Flame-retardant electrolyte and lithium secondary battery thereof

A lithium secondary battery and electrolyte technology, applied in secondary batteries, non-aqueous electrolyte storage batteries, lithium storage batteries, etc., can solve the problems of high cost, affecting battery power performance and cycle performance, complex process, etc., and achieve plasticity and Improved flexibility, improved electrochemical performance, and improved wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

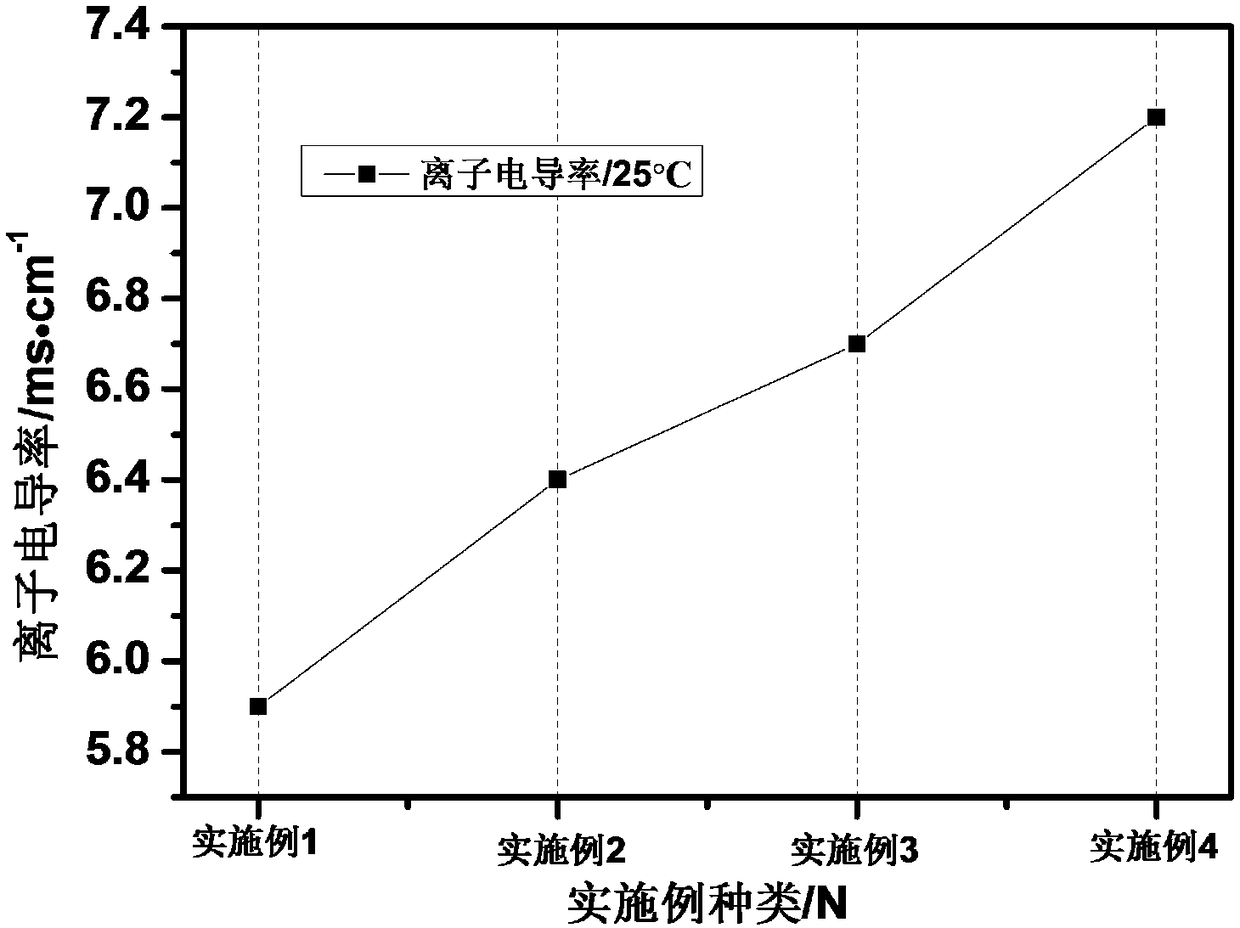

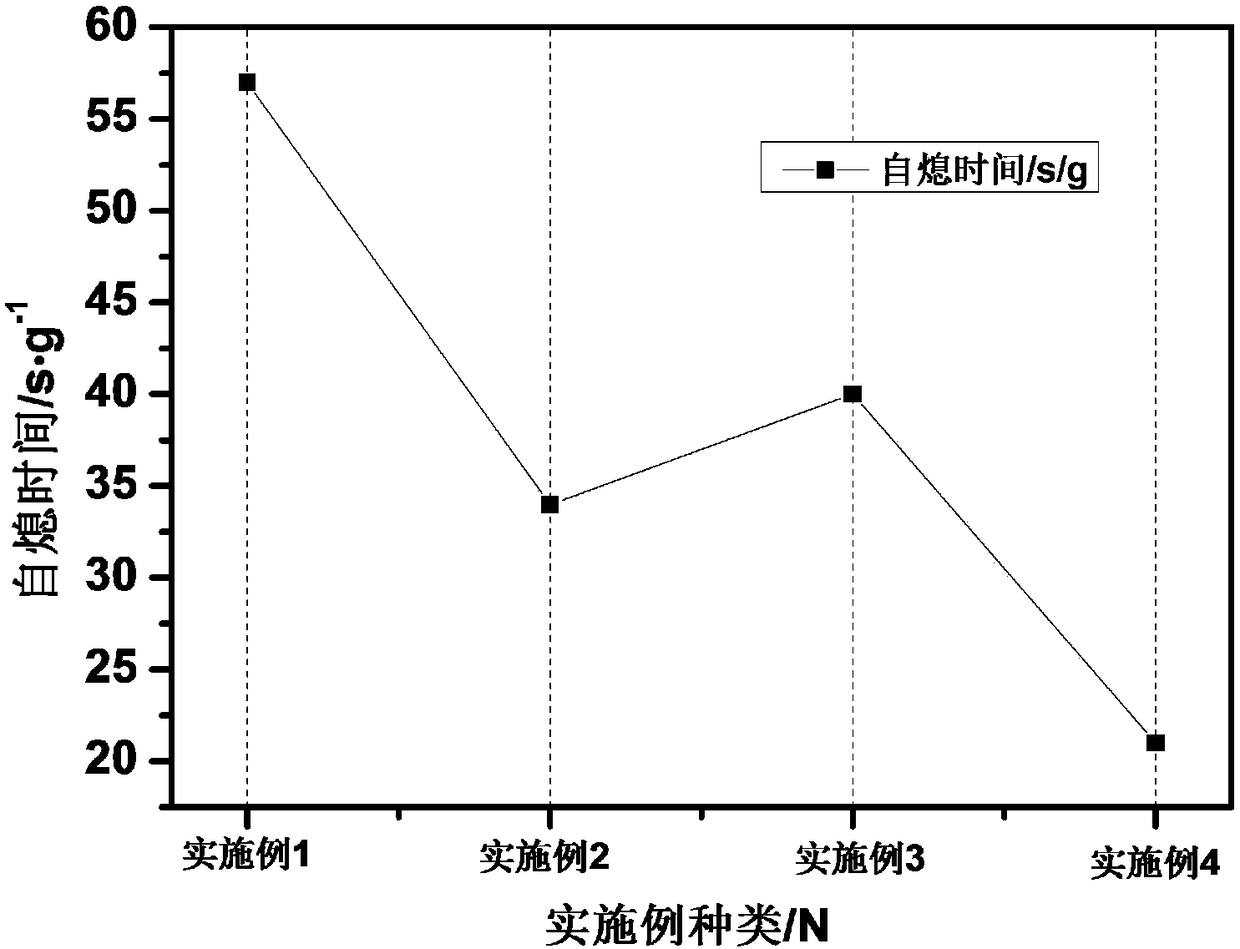

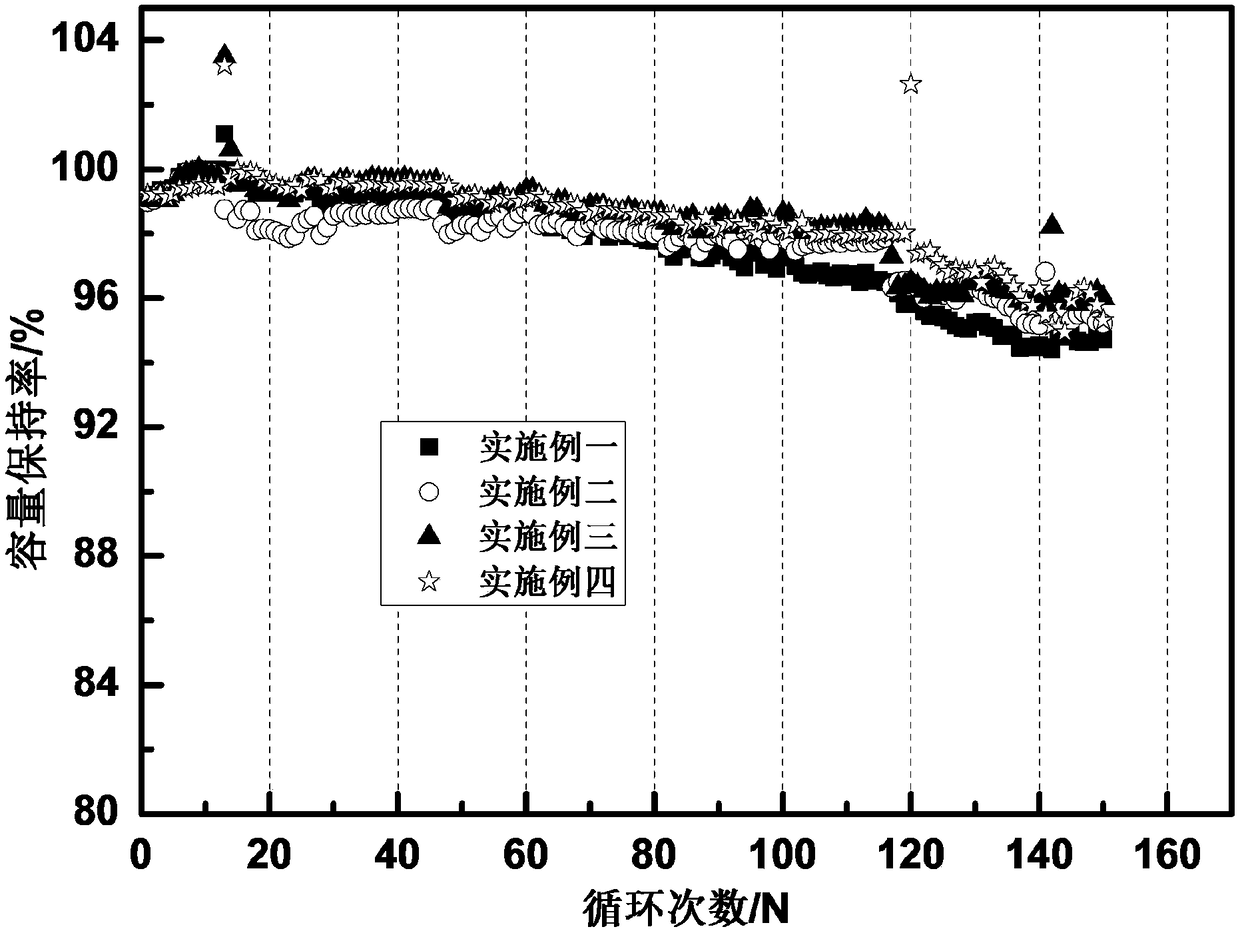

[0049] The non-aqueous solvents ethylene carbonate (EC), propylene carbonate (PC), dimethyl carbonate (DMC), ethyl methyl carbonate (EMC) and diethyl carbonate (DEC) according to the mass ratio in Table 1 (40: 10:25:20:5) to mix evenly, put the solvent into the refrigerator attached to the glove box, and place it at zero temperature for 12 hours. LiFSI (lithium bisfluorosulfonyl imide) 0.25mol / L) was added while stirring, and the monitored temperature should not exceed 40 degrees. After cooling to room temperature, add the film-forming agent (vinylene carbonate (VC) 2.0wt.%+1,3-propane sultone (1,3-PS) 1.5wt.%) and flame retardant (2-ethylhexyl diphenyl phosphate tripolyphosphazene (DPOF) 10.0wt .% + tris(2,2,2-trifluoroethyl) phosphite (TTFP) 5.0wt.% + dimethyl methylphosphonate (DMMP) 10.0wt.%), mix well to obtain electrolyte.

Embodiment 2

[0051] The non-aqueous solvents ethylene carbonate (EC), propylene carbonate (PC), dimethyl carbonate (DMC), ethyl methyl carbonate (EMC) and diethyl carbonate (DEC) according to the mass ratio in Table 1 (40: 10:25:20:5) to mix evenly, put the solvent into the refrigerator attached to the glove box, and place it at zero temperature for 12 hours. LiFSI (lithium bisfluorosulfonyl imide) 0.15mol / L) was added while stirring, and the monitored temperature should not exceed 40 degrees. After cooling to room temperature, add the film-forming agent (vinylene carbonate (VC) 2.0wt.%+1,3-propane sultone (1,3-PS) 1.5wt.%+fluoroethylene carbonate (FEC) 1.0wt.%) and flame retardant (2-ethylhexyl di Phenyl phosphate tripolyphosphazene (DPOF) 5.0wt.% + tris(2,2,2-trifluoroethyl) phosphite (TTFP) 10.0wt.% + dimethyl methylphosphonate (DMMP) 10.0wt.%), mixed evenly to obtain electrolyte.

Embodiment 3

[0053] The non-aqueous solvents ethylene carbonate (EC), propylene carbonate (PC), dimethyl carbonate (DMC), ethyl methyl carbonate (EMC) and diethyl carbonate (DEC) according to the mass ratio in Table 1 (40: 10:25:20:5) to mix evenly, put the solvent into the refrigerator attached to the glove box, and place it at zero temperature for 12 hours. LiFSI (lithium bisfluorosulfonyl imide) 0.05mol / L) was added while stirring, and the monitored temperature should not exceed 40 degrees. After cooling to room temperature, add the film-forming agent (vinylene carbonate (VC) 2.0wt.%+1,3-propane sultone (1,3-PS) 1.5wt.%+ethylene sulfate (DTD) 1.0wt.%) and flame retardant (2-ethylhexyldiphenyl Phosphate-based tripolyphosphazene (DPOF) 10.0wt.% + Tris(2,2,2-trifluoroethyl) phosphite (TTFP) 5.0wt.% + Dimethyl methylphosphonate (DMMP) 10.0 wt.%), mixed evenly to obtain the electrolyte.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com