Integrated type ox-horn glue-hole electrode and design method thereof

A design method and integrated technology, applied in electrode manufacturing, electric processing equipment, metal processing equipment, etc., can solve problems such as difficult processing of horn submerged glue joints, pressure loss of horn submerged glue joints, failure to meet product surface quality requirements, etc. , to save processing time, improve processing yield, and facilitate clamping and positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment example 2

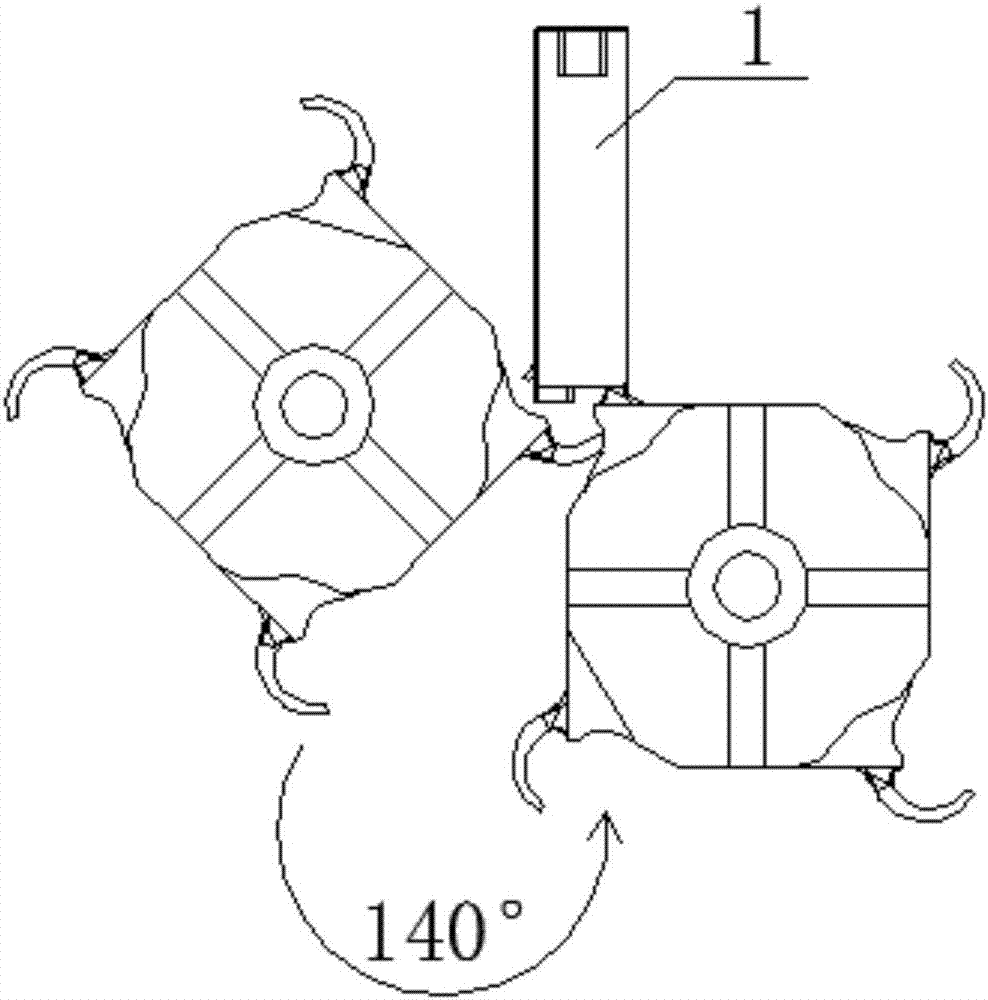

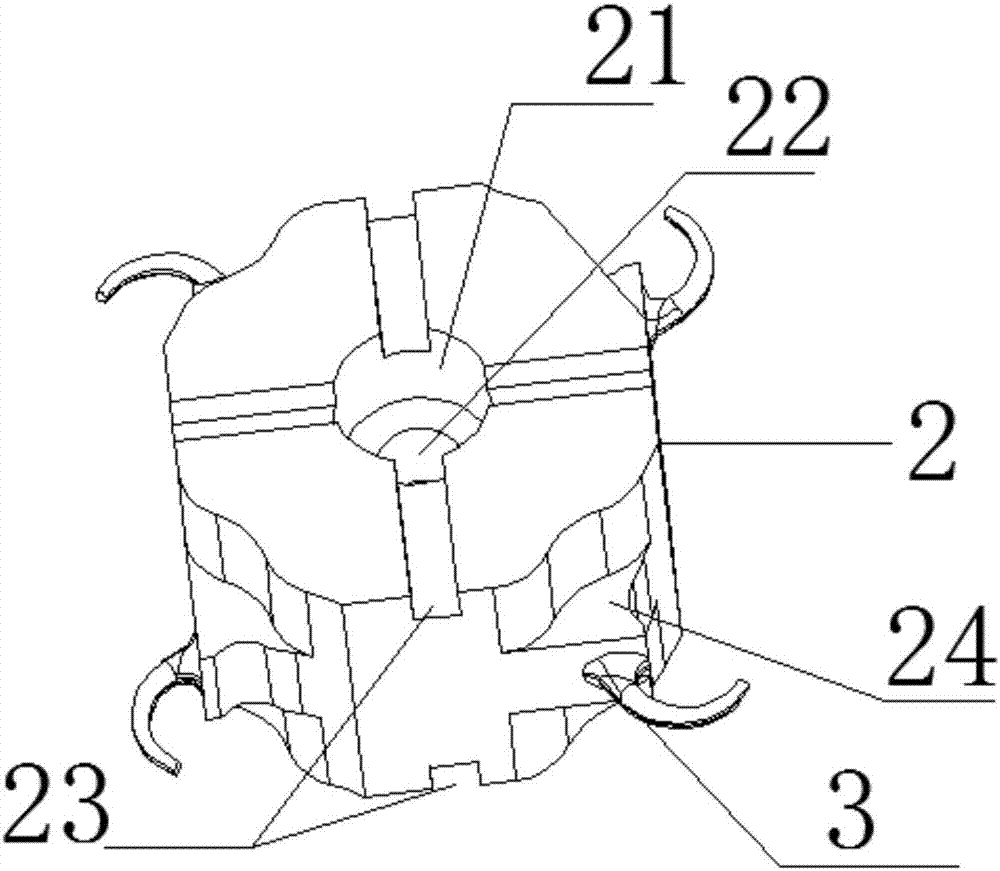

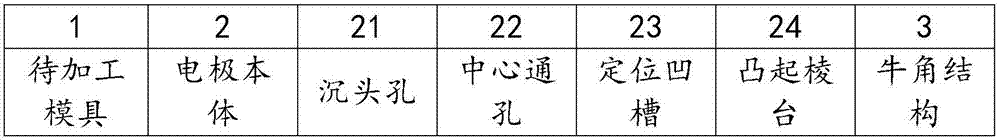

[0037] An integral horn-shaped electrode, the main steps of which include: an electrode body 2, a countersunk hole 21, a central through hole 22, and a horn structure 3, wherein the electrode body 2 is a cylinder with an irregular cross section, and is arranged on both sides of the electrode body 2. The center of the end counterbore 21 coincides with the center of the central through hole 22 and is arranged at the center of the electrode body. The upper and lower end surfaces of the electrode body 2 are provided with a "+"-shaped positioning groove 23; the 1 / 2 height position of the side of the electrode body 2 There is a horizontally extending protruding prism 24, and the horn structure 3 is arranged at the position of 1 / 2 thickness of the prism, the number is 3, and the adjacent angle is 120°. The integral horn glue inlet electrode is used to process the integral horn glue inlet on the mold, replacing the traditional two-petal horn glue inlet, reducing the pressure breakage r...

specific Embodiment example 3

[0047] An integral horn-shaped electrode, the main steps of which include: an electrode body 2, a countersunk hole 21, a central through hole 22, and a horn structure 3, wherein the electrode body 2 is a cylinder with an irregular cross section, and is arranged on both sides of the electrode body 2. The center of the end counterbore 21 coincides with the center of the central through hole 22 and is arranged at the center of the electrode body. The upper and lower ends of the electrode body 2 are provided with a "+"-shaped positioning groove 23; There are horizontally extending protruding prisms 24, and the horn structure 3 is arranged at 1 / 2 thickness of the prisms, the number is 4, and the adjacent angle is 90°. The integral horn glue inlet electrode is used to process the integral horn glue inlet on the mold, replacing the traditional two-petal horn glue inlet, reducing the pressure breakage rate, avoiding the occurrence of seams on the surface of the product, and improving t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com