Method for preparing nano structure on surface of (111) silicon wafer

A nanostructure, silicon wafer surface technology, applied in nanotechnology, chemical instruments and methods, semiconductor/solid-state device manufacturing, etc., can solve the problems of high preparation cost, expensive SOI silicon wafer material, and single nanowire structure of the preparation object. Achieve the effect of good crystal alignment, complete lattice structure and good scale uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

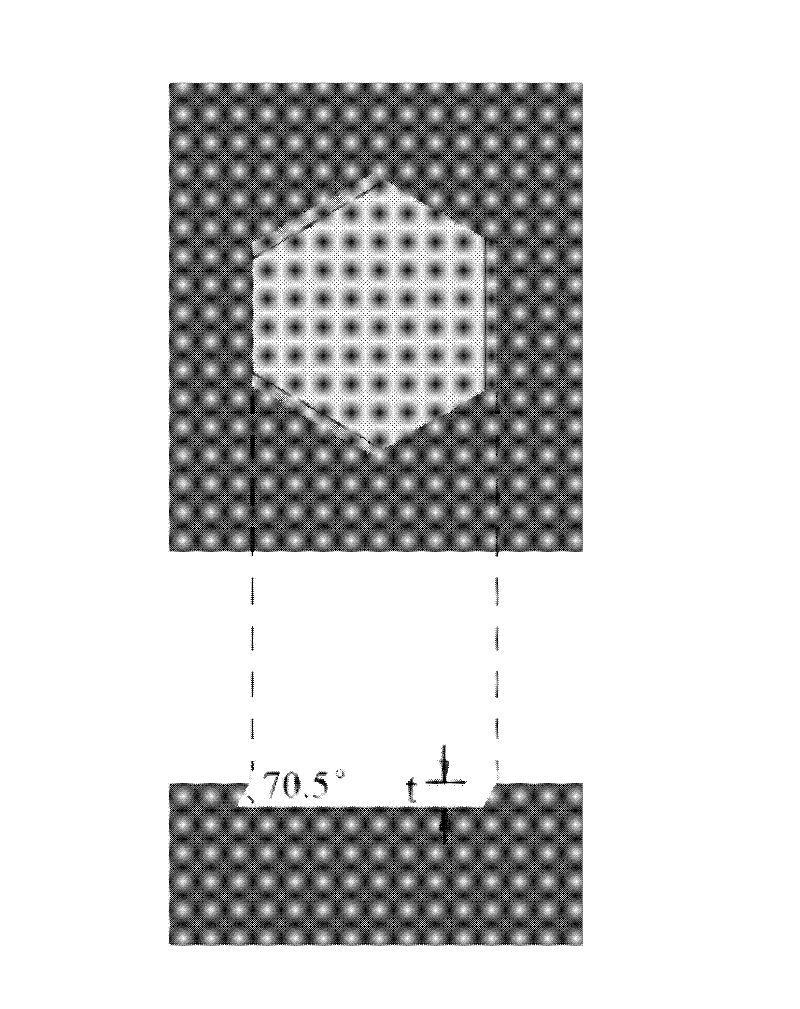

[0034] (111) Design of etching windows on silicon wafers.

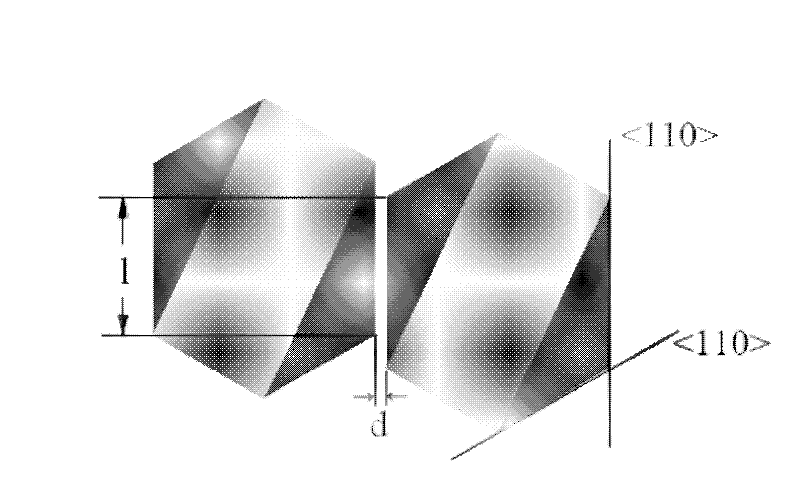

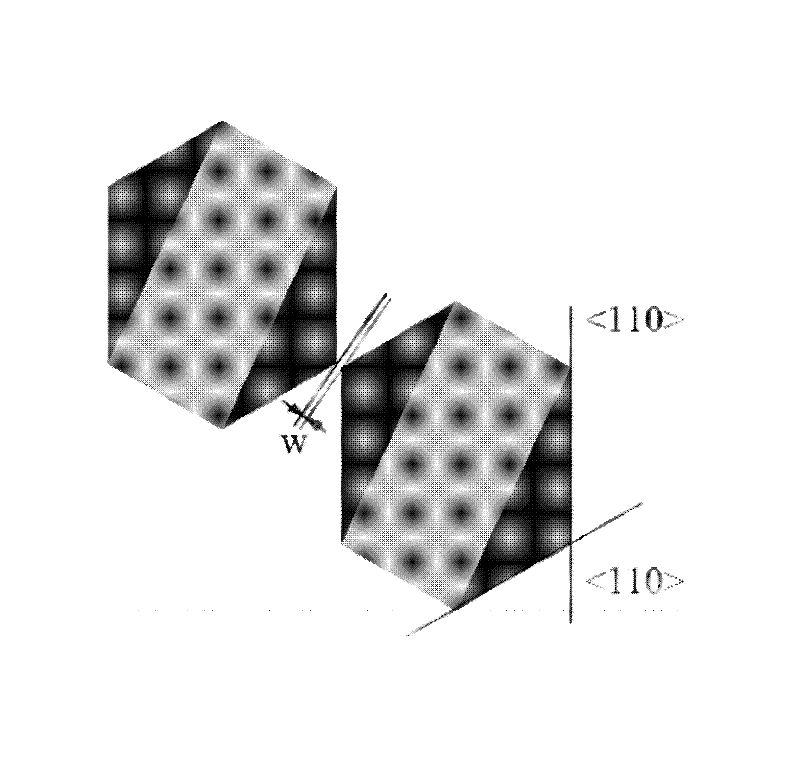

[0035] Assume that the x-axis is along the main cutting edge direction of the (111) type silicon wafer, the y-axis is along the crystal direction perpendicular to it, and two identical oblique rectangles are arranged side by side along the x-direction, and the length of the short side of the rectangle is a, The length of the long side of the rectangle is b, the distance between two rectangles is c, and the angle between the short side and the x-axis is α. Under the condition that a, b, and c are all greater than the minimum line width requirement of the mask, two parallel hexagonal etching grooves are formed after anisotropic wet etching of silicon, leaving a wall-shaped single crystal silicon structure in the middle, Its width is d, its length is l, and its inclination angle is 70.5°. When d is on the order of nanometers, a single crystal silicon nanowall structure is formed.

[0036] Preferably, set α=30°, Then...

Embodiment 2

[0041] (111) Process flow for preparing single crystal silicon nanowires on silicon wafer ( Figure 6 ).

[0042] a. Take (111) silicon wafers, after cleaning, high temperature dry oxygen oxidation to form an oxide layer with a thickness of 150nm as a corrosion protection layer;

[0043] b. Design the etching window according to Example 1, get a=6um, b=10.4um, c=3.1um, α=30 °, glue photolithography, BOE (buffer etchant) to remove silicon oxide in the window;

[0044] c.RIE etches the monocrystalline silicon layer to a depth of 500nm, and removes the glue;

[0045] d. KOH etching, due to the anisotropic wet etching characteristics of (111) silicon wafers, the original two inclined rectangular windows become two hexagonal etching grooves, and a single crystal direction is formed between the two etching grooves. The crystal silicon wall structure has a cross-section of a parallelogram with an inclination angle of 70.5° and a height of about 500nm. The length and width can be d...

Embodiment 3

[0049] A method for preparing single crystal silicon nanostructures on (111) type SOI wafers.

[0050] The method for preparing a single crystal silicon nanostructure on a (111) type SOI sheet is basically the same as the embodiment, the difference is that the height of the nanostructure can be determined by the thickness of the top layer of silicon on the SOI sheet (also including the top layer of silicon that has been thinned by peroxidation in advance). If the thickness is on the order of nanometers, the single crystal silicon nanowall prepared according to the method described in Example 1 also directly forms a nanowire structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com