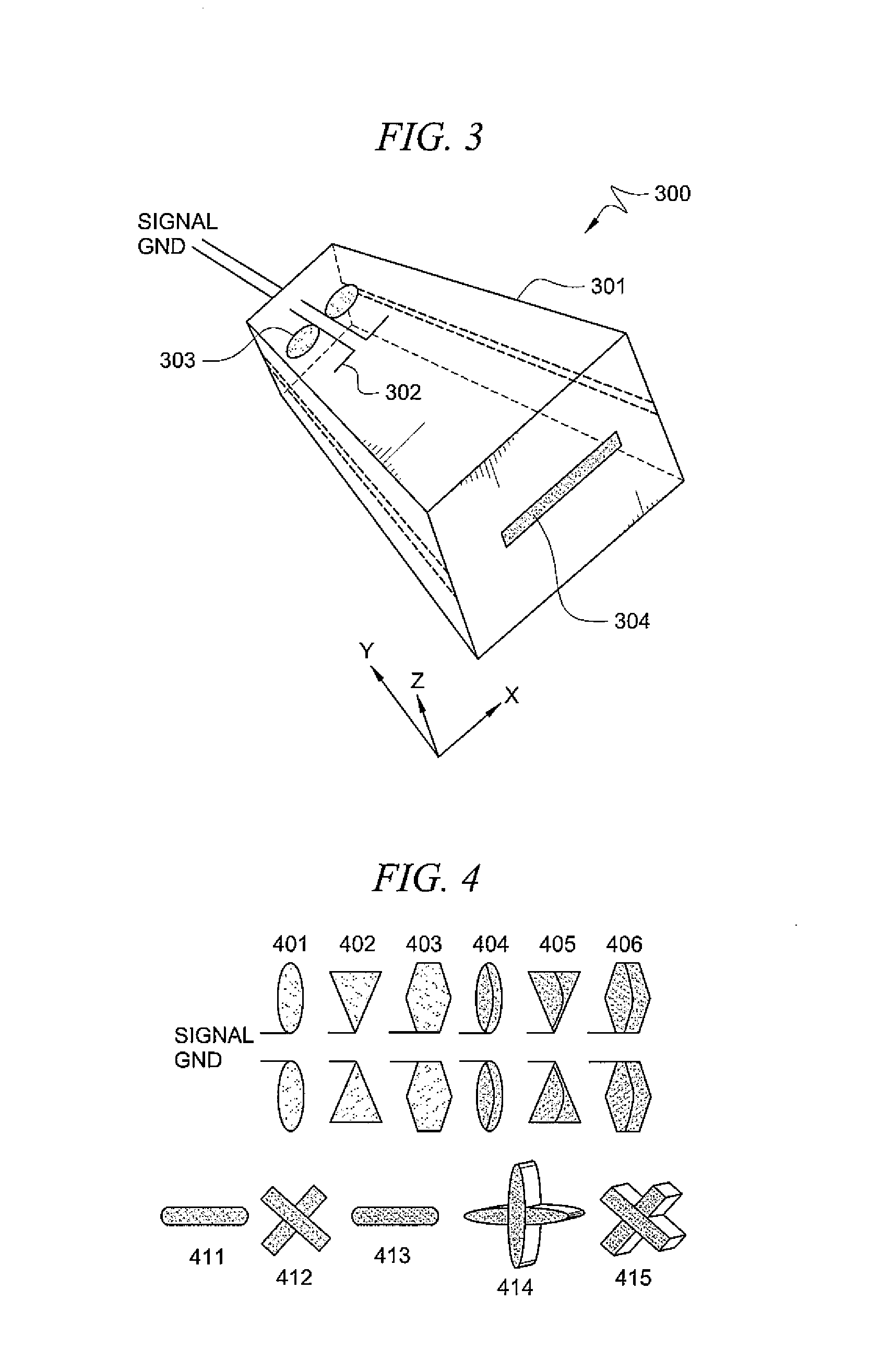

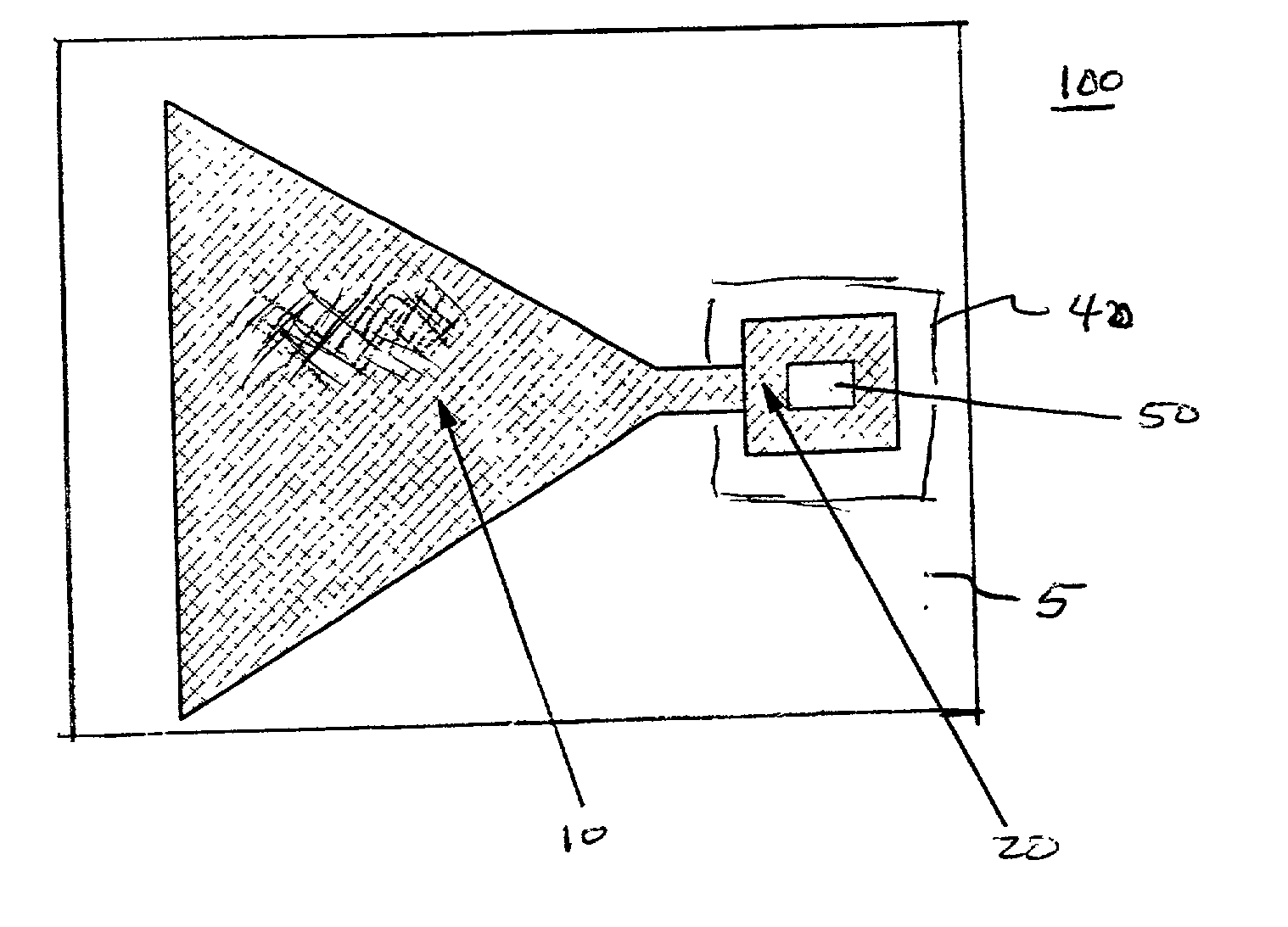

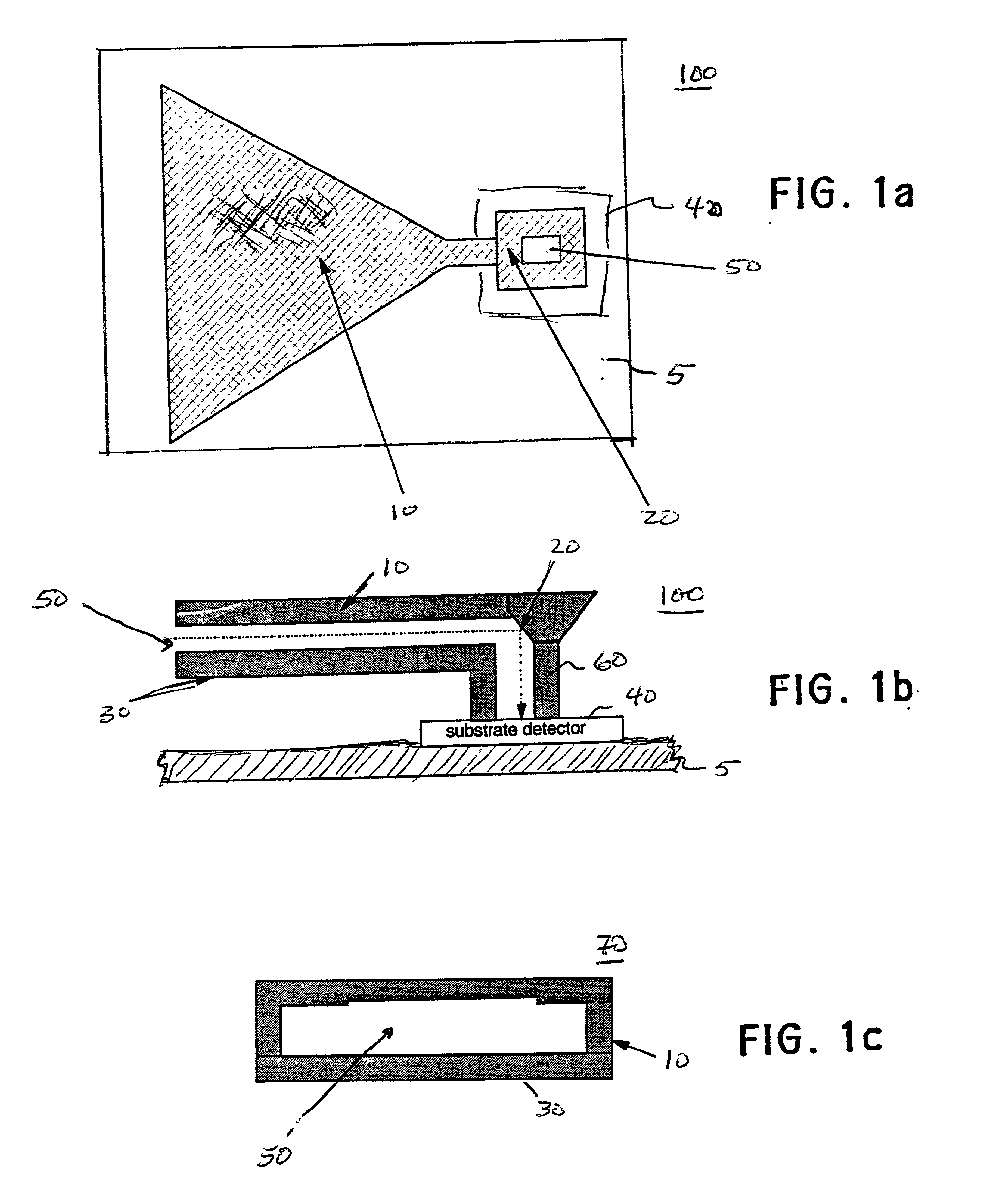

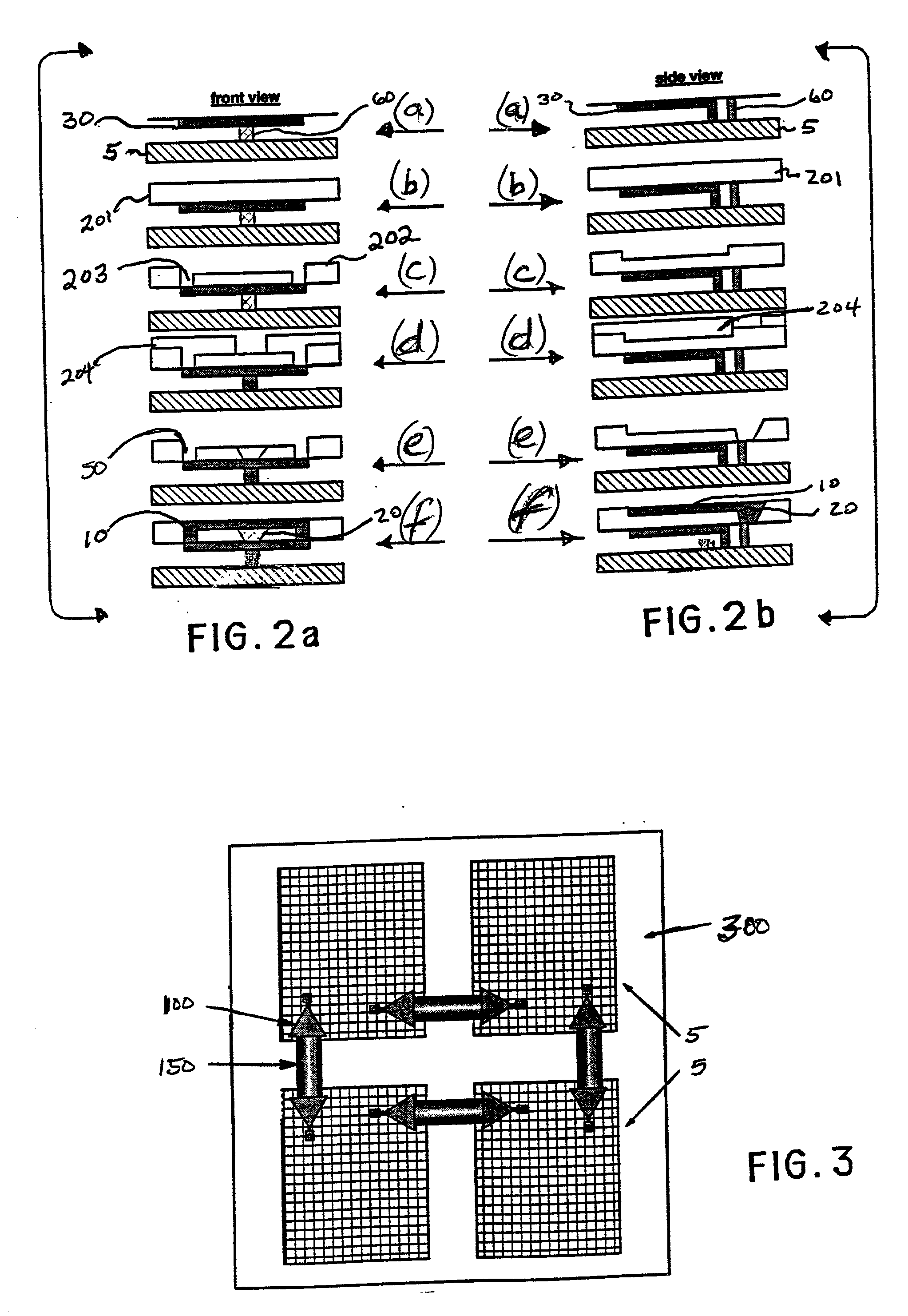

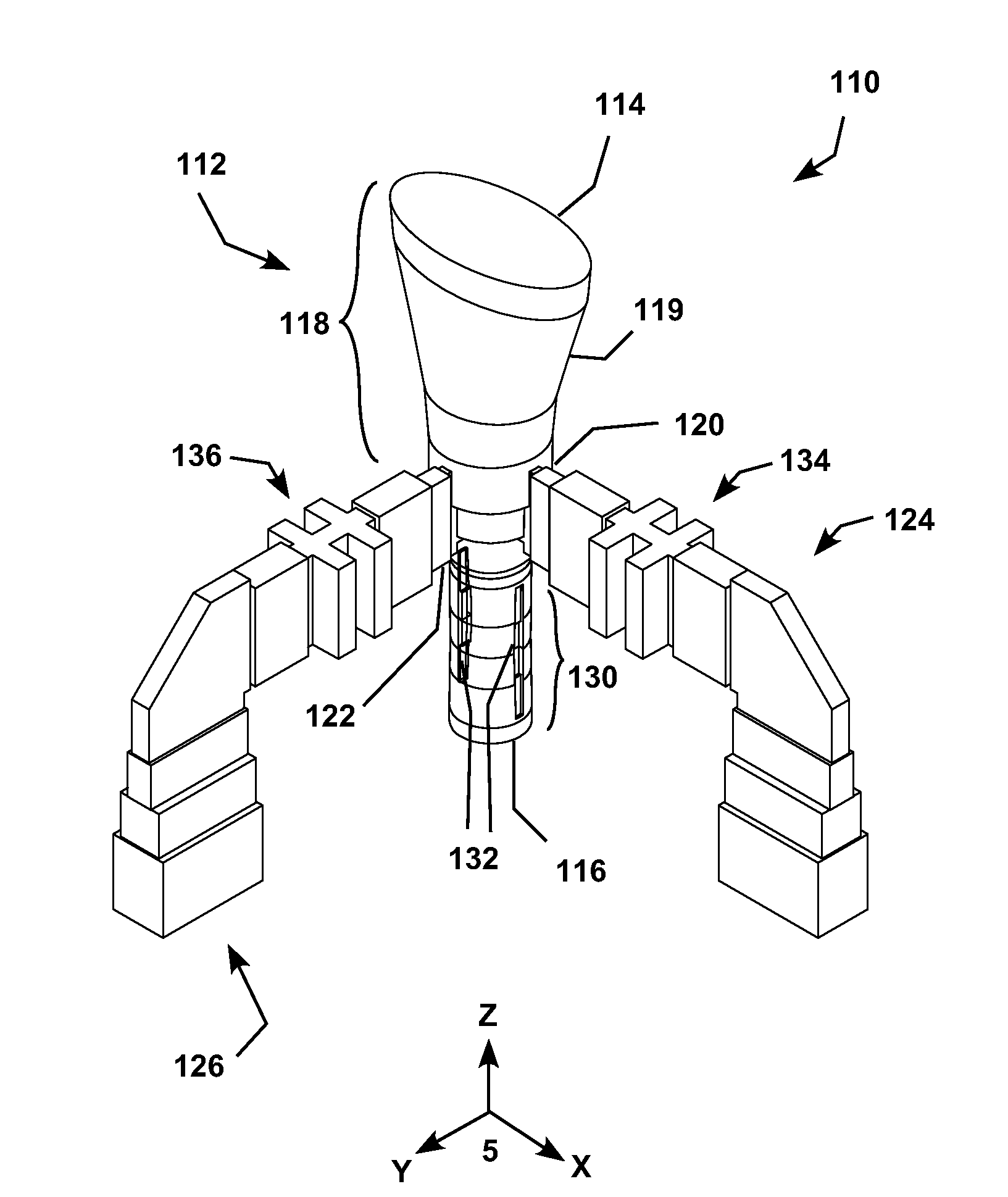

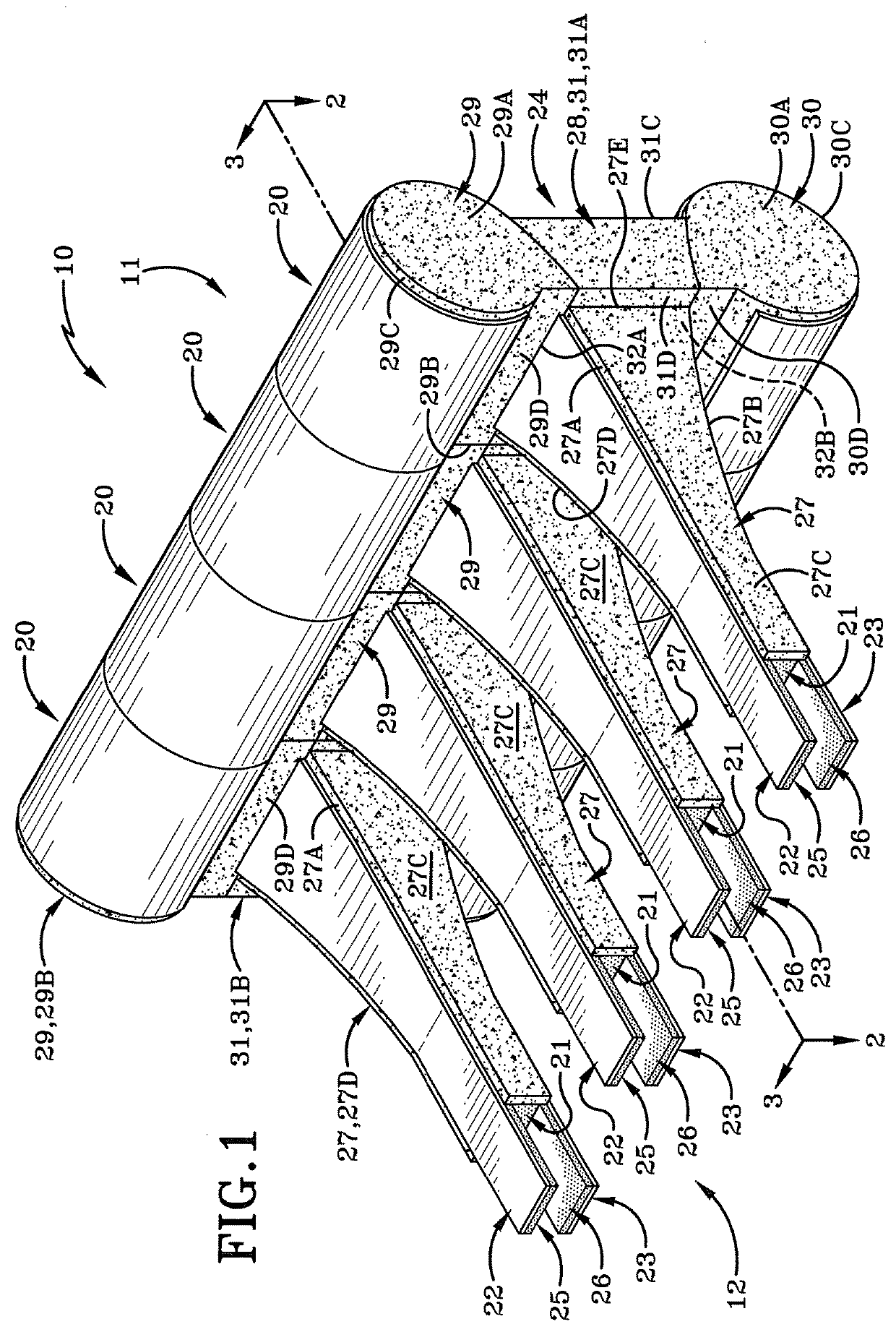

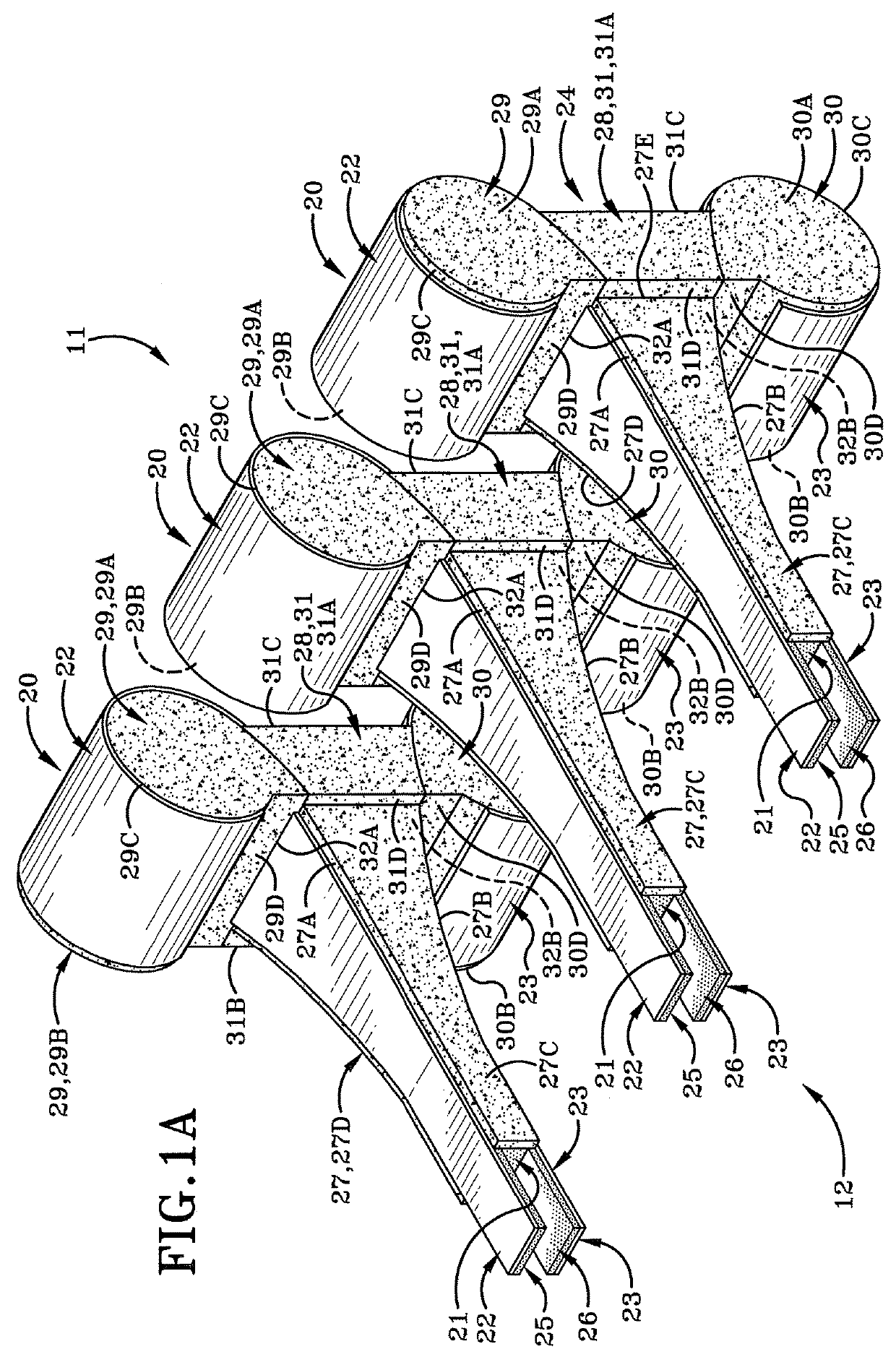

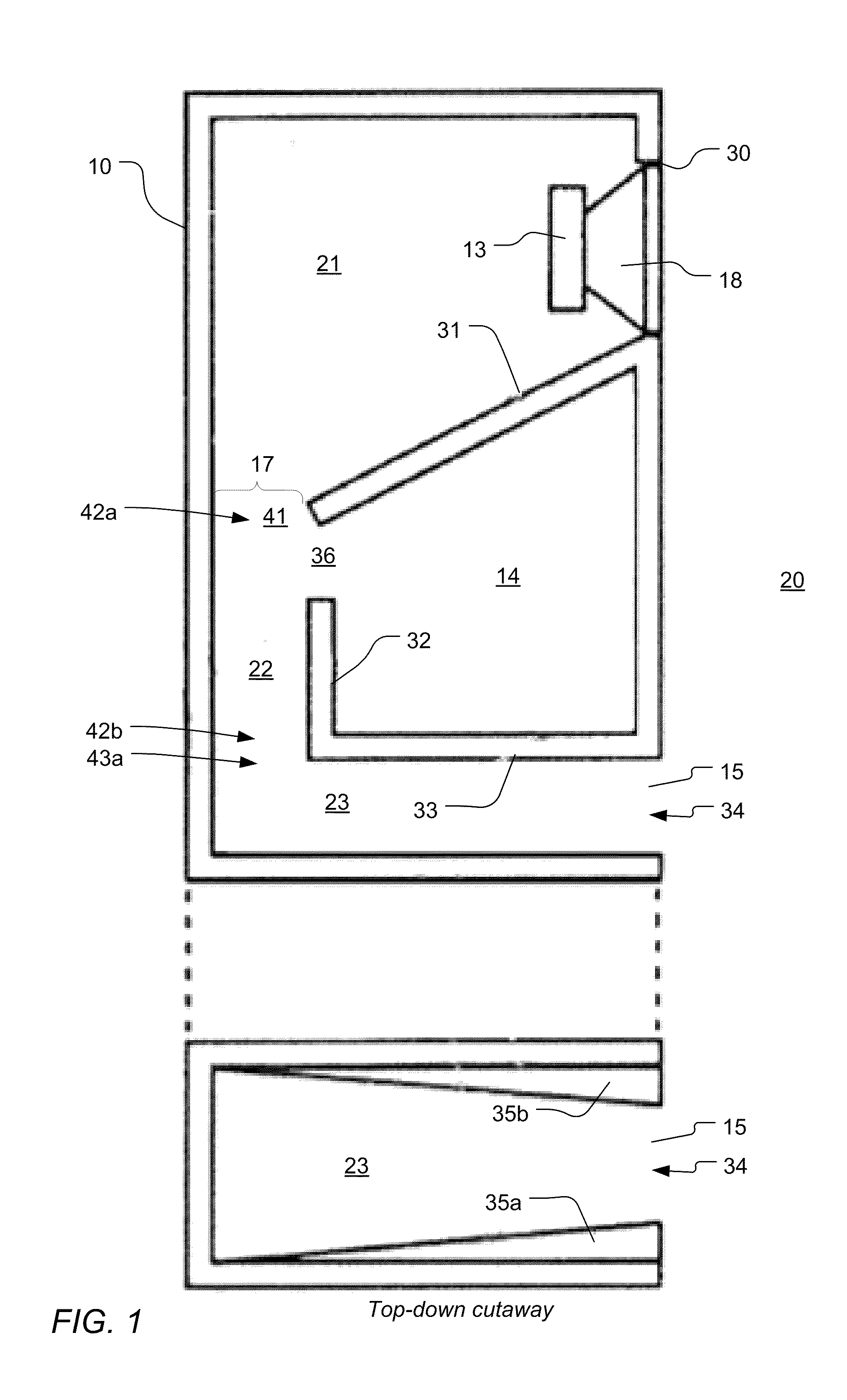

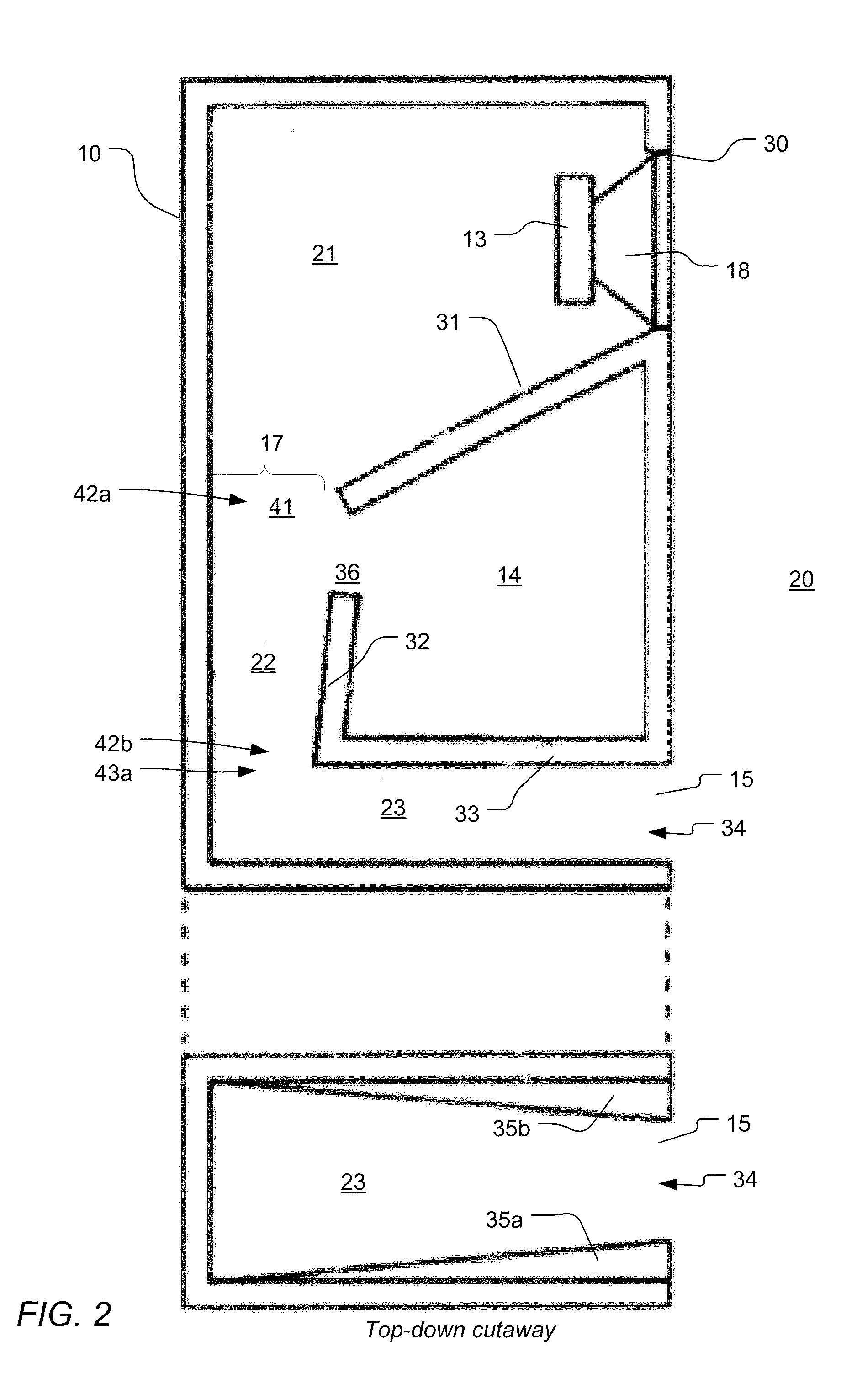

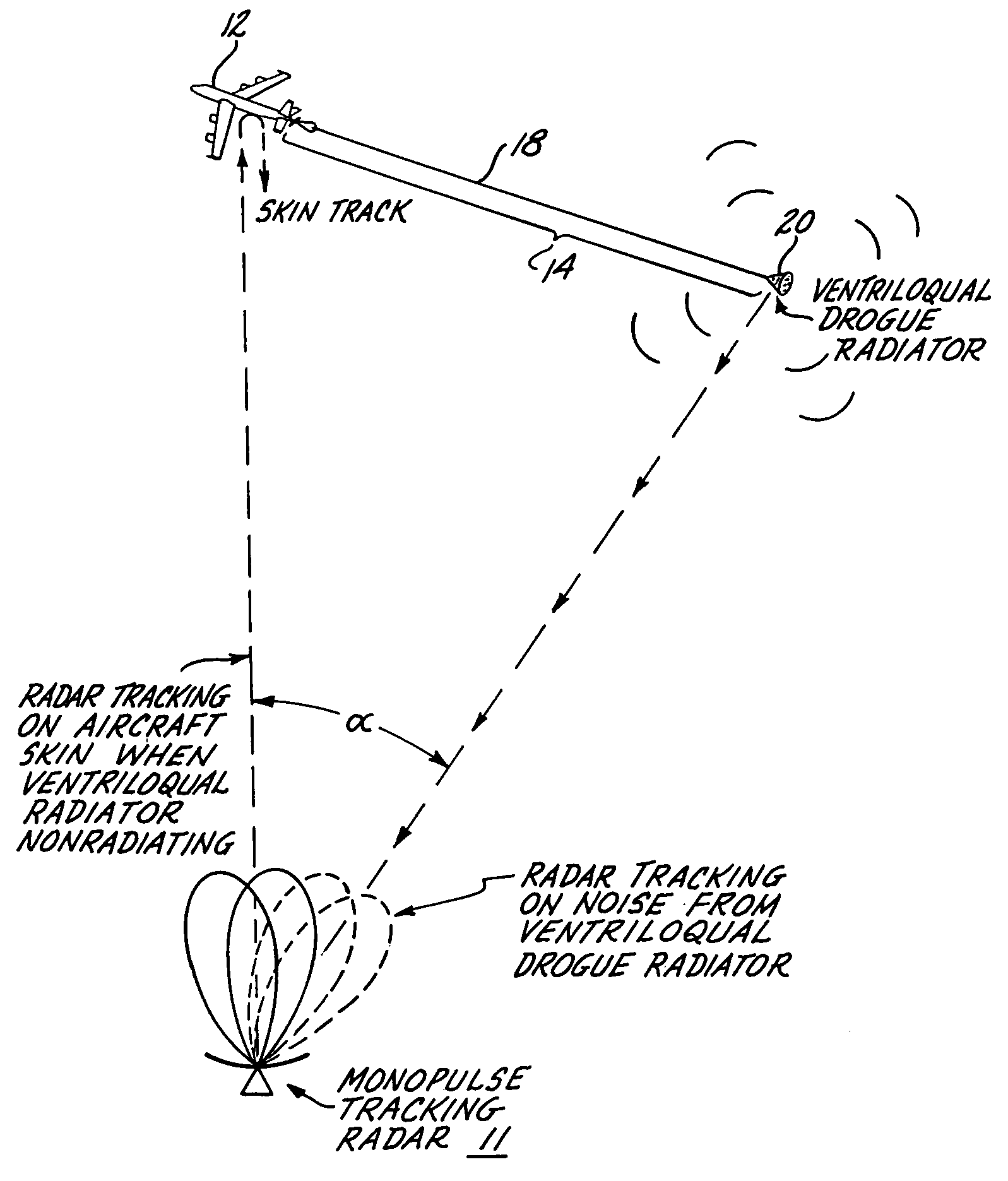

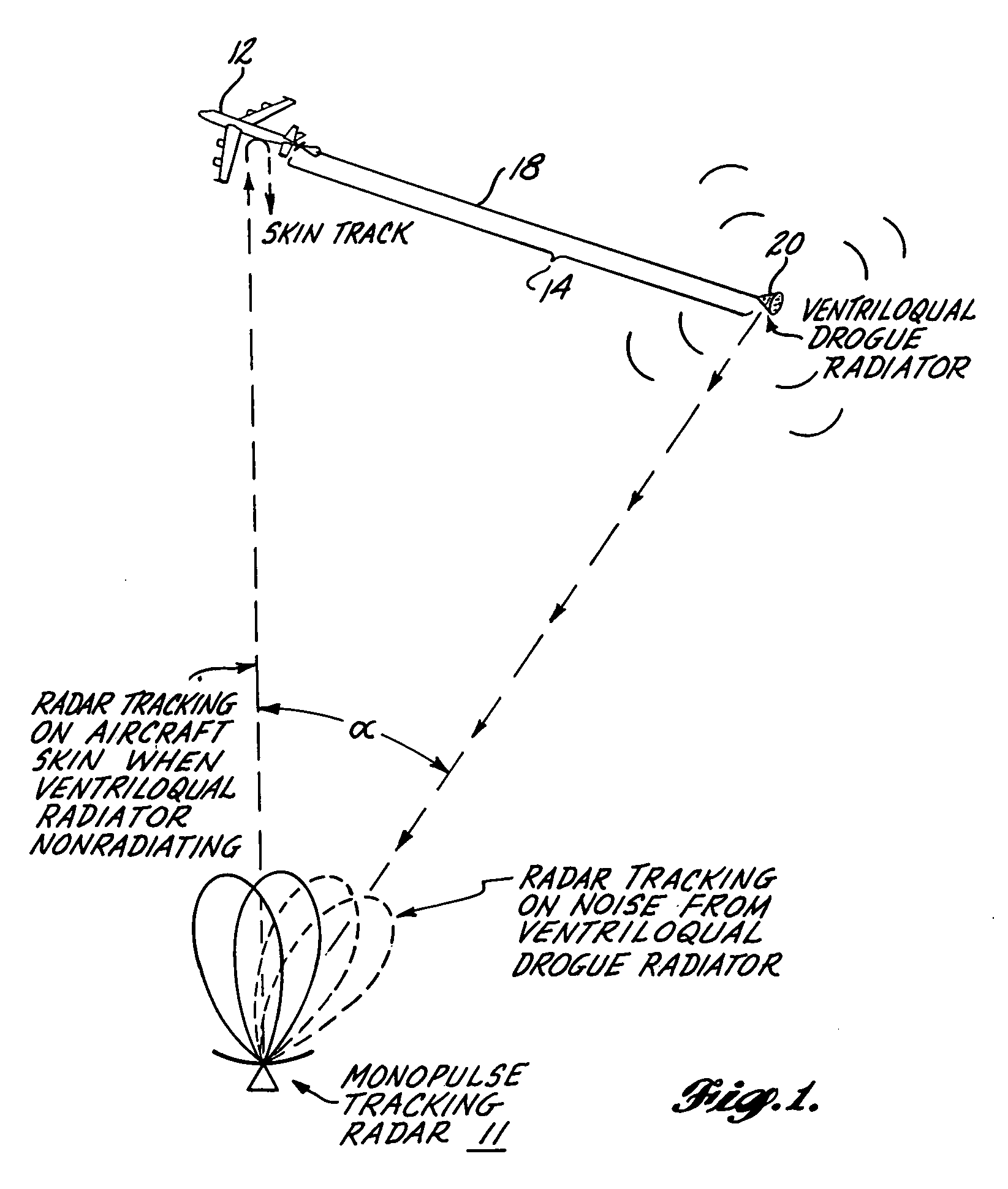

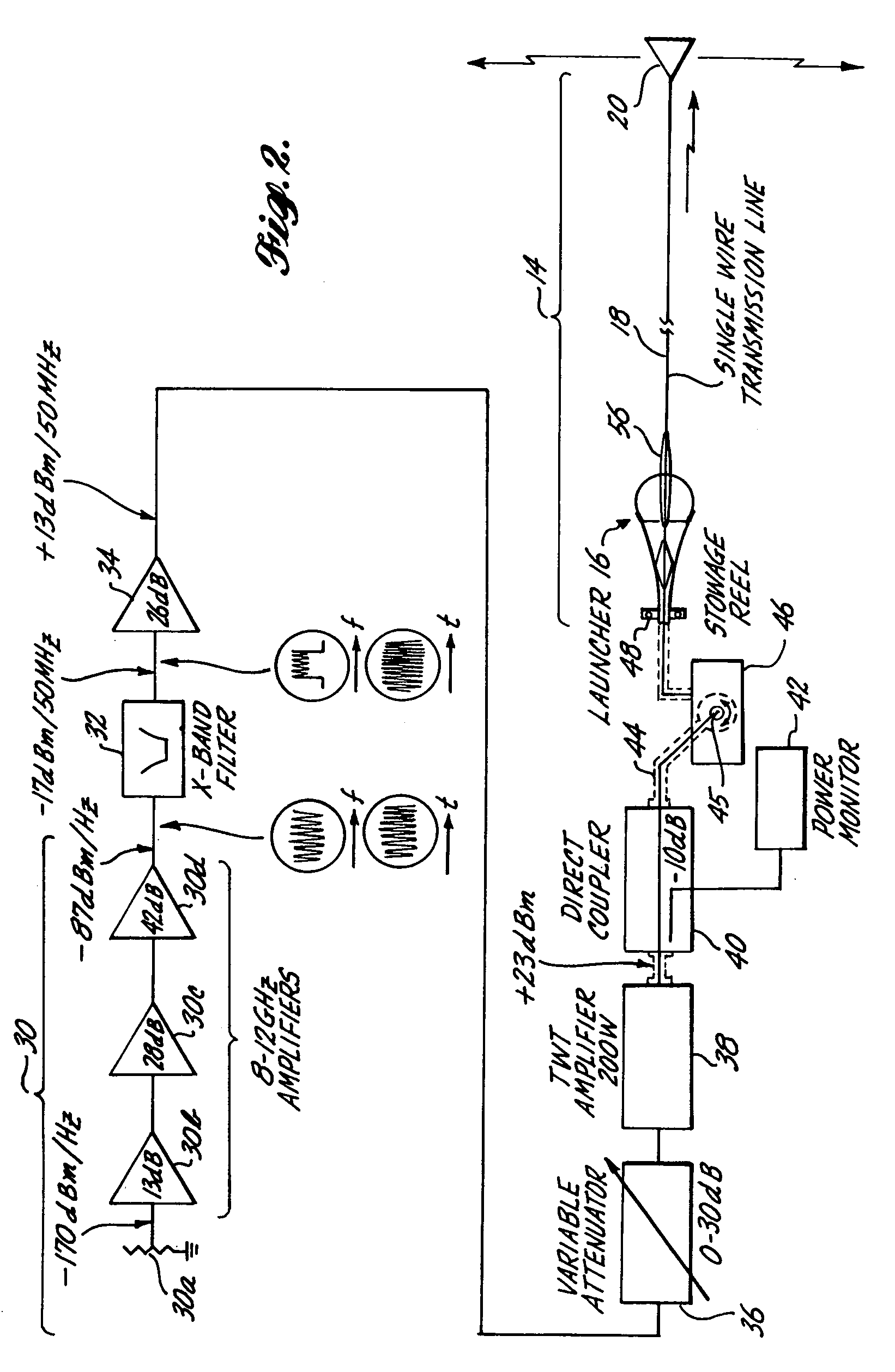

Airborne radar jamming system

A radar jamming signal generated by equipment carried by a target aircraft, is launched onto the leading end of a towed single wire transmission line so as to travel the length of the line as a nonradiating surface wave. A drogue radiator is attached to the trailing end of the line for radiating the jamming signal transversely of the towed line so as to be received by and cause jamming of tracking and / or fire control radar. The length of the single wire transmission line is selected so that the trailing radiator causes the jamming signal to emanate from a position sufficiently behind the aircraft so as to be outside the destructive radius of weapon fire directed at the apparent source of the jamming signal by fire control radar. A ventriloqual-like deception of the radar is thus achieved. A wave launcher couples the jamming signal to the leading end of the transmission line and for this purpose includes an electrically conducted horn-shaped structure, a tunable coaxial feed end at the constricted end of the horn structure, an inner transition conductor connecting the inner conductor of the coaxial feed to a leading end of the single wire transmission line, and a plurality of annular dielectric lenses and dielectric guides cooperatively shaped and fitted to the horn structure in a manner that effectively matches the bounded electromagnetic transmission wave characteristics of the coaxial feed cable with the surface wave transmission characteristics of the single wire transmission line. Coacting with the ventriloqual-like radiation of the jamming signal from the trailing end of the transmission line is an anti-integration network that hides the return radar signal reflected off the target aircraft in a signal energy “hole” created for such purpose in a secondary low level noise signal transmitted directly from the aircraft.

Owner:THE BOEING CO

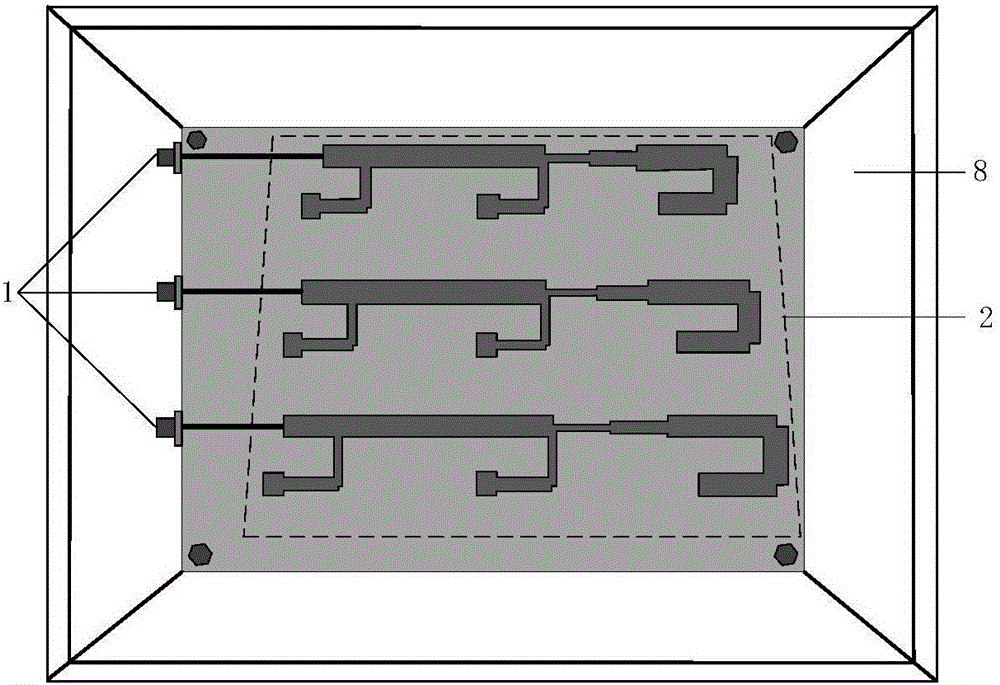

Small frequency scanning horn antenna based on microstrip array feed

ActiveCN106099376AMiniaturizationSave spaceWaveguide hornsRadiating elements structural formsDielectric substrateMiniaturization

The invention discloses a small frequency scanning horn antenna based on microstrip array feed, so as to solve the problem that the size of a high-gain horn antenna in the prior art is over large. An upper dielectric substrate is embedded at the bottom port of the horn antenna; a radiant floor is located between the upper dielectric substrate and a lower dielectric substrate; a patch array is etched on the upper surface of the upper dielectric substrate; a feed network is etched on the lower surface of the lower dielectric substrate and is connected with a coaxial feed connector arranged on the side surface; and a microstrip array is formed on the whole. The patch array is formed by sub arrays with different sizes corresponding to different working frequencies. Through using the microstrip array to replace a rectangular waveguide to feed the horn structure, on the premise of ensuring the same gain, the size of the horn antenna can be effectively reduced, the scanning effects of a radiation pattern at different frequencies are realized at the same time, the view point of the antenna is expanded, functions of miniaturization, multi-frequency beam scanning and the like are effectively realized, and the small frequency scanning horn antenna based on microstrip array feed of the invention is applicable to the field such as wireless communication.

Owner:XIDIAN UNIV

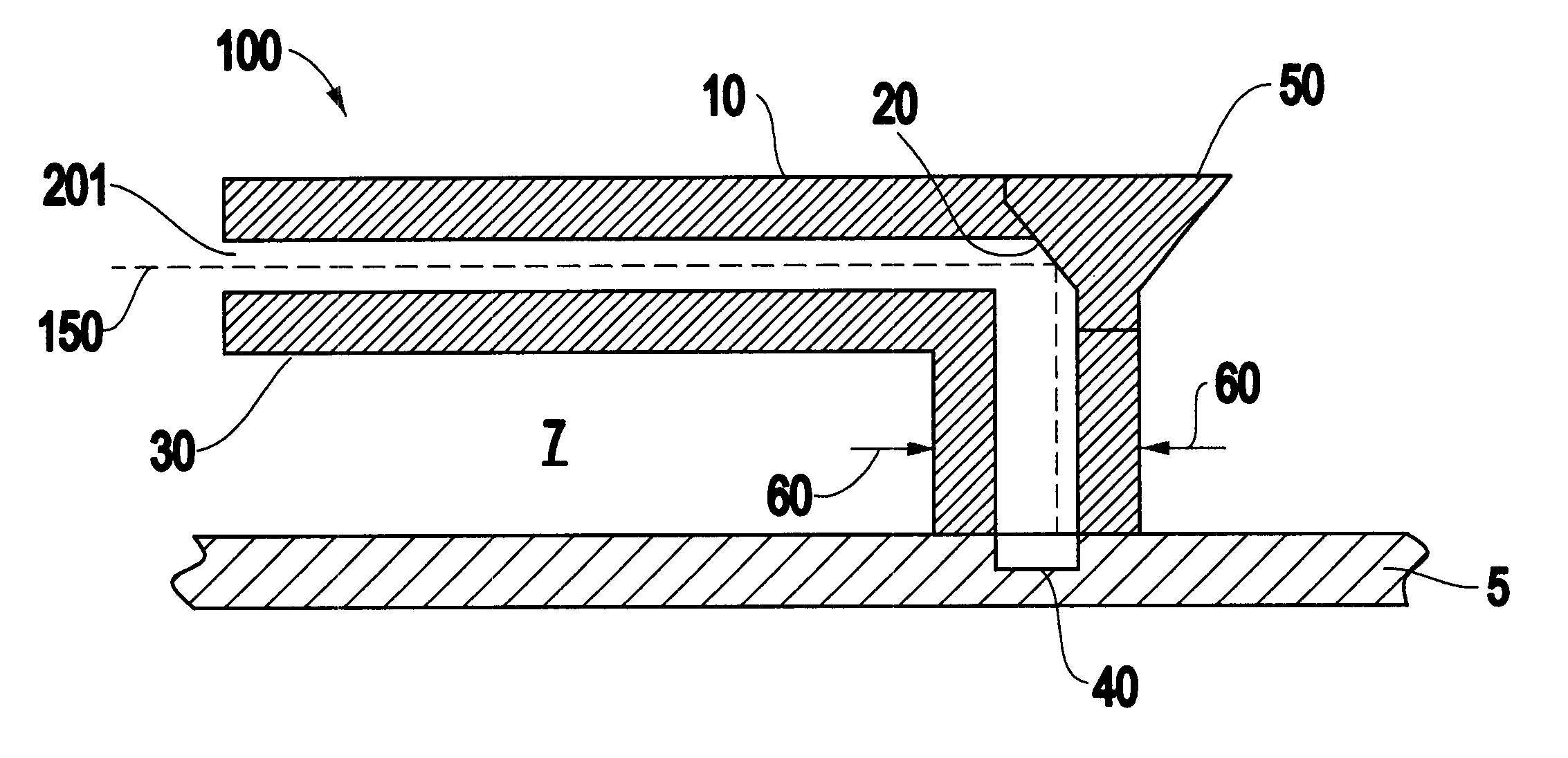

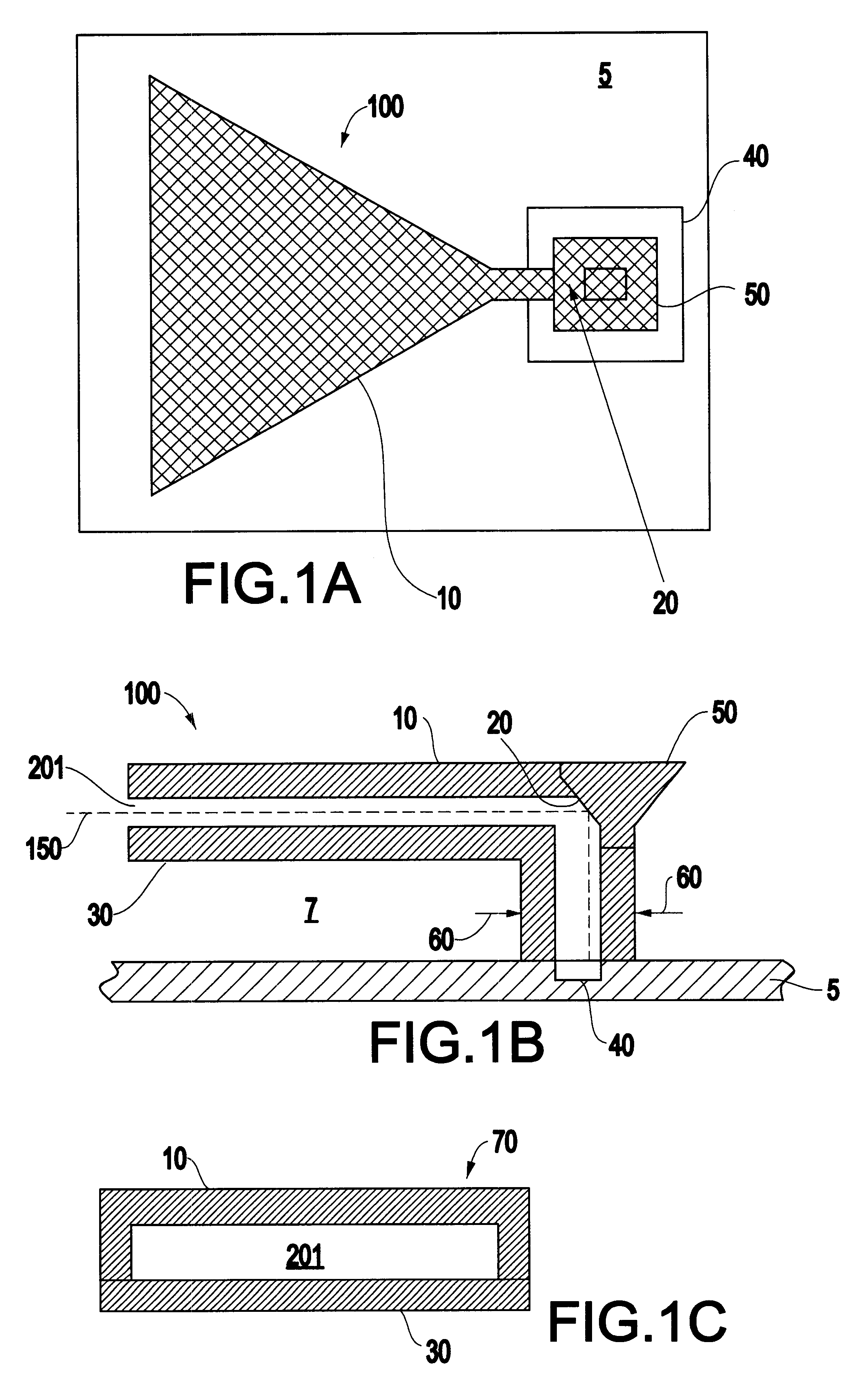

Dual damascene horn antenna

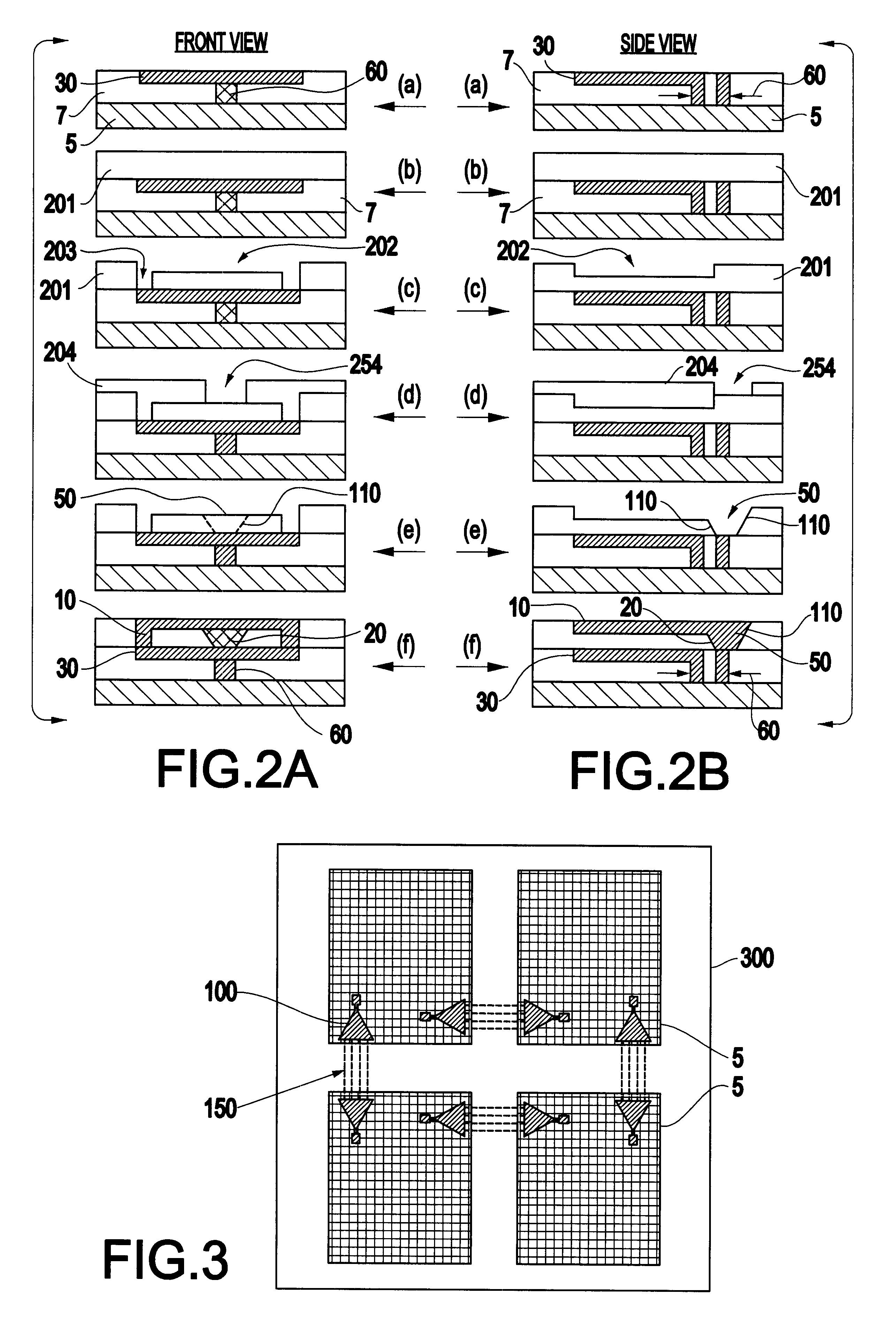

InactiveUS6522304B2Improve efficiencyReduce noiseWaveguide hornsWaveguide mouthsTransceiverDevice form

An integrated horn antenna device with an integrated circuit (IC) chip including a metallic horn structure having a wide aperture, a horizontal waveguide with a tapered via that electromagnetically communicates with a vertical waveguide structure to transmit energy to and from an electronic sub-component transceiver device forming part of the IC chip. Another embodiment of the invention comprises a plurality of multiple discrete IC chips having the integrated horn antenna devices incorporated therewith forming a module for data transmissions between these IC chips. Another embodiment of the invention includes additional external waveguide structures such as optical fibers external to the chips, where radiation is aligned between the horn structures and these waveguides. Dual damascene processing is used to fabricate the horn antenna device within the IC chip.

Owner:GLOBALFOUNDRIES US INC

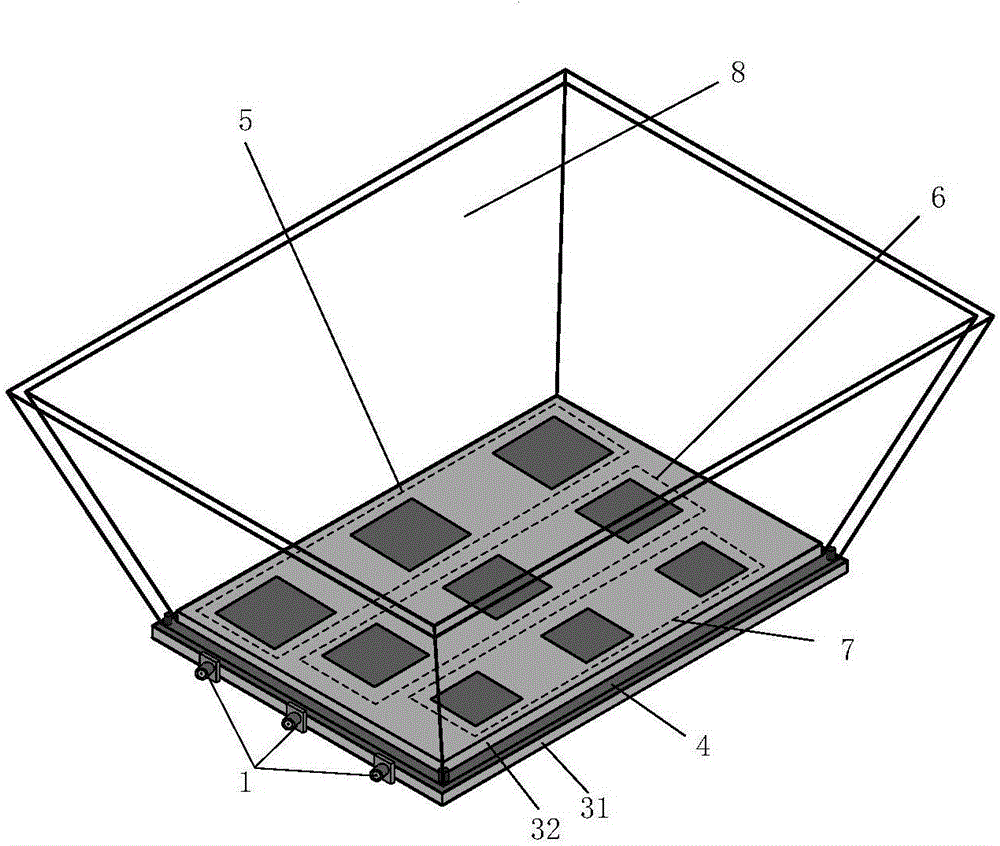

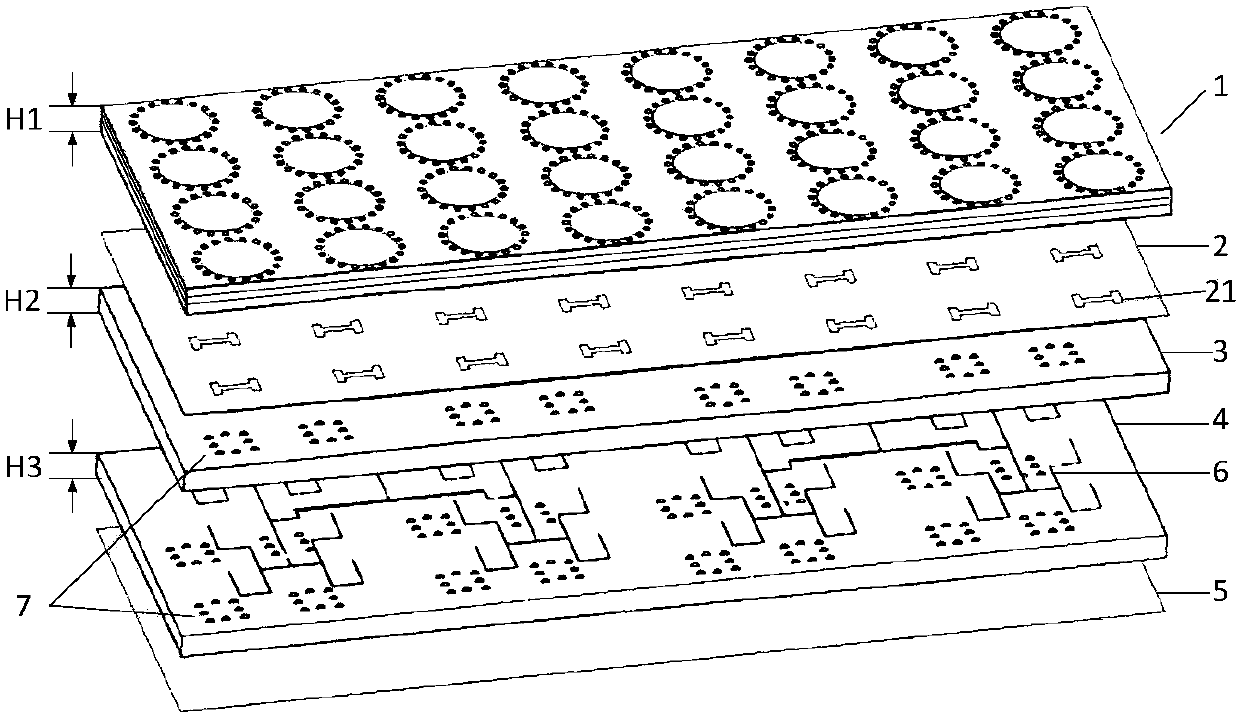

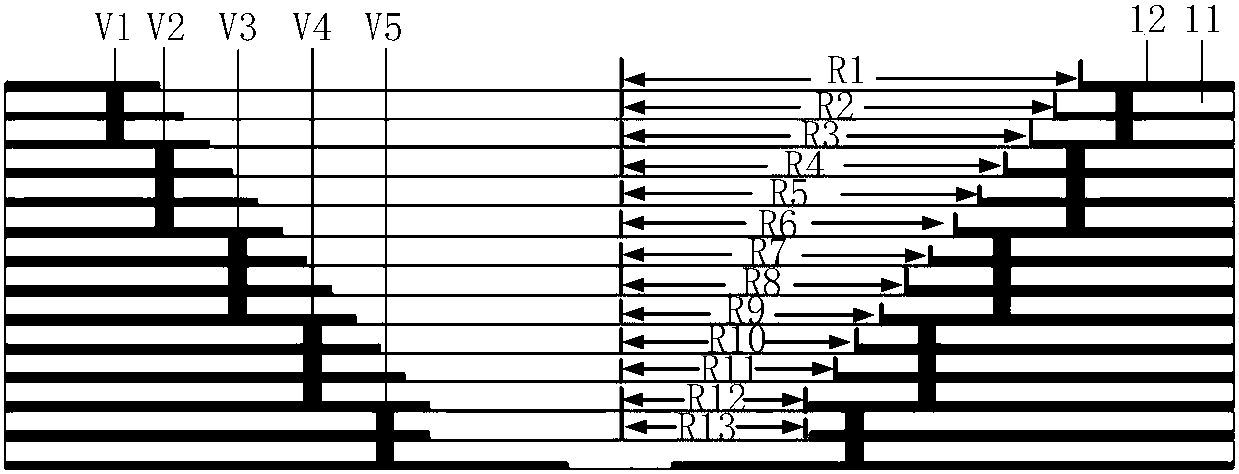

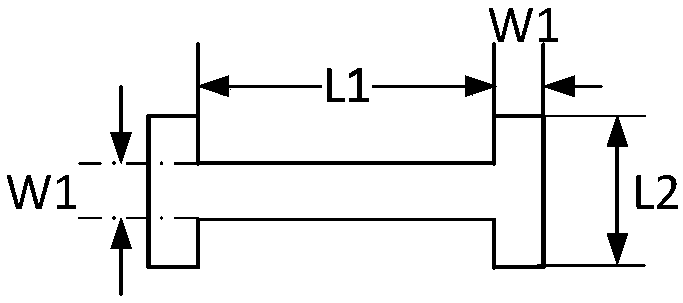

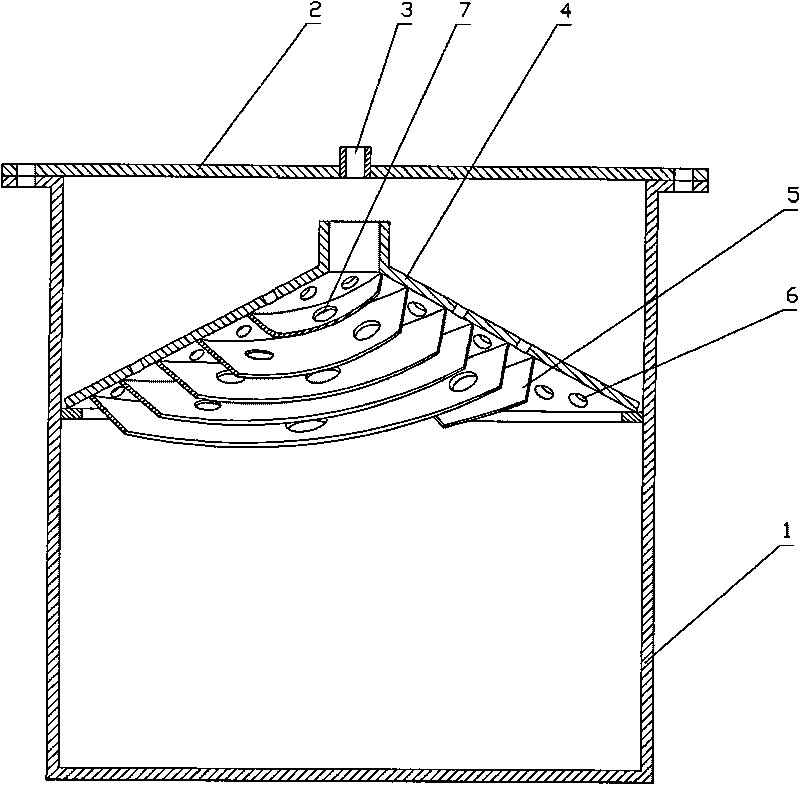

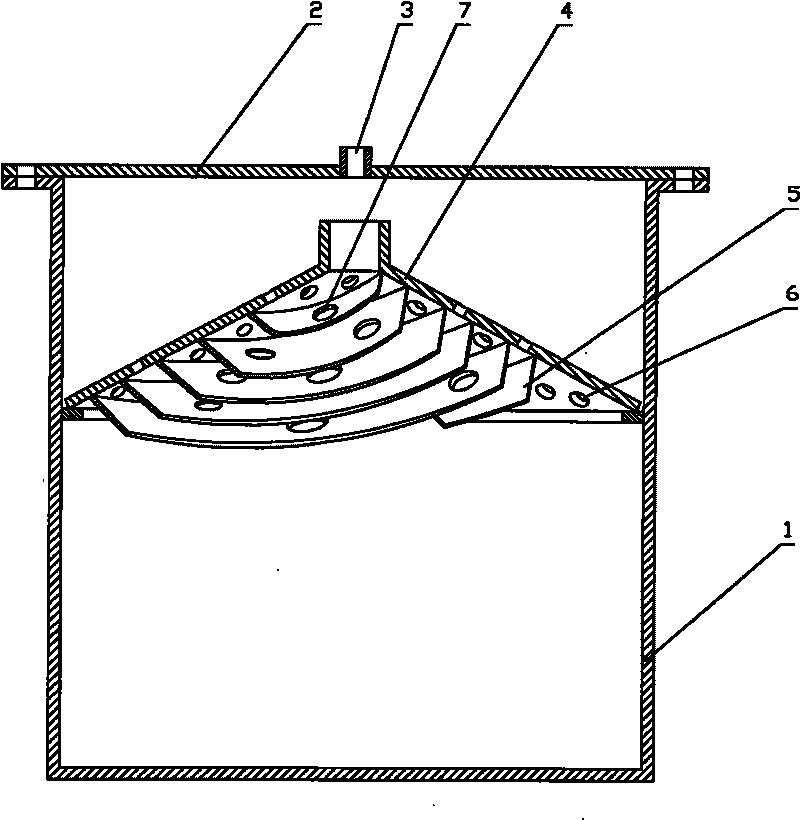

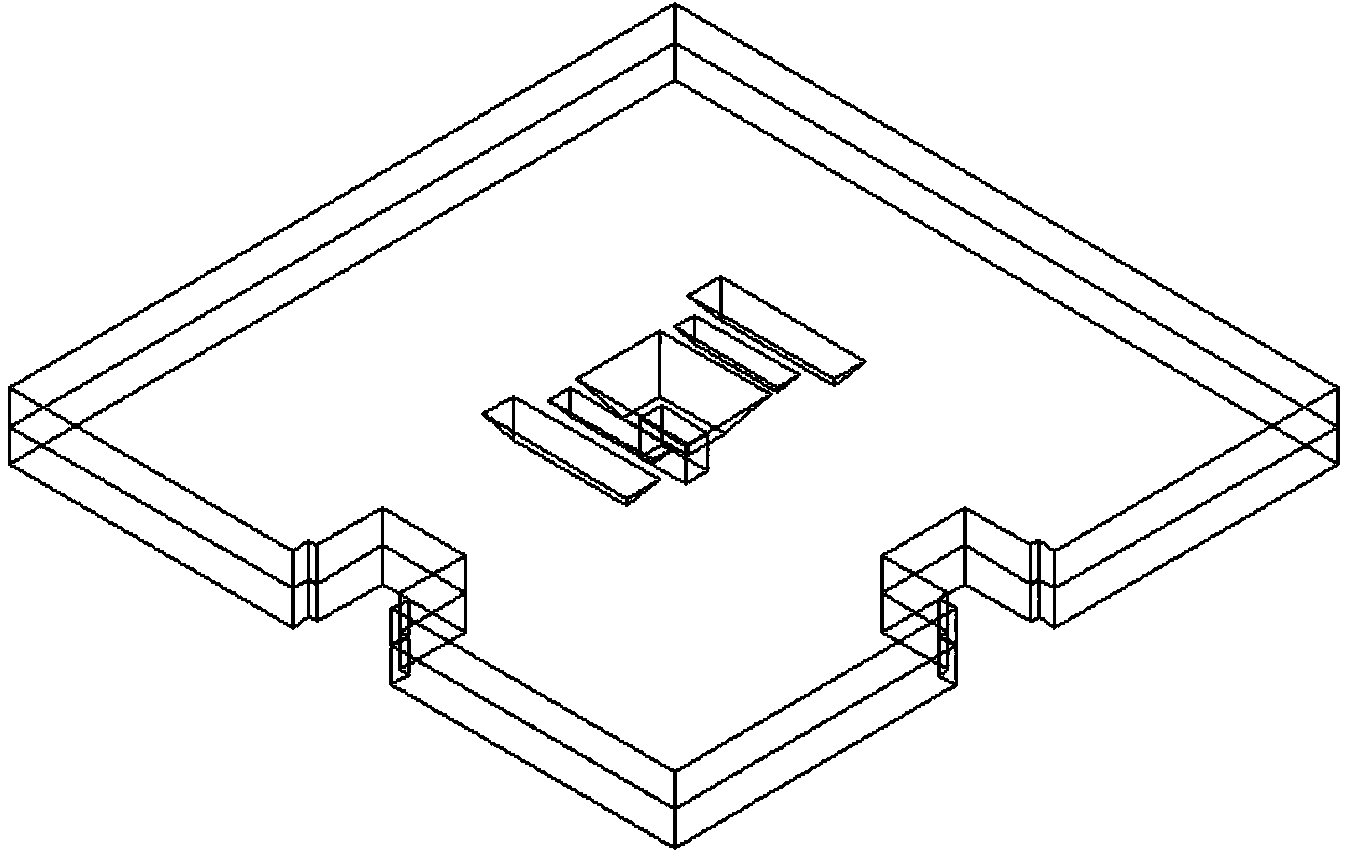

Multi-layer structure-based millimeter wave array antenna

InactiveCN107634335AReduce problemsImprove directionalityIndividually energised antenna arraysAntenna earthingsDielectric plateCoupling

The invention proposes a multi-layer structure-based millimeter wave array antenna. By the multi-layer structure-based millimeter wave array antenna, the gain is improved, and meanwhile, the miniaturization of the millimeter wave array antenna is achieved. The multi-layer structure-based millimeter wave array antenna comprises (m*n) antenna units, a first dielectric plate and a second dielectric plate, wherein the first dielectric plate and the second dielectric plate are vertically laminated, an internal grounding plate is printed on an upper surface of the first dielectric plate, an externalgrounding plate is printed on a lower surface of the second dielectric plate, (m*n) radiation gaps are etched in the internal grounding plate, the antenna units are fixed on the internal grounding plate and are arranged right above the radiation gaps, a feeding network is arranged between the first dielectric plate and the second dielectric plate and is used for performing coupling feeding on theantenna units, each antenna unit comprises a multi-layer dielectric plate, a metal plate is printed on an upper surface of each layer of dielectric plate, a round opening is formed in a plane centerof each layer of metal plate, and adjacent metal plates are connected via a metal through hole encircling an outer side of the round opening so as to form a round horn structure of which a caliber surface is gradually increased from bottom to top.

Owner:XIDIAN UNIV

Horn antenna array systems with log dipole feed systems and methods for use thereof

InactiveUS20080238797A1High gainImprove directivityWaveguide hornsLogperiodic antennasHorn antennaHorn structure

An antenna array comprises a plurality of elements, at least one of the elements including a log dipole isolated from others of the elements by a horn structure.

Owner:HONG KONG APPLIED SCI & TECH RES INST

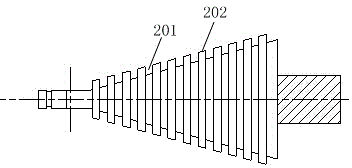

A precise electroforming method for making the subtle structure of a high frequency corrugation feed horn

ActiveCN104152948ACorrosion is notImprove structural strengthElectroforming processesEngineeringWidth ratio

The invention provides a precise electroforming method for making the subtle structure of a high frequency corrugation feed horn. The feed horn is obtained in the following way: an electroforming mandrel of the feed horn is made according to the structure form of the inner chamber of the corrugation feed horn; after the treatment that the surface of the mandrel is additionally coated with an anti-corrosion layer, with the combined action of ways of pictographic anode, cathode rotation, plating solution jet flow, bidirectional pulse, physical polishing and grinding, and so on, the mandrel is precisely electroformed with copper so that a feed horn electroformed piece is obtained; the demoulding operation of the electroformed piece and the mandrel is performed so that a feed horn is obtained. With the precise electroforming method of the invention, the problem that the inner corrugations, with a high depth-to-width ratio, of a high frequency corrugation feed horn are difficult to process is solved. With the precise electroforming technology, a high frequency corrugation feed horn with low surface roughness and without a chamber in the annual teeth can be obtained. The precise electroforming method greatly enhances the structure strength of a feed horn manufactured with the electroforming technology. At the same time, the low surface roughness of the horn surface effectively enhances the transmission reliability of microwave signals.

Owner:SHANGHAI SPACEFLIGHT ELECTRONICS & COMM EQUIP RES INST

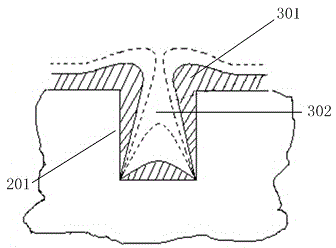

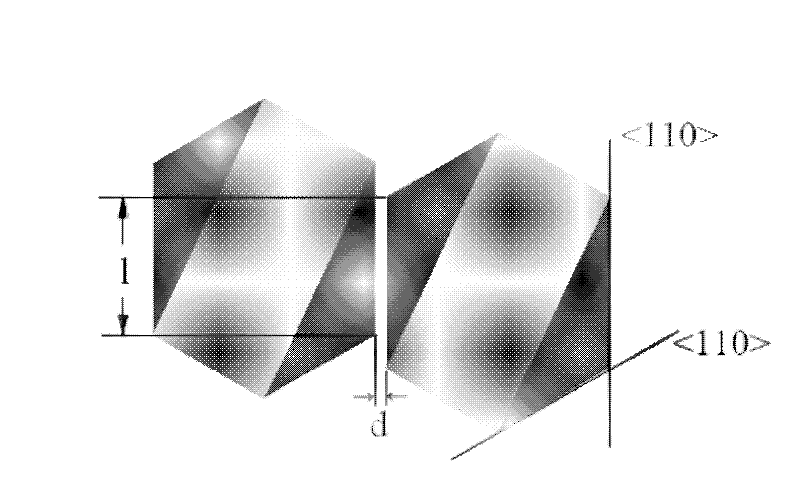

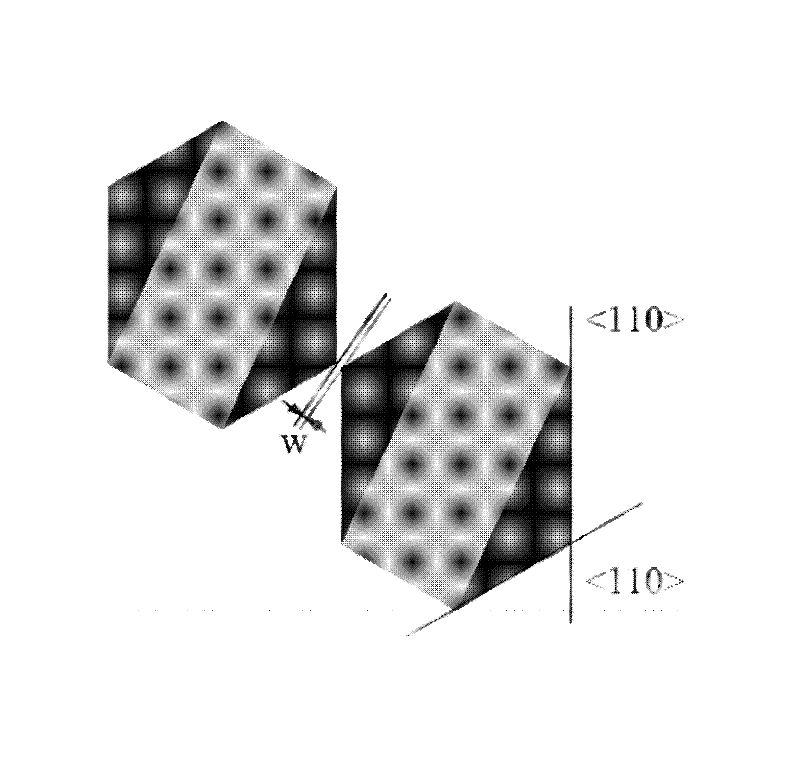

Method for preparing nano structure on surface of (111) silicon wafer

InactiveCN102437017AOvercome the disadvantage of being expensiveSimple processAfter-treatment detailsSemiconductor/solid-state device manufacturingNanowireNano structuring

The invention relates to a method for preparing a nano structure on a surface of a (111) silicon wafer, belonging to the technical field of nano. The invention is characterized in that a monocrystalline silicon nano wall structure or nano horn structure of which the characteristic dimension is on a nano level is prepared on the surface of a (111) silicon wafer by utilizing the anisotropic wet-process corrosive characteristic of the silicon material, or a self-restricting oxidation technique is combined to further prepare a monocrystalline silicon nanowire structure of which the cross section is in an inverted triangle shape. The invention has the advantage of simple technique, only relates to conventional photoetching, anisotropic wet-process etching mask manufacturing, corroding and etching techniques, can implement large-scale manufacture, and is a convenient micro / nano integration technology. The nano structure manufactured by the method provided by the invention can be used for researching properties (including mechanical, thermal, electric and other properties) of a low-dimension monocrystalline silicon material structure, can be used as a functional structure component of a sensor, and has application prospects.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Dual damascene horn antenna

InactiveUS20020149530A1Improve efficiencyReduce noiseWaveguide hornsWaveguide mouthsTransceiverDevice form

An integrated horn antenna device with an integrated circuit (IC) chip including a metallic horn structure having a wide aperture, a horizontal waveguide with a tapered via that electromagnetically communicates with a vertical waveguide structure to transmit energy to and from an electronic sub-component transceiver device forming part of the IC chip. Another embodiment of the invention comprises a plurality of multiple discrete IC chips having the integrated horn antenna devices incorporated therewith forming a module for data transmissions between these IC chips. Another embodiment of the invention includes additional external waveguide structures such as optical fibers external to the chips, where radiation is aligned between the horn structures and these waveguides. Dual damascene processing is used to fabricate the horn antenna device within the IC chip.

Owner:GLOBALFOUNDRIES US INC

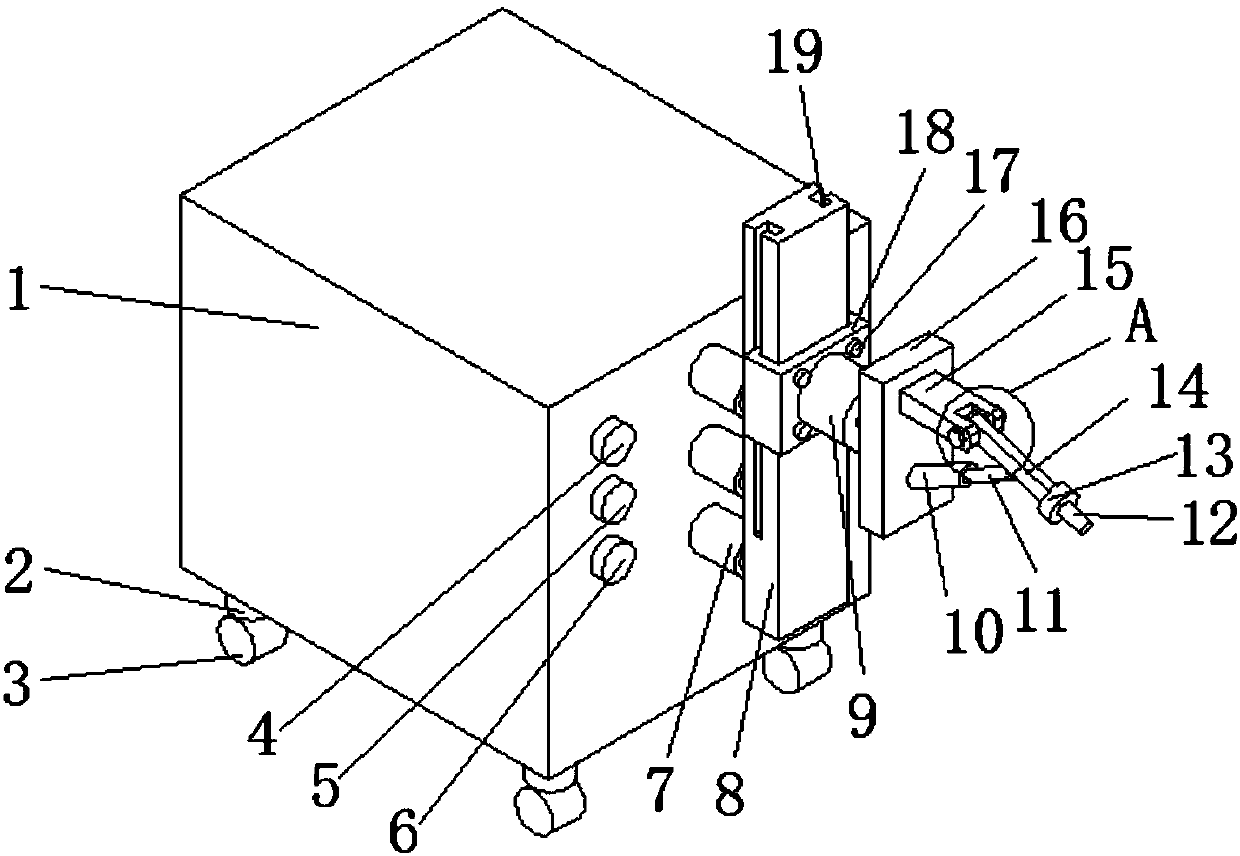

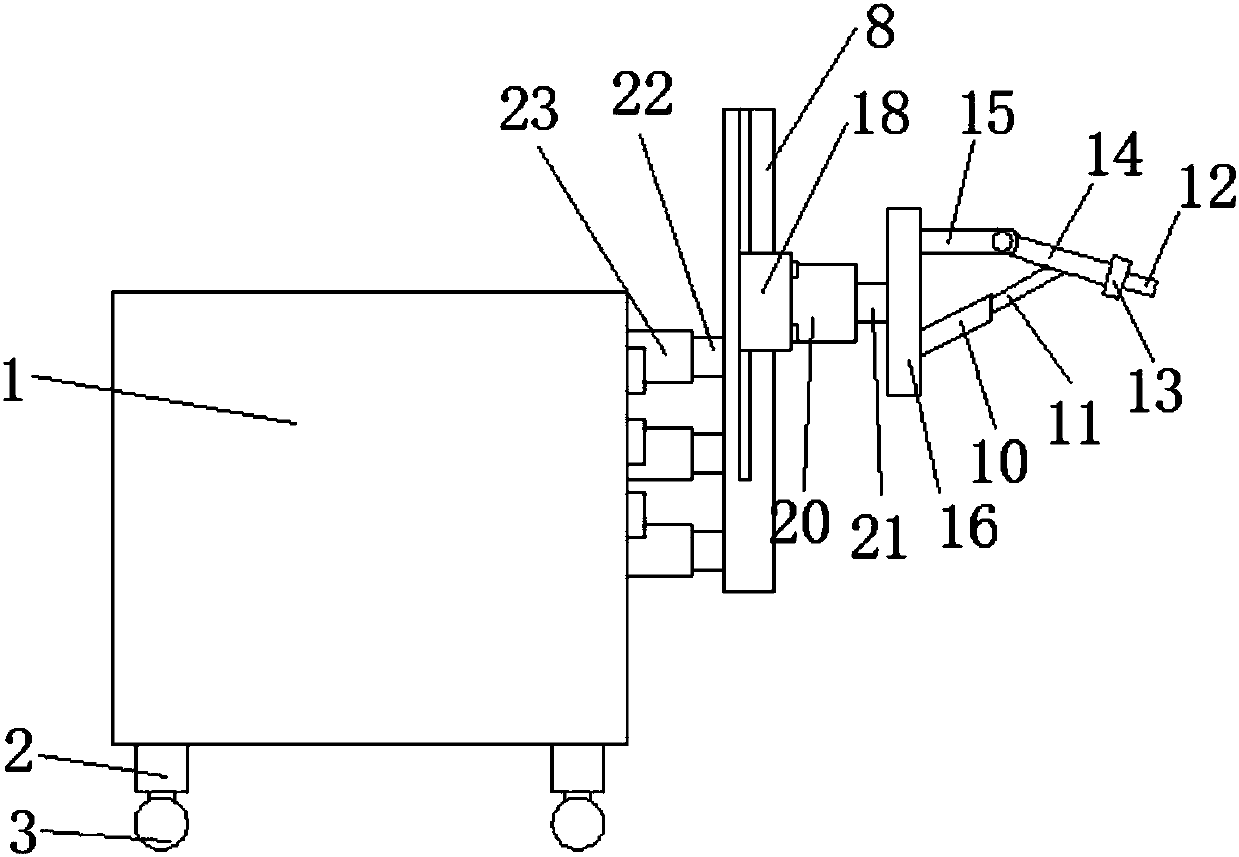

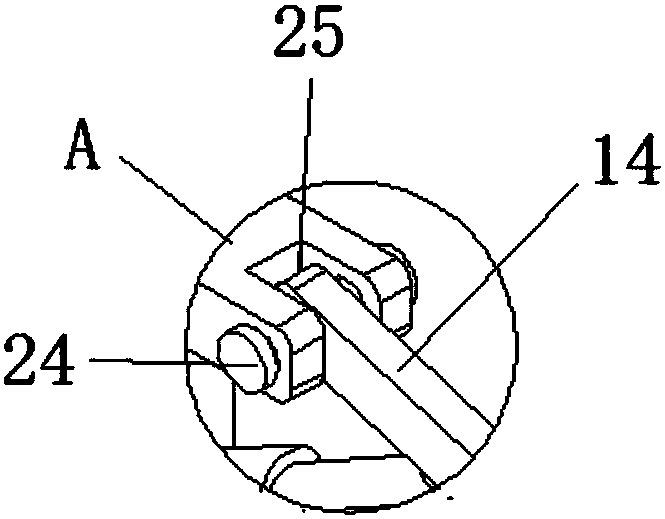

Angle-adjustable welding head structure of welding machine

InactiveCN107671399AIncrease welding distanceEasy to moveElectrode holder supportersBody right sideSlide plate

The invention discloses an angle-adjustable welding head structure of a welding machine, which comprises a welding machine body, and a first control switch, a motor switch and a second control switch are arranged on the right side of the welding machine body. There is a telescopic device in the middle of the surface, and one end of the telescopic device is provided with a strip plate. The side surface of the strip plate is slidingly mounted with a slide plate. The slide plate is fastened to the strip plate by screws. One end of the connecting plate is provided with a connecting plate, the upper part of the side surface of the connecting plate is provided with a supporting plate, the end of the supporting plate is provided with a through groove, and a connecting rod is arranged in the through groove, and the connecting rod is rotationally connected with the supporting plate through a rotating rod. One end is provided with a welding head installation seat, and the side surface of the welding head installation seat is provided with a welding head. The welding head structure of the welding machine with adjustable angle is convenient to move, the height of the welding head can be adjusted, and the angle of the welding head can be adjusted, and the angles are various, which brings great convenience to the use.

Owner:黄石市盛兴机械科技股份有限公司

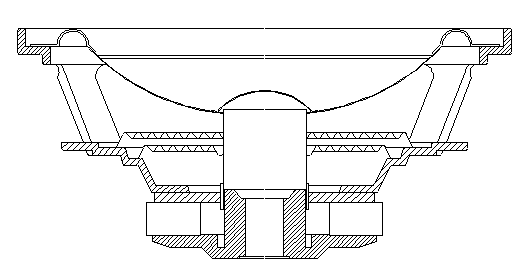

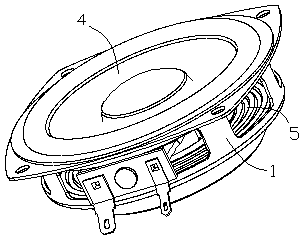

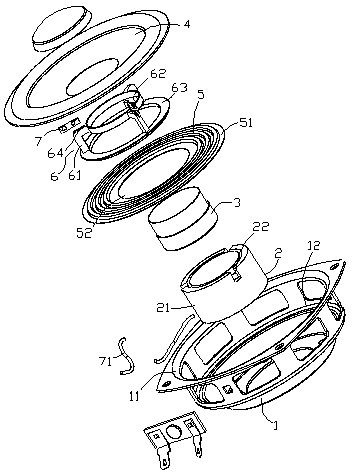

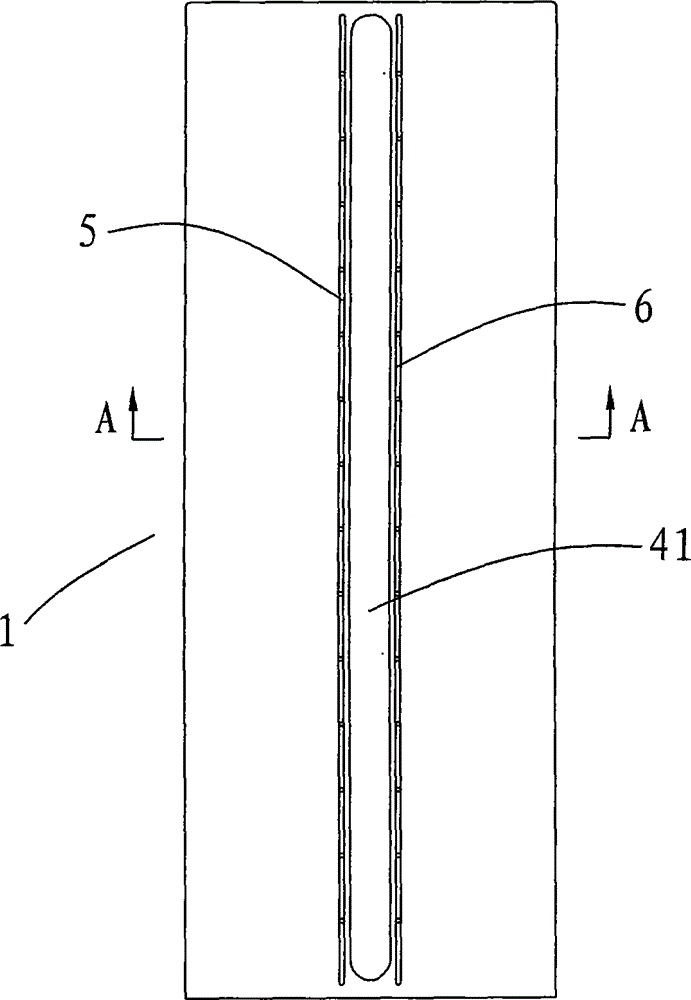

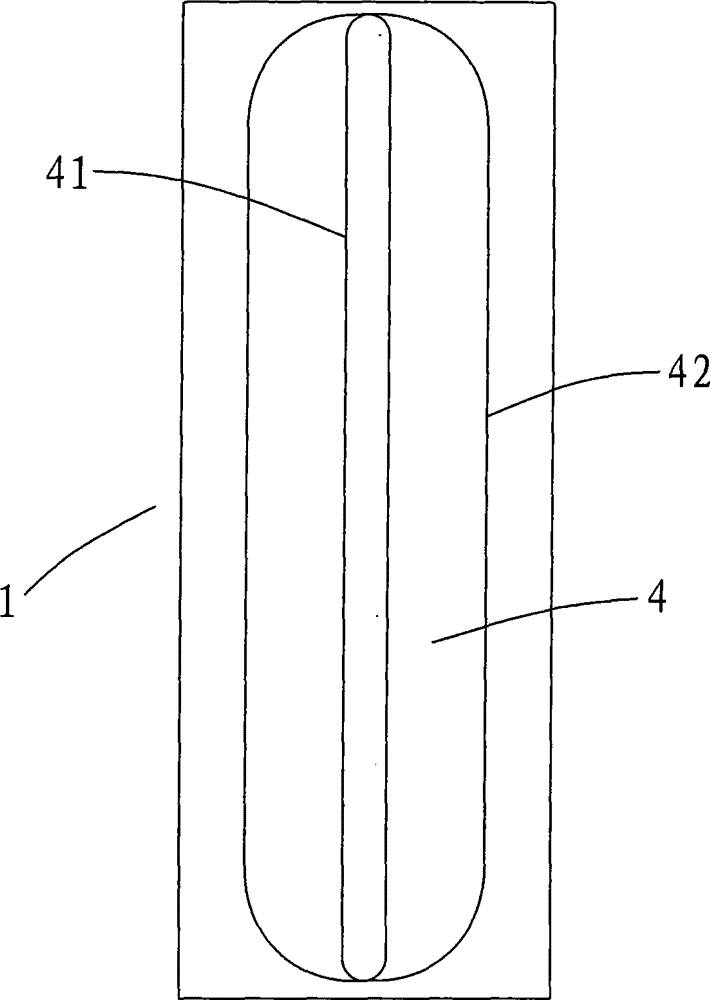

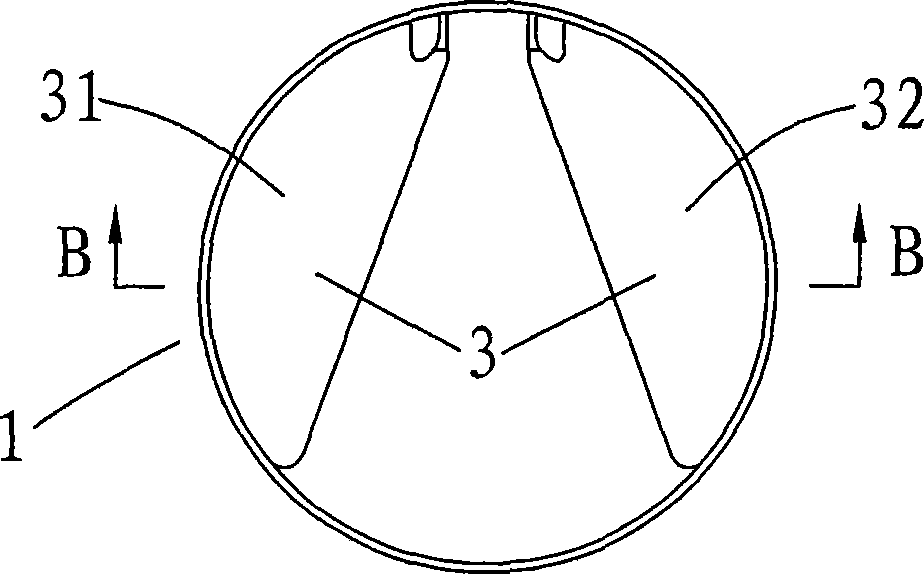

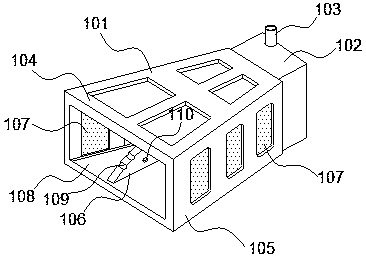

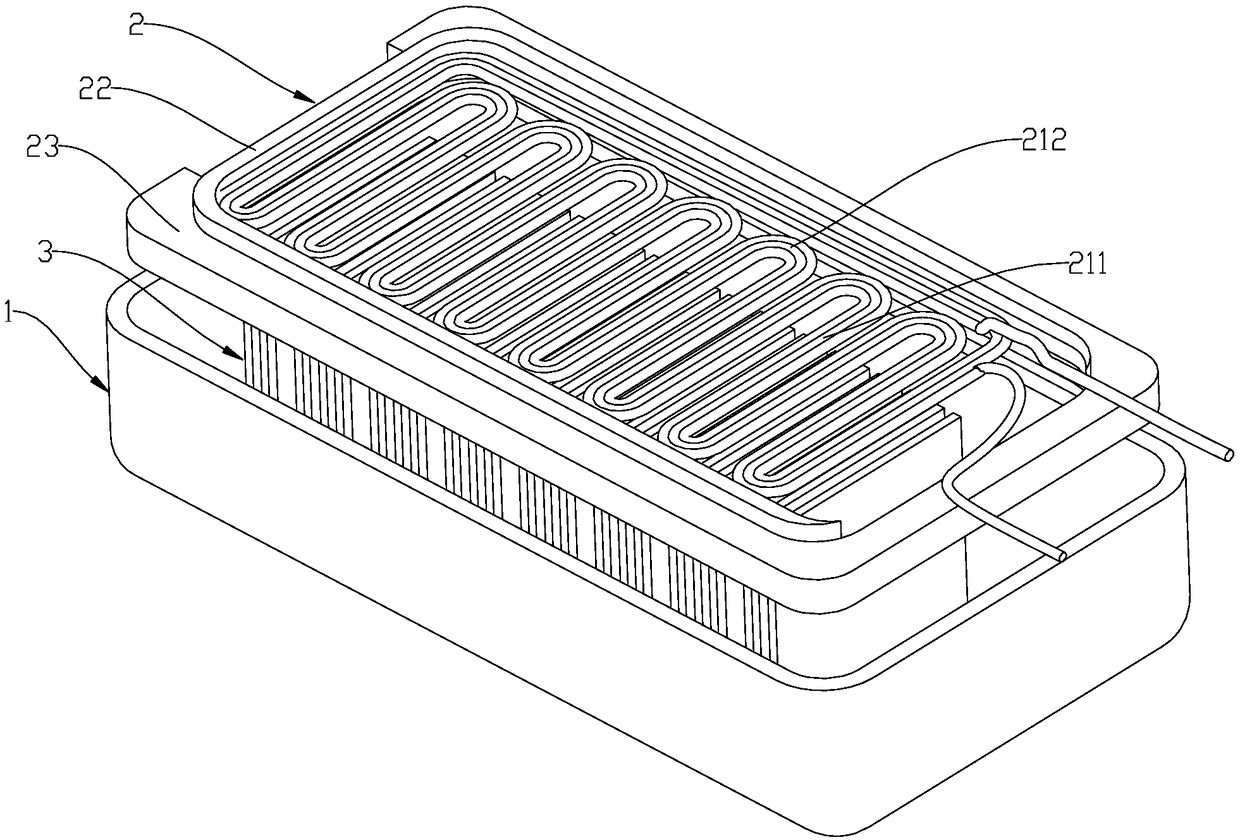

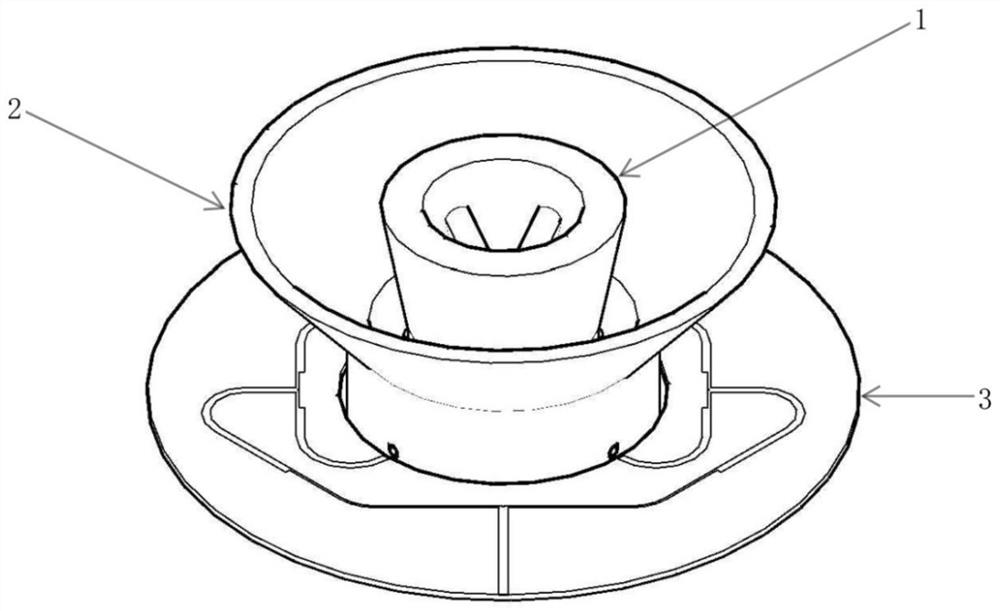

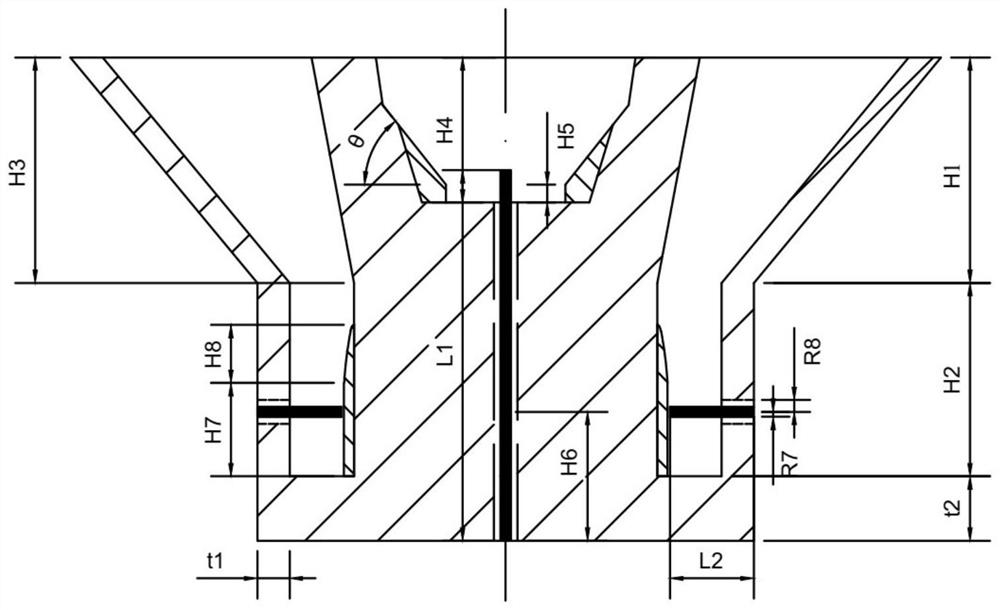

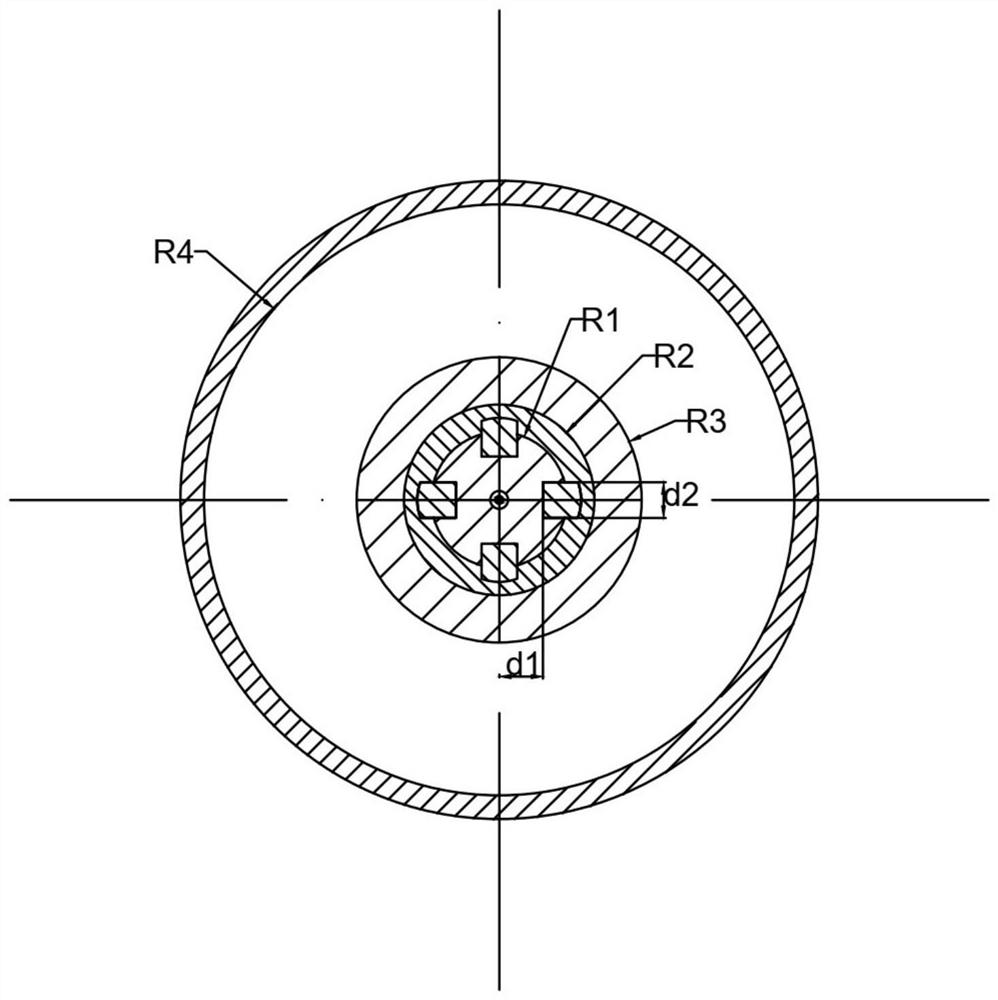

Horn structure with internal bracket

InactiveCN102932716ACombined height reductionIncrease vibration amplitudeElectrical transducersHysteresisVibration amplitude

The invention discloses a horn structure with an internal bracket. The horn structure mainly comprises a shell, a voice coil and a vibrating diaphragm, wherein a dilated opening is formed in front of the shell and a hysteresis loop is accommodated behind the shell; the voice coil is arranged in the middle of the hysteresis loop; the vibrating diaphragm is arranged on the dilated opening of the shell, and the inner diameter of the vibrating diaphragm is adhered with the voice coil. The horn structure is characterized by further comprising an elastic wave plate and the internal bracket, wherein the outer edge of the elastic wave plate is arranged on an inner step of the shell, an inner hole is formed in the side wall of the hysteresis loop in a clearance sleeving manner, and a plurality of profiled grooves are formed above the hysteresis loop in the axial direction at intervals; the upper side of the internal bracket is arranged on the side wall of the voice coil, the lower side of the internal bracket is arranged at the edge of the inner hole of the elastic wave plate, and a plurality of connecting legs which stretch outwards are arranged in the middle of the internal bracket and are over against the upper sides of the plurality of profiled grooves of the hysteresis loop; and therefore, the whole combination height and the size of the horn are effectively reduced, so that the elastic wave plate can be lowered to be arranged on the middle section (or upper edge) of the side wall of the hysteresis loop; and when the voice coil vibrates up and down by assistance of the internal bracket, the plurality of connecting legs can avoid the plurality of profiled grooves above the hysteresis loop; and when the vibration amplitude and the vibration stability of the horn are appropriately increased, and the low-voice response is enhanced so as to improve the sounding quality.

Owner:MEILOON INDAL

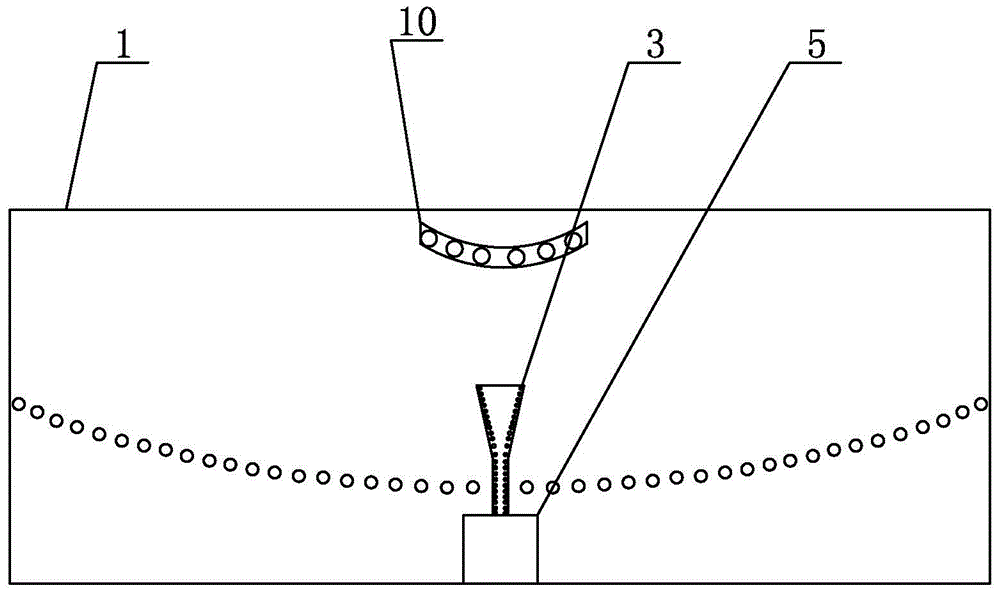

Nozzle of bladeless fan

The invention relates to a nozzle of a bladeless fan. The nozzle comprises a nozzle body, a receiving opening used for receiving basic airflow and an inner channel are formed in the nozzle body, the nozzle body is further provided with an air guide opening used for guiding outer air to pass, a strip-shaped narrow opening is formed in the front end of the air guide opening, a wide opening is formed in the rear end of the air guide opening, exhaust openings are formed in the surface of the nozzle body along the periphery of the strip-shaped narrow opening, and the basic airflow received by the inner channel is jet outwards out of the exhaust openings. The nozzle of the bladeless fan is approximately designed in a cylinder shape, the occupied use area is small in the use process, two paths of airflow are jet out of the exhaust openings and are joined to form one path of airflow in front of the nozzle, the jetting speed of the airflow is improved, the air supply distance is increased, and the aim of fast cooling a user can be achieved. Meanwhile, the air guide opening is of a horn structure with the narrow front end and the wide rear end, the airflow flowing speed can be multiplied when the outer air is guided to pass, and therefore the air amount is improved.

Owner:应辉

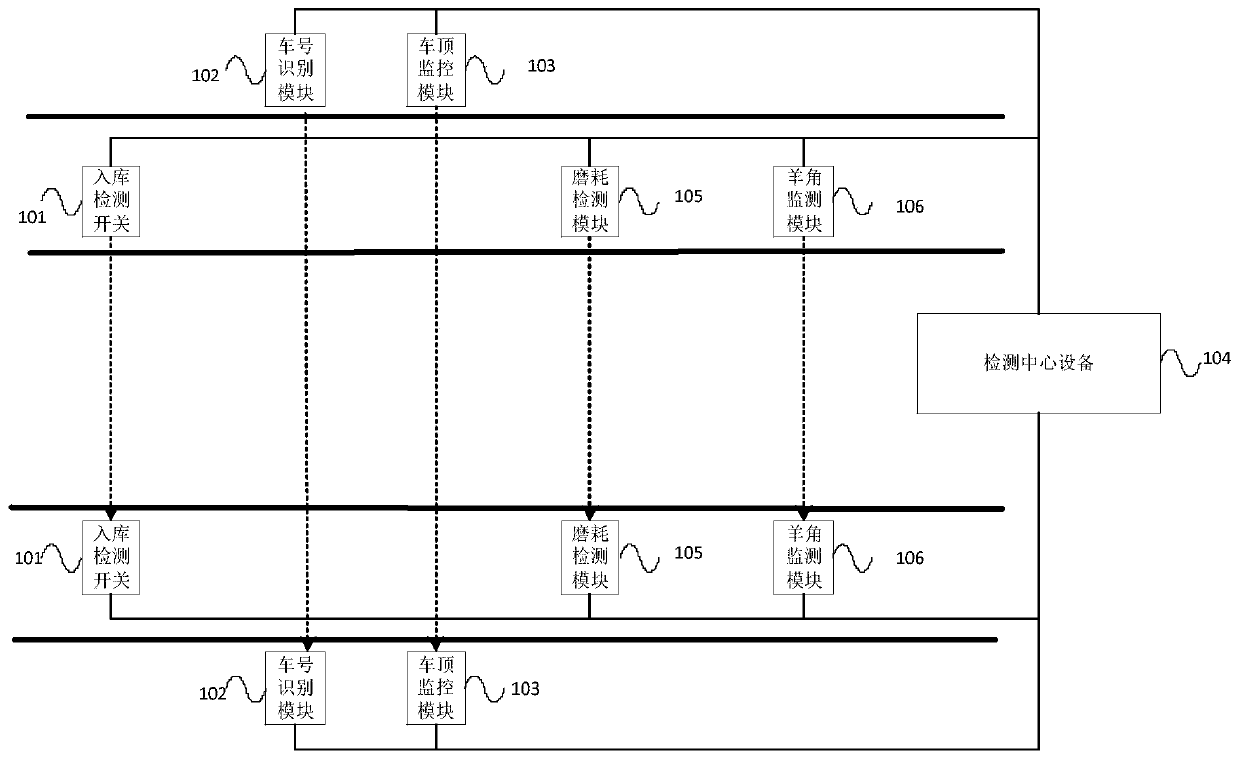

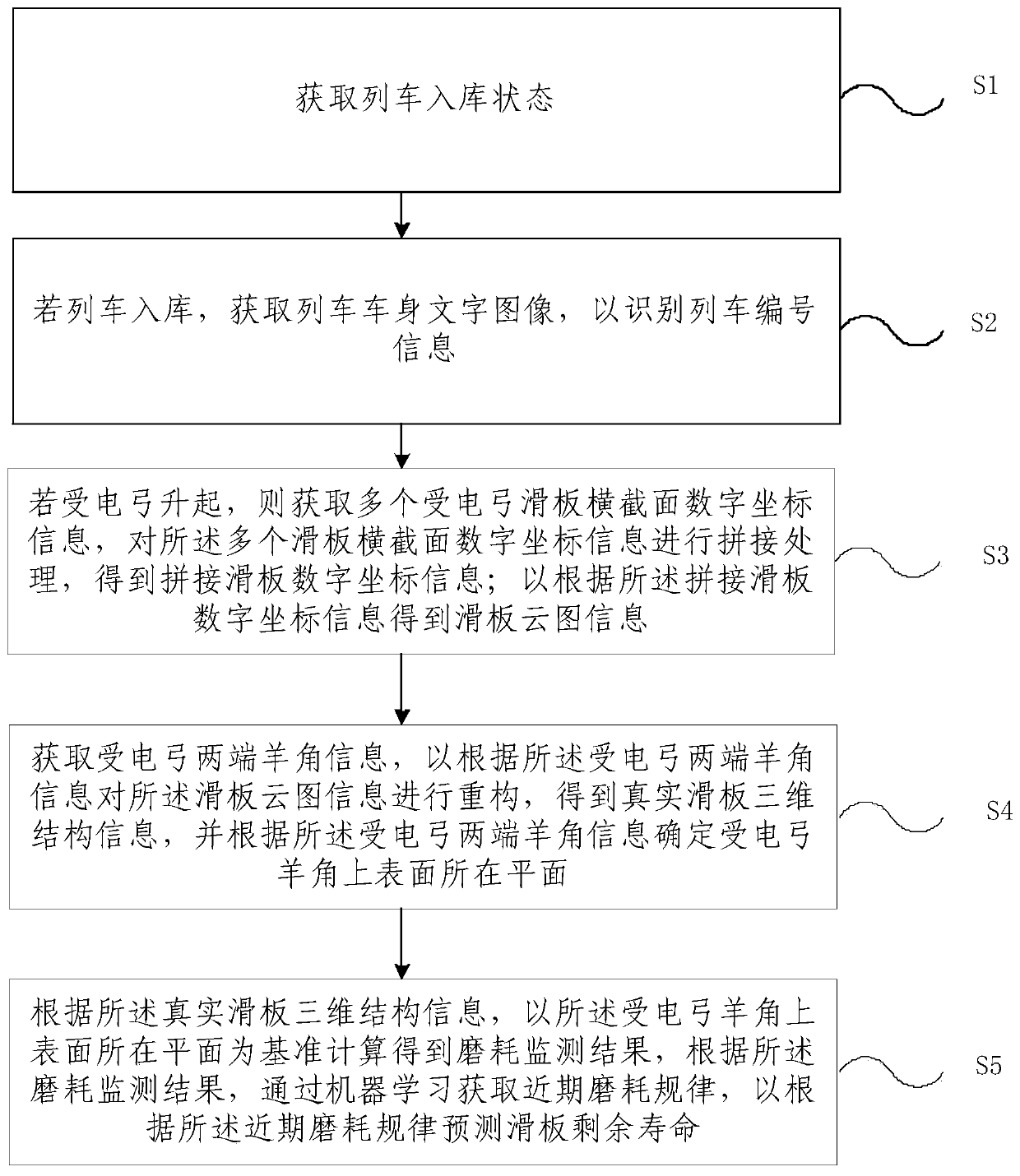

Pantograph slide plate condition monitoring system and method thereof

ActiveCN110455214AWear status monitoring is accurate and efficientUsing optical meansElectricityInterference factor

The embodiment of the present invention provides a pantograph slide plate condition monitoring system and method thereof, the system comprises: an inbound monitoring switch, a train number identification module, a train roof monitoring module, a monitoring center device, an abrasion monitoring module and a horn structure monitoring module; wherein the inbound monitoring switch is configured to detect a train inbound state; the abrasion monitoring module acquires a plurality of slide plate cross-section digital coordinate information when a pantograph is raised, and obtains slide plate cloud map information; the horn structure monitoring module acquires shape information of the pantograph's horn structure, and reconstructs the slide plate cloud map information according to the shape information of the pantograph's horn structure, to obtain real three-dimensional structure information of the slide plate; and the monitoring center device calculates the abrasion monitoring result based ona plane of the upper surface of the pantograph horn, according to the real three-dimensional structure information of the slide plate, and predicts remaining life of the slide plate according to rules of recent abrasion. The acquired data is not interfered with common interference factors, thus accurate and efficient detection is achieved.

Owner:CRRC QINGDAO SIFANG CO LTD

Multi-band antenna for simultaneously communicating linear polarity and circular polarity signals

InactiveUS20100194655A1Improve high-band gain and bandwidth performanceWaveguide hornsSimultaneous aerial operationsLinear componentMulti band

Multi-band antennas for simultaneously communicating linear polarity low-band signals and circular polarity high-band signals via a single antenna horn structure. The antennas horn structures have circular and oblong cross-sections. Strategic location and orientation of low-band and high-band ports with respect to internal ridges in transition sections and the major and minor axes of the oblong horn allows the antenna to simultaneously manipulate the high-band circular polarity signal without affecting the linear polarity low-band signals. The oblong horn shape and ridges may apply additive or oppositely sloped differential phase shifts to the linear components of the circular polarity high-band signal. For the horns with circular cross-section, the internal ridges may apply additive or oppositely sloped differential phase shifts to polarize the circular polarity high band signals without assistance from the internal shape of the horn.

Owner:COOK SCOTT

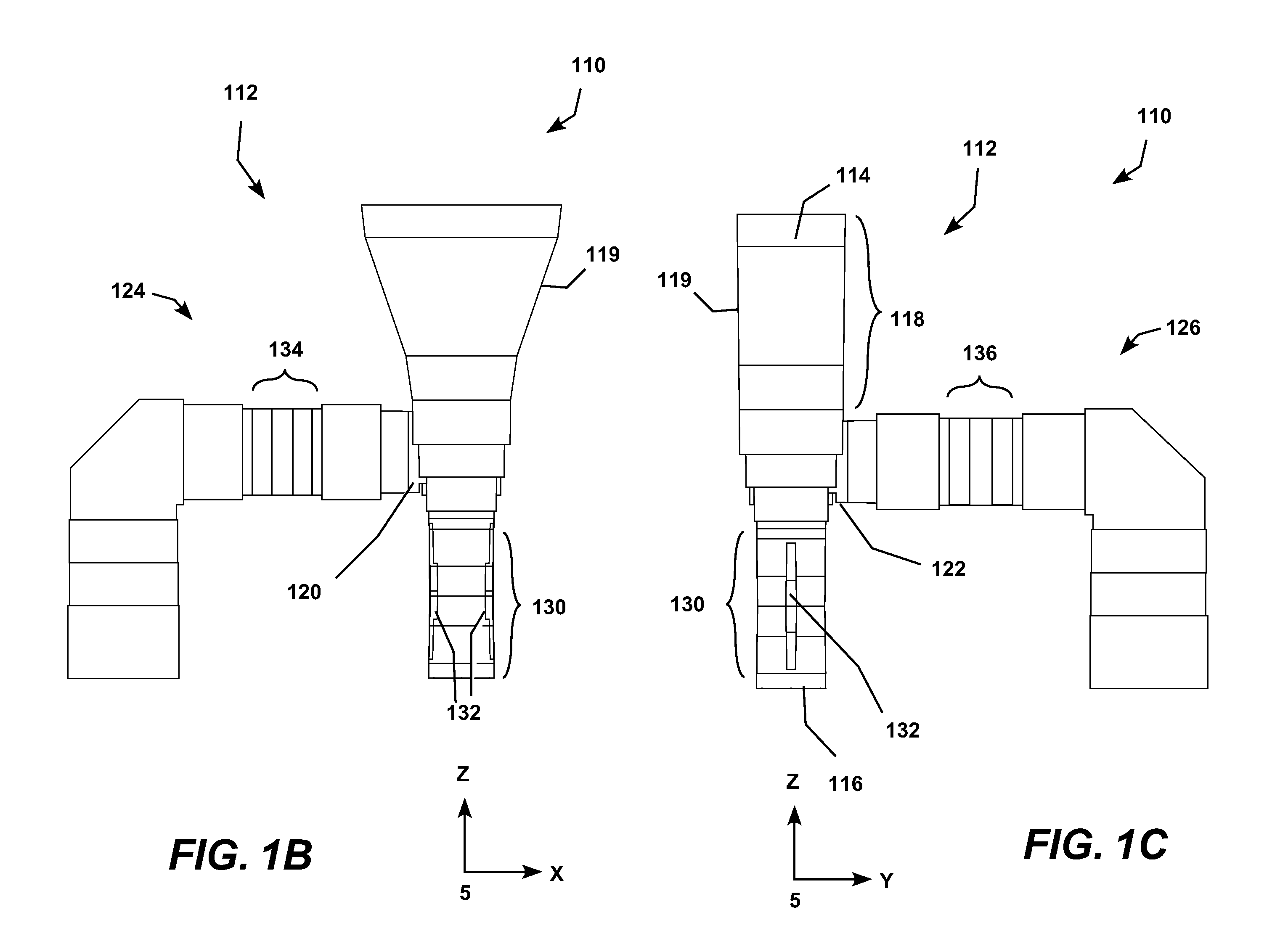

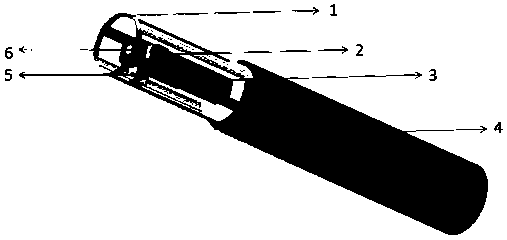

Vector microphone with horn structure

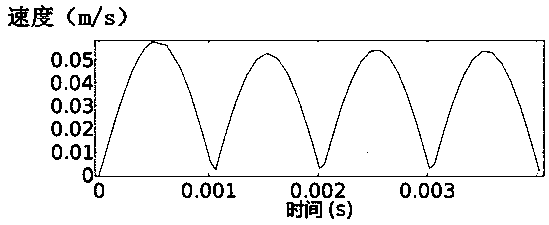

PendingCN107687890AHigh sensitivityImprove signal-to-noise ratioVelocity propogationUsing electrical meansNoiseSound wave

The invention discloses a vector microphone with a horn structure. The vector microphone comprises a supporting rod, a sound pressure microphone is embedded in the upper end of the supporting rod, a sensitive element with a horn mouth in the x direction and a sensitive element with a horn mouth in the y direction are pasted on two adjacent sides of the supporting rod respectively and used for measuring vibration velocity information in each direction, and the horn mouths are used for increasing flow rate of sound waves. Sensitivity of a hot wire type vector sensor is improved by applying a horn mouth sensibilizing structure. A vector sensor sensitive unit structure based on a hot wire structure is provided, and a tandem type mirror image bridge pre-amplification circuit structure is applied, so that signal-noise ratio is increased.

Owner:CHINA JILIANG UNIV

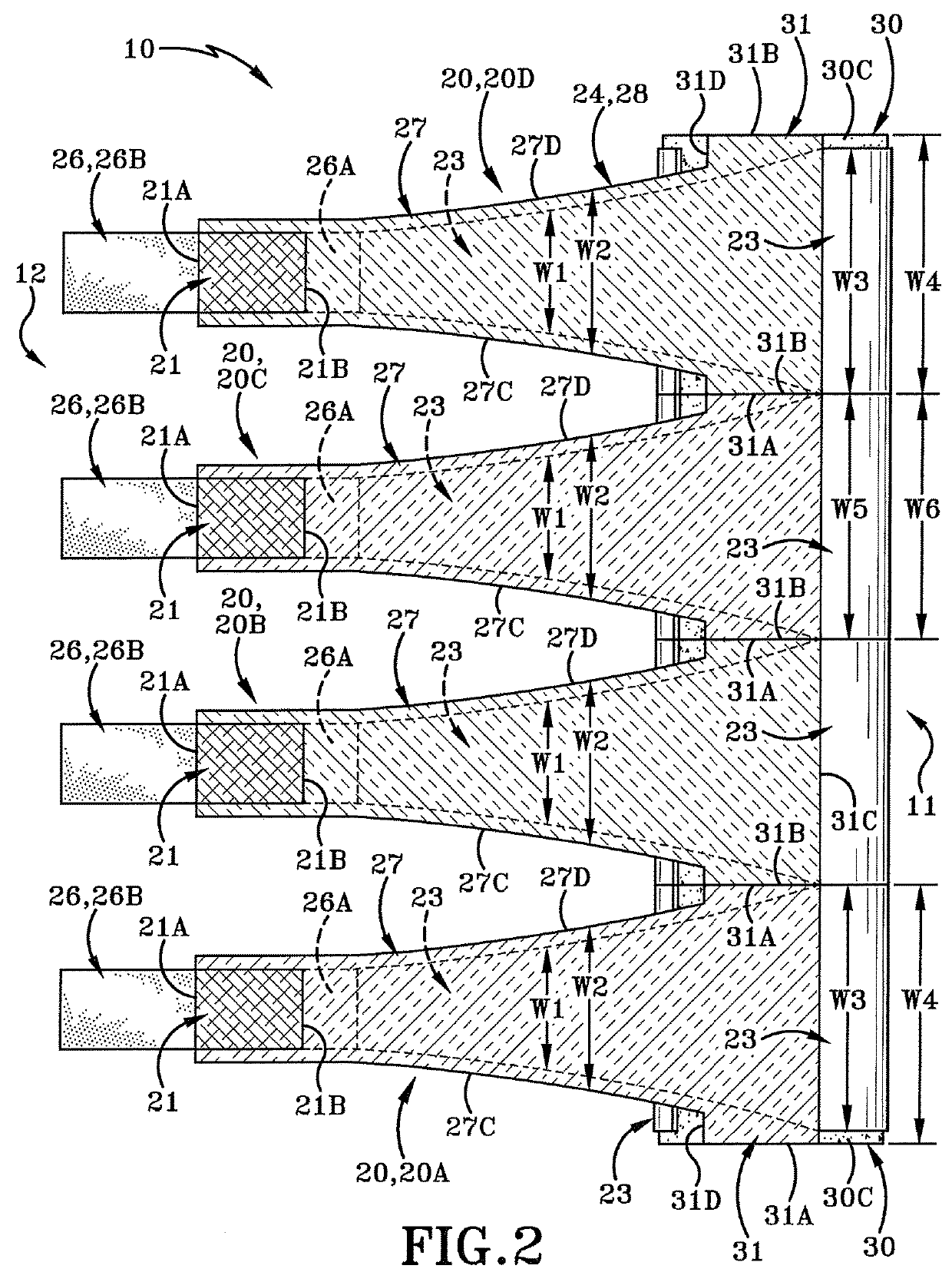

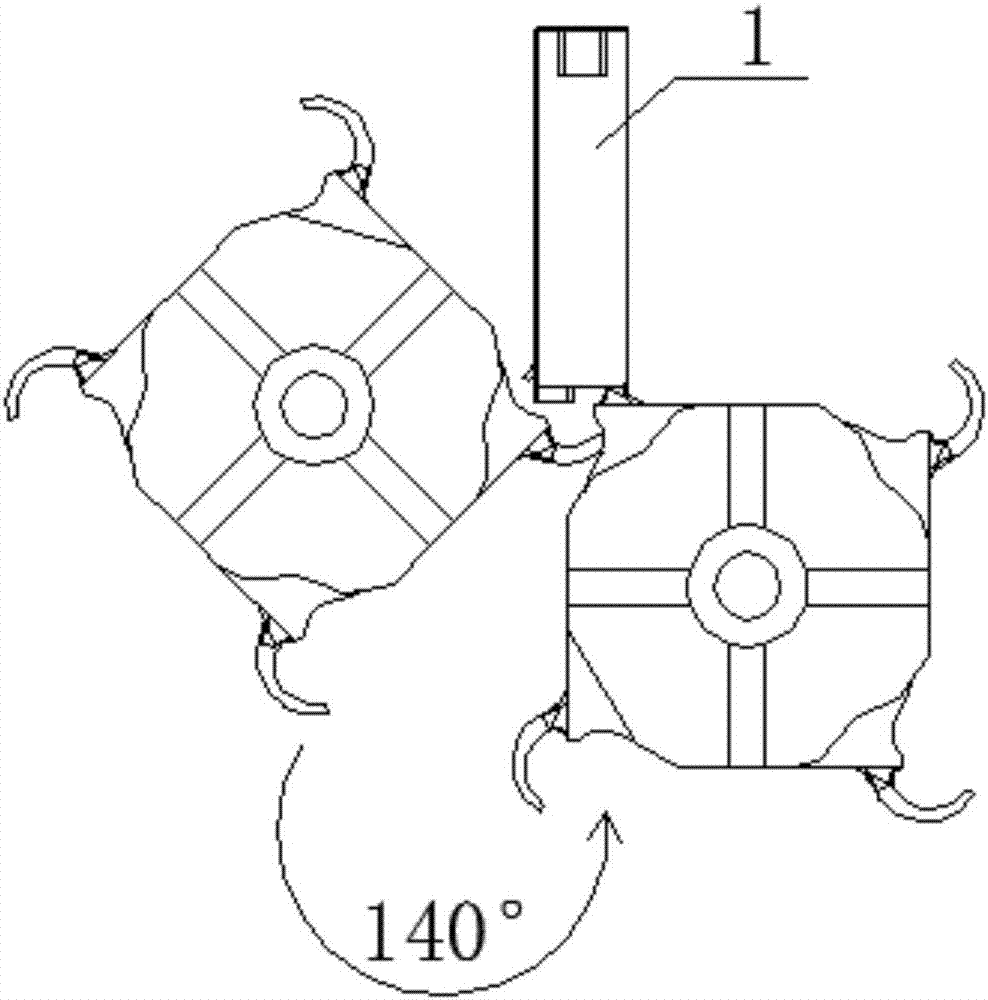

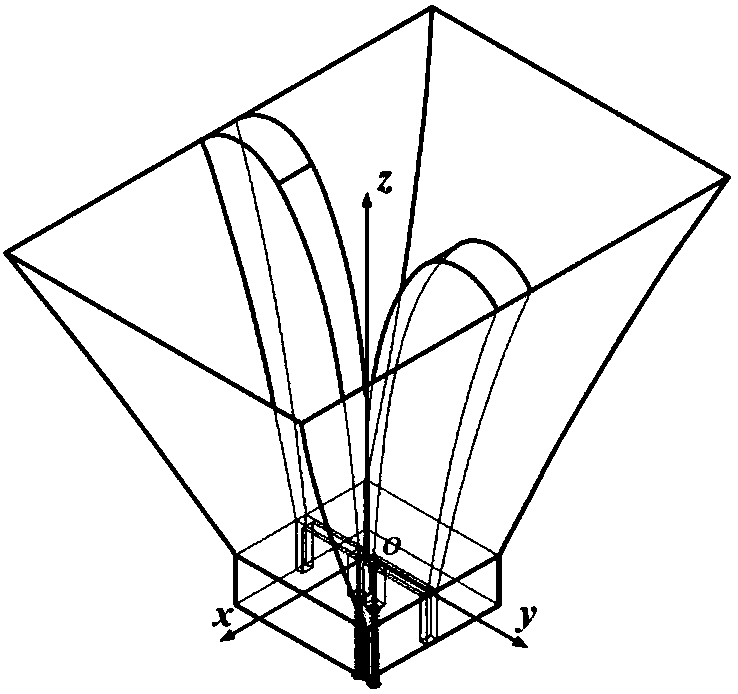

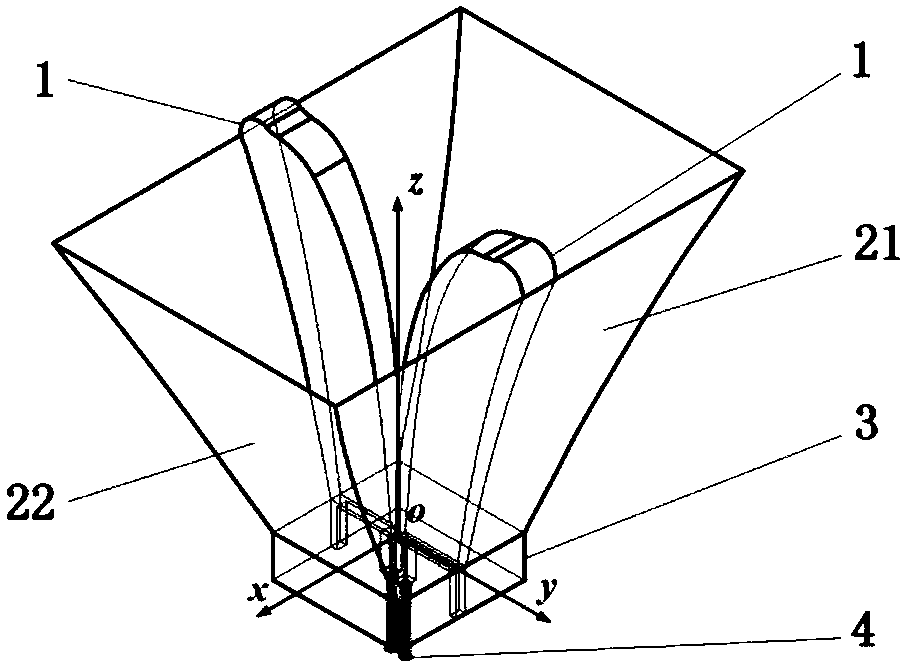

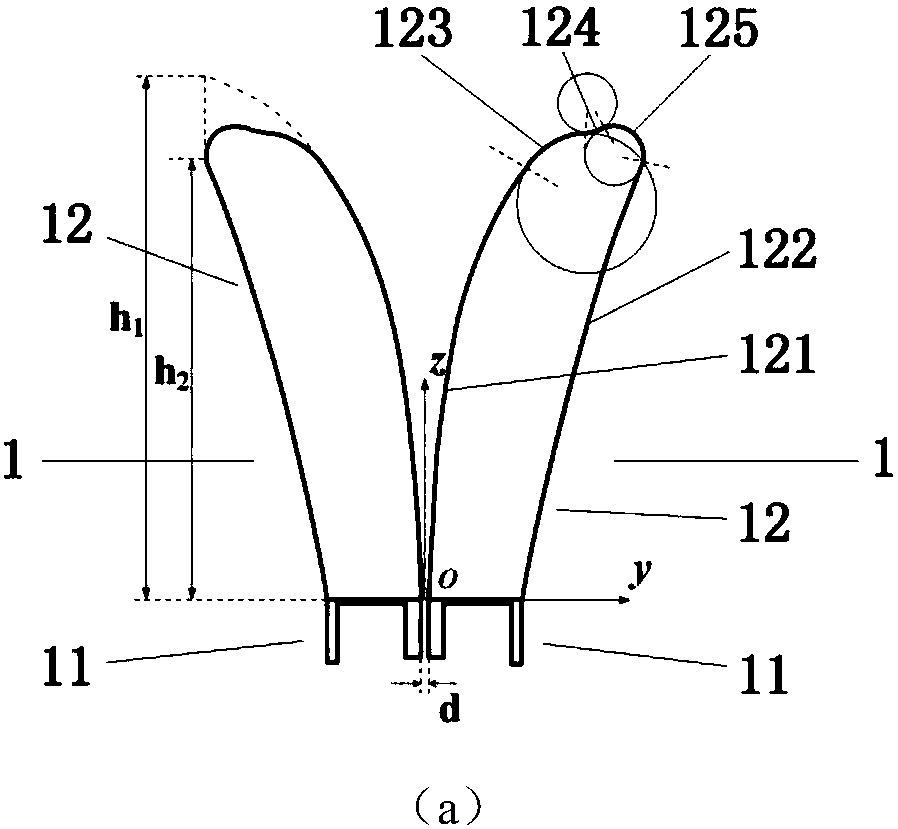

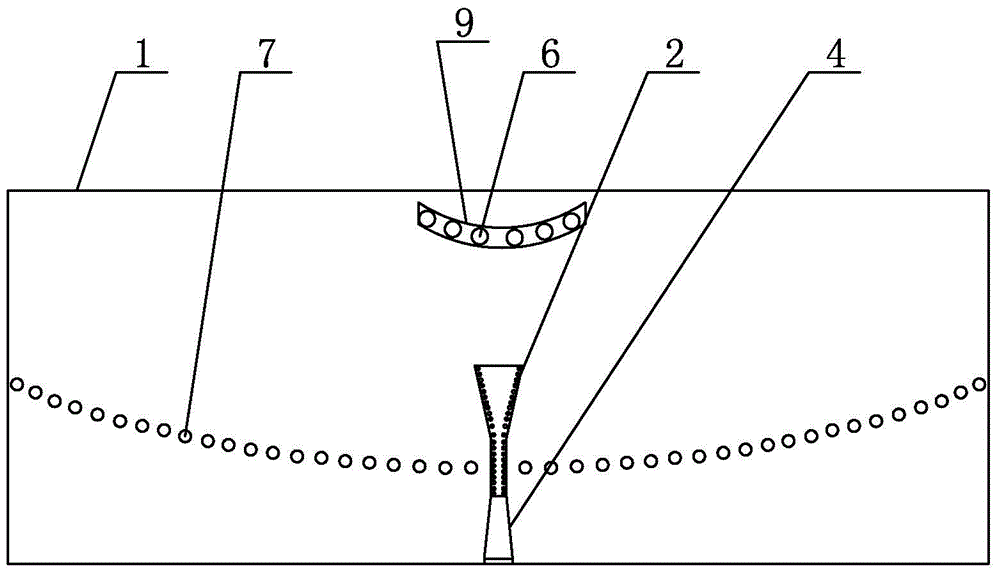

Transverse electromagnetic horn antenna having a curved surface

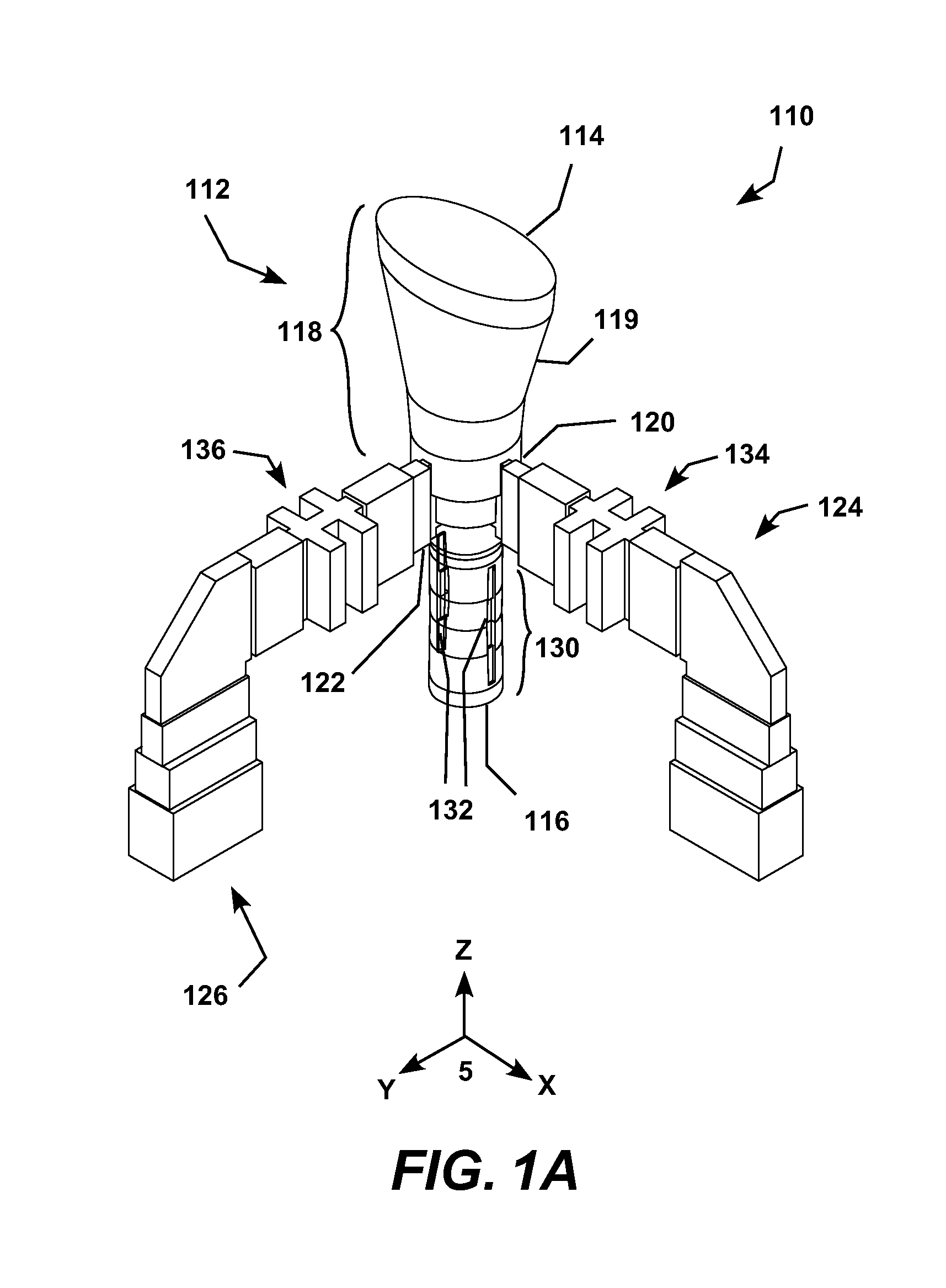

ActiveUS20180166786A1Increase forward lobeSuppresses back-lobe radiationWaveguide hornsIndividually energised antenna arraysRadar systemsHorn antenna

The current disclosure is directed to a radar system. More particularly, the current disclosure relates to a fabrication of aperture-matched array of TEM horn antenna system and use of the same. Specifically, the current disclosure is directed to a compact and lightweight impulse radiating TEM array antenna system with high forward-to-back lobe ratio. Furthermore, the current TEM horn antenna system shows radiation efficiency close to 1 at the frequency bands between 150 and 250 MHz. More particularly, the current disclosure provides transverse electromagnetic (TEM) horn antenna including a curved surface extending arcuately at least 180° degrees from an antenna aperture opening defined at a signal-receiving forward end of a horn structure, wherein the curved surface is adapted to suppress large back-lobe properties.

Owner:BAE SYST INFORMATION & ELECTRONICS SYST INTERGRATION INC

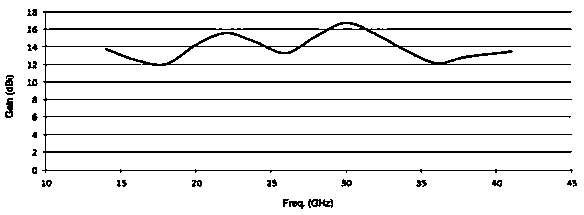

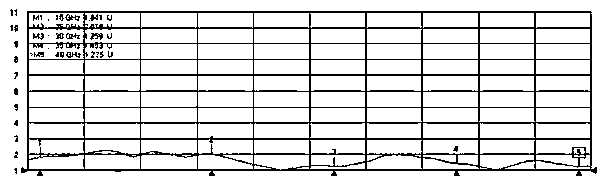

High-gain broadband horn antenna

PendingCN109509982AImprove low frequency characteristicsSmall VSWRWaveguide hornsAntennas earthing switches associationBroadbandHorn antenna

The invention discloses a high-gain broadband horn antenna. The high-gain broadband horn antenna includes a square horn, a waveguide and a coaxial connector, wherein the square horn is connected withthe waveguide; the waveguide and the coaxial connector are detachably connected; the square horn includes a horn housing, an upper ridge and a lower ridge; the upper ridge and the lower ridge are arranged in the horn housing; the horn housing is a rectangular horn structure which is formed through mutual splicing of a pair of narrow-surface metal walls and a pair of wide-surface metal walls; the upper ridge and the lower ridge are arranged on the wide-surface metal walls; one end, of each of the upper ridge and the lower ridge, close to a feeding point, is an arc structure; one end, of each ofthe upper ridge and the lower ridge, close to the opening of the horn housing, is provided with a plurality of rippled grooves; and the waveguide is a rectangular waveguide structure with a cavity. For the high-gain broadband horn antenna, by setting a plurality of rectangular holes on the narrow-surface metal walls, the antenna can obtain better low frequency characteristic while no deviation occurs on a high frequency radiation directional diagram; and due to the curve structure of the ridge body of the high-gain broadband horn antenna, the standing-wave ratio of the antenna can be reduced,and better radiation effect can be obtained.

Owner:安徽站乾科技有限公司

Inverse horn loudspeakers

InactiveUS8094855B2Improve efficiencyEfficient couplingBending wave transducersSound producing devicesResonanceCombined use

In a low frequency transducer system a multi-compression chamber, inverse horn structure is employed in combination with a resonance-distortion filter chamber. The filter chamber effectively expands the effective enclosure volume at low frequencies and connected to one of the compression chambers filter parasitic resonances and distortion and allowing the system to more efficiently reproduce low frequencies while being able to use smaller diameter transducers and maintaining good system sensitivity. Compression chambers are organized for constant or continuous compression on a section-by-section basis throughout the inverse horn system.

Owner:CLEMENTS PHILIP R

Ventriloqual jamming using a towed transmission line

InactiveUS7154430B1Jamming signal efficientlyGuaranteed normal transmissionWave based measurement systemsAntenna adaptation in movable bodiesDielectricElectricity

Owner:THE BOEING CO

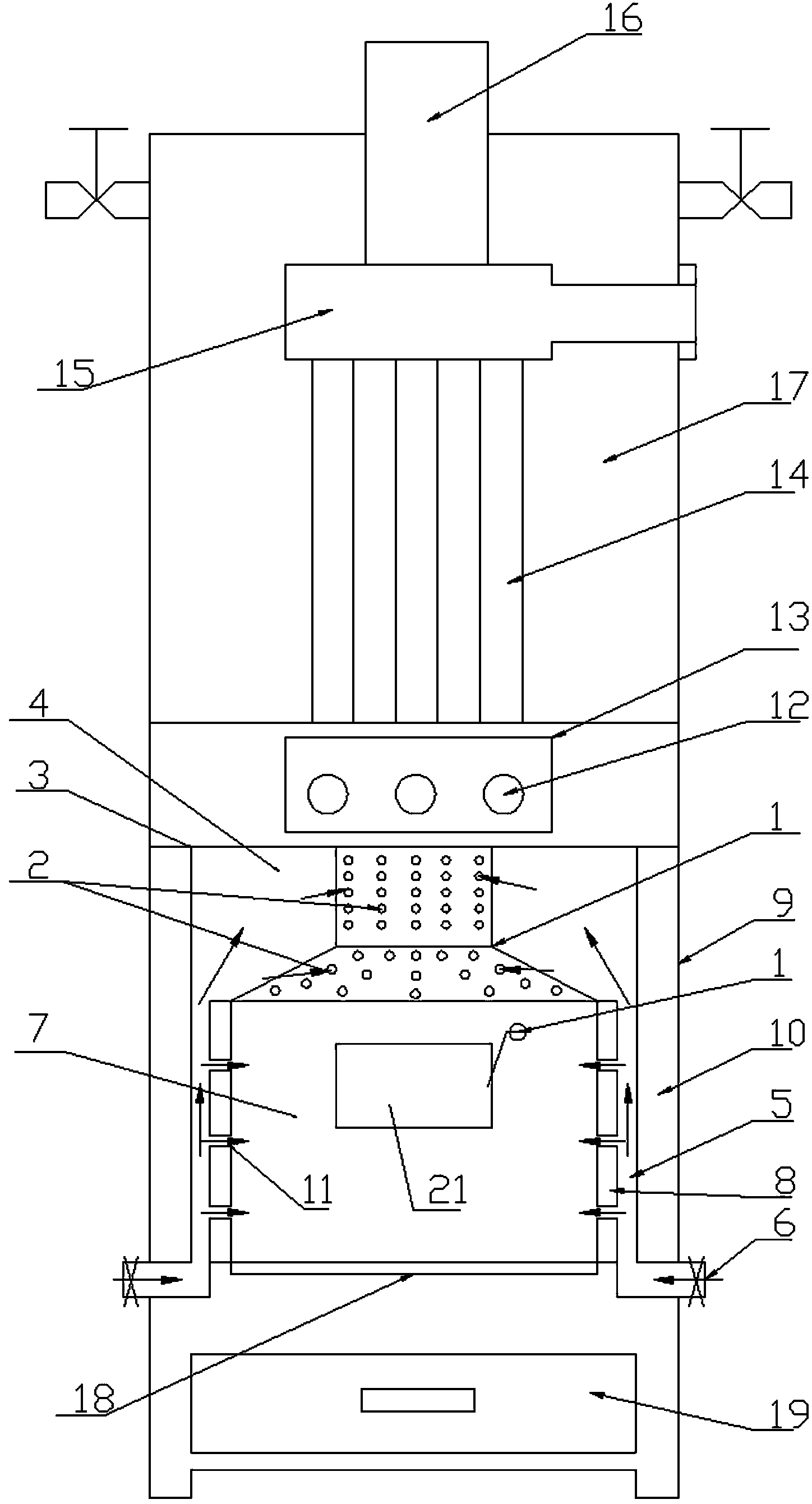

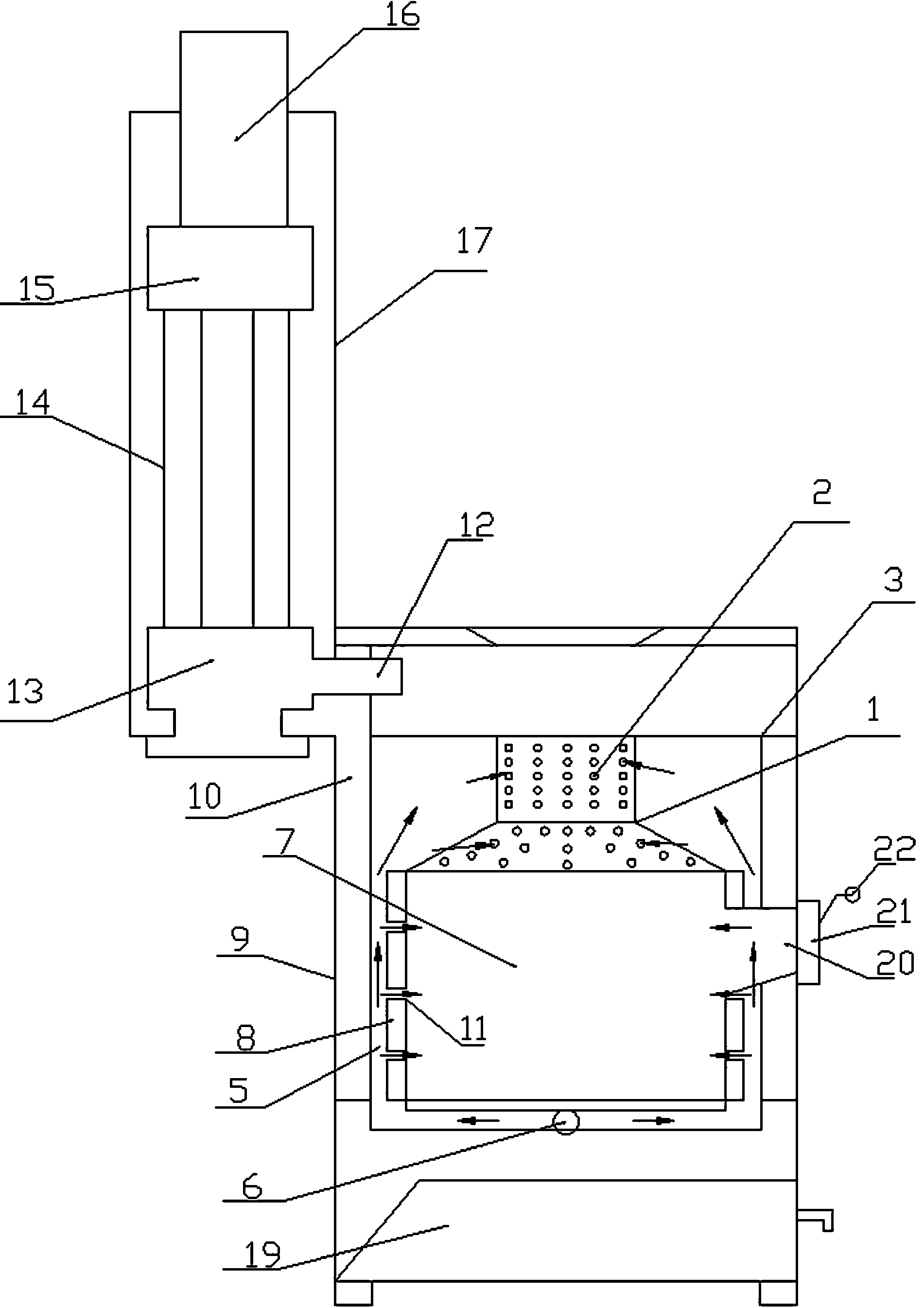

Marsh gas reactor with crusting resistance device

InactiveCN101724552AFully fermentedAccelerate emissionsGas production bioreactorsWaste based fuelSlagEngineering

The invention discloses a marsh gas reactor with a crusting resistance device, which comprises a fermenting tank, a sealing cover and a crusting resistance device, wherein the sealing cover covers the fermenting tank; a marsh gas outlet hole is arranged on the sealing cover; and the crusting resistance device comprises slag baffle plates and a gas collecting cover with a horn structure. The gas collecting cover is arranged on the inner wall of the fermenting tank, and the opening faces downwards. A gas through hole I is arranged on the gas collecting cover. The slag baffle plates are staggered and arranged on the periphery of the inner wall of the gas collecting cover, and form a certain included angle with the horizontal plane. As the gas collecting cover with the horn structure is arranged in the fermenting tank, and the slag baffle plates are staggered and arranged on the periphery of the inner wall of the gas collecting cover, and form a certain included angle with the horizontal plane, when the gas pressure in the fermenting tank is changed, the marsh gas liquid fluctuates up and down, the marsh gas slag is sheared by the slag baffle plates in a nonuniform way, is abraded and extruded by the slag baffle plates, and is prevented from further floating onto the liquid surface, and then the invention prevents the marsh gas slag from crusting on the liquid surface, and also can break the formed crust.

Owner:CHONGQING UNIV

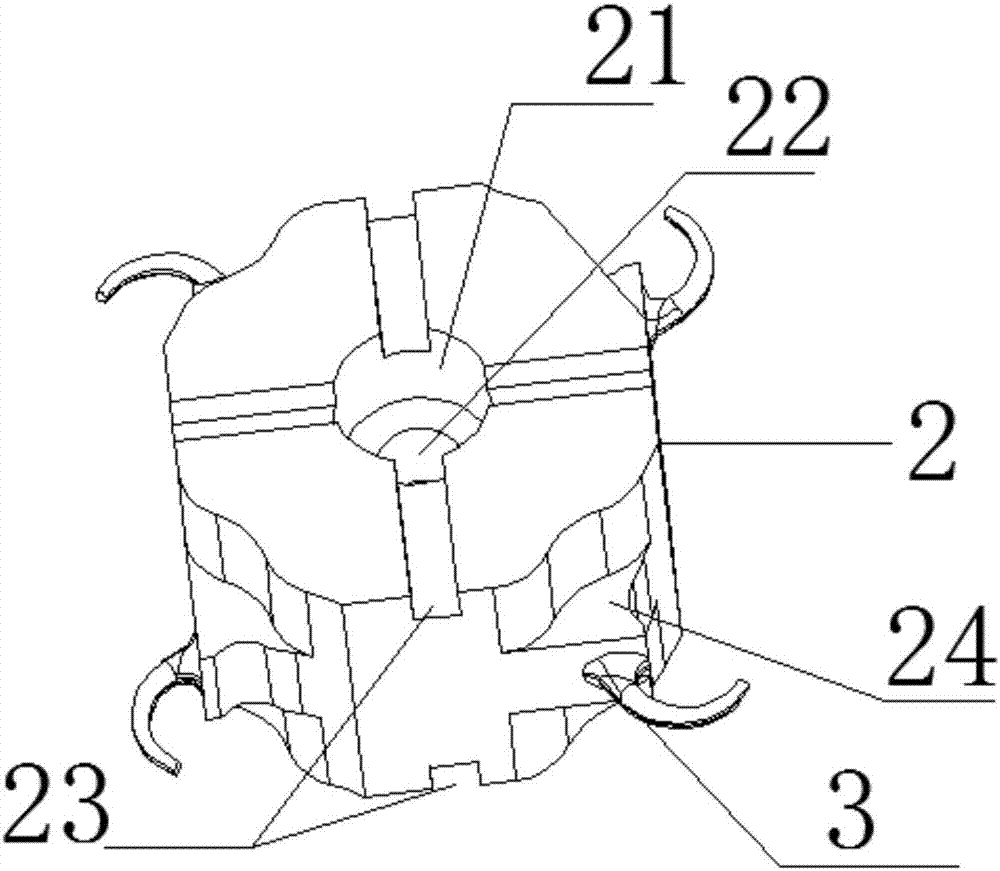

Integrated type ox-horn glue-hole electrode and design method thereof

ActiveCN107498123AAvoid mistakesPrecise positioningElectrical-based machining electrodesAgricultural engineeringHorn structure

The invention discloses an integrated type ox-horn glue-hole electrode. The integrated type ox-horn glue-hole electrode comprises an electrode body, an integrated type ox-horn structure, and further comprises a counter bore for clamping and positioning, a central through hole and a positioning groove, wherein the ox-horn structure can be one or more. The integrated type ox-horn glue-hole electrode is used for processing an integrated type ox-horn glue hole in a mould to replace a conventional two-section type mould ox-horn glue hole, so that surface quality of products is improved. A design method for the integrated type ox-horn electrode comprises the following steps of: designing a to-be-processed mould; designing ox-horn glue hole electrode blank; designing an ox-horn glue hole electrode hole; designing an electrode body of the ox-horn glue hole electrode; and designing an ox-horn structure. The design method utilizes a UG software to implement, and also can utilize the UG software to perform multi-time processing analogue simulation to optimize the processing method.

Owner:苏州沃思诺精密模具有限公司

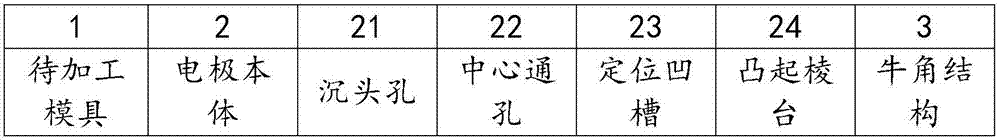

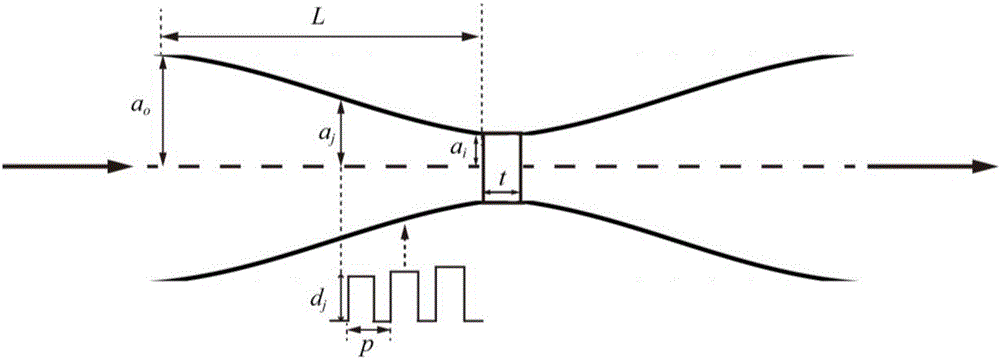

Gaussian beam filter with diagonal horn structure and implementation method thereof

ActiveCN107528106AHigh puritySolve the problem that is not idealWaveguide type devicesGaussian beamEngineering

The present invention discloses a Gaussian beam mode filter with a diagonal horn structure and an implementation method thereof. The Gaussian beam mode filter with the diagonal horn structure is designed on the basis of a characteristic that a corrugated horn can generate high-purity hybrid HE11 modes and the principle of antenna reciprocity; when undesired Gaussian beams radiated from an gyrotron output window pass through a first corrugated horn, only a single TE11 mode passes the first corrugated horn; the TE11 mode is subjected to mode conversion of a second corrugated horn, so that highly-pure mixed HE11 modes are generated; and the highly-pure mixed HE11 modes are finally fed into an overmoded waveguide transmission line. With the Gaussian beam mode filter with the diagonal horn structure and the implementation method thereof of the invention adopted, the problem of undesired Gaussian modes of quasi-optical transmission can be solved, the purity of Gaussian modes fed into the transmission line can be effectively improved, and therefore, the high-efficiency transmission of terahertz waves can be realized.

Owner:PEKING UNIV

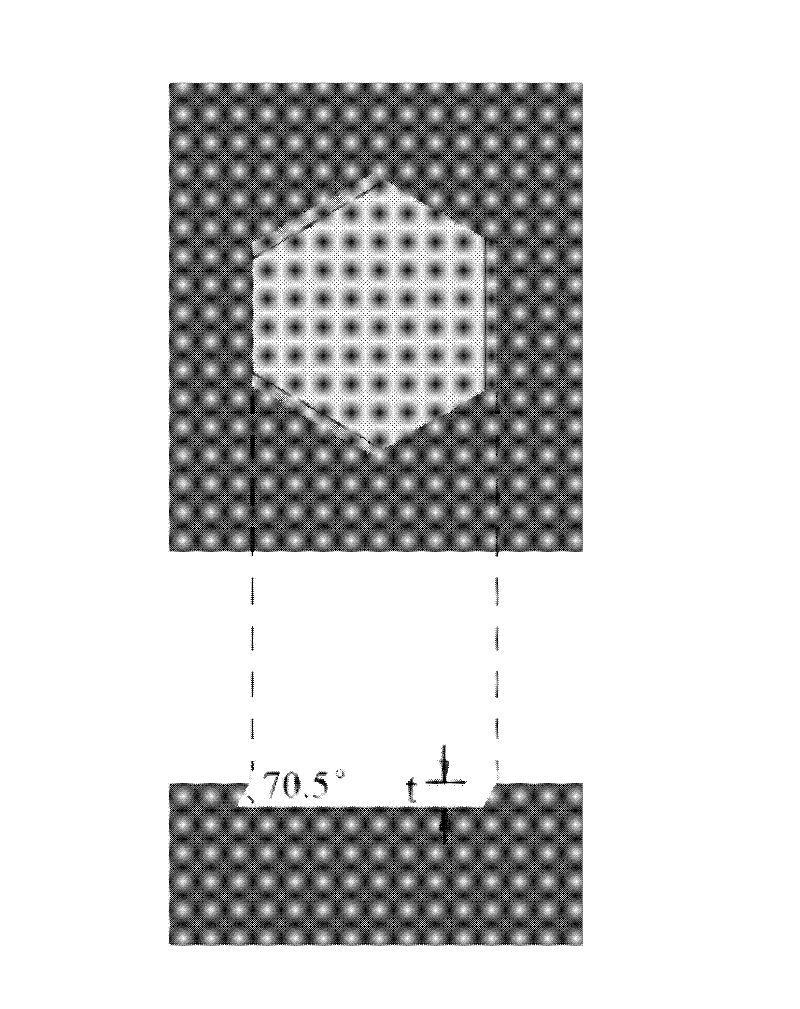

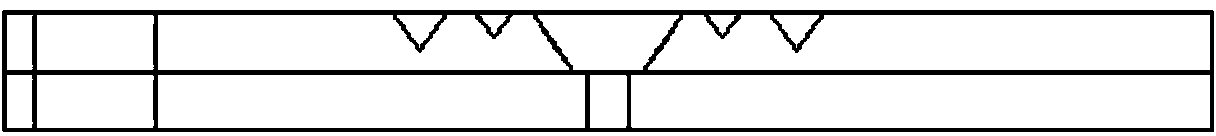

0.5THz corrugated horn antenna and preparation method using MEMS technology

InactiveCN103560326AHigh gainHigh precisionWaveguide hornsTelevision system detailsShortest distanceEngineering

The invention relates to a 0.5THz corrugated horn antenna and a preparation method using an MEMS technology. The 0.5THz corrugated horn antenna and the preparation method using the MEMS technology are applicable to a terahertz-band imaging system or a short-distance terahertz communication system. The 0.5THz corrugated horn antenna comprises an expanded horn, V-shaped corrugated grooves, locating grooves and a step on the throat portion of the horn, wherein compared with a waveguide, the horn can improve radiation efficiency and rotation symmetry of a directional diagram; the V-shaped corrugated grooves are used for cutting off a surface current, the gain is effectively increased, and influence of metal structures around the 0.5THz corrugated horn antenna on the performance of the 0.5THz corrugated horn antenna can be reduced; the locating grooves can ensure accurate alignment when installation butt joint of the 0.5THz corrugated horn antenna is carried out; due to the step on the throat portion of the horn, the design freedom of the structure of the horn can be remarkably improved, influence of the alignment error between an upper layer silicon chip and a lower layer silicon chip on the performance of the 0.5THz corrugated horn antenna can be reduced, and the processing yield is improved. According to the thinking design, the 0.5THz corrugated horn terahertz antenna designed and obtained through the thinking is good in applicability, an array can be easily formed, and fixation and testing can be easily carried out. The 0.5THz corrugated horn antenna works within the 450GHz-530GHz frequency band, a standing wave of the 0.5THz corrugated horn antenna is lower than 1.6, the in-band gain is larger than 15dB, and the maximum gain can reach 16.6dB.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Double-ridged horn antenna based on specially-shaped ridge loading

ActiveCN108063315ASuppression of diffraction effectsReduce back radiationWaveguide hornsAntennas earthing switches associationCoaxial lineHorn antenna

The invention provides a double-ridged horn antenna based on specially-shaped ridge loading. While the matching characteristics in the working frequency band of the double-ridged horn antenna are ensured, the gain radiation characteristics of the antenna are enhanced. The antenna comprises two oppositely-arranged specially-shaped ridge plates, a horn shell, a back cavity and two feed coaxial lines, wherein each specially-shaped ridge plate comprises a back cavity matching section and a specially-shaped transition section, and the ridge line of the specially-shaped transition section is formedby two exponential curve sections and three arc sections in smooth connection; the horn shell adopts a rectangular horn structure formed by a pair of curved surface metal walls and a pair of plane metal walls in a mutual splicing mode; the two specially-shaped ridge plates are loaded to different curved surface metal walls; the back cavity adopts a cuboid thin wall structure; and the shielding layer of the feed coaxial line is connected with the back cavity, and the inner core passes through the sealing end of the back cavity to be connected with the back cavity matching section. The double-ridged horn antenna based on specially-shaped ridge loading has an ultra wide working frequency band, and can be applied to fields such as communication, remote sensing and antenna measurement.

Owner:XIDIAN UNIV +1

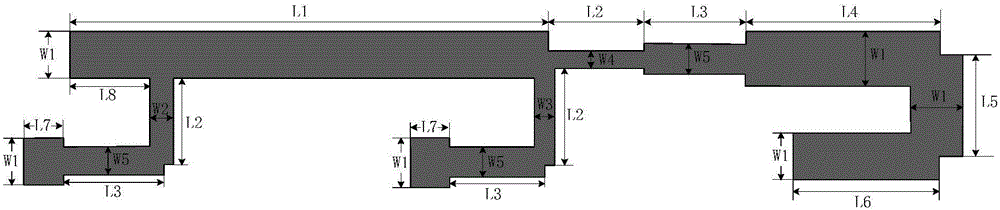

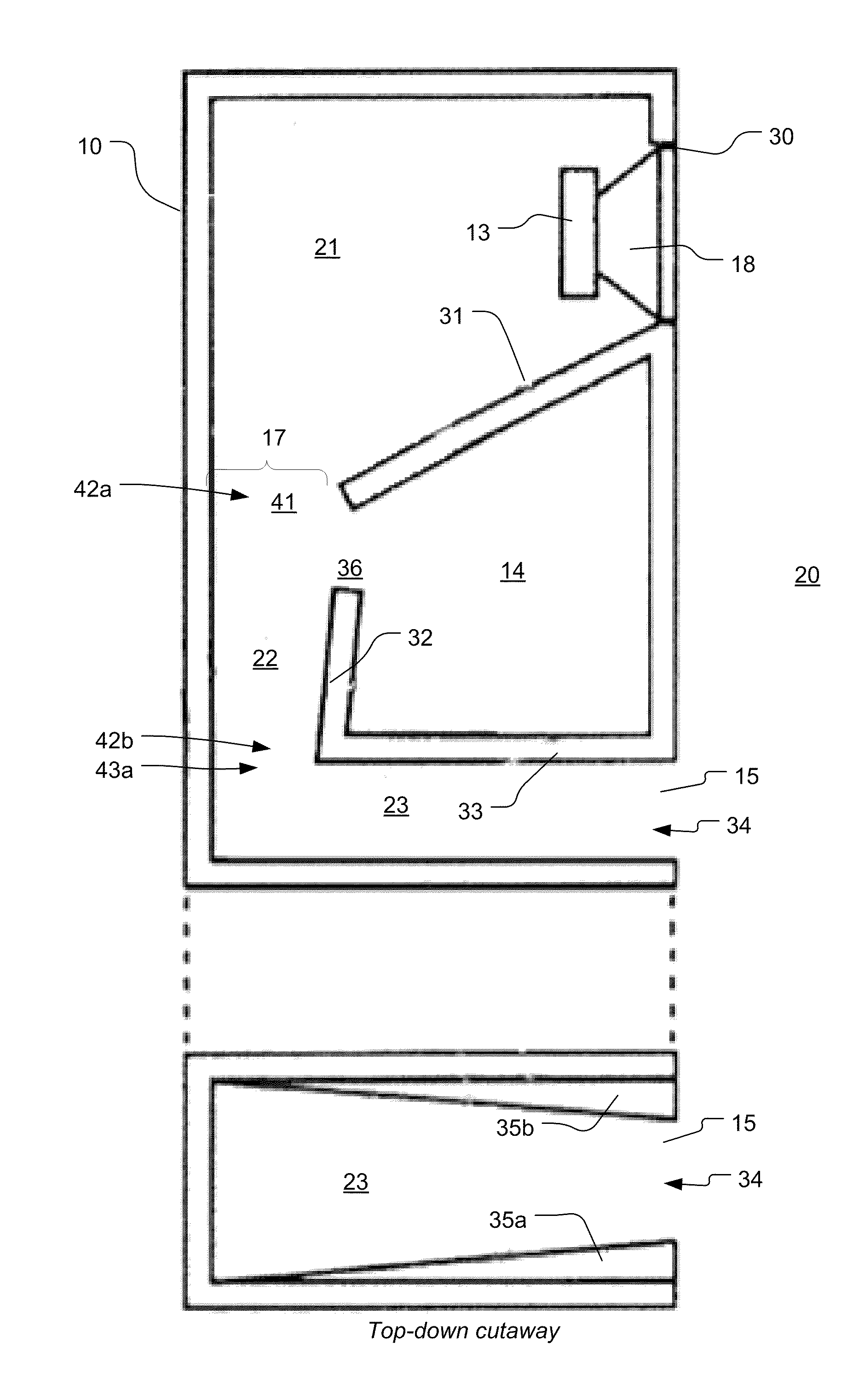

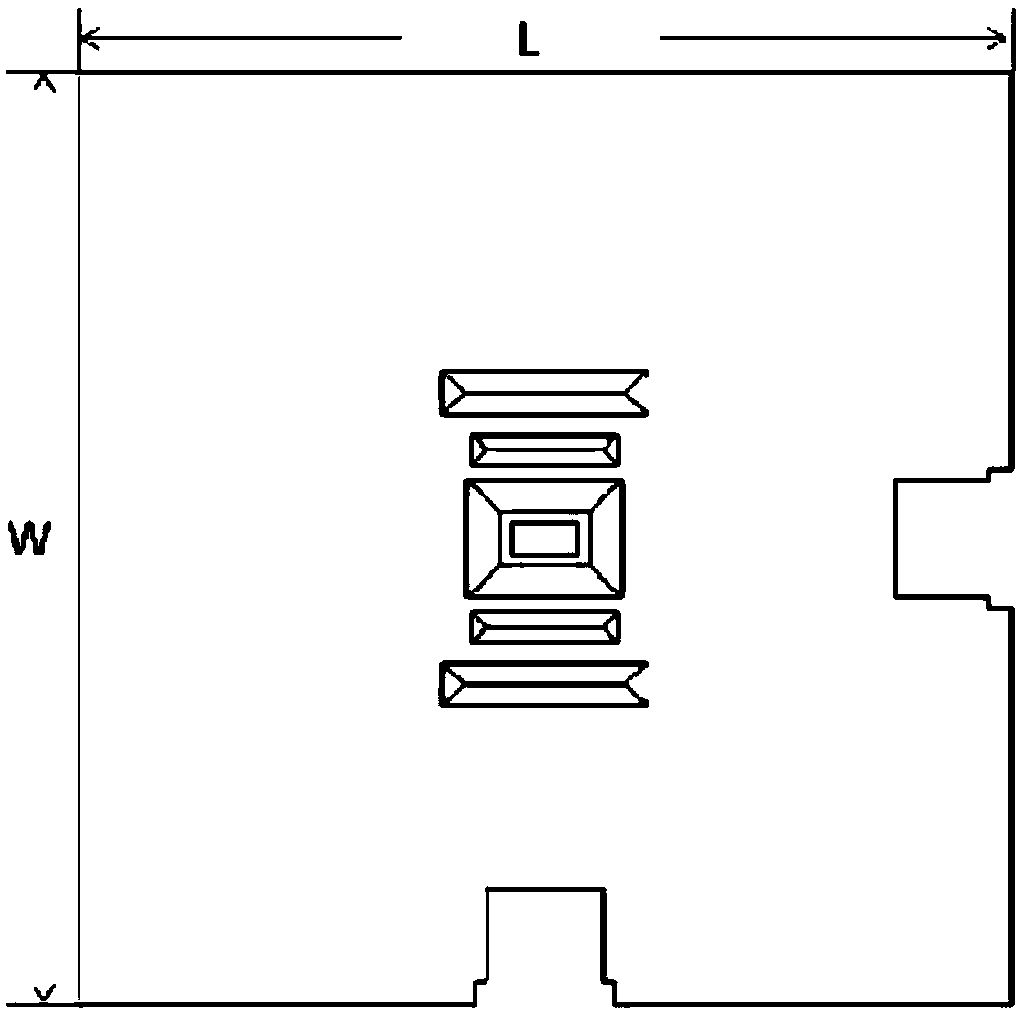

Substrate integrated waveguide-based loaded type Ka-band horn antenna

ActiveCN105071046ASmall reflection coefficientSmall sizeWaveguide hornsAntenna arraysDielectric substrateHorn antenna

The invention relates to a Ka-band horn antenna, in particular, a substrate integrated waveguide-based loaded type Ka-band horn antenna. The objective of the invention is to solve the problems of low gain and incapability of satisfying actual requirements of an existing Ka-band H-surface horn antenna. The substrate integrated waveguide-based loaded type Ka-band horn antenna of the invention comprises a dielectric substrate, a front-surface horn structure, a back-surface horn structure, a front-surface microstrip line and a back-surface microstrip line; the dielectric substrate is a rectangular plate body; the front surface and back surface of the dielectric substrate are respectively printed with an upper metal layer and a lower metal layer; the front-surface horn structure is arranged at the middle lower part of the front surface of the dielectric substrate; the center line of the front-surface horn structure along the length direction of the front-surface horn structure is vertical to the center line of the dielectric substrate along the length direction of the dielectric substrate; and the lower end of the front-surface horn structure is connected with the lower long edge of the front surface of the dielectric substrate through the front-surface microstrip line. The antenna of the invention is applied to the wireless communication field.

Owner:HARBIN INST OF TECH

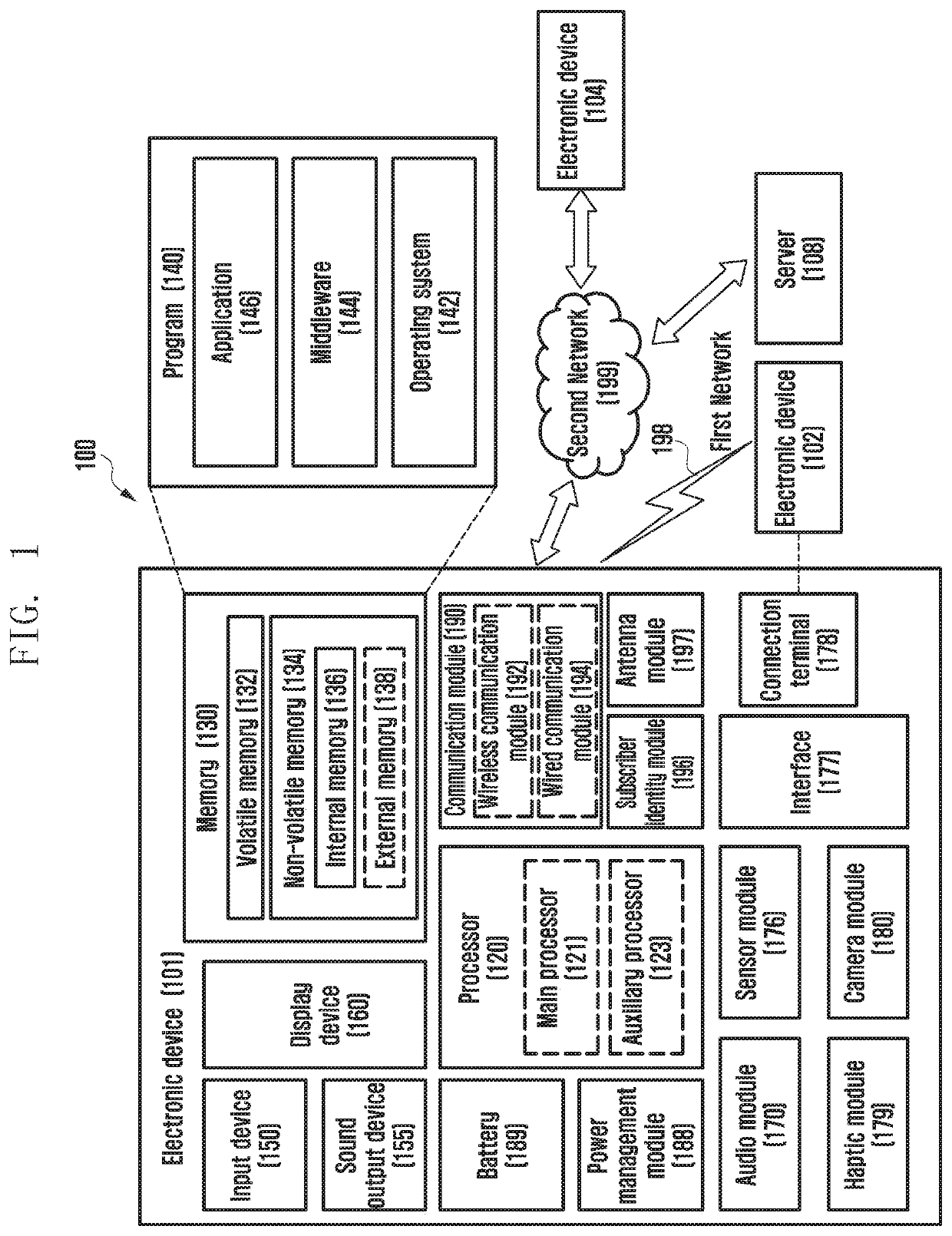

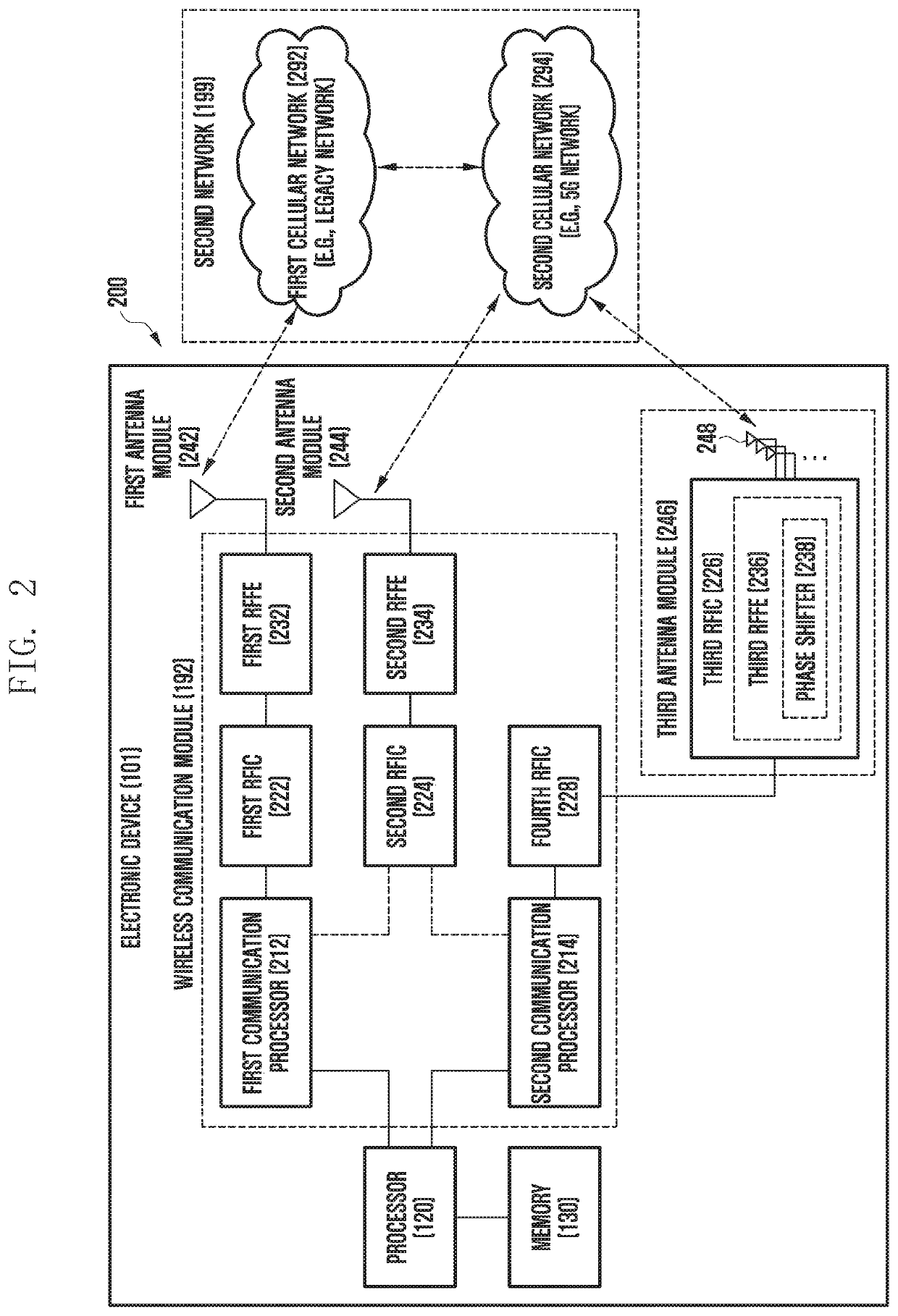

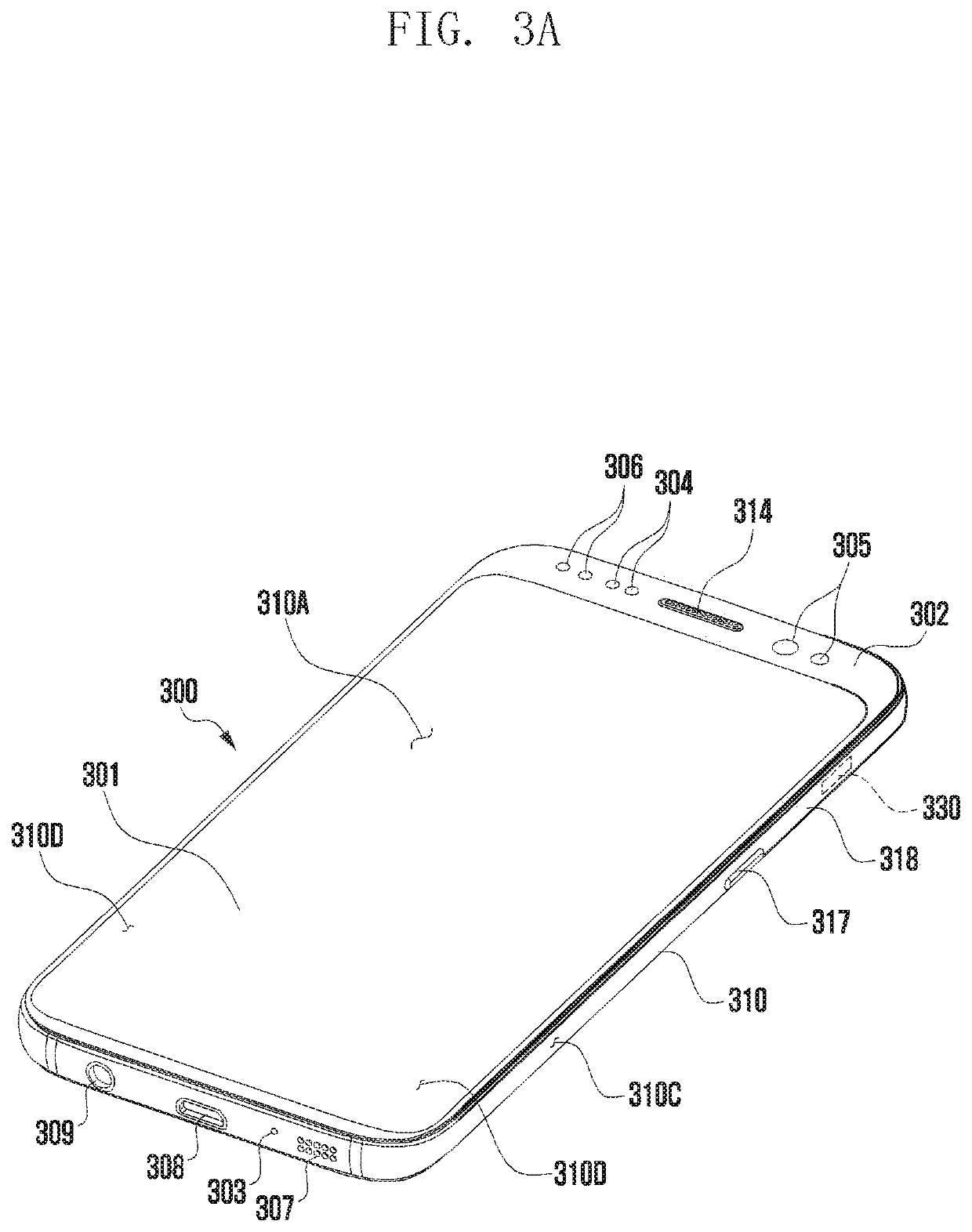

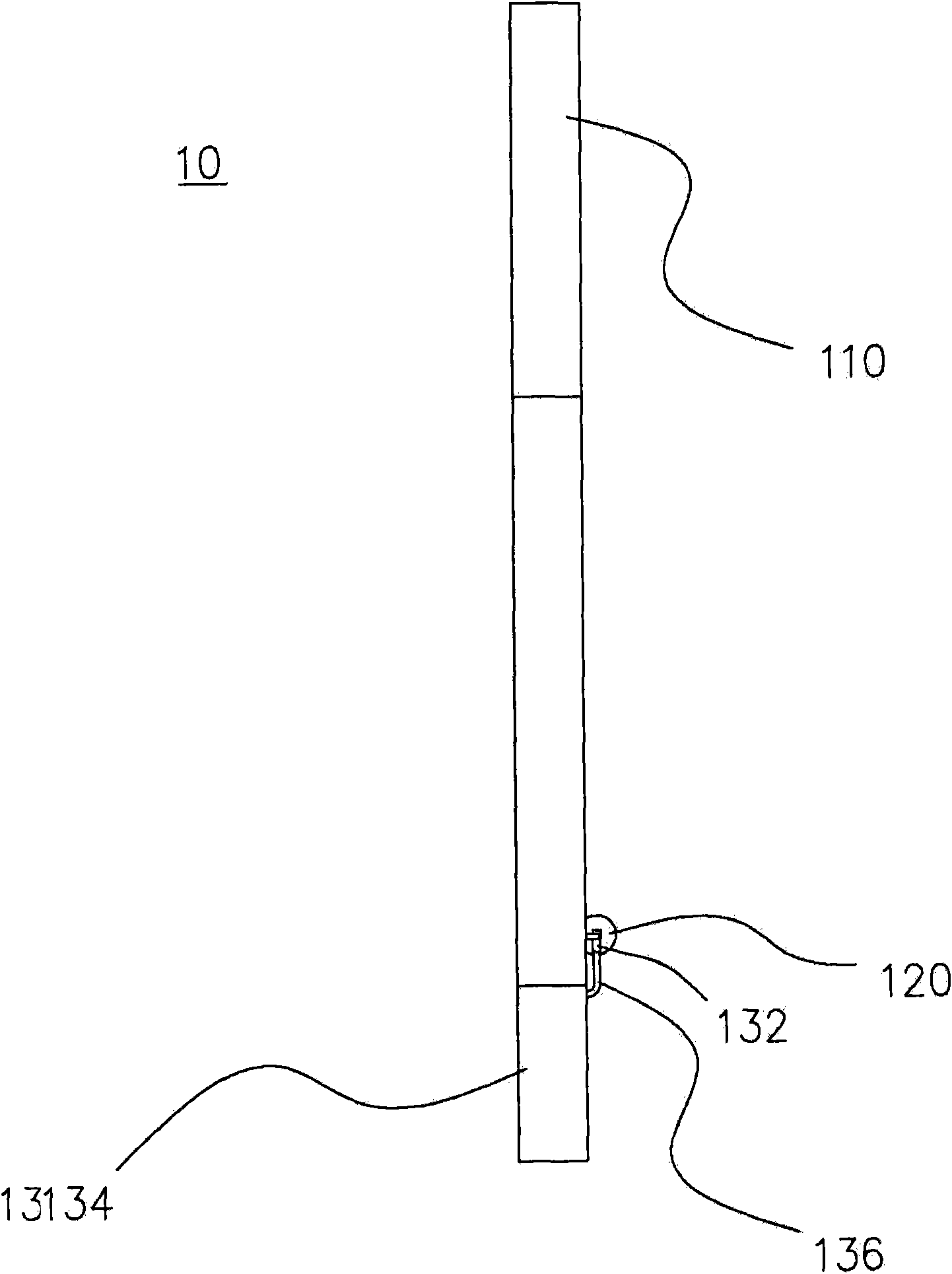

Antenna using horn structure and electronic device including the same

An electronic device in provided, including an antenna using a horn structure capable of using at least a portion of a metal member as a signal waveguide structure of the antenna. The device includes a housing, a display, a printed circuit board, and at least one wireless communication circuit, where a waveguide hole is provided to connect at least a portion of a through hole and an electronic component and is used as an operating channel of the electronic component together with the waveguide hole.

Owner:SAMSUNG ELECTRONICS CO LTD

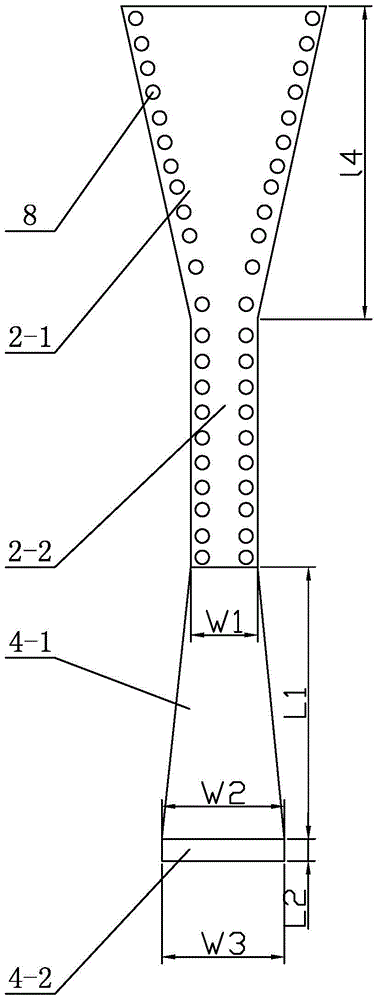

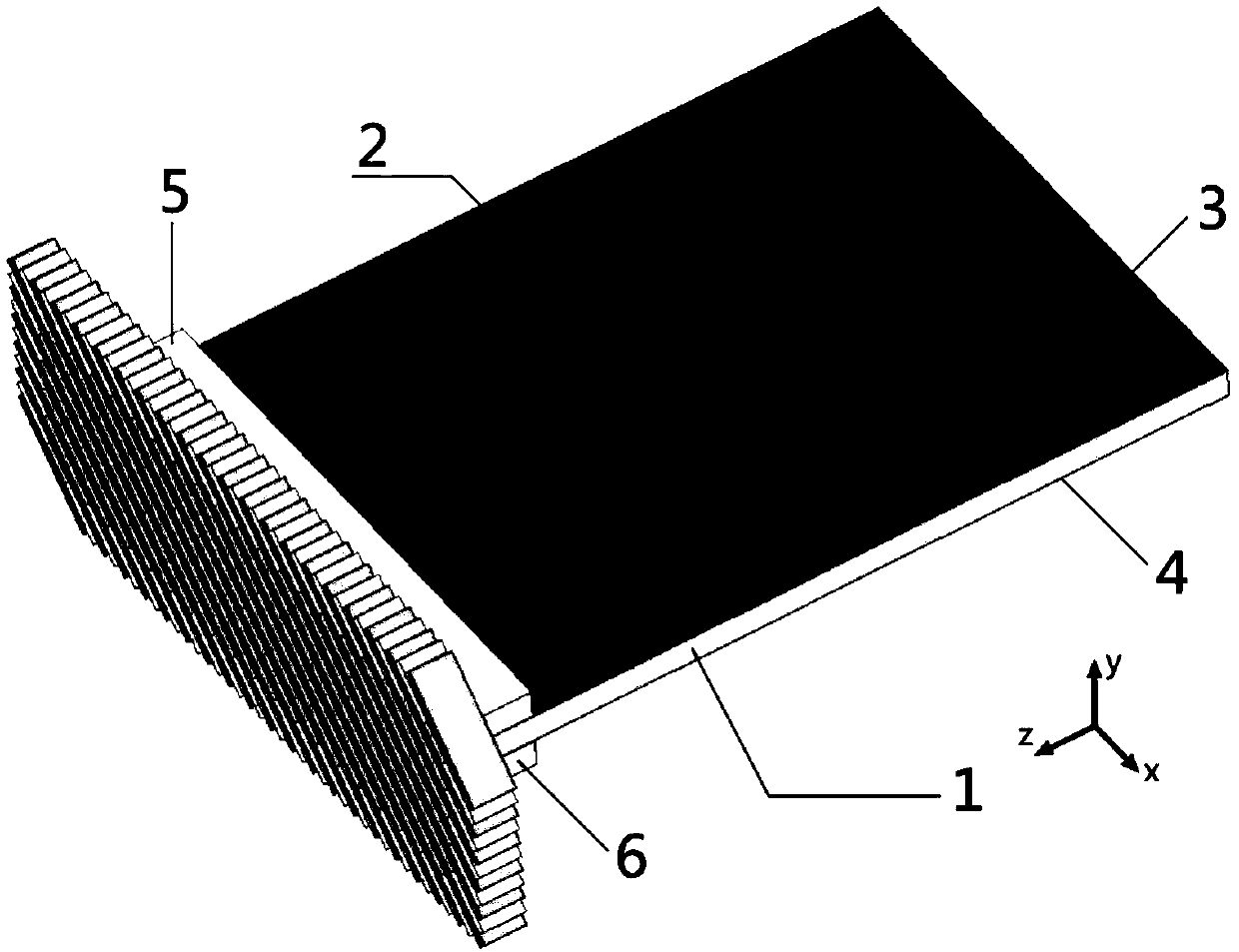

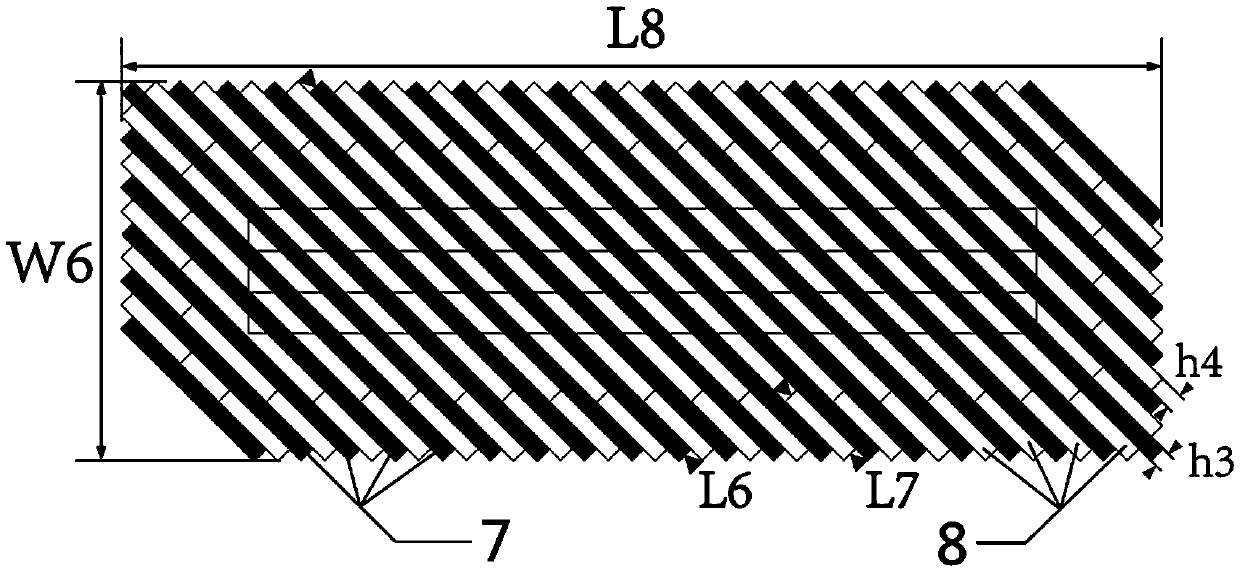

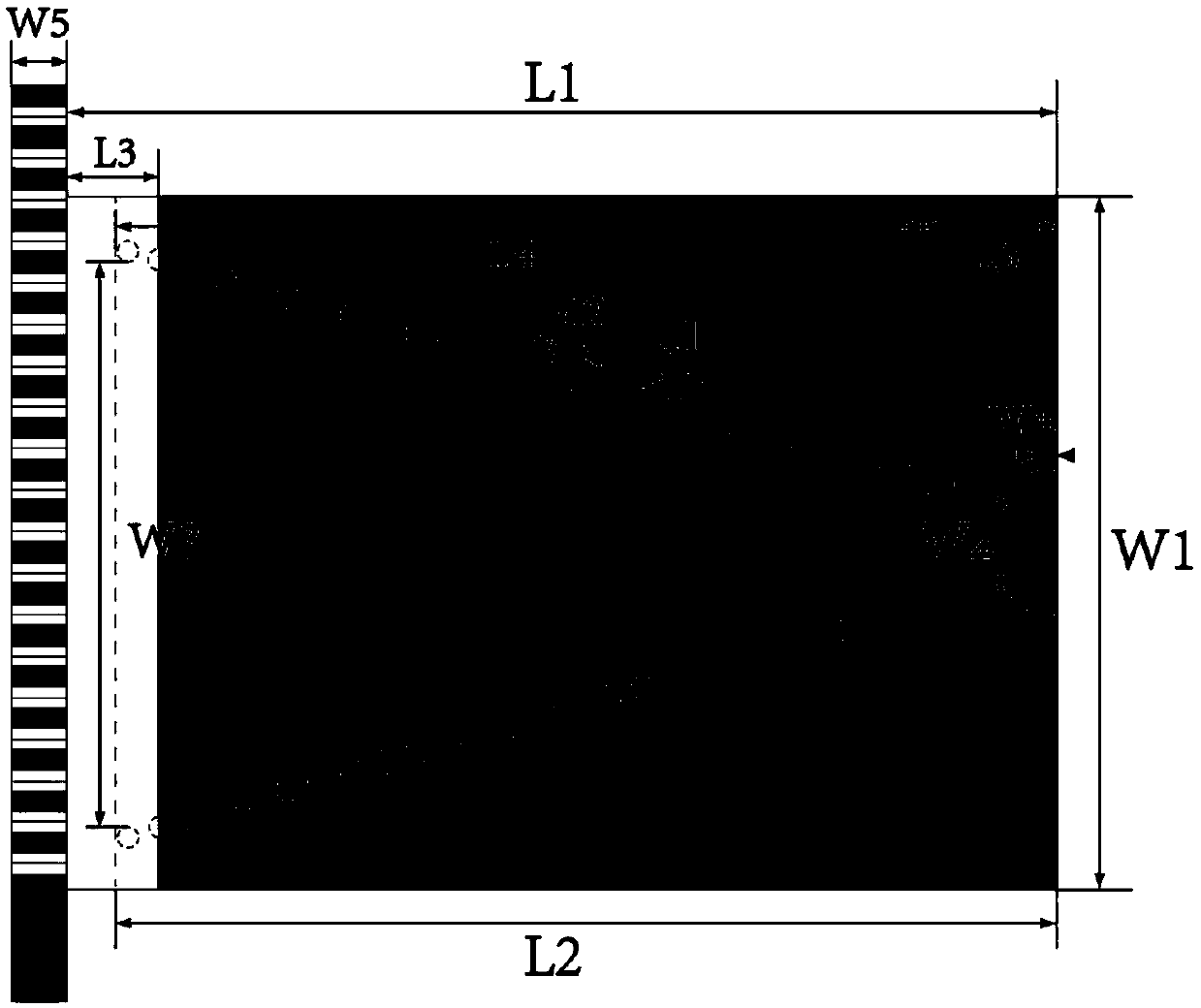

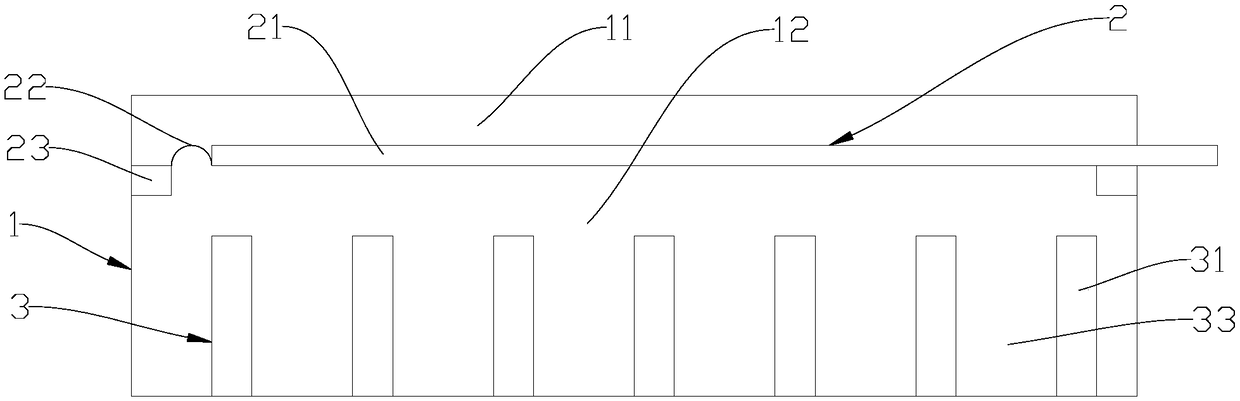

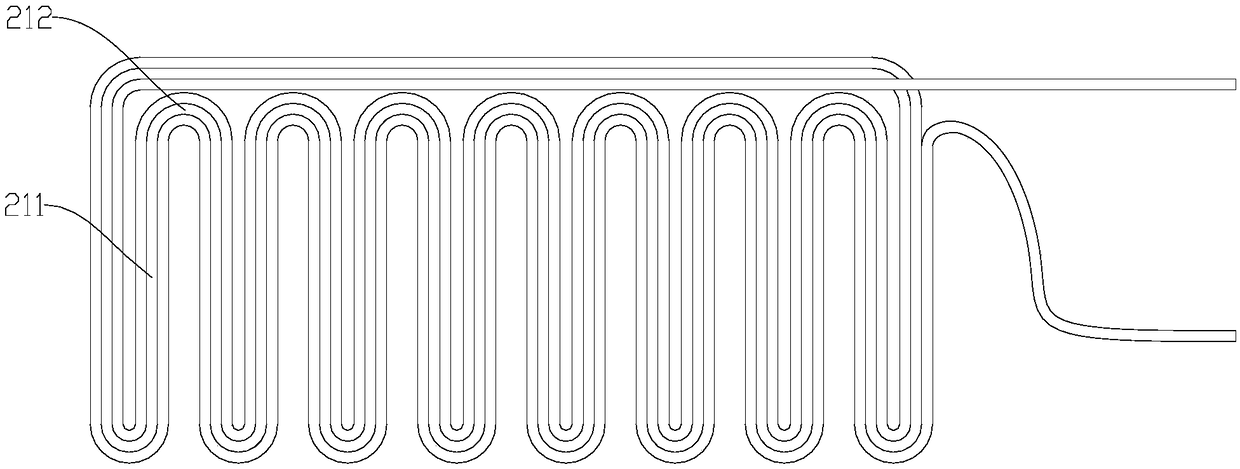

Millimeter wave broadband circularly polarized antenna based on substrate-integrated waveguide horn

ActiveCN109560388AReduce lossEasy to integrateWaveguide hornsRadiating elements structural formsCircularly polarized radiationWaveguide

The invention discloses a millimeter wave broadband circular polarized antenna based on a substrate-integrated waveguide horn, and aims to solve the problem of difficulty in realizing broadband circularly polarization in an existing substrate-integrated waveguide horn antenna. The millimeter wave broadband circularly polarized antenna comprises a dielectric plate (1), an upper metal layer (3), a lower metal layer (4), an upper dielectric block (5), a lower dielectric block (6), a polarized converter (7) and a polarized converter support structure (8), wherein the upper metal layer and the lower metal layer are located on an upper surface and a lower surface of the dielectric plate respectively; the dielectric plate is provided with a metallized through hole array (2) with gradually-varyinggaps in order to construct a feed-horn structure; the upper dielectric block and the lower dielectric block are arranged above and below a horn radiation aperture respectively to realize broadband impedance matching; and the polarized converter and the support structure thereof are located at the edge of the horn radiation aperture to realize stable broadband circularly polarized radiation. The millimeter wave broadband circular polarized antenna has the advantage of circularly polarized radiation with stable broadband under the millimeter wave frequency, and is suitable for a broadband millimeter wave wireless communication system.

Owner:XIDIAN UNIV

Loudspeaker structure

PendingCN109362004ASimple structureReduce thicknessElectrical transducersLoudspeakersAlternating currentLoudspeaker

The invention relates to a loudspeaker structure comprising a shell that comprises a front cavity and a rear cavity; a vibration component is arranged on at least one side of two opposite sides of thefront cavity; the vibration component comprises a membrane arranged in the front cavity and a permanent magnet array arranged in the rear cavity; the permanent magnet array comprises multiple first permanent magnets arranged at intervals, the polarities of each two adjacent first permanents are opposite and arranged in a staggered manner, and a driving space is formed between each two adjacent first permanents; the membrane comprises a FPC board provided with a driving circuit, the driving circuit and the driving space are correspondingly arranged, and the current directions of the two adjacent driving circuits are opposite. After alternating current is input into the loudspeaker structure, the FPC board vibrates up and down under the magnetic field effect of the permanent magnet array, so that air vibration is caused, and sound is generated; the structure is simple; only the shell, the permanent magnet array and the membrane are needed; the processing technology is simple, and meanwhile the thickness of the loudspeaker also can be reduced.

Owner:CHANGZHOU AMT

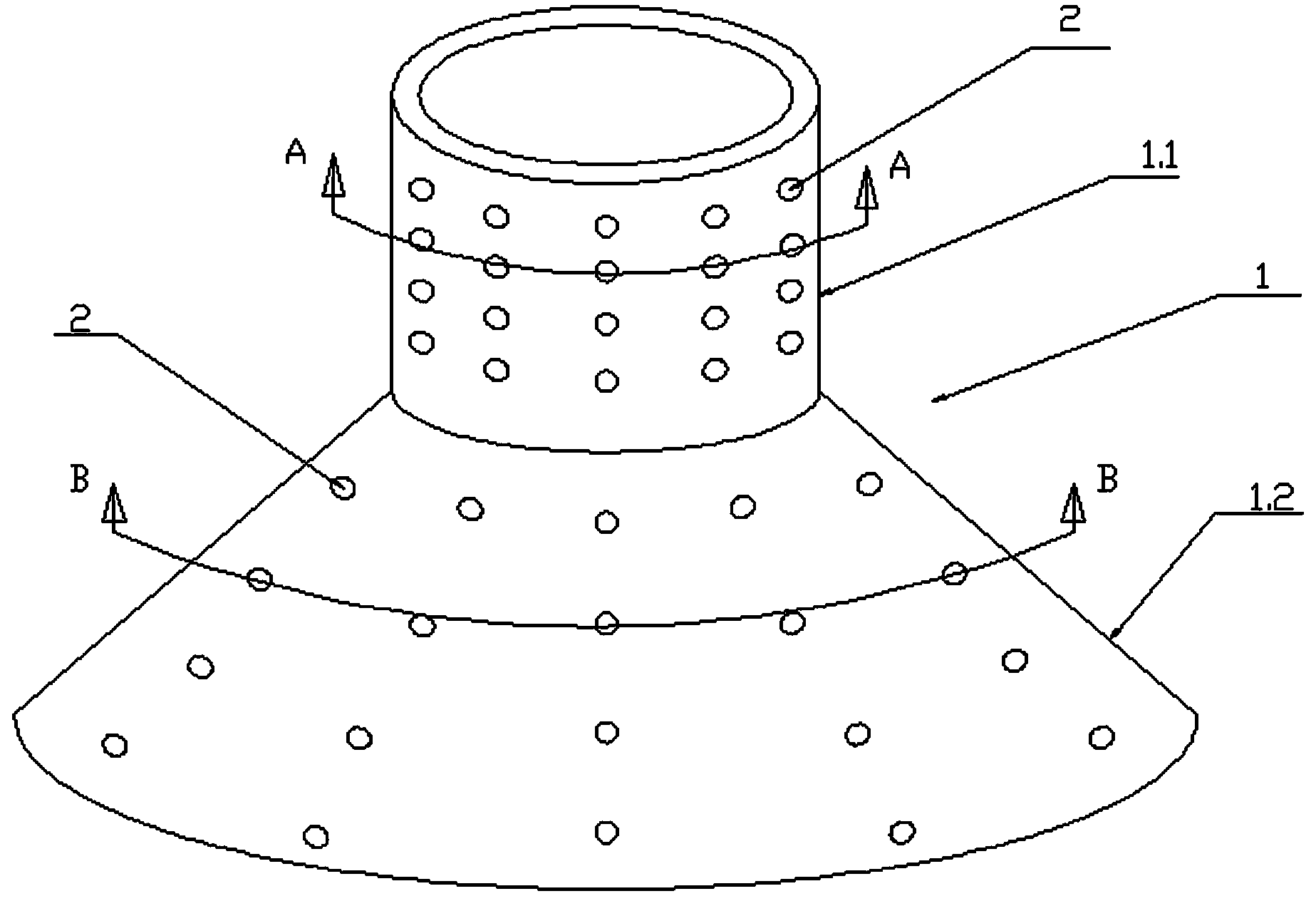

Novel gasification combustion device

InactiveCN104180364AIncrease profitEfficient use ofSolid fuel combustionCombustion apparatusCombustionHorn structure

The invention provides a novel gasification combustion device which comprises a gasification barrel. The surface of the gasification barrel is provided with gasification holes enabling a rotary air flow to be formed in the gasification barrel. The gasification barrel comprises a first part and a second part. The first part is of a straight barrel structure. The second part is of a big-end-down horn structure. The top end of the second part is connected with the first part. The gasification holes are evenly formed in the first part and the second part. The air outlet direction of the gasification holes in the first part is opposite to or the same as the air outlet direction of the gasification holes in the second part. The novel gasification combustion device has the advantages that the structure is simple, manufacturing is convenient, the manufacturing cost is low, the gasification effect is good, heat is centralized, and the energy utilization rate is improved by 15% to 30%.

Owner:徐万友

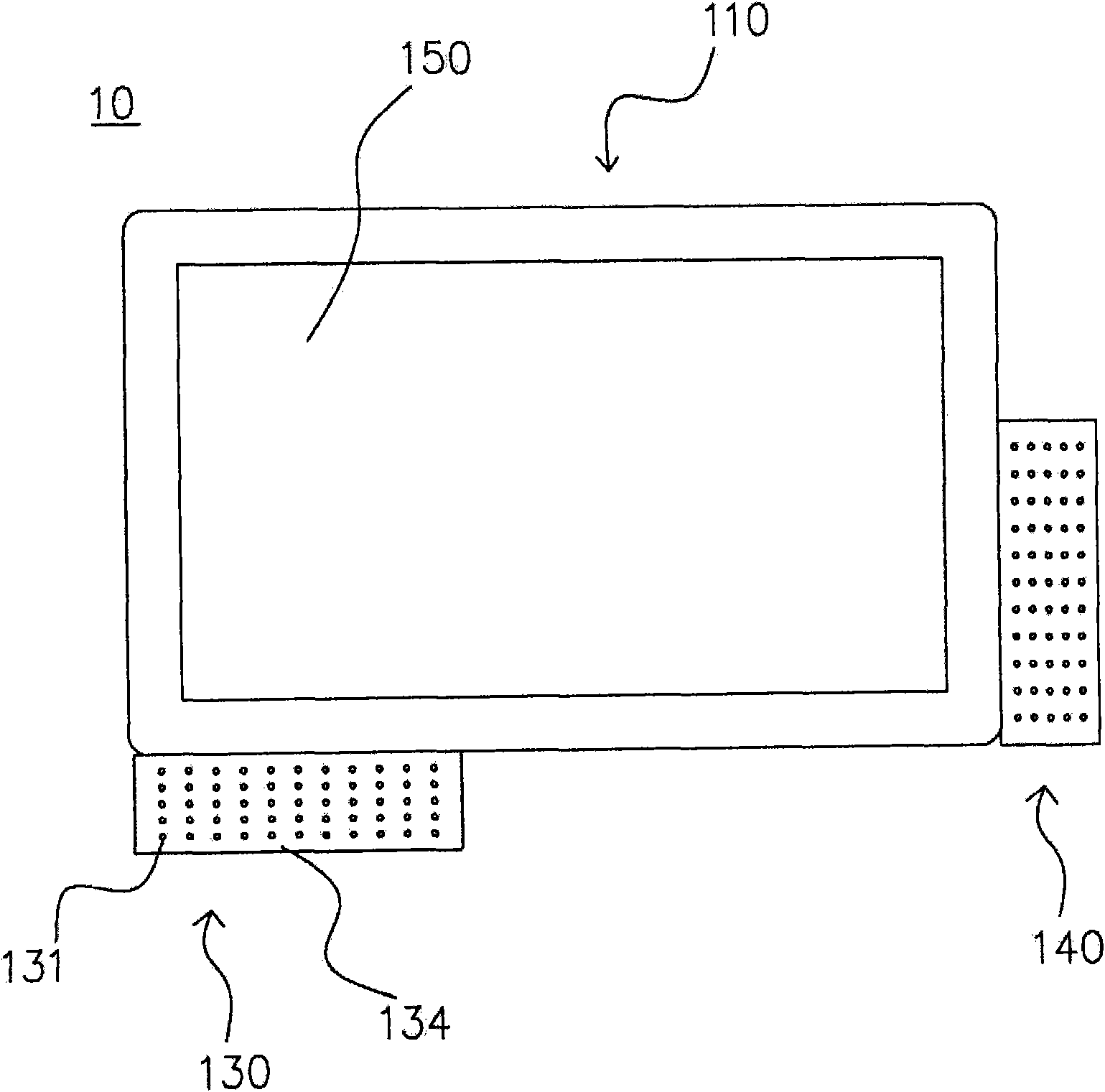

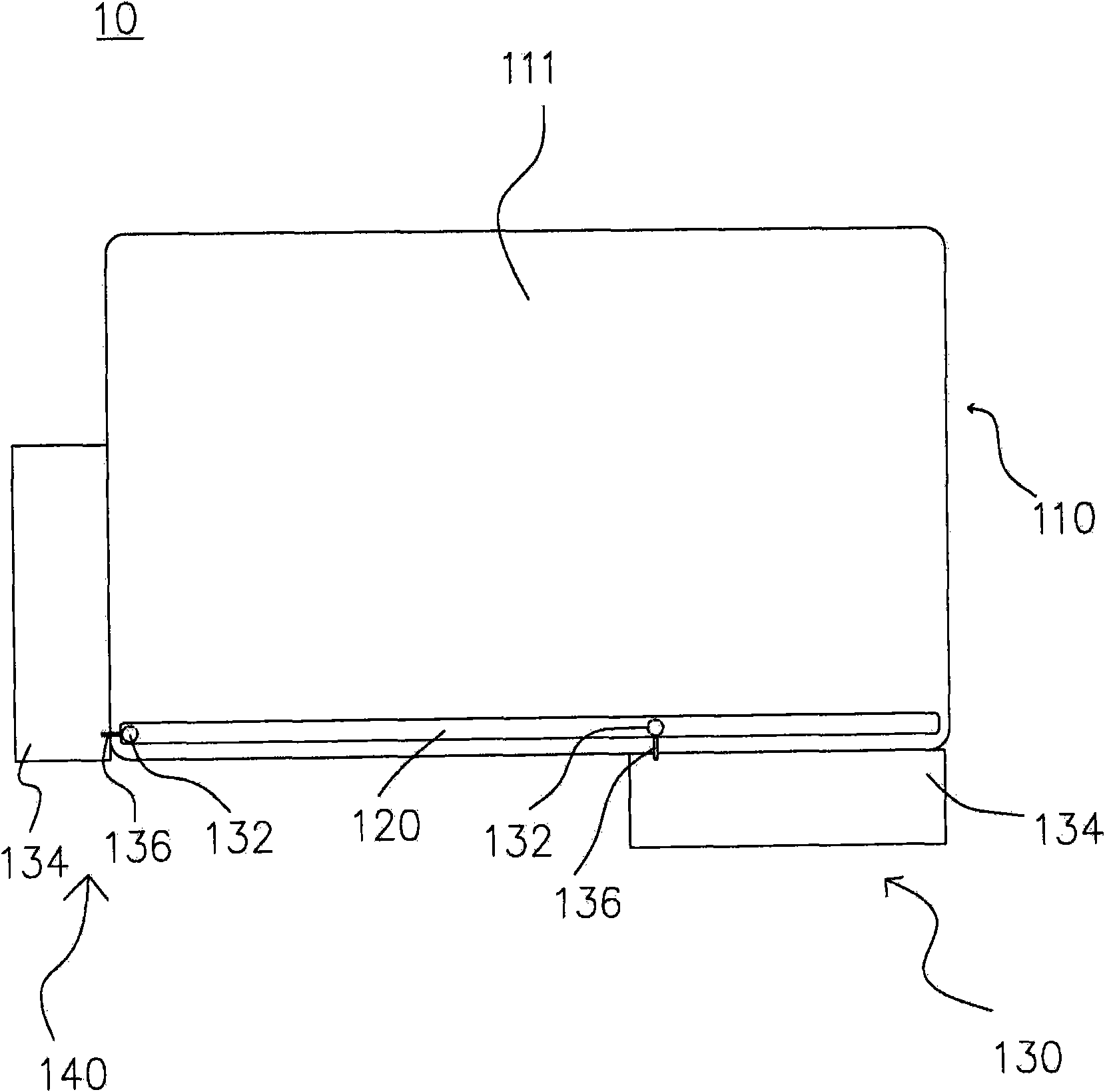

Flat-panel display with sliding-type horn structure

InactiveCN101593472AImprove the main problem that cannot be adjusted arbitrarilyImprove the problem that cannot be adjusted arbitrarilyAdvertisingTransducer casings/cabinets/supportsDisplay deviceHorn structure

The invention relates to a flat-panel display with sliding-type horn structure, comprising a display body, a chute arranged on the display body and at least a sliding-type horn part which comprises a sliding part, a horn body and a connecting part; the connecting part is connected with the sliding part and the horn body; the sliding part is arranged in the chute in a set fit mode of free movement; the effect of freely adjusting the position of the horn body according to the requirements of users is achieved via the fit structure of the sliding part and the chute, and further the efficacy of flexibly adjusting the angle of the horn is achieved via a pivot on the horn body, so as to better the problem that the position of the horn of the flat-panel display is fixed and can not be moved and that the angle of the sound field of the horn can not be randomly adjusted.

Owner:HANNSPREE INC

Ku/Ka waveband double-frequency conical beam horn antenna

ActiveCN111987464ACompact structureLight in massWaveguide hornsSimultaneous aerial operationsAntenna radiation patternsSoftware engineering

The invention discloses a Ku / Ka waveband double-frequency conical wave beam horn antenna. The antenna comprises a double-frequency radiation module and a feed module. The double-frequency radiation module adopts a nested horn structure; the double-frequency radiation module specifically comprises a circular waveguide horn and a coaxial horn nested outside the circular waveguide horn, the working frequency band of the circular waveguide horn is a Ka wave band and used for radiating Ka wave band signals, the working frequency band of the coaxial horn is a Ku wave band and used for radiating Ku wave band signals, and the feeding module is used for feeding the double-frequency radiation module. The radiation pattern of the antenna has conical wave beam characteristics in Ku / Ka wave bands.

Owner:NANJING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com