Low-heat-release polyurethane grouting reinforcement material and preparation method thereof

A technology of grouting reinforcement and polyurethane, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of high exothermic temperature of material reaction, limited application range, low thermal conductivity, etc., and achieve the increase of intermolecular distance , low exothermic temperature and high flash point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] (1) Put polyether polyol 303 (functionality 3, molecular weight 350, viscosity 350~550mPa s) and polyester polyol PF-2011 (functionality 2.4, molecular weight 500, viscosity 1000mPa s) in a vacuum drying oven Dry at 120°C for 1.5 hours, and seal and store after drying.

[0051] (2) When the polyether temperature drops to about room temperature (25°C), weigh 40 parts (by weight, the same below) of polyether polyol 303 and 60 parts of polyester polyol PF-2011 and place them in a dry container , and then sequentially weighed 0.5 parts of dibutyltin dilaurate (DBTDL), 0.5 parts of triethylenediamine alcohol solution (A33), 2 parts of foam stabilizer silicone oil AK-8805, 10 parts of dimethyl phosphonate ( DMMP), 200 parts of coumarone-indene resin, stirred with a glass rod for 40 s until the components were uniformly dispersed, and component A was obtained.

[0052] (3) Weigh 102 parts of polyisocyanate (PAPI) to obtain component B.

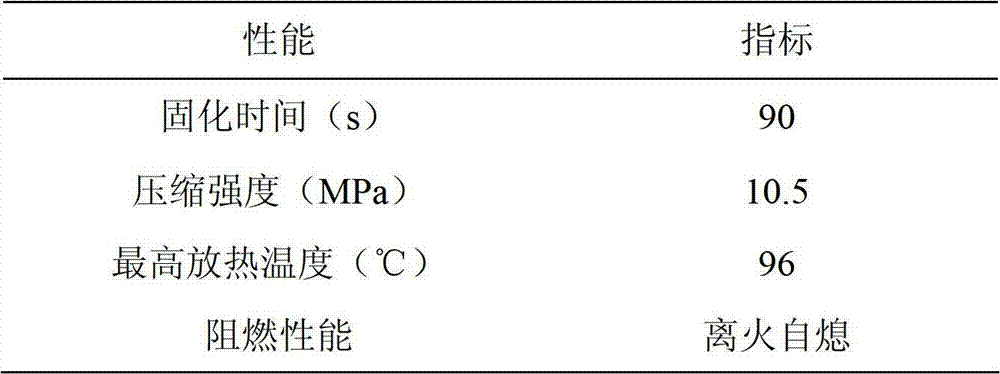

[0053] (4) Mix component A and compon...

Embodiment 2

[0057](1) Put polyether polyol 4110 (functionality 4, molecular weight 500, viscosity 3500~4500mPa s) and polyether polyol 303 (functionality 3, molecular weight 350, viscosity 350~550mPa s) in vacuum drying In the oven, dry at 120°C for 1.5h, and store in a sealed container after drying.

[0058] (2) When the polyether temperature drops to about room temperature (25°C), weigh 30 parts of polyether polyol 4110 and 70 parts of polyether polyol 303 and place them in a dry container, and then weigh 1 part of dilauric acid in turn Dibutyltin (DBTDL), 1 part alcohol solution of triethylenediamine (A33), 2 parts foam stabilizer silicone oil AK-8805, 10 parts dimethyl methylphosphonate (DMMP), 200 parts benzofuran-indene Resin, stirred with a glass rod for 40s until each component is uniformly dispersed, and component A is obtained.

[0059] (3) Weigh 135 parts of polyisocyanate PAPI to obtain component B.

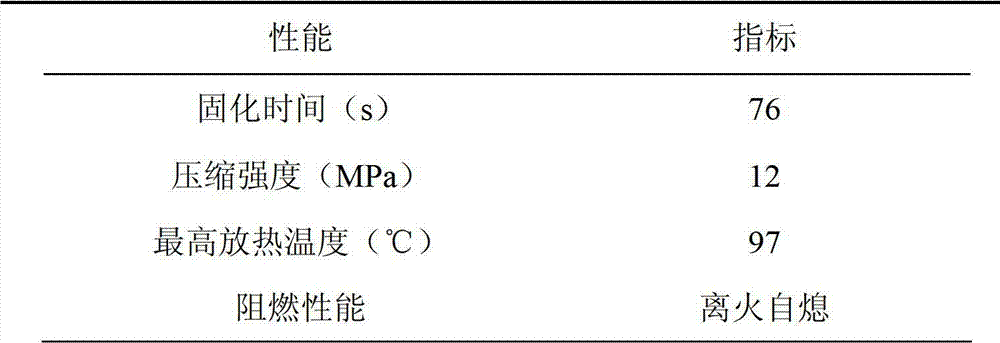

[0060] (4) Mix component A and component B according to the volume ratio o...

Embodiment 3

[0064] (1) Put polyether polyol 4110 (functionality 4, molecular weight 500, viscosity 3500~4500mPa s) and aromatic polyester polyol PF-2011 (functionality 2.4, molecular weight 500, viscosity 1000mPa s) in the Dry in a vacuum oven at 120°C for 1.5 hours, and store in a sealed container after drying.

[0065] (2) When the temperature of the polyether drops to about room temperature (25°C), weigh 30 parts of polyether polyol 4110 and 70 parts of aromatic polyester polyol PF-2011 in a dry container, and then weigh 0.5 Parts of dibutyltin dilaurate (DBTDL), 0.5 parts of alcoholic solution of triethylenediamine (A33), 2 parts of foam stabilizer silicone oil AK-8805, 7 parts of dimethyl methylphosphonate, 3 parts of trichloroethyl Phosphate ester, 200 parts of coumarone-indene resin, stirred with a glass rod for 40s until the components are evenly dispersed, and the reinforcement material component A is obtained.

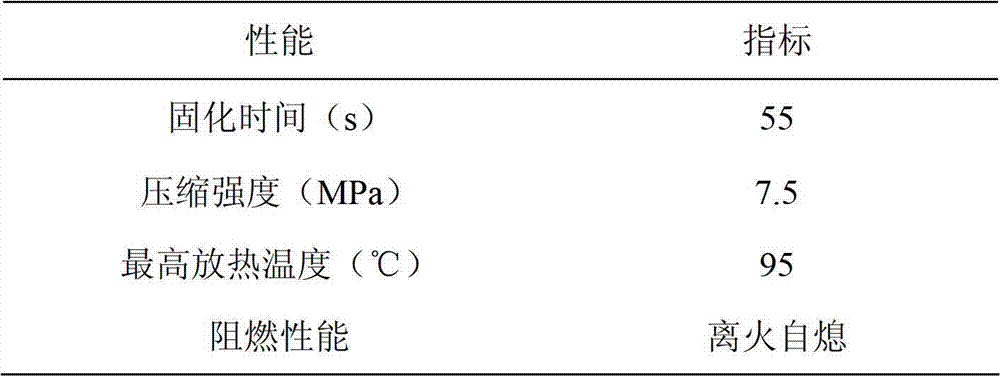

[0066] (3) Weigh 93 parts of polyisocyanate PAPI to obtain reinfor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com