Patents

Literature

242 results about "Dimethyl methylphosphonate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dimethyl methylphosphonate is an organophosphorus compound with the chemical formula CH₃PO(OCH₃)₂. It is a colourless liquid which is primarily used as a flame retardant.

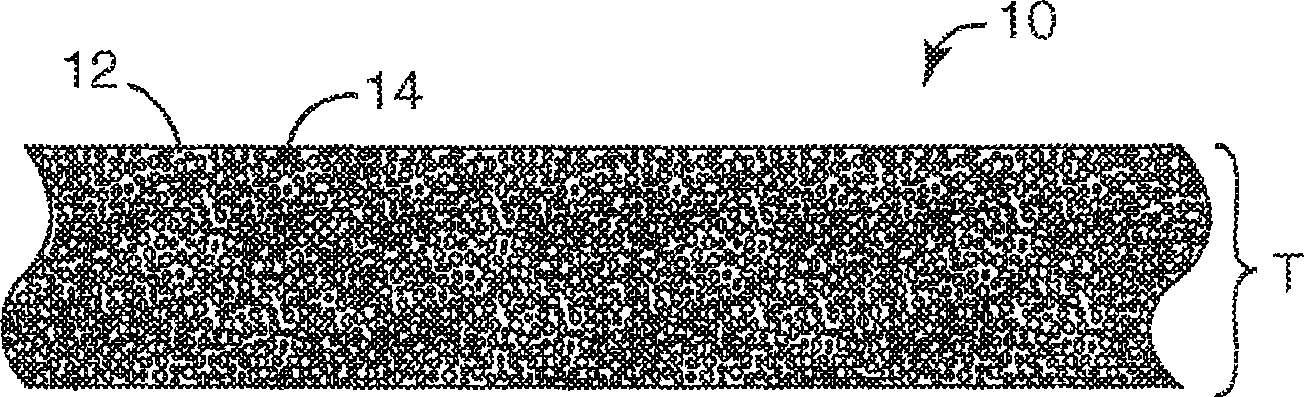

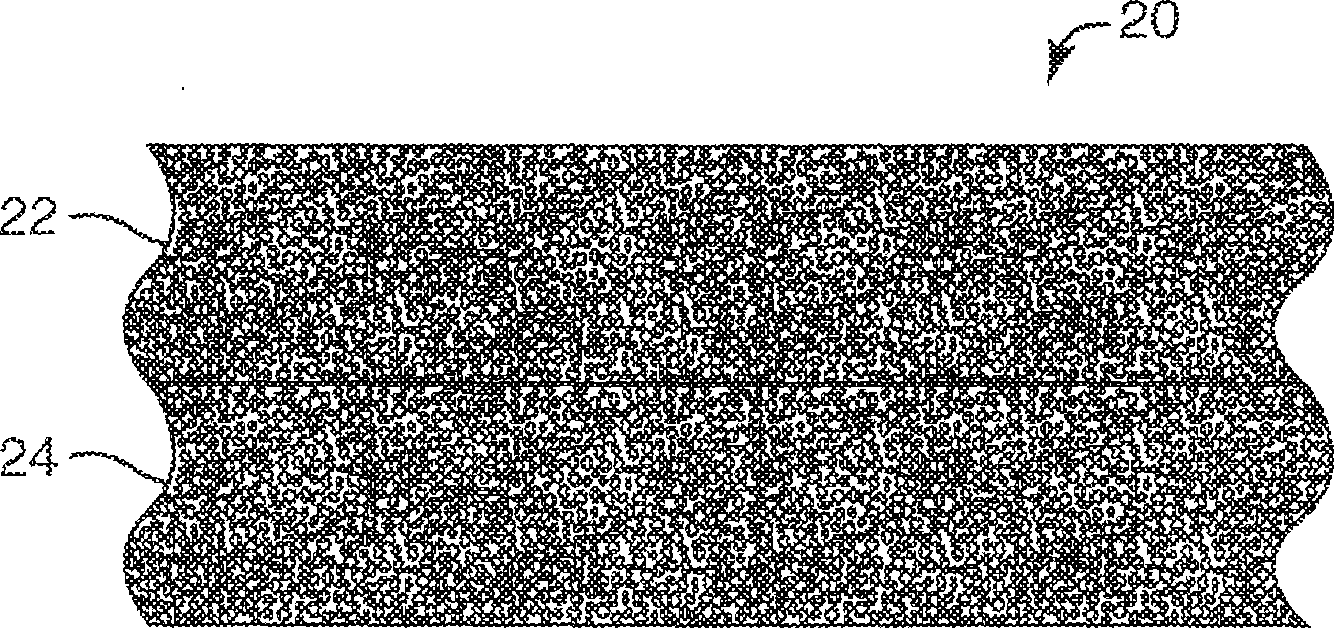

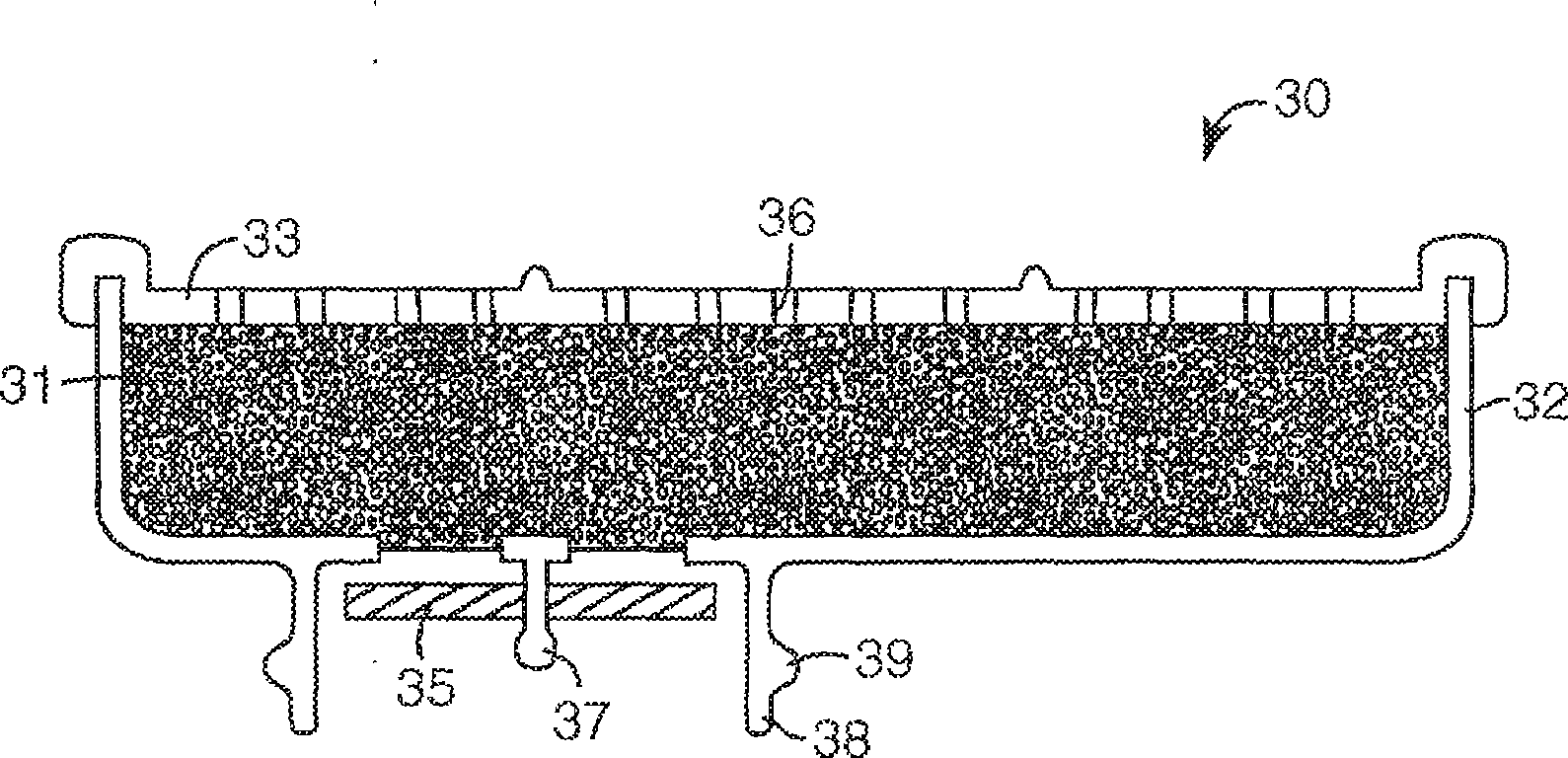

Particle-containing fibrous web

InactiveUS20060254427A1Lower overall pressure dropExtended service lifeBreathing filtersCellulosic plastic layered productsFiberDimethyl methylphosphonate

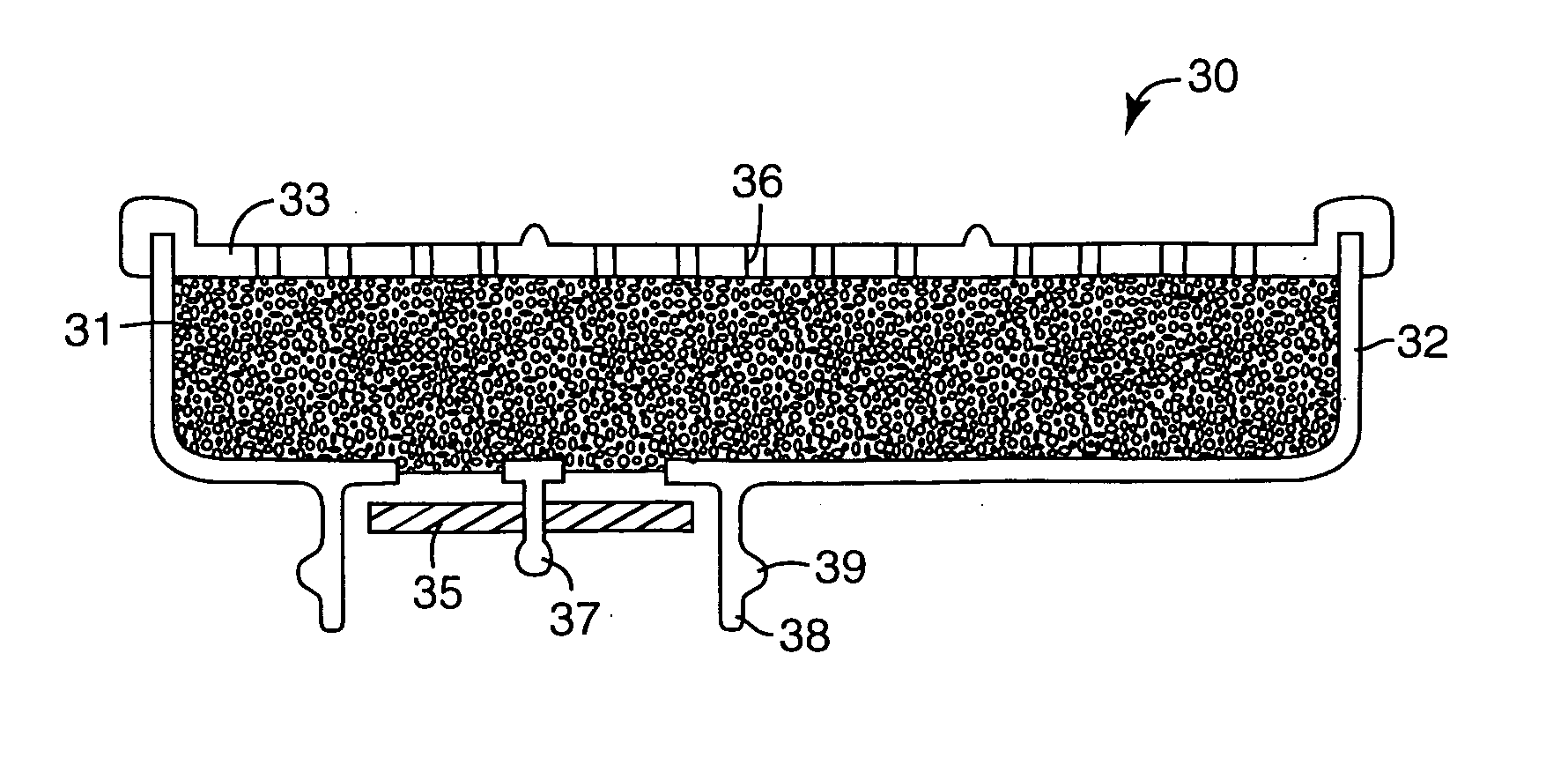

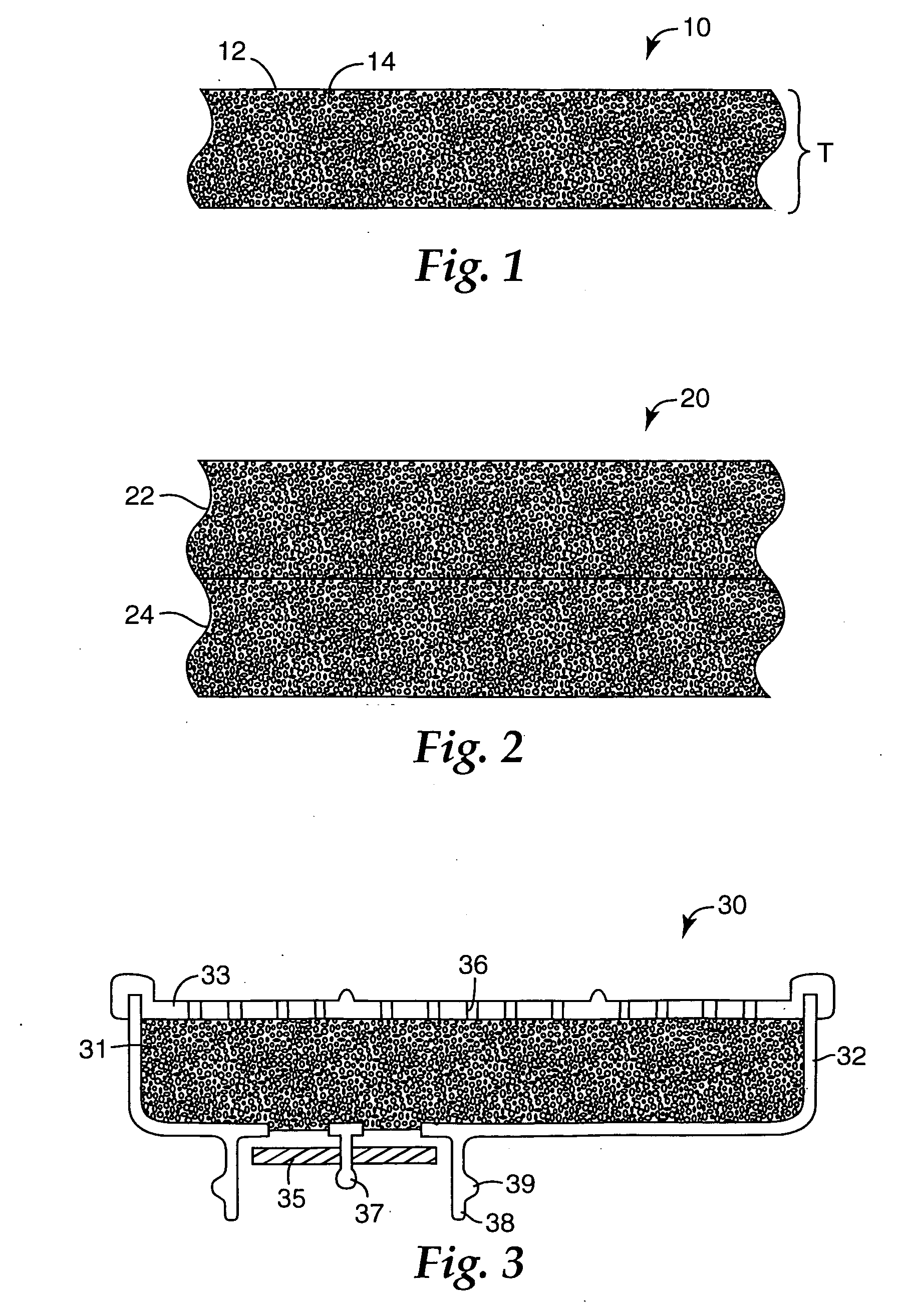

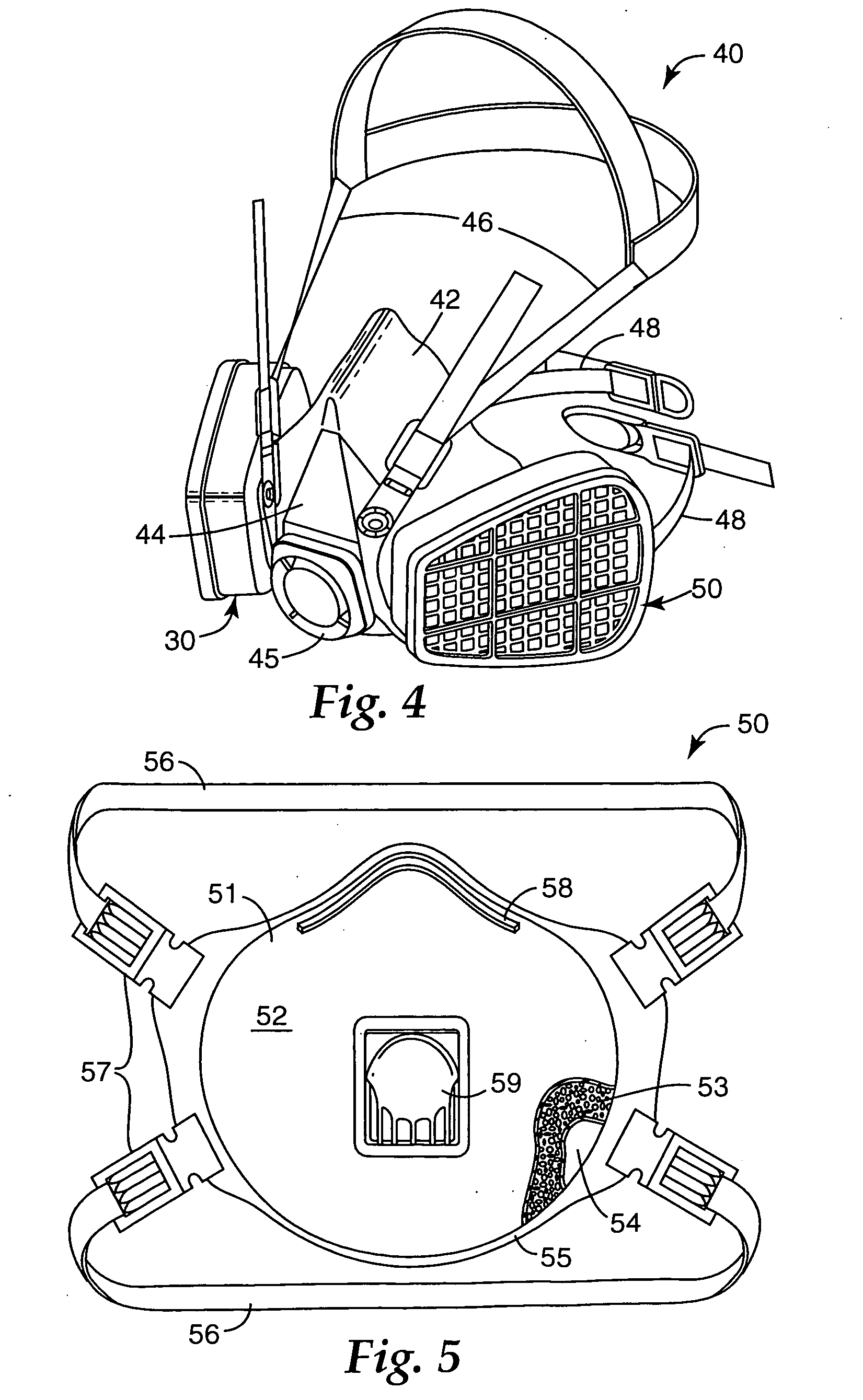

A porous sheet article including a self-supporting nonwoven web of less than 20 weight percent polymeric fibers exhibiting no more than about 1 weight percent dimethyl methyl phosphonate uptake and at least 80 weight percent sorbent particles enmeshed in the web, the sorbent particles being sufficiently evenly distributed in the web and the fiber polymer(s) being such that the web has an Adsorption Factor A of at least 1.6×104 / mm water. The articles have low pressure drop and can provide filter elements and other individual or collective protection devices having long service lives and an Adsorption Factor approaching and in some instances exceeding that of a packed carbon bed.

Owner:3M INNOVATIVE PROPERTIES CO

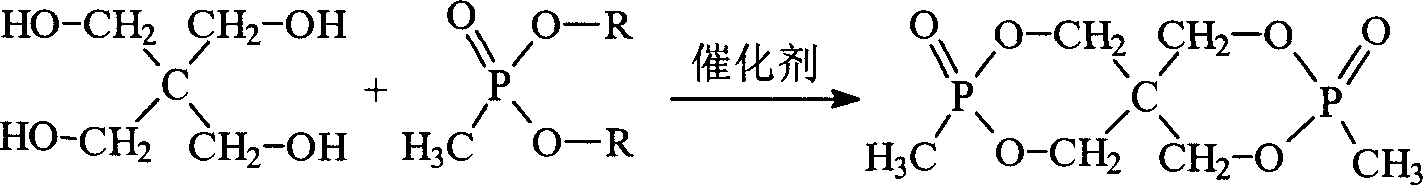

Method for preparing annular phosphonate or annular phosphate flame retardant

InactiveCN101230274AThe preparation method is simple and environmentally friendlyEasy to operateFlame-proof filament manufactureGroup 5/15 element organic compoundsDimethyl methylphosphonateTriethylphosphite

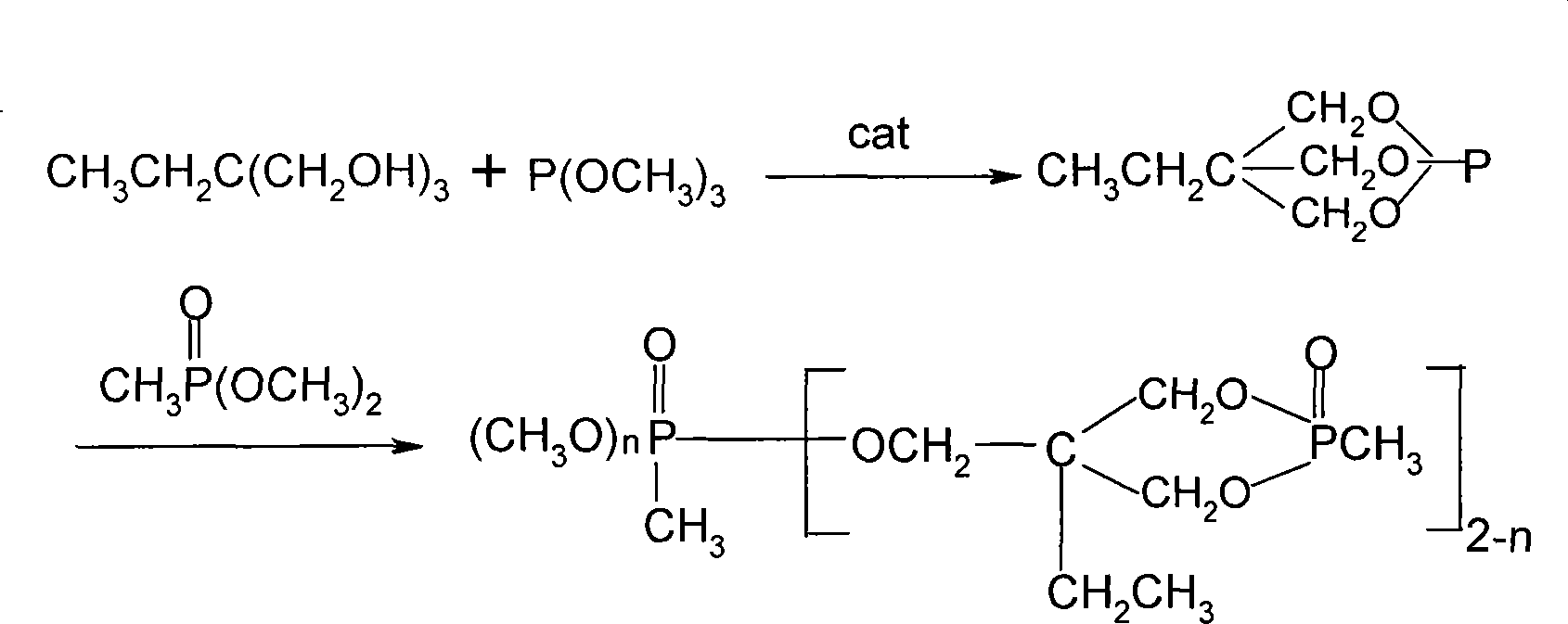

The invention provides a preparation method of annular phosphonate or annular organic phosphate flame retardant. The steps are that (1) trimethylolpropane and trimethyl phosphate or triethyl phosphate are taken as the material, and react to synthesize into midbody under the condition of catalyzer; (2) phosphonate or organic phosphate is added into the midbody and is heated, and then the product of annular phosphonate or annular organic phosphate flame retardant can be obtained. The phosphite ester is selected from trimethyl phosphate and triethyl phosphate. The phosphonate is selected from dimethyl-phosphine and diethyl ethyl phosphine. The organic phosphate is selected from trimethyl phosphate, triethyl phosphate, phosphate propyl, tributyl phosphate and tricresyl aromatic ester. The invention overcomes the shortcomings of the prior art, the new preparation method of annular phosphonate or annular organic phosphate flame retardant is environment-friendly, solution is not needed, and the operation is simple. The termination product has excellent color and luster, low acid value and excellent viscosity; and does not need additional decoloration.

Owner:NANJING NORMAL UNIVERSITY +1

Thermoplastic low-smoke halogen-free flame-retardant environment-friendly sheath material for power cables and preparation method thereof

ActiveCN103122097ADoes not affect physical and mechanical propertiesDoes not affect processabilityInsulated cablesPigment treatment with macromolecular organic compoundsCrack resistanceDimethyl methylphosphonate

The invention discloses a thermoplastic low-smoke halogen-free flame-retardant environment-friendly sheath material for power cables and a preparation method thereof. The thermoplastic low-smoke halogen-free flame-retardant environment-friendly sheath material for power cables comprises the following components in parts by weight: 60-80 parts of EVA (ethylene-vinyl acetate), 20-30 parts of HDPE (high-density polyethylene), 10-15 parts of EPDM (ethylene-propylene-diene monomer), 15-25 parts of compatiblizing agent, 100-150 parts of halogen-free flame retardant, 0.5-1 part of antioxidant 1035, 0.5-1 part of antioxidant DSTP, 1-2 parts of ethylene bis stearamide, 3-5 parts of DCP (dicumyl peroxide), 2-4 parts of zinc oxide, 1-2 parts of calcium stearate, 10-20 parts of dimethyl methyl phosphonate, 30-40 parts of nano kaolin, 2-3 parts of stearic acid and 0.5-1 part of isopropyl tri(dioctylpyrophosphate)titanate. The sheath material disclosed by the invention has the advantages of excellent physical and mechanical properties, excellent flame retardancy, favorable high / low temperature resistance, favorable oil resistance, favorable solvent resistance, favorable wear resistance, favorable ozone resistance, favorable aging resistance, high flexibility, crack resistance and the like, is very durable, environment-friendly and pollution-free, and can completely satisfy the requirements for modern power cables.

Owner:ANHUI HUAJIN CABLE GROUP

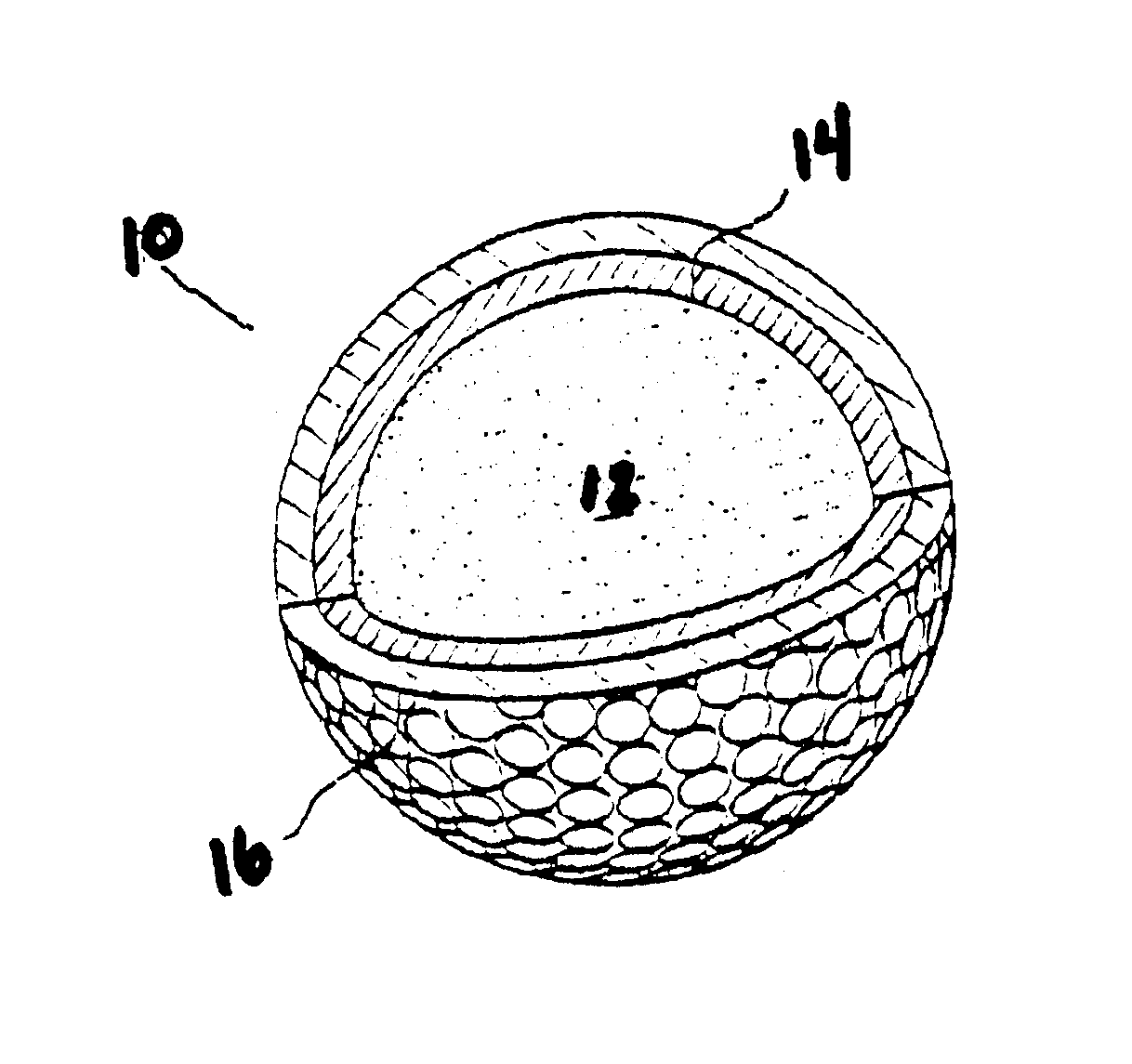

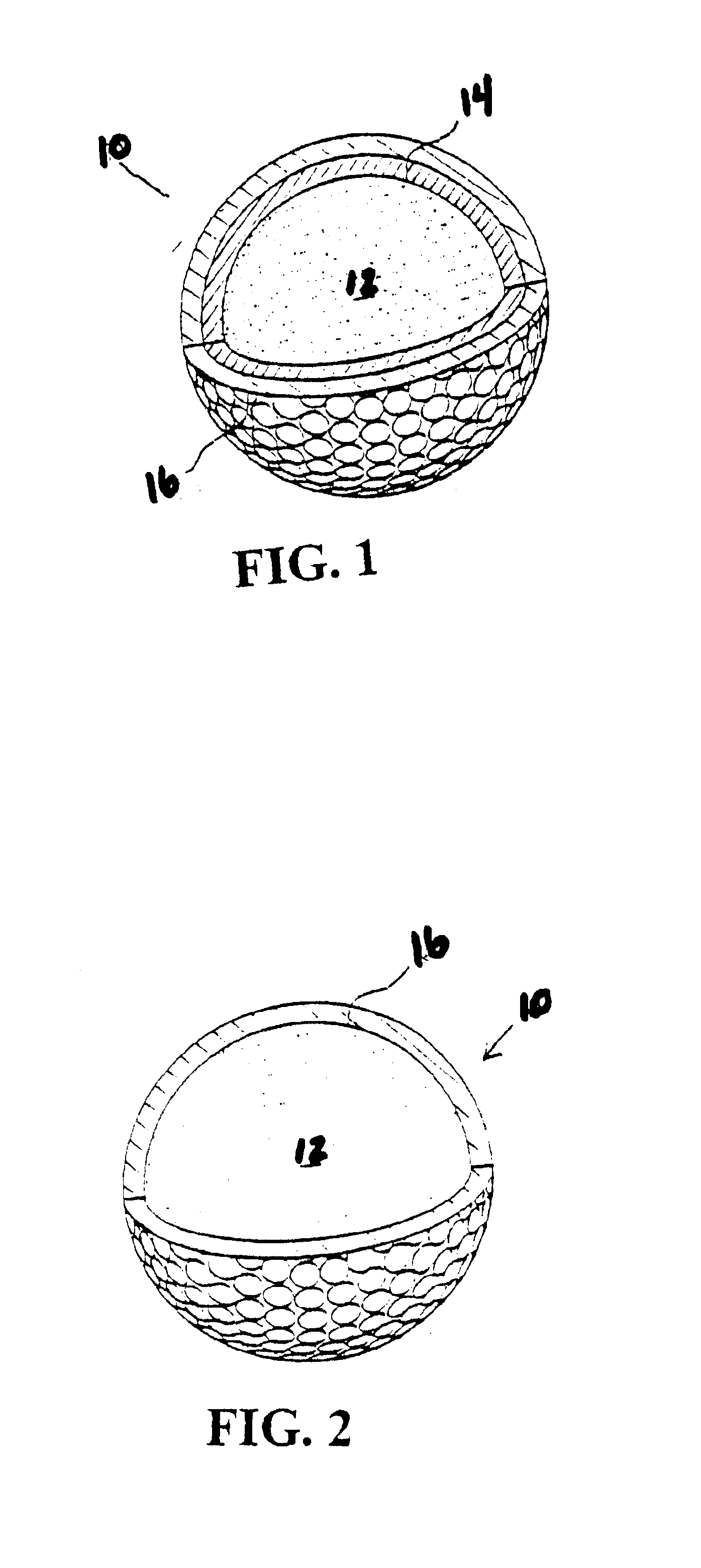

Thermosetting polyurethane material for a golf ball cover

A prepolymer blend for a thermosetting polyurethane material that allows for control of the reaction time is disclosed herein. The prepolymer blend is preferably composed of a polyurethane prepolymer and dimethyl methylphosphonate. The thermosetting polyurethane is preferably utilized as a cover for a golf ball. The cover is preferably formed over a core and boundary layer.

Owner:TOPGOLF CALLAWAY BRANDS CORP

Efficient halogen-free anti-inflaming polyurethane hard foam and preparation method thereof

InactiveCN101724254ALess flame retardant addedImprove flame retardant performancePigment treatment with macromolecular organic compoundsPolymer scienceDimethyl methylphosphonate

The invention relates to efficient halogen-free anti-inflaming polyurethane hard foam and a preparation method thereof. The foam contains 40 to 50 % of polymer MDI, 30 to 40 % of polyether polyalcohol, 1 to 5 % of foam stabilizer, 0.1 to 5 % of foaming agent, 1 to 10 % of ternary cladding microencapsulation red phosphorus, 0 to 10 % of dimethyl methyl phosphonate (DMMP), 0 to 10 % of 2,4,6-triphosphoric diethyl ester-1,3,5-triazine (CNCTP), according to weight percentage. The preparation method comprises the steps of: proportionally and uniformly mixing the ternary cladding microencapsulation red phosphorus, the dimethyl methyl phosphonate (DMMP) or the 2,4,6-triphosphoric diethyl ester-1,3,5-triazine (CNCTP), the foam stabilizer, the foaming agent and the polyether polyalcohol at room temperature, rapidly mixing with polymer MDI, and then foaming. The invention has the advantages of small moisture absorption property, high anti-inflaming property, small influence on mechanical property, and the like.

Owner:SHUNDE POLYTECHNIC

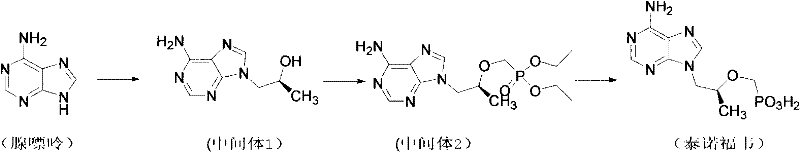

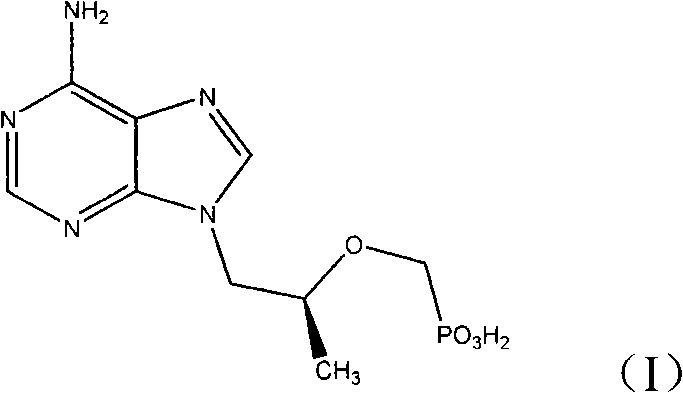

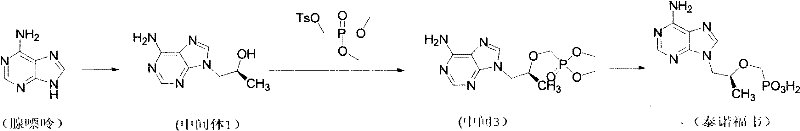

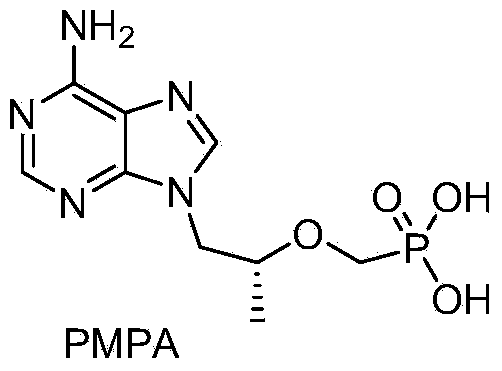

Novel production process of tenofovir

InactiveCN102219805ANo pollution in the processLow costGroup 5/15 element organic compoundsDimethyl methylphosphonateHydrolysis

The invention relates to a production process of drug tenofovir in the field of aids treatment. The process is a method of using adenine as a raw material, condensing toluenesulfonyloxy dimethyl methyl phosphonate by using an intermediate and then hydrolyzing by using an inorganic acid to finally prepare the tenofovir. The production process of the drug tenofovir, provided by the invention, has the characteristic of improving the hydrolysis activity of the intermediate so that the operation of the process production is largely simplified and the production cost of the tenofovir is largely reduced.

Owner:SUZHOU TENGLONG BIO PHARMA TECH

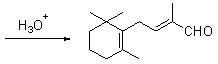

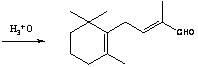

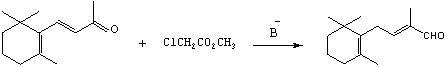

Preparation method of C-14 enol ether

InactiveCN102180774AThe reaction route is simpleRaw materials are easy to obtainEther preparationDimethyl methylphosphonateDiethyl methylphosphonate

The invention relates to a preparation method of C-14 enol ether. The C-14 enol ether is an intermediate of vitamin A, and the chemical name of the C-14 enol ether is 1-methoxy-2-methyl-4-(2,6,6-trimehtyl-1-cyclohexene-1-ly)-1,3-butadiene. The preparation method comprises the step of carrying out Wittig-Horner condensation reaction on beta-irisone as shown in a formula 4 and diethyl methylphosphonate as shown in a formula 8 at the temperature of minus 40-30 DEG C in an ether solvent or dipolar aprotic solvent in the presence of alkali so as to prepare the C-14 enol ether as shown in a formula7. According to the preparation method, reaction route is simple, and raw materials are simple and available.

Owner:SHAOXING UNIVERSITY

High-flame-retardancy paint

InactiveCN106366740AHigh tensile strengthImprove adsorption capacityFireproof paintsPolyurea/polyurethane coatingsWater basedDimethyl methylphosphonate

The invention discloses a high-flame-retardancy paint which is prepared from a water-based acrylate emulsion, a water-based polyurethane resin, aluminasol, an epoxy resin, polydimethylsiloxane, zinc oxide, hollow glass microspheres, nano zirconium oxide, montmorillonite, nano silicon dioxide, a film forming aid, a defoaming agent, a leveling agent, a wetting agent, a flame retardant and water. The flame retardant is formed by mixing boron oxide, dimethyl methyl phosphonate, phosphorus pentoxide, tri(2-chloropropyl) phosphate, guanylurea phosphate, ammonium polyphosphate, pentaerythritol, melamine and hexamethyl disiloxane. The high-flame-retardancy paint has the advantages of favorable water resistance, favorable wear resistance, excellent flame retardancy and long service life.

Owner:ANHUI JINDUN PAINT

Method for producing poly aluminum chloride by using byproduct of diethyl methylphosphonate production

ActiveCN108238621ASimple processLow costAluminium chloridesAlkali metal chloridesDimethyl methylphosphonateAluminium chlorohydrate

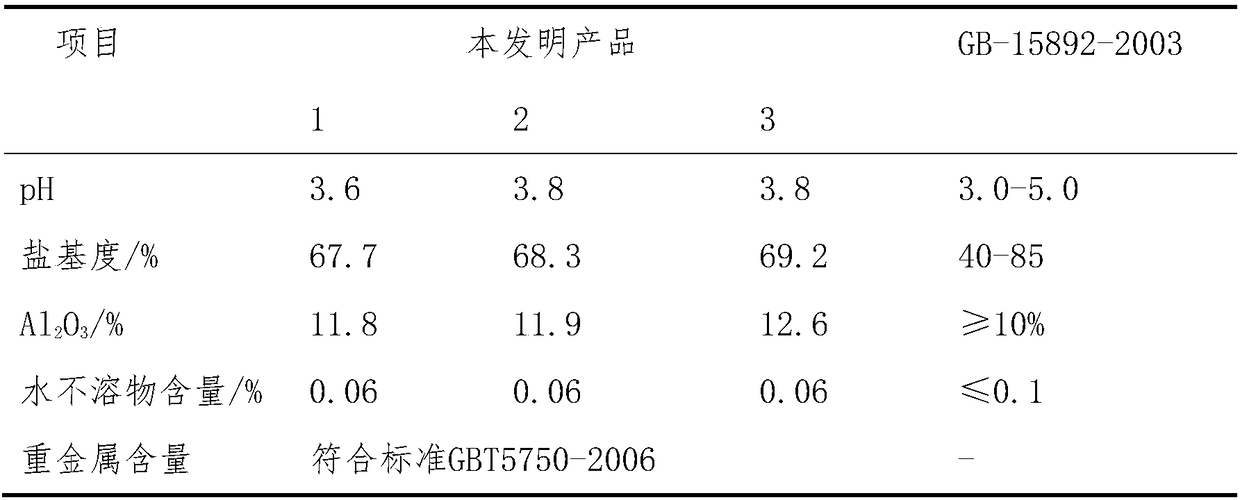

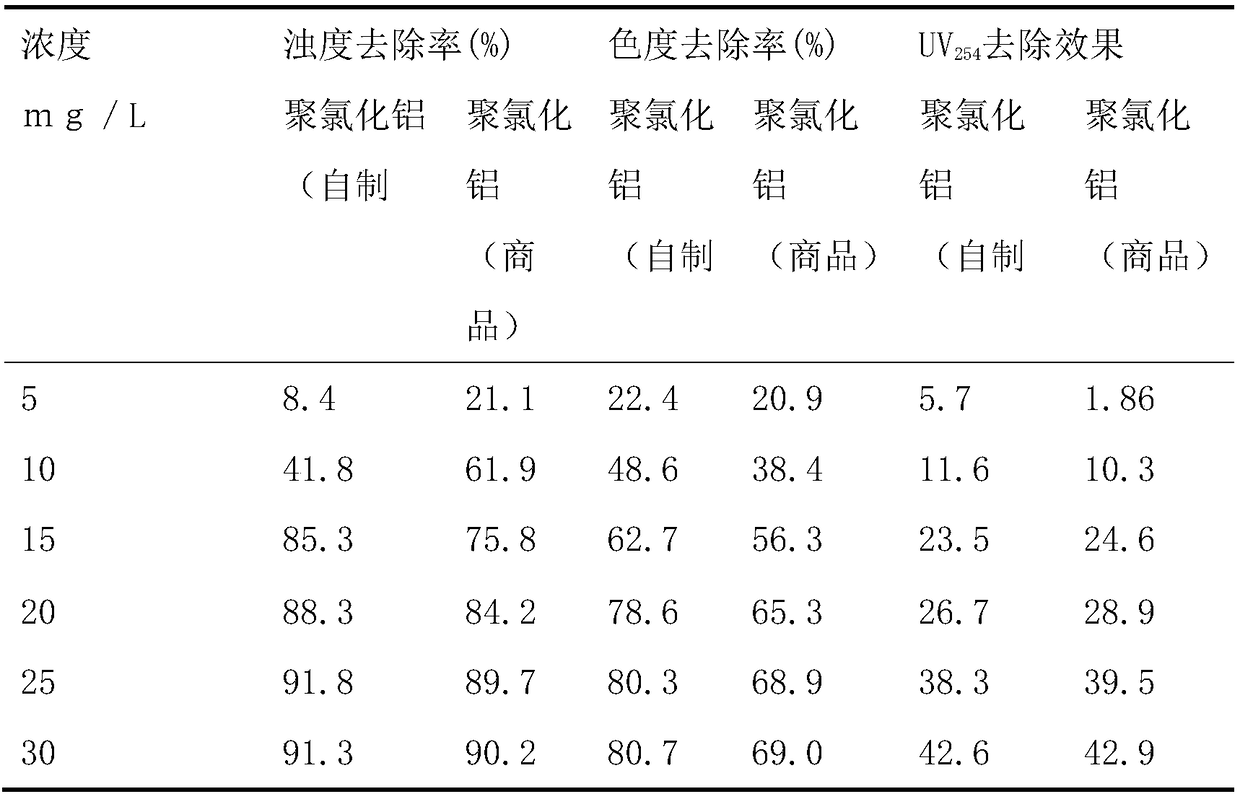

The invention relates to a method for producing poly aluminum chloride by using a byproduct of diethyl methylphosphonate production. The method comprises the following steps: (1) slowly adding a byproduct sodium tetrachloraluminate, rich in sodium tetrachloraluminate and obtained in a production process of diethyl methylphosphonate, into a dissolving kettle for dissolution, and collecting the solution; (2) adding ferric trichloride and hydrochloric acid; (3) sequentially adding aluminum hydroxide and calcium metaaluminate for polymerization reaction; (4) controlling the temperature to be 100 DEG C, and performing thermal reaction for 75min; and (5) cooling, and performing solid-liquid separation, wherein the filtrate is the product of the invention. The method disclosed by the invention has the advantages of simple process, high efficiency, low consumption, energy conservation, greenness and environmental friendliness and low cost.

Owner:洪湖源泰科技有限公司

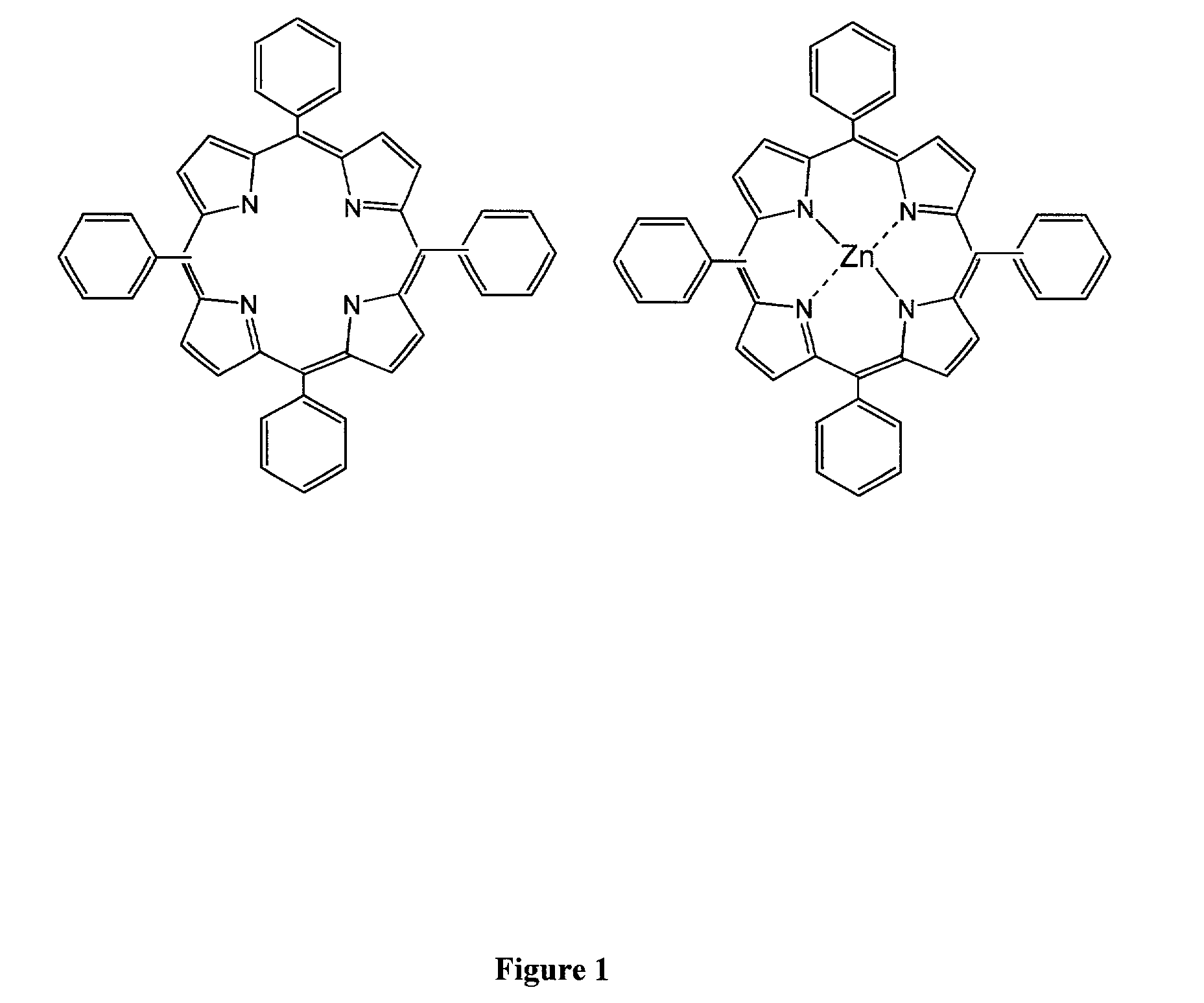

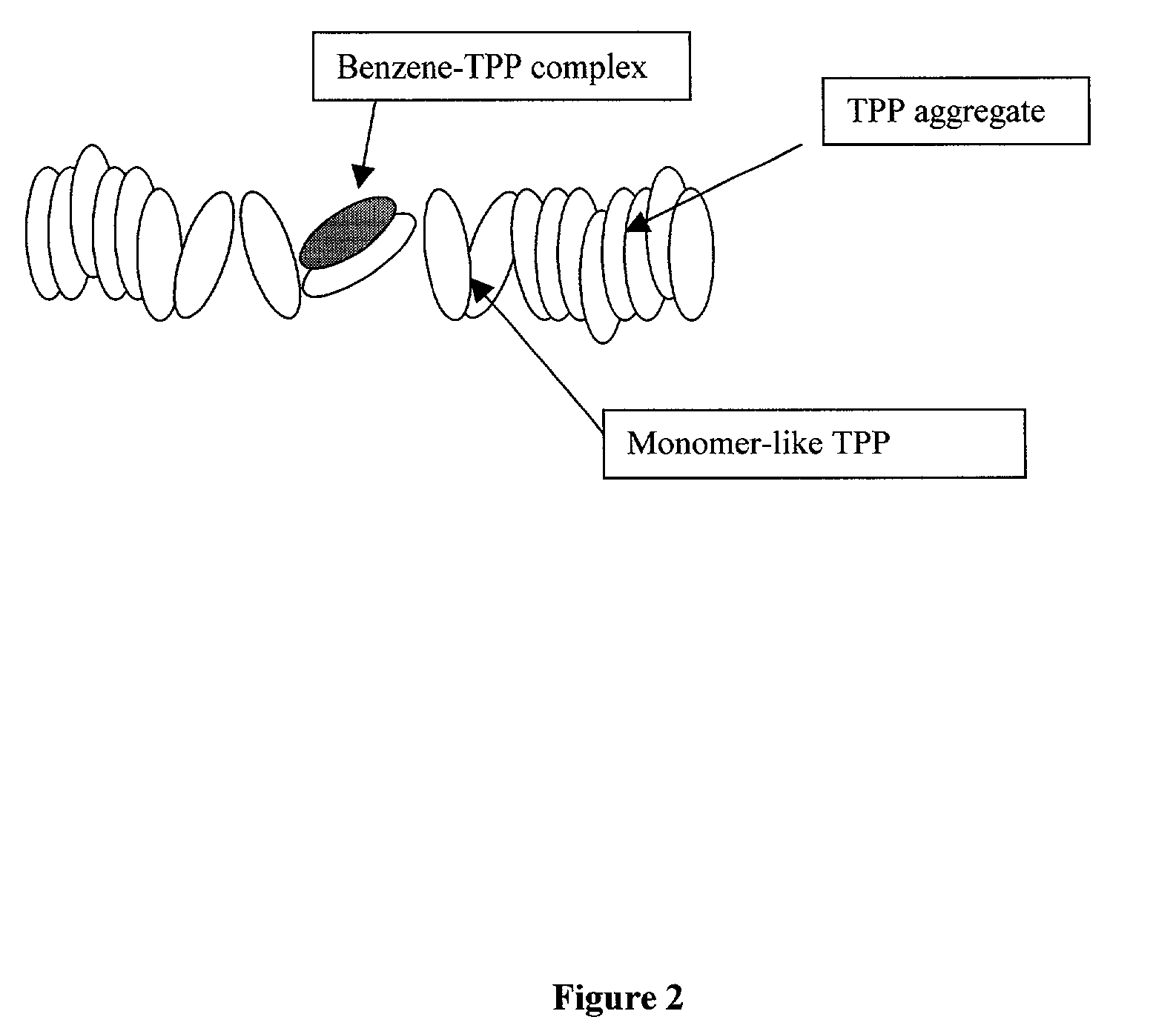

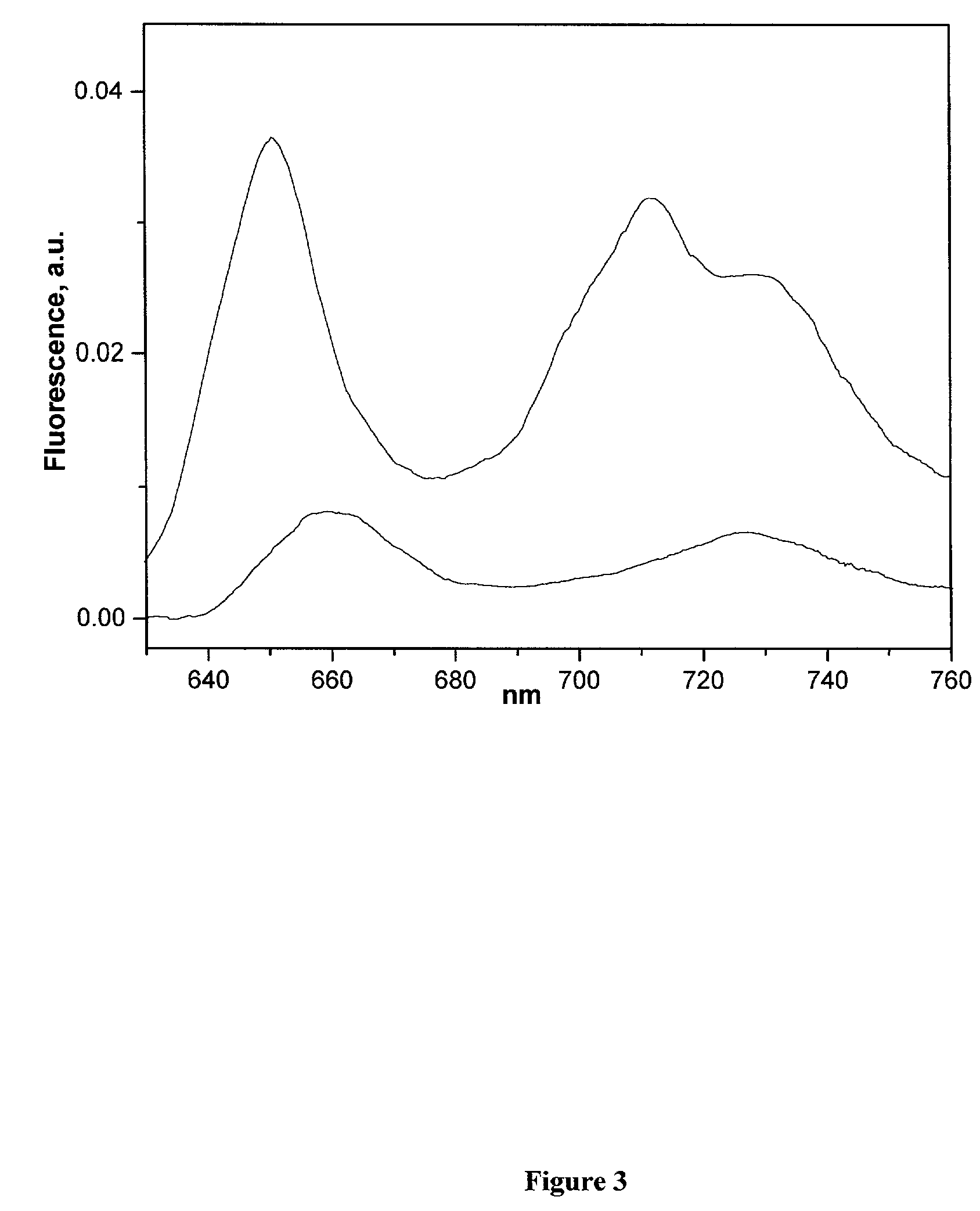

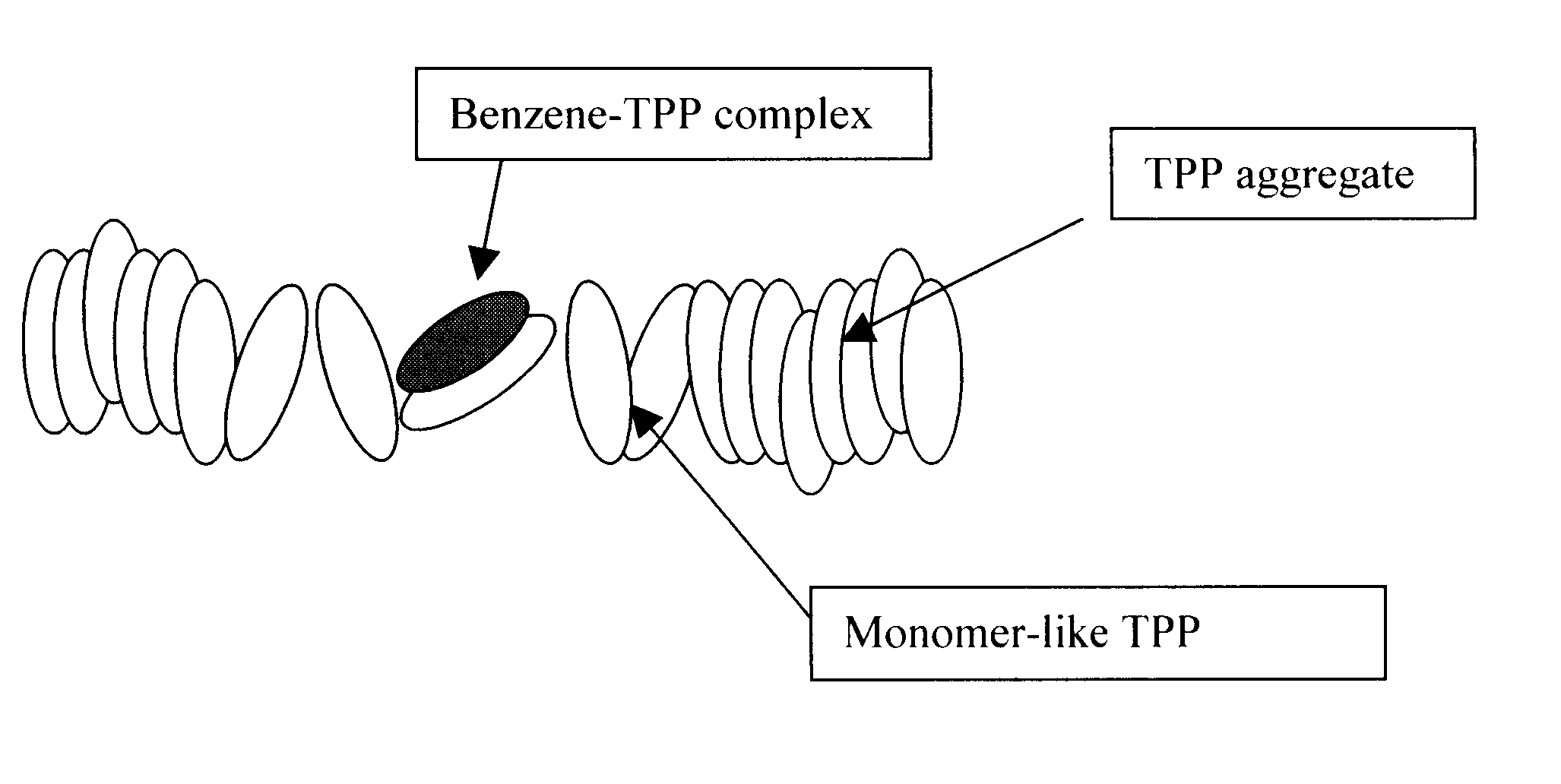

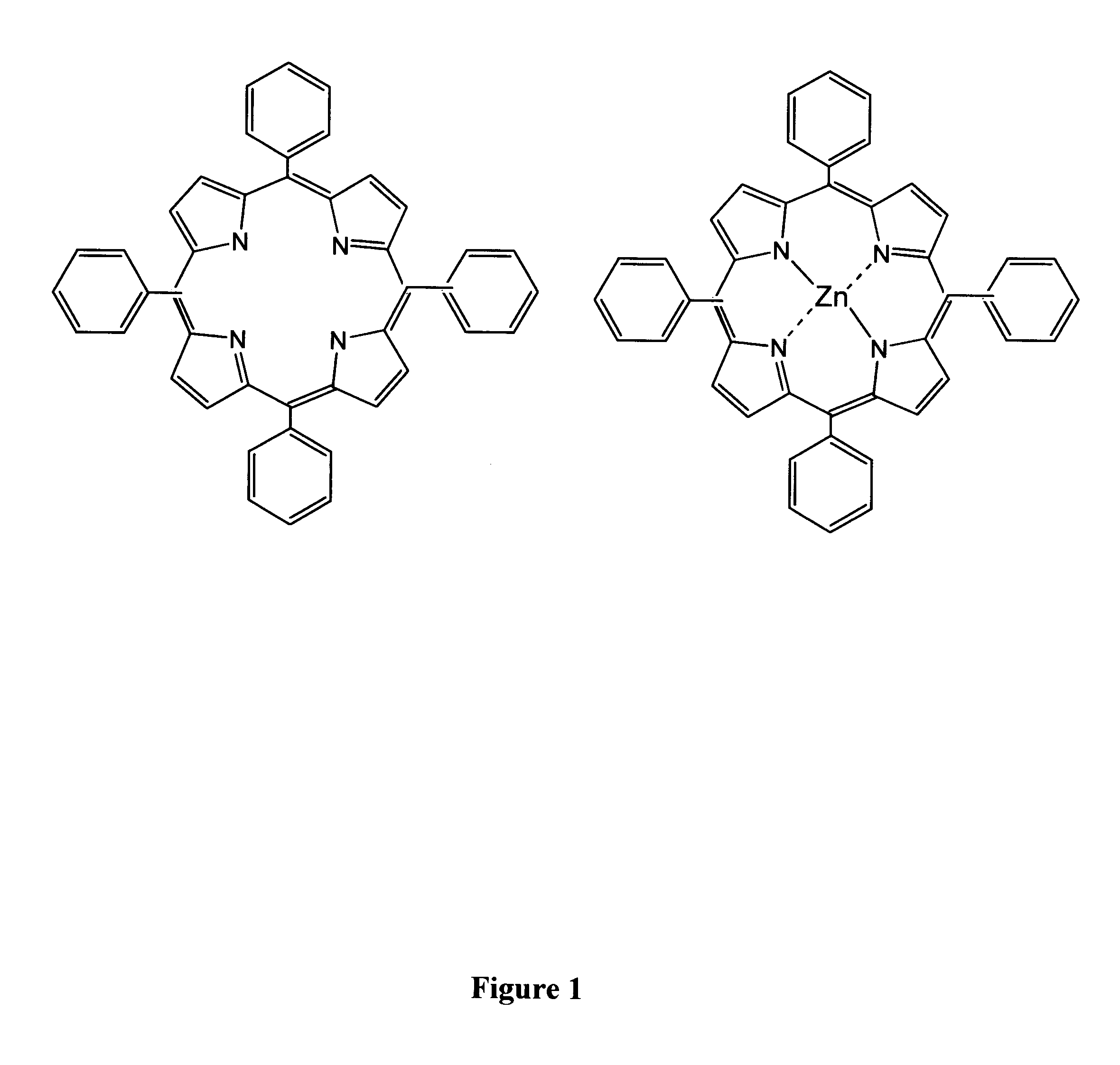

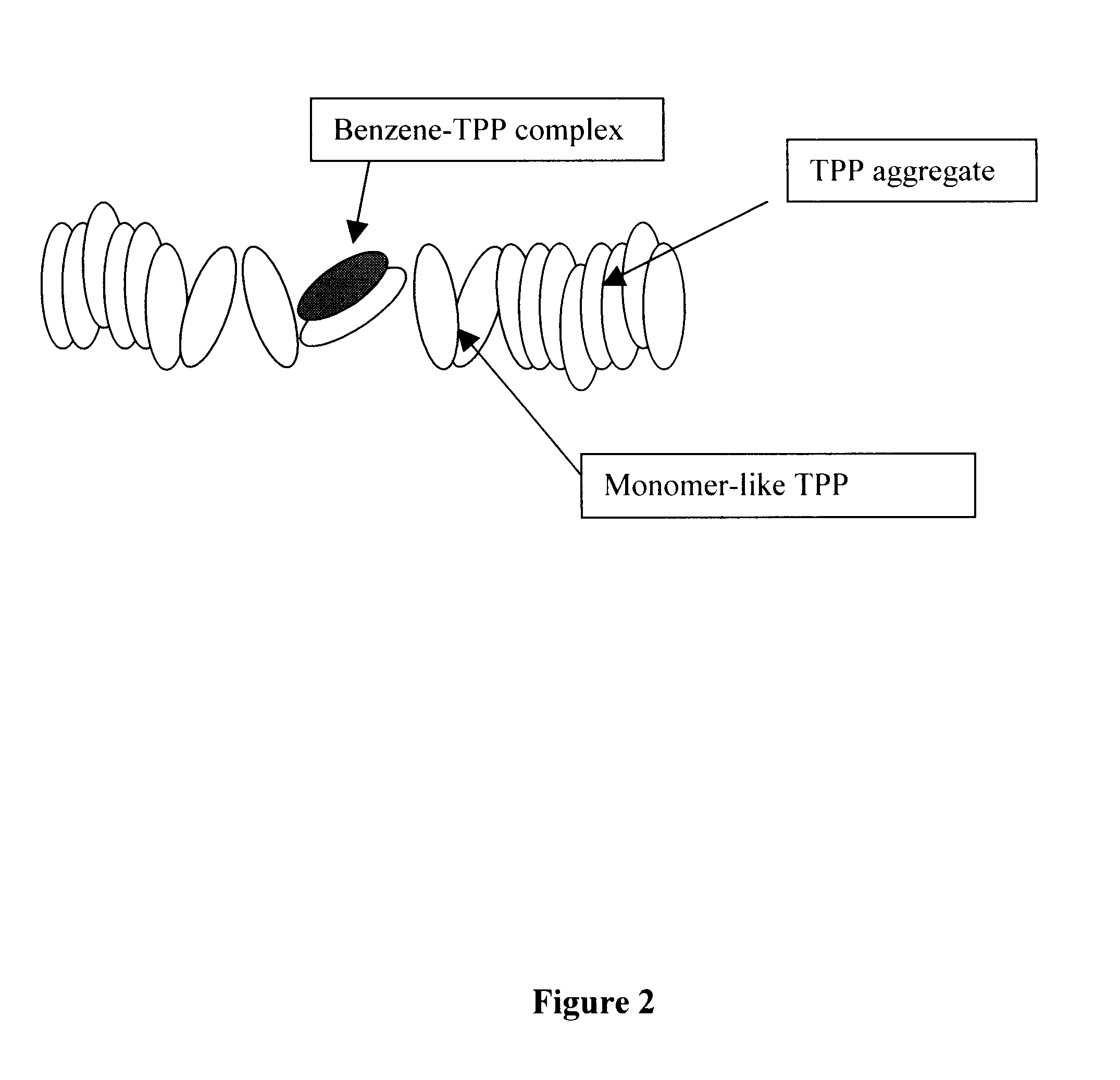

Method for detection of gases based on fluorescence enhancement in porphyrin aggregates

InactiveUS20020146837A1Improve performanceSimple and efficient of detectionMaterial analysis by observing effect on chemical indicatorChemiluminescene/bioluminescenceQuantum yieldPorphyrin molecule

A fluorescence-based method for highly sensitive and selective detection of molecules of organic gases such as benzene, alcohol, chloroform, basic vapors including dimethyl methylphosphonate (DMMP) that is a simulant of Sarin, Soman and other chemical warfare agents having basic properties, is proposed. The method employs the effect of strong fluorescence change in thin films of aggregated porphyrins. In one preferred embodiment, the aggregation of porphyrin molecules leads to initial depression of chromophore emission due to self-quenching effect. The binding of analyte molecules to porphyrin sensitive layer forms porphyrin-analyte complexes, which destroy initial aggregate structure and induce the strong fluorescence enhancement. Aggregate-sensing films usually provide higher and faster response than porphyrins isolated in a polymer matrix. That results in strong enhancement of the florescence quantum yield and shift of the fluorescent spectrum in the direction of shorter wavelengths. The method can be used in fluorescence chemical sensors of organic gases for different applications including environmental monitoring, control of industrial processes and medicine.

Owner:ALTAIR CENT

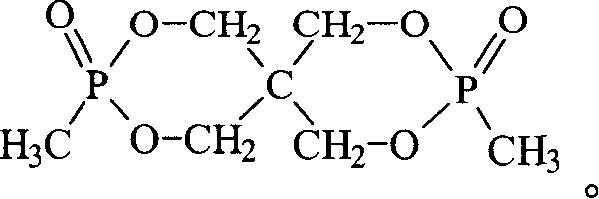

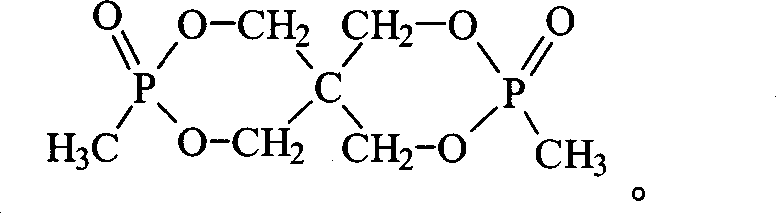

Dicyclic phosphonate fire retardant and its synthesis

InactiveCN1888013AHigh phosphorus contentImprove thermal stabilityGroup 5/15 element organic compoundsDimethyl methylphosphonatePtru catalyst

The present invention discloses one kind of dicyclic phosphonate fire retardant in the structure as shown. Its synthesis process includes the following steps: 1. setting pentaerythritol and dimethyl methyl phosphonate or diethyl methyl phosphonate in the molar ratio of 1 to 2-3 in some connector, adding solvent and catalyst, and stirring at 150-190 deg.c under the protection of inert gas for 3-28 hr; and 2. slowly raising the temperature to 150-180 deg.c, maintaining for 6-26 hr, eliminating excessive dimethyl methyl phosphonate or diethyl methyl phosphonate under vacuum, and lowering the temperature to room temperature to obtain the fire retardant. The synthesis process is simple, efficient, no halogen and environment friendly, and the fire retardant has high phosphorus content, is solid at normal temperature, heat stable and compatible with polymer, and may be used in different fire retardant systems.

Owner:DONGHUA UNIV

Method for detection of organic vapors based on fluorescence enhancement in porphyrin aggregates

InactiveUS6623973B2Improve performanceHigh quantum yieldMaterial analysis by observing effect on chemical indicatorChemiluminescene/bioluminescenceQuantum yieldDimethyl methylphosphonate

A fluorescence-based method for highly sensitive and selective detection of volatile organic compounds such as vapors of benzene, alcohol, chloroform, dimethyl methylphosphonate (DMMP) that is a simulant of Sarin, Soman and other chemical warfare agents, is proposed. The method employs the effect of strong fluorescence change in thin films of aggregated porphyrins. In one preferred embodiment, the aggregation of porphyrin molecules leads to initial depression of chromophore emission due to self-quenching effect. The binding of analyte molecules to porphyrin sensitive layer forms porphyrin-analyte complexes, which destroy initial aggregate structure and induce the strong fluorescence enhancement. Aggregate-sensing films usually provide higher and faster response than porphyrins isolated in a polymer matrix. That results in strong enhancement of the florescence quantum yield and shift of the fluorescent spectrum in the direction of shorter wavelengths. The method can be used in fluorescence chemical sensors of organic vapors for different applications including environmental monitoring, control of industrial processes and medicine.

Owner:ALTAIR CENT

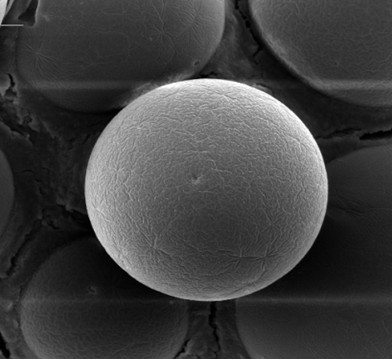

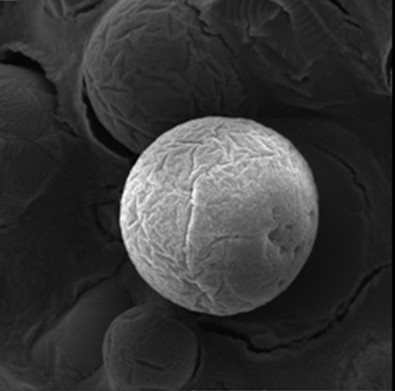

Preparation method of dimethyl methylphosphonate (DMMP) molecular imprinting polymer microspheres

InactiveCN102603972AAchieve separationAchieve enrichmentOther chemical processesAlkali metal oxides/hydroxidesFunctional monomerDimethyl methylphosphonate

The invention relates to a preparation method of a molecular imprinting polymer. The preparation method comprises the following steps: dissolving dimethyl methylphosphonate (DMMP), a functional monomer A and a functional monomer B in a pore former, performing ultrasonic degassing for at least 5 minutes, placing the mixture in a refrigerator for above 8 hours to obtain a template molecule-monomer complex, adding a crosslinking agent in the template molecule-monomer complex, performing ultrasonic vibration for at least 30 minutes, introducing nitrogen for at least 15 minutes while adding an initiator, sealing, performing thermal polymerization in a suspension prepared from polyvinyl alcohol, cooling to the room temperature to separate out precipitates, centrifuging, performing Soxhlet extraction on the obtained polymer to ensure that the polymer has no imprinted molecules, washing microspheres with chloroform to remove residual methanol and acetic acid, and drying the microspheres in vacuum to reach a constant weight and obtain DMMP molecular imprinting polymer microspheres. The DMMP molecular imprinting polymer microspheres prepared by the method have the advantages of obviously higher adsorption capacity, larger specific surface area and good selectivity.

Owner:CHONGQING UNIV

Resin-based composite material additive type flame retardant, flame-retarding composite material and preparation methods thereof

The invention discloses a resin-based composite material additive type flame retardant, which is prepared by mixing 30 to 50 parts of aluminium hydroxide, 0 to 20 parts of microcapsulated red phosphorus and 1 to 20 parts of dimethylmethylphosphonate. The invention also discloses a flame-retarding composite material, which is prepared mainly from a resin substrate, a reinforcing material, a curing agent and the flame retardant, wherein the ratio of the resin substrate to the flame retardant is 100:(31-80). The preparation method of the flame-retarding composite material comprises the following steps: preparing materials; adding the flame retardant; adding assistant; and forming by solidification. The flame retardant and the flame-retarding composite material have the advantages of low cost, simplicity of preparation, convenience for use, high flame retarding effect and the like.

Owner:NAT UNIV OF DEFENSE TECH

Preparation method of environmentally-friendly phosphorous intumescent flame retardant

InactiveCN102660302AHigh flame retardant efficiencyReduce generationTanning treatmentPolymer scienceDimethyl methylphosphonate

The invention discloses a preparation method of an environmentally-friendly phosphorous intumescent flame retardant. The preparation method comprises the following steps: adding dimethyl methylphosphonate and a phosphorylation reagent to a reaction system, fully reacting, adding a polyol, adding an acid anhydride, and reacting under stirring to obtain a colorless transparent liquid which is the phosphorous intumescent flame retardant. By the reaction of dimethyl methylphosphonate and the phosphorylation reagent, the content of phosphorus in the flame retardant is increased, so the flame retardation of the flame retardant is improved; the polyol is simultaneously adopted to modify obtained products, so the char formation performance of the intumescent flame retardant is increased; and the acid anhydride is also adopted to modify the products, so the compatibility of the products and polar substances is increased, thereby the flame retardant can be applied to the textile field, the synthetic leather field, the natural leather field, the papermaking field and the like.

Owner:YANTAI UNIV

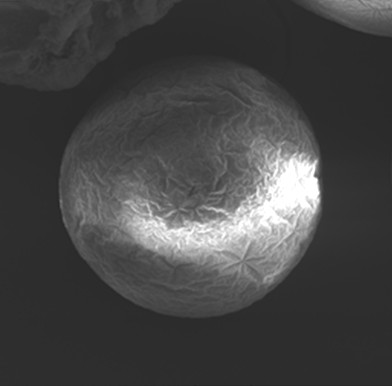

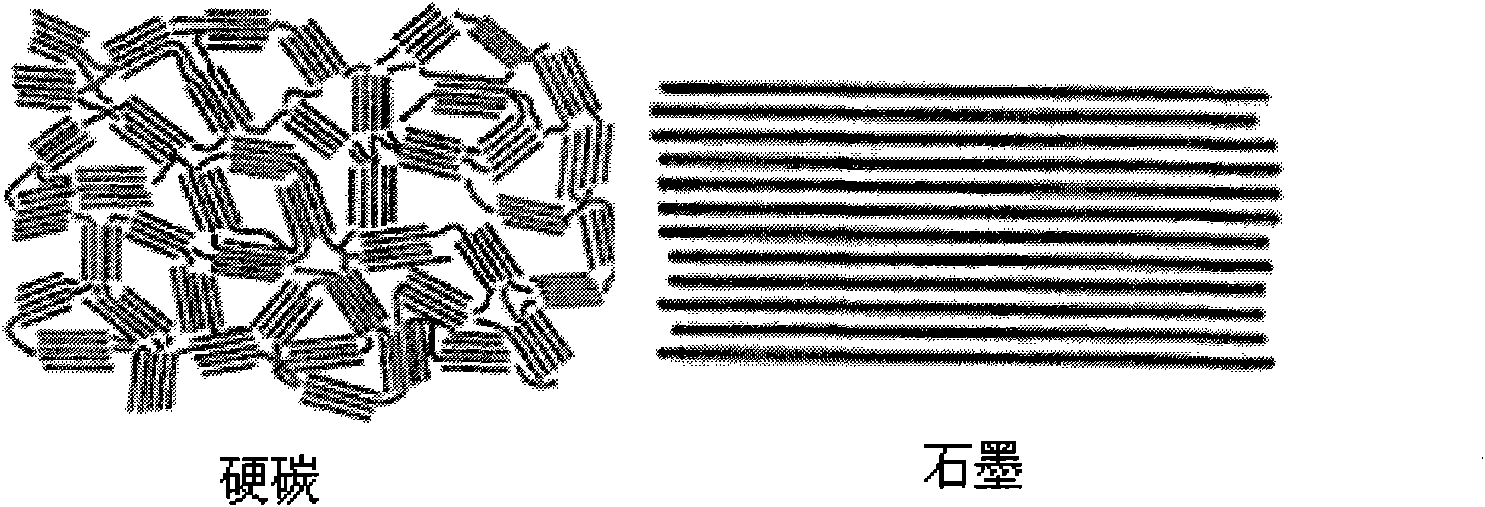

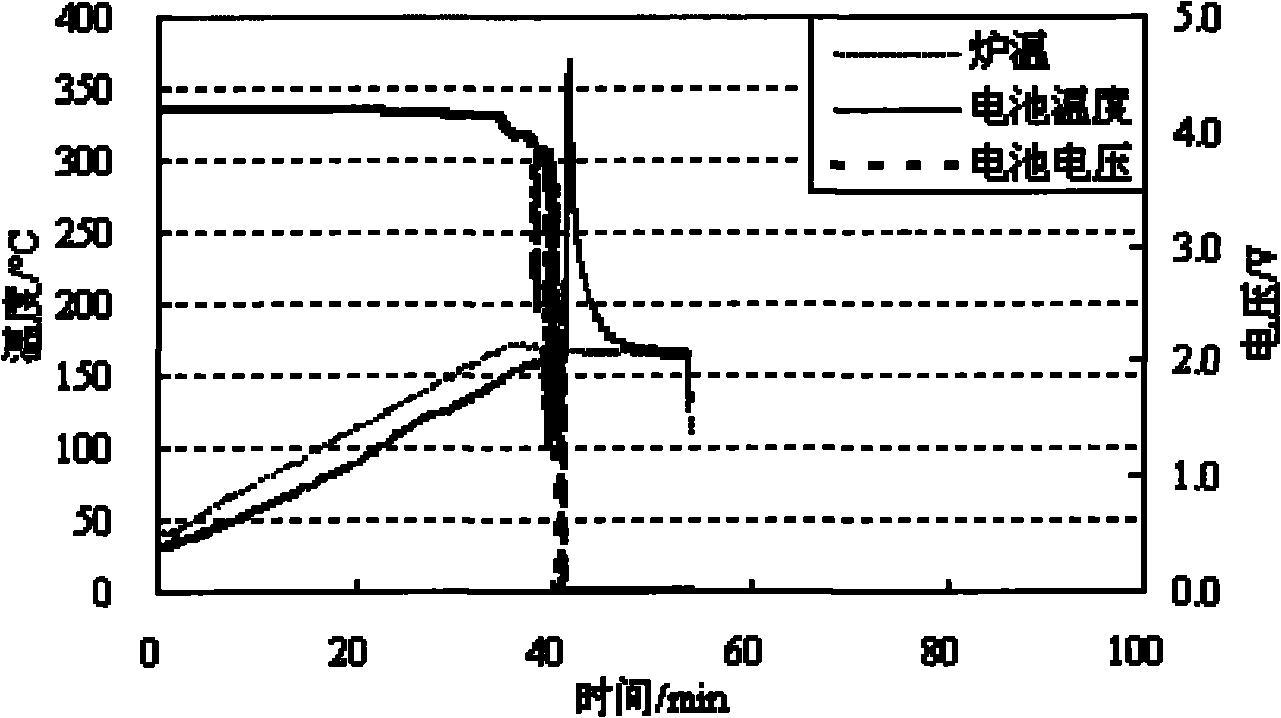

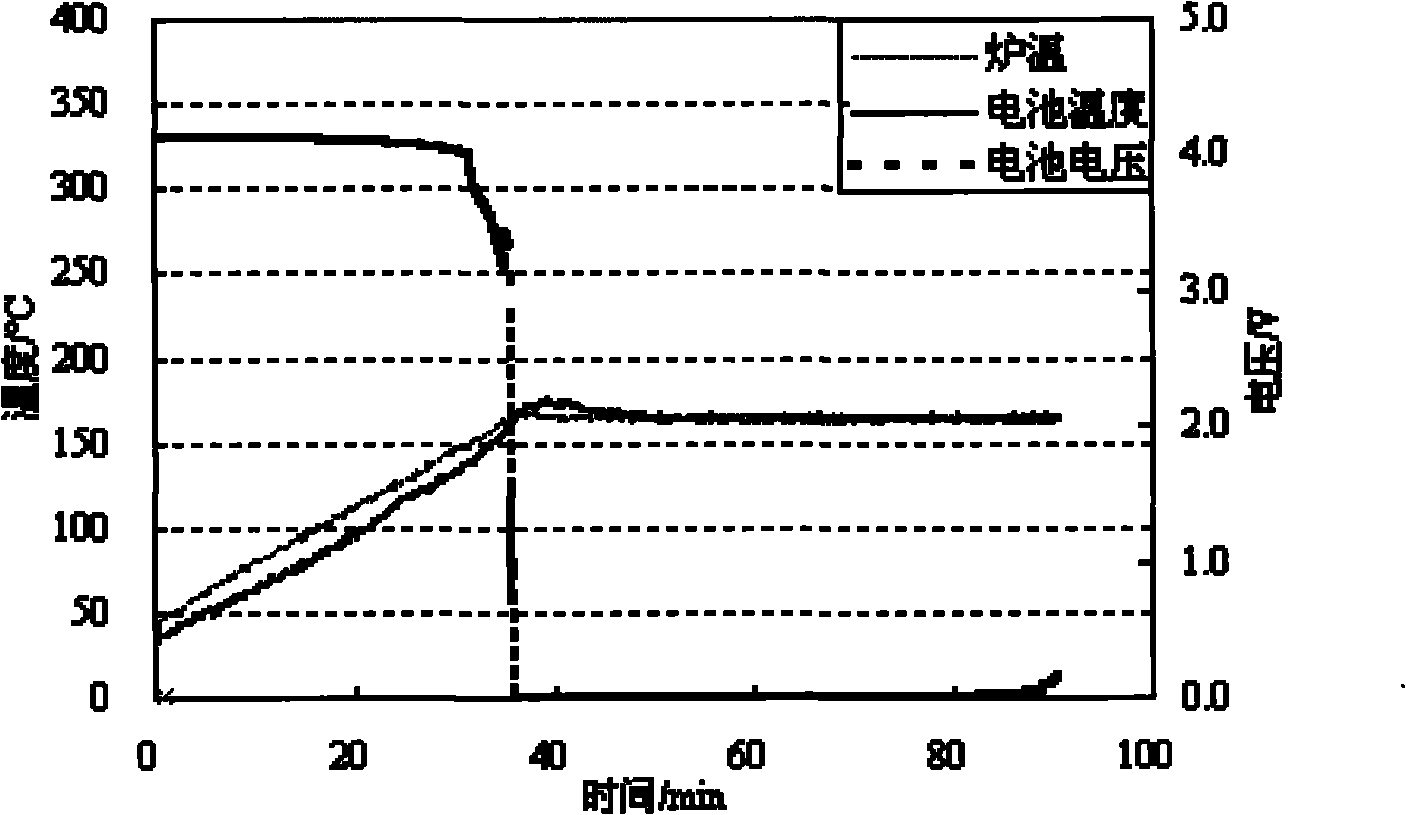

Lithium ion battery

InactiveCN101924243AImprove securityImprove electrochemical performanceCell electrodesSecondary cellsCarbon layerDimethyl methylphosphonate

The invention discloses a lithium ion battery. The lithium ion battery comprises a positive plate, a negative plate, an isolation membrane arranged between the positive plate and the negative plate and an electrolyte, wherein the positive plate comprises a positive current collector and a positive diaphragm which is attached to the positive current collector and contains a positive active substance; the negative plate comprises a negative current collector and a negative diaphragm which is attached to the negative current collector and contains a negative active substance; an electrolyte solvent contains dimethyl methylphosphonate; and the negative active substance is hard carbon. In the lithium ion battery, a structure that carbon layers of the hard carbon are randomly arranged reduces the destruction of the dimethyl methylphosphonate, and weakens a reduction reaction of the hard carbon and the dimethyl methylphosphonate in the formation process; and the first charge-discharge efficiency and capacity of the lithium ion battery are not reduced substantially due to the addition of the dimethyl methylphosphonate, and the safety of the lithium ion battery is improved.

Owner:DONGGUAN AMPEREX TECH

High-flame retardant rigid polyurethane foaming plastic and preparation method thereof

ActiveCN103709432ASolve the problem of poor flame retardancyMeet fire resistance requirementsPolymer scienceDimethyl methylphosphonate

The invention discloses high-flame retardant rigid polyurethane foaming plastic and a preparation method thereof. The preparation method comprises the following steps: evenly mixing polyol, a compound flame retardant, a foaming agent, a foam stabilizer and a catalyst to prepare a polyurethane composition A; controlling the material temperature and mould temperature, adding isocyanate into A, and stirring evenly; and pouring the evenly mixed liquid into a mould for foaming to obtain the high-flame retardant rigid polyurethane foaming plastic after foaming and curing. According to the high-flame retardant rigid polyurethane foaming plastic and the preparation method, halogen-free environment-friendly solid flame retardant aluminum hypophosphite, phenyl aluminum hypophosphite, and halogen-free liquid flame retardant dimethyl methylphosphonate are adopted for being compounded with cyclic phosphonate flame retardant to replace a conventional halogen-containing flame retardant, and a dispersant is adopted for enabling the solid-phase flame retardant to be evenly dispersed in the liquid-phase flame retardant, so as to achieve the effect of efficient synergistic flame retardance, effectively solve the problem that ordinary rigid polyurethane foam plastic is poor in flame retardance, meanwhile also maintain various superior performances of PU (Polyurethane) rigid foam.

Owner:ZHENJIANG SANWA FLAME RETARDANT ENG TECH CO LTD

High-density flame-retardant rigid polyurethane foam and preparation method thereof

The invention relates to polyurethane rigid foam, and concretely relates to high-density flame-retardant rigid polyurethane foam which is appropriate in material formula, protrude in foamed material performances and stable in quality, and a preparation method thereof. The foam plastic is prepared from polyether polyols, an auxiliary agent and a reinforcing material, and by taking the total mass proportions of the auxiliary agent and the polyether polyols as 100 parts, the polyether polyols comprise, 50-60 parts of cane sugar polyether polyol, 30-40 parts of polyether diol and 5-10 parts of pentaerythritol polyether polyol, and the auxiliary agent is a flame retardant composed of tris(2-chloropropyl)phosphate (TCPP) and dimethyl methylphosphonate (DMMP). The preparation method of the foam plastic comprises: weighing the polyether polyols, the auxiliary agent and the reinforcing material according to the formula, adding the auxiliary agent and the reinforcing material into the polyether polyols, stirring for 10 s for mixing by an electric stirrer, then pouring into a die, foaming, and after thorough slaking of the foam is finished, stripping form the mold for molding.

Owner:李肃

Aqueous fire retardation antirust coating material

InactiveCN103409011AStrong adhesionAvoid pollutionFireproof paintsAnti-corrosive paintsEpoxyDimethyl methylphosphonate

The present invention relates to an aqueous fire retardation antirust coating material, which is characterized by comprising the following raw materials, by weight: 100-120 parts of a styrene-acrylate emulsion, 8-10 parts of an epoxy resin, 15-25 parts of glass flakes, 0.1-0.3 part of zinc phosphate, 4-10 parts of dimethyl methylphosphonate, 2-4 parts of aluminum tripolyphosphate, 0.5-2 parts of sorbitan monooleate, 0.2-0.3 part of polyoxy ethylene nonyl phenyl ether, 0.1-0.2 part of triethylamine, 0.1-1 part of a dispersing agent, 0.1-0.5 part of an antifoaming agent, and 10-20 parts of deionized water. The product has characteristics of good corrosion resistance, strong adhesion to the substrate, substrate protection, rust resistance and good fire retardation, adopts water as a solvent so as to overcome pollution of the solvent type coating material on the environment, and is a green environmental protection coating material.

Owner:WUJIANG JUNDA ELEVATOR PARTS

Particle-containing fibrous web

A porous sheet article including a self-supporting nonwoven web of less than 20 weight percent polymeric fibers exhibiting no more than about 1 weight percent dimethyl methyl phosphonate uptake and at least 80 weight percent sorbent particles enmeshed in the web, the sorbent particles being sufficiently evenly distributed in the web and the fiber polymer(s) being such that the web has an Adsorption Factor A of at least 1.6x10<4> / mm water. The articles have low pressure drop and can provide filter elements and other individual or collective protection devices having long service lives and an Adsorption Factor approaching and in some instances exceeding that of a packed carbon bed.

Owner:3M INNOVATIVE PROPERTIES CO

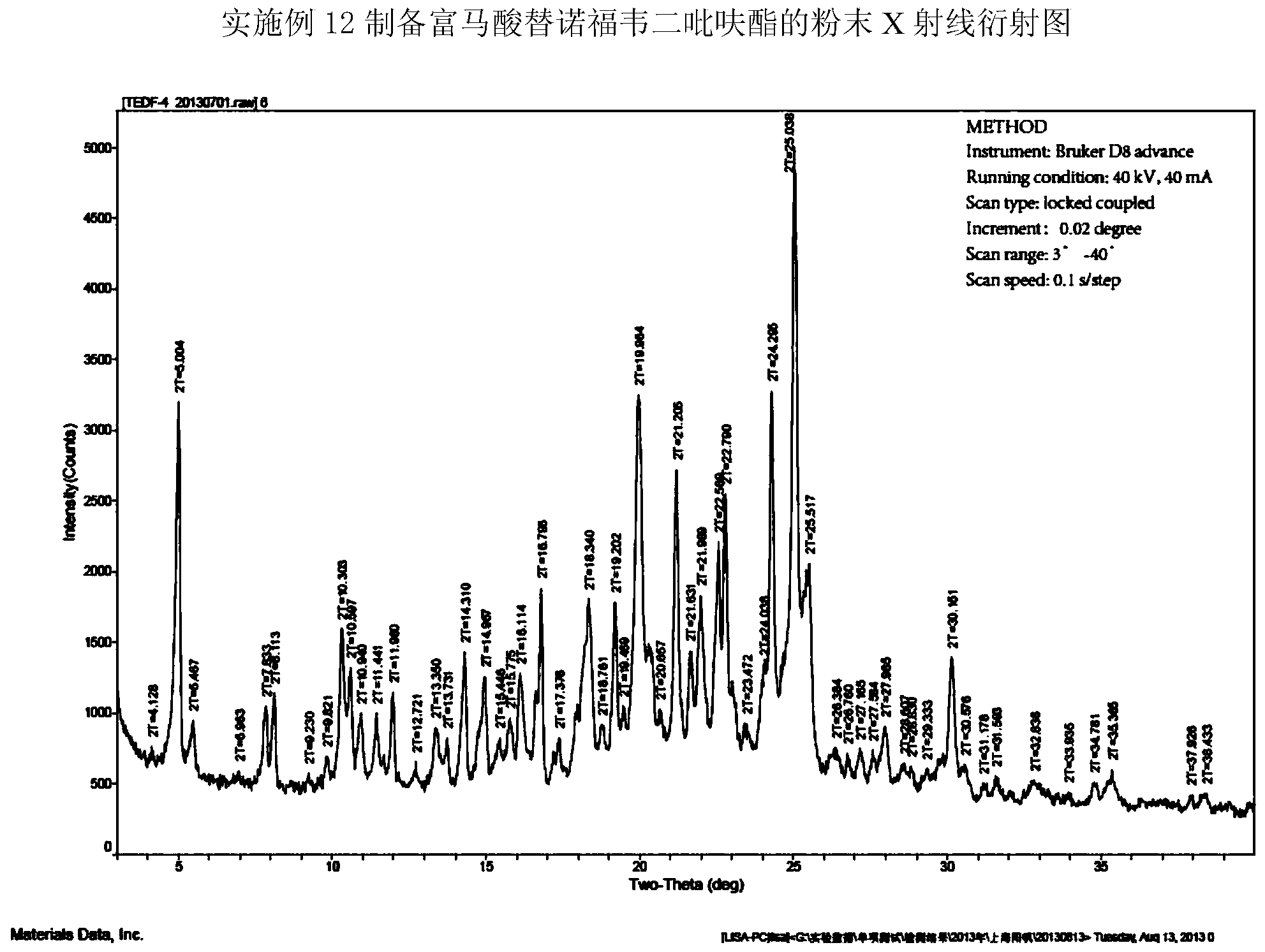

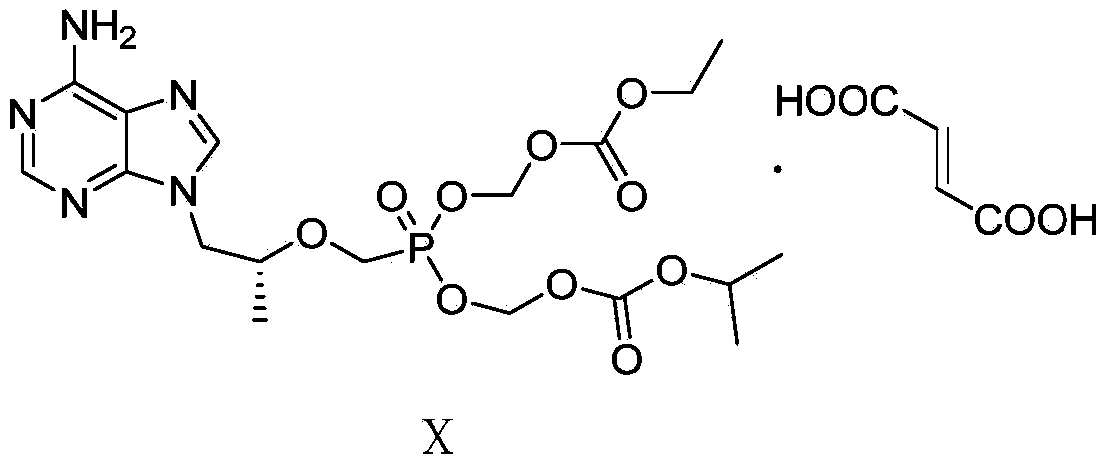

Tenofovir disoproxil fumarate and preparation method thereof

ActiveCN103641858AAdvantages and Notable ImprovementsSignificant progressGroup 5/15 element organic compoundsAntiviral drugDimethyl methylphosphonate

The invention relates to an antiviral drug tenofovir disoproxil fumarate and a novel preparation method thereof, belonging to the field of medicines. Content of related substances in the tenofovir disoproxil fumarate, especially content of impurity K is effectively lowered by taking toluenesulfonyloxy diethyl methylphosphonate as a starting material through hydrolysis, condensation and salifying. Moreover, the preparation method is gentle in reaction condition, low in production cost, simple and convenient to operate, and suitable for large-scale industrial production.

Owner:湖南千金湘江药业股份有限公司

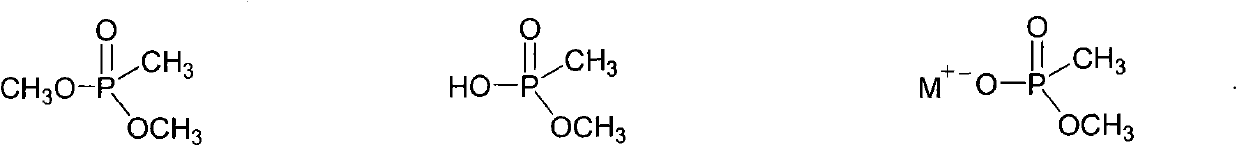

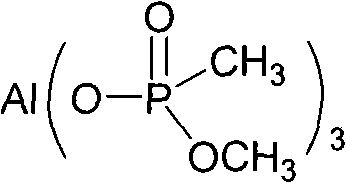

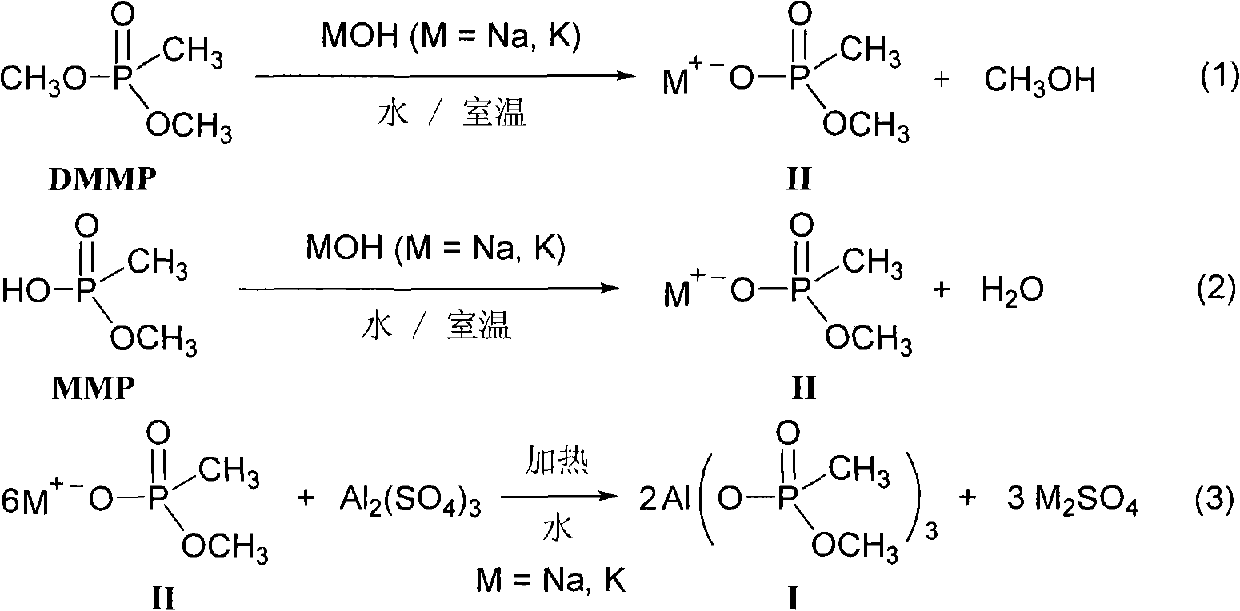

Organic aluminum phosphate fire retardant and preparation method and use thereof

The invention discloses a preparation method and use of an organic aluminum phosphate fire retardant. The method comprises: hydrolyzing dimethylmethylphosphonate under the action of sodium hydroxide or potassium hydroxide to form the sodium or potassium salt of dimethylmethylphosphonate, wherein the molar ratio of the dimethylmethylphosphonate to the sodium hydroxide or potassium hydroxide is 1:1; and reacting the aqueous solution of the sodium or potassium salt of dimethylmethylphosphonate with aluminum sulfate under heating and violently stirring CONDITIONS according to a molar ratio of 6:1 to form aluminum methyl methyl phosphonate. The aluminum methyl methyl phosphonate prepared by the invention only is formed by only reactions both of which are performed by using water as reaction medium, the process is simple and the efficiency is high. The thermal decomposition temperature of the aluminum methyl methyl phosphonate prepared by the method is above 325 DEG C, and the aluminum methyl methyl phosphonate can be used as V-0 grade fire retardant for thermoplastic plastics such as poly butylenes terephthalate (PBT) resin, poly(ethylene terephthate) (PET) resin, polyamide PA66 resin and poly(p-phenylene oxide) (PPO) resin.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Heat-resistant high flame-resistant fluororubber composite material

InactiveCN105367955AImprove low temperature resistanceEasy to processDimethyl methylphosphonateGas phase

The invention discloses a heat-resistant high flame-resistant fluororubber composite material. The heat-resistant high flame-resistant fluororubber composite material comprises following raw material: fluororubber, methyl vinyl phenyl polysiloxane rubber, polyvinylidene fluoride, polycaprolactone, EPDM, liquid butadiene-acrylonitrile rubber, a bulking agent, 2,4-dichlorobenzoyl peroxide, 1,1-Di-(tert-butylperoxy)-3,3,5-trimethylcyclohexane, triallyl cyanurate, silicon carbide, magnesium hydroxide, gas phase white carbon black, expansible graphite, diatomite, boron nitride, molybdenum disulfide, pentaerythritol, hydrotalcite, trioctyl phosphate, dimethyl methylphosphonate, hydroxyl silicone oil, an anti-aging agent, an accelerant, and a silane coupling agent. The heat-resistant high flame-resistant fluororubber composite material possesses excellent heat resistance, aging resistance, and flame resistance, and long service life.

Owner:ANHUI JINYANG FLUORINE CHEM

Heatproof PVC pipe with high impact strength and high tensile strength

The invention discloses a heatproof PVC pipe with high impact strength and high tensile strength. The heatproof PVC pipe comprises the following raw materials by weight: 80 to 120 parts of polyvinyl chloride, 20 to 40 parts of polyurethane elastomer, 10 to 30 parts of modified white carbon black, 5 to 15 parts of ammonium polyphosphate, 2 to 8 parts of dimethyl methylphosphonate, 1 to 5 parts of red phosphorus, 2 to 6 parts of dioctyl phthalate, 3 to 9 parts of epoxidized soybean oil, 4 to 8 parts of dicumyl peroxide, 1 to 5 parts of 2-phenylimidazole, 2 to 5 parts of zinc oxide, 4 to 6 parts of paraffin, 1 to 3 parts of a stabilizing agent, 2 to 4 parts of calcium stearate, 4 to 8 parts of an antioxidant, 2 to 6 parts of another antioxidant, 1 to 5 parts of polyethylene wax, 2 to 5 parts of titanium dioxide and 4 to 8 parts of inorganic material modified powder. The PVC pipe provided by the invention has excellent impact strength and tensile strength, and good heat resistance.

Owner:安徽宁国市高新管业有限公司

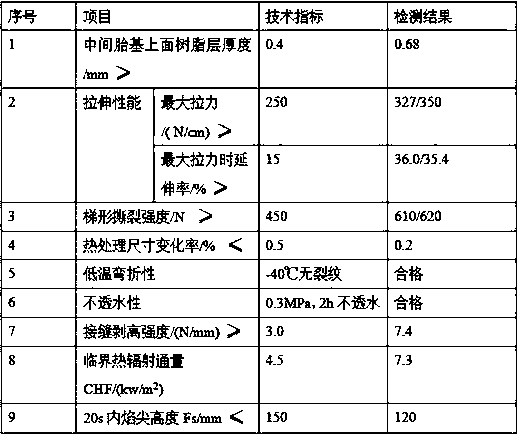

Flame-retardant TPO (thermoplastic polyolefin) waterproof coiled material and preparation method thereof

InactiveCN108081711AImprove physical performanceEnhanced mesh structureSynthetic resin layered productsLaminationThermoplasticPolyester

The invention discloses a flame-retardant TPO (thermoplastic polyolefin) waterproof coiled material which is of a three-layer structure. The upper surface and the lower surface of the waterproof coiled material are flame-retardant TPO coiled material layers, a polyester fiber mesh grid fabric reinforced layer is arranged in the middle of the waterproof coiled material, the TPO coiled material layer of the upper surface is white, the flame-retardant TPO coiled material layer takes thermoplastic polyolefin synthetic resin materials combining ethylene propylene rubber and polypropylene as base materials and takes flame-retardant mixture as an auxiliary, safety of a product in the storage, transportation and use process is guaranteed, the weather resistance and the color retaining performanceof the product are guaranteed by cooperatively using anti-aging agents, anchoring agents, bridging agents, dispersing agents, softening agents and toners, so that the prepared waterproof coiled material is good in flame resistance, combustion performance level reaches non-combustible level, the waterproof coiled material has the advantages of high reflectivity, excellent energy-saving effect and pollution resistance. The flame-retardant mixture is mixture of dimethyl methylphosphonate and micro-encapsulation red phosphorus, and the weight ratio of the dimethyl methylphosphonate to the micro-encapsulation red phosphorus is 1:2.

Owner:GUANGXI WUXUAN JINPAI WATERPROOF MATERIAL SCI & TECH CO LTD

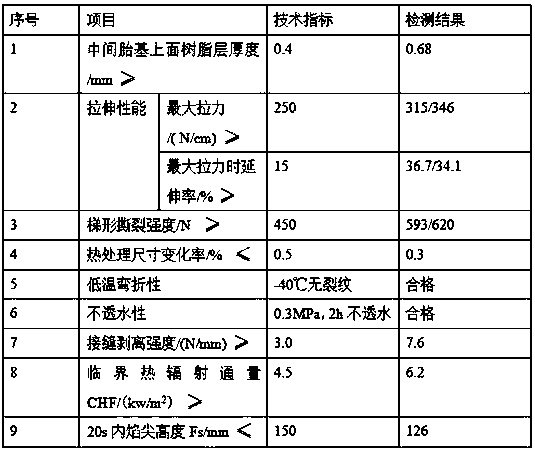

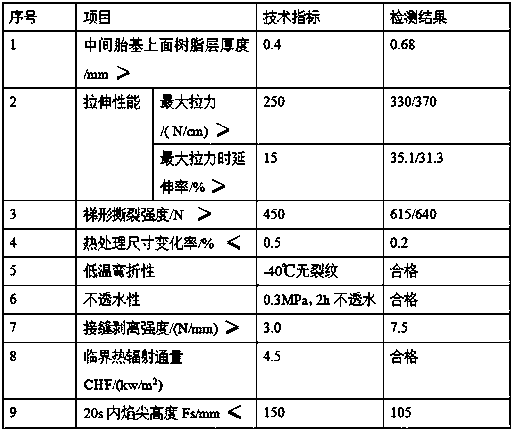

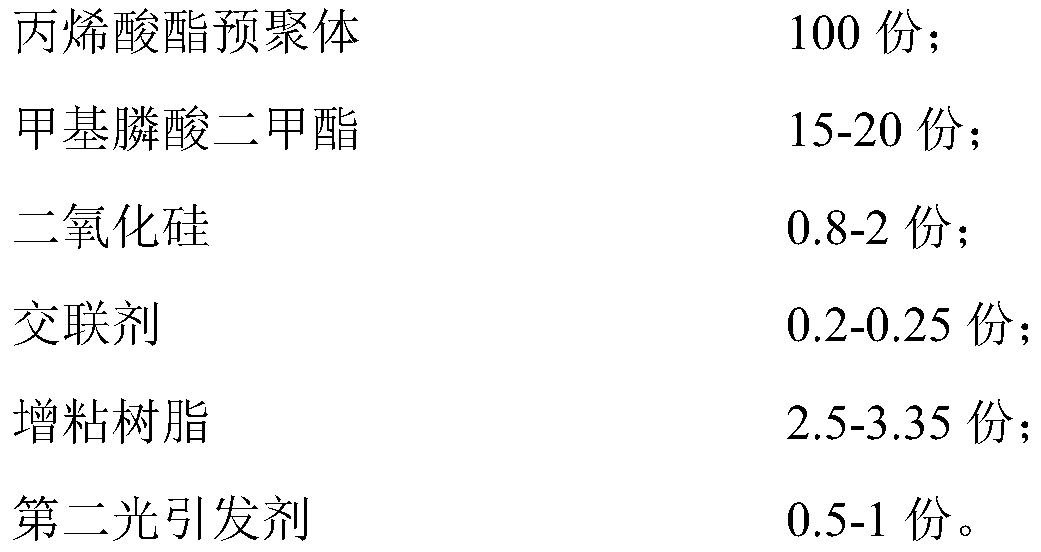

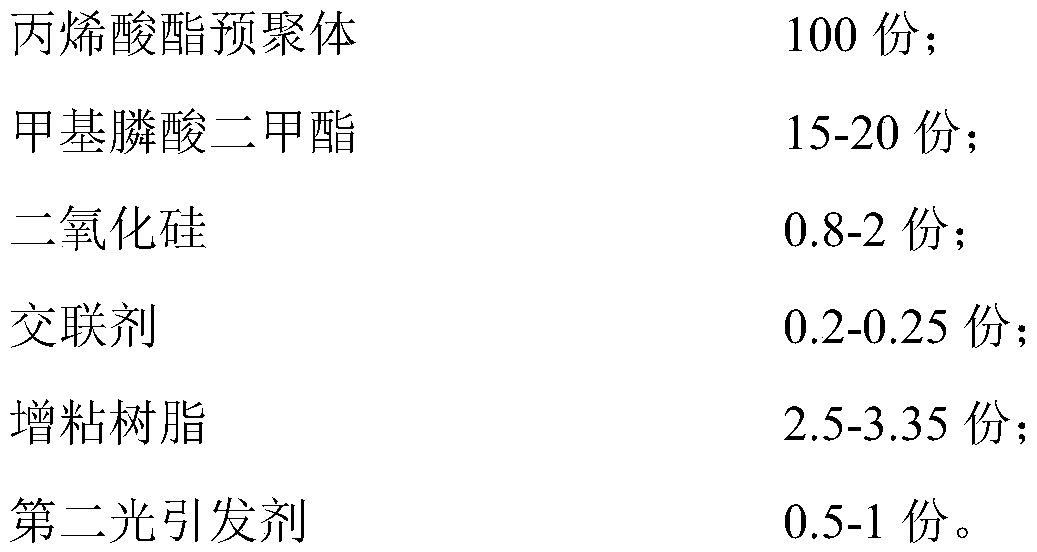

Halogen-free flame-retardant UV-cured acrylate pressure-sensitive adhesive and pressure-sensitive adhesive tape, and preparation method thereof

ActiveCN110655872AImprove flame retardant performanceImprove adhesionNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolymer scienceDimethyl methylphosphonate

The invention discloses a halogen-free flame-retardant UV-cured acrylate pressure-sensitive adhesive and a pressure-sensitive adhesive tape, and a preparation method thereof. The halogen-free flame-retardant UV-cured acrylate pressure-sensitive adhesive comprises the following raw materials in parts by weight: 100 parts of an acrylate prepolymer, 15 to 20 parts of dimethyl methylphosphonate, 0.8 to 2 parts of silicon dioxide, 0.2 to 0.25 part of a cross-linking agent, 2.5 to 3.35 parts of tackifying resin, and 0.5 to 1 part of a second photoinitiator. The pressure-sensitive adhesive tape formed by the halogen-free flame-retardant UV-cured acrylate pressure-sensitive adhesive is good in flame-retardant effect, excellent in pressure-sensitive adhesive property and wide in application range.

Owner:湖南省和祥润新材料有限公司

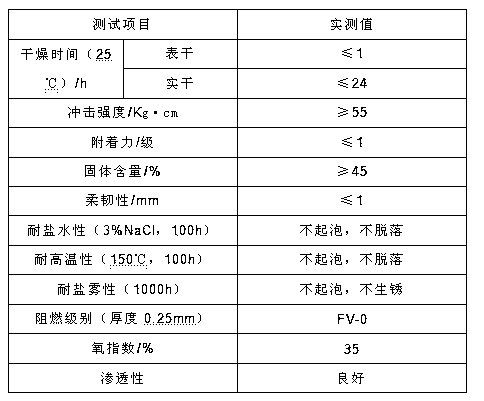

Mildew-proof and mothproof coating for ancient wooden buildings in humid environments in middle and lower reaches of Yangtze River and preparation method of mildew-proof and mothproof coating

ActiveCN104910796AIncrease crosslink densityStrong adhesionFireproof paintsAntifouling/underwater paintsDimethyl methylphosphonateMildew

The invention provides a mildew-proof and mothproof coating for ancient wooden buildings in humid environments in middle and lower reaches of Yangtze River and a preparation method of the mildew-proof and mothproof coating. The mildew-proof and mothproof coating is composed of two components A and B in the mass ratio of 1: 2; the component A is prepared from the following components in parts by weight: 90-120 parts of acrylate-polyurethane water dispersion, 0.5-1.5 parts of thixotropic agent and 5-20 parts of deionized water; the component B is prepared from the following components in parts by weight: 2-8 parts of propylene glycol methyl ether acetate, 0.5-5 parts of dispersant, 0.2-0.8 part of antifoaming agent, 10-30 parts of deionized water, 10-40 parts of super fine talc powder, 10-40 parts of kaolin, 10-30 parts of iron oxide red, 0.8-1.2 parts of dimethyl methylphosphonate, 10-20 parts of nano-silver oxide mildew-proofing agent and 4-8 parts of vegetable moth-proofing agent; and the invention also discloses a preparation method of the coating. The coating has the functions of waterproofing, fire resistance, mildew resistance and moth resistance, and is green and environment-friendly.

Owner:JIANGSU UNIV OF TECH

Composite environment-friendly flame retardant for polypropylene, and polypropylene flame retardant plastic

ActiveCN102888025AImprove heat resistanceImprove flame retardant performanceDimethyl methylphosphonateAluminium hydroxide

The invention discloses a composite environment-friendly flame retardant for polypropylene, and polypropylene flame retardant plastic; the composite environment-friendly flame retardant for the polypropylene comprises the following components in parts by weight: 10-20 parts of trimethylsilyl dimethyl methylphosphonate, 30-50 parts of melamine cyanurate, 10-20 parts of magnesium hydroxide and 40-60 parts of aluminium hydroxide; and the polypropylene flame retardant plastic comprises the following components in parts by weight: 100 parts of polypropylene resin and 25-40 parts of composite environment-friendly flame retardant for the polypropylene. The composite environment-friendly flame retardant for the HIPS does not contain halogen and has good flame retardant function; and the prepared polypropylene flame retardant plastic is not influenced in the aspects of thermal deformation temperature, mechanical temperature, electric insulation performance and the like, has long-term fire resistance, and can be used for easily processing parts with different shapes by injection molding technology, thus being used for making an automobile sealing part, various operating handles, a pull handle and the like.

Owner:深圳新诺包装制品有限公司

Modified polyurethane composition and preparation thereof

InactiveCN1746223ADifficult to escapeHigh tensile strengthBuilding insulationsEthylenediamineDimethyl methylphosphonate

A modified polyurethane composition and its production are disclosed. The process is carried out by taking propylene epoxide s-polyether, castor oil and toluene diisocyanate as raw materials, adding into ethylenediamine polyether, synthesizing A component, accelerating curing time after mixing A with B components, taking 3,-dichloride-4,4,diphenyl bisamine methane as raw materials, adding into vinyl chloride-vinyl acetate copolymer and dimethyl ester methyl phosphonate and producing B component from coal tar pitch. It achieves low cost, simple process, to increase tensile strength, dielectric strength, fire and water resistances of polyaminoresin. It can be used for various coating materials of cable, protective cover of wire and electronic components.

Owner:SHANXI NUOBANG POLYURETHANE

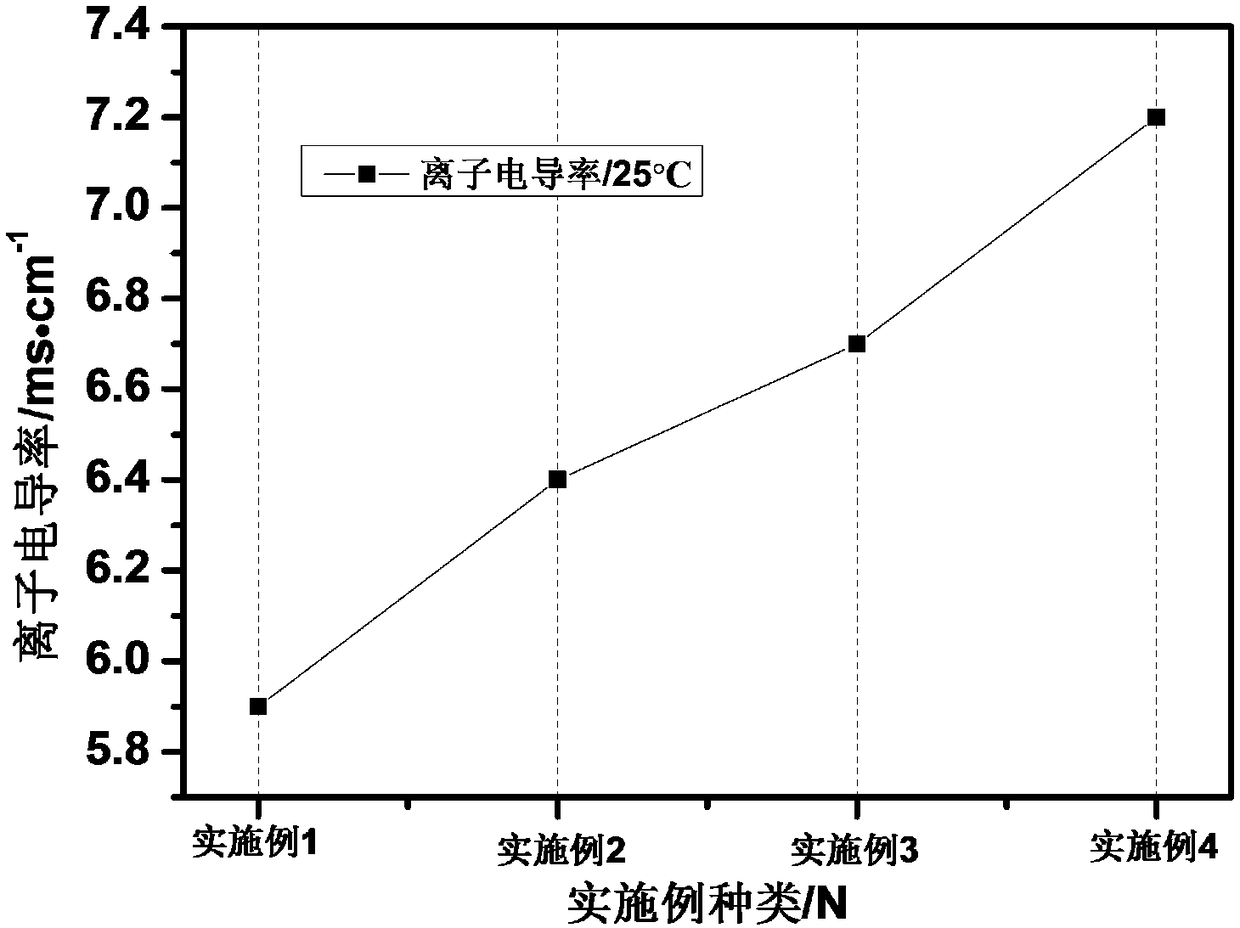

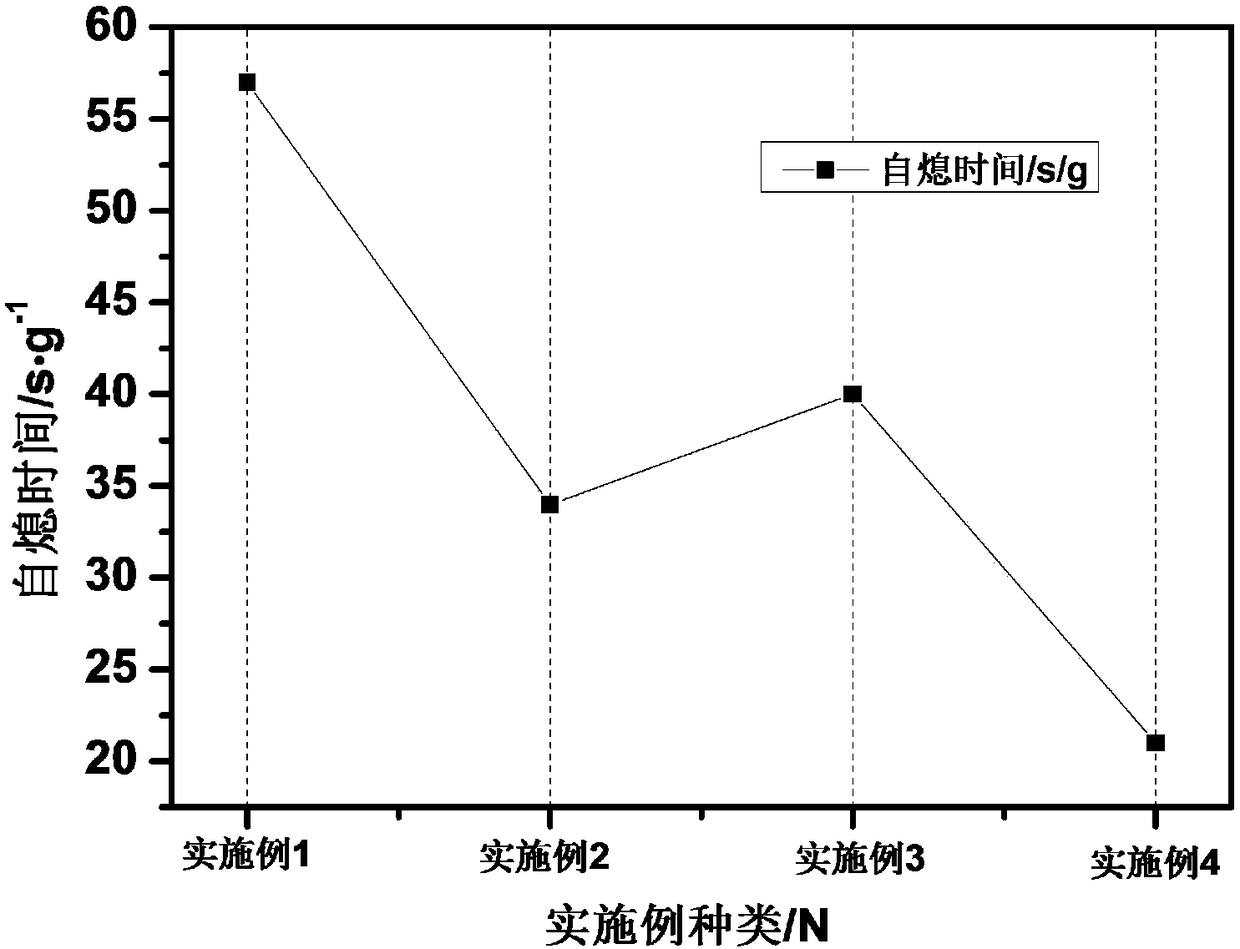

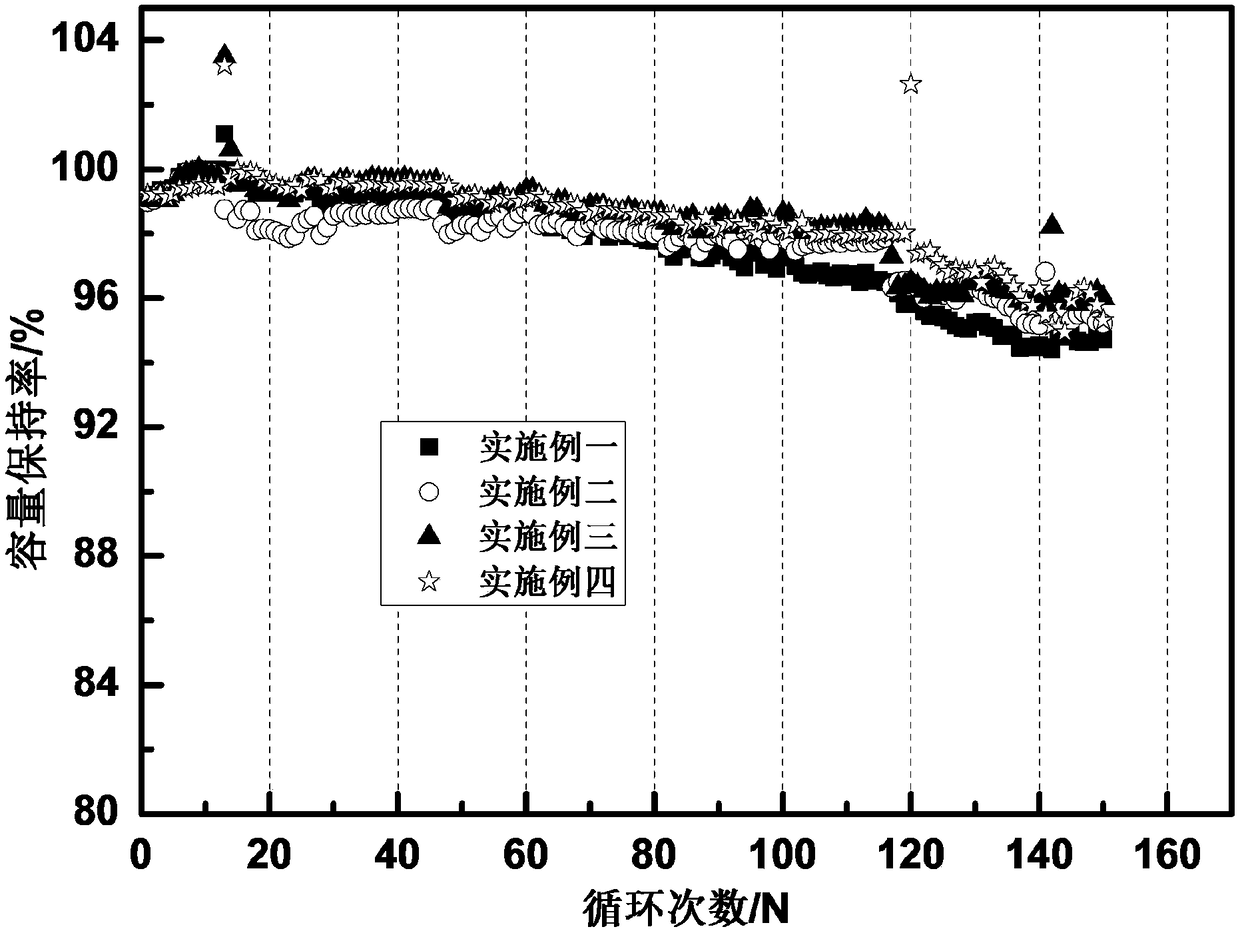

Flame-retardant electrolyte and lithium secondary battery thereof

InactiveCN109411812AImprove electrochemical performanceGood chemical propertiesLi-accumulatorsPolymer electrolytesDiphenyl phosphate

The invention discloses a flame-retardant electrolyte and a lithium secondary battery thereof. The flame-retardant electrolyte comprises electrolyte lithium salt, an organic solvent, a small amount ofa universal film forming additive and a flame-retardant additive. The flame-retardant additive mainly comprises a mixture of diphenyl phosphate and derivatives of diphenyl phosphate, trifluoroethyl phosphate and derivatives of trifluoroethyl phosphate, and dimethyl methylphosphonate and derivatives of dimethyl methylphosphonate. According to the invention, performance indexes of the processed electrolyte such as viscosity, ionic conductivity, wettability, pole pieces and diaphragm flexibility are basically unchanged when being compared with the conventional electrolyte, even improved, and a PVDF coating is arranged and then partially dissolved. The lithium-ion batteries prepared by different proportions of the flame-retardant additives not only have excellent safety performances similar to polymer electrolytes, but also have certain improvement effects on battery consistency and electrochemical performances.

Owner:福建冠城瑞闽新能源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com